Biopolymer-Based MetalNanoparticle Chemistryfor Sustainable Applications

Volume2:Applications

MahmoudNasrollahzadeh

DepartmentofChemistry,FacultyofScience,UniversityofQom, Qom,Iran

Elsevier

Radarweg29,POBox211,1000AEAmsterdam,Netherlands

TheBoulevard,LangfordLane,Kidlington,OxfordOX51GB,UnitedKingdom 50HampshireStreet,5thFloor,Cambridge,MA02139,UnitedStates

Copyright©2021ElsevierInc.Allrightsreserved.

Nopartofthispublicationmaybereproducedortransmittedinanyformorbyanymeans, electronicormechanical,includingphotocopying,recording,oranyinformationstorageand retrievalsystem,withoutpermissioninwritingfromthepublisher.Detailsonhowtoseek permission,furtherinformationaboutthePublisher’spermissionspoliciesandourarrangements withorganizationssuchastheCopyrightClearanceCenterandtheCopyrightLicensingAgency,can befoundatourwebsite: www.elsevier.com/permissions

Thisbookandtheindividualcontributionscontainedinitareprotectedundercopyrightbythe Publisher(otherthanasmaybenotedherein).

Notices

Knowledgeandbestpracticeinthisfieldareconstantlychanging.Asnewresearchandexperience broadenourunderstanding,changesinresearchmethods,professionalpractices,ormedical treatmentmaybecomenecessary.

Practitionersandresearchersmustalwaysrelyontheirownexperienceandknowledgeinevaluating andusinganyinformation,methods,compounds,orexperimentsdescribedherein.Inusingsuch informationormethodstheyshouldbemindfuloftheirownsafetyandthesafetyofothers, includingpartiesforwhomtheyhaveaprofessionalresponsibility.

Tothefullestextentofthelaw,neitherthePublishernortheauthors,contributors,oreditors, assumeanyliabilityforanyinjuryand/ordamagetopersonsorpropertyasamatterofproducts liability,negligenceorotherwise,orfromanyuseoroperationofanymethods,products, instructions,orideascontainedinthematerialherein.

LibraryofCongressCataloging-in-PublicationData

AcatalogrecordforthisbookisavailablefromtheLibraryofCongress

BritishLibraryCataloguing-in-PublicationData

AcataloguerecordforthisbookisavailablefromtheBritishLibrary

ISBN:978-0-323-89970-3

ForinformationonallElsevierpublications visitourwebsiteat https://www.elsevier.com/books-and-journals

Publisher: SusanDennis

AcquisitionsEditor: AnnekaHess

EditorialProjectManager: JohnLeonard

ProductionProjectManager: JoyChristel

NeumarinHonestThangiah

CoverDesigner: MarkRogers

TypesetbySPiGlobal,India

Contributors

Numbersinparenthesisindicatethepagesonwhichtheauthors’contributionsbegin.

MahmoudNasrollahzadeh (1,47,97,137,189,333,423,517,573,609,673), DepartmentofChemistry,FacultyofScience,UniversityofQom,Qom,Iran

ZahraNezafat (1,47,97,137,189,333,423,517,573,673),DepartmentofChemistry, FacultyofScience,UniversityofQom,Qom,Iran

NasrinShafiei (1,47,97,137,189,333,423,573,609),DepartmentofChemistry, FacultyofScience,UniversityofQom,Qom,Iran

FahimehSoleimani (47,189,333,673),DepartmentofChemistry,FacultyofScience, UniversityofQom,Qom,Iran

NayyerehSadatSoheiliBidgoli (137,189,333,423),DepartmentofChemistry, FacultyofScience,UniversityofQom,Qom,Iran

TalatBaran (189,333,573),DepartmentofChemistry,FacultyofScienceandLetters, AksarayUniversity,Aksaray,Turkey

MohaddesehSajjadi (517),DepartmentofChemistry,FacultyofScience,Universityof Qom,Qom,Iran

GurumurthyHegde (609),CentreforNano-materialsandDisplays,B.M.S.Collegeof Engineering,Basavanagudi,Bengaluru,India

Applicationofbiopolymersin bioplastics

MahmoudNasrollahzadeh,NasrinShafiei,andZahraNezafat DepartmentofChemistry,FacultyofScience,UniversityofQom,Qom,Iran

1.1Introduction

Plasticsarewidelyutilizedmaterials.Theyaredailyusedalmosteverywhere:in cellphones,packaging,toys,printers,pharmaceuticalindustry,electronics, automobiles,textiles,etc.Since1940s,syntheticplasticshaveattractedalot ofattentionduetotheirremarkablepropertiessuchasmechanicalstrength, lightness,flexibility,anddurability.Thesepropertiesareassignedtoamaterial oflowcost,whichiscapableofreplacingproductsmadefromothermaterials includingpaper,glass,andmetal [1,2].However,thereisanall-knownconcern aboutthedamagesmadebypetrochemical-derivedplasticstotheenvironment afterdisposal.Forinstance,mostlyaround7.8–8.2milliontonsoftheplastics entertheoceanseveryyear.Thenegativeeffectofthislong-lastingcontribution toenvironmentalcontaminationisdepictedin Fig.1.1[3–5].

Therefore,researchershavebeentryingtofindeco-friendlyalternativesto managethewasteofplastics,whichresultedinthestudy,production,and utilizationof“bioplastics.”Bioplasticsareplastics,whicharebiodegradable, biobased,orboth.Examplesofwell-known,nonbiodegradableandbiobased plasticsincludepolyethylene(PE),poly(ethyleneterephthalate)(PET),and polyamide(PA),poly(trimethyleneterephthalate)(PTT).Petroleum-basedbiodegradableplasticsincludepolybutyleneadipateterephthalate(PBAT)and polycaprolactone(PCL).Someplasticssuchaspolylacticacid(PLA),polyhydroxyalkanoates(PHAs),polybutylenesuccinate(PBS),andstarchblendsare bothbiobasedandbiodegradable(Fig.1.2).Biodegradabilityofacompound meansthatitcanbebrokenintosmallerpartsbyenzymaticactionsofmicroorganismstoformcarbondioxide,methane,water,biomassandvariousother naturalsubstances,whichcanbeeasilyeliminated.Thebiodegradationmechanismdependsonthethicknessandcompositionofthematerial.Theterm biobasedplasticreferstoplasticsderivedfromnaturalsourcesorbiomass. Theymaybebiodegradableornot,buttheyarerecyclable [6,7].

Biopolymer-BasedMetalNanoparticleChemistryforSustainableApplications https://doi.org/10.1016/B978-0-323-89970-3.00001-9 Copyright © 2021ElsevierInc.Allrightsreserved. 1

2 Biopolymer-basedmetalnanoparticlechemistryforsustainableapplications

Biopolymersaregreatcandidatesforthepreparationofbioplasticsasthey arenontoxic,recyclable,andwidelyproducedbynature.Biopolymersaregenerallyconsideredeco-friendlyalternativesforpetrochemicalpolymersdueto therenewablefeedstockusedtoproducethemandtheirbiodegradability.This

FIG.1.1 Negativeimpactofplasticwastedisposal [3]

FIG.1.2 Threedifferentclassesofbioplastics [6]

substitutionalsohelpsreducegreenhousegasemissions.Biopolymerscanplay animportantroleinCO2 cycleas,withgreateragriculturalproduction,more CO2 (resultingfrombiopolymerdegradation)isabsorbedand,hence, CO2 releasetotheatmosphereisreduced,therebyleadingtoreductioninglobal warming.Naturalpolymerscanbeobtainedfromdifferentresourcessuchas microorganisms,plants,animals,biowastes,etc.Polysaccharides(cellulose, chitin,gum,etc.),lipids(oils,fats,etc.),proteins(casein,gelatin,etc.),PLA, andsomebacterialcompounds(suchasPHA,xanthan,curdlan,andpullulan) aresomeexamplesofbiopolymers.Atpresent,themostcommonlyusedcommercialbioplasticsarePLAandstarch-basedplastics.PHAs,biopolymer blends,andsomebio-sourcedthermosetmaterialssuchasfuranresinalsoexist. PHAsareamongthemostdesiredbiodegradablebiopolymers,whichcanbe producedbybacteriaandplantsandusedtopreparebioplastics [4,6,8–15].

Theproductionofbioplasticsisestimatedtogrowfrom200,000tonsin 2006to1milliontonsin2011.Bioplasticsproducedthusfarhavehadlots ofapplicationsindifferentindustrialsectorssuchastransportation,packaging, furniture,agriculture,construction,andconsumerproducts.Theproducts, whichhaveusedbioplastics,canbelabeledtohelpdistinguishbetweenconventionalandbiobasedplastics.Inaddition,therearesomelogosshowingthecapabilityofproductstoberecycled,biologicallydegraded,andcompostable (Fig.1.3).Novelbio-sourcedbiopolymershavebeendevelopedtomeetthe requirementsofnovelapplications.Commonrequirementsfordistinctmaterialsinmassproductionarelow-price,processability,appropriateperformance,

FIG.1.3 Varioustypesofnotationsofbiodegradablesymbols. (Reproducedwithpermissionfrom GnanasekaranD.Greenbiopolymersanditsnanocompositesinvariousapplications:stateofthe art.In:GreenbiopolymersandtheirNanocomposites.Singapore:Springer,2019.p.1–27.)

Bioplastic symbol

4 Biopolymer-basedmetalnanoparticlechemistryforsustainableapplications

andlightweight.Weightreductioninproductscanbeachievedbydesign,materialchoices,andeventuallyfoaming.Thevarietyofbiomaterials,numberof materialcombinations,processingtechnologies,andapplicationsoffertremendousopportunities.However,therearemanychallenges,whichmustbemet duringthedevelopmentofbioplasticstomeetthedemandsofdifferentindustrialsectors [10,14,16].

1.2Degradationofbioplastics

Aplasticcanbeconsideredbiodegradableifasignificantchangeinthechemicalstructure,i.e.,degradation,occursintheexposedmaterialresultinginthe formationofcarbondioxide,water,inorganiccompounds,andbiomass(new microbialcellconstituents)butnovisibleortoxicresiduesundercomposting conditions.Duringthedegradationprocess,longpolymericchainsarebroken downduetotheeffectsofwater,temperature,andsunlight(i.e.,photodegradation)toshorteroligomers,dimmers,ormonomers.Theseshorterunitsaresmall enoughtopassthroughthecellwallsofmicroorganismsandbeusedassubstratesfortheirbiochemicalprocessesandcanthusbedegradedbymicrobial enzymes(Fig.1.4) [17,18].

FIG.1.4 Biodegradationofbiopolymers:aerobicvsanaerobicdegradation. Darkpink (darkgray inprintversion)symbolsrepresentthemicroorganismsinvolvedintheprocesses [17]

Twomainkindsofenzymesareinvolvedinmicrobialdepolymerization procedures:extracellularandintracellulardepolymerases.Theextracellular enzymesactoutsidethecellstobreakthelongerunitsdownintoshortermolecules,preparingthemforfurtherdegradationbyintracellularenzymes.Asbiodegradationcanoccurintwoways,aerobicallyandanaerobically,itofferstwo typesofbiologicalwastetreatment [17].

1.2.1Bioplasticbiodegradationunderdifferentenvironmental conditions

1.2.1.1Soil

Thedegradationrateofbioplasticsinsoiliscloselyrelatedtothemaincomponentspresentinthebioplastics,thephysicalandmechanicalpropertiesofthe bioplastic,andthebacterialbiomassinsoil.Severalmicroorganismssuchas Bacillus sp.and Aspergillus sp.havebeenisolatedandidentifiedasbioplastic degradersfromthesoilenvironment.Soilenvironmentsinvolveavastvariety ofmicroorganisms,whichenableplasticbiodegradationtobemorefeasiblein comparisonwithotherenvironmentssuchaswaterorair.Animportantobjectiveisthatthedegradationofbioplasticdoesnotaffectthenitrogencirculation inthesoil [17,18]

1.2.1.2Compost

Otherthansoil,compostisanotherecologicalcondition,whichcanbetaken intoaccountforthebiodegradationofbioplasticsasitcontainshighmicrobial diversity.Acompostableplasticisaplastic,whichundergoesdegradationby biologicalprocessesduringcompostingtoyieldwater,carbondioxide,inorganiccompounds,andbiomassatarateconsistentwithotherknowncompostablematerialsandleavesnotoxicorvisuallydistinguishableresidues.Thus,a compostableplasticisbiodegradablewhileabiodegradableplasticisnot alwayscompostable [19,20]

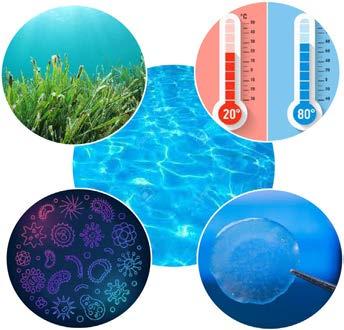

1.2.1.3Aquaticenvironments

Plasticwastesarealsowidelyfoundinmarineenvironments.Differenthabitats oftheseamayshowdifferentratesofbiodegradability.Sedimentsmayhavea favorableeffectonbiodegradation.Ithasbeenfoundthathighestbiodegradationcouldbeachievedattheinterfaceofwater-sedimentsincetheenvironmentalconditionsattheinterfacesupporttheactivityofplastic-degrading microorganisms.Thetemperatureofwatercanalsoaffectbiodegradationof bioplastics.ItwasreportedthattherateofbiodegradationofPHAfilmshad beendifferentintheyears1999and2000duetochangesintemperature. Anotherparameteraffectingthebiodegradationroleofaquaticsystemsisthe existingbioplastic-degradingmicroorganisms,whichmaynotbeidenticalin differentseawaterenvironments.Theshapeofthebiopolymerisalsoeffective onthedegreeofbiodegradationinmarinewater.Polymerswithalargersurface

6 Biopolymer-basedmetalnanoparticlechemistryforsustainableapplications

Bioplastic biodegradation in aquatic systems

FIG.1.5 Differentparametersaffectingbiodegradationofbioplasticsinaquaticsystems.

areaaredegradedfasterastheypresenthigherpolymer-waterinterfaceand facilitatetheattachmentofmicroorganismstothesurfaceofthebiopolymer (Fig.1.5) [19,21–25].

1.2.2Bioplastic-degradingmicroorganisms

Morethan90typesofmicroorganismsincludingaerobes,anaerobes,photosyntheticbacteria,archaebacterial,andlowereukaryoticpresentindifferentenvironmentalconditionsareresponsibleforbiodegradationandcatabolismof bioplastics.Thedegradationofbioplasticsbymicroorganismsisdistinguished throughtheappearanceofaclearzonesurroundingthegrowthinaplatecontainingthebioplasticastheonlycarbonsource,followedbytheconsideration ofthediameterforthebiodegradationextension.Intracellularorextracellular depolymeraseenzymesaffordedbymicroorganismsareresponsibleforenzymaticdegradationofbioplastics [19,26,27].Depolymeraseenzymesfrom Rhodospirillumrubrum and Bacillusmegaterium areresponsiblefordegrading polyhydroxybutyrate(PHB) [27,28].DegradationofPHBresultsinthetransitionofPHBgranulesintheintracellularcompartmentfromanamorphoustoa denaturedsemicrystallinestate.Lemoignefirstdiscoveredthat Bacillusmegaterium releasesPHBinanaqueousenvironment.Itisnowknownthatsuch secretionisduetotheactivityofPHBdepolymerase.ThecommercialproductionofrecombinantPHBdepolymerasefrom Streptomycesexfoliates isnow carriedoutbyimmobilizingtheenzymeonaninertadditivesuchasbovine serumalbumin [28].

Furthermore,PLAcanbedegradedbydifferentkindsofbacteriasuchas Amycolatopsis sp.,Saccharothrixsp., Lentzea sp., Kibdelosporangium sp., Streptoalloteichus sp.,and Burkholderiacepacia [29]

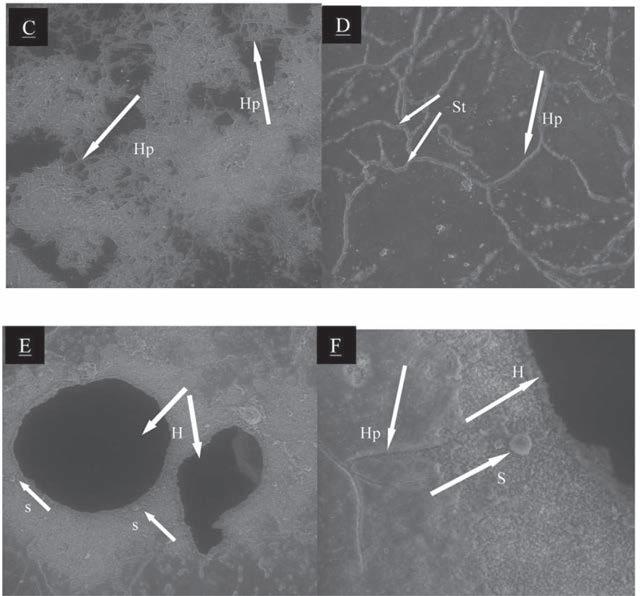

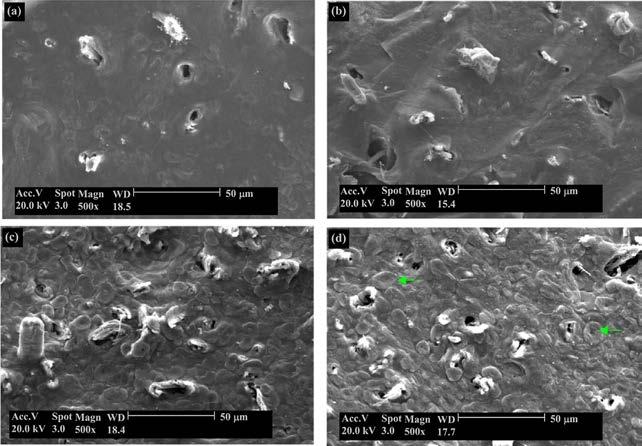

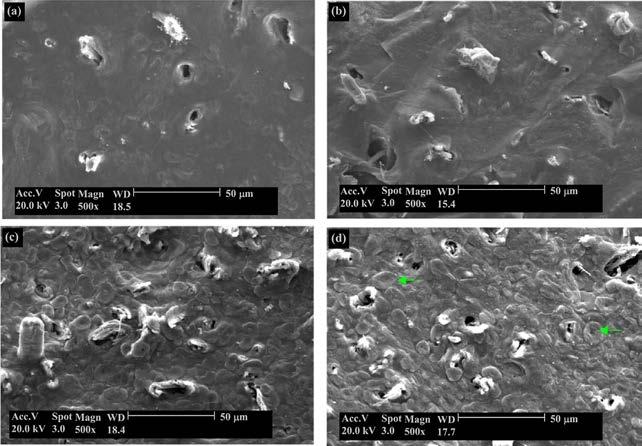

TherearedifferentkindsoffungicapableofdegradingPLA. Fennellomyces linderi and Fusariumsolani presentinsoil, Verticillium sp.and Lecanicillium saksenae presentincompost,and Thermomyceslanuginosus, Aspergillusfumigatus, Mortierella sp., Doratomycesmicrospores presentinbothsoilandcompostdegradePLAresidue [30].PLAcoupons(96% L-isomer)wereburiedin soilorcompostat25°CandunburiedPLAcouponsremainedtransparentafter 8weeks.However,whenPLAwasburiedincompostorsoilat50°C,films becameopaqueandwhiteafter1weekandphysicaldisruptionofthesurface wasvisiblewithholesdisruptingtheintegrityofthecoupons.WhilenomicroorganismswereobservedonthesurfaceofunburiedPLA(200 magnification; Fig.1.6A),orPLAcouponsburiedincompostorsoilat25°Cafter6weeks (datanotshown),extensivenetworksofbranchedhyphaewereobservedby ESEMwhenPLAwasburiedinsoilandcompostat50°Cfor6weeksat 200 and150 magnifications(Fig.1.6BandC).Morefungalhyphaewere observedonPLAcouponsburiedincompostcomparedwithPLAcouponsburiedinsoil.Atahighermagnification(1000 ),septawerevisiblewithinthe hyphae(Fig.1.6D).Fungalspores(ca.8 μmdiameter)werealsoobservedadjacenttotheholesinthePLAsurfacerecoveredfromcompostat500 and 2000 magnifications(Fig.1.6EandF) [30].

Furthermore,thedepolymerizeenzymeresponsibleforPCLdegradation wasisolatedfrom Streptomycesthermoviolaceus subsp. Thermoviolaceus 76T-2 [31].Otherenzymessuchaslipasefrom Alcaligenesfaecalis,esterase from Comamonasacidovorans,andserinefrom Pestalotiopsismicrospora arealsoprominentforbioplasticbiodegradation [32]. Table1.1 presentssome examplesofmicroorganismsresponsibleforthebiodegradationofbioplastics. Biodegradabilityofbioplasticsaffordsthechanceforthemtoberecycled. Properdisposalentersbioplasticsintherecyclingprocess(Fig.1.7) [4]

1.3Biopolymericsourcesofbioplastics

Biopolymersareattractivefeedstockstoproducebioplastics.Theymaybe foundinthenatureintheshapeofpolymerspreparedbyanimals,plants,or microorganisms,oritsmonomersmayhavenaturalsources,whicharethen polymerizedtoaffordbiobasedpolymers [64]

1.3.1Polyethylene

Polyethylene(PE)isoneofthemostwidelyusedthermoplasticsknownas HDPE,LLDPE,andLDPE(highdensityPE,linearlow-densityPE,and low-densityPE,respectively).Itisanaliphaticpolyolefinproducedbypolymerizationofethylene(Fig.1.8)andrepresentsmorethan30%oftheglobal plasticmarket.Bio-ethylene,madefromethanolbasedonbiomass,represents achemicallyidenticalalternativetoethylenefrompetrochemicalfeedstock. However,theoverallproductionprocessofethylenefromsugar-basedethanol

8 Biopolymer-basedmetalnanoparticlechemistryforsustainableapplications

FIG.1.6 Environmentalelectronscanningmicroscopy(ESEM)ofthesurfaceofPLAcoupons showingfungalcolonizationanddegradation.(A)Unburiedcontrol;(B)buriedat50°Cfor6weeks insoil;(C–F)buriedat50°Cfor6weeksincompost.Hyphae(Hp),septa(St),spores(S),andholes (H)wereclearlyvisibleandareindicatedby arrows (ReproducedwithpermissionfromKaramanliogluM,HouldenA,RobsonGD.Isolationandcharacterizationoffungalcommunitiesassociated withdegradationandgrowthonthesurfaceofpoly(lactic)acid(PLA)insoilandcompost.IntBiodeteriorBiodegradation2014;95:301–310.)

(A)

(E)

(F)

TABLE1.1 Isolatedbioplastic-degradingmicroorganismsfromdifferentenvironments.

Environmental conditions

Soil

Typeof microorganismMicroorganism

Bacteria Amycolatopsis sp., Amycolatopsisthailandensis, Thermoactinomyces sp., Laceyella sp., Nonomuraea sp., Bacilluslicheniformis, Actinomadura keratinilytica, Micromonospora sp., Streptomyces sp., Bortetellapetrii, Paenibacillusamylolyticus, Paenibacillus sp.

Bacillusstearthermophilus

Streptomycesbangladeshensis

[38]

[39] Bacteria Pseudomonasaerogusina,Bacillussubtilis

Bacteria Pseudomonasfluorescens, Pseudomonasputida, Pseudomonas aeruginosa, Pseudomonas sp.

[40]

[41,42] Bacteria Pseudomonaslemoignei

[43]

Bacteria Actinomadura sp.PHBVb [44]

Bacteria Clostridiumacetobutylicum Starch-based [45]

Bacteria Laceyellasacchari PLLAc +Starchbased [46]

Bacteria Stenotrophomonas Nylon4(PA) [47]

Bacteria Amycolatopsis sp., Streptomyces sp., Streptomycesthermovioaceus, Paenibacillus sp.

Bacteria Paenibacillusamylolyticus

[31,37]

TABLE1.1 Isolatedbioplastic-degradingmicroorganismsfromdifferentenvironments—cont’d

Environmental conditions

Typeof microorganismMicroorganism

Bacteria Amycolatopsis sp., Streptomyces sp., Paenibacillus sp., Paenibacillus amylolyticus

Bacteria Paenibacillusamylolyticus, Pseudomonasaeruginosa, Burkholderia cepacia, Bacilluspumilus

[33,37]

[26,33, 48–51] Bacteria Paenibacillusamylolyticus

Fungi Candidaalbicans, Fusariumoxysporum

Fungi Aspergillusniger

Fungi Penicillium sp., Trichodermapseudokoningii, Paecilomyceslilacinus, Cogronella sp., Acremoniumrecifei

[26,33]

[40]

[43]

[52]

Fungi Fusarium sp., Fusariumsolani, Fusariumoxysporum, Clonostachysrosea Nylon4(PA) [47,53]

Fungi Purpureocillium sp., Cladosporium sp.PCL [37]

Fungi Purpureocillium sp., Cladosporium sp., Aspergillusfumigatus, Aspergillus niger, Fusariumsolani PBS [37, 54–56]

Fungi Aspergillusclavatus

[57]

Compost/soilFungi Penicillium sp., Aspergillus sp.PHB [58]

Fungi Aspergillus sp.Starch-based [59]

Compost Bacteria Streptomycesthermonitrificans

AquaticsystemsBacteria Streptomyces sp., Burkholderiacepacia, Bacillus sp., Cupriavidus sp. Mycobacterium sp., Nocardiopsis sp.

[52,61] Bacteria Streptomyces sp.

[61]

aPoly-D-lactide.

Bacteria Pseudomonasputida, Leptothrix sp., Variovorax sp.

[23] Bacteria

sp., Bacillus sp., Gracilibacillus sp.

[26] Bacteria Pseudomonas sp., Tenacibaculum sp., Alcanivorax sp.

[24]

Bacteria Psychrobacter sp., Pseudomonas sp., Moritella sp., Shewanella sp.PCL [63] Bacteria Streptomyces sp.

bPoly(3-hydroxybutyrate- co-3-hydroxyvalerate).

cPoly-L-lactide.

dPoly(butylenesuccinate-co-adipate).

ePoly(ethylenesuccinate).

ReproducedwithpermissionfromEmadianSM,OnayTT,DemirelB.Biodegradationofbioplasticsinnaturalenvironments.Wastemanage2017;59:526–536.

Biopolymer-basedmetalnanoparticlechemistryforsustainableapplications

Proposedpresentationforreuseofbioplastics [4]

ProductionroutetoPEbioplastics [64]

hastobefurtheroptimized.Themostwell-developedproductionroutesfor bio-ethanolarethefermentationofsucrose(e.g.,sugarcanefeedstock) andhydrolysisfollowedbyfermentationofstarchybiomass(e.g.,corn feedstock) [64]

FIG.1.7

FIG.1.8

Applicationofbiopolymersinbioplastics Chapter 1 13

1.3.2Polylacticacid

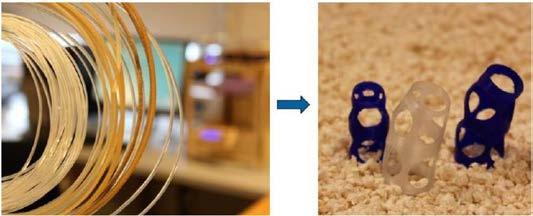

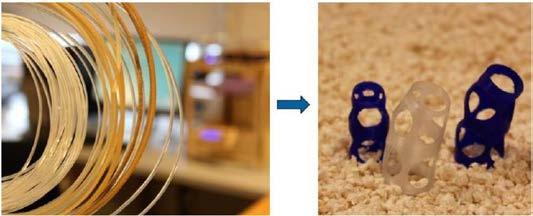

Polylacticacid(PLA)isanaliphaticpolyesterproducedbythepolymerization oflacticacidobtainedfromagriculturalresourcessuchascorn,cottonwaste, coffeewaste,andfoodwaste(Fig.1.9).Polylacticacidisthesecondmostproducedbioplasticatpresenttimesafterstarch-basedmaterials.Ithashigh strengthandhighmoduluswithlowpercentelongation [64,65].Itsabundant renewablesource,hightransparency,andexcellentmechanicalpropertieshave madeitagoodalternativefortraditionalpetrochemicalplastics.Inastudyby Tengrangandco-workers,thetransparencyofPLAhasbeencomparedwith thatofPBSandMater-Bi,astwootherbioplasticsandPLAhaveshowntohave thehighesttransparency [66].PLAcanbeusedinawiderangeofapplications includinggeotextile,agriculturalfilm,packaging,asbinderfiberforcellulosic nonwovensandrecentlyasonemajorthermoplasticfor3Dprinting,usingthe fuseddepositionmodelingmethod(Fig.1.10) [64].

FIG.1.10 PLA-basedfilamentscontainingwoodfibersfor3Dprintingbyfuseddeposition modeling(left).PLA-based3Dprintedfingerorthosis(right). (Reproducedwithpermissionfrom BrodinM,VallejosM,OpedalMT,AreaMC,Chinga-CarrascoG.Lignocellulosicsassustainable resourcesforproductionofbioplastics—areview.JCleanProd2017;162:646–664.)

FIG.1.9 ProductionroutetoPLAbioplastics [64]

14 Biopolymer-basedmetalnanoparticlechemistryforsustainableapplications

However,givenitsintrinsicchemicalstructureandcomposition,PLAsuffersfromhighflammabilitywithaverylowlimitingoxygenindex(LOI)of19–21vol%.Moreover,uponignition,iteasilygivesrisetomeltdrippingduring burning,whichextremelyrestrictsitspracticalapplicationsinmanyfieldssuch aspackaging,textile,electricandelectronic,andagriculture [67–70].PLA showsjustaslightdecreaseinmechanicalpropertiesafterrecycling.Recycled PLAcanbeeasilyusedasanadditiveintheprocessingofPLA [71]

Inastudy,bioplasticcompositesweresuccessfullypreparedbyextrusion andcompressionmoldingofstarch-basedbioplasticsandPLAonasmallscale todetermineitsproperties.ItwasprovedthatraisingPLAconcentrationcan decreasethedensityofbioplasticcompositetobecomelightbioplastic,which wouldbeanadvantageforbioplastics.PLAcanalsoincreasethestabilityof hydrophobiccharacteristicsandinsolubleproperties.ItwasobservedthataddingPLAcanresistwatermoleculesupto20%comparedwithbioplasticwithout PLA.Thus,bioplasticcompositeshaveagoodresistanceagainstdissolution inwater.Furthermore,addingPLAcanimprovethemechanicalpropertiesof bioplasticcompositesupto5MPa(10wt%ofPLA) [72].

Inanotherstudy,differentcompositeswerepreparedbasedonpoly(L-lactic acid)(PLLA)incombinationwithDNA,wheyprotein(WP),andcollagen (COL).Throughthecondensationofaminoandcarboxylgroups,whether fromDNA,WP,orCOL,chainscouldbegraftedontothePLLAmolecules. COL/PLLAcompositesexhibitedahigherheatresistancecomparedwith DNA/PLLAandWP/PLLAcomposites.Moreover,COLexhibitedthemaximumimprovementoftensilestrengthandelongationatbreakcomparedwith DNAandWP,andtheincreasesintherateoftensilestrengthandtheelongation atbreakwere88.6%and154.9%,respectively [73].

1.3.3Polyhydroxyalkanoates

PHAsarealargeclassofbiobasedpolyesterswithhomopolymerandcopolymerstructures,producedfromrenewablefeedstocks(e.g.,glucose,sucrose,and fattyacids)viabiotechnologicalroutesusingdifferentmicroorganisms (Fig.1.11).Whenacompleterangeofnutrientsisnotavailableforcellgrowth, microbessynthesizeandstorethepolyestersfromageneroussupplyofcarbon source.ThebiosynthesisofPHAispromotedbyalackinoneormultiplenutrients,includingsulfate,magnesium,nitrogen,phosphate,andoxygen.Dependingoncarbonsource,thechoiceofmicroorganism,processconditions,and additives,polymerswithdifferentmonomericcompositionsandcharacteristics (suchascrystallinity,chainlength,brittleness,andelasticity)willbeobtained [64,74–76].Ingeneral,PHAsareconsideredformaterial,whichareusedupin theenvironment,suchasflowerpotsusedinplanting,foils,bags,fishinglines, andnets(whichshoulddecomposeiflost),materialsusedinbiomedicalapplications,andotherdisposableitemssuchasbottles,cups,plates,andcutlery, whichcanbecompostedbutnotrecycled [13].

TheutilizationofactivatedsludgetoconvertcarbonsourcesintoPHAscan notonlyproducebioplasticsbutitmayalsosolvepartoftheproblemofthe disposalofmunicipalactivatedsludge.Theselectionofindustrialfoodwastes asacarbonsourcecanalsofurtherdecreasethecostofproductionofPHAs [77].

Polyhydroxybutyrate(PHB)isabiocompatibleandbiodegradablethermoplasticproducedbyvariousmicroorganismsasstoredfood.Theorganismneeds anaerobicconditionswithCO2 andNsourcestoformPHB.Thisbioplasticcan beconvertedintofilms,sheets,fibers,ormoldedtotheshapeofabagandbottle.However,consideringthesmallshareofPHBintotalbioplasticsandits uniquecharacteristics,itisworthwhiletodevelopPHBforbiomedicaldevices fortissueandorganengineering,cosmeticsandhealthproducts,foodpackaging materials,anddeliverysystemsforthecontrolledreleaseofdrugs,fertilizers, andpesticides [28,78–81].PHBmonomerisachiralmolecule,whichisinsolubleinwaterandexhibitsahighdegreeofpolymerization.Beingchiral,the monomerscanbeusedforthesynthesisofcomplexchiralpharmaceuticalcompounds.PHBissuggestedasasourceforchiralbiopolymers.Forinstance, R-hydroxycarboxylicacidpreparedbytheacidicalcoholysisofPHBiswidely usedinthesynthesisofchiralmolecules [82,83].PHBcanbeimplantedinthe bodywithnoinflammatoryresponseduetoitsbiocompatibility.Degradationof PHBtakesplaceslowlyinsidethehumanbody.Hence,PHBcanbeusedasa carrierfortheslowreleaseofpharmaceuticals.ThebiocompatibilityofPHB canalsomakeitsuitableforapplicationinthefieldoftissueengineering. ThispropertycanbeimprovedbytreatingPHBwithlipaseandNaOH.

FIG.1.11 ProductionroutetoPHAbioplastics [64].

16 Biopolymer-basedmetalnanoparticlechemistryforsustainableapplications

ThemechanicalandbiocompatibilitypropertiesofPHAscanbeenhancedfurtherbyblendingthemwithotherpolymers,modifyingthesurfaceorcombining PHAwithotherinorganicmaterialstomakethemappropriateforawiderrange ofapplications.ThebiocompatibilityofPHBinvitrohasbeendemonstratedon differentcelllines:fibroblasts,mesenchymalstemcells,osteoblasts,bonemarrowcells,articularcartilagechondrocytes,endothelialcells,smoothmuscle cells,etc. [28,84,85]

Poly-3-hydroxybutyrate(P(3HB))isthemostcommontypeofPHAsproducedbymicroorganisms.P(3HB)homopolymerisahighlycrystalline,stiff, yetrelativelybrittlematerialdependingonthemolecularweight [86].Compared topolylacticacid(PLA),whichisapopular,commerciallyavailable,renewable andbiodegradablepolymer,diversecombinationsofPHAmonomericsubunits offerawiderangeofproperties [87,88].Poly-3-hydroxyvalerate(P(3HV)) homopolymerexhibitsatensilestrengthof31MPaandanelongationtobreak of14%,whichdemonstratesthatP(3HV)showslessstiffnessandhigherflexibilitythanP(3HB).P(3HB-co-3HV)copolymerisuniqueamongthePHAfamilyofcopolymersinthatthesizeandstructureof3HBand3HVmonomersare similar.Thissimilarityallows3HBand3HVtoparticipateinaco-crystallization process,inwhich3HVcouldbeincorporatedintothe3HBcrystallatticeandvice versa.Asaresult,themeltingtemperaturesoftheP(3HB-co-3HV)copolymers decreasetoaminimumpointastheratioof3HVto3HBrepeatingunitsincreases, and,afterthisminimummeltingtemperatureisreached,itincreasesasthe3HV molefractionfurtherincreases.PHAcopolymerswithlowermeltingtemperaturesareimportantlyadvantageousinindustrialapplications,whichrequiremelt processingatlowertemperatures [88,89]

PHBVisanothercopolymerformofPHAsobtainedfrombacterialresources, specificallyfromthebacteria Alcaligeneseutrophus [90].Differentfeeding, glucose,andpropionicacidratiosproducedifferentcopolymercompositions, withthevaleratecontentvaryingfrom0%to24%.Thevaleratecontentinthe PHAfamilyofpolymershelpsincreasetheirprocessabilityandelasticity [91]. Asshownbydifferenttests,PHBVbioplasticisrecyclableandcanbeprocessed multipletimeswithnosignificantlossintheproperties [91].

1.3.4Polybutylenesuccinate

Poly(butylenesuccinate),analiphaticpolyester,isabiodegradableandeconomicalbiopolymersynthesizedfrombiobasedresources,providingfurther incentivetostudythismaterial [92–94].ThesynthesisofPBSnormally involvespolycondensationreactionbetween1,4-butanediolandsuccinicacid [95].Comparedwithotheraliphaticpolyesters,PBSshowsbetterbiodegradability,thermalproperties,meltprocessability,andchemicalresistance,which makeitappealingasthecorematerialintheplasticindustry.PBShasalready beenusedinmakinginjection-moldedproducts,fibers,andfilms [95–97].To enhancethepropertiesofthematerialsmadeofPBS,variousstudieshavebeen

conductedandseveralmethodshavebeenintroduced.Thebestapproachfor enhancingPBSpropertiesismixingitwithfillers.Notonlyisthisapproach easyandeconomicalbutitisalsoefficient.Insteadofusingartificialfiberssuch asglass,carbon,oraramid,scientistsareincreasinglyconsideringtheapplicationofnaturalandbiodegradablefibersasthereinforcingfillersincomposite materials [98].Recently,greateffortshavebeenmadetotailorthepropertiesof PBSandmanyworkshavebeenpublishedonPBS-basedcopolymersandcompositesfordifferentkindsofapplications.Insomestudies,PBShasbeenadded tothePLAmatrix.ThepresenceofPBSinsidePLAstronglyincreasesthe nucleationofPLA,thusleadingtohighcrystallinityofthematerialbycold crystallization [99,100].

1.3.5Thermoplasticstarch

Starchisoneofthemajorresourcesinthedevelopmentofbioplasticsobtained fromagreatvarietyofcrops.Forexample,inastudybyJohariandSultan,it wasreportedthatbananapeelandcornstarchmayhaveagoodfutureinthe developmentofbioplastics [101].Duetoitslargeavailability,lowcost,renewability,interestingphysicochemicalcharacteristics,andbiodegradability, starchiscommonlyusedintheproductionofbioplastics.Currently,about 50,000tons/yearofstarchareconvertedtoplasticmaterials.Ithasbeeninvestigatedwidelyforthepotentialmanufactureofproductssuchaswater-soluble pouchesfordetergentsandinsecticides,flushablelinersandbags,andmedical deliverysystemsanddevices [102].Nativestarchcommonlyexistsinagranular structurewithabout15%–45%crystallinity [103].Itcanbehavelikeathermoplasticwhenplasticizers,elevatedtemperatures,andsheararepresent.During thethermoplasticprocess,waterandotherplasticizersplayanindispensable rolebecauseplasticizerscanformhydrogenbondswithstarch.Thisisbecause starchisamultihydroxylpolymerwiththreehydroxylgroupspermonomer. Therearevastintermolecularandintramolecularhydrogenbondsinstarch. Whentheplasticizersformhydrogenbondswithstarch,theoriginalhydrogen bondsbetweenthehydroxylgroupsofstarchmoleculesarebroken,thus enablingstarchtodisplayplasticization [103,104].Thermoplasticstarch (TPS)canbepreparedbykneading,extrusion,compressionmolding,andinjectionmoldingofseveralnativestarcheswiththeadditionofglycerolasaplasticizer.ThechoiceofplasticizeraffectsTPSevenwhenthesehavesimilar plasticizationprinciples.Nativestarch-basedfilmsarelimitedduetohighwater affinityandbrittleness.Therefore,othernaturalbiopolymersareoftenaddedas fillerstomodifyandimprovethepropertiesoffilms [105–109].Unfortunately, thepropertiesofTPSarenotappropriateforapplicationssuchaspackaging. TPShastwomaindisadvantagesincomparisontomostplasticscurrentlyin use,i.e.,itismostlywatersolubleandhaspoormechanicalproperties.The waterresistanceofTPSmaybeimprovedbymixingitwithbiodegradablepolymers,addingcross-linkingagentssuchastrisodiumtrimetaphosphate,

18 Biopolymer-basedmetalnanoparticlechemistryforsustainableapplications

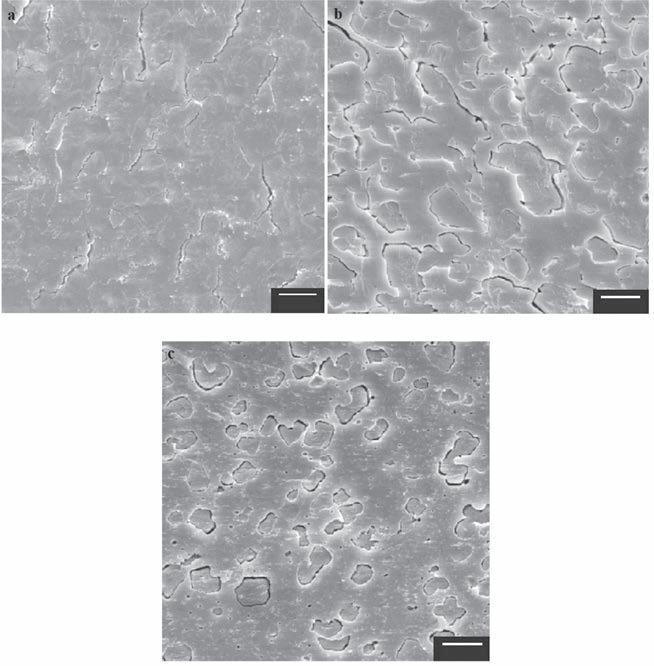

Na3P3O9,oradoptingthemultilayertechnique.Multilayerfilmsbasedonplasticizedwheatstarch(PWS)andvariousbiodegradablealiphaticpolyestershave beenpreparedthroughflatfilmco-extrusionandcompressionmolding.Biodegradablealiphaticpolyestersarechosenastheouterlayersofthestratified “polyester/PWS/polyester”filmstructure [110–112].Furthermore,another approachistheuseoffibersasthereinforcementforTPS.Thefibersreported intheliteratureforthispurposearenaturalfibers,cellulosemicrofibers,and commercialregeneratedcellulosefibers [113–115].TheSEMmicrographof thefragilefracturedsurfaceofTPSfilledwithdifferentfibercontentsshown in Fig.1.12 revealsthedispersionofthefiberintheTPSmatrix.Thesurface ofthefiberappearedtobecoveredbyTPSandfiberbreakagewasclear.This wasattributedtothestronginteractionbetweenthefiberandTPS.However,a spotofstarchgranularfigures,pointedoutbythearrowsin Fig.1.12candd, existedinTPScontaining15%or20%fibercontentswhiletherewerenoobviousstarchgranularfiguresinTPSwithlowfibercontent(asshownin Fig.1.12a andb).Thisindicatesthatbyincreasingthefibercontent,thestarchgranular fusionwasaffectedbythefiberduringthethermoplasticprocessingofTPS. Thefibercontentwaslimitedbyhighviscosityorinsufficientdispersionduring

FIG.1.12 SEMmicrographat500 magnificationoffragilefracturedsurfaceofTPSfilledwith differentfibercontents.(a)5%Fibercontents,(b)10%fibercontents,(c)15%fibercontents,and (d)20%fibercontents. (ReproducedwithpermissionfromMaX,YuJ,KennedyJF.Studieson thepropertiesofnaturalfibers-reinforcedthermoplasticstarchcomposites.CarbohydrPolym 2005;62(1):19–24.)

processing.TPSwithlessthan15%fibercontentcouldbeprocessedquitewell withouttheadditionalplasticizerwhentheweightratioofthegrossplasticizer andcornstarch(0.3:1)waskeptconstant [103].

InastudybyCorradiniandco-workers,blendsofTPSandzeinwere obtainedbymeltprocessingofcornstarchandzein,bothplasticizedwithglycerol.Zeinreducesthewaterabsorptionoftheblendsanddecreasestheirwater diffusioncoefficientevenatthelowestcontents.Moreover,theprocessingof theblendsisgreatlyfacilitatedbyzeinduetoastrongreductionintheirviscosity.Thesetwofavorablefactorsmakezeinasuitableandpromisingfullybiodegradablecompoundforblendingwithstarch(Fig.1.13) [116].

FIG.1.13 SEMoffragilefracturesurfacesobtainedinliquidnitrogenofstarch/zeinblendsplasticizedwith20%glycerol:(a)80/20;(b)50/50;and(c)20/80. (Reproducedwithpermissionfrom CorradiniE,deCarvalhoAJF,daSilvaCurveloAA,AgnelliJAM,MattosoLHC.Preparationand characterizationofthermoplasticstarch/zeinblends.MaterRes2007;10(3):227–231.)

1.3.6Zein

Formorethan100years,therehasbeenongoinginterestinusingcerealprolaminproteinssuchasmaizezeintomakeplasticsbecauseofitsvariousadvantageoussuchasgoodfilm-formingproperties,goodtensileandmoisture properties,antimicrobialandantifungalactivity,goodmechanicalproperties, andlowoxygenandCO2 permeability.Zeinisfoundincornendospermand hasbeentheobjectofresearch,aswellasindustrialinterest,foritsfilm-forming abilityanduniquehydrophobicity,whichisduetoitshighcontentofnonpolar aminoacids.Likeanyotherprotein,uponisolationfromthenativestate,zein showshighdensityandbrittlebehavior.Itsbrittlenesscanbeovercomebyusing plasticizerssuchaswater,glycerol,andethyleneglycol [117–120]

InastudybyDiMaioandhisresearchgroup,itwasshownthatthesupramoleculardesignoftheproteincanbeachievedbymodifyingthehierarchical structureofzeinusingahighlyinteractiveadditivesuchaslignintoobtainbionanocompositescharacterizedbyenhancedmechanicalperformancesandspecificfunctionalproperties(fromhydrophilictohydrophobicbehavior)suitable forspecificapplications(frombiomedicalusestofoodpackaging) [119].

1.3.7Cellulose

Celluloseinitsunmodifiedformisthedominantcomponentofmanymajor agriculturalandforestryproducts.Purifiedcelluloseisproducedmainlyfrom thebleachedwoodpulpresultingfromthesulfiteorKraftprocess,which removesmostoftheassociatedhemicellulose,lignin,pectin,andothercompounds.Isolatedcellulosecannotbeusedforplasticsbecauseitiscrystalline, hasastiffrod-likeconformation,andtheindividualchainsaretootightlyconnectedbyhydrogenbonds.Unmodifiedcellulosefibersareusedasreinforcing agentsinbiocomposites,improvingtensileandflexuralmodus [121].Cellulose canbeinvolvedinvariouschemicalmodificationsortreatmentstoafford differentapplicability.

Nitrocellulosecombinedwithcamphorandothercomponentsyieldedthe firstthermoplastic,knownasParkesineandCelluloid,whichwasusedasan ivoryreplacement.Givenitsflammabilityandeasydecomposition,onlyminor applicationssuchasthoseinguitarpicksandtabletennisballssurvived [13].

Cellophaneismadeofrestructuredcelluloseproducedbydissolvingitina baseandcarbondisulfide(thesolutionisknownasviscose),extrudingthrough aslitintodilutesulfuricacidandsodiumsulfate,washing,andaddingglycerol. Theresultingfilmisstillwidelyusedforfoodpackaging [13].

Celluloseacetate,preparedbythetreatmentofpurifiedcellulosewithglacialaceticacid,isusedinframesforeyeglasses,adhesives,photographyfilms, paint,textilefibers,packagingmaterials,artificialkidney,reverseosmosis membranes,andmanyotherapplications.Otherderivativesarecarboxymethyl cellulose(CMC),methylcellulose(MC),hydroxypropylcellulose(HPC),and

hydroxyethylcellulose [13,122].Plasticmaterialsmadeofcellulosederivativesareproducedbytherouteshownin Fig.1.14[64].

ThemechanicalpropertiesofCAcangetbetterwhencombinedwithstarch acetate(SA).TheresultingfilmscombinetheadvantagesofCAandSAwhile reducingtheirdisadvantages.Forexample,SAfilmisfragileandeasilytorn, andCAfilmdegradesslowlywhenburiedinthesoil.However,bychanging theproportionofSA,themechanicalpropertiesofthefilmimproveandthedegradationpropertiescanbecontrolled [122].

AstudybyMohantyetal.wasfocusedonthefabricationoflow-cost,valueaddedbiodegradablecompositematerialsfromarecycledbiobasedproduct suchasrecycledcellulosefibers(RCF)andPHBV.Theincorporationof RCFconsiderablyimprovedthepropertiesofPHBVsuchastensile,storage moduli,andheatdeflectiontemperature.ThebiodegradablenatureandcompetentpropertiesofRCF-reinforcedPHBVcompositesmakeitasustainablealternativetoconventionalthermoplastic-basedmaterials [123].

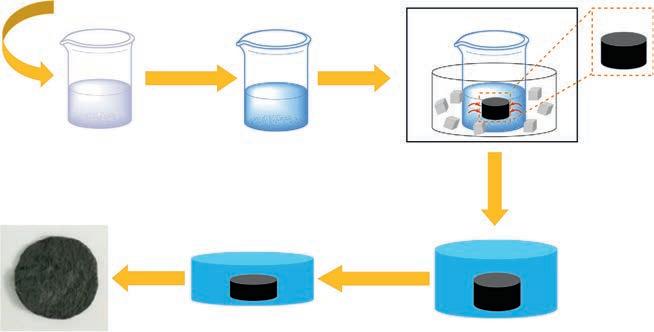

Inanotherstudy,Caietal.fabricatedbioplasticsofanewclassfromcellulosehydrogelspreparedinanalkalihydroxide/ureaaqueoussolutionbychangingtheaggregatedstructureviahotpressingprocess(Fig.1.15) [124].The bioplasticshadauniformlyorientatedstructureintheparalleldirectionanddisplayedgoodopticaltransmittance.Moreover,thecellulosebioplasticexhibited muchhighertensilestrength,flexuralstrength,andthermalstability,aswellasa lowercoefficientofthermalexpansionthancommonplasticsandtheregeneratedcellulosefilms.

FIG.1.14 Productionroutetobioplasticsmadeofcellulosederivatives [64]

22 Biopolymer-basedmetalnanoparticlechemistryforsustainableapplications

FIG.1.15 Schematicrepresentationofthepreparationapproachforthecellulosebioplastic: (i)generationofhomogeneouscellulose/NaOH/ureaaqueoussolution;(ii)formationofphysical hydrogelviaanonsolventandthenwashing;(iii)preparationofcellulosebioplasticbysimple hotpressingofthehydrogel [124]

Shiandco-workersalsopreparedfunctionalcellulosebioplasticswithisotropicthermalproperties,whichwereenhancedbythree-dimensionalinterconnectedgrapheneaerogels(Fig.1.16) [125].Hence,thethree-dimensional interconnectedGAendowsthecellulosebioplasticwithhighthermalconductivityand,inturn,thecellulosebioplasticstrengthensthefragileGA,resulting inthebettermechanicalperformanceofthecomposites,whichwillreplace fossilfuelplasticsinthefieldofthermalmanagementandbroadentheapplicationsofthecellulosebioplastic. Fig.1.17 showsthephotographsofcellulose, cellulose/GA,andGA.

1.3.8Lignin

Of70milliontonsofligninobtainedfromthepaper-makingindustry,only2% isprocessedandutilizedasligninandtherestisaddedintofuels.Inbioplastics, lignincanbeusedasreinforcement.Blendingthisbiopolymerwithother

FIG.1.16 Fabricationprocessofcellulose/GAcomposites [125]