https://ebookmass.com/product/green-sustainable-process-for-

Instant digital products (PDF, ePub, MOBI) ready for you

Download now and discover formats that fit your needs...

Green Sustainable Process for Chemical and Environmental Engineering and Science: Supercritical Carbon Dioxide as Green Solvent Dr. Inamuddin (Editor)

https://ebookmass.com/product/green-sustainable-process-for-chemicaland-environmental-engineering-and-science-supercritical-carbondioxide-as-green-solvent-dr-inamuddin-editor/ ebookmass.com

Green Sustainable Process for Chemical and Environmental Engineering and Science: Switchable Solvents Dr. Inamuddin

https://ebookmass.com/product/green-sustainable-process-for-chemicaland-environmental-engineering-and-science-switchable-solvents-drinamuddin/

ebookmass.com

Green Sustainable Process for Chemical and Environmental Engineering and Science: Sonochemical Organic Synthesis 1st Edition Dr. Inamuddin (Editor)

https://ebookmass.com/product/green-sustainable-process-for-chemicaland-environmental-engineering-and-science-sonochemical-organicsynthesis-1st-edition-dr-inamuddin-editor/

ebookmass.com

(eTextbook PDF) for Microbiology: A Systems Approach 4th Edition

https://ebookmass.com/product/etextbook-pdf-for-microbiology-asystems-approach-4th-edition/

ebookmass.com

Advanced Fiber Access Networks Cedric F. Lam https://ebookmass.com/product/advanced-fiber-access-networks-cedric-flam/

ebookmass.com

Coming In Hot (Brothers of Fire Book 6) Kathryn Shay

https://ebookmass.com/product/coming-in-hot-brothers-of-firebook-6-kathryn-shay/

ebookmass.com

Holidays on the Ranch Carolyn Brown

https://ebookmass.com/product/holidays-on-the-ranch-carolyn-brown/

ebookmass.com

The War of 1812 Carl Benn

https://ebookmass.com/product/the-war-of-1812-carl-benn/

ebookmass.com

Teaching and Learning for Social Justice and Equity in Higher Education: Foundations 1st ed. Edition Laura Parson

https://ebookmass.com/product/teaching-and-learning-for-socialjustice-and-equity-in-higher-education-foundations-1st-ed-editionlaura-parson/

ebookmass.com

Les Hill

https://ebookmass.com/product/les-terres-dissidentes-tome-2-lesoulevement-nastasia-hill/

ebookmass.com

GREEN SUSTAINABLE PROCESSFOR CHEMICALAND ENVIRONMENTAL ENGINEERING ANDSCIENCE GREEN SUSTAINABLE PROCESSFOR CHEMICALAND ENVIRONMENTAL ENGINEERING ANDSCIENCE CarbonDioxideCapture andUtilization Editedby

Inamuddin

DepartmentofAppliedChemistry,ZakirHusainCollegeofEngineeringandTechnology,Facultyof EngineeringandTechnology,AligarhMuslimUniversity,Aligarh,UttarPradesh,India

TariqAltalhi

DepartmentofChemistry,CollegeofScience,TaifUniversity,Taif,SaudiArabia

Elsevier

Radarweg29,POBox211,1000AEAmsterdam,Netherlands

TheBoulevard,LangfordLane,Kidlington,OxfordOX51GB,UnitedKingdom

50HampshireStreet,5thFloor,Cambridge,MA02139,UnitedStates

Copyright©2023ElsevierInc.Allrightsreserved.

Nopartofthispublicationmaybereproducedortransmittedinanyformorbyanymeans,electronic ormechanical,includingphotocopying,recording,oranyinformationstorageandretrievalsystem, withoutpermissioninwritingfromthepublisher.Detailsonhowtoseekpermission,further informationaboutthePublisher’spermissionspoliciesandourarrangementswithorganizationssuch astheCopyrightClearanceCenterandtheCopyrightLicensingAgency,canbefoundatourwebsite: www.elsevier.com/permissions.

Thisbookandtheindividualcontributionscontainedinitareprotectedundercopyrightbythe Publisher(otherthanasmaybenotedherein).

Notices

Knowledgeandbestpracticeinthisfieldareconstantlychanging.Asnewresearchandexperience broadenourunderstanding,changesinresearchmethods,professionalpractices,ormedicaltreatment maybecomenecessary.

Practitionersandresearchersmustalwaysrelyontheirownexperienceandknowledgeinevaluating andusinganyinformation,methods,compounds,orexperimentsdescribedherein.Inusingsuch informationormethodstheyshouldbemindfuloftheirownsafetyandthesafetyofothers,including partiesforwhomtheyhaveaprofessionalresponsibility.

Tothefullestextentofthelaw,neitherthePublishernortheauthors,contributors,oreditors,assume anyliabilityforanyinjuryand/ordamagetopersonsorpropertyasamatterofproductsliability, negligenceorotherwise,orfromanyuseoroperationofanymethods,products,instructions,orideas containedinthematerialherein.

ISBN:978-0-323-99429-3

ForInformationonallElsevierpublicationsvisitourwebsiteat https://www.elsevier.com/books-and-journals

Publisher: SusanDennis

AcquisitionsEditor: AnitaKoch

EditorialProjectManager: FranchezcaA.Cabural

ProductionProjectManager: SwapnaSrinivasan

CoverDesigner: ChristianJ.Bilbow

TypesetbyAptara,NewDelhi,India

Contributorsxi

Chapter1Carbondioxidecaptureandits utilizationtowardsefficientbiofuels production1

AbhinayThakur,andAshishKumar

1.1Introduction1

1.2Utilizationofcapturedcarbondioxide forbiofuelproduction5

1.3Conclusionandfutureperspectives13 References13

Chapter2Deepeutecticliquidsforcarbon capturingandfixation17

ZainabLiaqat,SumiaAkram,HafizMuhammadAthar, andMuhammadMushtaq

2.1Carbondioxideemissions17

2.2Deepeutecticliquids19

2.3Typesofdeepeutecticliquids19

2.4PreparationofDELs20

2.5AuthenticationofDELs21

2.6DELbasedCO2 absorption22

2.7Carboncaptureefficiencyofvarious HBDs24

2.8CO2 absorptioninaqueoussolution ofDELs40

2.9CO2 absorptioninternaryDELs41

2.10Ammonium-BasedDELs42

2.11PhosphoniumbasedDELs44

2.12AzolebasedDELs44

2.13Bio-phenolderivedsuperbasebasedDELs45

2.14HydrophobicDELs45

2.15Non-ionicDELs46

2.16DELsupportedmembranes46

2.17DELswithmultiplesitesinteraction47

2.18Conclusionandfutureprospects48

Acknowledgment49 References49

Chapter3Cookstovesforbiochar productionandcarboncapture53 MashuraShammi,JulienWinter,Md.MahbubulIslam, BeautyAkter,andNazmulHasan

3.1Introduction53

3.2Cookstovesdesignedforbiochar production54

3.3Biocharproductionandclimate-change implications62

3.4Conclusion64 References65

Chapter4Metalsupportinteractionfor electrochemicalvalorizationofCO2 69 AbinayaStalinraja,andKeerthigaGopalram

4.1Introduction69

4.2MetalsupportsforECRofCO2 70 4.3Conclusion80 Acknowledgment80 References81

Chapter5Utilizationofcarbondioxideasa buildingblockinsynthesisofactive pharmaceuticalingredients85 MuhammadFaisal

5.1Introduction85

5.2 N–Nucleophile-triggered CO2 -incorporatedcarboxylation toformC–Nbonds87

5.3 N–Nucleophile-triggered CO2 -incorporatedmethylation toformC–Nbonds95

5.4 O–Nucleophile-triggered CO2 -incorporatedcarboxylation toformC–Obonds96

5.5CO2 -catalyzedoxidationof alcoholstoformC–Obonds97

5.6 C-Nucleophile-triggered CO2 -incorporatedreductivecarboxylation toformC–Cbonds97

5.7 C-nucleophile-triggered CO2 -incorporateddirectC–Hcarboxylation toformC–Cbond99

5.8 C-nucleophile-triggeredCO2 -incorporated organozinc-mediatedcarboxylationtoform C–Cbonds101

5.9 C-nucleophile-triggeredCO2 -incorporated organolithium-mediatedcarboxylation toformaC–Cbond102

5.10 C-Nucleophile-triggeredCO2 -incorporated organomagnesium-mediatedcarboxylation toformaC–Cbond108

5.11Conclusion111

References113

Chapter6ElectrochemicalCarbonDioxide Detection119 S.Aslan,C.I¸sık,andA.E.Mamuk

6.1Introduction119

6.2CapturetechnologiesofCO2 121

6.3Fundamentalsofelectrochemistry126

6.4Directpotentiometricmethods128

6.5Summaryandconclusion139 References141

Chapter7Carbondioxideinjectionfor enhancedoilrecoveryandunderground storagetoreducegreenhousegas149 ShubhamSaraf,andAchintaBera

7.1Introduction149

7.2OilrecoveryusingCO2 156

7.3Undergroundstorageof CO2 inunconventionalreservoirs167

7.4Currentstatus,challengesand futuredirections169

7.5Conclusions170 Acknowledgment172 References172

Chapter8Ionicliquidsaspotential materialsforcarbondioxidecapture andutilization177

MdAbuShahynIslam,MohdArhamKhan,NimraShakeel, MohdImranAhamed,andNaushadAnwar

8.1Introduction178

8.2TypesofILs179

8.3FutureapplicationsofILandGR-basedIL191

8.4Conclusion192 References193 Chapter9Recentadvancesin carbondioxideutilization asrenewableenergy197

MuhammadHussnainSiddique,FareehaMaqbool,TanvirShahzad, MuhammadWaseem,IjazRasul,SumreenHayat,MuhammadAfzal, MuhammadFaisal,andSaimaMuzammil

9.1Introduction197

9.2CO2 utilizationtechnologies198

9.3DevelopmentsinworldwideCO2 utilizationprojects204

9.4Marketscaleandvalue205

9.5Regulationandpolicy205

9.6Conclusionandfutureprospects206 References206

Chapter10MetalOrganicFrameworks asanEfficientMethodforCarbon dioxidecapture211

BhartiKataria,andChristineJeyaseelan

10.1Introduction211

10.2Metalorganicframework(MOF)212

10.3SynthesisofsomeMOFS215

10.4PropertiesofMOFs217

10.5CO2 captureusingMOF217

10.6Adsorptionofcarbondioxidein metalorganicframeworks219

10.7MethodstoenhanceCO2 adsorption219

10.8MethodstoenhanceMOF stability222

10.9Conclusion227 References227

Chapter11Industrialcarbondioxide captureandutilization231

UzmaHira,AhmedKamal,andJaveriaTahir

11.1Introduction231

11.2CO2 collectionsystemsbasedonliquid233

11.3CO2 capturingwithionicliquidsolvents242

11.4Applications,implementation andchallenges244

11.5SolidCO2 adsorbentsforlow-temperature applications245

11.6Carbonadsorbents246

11.7Zeoliteadsorbents248

11.8AdsorbentsoftheMOF(metal–organic framework)type250

11.9Adsorbentspredicatedon carbonate-basedalkalis252

11.10Layereddoublehydroxides (LDHs)-basedadsorbents254

11.11Adsorbentsmadeofmagnesium oxide(MgO)255

11.12SolidCO2 sorbentsfor high-temperatureapplications257

11.13Pre-combustionapplications, implementationandproblems260

11.14TheutilisationofCO2 in industrialprocesses262

11.15Conclusionsandprospects268 References270

Chapter12Ionicliquidsforcarbon capturingandstorage279

FaizanWaseemButt,HafizMuhammadAthar,SumiaAkram, ZainabLiaqat,andMuhammadMushtaq

12.1Introduction279

12.2CO2 capturetechnologies280

12.3Ionicliquids(ILs)281

12.4FeaturesofILs281

12.5ILasabsorbentsforCO2 capture283

12.6ILhybridsasadsorbentsfor CO2 capture289

12.7ILhybridswithmembranesfor CO2 capture289

12.8Ionicliquidsupportedmembrane290

12.9PolyILsmembrane290

12.10Compositemembranes290

12.11Conclusionandfutureinsights291 References291

Chapter13Advancesin utilizationofcarbon-dioxideforfood preservationandstorage297

AdeshinaFadeyibi

13.1Introduction297

13.2Utilizationofcarbon-dioxidein foodpreservation298

13.3Utilizationofcarbon-dioxidein foodstorage302

13.4Prospectsandconclusion305 References305

Chapter14Aninsightintotherecent developmentsinmembrane-basedcarbon dioxidecaptureandutilization311

PritamDey,PritamSingh,andMitaliSaha

14.1Introduction311

14.2Carbondioxidecapturetechnologies312

14.3Abriefaboutmembranetechnology314

14.4CO2 separationusingmembranes316 14.5CO2 utilizationusingmembranes321 14.6Conclusions322 References323

Chapter15Carbondioxidetofuelusing solarenergy327

SrijitaBasumallick

15.1Introduction327

15.2CO2 reductionontosemiconductor surface327

15.3MajorbottleneckforCO2 reduction328

15.4Differenttypesofphotocatalyst329

15.5ReductionofCO2 tomethanol usingCu2 Oasphotocatalyst330

15.6ReductionofCO2 tomethanolusing Cu2 Oaselectrocatalyst330

15.7BenefitsofusingRGOinthe compositecatalyst331

15.8Conclusions333

Acknowledgment333 References333

Chapter16Adsorbentsforcarbon capture337

VijayVaishampayan,MukeshKumar,MuthamilselviPonnuchamy, andAshishKapoor

16.1Introduction337

16.2Carboncaptureprocesses338

16.3AdsorbentsforCO2 capture338

16.4Futureperspectiveandconclusion342 References342

Chapter17Carbondioxidecaptureand utilizationinionicliquids345

GuocaiTian

17.1Introduction345

17.2CaptureofCO2 inILs349

17.3ElectroreductionofCO2 inILs391

17.4Conclusions406 Acknowledgments407 References407

Chapter18Hydrothermalcarbonizationof sewagesludgeforcarbonnegativeenergy production427

MilanMalhotra,AnushaSathyanadh,andKhanh-QuangTran

18.1Introduction427

18.2Sludgeasapotentialsourceof alternateenergy431

18.3Hydrothermal(HT)treatmentsforthe productionoffuel432

18.4Hydrothermalcarbonization+ gasification+ccs437

18.5Conclusion437 Acknowledgement438 References438

Chapter19Utilizationofsupercritical CO2 fordryingandproduction ofstarchandcelluloseaerogels441

JeieliWendelGasparLima,ClaraPrestesFerreira,

JhonatasRodriguesBarbosa,andRaulNunesdeCarvalhoJunior

19.1Introduction441

19.2CO2 application–Supercriticaldrying442

19.3StarchaerogelandCO2 utilization445

19.4CelluloseaerogelsandCO2 utilization447

19.5Conclusions448 Authorcontributions449 Ethicalapproval449 Declarationofcompetinginterest449 Acknowledgment449 References449

Chapter20Advancesincarbon bio-sequestration451

NigelTwi-Yeboah,DacostaOsei,andMichaelK.Danquah

20.1Introduction451

20.2Carbonsequestrationmethods452

20.3Limitationsofcarbonsequestration methods453

20.4Overviewofbiologicalsequestration (Cycle/Mechanism)454

20.5Bioresourcesforcarbon bio-sequestration455

20.6Cyanobacteria456

20.7Microalgae457

20.8Plants457

20.9Bacteria458

20.10Nanomaterialsincarbonsequestration458

20.11Futureperspectives459

20.12Conclusion459 References460

Chapter21Photosyntheticcellfactories, anewparadigmforcarbondioxide (CO2 )valorization463

BijayaNag,AbdalahMakaranga,MukulSureshKareya, AshaArumugamNesamma,andPannagaPavanJutur

21.1Introduction463

21.2Carboncapture,utilizationand storagemechanism465

21.3Biologicalmechanismofcarboncapture469

21.4ProductsfromCCU470

21.5Challengesandopportunities472

21.6Futureperspectivesandconclusions475 Fundinginformation476 References476

Chapter22Carbondioxidecapture andsequestrationtechnologies–currentperspective,challenges andprospects481

IfeanyiMichaelSmarteAnekwe,EmmanuelKweinorTetteh, StephenAkpasi,SamailaJoelAtuman, EdwardKwakuArmah,andYusufMakarfiIsa

22.1Introduction481

22.2Carboncaptureandsequestration(CCS) technologies484

22.3CO2 transportation,storage andopportunities/applicationsfor CCStechnologies493

22.4Currentperspectiveandpoliciesof CSStechnologiesinvariouscountries throughouttheworld497

22.5Challengesandsocio-economic implicationsofCCStechnologies501

22.6Applicationsandopportunities forCCStechniques504

22.7Prospectsandfuturework considerationsforCCSapproaches507

22.8Conclusion508 References509

Chapter23Microbialcarbon dioxidefixationfortheproduction ofbiopolymers517

TubaSaleem,IjazRasul,MuhammadAsif,andHabibullahNadeem

23.1Introduction517

23.2SourcesofCO2 emission519

23.3SequestrationmethodsofCO2 519

23.4Carbonconcentratingmechanisms520

23.5Advancementsincarboncaptureand storage&carboncaptureutilization521

23.6Carbondioxidefixationpathways521

23.7Factorsaffectingthecarbondioxide biofixation527

23.8Productionofbiopolymers/bioplastics527

23.9Conclusion529 References529

Chapter24Carbondioxidecapture anditsenhancedutilization usingmicroalgae531

PinkuChandraNath,BiswanathBhunia, andTarunKantiBandyopadhyay

24.1Introduction531

24.2PhotosynthesisandCO2 fixationusing microalgae532

24.3Cultivationsystemsforcarbondioxide capturebymicroalgae533

24.4CO2 captureimprovementstrategies541

24.5Conclusion541 References541

Chapter25Supportedsingle-atom catalystsincarbondioxide electrochemicalactivation andreduction547

AmosAfugu,CarolineR.Kwawu,ElliotMenkah,andEvansAdei

25.1Introduction547

25.2CO2 ERRproducts549

25.3Single-Atomcatalystsefficiency descriptors549

25.4Single-Atomcatalystsupports551

25.5MechanismsforCO2 ERRon single-atomcatalysts554

25.6Conclusion556 References557

Chapter26Organicmatterand mineralogicalacumensinCO2 sequestration561

SantanuGhosh,TusharAdsul,andAtulKumarVarma

26.1Overview562

26.2Introduction562

26.3Geo-sequestration563

26.4Bio-sequestration563

x Contents

26.5Mechanismsofcarboncapture564

26.6Transportofcarbondioxide566

26.7Mechanismofcarbonaccommodation566

26.8Carbondioxidesequestration inorganicmatter566

26.9Mineralogicalacumenofcarbon sequestration573

26.10AnoteonCO2 disposalinbasalt formations587

26.11Summary587 References588 Index595

Contributors EvansAdei DepartmentofChemistry,Kwame NkrumahUniversityofScienceandTechnology,Kumasi,Ghana

TusharAdsul CoalGeologyandOrganicPetrologyLaboratory,DepartmentofAppliedGeology,IndianInstituteofTechnology(Indian SchoolofMines)Dhanbad,Jharkhand,India

AmosAfugu DepartmentofChemistry,Kwame NkrumahUniversityofScienceandTechnology,Kumasi,Ghana

MuhammadAfzal DepartmentofBioinformaticsandBiotechnology,GovernmentCollege UniversityFaisalabad,Faisalabad,Pakistan

MohdImranAhamed DepartmentofChemistry,FacultyofScience,AligarhMuslimUniversity,Aligarh,UP,India

StephenAkpasi GreenEngineeringResearch Group,DepartmentofChemicalEngineering, FacultyofEngineeringandtheBuiltEnvironment,DurbanUniversityofTechnology,Durban,SouthAfrica

SumiaAkram DivisionofScienceandTechnology,UniversityofEducationLahore,Pakistan

BeautyAkter DepartmentofEnvironmental Sciences,JahangirnagarUniversity,Dhaka, Bangladesh

IfeanyiMichaelSmarteAnekwe Schoolof ChemicalandMetallurgicalEngineering, UniversityoftheWitwatersrand,Johannesburg, SouthAfrica

NaushadAnwar DepartmentofChemistry,FacultyofScience,AligarhMuslimUniversity, Aligarh,UP,India

EdwardKwakuArmah SchoolofChemicaland BiochemicalSciences,DepartmentofApplied Chemistry,C.K.TedamUniversityofTechnologyandAppliedSciences,Navrongo,Upper EastRegion,Ghana

MuhammadAsif DepartmentofBioinformatics andBiotechnology,GovernmentCollegeUniversityFaisalabad,Faisalabad,Pakistan

S.Aslan DepartmentofChemistry,Facultyof Science,MuglaSitkiKocmanUniversity,Mugla, Turkey

HafizMuhammadAthar DepartmentofChemistry,GovernmentCollegeUniversity,Lahore, Pakistan

SamailaJoelAtuman SchoolofChemicaland MetallurgicalEngineering,Universityofthe Witwatersrand,Johannesburg,SouthAfrica; DepartmentofChemicalEngineering,Faculty ofEngineering,AbubakarTafawaBalewaUniversityBauchi,Nigeria

TarunKantiBandyopadhyay Departmentof ChemicalEngineering,NationalInstituteof TechnologyAgartala,Jirania,Tripura,India

JhonatasRodriguesBarbosa InstituteofTechnology(ITEC),FacultyofFoodEngineering (FEA),FederalUniversityofPara(UFPA),Rua AugustoCorrêaS/N,Guamá,Belém,PA,Brazil

SrijitaBasumallick AsutoshCollege,University ofCalcutta,Kolkata,India

AchintaBera DepartmentofPetroleumEngineering,SchoolofEnergyTechnology,PanditDeendayalEnergyUniversity,Gandhinagar, Gujarat,India

BiswanathBhunia DepartmentofBioEngineering,NationalInstituteofTechnologyAgartala, Jirania,Tripura,India

FaizanWaseemButt DepartmentofChemistry, GovernmentCollegeUniversity,Lahore,Pakistan

MichaelK.Danquah DepartmentofChemical Engineering,UniversityofTennessee,ChattanoogaTN,UnitedStatesofAmerica

PritamDey DepartmentofChemistry,National InstituteofTechnologyAgartala,Tripura,India

AdeshinaFadeyibi DepartmentofFoodand AgriculturalEngineering,FacultyofEngineeringandTechnology,KwaraStateUniversity, Ilorin,KwaraState,Nigeria

MuhammadFaisal CreativeResearchCenterfor BrainScience,BrainScienceInstitute(BSI),KoreaInstituteofScienceandTechnology(KIST), Seoul,RepublicofKorea;DivisionofBioMedicalScience&Technology,KISTSchool, KoreaUniversityofScienceandTechnology (UST),Seoul,RepublicofKorea;Department ofChemistry,Quaid-i-AzamUniversity,Islamabad,Pakistan;InstituteofPlantBreedingand Biotechnology,MNS-UniversityofAgriculture, Multan,Pakistan

ClaraPrestesFerreira InstituteofTechnology (ITEC),FacultyofFoodEngineering(FEA), FederalUniversityofPara(UFPA),Rua AugustoCorrêaS/N,Guamá,Belém,PA, Brazil

SantanuGhosh CoalGeologyandOrganic PetrologyLaboratory,DepartmentofApplied Geology,IndianInstituteofTechnology(Indian SchoolofMines)Dhanbad,Jharkhand,India; OrganicGeochemistryLaboratory,Department ofEarthSciences,IndianInstituteofTechnology Bombay,Mumbai,Maharashtra,India;DepartmentofGeology,MizoramUniversity,Aizwal, Mizoram,India

KeerthigaGopalram DepartmentofChemical Engineering,SRMInstituteofScience&Technology,Kancheepuram,TamilNadu,India

SumreenHayat DepartmantofMicrobiology, GovernmentCollegeUniversityFaisalabad, Faisalabad,Pakistan

NazmulHasan TheUnitedGraduateSchoolof AgriculturalSciences,KagoshimaUniversity, Kagoshima,Japan;FruitScienceLaboratory, SagaUniversity,Saga,Japan

UzmaHira SchoolofPhysicalSciences(SPS), UniversityofthePunjab,Lahore,Pakistan

YusufMakarfiIsa SchoolofChemicalandMetallurgicalEngineering,UniversityoftheWitwatersrand,Johannesburg,SouthAfrica

Md.MahbubulIslam BangladeshBiocharInitiative,Dhaka,Bangladesh

MdAbuShahynIslam InterdisciplinaryNanotechnologyCentre,ZHCET,AligarhMuslim University,Aligarh,UP,India

C.I¸sık DepartmentofChemistry,FacultyofScience,MuglaSitkiKocmanUniversity,Mugla, Turkey

ChristineJeyaseelan DepartmentofChemistry, AmityInstituteofAppliedSciences,AmityUniversity,Noida,UttarPradesh,India

RaulNunesdeCarvalhoJunior Instituteof Technology(ITEC),FacultyofFoodEngineering(FEA),FederalUniversityofPara(UFPA), RuaAugustoCorrêaS/N,Guamá,Belém,PA, Brazil

PannagaPavanJutur OmicsofAlgaeGroup,IndustrialBiotechnology,InternationalCentrefor GeneticEngineeringandBiotechnology,New Delhi,India

AhmedKamal SchoolofPhysicalSciences(SPS), UniversityofthePunjab,Lahore,Pakistan

AshishKapoor DepartmentofChemicalEngineering,HarcourtButlerTechnicalUniversity, Kanpur,UttarPradesh,India

MukulSureshKareya OmicsofAlgaeGroup, IndustrialBiotechnology,InternationalCentre forGeneticEngineeringandBiotechnology, NewDelhi,India

BhartiKataria DepartmentofChemistry,Amity InstituteofAppliedSciences,AmityUniversity, Noida,UttarPradesh,India

MohdArhamKhan InterdisciplinaryNanotechnologyCentre,ZHCET,AligarhMuslim University,Aligarh,UP,India

AshishKumar NCE,DepartmentofScienceand Technology,GovernmentofBihar,India

MukeshKumar DisciplineofChemistry,Indian InstituteofTechnology,Gandhinagar,Gujarat, India

CarolineR.Kwawu DepartmentofChemistry, KwameNkrumahUniversityofScienceand Technology,Kumasi,Ghana

ZainabLiaqat DepartmentofChemistry,GovernmentCollegeUniversity,Lahore,Pakistan

JeieliWendelGasparLima InstituteofTechnology(ITEC),FacultyofFoodEngineering

(FEA),FederalUniversityofPara(UFPA),Rua AugustoCorrêaS/N,Guamá,Belém,PA,Brazil

AbdalahMakaranga OmicsofAlgaeGroup,IndustrialBiotechnology,InternationalCentrefor GeneticEngineeringandBiotechnology,New Delhi,India

MilanMalhotra DepartmentofEnergyandProcessEngineering,NorwegianUniversityofScienceandTechnology,Trondheim,Norway

A.E.Mamuk DepartmentofPhysics,Facultyof Science,MuglaSitkiKocmanUniversity,Mugla, Turkey

FareehaMaqbool DepartmentofBioinformatics andBiotechnology,GovernmentCollegeUniversityFaisalabad,Faisalabad,Pakistan

ElliotMenkah DepartmentofChemistry, KwameNkrumahUniversityofScienceand Technology,Kumasi,Ghana

MuhammadMushtaq DepartmentofChemistry,GovernmentCollegeUniversity,Lahore, Pakistan

SaimaMuzammil DepartmantofMicrobiology, GovernmentCollegeUniversityFaisalabad, Faisalabad,Pakistan

HabibullahNadeem DepartmentofBioinformaticsandBiotechnology,GovernmentCollege UniversityFaisalabad,Faisalabad,Pakistan

BijayaNag OmicsofAlgaeGroup,Industrial Biotechnology,InternationalCentreforGenetic EngineeringandBiotechnology,NewDelhi, India

PinkuChandraNath DepartmentofBioEngineering,NationalInstituteofTechnologyAgartala,Jirania,Tripura,India

AshaArumugamNesamma OmicsofAlgae Group,IndustrialBiotechnology,International CentreforGeneticEngineeringandBiotechnology,NewDelhi,India

DacostaOsei ChemicalandPetroleumEngineeringDepartment,UniversityofKansas,KS, UnitedStatesofAmerica

MuthamilselviPonnuchamy Departmentof ChemicalEngineering,CollegeofEngineering andTechnology,SRMInstituteofScienceand

Technology,Potheri,Kattankulathur,Tamil Nadu,India

IjazRasul DepartmentofBioinformaticsand Biotechnology,GovernmentCollegeUniversity Faisalabad,Faisalabad,Pakistan

MitaliSaha DepartmentofChemistry,National InstituteofTechnologyAgartala,Tripura,India

TubaSaleem DepartmentofBioinformaticsand Biotechnology,GovernmentCollegeUniversity Faisalabad,Faisalabad,Pakistan

ShubhamSaraf DepartmentofPetroleumEngineering,SchoolofEnergyTechnology,PanditDeendayalEnergyUniversity,Gandhinagar, Gujarat,India

AnushaSathyanadh DepartmentofEnergyand ProcessEngineering,NorwegianUniversity ofScienceandTechnology,Trondheim, Norway

NimraShakeel DepartmentofChemistry,FacultyofScience,AligarhMuslimUniversity,Aligarh,UP,India

MashuraShammi Hydrobiogeochemistryand PollutionControlLaboratory,Departmentof EnvironmentalSciences,JahangirnagarUniversity,Dhaka,Bangladesh

TanvirShahzad DepartmantofEnvironmental SciencesandEngineering,GovernmentCollege UniversityFaisalabad,Faisalabad,Pakistan

MuhammadHussnainSiddique Department ofBioinformaticsandBiotechnology, GovernmentCollegeUniversityFaisalabad, Faisalabad,Pakistan

PritamSingh DepartmentofChemistry,NationalInstituteofTechnologyAgartala,Tripura, India

AbinayaStalinraja DepartmentofChemicalEngineering,SRMInstituteofScience&Technology,Kancheepuram,TamilNadu,India

JaveriaTahir SchoolofPhysicalSciences(SPS), UniversityofthePunjab,Lahore,Pakistan

EmmanuelKweinorTetteh GreenEngineering ResearchGroup,DepartmentofChemicalEngineering,FacultyofEngineeringandtheBuilt Environment,DurbanUniversityofTechnology,Durban,SouthAfrica

Contributors

AbhinayThakur DepartmentofChemistry,FacultyofTechnologyandScience,LovelyProfessionalUniversity,Phagwara,Punjab,India

GuocaiTian StateKeyLaboratoryofComplex NonferrousMetalResourcesCleanUtilization, FacultyofMetallurgicalandEnergyEngineering,KunmingUniversityofScienceandTechnology,Kunming,YunnanProvince,China

Khanh-QuangTran DepartmentofEnergyand ProcessEngineering,NorwegianUniversityof ScienceandTechnology,Trondheim,Norway

NigelTwi-Yeboah OperationsDepartment, GhanaNationalGasCompany,WesternRegion, Ghana

VijayVaishampayan DepartmentofChemical Engineering,IndianInstituteofTechnology, Ropar,Punjab,India

AtulKumarVarma CoalGeologyandOrganic PetrologyLaboratory,DepartmentofApplied Geology,IndianInstituteofTechnology(IndianSchoolofMines)Dhanbad,Jharkhand, India

MuhammadWaseem DepartmantofMicrobiology,GovernmentCollegeUniversityFaisalabad,Faisalabad,Pakistan

JulienWinter Privateconsultant,Cobourg,ON, Canada

1 Carbondioxidecaptureandits utilizationtowardsefficient biofuelsproduction AbhinayThakur a andAshishKumar b a DepartmentofChemistry,FacultyofTechnologyandScience,LovelyProfessional University,Phagwara,Punjab,India b NCE,DepartmentofScienceandTechnology, GovernmentofBihar,India

1.1Introduction Whenreleasedintotheatmosphere,carbondioxide(CO2 ),aforemostgreenhousegas, retainsheatbyreflectinginfraredlightbacktotheEarth’ssurface.Asaresult,increasedCO2 emissionsareaworldwideproblembecausetheyareoneoftheprimarycausesofclimate disruption [1–4].Furthermore,worldwideCO2 emissionpatternsindicateanannuallyrise, whichisaccompaniedbyanannuallyriseinoverallwarming.TheriseinCO2 concentration was2.460.26ppm y 1 inOctober2021,aspercurrentstatistics,butthetemperaturehas enhancedatanannualizedlevelof0.08Cperdecadesince1980,asperNationalOceanicand AtmosphericAdministration(NOAA)2020annualclimatedisclose.Theresultisprogressive warmingandwitheringoftheenvironment,which,amongotherthings,iscreatingenormous anddisastrouswildfiresaroundtheworld,whichinturnemitenormousvolumesofCO2 intotheenvironment,makingcarbonreleasesevenmoreofaproblem [5–7].Inactuality, risingCO2 levelsintheenvironmenthaveavarietyofotherenvironmentalconsequences, includingadjustmentsinthehydrogeologicalprocess,theenhancedincidenceofnumerous severeclimateoccurrences,sea-levelrise,speciationmigratory,harvestlosses,andenhanced eventsthatoccurredofinfectiousdiseases,andsoon.From2010to2040,consumptionfor fossilfuelsisexpectedtoincreaseby40percent.Asaresult,alternateenergysourceshavebeen andcontinuetobeinvestigatedinordertomeetourenergyrequirements.Renewableenergy resourcesincludesunlight,air,andbiomass.Inthelastseveralyears,biomass,whichisformed throughaphysiologicalorigin,hasbeenexploitedtogeneratebiofuelsandbio-products. Thereare4phasesofbiofuels,basedonthesortofbiomass.Biodiesel,bioethanol,bioethanol,

1.Carbondioxidecaptureanditsutilizationtowardsefficientbiofuelsproduction biohydrogen,andbioethersareexamplesofbiofuels.Bioethanolandbiodiesel,whichboth constitutethefirstgenerationofbiofueltechnologies,arethemostcommonbiofuels,as pertheDepartmentofEnergy.TheUnitedStatesofAmerica,Australia,andtheEuropean Unionhaveallfinancedbiofuelexperiments.TheUnitedStatesprovidedfinancingtoNew Mexico(2009),Arizona(2008),Florida(2013),andMassachusetts(2011)whiletheEuropean Unionprovidedfundsforfourexperimentalinitiatives,threeoftheseoperatedduring2011to 2015/16andtheremainingbetween2012and2017.Biomassisconsideredasdiametrically opposedtotheusageoffossilfuels,andhencepreventsthereleaseoffreshCO2 intothe environment.Utilizingbiomass(andbiofuelsproducedfromit)isregardedanoperationthat doesnotaddCO2 totheenvironmentfromfossilfuels.Althoughthoughitisn’tpreciselyso, burningbiomassorbiofuelsisregardedazero-emissionsolutionforpowergenerationand consumption.Despitecontrast,comprehensivelifecycleanalysisinvestigationsdemonstrate that,intheexistingproduction–utilization–accountingframework,theusageofbiofuelsisa carbontransmissionthroughsubsurfacesubsoiltotheenvironment,equivalenttotheusage offossilfuels,albeitconsiderablylessintensively.Intruth,biomassismadeupofCO2 from theenvironment,andwhenburnt,itisthoughttorestoretheequivalentquantityofCO2 tothe environment,asiftheprocesswereacomponentofthebiologicalprocess.Inreality,unlike inreality,thecycleisnottrulyended.Inessence,incontrasttothecarbondioxideproduced bycombustionprocesses,onemustalsoevaluatethequantityofCO2 releasedbynumerous humanactionsthatprecedebiomassgenerationandprocessing,aswellasthesoilcarbon depletioninducedbyagriculturalmethods[8–15].

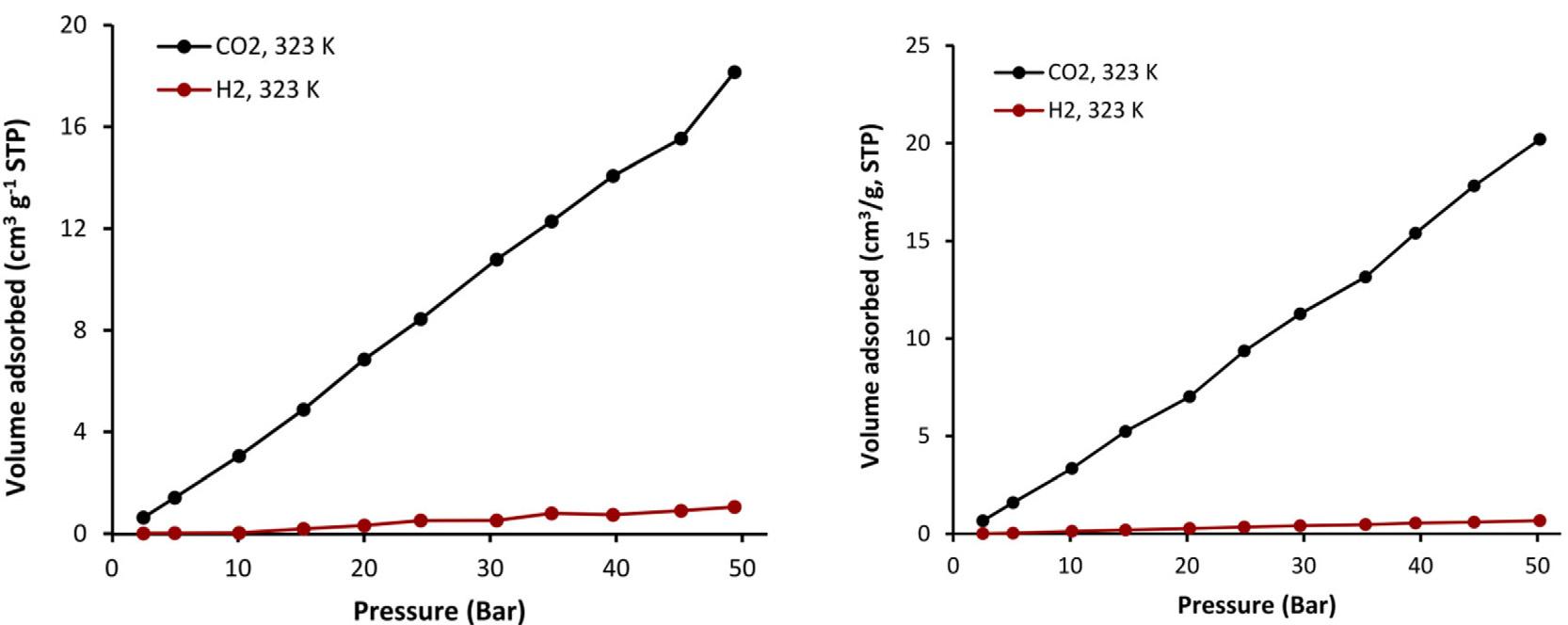

Bycombiningtelmisartanandasuitabletin(IV)chloride,Hadietal. [16] wasableto createunique,permeable,extremelyaromaticorganotin(IV)structures.Thesurfaceareaof theproducedmesoporousorganotin(IV)complexeswas32.3–130.4m 2g 1 ,theporecapacity was0.046–0.162cm 3g 1 ,andtheporediameterwasroughly2.4nm,accordingtoBrunauer–Emmett–Teller(BET)calculations.Tincomplexeswithabutylgroupwerefoundtobemore effectiveascarbondioxidestoragedevicesthanthosewithaphenylgroup.Ataregulatedtemperature(323K)andcompression,thedibutyltin(IV)moleculeofferthegreatestBETinterface region(128.871m 2g 1 ),thehighestquantity(0.162cm 3g 1 ),andtermedtobeeffective forCO2 retention(8.3wtpercent)(50bars).Thesorptionofcompoundswasinvestigated underaspecifiedtemperature(323K)andstrain.TheH2 andCO2 adsorptionisothermsin thepresenceofcompoundsareshownin Fig.1.1.ComplexesabsorbedalotofCO2 ,which mightownbecauseofintensevanderWaalscontactamongthemandCO2 .Forcomplexes, theamountofabsorbedCO2 was17.9,21.2,15.7,and34.9cm 3g 1 .Evidently,thesestructures havethemaximumCo2 absorptionaperture(6.9wtpercent)oftheorganotin(IV)compound, thatcouldbeduetothefactthattheyhavethebiggestBETinterfaceregion(128.871m 2g 1 ). Furthermore,withintheorganotin(IV)complexes,significantdipole-quadrupoleencounters inCO2 orH2 bondingandheteroatomsmayoccur.Whencomparedtoothergaseslikenitrogen andmethane,highlypermeableorganicpolymershavingnitrogen,oxygenorsulphuratoms areefficientatpreferentiallyabsorbingCO2 .Furthermore,insimilarcircumstancesasthose employedforCO2 absorption,complexesdisplayverylittleH2 adsorption(0.5–1.1cm 3g 1 ). It’spossiblethatthisbehaviorisowingtominimalcontact.

Similarly,Nasiretal. [17] usedthepartialpressuresofmethaneandCO2 ,aswellas theproportionsofseveralmembranematerials(polymer,amine,andfiller),tolinkthree optimalresultsinaunifiedmodel:CO2 permeance,CH4 permeance,andCO2 /CH4 selectivity.

FIGURE1.1 CO2 andH2 adsorptionisothermsforcomplex(AdaptedfromRef. [16])MDPI2019.Publishedin accordancewithCreativeCommonattributionLicenseCCBY4.0.

Thesevariablesaidedinforecastingmembraneefficiencyandinfluencingsecondaryvariables includingmembranelife,effectiveness,andproductquality.ForCO2 permeability,CH4 permeability,andCO2 /CH4 selectivity,themodelfindingsaccordwithexperimentaldata havinganrelativedeviationof5.9percent,3.8percent,and4.1percent,approximately.The findingssuggestthatthemodelcouldforecastvaluesunderavarietyofmembraneformation configurations.

Scholesetal. [18] investigatedthecapacityofacovalentlylinkedpolyether-polyamideblock copolymer(PEBAX2533)andpolyethyleneglycoldiacrylatetoextractcarbondioxidethrough N2 andCH4 inabasicandintegratedgascircumstances,aswellaswhen500ppmH2 Swas involved.TheLennardJoneswelldepthwasfoundtobeastrongerpredictorofgassolubility withinthesepolymersthanessentialtemperature.DuetocompetingsorptionfromCH4 or N2 ,CO2 penetrationwasdecreasedindrymixedgascircumstancesrelativetosinglegas measurements.Bothpolymers,though,maintainedCO2 selectivity.Waterinthefeedcaused thePEGmembranetoexpand,leadinginaconsiderableimprovementinCO2 penetrationas comparedtothegas(dry)environment.Interestingly,thesensitivitywasmaintainedeven whenthesupplygaswasmoist.TheinclusionofH2 SreducesCO2 penetrationviaboth membranesmerelyslightly.

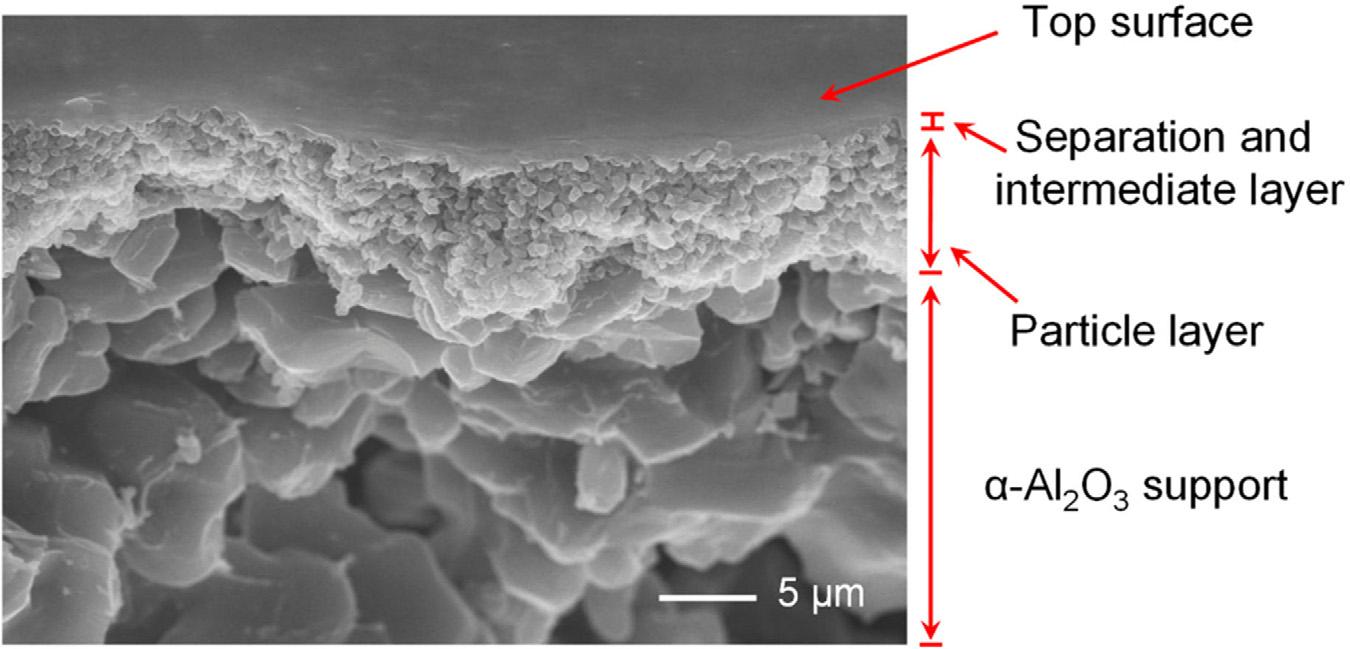

Jiangetal. [19] conductedextensiveresearchontheeffectsofcalcinationdegreesuponthe systemarchitecturesoforganosilicafilms.TheprecursorBis(triethoxysilyl)acetylene(BTESA) waschosenformembranemanufacturingusingthesol-gelmethod.Calcinationdegrees influencedfilmporouswidthandsilanoldensity,asindicatedbyTG,FT-IR,N2 adsorption, andmoleculetunablegaspermeationmeasurements.Thedisintegratedacetylenebridges resultedinaloosearchitectureintheBTESAmembrane,whichhadanextremehighCO2 permeationof15,531GPUbutalimitedCO2 /N2 sensitivityof4.1.BTESAmembranesshowed remarkablepotentialforCO2 extractionapplicationswhentheywerecalcinedat100°C,with aCO2 permeabilityof3434GPUandaN2 /CO2 sensitivityof21.FE-SEMwasusedtoanalyse BTESAcompositemembranesthathadbeencalcinedat100°Cinordertolearnmoreabout theirchemistry,asshownin Fig.1.2.

FIGURE1.2 SEMimagesoftheBTESA-100porousfilm.(AdaptedfromRef. [19])MDPI2022.Publishedin accordancewithCreativeCommonattributionLicenseCCBY4.0.

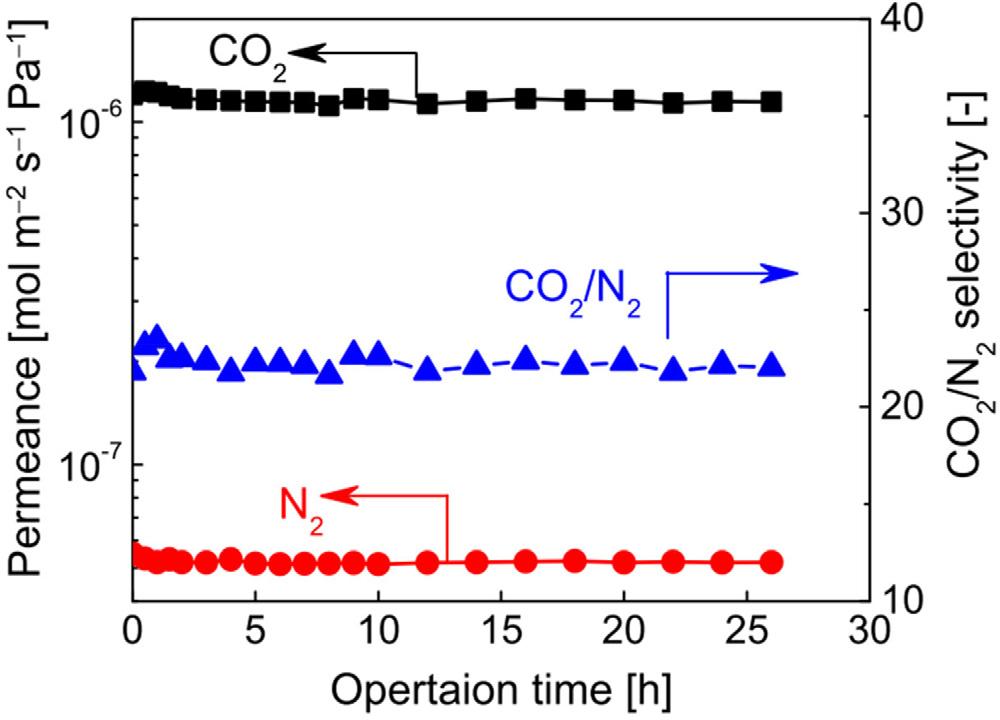

TheBTESA-100membranewasusedtoseparateCO2 /N2 mixturesforanalyticalpurposes. Astudyforthelong-termoperatingdurabilityofbinaryCO2 /N2 (14/79)segregationconductedat323Ktodemonstrateitsdurabilityofitsextractionefficiency,andthefindings arepresentedinFig.3.Inaconstantoperationlastingupto26h,negligiblediscernible lossinCO2 /N2 extractionefficiencyforCO2 /N2 sensitivityandCO2 permeability.During alongextractionexperiment,theBTESA-100membranewasproventobedependable,and ithasalotofpossibilitiesinCO2 collectionapplications.However,owingtothepresence ofmoistureintheoperationalCO2 /N2 separationprocedure,themembranestabilityin humidifiedconditionsmustalsobeevaluated.

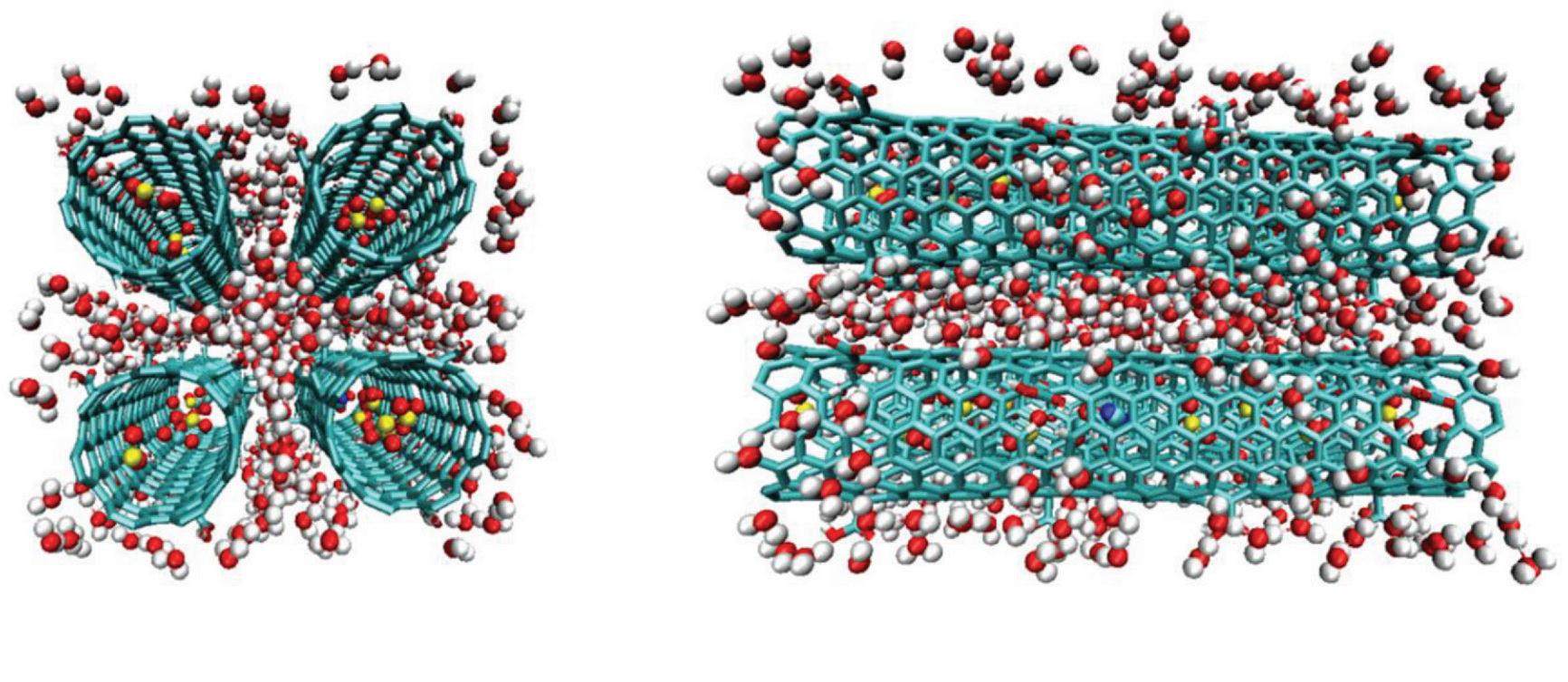

Furthermore,Suetal. [20] investigatedtheeffectofpollutantsinthefluegaseous,likeH2 O vapor,O2 andSO2 forthesorptionofCO2 /N2 integrationincarboxyldopedCNTmatrixand carbonnanotubes(CNTs)usingalargecanonicalMonteCarlosimulation.Themosteffective inhibitorofCO2 adsorptionwhenasolitaryuncleangasSO2 wasintroduced,whilewater onlyhadasignificantimpactatlowpressures(0.1psi),whena1DlatticeofH2 -bonded monomersformed.Furthermore,O2 wasdiscoveredtohavenoeffectonCO2 purificationand segregation.Withthreecontaminantsinfluegas,SO2 performedakeyfunctioninsuppressing CO2 adsorptionbydrasticallyloweringtheadsorptionquantity.Thiswasduetothefactthat SO2 exhibitedagreateraffinitywithcarbonwallsthanCO2 .Becauseofcorrelationsamong distinctentities,theinclusionofthreecontaminantsinfluegasincreasedtheadsorption intricacy.TheCNTmatrix’externaladsorptionregionwasheavilydominatedbyH2 O,which hydrophiliccarboxylgroupsmodified,andSO2 effectivelyadsorbsCO2 insidetheduct.These twoimpactsrestrictedCO2 adsorptionwhileincreasingCO2 /N2 selectivity,andthecontest amongthemcontrolledtheCO2 adsorptionpatternwithinandwithoutthetube.Furthermore, itwasdiscoveredthatintheexistenceofimpuritygas,carbonnanotubeconsistentlyretained theoptimumCO2 /N2 sorptionandsegregationefficiency,inbothsingleCNTandCNTarray situations.

Aconsiderableamountofwatermoleculesareabsorbedandaccumulatedamongtubesto createchainformations,asperthemolecularimageofwatermoleculesdepositedin(7,7)

CNTarrayinFig.4,althoughwatermoleculeadsorptionintubesisscarcelydetected.Atthe sametime,astuberadiusincreases,theadsorptionrateofwatermoleculesreduces.Measuring theweightfractionofinterferingcarboxylrevealsthatcarboxylconcentrationhasasignificant impactonwatermoleculeadsorptioncapability.Themasspercentageofcarboxylgroupdrops asthewidthofthetubeincreases,resultinginareductionintheadsorptioncapabilityof watermolecules.TheabsorptionofSO2 insmall-diameternanotubearrayswasaidedbythe existenceofwatermolecules.

1.2Utilizationofcapturedcarbondioxideforbiofuelproduction Worldwideclimatewarmingandrisinggreen-housegasemissions,andtheexhaustionof traditionalfuelsources,havebecomeanincreasingsourceofconcerninrecentdecades.Coal, oil,andnaturalgasburningreleaseupwardsof6billiontonnesofCO2 intotheenvironment eachyear[5,21–29].Inthiscontext,physiologicalCO2 reductionisincreasinginterestsinceit resultsintheproductionofenergythroughbiomassgeneratedbyCO2 fixationviaphotosynthesis.Becauseitisenergyeconomical,durable,andecologicallyfriendly,photosyntheticCO2 fixationisregardedtobeaviabletechnique.GreenplantsmaycaptureCO2 viaphotosynthesis, whichisanaturalprocess.Furthermore,duetothemitigatedratesofgrowthoftraditional landplants,CO2 collectionthroughsustainablenaturalsourcespredictedtobejust4–7percent offossilfueloutputs[12,30–33].Microalgae,oneitherhand,couldpresentapossibilitybecause toitsquantityandrapiddevelopmentproportion.Rapidlymaturingsinglecelledmicrobes calledmicroalgaehavea10–50percentgreatercapacitytoabsorbphotovoltaicradiation overbryophytessimultaneouslyfixingCO2 .Carbonicanhydrase(CA),anextracellularzinc metalloenzyme,aidsintheabsorptionofCO2 fromtheenvironmentbymicroalgalcells. CAcatalyzesthetransformationofCO2 tobicarbonates,thatareabsorbedbymicroalgal cellsviatransporter.TheCO2 collectedbymicroalgaeisretainedascarbohydrates,lipids,or proteins,basedonthegenus.ItmaybepossibletoextractCO2 frommicroalgaelipidstores anduseitasabiofuel.OneoftheleaststudiedmethodsforcapturingCO2 isthebiological pathwayviamicroalgae,inwhichCO2 isinstantlyconvertedtobiomassviasinglesource dischargesinspeciallydesignedplatformslikephotobioreactors.Phototrophicalgae’scarbon fixationhastheabilitytoreduceCO2 emissionsintotheenvironment,hencereducingglobal warming.MicroalgalCO2 biofixationinphotobioreactorsisapotentialmethodforproducing morebiomassandethanol.TheusageofphotobioreactorsforCO2 capturebymicroalgaehas severalbenefits,includingincreasedmicroalgalproductionowingtoregulatedatmospheric factorsandenhancedareaorvolumetricutilization,resultinginmoreeffectiveutilizationof expensiveland.Microalgaemightthusserveadualpurposebyloweringgreenhousegases throughCO2 sequestrationandsupplyingcleanerenergytomeettheexpandingneedfor energy.

1.2.1Photosynthesisandphotooxidationofwater

Photosynthesisisknowntobeabiologicalactivitythatisperformedoutbybacteria, algae,andelevatedplants.Itrelatestotheprocessthroughwhichspeciesturnlightenergy tothechemicalenergythroughgatheringlightandusingitforfuelbyCO2 adsorption.

1.Carbondioxidecaptureanditsutilizationtowardsefficientbiofuelsproduction

FIGURE1.3 At50°Celsius,aextended durabilityexperimentofCO2 /N2 (14/79) mixturesegregationfortheBTESA-100 porousfilmwasperformed.(Adapted fromRef. [19])MDPI2022.Published inaccordancewithCreativeCommon attributionLicenseCCBY4.0.

(A)(B) FIGURE1.4 At1.0bar,300K,amolecularimageofthe(7,7)CNTarrayincross-sections(A)andaxialaxis(B). (AdaptedfromRef. [20])MDPI2022.PublishedinaccordancewithCreativeCommonattributionLicenseCCBY4.0.

Carbongetstransferredfromtheenvironmentintobiomassinthismanner.Thewatersplittingprocess,whichresultsinthecreationofoxygen,isabonuselementofalgae’s photosynthesis.Thephotosynthesisreactionoccurredinchloroplasts,whicharespecialized organelles.Thephysicochemicalandbiologicalprocessesarethetwoseriesofstepsthat makeupphotosynthesis.Thebiophysicalprocessestakeoccurinthechloroplasts’thylakoid discs [34–39].Theabsorbingoflightphotonsbyessentialpigmentssuchaslikexanthophylls andcarotenesisreferredtoasphotonabsorption.Thewaterisoxidized,releasingoxygen (Fig.1.3).Thereductionofnicotinamideadeninedinucleotidephosphateandproductionof adenosinetriphosphate(ATP)arebothaidedbytheelectronsreleasedfromwatermolecules

FIGURE1.5 Photosynthesisandphotolysispathwaysofphotoautotrophicbacteriaaredepictedschematically. (AdaptedfromRef. [40])Springer2017.PublishedinaccordancewithCreativeCommonattributionLicense CCBY4.0.

(NADPH).TheenergyproducedwhileNADPHandATPareintheiractivestatesisusedin thedarkprocessestobindCO2 .Thestromaiswherethemetabolicresponseoccurs,andthe endmetabolitesareprimarilysugarmoleculesandafewotherchemicalcompoundsrequired formetabolicactivityandcellfunction.

1.2.2Bio-sequestrationofCO2

CO2 fromtheenvironmentisabsorbedduringthephotosyntheticcycle,thatiscarriedout bymicroalgaetoproducefeed.TheC3andC4routesarethetwoprocessesthroughwhich greenplantsassimilateCO2 fromtheenvironment.Around250,000speciesofC3plantsand 7500kindsofC4plantshavebeenidentified.ForCO2 fixation,manyalgaeutilizetheC3 pathway(CalvinCycle).CO2 ismixedusinga5-carbonmoleculetoproducedual3-carbon chemicalsinthisprocess.Ribulose-1,5-bisphosphatecarboxylase/oxygenase(RuBisCo)is referredtobeanenzymewhichcatalyzesthisprocess.Mostalgaearephotoautotrophs,which meanstheycanobtainalloftheirenergyfromphotosynthesisandmostoftheircarbonthrough carbondioxideabsorption.DiatomsarecategorisedasC4plantsbecauseitcouldabsorbCO2 inadifferentwaythanterrestrialagriculturalplantslikecorn,cotton,andwheat.C4plants combineCO2 usingatri-carbonmoleculetocreateatetra-carbonmoleculeinsteadusing

1.Carbondioxidecaptureanditsutilizationtowardsefficientbiofuelsproduction

RuBisCotocreatedualthree-carbonmolecules,limitingphotorespirationlossandimproving theefficiencyofCO2 fixation.C4plantsarebelievedtopossessdoublethephotosynthetic rateofC3plants,thoughthatthisadvantagehasbecomefewernoticeablewhenCO2 levels aresufficient.TheabsorbedCO2 isretainedascarbohydratesandlipidsinthealgalcells. TheHatchSlackphaseisusedbyC4plantsincomplementtotheBensonCalvinprocess. Inthisadditionalcycle,thephosphoenolpyruvatecarboxylase(PEPcase)enzymeachievesa pre-acquisitionofcarbondioxideintheformofatetra-carbonmolecule.Thebyproductsof thisprocessareemployedtoincreasethelevelofCO2 atthelocationwhereinRuBisCO(the carboxylationenzymeoftheBensonCalvincycle)isactive,preventingphotorespiration.The extracellularcarbonicanhydrase(CA)enzymeaidsintheabsorptionofCO2 bymicroalgal cells.It’sthoughttobethecarbonconcentratingmechanism’slikelymainenzyme.Theenzyme isinvolvedinabroadvarietyofmacroandmicroalgalorganisms.ItaidsinCO2 absorption bycatalysingtheinteractionbetweenHCO3 andCO2 .Ithasbeendiscoveredthatintracellular CAcanhappenintheidenticalcell.ThegenescodefortheCAisoformsarecontrolledbythe inorganiccarboninthemedia.Asaresult,theactionofCArisesastheamountofinorganic carboninthemediadecreases.InordertoconvertCO2 intoHCO3 inthecytosolduringC4 photosynthesisandfurnishsubstratesforPEPcarboxylase,CAisrequired.Theinformation gatheredfromtheresearchconductedwithCAinhibitorshasprovedthepresenceofCA. AlthoughCAactivityhasbeenstudiedinavarietyofmicroandmacroalgae,investigationsof thestandardgreenalgaChlamydomonasreinhardtiihaveprovidedthemajorityofthepresent knowledgeofthefunctionofCAinalgae.

Enhancingpassiveandactivecarbonabsorptionfromtheatmosphere. ReducingCO2 escapefromhigh-CO2 -concentrationareaswithinthecell.

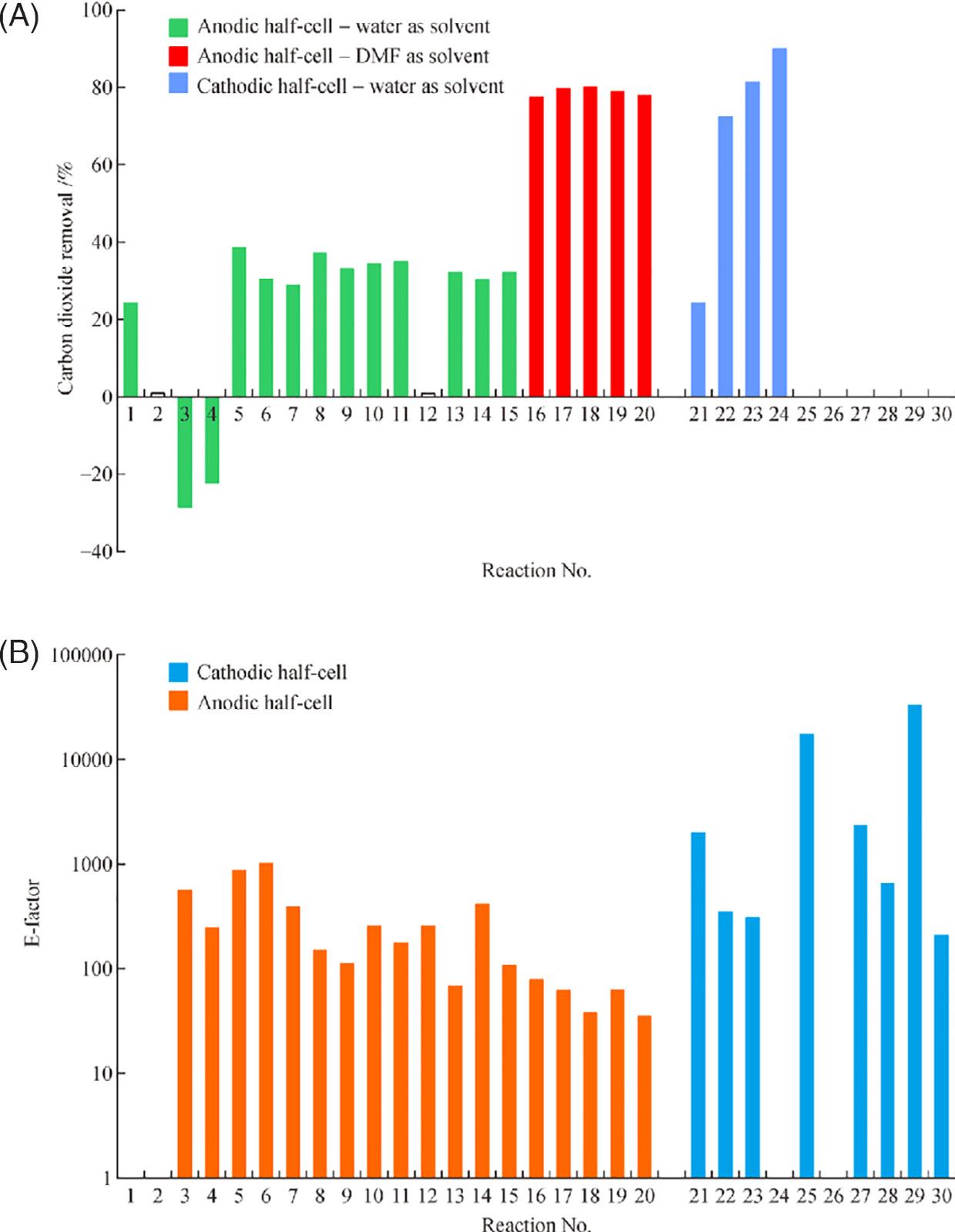

Montazersadghetal. [41] decidedtogenerateanovelelectrochemicalsystemforproducing low-carbone-biofuelsusingmultipurposeelectrosynthesisandintegratingCO2 covalorizationofbiomassresources.Drop-infuelswereproducedbyreducingCO2 nearthecathode, whereasvalue-enhancedchemicalswereproducedneartheanode.Inthisstudy,amathematicalanalysisofacontinuous-flowarchitecturewasestablishedtoevaluatethemosttechnoeconomicallyviablecombinationsbasedonenergyeffectiveness,environmentaleffect,and economicalideals.Afterthen,thereactorarchitecturewastweakedusingparametricstudy. Aconstantelectrolyticcellwasdesignedandconfirmedanalytically.Thealgorithmwasthen utilizedincombinationwithmultiplecellkineticstoestimatetheoptimalcellarchitecture fordistinctescenarios.Aselectionoforganiccompoundswithatleastoneinteractionfrom eachgroupwereusedtogeneratethekinetics.Themostcurrentdevelopmentsinbiomass oxidationforbiofuelgenerationandCO2 electroreductiondynamicsandarealsocoveredin thisresearch.Theoverallperformanceofthecellisimprovedbyusinganon-watersolvent becauseHERwasnotpredominantatthecathode.Whereastheenergycontentoftheprimary commodityprimarilydeterminestheenergyeffectivenessofthecell,properlychoosingthe reactorkineticscouldsignificantlyincreasetheefficiencyofCO2 conversion.Whencontrasted tocertainothermanufacturingapplications,thecumulativeenvironmentalimpact(E-factor) isconsiderable.Thisisowingtothesolvent’shugequantityincomparisontotheoutput, anditcouldbeminimizedbycyclingthesolventthroughtheprocess.Thebyproductsat theanodeforthespecifiedreactionmechanisminfluencethecell’seconomicallyadditional valueoneofthemost.BecausebothcompoundspossessarelativelyhighGibbsenergyoutput,

FIGURE1.6 Forseveralhalf-cellreactions,(A)CO2 captureratioand(B)E-factor.(AdaptedfromRef. [41]) Springer2021.PublishedinaccordancewithCreativeCommonattributionLicenseCCBY4.0.

theincreasedcellularenergyperformancewasenhancedto340percent.CO2 transformation frequencyof69.3percent,presentefficacyof56.7percentwithE-factorof704aresome oftheothercelleffectivenessparameters.TheCO2 conversionrateisalsoanothercrucial productivitycomponentthatcouldbeimproved(see Fig.1.6).BecausetheHERwasnot presentatthecathode,DMFwaspresumedtobethesolvent.

Similarly,Zdebetal. [42] discussedtheempiricalfindingsofincorporatingcarbondioxide asareagentinthevalorizationprocessincoalgasification.Threebasicsetupsfeaturingvaried modeledwasteheatusesituationsweretestedonabatchprocessmovingbedgasifier.CO2 , O2 ,andacombinationof30percentCO2 inO2 wereutilizedasgasificationreagentsat

FIGURE1.7 Configurationonalabscalewitharollingbedreactorandagasificationreagentpre-heatingsystem: (A)aperspectiveand(B)agraphicillustration.(AdaptedwithRef. [42])MDPI2019.Publishedinaccordancewith CreativeCommonattributionLicenseCCBY4.0.

temperaturesof700,800,and900°Celsius.Thecumulativeinfluenceofprocessingparameters oncoaltreatmentefficiencyofgasproductivity,content,andcalorificrangewasinvestigated, andtheempiricalvaluewasanalyzedutilizingPrincipalComponentAssessment.

Inthecontrolledsituationsused,thetrialsconfirmedthepossibilityofproducinggaswith acaloriecontentof4–6MJ/m3 bypyrolysiswithacarbondioxide-containinggasifyingagent. Eventhoughencouraginginthedevelopmentofenergy-efficientandlow-carbonfootprint processes,theconceptofcarbondioxidevalorizationandwasteheatutilizationincoal gasificationrequiresmuchfurtherbreakthroughsinrelationtoworkingassimilationaswell ascost-competitivenessmetricsuntilitcanberegardedforwidespreadapplication.

Similarly,Ahmadetal. [43] createdasystemofdata-basedsoftsensorsthatusesan ensembletechniquecalledboostingtoforecastthecontent,amount,andgradeoffattyacid methylesters(FAME)inthebiofuelsynthesisprocedureusingtheoilofseveralvegetables. Thenon-intrusivepolynomialchaosexpansion(PCE)techniquewasaddedintothesensitive detectorsdesigntoevaluatehowambiguityaffectedtheresults.Ineachoftheelements,flow rateandcetane,auniquemodel(softsensor)wascreated.TheanticipatedresultsofMethyl-Li, -O,-M,-P,-S,FAMEtransmissionrate,andcetanefrequencywere0.27479,0.32227,2.41208, 0.1651,0.82135,0.96546,and0.97013with1percentvariationinallsupplyparametersofthe sensitivedetectorswere0.27479,0.32227,2.41208,0.1651,Thesensorsareextremelypreciseat predictingandquantifyingambiguity,makingthemidealforpracticaluses.

Zhangetal. [44] focusedonthetechnicalandeconomicalconfigurationofsolid-oxideelectrolysisforthemanufactureofgreenmethanolbyHydrogenationofcarbondioxide.System unification,technicalandeconomicalanalysis,andmulti-objectivemanagementarecarried outsuccessfullyforaresearchproject.Theresultsshowatrade-offbetweenenergyefficiency andthecostofgeneratingCH3OH.Theassessedexample’sannualmethanolproduction was100kton,withaqualityof98.6percentweightandacarbondioxideusageof150kton,

offeringitanannualretentioncapacityof800GWhsustainableenergy.Methanolproduction costsapproach560$/tonhavinganelectriccostof74.26$/MWh,makingitcommercially unworkablewithanusablelifeofover13years,despitetheperformancebeingabout70 percentandvaryingwithinasmallrange.Whenthepriceofenergyisreducedto47dollars permegawatthourandsubsequentlyto24dollarspermegawatthour,thecostofproducing methanolfallsto365and172dollarsperton,respectively,witha4.6and2.8-yeareconomic success.Thecostofpowerhasaconsiderableinfluenceonprojectexecution.Thecostofpower variesbycountry,resultinginvariedpaybacktimesinvariousplaces.

Estevesetal. [45] examinedattheeffectsofdifferentlightfrequenciesonbiomassproduction,carbondioxidereduction,andnutrientremovalthroughasyntheticdischarge inTetradesmusobliquus,ChlorellavulgarisandNeochlorisoleoabundans.Light-emitting diodes(LEDs)havingvariedwavelengthswereusedintheexperimentations:620–750nm (red),380–750nm(white)and450–495nm(blue).N.oleoabundanswithwhiteLEDshadthe highestspecificgrowthrate(0.2640.005 d 1 ),whileC.vulgarishadthehighestbiomassoutput (144mgCO2 L 1 d 1 )andCO2 fixationrates(12.5mgCO2 L 1 d 1 ).Thethreemicroalgae investigatedhadthegreatestnitrogenandphosphorusextractionefficiencywhenexposedto whitelight.

Molinoetal. [46] developedScenedesmusalmeriensisintoagreenmicroalgaonabenchscaletotrapCO2 andproducelutein.Inaverticallyhydrodynamiccavitationphoto-bioreactor withasteadystreamofamixtureofgasesofN2 ,O2 andCO2 withtheformerhaving aconcentrationof0.0–3.0percentv/v,heterotrophicgrowthofS.almeriensiswascarried successfully.Batchingwasusedintheliquidphase.ThedevelopmentofS.almeriensiswasoptimized.Furthermore,luteinseparationwasconductedoutat59°Cand9MPautilizingrapid solventseparationusingC2 H5 OHtobeaGenerallyRecognizedasSafe(GRAS)substrate. Utilizingacarbondioxideconcentrationof2.9percentv/v,thehighestbiofuelproductivityof 129.24mgL 1 d 1 wasattainedduringinthedevelopment,allowingforaluteinconcentration of8.54mgg 1 ,thatwas5.6-foldgreaterthanthesimilarprocedureperformedwithoutCO2 . TheionchemistryanalysisofthegrowingmediumrevealedthatrisingCO2 concentrationprogressivelyboostednutrientintakethroughoutthegrowthstage.Becauseitfocusesonpigment creationfromanaturaloriginwhilealsocapturingCO2 ,thisresearchcouldbeofrelevancefor luteinharvestingatanindustriallevel. Fig.1.8 showstheinfluenceofCO2 concentrationon nutrientabsorptionasassessedattheconclusionofS.almeriensis’development.Theresults revealedafullphosphateionconsumption,thatwouldimpedecellularproliferation.The efficiencyofnutrientintakeimprovedasCO2 levelraised.Theextendedcultureperiods(i.e., 20daysforCO2 = 0.5percentv/v;16daysforCO2 = 1.5percentv/v;13daysforCO2 = 3.0percentv/v)did,though,helptoincreasenutritionalintake.Duringinthedevelopment period,nitrateandphosphatewerethemostheavilyabsorbednutrients.Aproposedreason forthisphenomenaisthatproteinproductionrequiresanitrogensupply,andluteinoccurs inmicroalgaeasanitrogenousmacromolecule.ThecurrentinvestigationshowedthatNO3 andPO4 3 ionsarethemostessentialnutrientforcellgrowthinmicroalgaedevelopment. Furthermore,withCO2 levelsof0.0,0.5,1.5,and3.0percentv/v,theabsorptionofNO3 ionswas5.0,59.88,77.26,and87.22percent,correspondingly,throughoutdevelopment.This findingcouldbeexplainedbyarestrictedcarbonsource,thatcausesstraininmicroalgae growthcells,resultinginreducedbiologicalnutrientabsorption.Incontrasttotheintakeof othernutrients,therewasareducedintakeofbothNa+ andClionsattheconclusionofthe