Bioreactors:SustainableDesignandIndustrial ApplicationsinMitigationofGhgEmissions1st EditionLakhveerSingh(Editor)

https://ebookmass.com/product/bioreactors-sustainabledesign-and-industrial-applications-in-mitigation-of-ghgemissions-1st-edition-lakhveer-singh-editor/

Instant digital products (PDF, ePub, MOBI) ready for you

Download now and discover formats that fit your needs...

Applications in Design and Simulation of Sustainable Chemical Processes 1st Edition

Dimian A.

https://ebookmass.com/product/applications-in-design-and-simulationof-sustainable-chemical-processes-1st-edition-dimian-a/

ebookmass.com

Innovation in Nano-polysaccharides for Eco-sustainability: From Science to Industrial Applications Preeti Singh

https://ebookmass.com/product/innovation-in-nano-polysaccharides-foreco-sustainability-from-science-to-industrial-applications-preetisingh/

ebookmass.com

Industrial Applications of Nanocrystals Shadpour Mallakpour

https://ebookmass.com/product/industrial-applications-of-nanocrystalsshadpour-mallakpour/

ebookmass.com

Delmar's Standard Textbook of Electricity, 7th Edition

Herman

https://ebookmass.com/product/delmars-standard-textbook-ofelectricity-7th-edition-herman/

ebookmass.com

Hacking Digital: Best Practices to Implement and Accelerate Your Business Transformation Michael Wade

https://ebookmass.com/product/hacking-digital-best-practices-toimplement-and-accelerate-your-business-transformation-michael-wade/

ebookmass.com

Blueberry Truffle Murder (Maple Hills Mystery 3) Wendy Meadows

https://ebookmass.com/product/blueberry-truffle-murder-maple-hillsmystery-3-wendy-meadows/

ebookmass.com

Physics Fifth Edition Robert Coleman Richardson

https://ebookmass.com/product/physics-fifth-edition-robert-colemanrichardson/

ebookmass.com

Precálculo: matemáticas para el cálculo 7th Edition James Stewart

https://ebookmass.com/product/precalculo-matematicas-para-elcalculo-7th-edition-james-stewart/

ebookmass.com

Sociologies of New Zealand 1st ed. Edition Charles Crothers

https://ebookmass.com/product/sociologies-of-new-zealand-1st-ededition-charles-crothers/

ebookmass.com

Applications and Metrology at Nanometer Scale 2: Measurement Systems, Quantum Engineering and RBDO Method, Volume

10 Pierre Richard Dahoo https://ebookmass.com/product/applications-and-metrology-at-nanometerscale-2-measurement-systems-quantum-engineering-and-rbdo-methodvolume-10-pierre-richard-dahoo/

ebookmass.com

Bioreactors Editedby

LAKHVEERSINGH DepartmentofEnvironmentalScience,SRMUniversity, Amaravati,India

ABUYOUSUF DepartmentofChemicalEngineeringandPolymer Science,ShahjalalUniversityofScienceandTechnology, Sylhet,Bangladesh

DURGAMADHABMAHAPATRA TERI-DeakinNanoBiotechnologyCentre,TheEnergy andResourcesInstitute,Gurugram,India DepartmentofBiologicalandEcologicalEngineering, OregonStateUniversity,Corvallis,OR,UnitedStates

Elsevier

Radarweg29,POBox211,1000AEAmsterdam,Netherlands TheBoulevard,LangfordLane,Kidlington,OxfordOX51GB,UnitedKingdom 50HampshireStreet,5thFloor,Cambridge,MA02139,UnitedStates

Copyright©2020ElsevierInc.Allrightsreserved.

Nopartofthispublicationmaybereproducedortransmittedinanyformorbyanymeans,electronicor mechanical,includingphotocopying,recording,oranyinformationstorageandretrievalsystem,without permissioninwritingfromthepublisher.Detailsonhowtoseekpermission,furtherinformationabout thePublisher’spermissionspoliciesandourarrangementswithorganizationssuchastheCopyright ClearanceCenterandtheCopyrightLicensingAgency,canbefoundatourwebsite:. www.elsevier.com/ permissions.

ThisbookandtheindividualcontributionscontainedinitareprotectedundercopyrightbythePublisher (otherthanasmaybenotedherein).

Notices

Knowledgeandbestpracticeinthisfieldareconstantlychanging.Asnewresearchandexperience broadenourunderstanding,changesinresearchmethods,professionalpractices,ormedicaltreatment maybecomenecessary.

Practitionersandresearchersmustalwaysrelyontheirownexperienceandknowledgeinevaluatingand usinganyinformation,methods,compounds,orexperimentsdescribedherein.Inusingsuchinformation ormethodstheyshouldbemindfuloftheirownsafetyandthesafetyofothers,includingpartiesfor whomtheyhaveaprofessionalresponsibility.

Tothefullestextentofthelaw,neitherthePublishernortheauthors,contributors,oreditors,assumeany liabilityforanyinjuryand/ordamagetopersonsorpropertyasamatterofproductsliability,negligence orotherwise,orfromanyuseoroperationofanymethods,products,instructions,orideascontainedin thematerialherein.

BritishLibraryCataloguing-in-PublicationData

AcataloguerecordforthisbookisavailablefromtheBritishLibrary

LibraryofCongressCataloging-in-PublicationData

AcatalogrecordforthisbookisavailablefromtheLibraryofCongress

ISBN:978-0-12-821264-6

ForInformationonallElsevierpublications visitourwebsiteat https://www.elsevier.com/books-and-journals

Publisher: BrianRomer

AcquisitionsEditor: PeterAdamson

EditorialProjectManager: AkehAndrae

ProductionProjectManager: KameshRamajogi

CoverDesigner: GregHarris

TypesetbyMPSLimited,Chennai,India

1.MicroalgaebiofuelbioreactorsformitigationofindustrialCO2 emissions1

CoreyA.LaamanenandJohnA.Scott

1.1 Introduction1

1.2 Microalgae2

1.3 Microalgaegrowthparameters3

1.4 MicroalgaecultivationsystemsforCO2 capture8

1.5 Conclusion13 References14

2.Microbiologyandbiochemistryofanaerobicdigesters:an overview17

SpyridonAchinas,VasileiosAchinasandGerritJanWillemEuverink

2.1 Introduction17

2.2 Anaerobicdigestionsteps18

2.3 Challengesinanaerobicdigestersoperation19

2.4 Microbialecology20

2.5 Microbiologicaldynamics22

2.6 Conclusion23 References24

3.Processintensificationfortheproductionofcanola-basedmethyl esterviaultrasonicbatchreactor:optimizationandkineticstudy27 AwaisBokhari,SuzanaYusup,SairaAsif,LaiFattChuahand LeowZiYanMichelle

3.1 Introduction27

3.2 Feedstocksforbiodieselproduction31

3.3 Currentresearch33

3.4 Materialsandmethodology34

3.5 Resultsanddiscussion34

3.6 Conclusion40 Acknowledgments40 References40 v

4.Conversionofrubberseedoiltobiodieselusingcontinuous ultrasonicreactor43 HuongTrinhandSuzanaYusup

4.1 Introduction43

4.2 Rubberseedoilasfeedstock43

4.3 Ultrasonicmethodinbiodieselproduction44

4.4 Materialandmethodology46

4.5 Resultsanddiscussion49

4.6 Conclusion51 Acknowledgment52 References53

5.Conversionofbiomassintobiofuel:acutting-edgetechnology55 Md.SaifulAlamandMd.SifatTanveer

5.1 Introduction55

5.2 Classificationofbiofuels57

5.3 Barriersofbiofuels71

5.4 Conclusion71 References72

6.Dryfermentersforbiogasproduction75

AbuYousuf,AhasanulKarim,M.AmirulIslam,ShefaUlKarim, Md.MaksudurRahmanKhanandCheKuMohammadFaizal

6.1 Introduction75

6.2 Differentkindsofdryfermentersforbiogasproduction77

6.3 Conclusion85 Acknowledgment85 References85

7.Biogasproductionfromwaste:technicaloverview,progress, andchallenges89 PoojaGhosh,GoldyShah,ShivaliSahota,LakhveerSinghand VirendraKumarVijay

7.1 Introduction89

7.2 Currentstatusofbiogasproduction90

7.3 Availablewastesforbiogasproduction91

7.4 Technologicaladvancementsinbiogasproduction94

7.5 Challengesassociatedwithbiogastechnologydissemination99

7.6 Conclusion100 Acknowledgment100 References100

8.Lifecycleassessmentofwaste-to-bioenergyprocesses:areview105 PoojaGhosh,SubhanjanSengupta,LakhveerSinghandArunadityaSahay

8.1 Introduction105

8.2 Globalwastegenerationscenario106

8.3 Needforwaste-derivedbioenergy107

8.4 Differenttechnologiesforconvertingwaste-to-energy108

8.5 Lifecycleassessmentforwaste-derivedbioenergysystems110

8.6 Keychallengesinlifecycleassessmentstudiesandfuture recommendations117

8.7 Conclusion119

8.8 Acknowledgment119 References119

9.Bioethanolproductionfromlignocellulosicbiomass (waterhyacinth):abiofuelalternative123 SanthanaKrishnan,MohamadFaizalAhmad,NurAzmiraZainuddin, Mohd.FadhilMd.Din,ShahabaldinRezania,ShreeshivadasanChelliapan, ShazwinMatTaib,MohdNasrullahandZularisamAbdulWahid

9.1 Introduction123

9.2 Studybackground124

9.3 Methodology128

9.4 Resultsanddiscussion132

9.5 Conclusion140 Acknowledgments141 References141

10.Workingprincipleoftypicalbioreactors145 P.Jaibiba,S.NagaVigneshandS.Hariharan

10.1 Introduction145

10.2 Aerobicandanaerobicbioreactors146

10.3 Plugflowbioreactor148

10.4 Upflowanaerobicsludgeblanketbioreactor150

10.5 Photobioreactor153

10.6 Reversemembranebioreactor157

10.7 Immersedmembranebioreactor158

10.8 Fluidizedbedbioreactor161

10.9 Packedbedbioreactor162

10.10 Activatedsludgebioreactor163

10.11 Membranebioreactor165

10.12 Immobilizedcellbioreactor167

10.13 Futureperspective169

10.14 Conclusion170 Acknowledgment170 References171

11.Anaerobictreatmentofmunicipalsolidwastelandfill leachate175

ShreeshivadasanChelliapan,NithiyaArumugam,Mohd.FadhilMd.Din, HesamKamyabandShirinShafieiEbrahimi

11.1 Introduction175

11.2 Municipalsolidwastemanagement176

11.3 Landfill176

11.4 Overviewonlandfillprocessing178

11.5 Landfillleachate179

11.6 Leachatecharacterization179

11.7 Treatmentoflandfillleachate181

11.8 Anaerobictreatmentofleachate182

11.9 Conclusion190 Acknowledgments190 References190

12.Advancementsinhydrothermalliquefactionreactors:overview andprospects195

S.N.Sahu,N.K.Sahoo,S.N.NaikandD.M.Mahapatra

12.1 Introduction195

12.2 Backgroundonhydrothermalliquefaction196

12.3 Hydrothermalliquefactionbiomassfeedstocks200

12.4 Conclusion208 References209

13.Anoverviewofalgalphotobioreactorsforresourcerecovery fromwaste215

SurjithRamasamy,S.ArunandKannanPakshirajan

13.1 Introduction215

13.2 Photobioreactorsusedforalgalcultivation217

13.3 Controlsystemsandtheirstrategiesinphotobioreactors227

13.4 Speciestransportmodelsforbubblemovement230

13.5 Lightintensityanddistributioninphotobioreactors233

13.6 Kineticsofmixinginairliftandbubblereactors242

13.7 Conclusion244 References244

14.Anoverviewofbioreactorconfigurationsandoperational strategiesfordarkfermentativebiohydrogenproduction249 ArindamSinharoy,ManojKumarandKannanPakshirajan

14.1 Introduction249

14.2 Bioreactorsforhydrogenfermentation252

14.3 Conclusion283

References283

15.Bioreactorforalgaecultivationandbiodieselproduction289 RashmiChandra,GarimaVishal,CarlosEduardoGámezSánchezand JanetAlejandraGutiérrezUribe

15.1 Introduction289

15.2 Algalproductandchemistryofbiosynthesis290

15.3 Cultivationbioreactorssystems291

15.4 Methodsformicroalgaebiodieselextraction295

15.5 Osmoticpressure302

15.6 Pulsedelectricfieldtechnologies302

15.7 Photobioreactorinpresentscenarios302

15.8 Conclusion303

Acknowledgments304 References304

309

Listofcontributors SpyridonAchinas

FacultyofScienceandEngineering,UniversityofGroningen,Groningen,The Netherlands

VasileiosAchinas

InstituteforLifeScienceandTechnology,HanzeUniversityofAppliedSciences, Groningen,TheNetherlands

MohamadFaizalAhmad

CentreforEnvironmentalSustainabilityandWaterSecurity(IPASA),ResearchInstitute ofSustainableEnvironment(RISE),SchoolofCivilEngineering,FacultyofEngineering, UniversitiTeknologiMalaysia(UTM),Skudai,Johor,Malaysia;SchoolofCivil Engineering,FacultyofEngineering,UniversitiTeknologiMalaysia,Skudai,Malaysia

Md.SaifulAlam

DepartmentofPetroleum&MiningEngineering,ShahjalalUniversityofScienceand Technology,Sylhet,Bangladesh

NithiyaArumugam

DepartmentofEngineering&Technology,RazakFacultyofTechnologyand Informatics,UniversitiTeknologiMalaysia,KualaLumpur,Malaysia

S.Arun

DepartmentofBiosciencesandBioengineering,IndianInstituteofTechnologyGuwahati, Guwahati,India

SairaAsif

DepartmentofBotany,PMASAridAgricultureUniversity,Rawalpindi,Pakistan

AwaisBokhari

DepartmentofChemicalEngineering,BiomassProcessingCluster,HICOE-Centrefor BiofuelandBiochemicalResearch,InstituteofSelf-SustainableBuilding,Universiti TeknologiPETRONAS,SeriIskandar,Perak,Malaysia;ChemicalEngineering Department,BiomassConversionResearchCenter(BCRC),COMSATSUniversity Islamabad(CUI),Lahore,Pakistan

RashmiChandra

TecnologicodeMonterrey,SchoolofEngineeringandScience,Toluca,Mexico

ShreeshivadasanChelliapan

DepartmentofEngineering&Technology,RazakFacultyofTechnologyand Informatics,UniversitiTeknologiMalaysia,KualaLumpur,Malaysia

LaiFattChuah

MalaysiaMarineDepartmentNorthernRegion,Gelugor,Penang,Malaysia

Mohd.FadhilMd.Din

CentreforEnvironmentalSustainabilityandWaterSecurity(IPASA),ResearchInstitute ofSustainableEnvironment(RISE),SchoolofCivilEngineering,FacultyofEngineering, UniversitiTeknologiMalaysia(UTM),Skudai,Johor,Malaysia;SchoolofCivil Engineering,FacultyofEngineering,UniversitiTeknologiMalaysia,Skudai,Malaysia

ShirinShafieiEbrahimi

SchoolofEducation,UniversitiTeknologiMalaysia,JohorBahru,Malaysia

GerritJanWillemEuverink

FacultyofScienceandEngineering,UniversityofGroningen,Groningen,The Netherlands

CheKuMohammadFaizal

FacultyofEngineeringTechnology,UniversitiMalaysiaPahang,Pahang,Malaysia

PoojaGhosh

CentreforRuralDevelopmentandTechnology,IndianInstituteofTechnology,New Delhi,India

S.Hariharan

DepartmentofBiotechnology,SriVenkateswaraCollegeofEngineering,Sriperumbudur, India

M.AmirulIslam

FacultyofChemicalandNaturalResourceEngineering,UniversitiMalaysiaPahang, Pahang,Malaysia

P.Jaibiba

DepartmentofBiotechnology,SriVenkateswaraCollegeofEngineering,Sriperumbudur, India

HesamKamyab

DepartmentofEngineering&Technology,RazakFacultyofTechnologyand Informatics,UniversitiTeknologiMalaysia,KualaLumpur,Malaysia

AhasanulKarim

FacultyofEngineeringTechnology,UniversitiMalaysiaPahang,Pahang,Malaysia

ShefaUlKarim

DepartmentofGeologicalSciences,ChiangMaiUniversity,ChiangMai,Thailand

Md.MaksudurRahmanKhan

FacultyofChemicalandNaturalResourceEngineering,UniversitiMalaysiaPahang, Pahang,Malaysia

SanthanaKrishnan

CentreforEnvironmentalSustainabilityandWaterSecurity(IPASA),ResearchInstitute ofSustainableEnvironment(RISE),SchoolofCivilEngineering,FacultyofEngineering, UniversitiTeknologiMalaysia(UTM),Skudai,Johor,Malaysia;SchoolofCivil Engineering,FacultyofEngineering,UniversitiTeknologiMalaysia,Skudai,Malaysia

ManojKumar

DepartmentofBiosciencesandBioengineering,IndianInstituteofTechnologyGuwahati, Guwahati,India

CoreyA.Laamanen

BhartiSchoolofEngineering,LaurentianUniversity,Sudbury,ON,Canada

D.M.Mahapatra

Biological&EcologicalEngineering,OregonStateUniversity,Corvallis,OR,United States

LeowZiYanMichelle

DepartmentofChemicalEngineering,BiomassProcessingCluster,HICOE-Centrefor BiofuelandBiochemicalResearch,InstituteofSelf-SustainableBuilding,Universiti TeknologiPETRONAS,SeriIskandar,Perak,Malaysia

S.NagaVignesh

DepartmentofBiotechnology,SriVenkateswaraCollegeofEngineering,Sriperumbudur, India

S.N.Naik

CentreforRuralDevelopmentandTechnology,IndianInstituteofTechnologyDelhi, NewDelhi,India

MohdNasrullah

FacultyofCivilEngineeringTechnology,UniversitiMalaysiaPahang,Kuantan,Malaysia

KannanPakshirajan

DepartmentofBiosciencesandBioengineering,IndianInstituteofTechnologyGuwahati, Guwahati,India

SurjithRamasamy

DepartmentofBiosciencesandBioengineering,IndianInstituteofTechnologyGuwahati, Guwahati,India

ShahabaldinRezania

CentreforEnvironmentalSustainabilityandWaterSecurity(IPASA),ResearchInstitute ofSustainableEnvironment(RISE),SchoolofCivilEngineering,FacultyofEngineering, UniversitiTeknologiMalaysia(UTM),Skudai,Johor,Malaysia;SchoolofCivil Engineering,FacultyofEngineering,UniversitiTeknologiMalaysia,Skudai,Malaysia

ArunadityaSahay

BirlaInstituteofManagementTechnology,GreaterNoida,India

N.K.Sahoo

CentreforRuralDevelopmentandTechnology,IndianInstituteofTechnologyDelhi, NewDelhi,India

ShivaliSahota

CentreforRuralDevelopmentandTechnology,IndianInstituteofTechnology,New Delhi,India

S.N.Sahu

CentreforRuralDevelopmentandTechnology,IndianInstituteofTechnologyDelhi, NewDelhi,India

CarlosEduardoGámezSánchez

TecnologicodeMonterrey,SchoolofEngineeringandScience,Toluca,Mexico

JohnA.Scott

BhartiSchoolofEngineering,LaurentianUniversity,Sudbury,ON,Canada

SubhanjanSengupta

BirlaInstituteofManagementTechnology,GreaterNoida,India

GoldyShah

CentreforRuralDevelopmentandTechnology,IndianInstituteofTechnology,New Delhi,India

LakhveerSingh

FacultyofCivilandEnvironmentalEngineering,UniversityMalaysiaPahang,Kuantan, Malaysia

ArindamSinharoy

DepartmentofBiosciencesandBioengineering,IndianInstituteofTechnologyGuwahati, Guwahati,India

ShazwinMatTaib

CenterforCoastalandOceanEngineering,ResearchInstituteforSustainable Environment,UniversitiTeknologiMalaysia,KualaLumpur,Malaysia

Md.SifatTanveer

DepartmentofPetroleum&MiningEngineering,ShahjalalUniversityofScienceand Technology,Sylhet,Bangladesh

HuongTrinh

ChemicalEngineeringDepartment,UniversitiTeknologiPETRONAS,Ipoh,Malaysia

JanetAlejandraGutiérrezUribe

TecnologicodeMonterrey,SchoolofEngineeringandScience,Puebla,Mexico

VirendraKumarVijay

CentreforRuralDevelopmentandTechnology,IndianInstituteofTechnology,New Delhi,India

GarimaVishal

DepartmentofChemicalEngineering,IndianInstituteofTechnology,NewDelhi,India

ZularisamAbdulWahid

FacultyofCivilEngineeringTechnology,UniversitiMalaysiaPahang,Kuantan,Malaysia

AbuYousuf

DepartmentofChemicalEngineeringandPolymerScience,ShahjalalUniversityof ScienceandTechnology,Sylhet,Bangladesh

SuzanaYusup

ChemicalEngineeringDepartment,UniversitiTeknologiPETRONAS,Ipoh,Malaysia; DepartmentofChemicalEngineering,BiomassProcessingCluster,HICOE-Centrefor BiofuelandBiochemicalResearch,InstituteofSelf-SustainableBuilding,Universiti TeknologiPETRONAS,SeriIskandar,Perak,Malaysia

NurAzmiraZainuddin

CentreforEnvironmentalSustainabilityandWaterSecurity(IPASA),ResearchInstitute ofSustainableEnvironment(RISE),SchoolofCivilEngineering,FacultyofEngineering, UniversitiTeknologiMalaysia(UTM),Skudai,Johor,Malaysia;SchoolofCivil Engineering,FacultyofEngineering,UniversitiTeknologiMalaysia,Skudai,Malaysia

CHAPTER1 Microalgaebiofuelbioreactors formitigationofindustrialCO2 emissions CoreyA.LaamanenandJohnA.Scott BhartiSchoolofEngineering,LaurentianUniversity,Sudbury,ON,Canada

1.1Introduction Therelianceonfossilfuelscontinuestobeanunsustainableoptiondueto thedepletionofreservesandtheproductionofgreenhousegases,inparticularcarbondioxide(CO2),releasedbytheircombustion.Thishasled toasignificantinterestinrenewable,sustainableenergysources,oneof whichisbiofuels.

Biofuelsourceshavebeenextensivelyresearchedforthepastseveral decades,andtheirproductioncanbedividedintothreegenerations, namelyfoodcrops,energycrops,andmicroalgae [1].Thefirstgeneration isbasedonfoodcropssuchascornbeingdivertedintoenergy.Inlightof thefoodversusfueldebate,thesecondgenerationtransitionedintothe growthofdedicatedenergycropssuchas Jatropha.Whilethismarkeda stepchangeinarealenergyproduction(from172L/haforcornto 1892L/ha) [2],arablelandwasstillrequiredtogrownonfoodcrops.To moveawayfromarablelandrequirements,aquaculturerepresentsthe thirdgenerationofbiofuels.Thisincludesthecultivationofphototrophic microalgae,whichuseCO2 astheircarbonsource.Usingmicroalgaeto producebiodieselrepresentsanotherorderofmagnitudeincreaseinareal energyproduction(58,700L/haformicroalgaeat30%oilbyweight) [2].

Fortheproductionofbiodiesel,microalgaecellsareselectedthataccumulatebetween15%and85%lipidcontent.Theselipids(triglycerides) canbedirectlyconvertedintofattyacidmethylesters(biodiesel)through atransesterificationreaction.Thetriglyceridesarereactedwithmethanol inthepresenceofacatalyst(typicallysulfuricacid)toproduceglycerol andbiodiesel.Transesterificationcanbeshownas:

CH2–OCOR1

CH–OCOR2

CH2–OCOR3

Triglyceride (Lipids) 3HOCH3

R1–COOCH3

R2–COOCH3

R3–COOCH3

Methylesters (Biodiesel) + +

ð1:1Þ

Phototrophicmicroalgae,inadditiontonotrequiringarableland, growfasterandareabletocapturemoreCO2 perunitareathanterrestrial plants [3].ThecaptureofanthropogenicCO2 canbefurtherenhancedby passingthroughaqueousmediumindustrialoff-gasesthathaveanelevated CO2 content.Thatis,industrialCO2 canbemitigatedbymicroalgae usingitastheircarbonsource [4].Asithasbeenshown,microalgalbiomassisapproximately50%carbon [3],whichtranslatesto:

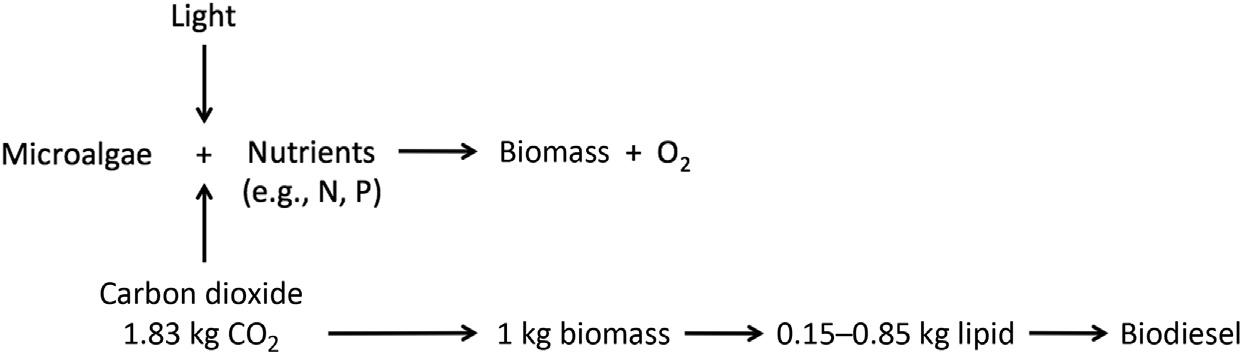

Thatis,foreverygram(dryweight)ofmicroalgae,1.83gofCO2 is takenup.Theconceptofcarboncaptureusingmicroalgaeandsubsequent biofuel(biodiesel)productionisshownin Fig.1.1.

1.2Microalgae Microalgaecanbebiologicallyclassifiedassingle-celledplantsthataccumulatedifferentproductsasaresponsetotheirenvironmentalconditions, whichiscentraltobiodieselproduction.Throughthecontroloftheprocessparametersandtheselectionofmicroalgaestrains,theoutcomecan beaimedtowardtheproductionoflipids,whicharecellularenergystoragecompounds [5].Microalgalcellscanaccumulatelipidstoupto85% oftotalcelldryweight [6]

Figure1.1 Carbondioxide(CO2)captureandbiofuelproductionusingmicroalgae.

Tobeabletobestutilizedifferentmetabolicpathwaysatwo-stage cultivationstrategyisoftenutilized,thephotosyntheticproductionofbiomassandtheaccumulationoflipids.Inthefirststage,idealgrowthconditionsareprovidedtoallowfortheproductionofmicroalgalbiomass.For anymicroalgalstrain,theseidealconditionswillberelatedtopH,temperature,andCO2 andnutrientlevels.Asecondstagewillthenbeusedto applystressbychangingoneormoreoftheseconditions,therebytriggeringtheaccumulationoflipids [5].

Anotherbenefitofmicroalgaecultivationfortheproductionofbiofuelsisthatthebiomassremainingafterlipidextractioncanalsobeofsignificantvalue.Thisbiomasshasbeenexaminedforhumandietary benefits,aproteinsourceforfishfarmsorlivestock,cosmetics,fertilizers, pharmaceuticals,andnutraceuticals [7 11].Whilebiofuelisarelatively low-valuebulkproduct,additionalhighvaluecoproductscanprovidethe economicbenefittomaketheentireoperationprofitable.

1.3Microalgaegrowthparameters Microalgaegrowthdependsonanumberofdifferentparametersforthe operationincludingtheavailabilityofnutrients(inparticularthemacronutrientsnitrogenandphosphorus),theconcentrationofdissolvedCO2, pH,lightintensityandphotoperiod,andtemperature.Thetypicalranges foroperationsare15°C 30°C,apHvaluebetween4and11,andlight intensitiesof1000 10,000lux [12].Thesecanbemodifiedtopromote biomassproduction,ortomoveawayfromidealgrowthconditionsin ordertotriggerotherpathwaysthatleadtotheaccumulationoflipidsfor biodieselproduction [13].

1.3.1Light Microalgaeuselightastheirsourceofenergy,andboththeintensityand duration(photoperiod)mustbeoptimized.Iftheintensityisabovethe saturationlimit(around6500lux) [14],thenphotoinhibitioncanoccur, whichreducestheefficiencyofthesystem [15].Wahidinetal. [14] found thatfora Nannochloropsis sp.,boththelightintensityandphotoperiod neededtobeoptimized,ratherthanmaximized,toachievethebest growthrate.

Microalgaecanonlyutilizewavelengthsbetween400and700nm, whichaccountsforabout50%ofsunlight.Thislimitstheirpotentialphotosyntheticefficiency,whichisfurtherreducedthroughreflectionand

cellularrespiration [15].Onacellularbasis,themaximumphotoconversionefficiencythatlightisusedforphotosynthesisandbiomassproduction isapproximately9% [16].Thisrepresents,however,asignificantincrease comparedtoterrestrialplants,whichhavemaximumsinthe4.6% 6.0% range [16]

Lightdelivery,intensity,spectra,photoperiods,thefrequencyoflight/ darkcycles,andtheamountoflightexposedsurfaceareahaveallbeen reportedtohaveasignificantimpactonmicroalgalbiomassformation. Lightcharacteristicshavealsobeenshowntoinfluencethelipidcontent ofmicroalgalcells,aswellastheproductionofcarbohydrates,proteins, andothercellularcomponents [17].

Toprovidelight,itisidealtoutilizeonlysunlight,asthisreducesthe capital,maintenance,andenergycostsassociatedwithartificiallightingsystems.This,however,limitsthedepthorlengthofthelightpathforsystems, duetomicroalgalself-shadingasbiomassconcentrationsincrease [18,19].

Withrespecttoartificiallighting,assumingacultureislitovera 3-weekcyclefor18haday [14],thenforevery100Woflightsupplied andwitha100%efficientlightbulb,theamountofenergyusedis:

Basedontheaboveenergyrequirement,withabiomasscomposedof 25%lipid,abiodieselenergydensityof37.8MJ/kg,anda90%conversionrateoflipidstobiodiesel [20],theamountofbiomass(dryweight) requiredtobreakevenwouldbe:

Thatis,overa3-weekcycle,theadditionof100Woflightingwould requireanadditional16kgofmicroalgaetobreakevenonanenergy balance.

Theaboveexamplehighlightsamajorissuewithtraditionalindoor andartificiallylitbioreactorsformicroalgae.Bymovingaproductionsystemoutdoors,whilstlosingtheabilitytoexactlycontroltemperature,by utilizingsunlightandavoidingheatingcosts,overallelectricityconsumptioncanbereducedby90% [20].Toovercomeself-shadingwhenutilizingonlysunlight,microalgalculturescanbecontinuallyvertically

circulated,resultinginindividualmicroalgaecellscyclingbetweenlight anddarkareas [21].

Inmovestowardutilizingsunlightexclusivelyinbioreactors,workis beingdoneonincreasingtheefficiencyoftheirutilization.Thislargely involvesdifferentcaptureanddistributionmechanismssuchasfiberoptics orlightguides [17].Sunetal. [22] used3cmlonghollowhorizontal tubesonaflatplatereactor,whichledtoa23%increaseinbiomassproductivity.Morecomplexdesignshaveincludedtheuseoflensestofocus sunlightintoadistributionsystem [23].However,ascomplexityincreases sodocapitalandmaintenancecosts.Furthermore,anyadditionalcomponentsaddedtoabioreactor,especiallyforthedistributionoflight,runthe riskofaccumulatingsurfacebiofilmsthatreduceefficiency.Thedesignof lighttransmittingdevicesmust,therefore,considerpreventingbiofouling toavoidfrequentmaintenance [9].

Anapproachforavoidingtheaccumulationofbiofilmsistheuseof simpledesignssuchaslighttubes [17].Lighttubesareverticaltubescontainingwaterthatareinsertedintotheculturesolution.Astheinteriorof thetubedoesnotcontainmicroalgae,itprovidesapathforsunlightto passintotheculturemedium.Byprovidinglightdeeperintothesystem, theuseofthesetubeshasresultedina33.6%increaseinbiomassproduction [17].Theyarealsoideallylocatedabovegasspargersthatbubblein off-gasCO2,withrisinggasbubbles “scrubbing” thelighttubesurfaces.

Tofurtherincreasetheireffectiveness,lighttubescouldalsobecombinedwithothersunlightfocusingsystemssuchasthelensesdescribedin Ref. [23].Low-costsolutionsforimprovingtheutilizationofsunlight, andtherebyincreasingbioreactorperformance,holdsignificantpromise formoreeconomicproductionofalgalbiofuelandotherproducts.

1.3.2Nutrients Aknownlimitationinthelarge-scaleproductionofbiofuelsisalackof sustainablesourcesoflow-costnutrients,butrelativelylittleresearchhas beendoneregardingthisissue.

Atthelaboratoryscale,mostexperimentsgivenutrientsinexcessto promotemicroalgaegrowth,reducingthemonlytoinducestressinorder totriggerlipidaccumulation.Seyedetal. [13] didnot,however,finda significanteffectfromvaryingmediaconcentrations.Thisisinaccordance withresultsfrom [24],whichshowed,withtheexceptionofpotassium phosphate,nosignificantchangeswhendiluting3N-BoldBasalmedium

sixfold.Thissuggeststhatprojectionsfornutrientcostforlarge-scale productioncouldbetoohigh,andiftoomanynutrientsareprovided, theeconomicsoftheoperationcouldbenegativelyimpacted.

Toeconomicallyprovidemicroalgalmacronutrients,namelynitrogen andphosphorus,awidelyproposedsolutionistoadaptcurrentmicroalgal systemsusedtotreatmunicipalorindustrialwastewaterstoremovethese nutrients.ThecombinationofwastewaternutrientremovalandCO2 capturefromindustrialoff-gasesisapromisingapproach,therefore,for microalgalbiofuelproduction.Thisroutecouldpotentiallyreducemicroalgalproductioncosts,asithasbeenestimatedthatnutrients,water,and CO2 contributeto10% 30%ofthetotalproductioncostsofcommercial microalgaecultivation [25].

1.3.3Carbondioxide Microalgaearephotosyntheticmicroorganismsthatutilizelightenergyto capturecarbonfromCO2 andreleaseoxygenasaby-product.Thisoxygenby-productisimportantinthedesignofbioreactors,ashighconcentrationsofdissolvedoxygen(DO)cantriggerphotorespiration(where oxygenisconsumedandCO2 isreleased),andhighDOconcentrations canbetoxictomicroalgae [15]

CarboncapturebymicroalgaereliesonatmosphericCO2 (approximately380ppmv)dissolvingintowater,butthiscanbeenhancedthrough theuseofindustrialoff-gas.TheuseofatmosphericCO2 alonelimitsbiomassproductivityduetoitslowconcentrationandthehighsurfacetensionofwater [26].Thereforethedirectapplicationofindustrialoff-gas containingelevatedlevelsofCO2 isapromisingstrategytopromote greatergasmasstransferintotheculturemediumandimprovedbiomass productivity.However,toachievethenecessarymasstransferintotheliquid,anappropriatesurfaceareaandresidencetimemustbeprovided.

Toenhancethesurfaceareaformasstransfer,thegasiscommonly spargedintothemediumtoproducefinebubbles.Foragivengasflow rate,thesmallerthebubblesthegreaterthesurfaceareaperunitgasbubblevolume.Toachievethisgoal,workhasbeendoneonfluidicoscillationtodecreasethebubblesizesoutofasparger,therebyincreasingmass transferrates [26].

Thegasresidencetimeisafunctionofthelengthofthebubblepath throughtheculturemedium.Forexistingcommercialopenpondsystems, thisrelatestothedepth,whichistypicallylimitedduetoself-shadingto

15 35cm [27].Thismeansthatthebubbleresidencewillbeshortand themasstransferwillbelow.Thisresultsinan80% 90%lossofCO2 to theatmospherefromopenpondsystems [28].

Thereareseveralindustrialprocessesthatemitsignificantamountsof CO2 includingnaturalgascombustion(9%CO2 [29]),fossilfuelpower plants(5% 15% [30,31]),steelandironproduction(30% [29]),cement production(15% 25% [32,33]),smelterfurnaces(6% 7% [4]),andwaste incineration(11% [34]).

Theseoff-gassescanbeutilizedasacarbonsourceformicroalgae growth,buttheycanalsocontaincomponentsthatarenotnecessarily beneficialtomicroalgae.Theseincludeacidgassessuchassulfurdioxide (SO2)andnitrogenoxides(NOx),whichreducethepHofculturemedia. Despitethis,manyreportedexperimentshavebeencarriedoutusingsimulatedoff-gas,whichisonlyairmixedwithCO2.Whilstlowconcentrations,intherangeof100ppmNOx andSO2,maynotaffectmicroalgae growth [34,35],itisneverthelessimportanttoconsiderthemandhow theymayaffectmicroalgalcultures.

1.3.4Temperature Thetemperaturerangesforthemajorityofmicroalgaestrainsusedfor biodieselproductionis15°C 30°C [36],whichhaslimitedoutdoorproductionintropicandsubtropicareasworldwide.Warmregionsareoften onesinwhichfreshwaterislimited,andasaconsequencemicroalgaeproductionmayberestrictedtosalt(sea)waterspecies.However,themajorityofworldwideregionsfallbelow15°Cforaportionoftheyear.

Inhotclimates,ithasbeenshownth atoutdoorbioreactortemperaturescanreach10°C 30°Cabovetheambienttemperature [15] .To mitigateanylossofproductivity,thereisneedforcoolingsuchasis achievedbysubmergingtheentirebioreactorinawaterpool,spraying thebioreactorsurfacewithwater,shadingthesurface,orusingaheat exchanger.Usingwatertocoolbioreactorsystemsaddssignificantadditionalpumpingcosts,whilstshad ingdecreasestheamountofsolar energyavailableforbiomassproduction [15] .Incoldclimates,the reverseissueispresentastemperaturesfallbelowtheoptimalrange, therebyrequiringheating.Temperatureissuescanbeaddressedbymovingoperationsindoors,butbuildingsizecansignificantlyreducethe productionvolume,andincreasedoperationalcostscanarisefromfactors suchasartificiallighting.

Manyindustriesthatproduceoff-gassesdo,however,producelarge amountsofwasteheat.Ithasbeenproposedforasmelter,thatanintegratedsystemcoulduseCO2 inthefurnaceoff-gas [37],andwasteheat fromtheroasteroff-gas [4,38]. Thecaptureofwasteheatprovidesa potentialsolutiontoexpandingoutdoorcultivationintocoldclimates.

1.4MicroalgaecultivationsystemsforCO2 capture Currentlarge-scaleoperationsmainlyutilizeshallow(30 50cm)open pondsystemsduetotheirrelativelylowcost.Studieshaveshownthat bothtemperatureandcontaminationhaveasignificantinfluenceoverthe productivityofopenpondsystems [39].Thesesystemsalsoprovidelimitedcontrolinthemaintenanceofmicroalgaespecies(e.g.,avoidanceof invasivespecies)andproducelowfinalbiomassconcentrations [16],which makesdownstreamprocessing(theseparationofbiomassfromtheliquid medium)expensive.Furthermore,duetotheshortresidencetimeofany sparged-inindustrialoff-gas,CO2 adsorptionwillbelow.Thereforeother typesofbioreactorshavebeenexaminedforthecaptureofCO2 emissions andthesubsequentproductionofmicroalgalbiofuel.

SinghandSharma [9] listedseveralrequirementsforamicroalgalbioreactorthatimprovesontheperformanceofshallowopenponds:

• minimizedcontaminationtoallowforasinglestrainculture;

• increasedcontroloverprocessconditions(e.g.,pH,light,temperature, andCO2 concentration);

• reducedCO2 losses;

• reducedwaterevaporativelosses;

• increasedmicroalgalcellconcentrations;and

• allowancefortheproductionofbiopharmaceuticalsandotherspecialty chemicals.

Themajortrade-offisbetweenimprovedconditionsandtheresulting increaseinoperationalcostsduelargelytotheincreasedcomplexityleadingtogreaterconstructionandmaintenancecosts,aswellasauxiliary energyneeds [16].Thesecostscanbereducedthroughtheoptimization ofbioreactorgeometry,orientation,andtheutilizationofavailable resourcessuchaswasteheat.

Inconsiderationofbioreactordesign,severalareasshouldbeoptimized toachievemaximizedbiomassandbiofuelproductionincluding [15]:

• harvestingasmuchsunlightaspossibleandefficientlydistributingitto allowbiomassformation;

• convenientandprecisecontrolofoperationalparameters;

• minimizingcapitalandoperationalcosts;and

• minimizingenergyconsumption.

Numeroustypesofbioreactorshavebeendevelopedincludingvertical column(airliftandbubblecolumn),flatplate,andhorizontaltubularbioreactors.However,nosingletypeofbioreactorsatisfiesallofthenecessary requirementsofanidealbioreactor [25].

Oneapproachistoemployahybridsystem,thatis,asystemthathas thecharacteristicsofbothanopenpondandabioreactor.Thesimplestof theseisanopenpondthatiscoveredtoprovideacontainedgaseousspace abovetheculturesurface.Thisallowsfortheincreasedcapture(adsorption)ofCO2,thereductionofcontamination,andanincreasedabilityto controlcultureconditions [25].Anotherexampleistheuseofdeeper ponds [21],therebyincreasingtheoff-gasresidencetime,whichcanbe achievedusingagas-liftsystemtopromoteculturecirculation.

Bioreactorscanberuninbatch(discontinuous),fed-batch,semicontinuous,orcontinuousmodes.Mostcommon,duetothetimerequirementsforgrowingmicroalgaetoadesiredbiomasslevel,arebatchor fed-batchsystems.Theseallowforasimpleoperation,butarenot necessarilyfullyefficient.Whereasacontinuoussystem,inwhichsomeof thecultureiscontinuouslybled-offandprocessed,providesmanybenefits. Theseincludeaconstantproductstream,easyautomation,andtheability tokeepthesystematitsmostproductive.Continuousoperationcan allowforbettervolumetricproductivitiesovertime,butasmostarethe resultoflaboratorystudies,significantworkstillneedstobedoneto translateresearchoutcomesintofull-scaleoperations [12]

ForanyCO2 capturesystem,theconfigurationandoperationalmode ofthebioreactorfundamentallydeterminethesystem’sperformance. Thesefactorscontributetotheoperationalcostsofthereactorfrom energyconsumptionforanyappliedlightingtoachievingmixingandgas sparging.Thisauxiliaryenergymustbeconsideredinthedesignasit directlyaffectsthenetenergyreturnoftheoperation.Forbubbleplates andairliftreactors,theenergyinputsareintherangeof50 70W/m3, whileforahorizontaltubularreactoritcanbenearly2000W/m3 [16]

Thedirectapplicationofoff-gas(bubblingin)totheculturemedium inaverticalcolumnislikelytoprovidethebestcapturerateofCO2. However,therelativelysmalltopsurface-to-volumeratioreducesoverall solarenergycapture,therebylimitingmaximumpotentialgrowthrates (albeitreducingtheriskofphotoinhibition).Itisimportant,therefore,to

obtainmixingfromthebubbledinoff-gasinordertoprovideaneven distributionofmicroalgaeandtopromotetheirexposuretolightthrough circulatingthemfromthebottomtothetop.Providinglight darkexposurecyclescanimprovephotosyntheticefficiency [13,25].Furthermore, off-gasbubblescanhelpremoveoxygenfromthemediumproducedduringphotosynthesisandtoavoidaccumulationissues [9].

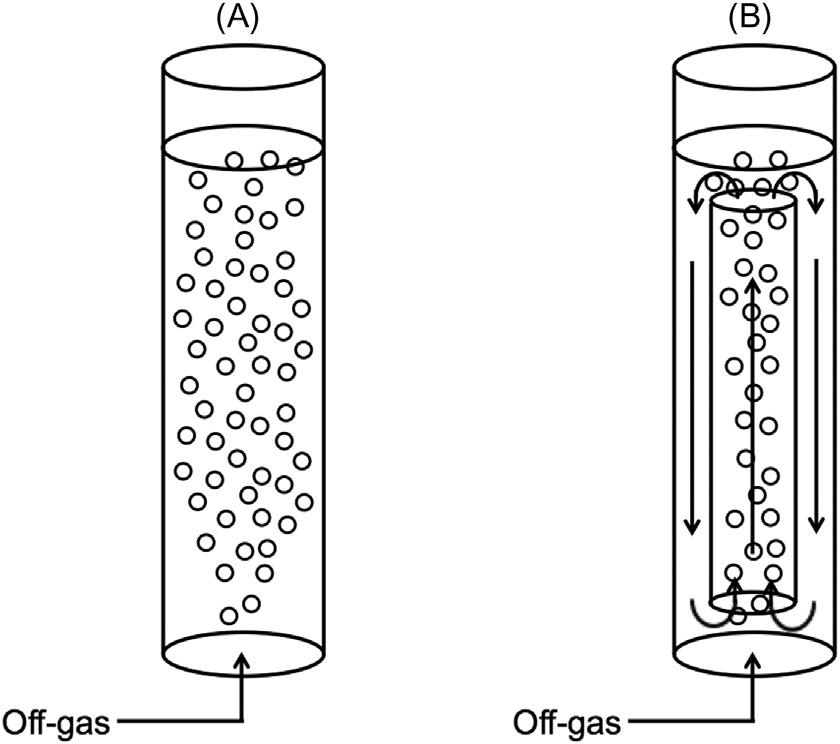

Columnbioreactorscanbedividedintotwosimilaroperations, namelybubbleandgas-liftcolumns(Fig.1.2).

Inbothoperations,industrialoff-gascouldbeinjectedintothebottom ofthecolumnandallowedtobubbleupthroughthemicroalgalmedium. ThisprovidesanoptimumresidencetimeforCO2 masstransferandvaryingdegreesofmixing.Themaindifferencebetweenthetwotypesisthat withagas-lift,thegasbubblesascendthroughariser(averticaltube abovethegassparger),someofwhichcanthenbeentrainedintheflow backdownthedowncomer(Fig.1.2).Gas-liftsystems,therefore,provide moreeffectivesolutionmixingandmasstransfer [7,13].Bubblerisingand circulationinbothtypesofcolumnbioreactorneedtobegentleenough thattheshearcreatedcausesnocelldamage [15].Atableofresultsfrom variouscolumnbioreactorsisgivenin Table1.1.

Zimmermanetal. [26] usedfluidicoscillationtomakesmallerbubbles inanairliftcolumnoperationconnecteddirectlytosteelplantexhaustgas (B20%CO2 andunmeasuredquantitiesofNOx andSOx).Theresults showedacarboncaptureratefor Dunaliella salina of0.1g/L/day,withno

Figure1.2 (A)Bubblecolumnand(B)gas-liftsystems.

Table1.1 ColumnbioreactorresultsusedforCO2 capture.

MicroalgaestrainReactorCO2 sourceCO2

Dunaliellasalina (culturecollection)AirliftSteelplantoff-gas200.1 [26]

Spirulina sp.(culturecollection)BubblecolumnSynthetic120.27 [40]

Scenedesmusobliquus (bioprospected)BubblecolumnSynthetic120.22 [40]

Chlorella sp.MTF-15(bioprospected)BubblecolumnSteelplantoff-gas24 260.942(calculated) [41]

Chlorella sp.MTF-15(bioprospected)BubblecolumnSteelplantoff-gas12 13 (50%diluted) 0.966(calculated) [41]

Scenedesmus sp.(culturecollection)AirliftSynthetic60.110(calculated) [21]

Chlorella sp.(culturecollection)BubblecolumnSynthetic100.249 [42]

Chlorella sp.(culturecollection)BubblecolumnCokeoven10 150.175 [42]

inhibitionduetothepresenceofNOx orSO2.Itshouldbenoted, however,thattheuseofbubblecolumns,especiallywithsmallbubbles, whilstincreasingsurfaceareaforcarboncapture,canlimitlightcapture effectivenessduetobubblereflection [43]

Differentsourcesofoff-gasfromsteelplants(24% 26%)wereexaminedbyKaoetal. [41].Cokeovenoff-gasshowedparticularlypromising results.Using Chlorella sp.MTF-15inabubblecolumn,acapturerateof 0.942g/L/daywascalculated.Thecapturerateincreasedto0.966g/L/ daywhenusinghalfconcentrationcokeovenfluegas,whichwasinline withthemorecommonlytestedCO2 percentageusedformicroalgae cultivation.

Moraisetal. [40] utilizedathree-stagesequentialbubblecolumnusing syntheticcoalcombustionoff-gas(12%CO2)toincreasecarboncapture efficiency.Theresultsshowedacapturerateof0.27g/L/dayforaspecies of Spirulina sp.and0.22g/L/dayusingastrainof Spirulinaobliquus thatwas isolatedfromnearacoalpowerstation.Interestingly,theisolated S.obliquus strain,whenexposedtoNOandSO2 (upto100ppmand60ppm,respectively),showednosignificanteffectregardingcarboncapture.

Leeetal. [44],using2% 4%CO2 andfourbubblecolumnsinseries with Haematococcuspluvialis,sawa3.63-foldincreaseincaptureefficiency (upto49.37%)ascomparedtoasinglecolumn.Chengetal. [45] useda 14-stagesequentialbubblecolumnsystem,andwithasyntheticoff-gas (15%CO2),obtainedacaptureefficiencyof85.6%.However,theexperimentalresultsmaybeoflimitedvalueintermsofuseinscaling-uptoa full-sizedsystem,astheywereobtainedusingcolumnswithaworking volumeofonly300mL.

Furtherexperimentsontheimpactofpotentiallyhinderingcomponentsofindustrialoff-gaswerecarriedoutbyDuarteetal. [46].Usinga bubblecolumnfedwithsimulatedcoal-firedpowerstationoff-gas(10% CO2,NOx,SO2,andash),culturesof Chlorellafusca LEB111(isolated fromathermoelectricplant)showedsignificantresistance.Increasingthe concentrationsofbothNOx andSO2 to200ppmandtheconcentration ofashto40ppmdidnotshowanynegativeimpactsongrowth.

Yadavetal. [42] testedbothasyntheticoff-gaswith10%CO2,and coal-firedfluegaswith10% 15%CO2.Theresultsshowedacapture rateof0.249and0.175g/L/dayforthesyntheticandindustrialgases, respectively.Thestrainof Chlorella sp.usedwasnot,however,isolated fromtheregionandhadnot,therefore,beenacclimatizedtotheelevated CO2 levelsoracidgascomponents.

Mostexperimentalsystemsareoperatedwithcontinuousexposureto CO2-enhancedgases,butsomehaveusedintermittentexposuretotry andincreasethecapturepercentage(i.e.,thesolutionwouldnotbecontinuousCO2 saturation).Chiuetal. [47] testedagas-liftcolumnwitha porousriserusingasyntheticoff-gas(10%CO2).Semicontinuousharvestingwasemployedinwhichaportionoftheculturewasbled-offandits volumereplenished.When25%ofthevolumewasbled-offeverytwo days,themaximumcarboncapturerateof1.098g/L/daywasconsiderablyhigherthanthatachievedbyYadavetal. [42]

Toincreasethetemperatureresilienceofcolumnbioreactorsforoutdooroperationincoldclimates,researchhasbeencarriedoutontheconceptofburyingthemwithonlythetopexposed [4].Buryingthecolumns providesatrade-offbetweentheincreaseinthermalinsulationandthe decreaseinilluminatedarea.However,deeptop-litcolumnswithadequateverticalmixingcanprovidebetterarealproductivitiesthantraditionalshallowopenpondsystems [13].Thisissignificantintermsofthe requiredoverallbioreactorfootprintwhenlocatedonanindustrialsite.

1.5Conclusion CurrentlythecaptureandmitigationofindustrialCO2 emissionsthrough theproductionofmicroalgalbiofuelsisnotconsideredeconomicallyviableasacompetitiveenergysource [48 50].However,withincreasing fossilfuelcosts,improvementsinmicroalgalproductiontechnologies,and potentialcarboncreditbenefitsfromCO2 capture,thetippingpointfor economicviabilityislikelyinthenearfuture.

Therearemanypromisingresultsfromcolumnbioreactors,whichcan beadaptedforspecificscenarios.Thatsaid,furtherworkneedstobedone totestotherdesignsforthedirectcaptureofCO2 fromindustrialoffgases,andtowardtakingdesignsfromthelaboratorytotheindustrial scale.

Therearecertainareasrequiringadditionalresearchincludingthe applicationofrealoff-gasesratherthansimulatedgasesthatuseair CO2 mixtures(i.e.,theinclusionofacidgasses),theidentificationofmorealgal strains(i.e.,acidgas resistant)fordifferentindustrialoperations,the scaling-upoflaboratorytechnologies(e.g.,CO2 adsorptionandlight transfer),andtheunderstandingofhowprocessconditions,particularlyfor outdoorsystems,affectoperationalperformances(e.g.,variablesolarlight andconvectiveheatlosses).