DeliveringLow-Carbon Biofuelswith BioproductRecovery

Editedby LakhveerSingh

DepartmentofEnvironmentalScience,SRMUniversity-AP, Amaravati,India

DurgaMadhabMahapatra

TERIDeakinNanobiotechnologyCenter(TDNBC),TERI,India

Elsevier

Radarweg29,POBox211,1000AEAmsterdam,Netherlands

TheBoulevard,LangfordLane,Kidlington,OxfordOX51GB,UnitedKingdom 50HampshireStreet,5thFloor,Cambridge,MA02139,UnitedStates

Copyright©2021ElsevierInc.Allrightsreserved.

Nopartofthispublicationmaybereproducedortransmittedinanyformorbyanymeans,electronic ormechanical,includingphotocopying,recording,oranyinformationstorageandretrievalsystem, withoutpermissioninwritingfromthepublisher.Detailsonhowtoseekpermission,further informationaboutthePublisher’spermissionspoliciesandourarrangementswithorganizationssuch astheCopyrightClearanceCenterandtheCopyrightLicensingAgency,canbefoundatourwebsite: www.elsevier.com/permissions.

Thisbookandtheindividualcontributionscontainedinitareprotectedundercopyrightbythe Publisher(otherthanasmaybenotedherein).

Notices

Knowledgeandbestpracticeinthisfieldareconstantlychanging.Asnewresearchandexperience broadenourunderstanding,changesinresearchmethods,professionalpractices,ormedical treatmentmaybecomenecessary.

Practitionersandresearchersmustalwaysrelyontheirownexperienceandknowledgeinevaluating andusinganyinformation,methods,compounds,orexperimentsdescribedherein.Inusingsuch informationormethodstheyshouldbemindfuloftheirownsafetyandthesafetyofothers,including partiesforwhomtheyhaveaprofessionalresponsibility.

Tothefullestextentofthelaw,neitherthePublishernortheauthors,contributors,oreditors,assume anyliabilityforanyinjuryand/ordamagetopersonsorpropertyasamatterofproductsliability, negligenceorotherwise,orfromanyuseoroperationofanymethods,products,instructions,orideas containedinthematerialherein.

BritishLibraryCataloguing-in-PublicationData

AcataloguerecordforthisbookisavailablefromtheBritishLibrary LibraryofCongressCataloging-in-PublicationData

AcatalogrecordforthisbookisavailablefromtheLibraryofCongress ISBN:978-0-12-821841-9

ForInformationonallElsevierpublications visitourwebsiteat https://www.elsevier.com/books-and-journals

Publisher:BrianRomer

AcquisitionsEditor:GrahamNisbet

EditorialProjectManager:RubyGammell

ProductionProjectManager:PoulouseJoseph

CoverDesigner:MatthewLimbert

TypesetbyMPSLimited,Chennai,India

ListofContributors..................................................................................................xi

CHAPTER1Electricalenergyproducedbymicrobialfuelcells usingwastewatertopoweranetworkofsmart sensors .......................................................................... 1

P.M.D.SerraandA.Esp´ırito-Santo

1.1 Introduction....................................................................................1

1.2 Microbialfuelcells........................................................................4

1.2.1Microbialfuelcellstheoreticalanalysis.............................4

1.2.2Energyextractionfrommicrobialfuelcells......................6

1.3 Energyproduction,regulationandstorage..................................21

1.3.1Energyregulationandstorage..........................................21

1.4 Smartsensorstructureandoperation...........................................25

1.5 Conclusions..................................................................................27 Acknowledgments.......................................................................27 References....................................................................................28

CHAPTER2Applicationofbioelectrochemicalsystemsin wastewatertreatmentandhydrogenproduction ....... 31 SanthanaKrishnan,AbudukeremuKadier,MohdFadhilBin MDDin,MohdNasrullah,NurulNazleatulNajiha, ShazwinMatTaib,ZularisamAbWahid,YuYouLi,YuQin, KamalKishorePant,ShreesivadasanChelliapan, HesamKamyab,ImranAhmadandLakhveerSingh

2.1 Introduction..................................................................................31

2.2 MECfundamentalsandworkingprinciples................................32

2.3 Electrontransfermechanism........................................................34

2.4 MECtechnologyinhydrogenproductionusingwastewater......35

2.5 Agrowastewater...........................................................................36

2.6 Domesticwastewater..................................................................36

2.7 Industrialwastewater....................................................................38

2.8 Fermentationeffluent...................................................................38

2.9 NutrientandheavymetalsremovalsinMEC.............................39

2.10 IntegratedMECapproach............................................................40

2.11 Conclusions..................................................................................42 Acknowledgments.......................................................................42 References....................................................................................42 v

CHAPTER3Nutrientremovalandrecoveryin bioelectrochemicalsystems ....................................... 45 AryamaRaychaudhuriandManaswiniBehera

3.1 Introduction..................................................................................45

3.2 Nitrogenremovalandrecovery...................................................47

3.2.1Issuesrelatedtoconventionaltechnologies.....................48

3.2.2Nitrogenremovalinbioelectrochemicalsystem..............49

3.2.3Ammoniarecovery............................................................59

3.2.4Challengesinnitrogenremovalandrecovery..................62

3.3 Phosphorusremovalandrecovery...............................................66

3.3.1Issuesrelatedtobiologicalphosphorusremoval.............66

3.3.2Struviteprecipitation.........................................................68

3.3.3Phosphorusremovalandrecoveryin bioelectrochemicalsystem................................................69

3.3.4Challengesinphosphorusremovalandrecovery.............71

3.4 Conclusionandfutureperspectives.............................................74

CHAPTER4Roleofbioelectrochemicalsystemsfor bioremediationofwastewatersandbioenergy production ................................................................... 85 MuhammadFaisalSiddiqui,ZahidUllah,LakhveerSingh, FarhanaMaqbool,SadiaQayyum,IhsanUllah, ZiaurRahmanandFazalAdnan

4.1 Introduction..................................................................................85 4.2 Principleofbioelectrochemicalsystems.....................................86 4.3 Kindsofbioelectrochemicalsystems..........................................87

4.3.1Microbialfuelcells...........................................................87

4.3.2Microbialelectrolysiscellsforenergy.............................88

4.3.3Microbialelectrosynthesisforenergyproduction............88

4.3.4Enzymaticfuelcellsforenergyproduction.....................88

4.3.5Microbialsolarcellsforenergyproduction.....................89

4.3.6Plantmicrobialfuelcellsforenergyproduction.............89

4.3.7Microbialdesalinationcellsforenergyproduction.........90

4.4 Roleofbioelectrochemicalsystemsinremediationof pollutants......................................................................................90

4.4.1Remediationoforganicxenobiotics.................................90

4.4.2Treatmentofinorganicpollutants....................................92

4.5 Sustainabilityofthetechnology..................................................93

4.6 Scalingupofthetechnology.......................................................94

4.7 Conclusion....................................................................................94

Acknowledgments.......................................................................95 References....................................................................................95

CHAPTER5Energygenerationfromfish-processingwaste usingmicrobialfuelcells ........................................ 101

A.R.AbdulSyukor,SuryatiSulaiman,JadhavPramod Chandrakant,PuranjanMishra,MohdNasrullah, LakhveerSinghandA.W.Zularism

5.1 Introduction................................................................................101

5.2 NationalGreenTechnologyPolicy............................................103

5.2.1Wastefromfreshmarkets...............................................103

5.2.2Fish-processingwastewatercharacteristics....................105

5.3 Microbialfuelcellsystem..........................................................107

5.3.1Substratesusedinmicrobialfuelcell.............................109

5.3.2Fish-processingwasteassubstrate.................................109

5.4 Treatmentmethodologyoffish-wasteusingmicrobialfuel cell(aMalaysiancasestudy).....................................................110

5.4.1Preparingthesubstrate....................................................110

5.4.2Testingforphysical,chemical,andbiological parameters.......................................................................110

5.4.3Electrode.........................................................................111

5.5 Resultsobservation....................................................................113

5.5.1Voltageproduction..........................................................113

5.5.2Biochemicaloxygendemandremoval...........................115

5.5.3Chemicaloxygendemandremoval................................115

5.5.4Nitrogen...........................................................................116

5.5.5Phosphorous....................................................................118

5.6 Conclusion..................................................................................119 References..................................................................................120

CHAPTER6Microbialelectrosynthesis:Recoveryof high-valuevolatilefattyacidsfromCO2 .................. 123 NarnepatiKrishnaChaitanya,AkashTripathiand PrithaChatterjee

6.1 Introduction................................................................................123

6.2 Basicprincipleofmicrobialelectrosynthesiscell.....................124

6.3 Factorsaffectingproducttiter....................................................124

6.3.1TheeffectofpH..............................................................125

6.3.2Fluctuationsinelectricitysupply....................................126

6.3.3Impactofinoculum.........................................................127

6.3.4Electrodematerials..........................................................128

6.3.5Effectofelectrodepotential...........................................129

6.3.6Effectofreactordesign...................................................130

6.4 Strategiestoimproveproducttiter............................................131

6.5 Economicevaluation..................................................................134

6.6 Futurescopeofwork.................................................................136

6.7 Conclusion..................................................................................137

CHAPTER7Lowcarbonfuelsandelectro-biocommodities ....... 143

BahaaHemdan,S.BhuvaneshandSurajbhanSevda

7.1 Introduction................................................................................143

7.2 Workingmechanismofbioelectrochemicalsystems................144

7.3 Applicationofmicrobialelectrochemicaltechnologiesin wastewatertreatment..................................................................146

7.4 Electro-biocommoditiesandvalue-addedbiochemical’s production...................................................................................148

7.4.1Biohydrogenproduction.................................................149

7.4.2Biomethaneproduction...................................................149

7.4.3Bioethanolproduction.....................................................151

7.4.4Acetateproduction..........................................................152

7.4.5Hydrogenperoxideproduction.......................................153

7.4.6Othervalue-addedbiochemicalproduction....................153

7.5 Recentprogressforelectro-biocommoditiesgenerationina bioelectrochemicalsystem.........................................................154

7.6 Conclusion..................................................................................156 Acknowledgment.......................................................................156 References..................................................................................157

CHAPTER8Potentialofhighenergycompounds:Biohythane production ................................................................. 165

SurajbhanSevda,VijayKumarGarlapati,SwatiSharma andT.R.Sreekrishnan

8.1 Introduction................................................................................165

8.2 Mainaspectsofthebiohythanegenerationin bioelectrochemicalsystem.........................................................166

8.3 Substrateforbiohythanegeneration..........................................167

8.4 Recentprogressforbiohythanegenerationin bioelectrochemicalsystem.........................................................169

8.5 Useofbiohythane......................................................................172

8.6 Futureprospectsandconcludingremarks.................................173

Acknowledgment.......................................................................173 References..................................................................................173

CHAPTER9Biologicalandchemicalremediationoftreated woodresidues ........................................................... 177

LaisGonc¸alvesdaCosta,YonnyMartinezLopez, VictorFassinaBroccoandJuarezBenignoPaes

9.1 Introduction................................................................................177

9.2 Environmentalrisksoftreatedwood.........................................178

9.3 Remediationandrecoveryoftreatedwood...............................180

9.3.1Bioremediation................................................................180

9.3.2Mechanismsusedbyfungiintheremediation process.............................................................................183

9.3.3Chemicalremediation.....................................................186

9.4 Concludingremarks...................................................................189 References..................................................................................189

CHAPTER10Anoverviewondegradationkineticsoforganic dyesbyphotocatalysisusingnanostructured electrocatalyst .......................................................... 195 RishuKatwal,RichaKothariandDeepakPathania

10.1 Introduction................................................................................195

10.2 Organicdyes...............................................................................196

10.3 Classificationoforganicdyes....................................................196

10.4 Methodsfortheremovalofpollutants......................................196

10.5 Advancedoxidationprocesses...................................................197

10.6 Photocatalysis.............................................................................198

10.7 Photocatalysts.............................................................................200

10.8 Photocatalystsurfacemodifications..........................................201

10.9 Kineticsofphotocatalyticdegradation......................................202

10.10 Photocatalyticreactionparameters............................................203

10.11 Photocatalyticactivityofnonmetalsandmetalloids supportednanophotocatalyst......................................................204

10.12 Photocatalyticactivityofpolymersupported nanophotocatalyst.......................................................................206

10.13 Conclusions................................................................................207 References..................................................................................207 Index......................................................................................................................215

ListofContributors

A.R.AbdulSyukor

FacultyofCivilEngineeringTechnology,UniversitiMalaysiaPahang(UMP), Kuantan,Malaysia

FazalAdnan

AttaurRahmanSchoolofAppliedBiosciences,NationalUniversityofSciences &Technology,Pakistan

ImranAhmad

DepartmentofEngineering,RazakFacultyofTechnologyandInformatics, UniversitiTeknologiMalaysia,JalanSultanYahyaPetra,KualaLumpur, Malaysia

ManaswiniBehera

SchoolofInfrastructure,IndianInstituteofTechnologyBhubaneswar, Bhubaneswar,India

S.Bhuvanesh

Director’sResearchCell,CSIR-NationalEnvironmentalEngineeringResearch Institute,Nagpur,India

VictorFassinaBrocco

CenterforHigherStudiesofItacoatiara,AmazonasStateUniversity(CESIT/ UEA),Itacoatiara,Brazil

NarnepatiKrishnaChaitanya

DepartmentofCivilEngineering,IndianInstituteofTechnologyHyderabad, Hyderabad,India

JadhavPramodChandrakant

FacultyofCivilEngineeringTechnology,UniversitiMalaysiaPahang(UMP), Kuantan,Malaysia

PrithaChatterjee

DepartmentofCivilEngineering,IndianInstituteofTechnologyHyderabad, Hyderabad,India

ShreesivadasanChelliapan

DepartmentofEngineering,RazakFacultyofTechnologyandInformatics, UniversitiTeknologiMalaysia,JalanSultanYahyaPetra,KualaLumpur, Malaysia

LaisGonc¸alvesdaCosta

DepartmentofForestandWoodScience,FederalUniversityofEsp´ıritoSanto, Jero ˆ nimoMonteiro,Brazil

A.Esp´ırito-Santo

DepartmentofElectromechanicalEngineering,UniversityofBeiraInterior, Covilha ˜ ,Portugal;IT—InstituteofTelecommunications,Covilha ˜ ,Portugal

MohdFadhilBinMDDin

CentreforEnvironmentalSustainabilityandWaterSecurity(IPASA),Research InstituteofSustainableEnvironment(RISE),SchoolofCivilEngineering, FacultyofEngineering,UniversitiTeknologiMalaysia,Skudai,Malaysia

VijayKumarGarlapati

DepartmentofBiotechnologyandBioinformatics,JaypeeUniversityof InformationTechnology,Waknaghat,India

BahaaHemdan

DepartmentofBiosciencesandBioengineering,IndianInstituteofTechnology Guwahati,Guwahati,India;WaterPollutionResearchDepartment, EnvironmentalResearchDivision,NationalResearchCentre,Giza,Egypt

AbudukeremuKadier

LaboratoryofEnvironmentalScienceandTechnology,TheXinjiangTechnical InstituteofPhysicsandChemistry,Key LaboratoryofFunctionalMaterialsand DevicesforSpecialEnvironments,ChineseAcademyofSciences,Urumqi,China

HesamKamyab

DepartmentofEngineering,RazakFacultyofTechnologyandInformatics, UniversitiTeknologiMalaysia,JalanSultanYahyaPetra,KualaLumpur, Malaysia

RishuKatwal

Departmentofchemistry,CSKHPKV,Palampur,India

RichaKothari

DepartmentofEnvironmentalSciences,CentralUniversityofJammu,Bagla (Rahya-Suchani),Samba,Jammu&Kashmir,India

SanthanaKrishnan

CentreforEnvironmentalSustainabilityandWaterSecurity(IPASA),Research InstituteofSustainableEnvironment(RISE),SchoolofCivilEngineering, FacultyofEngineering,UniversitiTeknologiMalaysia,Skudai,Malaysia

YuYouLi

DepartmentofCivilandEnvironmentalEngineering,GraduateSchoolof Engineering,TohokuUniversity,Sendai,Japan

YonnyMartinezLopez

DepartmentofForestandWoodScience,FederalUniversityofEsp´ıritoSanto, Jero ˆ nimoMonteiro,Brazil

FarhanaMaqbool

DepartmentofMicrobiology,HazaraUniversity,Mansehra,Pakistan

PuranjanMishra

FacultyofCivilEngineeringTechnology,UniversitiMalaysiaPahang(UMP), Kuantan,Malaysia

NurulNazleatulNajiha

CentreforEnvironmentalSustainabilityandWaterSecurity(IPASA),Research InstituteofSustainableEnvironment(RISE),SchoolofCivilEngineering, FacultyofEngineering,UniversitiTeknologiMalaysia,Skudai,Malaysia

MohdNasrullah

FacultyofCivilEngineeringTechnology,UniversitiMalaysiaPahang(UMP), Kuantan,Malaysia

JuarezBenignoPaes

DepartmentofForestandWoodScience,FederalUniversityofEsp´ıritoSanto, Jero ˆ nimoMonteiro,Brazil

KamalKishorePant

DepartmentofChemicalEngineering,IITDelhi,NewDelhi,India

DeepakPathania

DepartmentofEnvironmentalSciences,CentralUniversityofJammu,Bagla (Rahya-Suchani),Samba,Jammu&Kashmir,India;DepartmentofChemistry, SardarVallabhbhaiPatelClusterUniversity,Mandi,HimachalPradesh,India

SadiaQayyum

DepartmentofMicrobiology,HazaraUniversity,Mansehra,Pakistan

YuQin

DepartmentofCivilandEnvironmentalEngineering,GraduateSchoolof Engineering,TohokuUniversity,Sendai,Japan

ZiaurRahman

DepartmentofMicrobiology,AbdulWaliKhanUniversityMardan,Khyber Pakhtunkhwa,Pakistan

AryamaRaychaudhuri

SchoolofInfrastructure,IndianInstituteofTechnologyBhubaneswar, Bhubaneswar,India

P.M.D.Serra

DepartmentofElectromechanicalEngineering,UniversityofBeiraInterior, Covilha ˜ ,Portugal;IT—InstituteofTelecommunications,Covilha ˜ ,Portugal

SurajbhanSevda

DepartmentofBiotechnology,NationalInstituteofTechnologyWarangal, Warangal,India

SwatiSharma

DepartmentofBiotechnologyandBioinformatics,JaypeeUniversityof InformationTechnology,Waknaghat,India

MuhammadFaisalSiddiqui

DepartmentofMicrobiology,HazaraUniversity,Mansehra,Pakistan

LakhveerSingh

DepartmentofEnvironmentalScience,SRMUniversity-AP,Amaravati,India

T.R.Sreekrishnan

DepartmentofBiochemicalEngineeringandBiotechnology,IndianInstituteof TechnologyDelhi,NewDelhi,India

SuryatiSulaiman

FacultyofCivilEngineeringTechnology,UniversitiMalaysiaPahang(UMP), Kuantan,Malaysia

ShazwinMatTaib

CentreforEnvironmentalSustainabilityandWaterSecurity(IPASA),Research InstituteofSustainableEnvironment(RISE),SchoolofCivilEngineering, FacultyofEngineering,UniversitiTeknologiMalaysia,Skudai,Malaysia

AkashTripathi

DepartmentofCivilEngineering,IndianInstituteofTechnologyHyderabad, Hyderabad,India

IhsanUllah

DepartmentofBiologicalSciences,FacultyofScience,KingAbdulaziz University,Jeddah,SaudiArabia

ZahidUllah

DepartmentofMicrobiology,HazaraUniversity,Mansehra,Pakistan

ZularisamAbWahid

FacultyofCivilEngineeringTechnology,UniversitiMalaysiaPahang(UMP), Kuantan,Malaysia

A.W.Zularism

FacultyofCivilEngineeringTechnology,UniversitiMalaysiaPahang(UMP), Kuantan,Malaysia

Electricalenergyproduced bymicrobialfuelcellsusing wastewatertopowera networkofsmartsensors

P.M.D.Serra1,2 andA.Esp´ırito-Santo1,2

1DepartmentofElectromechanicalEngineering,UniversityofBeiraInterior,Covilha,Portugal 2IT—InstituteofTelecommunications,Covilha,Portugal

1.1 Introduction

Humanpopulationisthriving,anditsnumberscontinuetogrow,evenindevelopingcountries,whereitcouldreach9billionpeopleby2050(WWAP,2014).Our planet’snaturalresourcescontinuebeingexploredand,morefrequentlythannot, irresponsiblyspent.Insomedevelopedcountries,technologicaladvancementsare beingthoughtofwithenvironmentallyfriendlyconcernsgaininggroundtodisposablesolutionsandcounterbalancingnegligentbehavior.Food,water,and energysuppliesarealsobeingstudiedforadequatemanagement,beingthemost basicnecessitiesforthesustainabilityanddevelopingoflife.Foodcannotbeproducedwithoutwater;watercannotbemadeavailablewithoutenergy;andenergy andelectricityproductionareextremelylimitedwithoutwater.Thiscloseinterconnectioncreatedanewresearchtopic,referredtoastheenergy-waternexus. Consideringcurrenttrendsofresourcedepletionandclimatechanges,waterand energywillleveragefoodproduction,resourcesustainability,andtechnology development,balancingsupplyanddemand(USDepartmentofEnergy,2014).

Thebusinessofenergyimpliesmoremoneythanthewatercounterpart:direct costswithenergyarerelatedtoexploration,treatmentorgeneration,distribution andenvironmentaltaxeswhilewater-relatedcostsaremostlyconnectedwith treatmentanddistribution,sincewaterisafreeendogenousrawmaterial.Ontop ofthis,energyexpendituredataisricherthanwaterexpenditureanddistribution (Walshetal.,2015).By2012,around700millionpeopledidnothaveaccessto animprovedwatersource,while1.3billionpeoplehadnoaccesstoelectricity (Walshetal.,2015;Halsteadetal.,2014).Allthesefactorshaveasignificant influenceonpolicies,ensuingstricterenergymanagementproceduresthanwater regulations.However,acloserlookatenergyorwaterexpendituredatashows theirrelationship,andrecentdatapointstotheneedofapplyingsimilarcontrol strategiestohinderresourceandwaterscarcity.Waterisusedinalmostevery

sectorofhumanactivity,butfromthemall,theenergysectorcomesinsecond. Onlywateruseforirrigatedculturescomesfirst.InEurope,in2015,of247,000 millioncubicmetersofwater,44%wasspentonenergyproduction.Forenergyrelatedactivities,waterisusedforfuelextraction,refining,andprocessing.It alsoplaysasignificantpartonthecoolingofthermalpowerplants,accounting for50%ofthetotaloffreshwaterwithdrawalsintheUnitedStatesandover10% inChina.Itisalsovitalforbioenergyandbiofuelfeedstockcrops,anenergy solutioneasilybelievedtobeeco-friendlyandthatisestimatedtoachieve7.5% ofglobalelectricityproductionby2050(Walshetal.,2015;Halsteadetal.,2014; Wakeeletal.,2016;HightowerandPierce,2008).

Waterextraction,distribution,treatment,anddisposalareverydifferentin countrieswithandwithoutlimitedenergyaccess.By2025,800millionpeople willliveinwater-scarceregionsandaround65%oftheglobalpopulationwill liveinseverewaterstressconditions.By2050,waterusedforirrigationwillbe surpassedbythewaterwithdrawnforenergy,industrialprocesses,andmunicipal applications.Energyisneededtoextractandconveywater,fromsourcetodestination,anddependsmostlyontopography,distanceandtherelationshipbetween thesource’svolumeofwaterandtheamountneededatthedestination(small aquifersimplymoreenergyforwaterpumping).Watertreatmentalsodealswith largeamountsofenergytoconvertwastage,rain,orseawatertoausefulandsafe version,bothforhumansandfortheenvironment:thedirtierthewater,themore energyisneededtocleanit(Walshetal.,2015;Halsteadetal.,2014;Wakeel etal.,2016;doAmbiente,2012;Copeland,2014).

Theconceptofenergy-waternexuswasfirstexploredby Gleick(1994).For sometime,sincethen,severaleventshavehighlightedtheneedforstricterregulationsinwatermanagement.In2001,therewasasignificantperiodofwatershortageinCalifornia,inaneventknownas“TheCalifornianEnergyCrisis.”Political decisionstakenatthetimefavoredshort-termhumancomfortindetrimentforthe environmentandamoresustainablewatermanagement.Thisincident,andthe likesofthese,showthatifnopoliciesareappliedonwatermanagement,the onsetofwaterscarcitywillhappensooner.China,theMiddleEast,NorthAfrica, andSpainaretheregionsatmostperil.Simplemeasureslikeefficientwater appliancesandreducedleaksinwaterdistributionareagoodwaytostart. Sourcingwaterbodyfarfromitsdestination,moreenergywillbespentonwater transport.ThisishappeningallacrossEurope,makingwatersupplymoreenergy intensiveintheseterritoriesthaninAsiancountries.Trailingthis,governments shouldinvestonaugmentingthewatersupplywithadditionalsources,treating andreusingstormwater,andinvestigatingtechnologicalsolutionsforfreshwater production,withreverseosmosiswaterrecyclingsystemsanddesalinationplants. Onpowerplants,alternativewatersourcescanbeusedforcoolingandwastewatercanalsobeusedforenergyrecovery(Walshetal.,2015;Wakeeletal.,2016; Hamicheetal.,2016).

InEurope,legislationisinplaceforenergymanagement,withtheEuropean directive2012/27/EU(the“EnergyEfficiencyDirective”)andtheadoptionofthe

ISO50001.Thisdirectiveestablishesenergyutilizationtargets,enforcesperiodical energyauditsandrequiressustainedupgradesonenergymanagementanddeliverytools.Forwater,similardirectivesarebeingstudiedandimplemented.The waterfootprintassessmentisaconcept,verysimilartothecarbonfootprint,used toquantifythewaterusedbasedonlifecycleassessments(LCA)andimplementedwithaninternationalstandard,theISO14046.TheISO14046evaluatesthe waterexpenditureanditsimpactontheenvironmentindifferentlifecycles stages,informingusersandindustryplayersofthewaterimpactsoftheiractivitiesandchoices(Walshetal.,2015;InternationalOrganizationfor Standardization,2017).

ByadoptingtheISO50001,severalorganizationsshowedsignificantdecreases onenergyandwaterusagelevelsaswell.InIreland,forinstance,theUniversity ofCork,whichadoptedthestandardin2011,sawan18%reductionofthespent water,thoughanincreasedstudentactivitywasregisteredduringthatyear.This decreasecouldhavebeenhigherifthestandardhadsimilarmeasuresforwater relatedissues,likeleakages,oldpipes,faultymetersandoperationofsanitary facilitiesinlowoccupationperiods.Theimplementationofthissamestandardby CocaColaresultedina10%decreaseinwaterand16.5%inenergyconsumption (Walshetal.,2015;Johnsonetal.,2012).

Followingthepreviousbackgrounddiscussion,thischapterdiscussestheviabilityofproducingelectricityasabyproductofwastewaterprocessing.Thisdiscussion allowstodemonstratethattheextractedenergycanbemadeusefultopowersensors thatintegrateanetworkofsmarttransducerscompatiblewiththeIEEE1451standard.Thisisaclearexampleoftheinterconnectionthatispossibletoachieve betweentwoessentialgoods,suchasenergyandwater:orthewater-energynexus.

Aftertheintroductorysection,thechapterdescribestheoperationofamicrobialfuelcell(MFC)andtheenergyconversionprocessassociatedwithit,which useswastewatertoproduceenergy,while,atthesametime,removestheorganic contentofthewater. Section1.3 demonstratestheabilitytosimultaneouslyobtain twoproductsofhighfinancialandenvironmentalvalue:electricityandwater withaloworganicmattercontent.Awastewatertreatmentplantcanthusbeseen notonlyasanenergyconsumer,butalsoashavinganenergyproductionpotential associatedwithitsoperation.AnMFC’soperationefficiencydependsontheits operationmode.Asfarassubstrateflowisconcerned,therearetwopossibilities: batchprocessingorcontinuousprocessing.

FortheMFC’sbatchoperatingmode,amaximumoperatingpointisidentified in Section1.3.Theefficiencyoftheconversionprocessdependsofseveralfactors:theelectricalloadobservedbytheMFC,itstemperatureofoperation,or organicmatteravailabilitytothebacteriaareafewexamples.Theseparameters willchangecontinuouslywithtimeandcontributetochangetheoperatingpoint continuously.ToincreasetheextractionofenergyfromtheMFC,atracking mechanism,thatadjuststheelectricalloadtotheMFC’sinternalimpedance, needstobeadopted.Properregulationandstorageoftheharvestedenergywill supporttheoperationofasmartsensornetwork.

Inthischapter,theenergyproductionprocessisassociatedwithanartificial wetland,aswhatoccursinsidetheMFCissimilartosomestagesinwastewater treatmentprocesses.Ontheotherhand,thistypeofinfrastructureislocatedoutsidelargeurbancenters.Intheseplaces,energyavailabilityisreduced,whichis whytheproductionofenergyinsituisanasset.Atthesametime,intermsof monitoring,thegeographicalareatobecoveredisvast.Consideringtheprevious arguments,thechapterproposes,in Section1.4,theuseoftheenergyproduced bytheMFCtopowerwirelesssensornodesthatintegrateasensornetwork,and thatcollecttheinformationnecessaryforthemanagementofthetreatmentprocess.Thesensornetworkthusbecomesenergyindependentasitobtainsitspower fromtheprocessitself.Thisavoidstheneedtouseconventionalbatteries,and theirreplacementwork,whichcanbedifficulttoperform,duetothehighnumber ofnetworknodes,andbecausetheycanbeplacedindifficultordangerouslocationsinsidethetreatmentplant.Theapplicationscenariowillillustratewhatdata needstobeacquiredatthewastewatertreatmentplant(waterlevels,pH,ORP, O2),andthenintroducetheIEEE1451standardanditsusefulnessinthedevelopmentofthesolution.

1.2 Microbialfuelcells

1.2.1

Microbialfuelcellstheoreticalanalysis

Balancebetweenenergyproductionandexpenditureisfragile.Althoughanoverallenergysurplusisdesirable,energydeficitconditionsarefarmoreproneto occur.Thedevelopmentofwastewaterusealternatives,namelyforenergyproduction,cantipthescales.MFCsbeganbeingexploredwiththeknowledgegatheredfromtraditionalfuelcelltechnologyandthepreviouslymentionedgoal. Thesedevicesoperateonoxidation-reductionreactions,manipulatedinawaythat theproducedelectronscanberedirectedforenergyproduction.

FuelcellresearchbeganwiththeworksbyWilliamGrovein1839.Onlyafter 1950didthetechnologyreachadevelopmentleveladequateforindustryuse. Specifically,forthefirstAmericanspaceprograms,followedbythesameprograms inJapanandinEurope.Environmentalconcernssteeredstudiesonefficiencyoptimizationandreducedemissionsinmorerecentyears.Astheseareasentaildifferent knowledgeareas,aplethoraoffuelcelltypologiesrose.Theelectrolytenatureultimatelydeterminesthefuelcelltype,sinceallfuelcellssharethesamefunctional elements:ananode,acathode,andanelectrolyte(thatcanbesolidorliquid) (LarminieandDicks,2003;Scottetal.,2016).

MFCsareoneofthosespecificfuelcelltypeswheretheelectrolytecanbe anywastewatertype:domestic,piggerywastewater,brewerywastewater,and dyeingwastewaterareafewexamples(SerraandEspirito-Santo,2016).For MFCs,theanodealsohasamajordifferencefromotherfuelcelltypes:itmust becolonizedbyexoelectrogenicanaerobicbacteria.Infact,nousefulenergy

productionispossiblefromMFCsbeforetheanodicbiofilmisadequatelydevelopedandmatured.Thebacterialcolonywillbesolelyresponsibleforconverting thewastewaterorganicsource(biomoleculesasglucoseandacetate)toenergy. Thereactorappliesconditions,anaerobiosis,suchthatbacterianeedboththeelectrodestofinishthemetabolicpathwayfromwhichtheyproduceenergy.The overallreactioncanbedescribedasfollows(Serraetal.,2020a):

1. Theelectrolyteorganicsourceissequesteredbybacteria.

2. Throughanaerobicrespiration,theorganicsourceisconvertedtocarbon dioxideandprotons,withconcomitantelectronproduction.

3. Thefinalacceptoroftheseelectrons(O2)ismadeavailableatthecathode;the anodeandcathodeareconnectedoutsideoftheelectrolyte,andthecathode materialischosensothatithasahigherpotentialthantheanode;thisultimately forcestheexoelectrogenicbacteriatodelivertheelectrontotheanode.

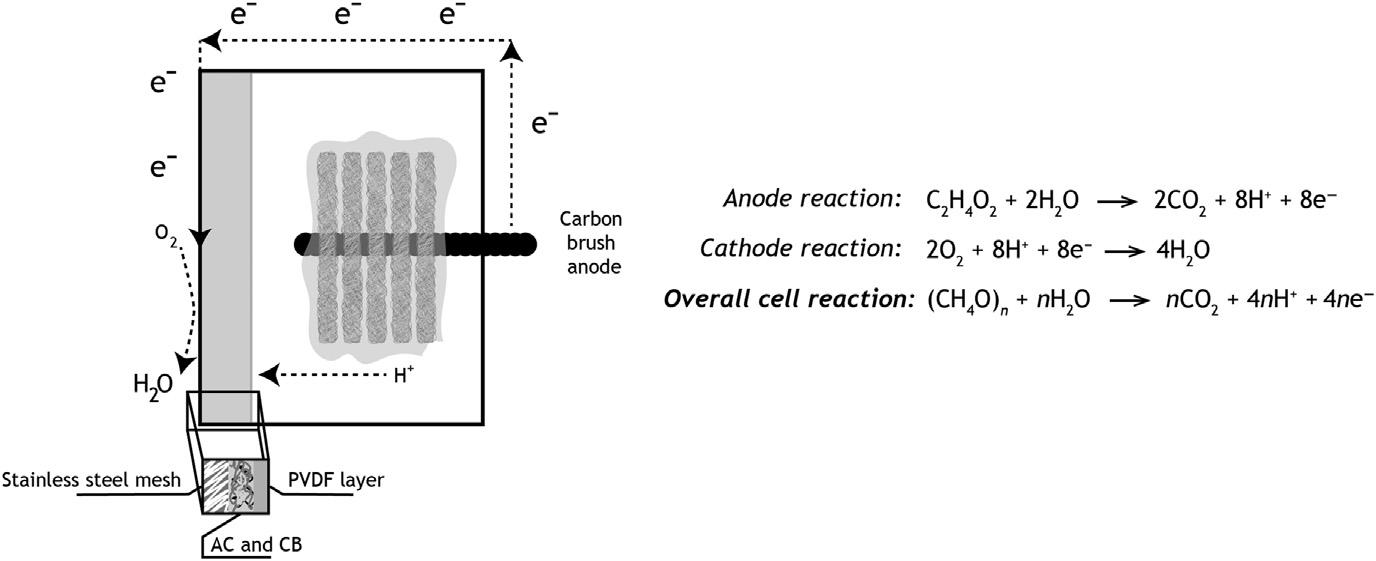

Theimageon Fig.1.1 presentsagraphicaloverviewofthisprocess,highlightingtheoverallchemicalreaction.

ThereareseveraltypesofMFCs,sortedbyreactortypeorelectrodedisposition[Serraetal.(2020b) tobepublishedin InstrumentsandExperimental Techniques,Springer].Theuseofsingle-chamberreactorsprovideamoreattractivesolutionforincreasedpowergenerationsincedecreasedinternalresistances havebeenregisteredinsuchconfigurations(Fanetal.,2008).Thebestperformancepairfortheelectrodesistohaveabrushanodeandaplanarcathode.The brushshapegreatlyincreasesthereactionarea,whiletheplanarcathodeissuccessfulinguaranteeingthereactorwatertightness.Thissetisalsoveryusefulfor fixingtheelectrodedistance,whichhasbeenfoundtobeoptimized,forenergy production,for1cmbetweenthelastbrushbristlesandthecathodesurface

FIGURE1.1

Agraphicalrepresentationofamicrobialfuelcellwithadetailofthecathodecomposition. AC,Activatedcarbon; CB,Carbonblack.Thegoverningequationoftheoperationprocess isalsopresented,atright.Detailsonthiscanbefoundin Serraetal.(2020a).

(WatsonandEstadt,2007).Whenrelatingthecathodeproductioncost,durability andpowerproductioncapabilities[asitisthebottleneckelementforMFCpower production(Fanetal.,2008)],theactivated-carbonaircathodesproducedin (Yangetal.,2014)presentasatisfactorycompromise.Theresearchteamofthis workiscurrentlyworkingwithsingle-chamberair-cathodereactors,asdescribed in Serraetal.(2020a),thatfollowtheaforementionedrecommendations.

1.2.2 Energyextractionfrommicrobialfuelcells

1.2.2.1

Generalprinciple

Themaximumvoltageproducedbyafuelcellcorrespondstoitselectromotive force,or Eemf ,derivedfromtheNernstequation:

In Eq.(1.1), Ecat representsthecathodepotentialand Ean theanodepotential.To determinethesepotentials,thereactionequation,theconcentrationofeachoxidizingandreducingagent,andthespecifictemperatureareneeded.Whenknown, theelectrodepotentialscanbededucedfrom Eqs.(1.2)and(1.3):

where, E 0 cat and E 0 an representtheelectrodepotentialinstandardconditions (298.15K,1barpressure,1Mforallspecies), R correspondstotheuniversalgas constant, T isthetemperatureinKelvin,and L isthereactionquotient.

ForMFCs,consideringapHof7,andthegeneralgoverningequationin Fig.1.1,thetheoretical Eemf is1.1V.Thistheoretical Eemf value,however,cannotbeachievedbecauseMFCs,asotherfuelcells,inherentlyloseenergydueto, forinstance,unbalancedproportionsbetweenreactantsandproducts,thereversibilityoftheoxidation-reductionreaction,thecell’sinternalresistance—aresult fromthematerialsandgeometrieschosenforthereactor,thebacterialprofile, andthesubstratecomposition.AllthesevariablesplayaroleontheMFC’slosses andintroduceamplevariabilityandcontroldegrees.

TheMFCenergylossesneedtobeminimizedtoincreasethedevice’senergy production.Todoso,theyfirstneedtobeidentifiedandmeasured.Thisstepis crucialifefficientadjustmentsaretobeapplied.Measuresofthecell’svoltage andcurrentwithrespecttoexternalresistanceandelectrode’spotentialasafunctionoftimearekeystoneforsuchstudies.PolarizationreportsarethemostfundamentalstudiesthatcanbeconductedonanMFC.Thecellcanbeanalyzedall altogetherorstudiescanbemadeindependentlytoeachelectrode.Forprobing thecell,usingapotentiometerandavoltmeter,thoughsimpleandextremely

accessible,produceslowdetaileddataandcanbeacumbersomeprocess,whether duetothelackofprecisioninthemagnitudeofchangesintheexternalload,or duetothelackoftimeprecisionofthosechanges.Adigitalpotentiometerand adigital-to-analogconverter(DAC)canhelpimprovethereliabilityofsucha methodevenmorewhencombinedwithamicroprocessor.Dataretrievedthrough thismethodwillallowforanadequatecellelectriccharacterization,althoughnot usefuliftheanalysisofbacterialchangesareofinterest.Whenneedingtoconductthesestudies,theuseofapotentiostatismoreadequate.Theresultsofusing thismeasuringinstrumentgowellbeyondtheelectricalcharacterizationofan MFCandcanalsocontributetotheelectrochemicalstudyofthecell’selectrodes andmicrobialcommunities.Allandall,apotentiostatcanretrievetheelectrochemicalactivityofmicrobialstrains,determinethestandardredoxpotentialsof redoxactivecomponents,testtheperformanceofcathodematerials,acquire polarizationcurves,quantifythe(overpotentialsandohmic)lossesofanMFC, conductcurrentinterrupttechniques,electrochemicalimpedancespectroscopy, linear,differentialpulse,cyclicvoltammetry,andchronostudies,namelychronoamperometryandchronopotentiometry(Loganetal.,2006;Logan,2012;Zhao etal.,2009).Nonetheless,thepotentiostatusefulnessandthefollowingdiscussion willconsiderpolarizationstudiesconductedwithapotentiometerandaDACona mbedLPC1768duetotheirprice,accessibility,andeaseofuse.

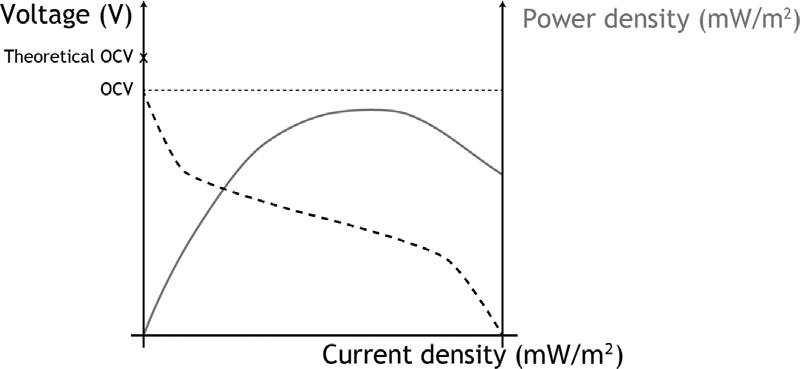

Atypicalpolarizationcurveisshownin Fig.1.2.

Thiscurvecanbebuiltbyapplyingasingle-cycleormultiple-cyclemethod. Asingle-cyclemethodisusedwhenseveralresistancechangesaremadeduring onbatchofwastewater,orifthecellisoperatedincontinuousflow.Multiplecyclemethodsareappliedinfedbatchreactorsandimplyaresistancechangeper batch,wherethenumberofbatcheswillbedependentontheresolutionneeded forthepolarizationcurve.Acommonoccurrencefoundinpolarizationcurvesis powerovershoot.Apowerovershootbehaviorcanbeidentifiedafterthemaximumpowerpointinpowergraphs,whentwodifferentpowerdensityvaluescan betracedbacktothesamecurrentdensity.Itisusuallyassociatedwiththeanode andimmaturebiofilms;theanodiccommunityisunabletomaintaintheincreasingelectrondemand;orinadequatemeasurementprocedureswithresistance

FIGURE1.2 Anexampleofapolarizationcurve.

changestooquickthatdonotallowthebiofilmtoadjust.Thiscanhappenfor anyreactortype,geometry,orevenforreactorsoperatedasastack.Tobypass suchevent,multiple-cyclemethodsarethebestchoice,since,providedtheadequatereadinessofthebiofilm,fullacclimationtotheexternalloadonthereactor isguaranteed(Logan,2012;Prakashetal.,2010;Vicarietal.,2017;Watsonand Logan,2011;Boghanietal.,2013;Winfieldetal.,2011;Hongetal.,2011).The weightanddiscussionofeachoftheMFClossesidentifiableinapolarization curvecanbefoundin(Serraetal.,2020a).Polarizationcurvesarefundamentalto adequatelycomparetheperformanceofdifferentMFCsetups.

1.2.2.2 Improvingenergyproductionfrommicrobialfuelcells

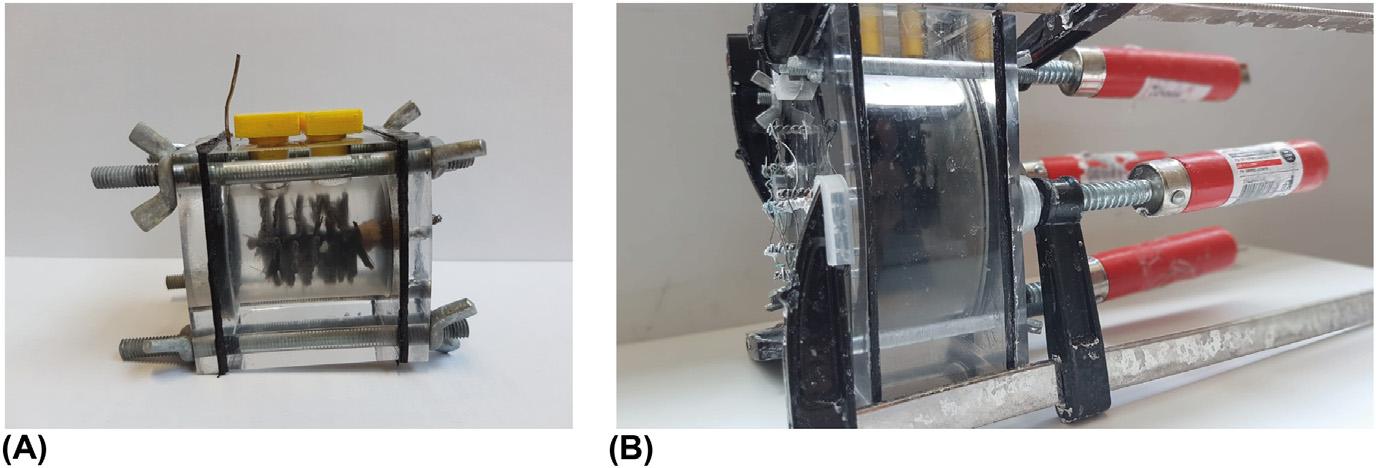

ThepowerproductioncapabilitiesofMFCsaredependentonamyriadoffactors, namelyonreactorandelectrodecharacteristics,andsubstratecomposition.To makeanunblemishedcomparison,thenextthreesubsectionsandrespective assumptionsaresupportedonpolarizationdataconductedontwotypesofreactors,picturedin Fig.1.3:smallvolumereactors, Rx,andbigvolumereactors, RBigx,where x denotesthereactornumber.

Theteamhasaccesstosixsmalltypereactorsandtwobigvolumereactors. Bothreactorssharethesameelectrodes:acarbonbrushanodeandanactivatedcarbonair-cathode,asdescribedinSection2.1.Theirinnerchamberalsohasthe samerectangularshapealthoughwithdifferentsizes.Theshapewaskeptinorder tomaintainthebestperformingelectrodedistance. Rx typereactorshaveanempty bedvolumeof28mL,whilethe RBigx topologyaccomplishesalmostninetimes thatvolume,reaching250mL.Anotherdifferencebetweenthetworeactortypesis ontheelectrodenumberandarea.ThesmallMFCshaveoneelectrodeofeach type,withacathodeareaof7cm2.Thebiggerversionhassixinterconnected anodes—disposedinapentagonshapewithacentralpoint—andalsoasinglecathode.Theinterconnectedanodesworkasasingleelectrodeandthelargecathodehas atotalareaofapproximately64cm2.Thisdataissummarizedin Table1.1.

FIGURE1.3

Ontheleft(A),apictureofoneofthesmallvolume(Rx)MFCs.Ontheright(B),the pictureofabigvolumereactor(RBigx). MFC,Microbialfuelcell.

Table1.1 Summaryofthemicrobialfuelcelltypesusedforpower improvementstudies.

Reactor type Anode (number) Cathode (number) Cathode area(cm2)

Emptybed volume (mL) Electrode distance

7281cm,measured fromtheanode’s lastbristles

Big: RBigx Carbon brush(6) 64250

Small: Rx Carbon brush(1) Activatedcarbonaircathode (1)

Intotal,thenumberofreactorsavailabletotheteamissix Rx (R1toR6)and two RBigx (R7andR8).

Thedataforbuildingthepolarizationcurveswasretrievedbythemulti-cycle method,throughvoltagemonitoringonasetofsevendifferentresistancesconnectedbetweeneachelectrodeofanindividualMFC(orbetweenelectrodesof differentreactorswhentestingforseriesandparallelassociations).Theloadsetis comprisedofresistancesof1000,500,200,100,68,50,and20 Ω.TheDACon anmbedLPC1768wasprogrammedfordataacquisitionevery2minutes.The retrieveddatapointswerefurtherprocessedinMATLAB2018b.Thevaluesused foreverypolarizationcurvecorrespondtothemaximumvalueretrievedfromthe hourlyaverageofthe2minutesacquiredvoltagevalues.Thisprocessingstep guaranteesanadequateshieldingfrommeasurementartifactsthatmayoriginate onpowerfluctuationsofmicroprocessorand/orloadconnectiondefects.

Thetrialsconductedforcontinuousversusintermittentmodeofoperationare notpolarizationcurvesandusethe2minutesacquiredvalues.Thediscussionon thistrialtypewillfollowintheappropriatesection.

Whicheverthetrial,thereactorswerealwaysfedwithanartificialwastewater (AW)preparation,a50mMsodiumphosphatebufferatpH7.Thefeedingsolutionfollowsthecomposition:

• CH3COONa—1g/L;

• NaH2PO4.2(H2O)—3.12g/L;

• Na2HPO4—4.26g/L;

• NH4Cl—0.31g/L;and

• KCl—0.13g/L.

Asolutionwithsuchcompositionhasaround9.8JofenergypermL (Eq.1.5),whichcanbeprovedbyusingtheorganicsourceconcentration,the equationdescribingtheenergyproductionprocess(Eq.1.4)andtheindividual standardGibbsfreeenergyofformation,displayedin Table1.2:

Thisvaluewillbeusedtoaccuratelypinpointtheefficiencyofeachtrial.

Table1.2 SummaryofthestandardGibbsfreeenergyofformationper compoundof Eq.(1.4)

1.2.2.2.1 Thebenchmark:polarizationcurveonasmallvolume microbialfuelcell

Thepolarizationtrialon Fig.1.4 hasbeenretrievedonasmallvolumereactor, R6.Theanodicbiofilmhas674daysandthecathodeappliedwasfreshlyproduced,withoutanyaerobicbiofilmdeposition.Theinoculationprocedurefollowedthemethodologyavailableon Serraetal.(2020a).Thisdatawillbeused tobenchmarkalltheothertrials.

Theanalysisofthedataon Fig.1.4 showsthatamaximumpowerdensityof 822mW/m2 (0.58mW)wasproducedat0.34mA/cm2 or100 Ω.Byapplyingthe maximumpowertransfertheory,thisloadvaluecanbeusedtotracethereactor’s internalresistance(Serraetal.,2020a).Alowerpowerdensitythanthecurve wouldanticipateisnoticeableatabout0.4mA/cm2.This,however,isnotcorroboratedbythetotalenergyextracted,asshownin Fig.1.5.

Theanalysisofthetotalextractedenergyperload,consideringtrialsrununtil substratedepletion,alsoshowsthatthemaximumenergyharvesteddoesnot occurattheloadformaximumextractedpower.Infact,betweenthetwoloads (200and100 Ω),moreenergyisextractedatthelowestcurrentvalue.Thedifferencecorrespondstoapproximately0.05J/h,wherethetrialfor200 Ω runfor 21hoursandthetrialfor100 Ω for17hours,bothuntilcurrentvaluesremained over0.1mA.Themaximumefficiencyofthereactorwasdeterminedtobe8.9%, with24.5Jextractedfrom28mLoftheAW(274.4J).

1.2.2.2.2 Increasingthesizeofthereactor

Todetermineifanincreaseinthereactorvolumecanberelatedwithanincrease inproducedpower,apolarizationtrialwasrunonabigvolumereactor,RBig8, andispresentedwith Fig.1.6.AswiththetrialonR6,theloadwasuninterruptedlyconnectedbetweentheelectrodesuntilsubstrateexhaustion.

Incomparisonwiththesmallvolumereactor,allthevoltagevaluesarehigher, althoughcurrentandpowerdensityfiguresarelower.As Table1.3 shows,the samecannotbesaidforabsolutepowerandcurrentvalues,whichpresenthigher valuesthanthesmallvolumereactorforloadsunder100 Ω,inclusive.Thecurve shapehintsthatthepolarizationrunloadvalueswerenotadequatetofindthe reactor’sinternalresistanceand,consequently,itsmaximumpowerproduction

Polarization curve for benchmarking: small reactor, R6.

FIGURE1.4

Polarizationcurveforasmallvolumereactor,R6,withafreshcathodeandananodic biofilmof674days(overone-and-a-halfyears).

FIGURE1.5

Stackedviewofthepowercurveandextractedenergyvaluesperloadforthesmall volumereactor,R6.

capabilities.Thelowestloadvalueontheset,20 Ω,seemstobeanoverestimationofthereactor’sinternalresistance.Nevertheless,andfor20 Ω,themaximum powerfoundforthetrialwasof487mW/m2 (3.1mW).As Fig.1.7 clearlyrepresents,thetotalextractedenergywashigherfor68 Ω,207J,whichalsocorroboratestheconclusionforthetrialwiththesmallreactor.

Polarizationcurveforabigvolumereactor,RBig8,withafreshcathodeandananodic biofilmof415days(over1year).

Thevolumerelationshipbetweenthetworeactortypesisninefold.However, neitherpowernorextractedenergyincreasedinthatproportion.Infact,power densitydecreasedandthereactorperformanceatthemaximumenergyextraction was5.8%lower.Atthemaximumpowerproductionload,thedifferencewas even3.3%higher,at9.1%.Noninefoldproportionwasfoundbetweenthereactor volumeincreaseandanyotherenergyproductionparameter,althoughtheanode numberandcathodesurfacewereincreased.

1.2.2.2.3 Seriesandparallelassociation

Anotherstrategythatcanbeusedtoimprovetheenergyproductionlevelsfrom MFCsistheseriesorparallelassociationoftworeactors.Theoretically,considering tworeactorsastwoequalvoltagesources,theirseriesassociationwillimprovethe totalvoltageoftheset,whiletheparallelgroupingwillcontributetohighercurrent levels.Thechoiceofthebestassociationwillultimatelyrelyontheapplication. Nevertheless,andconsideringthe100 Ω internalresistanceofthesmallreactors foundwiththebenchmarkingtrial,theseriesassociationisexpectedtoproducethe highestpowerlevelsfor200 Ω andtheparallelcombinationat50 Ω.Accordingto thisexpectation,seriesandparalleltrialswereconductedonlyforthreeloadvalues: 200,100,and50 Ω.Thebiofilmforthesetrialshasthesametime,674days.

TheseriestrialdatapointsaresuperimposedonthesmallMFCpolarization curvein Fig.1.8.

Thepolarizationcurveispresentedwithabsolutevaluesofpowerandcurrent sincenoassumptioncanbemadeonthereferenceareaforreaction:thereareno guaranteesthatthereactorsperformedthesamewayand,therefore,thecathode areacannotbedoubledonthatassumption.

Polarization curve for big volume reator: RBig8.

FIGURE1.6

Table1.3 Summaryonthedatausedtobuildtheplotssupportingtheconclusionsrelatedwithpowerimprovementintrialswith biggervolumereactors,seriesandparallelassociationandcommutedloadconnection.

VariableUnitTrial

CathodeDays0

Thistableshouldnotbeusedasreferencewithoutthetextreferringtoit. aCommutedloadoperation. bAftercommutedloadoperation. benchmark. 1 continuousoperation.

Stackedviewofthepowercurveandextractedenergyvaluesperloadforthesmall volumereactor,RBig8.

Polarizationcurveofthesmallreactor(R6)anddatapointsforseriesassociationoftwo smallvolumereactors(R5andR6).

Overall,theseriesassociationoftworeactorsproducedhighervoltagevalues, exceptfor50 Ω.Asfarascurrentisconcerned,thevalueswereapproximatelythe sameforasinglereactorortwoseriesconnectedMFCs.Thesedatapointsseemto pointthat,forlowerloads,theseriesbehaviorapproachestheperformanceofasingleMFC.Asfaraspowerisconcerned,duetothehighervoltagesresultingfrom theseriesassociation,valuesarealsohigherforhigherloads.Infact,forthe200 Ω load—correspondingtotheseriesassociationoftworeactorswithaninternalload

FIGURE1.7

Polarization data comparison between a single small reactor and a series association of 2 small volume reactors.

FIGURE1.8