ElectronicWaste

RecyclingandReprocessingforaSustainableFuture

Editedby MariaE.Holuszko

AmitKumar

DeniseC.R.Espinosa

Editors

Dr.MariaE.Holuszko

TheUniversityofBritishColumbia NBKInstitueofMiningEngineering 517-6350StoresRoad V6T1Z4Vancouver,BC Canada

Dr.AmitKumar

TheUniversityofBritishColumbia NBKInstitueofMiningEngineering 517-6350StoresRoad V6T1Z4Vancouver,BC Canada

Dr.DeniseC.R.Espinosa UniversityofSaoPaulo PolytechnicSchool,Departmentof ChemicalEngineering Av.Prof.LucianoGualberto 380–Butantã,SãoPaulo,SP05508-010 Brazil

CoverDesign: Wiley

CoverImage: ©AndreiKuzmik/ Shutterstock,Recylingsymbol–public domain

Allbookspublishedby WILEY-VCH arecarefully produced.Nevertheless,authors,editors,and publisherdonotwarranttheinformation containedinthesebooks,includingthisbook, tobefreeoferrors.Readersareadvisedtokeep inmindthatstatements,data,illustrations, proceduraldetailsorotheritemsmay inadvertentlybeinaccurate.

LibraryofCongressCardNo.: appliedfor BritishLibraryCataloguing-in-PublicationData Acataloguerecordforthisbookisavailable fromtheBritishLibrary.

Bibliographicinformationpublishedbythe DeutscheNationalbibliothek TheDeutscheNationalbibliothekliststhis publicationintheDeutscheNationalbibliografie;detailedbibliographicdataareavailable ontheInternetat <http://dnb.d-nb.de>

©2022WILEY-VCHGmbH,Boschstr.12, 69469Weinheim,Germany

Allrightsreserved(includingthoseof translationintootherlanguages).Nopartof thisbookmaybereproducedinanyform–by photoprinting,microfilm,oranyothermeans–nortransmittedortranslatedintoamachine languagewithoutwrittenpermissionfromthe publishers.Registerednames,trademarks,etc. usedinthisbook,evenwhennotspecifically markedassuch,arenottobeconsidered unprotectedbylaw.

PrintISBN: 978-3-527-34490-1

ePDFISBN: 978-3-527-81642-2

ePubISBN: 978-3-527-81640-8

oBookISBN: 978-3-527-81639-2

Typesetting Straive,Chennai,India PrintingandBinding

Printedonacid-freepaper 10987654321

Contents

Preface xiii

1Introduction,Vision,andOpportunities 1 MariaE.Holuszko,DeniseC.R.Espinosa,TatianaScarazzato,andAmit Kumar

1.1Background 1

1.2E-Waste 2

1.3Outline 8 References 9

2e-WasteManagementandPracticesinDevelopedand DevelopingCountries 15 PabloDias,AndréaM.Bernardes,andNazmulHuda

2.1Introduction 15

2.2OverviewonWEEEManagementandPractices 16

2.3InternationalWEEEManagementandTransboundaryMovement 18

2.4WEEEManagementandPractices–DevelopedandDeveloping Countries 19

2.5DevelopedCountries 21

2.5.1Switzerland 21

2.5.2Japan 22

2.5.3Australia 22

2.6DevelopingCountries 23

2.6.1Brazil 23

2.6.2India 23

2.6.3SouthAfrica 24

2.6.4Nigeria 25

2.6.5Taiwan 25

2.7Conclusions 26 References 26

3e-WasteTransboundaryMovementRegulationsinVarious Jurisdictions 33

PabloDias,MdTasbirulIslam,BinLu,NazmulHuda,and AndréaM.Bernarde

3.1Background 33

3.2InternationalLegislationandTransboundaryMovement 34

3.3ExtendedProducerResponsibility(EPR) 41

3.4RegulationsinVariousJurisdictions 41

3.4.1Europe 43

3.4.1.1France 43

3.4.1.2Germany 43

3.4.1.3Switzerland 44

3.4.1.4Norway 44

3.4.2Americas 45

3.4.2.1UnitedStatesofAmerica 45

3.4.2.2Canada 46

3.4.2.3Brazil 47

3.4.3Asia 47

3.4.3.1Japan 47

3.4.3.2China 48

3.4.3.3Taiwan 49

3.4.3.4India 49

3.4.4Africa 49

3.4.4.1SouthAfrica 49

3.4.4.2Nigeria 50

3.4.5Australia 50

3.5Conclusions 51 References 52

4ApproachforEstimatinge-WasteGeneration 61 AmitKumar

4.1Background 61

4.2EconometricAnalysis 61

4.3ConsumptionandUse/Leaching/Approximation1Method 62

4.4TheSales/Approximation2Method 63

4.5MarketSupplyMethod 63

4.5.1SimpleDelay 63

4.5.2DistributionDelayMethod 63

4.5.3CarnegieMellonMethod/MassBalanceMethod 64

4.6Time-StepMethod 64

4.7SummaryofEstimationMethods 65

4.8LifespanofElectronicProducts 65

4.9Globale-WasteEstimation 66 References 69

5MaterialsUsedinElectronicEquipmentandManufacturing Perspectives 73 DanielD.München,PabloDias,andHugoM.Veit

5.1Introduction 73

5.2LargeHouseholdAppliances(LHA) 75

5.3SmallHouseholdAppliance(SHA) 76

5.4ITandTelecommunicationsEquipment 78

5.4.1ComputersandNotebooks 78

5.4.2MonitorsandScreens 79

5.4.3MobilePhones(MP) 81

5.4.4PrintedCircuitBoards(PCB) 83

5.5Photovoltaic(PV)Panels 85

5.6LightingEquipment 86

5.7Toys,Leisure,andSport 86

5.8FutureTrendsinWEEE–Manufacturing,Design,andDemand 89 References 91

6RecyclingTechnologies–PhysicalSeparation 95 AmitKumar,MariaE.Holuszko,andShuleiSong

6.1Introduction 95

6.2Dismantling 96

6.3Comminution/SizeReduction 97

6.3.1Shredders 97

6.3.2HammerMills 98

6.3.3High-VoltageFragmentation 98

6.3.4KnifeMills 100

6.3.5Cryogrinding 100

6.4ParticleSizeAnalysis 100

6.5SizeSeparation/Classification 102

6.5.1Screening 102

6.5.2Classification 104

6.5.2.1CentrifugalClassifier 104

6.5.2.2GravitationalClassifiers 105

6.6MagneticSeparation 106

6.6.1Low-IntensityMagneticSeparators 106

6.6.2High-IntensityMagneticSeparators 107

6.7ElectricalSeparation 108

6.7.1CoronaElectrostaticSeparation 108

6.7.2TriboelectricSeparation 109

6.7.3EddyCurrentSeparation 110

6.8GravitySeparation 111

6.8.1Jigs 112

6.8.2Spirals 112

6.8.3ShakingTables 113

6.8.4Zig-ZagClassifiers 114

6.8.5CentrifugalConcentrators 114

6.8.6DenseMediumSeparation(DMBath/Cyclone) 115

6.9FrothFlotation 116

6.10Sensor-BasedSorting 119

6.11ExampleFlowsheets 119 References 123

7PyrometallurgicalProcessesforRecyclingWasteElectricaland ElectronicEquipment 135 Jean-PhilippeHarvey,MohamedKhalil,andJamalChaouki

7.1Introduction 135

7.2PrintedCircuitBoards 136

7.3PyrometallurgicalProcesses 137

7.3.1Smelting 138

7.3.1.1Copper-SmeltingProcesses–SulfideRoute 138

7.3.1.2Copper-SmeltingProcesses–SecondarySmelters 142

7.3.1.3Lead-SmeltingProcesses 142

7.3.1.4AdvantagesandLimitationsofSmeltingProcesses 146

7.3.2ElectrochemicalProcesses 147

7.3.2.1High-TemperatureElectrolysis 148

7.3.2.2Low-TemperatureElectrolysis 149

7.3.3OtherPyrometallurgicalOperationsUsedinElectronicWaste Recycling 152

7.3.3.1Roasting 152

7.3.3.2MoltenSaltOxidationTreatment 152

7.3.3.3Distillation 153

7.3.3.4Pyrolysis 155 References 157

8RecyclingTechnologies–Hydrometallurgy 165

DeniseC.R.Espinosa,RafaelP.deOliveira,andThamirisA.G.Martins

8.1Background 165

8.2WastePrintedCircuitBoards(WPCBs) 167

8.3PhotovoltaicModules(PV) 172

8.4Batteries 176

8.5Light-EmittingDiodes(LEDs) 178

8.6Trends 180 References 181

9RecyclingTechnologies–Biohydrometallurgy 189

FranziskaL.LedererandKatrinPollmann

9.1Introduction 189

9.2Bioleaching:MetalWinningwithMicrobes 189

9.3Biosorption:SelectiveMetalRecoveryfromWasteWaters 191

9.3.1BiosorptionViaMetalSelectivePeptides 194

9.3.2ChelatorsDerivedfromNature 196

9.4Bioflotation:SeparationofParticleswithBiologicalMeans 197

9.5BioreductionandBioaccumulation:NanomaterialsfromWaste 199

9.6Conclusion 201 References 202

10ProcessingofNonmetalFractionfromPrintedCircuitBoards andReutilization 213

AmitKumarandMariaE.Holuszko

10.1Background 213

10.2NonmetalFractionComposition 214

10.3BenefitsofNMFRecycling 215

10.3.1EconomicBenefits 215

10.3.2EnvironmentalProtectionandPublicHealth 216

10.4RecyclingofNMF 218

10.4.1PhysicalRecycling 218

10.4.1.1SizeClassification 219

10.4.1.2GravitySeparation 219

10.4.1.3MagneticSeparation 220

10.4.1.4ElectricalSeparation 220

10.4.1.5FrothFlotation 220

10.4.2ChemicalRecycling 221

10.5PotentialUsage 221 References 223

11LifeCycleAssessmentofe-Waste–WasteCellphone Recycling 231

PengweiHe,HaiboFeng,GyanChhipi-Shrestha,KasunHewage,and RehanSadiq

11.1Introduction 231

11.2Background 232

11.2.1TheoryofLifeCycleAssessment 232

11.3LCAStudiesonWEEE 234

11.3.1ApplicationsonWEEEManagementStrategy 234

11.3.2ApplicationsonWEEEManagementSystem 235

11.3.3ApplicationsonHazardousPotentialofWEEEManagementand Recycling 236

11.4CaseStudy 236

11.4.1GoalandScopeDefinition 237

11.4.1.1FunctionalUnit 237

11.4.1.2SystemBoundary 238

11.4.2LifeCycleInventory 238

11.4.2.1FormalCollection 239

11.4.2.2InformalCollection 239

11.4.2.3MechanicalDismantling 239

x Contents

11.4.2.4PlasticRecycling 240

11.4.2.5ScreenGlassRecycling 240

11.4.2.6BatteryDisposal 240

11.4.2.7ElectronicRefiningforMaterials 241

11.4.3LifeCycleImpactAssessment 241

11.4.4Results 241

11.4.4.1FeaturePhoneFormalCollectionScenario 241

11.4.4.2FeaturePhoneInformalCollectionScenario 243

11.4.4.3SmartphoneFormalCollectionScenario 244

11.4.4.4SmartphoneInformalCollectionScenario 246

11.4.5Discussion 247

11.5Conclusion 249 References 250

12BiodegradabilityandCompostabilityAspectsofOrganic ElectronicMaterialsandDevices 255 AbdelazizGouda,ManuelReali,AlexandreMasson,AlexandraZvezdin, NiaByway,DenisRho,andClaraSantato

12.1Introduction 255

12.1.1TechnologicalInnovationandWaste 255

12.1.2Eco-friendliness 257

12.1.3OrganicElectronics 257

12.1.4OpportunitiesforGreenOrganicElectronics 258

12.2StateoftheArtinBiodegradableElectronics 258

12.3OrganicField-EffectTransistors(OFETs) 260

12.3.1Fundamentals 260

12.3.2Anthraquinone,Benzoquinone,andAcenequinone 262

12.3.3Quinacridones 262

12.4ElectrochemicalEnergyStorage 264

12.4.1Quinones 264

12.4.2Dopamine 265

12.4.3Melanins 265

12.4.4Tannins 268

12.4.5Lignin 269

12.5BiodegradationinNaturalandIndustrialEcosystems 269

12.5.1DegradationandBiodegradation 270

12.5.2CompostingProcess 271

12.5.3MaterialsHalf-LifeUnderCompostingConditions 274

12.5.4BiodegradationintheEnvironment 275

12.6MicrobiomeinNaturalandIndustrialEcosystems 276

12.6.1TheRuminant–HayNaturalEcosystem 279

12.6.2TheTermite–WoodNaturalEcosystem 280

12.6.3TheIndustrialComposter–BiowasteEcosystem 281

12.6.3.1MunicipalCompostingFacility 281

12.6.3.2EngineeredCompostingFacility 282

12.6.4SpecializedInoculantAdaptedtoOrganicMatter 282

12.6.5SpecializedInoculantAdaptedtoHeavyMetals 283

12.7ConcludingRemarksandPerspectives 284 Acknowledgment 285 References 285

13CircularEconomyinElectronicsandtheFutureof e-Waste 299 NaniPajunenandMariaE.Holuszko

13.1Introduction 299

13.2DigitalizationandtheNeedforElectronicDevices 301

13.3RecyclingandCircularEconomy 302

13.4Challengesfore-WasteRecyclingandCircularEconomy 304

13.5DriversforChange–CircularEconomy 306

13.6DemandforRecyclableProducts 309

13.7Summary 310 References 312

Index 315

Preface

Digitalizationhasplayedanessentialroleinsocialandtechnologicaldevelopment globally,whileelectronicandelectricalequipmenthasbecomeintegraltooureverydaylives.Digitaldevicesprovidebroadaccesstoeducation,instantinformation, continuousentertainmentandcontributetomasscommunication,thusimproving theoverallqualityofourlives.DuringtheCOVID-19pandemic,theinternetallowed ustofunctionandremainaproductivesocietyworldwide.

Meanwhile,thelifeexpectancyofmostelectronicdevices,specificallysmall devicessuchascellphones,tablets,andlaptops,isgettingshorterandshorter, resultinginalarmingamountsofe-wastegeneration.Manydiscardedelectronics arebeingimproperlydisposedof,henceposingasignificantrisktotheenvironment andhumanhealth.Withanestimatedannualgrowthof3–4%,electronicwaste isthefastestgrowingwastestreamworldwide,exceeding50Mtannuallyin2019, whileonly20%ofthee-wasteiscollectedandrecycledglobally.Theelectronic deviceshavebeenreportedtocontaingoldandcoppergrades,significantlyexceedingthegradesofmanyoperatingmines.Theexistenceofpreciousmetalsine-waste providesaneconomicincentiveforrecycling.Ontheotherhand,thepresenceof hazardoussubstancesine-wastecallsforcomplexreprocessingtodecontaminate beforeitsfinaldisposal.

Thedevelopmentofefficiente-wasterecyclingmethodsandtherecoveryof preciousmetalsandcriticalmaterialsfrome-wasteareinterestingandtechnically challenging.Furthermore,theinformalurbanminingofe-wastecreatessignificant socialandpublichealthissues.Therefore,therewasaneedforacomprehensive overviewofthecurrentsituationwithe-wastegeneration,disposal,regulations, recyclingtechnologieswhileprovidingaglobalperspective.

Thisbookaimstooverviewthecurrentglobalsituationregardinge-waste, includingtechnologicalissueswithe-wasterecyclingandrecoveryofvaluefrom e-wastestreams.Thechaptersinthisbookoutlinethedefinitionofelectronic waste,exploremethodsfore-wasteestimation,identifychallengesrelatedtothe timelyinformationone-wastecollectionandmanagement,andelaborateonthe practicesindevelopedanddevelopingcountries.Thebookdeliversinformationon currentlyusedrecyclingtechnologies,includingphysicalseparationtechnologies, pyrometallurgy,hydrometallurgy,andbiohydrometallurgy,andreviewsmaterials usedinthemanufacturingofelectronicsaswellasthedevelopmentofnew

xiv Preface

materialsforgreen-ecologicalandbiodegradableelectronics.Additionally,methods andideasfornewpracticestofacilitatesustainabilityintheelectronicsindustryare proposedto“closetheloop”inindustrialproductiontominimizewastegeneration andpossiblytopromoteazero-wastescenario.Thebookconcludeswithachapter onthecirculareconomyinelectronicsandprovidessomeperspectiveonthefuture ofelectronicwaste.

Thisbookwasmadepossiblethroughcollaborationbetweeninternationalexperts inthefieldofe-wasterecycling.Itcollatesacademicandindustrialexpertiseto provideacomprehensiveoverviewofthescopeoftheproblemwithelectronics worldwide,specificallyontheirfatease-wasteandtherecyclingeffortstoshed lightonthecurrente-wasteparadigm.

Vancouver,July2021

MariaE.Holuszko

AmitKumar

DeniseC.R.Espinosa

Introduction,Vision,andOpportunities

MariaE.Holuszko 1 ,DeniseC.R.Espinosa 2 ,TatianaScarazzato 3 ,and AmitKumar 1

1 NBKInstituteofMiningEngineering,UniversityofBritishColumbia,6350,StoresRoad,Vancouver,BCV6T 1Z4,Canada

2 UniversityofSãoPaulo,PolytechnicSchool,DepartmentofChemicalEngineering,Av.Prof.Luciano Gualberto,380–Butantã,SãoPaulo–SP05508-010,Brazil

3 FederalUniversityofRioGrandedoSul,DepartmentofMaterials,9500,Av.BentoGonçalves,Porto Alegre–RS,91509-900,Brazil

1.1Background

TheconceptofsustainabilitydefinedbyTheUnitedNationsOrganizationin1987, whichisvalideventoday,isbasedontheideaof“meetingtheneedsofthepresent withoutcompromisingtheabilityoffuturegenerationstomeettheirownneeds” (Nations2019).SuchaconceptwascomplementedinTheJohannesburgDeclarationonSustainableDevelopmentinwhichthethreepillarsofsustainabilitywere defined:economic,environmental,andsocialdevelopment(Comission2002).

Notwithstanding,theworldcurrentlyfacesatransitionbetweenthethirdandthe fourthindustrialrevolutions,whichbeganaboutfivedecadesagoandhastransformedourwayofliving.AlsoknownastheInformationRevolution,thisperiod hasbeenmarkedbyswiftadvancesincomputertechnologies,massivepopularizationofhigh-technologydevices,andthegrowthofartificialintelligence(Carvalho etal.2018;RaiandLal2000).Thetechnologicalrevolutionbroughtupthecreation oflithium-ionbatteries,touchscreendevices,supercomputers,photovoltaicpanels, andnanocomposites,andpracticallyrevolutionizedthewaythesocietyinteracts, thewayenergyisstored,andtheadvancedmaterialsfieldforallindustrialsectors.

Electricalandelectronicequipmentisoneofthemajorconsumersofmetalssuch ascopper,gold,silver,andiron.Namias(2013)suggestedthatelectronicdevicescan containupto60differentelementsthatcouldbevaluableorhazardous.Natural ResourcesCanada(2019)showedthatglobally18%ofaluminum,31%ofcopper, 9.5%ofgold,9%ofplatinumgroupmetals,and24%ofrare-earthelementswere usedinelectricalandelectronicequipmentmanufacturingin2017.IntheUnited StatesofAmerica,9%oftotalaluminum,21%ofberyllium,19%ofcopper,40%

ElectronicWaste:RecyclingandReprocessingforaSustainableFuture, FirstEdition. EditedbyMariaE.Holuszko,AmitKumar,andDeniseC.R.Espinosa. ©2022WILEY-VCHGmbH.Published2022byWILEY-VCHGmbH.

1Introduction,Vision,andOpportunities

ofgold,and26%ofsilverwereusedintheelectricalandelectronicequipment manufacturingindustryin2019(U.S.GeologicalSurvey2019).BullionStreet (2012)showedthatapproximately290tonnesofgoldand6800tonnesofsilver areconsumedbytheelectronicindustryeveryyear.Inthecurrentscenario,the newmanufacturingindustrybecamedependentonless-knownrawmaterialsand increasedtheextractionofcommonmetalsfromoressimultaneously.Indium,for example,despitebeingdiscoveredin1863,wasfoundtobeindustriallyapplicable onlyin1934.Theuseofindiuminthin-filmcoatings,mainlyasindium-tin-oxide compound(ITO)inliquidcrystaldisplayscreens,increaseditsworldconsumption over1000%since1993(AlfantaziandMoskalyk2003).

Rare-earthelements(REEs)arealsowidelyusedindigitaltechnologiessuchas discdriversandcommunicationsystemsbutalsoinbatteriesandfuelcellsforhydrogenstorage,catalysts,light-emittingdiodes(LEDs),andfluorescentlighting.Backin 1950,theapplicationsofREEinmagnetsofelectricandelectronicequipmentwere alreadyknown.Nevertheless,until2010theirrecyclingratewaslowerthan1%due totheirrelativelylowprices(Gunn2013).Between2010and2015,thedemandfor REEsurpasseditssupplyandcontinuouslyincreased.Astheproductionisalmost totallyheldbyfewcountries,therecyclingofREEhasbecomeaparamountconcern (Edahbietal.2019).

1.2E-Waste

Withthedevelopmentofnewtechnologies,especiallyinlaptops,cellphones,and tablets,oldertechnologiesaregettingobsolete,reducingthelifespanofelectrical andelectronicsproductsandthuscontributingtoahigherrateofwastegeneration. Asaresult,closeto1billiondeviceswillbediscardedwithin4–5years.Thediscarded electricandelectronicequipmentortheirpartsareconsiderede-waste.TheEuropeanCommissionDirective2008/98/EC(2008)andtheEuropeanUnionDirective 2012/19/EU(2012)describede-wasteas:

anyelectricalorelectronicequipmentwhichiswaste(substanceorobject whichtheholderdiscardsorintendsorisrequiredtodiscard),includingall components,sub-assemblies,andconsumableswhicharepartoftheproduct atthetimeofdiscarding.

Basedonthedefinitionofe-waste,theelectricalorelectronicequipment(EEE) itselfwasdividedintosix(6)classesintheDirective2012/19/EU(TheEuropean Union2012).Thesecategorieswiththeitems(notlimitedto)inthecategoriesare listedas,

1)Temperature-exchangeequipment:refrigerators,freezers,airconditioning equipmentand,heatpumps

2)Screens,monitors,andequipmentcontainingscreens(surface > 100cm2 ): screens,televisions,LCDphotoframes,monitors,laptops,andnotebooks

3)Lamps:fluorescentlamps,high-intensitydischargelamps,includinghighpressuresodiumlampsandmetalhalidelamps,low-pressuresodiumlampsand LEDlamps

4)Largeequipment(externaldimensions > 50cm):washingmachines,dryers,dishwashers,electricstoves,musicalequipment,largecomputermainframes,large printingmachines,copyingequipment,largecoin-slotmachines,largemedical devices,largeautomaticdispensers,andphotovoltaicpanels

5)Smallequipment(externaldimensions < 50cm):vacuumcleaners,appliances forsewing,luminaires,microwaves,irons,toasters,electrickettles,clocksand watches,electricshavers,scales,radio,videocameras,electricalandelectronic toys,sportsequipment,smokedetectors,heatingregulators,thermostats,small electricalandelectronictools,smallmedicaldevices,andsmallautomatic dispensers

6)SmallITandtelecommunicationequipment(externaldimension < 50cm): mobilephones,GPS,pocketcalculators,routers,personalcomputers,printers, andtelephones

Thiselectronicwaste(discardedelectronics)hasbeenagrowingconcernaround theworld.Thetotale-wastegeneratedaroundtheglobein2019was53.6million tonnesandisexpectedtoreach74milliontonnesin2030.Thewastegeneratedper capitaincreasedfrom6.1kgperinhabitantin2016to7.3kgperinhabitantin2019 (Fortietal.2020).Wahlen(2019)reportedthatunderthebusiness-as-usualcase,the totale-wastegenerationwouldincreaseto120milliontonnesby2050.Thegrowth rateofe-wastegenerationhasbeenreportedtobe3–5%byCucchiellaetal.(2015), 3–4%byBaldéetal.(2017)andAaron(2019),andashighas8%byLeBlanc(2018). AccordingtoTransparencyMarketResearchreport(2017),theglobale-wastemarketisanticipatedtoincreaseatacompoundannualgrowthrateof5.6%byvolume from2016to2026.

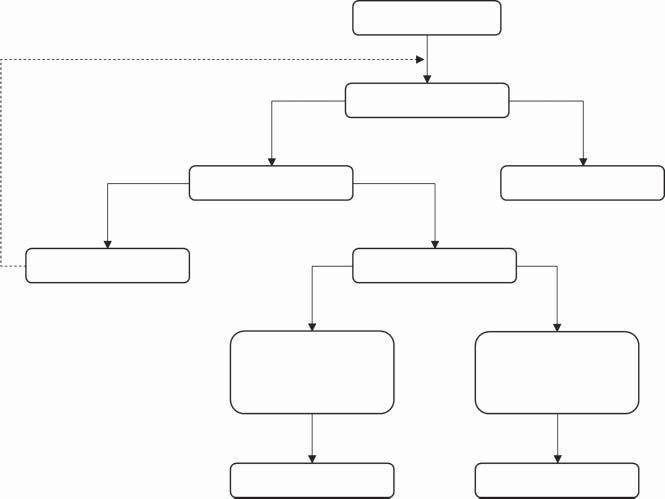

Thefateofthee-wastecanbedescribedbythesimplifieddiagramshown inFigure1.1.Theprimaryfocusofanycountryororganizationshouldbethe collectionandrecyclingofe-waste.However,notallthee-wasteiscollected,anda portionofthee-wastestreamisdisposedofinlandfills.Thecollectedmaterialsare sentforrecycling,andthehigh-valuecomponentssuchasmetalsandhigh-value plasticsarefedbacktothemanufacturingstream,whereaslow-valuematerialsare disposedofinlandfills.

Theprimaryfocusofanycountryororganizationshouldbethecollectionand recyclingofe-waste.However,notallthee-wasteiscollected,andaportionofthe e-wastestreamisdisposedofinlandfills.Thecollectedmaterialsaresentforrecycling,andthehigh-valuecomponentssuchasmetalsandhigh-valueplasticsarefed backtothemanufacturingstream,whereaslow-valuematerialsaredisposedofin landfills.Thee-wastecollectionvolumemustbeincreasedtoboostthecirculareconomyinanypartoftheworld,andthewastestreamaftertherecyclingprocesshasto bestudiedsimultaneouslyforitspotentialrecoveryandusagesothatthefractions tobedisposedofareminimized.

E-wasterecyclingdecreasestheamountofextractedrawmaterialsfromoresand solidwasteinadequatedisposal.Therecyclingroutesmustalsobetechnicallyand

End of life

End of life EEE sales

E-waste generation

E-waste collection

E-waste reuse

Recycled stream (metals + high value plastics)

E-waste recycling

Reuse

SimplifiedflowofEEEproducts.

amountEstimated value

E-waste disposal

Disposal Waste stream (non-metal + low value materials)

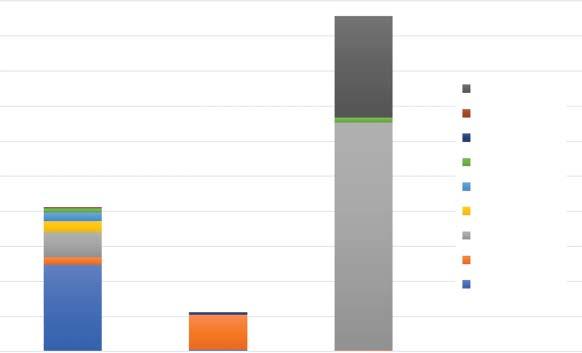

Figure1.2 Estimatedvalueofmaterialspresentine-waste.

economicallyfeasible.Giventheaddedvalueofpreciousmetalsandcriticalmetals foundinthemajorityofe-waste,suchrequirementsarenotdifficulttobefulfilled. Baldéetal.(2017)estimatedtheamountofvariouselementsandmaterialspresent ine-waste.Itshowedthatthetotalcontained/potentialvalueofselectedmetaland materialspresentine-wastewasUS$57billionin2019(Fortietal.2020).Figure1.2 showsabreakdownofthevariousmetalsandmaterialspresentine-wastewith theirtotalamountandestimatedvalues.Itshouldbenotedthattheestimatedvalue

Figure1.1

depictedinFigure1.2representsanideal-casescenarioof100%collectionandmetal recoveryandwithoutaccountingforcostsassociatedwithcollectionandrecycling. Itindicatestheeconomicopportunityfore-wasterecycling.

Itshouldalsobetakenintoconsiderationthattheconcentrationofmetalsinthe e-wasteissignificantlyhigherthanthatofaconventionalminingoperation.The globaloregradehasbeendecreasing,andtheincreasedglobalmetaldemandhas forcedminingoperationstoincreasetheplantthroughputandexcavatemorecomplexandfine-grainedoredeposits(LèbreandCorder2015).

Table1.1showstheconcentrationofvariousmetalsindifferenttypesofe-waste andanaverageorebody.Calvoetal.(2016)summarizedthattheglobalaveragecoppergradeforrun-of-mineoreis ∼0.62%andwilldeclineinthecomingyearsdueto theexhaustionofhigh-grademines.AMEResearch(2018)showedthattheaverage coppergradehasdecreasedfrom0.74%in2005to0.59%in2017,withacompound annualdeclinerateof1.8%.Theglobalaveragegoldgradeofallthedepositswas 1.01g/tin2013(Desjardins2014).Thehighestgoldgradefortheundergroundoperationwas21.5ppminFosterville,Australia,whereasforopenpitwas7.60ppmin WayLinggo,Indonesia(Basov2018).Theaverageoutputoftop-sixsilvermineswas 7.6oz(215g)pertonnein2012andhasdroppedto4–5ozpertonin2017(McLeod 2014;MoneyMetalsExchange2018).ThepalladiumgradereportedinTable1.1is basedontheaveragepalladiumgradeoftheLacdesIlesMinePropertyinNorthern Ontario.Itindicatesthattheaveragemetalgradepresentine-wasteissignificantly higherthanconventionalminesandthusprovidestheopportunityfortheextraction/urbanmining.

Table1.1 AveragemetalcontentinvariouswasteEEEandtypicalore.

CopperAluminumIronGoldSilverPalladium %%%ppmppmppm

Airconditioner6–197–9461558–Desktop7–202–418–4746–240207–57018–25

Laptop1–191–22032–630190–110019

Mobilephone10–333530–15002000–3800300–1700 Printedcircuitboard12–192–80–1129–1120100–520033–220 Refrigerator3–171–248–504442–Television1–211–1513–435–300120–6000–20 Washingmachine3–70–352–531751–e-Waste(average)12–351.5–55–1130–35080–100030–200 Typicalore0.5–320–2430–600.5–105–101–10

Sources:BasedonBizzoetal.(2014),Calvoetal.(2016),Desjardins(2014),I¸sıldar(2016),Bizzo etal.(2014),Calvoetal.(2016),Desjardins(2014),Fornalczyketal.(2013),I¸sıldar(2016),Khaliq etal.(2014),Liu(2014),McLeod(2014),Namias(2013),NorthAmericanPalladiumLtd.(2018), Shahetal.(2014),Tickneretal.(2016),Zengetal.(2016).

Figure1.3 AveragepercentweightofsomecommonmetalsfoundinPCB,photovoltaic modules,andHDmagnets(Caldasetal.2015;Diasetal.2016,2018;Kasperetal.2011; Münchenetal.2018;MünchenandVeit2017;Petteretal.2014;Rozasetal.2017;Sant’ana etal.2013;Silvasetal.2015;Stuhlpfarreretal.2015;Yamaneetal.2011).Sources:Based onCaldasetal.(2015),Diasetal.(2016),andKasperetal.(2011).

AsdepictedinFigure1.3,photovoltaicmodulespresentahighpercentweightofa singleelement(aluminum),whileprintedcircuitboardsarecomposedofamixture ofdifferentmetals,mainlycopper,iron,aluminum,tin,zinc,andnickel.Itisestimatedthatprintedcircuitboards(PCBs)maycontainanaverageof18elementsfrom theperiodictable(Caldasetal.2015;Kasperetal.2011;Petteretal.2014;Rozas etal.2017;Sant’anaetal.2013;Silvasetal.2015;Yamaneetal.2011).Remarkably, harddiskmagnets,althoughtheymaycontainhighamountsofiron,alsopresent excitingamountsofrare-earthelements,mainlyneodymium,praseodymium,and dysprosium(MünchenandVeit2017).

Metalsthatarepresentinsmalleramountsmayalsobeeconomicallyadvantageoustoberecovered.Goldandsilverincellphones,forexample,representabout 0.06%and0.045%inweight,respectively(Caldasetal.2015;Sant’anaetal.2013). Consideringthenumberofcellphonesworldwide(Kreyenhagen2018),itcanbe estimatedthatalmost300-tongoldispresentonlyincellphonedevices.

Theaddedvalueofsuchmetalssupportstheirrecyclingeveniftheyarepresentin lowpercentweight.Photovoltaicmodules,forexample,althoughpresentlessthan 1%ofsilverintheircomposition(Figure1.3),maybeeconomicallyfeasibletobe recycled,asshowninFigure1.4.

FromFigure1.4,itbecomesevidentthattheestablishmentoffeasiblerecycling routesmaybeadvantageousforreclaimingmetalsineitherhighorlowamounts. Thisisundoubtedlychallenging,ase-wastefromdistinctoriginswouldpresent differentcompositionsandstructures.Inamicroscopicvision,metalsandother elementsmaybebondedwitheachotherinmanypossibilities,whichmayrequire differenttechniquestoachievetheirextractionandrecovery.Thus,recycling

*Prices in US$/kg from London Exchange Metals on December/19

Figure1.4 (a)Compositionofphotovoltaicmodulesillustratedaskilogramsofeachmetal perkilogramofphotovoltaicmodule.(b)Valueofeachmetalperkilogramofphotovoltaic modules.

routesmustbeversatile.Electricandelectronicequipmentareconstantlybeing improved,andtheirchemicalcompositionmaychangeboththerequiredprocess andtheobtainedmaterials.Lithium-ionbatteries(LIBs)areagoodexampleof continuousimprovement.CathodesfromLIBsaretypicallycomposedoflithium, cobalt,manganese,andnickeloxides(Blomgren2017;Zhaoetal.2019).Because cobaltisconsideredacriticalmetal,novelcathodematerialsarebeingdeveloped, suchassulfur-basedcathodes,whicheliminatetheneedforcobalt(Lietal.2018). High-efficiencyanodesarealsobeingdevelopedtoincreasetheperformanceof LIBs,suchastitanium-niobiumbasedanodesforautomotiveapplications(Takami etal.2018).Consideringthespeedoftechnologicalevolution,inafewdecadesfrom now,thecompositionofobsoletelithium-ionbatteriesmaypresentasubstantial change.

Recyclingprocessingroutesaretypicallyhydrometallurgical,pyrometallurgical, orhydro-pyrometallurgical.Eachofthempresentsbothadvantagesanddisadvantages,andallofthemmayproducetoxictailings,whichmustbeconsidered.The pyrometallurgicalrecyclingroutesconsistofseveralprocessesthat,amongothers, includesmelting,combustion,pyrolysis,moltensaltprocessing,andpyro-chemical techniques.Asfordrawbackstothepyrolysisprocess,thereisusuallythereleaseof toxicgasesandhalogenformationarisingfromfireretardantsandplasticmixtures thatcomposethewasteelectricalorelectronicequipment(WEEE)scrap.Forthe efficientrecoveryofmetals,somemodernmethods,suchasvacuumpyrolysis,the moltensaltprocess,andpyro-chemistry,appeartobepromisingcandidatesbecause oftheirinnovativesolutionsforenvironmentalissuesandrecoveryefficiency.Nevertheless,theystillneedmorescientificandtechnicalcontributionscoupledwith industrialvalidation(Zhangetal.2015).

Hydrometallurgicalprocessinginvolvesasequenceofmethodsforproducing metalsandmetalcompoundsfromaqueousmedia.Ingeneral,theprocessis composedofleachingtechniques,followedbypurificationandrecoveryofmetals, resultinginthedesiredproduct.Suchaproductmaybeeithermetalsoralloys

(b) Metal prices* per kilogram of photovoltaic modules

(a) Average weight composition of photovoltaic modules (according to Figure 1)

andcompoundscontainingthemetalsofinterest,suchasoxides(Gupta2003). Precipitation,hydrolysis,electrochemistry,conversion,complexation,solvation, andionicdissociationareoftenusedindifferentprocessingsteps.However,such routesoftenrequiretheuseofaggressiveandconcentratedreactantsforleaching steps.Thetreatmentofthegeneratedwastebelongstothedevelopmentofa hydrometallurgicalroute.Inaddition,someprocessesstillpresentlowefficiency.To solvesuchissues,thescientificcommunityiscurrentlyfocusingonthedevelopment ofless-toxicprocessingroutes,using,forexample,ionicliquids,supercriticalfluids, andorganicacids,aimingatachievingoptimumextractionrateusinggreener chemicals.

Nevertheless,anotherimportantmatteristheefficientcollectionofthedisposedof WEEEtogettorecyclingindustries.Theincitementofreversallogisticsandcircular economyconceptsmustbeimprovedandoptimizedtoachievesatisfactoryratesof recycledWEEE.Inthissense,theestablishmentofstrictlegislationandefficient managementareaswellimportant.Indevelopingcountries,forexample,WEEE recyclingisstillincipient,thereislittlelegislation,andincentivesarelow.Evenin developedcountries,thereisstillmuchtobeimproved.

Theselegislationsandprogramsareessentialtoincreaseawarenessandboost thecollectionrate.Thee-wastemanagementprogramsalsoprovidecollectiontargets,summarize,andreportthecollectionvolumes,whichhelpstounderstandthe performanceandprovidebetterplanningtoolsforthefuture.Anefficiente-waste managementprogramcouldincreasethecollectionrates,provideabetterestimationofe-wastecollection,andwouldalsoprovideabetterunderstandingofthesteps requiredtoimprovee-wastecollectionandrecyclingandthuspromotecirculareconomy.Atthesametime,ahighercollectionrateintandemwithanefficientrecycling systemthatnotonlyrecoversmetalsbutalsoprovidesasolutionforthenonmetals wouldbenecessarytoincreasethee-wastecircularity.

Therefore,itbecomesevidentthate-wasterecyclingisaninterdisciplinaryand multidisciplinarytheme,asdepictedinFigure1.5.Technical,economic,legislative,social,andenvironmentalaspectsareinvolvedthroughoutthelifecycleof all-electricandelectronicequipment,includingrecyclingaftertheirdisposal.This bookseekstoprovideanoverviewofallaspectsofasustainablefuture.

1.3Outline

Tofullyunderstandthee-waste,thisbookpresentsvarioussectionstodescribedifferentaspectsofe-waste,e-wastemanagementsystemsandinvolvedtechnologies, andotherrelateddisciplines.

Chapter2presentsanoverviewofe-wastemanagementpracticesadopted indevelopedanddevelopingcountries.Thedifferencesintheavailabilityof regulationsinacountrydirectlyimpactthefateofe-wasteinthatcountry.

InChapter3,theregulationsrelatedtothetransboundarymovementofe-waste aroundtheworldarediscussed.Theimportandexportofe-wasteisanothermajor challengeinthee-wastemanagementsystem.

Figure1.5 Multidisciplinaryaspectsofe-wasterecycling.

Variousmodelsandmethodsusedforthequantificationoftotale-wasteglobally arepresentedinChapter4.Thesuccessofane-wasterecyclingordisposalfacility dependsontheannualthroughputtoplant.

Chapter5emphasizesthematerialsusedinthemanufacturingofelectronic devices.Thedeterminationoftypeandquantityofthematerialsusedinthe manufacturingprocessdefinethetechnologiesadaptedforrecycling.

Adetailedviewofrecyclingtechnologiesusedine-wasteprocessingispresented inChapters6–10.

Chapter11presentsinsightsintothelifecycleanalysisofobsoleteelectricand electronicequipment.Thelifecycleanalysisisanessentialtoolforquantifyingthe environmentalimpactofe-waste.

Finally,thefutureofelectronicdevicesande-wasteisdiscussedinChapters12 and13,focusingoninnovativeaspectsofmanufacturingelectronicdevices,green chemistry,andcirculareconomy.

References

Aaron,J.(2019).WhyisE-wastemanagementimportantin2019?https://get-greennow.com/e-waste-management(accessed15March2021).

Alfantazi,A.M.andMoskalyk,R.R.(2003).Processingofindium:areview. Minerals Engineering 16(8):687–694.https://doi.org/10.1016/S0892-6875(03)00168-7.

AMEResearch(2018).Copper–decliningcopperoregrades.https://aus.amegroup .com/Website/FeatureArticleDetail.aspx?faId=437(accessed15March2021).

Baldé,C.P.,Forti,V.,Gray,V.,etal.(2017).TheglobalE-wastemonitor–2017. https://www.itu.int/en/ITU-D/Climate-Change/Documents/GEM2017/Global-EwasteMonitor2017.pdf(accessed15March2021).

Basov,V.(2018).Highest-gradegoldminesin2017.https://www.mining.com/highestgrade-gold-mines-2017(accessed15March2021).

Bizzo,W.,Figueiredo,R.,anddeAndrade,V.(2014).Characterizationofprintedcircuit boardsformetalandenergyrecoveryaftermillingandmechanicalseparation.

Materials 7(6):4555–4566.https://doi.org/10.3390/ma7064555.

Blomgren,G.E.(2017).Thedevelopmentandfutureoflithiumionbatteries. Journalof theElectrochemicalSociety 164(1):A5019–A5025.https://doi.org/10.1149/2 .0251701jes.

BullionStreet(2012).Electronicsindustryuses320tonsofgold,7500tonsofsilver annually.http://www.bullionstreet.com/news/electronics-industry-uses-320-tonsof-gold7500-tons-of-silver-annually/2255(accessed15March2021).

Caldas,M.P.K.,Moraes,V.T.,DeJunca,E.etal.(2015).RecuperaçãoDePrata:Estudo DeUmaRotaHidrometalúrgicarecyclingofprintedcircuitboardsaimingsilver recovery. TecnologiaEmMetalurgia,MateriaiseMineração 12:102–108.

Calvo,G.,Mudd,G.,Valero,A.,andValero,A.(2016).Decreasingoregradesinglobal metallicmining:atheoreticalissueoraglobalreality? Resources 5(4):36.https://doi .org/10.3390/resources5040036.

Carvalho,N.,Chaim,O.,Cazarini,E.,andGerolamo,M.(2018).Manufacturinginthe fourthindustrialrevolution:apositiveprospectinsustainablemanufacturing. ProcediaManufacturing 21:671–678.https://doi.org/10.1016/j.promfg.2018.02.170. Cucchiella,F.,D’Adamo,I.,LennyKoh,S.C.,andRosa,P.(2015).RecyclingofWEEEs: aneconomicassessmentofpresentandfuturee-wastestreams. Renewableand SustainableEnergyReviews 51:263–272.https://doi.org/10.1016/j.rser.2015.06.010. Desjardins,J.(2014).Globalgoldmineanddepositrankings2013.http://www .visualcapitalist.com/global-gold-mine-and-deposit-rankings-2013(accessed15 March2021).

Dias,P.,Javimczik,S.,Benevit,M.etal.(2016).RecyclingWEEE:extractionand concentrationofsilverfromwastecrystallinesiliconphotovoltaicmodules. Waste Management 57:220–225.

Dias,P.,Schmidt,L.,Gomes,L.B.etal.(2018).Recyclingwastecrystallinesilicon photovoltaicmodulesbyelectrostaticseparation. JournalofSustainableMetallurgy 4 (2):176–186.https://doi.org/10.1007/s40831-018-0173-5.

Edahbi,M.,Plante,B.,andBenzaazoua,M.(2019).Environmentalchallengesand identificationoftheknowledgegapsassociatedwithREEminewastesmanagement. JournalofCleanerProduction 212:1232–1241.https://doi.org/10.1016/j.jclepro.2018 .11.228.

Fornalczyk,A.,Willner,J.,Francuz,K.,andCebulski,J.(2013).E-wasteasasourceof valuablemetals. ArchivesofMaterialsScienceandEngineering 63(2):87–92.https:// www.researchgate.net/publication/260706030_E-waste_as_a_source_of_valuable_ metals(accessed15March2021).

Forti,V.,Baldé,C.P.,Kuehr,R.,andBel,G.(2020).GlobalE-wasteMonitor2020: Quantities,flowsandthecirculareconomypotential.https://www.itu.int/en/ITU-D/ Environment/Documents/Toolbox/GEM_2020_def.pdf(accessed15March2021). Gunn,G.(2013). CriticalMetalsHandbook,1–439.Wileyhttps://doi.org/10.1002/ 9781118755341.

Gupta,C.K.(2003). ChemicalMetallurgyPrinciplesandPractice.Wiley. I¸sıldar,A.(2016). BiologicalVersusChemicalLeachingofElectronicWasteforCopper andGoldRecovery.UniversitéParis-EstMarne-la-Valléehttps://tel.archives-ouvertes .fr/tel-01738056/document(accessed15March2021).

Kasper,A.C.,Berselli,G.B.T.,Freitas,B.D.etal.(2011).Printedwiringboardsfor mobilephones:characterizationandrecyclingofcopper. WasteManagement 31(12): 2536–2545.https://doi.org/10.1016/j.wasman.2011.08.013. Khaliq,A.,Rhamdhani,M.,Brooks,G.,andMasood,S.(2014).Metalextraction processesforelectronicwasteandexistingindustrialroutes:areviewandAustralian perspective. Resources 3(1):152–179.https://doi.org/10.3390/resources3010152. Kreyenhagen,J.(2018). WhyCateringtoMobileUsersisVitaforToday’SServices. ForbesCommunicationsCouncil.

LeBlanc,R.(2018).E-wasterecyclingfactsandfigures.https://www.thebalancesmb .com/e-waste-recycling-facts-and-figures-2878189(accessed15March2021). Lèbre,É.andCorder,G.(2015).Integratingindustrialecologythinkingintothe managementofminingwaste. Resources 4(4):765–786.https://doi.org/10.3390/ resources4040765.

Li,G.,Chen,Z.,andLu,J.(2018).Lithium-sulfurbatteriesforcommercialapplications. Chem 4(1):3–7.https://doi.org/10.1016/j.chempr.2017.12.012.

Liu,S.(2014).AnalysisofelectronicwasterecyclingintheUnitedStatesandpotential applicationinChina[ColumbiaUniversity].https://secureservercdn.net/198.71.233 .185/epm.300.myftpupload.com/wp-content/uploads/2020/10/FINAL_Shumeng_ Thesis_Dec-20_2014.pdf.

McLeod,C.(2014).Topprimarysilverminersfacingdecliningoregrades.http:// investingnews.com/daily/resource-investing/precious-metals-investing/silverinvesting/top-primary-silver-miners-facing-declining-ore-grades(accessed15March 2021).

MoneyMetalsExchange.(2018).World’slargestsilvermines:sufferfallingoregrades& risingcosts/seekingalpha.https://seekingalpha.com/article/4141630-worlds-largestsilver-mines-suffer-falling-ore-grades-and-rising-costs(accessed15March2021).

München,D.D.,Bernardes,A.M.,andVeit,H.M.(2018).Evaluationofneodymiumand praseodymiumleachingefficiencyfrompost-consumerNdFeBmagnets. Journalof SustainableMetallurgy 4(2):288–294.https://doi.org/10.1007/s40831-018-0180-6. München,D.D.andVeit,H.M.(2017).Neodymiumasthemainfeatureofpermanent magnetsfromharddiskdrives(HDDs). WasteManagement 61:372–376.https://doi .org/10.1016/j.wasman.2017.01.032.

Namias,J.(2013). TheFutureofElectronicWasteRecyclingintheUnitedStates:Obstacles andDomesticSolutions.NewYork,UnitedStates:ColumbiaUniversity. NaturalResourcesCanada(2019).Mineralsandmetalsfacts.https://www.nrcan.gc.ca/ minerals-metals-facts/20507(accessed15March2021).

NorthAmericanPalladiumLtd.(2018).NorthAmericanPalladiumcompletesanew feasibilitystudyfeaturingamajorexpansionofundergroundreserves.https://www .nap.com/investors/news-releases/news-releases-details/2018/North-AmericanPalladium-Completes-a-New-Feasibility-Study-Featuring-a-Major-Expansion-ofUnderground-Reserves/default.aspx(accessed15March2021).

Petter,P.M.H.,Veit,H.M.,andBernardes,A.M.(2014).Evaluationofgoldandsilver leachingfromprintedcircuitboardofcellphones. WasteManagement 34(2): 475–482.https://doi.org/10.1016/j.wasman.2013.10.032.

Rai,L.P.andLal,K.(2000).Indicatorsoftheinformationrevolution. Technologyin Society 22(2):221–235.https://doi.org/10.1016/S0160-791X(00)00006-3.

Rozas,E.E.,Mendes,M.A.,Nascimento,C.A.O.etal.(2017).Bioleachingofelectronic wasteusingbacteriaisolatedfromthemarinespongeHymeniacidonheliophila (Porifera). JournalofHazardousMaterials 329:120–130.https://doi.org/10.1016/j .jhazmat.2017.01.037.

Sant’ana,H.B.S.,Moura,F.J.,andVeit,H.M.(2013).CaracterizaçãoFísico-QuímicaDe PlacasDeCircuitoImpressoDeAparelhosDeTelefoneCelular. TecnologiaEm MetalurgiaMateriaiseMineração 10(3):231–238.https://doi.org/10.4322/tmm.2013 .033.

Shah,M.B.,Tipre,D.R.,andDave,S.R.(2014).Chemicalandbiologicalprocessesfor multi-metalextractionfromwasteprintedcircuitboardsofcomputersandmobile phones. WasteManagement&Research 32(11):1134–1141.https://doi.org/10.1177/ 0734242X14550021.

Silvas,F.P.C.,JiménezCorrea,M.M.,Caldas,M.P.K.etal.(2015).Printedcircuitboard recycling:physicalprocessingandcopperextractionbyselectiveleaching. Waste Management 46:503–510.https://doi.org/10.1016/J.WASMAN.2015.08.030. Stuhlpfarrer,P.,Luidold,S.,andAntrekowitsch,H.(2015).RecyclingofNd2 Fe14 B magnets. WorldofMetallurgy-ERZMETALL 68(5):278–285.

Takami,N.,Ise,K.,Harada,Y.etal.(2018).High-energy,fast-charging,long-life lithium-ionbatteriesusingTiNb2 O7 anodesforautomotiveapplications. Journalof PowerSources 396(June):429–436.https://doi.org/10.1016/j.jpowsour.2018.06.059. TheEuropeanCommission(2008).Directive2008/98/ECoftheEuropeanParliament andofthecouncilof19November2008onwasteandrepealingcertaindirectives. OfficialJournaloftheEuropeanUnion L312:3–30.https://eur-lex.europa.eu/legalcontent/EN/TXT/PDF/?uri=CELEX:32008L0098&from=EN(accessed15March 2021).

TheEuropeanUnion(2012).Directive2012/19/EUoftheEuropeanParliamentandof theCouncilofthe4July2012onwasteelectricalandelectronicequipment(WEEE). OfficialJournaloftheEuropeanUnion L(June)https://eur-lex.europa.eu/legalcontent/EN/TXT/PDF/?uri=CELEX:32012L0019&from=EN(accessed15March 2021).

Tickner,J.,Rajarao,R.,Lovric,B.etal.(2016).Measurementofgoldandothermetalsin electronicandautomotivewasteusinggammaactivationanalysis. Journalof SustainableMetallurgy 2(4):296–303.https://doi.org/10.1007/s40831-016-0051-y.

TransparencyMarketResearch.(2017).E-scrapandprintedcircuitboard(PCB)E-scrap market.https://www.transparencymarketresearch.com/e-scrap-printed-circuitboard-e-scrap-market.html(accessed15March2021).

U.S.GeologicalSurvey(2019). MineralCommoditySummaries.U.S.GeologicalSurvey https://doi.org/10.3133/70202434.

UNDepartmentofEconomicandSocialAffairs(2002).TheJohannesburgDeclaration onSustainableDevelopment.https://www.un.org/esa/sustdev/documents/WSSD_ POI_PD/English/POI_PD.htm(accessed10January2021).

UNESCO(2019). SustainableDevelopment.https://en.unesco.org/themes/educationsustainable-development/what-is-esd/sd#:~:text=Sustainable%20development%20is %20the%20overarching,to%20meet%20their%20own%20needs.%E2%80%9D (accessed10January2021).

Wahlen,C.B.(2019).UNreporthighlightsenvironmental,healthrisksfromE-waste, urgescirculareconomyshift.https://sdg.iisd.org/news/un-report-highlightsenvironmental-health-risks-from-e-waste-urges-circular-economy-shift(accessed15 March2021).

Yamane,L.H.,Moraes,V.T.,DeCrocce,D.etal.(2011).RecyclingofWEEE: characterizationofspentprintedcircuitboardsfrommobilephonesand computers. WasteManagement 31(12):2553–2558.https://doi.org/10.1016/j.wasman .2011.07.006.

Zeng,X.,Gong,R.,Chen,W.-Q.,andLi,J.(2016).Uncoveringtherecyclingpotentialof “new”WEEEinChina. EnvironmentalScience&Technology 50(3):1347–1358. https://doi.org/10.1021/acs.est.5b05446.

Zhang,S.,Ding,Y.,Liu,B.etal.(2015).Challengesinlegislation,recyclingsystemand technicalsystemofwasteelectricalandelectronicequipmentinChina. Waste Management 45:361–373.https://doi.org/10.1016/j.wasman.2015.05.015.

Zhao,T.,Ji,R.,Yang,H.etal.(2019).Distinctiveelectrochemicalperformanceofnovel Fe-basedLi-richcathodematerialpreparedbymoltensaltmethodforlithium-ion batteries. JournalofEnergyChemistry 33:37–45.https://doi.org/10.1016/j.jechem .2018.08.005.

e-WasteManagementandPracticesinDeveloped andDevelopingCountries*

PabloDias 1,2 ,AndréaM.Bernardes 2 ,andNazmulHuda 3

1 UniversityofNewSouthWales,SchoolofPhotovoltaicandRenewableEnergyEngineering,Facultyof ScienceandEngineering,229AnzacParade,Kensington,Sydney,NSW2052,Australia

2 FederalUniversityofRioGrandedoSul,EngineeringSchool,DepartmentofMaterials,Av.BentoGonçalves, 9500,PortoAlegre–RS91509-900,Brazil

3 MacquarieUniversity,SchoolofEngineering,FacultyofScienceandEngineering,BalaclavaRd,NorthRyde, NSW2109,Australia

2.1Introduction

Wasteelectricalandelectronicequipment(WEEEore-waste)isclassifiedasa solidwastewithinthehazardouswastecategory(Goel2017).E-wasteconsistsin end-of-lifeelectronicandelectricalequipment,itcomprehends–butisnotlimited to–obsolete,broken,orusedcomputers,televisions,stereos,photocopiers,printers, faxes,monitors,andmobilephones(Westcott2012).Italsocomprehendstheless notableequipmentsuchasradios,washingmachines,microwaveovens,hairdryers, andphotovoltaicpanels(EUDirective2012;Robinson2009).Moreover,theWEEE definitionalsoincludesthecomponents,subsetofparts,peripheralaccessoriesand materialsusedinthemanufacturingoftheseequipment(EUDirective2012).

Thegenerationofe-wasteappearstobehigherindevelopedcountriesthanthat indevelopingeconomies(Goel2017),buttheWEEEgenerationhasbeenincreasing inbothrealities(Schluepetal.2009).Furthermore,apositivecorrelationbetween grossdomesticproduct(GDP)ande-wastegeneratedinagivencountrywasconfirmedinarecentresearch.Interestingly,nocorrelationwasfoundbetweene-waste generationandpopulation(Kumaretal.2017).

Thecurrente-wastegenerationpatternposesoneoftheworld’sgreatestpollution problems.Ontopofthegrowinggenerationpattern,e-wasteisaparticularlyimportantwastestreambecauseofitspotentialtobepollutantsthatposearisktothe environmentandtosustainableeconomicgrowth;andthepotentialtoberesources, giventhesignificantconcentrationofpreciousmetalsandhigh-demandmaterials itcontains(Babuetal.2007;Goosey2012;SugimuraandMurakami2016).

*Received20December2019.Revised01December2020.

ElectronicWaste:RecyclingandReprocessingforaSustainableFuture, FirstEdition. EditedbyMariaE.Holuszko,AmitKumar,andDeniseC.R.Espinosa. ©2022WILEY-VCHGmbH.Published2022byWILEY-VCHGmbH.