C Programming For Dummies 2nd Edition Dan Gookin

https://ebookmass.com/product/c-programming-for-dummies-2nd-editiondan-gookin/

ebookmass.com

The Economics of Optimal Growth Pathways: Evaluating the Health of the Planet’s Natural and Ecological Resources S. Niggol Seo

https://ebookmass.com/product/the-economics-of-optimal-growthpathways-evaluating-the-health-of-the-planets-natural-and-ecologicalresources-s-niggol-seo/

ebookmass.com

Neuroradiology Imaging Case Review Salvatore V Labruzzo

https://ebookmass.com/product/neuroradiology-imaging-case-reviewsalvatore-v-labruzzo/

ebookmass.com

Reluctant Cold Warriors: Economists and National Security

Vladimir Kontorovich

https://ebookmass.com/product/reluctant-cold-warriors-economists-andnational-security-vladimir-kontorovich/

ebookmass.com

Thermofluids:

From

Nature to Engineering Ting

https://ebookmass.com/product/thermofluids-from-nature-to-engineeringting/

ebookmass.com

First Aid for the Basic Sciences. General Principles 3rd Edition Tao Le

https://ebookmass.com/product/first-aid-for-the-basic-sciencesgeneral-principles-3rd-edition-tao-le/

ebookmass.com

Preparations,Properties,Applications andProspects

KazuyukiTakai

SeiyaTsujimura

FeiyuKang

MichioInagaki

Elsevier

Radarweg29,POBox211,1000AEAmsterdam,Netherlands

TheBoulevard,LangfordLane,Kidlington,OxfordOX51GB,UnitedKingdom 50HampshireStreet,5thFloor,Cambridge,MA02139,UnitedStates

Copyright©2020ElsevierInc.Allrightsreserved.

Nopartofthispublicationmaybereproducedortransmittedinanyformorbyanymeans,electronicor mechanical,includingphotocopying,recording,oranyinformationstorageandretrievalsystem,without permissioninwritingfromthepublisher.Detailsonhowtoseekpermission,furtherinformationaboutthe Publisher ’spermissionspoliciesandourarrangementswithorganizationssuchastheCopyrightClearance CenterandtheCopyrightLicensingAgency,canbefoundatourwebsite: www.elsevier.com/permissions

ThisbookandtheindividualcontributionscontainedinitareprotectedundercopyrightbythePublisher (otherthanasmaybenotedherein).

Notices

Knowledgeandbestpracticeinthis fieldareconstantlychanging.Asnewresearchandexperiencebroaden ourunderstanding,changesinresearchmethods,professionalpractices,ormedicaltreatmentmaybecome necessary.

Practitionersandresearchersmustalwaysrelyontheirownexperienceandknowledgeinevaluatingandusing anyinformation,methods,compounds,orexperimentsdescribedherein.Inusingsuchinformationor methodstheyshouldbemindfuloftheirownsafetyandthesafetyofothers,includingpartiesforwhomthey haveaprofessionalresponsibility.

Tothefullestextentofthelaw,neitherthePublishernortheauthors,contributors,oreditors,assumeany liabilityforanyinjuryand/ordamagetopersonsorpropertyasamatterofproductsliability,negligenceor otherwise,orfromanyuseoroperationofanymethods,products,instructions,orideascontainedinthe materialherein.

LibraryofCongressCataloging-in-PublicationData

AcatalogrecordforthisbookisavailablefromtheLibraryofCongress

BritishLibraryCataloguing-in-PublicationData

AcataloguerecordforthisbookisavailablefromtheBritishLibrary

ISBN:978-0-12-819576-5

ForinformationonallElsevierpublicationsvisitour websiteat https://www.elsevier.com/books-and-journals

Publisher: MatthewDeans

AcquisitionEditor: GlynJones

EditorialProjectManager: NaomiRobertson

ProductionProjectManager: SruthiSatheesh

CoverDesigner: MarkRogers

TypesetbyTNQTechnologies

Preface

TheNobelPrizeinPhysicsfor2010wasawardedtoProfs.A.GeimandK.Novoselovof theUniversityofManchesterfortheirgroundbreakingexperimentsongraphene.Theterm “graphene”wasproposedin1986inrelationtotheterminologyusedforgraphite intercalationcompounds.AftertheNobelPrize,scientificandtechnologicalinterestin grapheneincreasedrapidly;asaconsequence,atremendousamountofliteraturedeclaring itsresearchtargettobegraphenehasbeenpublished.Unfortunately,thisrapidgrowthin interesthascausedseriousconfusionregardingthedefinitionandterminologyofgraphene eveninscientificjournals.

Twoofthecurrentauthors,M.InagakiandF.Kang,haveauthoredthreebooksinaseries, entitled MaterialsScienceandEngineeringofCarbon:Fundamentals, AdvancedMaterials ScienceandEngineeringofCarbon,and MaterialsScienceandEngineeringofCarbon: Characterization.Itwasanticipatedthatthesebookswouldprovideacomprehensive understandingofawiderangeofcarbonmaterials(graphite,graphitizedcarbons,carbon blacks,activatedcarbons,pyrolyticcarbons,glass-likecarbons,porouscarbons,carbon fibers,etc.,inadditiontodiamond,fullerenes,carbonnanotubes,andgraphene)throughthe detailedexplanationanddiscussionoftheirstructures,nanotextures,andfundamental properties.However,theoccurrenceofmisperceptionsandtheflood-likeincreasein researchpapersongraphene-related(graphene-like)materialsledthesetwoauthorsto believeitwasnecessarytoeditabookfocusingongraphene-relatedmaterials,inaddition tothethreepreviouslymentionedbooks,althoughgrapheneisamembersofthecarbon family.Therefore,theyinvitedtwoauthors,K.TakaiandS.Tsujimura,whoarespecialists inthephysicalchemistryofgraphene,andelectrochemistryapplicationstobiomedicals, respectively,tocoverthewidelyspreadapplicationsofgrapheneinthisbook.

Inthisbook,theauthorsattemptedtoprovidesummariesandreviewsongrapheneandits relatedmaterialsbydifferentiatingmaterialswithahighperfectionofstructure(graphene) fromthosethatarehighlydefective,evenwithvariousfunctionalgroupsattached(reduced grapheneoxide).Inaddition,itisemphasizedthatthenumberoflayersgovernsthe propertiesoftheflakesofgraphene(thecharacteristicsofgraphene)whicharequite differentfromthoseofgraphite(manylayersstacked)andpossibletobeobtainedonthe flakeofonlyafewhighly-crystallinelayersstacked.

Tounderstandgrapheneanditsrelatedmaterials,awiderangeoffundamentalknowledge onvariouscarbonmaterialsisessential:thatis,knowledgesuchascarbonization, graphitization,intercalation,andsoon,inadditiontobasicknowledgeaboutchemistry, physics,biology,andothers.Forthereaders’convenience,itisrecommendedtoconsultthe threebooksmentionedpreviously,whicharepublishedbyTsinghuaUniversityPressand Elsevier.Thesebookswillsupplyfundamentalknowledgeaboutcarbonmaterialsand provideanunderstandingofabroadrangeoftopicsinthecurrentbook.

Itwillbetrulypleasingtoalloftheauthorsifthecontentofthisbookdeliversuseful informationtothereadersandwillleadreaderstothecorrectunderstandingofgraphene andrelatedmaterials.

Acknowledgments

Theauthorswouldliketoexpresstheirsincerethankstothepeoplewhokindlyprovided thedataandfiguresforthisbook.Thenamesandaffiliationsofthecontributingpersonsare mentionedinthecaptionsoffigures.Theauthorsalsothankallofthepeoplewhotookcare ofthisbookatTsinghuaUniversityPressandalsoatElsevier.

Introduction

ChapterOutline

1.1Whatisgraphene?1

1.2Fundamentalsofmaterialsscienceforcarbonmaterials5

1.2.1Classificationofcarbonmaterials5

1.2.2Structureandnanotextureofcarbonmaterials6

1.2.3Carbonizationandgraphitization8

1.2.4Carbonmaterials12

1.2.4.1Highlyorientedgraphitematerials12

1.2.4.2Syntheticgraphitematerials17

1.2.4.3Fibrouscarbonmaterials20

1.2.4.4Nanoporouscarbons23

1.2.4.5Sphericalcarbonmaterials26

1.2.4.6Glass-likecarbons28

1.3Constructionandpurposesofthecurrentbook29 References31

1.1Whatisgraphene?

Theterm“graphene”wasfirstlyproposedin1986 [1] andthenrecommendedbythe InternationalUnionofPureandAppliedChemistry [2] asthenameforasingletwodimensionallayerofcarbonatomsbondingusingsp2 hybridorbitals,whichoccursin graphiteintercalationcompounds.Thesinglecarbonlayeroccurringintheintercalation compoundswasproposedtobecalled“graphene”whichcomesfromthesuffix“-ene”for polycyclicaromatichydrocarbonssuchasnaphthaleneandanthraceneandtheprefix “graph-”fromgraphite.Intheearliestliterature [1],theauthorsnotedthat“itshouldbe adoptedforgraphiteintercalationcompounds.”Inthefirst-stagestructureofthe compounds,atwo-dimensional(2D)carbonlayerissandwichedbytwointercalatelayers andisolatedfromothercarbonlayers,althoughmorethantwocarbonlayersarestackedin parallelwithregularityincompoundswithhigherthanasecondstage,asschematically illustratedin Fig.1.1.

“Graphene”iscommonlydefinedasanisolatedsinglelayerofcarbonhexagonsconsisting ofsp2 hybridizedC Cbondingwith p-electronclouds.Fromanengineeringpointof view,thinflakesconsistingofafewlayersofcarbonatoms,includingsingle-layer

Graphene. https://doi.org/10.1016/B978-0-12-819576-5.00001-3 Copyright © 2020ElsevierInc.Allrightsreserved. 1

Stagestructureofgraphiteintercalationcompounds.

graphene,couldbeimportantbecauseoftheirinterestingstructural,chemical,andphysical characteristics.Thepromisingpotentialapplicationsofgrapheneanditsrelatedmaterials havebeenpointedoutintechnologicalfields.

Numerousreportshavebeenpublished,particularlyaftertheNobelPrizeinPhysicswas awardedin2010toProfs.A.GeimandK.NovoselovoftheUniversityofManchesterfor theirgroundbreakingexperimentsingraphene [3].Suddenscientificandtechnological interestingrapheneanditsrelatedmaterialshascausedsomeconfusionaboutthe definitionandterminologyofgraphene-relatedmaterials,eveninscientificjournals.A proposalregardingthenomenclaturefortwo-dimensionalcarbonmaterialswasbeen presentedinthejournal Carbon [4].Inmuchoftheliterature,however,theterm “graphene”hasnotbeenusedaccordingtoitsstrictdefinition,i.e.,asinglelayerofcarbon atomsconsistingofsp2 hybridizedbonds.Someauthorsdonotpayenoughattentionto howmanylayersarestackedintheirmaterials,althoughtheyhavecalledthem“graphene” Therefore,here,theterms“single-layergraphene”(ormonolayergraphene),“doublelayeredgraphene”(orbilayeredgraphene),and“multilayeredgraphene”areusedonlyfor productsthathaveconfirmednumbersofstackedlayers.

Numerousreviewshavebeenpublishedfromvariousviewpoints:providinganoverviewof graphenebypointingoutwhatisfascinatingaboutit [5 13],focusingonitsproductionin relationtoitsstructure [14 23],applicationsinelectronics [24 30],energystorage applications [31 48],biologicalapplicationsincludingsensors [49 68],functionalization includingtheformationofcomposites [69 80],mechanicalapplications [81,82],thermal properties [83,84],dopingtoimproveitsproperties [85,86],anditstoxicity [87,88]

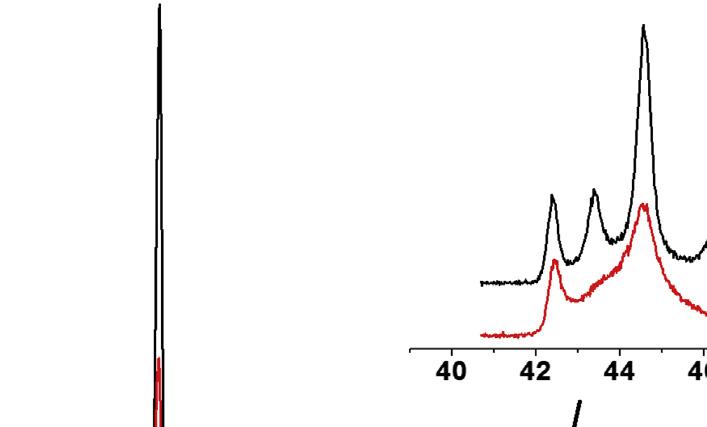

Figure1.1

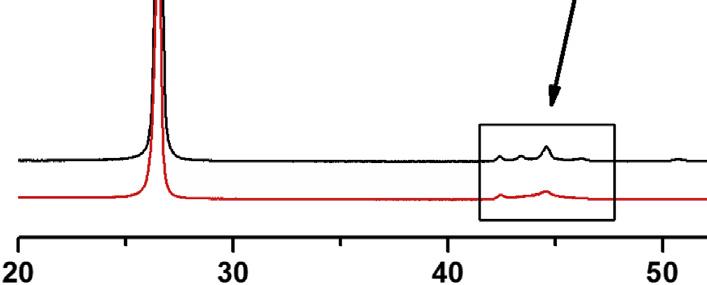

Beforesummarizingresearchongraphene-relatedmaterialsanddiscussingtheresults,it isworthwhiletounderstandtheflakesand/orfilmsthatdeterminehowmanynumbersof layerscanexhibittheuniquefunctionalitiescharacteristicofgraphene,todifferentiateit fromgraphite. Fig.1.2 comparesRamanspectraareforgraphiteandgrapheneflakes withdifferentnumbersofstackedlayers [89].Asshownin Fig.1.2A ,highlyoriented pyrolyticgraphite(HOPG),forexample,showsasharpandstrongG-bandandG0 -band (2Dband).Thelatterispresentedasdecomposingintotwobands,G0 1 andG 0 2,with heightsofroughly¼and½oftheG-band,respectively.Ontheotherhand,single-layer grapheneexhibitsasharpandsingleprofileforbothG-andG0 -bandsandtheG0 -band ismuchstrongerthantheG-bandbyalmostfourtimes.Asshownin Fig.1.2B,the G 0 -bandgraduallyshiftstoahigherposition,changingitsprofiletounsymmetricaland decreasesitsintensityrelativetotheG-bandwithanincreasingnumberofstacked layers.

Amarkedfieldeffectonelectricalconductionisacharacteristicofgraphene.Pioneering workswerereportedonfew-layeredgrapheneflakes [90] Fig.1.3A showsresistivity changewithgatevoltage Vg onfew-layeredgrapheneflakesasafunctionoftemperature, revealingamarkedfieldeffect,apeakofseveralkU withrapiddecaytoabout100 U at high Vg,andastrongdependenceontemperature.Thisfieldeffectisshownbyplotting therelativecarrierconcentration n/n0 (n0 istheconcentrationofcarriersat4K)against temperatureforthreeflakes,few-layeredflakes,few-layeredbutmuchthickerflakes,and multilayeredflakesin Fig.1.3B.Theresultsclearlyrevealthatthefieldeffectdependson thenumberofstackedlayers:thesmallerthenumberoflayers,thestrongerthefield effect.

Figure1.2

Ramanspectrameasuredbyalaserwith514-nmwavelengthforgraphitetosingle-layergraphene [89]:(A)comparisonofgraphiteandsingle-layergraphene,(B)ChangeinG0 -bandwith increasingnumberofstackedlayers. 2D,two-dimensional;a.u.,arbitraryunits.

Fieldeffectforfew-layeredgrapheneflakes [90]

Largest data

Averaged value

Theoretical prediction I

Theoretical prediction II

Figure1.4

Changeinthermalconductivityatroomtemperaturewithnumberoflayersstacked [91]

Extremelyhighthermalconductivity,morethan5000W/m K,isexpectedforsingle-layer graphene [91].Itdependsonthenumberoflayersstackedintheflake.In Fig.1.4,thermal conductivitiesexperimentallydeterminedfromthetemperaturedependenceoftheposition ofthemicro-RamanG-bandtogetherwiththeoreticalpredictionsareplottedagainstthe numberofstackedlayers [91].Amarkeddependenceofroomtemperaturethermal conductivityonthenumberoflayersisclearlyshown.Single-layergraphenehasextremely highconductivity,butthatofaflakecomposedoffourlayersiscomparabletobulkgraphite withhighcrystallinity,suchasHOPG,althoughitishighcomparedwithmetals.

Figure1.3

Thesethreeexperimentalresultssuggestthatweneedaflakeand/orfilmcomposedofless thanfourlayerstoobtaincharacteristicsintrinsictographene.

1.2Fundamentalsofmaterialsscienceforcarbonmaterials

Grapheneisamemberofcarbonmaterials,whichincludegraphite,carbonblacks,carbon nanotubes,carbonfibers,activatedcarbons,porouscarbons,diamond,andfullerenes.To preparegrapheneflakesandfilms,graphitematerialssuchasnaturalgraphite,HOPG,and kishgraphitehavebeenemployedasstartingmaterials.Inadditiontographene,other carbonmaterialssuchasactivatedcarbonsandporouscarbonsincludingcarbonfoamsand carbonnanotubeshavebeencitedinreferencesand/orcompetitivematerials.

Beforediscussinggraphene,thefundamentalsofcarbonmaterialssciencewillbebriefly explained,emphasizinghighlyorientedgraphitematerialsthathavebeenusedasraw materialsofgraphene.Foradetailedexplanationanddiscussionofcarbonmaterials, readersofthisbookaresuggestedtorefertofundamentalbookswrittenbythecurrent authors(M.I.andF.K.) [92,93].

1.2.1Classificationofcarbonmaterials

Manykindsofcarbonmaterialshavebeenmanufactured,synthesized,andwidelyusedin variousindustries.Thesecarbonmaterialsareproposedtobeclassifiedonthebasisof theirchemicalbondsofconstituentcarbonatomsusingsp3,sp2,andsphybridorbitals. Thesp2 hybridbondingofcarbonatomsresultsintwostructures:flatlayerscomposedof six-memberedcarbonrings,whichhadbeenrepresentedbygraphitebutnowinclude graphene;andcurvedlayers,whichintroducefive-memberedcarbonringsintosixmemberedrings,asoccursinfullerenes.Layerscomposedofsp2 orbitals,bothflatand curved,areintrinsicallyanisotropicandhave p-electroncloudsatbothsidesofthelayer, whichcreatesbroaddiversityinthestructureandpropertiesofthematerials.Carbon nanotubescanbeplacedbetweenfullereneandgraphene,becausethetipsofthetube includefive-memberedrings(fullerene-like)anditswalliscomposedofsix-membered ringsalthoughitisrolledup(graphene-like). Fig.1.5 showstheclassificationofcarbon materialsbasedonhybridbonds,togetherwiththediversityofeachmaterial.

Becauseoftheanisotropicnatureandthepresenceof p-electroncloudsinthecarbon materialscomposedmainlyofsp2 hybridorbitals,thenumberoflayersstackedinparallel hasastronginfluenceontheirproperties.Theimportanceofthenumberofstackedlayers hasbeenpointedoutforcarbonnanotubesandfullerenes,andnowforgraphene,as mentionedintheprevioussection.Largenumbersoflayersstackedwithregularityhave beencalledgraphite,andvariousgraphite-relatedmaterialshavebeenproducedin industriesandusedasimportantindustrialmaterials,someofwhicharelistedin Fig.1.5

sp3

Diamond

Crystalline Cubic Hexagonal

Non-crystalline Diamond-like carbon (DLC)

Crystalline Hexagonal Rhombohedral

P1=1.00

d002=0.3354 nm

Oriented

Planar orientation

Highly-oriented graphite

Planar Graphene

Single-layer to Multi-layered

Graphite

Synthetic (artificial) graphite

Intercalation compounds

Pyrolytic carbons

C 2s22p2

sp2 + π

Carbon nanotubes

Single wall

Chirality

Multi-walled

Graphitization degree

Nanotexture

Axial orientationPoint orientation

Carbon fibers C/C Composites

Figure1.5

Carbon blacks

Curved Fullerenes sp+ 2π

Single wall C60, C70, ··· Multi-walled

Carbyne

Chain length, etc.

Non-crystalline Turbostratic

P1=0.00

d002>0.344 nm

Not-oriented

Random orientation

Activated carbons

Glass-like carbons

Classificationsanddiversityofcarbonmaterials.

1.2.2Structureandnanotextureofcarbonmaterials

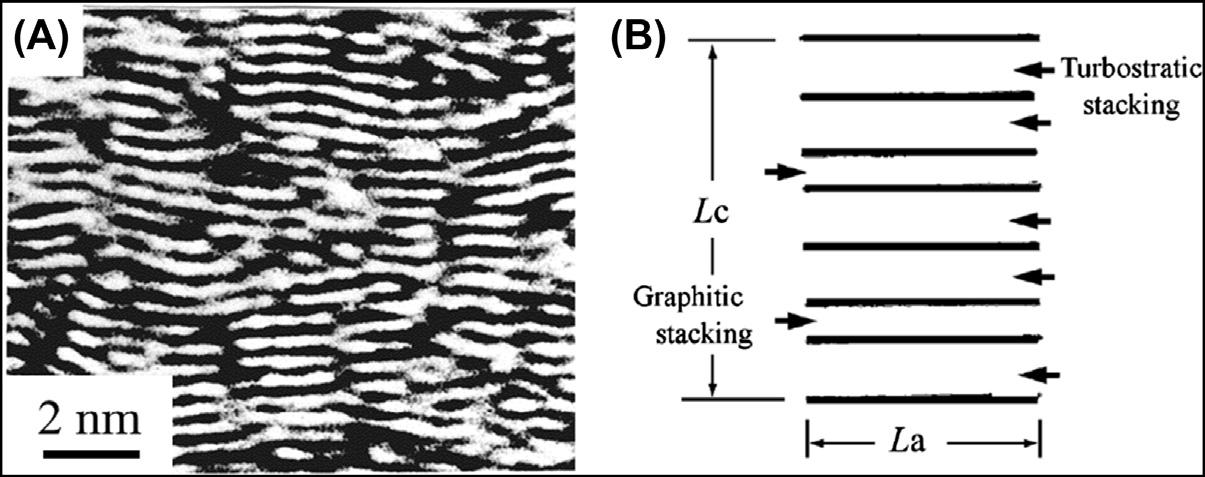

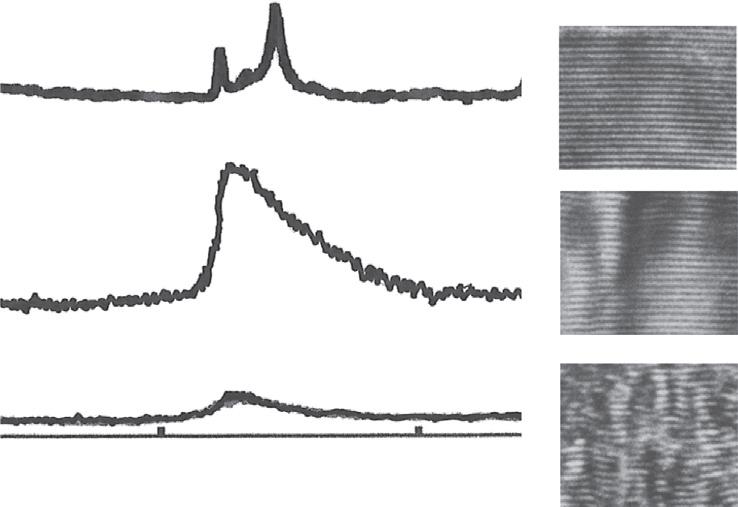

Mostcarbonmaterialscomposedofflatlayersusingsp2 hybridorbitalsconsistofsmall unitsoflayersstackedinparallel,asshownbythetransmissionelectronmicroscopy (TEM)latticefringeimageandschematicillustrationin Fig.1.6.Theseunitsarecalled basicstructuralunits(BSU)orcrystallites.Inaunit,twokindsoflayerscoexistwith stackingregularity:randomandregularstacking.Theformeriscalledturbostraticstacking andthelatterisgraphiticstacking(usuallywrittenasABstacking).TheseBSUsare stronglyanisotropicinthenatureoftheirbond,withstrongcovalentbondingusingsp2 hybridorbitalalongthelayerandweakvanderWaalsbondingacrossthelayers.

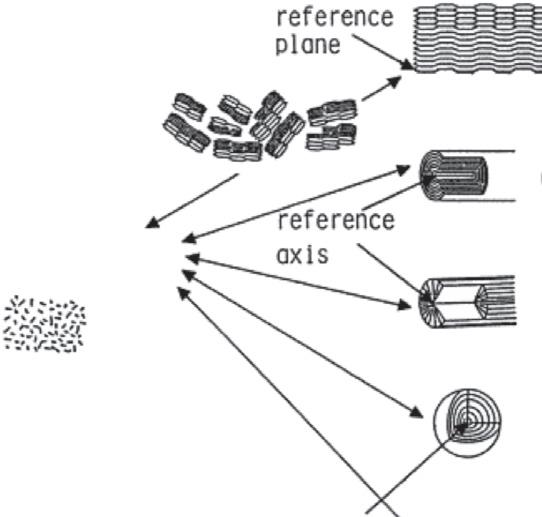

TheaggregationoftheseanisotropicnanosizedBSUsintheparticlesresultsindifferent texturesowingtothedifferentschemaofpreferredorientationsofanisotropicBSUs(i.e., planar,axial,point,andrandomorientations),asillustratedwithsomerepresentative carbonmaterialsin Fig.1.7.TheaggregationofBSUsindifferentschemaiscalled nanotextures.Bytheplanarorientationscheme,filmsandplateletsofhighlyoriented

Figure1.6

Basicstructuralunitofcarbonmaterials:(A)latticefringeimageand(B)schematicillustration ofaunit.

RANDOM NANOTEXTURE

Glass-like carbons

Random orientation

ORIENTED NANOTEXTURE

Planar orientation

Axial orientation

Figure1.7

Highly-oriented graphites

Cokes Carbon nanotubes

Carbon fibers

Point orientation

Fullerenes

Carbon blacks

Nanotexturesincarbonmaterialsonthebasesofpreferredorientationsofbasicstructuralunits.

graphiteareproducedandsomecokeparticlesareprincipallycomposedofplanar orientationofBSUs.Bytheaxialorientationscheme,fibrouscarbonmaterialsare producedfromdifferentprecursorssuchascarbonnanotubesandvapor-growncarbon fiberswithacoaxialmodeoforientationandsomemesophasepitch-basedcarbonfibers witharadialmode.Bythepointorientationscheme,variouscarbonspheresareproduced, aswellasvarioussizedfullereneparticlesanddifferentnanosizedcarbonblackswith concentricmodeandmesophasesphereswitharadialmode.Theparticlescomposedof theseorientednanotexturesarestillanisotropic.Inaddition,randomaggregationofsmall BSUsoccursinso-calledglass-likecarbon(glassycarbon),theparticlesofwhichare isotropicinnature.

1.2.3Carbonizationandgraphitization

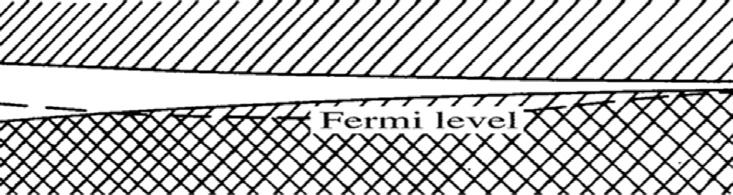

Mostcarbonmaterialsusedinindustryareproducedfromorganicprecursorssuchas pitches,biomasses,andorganicpolymersviaheattreatmentathightemperaturesinan inertatmosphereduringcarbonizationandgraphitizationprocesses. Fig.1.8 summarizes changesinchemicalandelectronicbandstructures.

Carbonizationisperformedafterpyrolysisoftheprecursorsfrom800to2000 C,inwhich theBSUsareformedandtheirbasicaggregationscheme(nanotexture)isestablished, accompaniedbytheemissionofforeignatoms,oxygen,hydrogen,andnitrogenasgases andthepolycondensationofsix-memberedcarbonrings.Becausethenanotextureofmost carbonmaterialsisestablished,thisprocessismostimportantintheproductionofvarious carbonandgraphitematerials.Thenanotexturegovernsthedevelopmentofcrystalline structuresincarbonmaterialsduringgraphitization.Duringthisprocess,alargeamountof shrinkageandtherapidemissionofgasspeciesoccurthatareassociatedwithcrackingof carbonparticlesthatoccurinmanycases.Therefore,theprocessofcarbonizationis appliedseparatelyfromthatofgraphitization.

Above2000 C,achangeincrystallinestructure(thedevelopmentofagraphitestructure) mainlyoccurs.Thedevelopmentofagraphitestructuremaybeevaluatedbydifferent techniques,includingx-raydiffraction(XRD),electromagneticpropertymeasurements, Ramanspectroscopy,andhigh-resolutionTEM.InBSUsformedduringcarbonization,

Schematicillustrationofchemical,crystallographic,andelectronicbandstructuresincarbon materialswithaplanarorientationnanotexture. MW,molecularweight.

Figure1.9

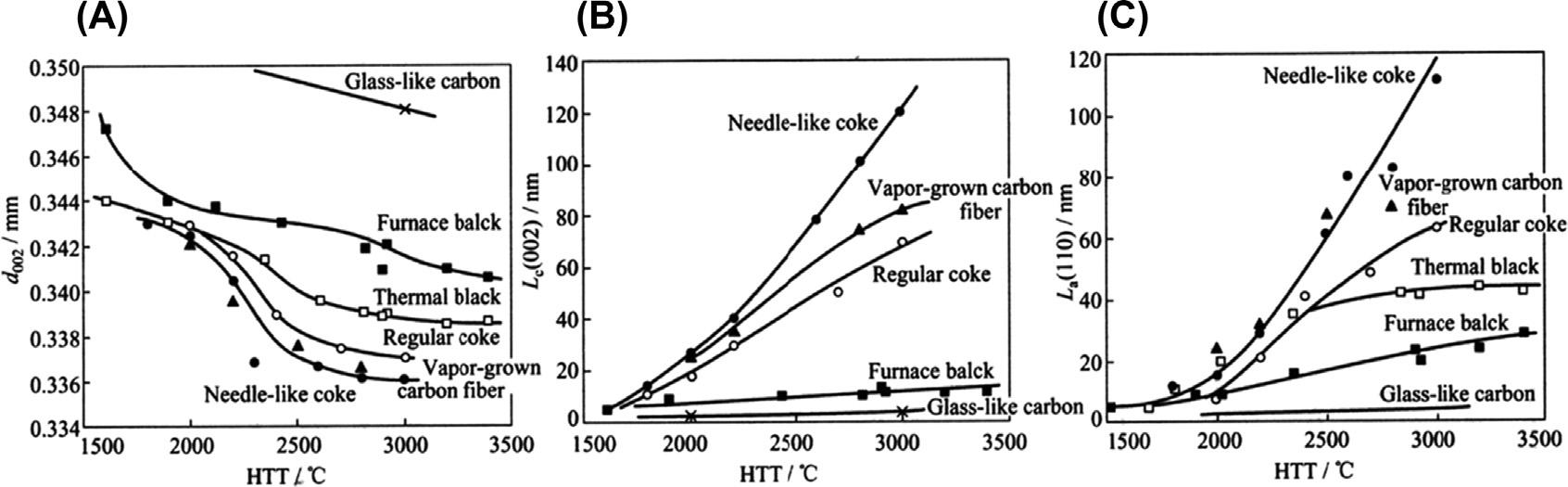

Changesinx-raydiffractionparameterswithheattreatmenttemperatures(HTT)forvarious carbonmaterials:(A) d002,(B) Lc measuredfroma 002 diffractionpeak,and(C) La froma 110 peak.

turbostraticstackingwithaninterlayerspacingofabout0.342nmisrandomlychangedto graphiticregularstackingwithaspacingof0.3354nm(thespacinginthegraphitecrystal) withanincreasingheattreatmenttemperature(HTT)ofabove2000 C,whichismeasured asadecreaseintheaveragedinterlayerspacing, d002,byXRD,associatedwiththegrowth ofBSUsizes(crystallitesize)alongthea-andc-axes, La and Lc.Thechangein d002 with HTTdependsonthematerialsaftercarbonization(carbonmaterials). Fig.1.9 showsthe changesintheseparameterswithHTTforvariouscarbonmaterials.Inneedle-likecoke withaplanarorientationscheme, d002 decreasesquickly,approachingthevalueofa graphitecrystal(0.3354nm),and Lc and La growrapidly.Inglass-likecarbonwitha randomorientationscheme,incontrast,thereisalmostnodecreasein d002 andno appreciablegrowthin Lc and La evenafter3000 Ctreatment(i.e.,nodevelopmentofa graphitestructure).Carbonblackswithapointorientationschemehaveintermediate behaviors:thelarge-sizedthermalblackshowsmoreimprovementinstructurethandoes thesmall-sizedfurnaceblack.

DiffractionpeaksofXRDforcarbonmaterialsareclassifiedintothreegroups: 00l, hk0, and hkl,mainlyowingtothestronganisotropyofBSUsandthecoexistenceoftwo interlayerspacings,asshownin Fig.1.6B.Diffractionpeakswithindicesof 00l give averagedinterlayerspacing,whichdecreasesgraduallyfrommorethan0.344nmfor highlydefectivelayersto0.3354nmforgraphiticstackingandabout0.342nmfor turbostraticstackingwithincreasingHTT:inotherwords,withimprovingcrystallinity ofcarbon,asshownin Fig.1.9A.Inturbostraticstackingoflayers,thereisno3D regularityinstacking(i.e.,no l indexisdefined),andsothediffractionpeakswith hk0 indicesforagraphiticstructureareexpressedas hk diffractionpeaksforcarbon materialsmainlyconsistingoftheturbostraticstackingoflayers.Regularandrandom stackings,graphiticandturbostratic,areclearlydemonstratedindiffractionprofilesof

Figure1.10

d002=0.3345 nm Regular stacking (graphite structure)

d002=0.342 nm Random stacking (turbostratic structure)

d002>0.344 nm Minute BSUs

(A)Correspondencebetweenx-raydiffraction(XRD)profileof hk lineand(B)transmission electronmicroscopy(TEM)image. BSU,basicstructuralunits.

hk0 and hk peaks,asshownfor 101 and 10 peaksin Fig.1.10 .Theprofileofthe 10 peakforaturbostraticstructureshowsacharacteristicunsymmetricalprofile,andthat ofa 100 peakforagraphiticstructureissharpandsymmetricalandisassociatedwith a 101 peakowingtotheformationof3Dstackingregularity.WithincreasingHTT,an unsymmetrical 10 peakismodulatedbytheappearanceofa 101 peak,togetherwithits sharpenedandimprovingsymmetry.Peakswithindicesof hkl arecausedbythe graphitestructure,andso 112 peakisoftenselectedastoindicatetheformationofa graphitestructure,becausethe 112 peakdoesnotoverlapwithotherpeaksalthoughthe 101 peakoverlapswiththe 100 peak,ascanbeseenin Fig.1.10.

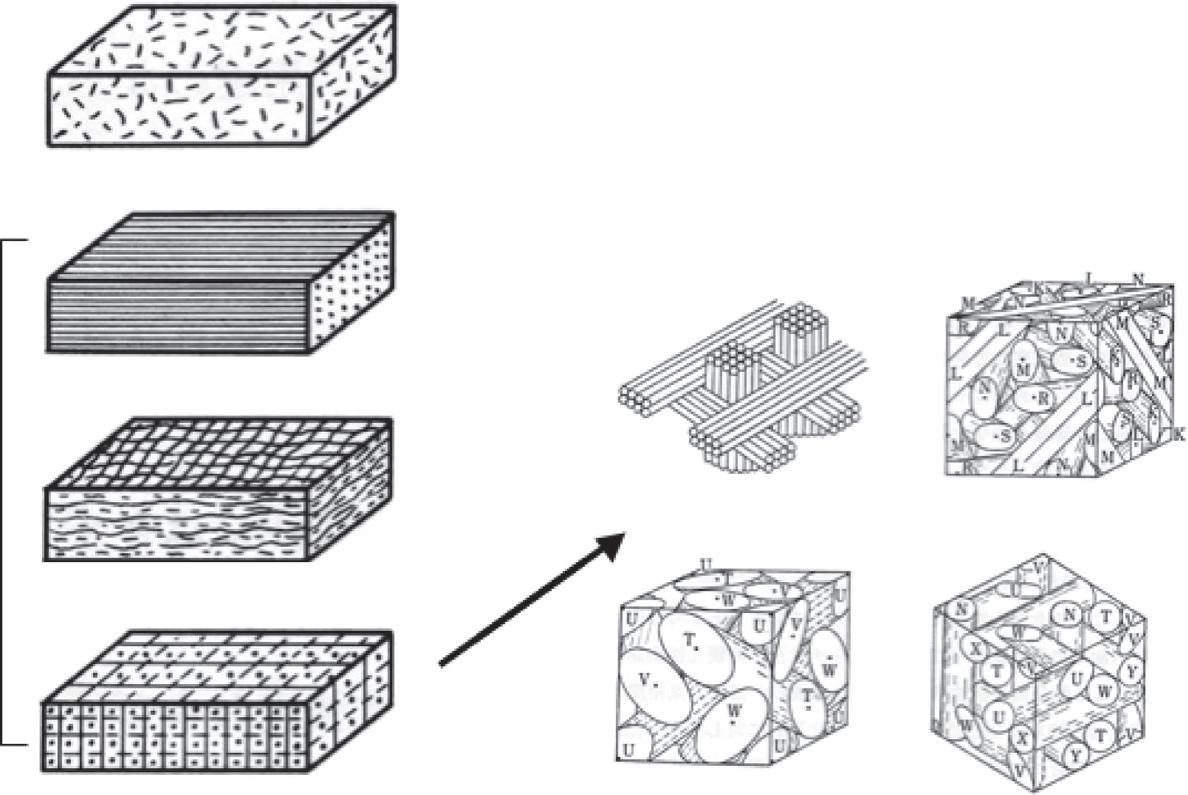

Becausemostcarbonparticlesaremoreorlessanisotropic,exceptforglass-likecarbon witharandomorientationscheme,theiraggregationintoablockgivestextureonanlarger scale,whichmaybecalledmicrotextureandmacrotexture.Thetechniqueforevaluating thesemicro-andmacrotextureshasnotyetbeenestablished. Figs.1.11and1.12 demonstrateexamplesofthesetextures,whichmustbecontrolledforpractical applications.In Fig.1.11,scanningelectronmicroscopy(SEM)imagesofcross-sections ofcommerciallyavailableisotropichigh-densitygraphiteareshown,demonstrating differentporestructures [94].Imageprocessingofthesemicrographssuggestsarelation betweenporestructureparameters(forexample,theporearea)andthemechanical propertiesofthesegraphiteblocks.Topreparecarbonfiber reinforcedplasticsandcarbon fiber carboncomposites,differentmacrotexturesbasedontheorientationofcarbonfibers areemployedtoobtainhighstrengthandahighmodulusofthecomposites,asshownin Fig.1.12.

TEM (002 lattice fringe image)

Figure1.11

SEMimagesofthecross-sectionsofisotropichigh-densitygraphiteblocks [94].

Chopped fibers

Random

One-directional

Long fibers

Three-dimensional

Two-directional

Three-directional

Figure1.12

Differentschemeforreinforcingcarbonfibersincomposites.

1.2.4.1Highlyorientedgraphitematerials

Theblocksorplatelets,whicharecomposedofbigcarbonlayersstackedinlargeamount withgraphiticregularity,arecalledhighlyorientedgraphite;theextremecaseofthisisa singlecrystalofgraphite.Inpractice,however,itisdifficulttoobtainsinglelargecrystals andalmostimpossibletogetthosethataremorethanafewsquaremillimeters.Thereare onlytwowaystofindsinglecrystalsofgraphite:innaturalgraphiteoresandinso-called kishgraphite.Resourcesofhigh-qualitynaturalgraphitearelimitedonearthandexistin SriLanka,Madagascar,andChina.Evenintheseores,thepossibilityoffindingsingle crystalsofacertainsizeisslim.Kishgraphiteisformedbytheprecipitationof supersaturatedcarbonfrommoltenironandcannotbelargeinsize,butsomehavevery highcrystallinityandcanbecalledsinglecrystals.Alternativestosingle-crystalgraphite areHOPGandgraphitefilmsderivedfromsomeorganicpolymerprecursorssuchas polyimidesviahigh-temperaturetreatment.

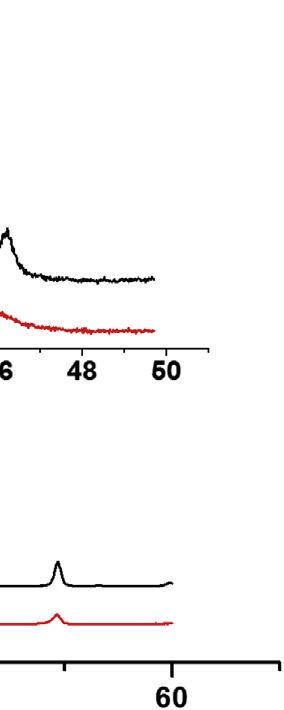

Naturalgraphite:Naturalgraphiteisusuallyrecoveredasapowderfromnaturalores throughmillingandpurificationprocesses.Afterthefinalpurificationprocess,thepowder hasusuallyapurityofmorethan99wt%.Someofitconsistsofflakyparticleswitha highlycrystallinestructureandhighlyorientednanotexture(flakygraphite),butsome consistsofaggregatesofsmallcrystals(calledamorphousgraphite) [95].Thesetwokinds ofnaturalgraphitecanbedifferentiatedbyXRD,asshownin Fig.1.13,whichshows

002

003

2θ / degree

Figure1.13

graphite

X-raydiffractionpatternsofflakyandmicrocrystallinenaturalgraphite [95]

flakygraphitewithsharp 100 and 101 peaksbutamicrocrystallinegraphitebroad 101 peak.Someflakygraphitecontainsmetastablerhombohedralmodificationofthegraphite structure,possiblyasaresultofshearstressduringmilling.

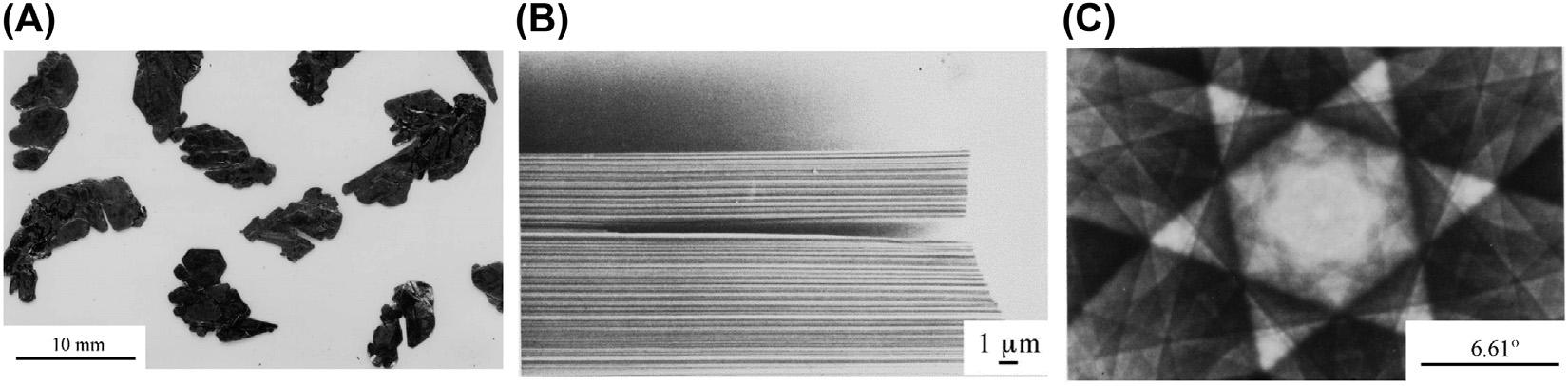

Kishgraphite:Apartofcarbonsdissolvedintomoltenironathightemperaturesis incorporatedintothecrystallatticeofirontoformalloys(differentsteels)andanotherpart segregatesasgraphite.Graphiteflakessegregatedfrommoltenironarecalledkish graphite [96 98].Relativelylargeamountsofkishgraphiteflakesareobtainedasabyproductduringsteelproduction;allofthemdonotalwayshavehighcrystallinitybecause itdependsonthesegregationconditions.Whentheyareproducedatthetemperatureat whichironevaporates,kishgraphiteflakeshaveasinglecrystalnature.Asshownin Fig.1.14,flakesarethinwithanirregularshape.Regularstackingoflayersisobservedby SEMandtheirsinglecrystalnatureisconfirmedbyawell-organizedelectronchanneling pattern.Thehighcrystallinityofkishgraphiteflakeswasalsoconfirmedbymeasurements oftheresistivityratio, r300K/r4.2K,maximumtransversemagnetoresistance,(Dr/r0)max, measuredat77K,andShubnikov-de-Haasoscillationinmagnetoresistance.

Graphitesinglecrystalshavebeensynthesizedfrommoltenironbycontrollingthe segregationprocess [99,100] andfromAl4C3 bytransportingdecompositiongases [101,102].

Highlyorientedpyrolyticgraphite:Carbondepositedonasubstrateby chemicalvapor deposition (CVD)ofhydrocarbongasessuchasmethaneandpropaneathightemperatures canhaveawell-orientedtextureandiscalledpyrolyticcarbon.Pyrolyticcarbonshave extensivelybeenstudiedtocontroltheirstructureandtexturebyapplyingdifferent depositionconditions,suchasprecursorhydrocarbon,theconcentrationandflowrate,the temperatureofdeposition,andthegeometryofthefurnace [103].Byhot-pressingathigh temperaturesunderhighpressure,thepreferredorientationofgraphitecrystallitesandtheir crystallinitycanbemarkedlyimproved.Typicalconditionsareshownin Fig.1.15[104].

Figure1.14

Kishgraphite:(A)opticalmicrograph,(B)scanningelectronmicroscopyimageoftheedge surface,and(C)electronchannelingpatternonthebasalplane. CourtesyofProf.Y.Hishiyamaof TokyoCityUniversity.

Hot pressing

2800-3000 °C, 30-50 MPa

Oriented pyrolytic graphite (OPG)

Annealing under pressure

3400-3600 °C, 10 kg/cm2

Pyrolytic carbon (PC) deposited at 2100-2500 °C mosaic spread of 40-50° mosaic spread of less than 0.5 °C density of 2.226 g/cm3 mosaic spread < 0.4°

Highly-oriented pyrolytic graphite (HOPG)

Figure1.15

Procedureoftheproductionofhighlyorientedpyrolyticgraphite.

TheproductsofthisprocessarecalledHOPG.Toachievehighcrystallinityandhigh orientation,thestartingpyrolyticcarbonsneedselected,aswellasthehot-pressing conditions.

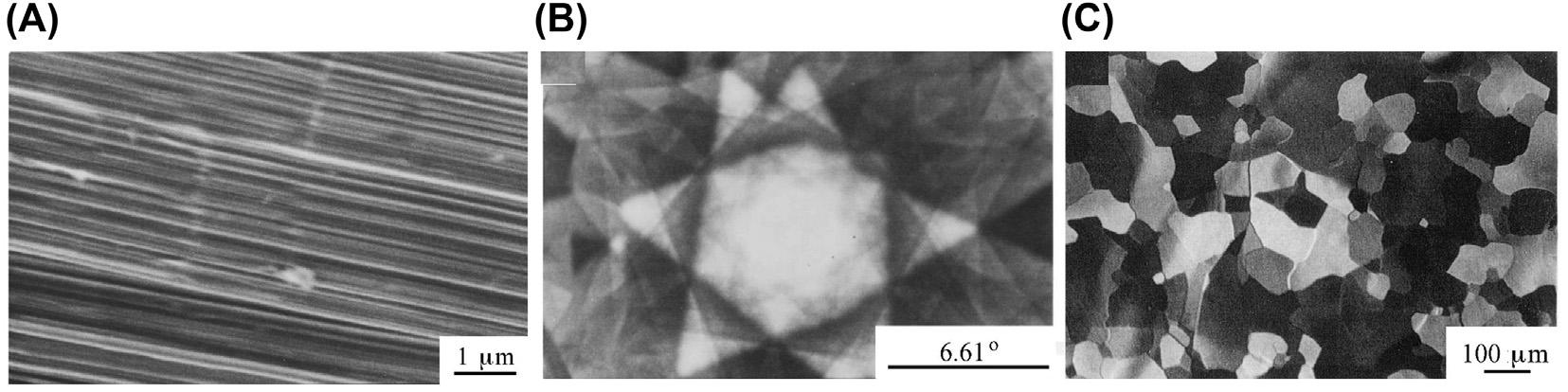

Asshownin Fig.1.16A,HOPGhasahighlyorientednanotexturealongitsplate,but electronchannelinganalysissuggeststhatHOPGconsistsofrandomlyorienteda-axesof crystallinedomains,althoughtheirc-axesarealmostperfectlyorientedperpendicularto theplate.Thechannelingpatternonthesurfaceoftheplate(Fig.1.16B)issomewhat distortedcomparedwiththatofkishgraphite(referto Fig.1.14C)andthechanneling contrastshowstherandomorientationofa-axesofthedomains(Fig.1.16C).

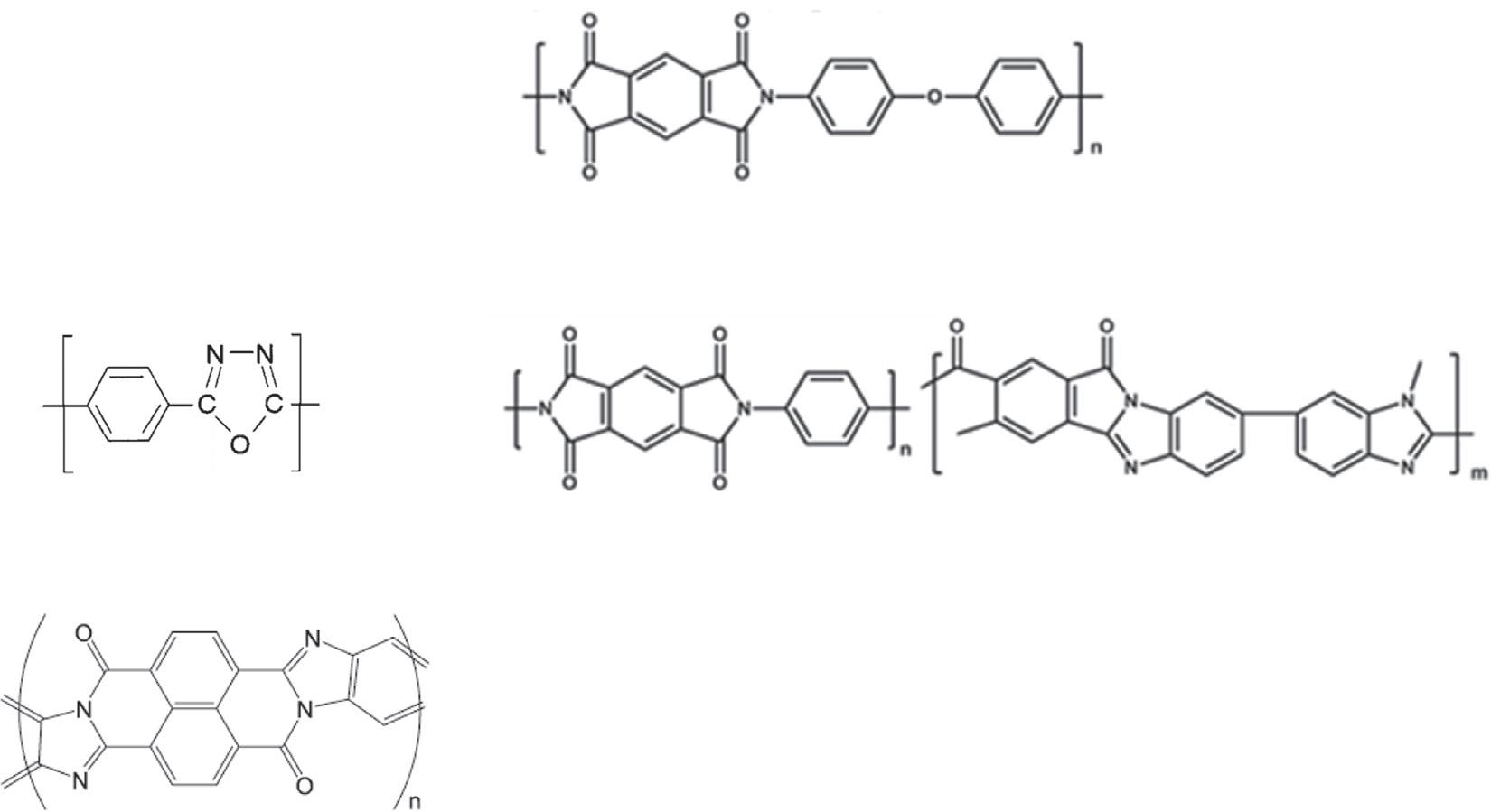

Graphitefilmsderivedfromorganicfilms:Highlycrystallizedgraphitefilmswereprepared fromfilmsoflimitednumbersoforganicprecursors,suchaspoly(p-phenylenevinylene) (PPV) [105],poly(p-phenylene-1,3,4-oxadiazole)(POD) [106,107],benzimidazobenzophenanthrolineladderpolymerBBL [107 110],andthecommerciallyavailablearomatic

Figure1.16

Highlyorientedpyrolyticgraphite:(A)scanningelectronmicroscopyimageofthecross-section, (B)electronchannelingpattern,and(C)electronchannelingcontrast. CourtesyofProf.A.Yoshida ofTokyoCityUniversity.

Molecularrepeatingunitsofpolymersgivinggraphitefilms. PPV,poly(p-phenylenevinylene); POD,poly(p-phenylene-1,3,4-oxadiazole); BBL,benzimidazobenzo-phenanthrolineladderpolymer; Kapton; PPT,commerciallyavailablearomaticpolyimidefilms.

polyimidesKaptonandPPT [111 113],therepeatingunitsofwhichareshownin Fig.1.17.HeattreatmentofPPV-derivedcarbonfilmsupto3000 Cgaveagraphitefilm; asshowninitsRamanspectrumin Fig.1.18A,noD-bandwasdetected [105].Thefilmof polyoxadiazoleheat-treatedat2800 Cgavesharpandstrong 00l diffractionprofilesand no hk0 diffractionlinesbyreflectionmodeandwell-resolved hk0 and hkl linesandno 00l linesbytransmissionmode,asshownin Fig.1.18B;thisrevealedtheformationofa highlyoriented,well-crystallizedgraphitefilm [106].

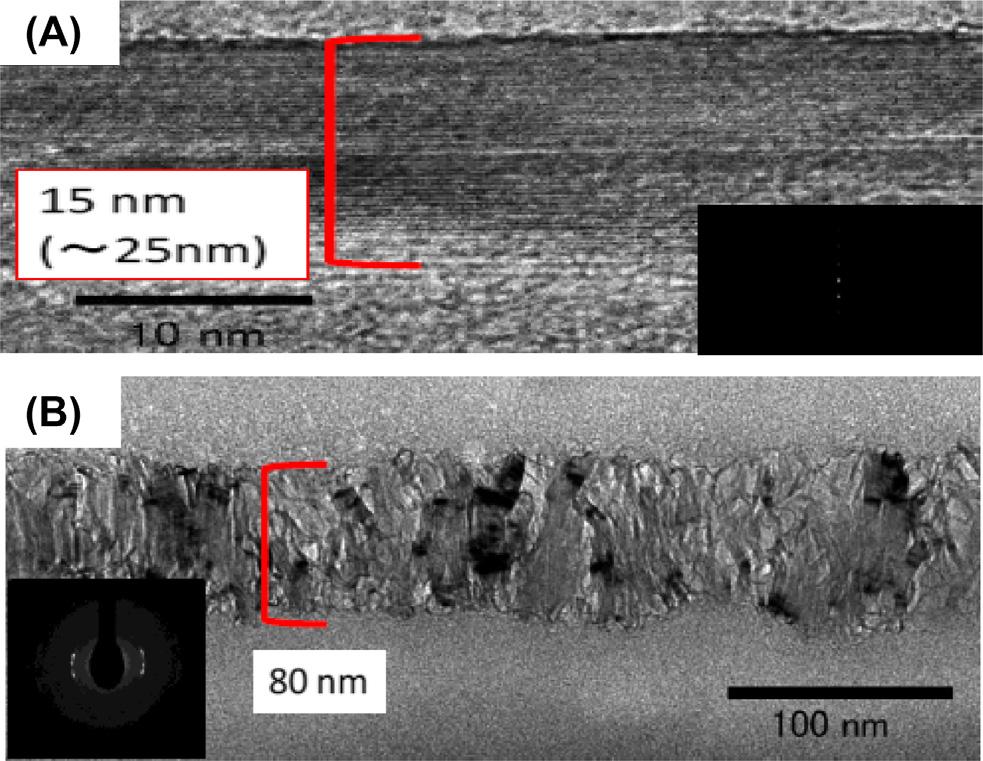

BBLpolymerfilmwascastontoaglasssubstratefromitssolutionof trifluoromethanesulfonicacid(TFMSA)andthenheat-treatedathightemperaturesto 3200 Cbysandwichingitbetweentwoartificialgraphiteplates [110].Theresultant ultrathinfilms,whichwerelessthan100nmthick,showedanelectronchanneling patternsimilartothatofHOPGandanorientationofgraphitebasalplanesparalleltothe filmsurface,asshownin Fig.1.19A .Byusingmethanesulfonicacidassolventforthe BBLpolymer,filmwithanorientationofbasalplanesperpendiculartothefilmsurface wasobtained,asshownin Fig.1.19B[109].

Twofilmsderivedfrompolyimidepolytrimethyleneterephthalate(PTT)andKaptonby heattreatmentat3200 Cunderasimplemechanicalconstraint(sandwichingbetweentwo

Figure1.17

Figure1.18

(A)ChangeinRamanspectrumwithheattreatmenttemperatureforpoly(p-phenylenevinylene) film [105] and(B)x-raydiffractionpatternsofpolyoxadiazolefilmheat-treatedat2800 C [106]. a.u.,arbitraryunits; cps,countspersecond.

Figure1.19

002 latticefringeimagesofthecross-sectionofgraphitefilmspreparedfromabasicstructural unitspolymerusingtrifluoromethanesulfonicacid(A)andmethanesulfonicacid(B)assolvents andheat-treatedat2800 C [109]

graphiteplates)gavehighcrystallinitycomparabletokishgraphiteandHOPG; rRT/r4.2K (oneparameterstoevaluatecrystallinityofgraphite)was4.90and4.79forPTT-and Kapton-derivedfilm,respectively,althoughitwas4.7 5.5forkishgraphiteand HOPG [112].

Exfoliatedgraphiteandflexiblegraphitesheets:Becauselargeflakesofnaturalgraphite arenotcommonlyavailableandnaturalgraphiteflakescannotbeformeddirectlyintoa sheet,atechniqueforpreparinggraphitesheetswithnobindingmaterialswasdeveloped byforminggraphiteoxidesandviatheirthermalexfoliationandreduction,followedby compressionintosheets.Theyarecalledflexiblegraphitesheetsandhavepromotedthe applicationofgraphite [114].Graphitesheetshavecharacteristicadvantagessuchas flexibility,resilience,andtheabilitytobeformedintovariousshapeseasily;inaddition, graphitehasintrinsicpropertiessuchaslubricity,chemicalandthermalstability,andhigh electricalandthermalconductivity.

Naturalgraphiteflakesarechemicallyorelectrochemicallyintercalatedtoformacovalent intercalationcompoundofgraphite,graphiteoxide,throughtheuseofamixtureof concentratedsulfuricandnitricacids.Afterrinsinganddrying,residuecompoundsare obtainedinwhichtheregularstagestructureislostbutsomesulfuricacidderivatives remaininthegraphitegallery.Theseresiduecompoundsarethenrapidlyheatedto 900 1200 C,inwhichintercalatesremaininginthegraphitegalleryaredecomposedinto gaseousproducts,yieldingmarkedexfoliationofthepristinegraphite.Thisexfoliated graphiteconsistsofworm-likeparticles,asshownin Fig.1.20.Theyareformedby preferentialexfoliationperpendiculartotheplanesurfaceofthepristineflakes.Worm-like particlesofexfoliatedgraphiteareeithermoldedorrolledintoasheetwithnoadhesives orbinders.Thesearecalledflexiblegraphitesheetsandarewidelyusedasseals,gaskets, andpackings.

Afterrinsinganddryingofintercalationcompounds,theresiduecompoundsare commerciallyavailableasexpandablegraphiteandareusedasthestartingmaterialfor thinflakesofgrapheneoxideinsomeliterature.

1.2.4.2Syntheticgraphitematerials

So-calledgraphitematerialshavebeenmanufacturedindustriallyintovariouslysized blocks,rods,andplatesfordifferentapplications,suchaslargedegreeelectrodesfor electricarcfurnaces,variousjigsforprocessingmetals,cruciblesandheatingelements togrowsemiconductorcrystals,brushesforelectricmotors,andneutronmoderatorsfor nuclearreactors.Graphitematerialsfortheseapplicationshavemostlybeenproduced usingcokeparticlesasfillerswithpitchesasthebinderthroughcarbonizationand graphitizationtreatmentathightemperatures.Theproductionprocessesaresummarized asablockdiagramin Fig.1.21.Briefly,pulverizedcokeparticlesaremixedand

Figure1.20

(A)Scanningelectronmicroscopyimagesofworm-likeparticlesofexfoliatedgraphite.(B) Appearanceoftheparticles.(C)Cross-sectionofaparticle.(D)Distributionofporeareaon cross-section.

Filler

Petroleum coke Pitch coke

Binder Pitch

Pulverization

Coase grains

Sieving

Fine grains

Re-calcination

Mixing & kneading

Pitch, Resin

Extrusion

Molding

Forming

Isostatic pressing

Impregnation

Halogen gases

Purification

Graphitization

Machining

Calcination (Carbonization)

Figure1.21

Productionprocessofsyntheticgraphitematerials.

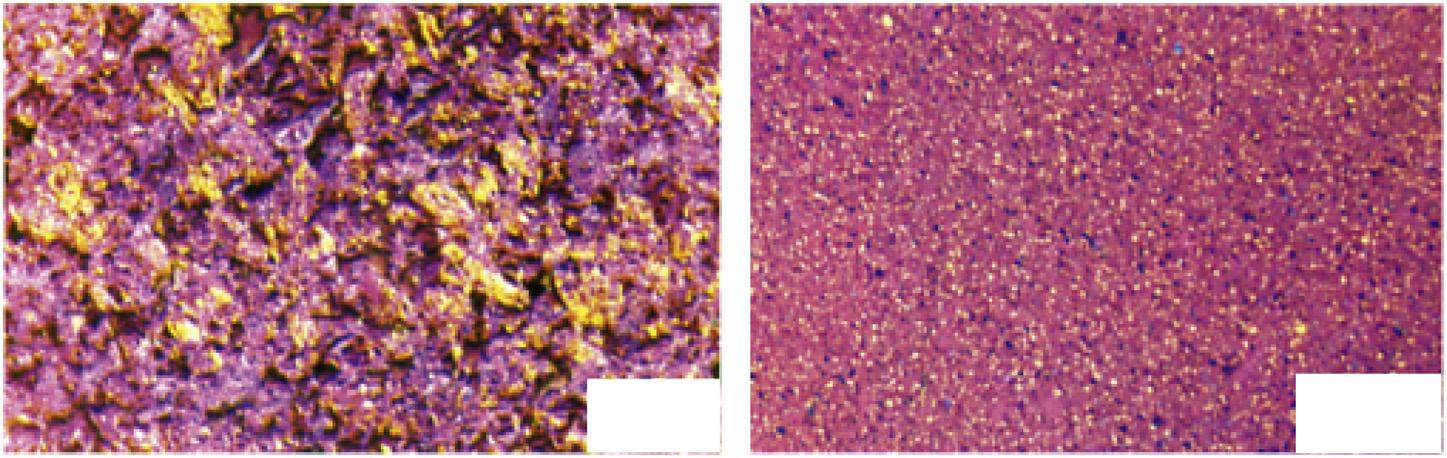

kneadedwithbinderpitchatatemperatureslightlyhigherthanthesofteningpointof thepitch,inwhichthenanotexture(eitherneedle-likeormosaic)andparticlesizeof thefillercokeandthemixingratioofthefillertothebinderhavetobecontrolled accordingtotherequirementsoftheapplications.Afterthemixtureisformedby extrusion,molding,orisostaticcompression,itisheat-treatedat1400 1800 C (calcinationorcarbonization),followedbyheattreatmentatahighertemperatureupto 2800 3000 C(graphitization)(see Fig.1.8).Thefinalproductsofthismanufacturing processarecalledsynthetic(artificial)graphitematerials.Allsyntheticgraphitesare polycrystallinesolids;ofthese,BSUs(crystallites)aremuchsmallerthanthoseinthe highlyorientedgraphitesdescribedpreviously.Toproducegraphitematerialsforusein anelectricarcfurnaceasanelectrode,coarse-grainedcokeparticleswithaneedle-like textureareusuallyemployedtoachievehighthermal-shockresistance.Theyareformed byextrusionormolding,andtheslightorie ntationofcokeparticlescannotbeavoided. Toproduceisotropichigh-densitygraphiteblocks,however,fine-grainedcokeparticles havetobeusedtoachieveahighdensity,andisostaticpressingmustbeemployedfor anisotropicnatureinthefinalblock.Microtexturesoftwographitematerials,electrode gradeandisotropicgrade,arecomparedin Fig.1.22.

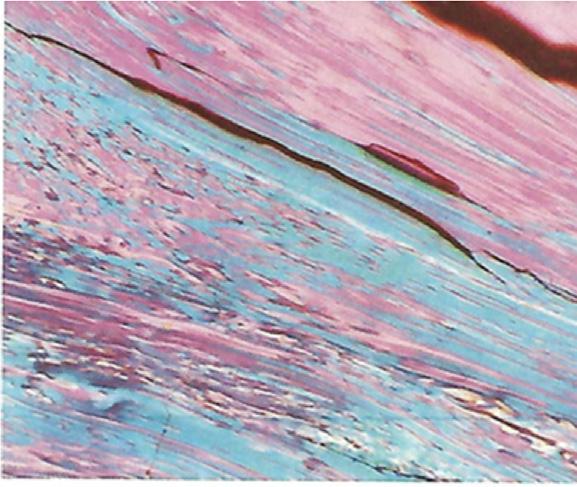

Mostsyntheticgraphitematerialsconsistoffillercokeandacarbonizedbinder(binder coke).Theformerisabletoattainahigherdegreeofgraphitestructuredevelopment (graphitizationdegree)comparedwiththelatter.Thedegreeofgraphitizationachieved afterfinalgraphitizationdependsonthenanotextureofthestartingcokeparticles,as shownin Fig.1.23A.Needle-likecokehasanextendedflowpatternowingtothepreferred orientationofcrystallites,andsothereisahigherdegreeofgraphitizationafterhightemperaturetreatmentcomparedwithmosaiccoke,whichhasashortrangeoforientation andislessordered(Fig.1.23B).However,thedegreeofgraphitizationreachedbyneedlelikecokeisfarlowerthanthatofhighlyorientedgraphitematerials.

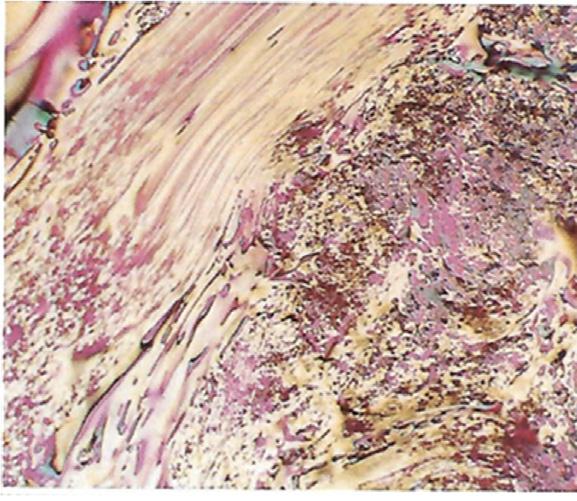

Figure1.22

Polarizedlightmicrographsofcross-sectionsofsyntheticgraphites:(A)electrodegradeand (B)isotropicgrade.

Polarizedlightmicrographsofcross-sectionofparticles:(A)needle-likeand(B)mosaiccoke.

1.2.4.3Fibrouscarbonmaterials

Avarietyoffibrouscarbonmaterialshavebeenpreparedbydifferenttechniques: electricarc-discharge,catalyticCVD,template-assistedCVD,melt-spinning,and electrospinning. Table1.1 classifiesthesefibrouscarbonsaccordingtowhetherthe 002 latticefringesofcarbonlayersareshortorlongandwhethertheirdiametersareonthe micrometerornanometerscale.Carbonlayersconstitutingthewallofcarbonnanotubes (CNTs)arelongandorientedexactlyparalleltothetube’saxis,butlayersofcarbon nanofibersareshortandorientedindifferentmodes,calledtubular,herringbone,and platelettypes,dependingonthemethodsandconditionsofsynthesis.Carbonfiberswith adiameterofabout7 m mareproducedindustriallybymelt-spinningfromdifferent precursors,polyacrylonitrile(PAN),isotropicandanisotropic(mesophase)pitches, cellulose,andphenolasfilamentyarns,clothes,chops,webs,etc.Vapor-growncarbon fibersonthemarketareproducedbycatalyticCVDandhavetubularnanotextures.By applyingelectrospinning,variousorganicpolymerscanbeusedasprecursorstofabricate carbonnanofibers [115].

Table1.1: Classificationoffibrouscarbonmaterials.

DiameteroffiberLongcarbonlayersShortcarbonlayers

NanometersizeCarbon nanotubes Single-walled Double-walled Multiwalled Carbon nanofibers

Tubulartype

Herringbonetype Platelettype

MicrometersizeGraphitewhiskerCarbonfibersPolyacrylonitrile-based Pitch-based,etc.

Vapor-growncarbon fibers

Figure1.23