https://ebookmass.com/product/braking-of-road-vehicles-2nd-

Instant digital products (PDF, ePub, MOBI) ready for you

Download now and discover formats that fit your needs...

Dynamics and Optimal Control of Road Vehicles D. J. N. Limebeer

https://ebookmass.com/product/dynamics-and-optimal-control-of-roadvehicles-d-j-n-limebeer/

ebookmass.com

Public & Private Families. 1st Edition Andrew J. Cherlin.

https://ebookmass.com/product/public-private-families-1st-editionandrew-j-cherlin/

ebookmass.com

When I Hit the Road Nancy J. Cavanaugh

https://ebookmass.com/product/when-i-hit-the-road-nancy-j-cavanaugh/

ebookmass.com

Clash of Kingdoms (Dirty Blood Book 6) Penelope Barsetti

https://ebookmass.com/product/clash-of-kingdoms-dirty-bloodbook-6-penelope-barsetti/

ebookmass.com

eTextbook 978-0133905045 Government in America: People, Politics, and Policy, 2014 Elections and Updates Edition

https://ebookmass.com/product/etextbook-978-0133905045-government-inamerica-people-politics-and-policy-2014-elections-and-updates-edition/

ebookmass.com

Passion In The Mountains (Greene Mountain Boys) Olivia T. Turner

https://ebookmass.com/product/passion-in-the-mountains-greenemountain-boys-olivia-t-turner/

ebookmass.com

Defending Revin: Sci-fi, Alien Warrior Romance - Hissa Warrior (Hissa Warrior Series Book 8) Rk Munin

https://ebookmass.com/product/defending-revin-sci-fi-alien-warriorromance-hissa-warrior-hissa-warrior-series-book-8-rk-munin/

ebookmass.com

Grounds for Love: A Later in Life Second Chance Steamy Romance (Faire Island Bride Series Book 3) Lizabeth Scott https://ebookmass.com/product/grounds-for-love-a-later-in-life-secondchance-steamy-romance-faire-island-bride-series-book-3-lizabeth-scott/

ebookmass.com

Chemical Engineering Process Simulation 2nd Edition Dominic C.Y. Foo

https://ebookmass.com/product/chemical-engineering-processsimulation-2nd-edition-dominic-c-y-foo/

ebookmass.com

Knight in Her Bed (Highland Knights Book 1) Sue Ellen Welfonder

https://ebookmass.com/product/knight-in-her-bed-highland-knightsbook-1-sue-ellen-welfonder/

ebookmass.com

BRAKINGOF ROADVEHICLES BRAKINGOF ROADVEHICLES SecondEdition

ANDREWDAY M.A.(Cantab),PhD.(Loughborough),C.Eng.,F.I.MechE., ProfessorEmeritus,UniversityofBradford,UK

DAVIDBRYANT MEng(Leeds),PhD.(Huddersfield),PGCert(Huddersfield),AMIMechE, AssociateProfessor,UniversityofBradford,UK

Butterworth-HeinemannisanimprintofElsevier

TheBoulevard,LangfordLane,Kidlington,OxfordOX51GB,UnitedKingdom 50HampshireStreet,5thFloor,Cambridge,MA02139,UnitedStates

Copyright©2022ElsevierInc.Allrightsreserved.

Nopartofthispublicationmaybereproducedortransmittedinanyformorbyanymeans,electronicor mechanical,includingphotocopying,recording,oranyinformationstorageandretrievalsystem,without permissioninwritingfromthepublisher.Detailsonhowtoseekpermission,furtherinformationaboutthe Publisher’spermissionspoliciesandourarrangementswithorganizationssuchastheCopyrightClearance CenterandtheCopyrightLicensingAgency,canbefoundatourwebsite: www.elsevier.com/permissions

ThisbookandtheindividualcontributionscontainedinitareprotectedundercopyrightbythePublisher (otherthanasmaybenotedherein).

Notices Knowledgeandbestpracticeinthisfieldareconstantlychanging.Asnewresearchandexperiencebroaden ourunderstanding,changesinresearchmethods,professionalpractices,ormedicaltreatmentmaybecome necessary.

Practitionersandresearchersmustalwaysrelyontheirownexperienceandknowledgeinevaluatingand usinganyinformation,methods,compounds,orexperimentsdescribedherein.Inusingsuchinformation ormethodstheyshouldbemindfuloftheirownsafetyandthesafetyofothers,includingpartiesforwhom theyhaveaprofessionalresponsibility.

Tothefullestextentofthelaw,neitherthePublishernortheauthors,contributors,oreditors,assumeany liabilityforanyinjuryand/ordamagetopersonsorpropertyasamatterofproductsliability,negligenceor otherwise,orfromanyuseoroperationofanymethods,products,instructions,orideascontainedinthe materialherein.

ISBN:978-0-12-822005-4

ForInformationonallButterworth-Heinemannpublicationsvisitourwebsiteat https://www.elsevier.com/books-and-journals

Publisher: MatthewDeans

AcquisitionsEditor: BrianGuerin

EditorialProjectManager: EmilyThomson

ProductionProjectManager: AnithaSivaraj

CoverDesigner: MarkRogers

TypesetbyAptara,NewDelhi,India

1.Introduction1 References 8

2.Frictionpairs9

2.1 Introduction 9

2.2 Thefrictionpair12

2.3 Resin-bondedcompositefrictionmaterials16

2.4 Thermophysicalproperties21

2.5 Brakeperformance25

2.6 Wear 32

2.7 Newfrictionpairs:composition,manufacture,andproperties34

2.8 Chaptersummary38 References 39

3.Brakingsystemdesignforpassengercarsandlightvans41

3.1 Introduction41

3.2 Weighttransferduringbraking42

3.3 Tyre/roadadhesion49

3.4 Brakingforceandwheelslip53

3.5 Brakingforcedistribution59

3.6 Wheellockandvehiclestabilityduringbraking63

3.7 Brakingefficiency64

3.8 Adhesionutilisation68

3.9 Chaptersummary71 References 73

4.Brakingsystemdesignforvehicleandtrailercombinations75

4.1 Introduction75

4.2 Carandlighttrailer76

4.3 Cartowingatrailerorcaravanwithoverrunbrakes80

4.4 Rigidtrucktowingacentre-axletrailer85

4.5 Rigidtrucktowingafull-trailer89

4.6 Articulatedcommercialvehicles—tractorsandsemi-trailers95

4.7 Loadsensingandcompatibility106

4.8 Chaptersummary108

References 108

5.Brakedesignanalysis109 5.1 Introduction109

5.2 Discbrakes111

5.3 Drumbrakes126

5.4 Brakefactorand η C∗ forair-actuatedcommercialvehiclebrakes155

5.5 Chaptersummary160

References 161

6.Brakesystemlayoutdesign163 6.1 Introduction163

6.2 Overviewofthevehiclebrakingsystemlayoutdesignprocess165

6.3 Steps3and4forPassengercarandlightcommercialvehiclebrakingsystems withhydraulicactuation175

6.4 Heavygoodsvehiclebrakingsystemswithpneumaticactuation209

6.5 Regenerativebraking224

6.6 Developmentsinroadvehiclebrakeactuationsystems225

6.7 Chaptersummary226

References 228

7.Electronicbrakingsystems229 7.1 Introduction229

7.2 Antilockbrakingsystem(ABS)230

7.3 Electronicstabilitycontrol(ESC)247

7.4 Electronicbrakeforcedistribution(EBD)254

7.5 Tractioncontrolsystem(TCS)255

7.6 RollStabilityControl(RSC)257

7.7 Additionalelectronicbrakingsystems261

7.8 Regenerativebraking267

7.9 Systemwarningsanddriverinterfaceswithelectronicbraking273

7.10 Chaptersummary274

References 276

8.Thermaleffectsinfrictionbrakes277

8.1 Introduction277

8.2 Heatenergyandpowerinfrictionbrakes279

8.3 Brakingenergymanagementandmaterials287

8.4 Brakethermalanalysis290

8.5 Heatdissipationinbrakes306

8.6 Chaptersummary321 References 322

9.Brakenoise,vibration,andharshness323

9.1 Introduction323

9.2 Brakenoise,vibration,andharshnessclassification326

9.3 Squeal 329

9.4 OtherclassesofbrakeNVH358

9.5 Brakejudder361

9.6 Computeranalysismethods368

9.7 Experimentalmethods378

9.8 Designrulesforquietbrakes382

9.9 Chaptersummary384

References 386

10.Braketesting389

10.1 Introduction389

10.2 Instrumentationanddataacquisitioninexperimentalbraketesting391

10.3 Experimentaldesign,testprocedures,andprotocolsforbraketesting402

10.4 Testvehicles,dynamometers,andrigs406

10.5 Experimentalbraketestprocedures411

10.6 Braketestdatainterpretationandanalysis428

10.7 Chaptersummary431

References 432

11.Brakinglegislation433

11.1 Introduction433

11.2 Europeanroadvehiclebrakingregulations435

11.3 USroadvehiclebrakinglegislation463

11.4 Complexelectronicvehiclecontrolsystems467

11.5 Regenerativebrakingsystems474

11.6 Automatedandautonomousvehicles478

11.7 Chaptersummary479

References 480

12.Casestudiesinthebrakingofroadvehicles483

12.1 Introduction483

12.2 Brakesystemdesignverification484

12.3 Brakingperformancevariation488

12.4 Interactionbetweenthebrakesandthevehicle497

12.5 BrakeNVH501

12.6 Mixed-modebraking:regenerativebrakingsystemdesign511

12.7 Chaptersummary519

References 521

Nomenclatureandglossaryofterms523 Index 531

Preface Aimedasanintroductorytextbookaboutthescienceandtechnologyofroadvehicle braking,thisSecondEditionofthe‘BrakingofRoadVehicles’bookhasbeenrevised, updated,andexpandedtoreflectrecenttechnologicaldevelopmentsandevolutioninthe originalsubjectmattersothatitcontinuestobeasourceofreferenceforbothnewand experiencedengineersworkingwithintheindustry.

DavidBryanthasjoinedtheFirstEditionauthorAndrewDayasco-authorofthis SecondEdition,andinitspreparation,wehaveeachdrawnuponourmanyyears’ experienceofteachingandresearchrelatingtobrakingandautomotivesystems.Oneof ourmostinfluentialsourceshasbeenourinteractionswiththemanyexpertpractitioners andhundredsofdelegatesthroughtheannual‘BrakingofRoadVehicles’shortcourse fortheindustryattheUniversityofBradfordsince1996(thecourseitselfstartedat LoughboroughUniversityin1966).Thesepeople,withtheirthirstforknowledge,have contributedtheirownexpertiseandaskedmanyquestions,givingfreelyoftheirtime.We extendourthankstoallcolleagues,companies,andorganisationswhohavesupported andhelpedustoadvanceourknowledgeoversomanyyears;wehavenamedsomeof thembelowbuttherearemanymoreun-namedtowhomwealsoowesomedebtof gratitude.

Thefieldofvehiclebrakingcontinuestobeafascinatingdisciplinewhichis constantlyevolvingandadaptingtomeetnewchallengesandrequirements,sowehave broadenedanddeepenedeachofthechapterstoreflecttheassociatedtechnologiesand developments.WhathasbecomeapparenttouswhilstwritingthisSecondEditionis theconsiderableinfluencethatregenerativebrakingisnowhavinguponallareasofroad vehiclebraking,whetheritbeadvancedcontrolsystemsandtechnologies,alternative materials,particulateemissions,orlegislativerequirements.

ThestructureofthebookremainsmuchthesameastheFirstEdition,although therehasbeensomere-orderingofchaptersandcontenttoimprovetheflow.Thefirst sixchaptersintroducethefundamentalengineeringtheory;Chapters7–11coverspecialist topics;andChapter12roundsoffwithaselectionofcasestudiesrelevanttotheindividual disciplinescoveredwithinthebook.

Chapter1(Introduction)hasbeenupdatedtoreflecthowrecentdevelopmentsin vehicledesign,inparticularpowertrains,haveinfluencedallareasofbrakingscienceand technology.

Chapter2(FrictionPairs)coversrecentdevelopmentsincludingnewandalternative materialsandthesignificanceofparticulateemissions.

Chapters3and4(BrakingSystemDesignforPassengerCarsandLightVans/Vehicle andTrailerCombinations)havebeenupdatedtoprovideadditionalclaritytothetext.

Chapter5(BrakeDesignAnalysis)includesseveralrevisedanalysesandanalternative methodofdrumbraketorquecalculationwithcomparisonstomoreclassicalmethods.

Chapter6(BrakeSystemLayoutDesign)nowincludescontentonbrakeactuation requirements,electro-mechanicalandelectro-hydraulicactuators,regenerativebraking, andmixed-modebrakeblending.

Chapter7(ElectronicandAutonomousBrakingSystems)hasbeenupdatedto includenewcontentonbrake-by-wiretechnologies,autonomousbraking,regenerative braking,andexpandedtextonthevariouselectroniccontrolstrategies.

Chapter8(ThermalEffectsinFrictionBrakes)includesadditionalcontenton numericalmodelling,andthermallocalisations,suchashotbandingandhotspotting.

Chapter9(BrakeNoise,Vibration,andHarshness)hasbeensubstantiallyupdated coveringexperimentalanalysisofbrakesqueal,judder,andcreepgroan,withadditional theoretical,experimental,andnumericalexamples.

Chapter10(BrakeTesting)hasbeenupdatedtoprovideadditionaldetail,examples, andclaritytothetextincludingrequirementsandproceduresforthemeasurementof brakeparticulateemissions.

Chapter11(BrakingLegislation)hasbeensignificantlyrewrittentoincorporaterecent changestoEUandUNlegislationwithcomparisonsdrawnwithotherlegislationinuse worldwide.

Chapter12(CaseStudiesinBraking)hasbeenextendedwiththreenewcasestudies onNVHandmixed-modebraking.

ThebookisdedicatedtotwoPeters,PeterNewcombandPeterHarding,who mentoredandguidedAndrewDaymanyyearsagothroughhisintroductiontoroad vehiclebraking.Theoriginal‘BrakingofRoadVehicles’book,co-authoredbyPeter NewcombandBobSpurrandpublishedbyChapman&Hallin1967,wastheclassic definitiveintroductorytextbookonthesubjectandprovidedgenerationsofBrake Engineerswiththefoundationsoftheirbrakingknowledge.PeterNewcombadvised AndrewthroughouthisPhDresearch,andwesubsequentlyworkedtogetherformany yearsonallaspectsofbraking,includingthe‘BrakingofRoadVehicles’shortcourse. PeterHardingwasagiftedEngineerandmanager(androck-climber)atMintexLtd., manufacturersoffrictionmaterials,whohadthemostremarkableknowledgeofbraking andfrictionmaterialsgainedfromalifetimeintheindustry.Muchoftheknowledge presentedinthisbookstartedfromthemandhasbeenassimilatedbybothofusover theinterveningyears.Althoughwecannotalwaysremembertheoriginalsources,where possiblewehaveattemptedtoreferencethem.

Ouracknowledgmentsandthanksgotothefollowingpeopleandorganisations: JohnBaggsandPeterMarshall(bothformerlyofFord),EddieCurry(formerlyof MIRA),andDaveBarton(LeedsUniversity)forsharingtheirknowledgeofpassenger carbrakingsystemdesignandbrakedesignanalysisonwhichChapters3and5arebased.

BrianShiltonandColinRoss(formerlyofWabcoandKnorr-Bremserespectively), andNeilWilliamsandPaulThomas(Meritor)forsharingtheirknowledgeofcommercial vehiclebrakingsystemdesignandbrakedesignanalysisonwhichChapters4and5are based.

JosKlapsandLudwigFein(formerlyofFord),ThomasSvensson(Ford),Mike MacDonald(formerlyofJaguarLandRover),NeilWilliams,ColinRoss,andBrian ShiltonforsharingtheirknowledgeofbrakesystemlayoutonwhichChapter6isbased.

IanMoore,ThomasSvensson(Ford),PierreGarnier(JaguarLandRover),Deaglán ÓMeachair(BrakeBetter),andColinRossforsharingtheirknowledgeofelectronic brakingsystemsonwhichChapter7isbased.

MarkoTirovic(CranfieldUniversity)forsharinghisvastknowledgeofthethermal analysisofbrakesonwhichChapter8isbased.

JohnFieldhouse(formerlyofHuddersfieldUniversity)whomentoredDavidBryant throughhisPhDresearch,forsharinghisextensiveknowledgeonbrakeNVHovermany yearsonwhichChapter9isbased.AlsotocolleaguesatBentleyMotorsandJaguarLand Roverfortheirresearchcollaborationonwhichmanyoftheresultsandanalysesare based.

NarcisMolina(ApplusIdiada),andRodMcLellanforsharingtheirknowledgeof brakeandvehicletestingonwhichChapter10isbased.

WinfriedGaupp(formerlyofTÜVNord)forsharinghisvastknowledgeofbraking legislationandespeciallyforhissubstantialhelpandadviceinwritingChapter11.

JosKlapsforsharinghiswealthofknowledgeaboutbrakingsystemsgenerally,and specificallysteeringdriftaspresentedinChapter12,andthemanydiagramsandfigures carriedoverfromthe1stEdition.

JohnReadleforhispatientandmeticulousworkreviewingandproofreadingevery aspectofthemanuscript.

JaguarLandRoverandValxforthecoverpictures.

Meritor,LinkEngineering,andArfesanfordiagrams,images,andinformationrelating totheirproducts.

Andfinally,themanyotherpeopleandorganisationsfortheknowledgeandinformationthatwehavegainedfromthemovertheyearsandusedintheFirstEditionas wellasthisSecondEdition.

AndrewDay,DavidBryant February2022

CHAPTER1 Introduction ‘Neverstartanythingyoucan’tstop’appliestomanyaspectsofmodernlifebutnowhere doesthismaximapplymoreappropriatelythantotransport.Forroadvehicles,whether intendedforpersonalorcommercialuse,itissurprisinghowperformancedatastill appearstoconcentrateonthecapabilityofthepowertraintoacceleratethevehicleand provideanattractivepower-to-weightratiotomaintainspeed,withscarcelyamention oftheabilityofthebrakingsystemtodecelerateitquicklyandsafely.

Almostsincethedawnofwheeledroadtransport,frictionbetweenarotor(attached tothewheel)andastator(attachedtothevehiclebody,chassis,oraxle)hasbeen utilisedinsomeformtoprovidecontrolledvehicleretardation.Othermethodshave historicallybeenemployed,e.g.draggingaheavyobjectontheroadbehindthevehicle, orsimplysteeringthevehicleintoaconvenientlypositionedobstacle,butthesedonot offermuchinthewayofsustainability,consistency,orreliability.Usingtransmissionmountedretardersand/orthevehicle’sinternalcombustionenginetoprovideretarding torque(enginebraking)isstandardpracticeincommercialvehiclestogeneratebraking torque,whilstaerodynamicallydesigned‘airbrakes’arefoundtobeeffectiveintakingon someofthedutyofthefrictionbrakesathighspeedsinhigh-performancecars.Butstill, theconventionalviewofvehiclebrakingsystems,eveninthetechnologicallyadvanced 21st-centuryworldofroadtransport,isthatbrakesare‘straightforward’;whatcouldbe simplerthanpushingonematerialagainstanothertocreateafrictionforcetoabsorbthe energyofmotionandslowthevehicledown?

Whenthefirsteditionofthisbookwaspublishedlessthan10yearsago,itstatedthat ‘thebrakingsystemofamodernroadvehicleisatriumphoftechnologicaladvances inthreedistinctscientificandengineeringdisciplines’.Thesewerematerialsscienceand engineering,advancedmechanicalengineering,andelectronicsandsoftwareengineering. Sincethen,therehasbeenrapiddevelopmentofafourthdiscipline,viz.,regenerative braking,wheredecelerationandkineticenergyconversionisachievedbynon-frictional means,whichhasaffectedmanyaspectsofthescienceandtechnologyofvehiclebraking asdescribedintherelevantchapters.

Materialsscienceandengineeringhavecontinuedtodelivertechnologicallyadvanced frictionpairsthatformanessentialpartofanyroadvehiclebrakingsystem.These advancedfrictionpairsprovidereliable,durable,andconsistentfrictionforcesunderthe mostarduousconditionsofmechanicalandthermalloadinginoperatingenvironments wheretemperaturesmayexceed800°C.Thematerialsusedareinmanywaysquite environmentallysustainable,e.g.thecastironforbrakediscsordrumsisarelatively

straightforwardformulationthatutilisesahighproportionofscrapiron,andmanyfriction materialsincludeintheirformulationnaturallyoccurringmaterialssuchasmineralfibres andfrictionmodifiers,togetherwithrecycledcomponentssuchasrubberintheformof tyrecrumb.

Secondly,advancedmechanicalengineeringdesignhascontinuedtoenablehighstrengthbrakingsystemcomponentstobeoptimisedtogenerateconsistentandcontrollablebrakingtorquesandforcesoverahugerangeofoperationalandenvironmental conditions.TheuseofComputer-AidedDesignandEngineeringmethodshasenabled stressconcentrationstobeidentifiedandavoided,withtheresultthatstructuralfailures ofbrakecomponentsareextremelyrareinanyaspectofmodernbrakingsystems.The modern‘foundationbrake’i.e.theconventionalfrictionbrakeunit,hasbeendesigned todissipatetheheatconvertedfromthekineticenergyofthemovingvehiclethrough theprocessoffrictiontotheenvironmentasquicklyandeffectivelyaspossible.Design advancessuchasventilatedbrakediscsandslidingcalipershaveonlybeenpossible throughtheuseofmodernmodellingandsimulationtechniquessothattheunderlying scientificprinciplescanbeappliedeffectively.

Thirdly,closeandaccuratecontrolofbrakingsystemsandcomponentsthrough electronicsandsoftwareengineeringhaspositionedbrakingfirmlyintheareaofactive vehiclesafety.Inthelate1960s,thefirstantilockbrakingsystems(ABS)demonstratedthe safetybenefitsofmaintainingdirectionalcontrolwhilebrakingunderhighdeceleration and/orlowadhesionconditions.Itquicklybecameclearthat‘intelligent’controlof thebrakingsystemhadmuchmoretooffer,rangingfromtractioncontrolwhere thebrakeonaspinningwheelcouldbeappliedtomatchthetyre/roadsliptothe availableadhesion,throughelectronicbrakingdistributiontomaximisethebraketorque dependingontheadhesionconditionsateachtyre/roadinterface,andmostrecentlyto electronicstabilitycontrol(ESC)wherejudiciousapplicationofindividualwheelbrakes accordingtocarefullydevelopedandextremelysophisticatedcontrolalgorithmscould helpmitigatetheeffectofpotentiallyhazardousmanoeuvres.Itisworthnotingthatthis requiredachangeinlegislation,inthesensethatnon-driver-initiatedbrakeapplication, or‘intervention’asitisknown,hadtobepermittedbeforesuchactivesafetycouldbe legallyincorporatedinproductionvehicles.Controlsystemsincorporatingautomatically commandedbrakingarenowcommonplaceonmodernmotorvehiclesandprovidea widerangeofsafetyimprovementsforvehiclesoperatingonthemarginsofstabilityor inabnormalconditions,andincludeforexample,rolloverstabilitycontrol,trailersway control,andtorquevectoringbybraking.

Thefourthdiscipline,regenerativebraking,requirestheconversionofkineticenergy toandfromamoreeasilystorableformofenergy,plusadevicetowhichthatenergy canbetransferred,stored,andre-used.Themostwidelyadoptedtechnologynow(2022) isbasedonelectricmotor/generatorandbatterytechnologywhichhasbenefitedfrom massivescientificandcommercialdevelopment.Largelydrivenbychangingconsumer attitudestowardstheenvironmentandglobalCO2 emissions,togetherwithgovernment

policiesandfinancialincentives,powertrains-basedsolelyoninternalcombustionengines poweredbyhydrocarbonfuelsarerapidlybeingreplacedinpartorwhollybythose incorporatingcompact,high-performance,electricmotor/generatorunits,andbattery storagesystemswithincreasinglyhighenergyandpowercapabilities.Approximately20% ofnewcarsregisteredintheUnitedKingdomin2020hadsomeformofkineticenergy recoverywithintheirpowertrainwhichdemonstratesclearlyhowregenerativebraking canbecombinedwithfrictionbrakingtocreateeffectivemixed-modebrakingsystems.

Theincreasedcomplexityandsophisticationofadvancedbrakingsystemswillrequire extensivetestingandverificationbutbyusing‘modelintheloop’,‘hardwareinthe loop’,and‘softwareintheloop’methodstoreplacethe‘traditional’rigandvehicletests (whichcanbeexpensive,time-consumingandpronetovariationduetoenvironmental effects),thisdoesnotnecessarilymeanthatdesignverificationwilltakemoretime. Legislationmustalsokeeppacewiththeserapidtechnologicaldevelopmentssuchthat anysafetyimprovementfacilitatedbythenewsystemscanbeembraced,butatthe sametimeadequatecontrolmeasuresareputinplacetopreventunintendedconsequences.Thecriticalimportanceofbrakingsystemreliabilityandmaintainabilityremains paramount.

Undernormaloperatingconditions,regenerativebrakingcanbethemainmode ofvehicleretardationforHybridElectricVehicles(HEV)andFullElectricVehicles (FEV);frictionbrakingisusedpurelytosupplementthebrakingforcerequirements insituationswherethemotor/generator,energytransfer,andenergystoragesystems cannotmeettheperformancerequirementsassociatedwithdownhilldragandemergency braking.Thisshiftinboththeperformancerequirementsandoperatingconditionsof thefrictionbrakeshasledtonewchallengesandopportunitiesfortheirdesignand implementation,whichhaveinfluencedallareasofbrakeengineering.Brakeblending togetherwiththecomplexitiesofusingbrakeforcesatindividualwheelstoinfluence thevehicledynamics(e.g.ESC)placesincreaseddemandsonthecontrolstrategies, necessitatingnewmethodsofcontrolintervention.Actuationsystemshavedeveloped toahighlevelofsophistication,withelectro-mechanicalandelectro-hydraulicbrake actuatorswhichfacilitatemixed-modeblendedbrakingwhilstmaintainingaconsistent pedalfeel.Forexample,theABS/ESCmodulatorisfullyintegratedwithinmanydesigns ofactuatorunit.Theconsequentreducedoperationaldutyofthefrictionbrakepresents opportunitiesforlightweightrotorandstatormaterialswithassociatedimprovedthermal management,whileatthesametimemaintainingthecapabilityofconsistentandstable frictionbrakingunderalloperatingconditions.Asaresult,newformulationsoffriction materialarelikelytoemerge;this,inturn,maymeanthatthenatureofissuesrelatingto brakeNoise,VibrationandHarshness(NVH)broadensandaddscomplexitytoanarea thatisstillnotfullyunderstood.Particulateemissionsfromfrictionbrakesarerecognised asanincreasingconcern,butevenwithnewfrictionpairsformixed-modebraking,the generation,chemicalcomposition,andparticlesizeofbrakeparticulateemissionswill continuetoberesearchedtoensurethatthreatstopublichealthareavoided.

Alongsidetheremarkabletechnologicaladvancesthathaveemanatedfromthesefour areasofendeavour,itshouldbenotedthatthefrictionbrakeofaroadvehicleisstilla remarkablylow-costpartoftheoverallvehicle,andthereliabilityandmaintainabilityof thebrakingsystemonanymodernroadvehicleisextremelyhigh.Despitethecomplexity andsophisticationoftheactuationsystems,andtheoftenenvironmentallychallenging conditionsunderwhichthefrictionbrakeshavetooperate,routinemaintenanceis mostlyallthatisrequired,andwhenreplacementof,e.g.thebrakepadsordiscsis required,thecorrectpartscanbeobtainedandfittedquicklyalmostanywhereinthe world.

Thebrakingsystemofanyroadvehicleissubjecttoextensivelegislativestandards andrequirementsinmanyregionsoftheworld.Inthisbook,thelegislativeframework focusesontheEuropeanUnion/UnitedNationsLegislationandRegulations13and 13-H(UNRegulation13-H,2015; UNRegulation13,2016),althoughcomparisonwith othercountries’legislationismadewhereappropriate.EUlawstatesthatallroadvehicles arerequiredtohaveaworkingbrakingsystemthatmeetsthelegislativerequirements. Includedinthebrakingsystemrequirementsare‘service’and‘secondary’brakingsystems sothatthevehiclecanbesafelybroughttorestevenintheeventofthefailureofonepart ofthesystem,anda‘parkingbrake’thatcanholdthevehiclesafelyonaspecifiedincline. InEurope,vehiclemanufacturershavetodemonstratethattheirvehiclemeetsthedesign andperformancestandardsspecifiedintheUNRegulationsthroughaprocessofType Approval.Onceavehicleissold,theresponsibilitypassestotheowneroruserofthe vehicletoensurethatthevehicle’sbrakingsystemcontinuestomeetlegalrequirements; usuallythistakestheformofaregularcompulsoryexaminationofthevehicle.Thedesign andperformancestandardsassociatedwithTypeApprovalareregardedasminimum standards,andmostvehiclemanufacturershavetheirown‘in-house’standardsthatexceed the‘legalrequirements’,oftenbyaconsiderablemargin.Forexample, UNRegulation 13-H(2015) statesthattheminimumservicebrakingperformancedefinedbythe‘Type0testwithenginedisconnected’forapassengercar(categoryM1 )isameandeceleration of6.43m/s2 foradriverpedaleffort(brakepedalforce)ofbetween6.5and50daN.Car manufacturerswouldtypicallydesignforsubstantiallymorevehicledecelerationforthis levelofpedaleffortbuthavetobearinmindtherequirementforthesecondarybraking systemtoprovideadecelerationofnotlessthan2.44m/s2 withinthesamerangeof pedaleffort.Pedaleffortisimportantbecauseofthelargerangeofphysicalcapabilityof differentdrivers.Likewise,theparkingbrakeiscoveredbyasetoflegislativerequirements andstandards,includingoperatingforcerequirement.

Fundamentaltothedesignofabrakingsystemforaroadvehicle(underUN regulations)isthatabrakeisrequiredateveryroadwheel.Theonlyexceptionislight trailers(CategoryO1 :trailerswithamaximummassnotexceeding0.75tonnes),which donotneedtobefittedwithwheelbrakes,relyinginsteaduponthebrakesofthe towingvehicle.Incommercialvehicleparlance,thebrakeunitatthewheelisknown

(A)Drumbrake;(B)discbrake.

asthefoundationbrake.Thisterm,whichisappliedexclusivelytofrictionbrakes,isused throughoutthisbooktodefinethewheelbrakeunitforallvehiclesincludingcommercial vehicles,passengercars,andtrailers.Thefunctionofthefoundationbrakeistogenerate aretardingtorquei.e.onethatopposesthedirectionofrotationofthewheeltowhich itisattached,whichisproportionaltotheactuationforceapplied.Therearetwodistinct typesofautomotivefoundationbrakeincommonusetoday,viz.,the‘drum’brakesee Fig.1.1A,wherethestatorsarebrakeshoesfittedwithfrictionmaterialliningsthatare expandedoutwardstopressagainsttheinnersurfaceofarotorintheformofabrake drum,andthe‘disc’brakesee Fig.1.1B,wherethestatorsarebrakepadsthatareclamped againsttheoutersurfacesofarotorintheformofabrakedisc.Includedinthedefinition offoundationbrakearethemountingfixturessuchasthe‘anchorplate’,(alsotermed ‘torqueplate’,‘spider’,or‘reactionframe’),whichisfirmlyboltedtotheaxleorsteering knuckle.Themechanismbywhichtheforceprovidedbytheactuationsystemisapplied tothestatorelements(padsorshoes)isalsoconsideredasbeingpartofthefoundation brake.

Thebrakeactuationsystemcomprisesthemechanical,electrical,andelectronic components,whichrecogniseandinterpretthe‘driverdemand’,typicallyfromthe movementofthebrakepedaland/ortheforceappliedbythedrivertoit,andconvertit intoforcesappliedtotheindividualfoundationbrakestogeneratetherequiredbrake torque.Atraditionalbasicbrakeactuationsystemtransmitstheforceappliedtothe brakepedalbythedriverthroughvariousmechanicalconnectionstothewheelbrake unit.Thesemechanicalconnectionshavetakentheformofcables,rodsandlinkages, hydrostatic,hydraulic,orpneumaticsystems,andfallintotwodistinctcategories,viz., thosethatrelyuponthe‘muscular’energyofthedriver,andthosethatrelyupona

Figure1.1

separateenergysourceunderthecontrolofthedrivertoprovidetheactuationforce. Theformerusuallyhasa‘servo’or‘booster’inthesystemtoprovidepowerassistance inordertoreducepedalefforts(termed‘powerbrakes’intheUnitedStates).Itstill formsthebasicsystemonlightervehiclessuchaspassengercarsandlightvans,largely becauseitcanprovidevehicleretardationevenifallothercontrolandactuationassist systemsfail.Thelattertypeofsystemisusedonheavycommercialvehiclesintheform ofpneumaticallyactuated(alsoknownasairbrake)systems.Powerhydraulicbraking systemsarealsofittedtosometypesofcommercialvehicle,sometimesintheformof combined‘airoverhydraulic’systemsbutthesearenotconsideredfurtherhere.

Thefundamentalscientificprinciplesofthedesignandanalysisofroadvehiclefriction brakesandtheirassociatedbrakeactuationsystemswereestablishedmanyyearsago. Thebasicperformanceofthebrakingsystemforanyroadvehicleisalwaysspecifiedin termsoftherequiredbrakeforceateachwheel.Thisdependsuponthevehicle’sdesign specificationsothisisalwaysthestartingpointforbrakingsystemdesign.Thedesign ofthebrake,actuationsystem,andassociatedcomponents,althoughaddressedinthis book,areusuallycompletedindetailbyspecialists,andfromthevehiclemanufacturer’s pointofview,brakingsystemdesignhastendedtobecomeaprocessofspecificationand selection.Somevehiclemanufacturershaveinthepastcontractedthebrakingsystem designoutto‘fullservicesuppliers’withthespecialistskillsandknowledgetodesign anddeliveravehiclebrakingsystemthatmeetstheirrequirements.Butincreasingly,the importanceofthebrakingsystemtotheoverallsafetyofthevehicle,theneedforclose integrationofthebrakingsystemwithothervehiclecontrolandmanagementsystems, andthesensitivityofthecustomerstobrakingsystemperformancehaveencouraged mostvehiclemanufacturerstoretainasubstantialinterestinthebrakingsystemdesign. Thishasmeantthatadetailedknowledgeofbrakesandbrakingsystemsisvaluableto thevehiclemanufactureranditisthepurposeofthisbooktoaddressthis.

Theend-userofthebrakingsystemonanyvehicleisthedriver,whoseexpectations arequitestraightforward;theyshouldbeabletoapplythebrakesinasmoothand controllablemannertogenerateanequallysmoothandcontrollablevehicledeceleration thatisconsistentthroughoutallconditionsofvehicleoperationandenvironments.In thefrictionbrake,thisrequiresremarkablestabilityinthefrictionalperformanceof thebrakefrictionpair,viz.,thefrictionmaterialandtherotor,overawiderangeof operationalandenvironmentalconditions.Mostdriversareverysensitivetochangesin thebrakingresponseofthevehicle,sobrake‘pedalfeel’isamajorattributeinasuccessful roadvehicletotheextentthatpoorbrakeresponsecanadverselyaffectvehiclesales. Addedcomplexitynowcomeswhereregenerativeandfrictionbrakingarecombined inmixed-modebraking.Thisrequireseitherpartialorfulldecouplingofthebrake pedalandactuatortofacilitateblendingofthebraketorque,andthisblendinghasto betransparenttothedriverbecauseofthesensitivitypreviouslynoted.‘Smoothand controllable’alsoincludestheNVHcharacteristicsofvehiclebrakingsystems;drivers

(togetherwithpassengersandotherroadusers)generallydonotliketheirbrakesto makeanoise,orcreateuncomfortablevibrationwhileapplied,soattentiontothenoise andvibrationaspectsofabrakeinstallationisveryimportantforthevehiclemanufacturer toavoidcustomerdissatisfaction.

Thisbookcoversthedesign,implementation,andoperationofbrakesandbraking systemsforcarsandcommercialvehicleswithassociatedtrailers,whichrepresentthe majorityofroadvehicles.Theprinciplesdescribeddoapplytoothertypesofroadvehicle, thoughforsomeothertypes(e.g.motorcycles)specificaspectsaresignificantlydifferent tothosepresentedhere.Examplesofanalysesandcalculationsareincluded,together withsomeexamplesof‘thingsthatcangowrong’andtheirlikelycauses.Itstartswitha considerationofthescienceandtechnologyoffrictionasappliedtofrictionmaterialsand vehiclefoundationbrakes;thisisbecauseanunderstandingoffrictionisstillconsidered tobefundamentallyimportantineffectiveroadvehiclebrakingsystemdesignincluding thoseincorporatingregenerativebraking.Thedeceleratingroadvehicle,includingthe specificconfigurationsoftwo-axledrigidvehiclesandmulti-axlevehicleandtrailer combinations,isthenanalysedtoestablishanunderstandingoftherequirementsofthe brakingsystemtoachievethelevelsofvehicledeceleration,stability,drivereffort,and performancethatareneededtoachievesafebrakingunderalloperationalconditions. Thedynamicdistributionofbrakeforceateachaxle(andwheel)isthenanalysedtaking accountoflongitudinalandlateralweighttransfer,andparameterssuchasadhesion utilisationandvehiclebrakingefficiencyaredefinedanddevelopedsothatsafeand legallycompliantbrakingsystemdesignsfordifferenttypesofroadvehiclesandtowing combinationscanbegenerated.Frictionintyre/roadcontactisalsoconsideredandthe importanceofthetyre/road‘grip’(adhesion)isexplainedandanalysed.

Frictionbrakedesignfocusesonautomotivediscbrakesanddrumbrakes.After developingthebasicmechanicaltheoryofthesetwotypesofbrake,theperformance characteristicsofeachareexplainedanddiscussed.Braketorquecalculation,whether forfrictionbrakesorregenerativebrakingsystems,enablestheactuationsystemtobe designedtoprovidetherequireddistributionofbrakingforcesateachaxle,andaneightstepproceduretodesignthebrakesystemlayoutisoutlined.Electronicbrakingmethods andpracticearedescribed,whichincludetheapplicationofadvancedtechnologiesin modernroadvehiclebrakingsystems,inparticularindividualbrakecontrolandwellestablishedfeaturessuchasABSandESC.Theimplementationofregenerativebraking andautonomousbrakingtechnologiesisconsideredintermsofthebasicprinciplesin theeight-stepsystemdesignprocedure.

Oneofthemostimportantoperationalchallengesinfrictionbrakedesignrelatesto frictionalenergytransformation,heattransfer,andthetemperaturesgeneratedduring braking.Thethermalanalysisofbrakesisexplained,includingthecalculationoftemperaturesreachedinthebrakecomponentsduringbraking,theeffectofvehiclespeed, load,anddeceleration,andtheimportanceofsizingthefoundationbrakestowithstand

thermalandmechanicalloads.Frictionbrake-relatedNVHisamajorconcerninall roadvehicles,rangingfrombrakesquealtobrakejudderinpassengercarsthroughto heavycommercialvehicles.Thephenomenaofbrakenoiseandjudderareintroduced, andexperimentalandtheoreticalapproachestominimisingtheirpropensityatthe designstagearedescribed.Theunderlyingtheoriesareexplainedtogetherwithpractical approachestobrakenoiseandjudderreduction.

Sincealldesignsultimatelyrequireexperimentalverification,component,systemand vehicletestingprinciples,procedures,andtechnologiesareexplainedforallpartsofthe brakingsystem.Aspectsofbrakinglegislationthatinfluencevehiclebrakingsystemdesign areexplainedanddiscussed.BecauseEuropeanandotherregions’legislationisbased onthesystemoftypeapproval,legalrequirements,designanalysis,andvalidationtest proceduresareexplained,andcomparisonsaredrawnwiththeself-certificationsystem usedintheUnitedStatesandelsewhere.Thebookendswithanextendedselectionof casestudiesthatareintendedtoillustratetheexperimentalverificationofbrakingsystem designandhowandwhytheactualperformanceofbrakesandbrakingsystemscanvary fromthedesign.

References UNRegulation13-H2015.RegulationNo13-HoftheEconomicCommissionforEuropeoftheUnited Nations(UN/ECE)-Uniformprovisionsconcerningtheapprovalofpassengercarswithregardto braking[2015/2364].OfficialJournaloftheEuropeanUnionL335,1–84.

UNRegulation13,2016.RegulationNo13oftheEconomicCommissionforEuropeoftheUnitedNations (UN/ECE)-UniformprovisionsconcerningtheapprovalofvehiclesofcategoriesM,NandOwith regardtobraking[2016/194].OfficialJournaloftheEuropeanUnionL42,1–262.

CHAPTER2 Frictionpairs 2.1Introduction

2.1.1History

Thebrakesofroadvehicleshaverelieduponfrictionforhundredsofyears.Theuseof frictionalforcesgeneratedbetweentwobodiesinslidingcontacttoprovidearetardation mechanismformovingbodiescanbetracedbackinhistoryalmosttotheoriginsof humanendeavour(Dowson,1979).Wheelbearingswerefirstnoted5000yearsago,but theuseofwheelbrakescannotbetracedbackthisfar;itisalmostcertainthatfrictional retardationwasfirstinvokedbydragging,e.g.alogbehindahorse-drawncartwhen descendingasteephill.Parkingwhileascending,toallowthehorsetorest,wouldbe achievedbya‘sprag’topreventrollingback.Amechanismthatpressedafrictionpad againstarotatingwheelwasasubsequenttechnologicaladvance,intheUnitedKingdom, probablydatingfromthe1700sonhorse-drawncarriages.Brakingdevicesofthisbasic formwerethenutilisedonrailwaycarriagesandtrucks,andthenonthefirst‘horseless carriage’roadvehiclesinEuropeinthelater1800s(NewcombandSpurr,1989) Fundamentaltotheoperationofthefrictionbrakeisthedynamicorsliding coefficientoffriction(μ)betweentherotorandthestatorcomponentsofthebrake, the‘FrictionPair’.Thesymbol μ isuniversallyusedforthecoefficientoffriction;in thisbook,itisusedspecificallytorepresentthe dynamic orslidingcoefficientoffriction whenthebodiesincontactaremovingrelativetoeachother.The static coefficientof friction,whenthebodiesincontacthavenorelativemotionbetweenthem,isrepresented hereby μs .Theirontyreonawoodencartwheelworkedwellasarotorsurfaceagainst materialssuchaswood,leather,andfelt,buttheseweresensitivetotheenvironment, e.g.mudandrain,andasvehiclespeed,size,andweightincreased,theamountof energytobedissipatedincreasedsothattheoperatingtemperaturesincreasedbeyond thelimitsofthesematerials.Recognisingtheimportanceoftemperaturestabilityof thecoefficientoffriction,resin-bondedcompositefrictionmaterialswereinventedover 100yearsagotoextendtheoperatingrangeanddurabilityofthefrictionmaterial. Modernfrictionpairscomprisingconventionalresin-bondedcompositestators(padsor linings)andcastironrotors(brakediscsordrums)havedevelopedsofarthatfewdrivers nowadaysgiveamoment’sconsiderationtothefunctionofthefrictionpairwhenthey applythebrakes.

2.1.2Frictionalcontactandslidingfriction Slidingfrictionbetweentwodrycontactingsurfacesisoftenknownas‘Coulombfriction’ afterCharlesCoulomb(1736–1806),butdespiteitseverydaynaturethefrictionforces involvedcanusuallyonlybeestimatedfrompreviousexperienceandexperimental evidence.Inbrakefrictionpairs,thefrictionsurfacesareoftencoatedwith‘transfer layers’asaresultoftheslidingprocess.Forexample,arotorfrictionsurfacemayhave superimposedonitlayersofmaterialtransferredfromthestatormaterialandviceversa. Thisisaself-healingprocessthatmitigatesdamagebyabrasion,adhesion,ordeformation duringfrictionalsliding.

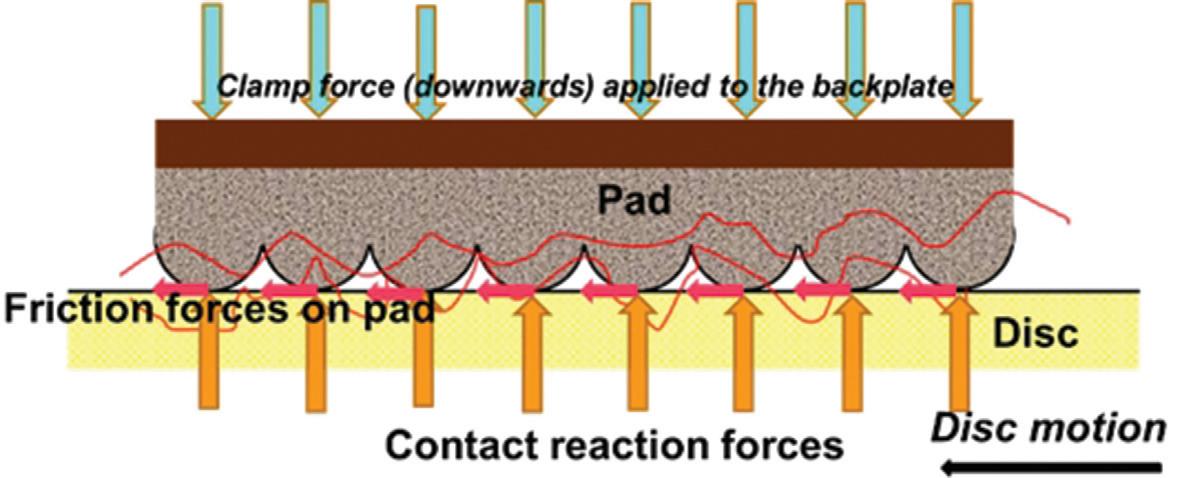

Africtionsurface,evenifitappearstobegeometricallysmooth,isroughonthe microscopicscale,withadistributionofasperitiesacrossit.Oneexplanationofthe genesisoffrictionistheinteractionofmicroscopicasperitiesbetweenthetwosurfaces, butwhentwosuchsurfacesareforcedtogetheritisverydifficulttosaywhereand howcontactbetweenthemoccurs.Modelsystemshavebeenstudiedinwhichthe materialsandsurfaceswerescientificallycontrolledintheexpectationthatoncethe frictionofsuchsystemswasunderstood,moreandmorecomplicatedsystemscouldbe examined.Althoughthescientificunderstandingoffrictionhasbenefitedfromsuch research,theextremelycomplicatednatureofbrakingfriction,involvinghighenergy, hightemperature,highspeed,andhighpressure,remainsaninexactsciencethatrelies uponspecialistknowledgeandunderstanding.Whilstfromanengineeringpointofview aconstantcoefficientoffrictionbetweentwoslidingbodiesmayseemareasonable assumption,workingwithfrictionbrakesrequiresanunderstandingthatthecoefficient offrictionislikelytovaryandofthereasonswhy.

Thebasicempiricallawsoffriction,knownasAmontons’lawsafterGuillaume Amontons(1663–1705),arestatedbelow.Coulombintroducedthefourthlawwhich statedthatthefrictionforceisindependentofslidingspeedbutwhereasAmontons’laws offrictionrepresentagoodpracticalbasisforbrakefrictionpairs,theCoulomblawdoes not,forreasonsexplainedlater.

1. Frictionforceisindependentofthenominalorapparentareaofthesurfacesinsliding contact.

2. Frictionforce F isproportionaltothenormalforce N betweentwobodiesinsliding contact,i.e.:

where μ isthecoefficientoffrictionbetweentherotorandthestator.

3. Thefrictionforcealwaysopposesthedirectionofsliding(i.e.therelativemotion).

Asimplephysicalexplanationofthefirsttwolawsrelatestothedifferencebetween the‘real’areaofcontact AR (basedonthetotalsurfaceareasofthemicroscopicasperities incontact)andthe‘apparent’(or‘nominal’)areaofcontact AN (indicatedbytheoverall sizeofthecontactinterface)atanyfrictioninterface.Therealareaofcontact AR is

Figure2.1 Idealisedmodeloffrictionalcontact.

verymuchlessthan,andindependentof,theapparentarea AN ,butisproportionalto thenormalforcebetweenthetwobodiesinslidingcontact.Asimplifiedmodelofthe contactingsurfacesbasedontheideaofcontactingasperitiesisshownin Fig.2.1;aseries ofelastichemispheresononesurfacepressingagainstanotherperfectlyflatrigidsurface.

Eachhemispherecanbeconsideredtoadheretotheflatsurfacesothatwhensliding occursashearforceisgeneratedthatisproportionaltotheareaofcontactbetweenit andtherigidsurface.Thesumofalltheareasofthehemispheresincontactwiththe rigidsurfaceequatestotherealareaofcontact:

Iftheconstant f (N/m2 )denotesthespecificfrictionforce(i.e.thetangentialfriction forceperunitrealareaofcontact),thenforanyindividualcontact‘i’:

Makingtheassumptionthattheareaofcontactbetweeneachhemisphereandthe rigidsurfaceisproportionaltothenormalforcebetweenthem:

andtherefore

Since μ = F N = fAR N therefore μ mustalsobeconstant. Thissimpletheoryassumesthatthesurfacesadheretooneanotherattherealareas ofcontactwhenpressedtogetherbyanormalforceandthatnoadhesionremains whenthenormalloadisremoved.Anyvariationin μ isattributedtovariationsin f arisingfromdifferingdegreesofcontaminationofthesurfaces.Forafullunderstanding ofthephenomenonoffriction,itwouldbenecessaryattheveryleasttobeableto determine AR and f,butthemorethisisinvestigatedthemorecomplicateditappears

andthereisnoeasywayofdoingthisforthetypesoffrictionmaterialpairsusedin modernautomotivebrakingsystems.Henceitremainsnecessarytomeasureratherthan calculatethefrictionalpropertiesofanyfrictionmaterial,althoughskilledformulators areabletoestimatefriction(andwear)behaviourbasedontheirknowledge,expertise, andexperience.

‘Tribology’isthegenericnameforthescienceoffriction,lubrication,andwear. Brakingfrictionmostlyconstitutes‘dry’frictioninwhichtherearethreemainmechanismsthatmaybeconsideredtocontributetothegenerationoffrictionandwearina brakefrictionpair(Spurr,1976):

1. Adhesion.Componentsofthefrictionmaterialadheretoasperitiesonthemating surface,andthefrictionforceisgeneratedbytheactionofshearingthosejunctions.

2. Abrasion.Componentsofthefrictionmaterialabradethematingsurface,physically removingpartsofanytransferfilmandthematingsurfacematerial.Theavoidance ofexcessivewearofthematingsurfacecanbeachievedbycarefullybalancingthose constituentsofthefrictionmaterialthatcontributetotransferfilmgeneration.

3. Deformation.Thefrictionmaterialisdeformedbytheactionofinterfacialshearing. Thehighhysteresisofthefrictionmaterialcausestheworkofdeformationtoappear asheat,whichisthendissipatedbyconductionbackintothefrictionmaterialand transferacrossthefrictioninterfaceintothematingbody.Theproportionofheatthat flowseachwayinfluencesheatenergytransferfromthebrakefrictioninterface. Thereareotherprocessesandmechanismsthatcontributetothetribologicalbehaviourofparticularbrakefrictionpairs,butthesethreemechanismsaresufficientfora practicalunderstandingofbrakefrictionscience.

2.2Thefrictionpair 2.2.1Rotorandstator

Amodernautomotivebrakefrictionpaircomprisesastatoroffrictionmaterialmounted onamechanicallystronganddurablebackplate(discbrake)orshoe(drumbrake)that rubsagainstarotorthatrotateswiththewheeltowhichitisattached.Therearemany differenttypesoffrictionpairsinusetoday.Someofthesearerelativelyhumble(castiron brakeshoesarestillusedonrailwaystock,matingonthetreadsofsteelwheels)while othersareexotic,suchascarbonfibrecomposites(carbon–carbon(C–C))onaircraft andFormula1racingcars,orcarbon–ceramic(C–SiC)asusedonhigh-performance roadcars.Sinteredmetalfrictionmaterialsareusedinsomeindustrialapplicationsand inhigh-duty,high-performanceapplications,suchasrallycarsandmotorcycles,while cork-orpaper-basedfrictionmaterialsarestillusedinlow-dutyapplications,usuallyoilimmersed,typicallyinautomatictransmissionsandclutches.However,themostwidely usedbrakefrictionpairisstillaresin-bondedcompositefrictionmaterialstatoroperating againstacastironrotor.

Table2.1 Typicalelements(additionaltoIron)inbrakedisccastironcompositions,after G.A.Ross (2019).

Element

Carbon 3.2–3.9

Silicon 1.4–1.9

Manganese >0.4

Phosphorus <0.08

Sulphur <0.08

Chrome 0.2–0.4

Molybdenum <0.05

Nickel <0.1

Copper 0.03–0.3

Tin <0.01

Titanium ∼0.02

Vanadium ∼0.01

Primarysourceofgraphite

Graphitisingagent

Addedtocounteractsulphur

Frompigironorscrapiron

Preventstheformationofgraphite

Promotespearliticstructure,increases strengthandhardness

Traceelement,promotespearlite

Controlspearliticstructure

Increasesstrengthandhardnessby promotingpearliticstructure

Promotespearliticstructure

Promotesundercooledgraphite

Increaseshardness,reduceswear

Grey(flakegraphite)castironhasbeenusedforbrakediscsanddrumsforover 100years.Itiswell-established,hasadequatestrengthforbrakingpurposes,stable mechanicalproperties,goodmachinability,andisreadilyavailableatalowcost.It ismechanicallyandthermallydurabledespiteitslowductilityandYoung’smodulus (comparedwithsteel)andhasgoodtribologicalcompatibilityincludingwearresistance withmanytypesoffrictionmaterial.Ithasverygoodheattransferproperties,especially thermalconductivityandspecificheat,withahighmaximumoperatingtemperature (MOT)seeChapters6and8.Itsrelativelyhighhystereticdampingpropertiesarevaluable inbrakenoise,vibration,andharshness(NVH)suppression,seeChapter9.Thegraphite flakesthatarecharacteristicofgreycastironmicrostructureareformedduringtheslow solidificationofthematerialfromitsmoltenstate.‘SpheroidalGraphite’(SG)castiron,in whichthegraphitetakesasphericalform,hashigherductilitybutreducedheattransfer properties,while‘CompactedGraphite’(CG)castironhasmicrostructureandproperties somewherebetweengreyandSGcastirons.SGandCGaremostlyusedforrotorsonly whenductilityisimportant,e.g.forgreatercrackandfatigueresistancethangreycast iron.Adescriptionofthetypicalelements(additionaltoiron)inbrakedisccastiron compositionsisshownin Table2.1.RefertoChapter8fordesignanalysisandmaterial propertiesrelatingtocastironrotors.

Thetypeofcastironusedforthebrakerotor,itsprecisemetallurgicalcomposition, microstructure,andmanufacturingprocesses,mustbecarefullycontrolled.Forexample, small(trace)amountsofelementssuchastitaniumandvanadiumhavebeenfoundto drasticallyaffectthefrictionandwearperformanceofcertaintypesofresin-bonded compositefrictionmaterials,whilemuchlargeramountsoftitaniuminacastironnot onlyaffectthefrictionandwearperformancebutalsocanrenderitalmostunmachineable