PREFACE

Diversityofcatalysts,forexample,catalysisbymineralacids,complexesoftransition metals,organicmolecules,enzymes,andalumosilicates,resultedinfragmentationof thediscipline.Separatecoursesaregivenbasedontextbookscoveringseparately,despite allsimilarities,homogeneous,heterogeneous,andenzymaticcatalysis.Moregeneral booksonphysicalchemistry,whilediscussingsomeaspectsofcatalytickinetics,cannot gointodetailstotheextentthatisoftenneeded.

Althoughinthechemicalindustry,themainfocusiscurrentlyonheterogeneous catalysis,otherfields(homogeneous,enzymatic,photochemical,electrochemical catalysis)shouldnotbeoverlooked,asveryoftentheindustrialaimistoproduceacertain chemicalinthemostoptimalway,butnotwithaparticulartypeofcatalyst.Theindustrial importanceofcatalysisalsodictatesanecessitytohaveabookdevotedtothefundamental aspectsofcatalytickinetics,aswellascatalyticengineeringand,morespecifically, transportphenomena.

Suchanintegratedapproachtokineticsandtransportphenomenaincatalysis,while stillrecognizingthefundamentaldifferencesamongdifferenttypesofcatalysis,was appliedinthefirsteditionofthisbook,publishedin2005.

Theauthorshavereceivedanumberofencouragingcommentsaswellascritiqueabout whatwasmissingandsuggestionsforhowthebookcouldbeimproved.Wewerealsovery happytolearnthatduetoapositiveresponse,Elsevierdecidedtoproceedwiththesecond editionofthisbookoncatalytickinetics.Theauthorscarefullydiscussedthematerialtobe includedintherevisedversion.Materialforchapters10.1–10.2,10.4,and11.3–11.6was preparedbyTapioSalmi,whiletheremainingtextwaswrittenbyDmitryYu.Murzin, whoalsooversawthesecondeditionandimplementationofallchanges.

Inthisedition,thecontentwasexpandedtocoverinmoredepthseveralareas,suchas organocatalysis;enzymatickinetics;nonlineardynamics;solventeffects;nanokinetics (structuresensitivity);kineticisotopeeffects;andpolynomialkinetics,tonameafew. Inaddition,aseparatechapteroncascadecatalysishasbeenwritten.

Eachandeverychapterinthesecondeditionalsocontainsexamplesandexercises, whichfacilitatesunderstandingandmasteringoftheunderlyingconcepts.

Inordertostaymorefocusedonthecoreofcatalytickinetics,asectionongas-liquid masstransfer,whichwaspresentinthefirstedition,wasnotincluded.

Inadditiontothesechanges,unfortunatemisprintswerecorrectedandgeneraleditingofthetext,introducingnewfiguresandexamples,wasperformed.

isnotconsumedbythereaction.Thisdefin itionallowsforthepossibilitythatsmall amountsofthecatalystarelostinthereaction orthatthecatalyticactivityisslowlylost.

1.2.CATALYSIS

Alreadyfromthesedefinitions,itisclearthatthereisadirectlinkbetweenchemical kineticsandcatalysis;accordingtotheverydefinitionofcatalysis,itisakineticprocess. Therearedifferentviews,however,ontheinterrelationbetweenkineticsandcatalysis. Whilesomeauthorsstatethatcatalysisisapartofkinetics,otherstreatkineticsasapartof abroaderphenomenonofcatalysis.

Despitethefactthatcatalysisisakineticphenomenon,therearemanyissuesincatalysiswhicharenotrelatedtokinetics.Mechanismsofcatalyticreactions,elementary reactions,surfacereactivity,adsorptionofreactantsonth esolidsurfaces,synthesis andstructureofsolidmaterials,enzymesororganometalliccomplexes,notto mentionengineeringaspectsofcatalysis,areobviouslyoutsidethescopeofchemical kinetics.

Somediscrepancyexistswhetherchemicalkineticsincludealsothemechanismsof reactions.Infact,ifreactionmechanismsareincludedinthedefinitionofcatalytickinetics,itwillbeanunnecessarygeneralization,ascatalysisshouldcovermechanisms.

Catalysisisofcrucialimportanceforthechemicalindustry.Thenumberofcatalysts appliedinindustryisverylarge,andcatalystscomeinmanydifferentforms,fromheterogeneouscatalystsintheformofporoussolidstohomogeneouscatalystsdissolvedin theliquidreactionmixturetobiologicalcatalystsintheformofenzymes.Catalysisisa multidisciplinaryfieldrequiringeffortsofspecialistsindifferentfieldsofchemistry,

WilhelmOstwaldandSvanteArrhenius

JönsJakobBerzelius

physicsandbiologytoworktogethertoachievethegoalssetbymankind.Knowledgeof inorganic,organometallic,organicchemistry,materialsandsurfacescience,solidstate physics,spectroscopy,reactionengineeringandenzymologyisrequiredfortheadvancementsofthedisciplineofcatalysis.

Despitethefundamentaldifferencesbetweenelementarystepsincatalyticprocesson surfaces,therearestrikingsimilaritiesalsointermsofchemicalkineticswithenzymesor homogeneousorganometalliccomplexes.Althoughsuperficiallyitisdifficulttofind somethingincommonbetweenthereactionofnitrogenandhydrogenformingammoniaonasurfaceofiron,D-fructose6-phosphatereactionwithATPinvolvinganenzyme phosphofructokinaseorozonedecompositionintheatmosphereinthepresenceofNOx, allthesetransformationsrequirethatthecatalystformsbondswiththereactingmolecules. Suchacomplexthenreactstoproducts,leavingthecatalystunalteredandreadyfortaking partinanextcatalyticcycle.

Fig.1.1 isanexampleofacatalyticreactionbetweentwomoleculesAandBwiththe involvementofacatalyst.

Inordertounderstandhowacatalystcanaccelerateareaction,apotentialenergy diagramshouldbeconsidered.

Fig.1.2 representsaconceptforanon-catalyticreaction.Arrheniussuggestedthat reactionsshouldovercomeacertainbarrierbeforeareactioncanproceed.

ThechangeintheGibbsfreeenergybetweenthereactantsandtheproducts ΔG does notchangeincaseofacatalyticreaction;however,thecatalystprovidesanalternative pathforthereaction(Fig.1.3).

Fig.1.1 Catalyticcycle.

Fig.1.5 Potentialenergydiagramofanenzymaticreaction. (From https://upload.wikimedia.org/ wikipedia/commons/thumb/c/c0/Enzyme_catalysis_energy_levels_2.svg/1280px-Enzyme_catalysis_ energy_levels_2.svg.png?1450038342767 ).

catalystandareactantshouldnotbetoostrong.Alternatively,ifitistooweak,thenthe catalyticcyclecouldnotproceed.

Chemicalkineticsasadisciplineaddresseshowthereactionratesdependonreactant concentration,temperature,natureofcatalysts,pH,andsolvent,tonameafewreaction parameters.

Chemicalkinetics,togetherwithothermeansofstudyingcatalyticreactionslikespectroscopyofcatalystsandcatalystmodels,quantum-chemicalcalculationsforreactants, intermediatesandproducts,calculationofthethermodynamicsofreactants,intermediatesandproductsfrommeasuredspectraandquantum-chemicalcalculations,formthe modernbasisforunderstandingcatalysis.

Kineticinvestigationsareoneofthewaystorevealreactionmechanisms.Thefollowingproblemscanbesolvedusingthekineticmodel:

•choosingthecatalystandcomparingtheselectivityandactivityofcatalystsandtheir performanceunderoptimumconditionsforeachcatalyst;

•thedeterminationoftheoptimumsizesandstructureofcatalystgrainsandthenecessaryamountofthecatalysttoachievethespecifiedvaluesoftheselectivityoftheprocessandconversionofthestartingproducts;

•thedeterminationofthecompositionofallbyproductsformedduringtheprocess;

•thedeterminationofthestabilityofsteadystatesandparametricsensitivity;thatis,the influenceofdeviationsofallparametersonthesteady-stateregimeandthebehaviorof thereactorunderunsteadystateconditions;

•thestudyofthedynamicsoftheprocessanddecidingiftheprocessshouldbecarried outunderunsteady-stateconditions;

•thestudyoftheinfluenceofmassandheattransferprocessesonthechemicalreaction rateandthedeterminationofthekineticregionoftheprocess;

•selectionofthereactortypeandstructureofthecontactunitprovidingthebest approximationstotheoptimumconditions.

Veryoften,theratesofchemicaltransformationsareaffectedbytheratesofotherprocesses,suchasheatandmasstransfer.Theprocessshouldbetreatedasapartofkinetics. Thegas/liquidmasstransferinmultiphaseheterogeneousandhomogeneouscatalytic reactionscouldbetreatedinasimilarway.Themathematicalframeworkformodeling diffusioninsidesolidcatalystparticlesofsupportedmetalcatalystsorimmobilized enzymesdoesnotdifferthatmuch,butpropercareshouldbetakenofthereaction kinetics.

Theimmenseimportanceofcatalysisinchemicalindustryismanifestedbythefact thatroughly85–90%ofallchemicalproductshaveseenacatalystduringthecourse ofproduction.

Fig.1.6 demonstratesapplicationsofcatalysisinindustry.Inthelastfewyears,thereis anincreaseofcatalyticapplicationsalsofornon-chemicalindustries,includingtreatment ofexhaustgasesfromcarsandothermobilesources,aswellaspowerplants(Fig.1.7).

Worldwidecatalystmarket.

Fig.1.7 CatalytictreatmentofNOx in(A)mobileand(B)stationarysources.

The catalyst group: The intelligence report: global shifts in the catalyst industry

Fig.1.6

(A)

(B)

Acomparisonbetweenhomogeneousandheterogeneouscatalystsfromtheviewpointofahomogeneouscatalysisexpertispresentedbelow:

Selectivity High Variable

Conditionsofreaction Mild Harsh

Lifetimeofcatalyst Variable Long

Sensitivitytodeactivation Low High

Problemsduetodiffusion None Difficulttosolve

Recyclingofcatalyst Usuallydifficult Caneasilybedone

StericandelectronicpropertiesEasilychanged Novariationpossible Mechanism RealisticmodelsexistNotobvious

Thetopicsaddressedabovewillbediscussedinmoredetailinthesubsequentchapters.

Agreatvarietyofhomogeneouscatalystsareknown,includingmetalcomplexesand ions,BrønstedandLewisacids,andenzymes.Homogeneoustransitionmetalsareusedin severalindustrialprocesses,afewofthemaregivenbelow: Process

Acetaldehyde 2.5 Pd/Cu375–4053–8 Aceticacid 4.0 Rh425–47530–60

Oxo-alcohols 7 CoorRh335–470200/30

Dimethylterephthalate3.3 Co415–4454–8

Terephthalicacid9.4 Co450–50515–30

Metalcomplexescanhaveaverysophisticatedstructurewithavarietyofligands.An exampleofsuchligandsforRhcatalyzedhydroformylationisgivenbelow(Fig.1.8) alongwithsomeimagesofheterogeneouscatalysts(Fig.1.9).

Enzymesrepresentaspecialtypeofhomogeneouscatalyst.Theyarelargeproteins (Fig.1.10)capableofincreasingthereactionratesbyafactorof106 atmildreactionconditionsanddisplayingveryhighspecificityandcapabilityofregulation.

Specificity(Fig.1.11)iscontrolledbytheenzymestructure;moreprecisely,aunique fitofsubstratewiththeenzymethatcontrolstheselectivityforthesubstrateandtheproductyield.

Superficially,thereisnotthatmuchincommonbetweenalargeproteinandaPt/ Al2O3 heterogeneouscatalyst.Atthesametime,thechemicalreactionswhichoccurwith bothtypesofcatalystsinvolvecertainactivesites;forexample,regionswherecatalysis occurs.Whateverthespecificreaction,itcanbeschematicallyrepresentedby

where A and B arereactants, C and D products,and a, b, c,and d arestoichiometriccoefficients.Anequationforachemicalreactioniswritteninsuchawaythatallthemolecules participatinginthereactionarebalanced.

Veryofteninchemicalreactionengineering,thestoichiometriccoefficient νi is definedastheamountofproductproducedafteronerunofthereaction.Itimpliesthat thestoichiometriccoefficientispositiveforaproductandnegativeforareactant.

Thus,forthereaction:

Thefollowingstoichiometriccoefficientshold:

Anextensivequantitydescribingtheprogressofachemicalreactionequaltothenumber ofchemicaltransformations(thetotalnumberofreactionruns)dividedbyAvogadro’s number(itisessentiallythe amount ofchemicaltransformations)iscalledtheextentof reaction.Thechangeintheextentofreactionisgivenbydξ ¼ dni/νi,where νi isthe stoichiometricnumber ofanyreactionentity i (reactantorproduct)and ni isthecorrespondingamountinmoles.

Thus,dξ/dt isanextensiveproperty,whichismeasuredinmolesandcannotbeconsideredareactionrate,asitisproportionaltothesizeofthereactor.

Ingeneral,forahomogeneousreactionforwhichboththereactionratechangeswith timeandisnotuniformoveravolumeofareactor,thereactionrateis:

where V standsforthereactorvolume.Ifthereactorvolumeisconstant,thenthereactionrateissimply:

where i isthereactantorproductwithcorrespondingstoichiometriccoefficient νi,and Ci istheconcentrationofcomponent i.Forareaction:

therateofconsumptionofreactant A isthen:

where nA isthenumberofmolesof A inthereactorand[A]istheconcentrationof A. Similarly,forthereaction:

1.4.ACQUISITIONOFKINETICDATA

Kineticdataforachemicalreactionaregatheredindifferenttypeofreactors,andwewill brieflymentionsomerequirementsforchemicalreactorsfromtheviewpointofkinetic analysis.Ahighprecisionofthedataisneededaslargedeviationsinthevaluesofthe experimentallymeasuredrateswillbeaseriousobstacleforquantitativeconsiderations. Reproducibilityofratemeasurementsoverabroadrangeofparametersisalsoofimportance.Anothernecessaryfeatureisthepossibilitytoreachagoalofobtainingthemaximumamountofkineticinformationinminimumtime.Analysisofproductsaswellas reactorlayoutshouldpreferablybeaseasyaspossible.

Essentialfeaturesforcatalyticreactionsarethereadinessinreduction/activationof heterogeneouscatalystsandapossibilitytoutilizethemintheneededgeometricalform. Despitethestrictdefinitionofcatalysis,whichstatesthatthecatalystdoesnotchange duringthecatalyticreactions,someactivitydeteriorationtakesplace;therefore,measurementsofcatalytickineticsshouldalwaysmonitorthecatalystactivity.

Differenttypesofreactorsareappliedinpractice(Fig.1.14).Stirredtankreactors (STR),veryoftenappliedforhomogeneous,enzymaticandmultiphaseheterogeneous catalyticreactions,canbeoperatedbatch-wise(batchreactor,BR),semi-batch-wise (semi-batchreactor,SBR)orcontinuously(continuousstirredtankreactor,CSTR).

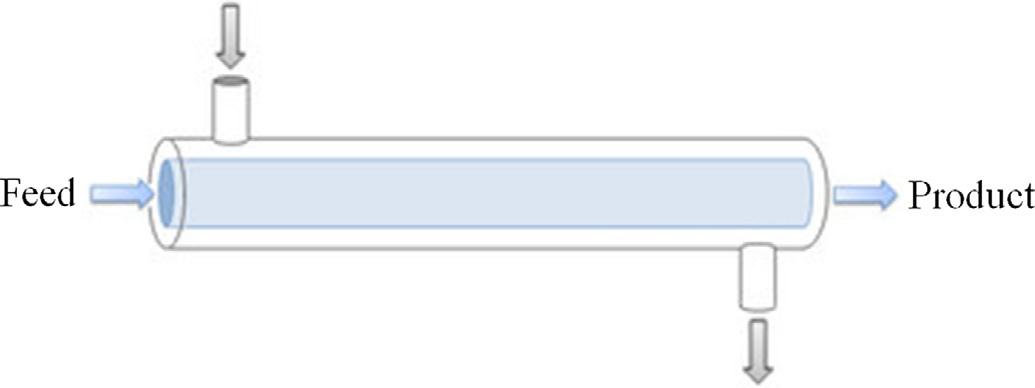

Alternatively,tubularreactorswithplugflow(pistonflow)(PFR)areusedandoperateincontinuousmode(Fig.1.15).

Fig.1.14 Differenttypesofstirredtankreactors.

Fig.1.15 Tubularreactors.

Fig.1.18 Avolumeelement.

Foraninfinitesimalvolumeelement ΔV in Fig.1.18,themassbalancecouldbewritteninaform:

IN+GENERATION ¼ OUT+ACCUMULATION

leadingtoafollowingequationintermsofmoles:

where n 0A and n A arethemolefluxes, ηA isthecatalysteffectivenessfactor(Chapter10) takingintoaccountmasstransfer.

ForabatchreactoritholdsthatIN ¼ 0,OUT ¼ 0;therefore:

Ifthevolumeisconstant,onegets:

FromEqs. (1.23) and (1.24):

makinguseoftherelationshipbetweenconcentrationandconversion α:

Assumingthatthecatalysteffectivenessfactor ηA isequalto1andtakingintoaccount boundaryconditions(t ¼ 0, α ¼ 0),wearriveat:

Infact,treatmentofheterogeneous,homogeneousandenzymaticreactionsisbasically thesamewiththeonlydifferenceintheexpressionsofreactionrates,whichreflectdifferentreactionmechanisms.Somespecificcaseswillbediscussedin Chapters5–7.Here wepresentfewexamples:

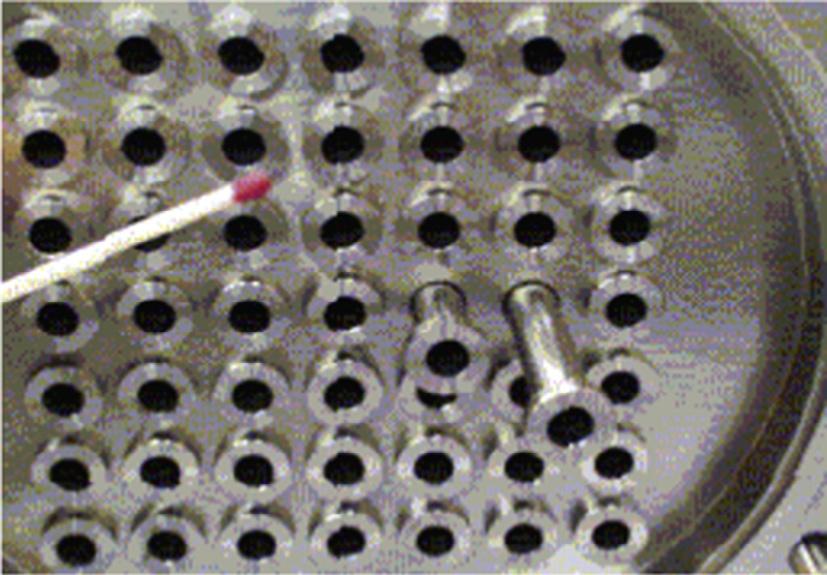

reactorsareefficientforcatalystscreening,especiallywhentheyarearrangedinaparallel mode(Fig.1.21).

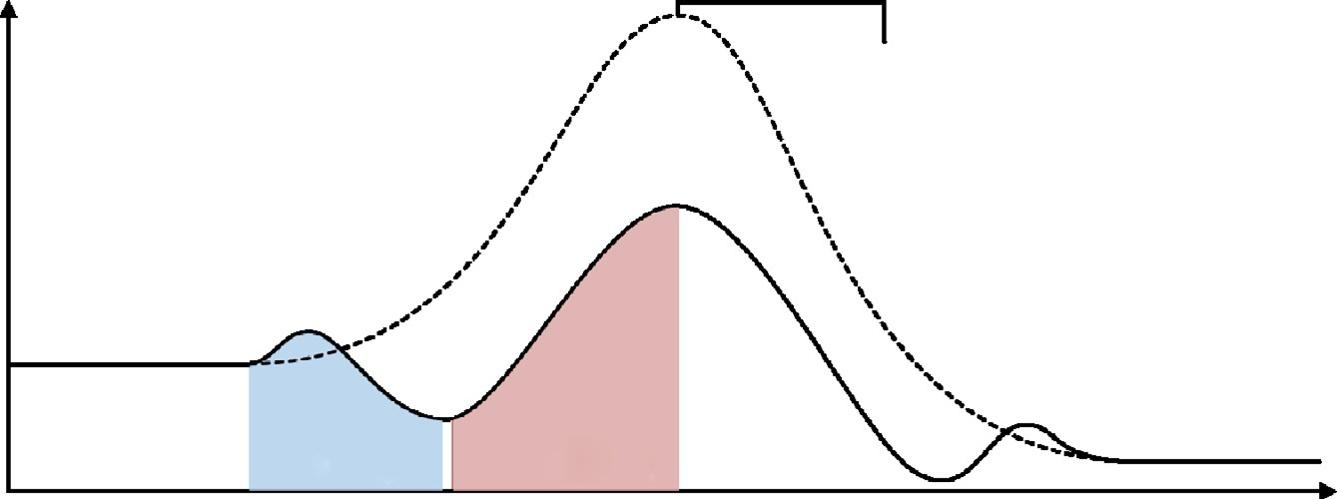

Theapparentdrawbackisthatoneexperimentleadstoonlyonedatapoint.Onthe otherhand,catalystdeactivationwithtimeonstreamcouldbeeasilyseen(Fig.1.22).

Quantitativetreatmentofplugflowreactorsissomewhatcumbersome;therefore, severalassumptionsareusuallymade.Thefluidcompositionisconsideredtobeuniform alongthereactorcrosssection(ie,thereisnoradialdispersion).Thisisvalidonlywhen:

Fig.1.20 Atubularreactor.

Fig.1.21 Multitubularreactor.

Forlargercatalystparticles,somegasbypassclosetothereactorwallsispossible.When thereactantsmovealongthereactor,thecompositionofthemixturechangesandaxial diffusioncanbecomeprominent.Toavoidthepossibleimpactofaxialdiffusionin kineticexperiments,thelevelofconversionshouldbebelow10–15%.

Ingeneral,non-isothermalbehaviorofatubularreactorshouldalsobetakeninto account,sinceso-calledisothermalreactorsareseldomisothermal(Fig.1.23);however, forthesakeofsimplicityitwillnotbeconsideredbelow.

Themassbalanceforaplugflowreactor(Fig.1.23)isthengivenby:

Fig.1.22 Catalystdeactivationwithtime-on-streamatdifferentconditions.

Fig.1.23 Temperatureprofileinatubularreactor.