FlowAssurance VolumeII

Editedby

QiweiWang

SaudiAramco,Dhahran,SaudiArabia

GulfProfessionalPublishingisanimprintofElsevier 50HampshireStreet,5thFloor,Cambridge,MA02139,UnitedStates TheBoulevard,LangfordLane,Kidlington,Oxford,OX51GB,UnitedKingdom

Copyright©2022ElsevierInc.Allrightsreserved.

Nopartofthispublicationmaybereproducedortransmittedinanyformorbyanymeans,electronic ormechanical,includingphotocopying,recording,oranyinformationstorageandretrievalsystem, withoutpermissioninwritingfromthepublisher.Detailsonhowtoseekpermission,further informationaboutthePublisher’spermissionspoliciesandourarrangementswithorganizationssuch astheCopyrightClearanceCenterandtheCopyrightLicensingAgency,canbefoundatourwebsite: www.elsevier.com/permissions.

Thisbookandtheindividualcontributionscontainedinitareprotectedundercopyrightbythe Publisher(otherthanasmaybenotedherein).

Notices

Knowledgeandbestpracticeinthisfieldareconstantlychanging.Asnewresearchandexperience broadenourunderstanding,changesinresearchmethods,professionalpractices,ormedical treatmentmaybecomenecessary.

Practitionersandresearchersmustalwaysrelyontheirownexperienceandknowledgeinevaluating andusinganyinformation,methods,compounds,orexperimentsdescribedherein.Inusingsuch informationormethodstheyshouldbemindfuloftheirownsafetyandthesafetyofothers,including partiesforwhomtheyhaveaprofessionalresponsibility.

Tothefullestextentofthelaw,neitherthePublishernortheauthors,contributors,oreditors,assume anyliabilityforanyinjuryand/ordamagetopersonsorpropertyasamatterofproductsliability, negligenceorotherwise,orfromanyuseoroperationofanymethods,products,instructions,orideas containedinthematerialherein.

ISBN:978-0-12-822010-8

ForInformationonallGulfProfessionalPublishingpublications visitourwebsiteat https://www.elsevier.com/books-and-journals

Publisher: CharlotteCockle

SeniorAcquisitionsEditor: KatieHammon

SeniorEditorialProjectManager: SaraValentino

ProductionProjectManager: SojanP.Pazhayattil

CoverDesigner: MilesHitchen

TypesetbyMPSLimited,Chennai,India

1.1 Introduction....................................................................................2

1.2 Fundamentalsofhydrate................................................................3

1.2.1Definition............................................................................3

1.2.2Structures.............................................................................3

1.2.3Phasebehavior....................................................................6

1.2.4Properties.............................................................................8

1.3 Hydrateformation........................................................................10

1.3.1Hydrateformationscenarios.............................................10

1.3.2Hydrateformationmechanism.........................................10

1.4 Hydratemanagementinproductionsystems...............................11

1.4.1Riskassessment.................................................................12

1.4.2Hydratemodeling..............................................................12

1.5 Temperaturecontrol.....................................................................27

1.5.1Thermalinsulation............................................................27

1.5.2Activeheating...................................................................32

1.6 Chemicalinhibition......................................................................36

1.6.1Thermodynamichydrateinhibitors...................................36

1.6.2Low-dosagehydrateinhibitors.........................................40

1.7 Dehydration..................................................................................64

1.8 Hydrateremediation.....................................................................66

1.8.1Depressurization................................................................66

1.8.2Heating..............................................................................67

1.8.3Chemicaldissociation.......................................................68

1.8.4Modelpredictionsforremediation...................................69

1.9 Casestudies..................................................................................69

1.9.1Hydratemanagementindrytreefacilityfacilities..........69

1.9.2Low-dosagehydrateinhibitorfieldapplication...............72

1.9.3Tommeliten-gammafield.................................................73

1.9.4RemediationofhydratepluginwestAfricadeepwater floatingproductionstorageandoffloading............................75

1.10 Summary.......................................................................................77 Nomenclature...............................................................................77 References....................................................................................78 v

CHAPTER2Paraffinmanagement

.................................................. 85 MikeNewberryandDavidW.Jennings

2.1 Historyofparaffinmanagementdevelopments..........................85

2.2 Crudeoilandparaffinchemistry.................................................88

2.3 Paraffinanalysisandcrudeoilcharacterization..........................91

2.3.1Paraffinanalysismethods.................................................91

2.3.2Crudeoilcharacterization.................................................93

2.4 Paraffindeposition.....................................................................103

2.4.1Paraffindepositionmechanisms.....................................103

2.4.2Paraffindepositionmodeling..........................................106

2.4.3Paraffindepositcharacteristics.......................................111

2.4.4Paraffindepositioncontrol..............................................114

2.5 Pourpoint/crudeoilgellingproblems.......................................153

2.5.1Crudeoilgellingmechanism..........................................153

2.5.2Gelledflowlinecharacteristics.......................................155

2.5.3Pourpointtreatment........................................................156

2.6 Casehistories..............................................................................165

2.6.1Formationdamage..........................................................165

2.6.2Welltubingdeposition....................................................168

2.6.3Flowlinedeposition.........................................................170

2.6.4Tankbottoms...................................................................175

2.7

3.2.1Compositionandstructure..............................................186

3.2.2Solubilityandaggregation..............................................188

3.3 Experimentaltechniquesforasphaltenestabilityprediction.........191

3.3.1Solidsdetectionsystem...................................................191

3.3.2DeBoerplot.....................................................................192

3.3.3Deadoiltests...................................................................192

3.4 Asphaltenestabilitymodeling....................................................194

3.4.1Asphalteneinstabilitytrendmodeling............................194

3.4.2Asphaltenedepositionmodel..........................................195

3.5 Asphalteneinhibitorlabtests.....................................................198

3.5.1Precipitationtests............................................................199

3.5.2Depositiontests...............................................................201

3.5.3Liveoiltests....................................................................207

3.6 Asphaltenecontrolinoilproduction.........................................211

3.6.1Prevention........................................................................211

3.6.2Remediation....................................................................213

3.7 Casestudies................................................................................213

3.7.1Labscreeningmethodsforfieldapplications................213

3.7.2Evaluatingasphalteneinhibitorsforanoffshore alaskanproducer.............................................................214

3.7.3Developmentofmultifunctionalstabilizersof asphaltenes......................................................................215

3.8 Conclusionandpathforward.....................................................215 Acknowledgment.......................................................................217 Nomenclature.............................................................................217 References..................................................................................218

CHAPTER4Naphthenateandcarboxylatesoaptreatment ......... 227 JonathanJ.Wylde

4.1 Introduction................................................................................228

4.1.1Overviewandchapterorientation..................................228

4.1.2Naphthenatesandrecenthistory.....................................228

4.1.3Definitions:acidcrudeoiland“naphthenates”..............231

4.1.4Originofacidiccrude.....................................................234

4.1.5Carboxylateandnaphthenatesoapoperational challenges........................................................................235

4.1.6Thecontinuummodel.....................................................237

4.2 Foulingmechanismsofnaphthenateandcarboxylate soaps...........................................................................................238

4.2.1Analyticaltechniquesforacidicspeciesin crudeoils.........................................................................238

4.2.2Soapemulsions...............................................................244

4.2.3Naphthenatesoapsolids..................................................252

4.2.4Highcalciumincrudecausedbyoil-dispersible naphthenates....................................................................259

4.2.5Refinerychallengesoverview.........................................262

4.3 Chemicalcontrolmethodologiesandlaboratorytesting...........263

4.3.1Introduction.....................................................................263

4.3.2Preventivechemicalstrategies........................................264

4.3.3Remediationandremedialchemicalstrategies..............270

4.3.4Laboratoryandfieldtesting............................................271

4.4 Concludingremarksandremainingchallenges.........................272

GordonMichaelGrahamandDarioMarcelloFrigo

5.1 Introduction................................................................................288

5.1.1Theroleofwater.............................................................289

5.1.2Inorganicmineralscalingintheoilenvironment..........291

5.2 Basicprinciplesofinorganicscaleformation...........................293

5.2.1Typesofinorganicmineralscale...................................293

5.2.2Inorganicmineralscaleformation..................................298

5.2.3Scalenucleationandgrowth...........................................305

5.2.4Thermodynamicsandkinetics........................................309

5.3 Scaleprediction..........................................................................311

5.3.1Scalepredictionasacomponentofscale management....................................................................311

5.3.2Scalepredictionoutputs..................................................312

5.3.3Theoryofscaleprediction..............................................315

5.3.4Importanceofqualityinputdata....................................319

5.3.5Exampleoftheutilityofmodernscale predictionpackages.........................................................321

5.3.6Limitationsofscaleprediction.......................................322

5.4 Scalecontrol...............................................................................323

5.4.1Treatmentoptionsandscalecontrolstrategies..............323

5.4.2Chemicalinhibition.........................................................330

5.4.3Typesofscaleinhibitorscommonlyusedinoil industry............................................................................334

5.4.4Briefhistoryofscaleinhibitordevelopment..................341

5.4.5Chemicaldeployment.....................................................342

5.4.6Chemicalinhibition.........................................................344

5.4.7Factorscontrollingtheperformanceof genericallydifferentinhibitorchemistries.....................348

5.4.8Laboratoryassessmentofscaleinhibitors......................359

5.4.9Chemicalqualification:finalconsiderations..................371

5.5 Scaleinhibitorsqueeze...............................................................372

5.5.1Chemicalsqueezeprocess..............................................372

5.5.2Chemicalretentionmechanisms.....................................381

5.5.3Chemicaltestingofscaleinhibitorsqueeze treatments:reservoirconditioncoreflooding................387

5.5.4Theimportanceofappropriatecorefloodtesting protocols..........................................................................388

5.5.5SIApplicationconsiderations:formationdamage andinhibitorretention/releaseproperties.......................392

5.5.6Importanceofaccurateassayandmonitoring................403

5.5.7Isothermderivationandnear-wellboresimulation.........406

5.6 Scaleremediation.......................................................................412

5.6.1Acidsolublevsacidinsolublescales.............................413

5.6.2MechanicalRemediation/PhysicalMethods...................414

5.6.3Chemicaldissolution.......................................................416

5.6.4Chemicaldeploymentinscaledissolution.....................417

5.6.5AcidsforScaleDissolution............................................419

5.6.6Chelatingagentsforscaledissolution............................422

5.7 Summary.....................................................................................426 Nomenclature.............................................................................426 References..................................................................................428

CHAPTER6Sandcontrolcompletionusingin-situresin

PhilipNguyenandMikeSanders

6.1 Sandcontrol................................................................................443

6.1.1Mechanismsandcausesofsandproduction..................443

6.1.2Problems/issuesofsandproduction...............................444

6.1.3Sandcontrolmethods......................................................444

6.1.4Otherwellborestabilizationmethodsfor sandcontrol.....................................................................447

6.1.5Perforatingtechniquesforcompletionsusing sand-consolidationtreatments.........................................448

6.1.6Chemicalsandconsolidation..........................................451

6.2 FinesMigrationcontrol..............................................................472

6.2.1Mechanismsandcauses..................................................472

6.2.2Previousfinesmigrationcontrolmethods......................474

6.2.3Controllingfinesmigrationintoproppantpack.............475

6.2.4Finesmigrationfieldcasehistories................................478

6.3 Proppantflowbackcontrol.........................................................479

6.3.1Primaryproppantflowbackcontrol................................479

6.3.2Remedialmethodsforproppantflowback.....................490

6.3.3Lessonslearned/recommendations.................................493 Nomenclature.............................................................................494 References..................................................................................494

CHAPTER7Condensateandwaterblockingremoval ................ 503 MashhadFahes

7.1 Introduction................................................................................503

7.2 Backgroundtheory.....................................................................505

7.2.1Fluidphasebehavior.......................................................505

7.2.2Pressureprofiles..............................................................506

7.2.3Two-phaseflowchallenges............................................509

7.3 Fieldexamplesandindustrypractice........................................514

7.3.1Ichthysgas-condensatefieldinAustralia.......................514

7.3.2Cupiaguagas-condensatefieldinColumbia..................515

7.3.3Otherexamples...............................................................516

7.4 Recentadvancesinresearchanddevelopment.........................520

7.4.1Wettabilityalteration......................................................520

7.4.2CO2 huff-n-puff...............................................................528

7.4.3Othernewtechnologies..................................................530

7.5 Finalremarks..............................................................................530 Nomenclature.............................................................................531

CHAPTER8Foam-assistedliquidlift

8.1 Introduction................................................................................542

8.2 Liquidloadinganddeliquification.............................................544

8.2.1Liquidloading.................................................................544

8.2.2Continuousdeliquification..............................................549

8.2.3Intermittentdeliquification.............................................551 8.3 Foam-assistedlift.......................................................................552

8.3.1Foam-assistedliftperformance.......................................552

8.3.2Foam-assistedliftoperatingenvelope............................555

8.3.3Foam-assistedgaslift......................................................556

8.3.4Surfacefoam-assistedlift................................................556

8.4 Foam-assistedliftapplication....................................................556

8.5 Wellperformance.......................................................................557

8.5.1Collectwelldata.............................................................557

8.5.2Diagnoseandforecastliquidloading.............................557

8.5.3Predictfoam-assistedliftoperatingparameters.............559

8.6 Laboratorytesting......................................................................562

8.6.1Foamerperformance.......................................................564

8.6.2Secondaryperformance..................................................566

8.7 Foam-assistedliftfieldtesting...................................................568

8.7.1Batchfoam-assistedlifttrial...........................................569

8.7.2Continuousfoam-assistedlifttrial..................................570

8.8 Foam-assistedliftapplication....................................................571

8.8.1Continuousorintermittentfoam-assistedlift.................571

8.8.2Solidorliquidfoamer.....................................................572

8.8.3Annulusorcapillary........................................................572

8.8.4Capillaryspecifications...................................................576

8.8.5Surfaceinjectionsystem.................................................578

8.9 Foam-assistedliftoperation.......................................................582

8.9.1Optimizingfoam-assistedlift.........................................583

8.9.2Sustainingfoam-assistedlift...........................................587

8.10 Casestudiesofsuccessfulfoamerapplications.........................590

8.10.1Optimizehorizontalwellswithbatchfoamer treatment........................................................................590

8.10.2Continuousfoaminconjunctionwithdry-gas-lift.......593

8.10.3Innovativefoamerassustainabledeliquification solution..........................................................................596

8.10.4Usefoamtoremoveliquidinsubseaflowlines andenhanceproduction................................................598

8.10.5Foam-assistedlifttooptimizematureoilwells...........602

8.11 Remainingchallenges................................................................603 Nomenclature.............................................................................604 References..................................................................................605

CHAPTER9Corrosioninhibition .................................................. 609 JeremyMoloney,DharmendrKumar, VenkataMuralidharKandThunyalukPojtanabuntoeng

9.1 Corrosioninhibitors....................................................................610

9.1.1Environmentalconditioners/scavengers.........................611

9.1.2Interfaceinhibitors..........................................................611

9.2 Mechanismofcorrosioninhibition............................................612

9.2.1Environmentalconditioners/scavengers.........................612

9.2.2Interfaceinhibitors..........................................................613

9.3 Measurementofcorrosioninhibition.........................................617

9.4 Oilfieldcorrosioninhibitorchemistryexamples.......................619

9.5 Molecularmodelingofcorrosioninhibitors..............................619

9.5.1Computationofquantumchemicaldescriptors..............625

9.5.2Metalinhibitorinteractionsusingdensityfunctional theory...............................................................................628

9.5.3Moleculardynamicsstudy..............................................630

9.5.4MonteCarlosimulations.................................................632

9.5.5Synergisticeffectstudyusingmolecularmodeling.......633

9.5.6Screeningofcorrosioninhibitorsusingmachine learning............................................................................635

9.6 Corrosioninhibitorperformanceevaluation..............................637

9.6.1Metalsamples.................................................................639

9.6.2Solutionchemistry..........................................................640

9.6.3Testparameters...............................................................641

9.7 Corrosionratemeasurementtechniques....................................654

9.7.1Gravimetry(weightlossmeasurements)........................654

9.9.1Atomicforcemicroscopy................................................666

9.9.2Fouriertransforminfraredspectroscopy........................667

9.9.3X-rayphotoelectronspectroscopy..................................668 9.9.4Others..............................................................................668 9.10 Compatibilitytests......................................................................668

9.10.1Compatibilitywithmetallicmaterials..........................669

9.10.2Compatibilitywithnonmetallicmaterials....................671

9.10.3Foamingandemulsiontendency..................................672

9.10.4Physicalproperties,productstability, andadditionalconsiderations.......................................674

9.11.1Corrosionmonitoring....................................................676

9.11.2Corrosioninhibitorresidualmeasurements..................677

9.11.3Waterchemistryanalysis..............................................679

9.12 Casestudies................................................................................680

9.12.1Fieldapplicationofcorrosioninhibitorsinsweet (carbondioxidecontaining)systems............................680

9.12.2Fieldapplicationofcorrosioninhibitorsinsour (hydrogensulfidecontaining)systems.........................684

9.12.3Learningsfromtheliteraturecasestudies....................688 9.13 Summary.....................................................................................689

CHAPTER10Microbialcontrol

XiangyangZhu

...................................................... 709

10.1 Introduction................................................................................709

10.2 Majormicroorganismsinoilandgasindustry..........................711

10.2.1Sulfate-reducingbacteriaandarchaea..........................712

10.2.2Methanogens.................................................................715

10.2.3Acid-producingbacteria................................................717

10.2.4Iron-andmanganese-oxidizingbacteria......................718

10.3 Biocideclassification.................................................................719

10.3.1Nonoxidizingbiocides..................................................720

10.3.2Oxidizingbiocides........................................................726

10.3.3Preservatives..................................................................728

10.4 Biocideselectionandperformanceevaluation..........................729

10.4.1Considerationsforbiocideselectionand performanceevaluation.................................................729

10.4.2Methodsforbiocideevaluation....................................732

10.5 Biocidetreatmentpractices........................................................743

10.6 Biocideresidualmonitoring.......................................................746

10.7 Microbialmonitoringfortreatmenteffectiveness.....................747

10.8 Alternativemethodsformicrobialcontrol................................749

10.8.1Nitrate............................................................................749

10.8.2Bacteriophage................................................................751

10.8.3Physicalprocesses.........................................................752

10.9 Finalremarks..............................................................................756 Nomenclature.............................................................................757 References..................................................................................758 Index......................................................................................................................775

Thispageintentionallyleftblank

1.2 Fundamentalsofhydrate

1.2.1 Definition

Intheoil/gasindustry,gashydrates,clathratehydrates,andhydratesareoftenused interchangeably.Theyareice-likesolid compoundsthattypicallyformunderhigh pressureandlow-temperatureconditions inpresenceofbothwaterandlighthydrocarbonmolecules [2].Naturalgashydratesarecomposedofapproximately85mol.% water,thereforetheyhavemanyphysicalpropertiessimilartothoseofice.For instance,theappearanceandmechanicalpropertiesofhydratesarecomparableto thoseofice.Thedensitiesofhydratesvarysomewhatduetothenatureoftheguest molecule(s)andtheformationconditionsbutaregenerallycomparabletothatofice.

Althoughhydrateswerefirstdiscoveredover200yearsago,nopractical implicationwasrealizeduntil1934whenitwasdiscoveredthatitwasgas hydrates,notice,thatpluggednaturalgaspipelines.Thisbroughtarenewedburst ofresearchinterestsongashydrates,especiallyfocusingondeterminingthermodynamicandstructuralpropertiesandpreventinghydrateplugs.

NaturallyoccurringnaturalgashydrateswerepredictedandfoundbyRussian researchersin1960s.Thisbroughtanothersurgeofresearchinterestthatconsidered gashydratesasapotentialenergyresourceandasanimportantfactoraffecting globalclimatechanges.Thecumulativeefforts,beginningwithHumphreyDavyin 1810,providedtremendousamountsofknowledgeaboutthethermodynamic,physical,andstructurepropertiesofgashydratesandarichcollectionofhydrateformers,includingnitrogen,carbondioxide,hydrogensulfide,methane,ethane, propane, iso-butane,n-butane,andsomebranchedorcyclicC5 C8hydrocarbons.

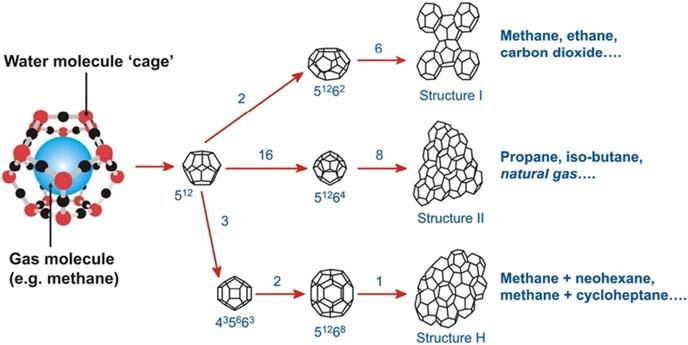

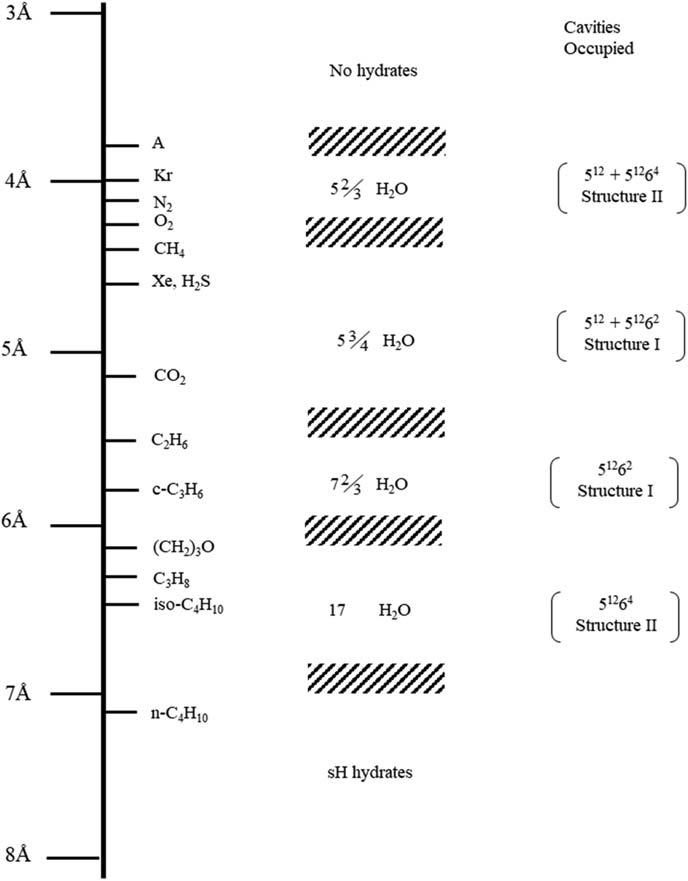

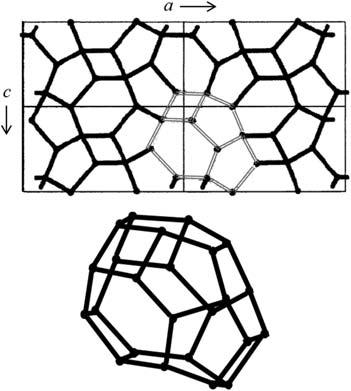

1.2.2 Structures

Inhydratestructures,watermoleculesarehydrogenbonded,whilegaseousmoleculesarebondedtothoseonlyviavanderWaalsforces.Thoughtheenergy requiredtodissociateonehydrogenbondisabout5kcal/mol,only0.3kcal/molis neededtobreakonevanderWallsbond,suggestingthatgaseousmoleculesare onlyconsideredphysicallybutnotchemicallyentrappedintocrystallinewater cages [2].Dependingonthesizesoftheguestmoleculesincludedinthegas hydrates,threehydratestructuresaretraditionallyfound,whicharestructureI,II, andH(Table1.1, Figs.1.1and1.2).ThebasicrepeatingunitinstructureIisa primitivecubiclatticeconsistingoftwopentagonaldodecahedra(512)(5isthe numberofedgesinafaceand12isthetotalnumberofthistypeoffacesina cage)andsixtetra-decahedra(51262)clathratecageswithatotalnumberof48 watermoleculesandadimensionof1.2nm.Theaveragecavityradiusofeach typeofcageis3.95and4.33A ˚ ,respectively.Methane,ethane,CO2 andXenon aretypicalstructureIhydrateformers.WhilemethaneandXenonoccupyboth small(512)andlarge(51262)cages,CO2 andethaneareonlysmallenoughto dwellinlargecages.

Table1.1 Characteristicsofhydratecagesofdifferentstructures.

StructureI(sI)StructureII(sII)StructureH(sH) SmallLargeSmallLargeSmallMediumLarge Cages512 51262 512 51264 512 435663 51268

No.ofcagesperunitcell26168321

No.ofwatersperunitcell4813634

Averagecageradius(Å)3.954.333.914.733.914.055.71

Coordinationnumber20242028202036

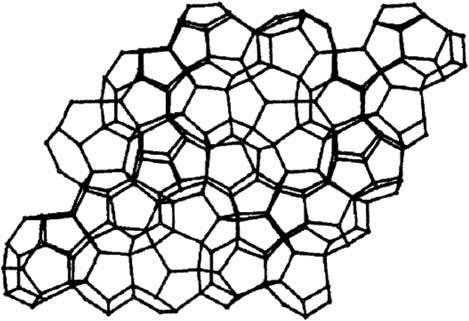

FIGURE1.1

DifferenttypesofcavitiesfoundinhydratesandrespectiveunitstructuresofsI,sIIandsH structures [3]

ReproducedwithpermissionfromE.D.Sloan,C.A.Koh,ClathrateHydratesofNaturalGases,thirded.,CRC Press,NewYork,2008.

TherepeatingunitofstructureIIhydratealsocontainstwotypesofcavities16 pentagonaldodecahedra512 (3.91A ˚ )and8hexadecahedra51262 (4.37A ˚ )composed of136watermolecules.Itslatticetypeisface-centeredcubicanditsunitdimension is1.7nm.Mosthydratesintheoil/gasindustryareexpectedtobestructureII hydrates.InstructureH,alayerof512 (3.91A ˚ )cavitiesconnectsalayerof51268 (4.06A ˚ )and435663 (5.71A ˚ )cavities.Initshexagonalunitcell(a 5 1.21nm, c 5 1.01nm),34watermoleculesformthree512,two51268,andone435663.One uniquefeatureofstructureHisthatbothsmallandlargesizesofmoleculesare requiredtostabilizethestructure.Forexample,neohexeneandcycloheptane,which cannotformhydratesalone,formstructureHhydrateswiththehelpofmethane. Thesethreehydratestructuresareimportantfortheoil/gasindustrybecausethetypes ofhydrocarbonsencounteredinthefieldcanformallthesethreetypesofhydrates.

Comparisonofguestmoleculesizesandcavitiesoccupiedassimplehydrates.

Withtheadvancementofexperimentaltechnologiesandcontinuousresearch effortsonclathratehydrates,somenewtypesofhydratestructuresathighpressures havebeenidentified,mostlynotrelevanttooil/gasindustry.Itwasdiscoveredthat underapressureof0.8GPa,tetrahydrofuran(THF)anddeuteriumoxide(D2O)

FIGURE1.2

FIGURE1.3

Packingandschematicviewofthespace-fillingpolyhedron. ReproducedwithpermissionfromA.Kurnosov,V.Komarov,V.Voronin,etal.,Newclathratehydratestructure: high-pressuretetrahydrofuranhydratewithonetypeofcavity,AngewandteChemieInternationalEdition,43 (2004):2922 2924.

formanorthorhombicstructure,inwhichwatermoleculesform14-hedracages withfourtetra-,fourpenta,andsixhexagonalfaces(445466)thatareabletopack three-dimensionallywithouttheneedforothertypesofpolyhedrons [4].Thestoichiometriccompositionofaunitcellcanbepresentedas4T3 24D2O,whereT3 isa 445466 cage.Projectionofthestructurealongthebaxisispresentedin Fig.1.3

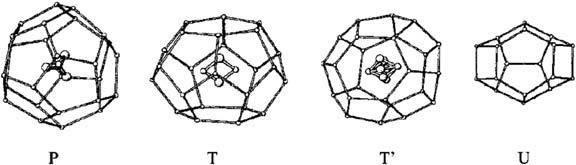

Whileinvestigatingdimethylether(DME)hydrateusingX-raydiffraction, Udachinetal. [5] identifiedanothernewhydratestructureTthatisdenseand highlycomplex(Fig.1.4).Itdoesnothave512 polyhedraandcancontain 51263(P),51262(T),4151063(T’)and425861(U)cages.Thishydratestructureistrigonal,spacegroupP321,a 5 34.995A ˚ ,c 5 12.368A ˚ ,andstoichiometrycanbe describedas12P 12T 24T 12U 348H2O.TheDMEmoleculesareaccommodated inallthreetypesoflargecages(P,T,T’)(Fig.1.5),givinganoverallcompositionofDME 7.25H2O.

1.2.3 Phasebehavior

Theconditionsrequiredforhydrateformationandtheresultinghydratephasediagramvarybasedonthetypesofhydrateformers.Thetypicalfourpillarsofhydrate formationarepresenceoffreewater,hydrateformer(s),highpressure,andlowtemperaturewithonlyafewexceptions,e.g.,THFandethyleneoxidecanformhydrate withwaterunderambientpressureat B4.5 Cand B11 C,respectively.

FIGURE1.4

GeneralviewofthestructureThydrateasdeterminedbysinglecrystal.

ReproducedwithpermissionfromK.Udachin,C.Ratcliffe,J.Ripmeester,Adenseandefficientclathrate hydrate,AngewandteChemieInternationalEdition,40(2001):1303 1305.

FIGURE1.5

Viewofthecagesinthestr.Thydrate.

ReproducedwithpermissionfromK.Udachin,C.Ratcliffe,J.Ripmeester,Adenseandefficientclathrate hydrate,AngewandteChemieInternationalEdition,40(2001):1303 1305.

Mosthydrocarbonsfoundintheoil/gasindustryrequirehighpressuretoform hydrate.Atthesametemperature,lighterhydrocarbonhydrateformerstypically requirehigherpressuretoformhydratethanheavierhydrocarbonhydrateformers. Forexample,at10 C(50 F)withfreshwater,methanehydrate’sequilibriumpressureisabout1000psiawhileitwouldonlyrequireabout250psiatoformethane hydrate.Inaddition,thesalinityofwaterplaysakeyfactorinthehydratephase diagram.Fromamolecularlevel,thepresenceofionsinthewatercancausedisruptionintheformationprocessofhydrogenbondingstructureofclathratecages. Thehigherthesalinity,thehigherthepressurerequiredtoformhydrate.Sincethe hydratestructureitselfissaltfree,thehydrateformationprocessinsaltwaterwould extractwaterinthesolutionandconvertthemtohydratewhilecausingthesalinity oftheremainingwatertoincrease.Forthisreason,thehydrateformationinsalty

FIGURE1.6

Typicalhydratephasediagramofablackoilsystem.

waterwillbecomeself-inhibitingatacertainpointoftheconversionprocess.The additionofwater-solublecompoundssuchasmethanol(MeOH)orglycolintothe waterwillrequirehigherpressuretoformahydrate,asimilareffectisobserved withhighersalinity.Thisisthefoundationtomanagehydrateriskwiththermodynamicinhibitors(mostlyMeOH,glycol,andtoalesserextentethanol). Fig.1.6 is atypicalhydratephasediagramofablackoilsystemwithdifferentsalinities.The hydratephasediagramsfornaturalgasaresimilarbutwithouttheinflectionpoints alongthecurvewheretheblackoilsystemtypicallygoesthroughthebubblepoint. Obtainingaccuratehydratephasediagramsisakeystepinproperhydraterisk assessmentandriskmanagementandwillbediscussedinmoredetailslater.

1.2.4 Properties

Allthehydratesimplicationsandapplicationsarerootedintheiruniqueproperties undervariousconditionsoftemperatureandpressure.Thefollowingareafew propertiesthatareparticularlyimportanttoenergyindustry.

1.2.4.1 Mechanicalproperties

Experimentaldeterminationofthemechanical propertiesofclathratehydratesisdifficultduetothechallengeofmakingpurenonporoushydratesamples.Inaddition,the presenceofresidualwater/iceandfreegasinthesystemduetoincompletehydrate

formationprocesscanalsocontributetothemeasurementreliability.Thereforethere areconsiderableuncertaintiesassociatedwithallthehydratemechanicalpropertymeasurements.Thefollowingareafewgeneralconclusionsaboutthemechanicalpropertiesofgashydratesbasedonexperimental/theoreticalstudiesandfieldobservations.

•Generallyspeaking,thehydratemechanicalpropertiesaresimilartothatofice. Onceformed,theycanbehardtoremovemechanicallyandcannotbescrapped offbysendingdownapiglikeremovingwaxdeposit.Doingsowillonlymake mattersworse.Thereforethemainhydratemanagementstrategyisfocusedon hydratepreventioninthefirstplaceandhydratedissociationonceformed.

•Theelasticpropertiesofgashydratedependontemperature,pressure,and hydratecomposition,includingstructure,guestmolecule,andcageoccupancy. Lowertemperatureandhigherpressurebothcontributetoanincreasedbulk modulusandconsequentlymakethehydrateharder.

•Whenwellwithinthestabilityzone,thecompressivestrengthofhydratesis higherthanthatoficehowever,thestrengthsbecomecloserinvaluewhen hydrateislesssupercooled.Thisdifferenceisattributedtothespecialhydrate latticestructureandthehost,guestandhost guestinteractions.

1.2.4.2 Self-preservationduringdissociation

Hydratedissociationisanendothermicprocesssimilartoicemelting,butitsheatof dissociation(B54kJ/molformethanehydrate)ismuchhigherthanthatofice (6kJ/mole).Duringdissociationprocess,hydratesseparateintowaterandguest moleculesbybreakinguphydrogenbondingnetworksofwatermoleculesandthe vanderWaalsinteractionforcesbetweenguestandhostwatermolecules.Thisprocesstakesupasignificantamountofheatfromtheenvironmentandcausesthetemperaturetodrop,whichcontributestothestabilityoftheremaininghydrate,thatis, aself-preserving/limitingphenomenon.Withoutactivesupplyofheatfromtheenvironment,ahydrateplugcantakeuptoayeartodissociatebyitself.Thereforecontinuoussupplyofheatiskeytomodulatetherateofhydratedissociation.

1.2.4.3

Largegas-to-hydratevolumeratio

Alargevolumeofhydrateformergascanbereleaseduponhydratedissociation. Forexample,onecubicfootofmethanehydratereleasesabout160cubicfeetof gasunderambientcondition.Thishastwokeyimplicationsforoil/gasindustry applications:

•Lowgas-to-oilratio(GOR)fluidcanbecomegas-starvedduringthehydrate formationprocessandbecomeself-limiting.Consequently,thehydrate pluggingriskduringshut-ininsuchsystemcanbemuchlowerthanahigh GORfluid.

•Gasreleaseduringhydratedissociationcanquicklybuildpressureupin confinedvolume,whichcaneithercausepressurecontainmentruptureor rapidaccelerationofdislodgedhydrateplugs.Thiscanposeassetintegrity risksandpersonnelsafetyrisks.