ElectricalSubmersible PumpsManual

Design,Operations,andMaintenance

SecondEdition GaborTakacs,Ph.D

2.4.2AlternatingCurrentCircuits,AlternatingCurrentPower40 2.4.3Transformers42

2.4.4ElectricMotors44

2.4.4.1InductionMotors44

2.4.4.2PermanentMagnetMotors45 2.4.5ElectricCable47

2.5BasicsofSystemsAnalysis

3.2.1BasicFeatures57

3.2.1.1PumpPerformanceCurves59

3.2.2FloatingVersusFixedImpellerPumps65

3.2.3PumpTemperature67

3.2.4NovelPumpStageDesignandManufacturing69

3.3TheESPMotor

3.3.1Induction-TypeAsynchronousMotors72

3.3.1.1MotorConstruction72

3.3.1.2OperationalFeatures80

3.3.1.3MotorPerformance81

3.3.1.3.1MotorTesting82

3.3.1.3.2PerformanceCurves83

3.3.1.3.3StartupConditions84

3.3.1.4MotorTemperature87

3.3.1.4.1HeatTransferCalculations89

3.3.1.4.2AllowedMotorTemperature96

3.3.1.5High-PerformanceMotors97

3.3.2PermanentMagnetMotors98

3.3.2.1Introduction98

3.3.2.2MotorControllersforPermanentMagnet Motors98

3.3.2.2.1ScalarControl99

3.3.2.2.2VectorControl102

3.3.2.3ConstructionalDetails103

3.3.2.4OperationalFeatures105

3.3.2.5UltrahighSpeedPermanentMagnet MotorApplications109

3.3.2.6ComparisonwithInductionMotors111

3.3.2.7CaseStudies115

3.3.2.8Conclusions116

3.4TheProtectororSealSection 118

3.4.1MainFunctions118

3.4.2BasicOperation119

3.4.3MainParts121

3.4.3.1TheThrustBearing121

3.4.3.2IsolationChambers123

3.4.3.2.1Labyrinth-TypeChambers124

3.4.3.2.2BlockingFluids126

3.4.3.2.3Bag-TypeChambers127

3.4.3.2.4MetalBellowsTypeChambers128

4. UseofESPEquipmentinSpecialConditions

4.3.1Low-RatePumps162

4.3.2Wide-Operating-RangePumps163

4.4ProductionofGassyWells 164

4.4.1Introduction164

4.4.2Free-GasVolumeCalculations165

4.4.3PumpPerformanceDegradation172

4.4.3.1GasInterferenceinCentrifugalPumps172

4.4.3.2PerformanceCriteria175

4.4.4PossibleSolutions177

4.4.4.1UtilizationofNaturalGasSeparation177

4.4.4.1.1PumpSetBelowthe Perforations177

4.4.4.1.2UseofMotorShrouds178

Contents

5.7DesignofaPermanentMagnetMotorInstallation 297

5.7.1DesignConsiderations297

5.7.1.1SelectionofthePump297

5.7.1.2SelectionofthePermanentMagnetMotor300

5.8ComparisonofInductionMotorandPermanentMagnet MotorInstallations 304 References 305

6. AnalysisandOptimization 307

6.1Introduction 307

6.2NODALAnalysis 307

6.2.1UsingtheHead RateCoordinateSystem309

6.2.1.1Single-PhaseCases310

6.2.1.1.1ConstantPumpingSpeed312

6.2.1.1.2VariablePumpingSpeeds315

6.2.1.1.3VariableWellheadPressures316

6.2.1.2MultiphaseCases318

6.2.1.2.1CalculationModel320

6.2.1.2.2Applications323

6.2.2UsingthePressure RateCoordinateSystem327

6.2.2.1Single-PhaseCases329

6.2.2.2MultiphaseCases334

6.3DeterminationofWellInflowPerformance 336

6.3.1TheConventionalMethod336

6.3.2UseofVariable-SpeedDrives339

6.3.3CalculationofBottomholePressures341

6.3.3.1Introduction341

6.3.3.2AnnularLiquidGradients342

6.3.3.2.1StaticConditions343

6.3.3.2.2FlowingConditions344

6.4PowerEfficiencyofESPInstallations 348

6.4.1PowerFlowintheESPSystem349

6.4.2EnergyLossesandEfficiencies351

6.4.2.1HydraulicLosses352

6.4.2.1.1TubingLosses352

6.4.2.1.2BackpressureLosses353

6.4.2.1.3PumpLosses354

6.4.2.1.4PowerLossinGasSeparator354

6.4.2.2ElectricalLosses354

6.4.2.2.1MotorLosses355

6.4.2.2.2CableLosses355

6.4.2.2.3SurfaceElectricalLosses356

6.4.3SystemEfficiency356

6.5OptimizationofElectricalSubmersiblePumpOperations 360

6.5.1Introduction360

6.5.2BasicsofEconomicOptimization361 References 365

7. Operation,Monitoring,andSurveillanceofElectrical SubmersiblePumpingSystems

7.1Introduction 367

7.2GuidelinesforRunningandPulling 367

7.2.1TransportationtotheWellsite368

7.2.2EquipmentInstallation368

7.2.2.1MotorInstallation368

7.2.2.2ProtectorInstallation369

7.2.2.3PumpInstallation369

7.2.2.4ESPCableInstallation370

7.2.2.5FinalMeasures370

7.2.3RunningEquipmentintheWell370

7.2.4SystemStartup371

7.2.5PullingESPEquipment372

7.3ProductionControl 373

7.3.1Introduction373

7.3.2TheEffectsofUsingWellheadChokes374

7.3.2.1TheNeedforWellheadChokes374

7.3.2.2UseofVariable-SpeedDriveUnits377

7.3.2.3SampleCalculations378

7.4MonitoringESPOperations 383

7.4.1Introduction383

7.4.2AcousticSurveys386

7.4.3DownholeMeasurements387

7.4.3.1InstrumentsandCommunications388

7.4.3.2MeasuredParametersandTheirUse389

7.4.4SurfaceControllers390

7.4.4.1Introduction390

7.4.4.1.1Fixed-SpeedDrives390

7.4.4.1.2Variable-SpeedDrives390

7.4.4.2ESPControllerFunctions391

7.5SurveillanceofESPOperations 391

7.5.1Introduction391

7.5.2KeyChallengesandRequirementsinProduction Operations393

7.5.3TheDigitalOilfield394

7.5.3.1AnOverview394

7.5.3.2DigitalOilfield:Step-by-StepProgression396

7.5.4ESPDataVisualization398

7.5.4.1WellStatusandWellGroupStatus398

7.5.4.2AnalysisUsingDataTrendVisualization401 References 404

8. FailuresandTroubleshooting

8.1Introduction

Thispageintentionallyleftblank

PrefacetotheFirstEdition

Electricalsubmersiblepumping(ESP)istheonlykindofartificialliftingfor whichtheoriginaltimeofinventionisknownexactlyandcanbeattributedtoone man, ArmaisArutunoff. HemadehisfirstexperimentsintheBakuoilfieldsat theCaspianSeainthelate1910s,andwaslaterthefounderofthecompany “RussianElectricalDynamoofArutunoff”whoseacronym REDA isstillvery wellknownallovertheworld.Arutunoff’s(whoalonereceivedabout90patents relatedtosubmersibleequipment)pioneeringworkstartedanindustrythattoday lifts w10%oftheworld’scrudeoilproduction.

Fromtheirearlydayson,ESPunitshaveexcelledinliftingmuchgreater liquidratesthanmostoftheothertypesofartificialliftandhavefoundtheirbest useinhigh-rateonshoreandoffshoreapplications.Continuoustechnological developmentinthelastalmost100yearshasenormouslymodifiedtheapplicationrangesforESPequipment.Highgasproduction,quicklychangingliquid productionrates,viscouscrudes,etc.,conditionsonceverydetrimentaltoESP operations,arenoweasilyhandledbypresent-dayunits.Alltheseendupinthe indispensabilityofESPequipmentinthepetroleumindustrynotonlytodaybut intheforeseeablefutureaswell.

Iwrotethisbookwiththeneedsofapetroleumengineeringgraduatestudent inmindandwiththeobjectiveofcoveringallaspectsofup-to-datetheoriesand practicesinESPtechnology.Whileworkingonthemanuscript,Iusedpartsof itinindustrialshortcoursesandIalwaysconsideredthefeedbackfrom participantswhenimprovingthematerial.Thisway,Ibelieve,thetarget audienceofthebookisevenbroaderandincludespracticingengineersaswell. Throughoutthetext,workedexampleshelpreadersunderstandbasicprinciples aswellasdesignandanalysisprocedures.

Thisbook,alongwithitstwopredecessors(ModernSucker-RodPumping, PennWell,1993and GasLiftManual,PennWell,2005),concludesmycoverage ofthethreemostimportantartificialliftmethods:sucker-rodpumping,gas lifting,andsubmersiblepumping.Becausethesearetheverytechnologiesused onthemajorityofartificiallyliftedoilwells,anyonestudyingthesebookswill havereadilyavailableacompleteandup-to-dateknowledgebaseencompassing themajorartificiallifttechnologies.Isincerelyhopethatreaderswillappreciate theadvantagesofauniformapproachandtreatmentofthedifferenttopics comingfromasingleauthor.

closeto300referencescitedinthetextprovethatallsignificantcontributionsto theadvancementofourindustryweredetectedandproperlyconsidered.

Whileresearchingforthebook,Ireceivedtremendousamountsofhelpfrom toomanyindividualstoname;theircontributionsaregratefullyappreciated.

GaborTakacs,PhD Budapest,May2017

Chapter1 Introduction

1.1ARTIFICIALLIFTING

Usually,oilwellsintheearlystagesoftheirlivesflownaturallytothesurface andarecalled flowingwells.Flowingproductionmeansthatthepressureat thewellbottomissufficienttoovercomethesumofpressurelossesoccurring alongtheflowpathtotheseparator.Whenthiscriterionisnotmet,naturalflow endsandthewell dies.Thetwomainreasonsforawell’sdeathareasfollows: (1)theirflowingbottom-holepressuredropsbelowthetotalpressurelossesin thewell,or(2)pressurelossesinthewellbecomegreaterthanthebottom-hole pressureneededformovingthewellstreamtothesurface.Thefirstcaseoccurs becauseoftheremovaloffluidsfromtheundergroundreservoir;thesecond caseinvolvesanincreasingflowresistanceinthewell.Thiscanbecausedby (1)anincreaseinthedensityoftheflowingfluidasaresultofdecreasedgas productionor(2)variousmechanicalproblemssuchasasmalltubingsizeand downholerestrictions.

Artificiallifting methodsareusedtoproducefluidsfromwellsalready deadortoincreasetheproductionratefromflowingwells;severallifting mechanismsareavailabletochoosefrom.Theimportanceofartificialliftingis clearlyseenfromthetotalnumberofinstallations:accordingtooneestimate thereare w2millionoilwellsworldwideofwhichabout50%areplacedon somekindofartificiallift [1].

Onewidelyusedtypeofartificialliftmethodusesa pump setbelowthe liquidlevelinthewelltoincreasethepressuresoastoovercomethepressure lossesoccurringalongtheflowpath.Otherliftingmethodsuse compressed gas,injectedfromthesurfaceintothewelltubingtohelpliftingofwellfluids tothesurface.Althoughallartificialliftmethodscanbedistinguishedbased onthepreviousbasicmechanisms,thecustomaryclassificationissomewhat differentasdiscussedbelow.

1.1.1GasLifting

Allversionsofgasliftusehigh-pressurenaturalgasinjectedintothewellstreamatsomedownholepoint.In continuousflow gaslift,asteadyrateof gasisinjectedintothewelltubingaeratingtheliquidandthusreducingthe

http://dx.doi.org/10.1016/B978-0-12-814570-8.00001-5

FIGURE1.1 Maximumliquidproductionratesversusliftingdepthforvarioushigh-rateartificial liftmethods.

(continuousflow)canproducethegreatestamountsofliquidfromanydepth. Inallcases,liftingdepthhasaprofoundimportanceontheliquidvolume lifted,withwellratesrapidlydecreasingindeeperwells.

Fig.1.2,ontheotherhand,includesartificialliftmethodsofmoderate liquidproductioncapacity:hydraulicpumping,progressivecavitypumping, rodpumping,andplungerlifting.Inmostcases,liftingdepthnegativelyaffects theliftingcapacityoftheartificialliftingmethods.Itcanbenotedthatsuckerrodandprogressingcavitypumpsproduceverysimilarratesfromthelifting

FIGURE1.2 Maximumliquidproductionratesversusliftingdepthforvariousartificiallift methodsofmoderatecapacity.

depthrangeof3,000to6,000ft;thisfactcombinedwiththemuchlowerinvestmentandproductioncostsofPCPinstallationsexplainsthegreatpopularityofPCPapplicationsoverrodpumpingapplicationsinrecentyears.

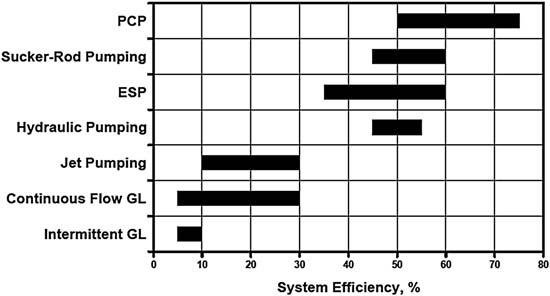

1.1.3.2SystemEfficiencies

Energyefficienciesofpresent-dayartificialliftmethodsareverydifferentas shownin Fig.1.3.Theoverallefficiencyofanartificialliftinstallationisfound fromthetotalenergyrequiredtooperatethesystemandthehydraulicpower spentonliftingthefluidstothesurface.Theefficiencyistheproductofthe individualefficienciesofthesystem’scomponents.Thedecisivepartofthe overallefficiencyisduetotheeffectivenessoftheliftingmechanism,e.g., theenergyefficiencyofthepumpused,butpowerlossesinthewellandonthe surfacecanalsohaveagreatimpactonthefinalfigure.Thebasicprerequisite forhightotalenergyefficiency,therefore,istheapplicationofahighlyefficientliftingmechanism.

Themostenergy-efficientdeviceavailableforartificialliftingistheprogressingcavitypumpthatcanbemorethan70%efficientinconverting mechanicalenergytohydraulicwork.Becausetheuseofprogressingcavity pumpsinoilwellsrequiresrelativelysimplesurfaceanddownholeinstallationswithlowlevelsofenergylossesinsystemcomponents,PCPsystemsarethemostefficientamongtheartificialliftmethods.Nowonderthat, whereverwellconditionsfallintheirapplicationranges,thenumberofPCP installationsisgrowingveryfast.

Nextintheline,asshownin Fig.1.3,aresucker-rodpumpingandESP installationswithmaximumsystemefficienciesofabout60%.Althoughsuckerrodandelectricsubmersiblepumpsalonecanhavequitehighenergyefficiencies,bothliftingmethodsareplaguedbyhighdownholelossesintheir powertransmissionsystem.Inadditiontotheselosses,freegasenteringthe