Listoffigures

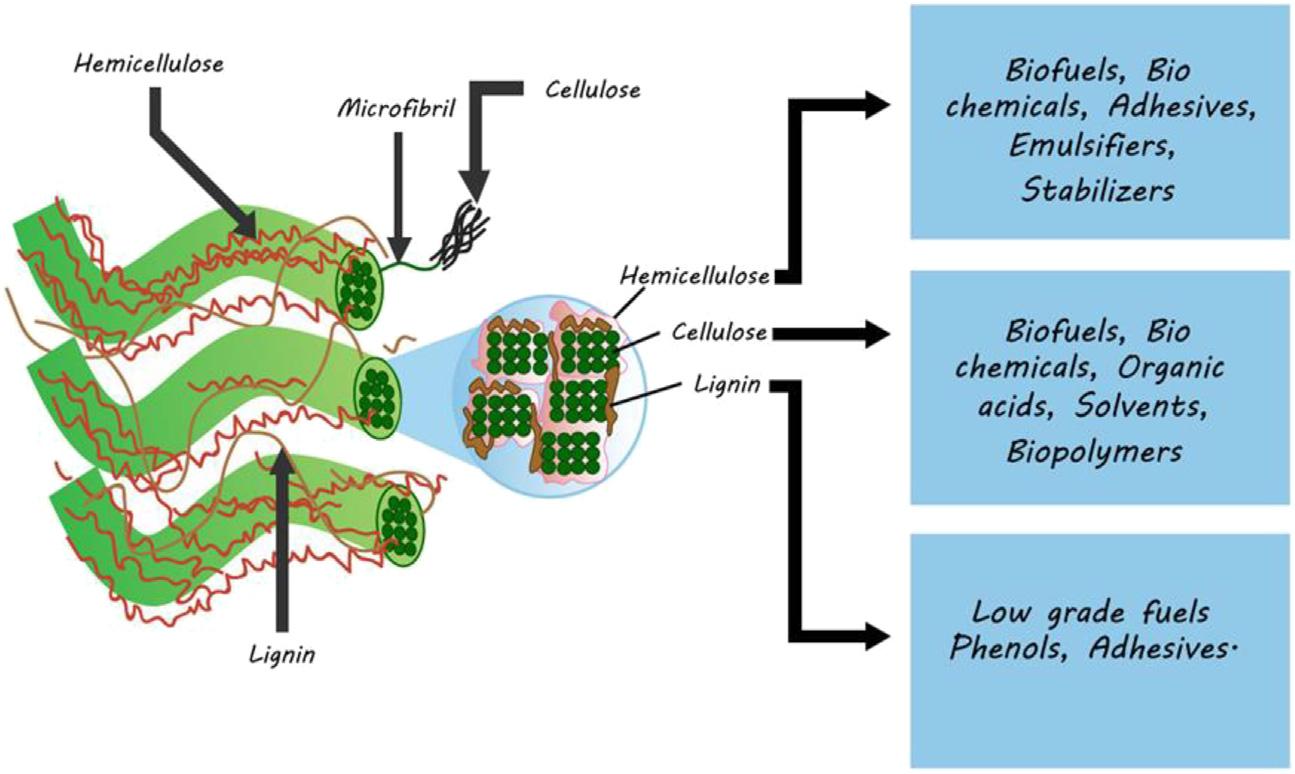

Figure1.1Structureoflignocellulosicbiomassanditsbiopolymers;cellulose, hemicellulose,andlignin.

Figure1.2Lignocellulosicbiomassalongwiththeirproducts.7

Figure1.3Thecellulosepolymerchainstructure.9

Figure1.4Schematicrepresentationforthemacromolecularstructureoflignin (Majormonolignolunitsarecoloredassinapylalcohol-red,guaiacyl alcohol-blue, p-coumarylalcohol-green).

Figure1.5Structureofhemicellulose.10

Figure1.6Schematicrepresentationofthesynergisticactionof cellobiohydrolases(CBHI,CBHII),endoglucanases(EG),and β-glucosidases(βG).

Figure1.7Overviewofthetwostrategies(freeorcell-boundcellulasesystems) fordegradingcellulose.Infreeextracellularsystems,endoglucanases andexoglucanasesactsynergistically,withtheendoglucanase cuttingamorphouscelluloseprovidingchainendsforexoglucanases toreleasecellobiose.Then, β-glucosidaescompletetheprocessof cellulosehydrolysisbyreleasingglucose.Also,cellodextrinsreleased byendoglucanasescanbefurtherhydrolyzedbycellodextrinases. Thecarbohydratebindingdomaindirectstheenzymestotheir specificsubstrates.Inthecellulosomesystem,allcellulasesare anchoredtoacommonscaffoldbutaregenerallythoughttofollow thesamesynergicmodeofaction.Thescaffoldingisboundtothe cellmembranethroughthesurfacelayerhomologydomain,whilea networkofdockerinandcohesindomainsamplifiesthenumberof cellulasesboundtothesamescaffoldingunit.Lastly,acarbohydrate bindingdomainisresponsibleforthetargetingofthewholecomplex tothesubstrate.

15

Figure1.8Variousstrategiesadoptedforimprovingbioprocessofcellulase production. 18

Figure2.1Renewableethanolproductionbyenduse(https://www.clariant. com). 27

Figure3.1Biofuelsgenerations.54

Figure3.2Differentgenerationsofbiofuelswiththeircharacteristics.55

Figure3.3Differentfeedstocksusedinthefirstandsecondgenerationbiorefinery forproducingbiofuels,biochemicals,food,andfeed. 55

Figure3.4Firstgenerationbiofuels.56

Figure3.5Typesofrawfeedstockforsecond-generationbiofuel.57

Figure3.6Biochemicalconversionsofsecond-generationfeedstockstobiofuels.59 Figure3.7Biofuelgenerationfrommicroalgae.62

Figure3.8Fourthgenerationbiofuelproduction.63

Figure3.9Aschematicdiagramofbioethanolproductionbasedondifferent generations. 64

Figure4.1Chartofvariousstepsinvolvedinabiomasssupplychain.70

Figure4.2Schematicrepresentationofbiologicalconversionoflignocellulosic componentsintovariouschemicalsandbiofuels. 79

Figure5.1DiagramofdifferentschemesforsequentialSSFandSmF.Thecolor ofthearrowsindicatesthesystemtowhichtheybelong(greenforA, redforB,andblueforC).

Figure5.2Differentproductionstrategiesforcommercialproductionof cellulases(A,Off-site;B,On-site;C,Integrated;D,Consolidated). 102

Figure7.1Enzymesinvolvedincellulosedegradation.120

Figure7.2Schematicrepresentationofthehydrolysisofcelluloseby noncomplexed(A)andcomplexed(B)cellulasesystems.a,cellulose; b,glucose;c,cellobiose;d,oligosaccharides;e,endoglucanasewith carbohydrate-bindingmodule(CBM);f,exoglucanase(actingon reducingends)withCBM;g,exoglucanase(actingonnonreducing ends)withCBM;h, β-glucosidase;i,cellobiose/cellodextrin phosphorylase;j,S-layerhomologymodule;k,CBM;l,type-I dockerin cohesionpair;m,type-IIdockerin cohesinpair.The figureisnotdrawntoscale.

Figure7.3Crystalstructuresoffamily6endoglucanaseandexoglucanase.(A) ThestructureofendoglucanaseCel6Aof Thermobifidafusca (PDB code: 1TML),whichexhibitsadeepcleftattheactivesite.(B)The structureofexoglucanaseCel6AofHumicolainsolens(PDBcode: 1BVW),inwhichtheactivesiteofitbearsanextendedloopthat formsatunnel.

Figure7.4Thesimulationofthesynergybetweenendoglucanaseand exoglucanasesintermsofsubstratecharacteristics(degreeof polymerization,A;andaccessibility,B)andexperimentalconditions (enzymeloading,C;andreactiontime,D).

Figure8.1Schematicdiagramofthesynergicactionofcellulasesoncellulosic biomasshydrolysis.

131

140

Figure8.2Roleofcellulasesduringthecompletebiofuelproductionprocess.141

Figure8.3Schematicdiagramforconversionoflignocellulosicbiomassinto ethanol.

141

Figure8.4Processingrouteforbioethanolproduction.145

Figure8.5Schematicofpretreatmenteffectonlignocellulosicbiomass.146

Figure8.6Separationprocessofbioethanolbyextractivedistillation.157

Figure8.7ClariantcompletesconstructionoffirstcommercialSunliquid cellulosicethanolplantinPodari,Romania(https://www.clariant. com).

Figure8.8Clariant’sflagshipcommercialSunliquidcellulosicethanolplantin Romania.(https://www.clariant.com).

161

161

Figure8.9SunliquidplantPodari(https://www.clariant.com).162

Figure8.10TheSunliquidprocessfortheproductionofcellulosicethanolfrom agriculturalresidues(https://www.clariant.com).

Figure8.11Sunliquid—afullyintegratedprocessdesign(https://www.clariant. com).Reproducedwithpermission.

Figure8.12Sunliquidtechnologyplatformfortheproductionofsustainable biobasedproducts.

Figure8.13Sunliquidtechnology:fivelicensessoldglobally(https://www. clariant.com).Reproducedwithpermission.

163

163

165

165

Figure8.14ReductionofCarbondioxideemissions(https://www.clariant.com).166

Figure8.15Sunliquid:fullyintegratedprocesssaves~95%GHGemissions (https://www.clariant.com).

Figure8.16ClariantBioethanolPilotPlant,Straubing,Germany(https://www. clariant.com).

166

167

Figure9.1Cellulosomestructureandassembly.188

Figure10.1Schematicdiagramoftheactionsofcellulasesandsynergistic proteinsinhydrolysisofcellulose.TheC1-Cxlignocellulose degradationmodelforcellulosedegradation.First,C1factors,such asexpansin,andlyticpolysaccharidemonooxygenases,which efficientlycatalyzeoxidativecleavageofglycosidicbondsinthe recalcitrantpolysaccharidesofcrystallinecelluloseusingmolecular oxygenandtheexternalelectrondonor,suchascellobiose dehydrogenase,ascorbicacidorgallicacid,creatingnicking, swollenanddisintegratedcellulosicstructure,formingnewinitiation sitesforconventionalcellulases,namely,Cxfactors.Second,the amorphouscellulosewashydrolyzedintomonosaccharideby cellulasesystem.Theendoglucanaseactsontheamorphous (internal)regionofthefibrilsbycleavageofthe β-glucosidiclinkage, thenthecellobiohydrolasereleasescellobiosefromtheendofthe polysaccharidechain,finally, β-glucosidasecompletesthe degradationprocessbyhydrolyzingcellobioseandother cellodextrinstoglucoseunits. BGL, β-glucosidase; CBHI, cellobiohydrolase1; CBHII,cellobiohydrolase2; CDH,cellobiose dehydrogenase;C1factor,cellulosehingdomains(CBMs),plant expansins,bacterialexpansins,andlyticpolysaccharide monoxygenases;Cxfactor,endoglucanase,cellobiohydrolase,and β-glucosidase; EG,endoglucanase; LPMO,lyticpolysaccharide monooxygenase.

Figure11.1Advantagesofenzymatichydrolysiscarriedoutatelevated temperature.

207

215

Figure11.2Strategiestoincreasecellulaseefficiencyandcharacteristics.226

Figure11.3Geneticmanipulationstrategiesinfungiforimprovedcellulase production.

227

Figure12.1Biomass-to-biofuelssupplychain.244

Elsevier

Radarweg29,POBox211,1000AEAmsterdam,Netherlands

TheBoulevard,LangfordLane,Kidlington,OxfordOX51GB,UnitedKingdom 50HampshireStreet,5thFloor,Cambridge,MA02139,UnitedStates

Copyright©2023ElsevierInc.Allrightsreserved.

Nopartofthispublicationmaybereproducedortransmittedinanyformorbyanymeans, electronicormechanical,includingphotocopying,recording,oranyinformationstorageand retrievalsystem,withoutpermissioninwritingfromthepublisher.Detailsonhowtoseek permission,furtherinformationaboutthePublisher’spermissionspoliciesandour arrangementswithorganizationssuchastheCopyrightClearanceCenterandtheCopyright LicensingAgency,canbefoundatourwebsite: www.elsevier.com/permissions.

Thisbookandtheindividualcontributionscontainedinitareprotectedundercopyright bythePublisher(otherthanasmaybenotedherein).

Notices

Knowledgeandbestpracticeinthisfieldareconstantlychanging.Asnewresearchand experiencebroadenourunderstanding,changesinresearchmethods,professionalpractices, ormedicaltreatmentmaybecomenecessary.

Practitionersandresearchersmustalwaysrelyontheirownexperienceandknowledgein evaluatingandusinganyinformation,methods,compounds,orexperimentsdescribedherein. Inusingsuchinformationormethodstheyshouldbemindfuloftheirownsafetyandthesafety ofothers,includingpartiesforwhomtheyhaveaprofessionalresponsibility.

Tothefullestextentofthelaw,neitherthePublishernortheauthors,contributors,oreditors, assumeanyliabilityforanyinjuryand/ordamagetopersonsorpropertyasamatterof productsliability,negligenceorotherwise,orfromanyuseoroperationofanymethods, products,instructions,orideascontainedinthematerialherein.

ISBN:978-0-323-99496-5

ForInformationonallElsevierpublications visitourwebsiteat https://www.elsevier.com/books-and-journals

Publisher: SusanDennis

EditorialProjectManager: MariaElaineDesamero

ProductionProjectManager: BharatwajVaratharajan

CoverDesigner: VictoriaPearson

TypesetbyMPSLimited,Chennai,India

4.Challengestobiofuelproduction

biofuels/biochemicals

4.2.1Feedstockproductionandlogistics68

4.2.2Lignocellulosicbiomasspretreatment71

4.2.3Enzymatichydrolysis74

4.2.4Microbialfermentationandbiomass77

4.2.5Biofuelcost78

4.2.6Waterrecycling79

4.2.7Generationofcoproducts80

5.2.1Submergedfermentations93

5.2.2Solid-statefermentation96

5.2.3Sequentialsolid-statefermentationandsubmerged fermentation99

5.2.4Useofmixedcultures102

7.2.3 β-Glucosidase126

7.2.4Othercellulasesandaccessoryproteins127

7.3Synergyamongcellulosedegradingsystem

8.Cellulasesforbiofuelsproduction

8.3Factorsaffectingbioethanolproduction

9.Advanceddevelopmentsinproductionprocessesof

10.Cellulasesandauxiliaryenzymes

11.Approachestoenhancecellulaseproductionto

cellulaseproducingfungi

11.4EnhancementofthermalandpHstabilityofcellulasesin thepresenceofnanomaterials

11.5RecombinantDNAtechnologyforincreasingcellulase activityandefficacy

11.6Useofsuitablecarbonsourceandnecessityof pretreatmentoflignocellulosicbiomass

11.7Optimizationofmediumandprocessparametersusing statisticalmethodsforimprovedproductionofcellulases

11.8Improvementsinproductionofcellulasesviamicrobial fermentationprocesses

11.9Microbialco-productionofotherimportantenzymesfor theoveralleconomyoftheprocess

Chapter1 Background

1.1Introduction

Thelimitednatureandspeedyexhaustionoffossilfuelsbecauseofincreasingglobalenergyrequirementsisharmfullyimpactingtheenvironment (Olguin-Macieletal.,2020;Alietal.,2019;Taghizadeh-Alisaraeietal., 2019;Nargotraetal.,2019;Pateletal.,2019;Poppetal.,2014).Replacing fossilfuelswithbiofuelshasthepotentialtoreducesomeunwantedaspects offossilfuelproductionanduse,includingconventionalandgreenhousegas (GHG)pollutantemissions,exhaustiblereductionofresources,anddependencyuponunstableforeignsuppliers.Thereforeintheory,theproduction anduseofbiofuelscouldbesustainedforanindefiniteperiod(http://www. epa.gov).Biofuelproductionhassubstantiallyincreasedinthelasttwenty yearswiththeaimofenvironmentalprotectionandensuringenergyindependence.Duetotheincreasingpricesoffossilfuels,theproductionofbiofuels hasreachedremarkablevolumesoverthelasttwodecades.Worldwidebiofuelproductionhasincreasedninefoldbetween2000and2020,in-spiteof rigorousreductionin2020,andshouldbouncebackby13%in2021overan expectedrecoveryinoildemandandstrengthenedormaintainedbiofuelsupportpolicies.Bioethanolaccountsfortwothirdoftheworldwidebiofuelproductionandbiodieselfor32%.First-generationbiofuelsfromsugarcaneand cornbasedbioethanolandvegetableoilbasedbiodieselcovermostofthe worldwideproduction.Bioethanolproductionandconsumptionisdominated byNorthAmerica—particularlytheUnitedStates—andLatinAmerica— particularlyBrazilwhereasbiodieselproductionandconsumptionisdominatedbyAsiaandEurope.Worldwidebiofuelconsumptionisexpectedto declinesubstantiallyby2029,becauseofthelikelyreductioninfueldemand, biggercompetitionbetweentransporttechnologiesandthedecarbonization developmentofpublicpolicies.First-generationbiofuelswillcontinueto takeoverglobalproductionby2030,withadvancedbiofuelslimitedto10% (expectedshareof31%intheEuropeanUnionthankstotheRenewable EnergyDirectiveIIdirective)(https://www.enerdata.net/publications/executive-briefing/biofuels-market-dynamics.html).

First-generationbiofuelsobtainedfromfoodrawmaterialssuchassugarcane,cerealgrains,rootcrops,andvegetableoilsarebecomingmoreand morecompetitivewithfoodproduction.Overthelastfewyears,therehas

beenaperiodoftheactivegrowthintheproductionofliquidbiofuels.In 2018,theworldwideproductionofbioethanolandbiodieseltogetherreached 167.9billionliters.About16.1%ofmaizegrain,1.7%ofwheatgrain,3.3% ofgrainofotherfeedgrainsand13.5%ofvegetableoilwereconsumed (Kurowskaetal.,2020).

Biomassisaversatilerenewableenergysource.Itcanbedirectlyconvertedintobiofuels.Biomassoffersseveralmanybenefitsoverfossilfuels. Biomassiscarbonneutralandisalwaysandextensivelyavailableasa renewablesourceofenergy.Itreducestheoverdependenceonfossilfuels andislesscostlythanfossilfuels.Biomassproductiongeneratesincomefor themanufacturers,alsogenerateslessergarbageinlandfillsandincreases energyindependence(Alietal.,2019;Taghizadeh-Alisaraeietal.,2019; Brinkmanetal.,2019;Muthuveluetal.,2019).

“Biomassisparticularlyimportantinprovidingrawmaterialsforthe productionofrenewableenergysources.Thetermbiomassreferstoall organicmatterinthebiosphere,ofbothplantandanimalorigin,andto materialsobtainedbyitsnatu ralorartificialconversion(Muresanand Attia,2017;Mehedintuetal.,2018;Contescuetal.,2018 ).Bysubmitting biomasstobiochemical,thermochemicalandbiologicalconversionprocesses,liquidandgasfuelsareobtained(bioethanol,biodiesel,biogas).Up tonow,biofuelshavebeenproducedmainlythroughalcoholfermentation ofstarchproducts(ethanol),munici palwaste,sewagesludgeandothers (biogas),drydistillationofwood(methanol)andtransesterificationofhigherfattyacids(biodiesel).Suchfuelsarecountedasthefirst-generation onesanditispredictedthattheywilldominateformanyyearstocome becausetheycanbeburntinexistingunmodifiedenginesandtheirproductioniseasyandeconomicallyviable.Currently,thereareattemptsto implementotherrenewablerawproductsinbiofuelproduction,likecellulose,whicharemuchmoredifficult toprocess,andtodesignmorecomplexbiotechnologicalmethods”(Kurowskaetal.,2020;NigamandSingh, 2011;Hilletal.,2006).

Someofthemostcommon(and/ormostpromising)biomassfeedstocks arelistedin Table1.1.

1.2Bioenergyandbiofuels

Bioenergyisenergyobtainedfrombiofuels.Biofuelsareproduceddirectly orindirectlyfromorganicmaterial—biomass—includingplantmaterialsand animalwaste.Thetermbiofuelreferstoanyliquid,gas,orsolidfuelmostly producedfromarenewablebiomassresources.

TheFoodandAgricultureOrganization(FAO)reportsthatbioenergy coversabout10%oftotalworldenergysupply.

Traditionalunprocessedbiomasssuchasfuelwood,charcoalandanimal dungaccountsformostofthisandrepresentsthemajorenergysourcefor

TABLE1.1 Mostcommonbiomassfeedstocks.

Grainsandstarchcrops

Sugarcane,corn,wheat,sugarbeets,industrialsweetpotatoes,etc.

Agriculturalresidues

Cornstover,wheatstraw,ricestraw,orchardprunings,etc.

Forestrymaterials

Loggingresidues,forestthinnings,etc.

Energycrops

Switchgrass,miscanthus,hybridpoplar,willow,algae,etc.

Foodwaste

Wasteproduce,foodprocessingwaste,etc.

Urbanandsuburbanwastes

Municipalsolidwastes(MSW),lawnwastes,wastewatertreatmentsludge,urban woodwastes,disasterdebris,trapgrease,yellowgrease,wastecookingoil,etc.

Animalbyproducts

Tallow,fishoil,manure,etc.

Source:Basedon https://www.eesi.org/topics/bioenergy-biofuels-biomass/description

mostofthepeopleindevelopingcountrieswhoareusingitmostlyforheatingandcooking.

Highlydevelopedandefficientconversiontechnologiesareallowingthe extractionofbiofuelsfromwood,cropsandwastematerial.Biofuelscanbe liquid,gaseousorsolid,althoughthetermismostlyusedinastrictsenseto referonlytoliquidbiofuelsfortransport.

Biofuelsmaybeobtainedfromagriculturalandforestryresidue,fast growingtreeplantationsandannualcrops,fisheryproductsormunicipal wastes,andalsofromfoodindustryandfoodserviceby-productsandwastes (http://www.greenfacts.org).

Adifferentiationismadebetweenprimaryandsecondarybiofuels. Primarybiofuelsareutilizedinanunprocessedform,mainlyforcooking, heatingorelectricityproduction.Theseincludefuelwood,woodchipsand pelletsandorganicmaterials.Secondarybiofuelsresultfromprocessingof biomass.Theseincludeliquidbiofuelssuchasbiodieselandethanolandcan beusedinvehiclesandindustrialprocesses.

Bioenergyismostlyusedinhomes(80%).Inindustry,itisusedtoa lesserextent(18%),whereasliquidbiofuelsusedfortransportarestillplayingalimitedrole(2%).

Althoughtheproductionofliquidbiofuelsfortransporthasgrown quicklyoverthelastfewyearsglobally,itpresentlyrepresentsonly1%of totaltransportfuelconsumptionandonly0.2% 0.3%oftotalenergyconsumption.Examplesofbiofuelarebioethanol,biomethanol,biosynthetic gas(biosyngas),biodiesel,biogas,biochar,bio-oil,biohydrogen,and FischerTropschproducedliquids(Alietal.,2019;Carrillo-Nievesetal., 2019).Biofuelsserveasabridgebetweentheagriculturalandenergymarketsasagriculturalcommoditiesaretheimportantrawmaterialsinbiofuel production(DebnathandGiner,2019).Mainadvantagesandpaybacks obtainablefromtheuseofbiofuelsasaformofrenewablefuelarepresented in Table1.2.

Liquidbiofuelsareofespecialinterestbecauseofthehugeinfrastructure alreadyinplacetousethem,particularlyfortransportation.Theliquidbiofuel—ethanolisingreatestproduction.Itisproducedbyfermentationof starchorsugar.UnitedStatesandBrazilareamongtheleadingproducersof ethanol.IntheUnitedStates,bioethanolismostlyproducedfromcornandit isnormallyblendedwithgasolineforproducing“gasohol.”Thiscontains 10%ethanol.InBrazil,ethanolisproducedmostlyfromsugarcane.Itisusuallyusedasa100%ethanolfueloringasolineblendscontaining85%

TABLE1.2 Benefitsofbiofuels.

Biofuelsarerenewableandarecarbon-andCO2/GHG-neutralduringtheprogression ofthelifecycle

LessGHGemissionsaregeneratedfromtheutilizationofbiofuelscomparedtoFB fuels

Biofuelsarebiodegradable,sustainable,andenvironmentallybenign

Biofuelsarelargelyproducedfromlocallyavailableandaccessibleresources,applying safeproductionmethods

Productionandutilizationofbiofuelsenhancehome-grownagriculturaldevelopment andinvestment

Biofuelsprovideimprovementsinthehealthandlivingconditionsofpeople

Biofuelscreatejobsandimprovementsinlocallivelihoodsandreduceenergy importation

Economically,biofuelhelpstostabilizeenergyprices,conserveforeignexchange,and generateemploymentatthemacroeconomiclevel

Householdusageofbiofueldoesnottriggerlife-threateninghealthconditions,as opposedtoFBfuels

Source:Basedon Awogbemietal.(2021); JanampelliandDarbha(2019); Wuetal.(2020); Appavuetal.(2021); Navasetal.(2020); DarbyandCallahan(2020); Smith(2019); Yaghoubi etal.(2019); Szabo (2019); Chintala(2019); Oyewoleetal.(2019); TopcuandTugcu(2020); SchuenemannandKerr(2019); Mattiodaetal.(2020); Siddiquietal.(2019)

TABLE1.3 Greenhousegasemissionsfromvariousbiofuelscomparedto gasoline.

FuelGasolineBioethanol1GBioethanol1GBioethanol2G FeedstockOilCrop/CornCaneAgricultural residues

Emissions100%48%22%14

Source:Basedon https://sunliquid-project-fp7.eu/wp-content/uploads/2014/09/ factsheet_sunliquid_en.pdf

ethanol.Unlikethe“first-generation”ethanolbiofuelproducedfromfood crops,“second-generation”cellulosicethanolisobtainedfromlow-valuebiomasswhichincludeswoodchips,cropresidues,andmunicipalwaste (Hassanetal.,2018).Ithasahighercellulosecontent.Cellulosicethanolis mostlyproducedfromsugarcanebagasse,orfromavarietyofgrassesthat canbegrownonlow-qualityland.Bagasseisawasteproductfromsugar processing.Cellulosicethanolismainlyusedasagasolineadditive;theconversionrateislowerascomparedtofirst-generationbiofuels.Cellulosicethanolfromagriculturalfeedstocksandenergycropsisusuallyconsideredto beenvironmentallysustainablebecauseitprovideshigherreductionofGHG emissionsandzeroorlowindirectemissionsfromlandusechangeincomparisontotraditionalethanolproductionfromfoodandfeedcrops. Table1.3 presentsGHGemissionsfromvariousbiofuelscomparedwithgasoline.

1.3Biomass

Biomassgenerallyincludes:plant-basedwoodybiomasswhicharemostly lignocelluloses,plant-basednon-woodybiomassmostlystarch,sugarand oilsandanimal/humanbasedbiomasswhichincludesanimalfatsandproteins,slurry/slaughterwastes,householdwastes,etc.Amongsttheplantbasedwoodybiomass,lignocellulosicbiomassisconsideredasapotential resourceforrenewableenergy.Itismostlyusedforlandfillingorsimply burnedoff.Lignocellulosicbiomassconstitutes60%oftheplantcellwall. About100billiontonsofplantdrymaterialisproducedintheworldbyphotosyntheticactivityyearly.Theleftoveroflignocellulosicbiomassismainly treatedaswastetherefore,extensiveresearchhasbeenconductedfortheefficientexploitationofthelignocellulosicbiomassforproducingenzymes,biofuels,feeds,antioxidantsetc.

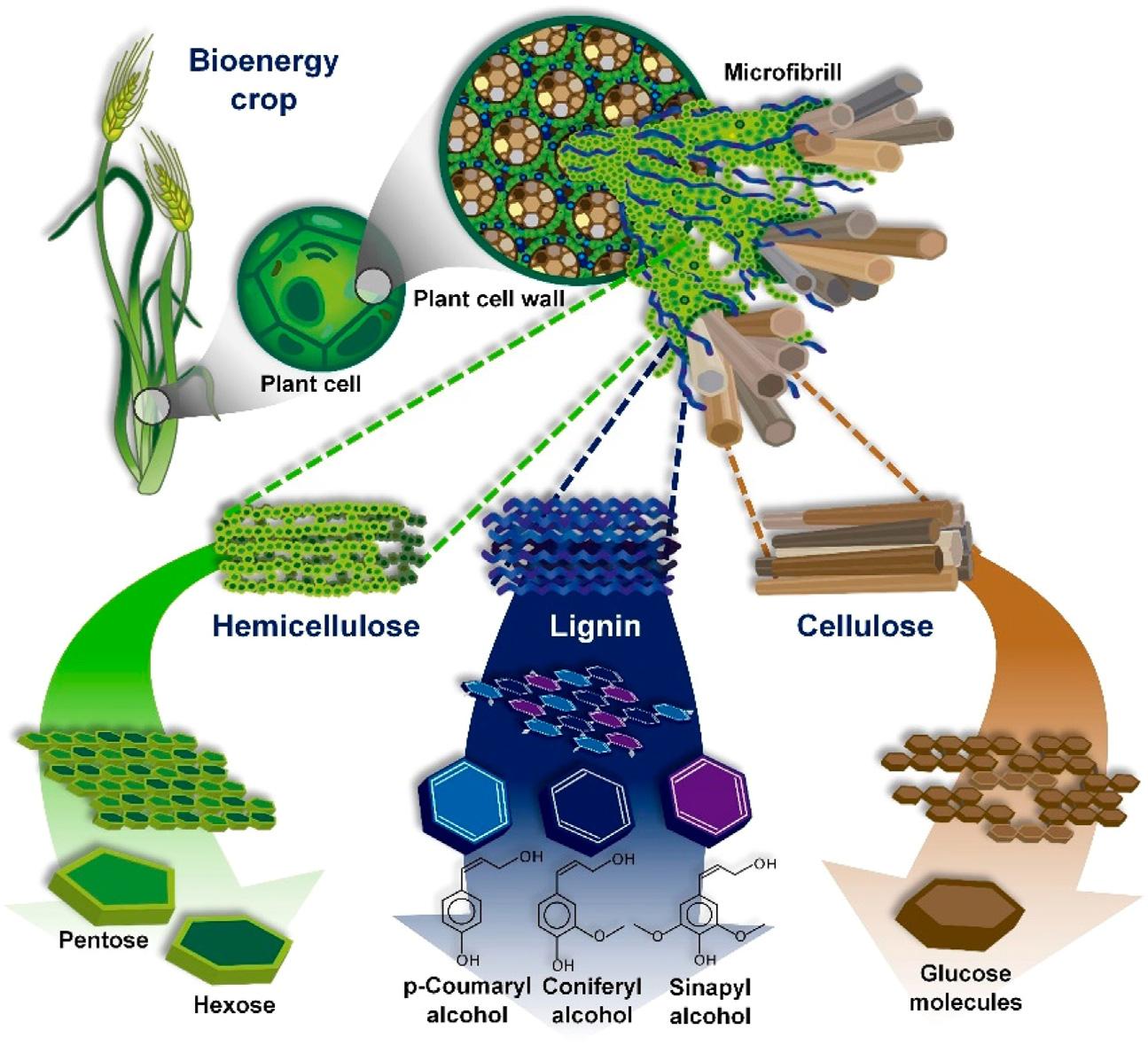

Themajorcomponentsofthelignocellulosicmaterialsarecellulose, hemicellulose,andlignin. Fig.1.1 showsthestructureoflignocellulosicbiomass. Fig.1.2 showstheproductsobtainedfromlignocellulosicbiomass.

FIGURE1.1 Structureoflignocellulosicbiomassanditsbiopolymers;cellulose,hemicellulose, andlignin(Hern ´ andez-Beltr ´ anetal.,2019). Hern ´ andez-Beltr ´ an,J.U.,Hern ´ andez-DeLira,I.O, Cruz-Santos,M.M,Saucedo-Luevanos,A,Hern ´ andez-Ter ´ an,F,Balagurusamy,N.,2019.Insightinto pretreatmentmethodsoflignocellulosicbiomasstoincreasebiogasyield:currentstate,challenges, andopportunities.Appl.Sci.Basel9(18),3721. https://doi.org/10.3390/app9183721.ThisFigureis distributedunderthetermsoftheCreativeCommonsAttribution4.0InternationalLicense.

Thecompositionofcellulose,hemicellulose,andligninisfoundtovary fromoneplantspeciestoanother(YusufandInambao,2019;Bajpai,2016, 2021;Shahzadietal.,2014;Walker,2010;Sheretal.,2021;Pottersetal., 2010).Forinstance,hardwoodspossesslargeramountsofcellulose,whilein thewheatstrawandleaves,thehigheramountofhemicellulosesarepresent. Theratiosbetweendifferentconstituentswithinasingleplantvarywiththe stageofgrowth,age,andotherconditions.Lignocellulosicrawmaterials needdestructivepretreatmenttoyieldasubstratewhichisreadilyhydrolyzed bycommercialcellulolyticenzymes,orbymicroorganismsproducing enzyme,forreleasingsugarsforfermentation.

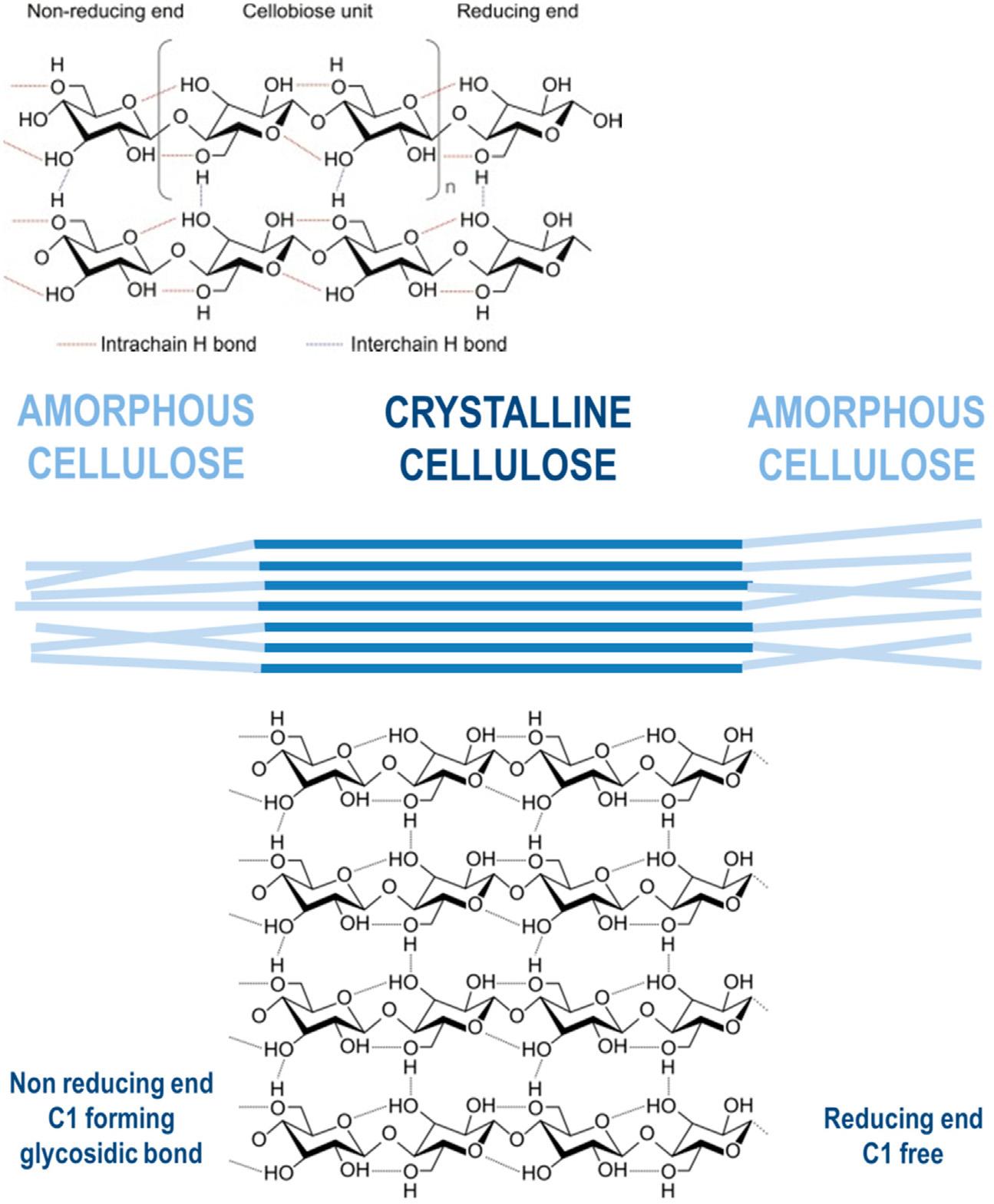

Inlignocelluloses,cellulosefiberstrandsareformedbycelluloselinking toeachotherthroughhydrogenbonds.Thecellulosestructureinsidethe polymerisnothomogenous.Crystallineregionsarewherecellulose

FIGURE1.2 Lignocellulosicbiomassalongwiththeirproducts(Haqetal.,2021). Haq,I.U., Qaisar,K.,Nawaz,A.,Akram,F.,Mukhtar,H.,Zohu,X.,etal.,2021.Advancesinvalorization oflignocellulosicbiomasstowardsenergygeneration.Catalysts,11,309. https://doi.org/ 10.3390/catal11030309.ThisFigureisdistributedunderthetermsoftheCreativeCommons Attribution4.0InternationalLicense.

nanofibrilsareorganizedinorderandcompact,whereasamorphousregions aredisorderedandareeasilyhydrolyzed(Tranetal.,2019;Perezetal., 2002).Cellulosefibersaresurroundedbyhemicelluloseandlignin.This structurenaturallyprotectsthepolysaccharidesfromhydrolysisbyenzymes andchemicals,thusraisingadifficultyinbothchemicalandbioconversion oflignocellulosetootherproducts,thatis“ethanol”(Bajpai,2021;Tran etal.,2019).

Cellulose,hemicellulose,andligninaretightlypackedwitheachother, protectingthemagainstattackofmicroorganismsandthereforemaketheir degradationnoteasy.Celluloseandhemicellulosescanbeconvertedinto fermentablesugarswhichcanbefurtherconvertedintobioethanolandother value-addedproducts(Singhetal.,2017).Therearenumerouswaysfor deconstructionofbiomasssuchasthermochemical,chemical,orbiological butthebiologicalroutebyusingenzymeisthemostwell-liked,asitis environment-friendlyandsustainable.

“Celluloseisconsideredthemostcopiousandbountifulrenewable sourcesforproducingvaluableproductsforenergysources,thispropertyof cellulosemakesitmoreimportanttouseitfortheproductionofvalue-added fuelsbythermochemicalorbiochemicalprocesses.Thishasbeenusedfor theproductionofbiofuelespeciallyformethaneandbioethanol.Besidethis, thecellulosehasalsowiderangeofapplicationanduseindifferent

industriessuchasfoodandbeverage,animalfeeds,detergent,agriculture, textile,pulpandpaperindustry.Ithasattractedtheinterestofindustrialscientists, sothesecanbeutilizedfortheproductionofseveralenzymesatbothlaband industrialscale.Ithasalsoattractedthe interestofscientistsastheyaretaking advantageofusingthislowcostenergysource(cellulose)fortheproductionof biologicalproducts,thatwouldaddintotheeconomyandenergysecurityofthe country.Celluloseusuallyoccursasfibers,denselypackedwithhydrogenbond andinsolubleinwatersoitisveryresistanttohydrolysiswithoutthechemicals andmechanicaldegradation.Hencecelluloseorotherpolysaccharidecompounds canbeconvertedintosimplesugarorglucoseunitsbytheactivityofcellulase enzymes.Itisalsoaverystablepartofplantcellwallmatrixandbiomass,that’s whyplantstakegreatbenefitofitasitplaysanimportantroletomaintainthe cellwallstabilityandintegrity.Thestructureofcellulosedeterminesthehydrolysispathwayandcompactnessincellulosic structuremakesitpronetothedegradation.Thiscompactandcrystallinestructureofcelluloseisduetointerand intramolecularhydrogenbonding.Thissupercrystallinestructureofcellulose makesitresistanttohydrolysisevenatveryextremereactionconditions,therefore,itmustbepre-treatedtoconvertthecellulosicbiomassorplantcellulosic partsintosimplesugars”(Sheretal.,2021).“Celluloseisalinearpolysaccharide. Inthispolymer,D-glucosesubunitsare attachedtogetherbyformationof β-1,4glycosidiclinkagesbetweenindividualglucosemolecules.Themolecularformula ofcelluloseis(C6H12O6)n.Thenindicatesthedegreeofpolymerization(DP).It symbolizesthenumberofglucosesubunitsconnectedwitheachother.Thisnumberisvaryingfromhundredstothousands.Twoglucoserepeatingunitstogether arecalledcellobiose.Inotherwords,thispolymerismadeby β-(1 - 4)-D-glucopyranoseunitsin4C1conformation.It consistsoflongchainsofanhydro-Dglucopyranoseunits(AGU)witheachcellulosemoleculehavingthreehydroxyl groupsperAGUwiththeexceptionoftheterminalends.Cellulosehasbothcrystallineandamorphousregionsinitsstructureinvariousproportions.Those regionsareintertwinedtoformthestructureofcellulose.Therearefourmajor crystallineforms,forinstance,Iα,Iβ,II,andIII.Thiscrystallinestructureisa resultofintramolecularandintermolecularhydrogenbondingbetweenglucose monomersincellulose.Thesehydrogenbondsconstructahugenetworkthat directlycontributestothecompactcrystalstructureofcellulosepolymer.Onthe otherhand,thisstrongintramolecularandintermolecularhydrogenbondformationleadstopoorsolubilityofcellulose”(Tranetal.,2019;Ciolacuetal.,2011).

Fig.1.3 Showsthecellulosepolymerchainstructure.

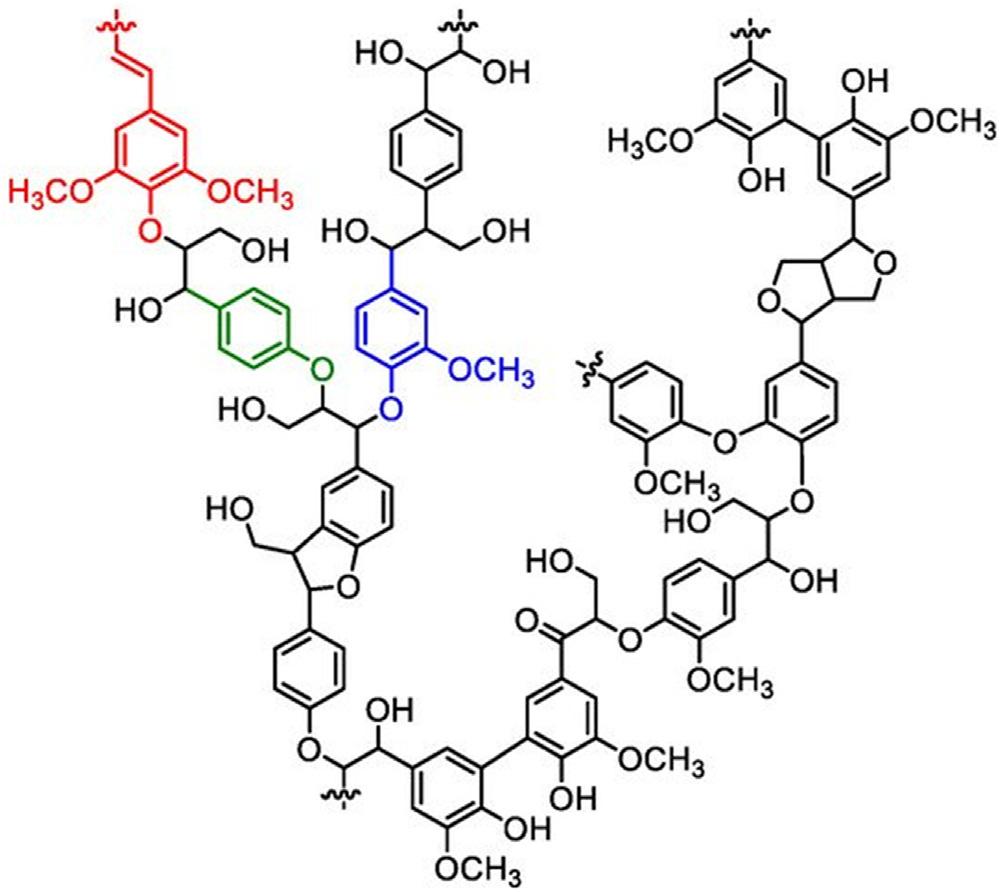

Ligninisthemajorstructuralcomponentoflignocelluloses.Itcontains threedifferenttypesofphenolicmonomers:p-coumarylalcohol,coniferyl alcohol,andsinapylalcohol(Fig.1.4).Itprovidesstrengthtothelignocellulosicbiomassandhamperstheactionofhydrolyticenzymesbyactingasa barricade.Itisoneofthemostrecalcitrantconstituentofthelignocellulosic biomassbecauseofitsstructuralcomplexity(Arevalo-Gallegosetal.,2017; GuptaandVerma,2015;Yaoetal.,2015).

FIGURE1.3 Thecellulosepolymerchainstructure(Suttieetal.,2017). ReproducedwithpermissionfromSuttie,E.,Hill,C.,Sandin,G.,Kutnar,A.,Ganne-Che´deville,C.,Lowres,F.,etal., 2017.Woodasbio-basedbuildingmaterial.PerformanceofBio-basedBuildingMaterials. WoodheadPublishing,pp.21-96,ElsevierandVasi ´ c,K.,Knez, ˇ Z.,&Leitgeb,M.(2021). Bioethanolproductionbyenzymatichydrolysisfromdifferentlignocellulosicsources.Molecules, 26(3),753.DistributedunderthetermsoftheCreativeCommonsAttribution4.0International License.

Hemicelluloseisthesignificantcomponentofplantcellwall.Itisthesecondmostabundantpolymer.Itcomprisesofshortlinearandbranchedpolymers(Fig.1.5).Hemicellulosehasanamorphousstructurecontraryto cellulose.Itconsistsofseveralheteropolymerssuchasxylan,galactomannan,

FIGURE1.4 Schematicrepresentationforthemacromolecularstructureoflignin(Major monolignolunitsarecoloredassinapylalcohol-red,guaiacylalcohol-blue, p-coumarylalcoholgreen)(KarunarathnaandSmith,2020). Karunarathna,M.H.,Smith,R.C.,2020.Valorizationof ligninasasustainablecomponentofstructuralmaterialsandcomposites:advancesfrom2011 to2019.Sustainability,12,734.MDPI. https://DOI:10.3390/su12020734.ThisFigureisdistributedunderthetermsoftheCreativeCommonsAttribution4.0InternationalLicense.

FIGURE1.5 Structureofhemicellulose(Machmudahetal.,2017). ReproducedwithpermissionfromMachmudah,S.,Wahyudiono,Kanda,H.,Goto,M.,2017.Hydrolysisofbiopolymers innear-criticalandsubcriticalwater.In:Herminia,D.,MariaJesus,G.M.(Eds.),Water ExtractionofBioactiveCompounds.Elsevier,Amsterdem,Netherlands,pp.69 107.

Background Chapter|1 11

glucuronoxylan,arabinoxylan,glucomannan,andxyloglucan.Hardwood (e.g.,dicotangiosperms)hemicellulosesmainlycontainxylans,whileglucomannansaremainconstituentsinsoftwood(e.g.,gymnosperms).Ascomparedtocellulose,hemicellulosegetsrapidlyhydrolyzedbecauseofits amorphousandbranchednature.

Theproductionofbioenergyandbio-basedmaterialsfromlessexpensive renewablelignocellulosicmaterialswouldbringadvantagestothelocal economy,environment,andnationalenergysecurity(Zhang,2008).

1.4Cellulaseenzyme

Cellulaseenzymeshavebeencommerciallyavailableformorethan40 yearsandbothbasicandappliedstudiesoncellulolyticenzymeshave showntheirbiotechnologicalpotentialinseveralindustries( Singh,1999; Singhetal.,2007 ).

Cellulaseenzymesplayanimportantroleintheenzymatichydrolysisof cellulosicpolymers.Cellulaseenzym esbreakdownthecelluloseofplant cellwallsintosimplesugarswhichcan befermentedbymicroorganismsto fuels,mainlyethanol,andalsochemicals,plastics,fibers,detergents,pharmaceuticals,andmanyotherproducts.Ligninisamainobstructiononthe wayofefficienthydrolysisofbiomass( Sainietal.,2016 ).Itcanbe removedtosomeextentbyalkalinepre treatmentofbiomassmakingcelluloseandhemicelluloseaccessibletoenzymes.Cellulosewhichconstitutea mainportionofthebiomass,c ontainsglucoselinkedwith β,1 4linkage. Cellulaseenzymesareabletohydroly zecelluloseintoglucose,buthardly evercelluloseispresentinpureforminnature,andisgenerallyassociated withhemicellulosesandlignin.Evenhe micellulosespresentaphysicalbarrierforcellulasestoaccesscellulosealongwithlignin( Volynetsand Dahman,2011).Therefore,cellulasesalongwithxylanasesarefoundtobe moreefficientfordegradationofbiomass.Inactualfact,xylanaseshydrolyzethehemicellulosicportionwhic hmakesthecellulosemoreaccessible tocellulase.Therefore,xylanaseswhencombinedwithcellulasesshow synergisticeffectandreleasemorefermentablesugarsfromthebiomass ( Huetal.,2011 ).

Table1.4 showsclassificationofcellulaseenzymes.

“Intheproductionofbiofuels,cellulasesarefundamentalenzymes responsibleforhydrolyzingcellulosicbiomassintofermentablesugars.As celluloseisacrystallineunbranchedpolymer,severalcellulasesareneeded todegradeitefficiently.Cellulaseshydrolyzethe β-1,4-D-glucanbonds, releasingcello-oligosaccharides,cellobiose,orglucose.Thecompletedegradationofcelluloseiscarriedoutbyanenzymaticcomplex,whichincludes endo-β-1,4-glucanases(EGEC3.2.1.4),cellobiohydrolases(CBHEC

TABLE1.4 Classificationofcellulaseenzymes(Roohietal.,2019).

NameofenzymeEC

Endo-1,4-β-d-glucanglucanohydrolaseEC 3.2.1.4

Exoglucanaseor1,4-β-d-glucan cellobiohydrolases(cellobiohydrolases)

Exoglucanasesor1,4β-d-oligoglucancellobiohydrolases

β-Glucosidasesor β-d-glucoside glucohydrolases

Cellobiose:orthophosphate α-d-glucosyl transferase

Cellobiose2-epimeraseEC 5.1.3.11

Cutatrandomatinternalamorphoussitesof cellulose,lichenin,andcereal β-d-glucans

Endo-1,4-β-dglucosidiclinkages

Nonreducingendsofcelluloseandcellotetraose Exo-1,4-β-dglucosidiclinkages

Cellooligosaccharide, p-nitrophenyl-β-dcellobioside Exo-1,4-β-dglucosidiclinkages

Terminalnonreducingendsofcellulose Exo-1,4-β-dglucosidiclinkages

Oligosaccharidesof variouslengths

Cellobiose

-d-Glucose

Cellodextrinsrangingfromcellotrioseto cellohexoses

Cellobiose

Phosphorolytic cleavage β-d-Glucose

Exo-1,4-β-dglucosidiclinkages 4-O-β-dGlucosylmannose

4-O-β-dGlucosylmannose

Source:ReproducedwithpermissionfromRoohi,B.R.K,Parveen,S.,Khan,F.,Zaheer,M.R.,Kuddus,M.,2019.Chapter8Advancementsinbioprocesstechnologyforcellulase production.In:Srivastava,N.,Srivastava,N.,Mishra,P.K.,Ramteke,P.W.,Singh,R.L.(Eds.),NewandFutureDevelopmentsinMicrobialBiotechnologyandBioengineering:From CellulosetoCellulase:StrategiestoImproveBiofuelProduction.Elsevier.