CurrentDevelopments inBiotechnologyand Bioengineering

BiocharTowardsSustainable

Environment

Editors

HuuHaoNgo

CentreforTechnologyinWaterandWastewater,SchoolofCivil andEnvironmentalEngineering,UniversityofTechnologySydney, Sydney,NSW,Australia

WenshanGuo

CentreforTechnologyinWaterandWastewater,SchoolofCivil andEnvironmentalEngineering,UniversityofTechnologySydney, Sydney,NSW,Australia

AshokPandey

CentreforInnovationandTranslationalResearch,CSIR-IndianInstituteof ToxicologyResearch,Lucknow,India;SustainabilityCluster,School ofEngineering,UniversityofPetroleumandEnergyStudies,Dehradun,India

SunitaVarjani

GujaratPollutionControlBoard,Gandhinagar,Gujarat,India

DanielC.W.Tsang

DepartmentofCivilandEnvironmentalEngineering,TheHongKongPolytechnic University,Kowloon,HongKong,China

Elsevier

Radarweg29,POBox211,1000AEAmsterdam,Netherlands TheBoulevard,LangfordLane,Kidlington,OxfordOX51GB,UnitedKingdom 50HampshireStreet,5thFloor,Cambridge,MA02139,UnitedStates

Copyright©2023ElsevierInc.Allrightsreserved.

Nopartofthispublicationmaybereproducedortransmittedinanyformorbyanymeans,electronicor mechanical,includingphotocopying,recording,oranyinformationstorageandretrievalsystem,without permissioninwritingfromthepublisher.Detailsonhowtoseekpermission,furtherinformationaboutthe Publisher’spermissionspoliciesandourarrangementswithorganizationssuchastheCopyrightClearance CenterandtheCopyrightLicensingAgency,canbefoundatourwebsite: www.elsevier.com/permissions.

ThisbookandtheindividualcontributionscontainedinitareprotectedundercopyrightbythePublisher (otherthanasmaybenotedherein).

Notices

Knowledgeandbestpracticeinthisfieldareconstantlychanging.Asnewresearchandexperiencebroadenour understanding,changesinresearchmethods,professionalpractices,ormedicaltreatmentmaybecome necessary.

Practitionersandresearchersmustalwaysrelyontheirownexperienceandknowledgeinevaluatingandusing anyinformation,methods,compounds,orexperimentsdescribedherein.Inusingsuchinformationormethods theyshouldbemindfuloftheirownsafetyandthesafetyofothers,includingpartiesforwhomtheyhavea professionalresponsibility.

Tothefullestextentofthelaw,neitherthePublishernortheauthors,contributors,oreditors,assumeanyliability foranyinjuryand/ordamagetopersonsorpropertyasamatterofproductsliability,negligenceorotherwise,or fromanyuseoroperationofanymethods,products,instructions,orideascontainedinthematerialherein.

ISBN:978-0-323-91873-2

ForinformationonallElsevierpublications visitourwebsiteat https://www.elsevier.com/books-and-journals

Publisher:SusanDennis

EditorialProjectManager:HelenaBeauchamp

ProductionProjectManager:KiruthikaGovindaraju

CoverDesigner:MilesHitchen

TypesetbySTRAIVE,India

Contributors

MukeshKumarAwasthi CollegeofNaturalResourcesandEnvironment,NorthwestA&F University,Yangling,ShaanxiProvince,PRChina

SanjeevKumarAwasthi CollegeofNaturalResourcesandEnvironment,NorthwestA&F University,Yangling,ShaanxiProvince,PRChina

YazidBindar DepartmentofChemicalEngineering;DepartmentofBioenergyand Chemurgy,FacultyofIndustrialTechnology,InstitutTeknologiBandung,Bandung, Indonesia

YogiWibisonoBudhi DepartmentofChemicalEngineering,FacultyofIndustrial Technology,InstitutTeknologiBandung,Bandung,Indonesia

S.WoongChang DepartmentofEnvironmentalEnergyEngineering,KyonggiUniversity, Suwon,RepublicofKorea

ZhuoChen EnvironmentalSimulationandPollutionControlStateKeyJointLaboratory, StateEnvironmentalProtectionKeyLaboratoryofMicroorganismApplicationandRisk Control(SMARC),BeijingLaboratoryforEnvironmentalFrontierTechnologies,Schoolof Environment,TsinghuaUniversity,Beijing,PRChina

DongleCheng CentreforTechnologyinWaterandWastewater,SchoolofCiviland EnvironmentalEngineering,UniversityofTechnologySydney,Sydney,NSW,Australia

LijuanDeng CentreforTechnologyinWaterandWastewater,SchoolofCiviland EnvironmentalEngineering,UniversityofTechnologySydney,Sydney,NSW,Australia

QuocCuongDo Chemical&ProcessTechnologyDivision,KoreaResearchInstituteof ChemicalTechnology(KRICT);DepartmentofCivilandEnvironmentalEngineering, KoreaAdvancedInstituteofScienceandTechnology(KAIST),Daejeon,RepublicofKorea

VivekK.Gaur AmityInstituteofBiotechnology,AmityUniversityUttarPradesh,Lucknow, India

WenshanGuo CentreforTechnologyinWaterandWastewater,SchoolofCiviland EnvironmentalEngineering,UniversityofTechnologySydney,Sydney,NSW,Australia

ZizhangGuo ShandongKeyLaboratoryofWaterPollutionControlandResourceReuse, SchoolofEnvironmentalScienceandTechnology,ShandongUniversity,Qingdao,China

MingjingHe DepartmentofCivilandEnvironmentalEngineering,TheHongKong PolytechnicUniversity,Kowloon,HongKong,China

PanditHernowo DepartmentofChemicalEngineering,FacultyofIndustrialTechnology, InstitutTeknologiBandung,Bandung,Indonesia

ZhenHu ShandongKeyLaboratoryofWaterPollutionControlandResourceReuse, SchoolofEnvironmentalScienceandTechnology,ShandongUniversity,Qingdao,China

WeiJiang SchoolofEnvironmentalScienceandEngineering,HuazhongUniversityof ScienceandTechnology,Wuhan,PRChina

JianxiongKang SchoolofEnvironmentalScienceandEngineering,HuazhongUniversity ofScienceandTechnology,Wuhan,PRChina

YanKang CollegeofEnvironmentandSafetyEngineering,QingdaoUniversityofScience andTechnology,Qingdao,China

GajasingheArachchigeGangaKavindi FacultyofLifeandEnvironmentalSciences, UniversityofTsukuba,Ibaraki,Japan

SunilKumar CSIR-NationalEnvironmentalEngineeringResearchInstitute,Nagpur,India

D.DuongLa InstituteofChemistryandMaterials,Hanoi,Vietnam

ZhongfangLei FacultyofLifeandEnvironmentalSciences,UniversityofTsukuba,Ibaraki, Japan

HuanyuLi InstituteofConstructionMaterials,TechnischeUniversit € atDresden,Dresden, Germany;SchoolofNavalArchitecture,OceanandCivilEngineering,ShanghaiJiaoTong University,Shanghai,China

ShuangLiang ShandongKeyLaboratoryofWaterPollutionControlandResourceReuse, SchoolofEnvironmentalScienceandTechnology,ShandongUniversity,Qingdao,China

DongqiLiu SchoolofEnvironmentalScienceandEngineering,HuazhongUniversityof ScienceandTechnology,Wuhan,PRChina

MishaLiu FacultyofLifeandEnvironmentalSciences,UniversityofTsukuba,Ibaraki, Japan

TaoLiu CollegeofNaturalResourcesandEnvironment,NorthwestA&FUniversity, Yangling,ShaanxiProvince,PRChina

XiaoningLiu StateKeyLaboratoryofWaterResourcesandHydropowerEngineering Science,SchoolofWaterResourcesandHydropowerEngineering,WuhanUniversity, Wuhan,PRChina

YangLiu JointResearchCentreforProtectiveInfrastructureTechnologyand EnvironmentalGreenBioprocess,SchoolofEnvironmentalandMunicipalEngineering, TianjinChengjianUniversity,Tianjin,China

YiLiu DepartmentofEnvironmentalScienceandEngineering,FudanUniversity, Shanghai,China

ViktorMechtcherine InstituteofConstructionMaterials,TechnischeUniversitat Dresden,Dresden,Germany

AminMojiri DepartmentofCivilandEnvironmentalEngineering,GraduateSchoolof AdvancedScienceandEngineering,HiroshimaUniversity,Hiroshima,Japan

HuuHaoNgo CentreforTechnologyinWaterandWastewater,SchoolofCiviland EnvironmentalEngineering,UniversityofTechnologySydney,Sydney,NSW,Australia

DinhDucNguyen DepartmentofEnvironmentalEnergyEngineering,KyonggiUniversity, Suwon,RepublicofKorea

ManhKhaiNguyen FacultyofEnvironmentalSciences,UniversityofScience,Vietnam NationalUniversity,Hanoi,Vietnam

ThuThuyNguyen CentreforTechnologyinWaterandWastewater,SchoolofCiviland EnvironmentalEngineering,UniversityofTechnologySydney,Sydney,NSW,Australia

Bing-JieNi CentreforTechnologyinWaterandWastewater,SchoolofCiviland EnvironmentalEngineering,UniversityofTechnologySydney,Sydney,NSW,Australia

AshokPandey CentreforInnovationandTranslationalResearch,CSIR-IndianInstituteof ToxicologyResearch,Lucknow;SustainabilityCluster,SchoolofEngineering,University ofPetroleumandEnergyStudies,Dehradun,India

AshutoshKumarPandey CentreforEnergyandEnvironmentalSustainability,Lucknow; CSIR-NationalEnvironmentalEngineeringResearchInstitute,Nagpur,India

AnpingPeng JointResearchCentreforProtectiveInfrastructureTechnologyand EnvironmentalGreenBioprocess,SchoolofEnvironmentalandMunicipalEngineering, TianjinChengjianUniversity,Tianjin,China

YongzhengRen SchoolofEnvironmentalScienceandEngineering,HuazhongUniversity ofScienceandTechnology,Wuhan,PRChina

SyedSaquib DepartmentofChemicalEngineering,FacultyofIndustrialTechnology, InstitutTeknologiBandung,Bandung,Indonesia

TjandraSetiadi DepartmentofChemicalEngineering,FacultyofIndustrialTechnology, InstitutTeknologiBandung,Bandung,Indonesia

XingdongShi CentreforTechnologyinWaterandWastewater,SchoolofCiviland EnvironmentalEngineering,UniversityofTechnologySydney,Sydney,NSW,Australia

YuqingSun DepartmentofCivilandEnvironmentalEngineering,TheHongKong PolytechnicUniversity,Kowloon,HongKong,China

B.X.Thanh KeyLaboratoryofAdvancedWasteTreatmentTechnology,VietnamNational UniversityHoChiMinh(VNU-HCM),HoChiMinhCity,Vietnam

ThiHienTran InstituteofEnvironmentalScience,EngineeringandManagement, IndustrialUniversityofHoChiMinhCity,HoChiMinhCity,Vietnam

ThiNhungTran DepartmentofCivilandEnvironmentalEngineering,KoreaAdvanced InstituteofScienceandTechnology(KAIST),Daejeon,RepublicofKorea

VanSonTran FacultyofEnvironmentalSciences,UniversityofScience,VietnamNational University,Hanoi,Vietnam

DanielC.W.Tsang StateKeyLaboratoryofCleanEnergyUtilization,ZhejiangUniversity, Hangzhou;DepartmentofCivilandEnvironmentalEngineering,TheHongKong PolytechnicUniversity,Kowloon,HongKong,China

SunitaVarjani GujaratPollutionControlBoard,Gandhinagar,Gujarat,India

StevenWahyu DepartmentofChemicalEngineering,FacultyofIndustrialTechnology, InstitutTeknologiBandung,Bandung,Indonesia

DanWang IntegratedResearchofEnergy,EnvironmentandSociety(IREES),Energyand SustainabilityResearchInstitute(ESRIG),UniversityofGroningen,Groningen,The Netherlands

LeiWang StateKeyLaboratoryofCleanEnergyUtilization,ZhejiangUniversity, Hangzhou,China

WeiWei CentreforTechnologyinWaterandWastewater,SchoolofCiviland EnvironmentalEngineering,UniversityofTechnologySydney,Sydney,NSW,Australia

JonathanW.C.Wong InstituteofBioresourceandAgriculture,HongKongBaptist University,KowloonTong,HongKong

LanWu CentreforTechnologyinWaterandWastewater,SchoolofCiviland EnvironmentalEngineering,UniversityofTechnologySydney,Sydney,NSW,Australia

HuijunXie EnvironmentalResearchInstitute,ShandongUniversity,Qingdao,China

JingtaoXu SchoolofMunicipalandEnvironmentalEngineering,ShandongJianzhu University,Jinan,China

JianYang SchoolofNavalArchitecture,OceanandCivilEngineering,ShanghaiJiaoTong University,Shanghai,China

YuanyaoYe SchoolofEnvironmentalScienceandEngineering,HuazhongUniversityof ScienceandTechnology,Wuhan,PRChina

JianZhang CollegeofSafetyandEnvironmentalEngineering,ShandongUniversityof ScienceandTechnology;ShandongKeyLaboratoryofWaterPollutionControland ResourceReuse,SchoolofEnvironmentalScienceandTechnology,ShandongUniversity, Qingdao,China

XinboZhang JointResearchCentreforProtectiveInfrastructureTechnologyand EnvironmentalGreenBioprocess,SchoolofEnvironmentalandMunicipalEngineering, TianjinChengjianUniversity,Tianjin,China

YuyingZhang DepartmentofCivilandEnvironmentalEngineering,TheHongKong PolytechnicUniversity,Kowloon,HongKong,China

ZengqiangZhang CollegeofNaturalResourcesandEnvironment,NorthwestA&F University,Yangling,ShaanxiProvince,PRChina

JohnZhou SchoolofCivilandEnvironmentalEngineering,UniversityofTechnology Sydney,Sydney,NSW,Australia

YuwenZhou CollegeofNaturalResourcesandEnvironment,NorthwestA&FUniversity, Yangling,ShaanxiProvince,PRChina

Preface

Thebooktitled BiocharTowardsSustainableEnvironment isapartoftheElseviercomprehensivebookserieson CurrentDevelopmentsinBiotechnologyandBioengineering (Editor-in-Chief:AshokPandey).Biochar,asarenewablematerial,canbeproducedfrom varioussustainablebiomassfeedstocksthroughpyrolysistechnologies.Reuseofbiomass wastesforbiocharproductionisasustainablestrategyforbiowastemanagementand environmentalprotection.Theobtainedbiocharwithspecificphysicochemicalandsurfacecharacteristicscanbefurtherappliedinwaterandwastewaterpurification,constructionanddrainagesystems,soilremediation,sustainableagriculturedevelopment, resourcerecycling,energystorageandconversion,aswellasclimatechangemitigation. Thisbookhighlightsthecontributionofbiochartoenvironmentalsustainability.Thebook providesadetailedoverviewofthesustainablebiomasswastesfeedstocksanddifferent technologiesforbiocharproduction,anditssustainableapplicationsinvariousfields. Thebookcomprises16chapters. Chapter1 discussesthesustainablebiocharproductiontechnologiesincludingsustainablebiomassresourcesforbiochar,reviewsof availablebiocharproductiontechnologies, projectionsonbiochardemand,environmentallyfriendlyandintensifiedbiocharproductiontechno logies,andtradeandeconomyofbiochar. Chapter2 describesthereuseofvarious biowastesasfeedstocksfor biocharproductionsustainablyinbiowastemanagementwhilefocusingontheenvironmentalbenefitsofthisstrategy. Chapter3 dealswiththetailoredproductionof engineeredbiochar,rolesandinteractionsof biocharinconstructionproducts,significanceofchemicalcompositionsandphysicalproperties,andmechanicalperformanceandfunctionalityofbiochar-augmentedconstructionproducts. Chapter4 focusesonthesignificanceanddesignofs ustainabledrainagesystems,identified needsforbiocharamendment,physicalimprovementbybiocharamendment,chemicalimprovementbybiocharamendment,bio logicalimprovementbybiocharamendment,andfutureresearchdirections. Chapter5 introducestheadvancesinthe sustainableapplicationofbiocharforwaterpurification,applicationofdifferentbiocharinwaterenvironment,mechanismofbi ocharinwaterpurification,andsustainableapplicationexamples. Chapter6 describestheapplicationofbiocharfortreating wastewaternotonlyasthemaintreatmentmethodbutalsoasthepretreatmentand theposttreatmentmethodsinintegratedtreatmentsystems. Chapter7 summarizesthe preparationandphysicochemicalcharacteristicsofbiocharandintroducestheperformanceofnutrients(i.e.,nitrogenandphosphorus)recoveryfromwastewater.This chapteralsodiscussestheexistingchallenges,futureresearchefforts,andopportunitiesforbiocharinnutrientsrecoveryfromwastewater. Chapter8 outlines

comprehensivelytherecentprogressesandbreakthroughsintheuseofbiocharinthe fieldofsludgetreatmentincludingsludgedewatering,aerobic/anaerobicsludgedigestion,andanaerobicsludgefermentationbyapplyingitsspecificproperties.Thischapterprovidesatheoreticalbasisandtechnicalreferencefortheapplicationofbiochar forimprovingsludgetreatment. Chapter9 reviewsstormwaterreuse,harvesting issues,characterizationofstormwater,po tentialforreuse,andthequantityandcharacteristicsofbiomass.Themodifyingtechniquesforbiocharproductionandtheapplicationandfutureperspectivesofbiochar forstormwaterreusearealsodiscussed.

Chapter10 providesareviewofcurrentbiocharproperties,itsuseasanadsorbent/ amendmentforsoilremediation,anditseffectonmicroorganismcommunitiesaswell asplantgrowth.Inaddition,thecontributionofbiochartobioeconomyisdiscussed. Chapter11 dealswiththeevolutionofbiocharprod uctiontechnologiesforsustainable agriculturepurposes,modificationofbiocha rforsustainableagriculture,influenceof biocharonsoilnutrientdynamicsandenzymes,andimpactofbiocharoncropgrowth andyield. Chapter12 providesanoverviewofthecommercialbiocharsanditsapplicationsforenergystorageandconversion.T hechallengesandopportunitiestogether withfutureperspectivesarealsodiscussed. Chapter13 describestheapplicationof biocharinpolyaromatichydrocarbonsremed iation.Integrationofbiocharwithother availabletechnologieshasbeendiscussedforenvironmentmanagement.Knowledge gapsandperspectivesinpolyaromatichydrocarbonsremediationaresummarized. Chapter14 comparestheproductionconditions,phy siochemicalproperties,andexistingandpotentialapplicatio nsbetweenbiocharandhydrocharinadditiontofuture challengesandresearchdirections,partic ularlyfromanenvironmentallysustainable perspective. Chapter15 providesanoverviewofthesignificance,application,and futuredevelopmentsofbiocharandintroduc esthesustainabilityassessmentconcept intermsofenvironmental,economic,social, andintegratedaspectsfortheevaluation oftheapplicationofbiochartowardssustainability. Chapter16 focusesonidentifying thesustainabilityimpactsofbiocharprodu ction,incombinationwithitsapplication viaanintegratedlife-cycleassessmentframeworkthatutilizesthreemethodologies: life-cycleassessment(LCA),life-cyclecosting(LCC),andsociallife-cycleassessment (S-LCA).

Weexpressourdeepestappreciationtotheauthorsandreviewersfortheirvaluable contributionstothebook.WearealsoverygratefultotheElsevierteamcomprisingDr. KostasMarinakis,formerSeniorAcquisitionsEditor;Dr.KatieHammon,currentSenior AcquisitionsEditor;BernadineA.Miralles,EditorialProjectManager;andtheentireproductionteamofElsevierforsupportingusconstantlyduringtheeditorialprocess.

DanielC.W.Tsang

HuuHaoNgo WenshanGuo AshokPandey SunitaVarjani

Sustainabletechnologiesforbiochar production

YazidBindara,b,YogiWibisonoBudhia,PanditHernowoa, StevenWahyua,SyedSaquiba,andTjandraSetiadia a DEPARTMENTOFCHEMICAL ENGINEERING,FACULTYOFINDUSTRIALTECHNOLOGY, INSTITUTTEKNOLOGIBA NDUNG,BANDUNG,INDONESIA b DEPARTMENTOFBIOENERGYAND CHEMURGY,FACULTYOFINDUSTRIALTECHNOLOGY,INSTITUTTEKNOLOGIBANDUNG, BANDUNG,INDONESIA

1.Introduction

Biocharisasolidproductleftoverfromthethermalconversionofbiomass.Thisthermal conversionprocessisknownasthepyrolysis.Biomasspyrolysisgivesthreeproductsat once.Thefirstproductisanoncondensablegasnamedbio-pyrolysisgas(BPG).Thesecondoneisaliquidproductresultingfromthecondensationofvolatileproductsreleased bythebiomasspyrolysisprocess.ThisliquidproductiscommonlytermedasBio-oil. However,itpresentsinacrudeform,i.e.,bio-crudeoil(BCO)whichwillfurtherprocessed forproperutilization.Theremainingsolidmaterialresultingfromthepyrolysisisreferred toasBiochar.Biocharhasacomplexchemicalmolecularstructurewithmolecularformulawhichisstillnotknownwithcertainty.Itischemicallyquantifiedfromthemassfractionoftheleadingorganicelementsthatmakeitup.Themainorganicelementsconsistof carbon(C),hydrogen(H),andoxygen(O).Besidesthem,Biocharisalsoformedbyminor elements,ifany,suchasnitrogen(N),sulfur(S),chlorine(Cl),andothers.Italsocontains inorganiccompoundssuchasmineralelementsthatarepresentinformofash.

Biocharstabilityisdescribedusingproximateanalysis.Thismethodprovidesinformationonthemassfractionofbiocharthatthermallydecomposedatatemperatureof900°C.It alsogiveinformationregardingthemassfractionofvariousotherconstituentsincluding volatilematter,fixedcarbonandashcontent.Highmassfractionofvolatilesindicateshigher degradabilitypotentialofBiochar.Whilehighfixedcarboncontentresultedinhighstability againstthedegradationinthesoil.Biocharparticlesasawholeareformedbyorganicmaterialresultingfromthecarbonizationprocess,uncarbonizedorganicmaterial,andinorganic ashformedbyvariousminerals(Oketal.,2016).Carbonizedorganicmatterbiocharhasa highCcontent.Thismaterialisformedbycarbonbondswithastructurethatisstillamorphous,withoutconstructingcrystallinestructurelikegraphite.Specificfunctionalgroups formsthesurfaceofsuchorganicmatter,thenporesformedinsideit.Themorphological characteristicsofBiochardescribetheexistenceoftheseholesinamicroview.

Biocharproductiontechnologyschemesaregenerallybasedontheheatingmethod, heatingrateandrawmaterialfeeding.Thefirstschemeinvolvesanindirectheating methodtobiomassforbiocharproductionwiththeabsenceofanycombustionreaction withoxygenattemperatureabove250°C(Basu,2013).Thesecondschemeemploysa directheatingmethodbysupplyingthehotcombustiongasestothepyrolysischamber toundergothepyrolysisreactionsofthebiomass.Thethirdschemeistheburningthe samebiomassontopofthebiomassforpyrolysisbysupplyingverysmallamountof theairinpyrolysischamber.Inthismethod,theproducedpyrolysisgasisburnedtogether withbiomassinthetopsectionofpyrolysischamber.Forasmall-scale,thisproduction technologywasshownby Shepard(2011).

Anotherbiocharproductiontechnologyisbasedoncontinuoustechnologywherethe pyrolysischamberisintheformofacylinderwhosebiomassisdrivenbyascrew.This pyrolysiscylindergetsheatingindirectlythroughitsouterwall.Thebiocharproductthat comesoutofthepyrolysiscylinderisfedtotheseparationchamberforobtainingbiochar andtheresultingvolatilegas.Biocharisthendischargedfromthebottomofthischamber throughascrewconveyorandcooleddownusingcoldwater.Suchproductiontechnology isalreadyexistsonacommercialscaleknownasthePyregtechnology(Pyreg,2021; Fesharaki andRath,2018).Variousbiocharproductiontechnologiesweredevelopedwithdifferent technologicalschemes;however,eachonehasthereadvantagesanddisadvantages.

Sustainableandenvironmentfriendlytechnologywithlesserpollutionisanessential requirementforlargescalecommercialbiocharproductionwithhigheconomicoutput. Acontinuousbiocharproductiontechnologywithaprocessingcapacityof240kg/daybiomassproduces72kg/dayofbiocharwithdieselfuelforheatinganauger-typepyrolyzer. TheeconomicsellingpriceofabiocharwassetatUS$ 1165pertonwiththebiomassfeed stockcostatUS$ 72pertonwhilethemarketpriceitselfwasaroundUS$ 2300perton(Pawar andPanwar,2020).Ahighyieldofqualitybiocharachievedwithoutreleasingvolatilematerialsandwithoutdirectcontactoflaterwithwateristhepreferredprocessflow.Thebiochar productionprocessdevelopedforcommercialuseshouldalsomaintainsimplerprocess technology.Biocharproducedfromthefastorlightningpyrolysisprovidesloweryields, morecomplexproductiontechnology,andhighproductioncosts.

Biocharproductiontechnologydevelopedmustmeettherulesofahighrecoveryrate, aproductioncapacitythatcanmeettheneeds,andattractiveeconomicfeasibility. Besidesthis,theproductiontechnologymustrelyonlyonthebiomassenergysource withoutinvolvingexternalenergysourcestobecomesustainable.Theuseofmaterials otherthanbiomasswhichmakestheproductiontechnologyunsustainableandcauses highproductioncostsshouldbeavoided.

Thefulfillmentofenvironmentallyfriendlyproductiontechnologyisacrucialrequirementforlargescaleproduction.Thepyrolysisofbiocharreleasesvolatilematerialswhich maycausepollutionwhendischargedintotheenvironment.Volatilematerialsconsisting ofhydroxycarboncompoundsmustbeburnedinthecombustionchambertoonlyliberateCO2 andH2Owhicharenonhazardouspollutingagents.Theproblemsthatexistare indeedrelatedtothesupplyofbiomassthatcanbeprovided.Sincetheavailablebiomass

ismostlyresiduefromagriculturalproducts,theavailabilityofthisbiomassisnotcentralized.Itisprovidedatcertaintimesoftheyearinmerequantities.Thedeterminedbiochar productiontechnologymustadapttosuchbiomasssupplyconditions.

2.Biomassasrawmaterialforproductionofbiochar

Therawmaterialusedfortheproductionofbiocharisbiomass.Thisbiomassincludes intentionallygrownrawmaterial,residuefromcrops,residuefromforestryproducts, ororganicwaste.Biomassthatisintentionallygrownasrawmaterialgenerallydoes notconsiderasfoodandhasashortgrowinglife.Agriculturalresiduebiomassgenerally hasnoorveryloweconomicvalue,suchasricehusksandstraw.Biomassobtainedfrom organicwasteisdisposedoforsortedasamaterialwithnoeconomicvalueanymore.

Sourcesofagriculturalresiduebiomassincludecorn( Tippayawongetal.,2018),wheat (Sedmihradska ´ etal.,2020),rice( Tsaietal.,2021),barley( Jazinietal.,2017),sorghum (Naiketal.,2017),soybean(Kongetal.,2011),rapeseed(AnginandSens € oz,2014),olive (Abdelhadietal.,2017),oilpalm(Idrisetal.,2014),sunflower(Klimek-Kopyraetal., 2021),coconut(Castilla-Caballeroetal.,2020),cassava( Tippayawongetal.,2017),sugarcane( Jeongetal.,2016),beet( Yaoetal.,2011),coffee(KiggunduandSittamukyoto,2019), cotton(Shenetal.,2015),andothers.

Theworld’spotentialforresidualbiomassin2017istheoreticallyestimatedinbetween 4000and12,000milliontons( WBA(Producer),2019).Theestimatedresidualbiomass potentialishigherthanthe2010estimate,whichwasaround3300milliontons(Born etal.,2014).Ofthisresidualbiomasspotential,10%isusedasfeed,78%isreturnedto agriculturallandintheformofburningorbiomassalone(Bornetal.,2014).Woodproductionforfuelwasreportedas1944millionm3 for2019.Thiswoodwasconvertedinto woodpelletsasmuchas38.9milliontonsandintocharcoalasmuchas53.1milliontons for2019( WBA(Producer),2020).Estimatesforbiomassplantedforenergyusearealso basedontheavailabilityof3500millionhaoflandwithbiomassproductivityof8tons/ha peryear(Hoogwijketal.,2005).

Biomassfromplantsisdividedintowoodandnonwood.Theprimaryconstituentof woodbiomassiscelluloseandlignin(Basu,2013).Inadditiontolignocellulose,plantsalso containextractivesandash.Forexamples,switchgrassisformedby40%cellulose,25% hemicellulose,and15%lignin(Milesetal.,1995),andfruitemptybunchconsistsof 44.4%cellulose,24.3%hemicellulose,and31.3%lignin(Nasseretal.(2016).Eachoflignocellulosiccomponentshasadifferentchemicalstructure.Biomasshasbeendesignated asarenewableenergysource.Biomassconversionintothermalenergyisdonethrough burning.Forthisconversiontothermalenergy,biomassisquantifiedbythecontentof volatilematerialsasproductsofthermaldecomposition,thefixedcarboncontentas organicsolidsleftafterthebiomassisthermallydecomposed,andtheashcontentas materialsthatdonotcontainthermalenergy.Biomassanalysisforthiscompositionis knownasproximateanalysis,whichprovidesdataonthemassfractionofvolatilematter (VM),fixedcarbonmaterial(FC),ashmaterial(A),andwater(M)ownedbybiomass.Its

calorificvalueofcombustionmeasuresthepotentialenergycontentofbiomass,reported inhighcalorificvalue(HHV)orlowcalorificvalue(LHV).Thesevaluesareusedinthe energyassessmentofbiomass.Thecurrentbiomassenergyassessoriscomparedtothe energycontentofcoal.Thelevelofitsenergycontentalsoreferredtomeasurestheeconomicvalue.

3.Biocharproductionprocesstechnology

Biocharproductiontechnologyisgenerallybasedonathermochemicalprocess.Thethermochemicalprocesscommonlyusedinbiocharproductiontechnologyispyrolysis (Brown,2009; Mullenetal.,2010; Manya ` etal.,2018; Kazawadietal.,2021).Anotherthermochemicalmethodusedforbiocharalongwithsynthesisgasproductionisthegasificationprocess.Anothermethodusedforbiocharproductionalongwithsynthesisgas productionisthegasificationprocess( Yaoetal.,2018).Thehydrothermalprocessthat useswaterasaheatingmediumathighpressureandtemperaturetoconvertbiomassinto biocharproductshasalsoreceivedattentioninthebiocharproduction.Theproductof thisprocessisoftencalledhydrochar(Sharmaetal.,2019).

Pyrolysismethodsinbiocharproductionbasedontheoperatingconditionsare expressedasslowpyrolysis,intermediatepyrolysis,fastpyrolysis,andflashpyrolysis ( Table1).Theslowpyrolysisoccursatlowheatingrate.Pyrolysiswithmoderateheating rateiscategorizedasanintermediatepyrolysis.Thefastpyrolysisitselftakesplaceathigh heatingrate.Flashpyrolysisiscarriedoutbyheatingthepyrolyzedbiomassveryrapidlyin amatterofmilliseconds(Basu,2013).Therequiredtimetoheatupthepyrolyzedbiomass atpyrolysistemperature Tpf isreferredasheatingtime tht.Theheatingrate β is approachedas ΔT/tht andconsideredtobeconstantduringtheprocess.Thetotaltime betweentheheatingtimeandthepyrolysisreactiontimecanbedefinedastheresidence time tct ofthepyrolyzedbiomass.Otherparameterstocategorizethepyrolysisprocess conditionarethetemperaturelevel,residencetimeandbiomassparticlediameter.

Theslowpyrolysisisoperatedattheheatingratebelow60°C/min.Thefastpyrolysis employstheheatingrateintherangeof600–12,000°C/min,whereasflashpyrolysisuse theheatingrateabove60,000°C/min(Balatetal.,2009).Theintermediatepyrolysisiscarried outatheatingrateabout200°C/min( Jouharaetal.,2018)orintherangeof60°C/minto600°C ( Tripathietal.,2016).Theyieldofbiocharsbecomeslowerforhigherheatingrateatthesame

Pyrolysismethod

Operatingconditions

Table1 Pyrolysiscategory.

pyrolysistemperaturethatisshownby29%biocharyieldatheatingrate6000°C/minand42% atheatingrate120°C/minforthepyrolysistemperatureat527°C(Demirbas,2004).Fastor flashpyrolysisprocessismeantforbio-oilproductionbecauseitproduceshighyieldof bio-oilproductabove70%andlowyieldofbiocharofnotmorethan15%.Sloworintermediatepyrolysisresultsbiocharabove20%yield(Bridgwater,2010).

Theheatsupplytechniqueforthebiomasspyrolysisprocessiscarriedoutwiththree possiblescenarios.Theheatissuppliedtothewallsofpyrolysischambertoheatupthe biomasspresentinside.Thisheatingscenarioisknownasanindirectheatingprocess.The secondheatingscenarioisthedirectcontactheatingwithaheatingmediumasaninertto thepyrolyzedbiomassinthepyrolysischamber.Thethirdispartialoxidationheatingsupplyinwhichsomeofthepyrolyzedbiomassinthepyrolysischamberisoxidizedwitha minimalamountofoxidizingairtogeneratetheheatforpyrolysis.

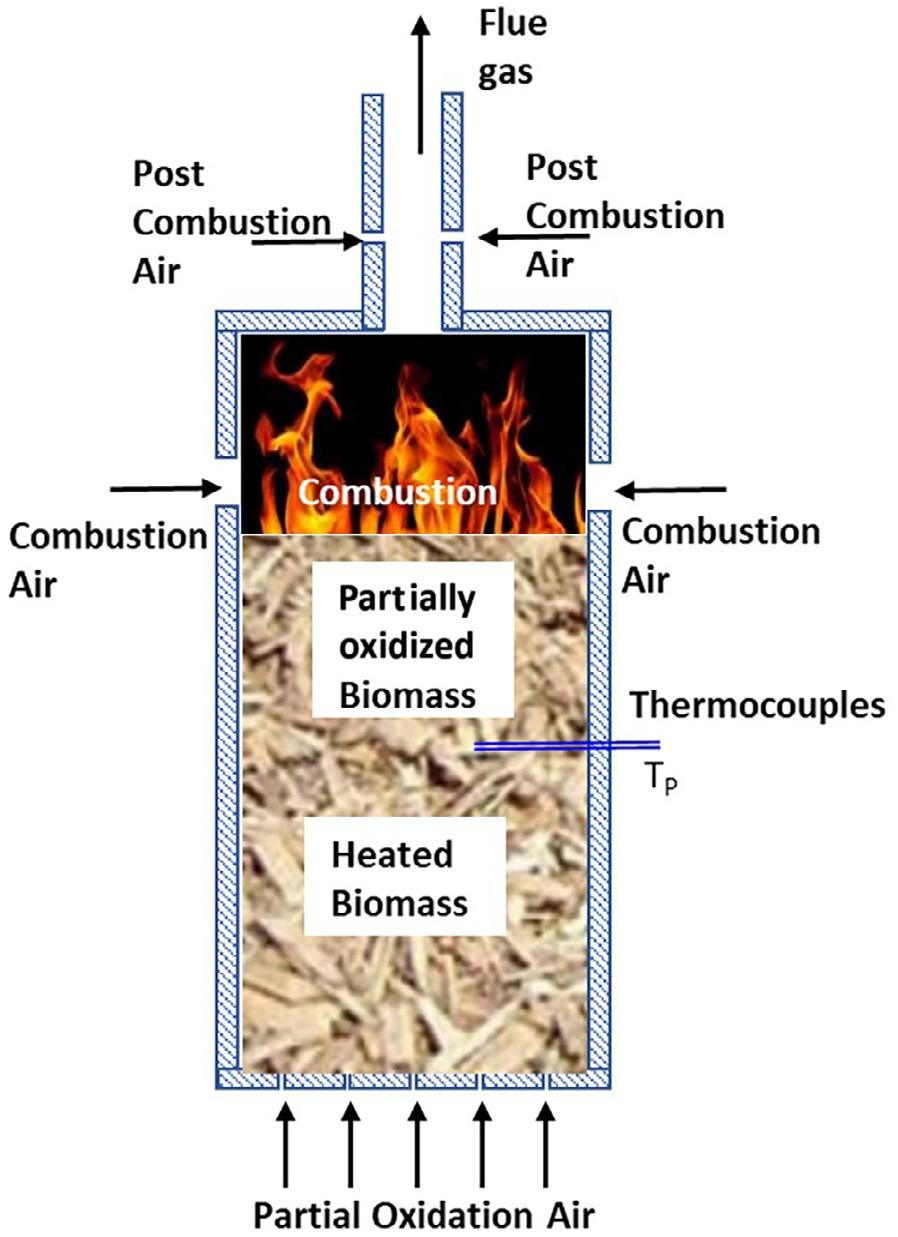

Themethodofsupplyingtherawmaterialaspyrolyzedbiomassiscarriedoutin batchesorcontinuously.Thispartyingmethodsuppliesrawmaterialsintothepyrolysis chamberinacertainamountwithinthepyrolysiscontinuityperiod.Duringthepyrolysisperiod,thebiomassinthepyrolysischamberissuppliedindirectlythroughthe wallsofthepyrolysischamber.Theheatsourcefordirectheatingofbiomassistheheat resultingfromfuelcombustion,whichhas alowereconomicvaluethanthepyrolyzed biomass.Theconceptualdesignofthispartialindirectheatingpyrolyzerisgiven in Fig.1 .

Thebatchmethodofproducingbiocharisalsocarriedoutbydirectheatingwiththe heatgeneratedbypartialoxidationofthepyrolyzedbiomassinthepyrolysischamber itself.Thismethodisdonebysupplyingtheairinaminimalamount.Directheatingwith aninertheatingmediumisrarelyusedforthepartialoxidationmethodinbiocharproductiontechnologyunlessdoneonalaboratoryscale.Theconceptofpartialoxidation fortheheatingmechanisminthepyrolyzerisshownin Fig.1.Onesuchpyrolyzerwas manufacturedfromanoilbarrelvesselwith200Lvolumeandusedtoproducethebiochar fromcorncobs,longanprunings,ricestraw,andbamboo( Tiyayonetal.,2016).Study reportedthepyrolysistemperatureabove400°C,77minofthetotalresidencetimeof thepyrolyzedbiomassand20%–40%ofthebiocharyields.

Theproductionofbiocharisalsocarriedoutthroughcontinuoussupplyofrawmaterials.Heatingforthiscontinuousmethodcanbedoneindirectly,directly,orincombination.Indirectheatingalonemightnotbeenoughtofulfilltheheatingraterequirementin continuousbiocharproductiontechnology.Duetothehighheatingraterequirementfor continuousprocesses,thisheatratecannotbesuppliedwithindirectheatingatarealistic operatingtemperature.Continuousbiocharproductiontechnologyismorecomplexthan batchproduction.

3.1Simpleautothermalbiocharproductiontechnology

Themethodofconvertingbiomasstobiocharproductscanbedoneautothermally (Nsambaetal.,2015).Therequiredheatisgeneratedfromthepartialcombustionof

FIG.1 Conceptualdesignofpyrolyzerforbiocharproductionwithpartialoxidationheatingforheatgenerationand batchslowpyrolysisofbiomass(Tiyayonetal.,2016).

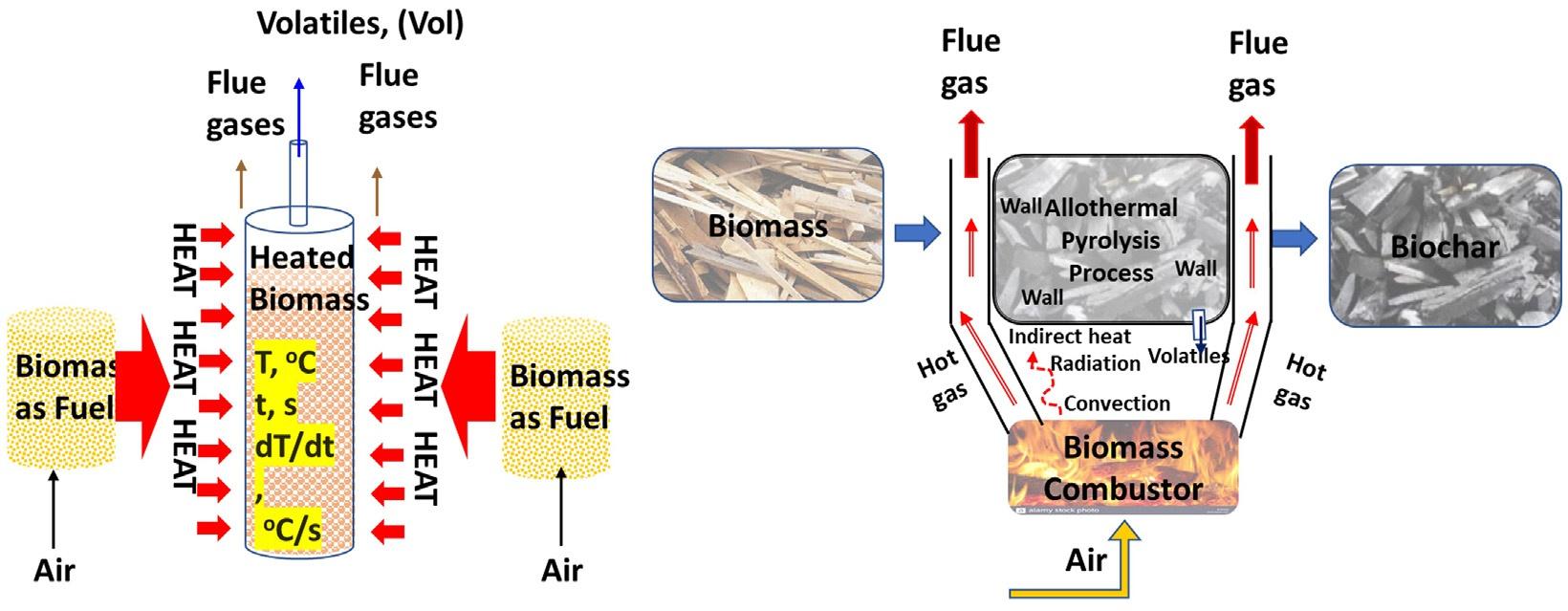

thebiomassinthepyrolysischamber.Airissuppliedtothechamberinaregulated amountsothatonlyasmallportionofthebiomassisburned.Theburntbiomassispresentatthetopofthepyrolysischamber,andtheheatgeneratedpropagatesthroughconductiontothepyrolyzedbiomassatthebottomlayer.Thisautothermalpyrolysismethod ispresentedintheformofadiagramin Fig.2.

FIG.2 Conceptdesignofautothermalpyrolysismethod.

Biocharproductionprocesstechnologywasdevelopedfromtraditionalmethodsto industrialmethods.Thesetraditionalmethodsaregenerallyappliedtosmall-scalebiocharproduction.Theyareconsideredasnoneconomicalandalsoleadtoenvironmental degradation. Fig.2 showstheautothermalconceptualtechnologyforthetraditional,lowcost,andsimplebiocharproductionprocess.Thebiocharproductionprocesstechnology describedaboveisconceptuallyeasytomanufactureandoperateatcommunitylevel. Stepsformanufacturingandinstallingthistechnologyinthefieldareshownin Fig.3.

Averysimplepyrolyzerusesanopenproductionunit,suchasstackinginabiomass mound.Thepileofbiomassisopenlyundergoingapartialoxidationprocessonthe topandsurface.Theheatgeneratedfromthepartiallyoxidizedbiomassistransferred byconductiontotheinnerbiomasspilewhichundergoesapyrolysisprocess.Thisbiomassstackisintheformofadomewithholesonthesidesandtopforairsupply.The airinthebiomasspileflowsfreelybynaturaldraft.Thewallsofthebiomasspilearemade ofsoilwhichactsasaninsulatortopreventheatlossandlimittheflowofairinthereactor. Theworkingprincipleofthemoundbiocharproductionunitisthatthebiomassis arrangedintheformofadomecoveredwithamoundofsoilasaninsulator.Someof thebiomassisburnedwithverylittleair.Thiscombustionprocesswillproduceheat whichwillbepartiallyretainedonthereactorwallsduetoitsinsulation.Afterthecombustionisdeemedsufficient,theholesinthemoundarecompletelyclosedsothatthe reactorisairtight.Fireisformedslowly,andheatgeneratedisusedtopyrolyzeunburned biomass.Thisprocesscantakeuptodaysuntilalltheheatisgone.Theweaknessofthe moundproductionunitisthedifficultyofcontrollingthetemperatureandheatingrate duringpyrolysis.Inaddition,theamountofbiomassburnedandpyrolyzedisalsochallengingtocontrol.Mostoftheheatduringthecombustionphasewillbewastedalong

1. Oil drum

3. Secondary air manufacture

4. Chimney opening manufacture

7. Simple Biochar production unit

6.Chimney

5. Secondary air holes

2. Holes on bottom for primary air

FIG.3 Onsitefieldlevelsimpleandinexpensivebiocharproductionunit(UrbanFoodPlus,2015).

withthecombustionsmoke.Therefore,thisunithasalowcharyieldofabout1kgforevery 8–12kgofbiomassfeedstockwhichisnotsufficient(Stassen,2002).Environmentalproblemswithsmokereleasedintotheopenairareaconcernassociatedwiththismethod.The advantagesarelowproductioncostsandeaseofimplementationatthetraditionaluser level.

Asmall,verysimpleandlow-costpyrolyzerisknownasthe“Kon-Tiki”openfire (SchmidtandTaylor,2014).Theairaroundthepyrolyzerwithheatedwallsflowsvertically bynaturalconvection.Thisairflowatthetopofthepyrolyzerwithanenlargedcrosssectionalareaformsacirculatingflowthatenteredtheinternalsectionreferredtoasvortexflow.Itservesasthecombustionairforthebiomassatthetopofthepyrolyzer.The burningbiomassatthetopgeneratesheat.Theheatgeneratedbythiscombustion,heats thebiomassinsidethepyrolyzerwhichundergoesapyrolysisprocesstoproducebiochar.

Therearemanytraditionalandstraightforwardmodelsofbiocharproductiontechnology.Thematerialsusedinthesimpletechnologyarelocallyavailableandinexpensive includesclay,bricks,anddrums.BiocharproductiontechnologiesincludeEarthKiln,PortableMetalKiln,DrumKiln,andCasamanceKiln(Oduoeetal.,2006).Generally,traditionalbiocharproductiontechnologyusestheautothermalmethod.Theproblems facedbythistraditionaltechnologyarelowproductivity,lessereconomyandtheenvironmentalconcerns.

3.2Simpleallothermalbiocharproductiontechnology

Pyrolysisofbiomassisalsocarriedoutbyheatingwithanexternalheatsource.Thistechniqueisknownasallothermalpyrolysis(Nsambaetal.,2015)(Fig.4).Theheatrequiredis generatedbythefuelcombustionwhichiscarriedoutoutsidethepyrolysischamber.Walls physicallyboundthepyrolysischamberandcombustionchamber.Theheatfromthefuel combustionoutsideistransferredtothepyrolysischamberwallsurfacethroughconvection andradiation.Theheatreachestheouterwallbyconductionthroughthepyrolysischamber wallandthentobiomassinthepyrolysischamber.Theheatreceivedbythebiomassisused

FIG.4 Conceptualdesignofallothermalmethodforbiomasspyrolysistoproducebiochar.

toraiseitstemperature.Thenitcarriesoutthepyrolysisreactionatsufficienttemperature. Anallothermalfixedbedpyrolyzerasapilotscalewiththebiomasscapacityof20kgwas testedtoproducebiocharfrompalmkernelshell(Zainaletal.,2018).Theoperationalconditionswerereportedtohavethepyrolysistemperatureintherangeof400–600°Candthe residencetimefrom30to60min.Theirbiocharyieldsare52%at400°Cfortheresidence time30minand33%at600°Cfortheresidencetime60min.

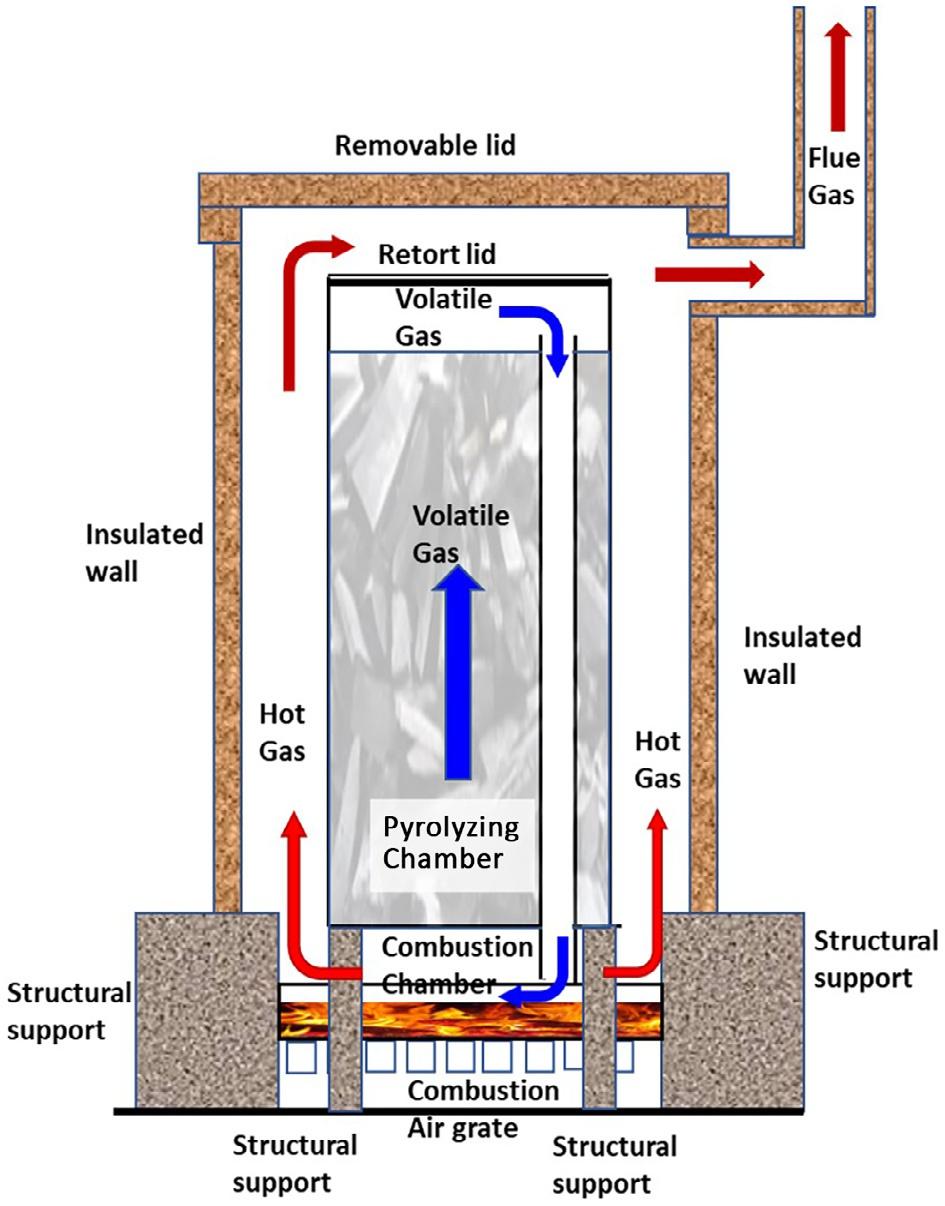

Thesimplebiocharproductiontechnologythatiswidelyusediscarriedoutusing drummethod.Thisproductiontechnologyisconceptuallysketchedin Fig.5.Biomass feedstockisfedintothedrumthroughthedoor(7).Thebiomassputintothedrumchamberreferredaspyrolysischamber(1)variesfromlargetosmallsize.Withthispattern,the efforttoadjustthesizeofthepyrolyzedbiomassisminimal.Theheatingofthepyrolyzed biomassinthedrumiscarriedoutwiththeheatgeneratedbythecombustionofthebiomassinthecombustionchamber(2),whichisseparatedbyawallfromthispyrolysis chamber.Heatingtakesplacebyindirectheating.Thevolatilegas(4)producedfrom thepyrolysischamberischanneledintothecombustionchambertobeburnedthrough aspeciallyconstructedpipeline.

Theburningofvolatileproductsiscarriedout.Thevolatilesdonotpollutetheenvironmentwhenthevolatilegasresultingfrompyrolysisisthrownawayoftendoneinvery simpleproductionunits.Furthermore,thepyrolysisprocesstakesplaceoveralong period.Thepeaktemperatureinsidesuchpyrolysischamberrangedbetween300and 700°C.Thetimetoreachthepeaktemperaturewasabout100–200minandthebiochar yieldwasreportedtobewithin24%–34%mass(Khawkomoletal.,2021).Theadvantages

FIG.5 Simplebatchbiocharproductionunitinadrumretortwithvolatilegascombustionsysteminthecombustion chamber. ModifiedfromthedrumretortdesignofKhawkomol,S.,Neamchan,R.,Thongsamer,T.,Vinitnantharat,S., Panpradit,B.,Sohsalam,P.,Werner,D.,Mrozik,W.,2021.Potentialofbiocharderivedfromagriculturalresiduesfor sustainablemanagement.Sustainability13,8147.

ofthisbiocharproductiontechnologyaresimplicity,easeofoperation,andeaseofmanufactureatalowcost.Theproblemisthatsmallproductioncapacity,longproduction time,andhighfuelconsumptionwiththermalefficiencyinheattransferarestillvery low.Theheatingrateofthisunitisrelativelylong.Itisbecausethediameterofthe Dpyr pyrolysischamberisverylarge.

Small-scalebiocharproducerswidelyusethisretortmodelproductiontechnology.The NGOs(nongovernmentalinstitutions)providemuchinformationabouttheproduction andperformanceofthebiocharproductunits.Informationlikethisisprovidedonline invideosonhowtomanufactureandoperateaproductionunitpubliclypublishedvia YouTube.Avideooftheoperationofthebiocharproductionunitmodelwaspublished by JP(Producer)(2018) viaYouTubeintermsofthesequenceofheatingoperationsby burningwoodfuelinthebiocharproductionunitisgivenwiththehighlightsofthe screenshotstakeninthisvideoasshownin Fig.6.Thevolatileproductsproducedare channeledintothecombustionchamberforburningtoformajetflamewithbrightfire shownin Fig.6 frame(c).Thejetfirefromthecombustionofvolatileproductsinthecombustionchamberisshownin Fig.6 frame(f).

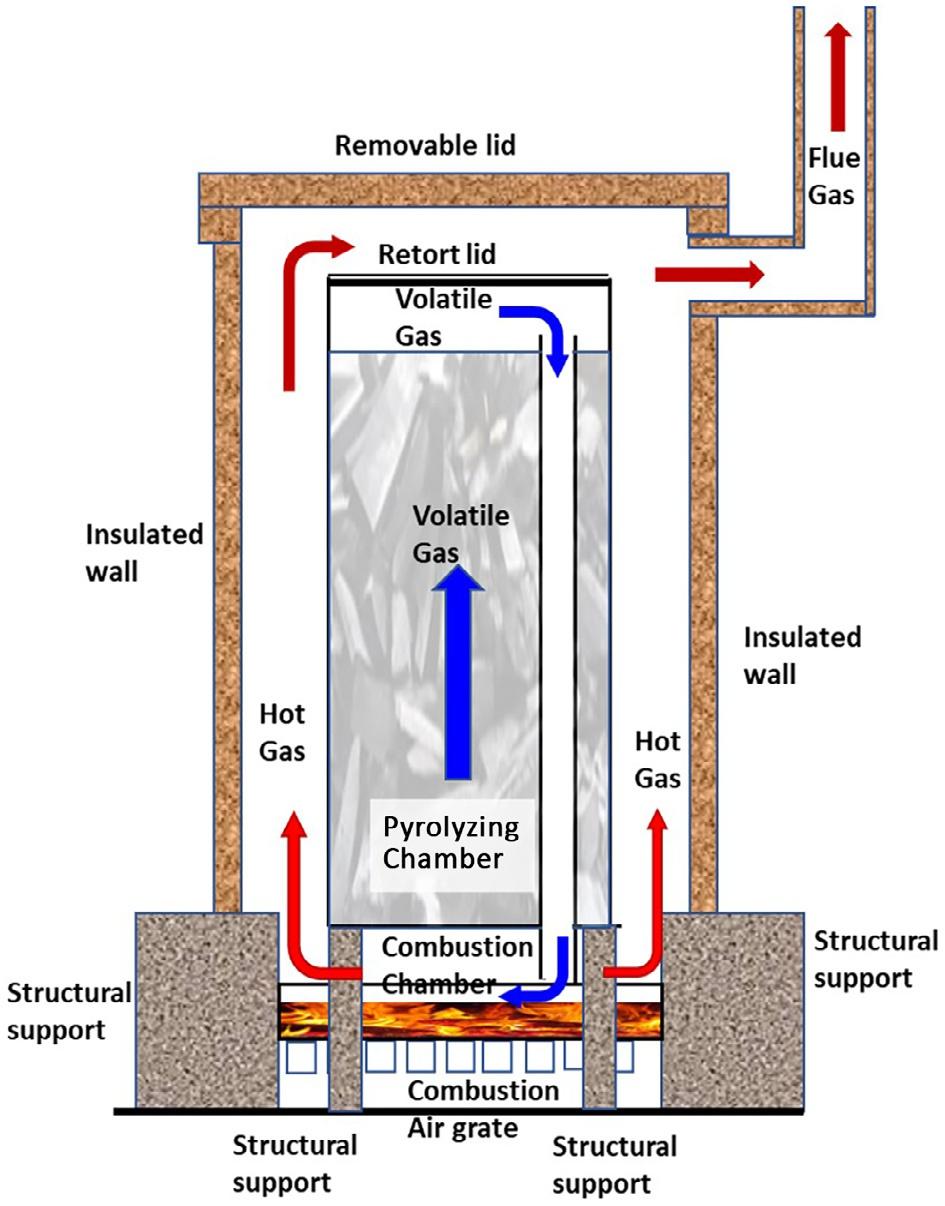

Thedevelopmentofthebiocharproductiontechnologywascarriedoutwithvertical orientationasamodifiedconceptualdesignfromCharcoalRetortV.2.0(Blacksmith, 2012).Thismodifiedtechnologyisdepictedin Fig.7.Thefirefromburningbiomass asfuelintheprimarycombustionchamberheatsthelowerpartofthepyrolysischamber.Thehotgasresultingfromthecombustionofbiomassmaterialsintheprimary combustionchamberflowsthroughachannelintothepyrolysischamber.Thehot gasthatnolongercontainsoxygendirectlyheatsthebiomassinthepyrolysischamber. Thepyrolysisproductisamixtureoffluegasandvolatilegasfromthepyrolysisproduct

FIG.6 Operationhighlightsoftheretortmodelbiocharproductionunitwiththecombustionofbiomassfuelfor heatingthedrum-shapedpyrolysischamber(JP(Producer),2018).

FIG.7 Simplebatchbiocharproductionunitinaverticaldrumretortwithindirectanddirectheatingandvolatilegas combustionsysteminthesecondarycombustionchamber.ModifiedconceptualdesignfromCharcoalRetortV.2.0 (Blacksmith,2012).

thatexitstothebottomofthepyrolysischambertothesecondarycombustionchamber. Theprimaryandsecondarycombustionchambertemperaturesweremonitoredwith thermocouples TC1 and TC2.Thetemperatureofthepyrolysischamberwasmeasured witha Tp thermocouple.

Anotherbiocharbatchproductiontechnologywasdevelopedfromtheimprovement inthebiomassfuelcombustionsystem.Oneformofthedevelopedtechnologymodelis depictedin Fig.8 reportedinPatentUS20110252699A1(Shepard,2011).Thistechnology hasaretortasacylindricalpyrolysischamberthatismountedhorizontally.Thecylindrical pyrolysischamberismountedhorizontallyabovethecombustionchamber.Thisprimary airflowsintothesidechamber,whichisboundedbythesidebafflewallwhichsimultaneouslyentersthecombustionchamberthroughthebackwallasshownin Fig.8.

Biocharproductiontechnologywithacylindricalverticalretortwithindirectheatingis givenin Fig.9.Thecombustionchamberwithbiomassfuelisplacedatthebottomofthe retortwhereheatingtakesplaceindirectly.Thisverticalretortisplacedintheheating chambersothatitssideandtopwallsgetheatedbythehotgasesfromthecombustion thatflowintothisheatingchamber.Thecombustiongasesaredischargedthroughtheflue gasexhaustduct.Airissuppliedforthecombustionthroughholesthathavebeenmadeat thebottomofthecombustionchamber.

Theproductiontechnologyofbiocharandbio-crudeoil(BCO)withoptimaldiameterverticalmultitubepyrolysischamberswasdevelopedby Bindaretal.(2021).Thecompleteflow

FIG.8 Simplebatchbiocharproductionunitinahorizontalretortdrumwithindirectheatingwiththeuseofanair guideandcombustiongases(Shepard,2011).

ofthisproductionprocessisshownin Fig.10.Thisproductionunitisorientedtoproducebiocrudeoil,bio-pyrolysisgas,andbiocharproducts.Whenthisproductionunitisusedtoproducebiocharonly,thevolatilegasproducedisreturnedtothecombustionchamberwithouta condensationprocess.Volatilegaswillburninthecombustionchamber.

Thesequenceofprocessesinthebiocharproductiontechnologyin Fig.10 involvesthe stagesoftheprocessandthestagesofproductionoperations.Thesestagesaresizereductionofbiomass(1),dryingshreddedbiomass(4)indryingunit(5),feedingthedryshreddedbiomassintopyrolysistube(11),supplyingthebiomassasfuelintothecombustion chamberthroughthefuelfeedline(10)tothecombustionchamber(12),combustionof biomassfuelinthecombustionchamber(12)withcombustionair(13)suppliedbya blower(15),indirectheatingofthewallsofthepyrolysistube(11)inthecombustion chamberandheating(12)byfireandhotgasesresultingfromcombustion,distribution ofvolatilegasproducts(16)outofthepyrolysistube(11),fullopeningofvalves(32) andfullclosingofvalves(30)and(34)forbiocharproductiononlywithoutBCOproduction,distributionofvolatilegasproductsthroughthereturnline(33)tothecombustion chamber,monitoringthetemperatureofthepyrolysischamberwithathermocouple(35), monitoringthetemperatureofthecombustionchamberwithathermocouple(36),operationofthebiocharproductionunitwiththedurationoftheheatingandholdingtimeat

FIG.9 Verticalretortbiocharproductionunitinanindirectheatingchamberfromthebottomandsideswithvolatile gasexpellingfromthepyrolysischambertothelowercombustionchambertobeburned.Modifiedconceptual designfromCharcoalRetortV.2.0(Blacksmith,2012).

FIG.10 Productiontechnologyofbiocharandbio-crudeoil(BCO)withoptimaldiameterverticalmultitubepyrolysis chamber(Bindaretal.,2021).

thespecifiedpyrolysistemperature,cessationofsupplyoffuelandcombustionairwhen thetargetoperatingtemperatureandtimehavebeenreached,coolingthebiocharproduct(27)inapyrolysistube(11)bynaturalcooling,andtakingoutthecoldbiochar(27)by openingthebiocharoutlet(28).

ThebiocharandBCOproductionunitin Fig.10 consistsof10verticalpyrolysistubes(11). Theseverticalpyrolysistubesarearrangedintwoparallelrows.Thediameterofeachtubeis 4in.Thisunitisequippedwithathermocoupletomonitorthetemperatureofthepyrolysis chamber(11)andthetemperatureofthecombustionchamber(12).Theindirectcontact condenserunit(17)isusedtocondensetheproductgasresultingfromthepyrolysiscoming outofthetopofthecylindricalreactoroftheuprightpyrolysisfurnace(11).Thecoolingwater pump(21)pumpsthecoolingwater(22)whichissuppliedtothecondenserunit(17).Thegas andliquidphaseseparationunit(18)separatesthenoncondensablegaseousproduct(20) andtheliquidproduct(19).Thenoncondensablegasreturnline(20)tothecombustion chamber(12)isusedtoburnthegaseousproductsinthecombustionchamber(12).The productholdingtankunit(29)isintendedforstoringBCOliquidproducts.Thebiocharproduct(27)isremovedfromthetubebyopeningthebottomcapofthetube(28).

TheproductionofbiocharandBCOiscarriedoutatthebiocharproductionunit in Fig.10 with60kgoflightbiomassthatwaschoppedtoasizeof15mm.Atotalof 30kgoflightbiomassisfedinto10verticalpyrolysistubesinthisunit.Eachtubecontains asmuchas3kgtobepyrolyzed.Theremaininglightbiomassispreparedtobeusedasfuel inthecombustionchamber(12).Thepyrolysisprocesslastsfor2h.Thecombustion biomassisfedcontinuously.Thebiomassfedtothecylindermodulewillbeconverted intoBCO,biochar,andbiopyrolysisgas(BPG).Biocharyieldis25%,withaBCOof 50%.Thepyrolysistemperaturewasmaintainedat500°C.

3.3Continuousbiocharproductiontechnology

Therearevariouscontinuouspyrolysistechnologiesdevelopedbyvariousresearchers. Suchtechnologiesarerotatinghotdiscablative,circulatedfluidizedbed(CFB),molten saltvacuumvessel,bubblingfluidizedbed,screw(auger),rotatingconeandrotarykiln pyrolysistechnologies( VenderboschandPrins,2010; Bridgwater,2012; Kernetal., 2012; Nacheniusetal.,2013; Ronsse,2016).Mostofthesetechnologiesarefastpyrolysis technologiesthatweredevelopedmainlytoproducethebio-oilproduct.Forthepurpose ofthebiocharproduction,fastpyrolysistechnologiesaretoocomplex,considerablyhigh capitalandoperationalcostandlowbiocharyield.Therefore,thesuitabletechnologyfor thebiocharproductionissloworintermediatepyrolysistechnology.Amongthesetechnologies,screw(auger)androtarykilnarecategorizedintocontinuesandsloworintermediatepyrolysistechnologies.Thenthecontinuousbiocharproductiontechnologiesto befocusedherearescrew(auger)androtarykilnpyrolysistechnologies.

3.3.1Augerpyrolysistechnology

Continuousbiocharproductiontechnologywasdevelopedwiththeprincipleofallthermalheatingmethods.Theheatingrateiskeptatahighlevelaspossible.Thepyrolyzed