https://ebookmass.com/product/encapsulation-of-active-

Instant digital products (PDF, ePub, MOBI) ready for you

Download now and discover formats that fit your needs...

Delivery of Drugs: Expectations and Realities of Multifunctional Drug Delivery Systems: Volume 2: Expectations and Realities of Multifunctional Drug Delivery Systems 1st Edition

Ranjita Shegokar (Editor)

https://ebookmass.com/product/delivery-of-drugs-expectations-andrealities-of-multifunctional-drug-delivery-systemsvolume-2-expectations-and-realities-of-multifunctional-drug-deliverysystems-1st-edition-ranjita-shegokar-edit/ ebookmass.com

Building Evidence for Active Ageing Policies: Active Ageing Index and its Potential 1st Edition Asghar Zaidi

https://ebookmass.com/product/building-evidence-for-active-ageingpolicies-active-ageing-index-and-its-potential-1st-edition-asgharzaidi/

ebookmass.com

Drug Delivery Aspects: Expectations and Realities of Multifunctional Drug Delivery Systems: Volume 4: Expectations and Realities of Multifunctional Drug Delivery Systems 1st Edition

Ranjita Shegokar (Editor)

https://ebookmass.com/product/drug-delivery-aspects-expectations-andrealities-of-multifunctional-drug-delivery-systemsvolume-4-expectations-and-realities-of-multifunctional-drug-deliverysystems-1st-edition-ranjita-shegokar/ ebookmass.com

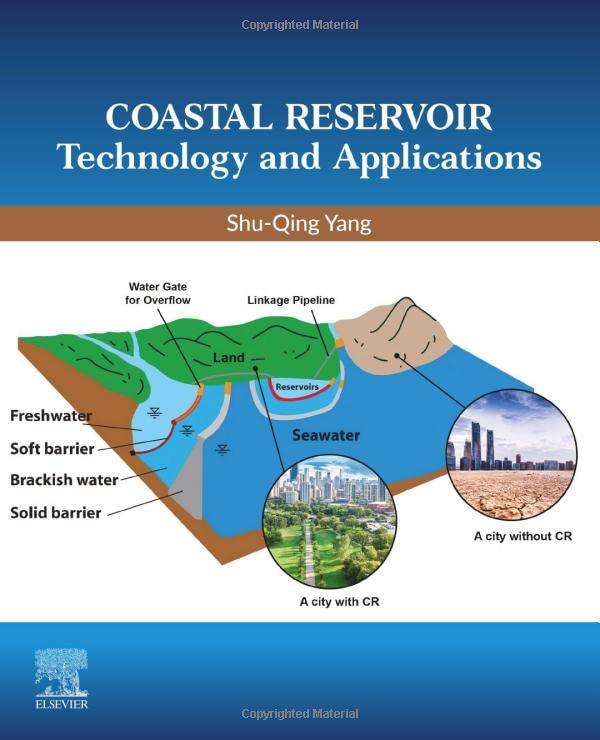

Coastal Reservoir: Technology and Applications 1st Edition

Shu-Qing Yang

https://ebookmass.com/product/coastal-reservoir-technology-andapplications-1st-edition-shu-qing-yang/

ebookmass.com

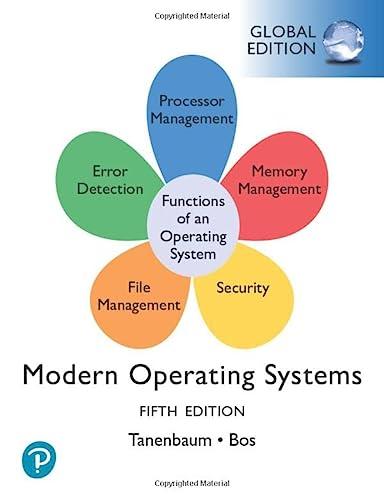

Modern Operating Systems, 5th Global Edition Andrew Tanenbaum

https://ebookmass.com/product/modern-operating-systems-5th-globaledition-andrew-tanenbaum/

ebookmass.com

Loose Leaf for The World of Music 8th Edition Willoughby

https://ebookmass.com/product/loose-leaf-for-the-world-of-music-8thedition-willoughby/

ebookmass.com

Alternative Investment Operations: Hedge Funds, Private Equity, and Fund of Funds 1st ed. Edition Jason Scharfman

https://ebookmass.com/product/alternative-investment-operations-hedgefunds-private-equity-and-fund-of-funds-1st-ed-edition-jason-scharfman/

ebookmass.com

Morphology controlled synthesis of Co(OH)2/TiO2 p-n heterojunction photoelectrodes for efficient photocathodic protection of 304 stainless steel Xiayu Lu & Li Liu & Jianwen Ge & Yu Cui & Fuhui Wang

https://ebookmass.com/product/morphology-controlled-synthesis-ofcooh2-tio2-p-n-heterojunction-photoelectrodes-for-efficientphotocathodic-protection-of-304-stainless-steel-xiayu-lu-li-liujianwen-ge-yu-cui-fuhui-wang/ ebookmass.com

Strategy in Politics: Plotting Victory in a Democracy F. Christopher Arterton

https://ebookmass.com/product/strategy-in-politics-plotting-victoryin-a-democracy-f-christopher-arterton/

ebookmass.com

The Cowgirl Gets The Bad Guy (Cowgirl Mysteries Book 1)

Susan Lower

https://ebookmass.com/product/the-cowgirl-gets-the-bad-guy-cowgirlmysteries-book-1-susan-lower/

ebookmass.com

EncapsulationofActive MoleculesandTheirDelivery System EncapsulationofActive MoleculesandTheirDelivery System Editedby ShirishH.Sonawane

ChemicalEngineeringDepartment, NationalInstituteofTechnology,Warangal,India

BharatA.Bhanvase

ChemicalEngineeringDepartment,LaxminarayanInstituteof Technology,RTMNagpurUniversity,Nagpur,India

ManickamSivakumar

ChemicalandEnvironmentalEngineeringDepartment, UniversityofNottingham,JalanBroga,Malaysia

Elsevier

Radarweg29,POBox211,1000AEAmsterdam,Netherlands TheBoulevard,LangfordLane,Kidlington,OxfordOX51GB,UnitedKingdom 50HampshireStreet,5thFloor,Cambridge,MA02139,UnitedStates

Copyright©2020ElsevierInc.Allrightsreserved.

Nopartofthispublicationmaybereproducedortransmittedinanyformorbyanymeans,electronicormechanical, includingphotocopying,recording,oranyinformationstorageandretrievalsystem,withoutpermissioninwritingfrom thepublisher.Detailsonhowtoseekpermission,furtherinformationaboutthePublisher’spermissionspoliciesandour arrangementswithorganizationssuchastheCopyrightClearanceCenterandtheCopyrightLicensingAgency,canbe foundatourwebsite: www.elsevier.com/permissions

ThisbookandtheindividualcontributionscontainedinitareprotectedundercopyrightbythePublisher(otherthanas maybenotedherein).

Notices

Knowledgeandbestpracticeinthisfieldareconstantlychanging.Asnewresearchandexperiencebroadenour understanding,changesinresearchmethods,professionalpractices,ormedicaltreatmentmaybecomenecessary.

Practitionersandresearchersmustalwaysrelyontheirownexperienceandknowledgeinevaluatingandusingany information,methods,compounds,orexperimentsdescribedherein.Inusingsuchinformationormethodstheyshould bemindfuloftheirownsafetyandthesafetyofothers,includingpartiesforwhomtheyhaveaprofessionalresponsibility.

Tothefullestextentofthelaw,neitherthePublishernortheauthors,contributors,oreditors,assumeanyliabilityforany injuryand/ordamagetopersonsorpropertyasamatterofproductsliability,negligenceorotherwise,orfromanyuseor operationofanymethods,products,instructions,orideascontainedinthematerialherein.

BritishLibraryCataloguing-in-PublicationData AcataloguerecordforthisbookisavailablefromtheBritishLibrary

LibraryofCongressCataloging-in-PublicationData AcatalogrecordforthisbookisavailablefromtheLibraryofCongress

ISBN:978-0-12-819363-1

ForInformationonallElsevierpublications visitourwebsiteat https://www.elsevier.com/books-and-journals

Publisher: SusanDennis

AcquisitionsEditor: AnitaA.Koch

EditorialProjectManager: AndreaDulberger

ProductionProjectManager: PrasannaKalyanaraman

CoverDesigner: GregHarris

TypesetbyMPSLimited,Chennai,India

Listofcontributorsxiii

1.Currentoverviewofencapsulation1 SHIRISHH.SONAWANE,BHARATA.BHANVASE,MANICKAMSIVAKUMAR ANDSHITALB.POTDAR

1.1Introductiontoencapsulation1

1.2Currenttrendsintheencapsulationprocesses4

1.3Encapsulationofactivesubstrateandtheirtarget applications6 References7 Furtherreading8

2.Physicochemicalcharacterizationtechniques intheencapsulationofactivemolecules9 SARANGP.GUMFEKAR

2.1Introduction9

2.2Particlesizeanditsdistribution10

2.3Surfacecharges12

2.4Imagingoftheencapsulatedmaterials12

2.5Thecrystallinityofencapsulationsystems15

2.6Rheologyoftheencapsulatedmaterials17

2.7Conclusionandoutlook20 References20

3.Ultrasoniccavitationassistedsynthesisofmultilayer emulsionsasencapsulatinganddeliverysystemsfor bioactivecompounds23

JITENDRACARPENTER,SUJAGEORGEANDVIRENDRAKUMARSAHARAN

3.1Emulsionsasencapsulatinganddeliverysystem23

3.2Stabilizationofemulsions25

3.3Applicationofultrasonicationforemulsification29

3.4Multilayeremulsionanditsapplicationfortheencapsulation ofbioactivecompounds33

3.5Casestudies38 References50

4.Encapsulationofactivemoleculesinpharmaceutical sector:theroleofceramicnanocarriers53 JOANAC.MATOS,LAURAC.J.PEREIRA,JOÃOCARLOSWAERENBORGHAND M.CLARAGONÇALVES

4.1Nanotechnologyinpharmacyandmedicine53

4.2Ceramicnanoparticlesasnanocarriers55

4.3Ceramicnanoparticles56

4.4Superparamagneticironoxidenanoparticles69 References80

5.Sonochemicalencapsulationoftaxifolininto cyclodextrineforimprovingitsbioavailabilityand bioactivityforfood85

IRINAKALININA,IRINAPOTOROKOANDSHIRISHH.SONAWANE

5.1Introduction85

5.2Conclusions100 Acknowledgments100 References100 Furtherreading102

6.Controlledreleaseoffunctionalbioactivecompounds fromplants103

S.D.TORAWANE,Y.C.SURYAWANSHIANDD.N.MOKAT

6.1Introduction103

6.2Bioactivecompounds104

6.3Conclusion107 References108

7.Bioactivemoleculeand/orcellencapsulationfor controlleddeliveryinboneorcartilagetissue engineering111

BHASKARBIRRU,P.SHALINIANDSREENIVASARAOPARCHA

7.1Introduction111

7.2Controlleddelivery112

7.3Cell/biomoleculeencapsulation115

7.4Bioactivemolecule/cellencapsulationforbone andcartilage122 References126

8.Areviewonapplicationofencapsulationin agriculturalprocesses131 MAYURIBHATIA

8.1Introduction131

8.2Encapsulationmaterial133

8.3Encapsulationtechniques134

8.4Encapsulationofactiveingredients135

8.5Challengesandfutureprospects138

8.6Conclusion138 References138

9.Nanofluids-baseddeliverysystem,encapsulation ofnanoparticlesforstabilitytomakestablenanofluids141

PARAGTHAKUR,SHRIRAMS.SONAWANE,SHIRISHH.SONAWANE ANDBHARATA.BHANVASE

Nomenclature142

9.1Introduction142

9.2Encapsulationofnanomaterials143

9.3Nanofluid-baseddeliverysystem145

9.4Targeteddrugdelivery148

9.5Applicationsofnanofluid-baseddeliverysystem148

9.6Conclusion149 References149

10.Corrosionandnanocontainer-baseddeliverysystem153

UDAYBAGALE,DIPAKPINJARI,SHRIKANTBARKADE ANDIRINAPOTOROKO

10.1Introductiontocorrosionproblem154

10.2Containerapproachforcorrosionprevention154

10.3Differenttypesofcontainerandtheirmethod preparation/fabrications156

10.4Distributionandperformanceofcontainerforprotective coating164

10.5Releaseofactivecompoundsfromcontainer165

10.6Casestudies165

10.7Commercialapplicationsandfutureprospectus170

10.8Conclusion/inference171 References171

11.Encapsulationanddeliveryofactivecompounds usingnanocontainersforindustrialapplications177

SHAILESHA.GHODKE,SHIRISHH.SONAWANE,BHARATA.BHANVASE ANDKALPANAJOSHI

11.1Introduction178

11.2Nanocontainersynthesis179

11.3Controlparametersfornanocontainerapplications185

11.4Activemoleculestobedelivered187

11.5Conclusionandfutureprospective190 References191

12.Virus-likeparticles:nano-carriersintargeted therapeutics197

GUNDAPPASAHA,PRAKASHSAUDAGARANDVIKASHKUMARDUBEY

12.1Introduction197

12.2Roleofvirus-likeparticlesasgooddrugdeliveryvectors199

12.3Virus-likeparticles:overcominglimitationsofother therapeuticapproaches200

12.4Prerequisitefactorsindesigningofvirus-likeparticles astherapeutics201

12.5Immuneresponsesinducedbyvirus-likeparticles203

12.6Currentapplicationsofvirus-likeparticlesastargeted therapeutics204

12.7Conclusion206 References206

13.Formulationdevelopmentandinvitromultimediadrug releasestudyofsolidself-microemulsifyingdrugdelivery systemofketoconazoleforenhancedsolubilityand pH-independentdissolutionprofile211

VINODMOKALE,SHIVRAJNAIK,TRUPTIKHATAL,SHIRISHH.SONAWANE ANDIRINAPOTOROKO

13.1Introduction212

13.2Materialandmethod212

13.3Resultsanddiscussion216

13.4Conclusion229 Acknowledgment230

Conflictofinterest230 References230

14.Molecularrecognition,selectivetargeting,andovercoming gastrointestinaldigestionbyfolicacid functionalizedoral deliverysystemsincoloncancer233

PALLABKUMARBORAHANDRAJKUMARDUARY Nomenclature234

14.1Introduction234

14.2Structureandfunctionofthefolatereceptor235

14.3Expressionoffolatereceptorinnormalandmalignant tissues236

14.4Folicacid functionalizeduptakeoforaldeliverysystems viafolatereceptor mediatedendocytosis237

14.5Functionalizationoffolicacidonoraldeliverysystems238

14.6Folicacid functionalizedsystemsforcoloncancer240

14.7Oraldeliverysystemsandgastrointestinaldigestion245

14.8Conclusion249

Acknowledgments250 References250

15.Mathematicalmodelingandsimulationoftherelease ofactiveagentsfromnanocontainers/microspheres257

ASHISHP.PRADHANE,DIVYAP.BARAI,BHARATA.BHANVASEAND SHIRISHH.SONAWANE

15.1Introduction258

15.2Mechanismofreleaseinnanocontainers258

15.3Modelingofreleaseofactiveagents268

15.4Simulationofreleaseofactiveagents281

15.5Summary284 References284

16.Flavorencapsulationandreleasestudiesinfood293

SHITALB.POTDAR,VIVIDHAK.LANDGE,SHRIKANTS.BARKADE, IRINAPOTOROKOANDSHIRISHH.SONAWANE

16.1Introduction294

16.2Aromaextractionmethods296

16.3Encapsulationtechniques:conventionalandnewer approach300

16.4Phenomenaofencapsulatedflavorrelease313

16.5Characterizationtechniquesforencapsulatedbioactive compounds315

16.6Conclusionandfutureprospective317 Acknowledgment317 References318

17.Encapsulationanddeliveryofantiparasiticdrugs: areview323

SANTANUSASIDHARANANDPRAKASHSAUDAGAR

17.1Introduction:encapsulationandtechniques324

17.2Needforencapsulateddrugsagainstparasite327

17.3Encapsulationofdrugsinvariousparasites328

17.4Encapsulateddrugsinclinicaltrialsandcommercialusage335

17.5Summaryandfutureoutlook336 References336 Index343

Listofcontributors UdayBagale DepartmentofFoodandBiotechnology,SouthUralState University,Chelyabinsk,RussianFederation

DivyaP.Barai ChemicalEngineeringDepartme nt,LaxminarayanInstituteof Technology,RashtrasantTukadojiMah arajNagpurUniversity,Nagpur,India

ShrikantS.Barkade ChemicalEngineeringDepartment,SinhgadCollegeof Engineering,Pune,India

BharatA.Bhanvase ChemicalEngineeringDepartment,Laxminarayan InstituteofTechnology,RTMNagpurUniversity,Nagpur,India

MayuriBhatia DepartmentofBiotechnology,NationalInstituteof Technology,Warangal,India;DepartmentofCivilEngineering,Indian InstituteofTechnologyHyderabad,Kandi,India

BhaskarBirru DepartmentofBiosciencesa ndBioengineering,Indian InstituteofTechnologyGuwahati,Guwahati,Assam,India

PallabKumarBorah DepartmentofFoodEngin eeringandTechnology, SchoolofEngineering,TezpurUniversity,Tezpur,India

JitendraCarpenter DepartmentofChemicalEngineering,MalaviyaNational InstituteofTechnology(MNIT),Jaipur,India

RajKumarDuary DepartmentofFoodEngineeringandTechnology,School ofEngineering,TezpurUniversity,Tezpur,India

VikashKumarDubey SchoolofBiochemicalEngineering,IndianInstituteof TechnologyBHU,Varanasi,India

SujaGeorge DepartmentofChemicalEngineering,MalaviyaNational InstituteofTechnology(MNIT),Jaipur,India

ShaileshA.Ghodke DepartmentofChemicalEngineering,Dr.D.Y.Patil InstituteofEngineering,Mana gementandResearch,Pune,India

M.ClaraGonçalves InstitutoSuperiorTécnico,UniversidadedeLisboa, Lisbon,Portugal

SarangP.Gumfekar DepartmentofChemicalandMaterialsEngineering, UniversityofAlberta,Edmonton,AB,Canada

KalpanaJoshi DepartmentofBiotechnology,SinhgadCollegeofEngineering, Pune,India

IrinaKalinina DepartmentofFoodTechnologyandBiotechnology,Schoolof MedicalBiology,SUSU,Chelyabinsk,Russia

TruptiKhatal DepartmentofPharmaceuticalTec hnology,UniversityInstitute ofChemicalTechnology,NorthMahara shtraUniversity,Jalgaon,India

VividhaK.Landge ChemicalEngineeringDepartment,NationalInstituteof Technology,Warangal,India

JoanaC.Matos InstitutoSuperiorTécnico,Uni versidadedeLisboa,Lisbon, Portugal;C 2 TN,CenterforNuclearSciencesandTechnologies,Instituto SuperiorTécnico,Universida dedeLisboa,Lisbon,Portugal

VinodMokale DepartmentofPharmaceuticalTechnology,University InstituteofChemicalTechnology,NorthMa harashtraUniversity,Jalgaon,India

D.N.Mokat DepartmentofBotany,Savitri baiPhulePuneUniversity,Pune, India

ShivrajNaik DepartmentofPharmaceuticalTec hnology,UniversityInstitute ofChemicalTechnology,NorthMahara shtraUniversity,Jalgaon,India

SreenivasaRaoParcha DepartmentofBiotechnology,NationalInstituteof TechnologyWarangal,Warangal,Telangana,India

LauraC.J.Pereira C 2 TN,CenterforNuclearSciencesandTechnologies, InstitutoSuperiorTécnico,UniversidadedeLisboa,Lisbon,Portugal

DipakPinjari NationalCenterforNanoscienceandNanotechnology, UniversityofMumbai,Mumbai,India

ShitalB.Potdar DepartmentofChemicalEngineering,NationalInstituteof Technology,Warangal,India

IrinaPotoroko DepartmentofFoodTechnologyandBiotechnology,Schoolof MedicalBiology,SUSU,Chelyabinsk,Russia

AshishP.Pradhane ChemicalEngineeringDepartment,Laxminarayan InstituteofTechnology,RashtrasantTukadojiMaharajNagpurUniversity, Nagpur,India

GundappaSaha DepartmentofBiosciencesandBioengineering,Indian InstituteofTechnologyGuwahati,Guwahati,India

VirendraKumarSaharan DepartmentofChemicalEngineering,Malaviya NationalInstituteofTechnology(MNIT),Jaipur,India

SantanuSasidharan DepartmentofBiotechnology,NationalInstituteof Technology,Warangal,India

PrakashSaudagar DepartmentofBiotechnology,NationalInstituteof TechnologyWarangal,Hanamkonda,India

P.Shalini DepartmentofChemicalEngineering,NationalInstituteof TechnologyWarangal,Warangal,Telangana,India

ManickamSivakumar ChemicalandEnvironmentalEngineering Department,UniversityofNotti ngham,JalanBroga,Malaysia

ShirishH.Sonawane ChemicalEngineeringDepartment,NationalInstitute ofTechnology,Warangal,India

ShriramS.Sonawane DepartmentofChemicalEngineering,Visvesvaraya NationalInstituteofTechnology,Nagpur,India

Y.C.Suryawanshi DepartmentofBotany,Savit ribaiPhulePuneUniversity, Pune,India

ParagThakur DepartmentofChemicalEngineering,VisvesvarayaNational InstituteofTechnology,Nagpur,India

S.D.Torawane DepartmentofBotany,Savit ribaiPhulePuneUniversity, Pune,India

JoãoCarlosWaerenborgh C 2 TN,CenterforNuclearSciencesand Technologies,InstitutoSuperiorTécn ico,UniversidadedeLisboa,Lisbon, Portugal

Currentoverviewofencapsulation ShirishH.Sonawane1,BharatA.Bhanvase2,ManickamSivakumar3, ShitalB.Potdar4 1 CHEMICALENGINEERINGDEPARTMENT,NATIONALINSTITUTEOFTECHNOLOGY, WARANGAL,INDIA 2 CHEMICALENGINEERINGDEPARTMENT,LAXMINARAYANINSTITUTEOF TECHNOLOGY,RTMNAGPURUNIVERSITY,NAGPUR,INDIA 3 CHEMICALAND ENVIRONMENTALENGINEERINGDEPARTMENT,UNIVERSITYOFNOTTINGHAM,JALAN BROGA,MALAYSIA 4 DEPARTMENTOFCHEMICALENGINEERING,NATIONALINSTITUTEOF TECHNOLOGY,WARANGAL,INDIA

ChapterOutline

1.1Introductiontoencapsulation....................................................................................................1 1.2Currenttrendsintheencapsulationprocesses........................................................................4 1.3Encapsulationofactivesubstrateandtheirtargetapplications............................................6

1.1Introductiontoencapsulation Encapsulationdatesbacktothe19thcentury.Intheyear1963,HarvardBusinessSchool preparedareportonencapsulationandunderlyingphenomenaofencapsulation.Fanger publishedanarticlein1974inthehistoryofencapsulation.Encapsulationistheprocessof stabilizationofactivecompoundsthroughthestructuringofsystemscapableofpreserving theirchemical,physical,andbiologicalproperties,aswellastheirreleaseordeliveryunder establishedordesiredconditions [1].Itisverywellknownthatnaturalplants,herbs,andfood materialshavevaluablecompoundsandpossessthepotentialtoutilizedforvariousapplications,suchasinthetreatmentofdiseaseslikecancer.Asanalternativetosyntheticpreservative andflavouringagentsithasbeenusedsincethedawnofmedicinetotreatvariousillnessesin Ayurvedaorfood-processingindustriesasanalternativetosyntheticpreservativesandflavoring agents.However,thesebioactivecompoundsaresubjectedtodegradationwithenvironmental conditionssuchastemperatureandmoisture.So, itisessentialtoextractandstorethesevaluablecompounds.Encapsulationisapromisingwaytopreservetheseactivecompounds.

Intheprocessofencapsulation,eitheroneo rthemixtureofbioactivematerialiscoated withanothersingleorcombinationofmaterial s.Inencapsulation,twomainterminologies

https://doi.org/10.1016/B978-0-12-819363-1.00001-6

arefrequentlyusedthematerialthatisbeingcoatedistermedastheactivematerialor corematerial,andanotheroneistheshellmaterialthatisalsotermedcarriermaterial (shell).Theshellmaterialcanbeintheform ofsolid,liquiddroplets,andgasbubblesto encapsulateliquidorgasinsideasacore.Thecoreandshellstructurecanbeinvarious shapessuchasthesphere,microcapsules,mi crobeads,monocore,multicore,matrix,and multishell.Thecoreandshellmaterialoftheencapsulationvarydependingontheapplicationsandpossessspecificcharacteristics ,forexample,corematerialsusedinfoodare essentialoils(actingasapreservativeandflavoringagent)andshellmaterialsarewhey protein,gumarabic,maltodextrin,etc.Inthe medicalfieldtheused,corematerialsare drugssuchastheinfluenzavirus,stemcells, DNA,andinsulinandshellmaterialsarepolymethylmethacrylate,andtheencapsulation methodsarecopolymerization,solventdisplacement,gelation,etc.

Encapsulationisusedinvariousareasfordifferentpurposes.Inbiology,itisusefulinthe encapsulationoflivingtissue,individualcells,hormones,enzymesorantibodies,andother biologicalmaterials.Inthefoodindustry,encapsulationiscarriedouttoaddflavortoproductsthatarereducedinvariousfood-processingsteps.Theextractionofadrugmolecule anditsencapsulationinthepharmaceuticalfieldgivenaturaldrugdeliveryandalsohelpto reducethesideeffectsofsyntheticdrugs.Encapsulationtechniqueisalsousedintheagriculturalfieldtoencapsulatepesticides,fertilizers,andotheragrochemicalsthatallow growerstopreciselycontroltheconditionsunderwhichtheactiveingredientisreleased. Encapsulationcanalsohelptominimizetheuseofpesticidesandreducetheirenvironmentalimpact.Nanocontainerpreparationforcorrosioninhibitionisalsoanattractiveareagainingtheattentionofmanyresearcherstousenanoparticlessuchastitania,zincmolybdateas corematerialandencapsulatethemwithdifferentpolymerseitherthroughlayer-by-layer approachorbyinsitupolymerization [2].

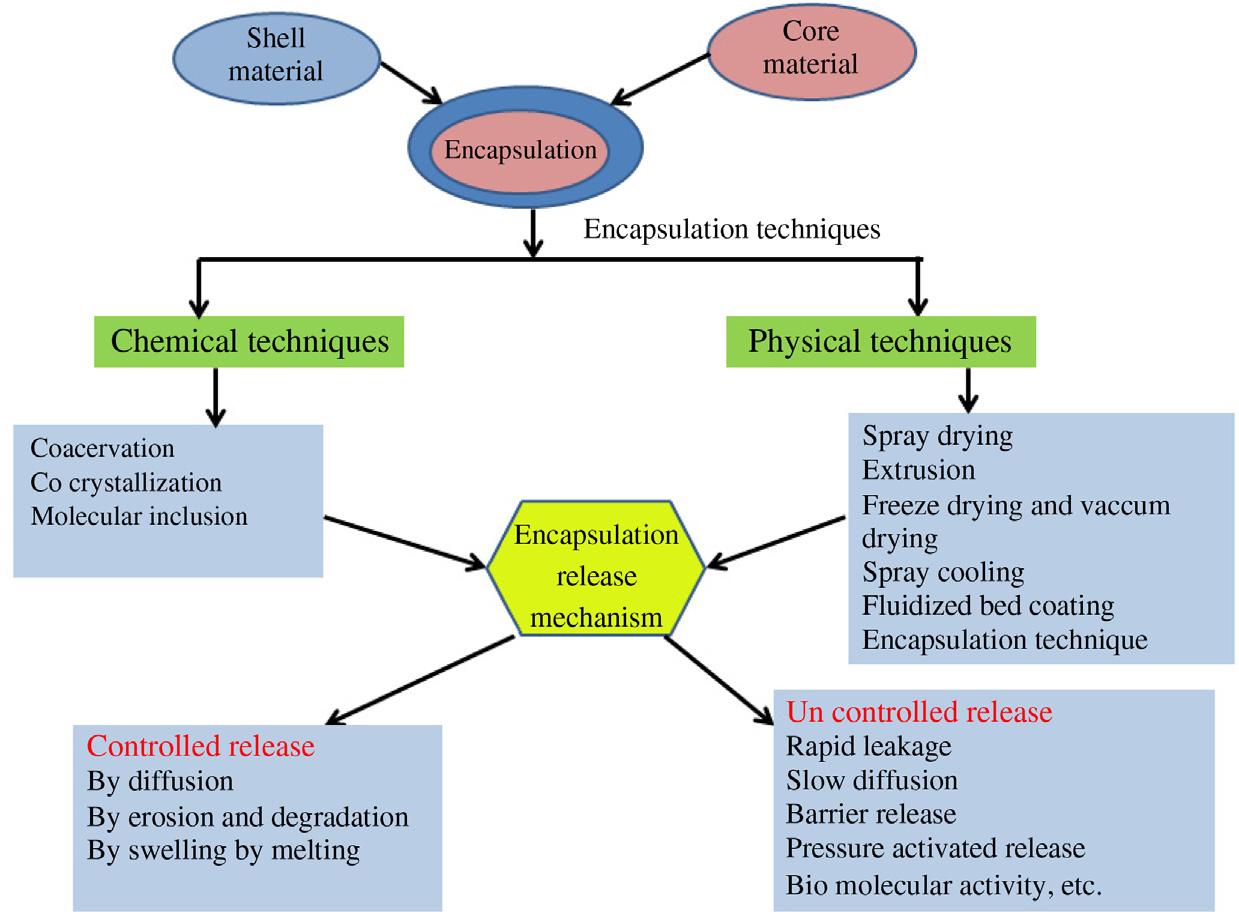

Withtimethedomainofencapsulationreceivedenormousattention,whilevariousmethodsofextractionandencapsulationhavebeendevelopeddependingupontheapplication andthecharacteristicsofmaterials.Variousmethodsofextractioncanbelistedashotwater bathextraction,Soxhletextraction [3],microwave-assistedextraction [4],extractionusingthe maceration [5],supercriticalcarbondioxideextraction [6],andultrasound-assistedextraction.Oncethebioactivecorematerialisextractedfromanaturalsource,itisdesiredto encapsulateusingvarioustechniques.Theencapsulationtechniquescanbebroadlydivided intotwomaincategories,thatis,chemicalandphysicalencapsulations.Therearethreedifferentmethodsofchemicalencapsulation,namely,coacervation,molecularinclusion [7], andcocrystallization [8].Physicalencapsulationisalsoknownasmechanicalencapsulation. Spray-drying [9,10],extrusion [11],freeze-dryingandvacuumdrying,spray-coolingorchilling,andfluidizedbedcoatingarethemethodsofphysicalencapsulation.Newagetechniquesofencapsulationincludehigh-andlow-energyemulsificationtechniques [12].Two typesofemulsionareformed,namely,microemulsionandnanoemulsion.Thefundamental differencebetweenthesetwotypesisthedropletsizeofemulsion.Thesizeformicroemulsionisonetoseveralmicrons,anditisintherangeoffewnanometersfornanoemulsion.

–1 Encapsulationtechniquesandthereleasemechanisms.

FIGURE1–2 Ultrasound-assistedminiemulsionencapsulationprocess. ReprintedwithpermissionfromSonawane, etal.,J.Phys.Chem.C114(2010)5148 5153.

Thenanoemulsiontechnologyisbecomingattractivebecauseofitsadvantagesovermicroemulsionsuchashigherencapsulationefficiencyandincreasedproductyield(Fig.1 1).

Ultrasound-assistedminiemulsionisoneoftheadvancedmethodsofencapsulation.In thismethod,miniemulsionpolymerizationiscarriedoutusingtheultrasound-assistedtechnique.Thepreparedemulsionusingultrasoundisshownin Fig.1 2.Usingultrasoundthe cavitationtechnique,itispossibletopreparetheinorganiccoresurroundedbypolymeric

FIGURE1

4EncapsulationofActiveMoleculesandtheirDeliverySystem

–3 Encapsulationofactivemoleculesandthereleasemechanism.

shelldispersedinthecontinuousmatrixsuchaswater.Usingtheultrasound-assisted method,itispossibletoencapsulateactivematerialinatinysizemaybeintherangeof 20 50nm.Theencapsulatedmaterialcouldbeusedasaphotoanode,drugdelivery system,etc.

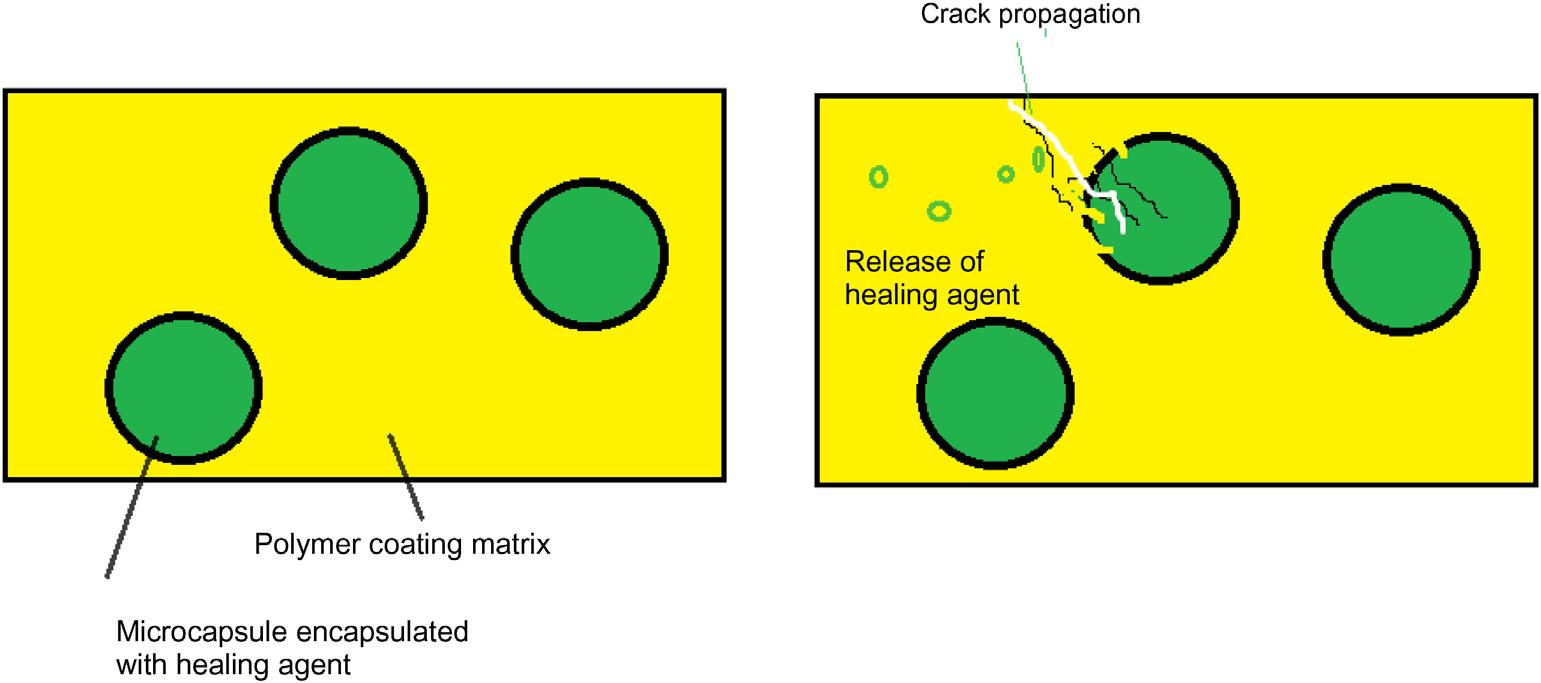

Thereleaseofencapsulatedcorematerialcanoccurbytwomechanisms:controlled releaseanduncontrolled(atriggeredmechanism)release.Thecontrolledreleaseofthe encapsulatedcorematerialisthecriticalstepintheprocess.Asshownin Fig.1 3,theliquid coreisencapsulatedusingapolymericshell.Basedonthecrackpropagation,thereleaseof activeagentsoccursfromthecore.Theliberatedmoleculesreactwiththepolymermatrix, andhealingoccurs.Thistypeofreleasemechanismisbasedonmechanicalstimulation.

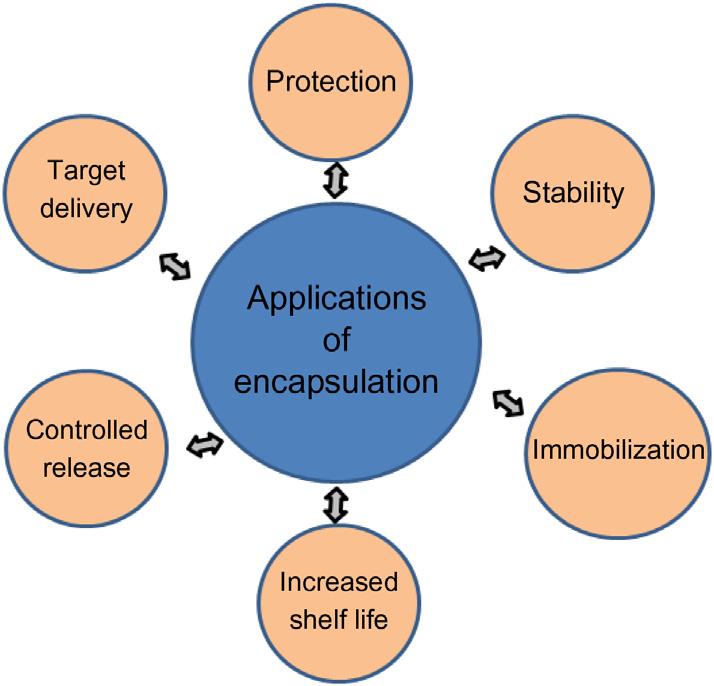

Thereleaseoftheencapsulateddruginacontrolledmannergivesthemaximumtherapeuticefficiencybydeliveringthedrugatthetargetedtissueatanoptimalamountandinan optimalperiod.Thecontrolledreleaseoffoodflavorisdesirableassometimesifanuncontrolledreleaseoccurs,theflavorislostwithinashortperiodbeforereachingtheconsumer forconsumption.Thebenefitsofencapsulationareshownin Fig.1 4.

Theefficiencyandbenefitsofencapsulationattracttheresearchersandscientiststostudy encapsulationtoovercomelimitationssuchasuncontrolledreleaseinitspracticalusein manyindustries.Thebasicsofencapsulationindifferentfieldssuchasfood,pharmaceutical, agriculture,andcorrosionhavebeenexplainedwithdetailedexperimentationandspecific examplesinthefollowingchapters.

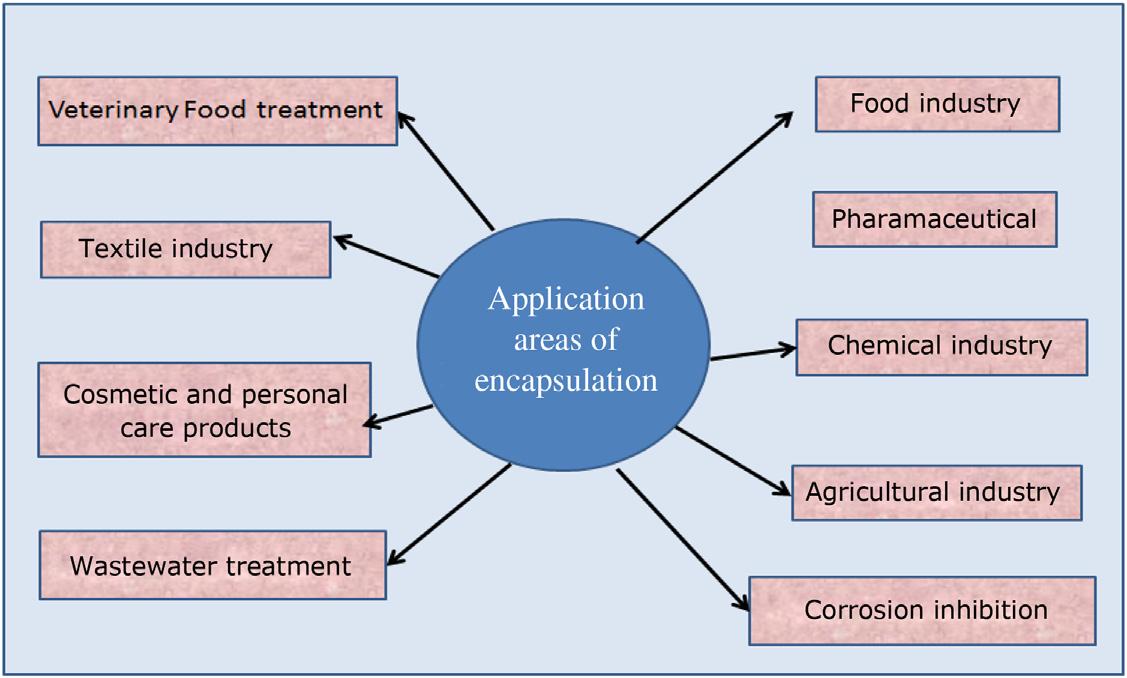

1.2Currenttrendsintheencapsulationprocesses Theadvantagesandbenefitsofencapsulationtechnologyhavebeenappliedinvariousareas ofapplication,fromfoodandbeverageindustry,wasteandenvironmentaltechnology,plant andanimal,medicalandpharmaceutical,energy,engineering,etc. Fig.1 5 showsthe functionalapplicationareasofencapsulation.

FIGURE1

Asdescribedintheabovesections,encapsulationisinuseformorethan60years.Inearlierdaysthefocuswasontheencapsulationofactivematerialforfoodandmostpharmaceuticaldrugpreparationonly.However,theareahasbecomevast,andtheencapsulation techniquesareusedinmanysectorsstartingfromdairyproductssuchaspersonalcare product,agriculturalproduct,andsurgerytoolsinmedicine.

Withtheadvancementinnanotechnology,scientistsareawareoftheadvantagesofnanoscaleproductsovermicroscaleproductsintermsofusingthesurfaceareaeffectively.So, thereisagrowingtrendinsynthesizingnanoscalecore shellemulsionencapsulation. Sometimes,itisfoundthatthesingleprocesswillnotgivehigherencapsulationefficiency, andthusthecombinationofencapsulationtechniquessuchassynthesizingcore shell emulsionusingultrasoundandmakingitmorestablebystoringitinpowderformbyspray

FIGURE1–5 Applicationareasofencapsulation.

FIGURE1–4 Applicationsofencapsulation.

dryingfacilityismoreuseful.Similarly,thecombinationofthecorematerialand/orthe combinationofshellmaterialisnowbeingwellpracticedbecauseoftheirunique characteristics.

Minimizationoftheuseofsyntheticproductsineachfieldisattractingresearchersand industriestoworkintheareaofencapsulation.Asanexample,thechemicallyprepared drugshavesideeffectsafterconsumption,andthus,naturaldrugsarerequired.Theorally administereddrugsaredissolvedcompletelyandinstantlybyinteractingwiththesolvent. Thusdrugencapsulationprovidesalayerofprotectionforthegradualreleaseofitsdrug contentwhenitisnaturallydissolved.Consumerssuspectthatsyntheticpreservativesand flavoringagentsinfoodareharmfultothebody,sotheyprefernaturalpreservatives.The extractofnaturalproductssuchasessentialoilsfromvariousfooditemssuchasgingerol, soyaseed,andsafflowerhavefoodpreservativeproperties,whereasextractsfromfruitsact asaflavoringagentandareprovedbeneficialforhealthfromancientyears.Nearlythesame isthescenarioforagriculturalproducts,syntheticpesticides,fertilizers,andotheragrochemicals,whichhelpinincreasingtheproductionattheexpenseoffertilitylossofsoil,whichis aseriousissuetoconsider.Productspreparedusingnaturalencapsulationwillnotonlystop fertilitylossofsoilbutalsohelptoimprovethesoilfertility.Becauseoftheuncertaintyof environmentalconditionssuchasrain,sometimestheactiveagentsinfertilizerandpesticidesgetdegradedbeforerainingstartsandfindnousefulnessingerminationandgrowth. Agrochemicalspreparedusingencapsulationleadstothecontrolledreleaseofactivematerialsthatareusefulinthegrowthwhenrainingoccurs.

1.3Encapsulationofactivesubstrateandtheirtarget applications Theresearchemploysmicroencapsulationtechnologyinhomecareproductssuchassmall microcapsuleslaundrypowder,personalcareproductssuchasmakeupcreams,facewash, lotions,andfragrances,whichwillneitherdegradewithenvironmentaltemperaturenor leavesideeffectsontheskin.Someoftheproductsavailableinthemarketnowgetdegraded underspecificenvironmentalchanges,therebylosingtheireffects.Theencapsulatedproduct willbesubjectedtotargetdeliveryoffragrancesuchasactivematerialstoreleaseunder desiredconditions.

Owingtotheuseofencapsulationinthepaintindustryself-healingpaintswhichhave beendesignedinawaythatpaintwillhavenanoparticlessuchaszinc,andtitaniawithanticorrosiveproperties.Theencapsulatedcoatingsandcementcouldmakemaintenanceeasier andlessexpensive.Theencapsulatedmicroparticleswhenmixedintopaintsandcoatings forinfrastructure,pipelines,andindustrialequipmentatriskforcorrosiondamage.

Microencapsulationisalreadyinusebythepharmaceuticalindustry,butnewencapsulationtechniquescouldexpandthepossibleusesfordrugdeliveryandleadtoexcitingnew therapies.Kreuterintheyear2007,reportedthatthesustainedreleaseofvaccineprovides moreprolongedimmunesystemstimulation.Besidesthevaccine,thesustainedreleasewas

alsoappliedtootherdrugssuchasfivebioactivecompounds,protein,DNA [13],andstem cell.Anotherusecouldbeinthestabilizationofvaccines.

Makingsaferandmoreeffectiveagrochemicalsisanothertargetapplicationofencapsulationtechnology.Itpossessesnumerousdifferentusesforagrobusiness.Microencapsulation couldbeusedtocombineincompatibleingredientsintooneshelf-stableproducttoreduce packagingandmakestorageandapplicationmoreconvenient.Itcouldalsobeusedto reducetheamountofchemicalthatfarmersneedtoapply.Agriculturalproductscoulduse microcapsulesthatopentodelivertheproductonlywhenitrains.

Encapsulationfindsanapplicationincivilengineeringforthepreparationofself-healing concretes.Itisageneralobservationthatthelifespanofconcretedeteriorates,andthe underlyingreasonforthisdeteriorationisduetothecrackingmechanism.Thisphenomenon willnotjustleadtocapitalandlaborcost,butitisdifficulttounderstandthedegreeofdamageoncetheconstructioniscomplete.Self-healingconcretesaresynthesizedusingencapsulationtechnology.Ifconcreteisformedbyacapsule-basedself-healing [14],theloss,as mentionedabove,ofcapitalandlaborcanbereduced.Inthistechnique,healingcapsules arepreparedusingmaterialssuchassodiumsilicatesolution;whentheseencapsulatedcapsulesgetrupturedduetocracking,itreleasessodiumsilicatesolutionintothematrixand therebyreactswithcalciumhydroxide(concretematerial)toformcalciumsilicatehydrate (C S H)thathelpsinhealingtheconcretecrack.Thecrackpropagationandhealingmechanismareshownin Fig.1 3.Concretecrackcanalsobehealedusingtheencapsulationof bacteriasuchassporesof Bacillussphaericus,withmaterialssuchasdiatomaceousearthas acarrier(shell)material.Theresearchinvestigationsemploydifferenthealingagentssuchas epoxy,resin,sodiumsilicatesolution,cyanoacrylatewithmaterialssuchasglass,gelatin,and silicagelasacarriermaterial [15].

Microencapsulationcouldalsotransformremediationmethods.Theoilandgasindustry isalreadyusingoil-eatingbacteriaforoilspillcleanup.Microencapsulationcouldmakethis techniquemorepracticalandconvenientbycreatingshellsthatkeepbacteriashelf-stable untiltheyarereleasedinthepresenceofhydrocarbons.

References [1] H.D.Silva,M.A.Cerqueira,A.A.Vicente,Nanoemulsionsforfoodapplications:developmentandcharacterization,FoodBioprocessTechnol.5(2012)854 867.

[2] S.E.Karekar,U.D.Bagale,S.H.Sonawane,B.A.Bhanvase,D.V.Pinjari,Asmartcoatingestablishedwith encapsulationofzincmolybdatecentrednanocontainerforactivecorrosionprotectionofmildsteel: releasekineticsofcorrosioninhibitor,CompositeInterfaces25(9)(2018)785 808.

[3] Y.Naude,W.H.J.DeBeer,S.Jooste,L.VanderMerwe,S.J.VanRansburg,Comparisonofsupercritical fluidextractionandSoxhletextractionforthedeterminationofDDT,DDDandDDEinsediment,Water SA24(1998)205 214.

[4] K.Ganzler,A.Salgo,K.Valkó,Microwaveextraction:anovelsamplepreparationmethodforchromatography,J.Chromatogr.A.371(1986)299 306.

[5] M.Z.Borhan,R.Ahmad,M.M.Rusop,S.Abdullah,ImpactofnanopowdersonextractionyieldofCentella asiatica,Adv.Mater.Res.667(2013)246 250.

8EncapsulationofActiveMoleculesandtheirDeliverySystem

[6] S.S.H.Rizvi,J.A.Daniels,A.L.Benado,J.A.Zollweg,SupercriticalFluidExtraction:OperatingPrinciples andFoodApplications,FoodTechnology,USA,1986.

[7] Y.H.Cho,J.Park,Encapsulationofflavourbymolecularinclusionusing β-cyclodextrin:comparison withspray-dryingprocessusingcarbohydrate-basedwallmaterials,FoodSci.Biotechnol.18(1)(2009) 185 189.

[8] C.I.Beristain,A.Vazquez,H.S.Garcia,E.J.Vernon-Carter,Encapsulationoforangepeeloilbycocrystallization,LWT FoodSci.Technol.29(7)(1996)645 647.

[9] Y.Wang,W.Liu,X.D.Chen,C.Selomulya,Micro-encapsulationandstabilizationofDHAcontaining fishoilinprotein-basedemulsionthroughmono-dispersedropletspraydryer,J.FoodEng.175(2016) 74 84.

[10] B.R.Bhandari,E.D.Dumoulin,H.M.J.Richard,I.Noleau,A.M.Lebert,Flavorencapsulationbyspray drying:applicationtocitralandlinalylacetate,J.FoodSci.57(1)(1992)217 222.

[11] G.A.Reineccius,Flavorencapsulation,FoodRev.Int.5(2)(1989)147 176.

[12] E.K.Silva,G.L.Zabot,M.A.A.Meireles,Ultrasound-assistedencapsulationofannattoseedoil:retention andreleaseofabioactivecompoundwithfunctionalactivities,FoodRes.Int.78(2015)159 168.

[13] T.Borodina,E.Markvicheva,S.Kunizhev,H.Möhwald,G.B.Sukhorukov,O.Kreft,Controlledreleaseof DNAfromself-degradingmicrocapsules,Macromol.RapidCommun.28(18 19)(2007)1894 1899.

[14] M.Kessler,N.Sottos,S.White,Self-healingstructuralcompositematerials,Compos.PartA:Appl.Sci. Manuf.34(8)(2003)743 753.

[15] G.Souradeep,H.W.Kua,Encapsulationtechnologyandtechniquesinself-healingconcrete,J.Mater. CivilEng.28(12)(2016)04016165.

Furtherreading T.Jung,Biodegradablenanoparticlesfororaldeliveryofpeptides:istherearoleforpolymerstoaffectmucosaluptake?Eur.J.Pharm.Biopharma.50(1)(2000)147 160.

T.M.Kauer,J.-L.Figueiredo,S.Hingtgen,K.Shah,Encapsulatedtherapeuticstemcellsimplantedinthe tumorresectioncavityinducecelldeathingliomas,Nat.Neurosci.15(2)(2011)197 204.

J.Kreuter,Nanoparticlesahistoricalperspective,Int.J.Pharm.331(1)(2007)1 10.

M.Zeisser-Labouèbe,N.Lange,R.Gurny,F.Delie,Hypericin-loadednanoparticlesforthephotodynamic treatmentofovariancancer,Int.J.Pharm.326(1 2)(2006)174 181.

Physicochemicalcharacterization techniquesintheencapsulationof activemolecules DEPARTMENTOFCHEMICALANDMATERIALS ENGINEERING,UNIVERSITYOFALBERTA, EDMONTON,AB,CANADA

ChapterOutline 2.1Introduction..................................................................................................................................9

2.2Particlesizeanditsdistribution...............................................................................................10

2.3Surfacecharges..........................................................................................................................12

2.4Imagingoftheencapsulatedmaterials...................................................................................12

2.5Thecrystallinityofencapsulationsystems.............................................................................15

2.6Rheologyoftheencapsulatedmaterials................................................................................17

2.7Conclusionandoutlook............................................................................................................20 References.........................................................................................................................................20

2.1Introduction Entrapmentofanactiveagentintoanothersubstance,whichincombinationproduces particlesofsizerangingfrommillimetertonanometer,isreferredtoasencapsulation.The internalspacethatencapsulatesactivemoleculesiscalledcore,fill,orpayloadphase. Similarly,thesubstancethatencapsulatesactivemoleculesiscalledshell,carrier,membrane, coating,ormatrix.Encapsulationtechnologyisusedindifferentareasfordiversepurposes. Forexample,encapsulationisusedinfoodtechnologytoprotectliquidorsolidactiveagents againstenvironmentalparameterssuchaslight,moisture,oxygen,andradicals.Inthepharmaceuticaldomainthedeliveryoftheactivemoleculesissignificantlyconsideredwhile designingtheencapsulationsystem.Variouspolymericmicrostructuresareusedasthecarrier fortheencapsulationofdifferentactivemolecules.Thusitisamultidisciplinaryfield,where researcherspossessingknowledgeintheareasofpolymers,biomaterials,self-assembly, surfacechemistry,biology,andmanymorecollaborate.Researchershavealsousedtheencapsulationtechnologytoprepareintelligentcoatingwhichcontainsencapsulatedcorrosion

SarangP.Gumfekar

inhibitor,whichself-releasesuponachangeinpH [1].Encapsulatedcalciumcarbonateisused inbio-basedself-healingconcretesinwhich,bacterialactivityinducestheprecipitationofcalciumcarbonatethatsubsequentlyhealsthecrackintheconcrete [2].Theinvestigationofthe correlationbetweenthedesignofanencapsulationsystem,themethodofencapsulation,and thereleaseperformancerequireaseriesofcharacterizationmethods.Todeterminewhichcharacterizationisnecessaryforaspecificencapsulationwork,itisessentialtounderstandwhyand howtheencapsulationisperformed.First,activemoleculescanbeencapsulatedbyforminga wallaroundorfirstmakingthewallmaterialandthenallowingtheactivemoleculestotransportinsidethewall.Second,itbecomesimperativetodetermineiftheundesiredleakagetakes placeornot.Finally,theselectivityoftheencapsulationsystemisimportanttokeeptheundesiredmaterialsoutofthecarriermaterial.Confirmationofthesegeneralstepsrequires extensivecharacterizationofacompleteencapsulationsystem.

Whilethereareanumberofindependentresearcharticlesandexhaustivereviews [3 5] ontheencapsulationmethodsandcarriermaterialsforavarietyofapplications,yetthereis noreviewthatbringstogetherthevariouscharacterizationtechniquesandtheirparticular useinthecontextofencapsulationsystems.Thischapterprovidesaguideforusingvarious techniquestocharacterizedifferentaspectsoftheencapsulationsystems.

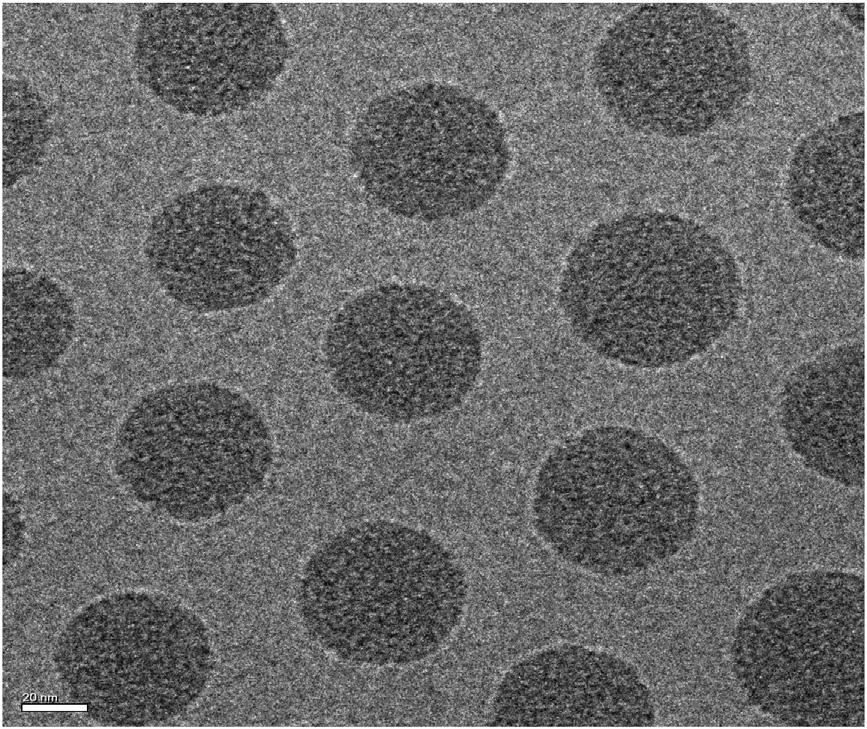

2.2Particlesizeanditsdistribution Particlesizeanditsdistribution(polydispersity)arethekeyparametersthatstronglycorrelatewiththestabilityoftheencapsulatedsystem.Particlecharacteristicsarealsonecessary tocreateanappropriatedeliverysystem.Researchershaveusednumerouswaystocontrol theseparameters,namely,surfactants,ionicmacromolecules/polymers,ultrasoniccavitation, andcross-linkingofgels [6,7].Thesizeofparticlesmayvaryfrom10nm(e.g.,nanoemulsions)to1mm(e.g.,hydrogelbeads).Colloidallystableencapsulatedparticlesoftentake sphericalshape,butothershapessuchasthedeformedsphere,cylinder,orirregularshapes arealsoreported,whichaffectvariousphysicalpropertiesandthereleasemechanismsof activemolecules [8].Polydispersityindirectlyindicatestheaggregationstateoftheencapsulatedsystem.Higherpolydispersityindicatesthepresenceofaggregates,whichmayinduce instabilityintheemulsion-basedencapsulationsystemsresultinginabreakdown.The encapsulationsystemissaidtobemonodispersedwhenpolydispersityislessthan0.2,while polydispersitylessthan0.5isalsoconsideredforpharmaceuticalapplications [9 11].In thecaseofemulsionsthedropletsizeisanimportantparameter,asadecreaseinthedroplet sizeandpolydispersityincreasesthestabilityoftheemulsion.Dynamiclightscattering(DLS) isthemostcommonwaytomeasureparticlesizeandpolydispersity.Yalcinetal.investigatedthestabilityofgemcitabinehydrochloride-loadedliposomesbymeasuringtheparticle sizeandpolydispersityatvaryingtemperaturesandtimefor6months [12].Theyalso reportedthatthecompositionofcarrierandphysicochemicalcharacteristicsofbioactive moleculeshadasignificanteffectontheparticlesizeoftheencapsulatedmaterial.Amore detailedstudyontheparticle-sizedistributionoftheencapsulatedmaterialwasperformed

byChebiletal.topreparedispersionsexhibitingmonomodaldispersity [13].Theyusedlaser sourceswithtwowavelengths,633and466nm,anddetectorsthatcoveredarangebetween 0.015and144degreestodefinethebroadnessofthedistributioncurve. Eq.(2.1) defines “Span,” whichcanbeusedtoinvestigatethemonomodalormultimodalbehaviorofthe encapsulatedparticles:

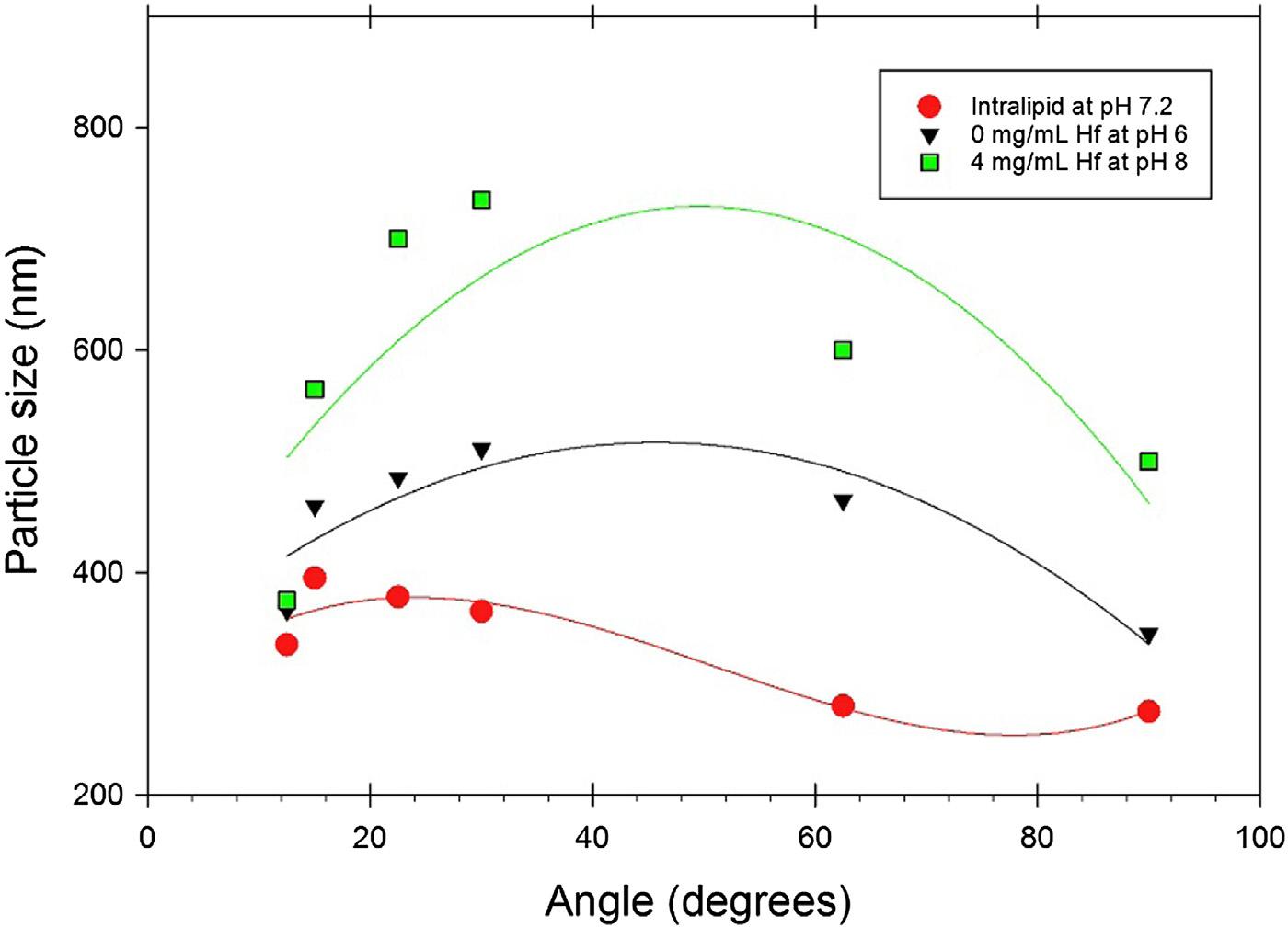

where d(0.9), d(0.5),and d(0.1)aretheparticlediametersat90%,50%,and10%cumulative volumes,respectively.Spanvalueslesserthan1.2wereconsideredtohavemonomodaldistributionsintheirexperiments.Haidaretal.probedthepolydispersityofHalofantrineencapsulatedparticlesusing “fingerprinting” particle-sizeanalysis [14].Theydemonstrated thisanalysisbymeasuringtheparticlesizeofcertainemulsionsasafunctionofthelightscatteringangle.Typically,90degreesisusedasthescatteringangleinthemajorityofthe DLStechniques.Theparticlesizeshouldnotchangeforamonodispersedsample,upona changeinthelight-scatteringangle.Sincetheextentofscatteringatvariousanglespartly dependsontheparticlesize,theintensity-averagedmeanparticlesizechangesforpolydispersedsamples [15]. Fig.2 1 showstheparticle-sizefingerprintingofvariouslab-prepared

FIGURE2–1 Particle-sizefingerprintingforvariousencapsulatedmaterials [14].Reprintedwithpermissionfrom I.Haidar,I.H.Harding,I.C.BowaterandA.W.McDowall,Physicalcharacterizationofhalofantrine-encapsulatedfat nanoemulsions, J.Pharm.Sci. 108(6),2019,2153 2161.

encapsulationsandcommercialIntralipidemulsion.Itcanbeseenthatthecommercial Intralipid(reddatapoints)hadrelativelymoreindependenceonthescatteringangle,while lab-madeemulsionsshoweddependenceonthescatteringangle.Thisfingerprintingdemonstratedthattheencapsulatedmaterialshadmultimodaldistributionswhentheyhadscatteringangle-dependantparticlesize.

2.3Surfacecharges Thesurfacechargeoftheencapsulatedmaterialssignificantlycorrelateswiththeirstabilityin dispersion.Zetapotentialisoftenusedtoinvestigatethesurfacechargesoftheencapsulated materials,whichindirectlyindicatesthedominanceofelectrostaticforces.Inthecontextof encapsulation,researchershavemeasuredzetapotentialtoinvestigatetheeffectoftheloading ofactivemoleculesonthesurfacepropertiesofthecarriermaterial.Theseexperimentsindicate thestabilityoftheencapsulatedmaterialsandrevealtheelectrostaticinteractionsbetween activemoleculesandcarriermaterial.Generally,itiswell-acceptedthattheparticledispersion ispossiblystableiftheabsolutevalueofzetapotentialishigh(whetherpositiveornegative). Inbiomimeticmineralizationofproteins,theyareencapsulatedincertainmaterials(cage)to protectandpreservethem.Typically,thisisachievedbynucleatingand furthergrowingacage materialontheproteinsurfacetoencapsulateit [16].Inthisprocessthesurfacechargeofthe loadedphaseplaysavitalroleinthenucleationandgrowthofthecarriermaterial.Recently, Maddiganetal.encapsulatedproteinsinmetal organicframeworksbycontrollingthesurface chargesoftheproteins [17].Theyshowedthatinducingnegativesurfacechargefacilitated encapsulation,whilepositivesurfacechargehinderedthemineralizationprocess. Fig.2 2 showstheexperimentalzetapotentialofbovineserumalbumin,pepsin,hemoglobin,andmyoglobin.Italsoshowsgeneralvariationinthezetapotentialafterchemicalfunctionalization.

Researchershaveencapsulatednanoparticles byviruscoatproteinstobetterunderstand virusassemblyandfurtherapplytheencapsulatednanoparticlesinbioimagingandtherapeutic applications [18,19].Linetal.investigatedthecorrelationbetweentheencapsulationefficiency ofnanoparticlesbyviruscoatproteinsandsurfacechargedensityofnanoparticles [20].They revealedthataminimumnegativesurfacechargedensityisrequiredfortheencapsulationto occur.Theencapsulationefficiencywasfoundto increasewithanincreaseinthesurfacecharge densityofthenanoparticles.Sinceionizablegroupsinducesurfacecharges,thedeviationinthe numberofionizablegroupsneartheaveragevalueisthehighestforpHneartheirpKavalue. Fig.2 3 illustratestheencapsulationefficiencyconcerningchangesinthesurfacechargedensity intheexperiments [21] andmodels [20].Gaussianmodelfitstheexperimentaldatawellasit considersthechargedistributionofthenanoparticlesagainstthefixed-chargemodel.

2.4Imagingoftheencapsulatedmaterials Electronmicroscopy(EM)andfluorescencemicroscopyarearguablyoneofthemostinformativeandoneofthewidelyusedinstrumentstoprobeparticlemorphology,biological