ListofContributors

S.H.Bai UniversityoftheSunshineCoast,MaroochydoreDC,QLD,Australia

S.Balasubramanian InstitutNationaldelaRechercheScienti fique,Institut Armand-Frappier,Laval,QC,Canada

R.Balasubramanian NationalUniversityofSingapore,Singapore

A.Bassi UniversityofWesternOntario,London,ON,Canada

S.K.Benerji UniversityofMissouri,Columbia,MO,UnitedStates

R.Boopathy NichollsStateUniversity,Thibodaux,LA,UnitedStates

W.Charles MurdochUniversity,Perth,Australia

K.Y.Cheng CSIROLandandWater,Floreat,WA,Australia;MurdochUniversity, Murdoch,WA,Australia

W.Daoud CityUniversityofHongKong,HongKong

M.Farrar UniversityoftheSunshineCoast,MaroochydoreDC,QLD,Australia

V.K.Garg CentralUniversityofPunjab,Bathinda,India

X.Y.Gu NanjingAgriculturalUniversity,Nanjing,People’sRepublicofChina

R.Gupta YMCAUniversityofScienceandTechnology,Faridabad,India

G.Ho MurdochUniversity,Perth,Australia

Y.Hu CityUniversityofHongKong,HongKong

S.Joseph UniversityofNewSouthWales,Sydney,NSW,Australia

A.H.Kaksonen CSIROLandandWater,Floreat,WA,Australia;Universityof WesternAustralia,Nedlands,WA,Australia

O.P.Karthikeyan HongKongBaptistUniversity,HongKongSAR,People’s RepublicofChina;NationalUniversityofSingapore,Singapore;JamesCook University,Townsville,QLD,Australia

S.Kumar CouncilofScienti ficandIndustrialResearch(CSIR) National EnvironmentalEngineeringResearchInstitute(NEERI),Nagpur,Maharashtra,India

T.H.Kwan CityUniversityofHongKong,HongKong

P.R.Lennartsson SwedishCentreforResourceRecovery,UniversityofBorås, Sweden

C.S.K.Lin CityUniversityofHongKong,HongKong

L.Luo UniversityofShanghaiforScienceandTechnology,Shanghai,China

K.Murugesan PeriyarUniversity,Salem,TamilNadu,India

R.B.Nair SwedishCentreforResourceRecovery,UniversityofBorås,Sweden

T.TNhanNguyen UniversityoftheSunshineCoast,MaroochydoreDC,QLD, Australia

A.Pandey CenterofInnovativeandAppliedBioprocessing,(ANationalInstitute UnderDeptofBiotechnology,MinistryofS&T,GovtofIndia),Mohali,Punjab,India

A.K.Patel DBT-IOCCentreforAdvancedBio-EnergyResearch,Faridabad,India

C.P.Rivero UniversityofManchester,UnitedKingdom

A.Selvam HongKongBaptistUniversity,HongKongSAR,People’sRepublicof China

A.Sil EnvironmentPolicyandResearchIndia(EPRI),Thane(W),Maharashtra,India

R.R.Singhania DBT-IOCCentreforAdvancedBio-EnergyResearch,Faridabad,India

Z.M.Solaiman TheUniversityofWesternAustralia,Crawley,WA,Australia

R.Y.Surampalli UniversityofNebraska-Lincoln,Lincoln,NE,UnitedStates

M.J.Taherzadeh SwedishCentreforResourceRecovery,UniversityofBorås, Sweden

C.Theodoropoulos UniversityofManchester,UnitedKingdom

R.D.Tyagi INRS-ETE,UniversitéduQuébec,Québec,Canada

M.Valix TheUniversityofSydney,Sydney,NSW,Australia

H.M.Wallace UniversityoftheSunshineCoast,MaroochydoreDC,QLD,Australia

X.Wang HongKongBaptistUniversity,HongKongSAR,People’sRepublicofChina

C.Webb UniversityofManchester,UnitedKingdom

J.W.C.Wong HongKongBaptistUniversity,HongKongSAR,People’sRepublicof China

S.Xu UniversityofShanghaiforScienceandTechnology,Shanghai,China

C-Y.Xu CentralQueenslandUniversity,Bundaberg,Queensland,Australia

T.C.Zhang UniversityofNebraska-Lincoln,Omaha,NE,UnitedStates

AbouttheEditors

JonathanW-C.Wong

Dr.JonathanW-C.WongisaprofessorintheDepartment ofBiology,HongKongBaptistUniversity,HongKongSAR. HeisalsoservingasthedirectoroftheSino-ForestApplied ResearchCentreforthePearlRiverDeltaEnvironment,as wellastheHongKongOrganicResourceCentre.He receivedhisM.Phil.fromtheChineseUniversityHong KongandPh.D.fromMurdochUniversity,Australia.He joinedtheHongKongBaptistUniversityin1992andcontinuestoserveinvariouscapacities.ProfessorWongis servingasaVisitingProfessorattheChinaUniversityof Agriculture,NanjingAgriculturalUniversity,and ShangdongUniversity,China.Heconductsresearchin organicwastemanagementandtreatmentwithparticular emphasisoncompostingandbioenergyproduction,strivingtowardzero-wasteorganic wastedisposal.HehaschairedthreeInternationalConferencesonSolidWaste(ICSWHK 2011,2013,and2015).HehasservedandisservingasamemberoftheInternational AdvisoryBoard,ScientificCommittee,andinothercapacitiesforvariousinternational conferences.ProfessorWongwasbestowedtheMedalofHonorbytheGovernmentof HongKongSpecialAdministrativeRegionin2011forhisserviceandcontributiontothe environment.HeisanelectedmemberoftheEuropeanAcademyofSciencesandArts. Heisservingontheeditorialboardsofsixjournals,notablyasregionaleditorof EnvironmentalTechnology andboardmemberof BioresourceTechnology.Professor Wonghasauthoredover500publicationsincludingrefereedjournals,conferenceproceedings,fourpatents,andmorethan100technicalreportsandhasedited12book/ journalvolumesandothers.

RajeshwarD.Tyagi

ProfessorR.D.Tyagiisaninternationallyrecognized professorofbiochemicalengineeringandbiotransformation withtheInstitutNationaldelaRechercheScientifique Eau, Terre,etEnvironnement,UniversityofQue ´ bec,Canada.He alsoholdsanadjunctprofessorpositionattheUniversityof Missouri Columbia,UnitedStates.ProfessorTyagihas publishedorpresentedover600papersinrefereedinternationalscientificjournalsandconferenceproceedings;heis theauthorof13books,75bookchapters,10researchreports, 9patents,118GenBanksubmissions,and52invitedlectures. Heisanassociateeditorof PracticePeriodicalofHazardous, Toxic, andRadioactiveWasteManagement (American SocietyofCivilEngineers)andservesontheeditorialboards of ProcessBiochemistry and BioresourceTechnology.Hehasbeenrecognizedwithmany awardsandhonors.HeisamemberoftheEuropeanAcademyofSciencesandArts. Heconductsresearchonhazardous/solidwastemanagement,water/wastewater treatment,andwastewatersludgetreatment/disposalandthebioconversionofwastewaterandwastewatersludgeintovalue-addedproducts.

AshokPandey

ProfessorAshokPandeyisEminentScientistattheCenterof InnovativeandAppliedBioprocessing,Mohali(anational instituteundertheDepartmentofBiotechnology,Ministry ofScienceandTechnology,GovernmentofIndia),and formerchiefscientistandheadoftheBiotechnology DivisionattheCSIR’sNationalInstituteforInterdisciplinary ScienceandTechnologyatTrivandrum.Heisanadjunct professoratMarAthanasiosCollegeforAdvancedStudies Thiruvalla,Kerala,andatKalasalingamUniversity,Krishnan Koil,TamilNadu.Hismajorresearchinterestsareinthe areasofmicrobial,enzyme,andbioprocesstechnology, whichspanvariousprograms,includingbiomasstofuels andchemicals,probioticsandnutraceuticals,industrial enzymes,solid-statefermentation,etc.Hehasmorethan 1100publicationsandcommunications,whichinclude16patents,50+books,125book chapters,and425originalandreviewpapers,withanhindexof75andmorethan23,500 citations(GoogleScholar).Hehastransferredseveraltechnologiestoindustriesandhas beenanindustrialconsultantforaboutadozenprojectsforIndianandinternational industries.

ProfessorPandeyistherecipientofmanynationalandinternationalawards andfellowships,whichincludeElectedMemberoftheEuropeanAcademyofSciences andArts,Germany;FellowoftheInternationalSocietyforEnergy,Environmentand Sustainability;FellowoftheNationalAcademyofScience(India);FellowoftheBiotech ResearchSociety,India;FellowoftheInternationalOrganizationofBiotechnologyand Bioengineering;FellowoftheAssociationofMicrobiologistsofIndia;honorarydoctorate degreefromtheUniversite ´ BlaisePascal,France;ThomsonScientificIndiaCitation LaureateAward,UnitedStates;LupinVisitingFellowship;VisitingProfessoratthe Universite ´ BlaisePascal,France,theFederalUniversityofParana,Brazil,andtheE ´ cole PolytechniqueFe ´ de ´ raledeLausanne,Switzerland;BestScientificWorkAchievement Award,GovernmentofCuba;UNESCOProfessor;RamanResearchFellowshipAward, CSIR;GBF,Germany,andCNRS,Francefellowships;YoungScientistAward;andothers. HewaschairmanoftheInternationalSocietyofFood,AgricultureandEnvironment, Finland(Food&Health)during2003 04.HeistheFounderPresidentoftheBiotech ResearchSociety,India(www.brsi.in);InternationalCoordinatoroftheInternational ForumonIndustrialBioprocesses,France(www.ifibiop.org);chairmanofthe InternationalSocietyforEnergy,Environment&Sustainability(www.isees.org);andvice presidentoftheAllIndiaBiotechAssociation(www.aibaonline.com).ProfessorPandey iseditor-in-chiefof BioresourceTechnology, HonoraryExecutiveAdvisorofthe Journalof WaterSustainability and JournalofEnergyandEnvironmentalSustainability, subject editorofthe ProceedingsoftheNationalAcademyofSciences(India), andeditorialboard memberofseveralinternationalandIndianjournals,andalsoamemberofseveral nationalandinternationalcommittees.

Preface

Thisbookisapartofthecomprehensiveseries CurrentDevelopmentsinBiotechnologyand Bioengineering (Editor-in-Chief:AshokPandey),comprisingninevolumes,andpresentsa collectionofchaptersdealingwithsolidwastemanagement.AccordingtoaWorldHealth Organizationreport,worldcitiesalonecurrentlygenerateabout1.3billiontonnesofsolid wasteperyear,andthisfigureispredictedtobearound2.2billiontonnesby2025.Tocope withthistremendousamountofwastegeneratedfromourdailylivingisnotjustanissueof handlingandtreatingitproperlywithoutanyimpactonourenvironmentormakingan eyesoreforthepublic.Mostofourwastesarebeinglandfilledwithoutconsideringthelife cycleofthematerials,whichleadstoadeclineinourworld’sresources.Itisamatterof resourceconservationandutilization.Wasterepresentsourfutureresourcesandsowasteis notwasteanymore.Scientistsarefacingachallengingpathaheadtodevelopinnovative technologiestoconvertwastetovaluablebio-products.

Biotechnologyisabroadtermcoveringarangeoffields.TheEuropeanFederationof Biotechnologydefinesbiotechnologyas“theintegrationofnaturalsciencesandengineering inordertoachievetheapplicationoforganisms,cells,partsthereofandmolecularanalogues forproductsandservices.”Since1995,thewasteindustryhaswitnessedbio-basedtechnologiesforwasteconversion.Thetechnologiescanbebroadlyclassifiedintotwocategories: onethatdegradesparticularcompoundsthatareverytoxicinnaturetoprevent/reducetheir environmentalimpactandanotherthatgeneratesavalue-addedproduct,concurrently achievingvolumereductionoreliminatingtheneedforsubsequentdisposal.Biological methodsarealsoappliedtotreattheairemissions.

Biotechnologyapplicationsinthebiofuelandbioenergysectorshavegainedsignificant advancementduemainlytotheincreaseinenergydemand.Forinstance,theglobalenergy consumptionhasbeenestimatedas104,426TWhbytheInternationalEnergyAgency,of which65%oftheneedwillbesuppliedbyfossilfuels.Thesereservesarenearcessation becauseofpeakutilizationratesinthe2010s.Althoughnewmethodsarebeingconstantly developedtoidentifyandextractthefossilsources,thiscannotbeindefinite,astheformation ofsuchfossilfuelstakescenturiesandcannotmeetthehumangreed.Therefore,itisessential todevelopalternatesolutions,andbiofuelproductionfromsolidwasteisgainingmomentum.Previously,energycropswereconsideredasanoptionbutthedebatecontinues overthecompetitionbetweenoilcropsandagriculturalcropsforourpreciousarableland. Thusorganicwastesaresustainableandlow-costoptions/substratesatthisstageandhave triggeredvitalandsignificantresearchinanumberofwastemanagementareassince1995.

Anaerobicdigestion(AD),apotentialwaste-to-energytechnology,wastraditionally appliedtothetreatmentofwastewater.However,currentlytheuseoffoodwasteandother organicwasteshavinghighersolidcontentsassubstratesisincreasing,withmanyindustrialscaleADplantsinoperationwithsuccessfulenergyrecovery.However,like“bettingonthe winninghorse,”oftenthetechnologieswithsignificantoperationalhistoryarepositively consideredduringthedevelopmentofnewplants,whereasnewmethodswithhigherenergy recoveryarestillhavingdifficultyfindingamarket.Therefore,acriticalanalysisthatgives weighttodemonstrationandinnovationinthisareaofresearchmustbeconsidered.Despite

historicaloperation,foodwasteasasubstrateforADposesseveralchallengesthathave resultedinthedevelopmentoftwo-phasesystemsorsingle-phasedrysystemsincontrastto thetraditionalsingle-phasewetsystem.Whilethedrysystemsaregaininginterest,thetwophasesystemsarenotquiteassuccessfulinthemarketdespitethereportsofhigherstability andenergyrecovery.Morerecently,microbialfuelcell-basedintegrationtoenhanceenergy recoveryaswellasachievingpollutantdegradationhasalsoattractedattention,althoughthe scale-upofthereactorsisbeingintensivelydebatedandresearched.Furthermore,the digestate,thesolidwastefromtheanaerobicdigesters,requiresappropriatedisposalandcan berecycledasasoilconditionerwithorwithoutadditionaltreatment.Thus,developinga sustainableorganicwastemanagementpracticethroughintegratedbiorefinerytechnologyis multidimensionalandthe“key”toprovidingtotalsolutions.

Compostinghasbeenpracticedforcenturies;however,compostinginacommercial setuprequiresstringentcontroltoreduceodoraswellasnutrientloss.Preventingodor emissionisaprerequisitefortheadaptionofcompostingasamethodofchoicefortreatment oforganicwastes,especiallyinanurbansetting.Similarly,nutrientlossintheformofnitrogencanresultinacompostproductwithlowmarketvaluethatwillaffectthesustained operationofacompostingplantinthelongrun.Manyapproacheshavebeeninvestigatedin thisdirectionandhavesignificantpotentialapplicationvalue.Vermicompostingstillremains anattractivecompostingapproachinviewofthehigh-endvermicastproduced.Interestingly, compostinghasbeendemonstratedtodegradetheantibioticsthatareusedintheanimal industriesandendupinanimalmanure.Especially,thethermophilicphasewaslinkedtoa significantreductioninantimicrobials;thuscompostingcanbeanimportanttreatment technologyforanimalmanure.

Plasticsoccupyasignificantplaceinourmodernlifestyle.Globalproductionofplastics isabout300milliontonnes,ofwhich95%isproducedfrompetroleum-basedfossilfuels. Althoughplasticsaredegradable,therateisveryslowinthenaturalenvironment;thusoften theyareconsiderednonbiodegradable.Thispersistencyhascreatedalotofissuesinboth waterandsoilmatrices,leadingtothedevelopmentofbioplastics.Inrecentyearsmany governmentshaveimposedrestrictionsontheusageofplasticbagsconsideringtheir persistence.Researchonmicrobialdegradationofplasticstoacceleratethedegradationrate isgainingattentionasanapproachtocleanupcontaminatedsites.Ontheotherhand, productionofmicrobial-drivenpolyhydroxybutyrate-andpoly(lacticacid)-basedbioplastics, whicharereadilybiodegradable,hasalreadymadesignificantprogress;however,thecostof productionisthecriticalcomponentaffectingtheirdominance,andinnovativeapproaches arerequiredtoreduceit.

Sewagetreatment,oneoftheoldestbiologicaltreatments,isanessentialcomponentof anycommunity.Thesludgegeneratedfromwastewatertreatmentplantsrepresentsasignificantfractionofwastedeliveredtothelandfills,contributingtotheemissionofgreenhouse gasesaswellasproductionoftoxicleachates.Leachatetreatmentisalsoanintegralpartof modernlandfillsandaerobic,anaerobic,andnaturalsystemsweredevelopedinthepastand innovationshavebeenintroducedrecently.Thesludgecakehasbeentypedasasubstratefor incineration,enablingmassreduction;however,thecontaminantsinthesludgeposechallengesandrequirecomplicatedabatementtechnologies.Alternativelysludgehasbeentargetedtoproduceavarietyofvalue-addedproductssuchasindustriallyrelevantenzymes, biofuels,bioplastics,biopesticides,bio-surfactants,andbio-fertilizers.Significantdevelopmentsinthisfieldhavebeenmadesince1995.Inaddition,microbial-mediatedbioflocculantsarebeingconsideredwiththepurposeofavoidingtheexpensiveand environment-deterioratingsyntheticflocculants.Iron-oxidizingbacteria,whichfindacritical placeintheminingindustriesaswellasinleachingpreciousmetalsfromelectronicwastes,

arecriticalplayerspositivelyinfluencingthesludgesettlinganddewaterability.Thusalotof potentialexistsinmicrobialflocculants,withadditionaladvantagesasevidencedfrom intensiveresearchsince2005.

Becauseoftherapidurbanizationandindustrialdevelopmentaroundtheworld,a steadyincreaseinwastegenerationisunavoidable,althoughgovernmentsarenowfocusing onwastereduction.Thuswithincreasingwastequantity,anddiversityofthewastetypes, developingbiotechnologicalsolutionsandrefiningandupdatingtheexistingmethodsare alsoequallyimportant.Thisbookcoversarangeoftopics,includingbio-products,bioenergy production,andthedegradationofpollutants,andprovidesthelatestdevelopmentsthatcan beusedasareferencepointonwhichnewresearchcouldbeconstructed.Webelievethatthe contentswillenlightenthereadersonthepotentialanddevelopmentsofbiologicalmethods todealwiththetremendousamountsofwastethatwegenerate.

TheeditorsgratefullyacknowledgethecontributorsandthankDr.KostasMarinakis, BookAcquisitionEditor;Ms.AnnekaHess;andtheentireproductionteamatElsevierfortheir helpandsupportinbringingoutthisvolume.Withouttheircommitment,efficiency,and dedicatedwork,thisvolumecouldnothaveeverbeenaccomplished.

Editors

JonathanW-C.Wong

BioplasticsFromSolidWaste

C.P.Rivero1,Y.Hu2,T.H.Kwan2,C.Webb1,C.Theodoropoulos1, W.Daoud2,C.S.K.Lin2, * 1 UNIVERSITYOFMANCHESTER,UNITEDKINGDOM;

1.1Introduction

Plasticsaresomeofthemostcommonlyusedarticlesontheglobe.Theglobalproductionofplasticshasbeengrowingformorethan50yearsandroseto299milliontons in2013,whichaccountsfora3.9%increasecomparedto2012 [1].Currently,conventionalpetroleum-basedplasticssuchaspolyethylene,polypropylene(PP),andpolyethyleneterephthalate(PET)constitutemorethan95%oftheplasticsmarket.Becauseof theenvironmentaldegradationcausedbypetroleum-basedplasticsandthedepletionof fossilfuelresources,thereis,however,anincreasinginterestinbioplastics.

Bioplasticsareafamilyofplasticmaterialsthatareeitherbio-basedorbiodegradable orpossessbothproperties.Theterm“bio-based”meansthematerialisderivedfrom biomasssuchascorn,sugarcane,andwheatstraw,whereasbiodegradationisa chemicalprocessinwhichmicroorganismspresentinnaturedegradethematerialsinto naturalsubstancessuchaswater,carbondioxide,andcompostwithouttheadditionof artificialadditives [1].Infact,allplasticsmaterials,includingbothbio-andpetroleumbasedplastics,aretheoreticallybiodegradable.Becausemostofthepetroleum-based plasticsdegradeataslowrateinthenaturalenvironment,theyareconsidered nonbiodegradable [2].

Startinginthe1980s,bioplasticswereintroducedtoreducetheuseofpetroleumbasedplastics,becausetheypossessanumberofadvantagesincludinghighresource efficiency,reductionofcarbonfootprintandgreenhousegasemissions,andsavingfossil resources [1].Nowadays,therearenumerousmanufacturersproducingbioplasticsfora widerangeofapplicationsincludingbiomedical,packaging,consumerelectronics, automotive,textiles,andagriculturalfields.Becauseofthegrowingdemandforasustainablebio-economy,theproductioncapacityforbioplasticshasbeenincreasedfrom 1.5milliontonsin2012to1.9milliontonsin2015andisforecastedtoreach6.7milliontonsin2018,accordingtoEuropeanBioplastics [1].However,comparedtoconventionalplastics,bioplasticsaccountedforonlylessthan5%ofthecurrentmarket

*CorrespondingAuthor.

CurrentDevelopmentsinBiotechnologyandBioengineering:SolidWasteManagement http://dx.doi.org/10.1016/B978-0-444-63664-5.00001-0 1 Copyright © 2017ElsevierB.V.Allrightsreserved.

sharebecauseoftheirlimitedmechanicalpropertiesandrelativelyhighproduction costs [3].Therefore,therecentresearchfocusesontheimprovementofbioplastics’ propertiesandutilizingwastematerialsassubstratesforreducingtheproductioncost.

Inthischapter,twotypesofthemostwidelyproducedbioplastics,viz.,polyhydroxybutyrate(PHB)andpoly(lacticacid)(PLA)willbeintroduced.Thehistoryof theirdevelopmentandtheirproperties,synthesis,commercialmarket,andlow-cost substratesthatareidentifiedforproductionwillbediscussed.

1.2Polyhydroxybutyrate

1.2.1HistoryofPolyhydroxybutyrate

PHBisthemostextensivelystudiedbiopolymerofthepolyhydroxyalkanoate(PHA) familyanditwasalsoitsfirstandonlymemberforalmost40yearsuntilthreeotherPHA typeswerediscoveredin1974 [4].Todaytherearemorethan150classes.Thepresence ofrefractiveintracellularbodieswasalreadyreportedbyBeijerinckin1888,butitwas theFrenchmicrobiologistMauriceLemoignewhoin1925determinedthattheformula ofthosegranular(etherinsoluble)inclusionsin Bacillusmegaterium was(C4H6O2)n [5]. Healsoprovedthattheycouldbeextractedwithchloroformresultinginproductswith differentmeltingtemperature.In1952,KepesandPeaud-Lenoelfoundthatthefractions isolatedbyLemoignecorrespondedtoautolysissegmentsofalinearpolyesterthat containedacarboxylgroupinoneendandanalcoholgroupintheother [6].

FollowingLemoigne’sstudies,MacraeandWilkinson(1958)investigatedthe biosynthesisofthepolymerandattributedthepresenceofPHBtounbalancednutrient conditions,i.e.,deprivationofsomenutrientsandexcessofcarbon [7].Baptistand Werber(1964)startedconductingfermentationstoproducePHBandevaluatethe feasibilityofitscommercialization [8].Loweryields,expensivesolventrequirementsfor extraction,andabundantimpuritiesinthefinalproductmadethemabandontheir initialinterestinPHBforindustrialapplication.Nonetheless,Baptistgotthefirstpatent forthePHBproductionprocess [9].

Manycompaniespromotedresearchanddevelopmentprogramsinbioplastics technologymotivatedbytheoilcrisisinthe1970sbutonlyafewcompaniesremained afterward:ImperialChemicalIndustries(ICI),PetrochemieDanubia(PCD),andChemie Linz.Whenpetrolpricesstabilized,PHBdidnotofferadvantagesoverPP,asitwasmore fragileandmuchmoreexpensive.Still,ICIcontinuedwiththeresearchanddevelopeda copolymer,namelypoly(3-hydroxybutyrate-co-3-hydroxyvalerate)(PHBV),with improvedproperties,whichboostedinterestinbiodegradableplasticsagain.PHBVwas commercializedunderthenameBiopolin1975andwasusedtomanufacturethefirst shampoobottlemadeofabiodegradableplastic. Ralstoniaeutropha wasthebacterium usedforthebiosynthesis,whichmostlyoccursatthelaststageoffermentation [10].

The1980sweremarkedbytheintroductionofnewPHBproducerstrainsandthe beginningofmetabolicengineeringstudies.ChemieLinzandPCDintroducedanew

strainthatwasabletoaccumulatethepolymerwhengrowinganddeSmet(1983)found that Pseudomonasoleovorans formspoly-b-hydroxybutyricacidusing n-octaneas feedstock [11].In1988thegenesof Alcaligeneseutrophus wereclonedandinsertedinto Escherichiacoli,afast-growingbacterium [12].

Copersucar,incollaborationwithSaoPauloUniversity,openedapilotplantinBrazil in1991.SugarcaneindustryresidueswereutilizedasfeedstockforPHBproductionas wellaspoly(3HB-co-3HV).InteresthadalsostartedrisinginAsia,andKohapLtd.in KoreabuiltapilotplantandboughtthepatentsforPHBproduction.Meanwhilein Europe,thecostofPHBwasstill16timesthatofPP [13].Metabolix,anewcompany focusedonstrainengineeringforthesynthesisofawiderangeofPHAs,appearedin 1992.AftercommercializationinAmericaandplanstoincreasecapacitiesinEurope, BiopolwassoldtoZenecaandthentoMonsanto,whichkeptituntil1998;itstechnology waslateracquiredbyMetabolix [14].

In1994thestrainandpatentofPCDwereboughtbyDr.UrsHanggitobecomethe companyBiomer.Plasticizers,nucleants,andadditivesaremixedwiththebiopolymerto createthreedifferentplasticswithimprovedpropertiesbutmaintainedbiodegradability. In2001,Procter&Gamble(P&G)andKanekaagreedtocommercializelargeamountsof biopolymerofstandardqualitycomparedtoconventionalplastics [15].ThelatestdevelopmentsinthecommercialproductionofPHBanditsderivativesarediscussedfurther.

1.2.2PropertiesandApplicationsofPolyhydroxybutyrate

PHAsareformedbyorganicacids,containingahydroxylgroupatoneendandcharacterizedbyaspecificradicalgroup,whicharelinkedtogetherbyesterbonds.3HydroxybutyricacidisthemonomerforPHBandconsistsofanalkylchainwitha methylradical.ThisrelativelysimplestructureandtheseveralfeasiblesynthesispathwaysmakeitthemostabundantnaturalPHA.Themolecularweight,acriticalcharacteristicforplasticcharacterization,rangingfrom50,000tomorethan1,000,000g/mol, placesPHBamongthecommercialpolymers.Thehighestmolecularweightreportedso farisupto20MDaforPHB,whichwasachievedbyKusakaetal.(1998)usingarecombinant E.coli strain [16].Themicroorganism,cultivationconditionsandcarbon source,fermentationtime,andextractionmethodsareallfactorsaffectingthemolecular weightofthepolymer [17].

However,biodegradabilityisthekeypropertyofPHBandreferstotheruptureofthe PHBmacromoleculeintosmallerunitsbymicrobialenzymesfromfilamentousfungi andbacteria.BecausePHBisproducedbycertainbacteriaascarbonandreducing powerstorage,thesecellscanalsoreversetheprocessanddegradePHBintracellularly; fordoingthat,themacromoleculeisfirstdepolymerizedinto R-b-hydroxybutyricacid, whichisthenoxidizedtoacetoacetate.Anesterificationreactionconvertsthelatterin acetoacetyl-coenzymeA,whichinturndegradestoacetyl-coenzymeA,andthisultimate moleculeoftheprocessentersthecarboxylicacidcycle,andduringcompleteoxidation, itisconvertedintocarbondioxidewiththecorrespondingenergyrelease [18].

Furthermore,someothermicroorganismsarecapableofsegregatingextracellular depolymeraseforbreakingthepolymerintomonomersordimers,whicharesoluble moleculesthatcanenterthecytoplasmofthosecellsandgetconvertedintocarbonor energy,carbondioxideandwaterbeingtheultimateproducts.AnobjectmadeofPHBin natureisdegradedextracellularlybybacteria,fungi,oralgae.Thetimefordegradation dependsontheenvironmentalconditionsandthicknessoftheobject,whichwillboth regulatethenutrientsavailableforthemicroorganismstogrow.Thesame50-mmfilmof PHBVcanbetotallydegradedin1 2weeksinresidualwaterunderanaerobicconditions orin7weeksinaerobicsystems.Itwilltake15weeksforittodegradeinseawateror 10weekstodosoinsoil [19].PHBVdoesnotdegradeinhumidair,whichguaranteesa longshelflifeforpackagingapplications.Microbialattackispronetohappeningin amorphousregionsandtolower-molecular-weightpolymers.

PHBcanalsodegradebyhydrolysisormechanical,thermal,oxidative,orphotochemicaldestruction.Itisthehydrolyticrupturethatenablesitsuseinmedicalapplications.Inaddition,PHBisnontoxic,itdoesnotcauseaninflammatoryresponse,and itsintermediateandultimateproductsarenontoxicandmetabolizedandclearedbythe body [20].ThefactthatPHBdegradesthermallycanlimititsprocessabilityinthemolten state.Additivesaresometimesusedtopreventthat [21].

PHBhassimilarcharacteristicscomparedtoPPregardingmeltingtemperature, crystallinitydegree,glasstransitiontemperature,andtensilestrength(Table1.1) [22]. Nevertheless,PHBisstifferandfragile,partlyowingtothespherulitesformedduringthe coolingofthemoltenform.Itisenantiomericallypureandstereoregular [23];theseoptical propertiesenableitsuseinisomerseparation.Becauseofitswaterinsolubilityandlow permeabilitytooxygenorcarbondioxide,itisanidealcandidateforfoodpackaging material(fivetimeslesspermeabletoCO2 thanPET).Itisalsopiezoelectric(whichisa rarepropertyforaplastic)andhencefindsapplicationinbonescaffoldprostheses [24].

PropertiesofPolypropylene,Polyhydroxybutyrate,and PolyhydroxybutyrateCopolymers

Density(g/cc)0.91 0.941.17 1.251.251.20

Crystallinity6060 7050 60N/A

Tensilestrength(MPa)34.518 2725 4010 20

Elongation(%)4006 172.5 3010 100

Tensilemodulus(GPa)1.4N/A1.2 3.0N/A

Meltingtemperature( C)171 186N/A147 175N/A

Estimatedprice($/m3)10554320N/AN/A

PHB,polyhydroxybutyrate; P(3HB-co-HV),polyhydroxybutyrate-co-hydroxyvalerate; P(3HB-co-HHx),poly(3-hydroxybutyrate-co-3hydroxyhexanoate).

DataadaptedfromS.P.Valappil,S.K.Misra,A.R.Boccaccini,I.Roy,Biomedicalapplicationsofpolyhydroxyalkanoates,anoverviewof animaltestingandinvivoresponses.ExpertReviewofMedicalDevices3(6)(2006)853 868;J.Asrar,K.J.Gruys,Biodegradablepolymer (Biopol ),in:BiopolymersOnline,Wiley-VCHVerlagGmbH&Co.KGaA,2005;G.Griffin,Chemistryandtechnologyofbiodegradable polymers.JournalofChemicalEducation72(3)(1995),A73.doi:10.1021/ed072pA73.10.

Table1.1

ThelowelongationtobreakandstiffnessmakenaturalPHBunsuitableforwithstandingimpact.Toimproveflexibility,ductility,ortenacity,plastificantsorblendswith other,notexclusivelyrenewable,moleculesareoftenused.Thenaturalcoproductionof variousmonomersoccurringinsomebacteriagrowinginvariouscarbonsourcesisalso exploitedforthesynthesisoftailor-madeplastics.Alsocheapmacromoleculesand organicpolymers(starch,wood)aremixedwithPHBtoproduceactivebio-based packagingtobeusedinagricultureapplications,forinstance [25].

Currently,PHBservesinthemanufactureofcommodityproductssuchasshampoo andcosmeticbottlesorsingle-usearticleslikecupsandfoodcontainers [26].Thefirst artificialesophagushasbeengeneratedbasedonPHB;treatmentforcardiovascular diseasesanduseasadrugcarrierorfornerveandtissueregenerationareonlyafewof theexamplesforwhichPHBemergesastheperfectcandidate [27].Beyondthemedical orpharmaceuticalfield,PHBisexpectedtofightforitsownplaceinelectroniccomponentsasareplacementforconventionalplasticssuchaslow-densitypolyethylene.

1.2.3MarketandIndustrialManufactureofPolyhydroxybutyrate

Themanufactureofplasticmaterialsisthemainsubsectorofthepetrochemicalindustry.Notonlythat,butithasexperiencedanexponentialgrowthoverthepastdecades andhasalreadyreachedanannualworldwideproductionthatexceeds200milliontons. Studiessuggestthatincreasingdemandcouldmakeitsproductionincreasebyfour-or fivefoldbytheendofthe21stcentury.Approximately5%ofcrudeoilproductionis currentlyusedforplasticproduction,butiftheforecastsprovetobecorrect,thisfigure couldgrowtoover20% [28].Otherenvironmentaldrivers,includingsavingsingreenhousegasemissions,cleaninguptheoceans,landfilldiversion,andruralregeneration, arepushingthedevelopmentofthebioplasticsector,withPHAsontheedgeofmass production.Thebio-basedpolymerdivisionrepresentsUS$15 30billionoftheUS $290billionforthisindustry [29].

Althoughthevolumeofbioplasticsisalsogrowingrapidly,PHBstillrepresentsa smallfraction,otherbio-basedthermoplasticsattractingmoreattention:evenifnot biodegradable,theircloseresemblancetotheconventionalcounterpartsallowsthemto entertherecyclingchains.Incontrasttobiofuelsandbioenergy,thereareveryfewincentivesandlittlelegislation(apartfromthatwhichregulatesplasticbaguseand disposal)thatsupportthisspecificsector,whichmayincurcompetitionforbiomassfor thevarioususes.Coproductionoffuelsandchemicalsisseenastherightstrategyto supporttheeconomicfeasibilityofbioplasticsinahigh-volumelow-marginscheme. Despitethat,therearesomeindustrialcompaniesoperatingatlowtomediumcapacities fortheproductionofPHBanditscopolymers.Someotherpilotplantandresearch projectspromisetheconstructionofnewfacilitiesorexpansionofexistingonesinthe nearfuture [30]

TellesisajointventurebetweenArcherDanielsMidlandCompanyandMetabolix thatcommercializescornsugar-basedPHBcopolymersthatcanactasperformance

additivesforpoly(vinylchloride)andPLAandotherapplicationsrequiringfunctional biodegradabilityunderthenameofMirel.TheplantinClinton(Iowa,USA)hasacapacityof50,000tons/yearandproduces10differentproducts,whichdegradeinvarious environments(soilandfreshorsaltwater) [31].Ithasannouncedacommercialalliance withHoneywellforcosmeticandpersonalcareproducts.

NodaxisthetradenameofthePHAcopolymerssynthesizedbyP&GChemicalsuntil 2006andbyMHGsincethen.Corn,sugarbeet,orvegetableoilisusedasfeedstockand applicationsforthesebioplasticsrangefrompackaging(detergentbottles,coffeecontainers)tolaminatesandcoating(papercupsandplates)ornonwovenfibers.

ThelargestPHBVproducer,TiananBiologicalMaterials,wasfoundedin2000in NingboCity(China)andhasthecapacitytomanufacture2000metrictonsofENMAT products [32].Dextrosefromcornorcassavaisusedasthenutrientfor R.eutropha Apatentedextractionprocessthatdoesnotrequireenzymesorchemicalisemployed.

TheDutchfirmDSMandtheChinesecompanyTianjinGreenBioscienceCompany havejointventurestoproduceGreenBiobioplastics.The10,000tons/yearcapacity plantwasbuiltin2009intheBinhaiDistrictinTianjin.SogreenP(3,4HB)isproducedas aresinmaterial,andamodifiedpolyestercanbeobtainedfromittoformplastic wrappings,packagingbags,andfilmproducts.

KanekaCorporationproduces3-hydroxybutyrateand3-hydroxyhexanoate (AONILESX)fromplantoilsinOsaka.AnotherplantinJapanrunbyMitsubishiGas ChemicalCompanyproduces10ktonofPHB(Biogreen)peryear;thepolymerisobtainedfrommethanolderivedfromnaturalgas(CH4)andobtainedfromexhausted gases(CO2 andH2).WastesarealsousedbyBio-ontoproduce100differentmonomers (MinervPHA);thefacilitylocatedinItalycanproduceupto100ktonofbiomaterial peryear.

Theintegratedproductionofbiodegradableplastic,sugar,andethanolwasdeveloped inBrazil,andBiocyclewasthefirstsugar-basedplasticproducerinthecountry. Siemens,BASF,MunichTechnicalUniversity,andtheUniversityofHamburghave createda70%greenpolymer(includingPHB)frompalmoilandstarchthathasthe potentialtoreplacepolystyrene-basedacrylonitrile-butadiene-styrene,ABS. Table1.2 summarizestheprincipalsuppliersofvarioustypesofPHB.

1.2.4BiosynthesisofPolyhydroxybutyrate

PHBisastoragecompoundthatcanbefoundinthecytoplasmofalargenumberof speciesofbacteriawhencellsaresubjectedtocultivationconditionsrichincarbon. BecausePHBisinsolubleinwater,itformsgranulesofvarioussizes(0.2 0.5 mm diameter)coatedbyaproteinlayer;thesegranulescanmergetoformbiggerinclusions [33].Itisnotyetconfirmedwhetherthelipidmono-orbilayerobservedoccursinvivoor itisaconsequenceoftheextractionprocessforisolatingnativePHB [34].ThePHB synthesisstartswhentwomoleculesofacetyl-coenzymeA(CoA)condensewitha thiolaseencodedby phaA toformacetoacetyl-CoA,whichissubsequentlyreducedby

Table1.2 MajorPolyhydroxybutyrateProducersWorldwide

CompanyTradeNameProductLocationRawMaterial

Capacity (tons/year)Price(V/kg)

TellesMirelPHB copolymers USACornsugar50,0001.5(2010)

MitsubishiBiogreenP(3HB)JapanMethanol10,0002.5 3.0(2010) GreenBio/DSMGreenBioP(3HB-4HB)ChinaSugar10,000N/A Bio-OnMinervPHBItalyN/A10,000N/A TianAnBiopolymerEnmatPHBVChinaDextrose/glucose20004.1 4.3(2012) KanekaKanekaPHBHJapanVegetableoil1000 PHBIndustrialBiocyclePHBBrazilSugarcane6002.5 3.0(2010) MGHNodaxPHBHUSAN/AN/AN/A BiotechnologyCo.BiomerN/AGermanySucrose503.0 5.0 BiomateraBiomateraPHBVCanadaSugarN/AN/A TianzhuTianzhuPHBHChinaN/AN/AN/A TephaN/AN/AUSAN/AN/AN/A TianjinNorthernFoodN/AN/AChinaN/A10N/A YikemanShandongN/AN/AChinaN/A3N/A ShenzenO’BioerN/AN/AChinaN/AN/AN/A Polyscience,Inc.N/APHBUSAN/AN/AN/A

PHB,polyhydroxybutyrate; P(3HB),poly(3-hydroxybutyrate); P(3HB-4HB) ,poly(3-hydroxybutyrate-4-hydroxybutyrate) PHBV, poly(3-hydroxybutyrate-co-3-hydroxyvalerate); PHBH,poly(3-hydroyxbutyrate-co-3-hydroxyhexanoate).

theactionofareductaseencodedby phaB (NADPH)to3-hydroxybutyl-CoA [35]. Theelongationofthechain(polymerization)isachievedwithasynthaseencoded by phaC.

PHBcanbemobilizedbythecellsunderstressfulconditionsasmentionedearlierin thechapter.PHBdepolymerase(PhaZ)hydrolyzesthepolymertoyield3-hydroxybutyric acid.Thiscanbethenmetabolizedtoobtaincarbonorenergyorexcreted.Formetabolizing3-hydroxybutyrate,itneedstobeconvertedintoacetoacetateoractivatedtoCoA derivativesbyvariousenzymeslikeacyl-CoAsynthetaseorthioesterase.Acetoacetate canbebrokenintotwomoleculesofacetyl-CoAbytheactionof b-ketothiolaseandthese moleculesenterthetricarboxylicacidorglycoxylatecycle.(R)-3-hydroxybutyl-CoAcan immediatelybeepimerizedtothe(S)-isomerandcatabolizedwiththeconsequentenergyreleasethroughthe b-oxidationpathway [36].

Morethan300PHAproducerspecieshavealreadybeendiscovered.Amongthem, gram-negativebacteria,including Cupriavidusnecator, Alcaligeneslatus, Pseudomonas putida, Pseudomonasoleovorans, Azotobactervinelandii,orrecombinant E.coli (operon C.necator)arethemostcommonones.Withinthegram-positivegroup,thegenus Bacillus,withspeciessuchas B.megaterium or B.cereus,isgainingpopularity.The genus Streptomyces hasalsobeenevaluatedasapotentialbiocatalystforthesynthesisof PHB.Thethickwallofgram-positivebacteriaisthoughttocomplicatetheextraction process,thusthelimitednumberofstudies.Ontheotherhand,PHBproducedby

gram-negativeorganismsmightcontainendotoxinsfoundintheoutermembrane lipopolysaccharide,whichputthebiocompatibilityofthepolymeratrisk.Bacteriafrom thegenus Bacillus havedemonstratedpromisingperformance.However,theconditions fortriggeringPHBarethesameasthoseforsporulation,whichcouldlowerthe yields [37].

Almostnoneoftheisolatedstrainsmeetalltherequirementsformassproduction,but theonesthathavebetterchancestosucceedinindustrializationarediscussedlaterinthe chapter. Alcaligeneslatus showshighPHBcontent,exhibitsfastgrowth,andisableto utilizecheapercarbonsources.Thehighestbiomassconcentrationobtainedwas160g/L andnotveryhighoxygendemandwasfoundwhenusing R.eutropha.Azotobacter vinelandii producesanextremelyhighmolecularweightpolymer(1 4millionDa)and doesnotrequiremuchoxygenintheproductionstage.Otherstrainsarenotconsidered potentialcandidatesbecauseoflongerdoublingtimesorloweroptimalgrowing temperatures,whichincreasefermentationcosts [38].

Therelativelowresourcesneededforplantcultivationpushedtheresearchinthe plantkingdomforhostsforPHBproduction.Thegenesof A.eutrophus havebeen introducedintotheplant Arabidopsisthaliana.Otherchallengesirretrievablyappear, suchasthecompartmentalizationofmetabolism,leadingtolessavailableCoAforthe polymersynthesis.Thereisnoindustrial-scaleplantation,butstudiesinmaize,cotton, orsoyhavebeendevelopedbyMetabolixintheUnitedKingdomandMonsantointhe UnitedStates.

GiventhatPHBproductioninbacteriaistriggeredbythelimitationofanessential nutrient(nitrogen,phosphorus,oroxygen,amongothers)andcarbonsurplus,themost commonfermentationstrategyisatwo-stepprocess,inwhichoneofthoseelementsis restrictedonceahigh-densitycultureisobtainedinthefirststage.Thus,forexample,the supplyofNH4OHsolutionforbothpHcontrolandcellproliferationattheearlystageof thefermentationandthelaterreplacementbyanNaOHsolutionthatregulatespHisa popularapproachinfed-batchcultivations.

Afterthefermentation,theintracellularpolymerneedstoberecoveredandpurified. Inthesamemannerastheupstreamoperation,theeconomyinthesestagescanhavea directeffectonthefeasibilityoftheoverallprocess.Otherfactorstoconsiderwhen choosingthedownstreamprocessingaretheenvironmentalimpact,molecularweight, andpurityoftheextractedform.Solventslikechlorinatedhydrocarbons,cycliccarbonates,orlowerchainketonescanextractahighlypurepolymerwithlowtolittle degradationandarealsoabletoremoveendotoxins.Thedownsideisthatunlessagood systemofsolventrecoveryisused,theuseofthistechniquecouldseriouslyaffectthe environmentallyfriendlynatureofPHBsynthesis.

ThealternativetosolubilizingthePHBgranulesistosolubilizethecellbiomass, whichisachievedthroughchemicalorenzymaticdigestion.Sodiumhypochloriteor surfactantsarethenormalchemicalstouse;inevitablythereisatrade-offbetween degradationandpurity.Meanwhile,thepriceofenzymeshampersitsselection.Still, Zenecaemploysproteasesforthisoperationandresearchershaveinvestigatedthe

utilizationofenzymessynthesizedby Microbispora sp.throughoutasecondfermentationwithoutfurthernutrientsupply [39].Althoughcellautolysiscannaturallyoccur, variousmethodscanboosttheruptureofthemembraneliberatingthepolymer,namely high-pressurehomogenization,bedmill,supercriticalfluid,increaseincellfragilityby osmoticpressure,aqueoustwo-phasesystem,or g-irradiation [40].

1.2.5PolyhydroxybutyrateProductionFromGlycerol andOtherLow-CostFeedstock

AcommonapproachistheuseofinexpensiverawmaterialsassubstratesforPHB productionwiththeultimategoalofminimizingfermentationcosts.Industrialbyproductsandagricultural,food,andmunicipalwasteshavetheirpotentialtoactas rawmaterialsinthebio-process.Theirwidevariability,presenceoftoxins,orneedfor pretreatmentstepsisthepricetopayforusingtheselow-costfeedstocks.

Withbiodieselgrowthcomestheincreaseinglycerol,acommonintermediate productincellmetabolismthatcanalsobesuppliedasacarbonsourceforthe fermentationofchemicalsandbiopolymers.Apilot-scalefermentationina42-Lreactor achievedhighPHBproductivitiesandyieldsofapproximately1g/Lhand0.25g/gwhen using Zobellelladenitrificans infed-batchmode;self-flotationofcelldebrisafter extractionwithchloroformservedaspurificationmethod [41].Productivityandmolecularweightarelowerthanthoseobtainedwithglucose.Thebindingofthehydroxybutyratepolymertothesecondaryhydroxylgroupsofglycerolisbelievedtoexplainthe reductioninlengthofthechain.Apartfromthose,thereisnosignificantdifferencein otherpropertiesbetweentheglycerol-basedPHBandtheglucosecounterpart [42]. Technoeconomicstudiesdemonstratedthatglycerol-basedPHBcouldbeproducedat industrialscalewithasellingpriceofUS$2.6/kg [43].

TheversatilityofPHBproducerstometabolizedifferentmoleculesmakeindustrial (brewery,milk,sugar,paper,ethanol)orevenwastewatertreatmentplanteffluents suitablefeedstocks.Agricultural(vegetableoilsandfats,dairywhey,molasses,meat,and bonemeal)andfoodwastes(bakeryresidues,orangepeel,spentcookingoil)canalsobe processedtosynthesizebiodegradableplastic [44].Inthisway,volatilefattyacidsarethe mediumcomponentsaftersugarcanemolassesundergoesacidogenictreatment,but acetate,propionate,orbutyratewillbethePHBprecursorifpalmoilmilleffluentorseed oilfrom Jatropha isusedastherawmaterialinstead.Wheneverlignocellulosicmaterials areemployed(grass,ricestraw,orsugarcanebagasse),amixtureofpentose(xylose, arabinose)andhexosesugars(glucose,sucrose)isusedinthefermentationmedium.

1.3Poly(LacticAcid)

Thedevelopmenthistory,properties,andcommercializationofPLAarepresentedin Sections1.3.1 1.3.4.Theproductionstatusandprocessoflacticacid(LA)andPLA productionareillustratedin Section1.3.5.

1.3.1TheHistoryofPoly(LacticAcid)

Intheearly1800s,PLAwasdiscoveredbyPelouzethroughpolycondensationfromLA [45].Almostacenturylater,in1932,Wallaceetal.inventedanewmethodtoobtainPLA byheatinglactide(thedimerofLA)inavacuum [46].Thismethod,namelyring-opening polymerization(ROP),waslaterpatentedbyDuPontin1954 [47].However,lowpurity andlowmolecularweighthinderedtheupscalingatthattime.

Thefirstsyntheticpolymerderivedfromfossilfuelwasathermosettingphenol formaldehyderesincalledBakelite,inventedin1907byLeoHendrikBaekeland [45]. Massproductionofpetroleum-derivedpolymersledtoseriousenvironmentalproblems, whichpushedresearchdevelopmentofenvironmentallyfriendlypolymersderivedfrom renewablesources.Inthe1990s,acommerciallyviablelactidering-openingreactionwas developedbyCargill,Inc.,topolymerizehigh-molecular-weightPLA [47].Sincethen,as oneofthemostpopularbioplastics,PLAattractsincreasingresearchattention. Fig.1.1 showsthenumberofpublicationsaboutPLAfrom1985to2014,obtainedfromtheWeb ofSciencewithkeywords“poly(lacticacid)”and“polylactide.”Itcanbeseenthat researchonPLAstartedincreasingexponentiallyaroundtheendofthe1990s.

Afterinvestigationforseveraldecades,theresearchdirectionhasshiftedfromsyntheticmethodstooptimizationofthesynthesisprocessandmodificationofPLA [39]. Theoptimizationmainlydemonstratesutilizationoflow-costfeedstockandinventionof high-efficiencyproducingapparatus [48].Renewablefeedstockssuchascornhavebeen usedtoproducemonomerLAbybacterialfermentation [49].Thenewlydeveloped apparatus,atwin-screwedextruder,whichcanconductreactiveextrusion,wasprovento

Number of publications

FIGURE1.1 Numberofpublicationsaboutpoly(lacticacid)from1985to2014.

improvePLAproductionyieldto99% [50].Bymodification,PLA-basednanocomposites withsuperiordispersionareplayingasignificantroleinmedicalapplicationsasdrugdeliverymaterials [51].AllthesetechniqueshavepushedPLAdevelopmenttoanew stageandtheincreasingmarketsharedescribedin Section1.3.4 demonstratesthis.

1.3.2PropertiesofPoly(LacticAcid)

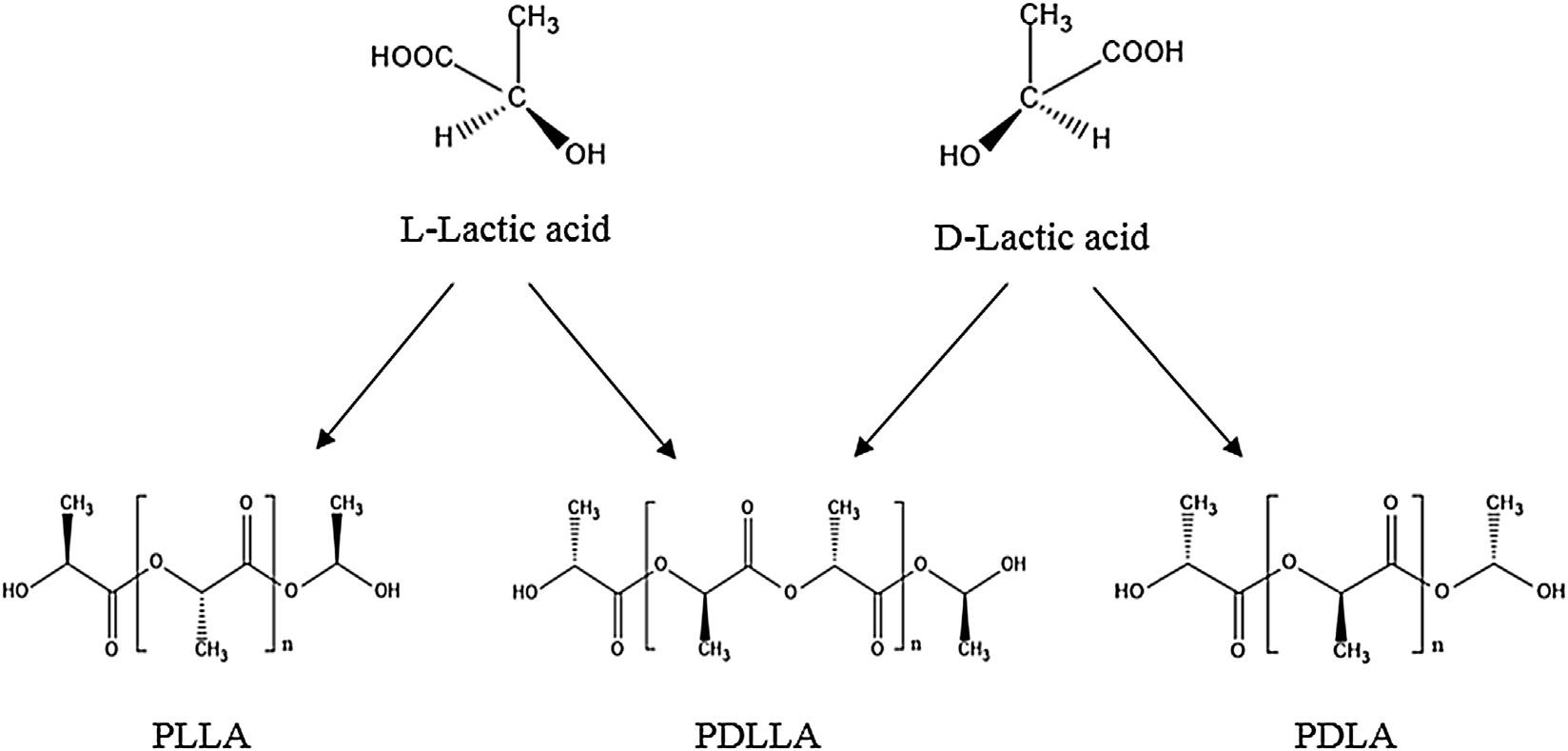

PLA[(C3H4O2)n]isfamousforitsgoodprocessability,biocompatibility,andbiodegradability.PLAisabiodegradablealiphaticsemicrystallinepolyesterproducedfromLA bypolymerization.LAexistsinthreedifferentenantiomericforms, L-LA, D-LA,and mesoLA(mixtureof L-and D-LA),asshownin Fig.1.2.

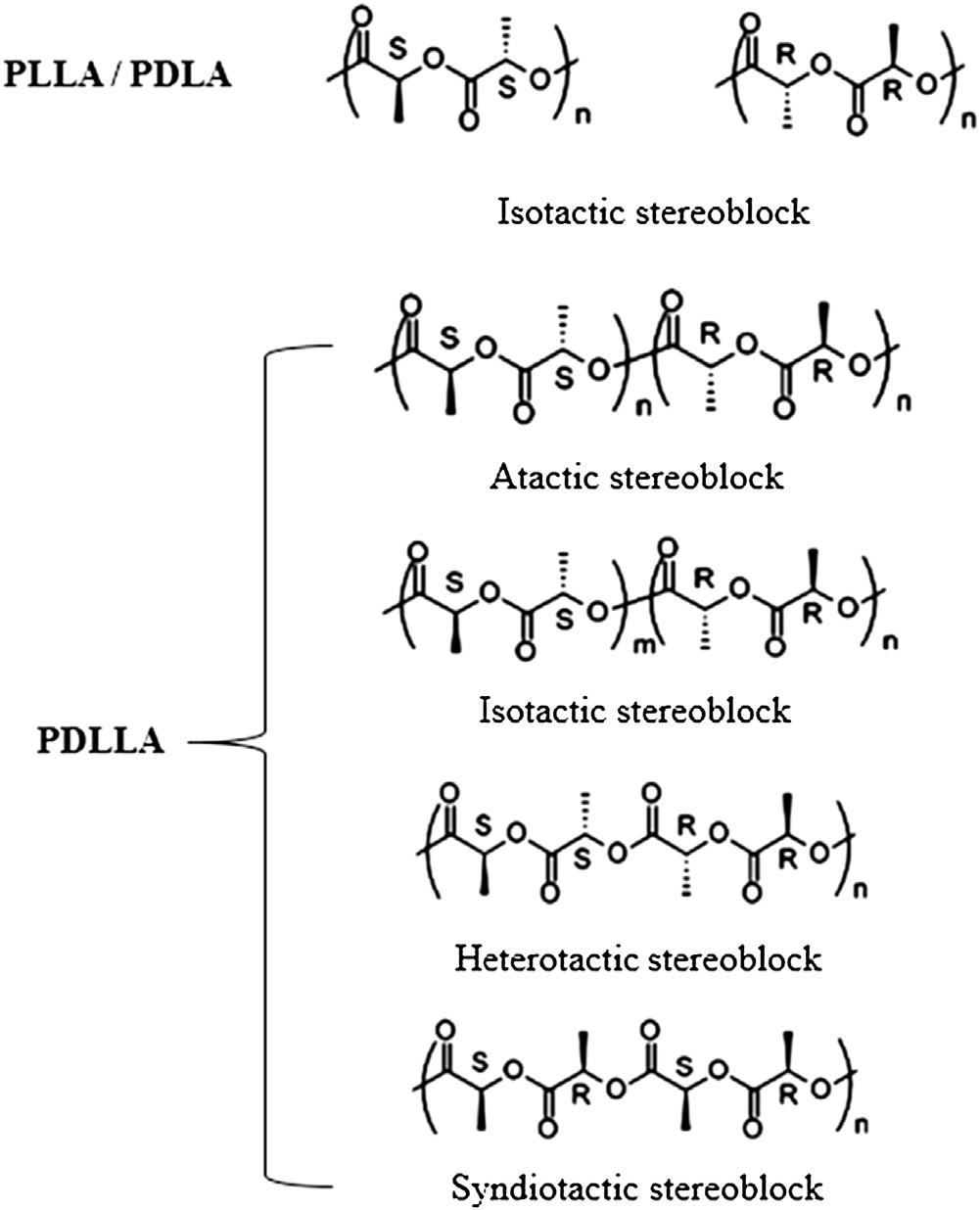

L-LA, D-LA,andtheirmixtureleadtodifferentPLAs,poly(L-LA)(PLLA),poly(D-LA) (PDLA),andpoly(D-, L-LA)(PDLLA) [52].Varioussequencesof D-and L-enantiomers couldleadtofourdifferentstereoblocksofPDLLA(Fig.1.3).Theratioof D-to L-enantiomers,whichisthestereochemicalcompositionofPLA,aswellasthestructureofthe PLAstereoblock,couldaffectseveralimportantproperties,suchastheextentofcrystallizationandthethermalproperties.

1.3.2.1PhysicalProperties

Asanalternativetotraditionalplastics,PLApossessesattractivephysicalproperties. Table1.3 comparesthemechanicalpropertiesbetweenPLAandtraditionalpetroleum polymers.Haze,alsonamedasturbidity,isthecloudinessofafluidortransparentsolid (plasticorglass)andismeasuredbythepercentageoflightthatitdeflectsorattenuates [53].Tensilestrengthisthemaximumstressthatapolymercanwithstandbefore breakingunderpulling [54].Transformingfromareferenceconfigurationtothecurrent

FIGURE1.2 Stereoformsoflacticacidandpoly(lacticacid). PDLA,poly(D-lacticacid); PDLLA,poly(D-, L-lacticacid); PLLA,poly(L-lacticacid).

FIGURE1.3 Poly(lacticacid)stereoblocks.

PDLA,poly(D-lacticacid); PDLLA, poly(D-, L-lacticacid); PLLA,poly(L-lactic acid).

configurationincontinuummechanicsiselongation [55].Tearresistanceisusedto determinehowwellamaterialcanwithstandtheeffectoftearing [56].

Asshownin Table1.3,PLApossesseshighdensity,elongation,andtearresistance, similartoPET,andbetterthanPP,nylon,andcellophane.Thisindicatesthepotentialof PLAasanalternativematerialtoconventionalplastics.Infact,PLAcanbemanufactured

Table1.3 MechanicalPropertiesofPoly(LacticAcid)andPetroleumPolymers [57]

PropertyPLAPPPETNylonCellophane

Density(g/cc)1.250.91.41.21.45

Haze(%)2.11 42 52 31 2

Tensilestrength(MPa)109.97189.95204.95249.9489.98

Tensilemodulus(MPa)3299.262399.463799.151824.594099.08

Ultimateelongation(%)160110140125N/A

Tearresistance(g/mm)0.3810.13160.45720.33020.1016

PET,polyethyleneterephthalate; PLA,poly(lacticacid); PP,polypropylene.

Table1.4

ThermalPropertiesofPoly(L-LacticAcid) Poly(D-, L-LacticAcid)

Copolymers [60]

CopolymerRatioGlassTransition( C)MeltingTemperature( C)

100:0(L /D,L)-PLA63178

95:5(L /D,L)-PLA59164

90:10(L /D,L)-PLA56150

85:15(L /D,L)-PLA56140

80:20(L /D,L)-PLA56125

PLA,poly(lacticacid).

withawiderangeofpropertiesbychangingthemolecularweight,composition,and distributionofstereoisomersofthepolymerchains,i.e.,thependentmethylgroupon the a-carbonatom.Withlowmolecularweight(<50,000Da),PLAisamorphous,witha meltingpointof130 150 C [13].InthecaseofPLLAandPDLA,withhighmolecular weight(>50,000Da),theyaresemicrystallinepolymerswithameltingpointof 170 180 C,andtheglasstransitiontemperatureisalsoincreasedfrom45to58 C [13].Theglasstransitionisthetemperatureatwhichthepolymerchangesfromahard andrelativelybrittlestatetoamoltenstate.Highertransitiontemperatureandmelting pointareindicationsofbetterthermalstabilityofthepolymer.

ForPDLLA,theisotacticandsyndiotacticstereoblocksbuildsemicrystallinepolymers withenhancedphysicalproperties,whereastheatacticandheterotacticstereoblocks, withrandomarrangementof L-and D-units,leadtoamorphousandlow-qualityPLA [58,59]. Table1.4 summarizesthermalpropertiesofPLAcopolymerizedbyPLLAand PDLLAatvariousratios [60].

Accordingly,ahighercontentofPDLLAwouldweakenthethermalstabilityofPLA. However,thesituationisdifferentwhentakinglactideasthecopolymerizationunit. Moonetal.reportedthataracemicmixtureof D-and L-lactideata50:50ratioproduced ahigh-molecular-weightpolymerwithimprovedmeltingpointtoover200 C [61].In contrast,thebarriersfortheapplicationsofPLAareitshydrophilicity,brittleness,and highcrystallinity [62,63].Currently,modificationtechniquessuchasbulkmodification andsurfacemodificationareusuallyappliedtoenhancePLAproperties [64].For instance,poly(lacticacid-co-glycolicacid)hasbeenconsideredtoimprovebiodegradabilityandsolubility.Itwas,therefore,recognizedasthebestbiomaterialindrugrelease application [62].

1.3.2.2BiologicalProperties

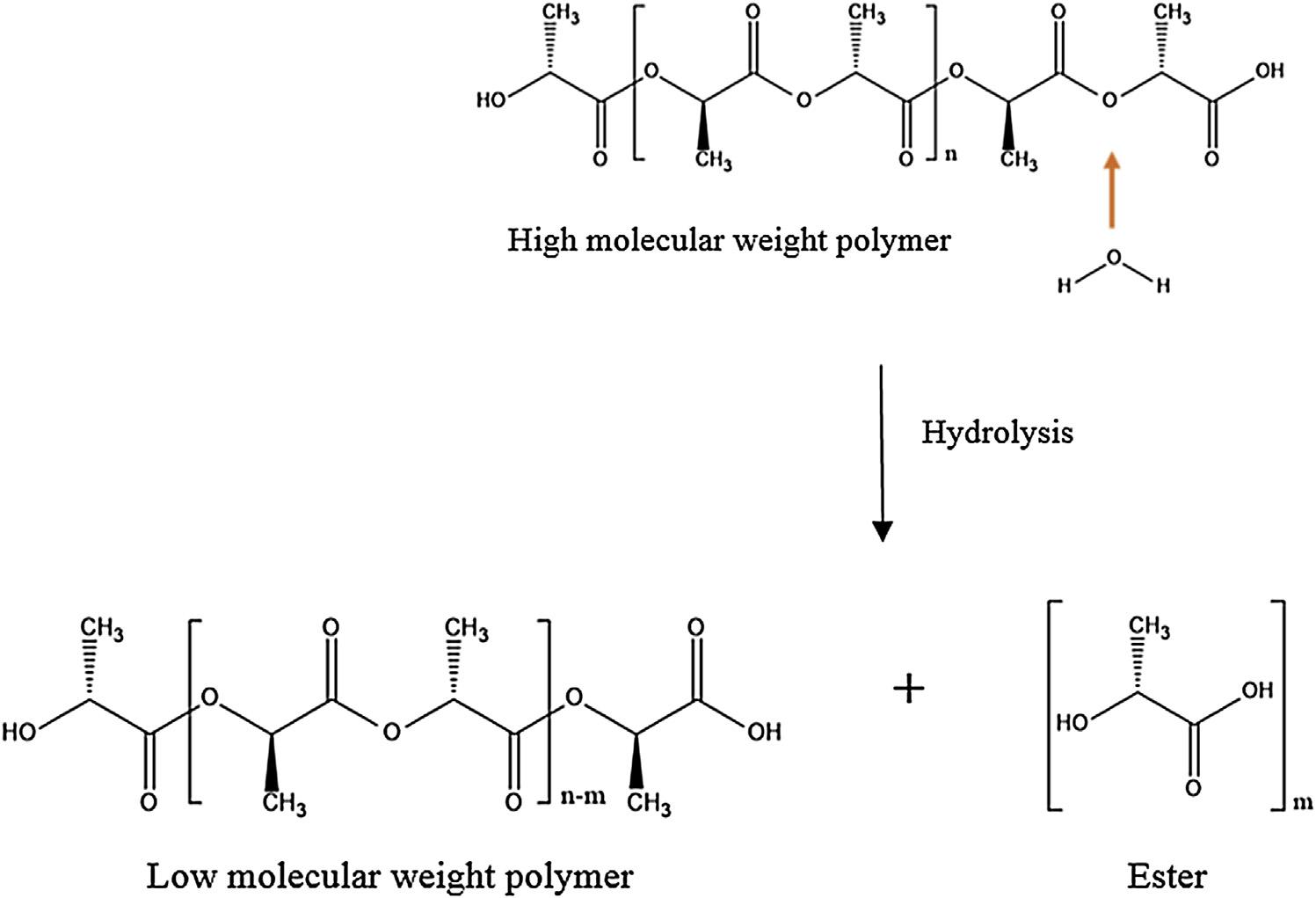

PLAiswellknownforitsgoodbiodegradableproperty,whichisenvironmentally friendly.TheEuropeanSocietyforbiomaterialsdefinedbiodegradationastheprocessin whichbiologicalagents(microbesandenzymes)playadominantroleindegradation [65].However,PLAwasteisdegradedbyhydrolyticcleavageofthepolymerbackbone (Fig.1.4),withonlylittleorevennoassistancefromenzymes.Therefore,thedegradation

Degradationprocessofpoly(lacticacid).

ofPLAisnotbiodegradationasforotherpolymers,butitiscommonlytermedasa biodegradablematerial.Thedecomposedcomponentsbecomenutrientsinthe biosphere.Forinstance,PLAcouldbehydrolyzedinboilingwaterorbyheatingsteamto LAasarecycledmonomer.Aurasetal.degradedPLLAto L-LAbyhydrolysisat 180 350 Cfor30min [39].Underalkalineconditions,PLAwasobservedtoreleasedimersinthedepolymerizationprocess [66].

Inacompostingenvironment,PLAhasbeenreportedtobedecomposedbyaccelerateddegradationinmanystudies.HeterogeneousPLAmixingwithmicrobialpopulationsfromprecompostedyardwasteinamoist,warm,andaerobicenvironment causeddecompositionintocarbondioxideandwaterwithin90days [67].Toshinorietal. (2002)reporteddecompositionoffoodresidueasthecompostingmaterial,inwhichPLA filmsamples,bandsamples,andropesamplesdecomposedin6weeks [68].

Innature,PLAproductsaretotallydegradedinsoilorcompostinseveralweeksby esterases,proteases,andlipasesreleasedbyfungiorbacteriasuchas Lentzea, Streptoalloteichus,and Amycolatopsis ofthePseudonocardiaceaefamily [69 71].

1.3.3ApplicationsofPoly(LacticAcid)

PLAistheoneofthemostpromisingandpopularbiodegradablepolymersbecauseof someidealproperties:lowweight,lowprocessingtemperature(comparedtometaland glass),noenvironmentalpollution,goodprintability,andeaseofconversioninto

FIGURE1.4

Table1.5 DomesticApplicationsofPoly(LacticAcid) [76]

ApplicationManufacturerProduct

ApparelMillDirectApparelJackets,caps,poloshirts

CodiceasbarreShirts

GattinoniWeddingdresses

DescenteSportswear

BottlesShiseido-UraraShampoobottles

PolenghiLASLemonjuicebottles

Sant’AnnaMineralwaterbottles

FoodpackagingLindarThermoformcontainers

InnoWarePlasticsThermoformcontainers

CarrefourBelgiumGrocerybags

HometextilesEcoCentricCushions

AhlstromTeabags

NaturalLivingMattresstoppers

Children’stoysKik&BooSofttoys filledwithPLA fiber

differentforms [60].In1970s,thegoodbiodegradabilityofthebodyandsafetyofthe decompositionproductofPLAwereverified,andthenitwascategorizedasgenerally recognizedassafe(GRAS)bytheU.S.FoodandDrugAdministration [72].TheseadvantagesmakePLAbroadlyapplicableinmanyareas.Initially,theapplicationsofPLA producedbydirectpolycondensationwerelimitedtomedicalpurposessuchasimplant devices,drugrelease,andinternalsutures [73].Throughthedevelopmentofvarious synthesistechniques,PLAwithhighmolecularweightwasproduced,whichpossesses satisfactorythermomechanicalpropertiesandisnowadayswidelyusedinpackaging, compostablebags,anddisposabletableware [74].Furthermore,theapplicationsinupholstery,disposablegarments,personalcareproducts,anddiapersareincreasingaswell [75].SomeofitsdomesticapplicationsaresummarizedbyLietal.(Table1.5).

Furthermore,PLAmaterialisalsoappliedinrigidconsumergoodssuchasiPodand iPadcoversmanufacturedbyBioserie,inbuildingengineeringasflooringandwallpaper materialsbyLGHausys,andinautomotivesasfiberforcarmatsbyTorayCompany [76]. Nevertheless,asmentionedbefore,PLA’snarrowpropertiesimpairitscompetitionwith theexistingpetroleum-basedplastics.UnorientedPLAhasgoodmechanicalstrength andstiffness,butitisalsoquitebrittle [77].TheIzodimpactstrengthandelongationof PLAaremuchpoorerthanthoseofhigh-densitypolyethylene [78].Therefore,further modificationstostrengthenthethermalandmechanicalpropertiesaresignificantfor wideningPLAapplicationsinthefuture.

1.3.4CommercializationofPoly(LacticAcid)(Poly(LacticAcid)Market)

AfterPLAproductionbyheatingoflactideinavacuumwasinventedbyDuPontscientist WallaceCarothers,theambitiouscompanyCargilldevelopedPLAproduction