https://ebookmass.com/product/gold-ore-processing-projectdevelopment-and-operations-2nd-edition-mike-d-adams/

Instant digital products (PDF, ePub, MOBI) ready for you

Download now and discover formats that fit your needs...

Agile Project Management: Creating Innovative Products (Agile Software Development Series) 2nd Edition, (Ebook PDF)

https://ebookmass.com/product/agile-project-management-creatinginnovative-products-agile-software-development-series-2nd-editionebook-pdf/ ebookmass.com

Head, Neck and Dental Emergencies 2nd Edition Edition Mike Perry

https://ebookmass.com/product/head-neck-and-dental-emergencies-2ndedition-edition-mike-perry/

ebookmass.com

Project Management ToolBox: Tools and Techniques for the Practicing Project Manager 2nd Edition, (Ebook PDF)

https://ebookmass.com/product/project-management-toolbox-tools-andtechniques-for-the-practicing-project-manager-2nd-edition-ebook-pdf/ ebookmass.com

Fantasy - How it Works Brian Attebery

https://ebookmass.com/product/fantasy-how-it-works-brian-attebery/

ebookmass.com

(eBook PDF) Introduction to Global Politics 5th Edition

https://ebookmass.com/product/ebook-pdf-introduction-to-globalpolitics-5th-edition/

ebookmass.com

Attraction (A Temptation Series Prequel) Leigh

https://ebookmass.com/product/attraction-a-temptation-series-prequelleigh/

ebookmass.com

eTextbook 978-0134163734 Criminal Law Today (6th Edition)

https://ebookmass.com/product/etextbook-978-0134163734-criminal-lawtoday-6th-edition/

ebookmass.com

L'infirmier(e) en néphrologie. Clinique Pratique et évaluation de la Qualité des Soins 4th Edition Edition Afidtn (Auth.)

https://ebookmass.com/product/linfirmiere-en-nephrologie-cliniquepratique-et-evaluation-de-la-qualite-des-soins-4th-edition-editionafidtn-auth/

ebookmass.com

Build Your Own Cybersecurity Testing Lab: Low-cost Solutions for Testing in Virtual and Cloud-based Environments Ric Messier

https://ebookmass.com/product/build-your-own-cybersecurity-testinglab-low-cost-solutions-for-testing-in-virtual-and-cloud-basedenvironments-ric-messier/

ebookmass.com

Dirty Plays (Florida Devils Book 2) (Florida Devils Series) Michelle A. Valentine

https://ebookmass.com/product/dirty-plays-florida-devilsbook-2-florida-devils-series-michelle-a-valentine/

ebookmass.com

GoldOreProcessing ProjectDevelopmentandOperations SecondEdition

Editedby MikeD.Adams FuguePteLtd,Singapore

Elsevier

Radarweg29,POBox211,1000AEAmsterdam,Netherlands TheBoulevard,LangfordLane,Kidlington,OxfordOX51GB,UK 50HampshireStreet,5thFloor,Cambridge,MA02139,USA

Copyright © 2016,2005ElsevierB.V.Allrightsreserved.

Nopartofthispublicationmaybereproducedortransmittedinanyformorbyanymeans,electronicormechanical,including photocopying,recording,oranyinformationstorageandretrievalsystem,withoutpermissioninwritingfromthepublisher. Detailsonhowtoseekpermission,furtherinformationaboutthePublisher’spermissionspoliciesandourarrangementswith organizationssuchastheCopyrightClearanceCenterandtheCopyrightLicensingAgency,canbefoundatourwebsite: www. elsevier.com/permissions

ThisbookandtheindividualcontributionscontainedinitareprotectedundercopyrightbythePublisher(otherthanasmaybe notedherein).

Notices

Knowledgeandbestpracticeinthis fieldareconstantlychanging.Asnewresearchandexperiencebroadenourunderstanding, changesinresearchmethods,professionalpractices,ormedicaltreatmentmaybecomenecessary.

Practitionersandresearchersmustalwaysrelyontheirownexperienceandknowledgeinevaluatingandusinganyinformation, methods,compounds,orexperimentsdescribedherein.Inusingsuchinformationormethodstheyshouldbemindfuloftheir ownsafetyandthesafetyofothers,includingpartiesforwhomtheyhaveaprofessionalresponsibility.

Tothefullestextentofthelaw,neitherthePublishernortheauthors,contributors,oreditors,assumeanyliabilityforanyinjury and/ordamagetopersonsorpropertyasamatterofproductsliability,negligenceorotherwise,orfromanyuseoroperationof anymethods,products,instructions,orideascontainedinthematerialherein.

BritishLibraryCataloguing-in-PublicationData

AcataloguerecordforthisbookisavailablefromtheBritishLibrary

LibraryofCongressCataloging-in-PublicationData

AcatalogrecordforthisbookisavailablefromtheLibraryofCongress

ISBN:978-0-444-63658-4

ForinformationonallElsevierpublications visitourwebsiteat https://www.elsevier.com/

Publisher: CandiceG.Janco

AcquisitionEditor: AmyShapiro

EditorialProjectManager: MarisaLaFleur

ProductionProjectManager: MohanapriyanRajendran

Designer: VictoriaPearson

TypesetbyTNQBooksandJournals

ListofContributors S.Acar,AcarConsultingLLC,HighlandsRanch,CO,USA

M.D.Adams,FuguePteLtd,Singapore

N.Ahern,AuTecInnovativeExtractiveSolutionsLtd., Vancouver,BC,Canada

A.U.Akcil,SuleymanDemirelUniversity,Isparta,Turkey

C.Aldrich,WesternAustralianSchoolofMines,Perth, Australia

J.E.Angove,AFTMetallurgy,NorthBeach,WA, Australia

E.Asselin,TheUniversityofBritishColumbia, Vancouver,BC,Canada

M.G.Aylmore,JohndeLaeterCentre,FacultyofScience andEngineering,CurtinUniversity,Perth,WA, Australia

J.Y.Baron,BarrickGoldstrikeMinesInc.,Carlin,NV, USA

P.Bateman ,InternationalCyanideManagementInstitute, Washington,DC,USA

G.Beale,Schlumberger,Denver,CO,USA

M.M.Botz,ElbowCreekEngineering,Sheridan,WY, USA

P.Breuer,CSIRO,Perth,WA,Australia

N.Briggs,SedgmanLimited,Perth,WA,Australia

A.R.G.Brown,AllanRGBrown&AssociatesPtyLtd, Booragoon,WA,Australia

A.Charitos,OutotecGmbH&Co.KG,Oberursel, Germany

Y.Choi,BarrickGoldCorporation,Toronto,ON,Canada

S.L.Chryssoulis,Amtel,London,ON,Canada

A.P.Cole,BarrickGoldstrikeMinesInc.,Elko,NV,USA

M.Costello,PreviouslyLycopodiumLtd.,Perth,WA, Australia

F.K.Crundwell,CMSolutions(Pty)Ltd,Johannesburg, SouthAfrica

G.Deschênes,BBAInc.,Toronto,ON,Canada

X.Díaz,UniversityofUtah,SaltLakeCity,UT,USA, EscuelaPolitécnicaNacional,Quito,Ecuador

D.Donato,DonatoEnvironmentalServices,Adelaide, Australia

D.B.Dreisinger,UniversityofBritishColumbia, Vancouver,BC,Canada

R.Dunne,WesternAustralianSchoolofMines,Curtin University(GoldTechnologyGroup),Perth,WA, Australia

S.Ellis,Perth,WA,Australia

C.J.Ferron,HydroProcConsultants,Peterborough,ON, Canada

S.Flatman,PreviouslyAngloGoldAshanti,Ergo Operation,Brakpan,SouthAfrica

C.A.Fleming,SGSMinerals,Lakefield,ON,Canada

M.Fullam,FLSmidthLtd,KnelsonTechnologies, Langley,BC,Canada

A.Götz,FraserAlexander,Boksburg,SouthAfrica

S.Gray,GekkoSystemsPtyLtd,Ballarat,VIC,Australia

B.Green,Retired(previouslyMintek,Randburg,South Africa)

N.Greenwald,InternationalCyanideManagement Institute,Washington,DC,USA

Y.Gu,YingshengTechnology,Darra,Queensland, Australia

J.Güntner,OutotecGmbH&Co.KG,Oberursel, Germany

F.Habashi,DepartmentofMining,Metallurgical,and MaterialsEngineering,LavalUniversity,QuébecCity, QC,Canada

J.Hammerschmidt,OutotecGmbH&Co.KG,Oberursel, Germany

R.J.Holmes,CSIROMineralResources,Melbourne,VIC, Australia

D.G.Hulbert,Retired(previouslyMintek,Randburg, SouthAfrica)

x ListofContributors

M.Jeffrey,Newmont,Denver,CO,USA

E.Johanson,LycopodiumEngineeringPtyLtd.,Perth, WA,Australia

J.Johnson,WesTechEngineering,Inc.,SaltLakeCity, UT,USA

D.W.Kappes,Kappes,Cassiday&Associates,Reno,NV, USA

B.Kerstiens ,OutotecGmbH&Co.KG,Oberursel, Germany

M.Kotze,Lanxess,SouthAfrica(previouslyMintek, Randburg,SouthAfrica)

G.Kyriakakis,ExtractiveResourcesLLC,Townville,SC, USA

H.Lacy,MWHGlobal,Perth,WA,Australia

G.Lane,AusencoLimited,Brisbane,QLD,Australia

G.T.Lapidus,UniversidadAutónomaMetropolitana, Iztapalapa,Mexico

A.Laplante,Metallurgist(1953 2006)

D.Lunt,StirlingProcessEngineeringLimited,Lincoln, UK

J.Mackenzie,MurdochMackenzieMetallurgy,Perth, Australia

T.J.Manning,Kappes,Cassiday&Associates,Reno,NV, USA

M.L.McCaslin,WesTechEngineering,Inc.,SaltLake City,UT,USA

J.McMullen,J.McMullen&Associates(previously BarrickGoldCorporation),Toronto,ON,Canada

P.Messenger,AusencoLimited,Brisbane,QLD,Australia

M.Millard,Metallurgist(1951 2007)

J.D.Miller,UniversityofUtah,SaltLakeCity,UT,USA

P.Miller,SulphideResourceProcessingPtyLtd,Hillarys, WA,Australia

J.Mitchell,PreviouslyAngloGoldAshanti,ErgoOperation,Brakpan,SouthAfrica

M.B.Mooiman,FranklinPierceUniversity,Manchester, NH,USA

J.B.Mosher,FreeportMcMoRanInc.,Phoenix,AZ,USA

T.I.Mudder,TimesLtd.,Sheridan,WY,USA

A.Muir,PreviouslyAngloGoldAshanti,ErgoOperation, Brakpan,SouthAfrica

J.Muller,OnkaparingaMining&MetallurgyPtyLtd, Perth,WA,Australia

N.D.Overdevest,DonatoEnvironmentalServices, Adelaide,Australia

M.S.Pearson,AutoclaveTechnologyGroup,HatchLtd, Mississauga,ON,Canada

M.Reuter,HelmholtzInstituteFreibergforResource Technology,Freiberg,Germany

D.Rogers,LycopodiumEngineeringPtyLtd.,Perth,WA, Australia

P.Rohner,CoreResources,Brisbane,Australia

A.Ryan,LycopodiumEngineeringPtyLtd.,Perth,WA, Australia

C.Sabbagha,PreviouslyAngloGoldAshanti,Ergo Operation,Brakpan,SouthAfrica

B.Sceresini,AustralianMining,Perth,WA,Australia

R.Shaw,GoldcorpInc.,Vancouver,BC,Canada

L.Simpson,ElemetalRe fining,Jackson,OH,USA

H.Smith,KWAKenwaltAustralia,Perth,WA,Australia

W.P.Staunton,WesternAustralianSchoolofMines, CurtinUniversity,Perth,WA,Australia

D.Stephenson,AusencoLimited,Brisbane,QLD,Australia

K.G.Thomas,KenThomas&AssociatesInc.,Oakville, ON,Canada

A.vanSchaik,MARAS,MaterialRecyclingand Sustainability,DenHaag,TheNetherlands

M.Virnig,BASF(previouslyCognisCorporation), Tucson,AZ,USA

R.Walton,RayWaltonConsultingInc.,Aurora,ON, Canada

R.-Y.Wan,Metallurgist(1932 2009)

J.Wates,FraserAlexander,Boksburg,SouthAfrica

B.Watson,ConsepPty,Perth,WA,Australia

T.Weeks,AquilaVenturesPtyLtd,Perth,WA,Australia

D.Williams,GolderAssociates,Perth,WA,Australia

J.Zhou,JoeZhouMineralogyLtd,Peterborough,Ontario, Canada

Foreword The fi rsteditionof AdvancesinGoldOreProcessing arrivedatatimewhenthegoldpricehadincreasedfromlowvalues ofaroundUS$270/troyozin2001toanaverageof$444/troyozin2005.Sincethattime,thepricehassoared,reachingan averageof$1669/troyozin2012beforesofteningtothe2015levelsof$1100/troyoz.Thisremarkableperformancehas ledtoaresurgenceinprimarygoldproductionworldwide,aswellasrenewedinterestinexploration,research,development,andtechnologicalinnovationthroughouttheindustry.However,thishasbeentemperedtoasignificantextentbya near-threefoldincreaseincashoperatingcostsfrom$269/troyozin2005to$750/troyozin2014andsimilarincreased ratiosincapitalcostsfornew(Green field)andexpansionproductioncapacity.Capitalcostintensityfornewgoldproductioncapacitynowrangesfrom$1500to$4500/annualtroyozproduced,dependingontheorefeedgrade,processing method,byproducts,andorecomplexity.Thisleavesmuchoftheindustryfacingsignificantchallengestoprofitabilityfor existingoperationsandforaddingnewcapacity.Akeypartofthisstoryisthataverageoregradeshavedecreased significantlyfromabout1.8g/tin2005toapproximately1.3g/tin2014.Oredepositsarebeingdevelopedwith increasinglycomplexmineralogyandmetallurgicalpropertiesasthemoreeasilytreatableresourcesaredepleted.Thisnot onlyaddstothecostofextraction,bothcapitalandoperatingbutalsoincreasesthedevelopmenttimeforprojectsandadds technicalrisk.

Theglobalgoldproductionprofilewasverydifferentin2005.SouthAfricawasthetopproducerwith300metrictons, followedbyAustralia,UnitedStates,China,andPeru.Totalglobalgoldproductionincreasedfromalmost2520metrictons in2005toover3100metrictonsin2014;however,Chinaincreaseditsproductiontotakethetopposition,followedby Australia,Russia,UnitedStates,andPeru.MuchofChina’sproductioncomesfromsmall,distributeddeposits,using conventionaltechnologythatcanbeappliedeffectivelyatasmallscale forexample,gravityconcentration, flotation, amalgamation,cyanidation,anddirectsmelting/processingofconcentrates.Inparallelwiththis,productionfrommanyofthe majorproducingminesdroppedoffsignificantly,suchasYanacocha,Peru(NewmontGold),andDriefontein,SouthAfrica (GoldFields).Thisservestounderscorethedramaticchangesthathaveoccurredwithintheindustryoverthepast10years.

Turningtotheprocessingaspectsoftheindustry,goldoreprocessingisdominatedbythecyanidationprocess.Since theinceptionoftheprocessinthelate1800s,cyanidehasbeenusedwidelytoextractgoldbecauseofitsrelativelylow cost,greateffectivenessforgoldandsilverdissolution,selectivityforgoldandsilveroverothermetals,aswellasrelative easeandefficiencyofmetalrecoveryfromsolution.Also,despitesomeconcernsoverthetoxicityofcyanide,itcanbe appliedwithlittlerisktohumanhealthandtheenvironment.Theoxidantmostcommonlyusedincyanideleachingis oxygen,usuallysuppliedfromair,whichcontributestotheattractivenessoftheprocess.

Sincethemid-1970s,alternativeleachingreagentschemestocyanidehavebeeninvestigatedforanyorcombinationsof thefollowingreasons:

l Environmentalpressures,andinsomecasesrestrictionsorlimitations,maymaketheapplicationofcyanidedif ficultin certainlocations;

l Somealternativereagentschemesprovidefastergold(and/orsilver)leachingkinetics;

l Severalcanbeappliedinacidicmedia,whichmaybemoresuitableforrefractoryoretreatment,and

l Somearemoreselectivethancyanideforgoldandsilveroverothermetals,suchascopperandzinc.

Someofthemoreimportantreagentsystemsthathavebeeninvestigated(orreinvestigated)arechlorine chloride, thiosulfate,thiocyanate,thiourea,ammonia,ammonia cyanide,alkalinesulfide,andotherhalidecombinations.Aside fromtheadvantageslistedhere,allofthealternativereagentschemeshavedisadvantagescomparedwithcyanideand,at thistime,noneappeartobewidelyapplicable,atleastnotwithoutfurthersignificantadvancesinthetechnology.However, thiosulfatehasemergedasthefrontrunnerofthealternativeschemesfornicheapplications,andBarrickGoldhas

advancedandimplementedthecommercialdevelopmentofthiosulfatetechnologytotreatcarbonaceous ‘preg-robbing’ materialatGoldstrikeinNevada.Carbonaceous,preg-robbingoresaretheprimarypotentialapplicationforthisemerging technology.

Theapplicationofultrafinegrindingtotreatoresandconcentratesbyliberatinggoldandsilvervaluesfromsul fideshas gainedmomentumfollowingthedevelopmentofefficient fine-millingequipment,includingtheXstrataIsaMill,theMetso SMDDetritor,andtheMetprotechmillasoptions.Thesedevelopmentspavedthewayformoreefficientgrindingdownto finersizes,around80%passing10 15 mmandbelow hence,theterm “ultrafine” grinding.Also,furtherdevelopment oftheMetsoVertimillfollowingmanysuccessfultertiarygrindingandregrindinginstallationshasledtoitsconsideration forultrafinegrindingapplications(downtoabout80%lessthan15 mm).Other finegrindingmillsareindevelopment.The abilitytoeconomicallygrindtosuch finesizespresentedtheopportunitytoliberatepreciousmetalsfromrefractorysulfi de oresandconcentrateswithouttheneedformorecostlyoxidativetreatment,suchasroasting,pressureoxidation,and biologicaloxidation.Whilenotthe firsttouseultrafinegrindingtotreatconcentrates,theapplicationatKalgoorlie ConsolidatedGoldMines(KCGM,WesternAustralia)in2001totreatrefractorysulfidegoldoretosupplementtheroaster capacityopenedupthetechnologytotheindustry.Theultra fi nemilledproductwascyanideleached,achievingagold recoveryofover90%.Thiswasasignifi cantdevelopmentasitwasthe firstmajorcommercialapplicationtoavoidthe needforoxidativepretreatment.UltrafinegrindinghassubsequentlybeeninstalledatKumtor(Kyrgyzstan)in2005,Pogo (Alaska)in2006,andLakeCowal(Australia)in2006.Theproductgrindsizeswere80%lessthan12 mm,80%lessthan 10 mm,and80%lessthan15 mm,respectively,fortheseoperations.In2015,manyotheroperationsareconsideringor usingasimilarprocessingapproach,emphasizingtheneedforcontinuedresearchanddevelopmentinthisarea.

Duringthepast10yearsorso,signi ficantinnovationshaveoccurredinprocessmineralogy.Attheforefrontofthis workhasbeenthedevelopmentofautomatedscanningelectronmicroscopytechniques(e.g.,QEMSCAN,providedby FEI,andtheMineralLiberationAnalyzer,developedbytheJKInstituteofTechnology,Australia).Thesetechniquesare nowwellknowntomostintheindustry,andthesignificanceofbeingabletoperformaccurate,quantitative,mineralogical analysisonrepresentativesamplesofore,intermediateprocessingproducts,andresiduesfromprojectsandoperations cannotbeoverstated.Theindividualmineralgrainidenti ficationandquanti fication,size-by-sizeanalysis,andmineral liberation/lockinganalysesthatcanbegeneratedhaverevolutionizedtheapproachtodesignandoptimizationofmineral andmetalextractionworldwide.Otheradvancedmineralogicaltechniquesarealsonowavailablethatprovideimportant diagnosticsforgoldandsilverrecoveryoptimization,troubleshooting,andprocessdesign.

Otherkeyareasofprocessdevelopmentsthatarecoveredwithinthisvolumeincludethefollowing:

l Centrifugalgravityconcentrationequipment,withincreasingvolumetreatmentrates

l Intensiveleachingequipmentandsystemstomosteffectivelytreathigh-gradegravityand flotationconcentrates

l Enhancedheap-leachingtechnology,especiallycoldclimateanddryclimateoperationsandthepotentialuseof high-pressuregrindingrollstoprepareheapleachfeedmaterial

l Refractoryoreprocessing,includingimprovedpressureoxidationandroastingtechnology

l Continuedandimprovedapplicationofbiologicaloxidationtotreat flotationconcentrates

l Gold copperandcopper goldoretreatment,includingtheuseofsulfi dization,acidi fication,recycle,andthickening (SART)technologyandeffectivecontrolofcyanidespeciation

Inparallelwiththeseprocessingdevelopments,amajoreffortwithrespecttothegoldextractionindustrywasthe publicationoftheInternationalCyanideManagementCode(2002),towhichmostofthemajorgoldandsilverproducers thatusecyanidehavecommittedtofollow.ThiscodewasdevelopedbytheInternationalCyanideManagementInstitute (ICMI),anonpro fitorganizationsetupundertheUnitedNationsEnvironmentProgram(UNEP)andtheInternational CouncilonMetalsandtheEnvironment(ICME).Allofthisactivityrepresentedsignifi cantlyincreasedemphasisonthe controlandtreatmentofgoldextractionbyproductsandeffluents,whichshouldbeconsideredasanintegralpartofgold extractionprocesses.Detoxificationofcyanidesolutionsandslurriesisanimportantaspectofgoldoreprocessingglobally andtherearemanyalternativesfordetoxi ficationofcyanide-containingsolutions.Whereapplicable,thepreferredmethod istoallowthecyanideconcentrationtodecaynaturallythroughthecarbon-in-pulp/carbon-in-leach(CIP/CIL)circuittothe pointatwhichitreacheslevelsacceptablefordischargetothetailingscontainmentfacility.Therearemanyoperationsthat areabletomeetstrictdischargelimitstotailingsfacilitieswithouttheneedforanyformofcyanidedestructionotherthan naturaldegradationovertime.However,theseoperationscarefullymanagecyanideconcentrationsdowntheleachingand CIP/CILcircuit,aswellaswashratiosinthickeners,usingre-circulated,reclaimedorfreshwaterinthecircuit.The cyanidedegradesfurtherovertimeinthetailingsfacility,ultimatelytonon-toxicproducts,andtheunderstandingofsuch degradationprocesseshasimprovedsignifi cantlyoverthepast25 30years,includingnaturaldegradationoffree,weak acid-dissociable(WAD)andtotalcyanidespecies,thiocyanate,andcyanate.Theuseoftailingsthickenersand,where

necessary,tailings filtrationcanassistwithrecoveringandrecyclingcyanide-bearingsolution.Allofthesepracticeshelpto reducecyanidenaturallywithintheoverallextractioncircuit.

Wheretheabovemethodsarenotsuffi cienttomeettheCyanideCodeguidelines(e.g., 50mg/LWADcyanide dischargetotailingsstoragefacilities)and/orregulatoryenvironmentalrequirements,othermethodsofdetoxifi cationmust beused,withtheexceptionofsomeoperationsusingthehypersalineprocesswaterintheEasternGoldfieldsofWestern Australia,wherenaturalprocessesprovideaCode-certi fiableprotectivemechanism.Afteralmost30yearsofapplicationat operationsthroughouttheworld,theuseofsulfurdioxide airhasbecomethepreferredandmostcost-effectivemethodof cyanidedestructionwherenaturaldegradationisnotadequate.Manyothermethodshavebeentestedandused commercially;forexample,hydrogenperoxideandCaro’sacid(hydrogenperoxideandsulfuricacid)havebothbeenused successfullyatavarietyofoperationsinvariousconfigurations.

Waterconservationis,andwillcontinuetobe,anareaforinnovationandthisishighlightedinthissecondedition. Dry-stackedtailing,suchasusedatLaCoipa(Chile),hasadditionalbenefitsofcyaniderecyclingandreducedenvironmentalconcernsforgroundwatercontamination.UseofbrackishandsalinewateriscommonplaceinWesternAustralia andiscurrentlyextendingtoapplicationsinChileandPeru.

Animportantlessonfromallofthemajorinnovationsingoldandsilverextractionisthatinnovationsarerarely “eureka” moments,butrathertheyresultfromasustainedperiodoftesting,investigating,modifying,andimprovinga particulartechnologicalapproachtoaproblem.Inthecaseofcyanidation,carbonadsorption,heapleaching,andrefractory oretreatmentprocesses,thetechnologyhadbeenknown,andversionsofeachprocesshadbeenpatented,testedandtried forseveraldecades.Thosewhosuccessfullycommercializedtheseinnovationslearnedfromthepriorversionsofthe technology,borrowedfromotherbranchesoftheindustry(andinsomecasesfromotherindustries),andimprovedthe applicationofthetechnologywithoftensimplemodi fications.The fi rst-userrecognizedthebenefitoftheemerging technologyovertheincumbentprocess;theywerepersistentandrelentlessintheirpursuitofsuccessfulcommercialization; andinallcasestheyreliedoninnovativeandtenaciousprocessoperators(notnecessarilytheinventororresearcher)to implementthetechnologyeffectively.Successwasnotintuitivelyobviousintheseefforts,andinmostcasestherewere severalfailuresor,atbest,marginaland/orsmallapplicationsofthetechnologythatprecededwidespread commercialization.

Assuch,thissecondeditionisparticularlytimelyandvalued.Theformatusedinthe firsteditionhasbeenretained,but thenumberofchaptershasbeenexpandedtocoverimportantissuessuchasgeometallurgicaldevelopments,CyanideCode compliance,alternativelixiviants,watermanagement,arsenicandmercurymanagement,goldrecoveryfrome-waste,and emergingandtransformationalgoldprocessingtechnologies asignificantenhancementandupdatetotheprevious edition.Thecontributingauthorsrepresentanexcellentglobalcrosssectionofgoldmetallurgists,researchers,developers, andexpertsinrelated fields.MikeD.Adamsistobecongratulatedonbringingtogetherthisvaluablecontributiontothe literatureongoldextractionandprocessing.

JohnO.Marsden,PE Phoenix,Arizona,USA August21,2015

PrefacetoSecondEdition Thissecondeditionof GoldOreProcessing arrivesadecadeafterthe firsteditionwaspublishedin2005andhas establisheditselfasawidespreadreferenceworkinthegoldprocessingandminingindustry.Arevisedandextended editionwasthereforetimely.The55chaptersinthissecondeditionvolumebringtogethermanytechnicalaspectsof relevancetogoldoreprocessing,fromprojectfeasibilitystudystage,throughoperationsstagetotheclosureandrehabilitationstage.Thevariousprocess flowsheetunitoperationsthatmaybeapplicabletoanyparticularoretypearecovered, alongwithnewemergingtrendsandpotentiallytransformationaltechnologies.Inadditiontoupdatesoftheexisting chapters,advancesinseveral fieldshavenecessitatedextensiverewrites,sometimeswithnewauthors.Ontheotherhand, scantdevelopmentsinseveralmatureareasmeantthatrevisionwasnotwarranted,witheditorialcommentsprovidingsome measureofupdate.

Thiseditionincorporates13newchapters,includingsome90contributingauthors,spanningenvironmentalconsiderations,moderninstrumentaltechniques,andemergingtechnologies.Additionaltopicscoveredareasdiverseasthe evaluationandfundingofcapitalprojects,solid liquidseparation,alternativelixiviants,goldrefining,tailingstreatment, andrecyclingofelectronicwasteinthecirculareconomy.Anewchapterongeometallurgyandautomatedmineralogyhas beenincluded.Increasingemphasisonenvironmentalaspectsingoldmininghasresultedinadditionalchapterscovering managementofarsenicandmercury,aswellaswatermanagement.Atthetimeofthe fi rstedition,theInternational CyanideManagementCodewasinitsinfancy afteradecadeofprogress,twonewchaptershavenowbeencontributed, coveringperspectivesfrombothregulatorandauditor.

Existingchaptershavebeenupdatedtoincluderelevantnewprocesses, fl owsheets,technologies,andphilosophies. Examplesandindicativedata,aswellasindustryprofilesforparticulartechnologies,havebeenreviewedandrevisedfor currencyandrelevancy.Somechaptershaveadditionalco-authorsorleadauthors.Sadly, firsteditioncontributorsAndré Laplante,DavidMuir,Rong-YuWan,andMartinMillardhavepassedonintheintervening10yearssincethe firstedition waspublished.

Thisbookshouldbeofuseacrossthegoldindustry,anditishopedthatmetallurgists,geologists,chemists,mining engineers,managers, fi nanciers,operations,projects,andresearchstaffalikewill findthecontentbothusefuland stimulating. MikeD.Adams

PrefacetoFirstEdition Thegold-processingindustryisexperiencingchange.Asfree-millingandoxideoresbecomedepleted,morecomplex polymetallicandrefractoryoresarebeingprocessed,coupledwithincreasingpressureforstricterenvironmental compliance.Recentyearshavealsoseenasteadyreductioninmineralprocessingandmetallurgygraduatesandagradual lossofolderoperatingexperience.Acontributiontodocumentingcurrentandfuturebestpracticeingoldoreprocessing seemstimely.

Thefocusofthisvolumeisonadvancesincurrentgoldplantoperation,fromconceptiontoclosure;eachchapteralso coversrecentinnovationsatthebenchandpilot-scalelevelthatwouldbeexpectedto findcommercialapplicationatsome stage.Coverageofessentialchemistryandengineeringaspectsisincluded.

PartIofthebookfocusesonprojectdevelopment,withanemphasisonthevariousaspectsoffeasibilitystudy managementandtakingthepaththroughcommissioning,safetyandenvironmentalmanagementinoperation,and finally closureofbothplantandtailingsstoragefacility.Withincreasingpressuresontheresourcecompanytoensureminimal socioenvironmentalimpactthroughtheentirelifecycleofthemine,itisimportanttoaimatgettingit “rightthe fi rsttime.”

PartIIcentresontheprocessplant,sequentiallyprobingthegenericgoldprocessing flowsheetforadvances,best practice,andpotentialfuturepracticalinnovations.Thisistheheartofthebook;thereiscoverageofthevariousunit operationsinvolvedwithcomminution,concentration,oxidation,leaching,goldrecovery,anddisposalofresiduesand effl uents.InnovationsdescribedinthecomminutionchapterincludethoseundertakenatFreeport,whichisoneofthe largestgoldmillsintheworld(despitebeingacoppermine).Concentrationofgoldbygravityhasseeninnovationdriven partlybythedevelopmentofnewitemsofequipmentandnovelapplicationwithinthemillingcircuit,suchasisnow commonplaceinareassuchaswesternAustralia.Flotationhassimilarlybeeninfluencedbytheadventof flashandcolumn flotation,aswellastheapplicationofdifferential floatsforcomplexores.

Treatmentofrefractoryoreshasnecessarilybecomeincreasinglyimportant,andthesectioncoveringpressureand bacterialoxidationaswellasroasting(bothoxygenatedand fl uidizedbed)hasparticularrelevancetothemoderngold metallurgist.Whilethesetechnologiescannowbedeemedasestablished,therecentadvancesoutlinedinthebookare clearlybothnovelandpractical.Developmentofmethodsthatincreaserecoverieswhiledecreasingreagentconsumption byminimizingcyanicideformationareclearlyattheforefrontoftheseareasandfurtherdevelopmentiscertain.

Again,intheleachingsection,theemphasisisontreatmentofproblematicoressuchasthosearisingfromoxidation processes.Therehasbeenadriveinrecentyearstowardthedevelopmentofalternativelixiviantsforgold,mainlyasa resultofenvironmentalpressures.Themostlikelycandidatefornicheapplicationisthiosulfateleaching;theamountof recentworkinthisareahaswarrantedinclusionofthistopicasaseparatechapter.Cyanidehasseenpracticalapplication formorethan100yearsnow,andthiswillcontinue,withtheongoingpositiveinitiativesincyanidemanagementsuchas theCyanideCode(whichhasalsowarrantedachapterinitsownright)andtheinherentbenefitsofareagentthat,ina well-designed flowsheet,islowlevelandbiodegradable.

Advancesintherecoveryofgoldfromleachsolutionareagaininfluencedbydevelopmentsinequipmentandreagents. Ongoingimprovementsintherefiningofgoldarealsobeingmade.InnovationssuchastheAngloAmericanCorporation (AAC)pumpcellcontactorandgold-selectiveresin-in-pulp(RIP)havefoundnicheapplicationatafewoperatingplants. Theextentoftheirusewilldependonanumberoffactors,butthetrendtowardpolymetallicandrefractoryoresislikelyto openupnewapplicationsthatmayrequiresomeinnovative flowsheetingifthebase-metalandprecious-metalvaluesare bothtobeeconomicallyrecovered.

Thereisanotherareathathasapositivebearingonthefutureofcyanideingoldprocessing.Theapplicationofcyanide detoxificationorrecoveryprocessesinto flowsheetsisbecomingmuchmoreprevalent.Thismaywellagainreflectan increasingsenseofenvironmentalstewardshipbyresourcecompanies,undoubtedlydrivenbytheneedforthetwoprongs ofpublicandoperatorperceptiontomeetinacommonreality.Anumberofnewtechnologiesfortheeconomicrecovery andrecycleofcyanidefromplanttailingshavenowbeendeveloped,andthismaywellbeakeyelementtotheongoing

responsibleuseofcyanide.Perhapsthemainareawherepublicperceptionhasbeennegativelyinfluencedhasbeenwith tailingsstoragefacilities.Placementofpasteordrytailingsusingtechniquessuchascentrallythickeneddischarge,for example,isaninnovationthataddressesissuesofdamstabilityandwaterrecovery,whileresultinginamore natural-lookinglandformonclosure.

PartIIIassessestheprinciplesanddevelopmentsoutlinedinthe firsttwoparts,bymeansoffocusedcasestudiesof typical flowsheetsforthetwomajortypesofproblematicgoldoresthatarebeingencountered polymetallicand refractoryores.Adistinctionismadeoneconomicgroundsbetweengold copperoresandcopper goldores;process flowsheetsandissuesdifferbetweenthetwo.Orescontaininghighsilver,base-metalandplatinum-groupmetal(PGM) gradeswillcontinuetobemoreofteninresourcecompanies’ fieldsofviewasthequestforpaydirtcontinues.Asorebodiesbecomemorecomplex,so,too,dotheprocess flowsheets,withanincreasingrelianceonhydrometallurgical treatmentsthatresultinavarietyofproducts,notonlygoldbutalsocopper,nickel,cobalt,silver,PGMs,andsometimes leadandzinc.

Whilerefractorysulfideshavebeenaroundforsometime,anunderstandingisbeinggainedofthesubtlechemistrythat canariseinhigh-pressureautoclavestreatingasometimesextensivemixofdifferentsul fideminerals.Asboththe knowledgebaseandthenumberofapplicationsincrease,sotheriskofapplyingtheseprocessesbecomessmaller.The samecanbesaidofotherproblematicores,suchascarbonaceouspreg-robbing,tellurides,andantimonialores.

Thegeneralprinciplebehindthestructureofthevolumeisthatof flowsheetingbasedonunitoperationsandappliedto amineralogicalclassifi cationofgoldoretypes.Knowledgeofthemineralogyofanorebodyisthekeytounlockingthe wealthcontainedwithin.Theextensivechaptercoveringthisaspectnecessarilydoessothroughprocesseyes; flowsheet definitioncanthenfollowusingthebuildingblockscomposingtheunitoperationsdescribedinthesecondpartofthe volume.

Practicalexperienceisvitaltothesuccessfuldevelopment,operation,andclosureofanyoperation.The42chapters havebeencontributedbyatotalof66authorsandcoauthorswhoareexpertsfromcountriesspanningtheglobeand representexhaustivepracticalknowledgecoveringmanydisciplinesrelevanttogoldprocessing.Withinthechaptersare numeroustidbitsofpracticalpersonalexperience,muchofwhichisasyetunpublished.Thecontentwillbeusefulto operators,engineersandresearchersworldwide.

TheoriginalintentionwastoprovideaselectionofappendicescoveringSIunits,conversionfactors,pulpdensity tables,andthelike.Thereadyavailabilityofthisinformationontheinternethasmadetheirinclusionredundant;however, aperiodictablekindlymadeavailablebyProf.FathiHabashihasbeenincluded.

Thisbookisintendedformineral-processingengineers,metallurgists,processmineralogists,miningengineers, environmentalengineersandconsultants,andresourcecompanymanagers.Itwillbeofinteresttoprofessionalsand studentsalike.

MikeD.Adams

Acknowledgments Thisvolumereflectstheeffortsofabodyofsome90expertindividuals,includingthecorrespondingauthorsandcocontributorsofthe55chapters,whoarethankedfortheirwillingnesstoassistwiththisendeavorandforthehours spenttowardgeneratingthisexhaustiveupdate.Gratitudeisexpressedtothevariouscompaniesthatarerepresentedinthe authorship,fortheirpermissiontoallowtheauthorstotackletheircontributionsand,insomecases,forthesupplyof materialandpermissiontopublishillustrationsandphotographs.Thehardwork,patience,andcooperationinparticularof MarisaLaFleur(EditorialProjectManager),andofAmyShapiro(AcquisitionsEditor,EarthandPlanetarySciences)and MohanapriyanRajendran(ProductionProjectManager),withthismajorundertakingaregratefullyacknowledged.Many thanksarealsoduetoCarolAdamsforherpatiencewiththiscommitmentandforpreparingsomeoftheillustrations.

ListofAcronyms AAC AngloAmericanCorporation

AARL AngloAmericanResearchLaboratories

AAS atomicabsorptionspectroscopy

ABA Acid-baseaccounting

AC activatedcarbon

ACF AuditorCredentialsForm

ADIS AutomatedDigitalImageSystem

AG autogenousgrinding

AGC AshantiGoldfieldsCompany

AI arti ficialintelligence

AI abrasionindex

AIA automatedimage-analysis

AIChE AmericanInstituteofChemicalEngineers

AIME AmericanInstituteofMining,Metallurgical,andPetroleumEngineers

AMD acidmine-drainage

AMICS AdvancedMineralIdentificationandCharacterisationSystem

ANC acidneutralizingcapacity

ANFO ammoniumnitrateandfueloil

APELL AwarenessandPreparednessforEmergenciesatLocalLevel

ARD acidrockdrainage

ASGM artisanalandsmall-scalegoldmining

ASTM AmericanSocietyforTestingandMaterials(nowASTMInternational)

AusIMM AustralasianInstituteofMiningandMetallurgy

AVR Acidi fication-volatilization-regeneration

AWWA AmericanWaterWorksAssociation

BAT bestavailabletechnology

BBMWI Bondball-millworkindex

BDAT best-demonstratedavailabletechnology

BEP bestenvironmentalpractice

BFB bubbling fluidizedbed

BGMI BarrickGoldstrikeMines

BMP bestmanagementpractice

BRMWI Bondrod-millworkindex

BRPS Bright/RarePhaseSearch

BSE back-scatteredelectron

BTAC-CIL bench-topautoclavingfollowedbycarbon-in-leach

BTU BritishThermalUnit

CAP CorrectiveActionPlan

CAPEX capitalexpenditure

CCD counter-currentdecantation

CCTV closed-circuittelevision

CCW counter-currentwash

CE circulareconomy

CEC cationexchangecapacity

CELP CANMETEnhancedLeachProcess

CEN CommitteeforStandardization

CEPA CanadianEnvironmentalProtectionAct

CESL ComincoEngineeringServicesLimited

CFB circulating fluidizedbed

CFD computational fluiddynamics

CIL carbon-in-leach

CIM CanadianInstituteofMining,MetallurgyandPetroleum

CIP carbon-in-pulp

CIS carbon-in-solution

CIS CommonwealthofIndependentStates

CM carbonaceousmatter

CMC carboxy-methylcellulose

COMEX CommodityExchange

CPS controlled-potentialsulfidization

CSTR continuousstirred-tankreactor

CTC carbon-tetrachlorideactivity

CTD centrallythickeneddischarge

CVAAS cold-vapouratomic-absorptionspectroscopy

CVAFS cold-vapouratomic- fluorescencespectrometry

CWI crushingworkindex

DAFR DetailedAuditFindingsReport

DCF discountedcash flow

DCS distributedcontrolsystem

DETA diethylenetriamine

DfD DesignforDisassembly

DfR DesignforRecycling

DfRE DesignforResourceEfficiency

DFS definitivefeasibilitystudy

DNA dionylamine

DO dissolvedoxygen

DOE DepartmentofEnergy

DPO dynamicprocessoptimization

DR directreduction

D-SIMS dynamicsecondary-ionmassspectrometry

DWI dropweightindex

EBRD EuropeanBankforReconstructionandDevelopment

EDS energy-dispersivespectrometry

EDTA ethylenediaminetetraaceticacid

EDX energy-dispersiveX-rayanalysis

EEE electricandelectronicequipment

EFA ecosystemfunctionanalysis

EHS environmental,healthandsafety

EMS engineeredmembraneseparation

ENR enhancednaturalremoval

EoL End-of-Life

EPA EnvironmentalProtectionAgency

EPC engineering,procurementandconstruction

EPCM engineering,procurementandconstructionmanagement

EPMA electron-probemicroanalysis

ESP electrostaticprecipitator

EU EuropeanUnion

EW electrowinning

FAG fullyautogenousgrinding

FAMS fluegasadsorbentmercuryspeciation

FAT factoryacceptancetesting

FB fluidizedbed

FRP fiber-reinforcedplastic

FSTM fluegassorbenttotalmercury

FSU formerSovietUnion

FTIR Fourier-transforminfraredspectroscopy

G&A generalandadministrative

GGFL Gekkogravity-float-leach

GPS globalpositioningsystem

GRG gravity-recoverablegold

GSA globalsensitivityanalysis

HAZOP hazardandoperabilitystudy

HBF horizontal-belt filter

HCR hydrographcontrolledrelease

HDPE high-densitypolyethylene

HMSO HerMajesty’sStationeryOffice

HOPG highlyorganizedpyrolyticgraphite

HPGR high-pressuregrindingrolls

HR-TEM high-resolutiontransmissionelectronmicroscopy

HSGE high-speedgold-electrolysis

HSSE high-speedsilver-electrolysis

ICME InternationalCouncilonMetalsandtheEnvironment

ICMI InternationalCyanideManagementInstitute

ICOLD InternationalCommissiononLargeDams

IEP isoelectricpoint

IFC InternationalFinanceCorporation

ILR InlineLeachReactor

IMM InstituteofMiningandMetallurgy

IoT Internet-of-Things

Io(M)T Internet-of-(Metallurgical)-Things

IPMI InternationalPreciousMetalsInstitute

IPS integratedpressurestrip

IR industrialrelations

IRMA InitiativeforResponsibleMiningAssurance

IRR internalrateofreturn

ISO InternationalStandardsOrganization

KPI keyperformanceindicator

LBMA LondonBullionMarketAssociation

LCA life-cycleassessment

LCD liquidcrystaldiode

LED light-emittingdiode

L-ICP-MS laserinductivelycoupled-plasmamass-spectrometry

LME LondonMetalExchange

LPG liquidpetroleumgas

LSTK lump-sumturnkey

MAC magneticactivatedcarbon

MAC MiningAssociationofCanada

MBT mercaptobenzothiozole

MCC MotorControlCentre

MCL maximumcontaminantlevel

MEBA MercuryExportBanAct

MGS MozleyGravitySeparator

MIBC methylisobutylcarbinol

MIBK methylisobutylketone

MLA MineralLiberationAnalyzer

MLS MozleyLaboratorySeparator

MNR MetallgesellschaftNaturalResources

MPA maximumpotentialacidity

MPC modelpredictivecontrol

MWMP MeteoricWaterMobilityProcedure

NAG netacidgeneration

NAPP netacid-producingpotential

NCV netcarbonatevalue

NGO non-governmentalorganization

NHE normalhydrogenelectrode

NIR nearinfrared

NPI NationalPollutantInventory

NPRI NationalPollutantReleaseInventory

NPV netpresentvalue

NRS netsmelterreturn

NSG non-sulfidegangue

OCS optimizingcontrolsystems

OM opticalmicroscopy

OPEX operatingexpense

ORP oxidation-reductionpotential

OSA opticalspectrumanalyzer

OT OutokumpuTechnology

PAX potassiumamylxanthate

PC personalcomputer

PCA principalcomponentanalysis

PCB printedcircuitboard

PCS processcontrolsystem

PECTU N-propyl-N-ethoxycarbonylthiourea

PFS preliminaryfeasibilitystudy

PGMs platinum-groupmetals

PI proportional-integral(feedbackcontrol-loops)

PIXE particle-inducedX-rayemission

PLC programmablelogiccontroller

PLS partialleastsquares

PLS pregnantleachsolution

PMs preciousmetals

POX pressureoxidation

PP polypropylene

PPE personalprotectiveequipment

PSA pressure-swingadsorption

PSD particle-sizedistribution

PTFE polytetrafluoroethylene

PTFI PTFreeportIndonesia

PVC polyvinylchloride

PVDF polyvinylidenedifluoride

QA qualityassurance

QEMSCAN QuantitativeEvaluationofMaterialsbyScanningElectronMicroscopy

RBC rotatingbiologicalcontactor

REQCM rotatingelectrochemicalquartz-crystalmicrobalance

RIL resin-in-leach

RIP resin-in-pulp

RIS resin-in-solution

RLE roast-leach-electrowinning

ROI returnoninvestment

ROL rapidoxidativeleach

ROM run-ofmine

RPS rarephasesearch

SABC SAGmill/ballmill/crusher

SAG semi-autogenousgrinding

SAIMM SouthAfricanInstituteofMiningandMetallurgy

SALI surfaceanalysisbylaserionization

SAR SummaryAuditReport

SART sulfidization-acidi fication-recycling-thickening

SCE saturatedcalomelelectrode

SCR selectivecatalyticreduction

SDGM SunriseDamGoldMine

SEM scanningelectronmicroscopy

SEM/EDX scanningelectronmicroscopy/energy-dispersiveX-rayanalysis

SERS surface-enhancedRamanspectroscopy

SET silver-enhancementtreatment

SG speci ficgravity

SHE standardhydrogenelectrode

SIBX sodiumisobutylxanthate

SIMP systemintegratedmetalproduction

SIMS secondary-ionmassspectrometry

SLS sodiumlaurylsulfate

SMC SAGMillComminution

SME SocietyforMining,MetallurgyandExploration

SPI SAGPowerIndex

SPL sparsephaseliberation

SPLP syntheticprecipitationleachingprocedure

SWEP specialwasteextractionprocedure

SX solventextraction

TBRC top-blownrotaryconverter

TCLP toxicitycharacteristicsleachingprocedure

TCM totalcarbonaceousmatter

TDM tertiarydodecylmercaptan

TDS totaldissolvedsolids

TIMA TESCANIntegratedMineralAnalyser

TLV thresholdlimitingvalue

TMS TheMinerals,MetalsandMaterialsSociety

TOA trioctylamine

TOC totalorganiccarbon

TOF-LIMS time-of- flightlaser-ionizationmassspectrometry

TOF-RIMS time-of- flightresonant-ionizationmassspectrometry

TOF-SIMS time-of- flightsecondary-ionmassspectrometry

TOMAC trioctylmethylammoniumchloride

TRI ToxicsReleaseInventory

TSF tailingsstoragefacility

UBC UniversityofBritishColumbia

UCS unconfinedcompressivestrength

UFG ultra- finegrinding

UFM ultra- finemilling

UNEP UnitedNationsEnvironmentProgramme

USEPA UnitedStatesEnvironmentalProtectionAgency

USMR USMetalsRefining

UV ultraviolet

VAW VereinigteAluminiumWerke

VMS volcanogenicmassivesulfide

VUV vacuumultraviolet

VUV-TOF-LIMS vacuumultravioletTOF-LIMS

WACC weightedaveragecostofcapital

WAD weak-aciddissociable(cyanide)

WDX wavelength-dispersiveX-rayanalysis

WEEE wasteelectricalandelectronicequipment

WGC WorldGoldCouncil

WHO WorldHealthOrganization

WoM WebofMetals

WoP WebofProducts

WWF WorldwideFundforNature

XANES X-rayabsorptionnear-edgestructurespectroscopy

XPS X-rayphotoelectronspectroscopy

XRD X-raydiffractometry

XRF x-ray fluorescence

m-PIXE micro-particle-inducedX-rayemission

ListofMineralFormulae acanthite Ag2S

altaite PbTe

alumina Al2O3

andorite Sb3PbAgS6

argentojarosite Ag2Fe3(SO4)4(OH)12

arsenianpyrite AsFeS2

arsenopyrite FeAsS auricupride Cu3Au

auroantimonate AuSbO3

aurostibite AuSb2

azurite 2Cu(CO)3,Cu(OH)2

bassanite CaSO4,1 2H2O

berthierite FeSb2S4

bezsmertnovite Au4Cu(Te,Pb)

bogdanovite Au5(Cu,Fe)3(Te,Pb)2

bornite FeS,2Cu2S,CuS

braggite PtS

calaverite AuTe2

chalcocite Cu2S

chalcopyrite CuFeS2

chlorargyrite(cerargyrite) AgCl

chlorite (Mg,Al,Fe)12[(Si,Al)8O20](OH)16

chrysocolla CuSiO3,nH2O

cinnabar HgS

coloradoite HgTe cooperite (Pt,Pd,Ni)S cordierite Mg2Al4Si5O18 corundum Al6Si2O13

covellite CuS cuprite Cu2O

dolomite CaMg(CO3)2 electrum (Au,Ag);20-80%molarAg enargite Cu3AsS4

fayalite Fe2SiO4 ferrihydrite 5Fe2O3,9H2O ferrisymplesite Fe(III)3(As(V)O4)2(OH)3,5H2O ferrouspyroarsenite Fe2AsO5 fischesserite Ag3AuSe2

galena PbS goethite FeO(OH) goldamalgam (Au,Ag)Hg gudmundite FeSbS guerinite Ca5(AsO4)2(AsO3OH)2,9H2O

gypsum CaSO4,2H2O haidingerite Ca(AsO3OH),H2O

hematite Fe2O3 hessite Ag2Te

hunchinite Au2Pb

hydroxyapatite

Ca10(AsxPyO4)6(OH)2;whereAs/P <0.2

iodargyrite AgI

iridicgold (Au,Ir)

jarosite H3OFe3(SO4)2(OH)6

kostovite CuAuTe4

kotulskite (Pt,Pd,Ni)(Te,Bi,Sb)2

krennerite (Au,Ag)Te2

laurite (Ru,Fe,Os,Ir,Pt)S2

litharge PbO

loellingite FeAs2

maghemite Fe2O3 with <5%FeO

magnetite Fe3O4

malachite 2CuCO3(OH)2

maldonite Au2Bi

marcasite FeS2

moncheite (Pt,Pd,Ni)(Te,Bi,Sb)2

montbrayite (Au,Sb)2Te3

mullite Al6Si2O13

muthmannite (Au,Ag)Te

nagyagite [Pb(Pb,Sb)S2][Au,Te]

nativecopper Cu

nativegold Au(<20%molarAg)

orpiment As2S3

palladiangold(porpezite) (Au,Pd)

parasymplesite Fe(II)3(As(V)O4)2,8H2O

pentlandite (Fe,Ni)9S8

petrovskaite AuAg(S,Se)

petzite Ag3AuTe2

pharmacolite CaHAsO4,2H2O

platinumgold (Au,Pt)

Pt-Fealloys Pt3Fe

pyrite FeS2

pyrophyllite AlSi2O5OH

pyrrhotite Fe1-xS

realgar AsS

rhodiangold(pyrite) (Au,Rh)

schwertmannite Fe(III)8O8(OH)x(SO4)y ,nH2O

scorodite FeAsO4,3.5H2O

sphalerite (Zn,Fe)S stibnite Sb2S3

sylvanite (Au,Ag)Te2

tennantite (Cu,Fe)12As4S13

tetra-auricupride AuCu

tetrahedrite (Cu,Fe,Ag,Zn)12Sb4S13 thucholite variablemixtureofhydrocarbons,uraniniteandsulfides tooeleite Fe(III)6(AsO3)4SO4(OH)4,4H2O uraninite UO2

uytenbogaardite Ag3AuS2

weilite CaHAsO4

weishanite (Au,Ag)3Hg2

zincblende ZnS zinkenite Pb9Sb22S42

Chapter1 Gold e AnHistoricalIntroduction F.Habashi

DepartmentofMining,Metallurgical,andMaterialsEngineering,LavalUniversity,QuébecCity,QC,Canada e-mail:Fathi.Habashi@arul.ulaval.ca

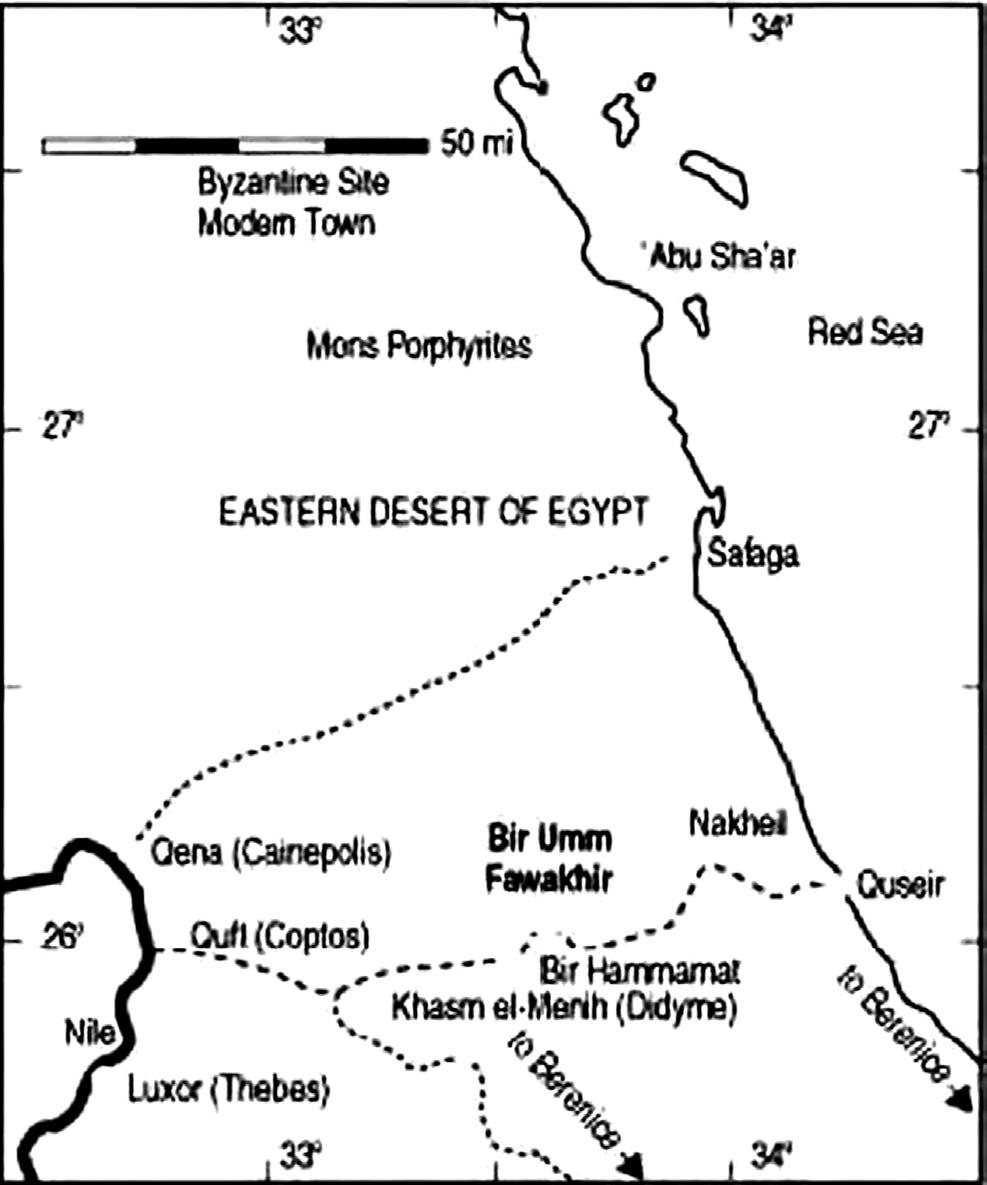

1.GOLDINANCIENTEGYPT Fromancienttimestothepresentday,goldhasbeenvaluedbyhumans.Egyptwastheprincipalgold-producingcountryin ancienttimes.Coptos,thepresentQuftontheeasternsideoftheRiverNile,wasthechieftownoftheNomosofHarawi andwasoncepoliticallyimportant.Intheeleventhdynasty(2133 1991BC)itwasovershadowedbyThebes,50kmto thesouth,whichbecamethecapitaloftheMiddleKingdom(2133BC)ofancientEgypt,thepresent-dayLuxor (Figure1.1).

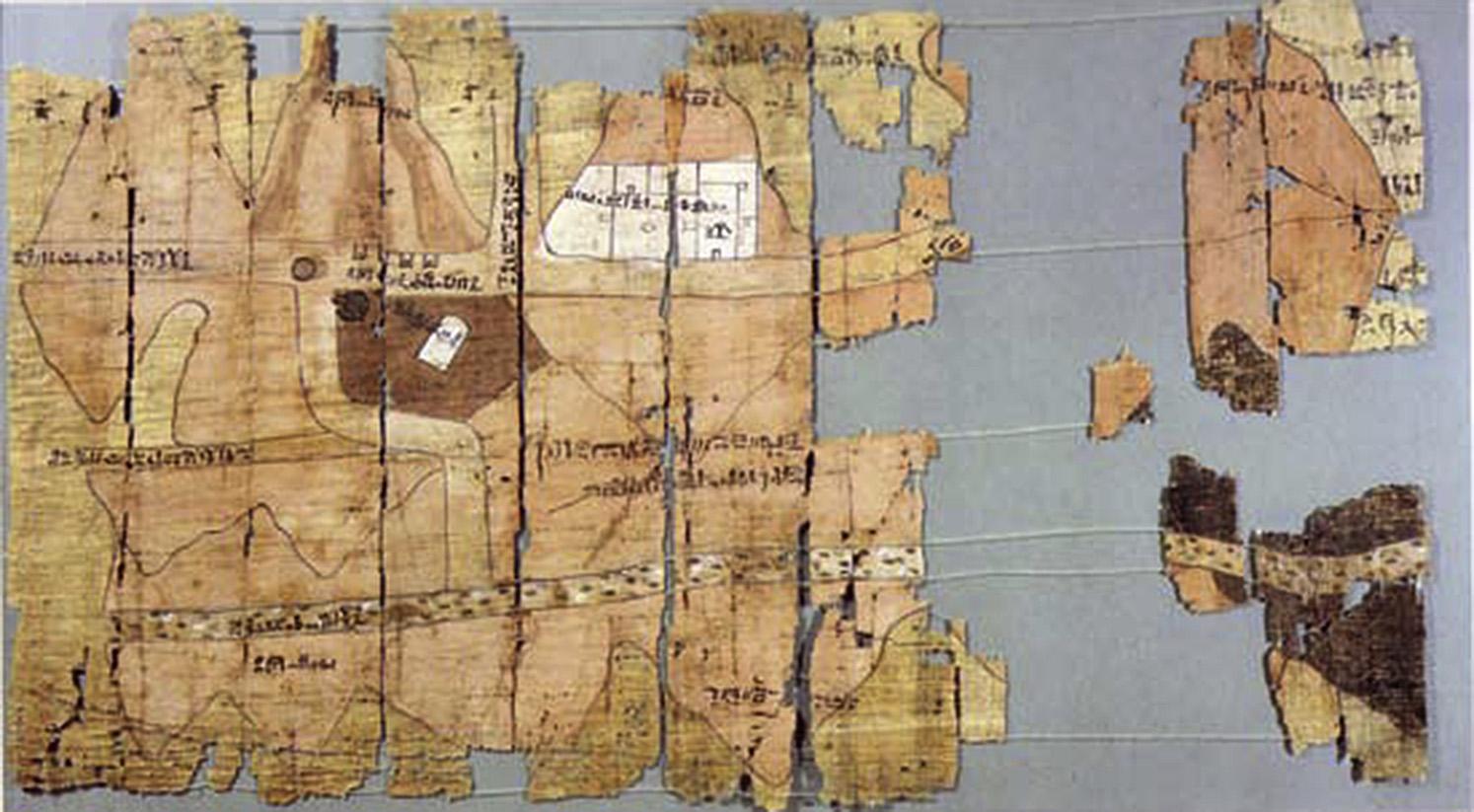

Coptoswastheworld’s fi rstgoldboomtown.ItwasthereintheWadiHammamatthatalluvialgoldhadbeenwashed downfromthegold-bearingveinsfoundlaterinthegranitehillsabove.Theworld’soldestminemap(Figure1.2),whichis madeonpapyrusandheldattheTurinMuseum(MuseoEgiziodiTorino)inItaly,showsthehutsoftheEgyptianminers, theroadtothegoldmines,andthehillswithinwhichthegoldveinsoccurred.Themapis0.4 2.8m;itisbelievedthatit

FIGURE1.1 LocationofCoptosinUpperEgypt,themostancientgold-miningcenter.

wasmadeduringthereignofRamsesIV(1162 1156BC).ThescrollwasfoundinatombnearThebesshortlybefore 1824whenitappearedinTurin.RuinsofthesehutscanbeseentodayatFawakhirintheEasternDesert.

IntheoldEgyptianlanguage,theword nubia signi fies “gold.” By1300BC,undergroundminingofveingoldwaswell establishedinNubiaunderEgyptiancontrol.Thereweremorethan100minesinthearea.Aseriesoffortswerebuiltto protectthe flowofNubiangoldalongtherichtraderoutes.EgyptbecamethedominantpowerintheMiddleEast,having thegreatestgold- filledtreasuryintheancientworld.

TheancientEgyptiansdidnothaveanimportantportontheMediterraneanandalltheirtradewasthroughtheRedSea. CoptoswasatthestartingpointofthetwogreatroutesleadingtothecoastoftheRedSea,onetowardtheportofTââou (MyosHormos)andtheothermoresoutherly,towardtheportofShashirit(Berenice).Underthepharaohs,thewholetrade ofsouthernEgyptwiththeRedSeapassedoverthesetworoads.UnderthePtolemys,andinRomanandByzantinetimes, merchantsfollowedthesameroadsforpurposesofbarterwiththecoastsofZanzibar,SouthernArabia,India,andtheFar East.Thisplaceandthesurroundingareawereknownfortherichnessofitsgoldminesandsemipreciousstones.Atemple wasbuilttherebyTahutmesIII,whoruledfrom1503to1450BCandwasco-regentwithQueenHatshepsutfor21years. TheareathatitoccupiedwasabouttwiceaslargeashistempleatMadinetHabuinLuxor.

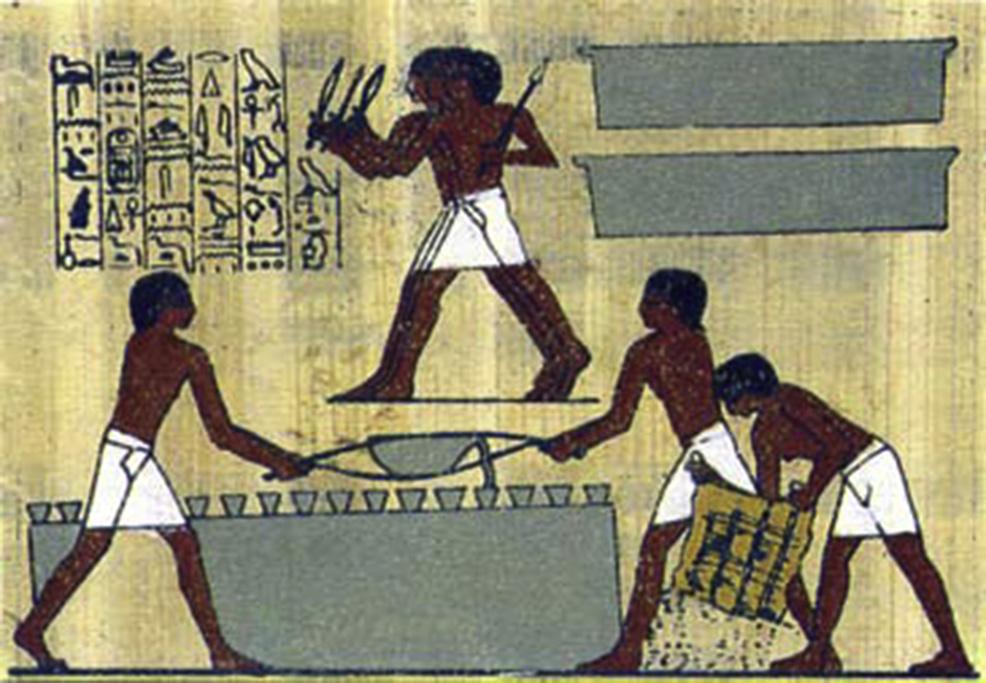

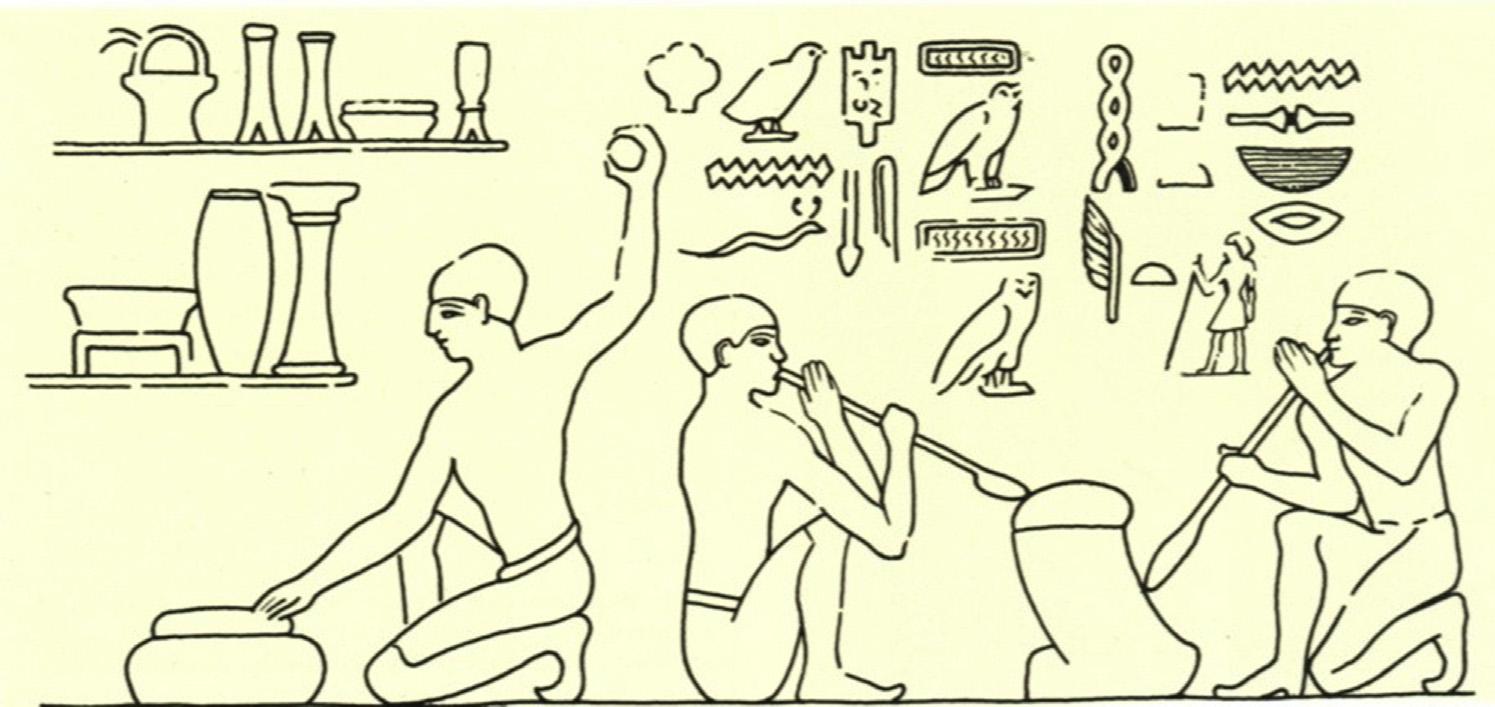

TheEgyptianswerethe firsttotreatgold-bearingrocks.Thisiswelldocumentedonwallpaintings,anexampleof whichisgivenin Figure1.3

FIGURE1.3 AncientEgyptianwallpaintingdatingfromabout1450BCinthetombofRekhmire,viziertoThothmesIIIatThebes,showingmetal workerscastingmoltengoldinthemolds.

FIGURE1.2 Theworld’soldestminemap.

2.EARLYGOLD-MININGCENTERS Herodotus(484 425BC)referstoseveralgreatgold-miningcentersinAsiaMinor,andStrabo(63BC)mentionsgold mininginmanydifferentplaces.Pliny(23 79AD)givesmanydetailsofancientplacermining,whichwasextensive.The Romanshadlittleofthemetalintheirownregions,buttheirmilitaryexpeditionsbroughtthemmajoramountsintheform ofbooty.Theyalsoexploitedthemineralwealthofthecountriestheyhadconquered,especiallySpain,whereupto40,000 slaveswereemployedinmining.Thestate’saccumulationofgoldbarsandcoinswasimmense,butduringthebarbarian invasionsandthecollapseoftheempirethisgoldwasscattered,andgoldmininglanguishedintheMiddleAges.

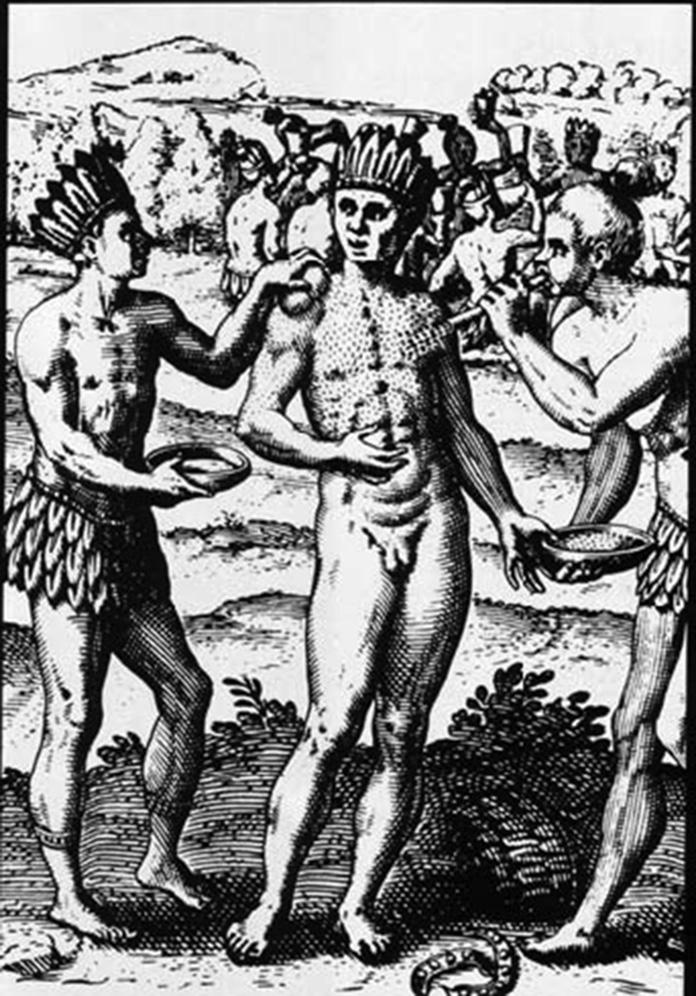

FollowingthediscoveryofAmericaattheendofthe fifteenthcentury,theSpaniardstransferredconsiderableamounts ofgoldfromtheNewWorldtoEurope.AlthoughtheconquistadorsfoundahighlydevelopedminingindustryinCentral America,theireffortstoincreasegoldproductionwerelargelyunsuccessfulbecausemostofthe findsconsistedofsilver. Colombia’sMuiscaIndians,whodweltinthehighlandsnearpresent-dayBogota,installedtheirkingsbydustingtheir nakedbodieswithgoldandthenwashingtheminnearbyLake.Totheconquistadores,thiswealthychieftainbecame knownasElDorado aSpanishwordmeaning “theGildedMan” (Figure1.4).

ItwasnotuntilthediscoveryofdepositsinBrazil,in1691,thattherewasanoticeableincreaseinworldgoldproduction.Sinceabout1750,goldhasbeenminedonamajorscaleontheeasternslopesoftheUralMountains.In1840, alluvialgoldwasdiscoveredinSiberiaandthenatColoma,California,inJanuary1848,afewdaysbeforethesigningofa treatybetweenMexicoandtheUnitedStatestoendtheirhostilities.CaliforniawasthuscededbyMexicoafteradiscovery thatwasapparentlynotknowntoeithergovernment.Colomaisabout50kmsoutheastofSacramentoontheslopesofthe SierraNevada.

ThediscoveryofgoldinBritishColumbiawasanepoch-makingevent.Inthelate1850s,alluvialgoldwasfoundalong theThompsonRiver,andin1858thefamousFraserRiverrushtookplace.Extraordinarilyrichdepositswerediscoveredin 1860onWilliamsandLightningcreeks.Formanyyears,BritishColumbiawastheleadinggoldproduceramongthe Canadianprovincesandterritories,butwiththediscoveryoftheKirklandlakedepositsin1911,andtheopeningupofthe Porcupinedistrictin1912,Ontarioheld fi rstplaceeversince.

GolddepositswerealsofoundinEasternAustralia(1851),Nevada(1859),Colorado(1875),Alaska(1886),New ZealandandWesternAustralia(1892),andWesternCanada(1896).However,thesedepositssoonlostmuchoftheir importance.Thestrongestimpetuswasgiventogoldproductionthroughthediscoveryofthegold fieldsofthe WitwatersrandinSouthAfricain1885.SouthAfricangoldsoonoccupiedacommandingpositionintheworldmarket. ProductiongrewcontinuouslyexceptforashortinterruptionbytheBoerWar(1899 1902).GoldmininginGhana(Gold Coast)begantoplayamodestroleinthetwentiethcentury,althoughthedepositswereknownintheMiddleAge.

FIGURE1.4 Eldorado.

3.GOLDANDALCHEMY Tothemedievalalchemists,goldhasbeenregardedasametalofperfection.Theyidentifieditwiththesunbyvirtueofits brightyellowcolor,anditwasgiventhesymbolofacirclewithadotinthecenter.Goldwassopreciousthatfromearliest timesmanhasleftnostoneunturnedinsearchingforitinnature.Itisnotsurprising,therefore,thathumansshouldhave soughttoconvertothermetalsintogold.Theagentfortransmutingbasemetalsintogoldwasknownasthe philosopher’ s stone.Inadditiontoitstransmutatorypower,thestonewasbelievedtohavethepropertiesofauniversalmedicinefor longevityandimmortality.Theattemptstotransmutebasemetalsintogoldandtoprolonglifeindefi nitelycontributed muchtomodernchemistryintheformofnewchemicalsubstancesandlaboratorytechniques.Alchemicalprincipleshave alsofoundtheirwayintomodernpsychologicalideas,notablybytheSwisspsychiatristCarlJung(1875 1961).

AncientEgyptisconsideredthebirthplaceofalchemy.Zosimos(ca.350 420),whotaughtinAlexandria,isthe earliestwriterknowntohavepracticedalchemy.Becauseoftheirlackofknowledgeofthecompositionofcommon substancessomealchemistsviewedmanyordinarychemicalreactionsastransmutations.Forexample,thedepositionof copperonironmetalplacedinasolutionofbluevitriol(coppersulfate),areactionknownsinceRomantimes,was assumedbysometobeatransmutationofironintocopperuntilthelateRenaissance.Similarly,themineralgalena[PbS], onheating,liberatessulfurdioxideandappearstobetransformedintosilver,whichisoftenpresentasanimpurityin galena.

Throughthecenturies,gold-makinghasbeenalternatelyencouragedandbannedbymonarchsandtheChurch.For example,Diocletian(AD245 316),EmperorofRomefrom284to313,fearingthattheEgyptians(Egyptwasthenunder thedominationoftheRomanEmpire)mightbecomepowerfulthroughtheirknowledgeofalchemy,orderedinAD296 thatallbooksandmanuscripts “whichtreatedtheartofmakinggoldandsilver” tobeburned.Consequently,onlyveryfew Egyptianalchemicalworkshavebeenpreserved.Duringmedievaltimes,Europeankingsandprincessupportedalchemists attheircourts,hopingtoacquirewealththroughtheirwork.

4.USESOFGOLD Humanshavevaluedgoldforitslustrouscoloranditsresistancetotarnishing,soitwasusedforspecialdecorative ornamentsandjewelry.Thevenerationreservedforgoldbytheancientshasledtoitsuseformanycenturiesforreligious artifacts.Goldwasoftencastintheformofidolsorhammeredintofoiltomakemasksforthedead.Goldwasusedfor barterandsubsequentlyforcoinage.BytheeighthcenturyBC,small,irregularbarsofimpuregoldwerebeingexchanged ascurrencyinAsiaMinor,andbythe fi fthcenturyBC,goldcoinswerebeingusedfreely.Eventoday,themajorityofthe goldproducedisturnedintogoldbars(i.e.,bullionthatactsasthestandardfortheworld’smonetarysystems),andtheyare usedininternationaltradeandexchange.

Golddiffersfrommostothermetalsinthatthemajorityofthemetalthathaseverbeenminedisstillinexistence.The totalamountofgoldnowinexistenceisestimatedtoamounttoaround125,000tons.Ifallofthisgoldcouldbecollected together,itwouldproduceacubewithanedgeofabout18.6m.Goldhasalwaysbeenasymbolofimmortality,andthis wasalsoacommonsubjectinmythology.Forexample,KingMidasrequestedthateverythingthathetouchedbeturned intogold.Whenthisblessinghadturnedouttobeacurseindisguise,MidasprayedtoBacchustotakebackhisgift.The mythoftheGoldenFleecehasbeensubjecttovariousinterpretations.ThelegendofElDorado,theIndianrulerwho plasteredhisbodywithgolddustinfestivals,ledtotherapidconquestofSouthAmerica.InanancientSanskrittext,there isareferenceto Pipilika gold(theSanskritwordfor “ants”),whichreferstogoldparticlesthatarecollectedbyantsand thenpresentedtothekinginaspecialceremony.In ThousandandOneNights,therearenumerousreferencestopalaces beingbuiltusingbricksmadeofgold.

GoldornamentshavebeenfoundinEgyptiantombsoftheprehistoricStoneAge,andtheEgyptiangoldsmithsofthe earliestdynastieswereskillfulartisans.Today,goldusedinjewelrysumstoabout2000tonsannuallyworldwide,which represents75%ofthetotalconsumption.Goldinjewelryservesdifferentpurposesindifferentpartsoftheworld.Inthe West,ithasaprimarilydecorativerole;itisnotnormallyregardedasaninvestmentandconsequentlythegoldusedforthis purposeislesspure.IntheEast,exactlythereverseistrue;goldhasastronglymonetaryrolethere,istypicallyhigh caratage(22carat 91.7%puregold,or24carat 100%gold),andisboughtandstoredasaninvestment.Itistypically wornbywomenandsohasanornamentalroleaswell;thepresenceoflargeamountsofgoldornamentsinOrientalbazaars atteststothisfact.TheAmericanIndiansbeforetheSpanishconquestusedgoldforornamentsbutalsoasofferingsin religiousceremonies,ortobeburiedwiththedeceased.

Theextremeductilityofthemetalisshownbythefactthat1gcanbepulledintoawire3kmlong.Thegoldthreads thatwereusedinembroideryandweavingweremadeinavarietyofways.Generallyspeaking,theyconsistedofmetal

stripsthatwereusedeitherdirectlyor,moreoften,intheproductionofcompositethreads,inwhichthemetalstrip waswoundarounda fibrouscoreofsilk,linen,cotton,orotheryarns.Wirewasalsouseddirectlyorforwindingaround suchcores.

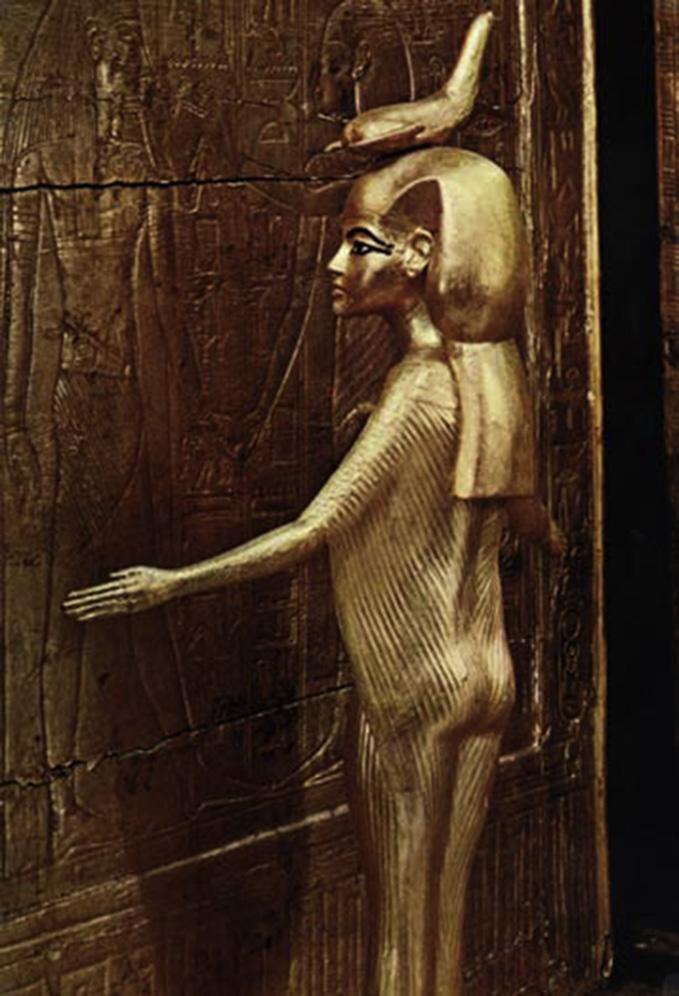

4.1Gilding Becauseofitsoccurrenceinnatureinminuteamounts,goldwasanexpensivemetal.Itwasnotnecessarytohavearticles madeofsolidgoldsinceitwaspossibletopreparegoldinthinfoilsandcovertheobjectcompletelywiththemsothatthey appearasiftheyweremadeofgold.Gildingistheartofapplyingandpermanentlyattachinggoldleaforgolddustto surfacesofwood,stone,andmetals.Goldisthemostmalleableofmetalsandcanbereducedtoextremelythinleavesby hammering.Suchleavessometimesdonotexceed0.1mm(1000Å)inthickness,andtheytransmitgreenlight.Onegram ofgoldcanbemadetocovernearly1m2 ofsurface.ManyobjectsgildedbytheEgyptianshavesurvivedtothisday;the treasureofTutankhamen’stombisoneexampleoftheirskill(Figure1.5).TheEgyptiansappeartohavebeentheearliest practitionersoftheartofmakingthingoldfoil,andtheillustrationsontombsatSaqqaraandThebesshowtheirgoldbeaters workingtogetherwithgoldfoundersandgoldsmiths(Figure1.6).

FIGURE1.5 ThingoldfoilcoveringawoodenstatuefromanancientEgyptiantomb.

FIGURE1.6 AnancientEgyptianwallpaintingshowingaworkerpoundingongoldtoprepareafoil.

Goldfoilwas firstusedforgilding;whenthetechnologywasdeveloped,thefoilbecamethinnerandthinnerandwas referredtoasgoldleaf.Theinventionofgoldleafwasimpossiblebeforetheperfectionofmethodsforthepurificationof gold,asonlypuregoldorgold-richalloysfreefromcertainimpuritiescanbebeatenouttoproducethethinnestleaf. Indeed,themethodsofbeatinggoldhavenotchangedsignificantlysincethedaysoftheearlyEgyptians.Therounded stonehasbeenreplacedbyacastironhammerwithawoodenshaftandsomemachineryhasbeenintroducedtoreducethe effortofbeatingbyhandbut,inessence,theprocessremainsthesame.Theabilitytomakegoldinverythinleavesmadeit moreeconomicaltouseforgildinglargeobjectssuchasstatues,ceilings,columns,domesofchurches,etc.,withthe minimumconsumptionofgold.Goldleafisinsuf ficientlystrongtosupportitsownmassandsonewmethodsofattaching ittothesubstratehadtobedeveloped.Oneobviouswaywastouseanadhesive,andthismethodisstillusedtodayforthe gildingofwoodandstoneandforthedecorationofleatherbook-binding.

4.1.1GildingofMetals Whenthegoldleafisappliedonmetal,theadhesionofthegoldisenhancedbytheapplicationofheattopromote interdiffusionwiththeunderlyingmetal.Tocoveralargemetallicobjectsuchasthedomeofachurchorastatuestanding inthestreetwithaverythinlayerofgoldthatwouldresistexposuretorainandwind,mercuryusewasmadeofasa stickingmedium.Copper,notbronzeorbrass,wasusuallythemetalofchoice,althoughitismoredifficulttocastthanthe alloys.Thereasonisthatthealloyingelementstin,zinc,andleadinterferewiththegildingprocessbecausethesemetals haveahighsolubilityinmercuryandthusresultinadefectivelayer.Althoughgildingwithmercurywasarareandcostly processinthe fi rstcenturyAD,ithadbecomethestandardmethodofgildingbythethirdorfourthcenturiesandit remainedunchallengedthroughouthistory.

Twoprocessesweredevelopedtogildacoppersubstrate.Inthecoldprocess,mercuryisrubbedonthecleancopper surfaceuntilithasamirror-like finish.Somecopperdissolvesinthemercuryandformsathinlayerofcopperamalgam. Anyexcessmercuryismechanicallyremoved.Goldleafisthenpresseduponthesurface.Itbondswiththe copper-amalgamvery firmly.Morethanonelayerofgoldleafisusuallynecessarytoobtainthedesiredcolor.Thehot processwasdevelopedatalaterdatetogildcopperalloysandovercomethediffi cultyofcastingunalloyedcopper.Inthis method,goldleafisdissolvedinmercury;thistakesplaceveryrapidly.Theamalgamisappliedonthecoppersubstrateto thedesiredthickness.Theobjectisthenheatedtoexpelthemercury,leavingatenaciousgoldlayer.Thepoisonousfumes emittedduringtheprocesswereahealthhazardnotonlytotheworkersbutalsotothoselivingintheneighborhoodofa gildingworkshop.St.Isaac’scathedralinSt.Petersburgwasconstructedinthe40-yearperiod1818 1858withagilded dome21.83mindiameter(Figure1.7).

4.1.2GildingofGlassandPorcelain Thegildingofglass,porcelain,andpottery,rangingfromthesimpleedgingonaplatetotheelaboratelydecoratedvase withrichlygiltpanels,hasalwaysbeenaprominentfeatureinindustry.TheChineseappliedgoldleafoveralayerof

linseedoilandlitharge[PbO],orwitheggwhiteorshellac;however,thesegildedlayerswerenotdurable.Otherworkers usedgoldleafgroundupinhoney,washed,dried,andappliedwitha flux;inthesecases;however,theproductwas expensivebecausethegoldlayerwasthick.TheGermanchemistJohannKunckel(1630 1703)discoveredtheprecipitationofgoldpowderbytheadditionofasolutionofferroussulfatetoasolutionofgoldin aquaregia.Thiswas publishedinhisbook LaboratoriaChymica,whichappearedin1716,13yearsafterhisdeath.Theprecipitate,separated bydecantationandthendried,wasthoroughlymixedwitha finelygroundlead-silicate fluxandappliedtotheware,then fixedbyheatinginakiln.In1827,anewgildingprocesswasdiscoveredintheMeissenfactorynearLeipzigbyHeinrich Kühn.Theprocessconsistedofasolutionofgoldchloridein balsamofsulfur,anoilysubstanceobtainedbyreacting sulfurwithturpentine.Thismedium,whichisofsomewhatunknownchemicalcomposition,hadbeenknownformany years.Kühnwasthusabletoproducealiquidpreparationofanorgano-goldcompoundthat,on firingatarelativelylow temperature,yieldedabrightandshininggoldthatneedednopolishing.

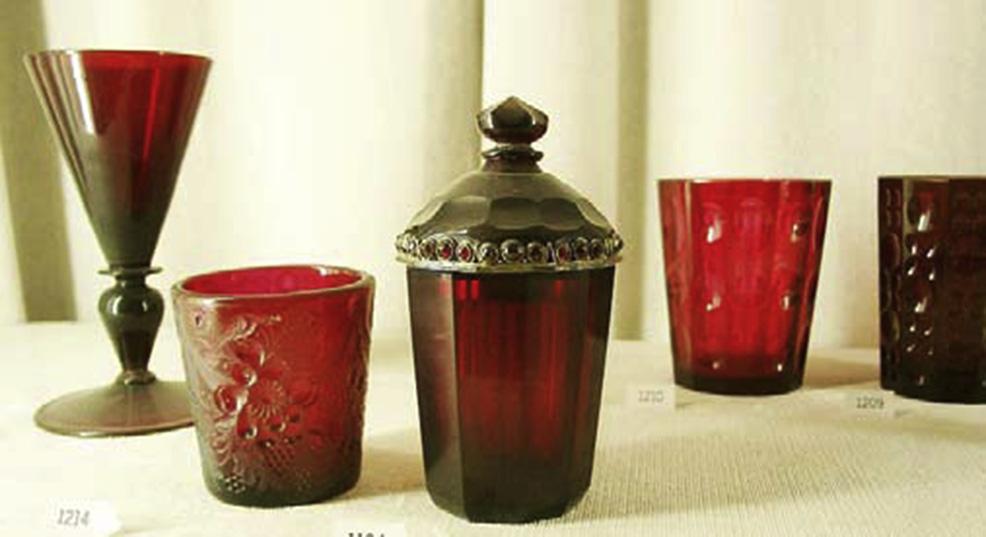

4.2GoldintheGlassIndustry Inthe1650s,theGermanchemistAndreasCassius(1605 1673)discoveredapurplepigmentthatcanbeusedincoloring glassandporcelain,yieldinganexceptionallybeautifulpurplecolor(Figure1.8).Thecolorwasknownas Purpleof Cassius.Itwaspreparedbyaddingasolutionofstannouschloridetoadilutegoldchloridesolutionandwasappliedinthe mostfamousglassandporcelainfactoriesofEuropeinMeissenandSèvre.Thenatureandconstitutionof Purpleof Cassius presentedscientistswithaproblemthatwastackledthroughoutthewholeofthenineteenthcenturybysomeofthe mostdistinguishedchemistsofthetime.Notuntiltheturnofthecenturywasthetruenatureofthispigmentelucidated. RichardZsigmondy(1865 1929),aViennesechemistwhohadspentsomeyearsstudyinggoldcolorsandhadjoinedthe SchottGlassworksinJenain1897,developedtheultramicroscopefortheexaminationofcolloids.Heshowedconclusively thatthe PurpleofCassius consistedofvery fi nelydividedgoldwithstannicoxide.Forthisinvestigation,hewasawarded theNobelPrizeinChemistryin1925.

Inmoderntimes,gold fi lmsdepositedonglassviathermalevaporationaresuperiortoothermetalsforrefl ectivityinthe infraredwavelengthrange.Such fi lmsappliedtoglasswindowsforofficespermitgoodvisionbysubstantiallyreducing thetransmissionofinfraredenergybyreflectionratherthanbyabsorption.Thecostofproductionisverylow,andthe economyinenergysavingduetocuttingdownonheatinginwinterorairconditioninginsummerisappreciable.Many modernofficebuildingsarenowconstructedusingglasswindowswithagoldcoatingabout0.01mmthick.Inthe depositionprocess,goldisheatedtoabout1390 Candatalowpressure.Thevaporizedgoldatomsmoveinnearly straightlinesfromthesourcetothesurfacetobecoated.

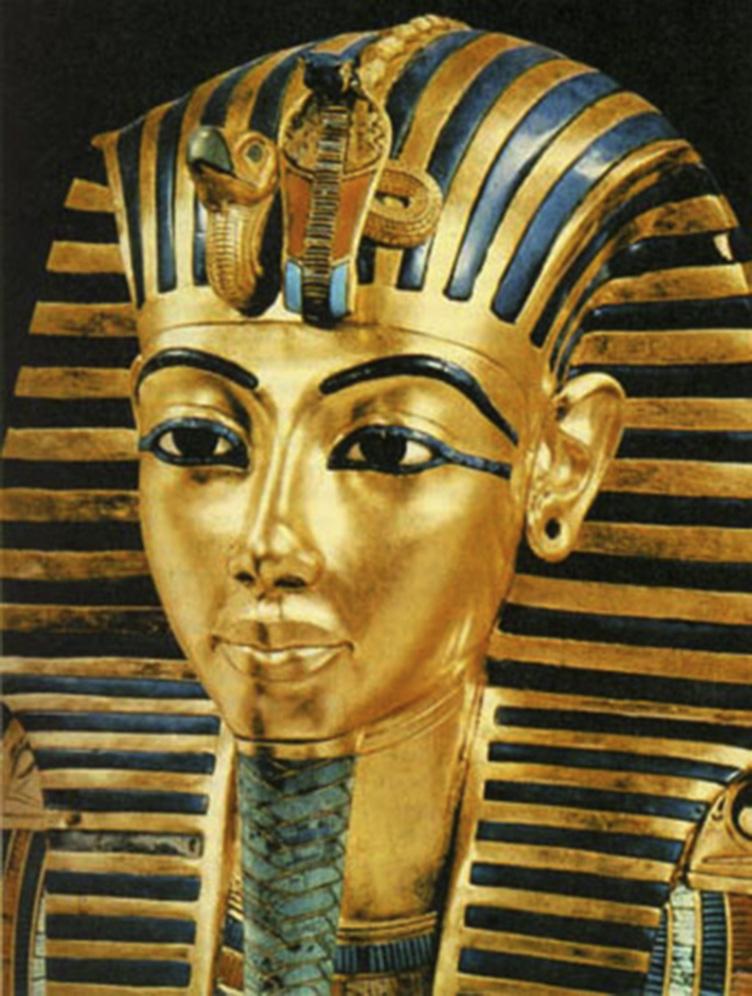

4.3GoldMasks Fromancienttimes,funeralgoldmaskswereusedtocoverfacesofthedead(Figures1.9 1.11).

5.OCCURRENCEOFGOLD Mostgoldoccursasnativemetal,nearlyallalloyedwithvariousamountsofsilverasthemineralelectrum,butnotwith copper.Certainmineralsarecharacteristicallyassociatedwithgold,andthemostimportantarepyrite[FeS2],galena[PbS],

FIGURE1.8 MuseumpiecesofglasscoloredwithPurpleofCassius.

zincblende[ZnS],arsenopyrite[FeAsS],stibnite[Sb2S3],pyrrhotite[Fe(1 x)S],andchalcopyrite[CuFeS2].Various seleniummineralsandmagnetite[Fe3O4]mayalsobepresent.InWitwatersrand,SouthAfrica,uraninite[UO2]and,toa lesserextent,thucholite[avaryingmixtureofhydrocarbons,uraninite,andsul fides]areassociatedwiththegoldore; uraniumwasrecoveredasabyproductofgoldmilling.Carbonaceousmatterisassociatedwithsomegoldores.Goldhas affinityfortellurium,anditformstwomaintellurideminerals:calaverite[AuTe2]andsylvanite[(Ag,Au)Te2].Itwasin thesemineralsthattelluriumwas firstdiscovered.Ontheotherhand,itoccurswithpalladiumasporpezite(Aucontaining 5 10%Pd)andwithrhodiumasresinrhodite[Au,Rh].Inplacerdeposits,itmaybepresentasminuteparticlesorlarge nuggets.Incertainoresknownas refractory ores,goldisassociatedwithsulfi demineralsinanextremely finelydivided state.

FIGURE1.9 AncientEgyptiangoldmask.

FIGURE1.10 AncientGreekgoldmask.