Conn's Current Therapy 2021 Rick D. Kellerman

https://ebookmass.com/product/conns-current-therapy-2021-rick-dkellerman/

ebookmass.com

TheoryandPractice

WeihuaZhang

Elsevier

Radarweg29,POBox211,1000AEAmsterdam,Netherlands

TheBoulevard,LangfordLane,Kidlington,OxfordOX51GB,UnitedKingdom

50HampshireStreet,5thFloor,Cambridge,MA02139,UnitedStates

Copyright©2020ChinaSciencePublishing&MediaLtd.PublishedbyElsevierInc.Allrightsreserved.

Nopartofthispublicationmaybereproducedortransmittedinanyformorbyanymeans,electronicor mechanical,includingphotocopying,recording,oranyinformationstorageandretrievalsystem,withoutpermission inwritingfromthepublisher.Detailsonhowtoseekpermission,furtherinformationaboutthePublisher’ s permissionspoliciesandourarrangementswithorganizationssuchastheCopyrightClearanceCenterandthe CopyrightLicensingAgency,canbefoundatourwebsite: www.elsevier.com/permissions

ThisbookandtheindividualcontributionscontainedinitareprotectedundercopyrightbythePublisher(otherthan asmaybenotedherein).

Notices

Knowledgeandbestpracticeinthis fieldareconstantlychanging.Asnewresearchandexperiencebroadenour understanding,changesinresearchmethods,professionalpractices,ormedicaltreatmentmaybecomenecessary.

Practitionersandresearchersmustalwaysrelyontheirownexperienceandknowledgeinevaluatingandusingany information,methods,compounds,orexperimentsdescribedherein.Inusingsuchinformationormethodsthey shouldbemindfuloftheirownsafetyandthesafetyofothers,includingpartiesforwhomtheyhaveaprofessional responsibility.

Tothefullestextentofthelaw,neitherthePublishernortheauthors,contributors,oreditors,assumeanyliability foranyinjuryand/ordamagetopersonsorpropertyasamatterofproductsliability,negligenceorotherwise,or fromanyuseoroperationofanymethods,products,instructions,orideascontainedinthematerialherein.

LibraryofCongressCataloging-in-PublicationData

AcatalogrecordforthisbookisavailablefromtheLibraryofCongress

BritishLibraryCataloguing-in-PublicationData

AcataloguerecordforthisbookisavailablefromtheBritishLibrary

ISBN:978-0-12-813375-0

ForinformationonallElsevierpublicationsvisitourwebsiteat https://www.elsevier.com/books-and-journals

Publisher: MatthewDeans

AcquisitionEditor: GlynJones

EditorialProjectManager: NaomiRobertson

ProductionProjectManager: SuryaNarayananJayachandran

CoverDesigner: MatthewLimbert

TypesetbyTNQTechnologies

Preface

TheauthorexperiencedtherapidgrowthofChina’spassengerrailwaysystem,hasbeen engagedinresearchonrailvehicledynamics,andintheconstructionofexperimental platformsforrailvehicledynamicsoverthepasttwodecades.AschairoftheBogie researchteam,theauthorwasinvolvedinthedevelopmentofChina’sfirsthigh-speedtrain, the ChinaStar.Since2006,theauthorhasservedasamemberofateamofexpertswho constitutetheinnovationresearchteamforChina’shigh-speedtrainsandhasbeeninvolved intheentiredevelopmentprocess:introduction,digestion,absorption,andre-innovation. Furthermore,theauthorcontributedtothedevelopmentofthe Harmony 380serieshighspeedtrainsandthe Fuxing 400seriesChinastandardhigh-speedtrains,whichsubstantially advancedinnovationinChina’shigh-speedtrains.OwingtothesehugelysignificantcontributionstotheChinahigh-speedrailway,theauthorhasbeenhonoredfivetimeswiththe NationalScienceandTechnologyAward.

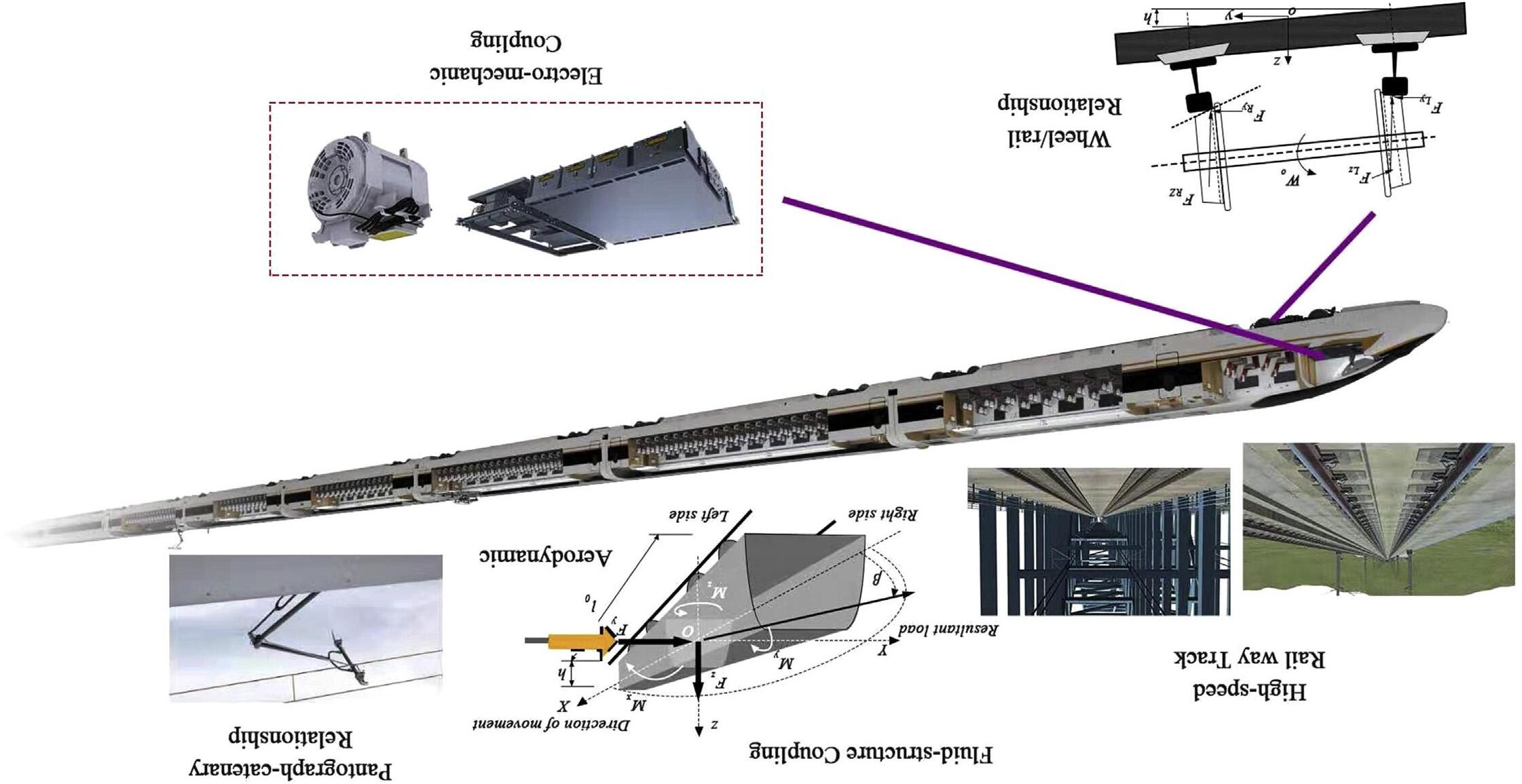

Theauthordevelopedthetheoreticalframeworkofthecoupledsystemdynamicsforthe high-speedrailwaysystem.Thistheorytreatsthehigh-speedtrainastheprimarycomponent andconsidersassociatedsub-systemsthatcouldaffectvehicledynamics(railwaytracks, airflow,powersupplysystem,pantograph,andoverheadcatenarysystem)toachieveglobal optimizationofthehigh-speedrailwaysystem.Thecoupledsystemdynamicsofhigh-speed trainsservesasanessentialtheoreticalframeworkforthelife-cycledynamicsresearchand testsystemforthedesign,manufacture,utilization,andmaintenanceofhigh-speedtrains. Furthermore,theauthordevelopedacyclicvariable-basedintegrationmethodthatacceleratesmodelingandcalculationefficiencyforalong-rangetrainsystem.Aslidingwindow methodwasproposedforthecoupledvehicle/trackdynamicmodel,enablingthecoupled systemdynamicmodelofhigh-speedtrainstosimulateatrainoperatingonatrackof infinitelength.Thearcduetocontactlossanditsassociatedarcforcearisingfromthe pantograph-catenaryinteractionundervibrationconditionswerealsoformulated.Basedon therelaxationfactorandequilibriumstate,anumericalsimulationmethodforfluid-structure couplinginahigh-speedtrainsystemwasdeveloped;itsubstantiallyimprovescalculation stabilityandefficiency.

Theauthoralsoheadedtheconstructionofadigitalsimulationplatform,abasicresearch andexperimentationplatform,andaserviceperformanceresearchandexperimentation platformforhigh-speedtrainsystems.Theseresearchplatformshavebecomethemost importantelementsofthelife-cycledynamicsresearchandtestsystemforhigh-speedtrains

andserveasthefoundationfortheestablishmentandverificationofthecoupledsystem dynamicmodelofhigh-speedtrains.Thisfurtherfacilitatestheapplicationofthecoupled systemdynamicmodelofhigh-speedtrainsininnovationresearchontheChinahigh-speed railwayandmakesthecoupledsystemdynamicmodelasignificantnoveltyofthe BeijingShanghaihigh-speedrailwayproject thatwontheNationalScience&TechnologyProgress Award(specialclass).

Thisbookisbasedontheauthor’spreviousbook TheoryandPracticeoftheDynamicsof CoupledSystemsofHigh-SpeedTrain publishedbyChinaSciencePressin2013,andthe author’srecentachievements.Throughoutthisjourney,theauthorreceivedconsiderable supportandhelp.Theauthorwouldliketoexpresssincereappreciationtohisdoctoral supervisor,ProfessorShenZhiyun,anacademicianattheChineseAcademyofSciences (CAS)andtheChineseAcademyofEngineering(CAE),whoconsistentlyencouragedthe authortoexplorethetheoryofdynamicsofcoupledsystemsofhigh-speedtrains.The authoralsothankscolleaguesattheStateKeyLaboratoryofTractionPowerfortheiractive cooperationandsupportthatensuredthefullcompletionofthelife-cycledynamicsresearch andtestsystemforhigh-speedtraindesign,manufacture,utilization,andmaintenance processes.Theauthorwouldalsoliketothankallteachersandgraduatestudentswho participatedinhisvariousscientificresearchprojects;theirresearchachievementsgreatly enrichthisbook.Finally,theauthorthankshisstudents,andteachersfromtheSchoolof ForeignLanguagesofSouthwestJiaotongUniversity,fortheirhardworkontheEnglish versionofthisbook.

Becausethetheoryofdynamicsofcoupledsystemsofhigh-speedtrainshasbeenproposed onlyrecently,itstheoreticalframeworkforthelife-cycledynamicsresearchandtestsystem ofhigh-speedtraindesign,manufacture,utilization,andmaintenancethusneedsfurther improvementinpractice.Owingtotheauthor’slimitedknowledgeontractionpowersupply andtractiondrive,andsomerelatedresearchesstillbeingunderinvestigation,thisbook,to somedegree,isnotquitesystematicanditscontentisincomplete.Hopefully,itwillbe graduallyimprovedinthecomingyears.Yoursuggestionsandcorrectionswillbehighly appreciated.

WeihuaZhang 19th September2018

Chengdu,SichuanProvince,China

Introduction

ChapterOutline

1.1DevelopmentandtechnicalfeaturesoftheChinahigh-speedrailway4

1.1.1DevelopmentoftheChinahigh-speedrailway4

1.1.2Chinahigh-speedrailwaytechnologies7

1.1.2.1Railwayline7

1.1.2.2Railwaytrack7

1.1.2.3Tunnel8

1.1.2.4Traincontrolsystem8

1.1.2.5Powersupplysystem9

1.1.3DevelopmentoftheChinahigh-speedtrain9

1.1.3.1Differentheadformsintheleadandtailcars11

1.1.3.2Smallaerodynamicresistanceonthecarbody12

1.1.3.3Largerwheelbaseinbogie13

1.1.3.4Hightractionpower13

1.1.3.5Developmentofanewnetwork13

1.1.3.6Applicationofnewmaterials13

1.2Literaturereviewofrailwaydynamics14

1.2.1Vehiclesystemdynamics14

1.2.1.1Huntingstability14

1.2.1.2Curvingdynamicperformance16

1.2.1.3Ridecomfort17

1.2.2Trainsystemdynamics19

1.2.2.1Longitudinaldynamicmodel20

1.2.2.2Lateraldynamicmodel21

1.2.2.3Verticaldynamicmodel22

1.2.3Tracksystemdynamics26

1.2.4Trainaerodynamics29

1.2.4.1Trainaerodynamicsinthepresenceofenvironmentalwind29

1.2.4.2Traincrossingaerodynamics31

1.2.4.3Traintunnelaerodynamics31

1.2.5Pantograph-catenarysystemdynamics33

1.3Thenecessityofstudyingthehigh-speedtraincouplingsystem37

1.3.1Particularityoftherailwaysystem37

(1)Scaleeffect37

(2)Timeeffect37

(3)Spatialeffect37

1.3.2Dynamicproblemsinthehigh-speedrailway37

1.3.2.1Huntingstability38

1.3.2.2Systemvibration38

1.3.2.3Pantograph-catenaryvibration39

1.3.2.4Aerodynamicdisturbance40

1.4Researchoncouplingsystemdynamicsofthehigh-speedtrain41

1.4.1Researchonvehiclesystemdynamics41

1.4.1.1Huntingstability41

1.4.1.2Runningsafety42

1.4.1.3Ridecomfort42

1.4.2Researchoncouplingrelationship42

1.4.2.1Wheel-railcontactrelationship43

1.4.2.2Pantograph-catenarycouplingrelationship43

1.4.2.3Fluid-structurecouplingrelationship43

1.4.2.4Electro-mechanicalcouplingrelationship44

References44

Thehigh-speedrailwayistheproductofoverhalfacenturyofcontinuousdevelopment, andmorethan37,000kmofhigh-speedrailwaylineshavebeenbuiltaroundtheworld. Presently,EuropeandAsia,characterizedbyGerman,French,Japanese,andChinese technologies,havebecometheepicenterofthehigh-speedrailway[1 27].Althoughthese technologysystemshavedifferentdesignphilosophies,eachone exploresnewdesign technology toachievefaster,safer,andmorecomfortablehigh-speedtrains.Thus,highly advancedandefficientmanufacturingtechnologiestogetherwithavastamountof operationalexperiencehavebeenemployedtodevelopnewhigh-speedrailwaysystems.

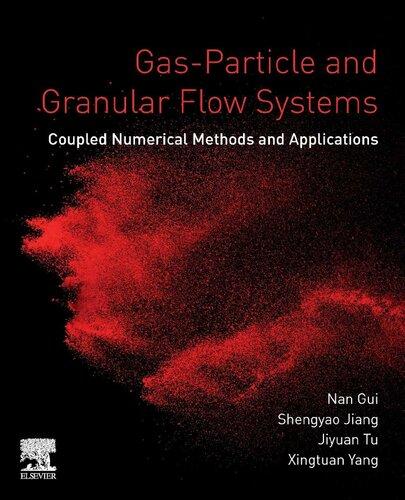

Asthecoreofthehigh-speedrailway,thehigh-speedtrainsystemconsistsofnotonlythe high-speedtrainbutalsothehigh-speedrailwaytrack,overheadcatenarysystem(power supplysystem),communicationssystem,andothersubsystems,asshowninFig.1.1.

Consideringthetractionmodeadopted,thehigh-speedtraincanbefurtherclassifiedasa concentratedpowertrainordistributedpowertrain.Owingtotheuniqueadvantagesof thesetractionmodes,bothtypesofhigh-speedtrainarewidelyusedacrosstheworld.The high-speedrailwaytracktechnologyalsoconstitutesoneoftheessentialcomponentsof thehigh-speedtrainsystem.Therearetwotypesoftracksystems:ballastedtrackandslab track.Theballastedtrackischaracterizedbylownoiseemission,andtheslabtrackiswell knownforitsrelativelysmalltrackirregularitiescomparedwiththeballastedtrack.

Designersofrailwaytracksmustbalancethetrade-offbetweenbothtracksystemsto achieveoptimaldynamicperformanceforthevehicleandtracksystems.Dependingonthe suspensiontype,thehigh-speedoverheadcatenarysystemcanbeclassifiedintosimple catenarysystem,stitchedcatenarysystem,andcompoundcatenarysystem.Considerable effortinvolvingtheoptimizationofcatenaryparametershasbeenmadetofurtherimprove thecurrentcollectionperformanceofdifferentcatenarysystems.

Figure1.1 High-speedtrainsystem.

1.1DevelopmentandtechnicalfeaturesoftheChinahigh-speedrailway 1.1.1DevelopmentoftheChinahigh-speedrailway

OnAugust16th,1999constructionbeganonChina’sfirsthigh-speedrailwayline,andthe 404kmQinhuangdao-ShenyanglinewascompletedonOctober12th,2003.ThishighspeedrailwayprojectwasdesignedandconstructedentirelybyChineserailwaydesigners andengineers.Thetopspeedwas200km/h,withareservecapacityof250km/h.

Intheprecedingdecades,thelowoperatingspeedandlimitedraillinesoftheChina railwaysystem,whichwasthemaindriveroftheChineseeconomy,hadseverelylimited thedevelopmentofChina’seconomyandthegrowthofitsmasstransitsystemforalong time.Inthetwenty-firstcentury,anagreementwasreachedbytheChinesegovernmentto developahigh-speedrailwaysystem,andamedium-longtermrailwaynetworkplanwas published.Theplanwasfortheraillinesofthehigh-speedrailwaywithdesignspeedsof 200km/hormoretobelongerthan12,000kmby2020[28].In2008,thisgoalwas adjustedto18,000kmwiththeapprovaloftheChinaStateCouncil.Thisincluded approvalforthe FourverticalsandFourhorizontals railwaynetworkandthreeintercity railwaylinesontheYangtzeRiverDelta,PearlRiverDelta,andCircum-Bohai-Sea[29]. Thesetogetherformanextensivehigh-speedrailwaynetwork.The Fourverticalsand Fourhorizontals high-speedrailwaynetworkconsistsof:

Fourverticalrailwaylinesrunningnorthtosouth:

Beijing-Shanghaihigh-speedrailwaylineorBeijing-Shanghairailwayline,BeijingWuhan-Guangzhou-Shenzhen(HongKong)high-speedrailwaylineorBeijing-Hongkong railwayline,Beijing-Shenyang-Harbin(Dalian)high-speedrailwaylineorBeijing-Harbin high-speedrailwayline,andShanghai-Hangzhou-Ningbo-Fuzhou-Shenzhenhigh-speed railwayline apassengerrailwaylineinChina’ssoutheastcoastalareas.

Fourhorizontalrailwaylinesrunningeasttowest:

Qingdao-Shijiazhuang-Taiyuanhigh-speedrailwaylineorQingdao-Taiyuanrailwayline, Xuzhou-Zhengzhou-Lanzhouhigh-speedrailwaylineorXuzhou-Lanzhourailwayline, Shanghai-Nanjing-Wuhan-Chongqing-Chengduhigh-speedrailwaylineor Shanghai-Wuhan-Chengdurailwayline,Shanghai-Hangzhou-Nanchang-ChangshaKunminghigh-speedrailwaylineorShanghai-Kunmingrailwayline.

OnJune29th,2016,theChinaStateCouncilannouncedaplantoexpandthealmost complete FourverticalsandFourhorizontals networktotheEightverticalsandEight horizontalsnetwork(showninFig.1.2),basedontheplanofthe FourverticalsandFour horizontals.Thenewplanconsiderspassengerflows,reasonablestandards,andother requirementsfortheexpansion.

Figure1.2

Medium-longtermplanfortheChinahigh-speedrailwaynetwork.

Thisplanaimstodevelopahigherstandardhigh-speedrailwaynetworkby2030,andthe EightverticalsandEighthorizontals railwaynetworkisthemaincorridorofthishighspeedrailwaynetworkwhileotherregionalandintercityrailwaylinessupplementthe maincorridor.Theplanalsospecifiestheconstructionstandardsforthehigh-speed railwaynetwork.

Thenewhigh-speedrailwaylinewillusestandardswithdesignspeedsof250km/hor higher(alowerstandardmaybeusedinsomeareasduetocomplexgeologicalorclimate conditions).Therailwaylinespassingthroughareaswithdensepopulation,built-upareas, andbigcitieswillusestandardswithdesignspeedsof350km/h,whileregionalrailway

lineswillusestandardswithspeedsof250km/horlower,andthedesignspeedofintercityrailwaylineswouldnotexceed200km/h.

The Eightverticals high-speedrailwaynetworkconsistsof:

TheCoastalline,Beijing-Shanghailine,Beijing-HongKong(Taiwan)line,BeijingHarbin-Beijing-HongKong-Macauline,Hohhot-Nanningline,Beijing-Kunmingline, Baotou(Yinchuan)-Haikouline,andLanzhou(Xi’an)Guangzhouline.

The Eighthorizontals high-speedrailwaynetworkconsistsof:

TheSufenhe-Manzhouliline,Beijing-Lanzhouline,Qinghai-Yinchuanline,Europe-Asia transportationline,therailwaylinealongtheYangtzeRiver,theShanghai-Kunmingline, Xiamen-Chongqingline,andGuangzhou-Kunmingline.

Basedonthe EightverticalsandEighthorizontals railwaynetwork,furtherexpansionis plannedforregionalrailwaylinestoincreasethecoverageofthehigh-speedrailway system.Bothhigh-speedandconventionalrailwaysystemsaresupported.

By2017,2,985high-speedtrainshadbeenmanufacturedbytheChinaRailwayRolling StockCorporation(CRRC)withover5,200high-speedtrainsoperatingontheChinahighspeedrailwaynetworkdaily.Thetotalrouteofthehigh-speedrailwayraillinesthatwere

Figure1.3 Ahigh-speedrailwayviaductinChina.

putintooperationalreadyexceeded25,000kmandcouldbeextendedto30,000kmby 2020.ThismakesChinathecountrywiththemosthigh-speedtrainsandthegreatest lengthofhigh-speedrailwaylines.The1,318kmJinHuhigh-speedrailwaylineis characterizedbythehighestdesignstandardsintheworld.Ithasatypicalslabtrack designthatallowsforanoperatingspeedof350km/h,with86.5%ofthelineconstructed asaviaductforsuperiortrackquality.

1.1.2Chinahigh-speedrailwaytechnologies

1.1.2.1Railwayline

InChina,mosthigh-speedrailwaysareconstructedasdoubletracks.Forhigh-speed railwaylineswithdesignspeedsof300km/handabove,thetrackspacingis5m,the trackgradientislessthan2%,andtheminimumcurveradiusis7,000m.Therailway viaduct,asshowninFigure1.3,iswidelyusedinhigh-speedrailwaystomaintaintrack irregularitiesatarelativelylowleveltoavoidtracksettlement,whichcouldbecausedby riversandgullies.Furthermore,therailwaydesignmustalsoconsidertheeffectsofthe horizontalandverticalalignmentoftherailwaylinetogetridoftheverticalvibration arisingfromthetrackdesign.

1.1.2.2Railwaytrack

Becauseofthecharacteristicsoflow-levelirregularities,theslabtrackiswidelyusedin theChinahigh-speedrailway.Theslabtracktechnology,however,wasinitiallyimported fromothercountriesduetolackofmanufacturingtechnologyfortrackslabsinChina.In September2004,a13.16kmtestslabtrackbuiltusingChinesetechnologyforthefirst timewasappliedtotheSuining-Chongqingrailwayline.In2007,afieldtestataspeedof 232km/hdemonstratedthattheperformanceofthistestslabtrackmeetsdesignstandards.

Todevelopa350km/hhigh-speedrailway,Chinaimportedadditionalslabtracksfrom Germancompanies,suchasMaxBogl,RAIL.ONE,andZublin.Beijing-Tianjinand Beijing-Shanghaihigh-speedrailwaylinesusetheMaxBo ¨ gltrackslab,WuhanGuangzhourailwaylineusestheRheda2000slabtrackprovidedbyRAIL.ONE,while Zhengzhou-XianrailwaylineusesZublintechnology.TheHarbin-Dalianrailwaylineuses JapaneseShinkanshenslabtracktechnology.InChina,slabtracksarefurtherclassified intofourtypesbasedondifferentiatingcharacteristics:ChinaRailwayTrackSystemtype-I (CRTSI),CRTSII,CRTSIIdual-blocktype,andCRTSIII.Theslabtrackbasedon JapaneseShinkanshentechnologyisclassifiedasCRTSI.CRTSIIandCRTSIIdualblocktypeslabtracksareslabtracksfromMaxBo ¨ glandRAIL.ONE,respectively.New slabtracksdesignedbytheChineserailwaycompanyinNovember2009aredesignated CRTSIIIandhavebeensuccessfullyappliedontheChengdu-Dujiangyanhigh-speed railwayline.

Basedonover20,000kmofoperatingexperienceandexperimentaldatafromdifferent typesofrailwaytracks,Chinaispresentlyabletodesign,manufacture,construct,and maintaindifferentrailwaytracks,andpossessesanunderstandingofthepropertiesofthe differentslabtracks,whichhasledtoasystematicincreaseinthedesignstandardsofthe Chinahigh-speedrailway.

Toreducetheinfluenceoftrackirregularitiesunderhigh-speedconditions,Chinafurther improvedtrackconstructionstandardstoreducetrackirregularities.Inadditiontoseamless railtechnology,significantefforthasbeenmadetoreducetolerancesinthemanufacturing andinstallationprocedures.Themanufacturingprecisionfortrackslabsis0.1mm,and allowabletolerancefortrackgaugeis þ/-1mm.Tolerancesinheight,torsionaldirection, andtrackdirectionarelessthan2mm,whileonlya1mmdeviationisallowedinthe horizontaldirection.Thematerial,U71MnK,isusedtomanufacturerailswithalengthof 100musingarollingprocedure.High-speedturnoutsarealsoemployedinhigh-speed railwaystoachievethehighspeeds,whichallowthetrainpassthroughtheturnoutata speedof350km/hfromthefacingdirectionandat120 250km/hfromthecurveside.

1.1.2.3Tunnel

InChina,thetunnelcross-sectionofmostpre-existingrailwaylinesisabout64m2. Becausethesectionareaoftunneldirectlyimpactsthevehicle’sairresistanceandair tightness,thetunnelsectionareaoftheChinahigh-speedrailwayismuchhigherat100m2. Furthermore,buffer-structuredentrancesandassistanttunnelwellsarebuilttoimprovethe aerodynamicperformanceofhigh-speedtrains.

1.1.2.4Traincontrolsystem

TheChinahigh-speedrailwaynetworkischaracterizednotonlybyitshighspeedsbut alsobythehigh-densityregionsitconnects.Thiscombinationmakesthehigh-speedtrain aviabletopchoiceforpublictransportation.AttherequestoftheChinahigh-speed railway,theChinesetraincontrolsystem(CTCS)wasdevelopedforbettercontrolof railwayoperations.IntheCTCS-2system,thetransponderandrailwaysignaltransmission systemsenablethedrivertooperatethetrainatspeedsof200 250km/h.TheCTCS-3 systemisbasedonawirelesssignaltransmissionsystemandpermitsthedrivertooperate thetrainatfurtherspeedsof300 350km/h.

Fromtheviewpointofcompatibility,theCTCS-3traincontrolsystemcanbe superimposedontotheCTCS-2traincontrolsystem,andtheCTCS-2canactasabackup systemfortheCTCS-3traincontrolsystem.Whentheradioblockcenterorwireless communicationfails,theCTCS-2traincontrolsystemcantakecontrolofthetrainin placeoftheCTCS-3controlsystem.DuetotheadvancedperformanceoftheCTCStrain controlsystem,theminimumoperatingintervalofaChinahigh-speedtrainis3minandis generallyabout5mininpractice.

1.1.2.5Powersupplysystem

ThepowersupplysystemoftheChinarailwaysystemisasingle-phasealternatingcurrent of27.5kV/50Hz,andthepowersupplymodeisAT(auto-transformer)witha50kmlong supplyarm.Thetraditionaloverheadcatenarysystemisthesimplecatenarysystem,which isalsoemployedintheBeijing-Tianjinintercityrailwayline,withadesignspeedof 350km/h.Tofurtherimprovethecurrentcollectionperformanceofthepantographcatenarysystem,especiallythatofthedouble-pantographataspeedof350km/h,the Chinahigh-speedrailwayadoptedthestitchedcatenarysystemwithatensileforceof30 kNinthecontactwire.

1.1.3DevelopmentoftheChinahigh-speedtrain

ResearchforthedevelopmentoftheChinahigh-speedtrainbeganattheendofthe previouscenturyandreachedfruitionwhenthefirstindependentlydevelopedhigh-speed train, ChinaStar (SeeFig.1.4),wasdevelopedbytheChinaRailwayCorporationatthe beginningofthiscentury.The ChinaStar isapower-concentratedtrainwithadesign speedof270km/h,whichemploysanACdrivesystemand2M9Tmarshalingandhasa capacityof726passengers.InafieldtestonNovember27th,2002,the ChinaStar electric multipleunit(EMU)reachedthehighestoperatingspeedonChineserailwayat321.5km/h.

Forhigherspeedsandmoreadvancedhigh-speedtraintechnology,theChinaState Councilproposedaguideline“introducingadvancedtechnology,jointdesignand manufacturing,andbuildingtheChinabrand.”Accordingly,theMinistryofRailway implementedaprojectforhigh-speedtrain“introduction,mastering,assimilation,and reinvention.”In2004,ChinaRailwayimported200km/hhigh-speedtrainsfromAlstom, Bombardier,andKawasaki,anda300km/hhigh-speedtrainfromSiemensin2006.

Figure1.4

The ChinaStar high-speedtrain.

“CR”Chinastandardhigh-speedtrain.

Therequirementsforhigh-speedrailways,suchaslongdistance,largecapacity,high density,andshorttraveltime,presentsignificantchallengestothedesign,manufacture, operation,andmaintenanceofthehigh-speedtrain.Tolocalizetheintroducedhigh-speed trainsanddevelopChina’sownhigh-speedtraintechnology,mostoftheresearchinstitutes wereconvenedtoinvestigatethecriticaltechnologiesinhigh-speedtrains:system integration,carbody,bogie,tractiontransformer,tractionconverter,tractionmotor, tractioncontrol,traincontrolnetworksystem,andbrakingsystem.Furthermore,ten supplementarytechnologieswerealsoconsidered:airconditionsystem,dejectaxcollecting device,door,window,windshield,couplerandbuffer,pantograph,powersupplysystem, interiordecoration,andseat.

Throughinnovativeresearchandthemasteringandassimilationofimportedtechnologies, thehigh-speedtrainhasbeensuccessfullylocalizedandsubjectedtofurtherself-sustaining innovation.Currently,twospeedseries,twobrands,andtentypesofhigh-speedtrains havebeendeveloped.Thetwospeedseriesarethe300 350km/hseriesandthe 200 250km/hseries.Eightofthetentypesofhigh-speedtrainsareoftheChinaRailway High-speed(CRH)brandwhiletwotypesareoftheChinaRailway(CR)brand.Underthe CRHbrandaretheCRH1producedjointlywithBombardierinChina,CRH2builtwith Kawasakitechnology,theCHR3(Siemenstechnology),CRH5(Alstomtechnology), CRH6(independentinnovation),andthenewgenerationofhigh-speedtrainsCRH380A, CRH380B,andCRH380D(jointlyproducedwithBombardierinChina).TheCRbrand representsChinastandardhigh-speedtrainCR400AFandCR400BF,asshownFigure1.5. Thefollowingillustratessomeofthetechnicalfeaturesandparametersofahigh-speed testtrainforhigherspeeds.ThistrainwasdevelopedindependentlybyCRRCQingdao

Figure1.5

SifangCo.Ltd.drawingonforward-looking,fundamental,andtheoreticalresearchwitha viewonsafetyandreliabilityundermuchhigherspeedconditions.Theprimarypurpose focusesonthreeobjectives:

(1)Toprovideatechnicalplatformforhigh-speedtrainsafetystudiesbecauserunning safetyisadeterminingfactorinthedevelopmentofhigh-speedtraintechnology.Thus, thetechnicalplatformisexpectedtoimprovethesafetymarginthroughtheexplorationofrunningstability,structuralstrength,train-tracknetworkmatchingrelationships, andothersafetysystemsforhigh-speedtrainsunderhigherspeedconditions,tocreate improvedguidelinesforhigh-speedtrainapplications.

(2)Toprovideatestplatformforfundamentalresearch.Withahigh-speedtesttrainfor higherspeeds,forward-looking,fundamental,andtheoreticalresearchonhigh-speed trainscanbeconductedwithinabroaderandhigherspeedrangethatcanrevealtrain dynamicbehaviorsunderhigh-speedconditions.Furthermore,suchstudieswill strengthentheindustry-universityresearchcollaboration,therebycreatingasustainable environmentforinnovation.

(3)Toprovideanapplicationandverificationplatformfornewmaterialsandnewtechnologies.Thehigh-speedtraintechnologysystemcanbeimprovedthroughresearchon variousnewmaterialsandtechnologies.Thepurposeofthisplatformistoensurethe sustainabledevelopmentofChina’shigh-speedtraintechnology,acceleratethetraining ofdesignteams,andimprovethestandardizingsystem.

The500km/htesttrainforhigherspeedsisbasedonindependent,innovativeproductsin thenewgenerationCRHhigh-speedtrain.Improvingthecriticalspeedandtractionofthe vehicle,incombinationwithlowerresistanceanddedicatedresearcheffortonsystem integration,headform,thecarbody,bogie,traction,braking,andothersystemshave contributedtotheachievementofoperationalsafetyandreliabilityathigherspeeds.The maintechnicalparametersofthistrainaresummarizedinTable1.1.

Maintechnicalfeatures:

1.1.3.1Differentheadformsintheleadandtailcars

Toachieve500km/htestspeed,theaerodynamicresistanceoftheleadcarandthe aerodynamicliftforceofthetailcarmustbereduced.Thus,differentheadformsare designedfortheleadandtailcars.Theheadformoftheleadcarisshapedlikea sword, whilethetailcarisshapedmorelikea rocket.Theheadformofthetailcarwasdesigned basedonapre-existingCRHtraincharacterizedbygoodaerodynamicperformance,while thesword-shapedleadcarisacompletelynewdesignwithlowerairresistanceandlateral force.BothleadandtailcarsareillustratedinFig.1.6[30].

Table1.1: Maintechnicalparametersofthe500km/hCRHhigh-speedtrain.

ParametersValue

Marshallingtypesixmotorvehicles

Operatingspeed400km/h

Testspeedontrack 500km/h

ControldeviceIGBTwater-cooledVVVF

BrakingmethodRegenerationbraking,direct-throughtype electricpneumaticbraking TrainnetworkIndustrialEthernet Powersupplymode25kv/50HzAC,powersupplyofaerialcable

Carlength153.5m

Headcarlength27/26.5m(differentheadforms) Middlecarlength25m

Widthofcarbody2950mm Carheight3650mm(newwheel,excludingpantograph)

Lengthbetweentwotruck centers 17,500mm

BogieBolsterlessbogiewithairspring Wheelbase2,800mm

Wheeldiameter920/860mm

Trackgauge1,435mm

Maximumaxleload15t

Tractionpower22,800kW(test)

Shaftpower950kW(test)

Testtrainforhigherspeeds.(A)Leadcarofthetesttrain(B)Tailcarofthetesttrain.

1.1.3.2Smallaerodynamicresistanceonthecarbody

Toreduceairresistanceandlateralaerodynamicforce,thesectionofthecarbodyis furtheroptimized.Thewidthofthecarbodyisreducedto2,950mmfrom3,380mmused inCRH380A,andtheheightofthecarbodyisdecreasedto3,650mmfrom3,700mm.

Tail car of the test train

Lead car of the test train

Figure1.6

Furthermore,theradiusoftheroofofthecarbodyisincreasedtoincreasethestiffnessof thecarbodyandreducethelateralaerodynamicforceonit.

1.1.3.3Largerwheelbaseinbogie

Toincreasethecriticalspeedofthetrainanditscompatibilitywithahigh-powermotor, thewheelbaseisincreasedto2,800mmfrom2,500mmusedintheCRH380A.The bogieisofabolsterlessdesignandisequippedwithananti-rollbarandanairspring system.Ayawdamperemploysaredundancydesigntoenhancestabilityanddampingin thebogie.Thisresultsinaveryhighcriticalspeedof750km/hforthehigh-speedtest trainforhigherspeeds,whichcaneffectivelyensuredynamicperformanceofthistrainat 500km/h.

1.1.3.4Hightractionpower

Toovercomeairresistanceunderhigh-speedconditions,thetractionpowerofthetrainis enhanced,inadditiontoreducethesectionareaofthecarbodyandheadform optimization.Thetractionpowerofeachaxleofthetesttrainreaches950kW,whichis thehighesttractionpowerofallhigh-speedtrains.

1.1.3.5Developmentofanewnetwork

ThetesttrainemploysanewnetworksystemdevelopedbyCRRCZhuzhouInstituteCo. ThisnetworksystemisbasedonindustrialEthernettechnology,whichpermitsaveryhigh informationtransmissioncapacityforthetrain’soperating,control,andsafetyinformation. Meanwhile,anetworksystemforthetestisalsoinstalledonthetraintosynchronously acquiretheexperimentaldata.

1.1.3.6Applicationofnewmaterials

Apartfromthenewtechnologiesinthenetworkandtheairresistancebrakingsystem, severalnewmaterials,suchascarbonfiber,magnesiumalloy,andnovelnanometer soundproofinghavebeenemployedinthedesignoftesttrain.

ThroughareviewofcriticaltechnologiesinFrench,German,Chinese,andJapanesehighspeedrailways,itcanbeconcludedthatthesetechnicalsystemshavetheirownunique characteristicsinthehigh-speedtrainorthehigh-speedrailwaylinethatmakesthe railwaysystemmorediverseandalsoculminatesinextensivedesignexperience.Highspeedrailwaytechnologyconsistsofnotonlyhigh-speedtraintechnology,high-speed tracktechnology,andhigh-speedoverheadcatenarytechnology,butalsothecoupling technologiesamongthesubsystems.Thehigheroperatingspeedisexpectedtointroduce strongercouplingeffectsonthetrain-track-tunnel-catenary-aerodynamicsystem environment.Thedesignofthesubsystemsthusmustconsiderthecouplingloadsarising fromthesecouplingsystems.Thelow-costtunnelsinJapanfacesignificantchallengesto

high-speedoperationbecausethesectionareaissmall evenwiththebuffersectionnear thetunnelentrancetakenintoconsideration.Thisisevidentfromthelongitudinalimpact arisingfromairresistanceandairpressurefluctuationwhenthetrainentersthetunnel. TheballastedtrackusedinFranceischaracterizedbylowconstructioncostandcan effectivelyabsorbwheel-railnoise(2 3dB).However,fromalong-termviewpoint, ballastimpactandtracksettlementmayaffectthetrain’sdynamicperformanceandthe reliabilityofequipmentunderthecarbody.

Inthelasthalf-century,railwaytechnologiesrelatedtovehicledynamics,trackdynamics, pantographdynamics,andaerodynamicshaveadvancedsignificantly.Underhigh-speed conditions,however,thecouplingeffectsamongtheseelementsbecomemuchmore criticalandinevitablyconstitutesatremendouschallengetohigh-speedrailwaydesign.

1.2Literaturereviewofrailwaydynamics

Apartfromthetraditionalvibrationproblemsinthemechanicalsystem,thehigh-speed trainisalsosubjecttothestabilityproblem.Themechanicalsysteminthehigh-speed trainhasmuchmorecomplexthanthetraditionalmechanicalsystem.Whenthetrain operatesonthetrack,lossofstabilitycouldoccurduetodisturbancesarisingfromthe track,airflow,andotherexternalexcitations.Theinstabilitycouldalsoaffectother subsystems.Therefore,thedynamicsorvibrationproblemsinthesubsystemsofhighspeedtrainsarealsoquiteimportant,althoughthedynamicsofthehigh-speedtrainisat thecoreofrailwaydynamics.Thedynamicsoftherailwaysystemmainlyincludesvehicle systemdynamicsortrainsystemdynamics,tracksystemdynamics,vehicle-trackcoupling dynamics,trainaerodynamics,andpantograph-catenarysystemdynamics.Onthe dynamicsofthehigh-speedtrain,acouplingsystemdynamicsofthehigh-speedtrain basedonthedynamicsofeachsubsystemwasproposedbytheauthor[31].

1.2.1Vehiclesystemdynamics

Vehiclesystemdynamics,takingtherailvehicleastheresearchobject,ismainly dedicatedtostudyingtherelationshipbetweenthevehicleandexternalexcitations.The primarypurposeisthustounderstandthedynamicbehaviorsoftherailvehicleandsome specialdynamicphenomenaduringoperation,suchashuntingstability,curvingdynamic performance,andridecomfort.

1.2.1.1Huntingstability

TheearliestdefinitionofstabilitywasgivenbyTorricelliinthe17thcentury,whileamore precisedefinitionwasgivenbyLyapunovin1892[32].Stabilitycanbefurtherclassified intostaticstabilityanddynamicstability.Intherailvehicle,theanti-overturningstability

andanti-derailmentstabilityofthevehicledeterminedbyforceequilibriumarereferredto asstaticstability.Thehuntingstabilityofthevehicle,asaninherentfeatureoftherail vehiclesystemdeterminingthedynamicperformanceofthehigh-speedtrainunderhighspeedconditions,isreferredtoasdynamicstability[33].

Thehuntingmotionofthewheelsetwasinitiallyobservedintheearlystagesofthe railway[34],whiletheearlystudieswereprimarilyfocusedonthewheel-railcontact relationshipratherthanthemechanismofhuntingstability.In1916,Carter[35]researched themechanismofhuntingstabilityandconcludedthathuntinginstabilityisprimarily relatedtothecone-shapedwheeltreadandthewheel-railcreepforcesatthewheel-rail interface.Theseconstitutethetheoreticalfoundationforhuntingstabilityandfacilitates researchonhuntingstabilityoftherailvehicle.Usingstabilitytheory,DePaterresearched thehuntingstabilityofrailwayvehicles.Matsudaira[36,37]researchedthelinearstability ofhuntingmotiontakingintoconsiderationthecone-shapedwheeltreadinabogiemodel. Wickens[38]studiedbogiehuntingstabilityusingalinearwheel-railcreepforcemodel andconcludedthatwheel-railcreepforcesandtheconicityofthewheeltreadarethemain causalfactorsofhuntingmotion,andamoredetaileddynamicmodelshouldbeusedin thecalculationofvehiclecriticalspeed.

Withthedevelopmentofwheel-railcontactmechanics,anumberofnonlinearwheel-rail creepforcemodelsweredevelopedtoevaluatewheel-railcreepforcesatthewheel-rail interface[39 41].Intheearlystages,linearmodelswerewidelyusedinresearchon vehiclehuntingstabilityduetolimitedcomputationalefficiency.Thestudiessuggestthat thelinearmodelyieldsresultswithrelativelylowaccuracycomparedtothoseobtained usinganonlinearmodel whichfacilitatesthedevelopmentofthenonlinearvehicle dynamicmodel.Consideringthenonlinearitiesinlateralandlongitudinalcreepforce, Cooperider[42]researchedthenonlineardynamicbehaviorsofrailvehicles.Wickens[43] studiedtheeffectsofthewornwheelprofileonthenonlinearstabilityofthebogie.Using thePoincare ´ sectionmethod,Knudsen etal. [44]researchedthebifurcationandchaos phenomenaofasinglewheelset.Considerableeffortwasalsoinvestedintoresearchon bifurcationandchaosofrailvehiclesbyPetersen[45,46]andHansTrue etal. [47 50] basedontheVermeulen-Johnsonnonlinearwheel-railcreepforcemodel.Consequently,a methodologyforcalculatingthenonlinearcriticalspeedofavehiclesystemwas developed.Zboinski etal. [51]studiedhuntingstabilityofrailvehiclesinacurve.Zeng Jing[52]researchedthecharacteristicvalueofavehiclesystemusingtheQRalgorithm andlinearstabilitytheory.Theshootingmethodwasalsoemployedtoidentifystableand unstablelimitcyclesinthevehiclesystem.ZhangWeihua[53]numericallyresearchedthe characteristicsofbifurcationandlimitcyclesinanonlinearvehiclesystemusingstability andbifurcationtheories,whichledtoacriterionfordeterminingthecharacteristicsofthe limitcycleandbifurcationinthevehiclesystem.Thesewerevalidatedthroughvehicle

rollerrigtestsattheStateKeyLaboratoryofTractionPower,SouthwestJiaotong University.

Activecontrolhasalsobeenemployedtocontrolhuntingstabilityofthebogie.Goodall etal. [54]derivedthemotionofequationsforbothanunconstrainedwheelsetandan independentwheelsetandformulatedthestateequationblockdiagramtoillustratethe feedbackeffectofwheel-railcreepforceandequivalentconicity.Theresearchproposes severalactivecontrolmethodsforwheelsethuntingstability.PearsonandGoodall etal. [55]pointedoutthattheyawdampercouldtransmithigh-frequencyvibrationstothecar bodyandthuscausesomeundesirableeffects.Toinvestigatetheyawfeedback-based activecontrolmethod,awell-validatedactivecontrolmodelcoupledwitharailvehicle modelwasdeveloped.Theresultssuggestthatco-simulationtechnologycanbeusedto designtheactivecontrol.Bruni etal. [56]designedandmanufacturedanactiveyaw damperbasedonbrushlessmotortechnology.Thelaboratorytestshowsthatthe controllablemotor-baseddampercandissipatemuchmoreenergythanthetraditionalyaw damperwithoutincreasingforcetransmissibilitytothecarbody.ShenGang[57]also conductedsomevaluableresearchonstabilitycontrol.

1.2.1.2Curvingdynamicperformance

Duetogeographicalconditions,themovementoftherailvehicleisinevitablysubjectedto curvesandnotjusttangentsalone.Considerableefforthasthusbeeninvestedinresearch oncurvingdynamicstobetterunderstandwheel-railinteractionandreducedynamicforces inthevehiclesystem,thuspreventingoverturningandderailment[58 59].

Thestudyofthecurvingdynamicsofrailvehiclesexperiencedfourphases[33].Inthe 1930s,HeumannandPoterstudiedcurvingnegotiationusingthefrictioncentermethod. Duetobreakthroughprogressinwheel-railcreeptheoryinthe1960s,Newlandand Boocock[60]pointedoutthatwheel-railcreepforcecanenhancethesteeringcapability ofthewheelsetinacurve.Becausethewheel-railcreepforcesandwheel-railcontact relationship,aswellasthesuspensionsintherailvehicle,areconsideredlinear characteristics,suchvehiclemotioninacurveisthusreferredtoassteady-statemotion. Steady-statemotionisdefinedasavehicleoperatingonatrack(withconstantcurvature andsuper-elevation)ataconstantspeed.Undersuchconditions,thecentrifugalforceis balancedbygravityinthelateraldirection,andthecurvingdynamicscanbeconverted intothestaticproblem.Inatightcurve,largelateraldisplacementofthewheelset, however,canyieldlargecreepageatthewheel-railinterfaceandintroducestrong nonlinearitiesinthewheel-railcreepforcesandwheel-railcontactrelationship.Inthelate 1970s,ElkinsandGostling et al.[61]developedanewcalculationmethodforthe nonlinearcurvepassingbyintroducingkinematicconstrainttodifferentcurvesections.In eachcurvesegment,themotionoftherailvehicleisconsideredassteady-statemotion.In the1980s,Nagurka,Hedrick,andWormley etal.[62]conductedmorecomprehensive

researchoncurvepassingconsideringthedynamicresponsesofthevehiclearisingfrom thetransitionsectionandcircularcurvesection.Consequently,morecompletecurving dynamicscanbeobtained.Thisproposedmethodyieldsmorerealisticresponsesandis thusreferredtoasadynamiccurvepassing.

Tostudydynamiccurvepassingandimprovethecurvingdynamicperformanceofrailway vehicles,considerableefforthasbeeninvestedinbothnumericalsimulationsand experimentalresearch.ChiMaoru[63,64]employedamagneto-rheologicalcoupled wheelsetinthefrontwheelsettogetherwithindependentrotationwheelsintherear wheelsettoimprovecurvingdynamicperformance.Furthermore,avarietyofradialbogies havealsobeendevelopedtoimprovecurvingdynamics[65 67].Inrecentyears,research intocontroltechnologiesoncurvingperformancehasbecomemuchmorepopularamong railways[68].Matsumoto etal. [69]fromJapan’sNationalTrafficSafetyand EnvironmentLaboratory(NTSEL)developedawell-validatedactivesteeringbogie.The bogiedesignincorporatesanactivesteeringmechanismbetweenthecarbodyandthe bogieframe,whichforcesthebogieintoaradialpositionasthevehiclenegotiatesacurve. Thenumericalandexperimentalresultsshowthattheactivesteeringbogiecan substantiallyreducelateralforceinbothinnerandouterwheels,thusimprovingcurving dynamicperformance.Shen etal. [57]conductedmanyfundamentalstudiesonbogie activecontrolstrategiesaimedatimprovingcurvingdynamicperformance,includingyaw motioncontrolforthewheelsetandbogieframe,wheelsetlateralmotionactivecontrol, primarysuspensioncontrol,andrelativemotioncontrolforwheelsets.Usingthe1/10scale vehiclemodel,fieldtest,aswellasthenumericalsimulation,Suda etal. [70]developeda wheel-railfrictioncontrollerforimprovedcurvingdynamicperformance.

1.2.1.3Ridecomfort

Apartfromhuntingstabilityandcurvingdynamicperformanceofrailwayvehicles,ride comfortisanotherimportantconcernforvehiclesystemdynamics.Researchonride comfortcouldbeutilizedinparameteroptimizationofpassivesuspension,control strategiesforactiveandsemi-activesuspension,andrigid-flexiblecoupling-basedhighfrequencyvibrationisolationandabsorption.

Toimprovetheridecomfortofrailvehicles,tuningofbogiesuspensionparametersisthe primarymethodformitigatingvibration[71 74].ChiMaoru[75,76]studiedthe influenceofhuntingmotiononvehiclelateralridecomfortandpointedoutthatthenatural frequenciesoftherailvehicleshouldbedistantfromtheexcitationfrequencies.Wu[77] researchedtheeffectsoftrackgauge,curvature,lateraldirection,andhorizontalsuperelevationonlateralaccelerationanddisplacementofacarbody,anddiscussedtrack maintenance-associatedproblems.Toinvestigatetheridecomfortprobleminducedbytail carwaggleintheShinkansonEMU,Fujimoto etal. [78]studiedtheinfluenceofstiffness anddampingbetweentwocarbodiesandconcludedthatthelongitudinaldamperbetween

twocarbodiescaneffectivelyeliminatetailcarwaggle.Thisconclusionwasfurther validatedbyexperimentalresults.Usingfrequencyresponseanalysis,Diedrichs etal. [79] performedasensitivityanalysisofridecomfortwithrespecttovehicleparameters,to understandridecomfortinahigh-speedlightpassengercarinatunnel.Theresultsshow thatthecarbodymasscansignificantlyinfluencelateralvibrationduetoaerodynamic forces.Asingle-carequivalentmodelconsideringthelateraldampersbetweencar-bodies wasformulatedbyToshimitsu etal. [80]toinvestigatetheeffectsoflateraldamperson lateralvibrationintherailvehiclearisingfromairpressurefluctuationinthetunnel.

Inthe1960s,activesuspensiontechnologywasproposedtofurtherimprovevehicleride comfort.Theactivesuspensionsystemequipment,however,includesasensor,actuator, andcontroldeviceaswellasanexternalenergysource,whichcouldsubstantiallyincrease thecost.Thesemi-activesuspensiontechnologyismorerealisticincomparisontothe activesuspension.In1974,Karnopp etal. [81],developedasemi-activesuspension systemusingacontrollabledamperthatcanadjustthedampingforcebasedonthe dampingcontrollaw.Basedonthisprotocol,thecontrolstrategiesofthesemi-active suspension,thestructureofthedamper,dampingcontrollaw,andparametersensitivity werealsowellresearched.Valasek etal. [82]proposedaskyhooksemi-activecontrol strategy,whichhasbeenwidelyemployedinsemi-activesuspensions.Sasaki[83]also conductedmultiplestudiesonthesemi-activesuspension.Asemi-activesuspensionwas developedandcompleted,anditsvaliditywasdemonstratedthrougharollerrigtestat SouthwestJiaotongUniversity.Theresultssuggestthatthelateralsemi-activesuspension caneffectivelylowerthepeakaccelerationofthecarbody.Furthermore,theon-offcontrol strategiesforthesemi-activesuspensionhavealsobeenwellresearchedusingnumerical simulation[84 87].YaoJianwei[88]andDongXiaoqing[89],oftheAcademyof RailwaySciences,theoreticallyandexperimentallystudiedthesemi-activesuspensionof railvehicles.

Elasticdeformationinthecarbodycouldalsocontributeconsiderablytopassengerride comfort,resultinginthedevelopmentofrigid-flexiblecoupleddynamicsintherailway. Thefrequencyofthefirstbendingvibrationmodeofthecarbodyisaround8w12Hz nearthesensitivityfrequencyrangeofthehumanbody,andcanthushaveasignificant influenceontheverticalridecomfortinavehicle.Itisthusexpedienttostudyrelated countermeasuresforloweringvibrationarisingfromthecarbody’selasticvibration.

Tomioka etal. [90]suggestedthatbendingvibrationisprimarilyrelatedtothetractionrod andanti-yawdamperbetweenthecarbodyandbogie.Thelinkagesbetweenthecarbody andbogiemustbeoptimizedtoreducethebendingvibrationofthecarbody,thereby improvingtheridecomfortoftherailvehicles.Tosuppresscarbodyvibrationinducedby thefirstbendingvibrationmode,Foo etal. [91]installedtwoelectro-hydrostaticactuators atboththefrontandrearends,andoneelectromagneticactuatoratthemediumposition ofthecarbody.Anactivecontrolalgorithmisusedtocontroltheseactiveactuators.

Tamai etal. [92]studiedtheLQGalgorithm-basedactivesystemforcontrollingelastic

vibrationofrailwayvehicles.Sugahara etal. [93]researchedtheeffectsofdampingofthe primarysuspensionandairspringontheelasticvibrationofthecarbody.Usingafinite elementmodelofasoft-seatcarbody,ZhuHao etal. [94]formulatedarigid-flexible coupledvehicledynamicmodeltoinvestigatethefeasibilityoffuzzycontrolstrategyin reducingtheelasticvibrationofacarbody.Suzuki etal. [95]appliedviscoelasticity materialandaconstraintlayertothecarbodytoimprovethedampingratioofthecar bodywithoutchangingitsstructure.Theresultssuggestthatthismethodcanalsolower theelasticvibrationofthecarbody.Usingasmall-scalesimulationmodel,Benatzkyand Kozek etal. [96]studiedtheactivecontrolabilityofapiezoelectricstackactuatoron elasticvibrationofacarbody.LuZhenggang etal. [97]researchedactivecontrolmethods forreducingtheelasticvibrationofahigh-speedpassengercarbody.ZhouJingsong etal. [98]researchedtheinfluenceofavibrationisolatoroncarbodyvibration.ZengJing etal. [99]alsotheoreticallyanalyzedtheelasticvibrationofrailwayvehicles,established theconceptofresonantspeedoftherailvehicle,anddiscussedtheapplicationofsemiactivecontrolintherailvehicle.HuangCaihong etal. [100]researchedtheeffectsof suspensionparametersontheelasticvibrationofthecarbody,e.g.,theeffectsoftrackrod stiffnessonelasticvibration.

Thesestudiessuggestthatthedevelopmentofvehiclesystemdynamicsexperiencedthree stages:fromalinearmodeltoanonlinearmodel,passivesuspensiontoactivesuspension, andlowfrequencytohighfrequency.

1.2.2Trainsystemdynamics

Intraditionalvehiclesystemdynamics,thesinglevehicleneglectingthelongitudinal degreeoffreedomandthelongitudinalconstraintsbetweentwocarbodiesisusuallytaken astheresearchobject.However,eachcarshowsaninconsistentresponsetothetimedelay causedbytractionandbraking.Thestudyoftrainsystemdynamicsisoriginallyaimedat investigatinglongitudinaldynamicbehavioroftrainsandlongitudinalforce transmissibility.Thedevelopmentofthestudyoftraindynamicswasdrivenbythe demandsofheavyhaultransportationinAmerica,Canada,Australia,andtheformer SovietUnion.Thesecountrieshaveconductedavastamountofresearchontrain dynamicstoimprovetheoperatingperformanceofheavyhaulvehicles.Japanhasalso performedseveralstudiesontraindynamics,withtheirresearchfocusedprimarilyonthe passengertrainbecauseofcarbodyvibrationsinthetailcarandotherassociated problems[101,102].

WiththeapplicationoftheheavyhaultraininAmericainthe1970s,problemsassociated withtraindynamicsbecameextremelyobviousduetoincreasedtrainlengthandloading. Thus,in1971,aresearchprogramontrain-trackdynamicswasundertakeninAmerica,

withitsprimaryfocusontheinfluenceoftrainoperation,topographicconditions,and climateontraindynamicperformance.Thisresearchplanwasimplementedprimarilyby theAssociationofAmericanRailroads(AAR).TheFederalRailroadAdministration (FRA)andtheGroundTransportationTechnologyCenteroftheNationalResearch CouncilCanada(NRC),asjointparticipants,alsoparticipatedinthisresearchprogram. Throughmorethan10yearsofresearchfundedbythisresearchprogram,trainsystem dynamicsachievedtremendousprogressinthenumericalsimulationmodel,whichgave risetomanytraindynamicmodels,suchasthelongitudinalmodel(quasi-staticmodel [103,104]anddynamicmodel[105]),quasi-staticlateralmodel[106 108],andvertical dynamicmodel[109].Meanwhile,considerableefforthasbeenmadethroughfieldteststo improvetherailwaytrack,vehicledesign,andrailwayoperation[110 112].Thesemainly include:

•Longitudinaldynamicbehaviorsoftrains:Toinvestigatelongitudinaldynamicbehaviorsofthevehicleandcouplerforce,thevehicleisusuallymodeledasaconcentrated massneglectingthewheel-railcontactrelationship.Eachvehicleisinter-connected throughanonlinearcouplermodeltoaccountforlongitudinalimpactsbetweentwocar bodies,especiallyduringtractionandbrakingproceduresandwhensubjectedtothe verticalrailwaylinecondition.

•Tractioncalculationfortrains:Thetraindynamicmodelisemployedtoinvestigatethe tractionandbrakingprocedureaswellasnormaloperatingconditionswhenthetrain operatesbetweentworailwaystations,toobtaintherelationshipsbetweenvehicle speed,tractionforce,andtractionpowerwithoperationalraillines.

•Quasi-staticlateraldynamicsofthetrain:Curvingdynamicsoftrainswasresearchedin termsofwheel-railcontactforce,couplerforce,andderailmentcoefficientinorderto studyrunningsafetyanddesignstandardsfortherailwaytrack.

•Trainoperationsimulator:Thetraindynamicmodelisalsousedtoprovideinputforthe trainoperationsimulatortosimulatetheoperatingbehaviorsofthetrain.Becausethe drivingsimulatorisatypicalsemi-physical(manipulatingsystem)andsemi-virtual (traindynamicmodel)hybridsimulationsystem,thelongitudinaltraindynamicmodel mustbesimplifiedtoimproveintegrationspeed.

Fromthe1980s,thetrainsystemdynamicmodels,representedbytheAmericatrain-track researchprogram,canbeclassifiedas:longitudinaldynamicmodel,lateraldynamic model,andverticaldynamicmodel.

1.2.2.1Longitudinaldynamicmodel

Theprimarypurposeofthelongitudinaldynamicmodelistostudythelongitudinal dynamicsoftrains.Basedondifferentpurposes,thelongitudinaltraindynamicmodelcan befurtherclassifiedintothequasi-staticmodelanddynamicmodel.

(1)Quasi-staticmodel

Thequasi-staticmodelisgenerallyusedtostudybrakingdistance,signalspace,and tractionpowerofthelocomotive,aswellasthequasi-staticforcebetweenthetrainand track.Becausetheinternalinteractionandtransientforcesofthevehiclearenotthefocus, numericalsimulationisusuallyimplementedusingasimplifiedmodel.Thefollowinglists someassumptionsemployedinthemodel:

a)Neglectsuspensionsinthebogie.

b)Neglectcontrolofthetrackcenter.

c)Twoadjacentcarsareconnectedbyarigidcoupler.

d)Withintheconsideredspeedrange,tractionandbrakingpropertiesaremodeledasa linearorparaboliccurve.

e)Onlythelongitudinaldegreeoffreedomistakenintoconsiderationforeachcar.

f)Transientforceofthecoupleriscalculatedusingthequasi-staticmethod.

g)Eachcarofthetrainissubjectedtoidenticalacceleration.

(2)Longitudinaldynamicmodel[105]

Thelongitudinaldynamicmodelisusedtostudythelongitudinaldynamicforcesbetween twoadjacentcarsduringoperation,anditfacilitatesthecouplerdesign.Inthismodel, eachvehicleismodeledasaconcentratedmassandcoupledwithcouplers.Thefollowing listssomeassumptionsusedinthemodeling:

a)Thegoodsinthevehicleareinrelativemotionwithrespecttothecarbody.The vehicleandgoodsarethusconsideredasaconcentratedmasspointinthedynamic model.

b)Onlylongitudinalmotionisconsidered,andothermotionsarisingfromthecurvingand verticalgradientarenotconsideredinthemodel.

c)Trackirregularityisignored.

d)Theunderframeofthecarbodyismodeledasrigid,althoughlongitudinalimpactcould leadtoelasticdeformationintheunderframe.

e)Thegravitycenterofthevehicleislocatedonthecenterlineofthecoupler,andthe pitchmotionofthevehicleisthusignored.

1.2.2.2Lateraldynamicmodel

Thelateraldynamicmodelismainlyusedtostudythecurvingdynamicperformanceofa trainandtheassociatedwheel-raillateralforcesandcouplerforcesarisingfromacurved track.Thismodelcanalsobeemployedtoinvestigatetrainbucklingcausedby longitudinalinstabilityoftrain.Inthetrain-trackdynamicsresearchprogram,AAR employedthismodeltoinvestigatetrackgeometryandcurvingdynamicsofthetrain[107, 108].Owingtolimitationsincomputationalefficiency,theproposedmodel,however,

neglectstheinfluenceofbraking,acceleration,andtrackirregularities,whichmakesthe modelaquasi-staticlateraldynamicmodel.Inthismodel,themodelingofthecoupleris key,anditalsoassumesthat:

a)Coordinatesofthetrackcenterisknown.

b)Thecouplerbetweentwocarsismodeledasarigidbarwithoutbendingdeformation.

c)Thereisnolimittotherollangleofthecoupler.

d)Thedistancebetweentwocarsremainsconstantregardlessoftheanglesofthecoupler.

1.2.2.3Verticaldynamicmodel

Intheverticaldirection,theverticaldynamicmodelisgenerallyemployedtoinvestigate theverticaldynamicresponseofthevehiclesysteminsteadofthequasi-staticmodel.Such verticaldynamicresponseismainlycausedbywheel-railverticalcontactforceatthe wheel-railinterfacearisingfromtrackirregularities[109].Inthetrain-trackdynamics researchprogram,theverticaldynamicmodelismodeledwiththreedegreesoffreedom (DOF),includinglongitudinal,vertical,andpitch.Intheheavy-haulvehicledynamic model,thegoodsareusuallymodeledwithalongitudinaldegreeoffreedom.Thismodel isthusabletoinvestigatedynamicresponsesofthevehicleandgoods.Therearesome assumptionsemployedintheverticaldynamicmodel:

a)Onlyverticalforcesandmotionsareconsidered.

b)Thecarbodyismodeledasrigid,andeachcarisconnectedthroughaspringelement representingthestiffnessoftheunderframeandcoupler.

c)Thegoodsaremodeledasarigidbodyfixedonthecarbodythroughthespring element.

d)Thebogieofeachcarismodeledasrigidandsubjectedtodynamicforcesfromboth primaryandsecondarysuspensions.

e)Resistancesarisingfromwind,ramp,andcurveareconsideredasnegligible.

f)Thecouplerrepresentedbythespringelementcanaffecttheverticalandpitchmotions ofthecarbody.Whentheverticalforceappliedonthecouplerisgreaterthantheverticalfrictionforcearisingfromthelongitudinalforceatthecouplerinterface,relative slidingcouldoccurbetweencouplers.

g)Allmotionsareverysmall.

Thelargenumberofdegreesoffreedomandstrongnonlinearitiesinthetrainsystem presentssignificantchallengestosolvetraindynamicproblemsusinganalyticalmethods, anditisnoteasytoobtainananalyticalresultevenifitisbasedonasimplifiedmodel.In theearlystages,thereweretwotypesofsimplifiedmodelsusedtoobtainanalytical solutions:continuousmasssystemanddiscretizedmasssystem.Inthecontinuousmass system,thevehicleisconsideredasanelasticbar,andtheelasticconstraintandmassin thevehiclearedistributedalongthevehiclelengthdirection,whilethelocomotiveis