https://ebookmass.com/product/engineering-of-highperformance-textiles-1st-edition-menghe-miao/

Instant digital products (PDF, ePub, MOBI) ready for you

Download now and discover formats that fit your needs...

Armstrong’s Handbook of Performance Management: An Evidence Based Guide to Delivering High Performance (Ebook PDF)

https://ebookmass.com/product/armstrongs-handbook-of-performancemanagement-an-evidence-based-guide-to-delivering-high-performanceebook-pdf/ ebookmass.com

Active Coatings for Smart Textiles 1st Edition Hu

https://ebookmass.com/product/active-coatings-for-smart-textiles-1stedition-hu/

ebookmass.com

Heterogeneity, High Performance Computing, SelfOrganization and the Cloud 1st ed. Edition Theo Lynn

https://ebookmass.com/product/heterogeneity-high-performancecomputing-self-organization-and-the-cloud-1st-ed-edition-theo-lynn/ ebookmass.com

Without Destroying Ourselves: A Century of Native Intellectual Activism for Higher Education John A. Goodwin

https://ebookmass.com/product/without-destroying-ourselves-a-centuryof-native-intellectual-activism-for-higher-education-john-a-goodwin/ ebookmass.com

Populism and Liberal Democracy: A Comparative and Theoretical Analysis Takis S. Pappas

https://ebookmass.com/product/populism-and-liberal-democracy-acomparative-and-theoretical-analysis-takis-s-pappas/

ebookmass.com

Learning to Think Things Through: A Guide to Critical Thinking Across the Curriculum – Ebook PDF Version

https://ebookmass.com/product/learning-to-think-things-through-aguide-to-critical-thinking-across-the-curriculum-ebook-pdf-version/

ebookmass.com

The Plymouth Brethren 1st Edition Introvigne

https://ebookmass.com/product/the-plymouth-brethren-1st-editionintrovigne/

ebookmass.com

Removing conscientious objection: The impact of ‘No Jab No Pay’ and ‘No Jab No Play’ vaccine policies in Australia Ang Li And Mathew Toll

https://ebookmass.com/product/removing-conscientious-objection-theimpact-of-no-jab-no-pay-and-no-jab-no-play-vaccine-policies-inaustralia-ang-li-and-mathew-toll/

ebookmass.com

A Nobleman's Guide to Seducing a Scoundrel (The Doomsday Books 2) 1st Edition Kj Charles

https://ebookmass.com/product/a-noblemans-guide-to-seducing-ascoundrel-the-doomsday-books-2-1st-edition-kj-charles/ ebookmass.com

Memory and Enlightenment: Cultural Afterlives of the Long

Eighteenth Century 1st ed. Edition James Ward

https://ebookmass.com/product/memory-and-enlightenment-culturalafterlives-of-the-long-eighteenth-century-1st-ed-edition-james-ward/

ebookmass.com

TheTextileInstituteBookSeries

IncorporatedbyRoyalCharterin1925,TheTextileInstitutewasestablishedastheprofessional bodyforthetextileindustrytoprovidesupporttobusinesses,practitionersandacademics involvedwithtextilesandtoprovideroutestoprofessionalqualificationsthroughwhichInstituteMemberscandemonstratetheirprofessionalcompetence.TheInstitute’saimistoencouragelearning,recogniseachievement,rewardexcellenceanddisseminateinformationaboutthe textiles,clothingandfootwearindustriesandtheassociatedscience,designandtechnology;it hasaglobalreachwithindividualandcorporatemembersinover80countries.

TheTextileInstituteBookSeriessupersedestheformer‘WoodheadPublishingSeriesin Textiles’,andrepresentsacollaborationbetweenTheTextileInstituteandElsevieraimedat ensuringthatInstituteMembersandthetextileindustrycontinuetohaveaccesstohighcalibre titlesontextilescienceandtechnology.

BookspublishedinTheTextileInstituteBookSeriesareofferedontheElsevierwebsiteat: store.elsevier.comandareavailabletoTextileInstituteMembersatasubstantialdiscount.TextileInstitutebooksstillinprintarealsoavailabledirectlyfromtheInstitute’swebsiteat: www. textileinstitute.org

Toplaceanorder,orifyouareinterestedinwritingabookforthisseries,pleasecontact MatthewDeans,SeniorPublisher: m.deans@elsevier.com

RecentlyPublishedandUpcomingTitlesinTheTextileInstitute BookSeries

HandbookofTechnicalTextiles,Volume1,2nd Edition,A.RichardHorrocksandSubhashC. Anand,9781782424581

HandbookofTechnicalTextiles,Volume2,2nd Edition,A.RichardHorrocksandSubhashC. Anand,9781782424659

Geotextiles,RobertKoerner,9780081002216

AdvancesinBraidingTechnology,YordanKyosev,9780081009260

AntimicrobialTextiles,GangSun,9780081005767

ActiveCoatingsforSmartTextiles,JinlianHu,9780081002636

AdvancesinWomen’sIntimateApparelTechnology,WinnieYu,9781782423690

SmartTextilesandTheirApplications,VladanKoncar,9780081005743

AdvancesinTechnicalNonwovens,GeorgeKellie,9780081005750

ActivatedCarbonFiberandTextiles,JonathanChen,9780081006603

PerformanceTestingofTextiles,LijingWang,9780081005705

ColourDesign,JanetBest,9780081012703

ForensicTextileScience,DebraCarr,9780081018729

PrinciplesofTextileFinishing,AsimKumarRoyChoudhury,9780081006467

High-PerformanceApparel,JohnMcLoughlinandTasneemSabir,9780081009048

TheTextileInstituteBookSeries Engineeringof High-Performance Textiles

Editedby MengheMiao

JohnH.Xin

WoodheadPublishingisanimprintofElsevier

TheOfficers’MessBusinessCentre,RoystonRoad,Duxford,CB224QH,UnitedKingdom 50HampshireStreet,5thFloor,Cambridge,MA02139,UnitedStates TheBoulevard,LangfordLane,Kidlington,OX51GB,UnitedKingdom © 2018ElsevierLtd.Allrightsreserved.

Nopartofthispublicationmaybereproducedortransmittedinanyformorbyanymeans,electronicor mechanical,includingphotocopying,recording,oranyinformationstorageandretrievalsystem,without permissioninwritingfromthepublisher.Detailsonhowtoseekpermission,furtherinformationaboutthe Publisher’spermissionspoliciesandourarrangementswithorganizationssuchastheCopyrightClearance CenterandtheCopyrightLicensingAgency,canbefoundatourwebsite: www.elsevier.com/permissions

Thisbookandtheindividualcontributionscontainedinitareprotectedundercopyrightbythe Publisher(otherthanasmaybenotedherein).

Notices

Knowledgeandbestpracticeinthisfieldareconstantlychanging.Asnewresearchandexperience broadenourunderstanding,changesinresearchmethods,professionalpractices,ormedicaltreatment maybecomenecessary.

Practitionersandresearchersmustalwaysrelyontheirownexperienceandknowledgeinevaluating andusinganyinformation,methods,compounds,orexperimentsdescribedherein.Inusingsuch informationormethodstheyshouldbemindfuloftheirownsafetyandthesafetyofothers,includingparties forwhomtheyhaveaprofessionalresponsibility.

Tothefullestextentofthelaw,neitherthePublishernortheauthors,contributors,oreditors,assume anyliabilityforanyinjuryand/ordamagetopersonsorpropertyasamatterofproductsliability,negligence orotherwise,orfromanyuseoroperationofanymethods,products,instructions,orideascontained inthematerialherein.

LibraryofCongressCataloging-in-PublicationData

AcatalogrecordforthisbookisavailablefromtheLibraryofCongress BritishLibraryCataloguing-in-PublicationData

AcataloguerecordforthisbookisavailablefromtheBritishLibrary

ISBN:978-0-08-101273-4(print)

ISBN:978-0-08-101885-9(online)

ForinformationonallWoodheadpublicationsvisitour websiteat https://www.elsevier.com/books-and-journals

Publisher: MathewDeans

AcquisitionEditor: DavidJackson

EditorialProjectManager: EdwardPayne

ProductionProjectManager: SuryaNarayananJayachandran

CoverDesigner: VictoriaPearson

TypesetbySPiGlobal,India

S.Yang,S.Gordon

5Fabricstructures:Woven,knitted,ornonwoven107

H.Gong,B.Ozgen

5.1Introduction

B.Kumar,J.Hu

8Easy-caretreatmentsforfabricsandgarments187 J.H.Xin,H.F.Lu

9Pilling-resistantknitwear217 L.Wang,X.Qian

PartThreeProductspecialization277

12Compressionandstretchfitgarments279 A.Yu,K.L.Yick

13Conductivetextiles305

K.(Kelvin)Fu,R.Padbury,O.Toprakci,M.Dirican,X.Zhang

14Insect-repellenttextiles335

J.H.Xin,X.W.Wang

15Camouflagefabrics349

Listofcontributors

K.Bilisik ErciyesUniversity,Kayseri,Turkey

R.J.Denning CSIROManufacturing,Geelong,VIC,Australia

M.Dirican NorthCarolinaStateUniversity,Raleigh,NC,UnitedStates

B.Fei HongKongPolytechnicUniversity,Kowloon,HongKong

K.(Kelvin)Fu NorthCarolinaStateUniversity,Raleigh,NC,UnitedStates

H.Gong UniversityofManchester,Manchester,UnitedKingdom

S.Gordon CSIROManufacturing,Geelong,VIC,Australia

C.Greb InstitutfuerTextiltechnikofRWTHAachenUniversity,Aachen,Germany

T.Gries InstitutfuerTextiltechnikofRWTHAachenUniversity,Aachen,Germany

J.Hu TheHongKongPolytechnicUniversity,HungHom,HongKong

Y.Ke JiangnanUniversity,Wuxi,China

B.Kumar IndianInstituteofTechnology,Delhi,India

M.Lengersdorf InstitutfuerTextiltechnikofRWTHAachenUniversity, Aachen,Germany

C.Lenz InstitutfuerTextiltechnikofRWTHAachenUniversity,Aachen,Germany

H.F.Lu TheHongKongPolytechnicUniversity,Kowloon,HongKong

N.Mao UniversityofLeeds,Leeds,UnitedKingdom

M.Miao CSIROManufacturing,Geelong,VIC,Australia

K.R.Millington DeakinUniversity,WaurnPonds,VIC,Australia

B.Ozgen EgeUniversity,Izmir,Turkey

R.Padbury NorthCarolinaStateUniversity,Raleigh,NC,UnitedStates

X.Qian TianjinPolytechnicUniversity,Tianjin,China

O.Toprakci NorthCarolinaStateUniversity,Raleigh,NC,UnitedStates

F.Wang TheHongKongPolytechnicUniversity,Kowloon,HongKong

L.Wang TianjinPolytechnicUniversity,Tianjin,China;RMITUniversity, Brunswick,VIC,Australia

X.W.Wang TheHongKongPolytechnicUniversity,Kowloon,HongKong

J.H.Xin TheHongKongPolytechnicUniversity,Kowloon,HongKong

S.Yang CSIROManufacturing,Geelong,VIC,Australia

K.L.Yick TheHongKongPolytechnicUniversity,HungHom,HongKong

A.Yu TheHongKongPolytechnicUniversity,HungHom,HongKong

X.Zhang NorthCarolinaStateUniversity,Raleigh,NC,UnitedStates

Preface

Producersandconsumerstodayarenotsatisfiedwithtextilesthatofferastandardperformance.Thisbookisaimedatassistingtextileengineersandproductdesignersto improvetheperformancestandardoftheirexistingproductsandtodevelopnewhighperformanceproducts.

Thedesignofhigh-performancetextilesstartswithselectingthemostsuitable fibers.Untilafewdecadesago,virtuallyalltextileshadbeenmadefromnaturalfibers obtainedfromplantsandanimals.Theadventofman-madefibershasenrichedthe materialssourcefortextileengineers.Syntheticfibersenteredtheworldofapparel andindustrialtextilesbyimitatingandblendingthemwithnaturalfibers,suchaswool andcotton.Manysyntheticfibersarenowhighlyspecializedandofferextremely high-performancepropertiesinchallengingapplicationsfarbeyondtraditional apparelandindustrialtextiles.

Textileengineeringresearchanddevelopmentinthelasthalf-centuryhavechangedthelandscapeofthetextileindustry.Whileringspinningisstillthedominantyarn manufacturingtechnology,unconventionalspinningmethods,suchasrotorspinning andair-jetspinning,arenowwidelyused.Shuttleloomsarereplacedbyshuttleless looms.Theuseofelectronicknittingmachinesiswidespread.Thenonwovenindustry hasexperiencedarapidexpansioninindustrialtextilesandapparelsduetothenew processingtechnologiessuchasspunlaceandduetothefastgrowthofsynthetic fibers.

Thefashionandtextileindustryhasalsoexperiencedrapiddevelopmentsinthe pastfewdecades.Syntheticdyesnowproduceamuchwidercolorgamutforbothnaturalandsyntheticfibers.Functionaltreatmentstofibers,fabrics,andevengarments todayprovidepropertiessuchaswrinklerecovery,waterrepellency,andflameretardancy.Withdecadesofdevelopmentincolorationandfinishing,producersandconsumersstartedthinkingoftheimpactofnewtechnologiesontheenvironment.The conceptofsustainabilityoftheecosystem,“greener”technology,biodegradability, andtheuseofnaturalproductshasbecomeatrend.Moreandmoreproductson themarketnowofferspecializedhigh-performanceproperties,suchasdirectional moisturetransfer,insectrepellency,andcamouflaging.

Inthisbook,thefirstthreechaptersdiscusstextilefibers,theirproperties,andsuitabilityfordifferenttextileend-uses. Chapter1 isaimedatprovidingaframeworkfor fiberselectionaccordingtotheirtechnicalattributes,influencesonproductcharacteristics,andrequirementsfortextileprocesses. Chapter2 reviewsfibersdevelopedin thelastfewdecadestofulfilltherequirementforgeneralusesandforspecializedhighperformancetextiles. Chapter3 dealswiththescienceandartoffiberblendingtomeet requirementsthatasingletypeoffibercannotfulfillsatisfactorily.

Chapters4–6 dealwiththeconversationoffibersintofit-to-purposeyarnsandfabrics. Chapter4 discussesfiber-to-yarnpropertypredictiontoolsbasedonthephysical andtheoreticalmodels. Chapter5 providessomebroadguidelinesforfabricdevelopmentbycomparingthecharacteristicsoffabricsproducedbydifferentcategoriesof fabric-formingmethods,namelyweaving,knitting,andnonwoven. Chapter6 attemptstolaydownthebasicprinciplesofmechanicsforunderstandingthefabric structure-propertyrelationship,particularlyinwovenfabrics.

Chapters7–11 reviewthemainperformancedeficienciesofcommonconsumer textilesandtechnologiesavailabletotextileengineersanddesignersforproduct improvementanddesign.

Mostgarmentsnowaredisposedbeforetheyarewornout.Colorfadingbecomes animportantreasonfordisposinggarments. Chapter7 discussestheinteraction betweenfiberanddye,thevariouschallengesthatinfluencethecolorfastnessofdyed fabricsinpractice,thefastnesspropertiesoffiber-dyesystems,colorfastnesstesting, andfinishingtreatmentstoimprovecolorfastness.Today’sbusyconsumersexpect thatgarmentsremainwrinklefreeafterdomesticlaunderingandtumbledrying. Chapter8 reviewsthechemistryandtechnologicalprogressesofeasy-caretreatments. Pillingisatraditionalperformanceproblemandtheproblemdeteriorateswiththe popularityofsofthandleknitwear. Chapter9 reviewsthemechanicsofpilling,influencesoffabricconstructiononpilling,treatments,andmanagementofknitwear pilling.

Apracticalimperativeofclothingistokeepthebodywarmincoldweather.Ifnot appropriatelydesigned,winterclothingcanbecomeheavyandbulky. Chapter10 beginswithadiscussiononthemechanismsofheattransferthroughfabrics,therelationshipbetweenheattransferandairgaptrappedwithintheclothingmicroclimate.It movesontodiscussthedesignofwarmfabricswithouttheunnecessaryweightand bulk.Sportsclothingisnownotonlywornbyathletesincompetitionbutalsoby almosteveryonetakingpartinexercisesandmanyotheractivities.Comingwiththis trendistherequirementforfabricstotransportsweatandheatefficiently. Chapter11 dealswiththemechanismsofwatervaporandliquidtransferthroughtextiles,theattributesoftextilematerialsthataffectthemoisturetransferprocess,andthemethods availabletodesignhigh-performancemoisturemanagementtextiles.

Theuseoftextilematerialsisnowfarbeyondapparelandhasbecomehighlyspecialized. Chapters12–18 discussanumberofhighlyspecializedtextilesthathave experiencedrapiddevelopmentandgrowthinrecentyears.

Chapter12 reviewscompressionandstretch-to-fitgarmentsusedinsportswearto improveathleticperformance,inthemedicaltreatmentsofhypertrophicscarsand venousdiseases,forbodyshaping,andasintimateapparel. Chapter13 discusses conductivetextilesmadeeitherfromconductivefibersorbydepositingconductive materialsontononconductivetextiles.Theend-usesforconductivetextilesare diverse,fromantistaticandelectromagneticshieldingtoelectronictextiles (eTextiles). Chapter14 dealswithinsect-repellentfabricsthataremadeintonets, uniforms,garments,andothertextilesforprotectinghumansfromthebiteofinsects orarthropodsintropicalandsubtropicalregions,rainforests,andotherenvironments ofinsectinhabitation.

Chapter15 reviewsthedevelopmentofcamouflagefabricsusedbythemilitary, hunters,gamewatchers,andthelike.Thischapterexploresthecurrentstateofcommercialdetectionsystemsandthecamouflagefabricsusedtodefeatthesesystems. Chapter16 dealswithfabricsdesignedfordefeatingballisticandstabthreatsfacing themilitaryandlawenforcementpersonnel.Itreviewstheprinciplesofdynamics behindbodyarmordesignandrecentdevelopmentsinballisticfibersandfabric structures.

Chapter17 beginswithanoverviewoftheperformancerequirementsofvarious filterfabricsandthetheoriesofdepthfiltration,surfacefiltration,andbloodfiltration. Itgoesontodiscusstheengineeringofwovenandnonwovenfilterfabricstoachieve optimumperformance. Chapter18 reviewsthefabricsdesignedforthereinforcement ofengineeringcomposites,especiallycarbonfiber-reinforcedpolymermatrixcomposites.Thechapterpresentswiderangesof2Dand3Dfabricpreformstructures,their characteristics,andmanufacturingtechnology.

Finally,weacknowledgethetimeandeffortsofourcontributors,whoareexperts intherespectiveareasdescribedinthisbook.

MengheMenghe

JohnH.Xin

TheHongKongPolytechnicUniversity May2017

PartOne Productdesign

Fiberselectionandsubstitution

M.Miao,S.Gordon CSIROManufacturing,Geelong,VIC,Australia

1

1.1Introduction

1.1.1Textilefibers

Theprimaryrawmaterialsfortextilemanufacturingarefibers.Traditionally,naturallyoccurringfiberswereusedintextiles.Theoriginsofthesenaturalfibersare mainlyplantsandanimalhairs.Naturalmineralfibersalsoexistsuchasasbestos, althoughnotcommonlyusedintextiles.

Themaincompositionofplantfibers(knownasvegetablefibers)iscellulose. Plantfibersgrowonseed(e.g.,cottonandkapok),asseedhairs,andwithintheleaves (e.g.,sisal)andstems(knownasbastfibers,e.g.,flaxandhemp)ofparticularplants. Cottonisthemostwidelyusednaturalfiber,accountingformorethanone-thirdofthe tonnageoffibersusedbytheworldtextileindustrytoday.

Themaincompositionofanimalfibersisprotein.Hairsofawiderangeofanimals, includingsheep(wool),goat(cashmere),camel,alpaca,rabbit,areusedtoproduce highlysought-aftertextileproducts.Silk,anotherhighlyvaluedtextilefiber,is producedbydrawingthesilkfilamentsfromsilkwormcocoons.Animalfibersare availableinmuchsmallerquantitiesthancotton.

Naturalpolymerssuchascelluloseandproteincanbeprocessedintosolutionsand extrudedintofibers.Thesefibersareoftenreferredtoasregeneratedfibers.Viscoseis animportantman-madefiber(MMF)regeneratedfromwoodcellulose.

Syntheticfibersaremadefrompolymersbuiltupfromchemicalelementsorcompounds.Thecompoundsthatareusedtomakethesefibersmostlycomefrom petroleum-basedchemicalsorpetrochemicals.About40%oftheworldtextilefiber consumptionispolyester.Othermaincommoditysyntheticfibersarenylon,acrylic, andpolyolefin.Environmentalandsustainabilityconcernsontheuseofpetrochemicalshavebeengrowinginrecenttime.Thishasledtothedevelopmentofnew fibersfromsustainablesources,forexample,polylacticacid(PLA)fiberfromcorn.

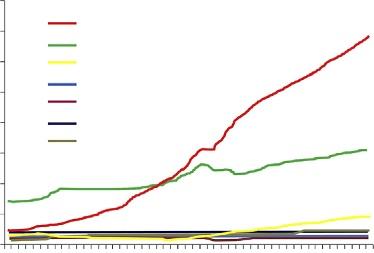

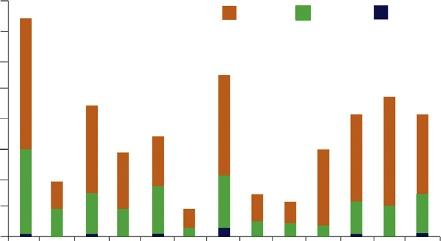

Fig.1.1A showsthehistoryofworldfiberdemandinmillionsoftons.Cottonhada dominantroleinthetextileindustryuntiltheturnofthemillennium.Theconsumption ofpolyesterpassedthatofcottonin2002andhascontinuedtogrowatasignificantly fasterratethanallotherfibertypes.In2014,theworldconsumerdemandforallfibers averaged11.4kg/capita(Fig 1.1B).VolumesvaryfromNorthAmericawithahighof 37kg/capitatoAfrica,theMiddleEastandIndiaat5kg/capita.

Fig.1.2 showsthepercentagechangeoffiberconsumptionbytype,between2007 and2010.Thedecreaseintheconsumptionofcottonandwoolwastakenupbythe increaseofpolyesterconsumption.

4EngineeringofHigh-PerformanceTextiles

Fig.1.1 Worldfiberdemandtrend.(A)Totalfiberdemand;(B)Globalfiberdemandpercapita (http://www.textileworld.com/textile-world/fiber-world/2015/02/man-made-fibers-continueto-grow/,accessed08.07.16).

Synthetic (noncellulosic) fibers

Fig.1.2 Compositionofworldapparelfiberconsumptionbyfibertype(FAO-ICAC,2013).

Withrapidprogressinpolymerscienceandfiberengineeringtechnologyoverthe lastthreetofourdecades,manynewMMFwithcharacteristicsthatsurpassnatural fibershaveemerged.ThesenewspecialtyfibersarecoveredinChapter2.

1.1.2Yarnproductionsystems

Historically,differentprocessing(spinning)systemsweredevelopedforcotton,wool, andtoalesserextent,forlinen(mainlyflax)andsilk.Amajordistinctionbetween themistheirabilitytodealwithdifferentfiberlengths.Woolcanbeprocessedon eithertheworstedorwoolensystems.Generallyspeaking,longwoolisprocessed ontheworstedsystem,whichinvolvescombing,repeatedgilling(pin-drawing) andhigh-draftspinning.Woolblendscontainingshorterfiberswithawidelengthdistributionareprocessedonthewoolensystem.Inthewoolensystem,fibersarefirst processedonacondensercardfollowedbylow-draftspinning.Cottonspinninghas alotofsimilaritieswithworstedspinning,butflat-cardingandrollerdrawing,instead ofroller-cardingandpin-drawing,areusedbecausecottonisconsiderablyshorterthan thewoolusedinworstedspinning.Therearedistinctdifferencesincharacteristicsof theyarnsprocessedbythesespinningsystems.

Cotton Wool Flax

Cellulosic fibers

Boththecottonandworstedsystemsconvertthefibers,viacarding,firstintoa sliverandthensubjecttheslivertohighratiodraftingthatattenuatesthesliverinto alighterassemblyoffibersthatisthentwistedintoayarn.Thefibersinspunyarnare mostlystraightandparallel,albeittwistedinahelicalmanner,givingacompact, smooth,andlustrousappearance.Becausewoolfibersaremuchcoarserandlonger thancottonfibers,thenumberoffibersinthesamelengthofyarnisfewer,withsubsequentlyfewerfiberendsonthesurface.Thismeansworstedyarnsaretypicallyless hairythancottonyarns.Suitingfabricisthetraditionalmarketforworstedyarn. Becauseofthelargequantitiesproduced,cottonyarnisusedwidelyinapparel,home textiles,andindustrialtextiles.

Thewoolenspinningsystemisamuchshortermanufacturingprocessthanworsted spinning.Thefiberwebformedonacardingmachineisdividedintostripsthatare rubbedtogethertoformslubbings,whicharestrandsofentwinedfibers.Theslubbings aretwistedintoyarnswithverylowdraft.Fibersinwoolenyarnsarecrossedandintertwined,incontrastwithparallelfibersinworstedyarns.Thislowfiberorientation givesacharacteristicmattedyarnstructurecontainingmanyairpockets.Typical productsfromwoolenyarnsareblankets,heavywintersuiting,andcarpets.

Man-madefibers(MMFs)wereinitiallymanufacturedtoimitatenaturalfibersfor textileapplications.ThefirstMMF,viscoserayon,wasintheformofamultifilament yarn,whichwasmarketedasartificialsilk.Flatfilaments(i.e.,parallel-laid)inamultifilamentyarncaneasilyseparate,causingprocessingproblems.Thus,multifilament yarnsusuallyarelightlytwistedorinterlacedtoimprovetheirprocessingperformance (MiaoandLui,1997).Multifilamentyarnscanbetexturizedtofurtherimpartstaple fiberyarncharacteristicsandspecialperformancessuchasstretch(Wilsonand Kollu,1987).

Man-madestaplefiberscanbeprocessedonthecottonorwoolspinningsystems dependingonthefiberlength.TheresultingMMFyarnsusuallybearsimilarcharacteristicsofthenaturalfiberyarnsprocessedonthesamesystem.Forthisreason,the cottonspinningsystemisknownasshortstaplespinningandthewoolspinningsystem (especiallytheworstedspinningsystem)isknownaslongstaplespinning.

Manycharacteristicsoftextilessuchasflexibility,softness,warmth,andaesthetics,derivefromtheslendershapeofthefibersandthewayinwhichthesefibers arearrangedinthetextileproducts.Thepriceoffiber,forexample,wool,canvary significantlydependingonitspropertiessuchasdiameter,length,color,andstrength. Selectionoffibersaccordingtotheirpropertiesisthefirststeptoproducing high-qualitytextileproducts.

1.2Fiberfineness

1.2.1Fibersaccordingtofineness

Aprimarycharacteristicoftextilefibersistheirhighflexibilityandtheirabilityto deformelasticallyunderalaterallyappliedload.Theflexibilityofaroundfiberis madepossiblebyitssmalldiameter(d ).Stiffness,theoppositeofflexibility,isproportionalto d4 . Forapparelfabrics,thefiberdiameteraffectsthetexture,drape,surface

6EngineeringofHigh-PerformanceTextiles

roughness,softnesstohandle,levelofmechanicalagitationtoskin(prickle),breathability,etc.Forsportandfiltrationfabrics,fiberdiameteraffectsthesizeandpopulation ofporesformedinthefabric,whichinfluencesfluidtransportproperties.Whenusedin polymer-matrixcompositematerials,fiberdiameterdeterminesthespecificinterfacial areabetweenthefiberandthematrixandthepermeabilityoffabricpreformto liquidresin.

Thefinenessofconventionalfibersismeasuredindifferentwaysdependingonthe fibertype.ThefinenessofMMFiscommonlymeasuredbyitslineardensity(weight/ length,intermsofdenier,decitex,millitex,andtex).Thefinenessofwoolfiberswas traditionallyassessedbythefinestyarncountthatcanbespunfromthefibers,andthis waschangedtoobjectivelymeasuredfiberdiameterusingmicroscopy,airflow,and imageanalysistechniques(OFDA,LaserScan)(Qietal.,1994;Sommerville,2000). Thefinenessofcottonfibersisassessedintermsofmicronaire,usingtheairflow method.However,themicronairevalueofcottondependsonitsaveragefineness andmaturity.Thelatterdescribesthethicknessofthecottonfiber’scellwall.The newCottonscopeinstrumentmeasurescottonlineardensity(millitex)independent ofmaturity(Gordonetal.,2012).

Silk,withalineardensityofabout1denier,isthefinestcommonlyusedtextilefiber. Cottonfibershaveakidney-shapedcross-sectionwithawidthofabout10–20 μm.The averagediameterofwoolfiberscanvaryfromlessthan15 μmtoabout50 μm.ConventionalMMFaremanufacturedtosimilardiametersasthesenaturalfibers,sothat theycanbeeasilyblendedwithnaturalfibersandprocessedonconventionalmachinery.Withtheadvanceofsyntheticfibermanufacturingtechnology,muchfinerfibers cannowbeproduced.Thespectrumoffiberdiameterisillustratedin Fig.1.3.

Microfibersaresyntheticfibersthatcanbefinerthansilk(aboutonedenieror decitex)(McIntyreandDaniels,1995).Thereareawiderangeofmethodsfor manufacturingmicrofibers(Mukhopadhyay,2002).Theshape,size,andcombination ofpolymersformicrofibersareselectedtoachievespecificcharacteristics,including softness,toughness,absorption,waterrepellency,electrostatics,andfilteringcapabilities.Microfibersareusedtoproduceman-madeleather(e.g.,ultra-suede),cleaning cloth,moisture-wickingandsoft-touchfabrics,andfiltrationmedia(e.g.,medical filters).

Conventional fibers > 1 decitex

Extruded fibers

Cotton Wool Silk

Direct extrusion

Melt blowing

Flash spinning

Bicomponent extrusion

islands-in-the-sea conjugate

Fig.1.3 Fiberfineness.

Bicomponent extrusion

Electrospinning

Catalytic synthesis (carbon nanotubes)

Self-assembly

Interfacial polymerization

Electrospinningisamethodforproducingsubmicronfibersfromavarietyofmaterials,forexample,polymersandcomposites.Inthepresenceofastrongelectricfield, anelectrostaticchargeisintroducedtoafinestreamofpolymersolutiondirectedata groundedcollectorplate.Theelectricallychargedjetofpolymersolutionaccelerates andthinsoutintheelectricfield.Ifasolventispresentitusuallyevaporatesbeforethe filamentreachesthecollectorplate.Mostelectrospunfibersareinthesubmicron diameterrange(100–500 μm)(Teoetal.,2016).Thepotentialapplicationsof electrospunfibersincludefiltration,cellgrowthscaffolding,energystorage,etc.

Nanofibers(<100 μm)havebeenthesubjectofintensiveresearchsincethe early1990s.Severalmethodsofmanufacturingnanofibershavebeeninvestigated (Pisignano,2013).Animportantfiberunderthiscategoryisthecarbonnanotube.Carbonnanotubesarethermallyandelectricallyconductive,andarethestrongestand stiffestmaterialsyetdiscoveredintermsoftensilestrengthandelasticmodulus (Yuetal.,2000).Thisstrengthresultsfromthecovalent sp 2 bondsformedbetween theindividualcarbonatoms.Carbonnanotubescanbemadeintononwovensheets (knownasbuckypapers)andmicrosizedyarns(Miao,2013).Awiderangeofpotential applicationshavebeeninvestigated,includingstrongtextileandcompositematerials, energystoragedevices,sensors,artificialmuscles,etc.

1.2.2Fiberfinenessandyarncountlimit

Withoutconsideringfibercurlingandyarnlengthcontractioncausedbytwistinsertion,thelineardensityofayarnisthesumofthelineardensitiesofallitsconstituent fibersintheyarncrosssection,whichisequaltothemeanfiberlineardensity multipliedbythenumberoffibersintheyarncrosssection.Modernstapleyarn manufacturingmachinerydoesnotarrangefibersendtoendintheresultingyarn. Thespinnercanonlycontroltheaveragenumberofalignedstaplefibers(n)inthe yarncrosssection,butnottheexactnumberoffibersinanyparticularcrosssection oftheyarn.Inanidealscenario,thenumberoffibersintheyarncrosssectionis randomwithastandarddeviationequaltothesquarerootoftheaveragefiber number(√ n)(Martindale,1945).Theirregularity(coefficientofvariation)ofthe yarnisreciprocalofthestandarddeviationoffibernumber(1=√ n).Yarnirregularity isaveryimportantqualityindicator.Tokeeptheyarnirregularityundercontrol,the averagenumberoffibersintheyarncrosssectionmustbesufficientlylarge(n > nmin). Therefore,thefinestyarnthatcanbespunisdirectlyrelatedtothemeanlineardensity ofthefiberused.Intheworstedindustry, nmin isgenerallyconsideredtobeabout 35–40,dependingonthemanufacturer’stoleranceofyarnirregularity.

Themassirregularityofacommercialyarnisalwaysgreaterthantheideal valuepredictedfromtheaveragefibernumber.Thisisbecause,first,theprocessing machineryisnotperfectandsecond,thefibersdonothaveidenticallineardensity. Vastamountsofcommercialdataarecollectedeachyearonyarnirregularityasa functionofyarnlineardensityandthedataarepublishedinUsterStatistics (https://www.uster.com/en/service/uster-statistics/).

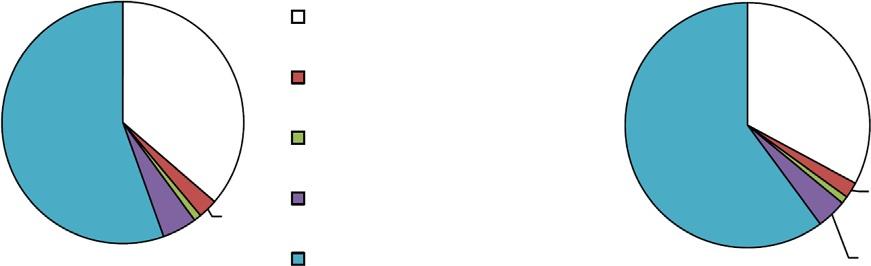

1.2.3Woolaccordingtodiameter

Woolconstitutesabout2%oftheworldapparelfiberproduction.Wool’slimited supplycoupledwithitsexcellenttextileperformancepropertieshaveresultedinwool productsbeingpositionedattheluxuryendofmostmarkets.Owingtotherangeof sheepbreedsandwooltypesproduced,woolisprocessedintoawiderangeofend products.Endusesaredeterminedbythemainfibercharacteristics,withfiberdiameterbeingthemostimportantparameter. Fig.1.4 showstheapproximaterangeof applicationsfordifferentwoolsaccordingtofiberdiameter.

Animportantconsiderationofwoolselectionfornext-to-skingarmentsiswhether thefiberscauseapricklesensationthatarisesfromthemechanicalstimulationof specificnerveendings(Garnsworthyetal.,1988).Fiberscoarserthanabout30 μm arestiffenoughtoupholdaforcelargeenoughtotriggerthispricklesensation (Naylor,1992).Woolfibershaveanaturalspreadofdiametersandthepercentage offibersgreaterthan30 μmisoftenreferredtoas“pricklefactor”ofthewool.In theory,thepricklefactorcanbeachievedbyeitherreducingthecoarseedgeofthe diameterdistributionorbyreducingthemeanfiberdiameter.Inpractice,reducing thecoarseedgeofwooldiameterdistributionisdifficulttoachieveandchanging toafinerwoolisalwaysthechoicetoeliminatefabric-evokedprickle.

AnotheranimalhairfiberthatdeservesspecialmentionisCashmeredownfiber. Cashmerecommandssomeofthehighestpricesintheworldoftextiles.Cashmere hasafiberdiameterbetween12.5and16.0 μm.Worldproductionofcleancashmere isestimatedatabout6500tones( https://en.wikipedia.org/wiki/Cashmere_wool). Theappealofcashmereanditsunrivalle dstatusasaluxuryfiberisrootedfrom itsvisualappealandextremesoftness,scarcity,anditsmystique.Cashmereiscommonlyspunintowoolenyarns,whichare usedinknitwear.Manyknitwearproducersusecashmerebutbecauseofitscostoftenuseitinblendswithother fibersincludingMMF.Cashmereisalsousedinwovenaccessories(scarves,shawls, Carpets

andstoles),rugs(especiallytravelrugs and“throws”)andclothforluxurycoats, jackets,andsuitsforthemensweartrade.

1.3Fiberlength

Fabricsmadefromcontinuousfilamentyarnsgiveabrightandsmoothappearance. Filamentyarnswithverylowornotwist(flatfilamentyarn)retainalmostallthe strengthoftheindividualfilaments.Fabricsmadefromsuchyarnsareespeciallysuitableforapplicationsthatrequiremaximumstrengthandmodulus,suchasengineering compositesandbodyarmors.

Thebulkofappareltextilesaremadefromstaplefibers,althoughtheuseoffilamentpolyesteryarnisincreasing.Thesurfaceroughness,hairiness,porosity(bulk)of staplefiberyarnsgivedullappearance,“natural”texture,softhandle,andwarmthto thefinalfabrics.Fiberlengthanditsdistributioninfluencethechoiceofyarn manufacturingmethodandfurtherprocessingtechnologyandaffectthestructure andpropertiesofthespunyarn.

1.3.1Fiberlengthmeasurement

Therearemanywaystoexpressfiberlength.Staplelengthisthecharacteristicfiber lengthestimatedbysubjectivevisualassessmentofafibertuftpreparedbyhand.The word“staple”originatedfromthewoolindustry,whereawoolstapleisanaturally formedlockofwoolfiberinafleece(McIntyreandDaniels,1995).

Theobjectivemeasurementoffiberlengthstartswiththepreparationofafiber lengthdistributiondiagram(“fiberbeard”)usingdifferentinstruments,forexample, thecombsorter,thefibrographinstrument(cotton),andthealmeter(wool).When thewoolisprocessedintoasliverform(wooltop),thefiberlengthismeasuredby Hauteur,themeanfiberlengthcalculatedfromtheproportionsbylineardensity(cross section)ofthefibers.Thevariabilityofthefiberlengthisreportedasthecoefficientof variation(CVH%).However,inthewoolenindustry,barbe,themeanlengthbiasedby fiberweight,isused.Barbe,Hauteur,anditsCVhavethefollowingmathematical relation(McIntyreandDaniels,1995)

Cottonfiberlengthor“staple”lengthcanbedefinedintermsofspanlength,thatis, thelengthexceededbyastatedpercentoffibersbynumber,orbytheupperhalfmean length(UHML)value,bothdeterminedfromthefiberdiagramproducedbythe Fibrographinstrument.The2.5%spanlengthisthelengthexceededbythelongest 2.5%bynumberoffibers,whereastheUHMListhemeanlengthbynumberof thelongeronehalfofthefibersbyweight.Cottonfiberlengthvariationmaybe expressedbyauniformityindex,whichistheratioofmeanlengthtotheUHML orbytheuniformityratio,whichistheratiobetweenthe50%and2.5%spanlengths. Theshortfibercontent(percentageoffibershorterthanastatedlength)value measuredbytheFibrographishighlyvariablebetweensamples,instruments,and laboratoriesandassuchcannotbepricedortradedon.

Barbe ¼ Hauteur 1+ CV 2

(1.1)