BIOFUELSFORA MORE SUSTAINABLE FUTURE

LifeCycleSustainability AssessmentandMulti-Criteria

DecisionMaking

Editedby

Elsevier

Radarweg29,POBox211,1000AEAmsterdam,Netherlands TheBoulevard,LangfordLane,Kidlington,OxfordOX51GB,UnitedKingdom 50HampshireStreet,5thFloor,Cambridge,MA02139,UnitedStates

© 2020ElsevierInc.Allrightsreserved.

Nopartofthispublicationmaybereproducedortransmittedinanyformorbyanymeans,electronic ormechanical,includingphotocopying,recording,oranyinformationstorageandretrievalsystem, withoutpermissioninwritingfromthepublisher.Detailsonhowtoseekpermission,further informationaboutthePublisher’spermissionspoliciesandourarrangementswithorganizations suchastheCopyrightClearanceCenterandtheCopyrightLicensingAgency,canbefoundatour website: www.elsevier.com/permissions.

Thisbookandtheindividualcontributionscontainedinitareprotectedundercopyrightbythe Publisher(otherthanasmaybenotedherein).

Notices

Knowledgeandbestpracticeinthisfieldareconstantlychanging.Asnewresearchandexperience broadenourunderstanding,changesinresearchmethods,professionalpractices,ormedical treatmentmaybecomenecessary.

Practitionersandresearchersmustalwaysrelyontheirownexperienceandknowledgeinevaluating andusinganyinformation,methods,compounds,orexperimentsdescribedherein.Inusingsuch informationormethodstheyshouldbemindfuloftheirownsafetyandthesafetyofothers, includingpartiesforwhomtheyhaveaprofessionalresponsibility.

Tothefullestextentofthelaw,neitherthePublishernortheauthors,contributors,oreditors,assume anyliabilityforanyinjuryand/ordamagetopersonsorpropertyasamatterofproductsliability, negligenceorotherwise,orfromanyuseoroperationofanymethods,products,instructions,orideas containedinthematerialherein.

LibraryofCongressCataloging-in-PublicationData

AcatalogrecordforthisbookisavailablefromtheLibraryofCongress

BritishLibraryCataloguing-in-PublicationData

AcataloguerecordforthisbookisavailablefromtheBritishLibrary ISBN:978-0-12-815581-3

ForinformationonallElsevierpublicationsvisitour websiteat https://www.elsevier.com/books-and-journals

Publisher: CandiceJanco

AcquisitionEditor: MarisaLaFleur

EditorialProjectManager: DevlinPerson

ProductionProjectManager: VigneshTamil

CoverDesigner: GregHarris

TypesetbySPiGlobal,India

Contributors

KathleenB.Aviso

ChemicalEngineeringDepartment,DeLaSalleUniversity,Manila,Philippines

EricAlbertoOcampoBatlle

FederalUniversityofItajuba ´ —UNIFEI,Itajuba ´ ,Brazil

MonicaCarvalho

FederalUniversityofParaı´ba—UFPB,Joa ˜ oPessoa,Brazil

JoseLuizCasela

IndustrialandSystemsEngineeringGraduateProgram(PPGEPS),PolytechnicSchool, PontificalCatholicUniversityofParana ´ (PUCPR),Curitiba,Brazil

MaurizioCellura

DepartmentofEngineering,UniversityofPalermo,Palermo,Italy

HungPhuocDuong

InternationalCooperationDepartment,MinistryofNaturalResourcesandEnvironment, HaNoi,VietNam

FrancescoGuarino

DepartmentofEngineering,UniversityofPalermo,Palermo,Italy

OsirisCanciglieriJunior

IndustrialandSystemsEngineeringGraduateProgram(PPGEPS),PolytechnicSchool, PontificalCatholicUniversityofParana ´ (PUCPR),Curitiba,Brazil

JuarezCorr^ eaFurtadoJu ´ nior

StateUniversityofCampinas—UNICAMP,Campinas,Brazil

DinhSyKhang

HoChiMinhCityUniversityofNaturalResourcesandEnvironment,HoChiMinhCity, Vietnam

KaiLan

DepartmentofForestBiomaterials,NorthCarolinaStateUniversity,Raleigh,NC,United States

RuojueLin

DepartmentofIndustrialandSystemsEngineering,TheHongKongPolytechnicUniversity, HongKongSAR,China

YueLiu

DepartmentofIndustrialandSystemsEngineering,TheHongKongPolytechnicUniversity, HongKongSAR,China

SoniaLongo

DepartmentofEngineering,UniversityofPalermo,Palermo,Italy

ElectoEduardoSilvaLora

FederalUniversityofItajuba ´ —UNIFEI,Itajuba ´ ,Brazil

YasuakiMaeda

ResearchOrganizationforUniversity-CommunityCollaborations,OsakaPrefecture University,Sakai,Japan

YiMan

DepartmentofIndustrialandSystemsEngineering,TheHongKongPolytechnicUniversity, HongKongSAR;SchoolofLightIndustryandEngineering,SouthChinaUniversityof Technology,Guangzhou,China

RosanaAdamiMattioda

IndustrialandSystemsEngineeringGraduateProgram(PPGEPS),PolytechnicSchool, PontificalCatholicUniversityofParana ´ (PUCPR),Curitiba,Brazil

MarinaMistretta

DepartmentofHeritage,ArchitectureandUrbanPlanning,UniversityofReggioCalabria, ReggioCalabria,Italy

PiergiuseppeMorone

BioeconomyinTransitionResearchGroup(BiT-RG),UnitelmaSapienzaUniversityof Rome,Rome,Italy

KeitoNakagawa

PlantEngineeringDivision,MitsubishiHeavyIndustriesEnvironmentalandChemical EngineeringCo.,Ltd.,Yokohama,Japan

TuAnhNguyen

GraduateSchoolofHumanitiesandSustainableSystemSciences,OsakaPrefecture University,Sakai,Japan

KojiOtsuka

GraduateSchoolofHumanitiesandSustainableSystemSciences,OsakaPrefecture University,Sakai,Japan

JoseCarlosEscobarPalacio

FederalUniversityofItajuba ´ —UNIFEI,Itajuba ´ ,Brazil

SunkyuPark

DepartmentofForestBiomaterials,NorthCarolinaStateUniversity,Raleigh,NC, UnitedStates

MichaelAngeloB.Promentilla

ChemicalEngineeringDepartment,DeLaSalleUniversity,Manila,Philippines

LuisF.Razon

ChemicalEngineeringDepartment,DeLaSalleUniversity,Manila,Philippines

JingzhengRen

DepartmentofIndustrialandSystemsEngineering,TheHongKongPolytechnicUniversity, HongKongSAR,China

SerenellaSala

EuropeanCommission,JointResearchCentre(JRC),Ispra,Italy

LaurenceStamford

SchoolofChemicalEngineeringandAnalyticalScience,TheUniversityofManchester, Manchester,UnitedKingdom

AndrzejStrzałkowski

BioeconomyinTransitionResearchGroup(BiT-RG),UnitelmaSapienzaUniversityof Rome,Rome,Italy;UniversityofWarsaw,Warsaw,Poland

RaymondR.Tan

ChemicalEngineeringDepartment,DeLaSalleUniversity,Manila,Philippines

AlmonaTani

BioeconomyinTransitionResearchGroup(BiT-RG),UnitelmaSapienzaUniversityof Rome;FoodandAgricultureOrganization—FAO,Rome,Italy

DavidRibeiroTavares

IndustrialandSystemsEngineeringGraduateProgram(PPGEPS),PolytechnicSchool, PontificalCatholicUniversityofParana ´ (PUCPR),Curitiba,Brazil

OsvaldoJoseVenturini

FederalUniversityofItajuba ´ —UNIFEI,Itajuba ´ ,Brazil

YuanYao

DepartmentofForestBiomaterials,NorthCarolinaStateUniversity,Raleigh,NC,United States

KristaDanielleS.Yu

SchoolofEconomics,DeLaSalleUniversity,Manila,Philippines

JadwigaR.Ziolkowska DepartmentofGeographyandEnvironmentalSustainability,TheUniversityofOklahoma, Norman,OK,UnitedStates

JadwigaR.Ziolkowska DepartmentofGeographyandEnvironmentalSustainability,TheUniversityofOklahoma,Norman,OK,

1Introduction

Biofuelsaredefinedasfuelsproducedfromlivingplantmatteror by-productsofagriculturalproduction;theyareprimarilygroupedintobiodieselandethanol.Biofuelscanbedividedandseparatedintoseveralgroups basedontheirtechnologies,processes,andfeedstocks.

Biofuelstechnology canbedefinedasapplicationoffeedstocksina sequenceofprocessesleadingtotheproductionofdifferentbiofuelstypes. Biofuelsprocesses areeithernaturalorchemicalstagesofanindustrialorpilot projectdevelopmentleadingtothefinalproductionofbiofuels. Biofuelsfeedstocks areanyliving,dead,ordecomposedplantmaterialssuitableforprocessingandconversiontobiofuelsbymeansofdifferentprocesses.

Fromtheperspectiveoftheindustrialdevelopmentandmarketpresence, biofuelsfeedstocks,processes,andtechnologiescanbeclassifiedas “developed”(withwell-establishedmarkets),“developing”(withnewly createdorprogressingmarketshares),orinthe“demonstration”stage

(describingpilotprojectsorpotentialfuturedevelopments)(compare: Lane, 2017).Duetoahighfeedstockvariabilityaccessibletobeutilizedforbiofuelsgenerationtheexistingbiofuelstechnologiesandprocesseshave expandedovertimethuscreatingawidenetofproductionopportunities andinnovationpotentialinthisfield.

Generally,biofuelstechnologiescanbedividedinto“conventional”and “advanced”biofuels(Fig.1.1).Conventionalbiofuels(alsocalled“firstgenerationbiofuels”)designateethanolandbiodieselgeneratedfromeatable crops.Advancedbiofuels(encompassingthe“second,thirdandfourthgenerationbiofuels”)aredefinedasliquidfuelsfromnonfood/nonfeedsustainablygrownfeedstocksandagricultural(municipal)wastes.Theneedfor advancedbiofuelsoriginatedfromaconcernaboutthecompetitionfornaturalresources(e.g.,water,energy,land)betweenfuelandfoodproduction (Rathmannetal.,2010; HarveyandPilgrim,2011, Ajanovic,2011). Accordingly,advancedbiofuelscannotcreateanycompetitionwithfood cropproduction,whiletheyneedtomeethighersustainabilityrequirements,thatis,contributetogreenhousegas(GHG)emissionreduction byalargerpercentagethanconventionalbiofuels.

Thedesignationofbiofuels“generations”isdirectlylinkedandsubject tothespecifictechnologyandfeedstockusedforbiofuelsproduction.Italso relatestothetemporaldevelopmenttrendsoveryearsandthecomplexityof

Fig.1.1 Biofuelstechnologieswithcorrespondingdevelopmentstages. (Authors’ presentationmodifiedfromZiolkowska,J.R.,2014.Prospectivetechnologies,feedstocks andmarketinnovationsforethanolandbiodieselproductionintheUS.Biotechnol. Rep.4,94–98;Ziolkowska,J.R.,2018.Introductiontobiofuelsandpotentialsof nanotechnology.In:Srivastava,N.,Srivastava,M.,Pandey,H.,Mishra,P.K., Ramteke,P.W.(Eds.),GreenNanotechnologyforBiofuelProduction.Biofueland BiorefineryTechnologies.Springer,Basel,pp.1–15.)

thebiofuelsmarketwithagrowingnumberofpotentialfeedstockstobe usedforbiofuelsproduction.

Firstgenerationbiofuels areproducedfromfoodcrops:(a)biodiesel extractedfromoilplants/plantmaterials(inthechemicalprocessoftransesterificationandesterification),and(b)ethanolextractedfromsugarcontainingplants/plantmaterialsandconvertedtofuelintheprocessof fermentation. Secondgenerationbiofuels areproducedfromnonfoodcrops (e.g.,cropwaste,greenwaste,wood,andenergycropsplantedspecifically forbiofuelsproduction). Thirdgenerationbiofuels arebasedonimprovements inbiomassproduction,withalgaebeingthemainfeedstockrepresentingthis groupasoftoday. Fourthgenerationbiofuels aimatprovidingmoresustainable productionoptionsbycombiningbiofuelsproductionwithcapturingand storingCO2 withtheprocessofoxy-fuelcombustionorbyapplication ofgeneticengineeringornanotechnology.

Duetothewiderangeoffeedstockapplicationandprocessdevelopment theevaluationofdifferentbiofuelsintermsoftheirsustainabilitywillclearly dependonthecombinationofthosefactors.Thusinthefaceofthemultitudeofdiscussionsinthisfield,acloserlookateachofthebiofueltypesis neededforaholisticandscience-basedevaluation.

Althoughthischapterdoesnotaimatinvestigatingsustainabilityofthe respectivebiofuelstechnologies,processes,andfeedstocksperse,itwillprovideanoverviewforabetterunderstandingofthoseissuestobeaddressedin thefollowingchaptersinthisbook.

2Biofuelstechnologiesandfeedstocks

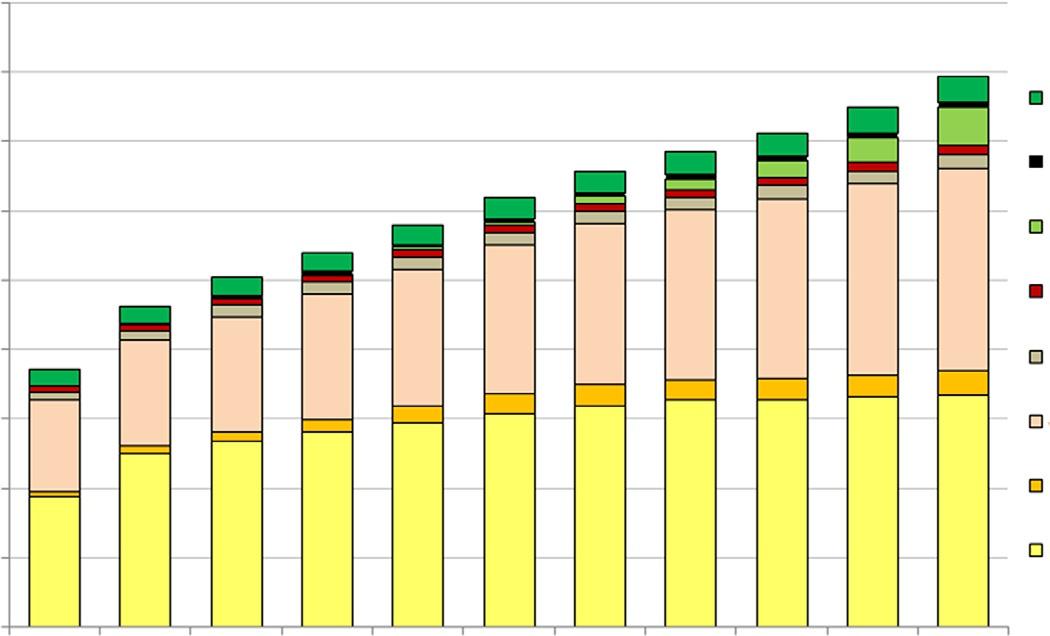

Globally,thetotalbiofuelsproductionhasincreasedovertime,withanestimatedethanolproductionat160billionliters(42.3billiongallons)in2019 andbiodieselproductionat41billionliters(11billiongallons)(OECD, 2010)(Figs.1.2and1.3).Thefeedstockcompositionintheglobalbiofuels productionhasvariedandchangedconsiderablyovertimeaswell.Accordingto OECD(2010) projections,ontheethanolmarket,coarsegrains (includingcorn)havereachedthepeakin2016,whileethanolproduction fromsugarcanewillincreasethroughout2019.Anincreasingtrendwasalso projectedforbiomass-basedethanolwith11billionliters(2.9billiongallons) onthemarketin2019.Onthebiodieselmarket,vegetableoilsconstitutethe mainfeedstockthatisexpectedtoincreaseupto30.7billionliters(8.1billiongallons)by2019(OECD,2010).Alsojatrophaandothernonagriculturalfeedstocks(animalfats)makeasmallershareinthebiodiesel 3

Others feedstocks

Roots

Biomass based (second generation)

Fig.1.2 Globalethanolproductionbyfeedstock projections(2007–19). (Modified fromOECD-FAO,2010.AgriculturalOutlook2010.BiofuelProduction2010–19; Ziolkowska,J.R.,2018.Introductiontobiofuelsandpotentialsofnanotechnology.In: Srivastava,N.,Srivastava,M.,Pandey,H.,Mishra,P.K.,Ramteke,P.W.(Eds.),Green NanotechnologyforBiofuelProduction.BiofuelandBiorefineryTechnologies.Springer, Basel,pp.1–15.)

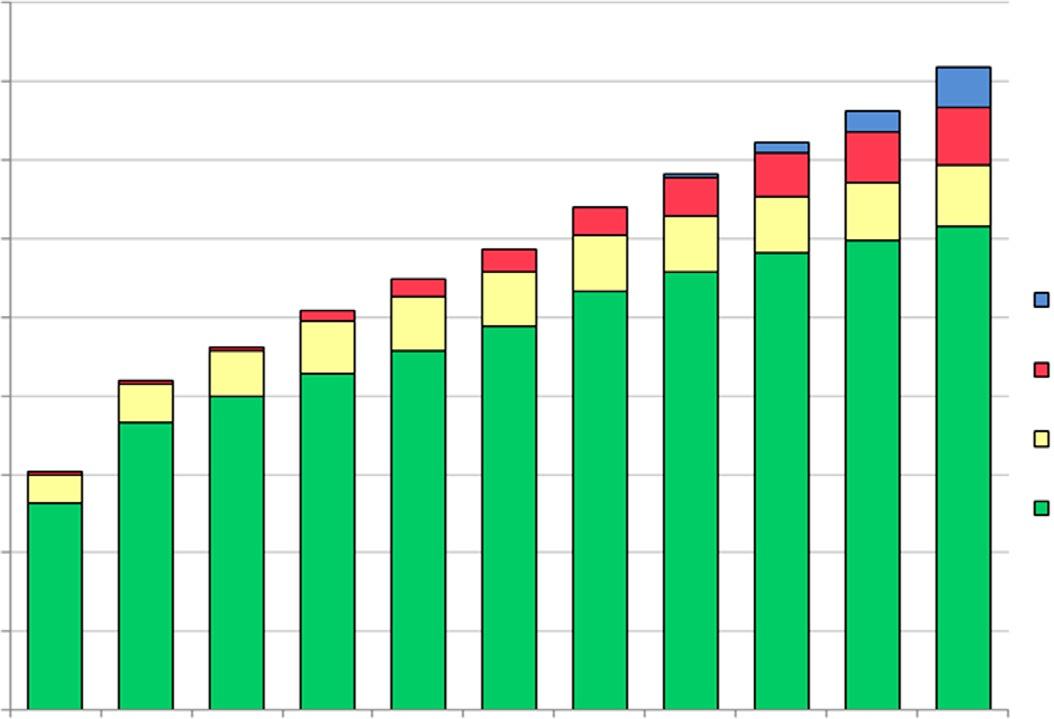

Biomass-based (second generation)

Jatropha

Nonagric. (animal fats)

Vegetable oil

Fig.1.3 Globalbiodieselproductionbyfeedstock projections(2007–19). (Modified fromOECD-FAO,2010.AgriculturalOutlook2010.BiofuelProduction2010–19; Ziolkowska,J.R.,2018.Introductiontobiofuelsandpotentialsofnanotechnology.In: Srivastava,N.,Srivastava,M.,Pandey,H.,Mishra,P.K.,Ramteke,P.W.(Eds.),Green NanotechnologyforBiofuelProduction.BiofuelandBiorefineryTechnologies.Springer, Basel,pp.1–15.)

production.However,theirusehasincreasedovertimeandcouldeven becomeofahigherimportanceinthefuture.Biodieselproductionfrom animalfats,however,hasremainedratherstableovertimeintermsofthe percentageshareinthetotalbiofuelsproduction(Fig.1.3).

2.1Conventional(firstgeneration)biofuels

Thefirstattemptsofbiofuelsengineoperation(peanutoilenginerunby RudolfDieselin1900andvegetableoilrunenginesin1930s)aswellthe firstindustrialbiofuelswerebasedonfoodcrops(Ziolkowska,2018).In thepastdecades,foodcropapplicationforbiofuelsproductionhasincreasinglybeencriticizedduetotwomajorissues:“fuelvs.food”trade-offand concernsabouttherealCO2 reductionpotentialofbiofuels(somebiofuels couldreleasemorecarbonintheirproductionprocessthansequesteritinthe feedstockgrowthprocess).

Becauseoftheseurgentissues,moststudiesinthisareafocusoncompetitionforresourcesresultingfromcropcultivationandtheirapplication eitherforfood/feedorbiofuelsproduction.Thistrade-offsituationforfood, feed,fuel,andproductionfactorscanimpactproducers,distributors,andthe relatedmarkets,andfinallyregionalandnationaleconomies(Tomeiand Helliwell,2016; Baffes,2013; Filipetal.,2017).Mostattentionintheliteraturehasbeengiventolandresources(Rathmannetal.,2010; Harvey andPilgrim,2011)andimpactsofbiofuelsproductiononfoodmarketprices (Ake,2017; Encisoetal.,2016; Tyner,2013; Ajanovic,2011).

Conventionalbiofuelsencompassethanol(producedfromcropswith highsugarcontents,e.g.,corn,cereals,sugarbeet/sugarcane)andbiodiesel (producedfromhigholeicplants,e.g.,soybean,rapeseed,palmoil,animal fats,wasteoils).

Inthepastdecades,conventionalbiofuelshavedevelopedintoflourishingfuelmarkets.In2015intheUnitedStatesalone,theconsumptionof ethanolinBTUenergyunits(1BTU ¼ 1055J)amountedto1.14quadrillionBTU,whilebiodieselconsumptiontotaled0.26quadrillionBTU.The totalcapacityofethanolconsumptionwasestimatedat15billiongallons(57 billionliters),while2billiongallons(7.6billionliters)forbiodiesel (USEIA,2016).

Productionofconventionalbiofuelshasvariedindifferentpartsofthe world,subjecttofeedstockavailability.Globalproductionofconventional biofuelsforthetransportsectorreached140billionliters(37billiongal)in 2017(IEA,2018).In2015,BrazilandtheUnitedStatesaccountedfor 70%

oftheglobalbiofuelsupplyofsugarcane-andcorn-basedethanol(REN21, 2016; Arau ´ joetal.,2017).Othersuppliers,thatis,EuropeanUnioncountriesandAsiahaveenteredthebiofuelsmarketinthelasttwodecades.BiofuelsproductionintheEuropeanUnionismainlybasedonbiodieselfrom waste,soybeans,rapeseed,andpalm(HuentelerandLee,2015),whileinthe AmericasandAsiaethanolproductionisprevailingwiththefollowingfeedstocks:sugarcane,corn,wheat,andcassava.InAsia,additionaleffortsand investmentsinrecentyearshavecontributedtoagrowingbiodieselmarket utilizingpalm,soybean,rapeseed,andJatrophafeedstocks.Theregionaland feedstockdiversificationhasbeenrecognizedbyseveralGermanassociations andagencies(GTZ,2006)aspotentiallyconducivetotheformationofan internationalbiofuelcommoditiesmarket.

2.2Advancedbiofuels

Thedevelopmentofadvancedbiofuelswaspropelledinresponsetoconcernsrelatedtothe“fuel-foodtradeoff”aswellasenvironmentalandeconomicquestionssurroundingconventionalbiofuels(UNReport,2007).By utilizingbiomass(notsuitableeitherforfoodorfeedpurposes)andinmany casesgrownonmarginallands,theproblemofresourcecompetitionin food/fuelproductioncouldpotentiallybemitigatedtosomedegree.At thesametime,emergingrecognitionsandnewknowledgeaboutenergy valueofbiofuels(comparedtofossilfuels)spurredquestionsabouteconomic efficiencyofbiofuelsingeneral(Czekałaetal.,2018).Forinstance,productionofcellulosicbiofuelishighlyenergyintensivemeaningthatenergycontainedinthistypeofbiofuelislowerthantheenergyrequiredforits production(GeandLi,2018).

EnvironmentalquestionsaboutadvancedbiofuelsrelatedirectlytoCO2 emissionreduction.ManystudiesprovidedevidencethatbiofuelscontributetoCO2 emissionreductionsinthefuelburningprocess(Mendiaraetal., 2018; KousoulidouandLonza,2016; Subramanianetal.,2018).However, itneedstobeemphasizedthattheexactemissionreductionlevelsstrongly dependontheappliedfeedstock,withalgaebeingacknowledgedamongthe leadingfeedstocks(ShubaandKifle,2018; Suetal.,2017; SavakisandHellingwerf,2015)withcarbonnegativeproperties(ZiolkowskaandSimon, 2014).However,concernshavebeenraisedaboutotherbiomassfeedstocks (e.g.,timber)pointingoutthatforestbioenergyisnotcarbonneutraldueto highCO2 emissionsreleasedinthewoodburningprocess(Moomaw, 2018).Accordingto USEIA(2016),theconsumptionofwood/forestry

biomass(includingwoodpellets,hogfuel,andwoodchips)utilizedforelectricityandheatproductioninBTUenergyunitsislargerthanbioenergy fromconventionalbiofuels.IntheUnitedStatesalone,woodbiomassconsumptionamountedto2.04quadrillionBTUin2015,whileittotaled 11milliontonsinwoodpelletcapacity.

2.2.1Cellulosicethanol(secondgenerationbiofuels)

Cellulosicethanolcanbeproducedfromanymaterialcontainingcellulose andlignocellulose.Themainfeedstocksourcesforcellulosicethanolproductioncanbedividedasfollows:

(a) Energycropsgrownspecificallyforthepurposeofconversioninto biofuels(e.g.,switchgrass,miscanthus,wheatstraw,poplar,willow, jatropha).

(b) Greenwasteusedasaby-productofotherproductionprocesses(e.g., cornstoverandotherfieldresidue,e.g.,stalksandstubble(stems), leaves,seedpods,aswellasforest/parkresidues).

Accordingto Chenetal.(2010),40%–70%ofhemicelluloseand72%–90% ofcelluloseincorncobscouldbeconvertedtoethanolusingdifferentbacteriaandfungi.Alsoapplicationofmoreunconventionalfeedstockscontainingcelluloseorlignin(e.g.,kapokfiber,pineapplewaste,wastepapers,and coffeeresiduewasteforbioethanolproduction)hasrecentlybeeninvestigated(Duttaetal.,2014; Choietal.,2012; Ruangviriyachaietal.,2010; Chenetal.,2010).

Thequestionofeconomicefficiencyofthesecondgenerationbiofuels remainsopenduetohighcostsrelatedtobreakingdowncellulose,makingit alessercompetitivefeedstockandbiofuelingeneralcomparedtofossilfuels. Althoughmanyindustrialandlaboratoryattemptshavebeenundertakenin thepastdecadetolowertheproductioncostsofcellulosicethanol,the experimentswerenotassuccessfulasinitiallyanticipated,withtheaverage priceforcellulosicethanolstillnotbeingcompetitiveenoughwithtraditionalgasoline.Asof2010,productioncostsofcellulosicethanolequaled to $2.65/galoffuel(Coyle,2010),whichwas $1morethancostsofcorn ethanol.ThemorerecentresearchstudiesandscenariosbytheNational RenewableEnergyLaboratory(NREL)haveproventhatcellulosicethanol couldbecostcompetitiveat $2.15/gal(NREL,2013).Duetothiseconomiclimitationdeterminingthemarketaccess,moststudiesinthisarea arefocusedonimprovingtechnologicalprocessesofcellulosedecompositionandbreakdown(LiuandBao,2017; Gaoetal.,2018; Shadbahr etal.,2018; Songetal.,2018).Manystudiesattemptedtoprovidesolutions

tohighcostsofsecondgenerationbiofuelsbyintroducingmicrobialorfungalsystemsfacilitatingmoreeffectiveandfastercellulosebreakdownandfermentationprocess(Bhatiaetal.,2017; Ziolkowska,2014).However, researchanddevelopmentinthisfieldisongoingandnowide-scalecommercialsolutionhasbeenintroduced,whichagain,willdependonthe respectivefeedstocksandtheircelluloseandlignincontents.

Anadvantageofadvancedbiofuelsisthatfeedstocksusedfortheirproductiongenerallygenerategreatergreenhousegasemissionssavings,and thusaremoresustainableanddesirablefromtheenvironmentalpointof view.Forthisreason,intheUnitedStates,withthe2007EnergyIndependenceandSecurityAct,theRenewableFuelStandards(RFS)wereintroducedasamandatetoexpandthequantityofrenewablefuelsblendedinto transportfuelfrom9billiongallons(34.07billionliters)in2008upto36billiongallons(136.27billionliters)in2022(Ziolkowska,2018;Ziolkowska etal.,2010).Withinthesetotals,startingin2015,only15billiongallons (56.78billionliters)canbeprovidedonthemarketfromconventionalethanol,whiletheremainingannualmandatedquantityneedstobesupplied fromadvancedfeedstocks.InApril2010,theRFS2wasenactedbythe EPAasanextensionoftheoriginalmandatespecifyingminimumquantities fromdifferentfeedstocksorbiofueltypesneededtobeblendedtowardthe totalmandate(FAPRI,2010; Ziolkowskaetal.,2010).Accordingly,thecellulosicethanolproductionwasmandatedtoincreaseeachconsecutiveyear withthegoalof16billiongallons(60.5billionliters)in2022(USEPA, 2010).Furthermore,cellulosicethanolwasassignedaLifeCycleAssessment requirementtobeeffectivewithreducingGHGemissionsbyatleast60% comparedtotheemissionlevelsgeneratedfromcombustionoftraditional gasoline(i.e.,fossilfuelsusedintransportation)(Table1.1).Duetothe 2007EnergyIndependenceandSecurityActandrenewablefuelstandards establishedasmandates,productionofcellulosicethanolandcompliance withitssupplyforblendinghasbeenmainlydiscussedintheUnitedStates. InEurope,wherebiofuelspolicyisbasedonvoluntarytargetsratherthan mandates,cellulosicethanolproductiontookoffatalatertimeandhas gainedlessattentioningeneral.

Itneedstobementionedthatinadditiontobioethanolproductionfrom thesecondgenerationfeedstocks,alsootheradvancedbiofuels(isopropanol, butanol,isobutanol,andfarnesol)havebeengainingonimportancedueto theirhighenergydensityaswellaslowerhygroscopicpropertiesandlower corrositytopipelinesduringtransportationthanotherfuels(Chenetal., 2013; Yuaetal.,2011).Inaddition,metabolicengineeringofbiosynthetic fuelscanleadtoevengreaterproductivityofthesealcohols.

Biodiesel1billiongal(3.79 billionI) 50%For2012andbeyonda

Cellulosic biofuel

16billiongal(60.57 billionI)

Advanced biofuel 21billiongal(79.49 billionI)

Renewable biofuel 36billiongal (136.27billionI)

a Couldbeincreasedfrom2013onward.

60%Subjecttoannual assessments

50%Anythingbutcornstarch, minimumof4billiongal additional

20%b

Minimumof15billiongal additional

b Onlyappliestofuelfromnewfacilities.”Grandfathered”facilitiesarethose(domesticandforeign)that commencedconstructionbefore31December2007andethanolfacilitiesthatcommencedconstruction priorto31December2009andusenaturalgasand/orbiomassforprocessheat.

DatafromUSEnvironmentalProtectionAgency(EPA),2010.NationalRenewableFuelStandard Program—Overview.OfficeofTransportationandAirQuality,USEPA,Washington,DC,April14; Ziolkowska,J.,Meyers,W.H.,Meyer,S.,Binfield,J.,2010.Targetsandmandates:lessonslearnedfrom EUandUSbiofuelpolicymechanisms.AgBioForum13(4),398–412.

2.2.2Algaebiofuels(thirdgenerationbiofuels)

Thethirdgenerationofbiofuelsaimsatimprovingtheproductionofbiomasstomakeitamoreviable(andsustainable)feedstock.Sincethebeginningsofthistechnology,thethirdgenerationbiofuelshavereliedonalgaeas themainfeedstock(growneithernaturallyorartificially).Manystudiesconfirmedthatthealgaefeedstockcanbecompetitivewithotherbiomass sources( JonesandMayfield,2012; ZiolkowskaandSimon,2014; Laurens etal.,2017; Adeniyietal.,2018),thusmakingit,inmanycases,moreprospectiveforcompanyinvestmentsthancellulosicethanol.Theadvantagesof algaeasafeedstockrelateto:

(a) Negative(carbonneutral)environmentalfootprintasbygrowingalgae 2gofCO2 areconsumedforeverygofgeneratedbiomass(Pienkosand Darzins,2009).Atthesametime,onetonofCO2 canbeconvertedinto 60–70galofalgae-basedethanol(Hon-Nami,2006;Hirayama etal.,1998).

(b) Possiblynocompetitionforfreshwaterasalgaecangrowinwaste/ salinewaterenvironment.

(c) Nocompetitionforfertileland(i.e.,nodirectfood-fueltrade-off)as algaeisgrowninclosedphotobioreactorsoropenponds(waterenvironments)whichcanbelocatedonanyplotoflandnotsuitablefor

otherpurposes,whichthuseliminatespotentialopportunitycosts (ZiolkowskaandSimon,2014).

(d) Highoilcontentsinalgaebiomassmakeitsuitabletoproduce10–100 timesmoreoilperacrethantraditionaloilcrops(suchasoilpalm)

(e) Fastgrowingrateasalgaecangrow20–30timesfasterthanfoodcrops (ZiolkowskaandSimon,2014).

(f) Highfueldiversityasalgaebiomasscanbeconvertedintoamultitudeof fueltypes,suchasdiesel,petrol,andjetfuel(seealso Jonesand Mayfield,2012).

(g) Highnutritionaldiversityofthefeedstockasitcanbeprocessedboth throughsugarandoilprocessingprocedurestoextractsugars/oilsfor biofuelsproduction.

(h) Highcompatibilitywithtraditionalgasolineengines(thuseliminating theneedofautomobileengineadjustments)duetothesamebiochemicalcharacteristicsandcomposition(energydensity,numberofcarbon atomspermolecule)aspresentingasoline(Solazyme,2012).

Despitethemanyadvantagesofalgaebiomassandalgae-basedfuels,itseconomicfeasibilityhasbeenquestionedandchallengedmanytimes(Doshi etal.,2016; VassilevandVassileva,2016).Also,economicandpolicyissues havebeenpointedoutaspossibledeterminantsoffuturedevelopments (Doshietal.,2016).In2008,thepriceforalgae-basedfuelsamountedto approximately $8/gal(USDOE,2008),whilethereisnouniformmarket estimateasthefinalpriceisdeterminedbyeachproducingcompanysubject totheappliedtechnologyandproductionfactors.Formanydecades,the industryhasstruggledwithbringingdowntheproductioncostandthus thefinalpriceofalgae-basedfuelsthroughreducingcostsofsystemsinfrastructureandintegration,algaebiomassproductionprocess,harvestingand dewateringtechniques,extractionandfractionation,andfinallybiofuels conversionprocess(USDOE,2010).Sustainableormarketcompetitive solutionshavenotbeenfoundtodatetomakealgae-basedfuelaviable anddesirablefuelduetothehighfuelunitcosts.

2.2.3Futuretechnology(fourthgenerationbiofuels)

Thefourthgenerationbiofuelsareinthedevelopmentandexperimental stages,thustheycombineadiversityofdifferent(potential)applicationsboth onthetechnology,processing,andfeedstocklevel.

Themainfeedstockforthefourthgenerationbiofuelsproductionis geneticallyengineered,highlyyieldingbiomasswithlowligninandcellulosecontents(thuseliminatingtheissuespresentinthesecondgeneration

biofuelsproductionline)ormetabolicallyengineeredalgae(withhighoil contents,increasedcarbonentrapmentability,andimprovedcultivation, harvesting,andfermentationprocesses)(thusimprovingthethirdgeneration production)(Duttaetal.,2014).Whilealgaehavecommonlybeenrecognizedforitshighoilcontents,theexactparametersdependontherespective algaestrains. Botryococcusbraunii,Chaetoceroscalcitrans,Chlorella species, Isochrysisgalbana,Nannochloropsis,SchizochytriumlimacinumandScenedesmus specieshavebeenanalyzedintheliteraturesofarfortheirapplicabilityand suitabilityforbiofuelsproduction(Chisti,2007; Rodolfietal.,2008; Singh andGu,2010).Ithasbeenfoundthatthefastgrowingalgae(e.g.,Spirulina) havelowoilcontent,whilealgaestrainshighinlipidcontentsarecharacterizedbyslowergrowthrates.Thusintroducingnewtechnologieslike metabolicengineeringforacceleratedgrowthofalgaebiomassorincreased lipidcontentscanresultinfastercommercializationandimprovedeconomic feasibilityoffourthgenerationbiofuels(SinghandGu,2010).Nanotechnologycouldalsobeappliedinalgaefuelproductiontoincreaseefficiencyof algaebiomassanddecreaseproductioncosts,thusmakingitacostcompetitiveadditiontothebiofuelmarket(Ziolkowska,2018).

Thefourthgenerationbiofuelsisdistinguishedfromotherbiofuelsproductiontechnologiesalsobythefactthatinmostcasestheyrepresentacombinationofdifferenttechnologies,forexample,sustainableenergy production(biofuels)andcapturingandstoringCO2 emissions.Biomass absorbingCO2 duringitsgrowthismanufacturedintobiofuelbymeans ofthesameorsimilarprocessesassecondgenerationbiofuels.Thedifference betweenthefourthgenerationbiofuelscomparedtothesecondandthird generationproductionisthattheformercapturesCO2 emissionsatallstages ofthebiofuelsproductionprocessbymeansofoxy-fuelcombustion (Ohetal.,2018; Sheretal.,2018).Oxy-fuelcombustionisaprocessutilizingoxygen(ratherthanair)forcombustionyieldingfluegasCO2 andwater (Markewitzetal.,2012).Whiletheprocessismoreeffectiveingenerating CO2 streamofahigherconcentration(themassandvolumearereducedby about75%),makingitmoresuitableforcarbonsequestration,theeconomic problemoccursmainlyattheinitialstageofseparatingoxygenfromtheair andusingitforcombustion.Theprocessrequireshighenergyinputs;nearly 15%ofproductionofacoal-firedpowerstationcanbeconsumedforthis process(UniversityofEdinburgh,n.d.),whichcanultimatelydriveupproductioncostsandmakethefinalprocesseconomicallyinfeasible.Even thoughcurrentlystillnotcompetitive,oxy-fuelcombustionhasbeenstudiedasapotentialalternativeincombinationwithbiofuelsproduction.For

thisreason,thistechnologyisinthedevelopingstageasoftoday.However, ifsuccessfullyvalidatedinthefuture,itcouldbeusedtogeosequesterCO2 bystoringitinoldoilandgasfieldsorsalineaquifers.Inthisway,through carboncapturingandstorage,thefourthgenerationbiofuelsproduction couldbecalledcarbonnegativeratherthancarbonneutral.Thusenvironmentaladvantagesarisebothfromcarbonstorageandfromreplacingfossil fuelswithbiofuels(UniversityofEdinburgh,n.d.).

Theremainingfuelfromoxy-fuelcombustioniscleanedandliquefied andyieldsultracleanbiohydrogen,biomethaneorsyntheticbiofuelsthat canbeusedinthetransportsectoraswellasforelectricitygeneration.

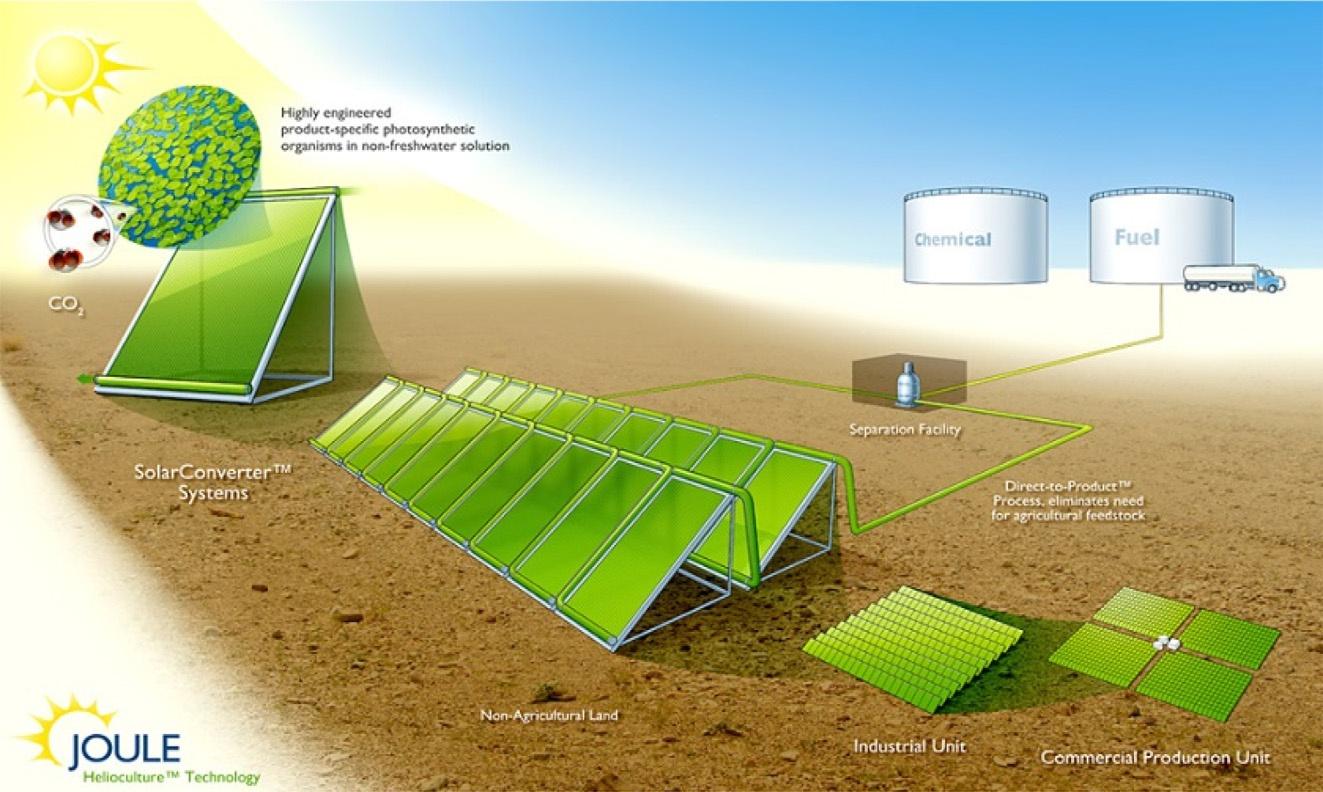

Anotherpotentialtechnologicalcombinationforbiofuelsproductionhas beenproposedbytheJoulecompanywiththeirrenewablesolarfuelgeneration(Fig.1.4).

Thecompanydevelopedaprocessforhydrocarbon-basedfuelgenerationthroughtheapplicationofnonfreshwater,nutrients,cyanobacteria, carbondioxide,andsunlight.Theprocessisbasedonheliocultureusing photosyntheticorganisms;however,itisdistinctfromthetraditional algae-basedfuelinthatthelatterneedtoberefinedintofuel,whilehelioculturedirectlyproducesfuel(eitherethanolorhydrocarbons)notrequiring

Fig.1.4 Joulehelioculturerenewablesolarfuel. (FromSt.John,J.,2010.Joule PatentsSecretSauceforDiesel-ExcretingOrganisms.2010.GigaOm,September14. https://gigaom.com/2010/09/14/joule-patents-secret-sauce-for-diesel-excreting-organisms (24November2018).)

anyrefinement.Theprocessdoesnotproducebiomasseither,thusmaking thetechnologyeasiertoapplyinpractice.AlthoughthecompanywasdiscontinueditsoperationinAugust2017duetodifficultieswithraisingadditionalfundsforfuturedevelopments,thesuggestedinnovationbasedon helioculturepresentsanattractivetechnologicalattempt.Thecompany claimedtobeabletoproducemorethan20,000galoffuelperacreperyear (19,000m3/km2).TheeconomicestimatesbyJouleUnlimitedclaimedits producttobecostcompetitivewithcrudeoilat $50abarrel($310/m3) (St.John,2010).

Moreover,nanotechnologyhasalsobeenconsideredasatechnological solutiontoalleviatechallengesrelatedtoalgalbiomassgrowthandcultivation(Sekoaietal.,2019; GavrilescuandChisti,2005),mainlyhighcostsof algaeharvestingandproductionaswellasenergy-intensivelipidextraction (PattarkineandPattarkine,2012).Anewformof“nanofarming”technologyiscurrentlyinthepilotstageandcouldfindwidecommercialapplication.Itfacilitatesoilextractionfromalgaeevenmoreefficientlyasitrelieson aprocessof“milkingalgae,”thususingbiomasscontinually(upto70days) ratherthandestroyingitasisthecommoncasewithconventionalmaterial scienceprocesses(Vinayaketal.,2015; Chaudryetal.,2016; Ziolkowska,2018).

3Biofuelsprocesses

Fromthetechnologicalperspective,fourmainprocessescanbedistinguishedforbiofuelsproduction:

(a) Mechanicalprocesses involvingtraditionalprocessingofwoodmaterials throughmechanicaltreatment,forexample,chippingorgrinding, andpotentiallythefollowingdensificationofthematerialbypelletizing thebiomass.

(b) Thermochemicalprocesses convertingbiomassintoenergythroughcombustion,followedbypyrolysis.Thisprocessismoreefficientthan mechanicalprocessesduetogreaterenergydensityaswellaschemical andphysicalfuelpropertiesbeingmoresimilartofossilfuels.Another possibleprocessisgasificationgeneratingsyngasfortheproductionof differentliquidbiofuels,throughtheFischer-Tropsch(FT)process.

(c) Chemicalprocesses areusedmainlyfortheproductionoftransportation fuels,suchasbiodieselandcellulosicethanol.

(d) Biochemicalprocesses appliedtoproducefuelethanol,forexample,sugar/ starchfermentationleadingtobiogas(methane)generationinanaerobic conditions.

Intheproductionprocessoffirstgenerationbiofuels,mainlysugarfermentationfollowedbythedistillationprocessisappliedtoproducedryethanol. Biodieselisproducedthroughtransesterificationofoilswithachemicalcatalyst(acid/alkali)orenzyme(Duttaetal.,2009; vanGerpenetal.,2002), followedbyatwo-stepdistillationtoremoveby-products(e.g.,glycerol).

Inregardtothesecondgenerationbiofuelsproduction(e.g.,cellulosic ethanol,butanol),thefollowingprocessesareapplied:pretreatmenttoseparatecelluloseandhemicellulosefromlignin,enzymatichydrolysis(i.e.,saccharification)toextractsimplesugars,fermentation,andfinallydistillation. Alsobiogasscanbeproducedthroughthesamesequenceofthebiochemical processesuptodistillation.Accordingly,gasificationorpyrolysis(thermochemicalprocesses)isappliedtoconvertbiomassathighertemperatures andpressuresthanthoseappliedinbiochemicalprocesses.Theprocessof biomassgasificationanddirectliquefactioniscommonlycalled“biomassto-liquid.”Gasificationismorecostintensivethanotherprocesses;however,itproducescleanerfuelthatcanbedirectlyusedinengines(Larson, 2007).Throughthegasificationprocess,avarietyofbiofuelscanbeproduced,suchasFischer-Tropschliquids(FTL),dimethylether(DME), andotheralcohols(FitzPatricketal.,2010; Duttaetal.,2014).

Thethirdandfourthgenerationbiofuelscanbeextractedwiththesame processes,whilethedifferencerelatesonlytothefeedstockusedattheinput stage(traditionallycultivatedalgaeforthethirdgenerationfuels,andgeneticallymodifiedalgaebiomassforthefourthgenerationfuels).Thusdifferent finalindustrialfuelscanbeextractedindifferentprocessesofthethirdand fourthgenerationbiofuelsproduction,asfollows:

(a) Biodieselthroughoilextraction,transesterification,anddistillation.

(b) Ethanol,biomethane,andbiobuthanolthroughbiochemicalprocesses, whilebiomethaneandbiobuthanolareprocessedinadditionthrough anaerobicdigestion.

(c) Syngas,syntheticdiesel(aviationfuel),andbioenergythroughthethermochemicalprocessofgasification(Duttaetal.,2014).

4Summaryandconclusions

Biofuelsproductionhasfacedmanysustainabilitychallengesoverthe decadesoftechnological,feedstock,andprocessdevelopments.Highcosts

offeedstockprocessingandenvironmentalconcernshavebeenamongthe majorissuesdiscussedinscientificdebatesandpolicyconsiderations.While conventionalbiofuelswereintroducedwithanefforttoincreaseenergy independencyfromfossilfuels(andforeignfuelimports),advancedbiofuels emergedasinnovationspilloversandexpandedataprogressivepace. Accordinglyavarietyofnewfeedstockshasbeenexploredandexperimentedwithtoalleviateeconomiclimitationstothosenewtechnologies.The mainpurposeoftheseinvestmentswastobringdowntheproductioncosts andthefinalpriceofadvancedbiofuels,withtheaimofmakingthemcompetitivewithfossilfuelsastransportationfuelandbioenergy.Althougha considerablesuccesshasbeenachievedintheseareas,challengesstillexist. Newtechnologicalinventions,suchasnanotechnologyandgeneticengineeringofbiofuelfeedstockscouldproveasaviablesolution.However, environmentalandsocialissuesofthesetechnologies(includingunexplored consequencesoftheirapplicationandpotentialimpactsonwaterresources, soil,andthefollowinginfluenceonhumans)havenotbeenfullyexplored yet.Socialresistancetothesetechnologies(ascurrentlyalsoanalyzedinthe foodsector)mightbedecisiveinthemid-andlong-termalsoforbiofuels production.

Governmentalandprivatefundingforresearchanddevelopmentofnew biofuelstechnologiescanbringaboutprospectivesolutionstothosequestionsandmakenewgenerationbiofuelsmoreeconomicallyfeasible,environmentfriendly,andsociallyacceptable.

References

Adeniyi,O.M.,Azimov,U.,Burluka,A.,2018.Algaebiofuel:currentstatusandfuture applications.Renew.Sust.Energ.Rev.90,316–335.

Ajanovic,A.,2011.Biofuelsversusfoodproduction:doesbiofuelsproductionincreasefood prices?Energy36(4),2070–2076.

Ake,S.C.,2017.Thenonlinearrelationbetweenbiofuels,foodprices.Investig.Econ. 76(299),3–50.

Arau ´ jo,K.,Mahajan,D.,Kerr,R.,daSilva,M.,2017.Globalbiofuelsatthecrossroads:an overviewoftechnical,policy,andinvestmentcomplexitiesinthesustainabilityofbiofuel development.Agriculture7,32. https://doi.org/10.3390/agriculture7040032

Baffes,J.,2013.Aframeworkforanalyzingtheinterplayamongfood,fuels,andbiofuels. GlobalFoodSecurity2(2),110–116.

Bhatia,S.K.,Kim,S.-H.,Yoon,J.-J.,Yang,Y.-H.,2017.Currentstatusandstrategiesfor secondgenerationbiofuelproductionusingmicrobialsystems.EnergyConvers.Manag. 148(15),1142–1156.

Chaudry,S.,Bahri,P.A.,Moheimani,N.R.,2016.Selectionofanenergeticallymorefeasiblerouteforhydrocarbonextractionfrommicroalgae—milkingof B.braunii asacase study.Comput.AidedChem.Eng.38,1545–1550.

Chen,Y.,Dong,B.,Qin,W.,Xiao,D.,2010.Xyloseandcellulosefractionationfromcorncobwiththreedifferentstrategiesandseparatefermentationofthemtobioethanol.Bioresour.Technol.101(18),6994e9.

Chen,W.H.,Chen,Y.C.,Lin,J.G.,2013.Evaluationofbiobutanolproductionfromnonpretreatedricestrawhydrolysateundernon-sterileenvironmentalconditions.Bioresour. Technol.135,262e8.

Chisti,Y.,2007.Biodieselfrommicroalgae.Biotechnol.Adv.25(3),294e306.

Choi,I.S.,Wi,S.G.,Kim,S.B.,Bae,H.J.,2012.Conversionofcoffeeresiduewasteinto bioethanolwithusingpoppingpretreatment.Bioresour.Technol.125,132e7.

Coyle,W.T.,2010.Next-GenerationBiofuelsNear-TermChallengesandImplicationsfor Agriculture,FDS-10k-01. http://www.ers.usda.gov/publications/bio-bioenergy/bio01-01.aspx.(Accessed12December2013).

Czekała,W.,Bartnikowska,S.,Dach,J.,Janczak,D.,Mazurkiewicz,J.,2018.Theenergy valueandeconomicefficiencyofsolidbiofuelsproducedfromdigestateandsawdust. Energy159,1118–1122.

Doshi,A.,Pascoe,S.,Coglan,L.,Rainey,T.J.,2016.Economicandpolicyissuesintheproductionofalgae-basedbiofuels:areview.Renew.Sust.Energ.Rev.64,329–337.

Dutta,K.,Sen,S.,Dasu,V.V.,2009.Production,characterizationandapplicationsofmicrobialcutinases.ProcessBiochem.44,127e34.

Dutta,K.,Daverey,A.,Lin,J.-G.,2014.Evolutionretrospectiveforalternativefuels:firstto fourthgeneration.Renew.Energy69,114–122.

Enciso,S.R.A.,Fellmann,T.,Dominguez,I.P.,Santini,F.,2016.Abolishingbiofuelpolicies:possibleimpactsonagriculturalpricelevels,pricevariabilityandglobalfoodsecurity.FoodPolicy61,9–26.

Filip,O.,Janda,K.,Kristoufek,L.,Zilberman,D.,2017.Foodversusfuel:anupdatedand expandedevidence.EnergyEcon.(inpress),correctedproof.Availableonline6 November2017.

FitzPatrick,M.,Champagne,P.,Cunningham,M.F.,Whitney,R.A.,2010.Abiorefinery processingperspective:treatmentoflignocellulosicmaterialsfortheproductionofvalueaddedproducts.Bioresour.Technol.101,8915–8922.

FoodandAgriculturalPolicyResearchInstitute(FAPRI),2010.FAPRIU.S.BaselineBriefingBook(FAPRI-MUReportNo.01–10),Columbia,MO..

Gao,X.,Gao,Q.,Bao,J.,2018.ImprovingcellulosicethanolfermentabilityofZymomonas mobilisbyoverexpressionofsodiumiontolerancegeneZMO0119.J.Biotechnol. 282(20),32–37.

Gavrilescu,M.,Chisti,Y.,2005.Biotechnology—asustainablealternativeforchemical industry.Biotechnol.Adv.23,471–499.

Ge,Y.,Li,L.,2018.System-levelenergyconsumptionmodelingandoptimizationforcellulosicbiofuelproduction.Appl.Energy226(15),935–946.

GermanAgencyforTechnicalCooperation(GTZ);Worldwatch;GermanFederal MinistryofFood;AgricultureandConsumerProtection(BMELV),2006.Biofuels forTransportation.Availableat:http://www.worldwatch.org/system/files/EBF008_1. pdf.(Accessed10October2016).

Harvey,M.,Pilgrim,S.,2011.Thenewcompetitionforland:food,energy,andclimate change.FoodPolicy36(1),S40–S51.

Hon-Nami,K.,2006.Auniquefeatureofhydrogenrecoveryinendogenousstarchtoalcoholfermentationofthemarinemicroalga, Chlamydomonasperigranulata.Appl.Biochem.Biotechnol.131,808–828.

Hirayama,S.,Ueda,R.,Ogushi,Y.,Hirano,A.,Samejima,Y.,Hon-Nami,K.,etal.,1998. Ethanolproductionfromcarbondioxidebyfermentativemicroalgae.Stud.Surf.Sci. Catal.114,657–660.

Huenteler,J.,Lee,H.,2015.TheFutureofLowCarbonRoadTransport;Rapporteur’s Report.BelferCenter,KennedySchoolofGovernment,HarvardUniversity, Cambridge,MA.

InternationalEnergyAgency(IEA),2018.BiofuelsforTransport.TrackingCleanEnergy Progress. https://www.iea.org/tcep/transport/biofuels .(Accessed22November2018).

Jones,C.S.,Mayfield,S.P.,2012.Algaebiofuels:versatilityforthefutureofbioenergy.Curr. Opin.Biotechnol.23(3),346–351.

Kousoulidou,M.,Lonza,L.,2016.Biofuelsinaviation:fueldemandandCO2emissions evolutioninEuropetoward2030.Transp.Res.PartD:Transp.Environ.46,166–181. Lane,2017.TheIndustrialStatusofBiofuelTechnologies. https://www.biofuelsdigest. com/bdigest/2017/01/11/the-industrial-status-of-biofuel-technologies .(Accessed22 November2018).

Larson,E.D.,2007.BiofuelProductionTechnologies:Status,ProspectsandImplications forTradeandDevelopment.UnitedNationsConferenceonTradeandDevelopment, NewYork.UNCTAD/DITC/TED/2007/10.

Laurens,L.M.L.,Chen-Glasser,M.,McMillan,J.D.,2017.Aperspectiveonrenewablebioenergyfromphotosyntheticalgaeasfeedstockforbiofuelsandbioproducts.AlgalRes. 24(PartA),261–264.

Liu,G.,Bao,J.,2017.Maximizingcellulosicethanolpotentialsbyminimizingwastewater generationandenergyconsumption:competingwithcornethanol.Bioresour.Technol. 245(PartA),18–26.

Markewitz,P.,Leitner,W.,Linssen,J.,Zapp,P.,Muller,T.,Schreiber,A.,2012.Worldwideinnovationsinthedevelopmentofcarboncapturetechnologiesandtheutilization ofCO2.EnergyEnviron.Sci.6,7281–7385.

Mendiara,T.,Garcı´a-Labiano,F.,Abad,A.,Gaya ´ n,P.,Ada ´ nez,J.,2018.NegativeCO2 emissionsthroughtheuseofbiofuelsinchemicalloopingtechnology:areview.Appl. Energy232,657–684.

Moomaw,W.R.,2018.EUBioenergyPoliciesWillIncreaseCarbonDioxideConcentrations.GlobalDevelopmentandEnvironmentInstituteTuftsUniversity.ClimatePolicy BriefNo.7,February.

NationalRenewableEnergyLaboratory(NREL),2013.At $2.15aGallon,CellulosicEthanolCouldBeCostCompetitive.Continuum5.Fall,Availableat: https://www.nrel. gov/continuum/sustainable_transportation/cellulosic_ethanol.html .(Accessed23 November2018).

OECD-FAO,2010.AgriculturalOutlook2010.BiofuelProduction2010–19..

Oh,Y.K.,Hwang,K.-R.,Kim,C.,Kim,J.R.,Lee,J.-S.,2018.Recentdevelopmentsand keybarrierstoadvancedbiofuels:ashortreview.Bioresour.Technol.257,320–333. Pattarkine,M.V.,Pattarkine,V.M.,2012.Nanotechnologyforalgalbiofuels.In:Gordon,R., Seckbach,J.(Eds.),TheScienceofAlgalFuelsVolume25oftheSeriesCellularOrigin, LifeinExtremeHabitatsandAstrobiology,pp.147–163. Pienkos,P.,Darzins,A.,2009.Thepromiseandchallengesofmicroalgal-derivedbiofuels. BiofuelsBioprod.Biorefin.3,431–440. Rathmann,R.,Szklo,A.,Schaeffer,R.,2010.Landusecompetitionforproductionoffood andliquidbiofuels:ananalysisoftheargumentsinthecurrentdebate.Renew.Energy 35(1),14–22.

RenewableEnergyNetwork21(REN21),2016.GlobalStatusReport.REN21,Paris. Rodolfi,L.,Zittelli,G.C.,Bassi,N.,Padovani,G.,Biondi,N.,Bonini,G.,2008.Microalgae foroil:strainselection,inductionoflipidsynthesisandoutdoormasscultivationinalowcostphotobioreactor.Biotechnol.Bioeng.102(1),100e12. Ruangviriyachai,C.,Niwaswong,C.,Kosaikanon,N.,Chanthai,S.,Chaimart,P.,2010. Pineapplepeelwasteforbioethanolproduction.J.Biotechnol.150S,S10.

Savakis,O.,Hellingwerf,K.J.,2015.Engineeringcyanobacteriafordirectbiofuelproduction fromCO2.Curr.Opin.Biotechnol.33,8–14.

Sekoai,P.T.,Ouma,C.N.M.,duPreez,S.P.,Modisha,P.,Ghimire,A.,2019.Applicationof nanoparticlesinbiofuels:anoverview.Fuel237,380–397.

Shadbahr,J.,Zhang,Y.,Khan,F.,Hawboldt,K.,2018.Multi-objectiveoptimizationof simultaneoussaccharificationandfermentationforcellulosicethanolproduction. Renew.Energy125,100–107.

Sher,F.,Pans,M.A.,Sun,C.,Snape,C.,Liu,H.,2018.Oxy-fuelcombustionstudyofbiomassfuelsina20kWthfluidizedbedcombustor.Fuel215,778–786.

Shuba,E.S.,Kifle,D.,2018.Microalgaetobiofuels:promisingalternativeandrenewable energy,review.Renew.Sust.Energ.Rev.81(Part1),743–755.

Singh,J.,Gu,S.,2010.Commercializationpotentialofmicroalgaeforbiofuelsproduction. Renew.Sust.Energ.Rev.14,2596e610. Solazyme,2012.MeetingtheGrowingNeedforRenewableFuels. http://solazyme.com/ fuels.(Accessed19October2012).

Song,C.,Qiu,Y.,Liu,Q.,Ji,N.,Hou,X.,2018.Processintensificationofcellulosicethanol productionbywasteheatintegration.Chem.Eng.Res.Des.132,115–122.

St.John,J.,2010.JoulePatentsSecretSauceforDiesel-ExcretingOrganisms.GigaOm.September14, https://gigaom.com/2010/09/14/joule-patents-secret-sauce-for-dieselexcreting-organisms.(Accessed24November2018).

Su,Y.,Song,K.,Zhang,P.,Su,Y.,Chen,X.,2017.Progressofmicroalgaebiofuel’scommercialization.Renew.Sust.Energ.Rev.74,402–411.

Subramanian,T.,Varuvel,E.G.,Leenus,J.M.,Beddhannan,N.,2018.EffectofelectrochemicalconversionofbiofuelsusingionizationsystemonCO2emissionmitigation inCIenginealongwithpost-combustionsystem.FuelProcess.Technol.173,21–29. Tomei,J.,Helliwell,R.,2016.Foodversusfuel?Goingbeyondbiofuels.LandUsePolicy 56,320–326.

Tyner,W.E.,2013.Biofuelsandfoodprices:separatingwheatfromchaff.GlobalFoodSecurity2(2),126–130.

UNReport,2007.SustainableBioenergy:AFrameworkforDecisionMakers.April. UniversityofEdinburgh,n.d.,GenerationsofBiofuels. http://energyfromwasteandwood. weebly.com/generations-of-biofuels.html (accessed11/22/2018).

USDOE,2008.Algalbiofuels.In:BiomassProgram.DOE,Washington,DC. USDOE,2010.NationalAlgalBiofuelsTechnologyRoadmap.DOE,Washington,DC. USEIA2016.RenewableandAlternativeFuels,Overview,RecentData,(accessedDecember1,2016).

USEnvironmentalProtectionAgency(EPA),2010.NationalRenewableFuelStandard Program—Overview.OfficeofTransportationandAirQuality,USEPA, Washington,DC,April14.

vanGerpen,J.,Shanks,B.,Pruszko,R.,Clements,D.,Knothe,G.,2002.BiodieselProductionTechnology.NationalRenewableEnergyLaboratory.SubcontractorReport, August.

Vassilev,S.V.,Vassileva,C.G.,2016.Composition,propertiesandchallengesofalgaebiomassforbiofuelapplication:anoverview.Fuel181(1),1–33.

Vinayak,V.,Manoylov,K.M.,Gateau,H.,Blanckaert,V.,Herault,J.,Pencreac,G., Marchand,J.,Gordon,R.,Schoefs,B.,2015.Diatommilking:areviewandnew approaches.MarineDrugs13(5),2629–2665.

Yua,M.,Zhanga,Y.,Tangb,I.C.,Yanga,S.T.,2011.MetabolicengineeringofClostridium tyrobutyricumforn-butanolproduction.Metab.Eng.13(4),373e82.

Ziolkowska,J.R.,2014.Prospectivetechnologies,feedstocksandmarketinnovationsfor ethanolandbiodieselproductionintheUS.Biotechnol.Rep.4,94–98.

19 Biofuelstechnologies:Anoverviewoffeedstocks,processes,andtechnologies

Ziolkowska,J.R.,2018.Introductiontobiofuelsandpotentialsofnanotechnology.In:Srivastava,N.,Srivastava,M.,Pandey,H.,Mishra,P.K.,Ramteke,P.W.(Eds.),Green NanotechnologyforBiofuelProduction.BiofuelandBiorefineryTechnologies. Springer,Basel,pp.1–15.

Ziolkowska,J.R.,Simon,L.,2014.Recentdevelopmentsandprospectsforalgae-basedfuels intheUS.Renew.Sust.Energ.Rev.29,847–853.

Ziolkowska,J.,Meyers,W.H.,Meyer,S.,Binfield,J.,2010.Targetsandmandates:lessons learnedfromEUandUSbiofuelpolicymechanisms.AgBioForum13(4),398–412.

Furtherreading

Casey,T.,2012.U.S.DepartmentofEnergyAnnouncesNewBiofueltoReplaceGasoline. Cleantechnica.http://cleantechnica.com/2011/03/08/u-s-departmentof-energyannounces-new-biofuel-to-replace-gasoline/ .(Accessed3August2011).

Dubey,A.K.,Gupta,P.K.,Garg,N.,Naithani,S.,2012.Bioethanolproductionfromwaste paperacidpretreatedhydrolyzatewithxylosefermenting Pichiastipites.Carbohydr. Polym.88(3),825e9.

Stephanopoulos,G.,2007.Challengesinengineeringmicrobesforbiofuelsproduction. Science315(5819),801–804.

Tye,Y.Y.,Lee,K.T.,Abdullah,W.N.W.,Leh,C.P.,2012.Potentialof Ceibapentandra (L.) Gaertn.(kapokfiber)asaresourceforsecondgenerationbioethanol:effectofvarious simplepretreatmentmethodsonsugarproduction.Bioresour.Technol.116,536e9.

Vinuselvi,P.,Park,J.M.,Lee,J.M.,Oh,K.,Ghim,J.M.,Lee,S.K.,2011.Engineering microorganismsforbiofuelproduction.Biofuels2(2),153–166.