https://ebookmass.com/product/current-trends-and-futuredevelopments-on-bio-membranes-reverse-and-forward-osmosisprinciples-applications-advances-angelo-basile/

Instant digital products (PDF, ePub, MOBI) ready for you

Download now and discover formats that fit your needs...

Current Trends and Future Developments on (Bio-) Membranes Angelo Basile

https://ebookmass.com/product/current-trends-and-future-developmentson-bio-membranes-angelo-basile/

ebookmass.com

Current Trends and Future Developments on (Bio-)

Membranes: Recent Advances on Membrane Reactors Angelo Basile

https://ebookmass.com/product/current-trends-and-future-developmentson-bio-membranes-recent-advances-on-membrane-reactors-angelo-basile/

ebookmass.com

Current Trends and Future Developments on (Bio-) Membranes: Silica Membranes: Preparation, Modelling, Application, and Commercialization Angelo Basile (Editor)

https://ebookmass.com/product/current-trends-and-future-developmentson-bio-membranes-silica-membranes-preparation-modelling-applicationand-commercialization-angelo-basile-editor/

ebookmass.com

Football Fandom in Europe and Latin America: Culture, Politics, and Violence in the 21st Century Bernardo Buarque

https://ebookmass.com/product/football-fandom-in-europe-and-latinamerica-culture-politics-and-violence-in-the-21st-century-bernardobuarque/

ebookmass.com

A

Daughter Forged in Fire (Chronicles of the Tuatha, Book One) Jessica Leigh

https://ebookmass.com/product/a-daughter-forged-in-fire-chronicles-ofthe-tuatha-book-one-jessica-leigh/

ebookmass.com

Conversion to Islam in the Premodern Age: A Sourcebook

Nimrod Hurvitz

https://ebookmass.com/product/conversion-to-islam-in-the-premodernage-a-sourcebook-nimrod-hurvitz/

ebookmass.com

Career Development and Counseling: Theory and Practice in a Multicultural World (Counseling and Professional Identity) 1st Edition, (Ebook PDF)

https://ebookmass.com/product/career-development-and-counselingtheory-and-practice-in-a-multicultural-world-counseling-andprofessional-identity-1st-edition-ebook-pdf/ ebookmass.com

Investment Analysis & Portfolio Management 11th Edition

Frank Reilly

https://ebookmass.com/product/investment-analysis-portfoliomanagement-11th-edition-frank-reilly/

ebookmass.com

Rights As Security: The Theoretical Basis Of Security Of Person 1st Edition Rhonda Powell

https://ebookmass.com/product/rights-as-security-the-theoreticalbasis-of-security-of-person-1st-edition-rhonda-powell/

ebookmass.com

My First Knock-Knock Jokes Jimmy Niro

https://ebookmass.com/product/my-first-knock-knock-jokes-jimmy-niro/

ebookmass.com

Elsevier

Radarweg29,POBox211,1000AEAmsterdam,Netherlands TheBoulevard,LangfordLane,Kidlington,OxfordOX51GB,UnitedKingdom 50HampshireStreet,5thFloor,Cambridge,MA02139,UnitedStates

©2020ElsevierInc.Allrightsreserved.

Nopartofthispublicationmaybereproducedortransmittedinanyformorbyanymeans,electronicor mechanical,includingphotocopying,recording,oranyinformationstorageandretrievalsystem,without permissioninwritingfromthepublisher.Detailsonhowtoseekpermission,furtherinformationaboutthe Publisher’spermissionspoliciesandourarrangementswithorganizationssuchastheCopyrightClearance CenterandtheCopyrightLicensingAgency,canbefoundatourwebsite: www.elsevier.com/permissions.

ThisbookandtheindividualcontributionscontainedinitareprotectedundercopyrightbythePublisher(other thanasmaybenotedherein).

Notices

Knowledgeandbestpracticeinthisfieldareconstantlychanging.Asnewresearchandexperiencebroadenour understanding,changesinresearchmethods,professionalpractices,ormedicaltreatmentmaybecome necessary.

Practitionersandresearchersmustalwaysrelyontheirownexperienceandknowledgeinevaluatingandusing anyinformation,methods,compounds,orexperimentsdescribedherein.Inusingsuchinformationormethods theyshouldbemindfuloftheirownsafetyandthesafetyofothers,includingpartiesforwhomtheyhavea professionalresponsibility.

Tothefullestextentofthelaw,neitherthePublishernortheauthors,contributors,oreditors,assumeanyliability foranyinjuryand/ordamagetopersonsorpropertyasamatterofproductsliability,negligenceorotherwise,or fromanyuseoroperationofanymethods,products,instructions,orideascontainedinthematerialherein.

LibraryofCongressCataloging-in-PublicationData

AcatalogrecordforthisbookisavailablefromtheLibraryofCongress

BritishLibraryCataloguing-in-PublicationData

AcataloguerecordforthisbookisavailablefromtheBritishLibrary

ISBN: 978-0-12-816777-9

ForinformationonallElsevierpublications visitourwebsiteat https://www.elsevier.com/books-and-journals

Publisher: SusanDennis

AcquisitionEditor: KostasKIMarinakis

EditorialProjectManager: VincentGabrielle

ProductionProjectManager: AnithaSivaraj

CoverDesigner: MathewLimbert

TypesetbySPiGlobal,India

Contributors

FynnJ.Aschmoneit TechnicalUniversityofDenmark,Kgs.Lyngby,Denmark

AngeloBasile InstituteonMembraneTechnology,ITM-CNR,Rende,Italy

MuhammadRoilBilad ChemicalEngineeringDepartment,UniversitiTeknologi PETRONAS,BandarSeriIskandar,Malaysia

CristianoP.Borges ChemicalEngineeringProgram,AlbertoLuisCoimbraInstitutefor GraduateStudiesandResearchinEngineering(COPPE),TechnologyCenter,Federal UniversityofRiodeJaneiro(UFRJ),RiodeJaneiro,Brazil

AlfredoCassano InstituteonMembraneTechnology,ITM-CNR,Rende,Italy

M.Cunnington CSIRO,Pullenvale,QLD,Australia

SirshenduDe DepartmentofChemicalEngineering,IndianInstituteofTechnology Kharagpur,Kharagpur,India

RaminFarnood DepartmentofChemicalEngineeringandAppliedChemistry,University ofToronto,Toronto,ON,Canada

GimunGwak SchoolofCivil,EnvironmentalandArchitecturalEngineering,Korea University;CenterforWaterResourceCycleResearch,KoreaInstituteofScienceand Technology,Seoul,RepublicofKorea

ClausHelix-Nielsen TechnicalUniversityofDenmark,Kgs.Lyngby,Denmark

SeungkwanHong SchoolofCivil,EnvironmentalandArchitecturalEngineering,Korea University,Seoul,RepublicofKorea

G.P.SyedIbrahim MembraneTechnologyLaboratory,DepartmentofChemistry, NationalInstituteofTechnologyKarnataka,Surathkal,India

ArunM.Isloor MembraneTechnologyLaboratory,DepartmentofChemistry,National InstituteofTechnologyKarnataka,Surathkal,India

DavidInhyukKim SchoolofCivil,EnvironmentalandArchitecturalEngineering,Korea University,Seoul,RepublicofKorea

SihangLi CollegeofFoodScienceandEngineering,NorthwestA&FUniversity,Yangling, China

ZhenyuLi CollegeofFoodScienceandEngineering,NorthwestA&FUniversity,Yangling, China

ShengLi GuangzhouInstituteofAdvancedTechnology,ChineseAcademyofSciences, Guangzhou,China

SouravMondal DepartmentofChemicalEngineering,IndianInstituteofTechnology Kharagpur,Kharagpur,India

SaraR.Osipi ChemicalEngineeringProgram,AlbertoLuisCoimbraInstitutefor GraduateStudiesandResearchinEngineering(COPPE),TechnologyCenter,Federal UniversityofRiodeJaneiro(UFRJ),RiodeJaneiro,Brazil

NavinK.Rastogi DepartmentofFoodEngineering,CentralFoodTechnologicalResearch Institute,CouncilofScientificandIndustrialResearch,Mysore,India

ArgimiroR.Secchi ChemicalEngineeringProgram,AlbertoLuisCoimbraInstitutefor GraduateStudiesandResearchinEngineering(COPPE),TechnologyCenter,Federal UniversityofRiodeJaneiro(UFRJ),RiodeJaneiro,Brazil

S.Su CSIRO,Pullenvale,QLD,Australia

R.Thiruvenkatachari CSIRO,Pullenvale,QLD,Australia

DasTrishitman DepartmentofFoodEngineering,CentralFoodTechnologicalResearch Institute,CouncilofScientificandIndustrialResearch,Mysore,India

YusufWibisono BioprocessEngineeringDepartment,UniversitasBrawijaya,Malang, Indonesia

Preface

Thepracticalapplicationofreverseosmosis(RO)wasrealizedinCaliforniaintheearly 1960s.Sincethen,thedevelopmentofnew-generationmembranes,suchasthethin-film compositemembraneswithhighlyimprovedwaterfluxandsoluteseparationcharacteristics,hasresultedinmanyROapplications.Inadditiontothetraditionalseawaterand brackishwaterdesalinationprocesses,ROmembraneshavefoundusesinwastewater treatment,productionofultrapurewater,watersoftening,foodprocessing,andmany others.Asignificantdevelopmenthasbeenwitnessedinthistechnologywithrespect tomaterials,synthesistechniques,modifications,andmodulesoverthelastfewdecades.

Forwardosmosis(FO)isanemergingmembranetechnology,whichhasbeenimplementedwithfull-scaledemonstrationonlyinthepast3–5years.Ithasshownpromising outcomesinavarietyofapplicationsincludingseawaterandbrackishwaterdesalination, powergeneration,foodprocessing,andwastewaterreclamation.

ThecombinationofFOandRO,includingdirectandindirectapproaches,canplaya promisingroleforthecomprehensivemanagementofwaterresourceandpromotethe sustainabilityinwater-energynexus.

Thisbookprovidesacomprehensiveandthoroughcoverageofrecentdevelopmentsof FO,RO,andtheircombinationinintegratedsystemsforspecificapplicationsincluding waterdesalination,wastewatertreatment,powergeneration,andfoodprocessing.These applicationsareagoodexampleofstrategiesforengineeringdevelopmentandprocess intensificationofinterestforbothindustrialanddevelopingcountries.

Generalprinciples,membranemoduledevelopments,membranefoulingandmodeling,simulation,andoptimizationofbothtechnologiesarealsocovered.

Goingintothedetails,thebookisdividedinthreeparts:

I—Forwardosmosis,withfivechapters

II—Reverseosmosis,withfivechapters

III—IntegratedRO/FO,withfourchapters

Thefirstone, Chapter1 (Rastogi),considersthatthedemandofconsumersforhighestqualityconcentratedproductswithnaturalflavorandtaste,freefromchemicaladditives andpreservatives,triggeredthedevelopmentofanovelmembrane-basedprocessforthe concentrationofliquidfoods.Inthiscontext,FOisavalidalternative:itsvariousapplicationsinfoodprocessing,desalination,andpharmaceuticalsaredemonstratedbythe increaseinscientificreportsinthespecializedliterature.ThemostvitalfeaturesofFO areconcentrationofliquidfoodsatambienttemperatureandpressurewithoutconsiderablefoulingofmembrane.Lowenergyconsumption,lowfoulingpropensity,reducedor

easycleaning,lowcost,highsaltrejection,andhighwaterfluxarethefewadvantagesof FOovertheothermembraneprocesses.ThecurrentlimitationsofFOareconcentration polarization,foulingofmembrane,backdiffusionofdrawsolute,andthedesignandfabricationofmostsuitablemembrane.So,thischapterdiscussesthecurrentadvancesinFO andfocusesontheopportunitiesandchallengesassociatedwiththistechnology.

Chapter2 (Gwak,Kim,andHong)underlinesthatwhileFOprocesseshaveundergone greattechnologicaladvancements,thecontrolofreversesolutediffusionandtheeffective recoveryofdrawagentsarethemajorchallengesforthesystematicallysustainableand economicallyfeasibleuseofFOremain.Thischapterreviewspolymerhydrogel-and nanoparticle-baseddrawagentsthatcan(1)induceahighosmoticpressure,(2)result ininsignificantreversediffusionofsolutes,and(3)beeffectivelyregeneratedbysimple separationmethods. Chapter3 (WibisonoandBilad)introducesthedesignofFOsystems. Inparticular,FO,consideredanemergingmembraneprocess,haspotentialtobea“lowenergy”footprintforwaterandwastewatertreatment.However,theterm“lowenergy” mayonlybesuitablewhenFOisappliedasastand-aloneprocesswithoutrequiring thedrawsoluterecovery.Forthisreason,thischapterdiscussesthedesignsystemsfor FOimplementation,aseitherastand-alonesystemviatheosmoticconcentrationoras ahybridsystemforrecoveryofthedrawsolute,includingthethermalprocessviaevaporation,membranedistillationorcrystallization,stimuli-responseusing“smart”draw solute,pressure-drivenmembraneprocess,andotherrecoveryprocesses.Finally,the summaryofthecurrentreportedsystemdesignandfutureresearchtrendonFOsystem isprovided.Chapter4(AschmoneitandHelix-Nielsen)presentsthecomputationalfluid dynamics(CFD)processsequenceforthedevelopmentofaCFDmodel,designedforthe analysisofidealpackingdensitiesinFOhollow-fibermodules.EachCFDprocessisindividuallyoutlined,followedbyitsapplicationinbuildingtheCFDmodel,givingagood overviewofCFDmodelinginFOprocesses.Themodelshowsgoodagreementwithexperimentaldata,fordrawconcentrationofupto1M.Thesubsequentpackingdensityanalysisshowssevereexternalconcentrationpolarization(ECP)effectsforincreasingpacking densities,yieldingamaximumwaterfluxforpackingdensitiesintherange45%–80%. Nevertheless,thetotalpermeationratestillgrowswithincreasingpackingdensity:the effectofincreasingmembranesurfaceexceedstheincreasingECP,asthepackingdensity isincreased.However,theenormouspressuredroprisealongthemembranemodule limitsefficientapplicationswithhighpackingdensities.In Chapter5 (Rastogi),theapplicationsofFOprocessinfoodprocessingandfutureimplicationsarepresented.Infact,FO isconsideredasapromisingmembranetechnologythatfindsitsapplicationinfood industriesforliquidfoodconcentrationwhilepreservingtheheat-sensitivecompounds. Lowhydraulicpressure,lowtreatmenttemperature,lowfoulingtendency,andhighsolid contentarethemainadvantagesofFOcomparedwithboththermalandconventional membraneprocessing.Thechaptershowsacomprehensiveaccountofrecentadvances inFOtechnologyasrelatedtothemajorissuesofconcerninitsrapidlygrowingapplicationsinfoodprocessingsuchasconcentrationoffruitsandvegetablesjuices(grape,pineapple,redraspberry,orange,tomato,andredradishjuices)andnaturalfoodcolorants

(anthocyaninandbetalainextracts).Italsoprovidesaclearoutlineforresearchersonthe recentdevelopmentsinFO.

With Chapter6 (Ibrahim,Isloor,andFarnood)startsPartII.Thischapterendowsan inclusiveintroductiontothefundamentalsandbasicsoftheROprocessstartingfrom theshorthistory,plants,andtheoreticalcontextualofRO.Aconcisesummaryofthe recentadvancesinROmembranesandmaterialsthenfollows.Lastly,theusageofdifferenttypesofmodulessuchasspiralwoundpreparedfromflatsheetmembranesand hollow-fibermembranesusedinROdesalinationisdiscussedindetail.Inrecenttimes, manycommercial-scaleseawaterdesalinationplantshavebeenconstructedinwaterstressedcountries,whichisexpectedtoincreaseinthenearfuturetoincreasetheavailabilityofpotablewater.Inspiteofmanydevelopmentsinthedesalinationtechnologies, seawaterdesalinationusingROmembraneisbeingconsideredasthestate-of-the-art technology.Inthiscontext, Chapter7 (SyedIbrahim,Isloor,andFarnood)introduces thepretreatmenttechniques,foulingandcontrolstrategies.Theauthorssuggesttotake intoconsiderationthattherearealsosomelimitationstotheROmembranedesalination bytheunavoidablemembranefouling,whichincreasetheoperatingcostandtransmembranepressure.Here,thechapterreviewsthepotentialwaytotheROmembranefouling controlstrategies,whichincludestheroleofadvancedmaterials,surfacemodification, andfeedwaterpretreatment.In Chapter8,theauthors(MondalandDe)attributetheprimaryreasonbehindthedevelopmentofsciencefortheROmembranetoitspotentialin desalinationofbrackishwater.Thoughthetechnologyhasbeenwellestablishedformore thanadecadenow,thereareseveralscopesofimprovementinitsscaling-upandsmooth operation,whicharelinkedtotheunderstandingandmodelingoftheprocessdynamics. RO-basedprocessesarealsosuitableforseparation(andremoval)ofhighvaluedlow–molecularweightcompounds,whichisotherwisedifficultthroughchemicalroutes.In recentyears,therehasbeengrowthintheresearchofnewmembranematerialstargeted towardhighflux/highselectivity,showingpromiseingreatereconomicbenefitand reducedenergycosts.Inthiscontext,itisquiteimperativetounderstandthephysicalphenomenainvolved,withinthepurviewofmathematicaldesignequations,simulatingthe performanceforthegivenoperatingconditions. Chapter9 (Trishitman,Cassano,Basile, andRastogi)isdedicatedtotheROforindustrialwastewatertreatments.Consideringthat thefundamentalresourceofeconomic,social,andculturaldevelopmentoftheworldis water,itisevidentthataverysmallamountoftheglobalwaterisavailablefordirectaccessibility.Unfortunately,thislimitedamountofavailableglobalwaterhasbeenpollutedby industrialplants.Theever-evolvingandever-increasingstrictregulatorystandardsfordischargingeffluentsfromindustriesposehugeenvironmentalandeconomicimplications becauseofbulkdepositionintheenvironment.Whiletheworldfacesanincreasedscarcityinfreshwatersupply,itisgreatimportancethatthewastewaterfromtheindustries canbetreated,recycled,andreused.ROmembranescanbeappliedtoprocessorconvert thewastewaterintocleanwaterorintoeffluentsthatcanreturntothewatercycledirectly totheenvironmentorforreuse.Thischapterincludesthemajorsourcesofindustrial wastewater,theircharacterizationandevaluation,thesuppliersofROwastewater

treatmenttechnologies,andapplicationsofROsystemfordifferentindustrialwastewaters.Thenextwork, Chapter10 (Cassano,Rastogi,andBasile),isdedicatedtoROinfood processing.RO,recognizedasaleadingtechnologyindesalinationprocesses,isalsoa well-establishedapplicationinfoodprocessingduetoitsseveraladvantagesoverconventionalmethodologies(suchaspreservationofthermosensitivecompounds,lowenergy consumption,andlowinvestmentcosts).Thechapterfocusesonthemainapplications ofROinfoodprocessing,includingconcentrationoffruitandvegetablejuices,preconcentrationofmilkandwhey,improvementofmustqualityandwinedealcoholization. ThecontributionofROtotherecoveryofbiologicallyactivecompoundsfromagrofood wastewaters,accordingtothenewindustrialecologyandbiorefineryconcepts,isalsodiscussed.Inthesefields,thecombinationofROandothermembranefiltrationsystemswell contributestoredesignthetraditionalprocessingoffoodandbeverageswithinthelogicof theprocessintensificationstrategy,withremarkablebenefitsintermsofproductquality, plantcompactness,environmentalimpact,andenergeticaspects.Theseaspectsare addressedindetailaccordingtothelatestliteratureinputs.

With Chapter11 (S.LiandZ.Li)startsPartIII.ItconsidersbothFOandROinintegrated systems.SincetheosmoticpressureasdrivingforceinFOiscreatedbytheosmoticgradientbetweenfeedsolutionanddrawsolution,aposttreatmentofdrawsolutionisgenerallyrequiredandconductedbyROtorecoverproductwaterandreusedrawsolutes. Therefore,FOandROareoftencombinedinanintegratedmembranesystemtostudy salinewaterdesalination,wastewatertreatment,andrenewableenergygeneration.The harshfoulingofconventionalROprocesscanbeconvertedtoreversiblefoulingofFO intheintegratedsystem.Itispossibletoperformthedesalination,watertreatment, andenergygenerationsimultaneouslybyemployingdifferentwater(suchasquality impairedwater,salinewater,andconcentratedbrine)intheintegratedsystem.TheintegratedFO-ROmembranesystemcanplayapromisingroleforthecomprehensivemanagementofwaterresourceandpromotethesustainabilityinwater-energynexus.

Chapter12 (S.LiandZ.Li)describesFOandROindesalinationmembranesystems.After morethan40years’development,ROmembranedesalinationisawell-establishedtechnology,withsimilarmarketshareasconventionalthermaltechnologies.However,membranefouling,especiallybiofouling,stillremainsachallengefortheROdesalination. Transparentexopolymerparticlesrecentlyarereportedasakeymembranefoulingelement.FOcanbeusedfordesalinationifcombinedwithotherseparationtechnologies. TheFO-ROhybridsystemconsumesslightlymoreenergythanconventionalROunit, butitslifespancanbeextendedduetothereductionofROmembranefouling.In Chapter13 (Osipi,Secchi,andBorges),acostanalysisofFOandROisperformedbyconsideringacasestudy.Costsensitivityanalysisisanimportanttooltostudywatertreatmentprocessesandunderstandhowvariablesandparametersaffectwatercost.Itcan alsobeusedtosetthedriversforfutureresearch,sincethemembraneparameters,for example,canalsobeinvestigated.Inthischapter,FOandROasstand-aloneprocesses and,sequentially,thecombinedFO-ROprocessareinvestigatedusingsensitivityanalysis. Itisobservedthatthestructuralparameterisoneofthekeyinfluencersonproducedwater

costforthecombinedprocess.Additionally,severalparametersindicatethatFO-ROfeasibilityishighlysensitivetoROconditionsandsaltrepositioncost.Thisresultsuggests thatdifferentrecoverymethodsmaybemoresuitableforconcentratingthedrawsolution, especiallywhenthefeedisahigh-salinitystream.In Chapter14 (Thiruvenkatachari,Su, andCunnington),acombinedFO-ROprocessforminingwastewatertreatmentispresentedanddiscussed.Waterinteractionsinminingprocess,wastewatercharacteristics, treatmentmethodsadopted,andtheresearchtechnologygapsarebrieflydiscussed.A lab-scaleintegratedFO-ROwasusedtoestablishtheproofofconceptinapplyingthis technologyforminewatertreatment.Theintegratedsystemhasbeentestedunder extendedoperationwithvariousminewaters.TheFOcombinedwithROcouldminimize numberofpretreatmentstepsrequiredfortheRO.Thistechnologycanreducethebrine volumebyatleast80%andrecoverconsistentqualityreusablewater.Apilot-scaleFO-RO model(capacityof1m3/day)wasdesignedbyincorporatingtwodifferenttypesofFO membranes.Thestudyshowsthatthisprocesscanpotentiallyofferasignificantreduction inenergyuse,chemicaluse,pipinginfrastructure,andoperatingcostsindesalinating minewater,andthesuccessofthistechnologyisintheefficientprocessdesign,FOmembranemoduleconfiguration,membranechemistry,andthestructure.

Wewishtogreatlythankalltheauthorsofthechaptersfortheirexcellentworkandalso fortheirpatiencetocarefullyfollowoursuggestionsandcomments.WealsoaddourspecialthankstoallthestaffofElsevierfortheirconstantandprofessionallyhighqualified help.Wetrustthatthisbookwillbehelpfultothescientificcommunityinproviding in-depthviewandpromotingthepromisingdevelopmentofmembranetechnologyfor sustainablefuture.Besides,thisbookcanserveasanessentialreferencesourcetostudentsandresearchersattheuniversitiesandresearchinstitutions.

AlfredoCassano

Forwardosmosis:Principles, applications,andrecent developments

NavinK.Rastogi

DEPARTMENTOFFOODENGINEERING,CE NTRALFOODTECHNOLOGICALRESEARCH

INSTITUTE,COUNCILOFSCIENTIFICAND INDUSTRIALRESEARCH,MYSORE,INDIA

Listofacronyms

DS drawsolution

ECP externalconcentrationpolarization

FO forwardosmosis

ICP internalconcentrationpolarization

NF nanofiltration

RO reverseosmosis

UF ultrafiltration

Listofsymbols

AandB activelayerpermeabilitycoefficientsofthemembraneforwaterandsolute,respectively

Jw flux

k masstransfercoefficient

Κ soluteresistivityfordiffusionwithintheporoussupportlayer

Greeksymbols

ΔP differenceinpressure

π bulkosmoticpressure

π* osmoticpressureonmembranesurface

π0 osmoticpressureinsidetheactivelayer

Subscripts

d drawsolution

f feedsolution

w water

1Introduction

Osmosishasbeenasubjectofstudyinvariousscientificandengineeringdisciplines.Itis well-definedasamethodfortransportofwaterbasedonthedifferenceinosmotic CurrentTrendsandFutureDevelopmentson(Bio-)Membranes. https://doi.org/10.1016/B978-0-12-816777-9.00001-0

© 2020ElsevierInc.Allrightsreserved.

pressureacrossasemipermeablemembrane.Forwardosmosis(FO)isdefinedasamembraneprocessinwhichthedifferenceinosmoticpressureproducesmovementofwater fromthefeed(dilute)solution(lowosmoticpressure)sidetothedraw(concentrated) solution(highosmoticpressure)side,throughaselectivelypermeablemembrane.FO allowshigherconcentrationsofjuiceswithoutsignificantfoulingofthemembrane (Beaudry&Lampi,1990a; Nayak&Rastogi,2010a; Rastogi,2016).

Alsoknownbyothernamessuchasdirectosmosis,engineeredosmosis,andmanipulated osmosis,FOconcentratesliquidfoodsatambienttemperature.Theprocessutilizesan osmoticsolutiontoisolatewaterfromafeedthroughasemipermeablemembrane.Incontrast,thereverseosmosisprocessrequireshydraulicpressureasthedrivingforcefor separation.

Duetoitslowhydraulicpressurerequirement,FOhasseveralpotentialadvantagesin comparisontoprocessessuchasreverseosmosis(RO),nanofiltration(NF),andultrafiltration(UF).Itsmainadvantagesovertheconventionalprocessingmethodscanbesummarizedas(Babu,Rastogi,&Raghavarao,2006; Cath,Adams,&Childress,2005; Cath, Gormly,etal.,2005):

• Retentionoffreshfruitflavorandnutritional/bioactivecomponents

• Minimumcolordegradationandimprovedproductquality

• Concentrationatambientpressureandtemperature

• Absenceofthermaleffects,socookedtasteisnotimpartedtothefood

• Reductioninmembranefoulingpropensityoverpressure-drivenmembraneprocesses

• Useofsimpleequipmentandenergyefficiency

Manyfruitjuicescontainbioactivecompoundssuchasvitamins,phenoliccompounds, anthocyanins,andcarotenoids.Oncethecolorantsareextractedfromplantsources,the juiceisverydiluted( Thomas,1984).Thesejuicesaregenerallyconcentratedbyemploying thermalevaporationundervacuumtoavoidgrowthofmicroorganisms,toextendtheshelf life,andtoreducethecostofstoringandshipping.However,thisalsoresultsinthelossof thefreshjuicearomaandcolordeterioration(lossofhueandchroma),besidesthedevelopmentofacookedtaste,subsequentlyleadingtodegradationinthequalityoftheproduct (Bhaskaran&Mehta,2006; Patil&Raghavarao,2007).FOhasbeensuccessfullyusedforthe concentrationoffruitjuicesaswellasnaturalcolors(Babuetal.,2006; Bolin&Salunke, 1971; Loeb&Bloch,1973; Nayak&Rastogi,2010a,2010b; Nayak,Valluri,&Rastogi,2011; Popper,Camirand,Nury,&Stanley,1966; Rodriguez-Saona,Giusti,Durst,&Wrolstad, 2001; Zhao,Zou,Tang,&Mulcahy,2012),wastewatertreatment(Holloway,Childress,Dennett,&Cath,2007),andfreshwaterrecoveryfromseawater(Kravath&Davis,1975).

Thethermalconcentrationofliquidfoodsisveryenergyintensiveandresultsin lossofsensoryandnutritionalproductquality(Lazarides,Iakovidis,&Schwartzberg, 1990; Petrotos&Lazarides,2001).Increasingconsumerdemandforhigh-quality concentratedfruitjuicesandnaturalcolora ntshasmotivatedthedevelopmentofinnovativemethodssuchasfreezeconcentrationorreverseosmosisforconcentration,for improvedqualityandmoreefficientenergy utilization.Theseprocessesarecapital intensiveandalsosufferfrommanylimitati ons,e.g.,high-pressurerequirements,

aceilingonthemaximumattainableconcentration,andconcentrationpolarization (Babuetal.,2006; Rastogi&Nayak,2011).

Cost-effectivemethodsbasedonmembranesforwaterpurificationanddesalinating seawaterareneededtoproducepurifiedwaterfromsalinewater.Thedevelopmentof aneffectiveandefficientdrawsolutionwithalow-costenergyrecoverysystemisessential forincreasedperformanceofthisprocess,aswellasachievingalargerscaleforFO.The noveltyoftheprocessliesinutilizinganaturalosmoticprocessfordesalinationrather thanhydraulicpressure,asinRO.FOhasthepotentialtoachievehighwaterfluxalong withhighwaterrecovery,whichreducesthevolumeofdesalinationbrine,amajorenvironmentalissue(McCutcheon,McGinnis,&Elimelech,2005).

EasternEuropeanfarmershaveshownthatextractingjuiceintoabagandsubjectingit toaNaClsolutionresultsinahigherconcentrationoffruitjuice.However,thistechnique requiredalongertimetoachieveconcentrationofthejuices(Cussler,1984). Scott(1975) developedaprocessfortheconcentrationofliquidfoods,e.g.,fruitjuicesordairyproducts,byimmersingthepackedbagsofmembranematerial(celluloseorpolysulfones)into adrawsolutionatarelativelyhightemperaturewithcontinuousstirring.

SincethefeedduringFOisnotsubjectedtopressureortemperature,itmaintainsthe color,taste,aroma,andnutritionoftheoriginalproduct(Cath,Childress,&Elimelech, 2006;Yang,Wang,&Chung,2009a). Popperetal.(1966) indicatedthatfruitjuiceconcentrationusingtheFOprocesswaspossiblebyutilizingcelluloseacetatereverseosmosis membranes.However,thisresultedinloweraveragetransmembraneflux.Modifiedthin filmcompositeROmembranes(thickness25–85 μm)withincreasedturbulenceyield higherosmoticfluxandreducedfouling(Beaudry&Lampi,1990a,1990b; Herron, Beaudry,Jochums,&Medina,1994).Subsequently, Petrotos,Quantick,andPetropakis (1998,1999), PetrotosandLazarides(2001) showedthatuseofathinnermembranewith lessviscousosmoticmedium,e.g.,saltsolution,demonstratedimprovedperformanceas comparedtoamoreviscousosmoticmedium.Microfiltrationorultrafiltrationclarificationofthejuicebeforefiltrationledtohigherfluxes.FOconcentratedjuicewasfoundto beofimprovedqualityincomparisontojuiceconcentratedbyevaporation(Herron etal.,1994).

Inordertoimplementthistechnologyonalargescale,itisnecessarytoworkout strategieseitherforrecoveryoradisposaldrawsolution,whichisconsideredtobeanecessaryevilthatrequireshighenergyand/orcapitalcosts(Garcia-Castello,McCutcheon,& Elimelech,2009; McCutcheonetal.,2005).FOpromisestoemergeasalow-energy solutionifmethodsfortheregenerationofdrawsolutescanbefoundthatareeconomicallyandtechnicallysound(McGinnis&Elimelech,2007).Anumberofpublicationsare availableintheliteratureontheconcentrationofbeveragesandliquidfoodsusingFO; however,thesearegenerallyoflaboratoryscale(Raghavarao,Nagaraj,Patil,Babu,&Niranjan,2005).Reversedrawsolutefluxisoneoftheimportantparametersthatmustbe assessedwhenevaluatingtheperformanceoftheFOprocess.Thereversesaltdiffusion phenomenoncandecreasethenetosmoticpressureacrossthemembrane,whichresults influxdeclineandcanjeopardizetheprocess.Moreover,reversesalttransportisnotonly aneconomicalloss,butcanalsocomplicateconcentratemanagement.

ThecapabilitiesandlimitationsofFOhavebeenextensivelyreviewed(Cathetal.,2006; Chung,Zhang,Wang,Su,&Ling,2012; Jiao,Cassano,&Drioli,2004; McCutcheon&Elimelech,2007; Rastogi,2016; Rastogi&Nayak,2011; Wilf,2010; Wong&Winger,1999; Zhao etal.,2012).ThisreviewmainlyconcentratesonthevariousaspectsandbenefitsofFOin foodprocessing.ItfocusesondevelopmentsinFOmembranes,mechanismsofwater transport,andcharacteristicsofosmoticsolutions;theFOmembranesthemselvesaswell astheirusesarediscussedindetail.

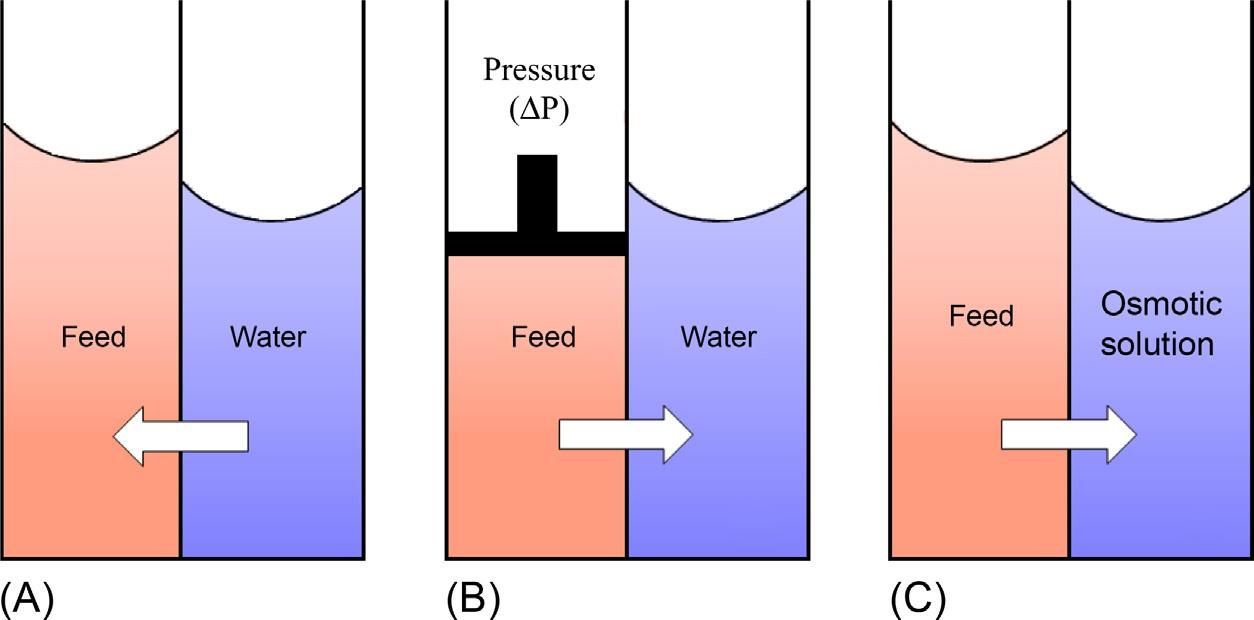

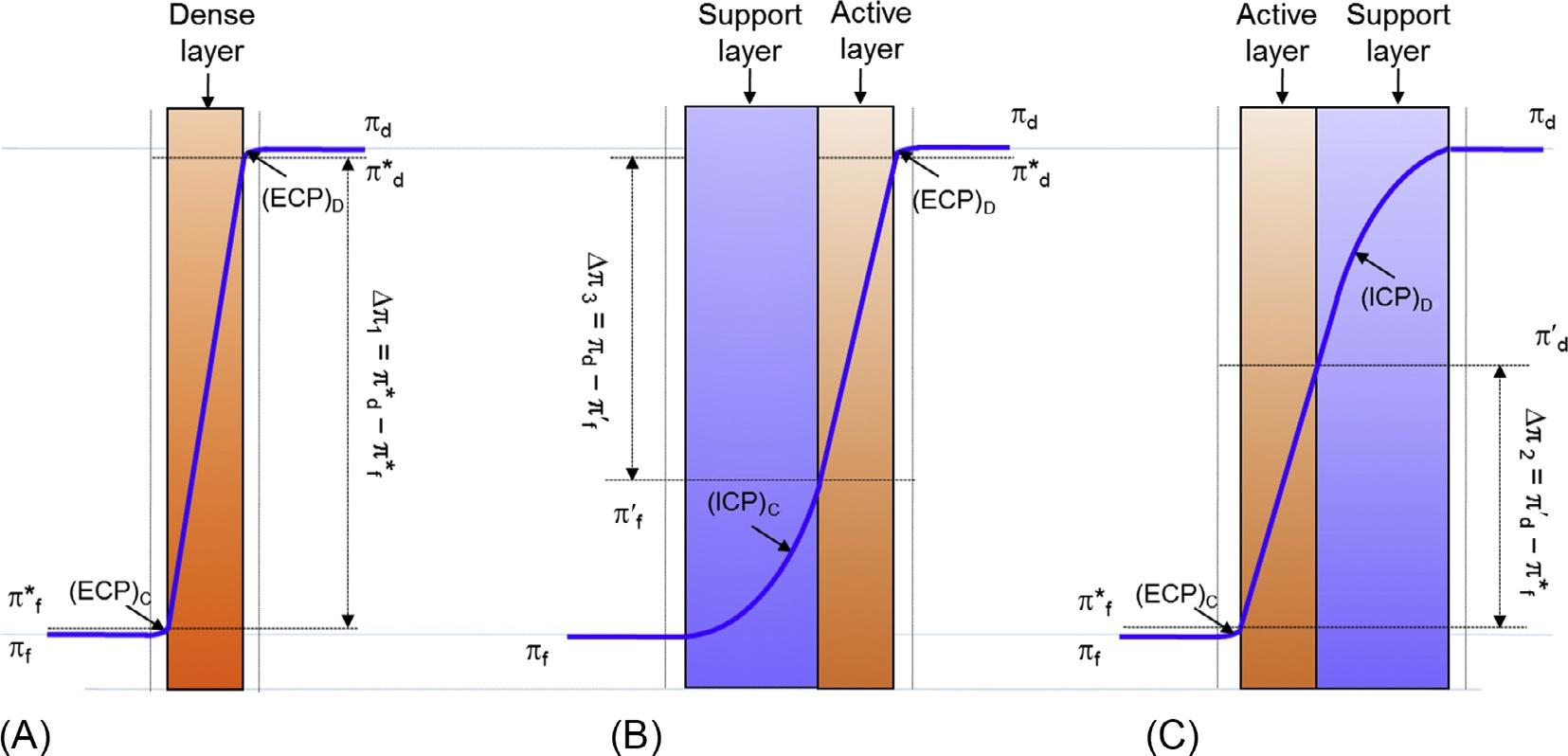

2Transportacrosstheforwardosmosismembrane

Osmosisisreferredtoasthediffusion-drivenmigrationofwatermoleculesfromalow concentrated(hypotonic)toahighlyconcentrated(hypertonic)solutionthroughaselectivelypermeablemembranewiththeaimofequalizingthechemicalpotential(soluteconcentrations)onbothsides.Thewateristransportedacrossthemembranesothatthe chemicalpotentialoneithersidebecomesidentical(Fig.1A).Thedifferenceinthepressureacrossthemembraneleadstotheconcentrationofliquidfoodswithoutaphase change.Hydraulicpressureisusedasadrivingforcetooffsettheosmoticpressuredifferential(Δπ)(Fig.1B).FOisanosmoticprocessinvolvingasemipermeablemembraneto separatethefeedfromthedrawsolution.Theosmoticpressuregradientbetweenthefeed andthedrawsolutionactsasthedrivingforcefortheseparationofwaterfromthefeed towardthedrawsolution,resultingintheconcentrationofthefeedsolution(Fig.1C) (Cathetal.,2006; Rastogi&Nayak,2011).

Therelationshipamongwaterflux,osmoticpressure,andhydraulicpressurescanbe describedas:

FIG.1 Migrationofwaterduring(A)osmosis,(B)reverseosmosis,and(C)forwardosmosis.The arrows indicatethe directionofmasstransfer. 4 Pisthehydraulicpressureand πf, πd, πw aretheosmoticpressuresoffeedsolution,draw solution,andwater. FromRastogi,N.K.(2016).Opportunitiesandchallengesinapplicationofforwardosmosisin foodprocessing. CriticalReviewsinFoodScienceandNutrition, 56,266–291.

where,Jw,A,and ΔParetheflux,membranepermeability,anddifferenceinpressure, respectively(Rastogi,2016; Xu,Peng,Tang,ShiangFu,&Nie,2010).

Concentrationpolarizationisabuildupofretainedmoleculesatthesurfaceofthe membrane,resultinginadecreaseinosmoticpressuredifferenceacrossthemembrane (reductionintransmembraneflux),whichisaprobleminpressure-drivenmembrane processes,e.g.,RO.InthecaseofadenseFOsymmetricmembrane,thisphenomenon canariseonbothsidesofthemembrane(towardboththefeedanddrawsolutions). Thesoluteisconcentratedonthefeedsideanddilutedonthedrawsolutionside,resulting inconcentrativeanddilutiveexternalconcentrationpolarization(ECP),respectively (Fig.2A).ThefluxequationforFOcanbegivenas:

Eq. (2) canbemodifiedforhigherfluxestoquantifythedilutiveaswellasconcentrative (feed/drawside)ECP(McCutcheon&Elimelech,2007):

FIG.2 Mechanismofforwardosmosisindicatingwatertransport(A)withadensesymmetricmembrane;with asymmetricmembrane(B)feedtowardthesupportlayer(modeI)and(C)feedtowardactivelayer(modeII); πd and πf arethebulkosmoticpressuresofdrawandfeedsolutions,respectively; π* d and π* f theosmoticpressureson membranesurfaceofdrawandfeedsolutions,respectively; π0 f and π0 d aretheosmoticpressuresofthefeedanddraw solutionsontheinsideoftheactivelayerwithintheporoussupportforconcentrativeinternalconcentration polarizationonfeedsideanddilutiveinternalconcentrationpolarizationondrawsideformodeIandmodeII, respectively.Notethat Δπ1, Δπ2,and Δπ3 arethecorrespondingeffectivedrivingforcein(A),(B),and(C)situations, respectively. FromRastogi,N.K.(2016).Opportunitiesandchallengesinapplicationofforwardosmosisinfood processing. CriticalReviewsinFoodScienceandNutrition, 56,266–291.

whereJw,kf,andkd arethewaterfluxandmasstransfercoefficientsonfeedaswellasdraw solutionsides,respectively; πf and πd arethebulkosmoticpressuresoffeedanddrawsolutions,respectively; π* f ¼ πf exp Jw kf and π* d ¼ πd exp Jw kd aretheosmoticpressuresof feedanddrawsolutions,respectively.

TheFOasymmetricmembrane(looselyboundedsupportlayerandthecompacted activemembranelayer)canbeemployedintwoalignments,withfeedtowardthesupport layer(normalmode,modeI)andfeedtowardtheactivelayer(reversemode,modeII), (Fig.2BandC)(Gray,McCutcheon,&Elimelech,2006; Nayak&Rastogi,2010a).Formode I,waterfromthefeedarrivesattheporoussupportlayeranddiffusesthroughtheactive layerintothedrawsolution.However,thesaltalsogoesinwithwaterintotheopenstructureandistransportedandretainedbytheactivelayer,resultinginariseinconcentration onthesideofthesupportlayer,whichiscalledconcentrativeinternalconcentration polarization(ICP).Thesupportlayercreatesnoresistancetowatermigrationandallows freepassageofthesolutethroughit.Hence,itisassumedthatnoconcentrativeECP occursonthesideofthesupportlayer(Cathetal.,2006).Onthepermeateside,dilutive ECPoccursduetotransferofdissolvedosmoticagentfromthemembranesurfaceleading tothereductionofeffectivedrivingforce(Fig.2B).

InthecaseofmodeII,whenfeedisonthesideoftheactivelayer,thedilutiveICPtakes placetowardthepermeateside.Themovementofwatertowardthedrawsolutionsideled toahigherconcentrationofsoluteontheactivelayerofthemembrane(increasesthe osmoticpressure),resultinginadecreaseinthedrivingforce.Thiseffectcannotevenbe reducedbyhydrodynamicssuchasturbulence,andhenceradicallylessenstheosmotic drivingforce(McCutcheon&Elimelech,2007).NoECPtranspiresatthedrawside(Fig.2C).

ThefluxesduringFOthroughanasymmetricmembrane,inthecasesofmodeI(feed towardthesupportlayer)andmodeII(feedtowardtheactivelayer),arerepresentedby Eqs. (4),(5),respectively.

Symbols π0 f and π0 d aretheosmoticpressuresofthefeedanddrawsolutionsonthe insideoftheactivelayerwithintheporoussupportforconcentrativeICPonthefeedside anddilutiveICPonthedrawsideformodeIandmodeII,respectively: π0 d ¼ πd exp( JwKd) and π0 f ¼ πf exp(JwKf );Kf andKd arethesoluteresistivitieswithintheporoussupportlayer formodeIandmodeII,respectively.FormodeI,concentrativeICPanddilutiveECPoccur simultaneously.Likewise,formodeII,dilutiveICPandconcentrativeECPexistatthe sametime.

NayakandRastogi(2010a) illustratedtheprocessofwatermigrationinFOfromafeed solutioncontainingamixtureoflowaswellashighmolecularweightcompounds.For modeI,highmolecularweightcompoundsareretainedonthesurfaceofthesupport layer,leadingtodevelopmentofmarkedECPonthefeedside.Atthesametime,low

molecularweightcompoundsdiffusewithinthesupportlayer,resultinginconcentrative ICP.However,theECPtowardtheosmoticagentsidewasalmostinsignificant.Formode II,thewaterfromthefeedisdiffusedintotheactivelayerandthenistransportedtothe bulkviathesupportlayer.ECPonthefeedsideisinsignificantincomparisontoICP (Nayaketal.,2011). MiandElimelech(2008,2010) alsoindicatedthatdepositionofhigh molecularweightcompoundsintheporousstructureresultsintheformationofacake layer.ThefollowingequationscouldbeemployedforthecalculationofmembraneresistivityduringtheFOprocessformodeIandII(Grayetal.,2006; Loeb,Titelman,Korngold,& Freiman,1997; McCutcheon&Elimelech,2007; Tang&Ng,2008):

whereJw isthetransmembranefluxduringFO,Kc andKd arethemembraneresistivity (s/m)formodesIandII,respectively; πd and πf aretheosmoticpressureofdrawandfeed solutions,respectively.TheconstantsAandBaretheactivelayerpermeabilitycoefficients ofthemembraneforwaterandsolute,respectively(Grayetal.,2006; Loebetal.,1997). Further,theeffectofinternalconcentrationpolarizationonthefluxbehaviorduring FOwasstudiedbymanyresearchers(Gruberetal.,2011; Lietal.,2011; Sagiv&Semiat, 2011; Tang,She,Lay,Wang,&Fane,2010; Zhao&Zou,2011a,2011b).

3Drawsolutionsforforwardosmosis

Recently,FOhasgainedrenewedinterestasanemergingtechnologyleadingtoalowenergydesalinationprocess.VitaltotheFOprocessarethedrawsolution(DS)and themembrane,becausebothplayanimportantroleinitsperformance.Hence,the selectionofanappropriateDSisessentialinobtainingprocessefficiency.FOemploys thenaturalosmoticpressuregradientbetweenadrawsolutionandafeedsolutionfor theproductionofpotablewater,offeringalow-energy,low-costalternativetomoreconventionaltreatmentmethods.Asapotentialsolutiontothecrisesofenergyand resources,FOhasbeenlimitedbythedevelopmentofdrawagents.Anidealdrawagent shouldgeneratehighosmoticpressureandbeeasilyrecoverable.Transferofsalttothe feedside(reversedrawsolutediffusion)reducesthewaterfluxandcontaminatesthe feedsolution.Thedrawsolutionshouldbewatersolubleanditshouldprovidegreater osmoticpressurethanthefeedsolutiontoobtainincreasedwaterfluxandminimal reversesaltdiffusion,andtoyieldasuitableprocessforeconomicalreconcentration. Reversesaltdiffusioncontaminatesthefeedsolution,diminishesthedrivingforce, andmayadverselyaffecttheproductquality.Inthecaseofpotablewater,drawsolutes shouldbenonexistentinthefinalproduct(water)oratleastbelowthemaximumallowablecontaminantlevel.

Achilli,Cath,andChildress(2010) establishedaprocedurefortheselectionofideal osmoticsolutionsforFOapplicationsbyevaluatingtheamountofwatertransport,salt diffusiontothefeedside,ROpermeateconcentration,andcostofreplenishment.Similarly, Kimetal.(2012) alsoplannedalogicalapproachforaviableandoptimaldrawsolute foranFOdesalinationprocess.AconcentratedNaClsolutioniscommonlyadoptedasan osmoticagentsolutionbecauseofitshighsolubility,nontoxicnature,andthepossibility ofconcentratingbyinvolvingconventionaldesalinationtechniques.Otherdrawsolutes, suchasCaCl2,MgCl2,KHCO3,andNaHCO3,canalsobeused.

Grayetal.(2006) demonstratedthattheconcentrationandmolecularweightofosmotic agentssuchasNaCl,sucrose,ordextroseusedasadrawsolutioninthecaseofmodeIdid nothaveasubstantialeffectonthetransmembranefluxbecauseofnosubstantialICPor ECP.However,inthecaseofmodeII,itledtodecreasedfluxduetosignificantICP. Petrotos etal.(1998,1999) examinedtheconcentrationoftomatojuicewithFOusingCaCl2, Ca(NO3)2,andNaCl. McCutcheonetal.(2005) and McCutcheon,McGinnis,andElimelech (2006) reportedamethodforseawaterdesalinationusingathermolyticdrawsolution basedonammoniaandcarbondioxide.

Mondal,Mahto,etal.(2015) and Mondal,Nataraj,etal.,2015 showedthefeasibilityof employingseveralapproachesfordeepeutecticsolventsasadrawagenttoenrichlow abundanceDNAandproteinsusinganFOprocess. DuttaandNath(2018a,2018b) discussedtheprospectofionicliquids(ILs)anddeepeutecticsolventsasnew-generation drawsolutions.ILswithsmallmolecularweightandlowviscosityshowedacomparable waterpermeabilitytotheNaClaqueoussolution,aswellasthepossibilityofrepeateduse. Itresultsinhighwaterrecoveryefficiencyandminimalreversediffusion.FOdesalination withapolyelectrolyte-baseddrawsolutiongainedmoreattentionduetolowreversesolutefluxandeasyrecoveryofthedrawsolution.

Hydrogelsarepromisingandinnovativeosmoticagents,whichmayrendertheFOprocesssimplerandmoreenergyefficient.Theycanbeadoptedasapossiblematerialfor hydrationbagsforfastandrepeatableproductionoffreshwaterfromsalinewateror wastewater( Yu,Zhang,&Yang,2017a,2017b). Li,Gao,andTang(2011) establishedthat polymerhydrogelparticleswithlight-absorbingcarbonparticlescouldbeusedasosmotic agentssuitabletoextractwaterthroughFOmembranes,whichcouldthenberecuperated byheatingorbyapplyingpressure,oracombination.Chemicalstructuremodificationof ahydrogelnetworkbyintegratingionicgroupsandlight-absorbingparticlescansignificantlyincreasetheeffectivenessofhydrogels.Largehydrogelparticlesresultedingreater liquidwaterrecoveryamounts,whereassmallerparticlesledtomorewaterrecovery underathermalstimulus(Razmjou,Simon,&Wang,2015).Electric-sensitivehydrogels asdrawagentscanreducereversesaltleakageandmaketheFOprocesssimpler.Similarly, stimuli-responsivehydrogelscancompletelyevadereversesolutediffusionandwatercan bereleasedsimplyunderexternalstimuli(Cui,Zhang,Jiang,&Yang,2018; Cui,Zhang,& Yang,2017; Cui,Zhang,Yu,&Yang,2018).Thepropensityofthesurfactantstoaggregate intomicellesandtoadsorbatinterfacesprovidesintriguingosmoticpressuresandoffers usablepropertiesbywhichosmoticsolutionscanberegenerated(Roach,Al-Abdulmalek, Al-Naama,&Haji,2014). 10CurrentTrendsandFutureDevelopmentson(Bio-)Membranes

Ling,Wang,andChung(2010) demonstratedthattheuseofhighlywater-solublemagneticnanoparticles(MNPs)cappedwithpolyacrylicacidasosmoticsolutesresultedin higherwaterflux.Amagneticfieldwasusedtocapturethenanoparticlesattheendfor recycling. LingandChung(2011a,2011b) developedanintegratedFO-ultrafiltrationsystemfordesalinationinvolvingsuperhydrophilicnanoparticlesasosmoticsolute,which wererecoveredfromtheosmoticsolutionbyultrafiltration. Kim,Han,andHong(2011) and Liu,Bai,Lee,andSun(2011) alsousednaturallynontoxicmagnetoferritinasadraw soluteforrecoveringdrinkingwaterinanFOprocesswithoutreversesaltdiffusion.These featuresoftheosmoticsolutionrenderFOasanecosustainableprocedure. Alejo,Arruebo, Carcelen,Monsalvo,andSebastian(2017) indicatedthatMNPsarethemostsuitable osmoticsolutionfordesalinationbecauseoftheirquickrecoverybyapplyingamagnetic fieldorbymembraneprocesses.Thetypesofdrawsolutesusedbymanyresearchersare presentedin Table1.

4Membranesforforwardosmosis

FOisdevelopingrapidlyandhasrevealeditsadvantagesinmanyapplications.However, challengessuchasreversesolutediffusion,concentrationpolarization,andmembrane foulingarethecurrentnecessaryevilsinFOprocesses.Tolessentheseproblems,substantialeffortshavebeenmadeinrecentyearstodesignsuitableFOmembranes.Chemical modificationofexistingmembraneshasbecomeavitalmethodinnovelFOmembrane studies(Xu,Chen,&Ge,2017).

ThemostcriticalaspectsindesigningFOprocessesaretheselectionofthemembrane. Membranesusedforreverseosmosis(dense,nonporous,andselectivelypermeable)can beusedforFO.However,thethicksupportlayerofROresultsinenhancedconcentration polarization,requiringaveryhighosmoticpressuredifferencetowithstandsatisfactory waterflux(Dova,Petrotos,&Lazarides,2007a,2007b;Grayetal.,2006; McCutcheon etal.,2005;McGinnis,McCutcheon,&Elimelech,2007).Thefeasibilityofadoptingbladdersofpigs,cattle,andfish,collodion(nitrocellulose),rubber,porcelain,andgoldbeater’s skinhasalsobeendemonstrated(Cathetal.,2006; Tang&Ng,2008).

IntheFOprocess,theconcentrationpolarizationormembranefoulingtakesplaceon thefeedaswellaspermeatesidesofthemembrane(Grayetal.,2006; McCutcheonetal., 2006).Thesupportfabriclayeradheredtothesupportlayerofasymmetricmembranes wasremovedandthesemembranesusedintheosmosisprocessby Loebetal.(1997), whoestablishedthatthemembranesupportlayersubstantiallyinfluencedthewater transport(McCutcheon&Elimelech,2008).

McGinnisandElimelech(2007) showedthat,thoughthewaterpermeabilityofthecellulosetriacetatemembranewasslightlylessthanthatofthereverseosmosismembranes, therewasanenormousdifferenceintheosmoticflux.Membranessuitableforreverse osmosiswereconsistingofaveryslimactivelayer(<10 μm)andabulkyporoussupport layer.ThefabricandsupportlayerspresentinROmembranesresultinsevereICPand, therefore,theysignificantlylessentheresultingwaterflux.

Table1 Severalnoveldrawsolutesusedbyvariousresearchersforforwardosmosis

ProductDrawsolutes

Ionicliquids

References

Protonatedbetainebis(trifluoromethylsulfonyl)imide Zhonget al. (2016)

Monocationicimidazolium,phosphonium,andammonium salts Zeweldietal.(2018)

1-Acetate-2,3-dimethylimidazoleionicliquidsodiumsalt

Polyelectrolyte

Poly(N-isopropylacrylamide-co-acrylic acid)

Hydrolyzedpoly(isobutylene-alt-maleicanhydride)

Cationicstarchbygrafting2,3-epoxyproplytrimethyl ammoniumchlorideontobackboneofcornstarch

Hydrogels

Chen,Ge,Xu,andPan(2019)

Wang etal.(2016)

Kumar,Al-Haddad,Al-Rughaib,and Salman(2016)

Laohaprapanonetal.(2017)

Polydiallyldimethylammoniumchlorideanditsmonomer HamadandChirwa(2019)

Acrylicacidandsodium p-styrenesulfonatemonomerswith hydrophilicgroup Cui,Zhang,Jiang,andYang(2018), Cui,Zhang,Yu,andYang(2018)

Ethyleneoxide-propyleneoxidecopolymer-thermoresponsive polyelectrolyte Ahmed,Kumar,Garudachari,and Thomas(2019)

Compositehydrogels:Reducedgrapheneoxideand hydrogels, e.g.,poly(sodiumacrylate)orpoly(sodium acrylate)-poly(N-isopropylacrylamide)

Polymerizationofmonomersodiumacrylate(SA)and cross-linker N,N0 -methylenebisacrylamide

Compositehydrogelmonolithscontainingthermoplastic polyurethane(TPU)microfibers

Hydrogel-polyurethaneinterpenetratingnetworkwith monolithformwaspreparedbycontrollingtheradical polymerizationofthemonomers(N-isopropylacrylamideand sodiumacrylate)

Grapheneoxidenanosheetscovalentlycross-linkedtosodium alginateformeda3-Dandhighlyporousaerogel

Electric-sensitivepoly(vinylalcohol)/poly(acrylicacid) (PVA/PAAc)hydrogels

Electric-responsivehydrogelsbyaqueoussolution polymerizationof2-acrylamido-2-methyl-1-propanesulfonic acidand2-(dimethylamino)ethylmethacrylate

Thermo-responsive N-isopropylacrylamidepolymer copolymerizedwithsuperabsorbentacrylicacidmonomer

Polymerhydrogel—Carboxymethylcelluloseandacrylicacid andquaternarygrapheneoxidenanomodifier

Copolymermicrogelsof N-isopropylacrylamideand acrylamide

Magneticnanoparticles

Citrate-coatedmagneticnanoparticles

Zengetal.(2013)

Li,Zhang,Simon,andWang(2013)

Ou,Zhang,Simon,andWang(2016)

Wei,Low,Ou,Simon,andWang (2016)

Yuetal.(2017a,2017b)

Cuietal.(2017)

Cui,Zhang,Jiang,andYang(2018), Cui,Zhang,Yu,andYang(2018)

GawandeandMungray(2015)

Shakerietal.(2019)

Hartanto,Zargar,Cui,Jin,andDai (2019)

Na, Yang, and Lee(2014), Kadhim, Al-Abodi,andAl-Alawy(2018)

Table1 Severalnoveldrawsolutesusedbyvariousresearchersfor forwardosmosis—cont’d

ProductDrawsolutes

Surfactants

Salts

References

Chitosan-anddehydroascorbicacid-coatedFe3O4 nanoparticles ShabaniandRahimpour(2016)

Hyperbranchedpolyglycerolcarboxylate-coatedmagnetic nanoparticles Yangetal.(2016)

Polyglycerol-graftedsilica-encapsulatedsuperparamagnetic ironoxidenanoparticles Nazarietal.(2017)

Magneticnanoparticle-crosslinkedferrohydrogel Shakeri,Salehi,Khankeshipour, Nakhjiri,andGhorbani(2018)

Micellarsolutionsofcetylpyridiniumchloride,sodiumdodecyl sulfate, and Triton X-100

Anionic(sodiumdodecylsulfate,1-octanesulfonicacid sodiumsalt)andcationicsurfactants(meristyltrimethyl ammoniumbromide,trimethyloctylammoniumbromide,or tetraethylammoniumbromide)

Ethylenediaminetetraaceticacid(EDTA)-2Nacoupledwith TritonX-100

TritonX100andNa3PO4

Poly(propyleneglycol)andTritonX100

Hexavalentphosphazenesalts

Oxalicacidcomplexes

Poly(asparticacidsodiumsalt)

EDTAcomplexes(EDTA-MgNa2,EDTA-CaNa2,EDTA-MnNa2, andEDTA-ZnNa2)

Chlorhexidinegluconate–basedmouthwashhaving antifungalandantimicrobialactivity

Gluconatesaltsforjuicereconcentration

Triethylenetetraminehexapropionicacidsodium (TTHP-Na)—Carboxyethylaminesodiumsalts

Ferric-lactatecomplex

Antiscalant-poly(asparticacidsodiumsalt)blendedsolution

Roachetal.(2014)

Gadelhaetal.(2014)

Nguyenetal.(2018)

Nguyenetal.(2015)

Rayetal.(2018)

Stone,Rae, Stewart, andWilson (2013)

GeandChung(2015)

Gwak,Jung,Han,andHong(2015)

Zhaoetal.(2016)

Rayetal.(2016)

Long,Qi,andWang(2016)

LongandWang(2016)

Yuetal.(2017a)

GwakandHong(2017)

Poly(4-styrenesulfonicacid-co-maleicacid)sodiumsalt Huang,Long,Xiong,Shen,and Wang(2017)

Glaubersalt—Sodiumsulfatedecahydrate

Oligomericcarboxylates—Polymaleicacidsodiumand poly(itaconate-co-acrylate)sodiumsalt

DuttaandNath(2018a,2018b)

Long,Huang,Xiong,Shen,and Wang(2018)

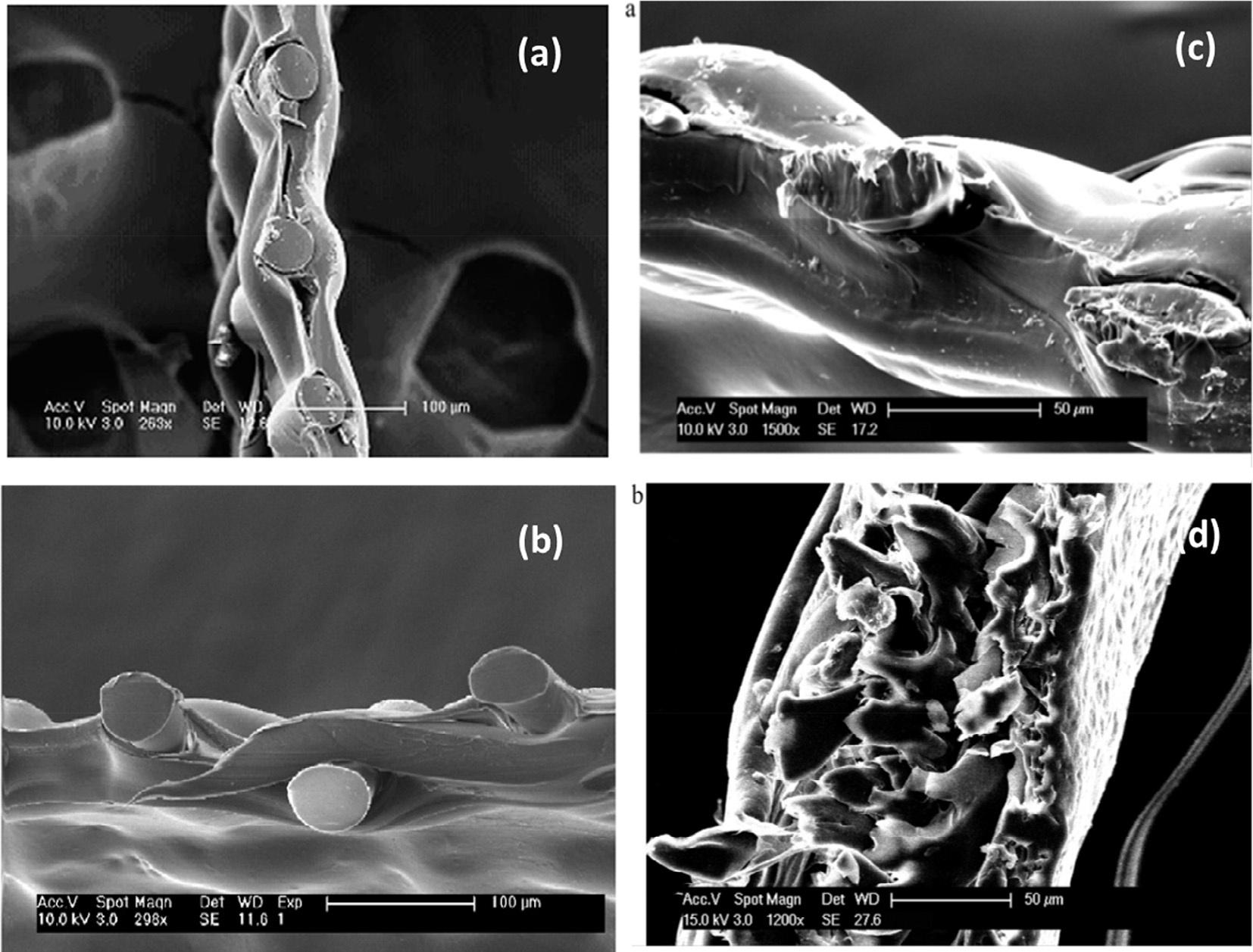

Subsequently,HydrationTechnologiesInc.intheUnitedStatesmanufacturedasuperior membraneforFOusingcellulosetriacetate,whichwasfixedinapolyestermeshtogivesupport,andasupportlayerwasprovided(<50 μm, Fig.3AandB)(McCutcheonetal.,2005;Ng, Tang,&Wong,2006).Thecross-sectionalSEMimagesofverythin( 50m)andthick

FIG.3 (A–D)SEMimagesofcross-sectionsofcellulosicforwardosmosismembrane(CA).Apolyestermeshis embeddedwithinthepolymermaterialformechanicalsupport.Themembranethicknessislessthan50 μm. From McCutcheon,J.R.,McGinnis,R.L.,&Elimelech,M.(2005).Anovelammonia–carbondioxideforward(direct)osmosis desalinationprocess. Desalination, 174,1–11;Garcia-Castello,E.M.,McCutcheonJ.R.,&Elimelech,M.(2009). Performanceevaluationofsucroseconcentrationusingforwardosmosis. JournalofMembraneScience, 338,61–66; Zhao,S.,Zou,L.,Tang,C.Y.,&Mulcahy,D.(2012).Recentdevelopmentsinforwardosmosis:Opportunitiesand challenges. JournalofMembraneScience, 396,1–21.

(>100m)asymmetricFOmembranesmadeofcellulosetriacetate(CTA)areshownin Fig.3C andD(Cathetal.,2006;Herronetal.,1994; Zhao&Zou,2011a,2011b).

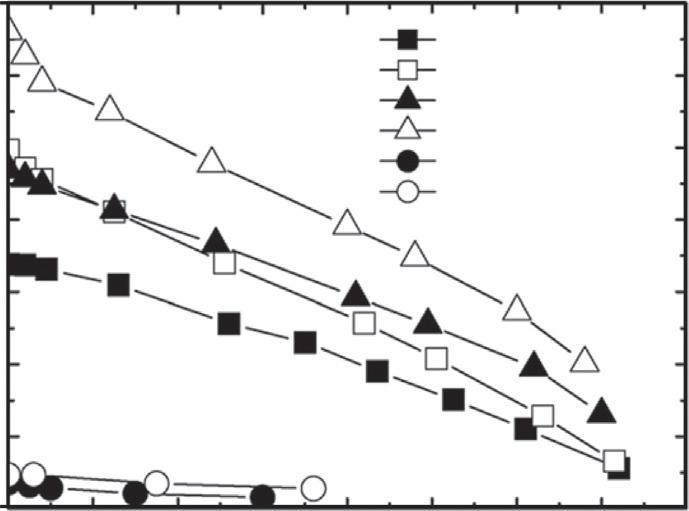

TheperformanceofthecellulosicmembraneproducedbyHydrationTechnologiesInc. (designatedasCA)andthereverseosmosismembranefromGeneralElectricInc. (Osmonics)(designatedasAG)wascompared,anditwaspointedoutthatthewaterfluxes fortheAGmembranewereonly7.7%oftheCAmembrane(Fig.4, Garcia-Castelloetal.,2009).

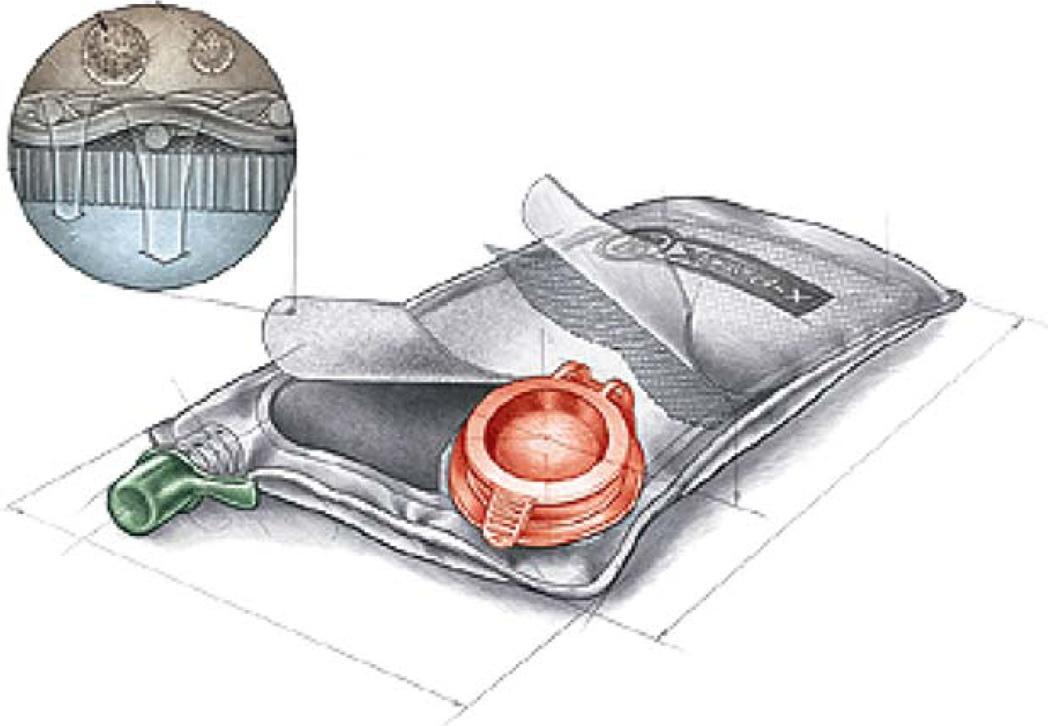

Cathetal.(2006) indicatedthatFOmembranecanbeusedformakingahydrationbag filledwithflavoredsucrose.Subjectingthebagtoanaqueoussolutiondiffuseswaterinto thebag(Fig.5)duetothedifferenceinosmoticpressureandslowlydilutesthedrawsolution.Thistechniquecanbeusedfortherecoveryofwater.Thehydrationbagsweredevelopedformilitaryandemergencyreliefsituationswherereliabledrinkingwaterwasnot available.

CA, 2 M DS, 20°C

CA, 2 M DS, 30°C

CA, 4 M DS, 20°C

CA, 4 M DS, 30°C

AG, 4 M DS, 20°C

AG, 4 M DS, 30°C

00.20.40.60.81.01.21.4 1.6

Sucroseconcentration (M)

FIG.4 Effectoftemperature,drawsolutionconcentration,andsucrosefeedsolutionconcentrationonpermeate waterfluxforboththeCAandAGmembranes.Experimentalconditions:feedsolution(sucrose)concentrationof 0–1.65M(0–48 °Brix),drawsolutionconcentrationof2or4MNaCl,andcross-flowratefordrawandfeedsolutionsof 1Lmin 1 (1.67 10 5 m3 s 1). FromGarcia-Castello,E.M.,McCutcheonJ.R.,&Elimelech,M.(2009).Performance evaluationofsucroseconcentrationusingforwardosmosis. JournalofMembraneScience, 338,61–66.

FIG.5 Illustrationofwaterpurificationhydrationbag. FromCath,T.Y.,Childress,A.E.,&Elimelech,M.(2006). Forwardosmosis:Principles,applications,andrecentdevelopments. JournalofMembraneScience, 281,70–87.

AhollowfiberFOmembranehavingaduallayerforproteinenrichmentconsistingofa fineselectiveskin( 10 μm),open-cellwaterchannels,andaporousspongesupportstructurewasdeveloped;itachievedincreasedpurityforlysozyme( Yangetal.,2009a;Yang, Wang,&Chung,2009b).

Zhangetal.(2010),Wang,Ong,andChung(2010),and Wangetal.(2010) prepareda celluloseacetateFOmembraneconsistingofaporoussublayerthatwassqueezedin betweentwoselectiveskinlayersforpreventingdrawsolutefrompenetratingintothe membranesupport,whichcausedincreasedwaterfluxandlesssaltmigration.Theactive layersshowedexcellentseparationpropertiesandgoodmechanicalstrength.

Wang,Yang,Chung,andRajagopalan(2009) fabricatedanFOmembranehavinghigh fluxandrejectionfordesalinationusingpolybenzimidazolenanofiltrationhollowfiber membranes,whichwerecross-linkedwith p-xylylenedichloride.Later, Su,Yang,Teo, andChung(2010) developedcelluloseacetatenanofiltrationmembranesbyexposing themtothermaltreatment,whicheffectivelyshrunkthemembraneporesleadingtoa higherrejectionofNaClandMgCl2 andlowpurewaterpermeability. Yip,Tiraferri,Phillip, Schiffman,andElimelech(2010) madeahigh-performance,thin-filmcompositemembranehavingaselectivepolyamideactivelayerformedbyinterfacialpolymerization ontopofapolysulfonesupportlayerontoathin(40-μm)polyesternonwovenfabric.

Augmentationofzwitterionwasfoundtoenhancethehydrophilicityandsurface roughnessofanFOmembrane,whichresultedinanimprovementinthewaterpermeability.Theanionicmoietyofthezwitterionwasexposedoutside,whilethecationicmoietiesofthezwitterionweremostlyretainedtowardthecore,assuggestedbynegativezeta potentialandproteinabsorption.Incorporationofzwitterionwasfoundtoenhancethe antifoulingpropertyofthemembrane(Chiaoetal.,2019). Jia,Li,Wang,Wu,andHu(2010) demonstratedthatcarbonnanotubemembranescanbeusedforseawaterdesalination usingFO,leadingtooptimumsaltrejectionandhigherwaterflux,besideshavingantifoulingabilityandgoodmechanicalstrength.Highwaterfluxesareattributedtothecapillarity ofZigzaggraphyne-3nanotubesandthehugeosmoticpressuredifferencebetweenthe feedsolutionanddrawsolution( Wu,Zhang,Chen,Chen,&Gai,2016).Thereasonfor thehighosmoticwaterfluxofthenanotubesisthelowtortuosity,highporosity,and lowthickness,resultinginareductionintheinternalconcentrationpolarizationphenomenon(An,Lee,&Park,2017).ToimprovetheperformanceofFOmembranes,researchers haveuseddifferentmaterialssuchaszwitterionicpolymer,graphene,nanomaterials (fiberandsheets),nanoparticles,andnanotubes.Thelistofdifferentmaterialsusedfor FObyvariousresearchersispresentedin Table2.

5Applicationsofforwardosmosis

ThediversifiedapplicationsofFOprocesshavebeenstudied.FOresultsinincreased rejectionandlessmembranefoulingincomparisontopressure-drivenmembraneprocesseslikereverseosmosis.FOwasusedfortheconcentrationandrecoveryofmanyproducts,suchasgrapejuice,pineapplejuice,raspberryjuice,orangejuice,tomatojuice, naturalfoodcolorant(Garciniaindica extract,beetrootjuice,redradish,etc.),modelfood systems,wheyproteins,ethanolproduction,microalgae,molassesdistillerywaste,sugars concentration,tunacookingjuice,organicacids,fattyacids,andinorganicsalts.The resultsobtainedbyseveralFOresearchersaresummarizedin Table3.

Exploitationofseawaterusingconventionaldesalinationtechnologiesislimiteddueto thesignificantenergyconsumption,highunitcosts,andenvironmentalimpacts.FOmay havepotentialforproducingpotablewaterinanenergy-efficientstyle.Itisamembranebaseddesalinationprocessandaviablealternativetoreverseosmosis,asalower-costand moreenvironmentallyfriendlydesalinationtechnology.Drivenbyosmoticpressure,FO hasattractedgrowingattentionforwaterforrecovery.FOisaneconomicalprocessthat

Table2 Differentmaterialusedbyvariousresearchersforforwardosmosismembrane

TypeMembranematerial

Zwitterionicpolymer

Poly(sulfobetainemethacrylate) (PSBMA)brushes

Hydrophilicsilicananoparticlesand zwitterionicpolymerbrushes

Poly[3-(N-2methacryloylxyethyl-N,Ndimethyl)ammonatopropanesulfonate]

N-Aminoethylpiperazinepropane sulfonate

Features

Super hydrophilic andultralowoil-adhesion properties

Higherfoulingresistance,reducedsurface roughness,enhancedhydrophilicity,and lowersurfacecharge

Lowermembranefoulingrate,lowerenergy requirement,andhigherwaterrecoveryrate

Superiorseparationperformanceand antifoulingproperty

Zwitterion-silvernanocompositeImprovedhydrophilicityandtransport properties;biofoulingresistancedueto antiadhesiveandantimicrobialproperty

Zigzaggraphyne-3nanotubesHigherwaterfluxes

Grapheneoxide-silver nanocomposites

Polyvinylpyrrolidonemodified grapheneoxide(PVP-GO)

NanofillersofTiO2 andgraphene oxide

Reducedgrapheneoxide laminatescoatedwithhydrophilic polydopamine(pDA-coatedrGO)

Polyamide-crosslinkedgraphene oxide(PA-GO)membrane

Magneticallyresponsivegraphene oxide(GO)/Fe3O4 nanohybrid

Nanosizedbactericidalgraphene quantumdots

Sulfonatedgrapheneoxide polyamidethin-filmcomposite membranes

Nanomaterials—Fiberandsheets

Nanocompositeofmesoporous silica nanoparticles andnanofibers

Antibiofoulingpropertywithoutsacrificing themembraneintrinsictransportproperties

Enhanceddesalinationperformance— Higherwaterfluxandlowerreversesolute flux

References

Zhang,Huang,Meng,Li, andCai(2017), Zhang, Tian,etal.(2017)

Liu,Lee,Ma,and Elimelech(2017), Liu, Wu,Liu,andWang (2017)

Lee,Goh,Lau,Ong,and Ismail(2018)

Wangetal.(2018)

QiuandHe(2018)

Wu et al. (2016)

Fariaetal.(2017)

Wu,Field,Wu,and Zhang(2017), Wu, Yoshioka,etal.(2017)

Improvedhydrophilicity,greaterporosity, higherwaterflux,andenhancedantifouling ability Lietal.(2017)

Outstandingwaterfluxandhighsalt rejectionrate

Highwaterfluxandlowsoluteflux

Higherfoulingresistance

Improvedsurfacehydrophilicity, antimicrobialactivity,andFOperformance

Highwaterflux,lowreversesaltflux,and decreasedfoulingpropensity

Yangetal.(2017)

Jin,Wang,Zheng,and Mi(2018)

Rastgar,Shakeri,Bozorg, Salehi,andSaadattalab (2018)

Seyedpour,Rahimpour, Shamsabadi,and Soroush(2018)

Galagedaraetal.(2018)

Osmoticwaterpermeabilityandsodium chlorideselectivityincreasedby7-foldand 3.5-fold,respectively

BuiandMcCutcheon (2016)

Graphene

18CurrentTrendsandFutureDevelopmentson(Bio-)Membranes

Table2 Differentmaterialusedbyvariousresearchersforforwardosmosis membrane—cont’d

TypeMembranematerial

Electrospunpolysulfone(PSf)/ titaniumdioxide(TiO2) nanocompositefibers

Positivechitosanandnegative grapheneoxide(GO)nanosheets

LaminarMoS2 nanosheet

Porousmetalorganiccopper1,4benzenedicarboxylatenanosheets

Nanoparticles

Al2O3 nanoparticlesintoboth substrateandpolyamideactive layer

Features

TiO2 additionresultedinhigher hydrophilicity,porosityandporesizeofthe substratesleadingtohigherwaterfluxthan commercialmembranes

Improvedwaterfluxandselectivityand foulingresistance

References

Zhang,Huang,etal. (2017), Zhang,Tian, etal.(2017)

Salehi,Rastgar,and Shakeri(2017)

Synergisticeffectsofsurfacehydrophilicity, porosityandfouling-releaseproperties Lietal.(2018)

Higherwaterpermeabilityandlowerreverse solutefluxforwaterdesalinationand wastewatertreatment

EnhancementofFOperformanceand stability

Fe3O4 magneticnanoparticlesImprovementofhydrophilicityand roughnessofthemembranes

ZnOandstableZnO-SiO2 coreshellnanoparticles

Longfinger-likeporeswithinthemembrane supportlayersresultedinpermeateflux enhancements

ZeolitenanoparticlesReducedinternalconcentration polarization,increasedsurfaceporosity,and enhancedwaterflux

Highlycompatiblepolyrhodanine nanoparticles

Nanotubes

Membranesurfacewassmootherandmore hydrophilic,providingimprovementin antimicrobial,antifouling,andtransport properties

Dai,Zhang,Liu,Wu,and Wang(2019)

Dingetal.(2017)

Chi,Zhang,Guo,andXu (2017)

Rastgar,Shakeri,Bozorg, Salehi,andSaadattalab (2017)

Salehi,Peyravi, Jahanshahi,Lau,andRad (2018)

Rahimpouretal.(2018)

Titanatenanotubes(TNT) Twotimesimprovementinwaterflux without sacrificing saltrejection Emadzadehetal.(2015)

Imologitenanotubes(INT) Enhancedthehydrophilicity,purewater flux,overallporosity,surfaceporosity,and roughness

Cyclicpeptidenanotubes(CPNT)Highselectivelybetweenwatermolecules andions

Aminefunctionalizedmultiwalled carbonnanotubes(CNTs)

Improvedsurfacehydrophilicitywithhigh waterpermeabilityandacceptablesalt rejection

Pan,Zhao,Gu,andWu (2017)

Wu,Field,etal.(2017), Wu,Yoshioka,etal. (2017)

Amini,Jahanshahi,and Rahimpour(2013)

candesalinatesalinewatersourcesatanotablylessercost.Itisanincreasinglyimportant technologythatishighlypromisingtoaddresswaterscarcityaroundtheglobe.Rapidprogressoverthepastdecadehasbeenmarkedbysignificantinnovationsinmembrane developmentandprocessdesign.Thekeyideaistodevelophybridsystemsinwhich theFOprocesscanreallyaddvalue.