https://ebookmass.com/product/carbon-fiber-2nd-editionbajpai/

Instant digital products (PDF, ePub, MOBI) ready for you

Download now and discover formats that fit your needs...

Cellulases in the Biofuel Industry Pratima Bajpai

https://ebookmass.com/product/cellulases-in-the-biofuel-industrypratima-bajpai/

ebookmass.com

Fiber-Optic Communication Systems 5th Edition Govind P. Agrawal

https://ebookmass.com/product/fiber-optic-communication-systems-5thedition-govind-p-agrawal/

ebookmass.com

Biobased Polymers: Properties and Applications in Packaging Pratima Bajpai

https://ebookmass.com/product/biobased-polymers-properties-andapplications-in-packaging-pratima-bajpai/

ebookmass.com

The Novel and the Multispecies Soundscape 1st ed. Edition Ben De Bruyn

https://ebookmass.com/product/the-novel-and-the-multispeciessoundscape-1st-ed-edition-ben-de-bruyn/

ebookmass.com

Geometry and Statistics - Handbook of Statistics, Volume 46 Frank Nielsen & Arni S.R. Srinivasa Rao & C.R. Rao (Editors)

https://ebookmass.com/product/geometry-and-statistics-handbook-ofstatistics-volume-46-frank-nielsen-arni-s-r-srinivasa-rao-c-r-raoeditors/ ebookmass.com

The Oxford History of the Ancient Near East, Volume II: From the End of the Third Millennium BC to the Fall of Babylon Karen Radner

https://ebookmass.com/product/the-oxford-history-of-the-ancient-neareast-volume-ii-from-the-end-of-the-third-millennium-bc-to-the-fall-ofbabylon-karen-radner/ ebookmass.com

Introducing Cultural Anthropology, 5th edition 5th Edition, (Ebook PDF)

https://ebookmass.com/product/introducing-cultural-anthropology-5thedition-5th-edition-ebook-pdf/

ebookmass.com

Applied Statistics in Business and Economics, 7e ISE 7th Edition David Doane

https://ebookmass.com/product/applied-statistics-in-business-andeconomics-7e-ise-7th-edition-david-doane/

ebookmass.com

Rift in the Soul Hunter

https://ebookmass.com/product/rift-in-the-soul-hunter/

ebookmass.com

https://ebookmass.com/product/five-first-chances-sarah-jost-3/

ebookmass.com

CARBONFIBER

CARBONFIBER

SECONDEDITION

PRATIMABAJPAI

Consultant-PulpandPaper,Kanpur,India

Elsevier

Radarweg29,POBox211,1000AEAmsterdam,Netherlands

TheBoulevard,LangfordLane,Kidlington,OxfordOX51GB,UnitedKingdom 50HampshireStreet,5thFloor,Cambridge,MA02139,UnitedStates

©2021ElsevierInc.Allrightsreserved.

Nopartofthispublicationmaybereproducedortransmittedinanyformorbyanymeans,electronicor mechanical,includingphotocopying,recording,oranyinformationstorageandretrievalsystem,without permissioninwritingfromthepublisher.Detailsonhowtoseekpermission,furtherinformationaboutthePublisher’ s permissionspoliciesandourarrangementswithorganizationssuchastheCopyrightClearanceCenterandthe CopyrightLicensingAgency,canbefoundatourwebsite: www.elsevier.com/permissions.

ThisbookandtheindividualcontributionscontainedinitareprotectedundercopyrightbythePublisher (otherthanasmaybenotedherein).

Notices

Knowledgeandbestpracticeinthisfieldareconstantlychanging.Asnewresearchandexperiencebroadenour understanding,changesinresearchmethods,professionalpractices,ormedicaltreatmentmaybecomenecessary.

Practitionersandresearchersmustalwaysrelyontheirownexperienceandknowledgeinevaluatingandusingany information,methods,compounds,orexperimentsdescribedherein.Inusingsuchinformationormethodsthey shouldbemindfuloftheirownsafetyandthesafetyofothers,includingpartiesforwhomtheyhaveaprofessional responsibility.

Tothefullestextentofthelaw,neitherthePublishernortheauthors,contributors,oreditors,assumeanyliability foranyinjuryand/ordamagetopersonsorpropertyasamatterofproductsliability,negligenceorotherwise,or fromanyuseoroperationofanymethods,products,instructions,orideascontainedinthematerialherein.

LibraryofCongressCataloging-in-PublicationData

AcatalogrecordforthisbookisavailablefromtheLibraryofCongress

BritishLibraryCataloguing-in-PublicationData

AcataloguerecordforthisbookisavailablefromtheBritishLibrary ISBN:978-0-12-821890-7

ForinformationonallElsevierpublications visitourwebsiteat https://www.elsevier.com/books-and-journals

Publisher: SusanDennis

AcquisitionsEditor: KostasMarinakis

EditorialProjectManager: MarianaL.Kuhl

ProductionProjectManager: JoyChristelNeumarin

HonestThangiah

CoverDesigner: GregHarris

TypesetbySPiGlobal,India

Dedication

“Thisbookisdedicatedtomybelovedparentsandfamily”fortheirlove,endlesssupport, encouragement,andsacrifices.

4.Conversionoflignintocarbonfiber

6.Recyclingofcarbonfiber-reinforcedpolymers

7.Manufacturingofcompositesfromrecycledcarbonfiber

8.Applicationsofcarbonfiber/carbonfiber-reinforcedplastic/recycled carbonfiber-reinforcedpolymers139

9.Thecarbonfiber/carbonfiber-reinforcedplastic/recycled carbonfiber-reinforcedpolymermarket157

10.Futuredirectionsofthecarbonfiberindustry

Listoffigures

Fig.1.1 Carbonfiberdemandovertheyears.5

Fig.2.1 Chemicalstructureof(A)polyacrylonitrile and(B)microstructureofMPcarbonfibers.14

Fig.2.2 Processformanufactureofcarbonfiberfrompolyacrylonitrile.15

Fig.2.3 Possiblereactionsoccurringduringthecarbonizationofstabilized polymerpolyacrylonitrileprecursor.17

Fig.2.4 Scanningelectronmicrographsofpolyacrylonitrile-basedcarbon fibers:(A)lowand(B)highmagnification.18

Fig.2.5 Processformanufactureofcarbonfiberfrompitch.19

Fig.2.6 Possiblereactionmechanismsoftheoxidativestabilizationofpitch precursor.(a)NP80;(b)NHP;and(c)A6021

Fig.2.7 Scanningelectronmicrographsofpitch-basedcarbonfibers: (A)lowand(B)highmagnification.22

Fig.2.8 Scanningelectronmicrographsofrayon-basedcarbonfibers: (A)lowand(B)highmagnification.24

Fig.2.9 Scanningelectronmicroscopy(SEM)micrographsofcellulose-based carbonfibers(CBCFs):(A)and(B)sidesurface,(C)and(D)crossing section.25

Fig.2.10 Scanningelectronmicroscopyimagesof(AandB)ligninfibers extrudedfromanorganicsolvent-extractedkrafthardwoodlignin; (CandD)oxidizedligninfiberatheatingratesof(C)0.05°Cmin 1 and(D)0.025°Cmin 1 showingdifferentdegreesoffusion; (EandF)carbonfiber,carbonizedto1000Cat2°Cmin 1 after stabilizationataheatingrateof0.01°Cmin 1.32

Fig.3.1 Monolignolmonomerspecies.(A) p-Coumarylalcohol (4-hydroxyphenyl[H]),(B)coniferylalcohol(guaiacyl[G]), (C)sinapylalcohol(syringyl[S]). 52

Fig.3.2 Chemicalstructureofhardwoodandsoftwoodlignin. 53

Fig.3.3 Photographsshowingthedifferencesinphysicalappearance foranumberoftypicaltechnicallignins. 62

Fig.4.1 Productionstepsinvolvedintheproductionofcarbonfiber fromlignin. 70

Fig.6.1 MaintechnologiesforCFRPrecycling.(A)Mechanicalrecycling. (B)Fiberreclamation. 95

Fig.6.2 Scanningelectronmicroscopyofrecycled(throughpyrolysis) carbonfibers.(A)Cleanrecycledfibers.(B)Recycledfibers withcharresidue.99

Fig.6.3 AdherentTechnologiesInc.’srecycledCFderivedfromthe catalyticconversionprocess.100

Fig.6.4 ATI’sPhoenixreactor,apilotscalevacuumpyrolysisunit.102

Fig.6.5 Low-temperature,low-pressurerecyclingreactor.103

Fig.6.6 Schematicofcarbonfiber-reinforcedpolymer(CFRP)waste treatmentbymicrowavethermolysis.104

Fig.6.7 ThemacroscopicappearancesoftheCFRPwastesamplesafter experiments(A)30minoftraditionalheatingat400°C,(B)30min oftraditionalheatingat450°C,(C)30minoftraditionalheating at500°C,and(D)13minofmicrowaveheatingat450°C.104

Fig.6.8 Productrangeof ELGCarbonFibreLtd.107

Fig.6.9 Recyclingfurnace(ELGcarbonFibreLtd.).107

Fig.6.10 Fluidizedbedmethod.108

Fig.6.11 Supercriticalfluidmethod.111

Fig.9.1 Amapofcarbonfibermanufacturingfacilities.158

Fig.9.2 ExamplesofdemonstratorsmanufacturedwithrecycledCFs: (A)Wingmirrorcovers(BMCcompression,Warrioretal.,2009), (B)Aircraftseatarm-rest(3-DEPprocess,George,2009),and (C)RearorWorldFirstF3car(wovenre-impregnation, Meredith,2009).165

Fig.A.1 Conceptualdiagramsofsingle-walledcarbonnanotubes(SWCNT) (A)andmultiwalledcarbonnanotubes(MWCNT)(B).188

Fig.A.2 Acarbonnanotubewithclosedends.188

Fig.A.3 Carbonnanotubestructuresofarmchair,zigzag,andchiral configurations.Theydifferinchiralangleanddiameter:armchair carbonnanotubesshareelectricalpropertiessimilartometals. Thezigzagandchiralcarbonnanotubespossesselectricalproperties similartosemiconductors.(A)Armchair.(B)Zigzag.(C)Chiral.189

Fig.A.4 Idealizedmodelsof(А)zigzagand(B)armchairmonolayernanotubes.190

Fig.A.5 Carbonnanotubesarcdischargeproductionmethod.193

Fig.A.6 Schematicsynthesisapparatus.(A)Classicallaserablationtechnique. (B)Ultrafastlaserevaporation(freeelectronlaser(FEL)).194

Fig.A.7 Catalyzedchemicalvapordeposition.195

Fig.A.8 TheSEMimagesofCNTs(A)after(B)beforepurificationstages withHCl.204

Fig.A.9 Scanningelectronmicroscopy(SEM)micrographsofthepristine nanotubes(PNTs)(A)andcutnanotubes(CNTs)(B).Afterthe mechanicaltreatmentthegeneralaspectofthesurfaceisclearly modified,andnanotubeswithshortlengthsareobserved.205

Fig.A.10 Typicaltransmissionelectronmicroscopymicrographofmultiwalled carbonnanotubes.206

Listoftables

Table1.1 Propertiesofcarbonfiber.2

Table1.2 Advantagesofcarbonfiber-reinforcedcarboncomposites.2

Table1.3 Applicationareaofcarbonfiber.3

Table1.4 Globalcarbonfiberdemandbyapplicationin1000tons(2013) (total46,500t).3

Table1.5 Estimatedglobalcarbonfiberconsumption.4

Table1.6 Marketshareofcarbonfibersdependingonprecursortype.6

Table1.7 RepartitionoftheproductioncostsofPAN-basedcarbonfibers.9

Table1.8 AdvantagesofligninoverotherprecursorslikeMPPandPAN.10

Table2.1 Advantagesofextrudingligninratherthanpolyacrylonitrile.26

Table2.2 Propertiesofcarbonfiberfromdifferenttypesoflignin.28

Table2.3 Physicalpropertiesofcarbonfibersfromblendsoflignin-PEO.30

Table2.4 Physicalpropertiesofcarbonfibersfromblendsoflignin.30

Table2.5 Mechanicalpropertiesofcarbonfibersmadefromlignin.31

Table3.1 Thecharacterizationoftechnicallignins.54

Table3.2 Characteristicsofthetechnicallignin.55

Table3.3 Someofthemajormanufacturersoflignins.55

Table3.4 Sulfurcontentandpurityofdifferenttypesoflignins.62

Table4.1 Mostcommonspinningtechniques.68

Table5.1 Comparisonofcarbonfiberspropertieswithothermaterials.78

Table5.2 Axialtensilepropertiesofcarbonfibers.79

Table5.3 Pricesofcarbonfiberofdifferentcategories.80

Table5.4 Classificationofcarbonfiber.81

Table5.5 Mechanicalpropertiesofdifferenttypesofcarbonfibers.82

Table5.6 Mechanicalpropertiesofcellulosicfibers.82

Table5.7 Propertiesofcarbonfibersfromdifferentprecursors.83

Table5.8 TypicalstructuralparametersfortheselectedpitchandPAN-basedcarbonfibers.84

Table5.9 Propertiesofcommercialcarbonfibers.85

Table5.10 Advantagesofcarbonfiber-reinforcedcarboncomposites.87

Table5.11 Propertiesofvariousengineeringfibers.87

Table5.12 Thermalconductivityandelectricalconductivityofcarbon fiberandcarbonnanotubes.87

Table6.1 Advantagesofrecycledcarbonfibers.92

Table6.2 Carbonfiberrecyclingindustryprogress.94

Table6.3 Gradesofsheetmoldingcompoundrecyclate fromERCOMGmbH.96

Table6.4 GradesofsheetmoldingcompoundrecyclatefromPhoenix Fibreglass,Inc.97

Table6.5 Tensilepropertiesofcarbonfiber.102

Table6.6 Productrangeof ELGCarbonFiberLtd.106

Table6.7 Fluidizedbedmethod.110

Table6.8 Supercriticalfluidmethod.111

Table6.9 Comparisonbetweenexistingrecyclingmethodsandthenew EHDmethod.114

Table6.10 Estimatedenergyconsumptionofthemainrecyclingprocesses.116

Table7.1 CompositematerialsmanufacturedwithrCFformechanical testing.130

Table7.2 Realpartdemonstratorandcommerciallyavailablesemiproducts madeofrCF.131

Table7.3 Benefitsandproblemswithdifferentprocessesusedfor remanufacturingofcompositesfromrecycledcarbonfibers.136

Table8.1 Currentapplicationsofcarbonfibercomposites.140

Table8.2 Globalcarbonfibersharebyapplicationin2017.146

Table9.1 CarbonfibermanufacturingcostbreakdownRockyMountain Institute(2015).158

Table9.2 Manufacturersofcarbonfiber.159

Table9.3 Worldwideproductioncapacitiesofcarbonfibers (metrictonsannually).159

Table9.4 Productionunitsofdifferentproducersindifferentregions oftheworld.160

Table9.5 DemonstratorsmanufacturedwithrecycledCFs.165

Table9.6 PotentialstructuralapplicationsforrCFRPs.166

Table10.1 Futuredirectionsofcarbonfiberindustry.172

TableA.1 PropertiesofCNTs.191

TableA.2 TabularrepresentationofCNTproperties.191

Preface

Carbonfibersarestate-of-the-artmaterialswithsuperiormechanicalproperties includinghigh-specificstrengthandhigh-specificmodulusandcharacteristicssuchas lowdensity,lowthermalexpansion,heatresistance,andchemicalstability.Inaddition, variouskindsofcarbonfiberswithdifferingfibermorphologyormechanicalperformancearedeveloped.Withthecharacteristicsmentionedearlier,carbonfibersare appliedtovariousfields.Carbonfibershavebeenextensivelyusedincompositesin theformofwoventextiles,prepregs,continuousfibers/rovings,andchoppedfibers. Thecompositepartscanbeproducedthroughfilamentwinding,tapewinding,pultrusion,compressionmolding,vacuumbagging,liquidmolding,andinjectionmolding.In recentyearsthecarbonfiberindustryhasbeengrowingsteadilytomeetthedemandfrom differentindustries.Mostofthecarbonfibermanufacturershaveplansforexpansionto meetthemarketdemand.However,thelarge-volumeapplicationofcarbonfiberin automotiveindustryhasbeenhinderedduetothehighfibercostandthelackof high-speedcompositefabricationtechniques.Thecurrentcarbonfibermarketisdominatedbypolyacrylonitrilecarbonfibers,whiletherestispitchcarbonfibersandavery smallamountofrayoncarbonfibertextiles.Differentprecursorsproducecarbonfibers withdifferentproperties.Globaldemandforcarbonfiberisforecasttogrowto140,000 tonnesby2020.Carbonfiber-reinforcedpolymer(CFRP)isalightfiber-reinforced polymerthatisincrediblystrong,composedofcarbonfibers.Thesecompositesarehighly desiredandhighvaluematerialsexhibitingsuperiorstrengthtoweightproperties.Polyepoxide(epoxy)isthepolymerusedmostofthetime,butotherpolymerslikevinyl, nylon,ester,orevenpolyestercanbeusedinsomecases.Otherfiberslikeglassfibers, Kevlar,andaluminummayalsobeusedalongwithcarbonfibers.

Todayasmallfractionofthecarbonfibercompositematerialsusedisrecycled.However,newlegislationpolicesandapproachingshortageofrawmaterials,incombination withtheeverincreasinguseofcarbonfibercomposites,forcesocietytorecyclethese materialsinthenearfuture.Theobjectiveofthisbookistobringtogetheravailableinformationontheproduction,properties,application,andfutureofcarbonfibers.Thiswill beofinteresttothoseinvolvedintheinvestigationofcarbonfiber,carbonfibermanufacturers,andtheusersofcarbonfibers.Thisbookwillalsobeofinteresttothose involvedintherecyclingofcarbonfiber-reinforcedpolymersandmanufacturingof compositesfromrecycledcarbonfiber-reinforcedpolymers.Studentsengagedinthe fieldofchemistry,materialsscience,andpolymersciencewillalsofindthisbookvery useful.

Acknowledgments

Iamgratefulforthehelpofmanypeople,companies,andpublishersforproviding informationandgrantingpermissiontousetheirmaterial.Deepestappreciationis extendedtoElsevier,Springer,Wiley,RoyalSocietyofChemistry,Hindawi,MDPI, andotheropen-accessJournalsandpublicationsforalltheinformationusedinthisreport.

SomeexcerptstakenfromBajpaiP.Carbonfibrefromlignin,SpringerBriefsin materialscience.Springer;2017.

SomeexcerptstakenfromHolmesM.Globalcarbonfibremarketremainsonupward trend.ReinfPlast2014;58:38–45.

SomeexcerptstakenfromXiaosongH.Fabricationandpropertiesofcarbonfibers. Materials2009;2:2369–2403.

SomeexcerptstakenfromZengF,PanD,PanN.ChoosingtheimpregnantsbythermogravimetricanalysisforpreparingRayon-basedcarbonfibers.JInorgOrgPolym Mater2005;15:261–267.

SomeexcerptstakenfromChanzyH,Paillet,M,Hagege,R.Spinningofcellulose fromN-methylmorpholineN-oxideinthepresenceofadditives.Polymer1990;31: 400–405.

SomeexcerptstakenfromSoutoF,CaladoV,PereiraN.Lignin-basedcarbonfiber: acurrentoverview.MaterResExpress2018;5:072001.

SomeexcerptstakenfromBakerDA,RialsTG.Recentadvancesinlow-costcarbon fibremanufacturefromlignin.JApplPolymSci2013;130:713–28.

SomeexcerptstakenfromYokoyamaA,NakashimaN,ShimizuK.Anewmodificationmethodofexplodedligninforthepreparationofacarbonfiberprecursor.JAppl PolymSci2003;48:1485–1491. https://doi.org/10.1002/app.1993.070480817

SomeexcerptstakenfromMatsushitaY.Conversionoftechnicalligninstofunctional materialswithretainedpolymericproperties.WoodSci2015;61:230–250. https://doi. org/10.1007/s10086-015-1470-2

SomeexcerptstakenfromNiaounakisM.Biopolymers:Applicationsandtrends. 1sted.2015.

SomeexcerptstakenfromLiJ,HenrikssonG,GellerstedtG.Lignindepolymerizationanditscriticalrolefordelignificationofaspenwoodbysteamexplosion.Biores Technol2007;98:3061–8.

SomeexcerptstakenfromMinusML,KumarS.Carbonfibre.Kirk-OthmerEncycl ChemTechnol2007;26:729–749.

SomeexcerptstakenfromZhuJH,ChenPi-yu,SuM,PeiaC,XingF.Recyclingof carbonfibrereinforcedplasticsbyelectricallydrivenheterogeneouscatalyticdegradation ofepoxyresin.GreenChem2019;21:1635–1647.

SomeexcerptstakenfromPickeringSJ.Recyclingtechnologiesforthermosetcompositematerials—currentstatus.ComposAApplSciManuf2006;37:1206–1215.

SomeexcerptstakenfromPimentaS,PinhoST.Recyclingcarbonfibrereinforced polymersforstructuralapplications:technologyreviewandmarketoutlook.Waste Management2011;31(2):378–392.

SomeexcerptstakenfromNahilMA,WilliamsPT.Recyclingofcarbonfibrereinforcedpolymericwaste.JAnalApplPyrol2011;91(1):67–75.

SomeexcerptstakenfromPickeringSJ,LiuZ,TurnerTA,WongKH.Applications forcarbonfibrerecoveredfromcomposites.IOPConfSerMaterSciEng2016;139: 1–18.

SomeexcerptstakenfromLesterE,KingmanS,Wong,KH,RuddC,PickeringS, HilalN.Microwaveheatingasameansforcarbonfibrerecoveryfrompolymercomposites:atechnicalfeasibilitystudy.MaterResBull2004;39(10):1549–1556.

CHAPTER1

Introduction

Carbonfiber—“theworld’sstructuralwondermaterial”—isalsoknownasgraphitefiber. Itisverylightweightandverystrongmaterial.Incomparisonwithsteel,itisfivetimes strongerandtwotimesstifferandlighter,whichmakesitanexcellentmanufacturing materialforseveralparts.Engineersanddesignersprefercarbonfiberformanufacturing. Thereasonsarepresentedin Table1.1

Thesefibersarenotusedassuch.Theyareusedtoreinforcematerialssuchasepoxy resinsandotherthermosettingmaterials.Thesematerialsaretermedascompositesasthey possessmorethanonecomponentandarequitestrongfortheirweight.Theyarevery strongincomparisonwithsteelbutverymuchlighter.Duetothisproperty,theymaybe usedtoreplacemetalsinseveralapplications,frompartsforairplanesandthespaceshuttle totennisracketsandgolfclubs.

Table1.2 showsadvantagesofcarbonfiber-reinforcedcarboncomposites. Carbonfibersdatebackto1879.ThomasEdisonbakedcottonthreadsorbamboo silversatelevatedtemperatures,whichcarbonizedthemintoanall-carbonfiberfilament. In1958RogerBaconofOhioinCleveland,Ohio,UnitedStates,producedhighperformancecarbonfibers.LesliePhilips,aBritishengineer,in1964,realizedthehigh strengthofcarbonfiber.Lateron,carbonfibersproducedfromrayonstrandsprocessed bycarbonationweredeveloped.AkioShindointheearly1960sproducedcarbonfibers fromPAN.FormanufacturingPAN-basedcarbonfibers,PANisprocessedtoafibrous shapebyspinningandthensubjectedtooxidation,carbonization,andsurfacetreatment. LeonardSingerproducedcarbonfibersfrompitchin1970.Themanufacturingprocess involvesinmakingpetroleumorcoalpitchintoafibrousshape;thenoxidation,carbonization,andsurfacetreatmentareperformed(Saitoetal.,2011).Thesefiberswerenot efficientandcontainedabout20%carbon.Thestrengthandstiffnesspropertieswere inferior.TheUSAirForceandNASAstartedusingcarbonfiberinaircraftandspacecraft application.

Duringthe1970s,workwasconductedtofindalternativerawmaterialsfortheproductionof carbonfibersmadefromapetroleumpitchobtainedfromoilprocessing.Thesefiberscontained about85%carbonandpossessedexcellentflexuralstrength.But,theyhadverylittlecompression strengthandwerenotverymuchaccepted.

(www.madehow.com )

Table1.1 Propertiesofcarbonfiber.

Highstrength-to-weightratio

Goodrigidity

Corrosionresistant

Electricallyconductive

Fatigueresistant

Goodtensilestrengthbutbrittle

Fireresistance/notflammable

Highthermalconductivity

Lowcoefficientofthermalexpansionandlowabrasion

Nonpoisonous

BiologicallyinertnessandX-raypermeability

Self-lubricating

Excellentelectromagneticinterferenceshieldingproperty

Relativelyexpensive

Requiresspecializedexperienceandequipmenttouse

Highdimensionalstability,lowcoefficientofthermalexpansion,andlow abrasion

Highdamping

Electromagneticproperties

http://www.innovativecomposite.com/what-is-carbon-fiber/; https://www. motioncomposites.com/en/about-carbon-fiber/

Table1.2 Advantagesofcarbonfiber-reinforcedcarboncomposites.

Resistancetohightemperaturesandweathering,lowflammability,low smokedensity,lowtoxicityofdecompositionproducts.Temperature resistanceofcoursedependsonchoiceofresin

Highchemicalstability

Largevarietyofpossiblecomponentshapesandsizes

Highdurabilityduetolongprepregstoragelife

Prepregscomprisetherangeofreinforcementsandresinmatrix combinations.Theyaremanufacturedonastate-of-the-artfusibleresin plant.Fusibleresinshavefewervolatileconstituentsandincreasethe compositematerials’mechanicalstrength.Theprepregmanufacturing plantisaccreditedtoDINANDISO9001qualityassurancestandards

Nowadays,carbonfibershavebecomeanimportantpartofseveralproducts,andnew applicationsarebeingdeveloped.TheleadingproducersofcarbonfibersaretheUnited States,Japan,andWesternEurope.

Worldwidecarbonfiberisinrapidlygrowingdemandasalightweightandstrong alternativetometalforvariousindustriessuchasaeronautics,automotive,marine,transportation,construction,electronics,andwindenergy(Fitzeretal.,1989; Hajduk,2005;

Huang,2009; Saitoetal.,2011; Barnesetal.,2007; Soutis,2005; Ogawa,2000; Nolan, 2008; vanderWoudeetal.,2006; Fuchsetal.,2008; ZhangandShen,2002; Aokietal., 2009; Tranetal.,2009; Olenicetal.,2009; Baughmanetal.,2002; Thostensonaetal., 2001; Roberts,2006; Todd,2019; Figueiredoetal.,1990; Chung,1994; Watt,1985; DonnetandBansal,1990; MinusandKumar,2005,2007).Carbonnanofibershavebeen exploredforuseinregenerativemedicineandalsofortreatmentofcancer(Ogawa,2000; Nolan,2008; vanderWoudeetal.,2006; Fuchsetal.,2008. ZhangandShen,2002; Aokietal.,2009; Barnesetal.,2007; Soutis,2005; Tranetal.,2009; Olenicetal., 2009; Baughmanetal.,2002; Thostensonaetal.,2001). Table1.3 showstheapplication ofcarbonfiber(Holmes,2014).Applicationsinaerospaceanddefense,sport/leisuresector,andwindturbineshavegrownsubstantially.Theautomotivesegmentisalsobecomingveryimportant.Thiscouldbebecauseoftheramp-upphasefortheproductionofthe i-modelsfromBMW.Otherapplicationsareconstructionofmoldingandcompounding plant,pressurevessels,civilengineering,andmarine. Table1.4 showsglobalcarbonfiber demandbyapplicationin1000tons(2013).

Table1.3 Applicationareaofcarbonfiber.

Polyacrylonitrileaerospace/high-endcarbonfiber: Toray(largestworldwidemanufacturer)

TohoTenax

Mitsubishi

Hexcel

Cytec

NipponGraphiteFiberCorporation

Polyacrylonitrilecommercialgradecarbonfiber: Zoltek

SGL

http://www.formula1-dictionary.net/carbon_fiber.html

Table1.4 Globalcarbonfiberdemandbyapplicationin1000tons (2013)(total46,500t).

Aerospaceanddefense

Moldingandcompound

Sportsandleisure

Windturbines

Automotive

Pressurevessels

Civilengineering

Marine

Others

13.9,30%

5.5,12%

6.4,14%

6.7,14%

5.0,11.0%

2.4,5%

2.3,5%

0.8,2%

0.5,7%

BasedonHolmesM.Globalcarbonfibremarketremainsonupwardtrend. ReinfPlast2014;58:38–45.

Thediameterofcarbonfiberisabout0.0002–0.0004in.andcontainsatleast90%carbonbyweight.Itisalong,thinstrandofmaterial(Figueiredoetal.,1990; Chung,1994; Watt,1985; DonnetandBansal,1990; MinusandKumar,2005).Thecarbonatomsare bondedtogetherinmicroscopiccrystals.Thesearemoreorlessalignedparalleltothelong axisofthefiber.Thecrystalalignmentmakesthefiberverystrongforitssize(Chung, 1994).Thousandsofcarbonfibersaretwistedtogethertoformayarn.Thiscanbeused byitselforwovenintoafabric.Theyarnorfabricisblendedwithepoxyandwound ormoldedintoshapeforproducingdifferenttypesofcompositematerials.Carbon fiber-reinforcedcompositesarebeingusedformakingaircraftandspacecraftparts,racing carbodies,golfclubshafts,bicycleframes,fishingrods,automobilesprings,sailboatmasts, andseveralothercomponentswherelightweightalongwithhighstrengthisrequired.

Severaltypesofcarbonareavailable.Theycanbesortorcontinuous.Thesearecrystalline,amorphous,orpartlycrystalline. Table1.5 showsestimatedglobalcarbonfiber consumption(Roberts,2006; Red,2006; PimentaandPinho,2011).

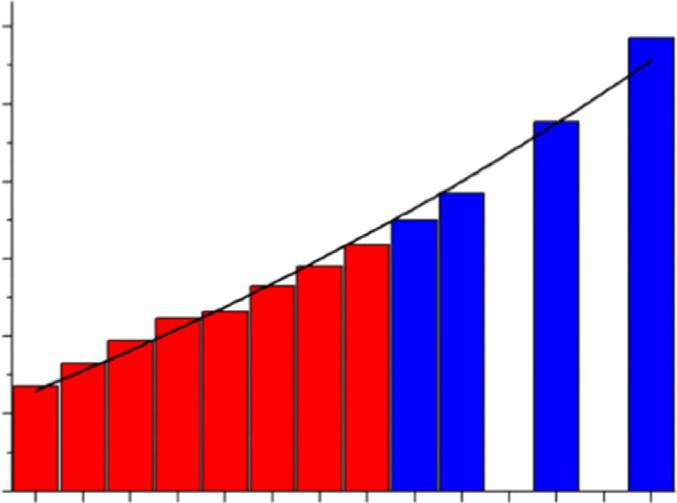

“DemandofCarbonfiberincreasedfrom26,500tonsin2009to63,500tonsin2016, whichyieldedarevenueupaboutUS$ 2.34billion(agrowthof8.7%relatedtotheyear 2015).Accordingtomarkettrendsitisexpectedanannualgrowthratebetween10%to 13%forthecomingyears,”(Fig.1.1)(Soutoetal.,2018; Wittenetal.,2015,2016,2017).

Demandforcarbonfibrewouldreach89,000tby2020andwouldgeneraterevenuesofover US$3.3billion.

(Holmes,2014)

Generally,mechanicalpropertiesareusedtoclassifytheirmaterial(MinusandKumar, 2005; Chen,2014; Hedgeetal.,2004).Itshouldbementionedthatdiameterandmorphologyarealsoanimportantcriteriaforclassifyingthefiberswhenitconfersimportant prominenceonmechanicalproperties(MinusandKumar,2005).

Carbonfiberswerefirstproducedinthe1950sasareinforcementforhightemperaturemoldedplasticcomponentsonmissiles(Figueiredoetal.,1990; Chung, 1994; Watt,1985; DonnetandBansal,1990; MinusandKumar,2005).Thesewere producedbyheatingstrandsofrayontilltheygetcarbonized.Theresultingfiberscontained 20%carbonandhadlowerstrengthproperties.Hence,thisprocessprovedtobe

Table1.5 Estimatedglobalcarbonfiberconsumption.

BasedonRobertsT.Thecarbonfibreindustry:globalstrategicmarketevaluation2006–2010.Watford:Materials TechnologyPublications;2006.pp.10,93–177,237;RedC.Aerospacewillcontinuetoleadadvancedcompositesmarket in2006.ComposManuf2006;7:24–33;PimentaS,PinhoST.Recyclingcarbonfibrereinforcedpolymersforstructural applications:technologyreviewandmarketoutlook.WasteManag2011;31:378–392.

Fig.1.1 Carbonfiberdemandovertheyears. (ReproducedwithpermissionSoutoF,CaladoV,PereiraJr N.Lignin-basedcarbonfiber:acurrentoverview.MaterResExpress2018;5:072001. https://doi.org/10. 1088/2053-1591/aaba00.)

inefficient.Thecarbonfiberswereusedsuccessfullyonacommercialscaleintheearly 1960s,astheneedoftheaerospaceindustry—especiallyformilitaryaircraft—forbetter andlightweightmaterialsbecameveryimportant.Inthisprocess,polyacrylonitrilewas usedasastartingmaterial.Thisprocessproducedacarbonfiberthathadverygood strengthproperties.Thereforethepolyacrylonitrileprocessrapidlybecamethemain methodformanufacturingcarbonfibers.“Carbonfibresarebeingusedwidelyincommercialandcivilianaircraft,recreational,industrial,andtransportationmarkets.Carbon fibresareusedincompositeswithalightweightmatrix.Carbonfibrecompositesareparticularlysuitedforapplicationswherestrength,stiffness,lowerweight,andoutstanding fatiguecharacteristicsarethemainrequirements.Theycanbealsousedwherehightemperature,chemicalinertnessandhighdampingareimportant”(www.carbonfiber-vinyl. com).Carbonfibersoffer10timesthestrengthofsteelataquarteroftheweight (Xiaosong,2009).

Carbonfibersmanufacturedfrompolyacrylonitrilehavebettermechanicalandphysicalpropertiesincomparisonwithrayon-basedones.Today,theyarethemostpromising rawmaterialsforproductionofhigh-strengthcarbonfibers.Carbonfibersbasedon mesophasepitchturnedoutasmoreexpansivefollowingacomplicatedandcomplex processofconversionofcheappitchesintomesophase-formingmodification. Table1.6 showsmarketshareofcarbonfibersdependingontheprecursortype (FitzerandHeine,2019).