Bio-BasedNanomaterials:SynthesisProtocols, MechanismsandApplicationsAjayKumarMishra

https://ebookmass.com/product/bio-based-nanomaterialssynthesis-protocols-mechanisms-and-applications-ajay-kumarmishra/

Instant digital products (PDF, ePub, MOBI) ready for you

Download now and discover formats that fit your needs...

Bio-Based Nanomaterials: Synthesis Protocols, Mechanisms and Applications Ajay Kumar Mishra

https://ebookmass.com/product/bio-based-nanomaterials-synthesisprotocols-mechanisms-and-applications-ajay-kumar-mishra/

ebookmass.com

Nanomaterials Synthesis: Design, Fabrication and Applications Yasir Beeran Pottathara

https://ebookmass.com/product/nanomaterials-synthesis-designfabrication-and-applications-yasir-beeran-pottathara/

ebookmass.com

Advanced nanomaterials for catalysis and energy: synthesis, characterization and applications Sadykov

https://ebookmass.com/product/advanced-nanomaterials-for-catalysisand-energy-synthesis-characterization-and-applications-sadykov/ ebookmass.com

Prestressed Concrete 5th Edition Warner Foster

https://ebookmass.com/product/prestressed-concrete-5th-edition-warnerfoster/

ebookmass.com

Clinical Immunology Nima Rezaei https://ebookmass.com/product/clinical-immunology-nima-rezaei/

ebookmass.com

Nutrition Counseling and Education Skills: A Guide for Professionals

https://ebookmass.com/product/nutrition-counseling-and-educationskills-a-guide-for-professionals/

ebookmass.com

(eTextbook PDF) for Wastewater Treatment Process Modeling, Second Edition 2nd Edition

https://ebookmass.com/product/etextbook-pdf-for-wastewater-treatmentprocess-modeling-second-edition-2nd-edition/

ebookmass.com

How to Cowboy Jennie Marts https://ebookmass.com/product/how-to-cowboy-jennie-marts-4/

ebookmass.com

Java: The Complete Reference, Twelfth Edition Schildt https://ebookmass.com/product/java-the-complete-reference-twelfthedition-schildt/

ebookmass.com

Talent Makers : How the Best Organizations Win through Structured and Inclusive Hiring 1st Edition Daniel Chait

https://ebookmass.com/product/talent-makers-how-the-bestorganizations-win-through-structured-and-inclusive-hiring-1st-editiondaniel-chait/

ebookmass.com

Bio-BasedNanomaterials Thispageintentionallyleftblank

Bio-BasedNanomaterials SynthesisProtocols,Mechanismsand Applications Editedby

AJAYKUMARMISHRA AcademyofNanotechnologyandWasteWaterInnovations, Johannesburg,SouthAfrica

CHAUDHERYMUSTANSARHUSSAIN DepartmentofChemistryandEnvironmentalScience,NewJersey InstituteofTechnology,Newark,NJ,UnitedStates

Elsevier

Radarweg29,POBox211,1000AEAmsterdam,Netherlands

TheBoulevard,LangfordLane,Kidlington,OxfordOX51GB,UnitedKingdom

50HampshireStreet,5thFloor,Cambridge,MA02139,UnitedStates

Copyright©2022ElsevierInc.Allrightsreserved.

Nopartofthispublicationmaybereproducedortransmittedinanyformorbyanymeans, electronicormechanical,includingphotocopying,recording,oranyinformationstorageand retrievalsystem,withoutpermissioninwritingfromthepublisher.Detailsonhowtoseek permission,furtherinformationaboutthePublisher’spermissionspoliciesandourarrangements withorganizationssuchastheCopyrightClearanceCenterandtheCopyrightLicensingAgency, canbefoundatourwebsite: www.elsevier.com/permissions .

Thisbookandtheindividualcontributionscontainedinitareprotectedundercopyrightbythe Publisher(otherthanasmaybenotedherein).

Notices

Knowledgeandbestpracticeinthisfieldareconstantlychanging.Asnewresearchand experiencebroadenourunderstanding,changesinresearchmethods,professionalpractices,or medicaltreatmentmaybecomenecessary.

Practitionersandresearchersmustalwaysrelyontheirownexperienceandknowledgein evaluatingandusinganyinformation,methods,compounds,orexperimentsdescribedherein.In usingsuchinformationormethodstheyshouldbemindfuloftheirownsafetyandthesafetyof others,includingpartiesforwhomtheyhaveaprofessionalresponsibility.

Tothefullestextentofthelaw,neitherthePublishernortheauthors,contributors,oreditors, assumeanyliabilityforanyinjuryand/ordamagetopersonsorpropertyasamatterofproducts liability,negligenceorotherwise,orfromanyuseoroperationofanymethods,products, instructions,orideascontainedinthematerialherein.

BritishLibraryCataloguing-in-PublicationData

AcataloguerecordforthisbookisavailablefromtheBritishLibrary

LibraryofCongressCataloging-in-PublicationData

AcatalogrecordforthisbookisavailablefromtheLibraryofCongress

ISBN:978-0-323-85148-0

ForInformationonallElsevierpublications

visitourwebsiteat https://www.elsevier.com/books-and-journals

Publisher: MatthewDeans

AcquisitionsEditor: SabrinaWebber

EditorialProjectManager: MarianaKuhl

ProductionProjectManager: PoulouseJoseph

CoverDesigner: ChristianBilbow

TypesetbyMPSLimited,Chennai,India

Listofcontributors xi

1.Cellulose-basednanomaterialsfortextileapplications1 BapunBarik,BanalataMaji,DebasishSarkar,AjayKumarMishraandPriyabratDash

1.1 Introduction 1

1.2 Biomaterialsanditssources3

1.3 Chitosan,cellulose,banana,andjutefiberderivativesandtheiradvantages4

1.4 Nanochitosan,nanocellulose,andnaturalfibers5

1.5 Applicationsofbiobasednanomaterials7

1.5.1 Textileapplicationsofnanochitosan8

1.5.2 Textileapplicationsofnanocellulose10

1.5.3 Textileapplicationsofbananafiber13

1.5.4 Textileapplicationsofjutefiber14

1.6 Conclusionandfutureperspectives14 References 15

2.Strategiesforsustainablesynthesisprocessesofnanocarbonsfrombiomass21 AnaL.CukiermanandPabloR.Bonelli

2.1 Introduction 21

2.2 Biomassandcarbonnanostructures22

2.2.1 Biomasschemistry22

2.2.2 Carbonnanostructurescharacteristics26

2.3 Synthesisprocessesofbiomass-basednanocarbonmaterials29

2.3.1 Graphene30

2.3.2 Graphenequantumdots36

2.3.3 Carbonnanotubes41

2.4 Summaryandoutlook46 Acknowledgment 47 References 47

3.Productionofbiopolymer-basednanoparticles53 GeetanjaliandRamSingh

3.1 Introduction 53

3.2 Briefsofbiopolymers54

3.3 Synthesisofbiopolymer-basednanoparticles55

3.3.1 Cellulose-basednanoparticles55

3.3.2 Lignin-basednanoparticles58

3.3.3 Pectin-basednanoparticles60

3.4 Summaryandfutureaspects61 References 61

4.Bio-basednanomaterialsforpropertiesandapplications67 NaveenBunekarandTsungYenTsai

4.1 Introduction 67

4.2 Preparationandapplicationsofbio-basednanomaterials68

4.3 Futureprospectsandconclusion69

Acknowledgments70 References 71

5.Enhanceddyerecoveryfromtextileeffluentsbymeansofbiobased nanomaterials/polymerloosenanofiltrationmembranes73

DerrickS.Dlamini,GcinaD.Vilakati,ChristineMatindi,AjayK.Mishra, JusticeM.Thwala,BhekieB.MambaandJianxinLi

5.1 Introduction 73

5.2 Materialsandmethods74

5.2.1 Materials74

5.2.2 Membranefabrication74

5.2.3 Membranecharacterization75

5.2.4 Membraneperformancetestsandsolutetransport76

5.3 Resultsanddiscussion77

5.3.1 Scanningelectronmicroscopy77

5.3.2 Membranewettability80

5.3.3 Zetapotential84

5.3.4 Membraneporosityandporesize85

5.3.5 Membraneperformance86

5.4 Conclusions 89 Acknowledgments90

90

6.Biodegradationandwaterabsorptionstudiesofnaturalgum rosin-basedhydrogel93

RachnaSharma,RajeevJindal,BalbirSinghKaith,VaneetKumar,Saruchi, AjayMishraandShivaniMishra

6.1 Biodegradationofhydrogels93

6.2 Methodsofbiodegradation94

6.2.1 Chemicalprocess94

6.2.2 Hydrolysisprocess94

6.2.3 Microbial/enzymaticprocess95

6.3 Water-absorptionstudies97

6.4 Resultsanddiscussion97

6.4.1 Compostingmethodofbiodegradation97

6.4.2 Soilburialmethodofbiodegradation97

6.4.3 Evidencesofbiodegradation100

6.5 Waterabsorptionpropertiesofhydrogelinsoilsamples103

6.6 Impactofbiodegradationofsynthesizedsamplesonsoil104

6.7 Conclusion 105 References 105

7.Nanobiochar agreencatalystforwastewaterremediation109 ShivaniGoswami,AnamikaKushwaha,LalitGoswami,NidhiRaniGupta, VinitKumar,UdayBhan,BezawadaSridharReddyandKumudMalikaTripathi

7.1 Introduction109

7.2 Modificationofsurfacepropertiesofbiochar112

7.2.1 Tuningofsurfacefunctionalitiesofbiochar112

7.2.2 Surfacecompositionengineering115

7.2.3 Porestructuretailoring118

7.3 Propertiesintricateinreactivespeciesandradicalgeneration119

7.3.1 Abundantoxygenfunctionalgroups119

7.3.2 Developmentofenvironmentalpersistentfreeradicals119

7.3.3 Redoxproperties120

7.4 Biochar-basedcatalystsforwastewatertreatment120

7.4.1 Applicationofbiocharinredoxsystem120

7.4.2 InFenton-likesystem122

7.4.3 Applicationofbiochar-basedcatalystsinsonocatalyticsystem125

7.4.4 Applicationofbiochar-basedcatalystsinphotocatalysis126

7.5 Conclusions 127 References 128

8.Polyhydroxyalkanoatesbasedsystems:thefutureofdrugdelivery andtissueengineeringdevices133

BenediniLuciano

8.1 Introduction133

8.2 Biosyntesis,mainfeatures,chemicalmodifications,degradation,andgeneral applicationsofpolyhydroxyalkanoates136

8.2.1 Biosynthesisofpolyhydroxyalkanoates136

8.2.2 Harvestandmainfeaturesofpolyhydroxyalkanoates138

8.2.3 Chemicalmodificationsofpolyhydroxyalkanoates140

8.2.4 Degradationofpolyhydroxyalkanoates140

8.2.5 Applicationofpolyhydroxyalkanoates141

8.3 Polyhydroxyalkanoatesfordrugdeliverysystemsdesign142

8.3.1 Drugdeliverysystems142

8.3.2 Drugdeliverysystemsbasedonpolyhydroxyalkanoates144

8.4 Polyhydroxyalkanoatesastissueengineeringmaterials153

8.5 Perspectivesandchallenges159

8.6 Conclusion 160 Acknowledgments160 References 160

9.Advancedapplicationsofbiomassforenergystorage171 KwadwoMensah-Darkwa,StefaniaAkromahandRamK.Gupta

9.1 Introduction171

9.1.1 Renewableenergysources172

9.1.2 Energystoragemechanisms173

9.2 Materialsusedforenergystoragedevices174

9.2.1 Carbonaceousmaterials175

9.2.2 Biomass-derivedcarbons176

9.3 Energystoragemechanismincarbon-basedmaterials178

9.3.1 Storagemechanismincarbonelectrodes179

9.3.2 Storagemechanismsinhybridelectrodes179

9.4 Biomass-derivedcarbonforenergystorageapplications180

9.4.1 Biomass-derivedcarbonforsupercapacitors182

9.4.2 Biomass-derivedcarbonforbatteries196

9.5 Summaryandoutlook203

References 203

10.Sericin-basednanomaterialsandtheirapplicationsindrugdelivery211 SathishSundarDhilipKumarandHeidiAbrahamse

10.1 Introduction211

10.2 Propertiesofsericin213

10.3 Sericin-basedbiomaterialsandtheirbiomedicalapplications214

10.4 Therapeuticpotentialofsericin-basednanomaterialsindrugdelivery219

10.5 Clinicalapplicationofsericin-basedbiomaterials220

10.6 Futureperspectivesandconclusions220 Authorcontributions226

Conflictsofinterest226

Acknowledgments226

References 226

11.Bonetissuerestorationbynanoscalefeaturesofbiomaterials231

A.NoelGravina,NoeliaL.D’Elía,JavierSartuquiandPaulaV.Messina 11.1 Introduction231

11.1.1 Bonetissue:structureandcomposition231

11.1.2 Currentconceptsandmechanismofperi-implantboneregeneration232

11.1.3 Importanceofnanoscalesurfacesonbonehealinginduction235

11.2 Formationofabloodclotonabiomaterialduringbonehealing235

11.2.1 Bloodcoagulationcascadeactivationonbiomaterials236

11.2.2 Fibrinclotformationonthebiomaterialsurface237

11.2.3 Plateletsadhesionandactivation238

11.3 Osteogenicdifferentiationofstemcellsinducedbybiomaterials:mechanismand pathways 239

11.3.1 Functionalizationofmaterials239

11.3.2 Thebindingeffectoftheimplantsurface/extracellularmatrixinteraction andanchorageproteins240

11.3.3 Processesaftercellattachment241

11.4 Neovascularizationduringbonehealing243

11.4.1 Biomaterialsandadditives244

11.4.2 Endothelialcellsandneovascularization245

11.4.3 Increasingcomplexity:cocultureofcells246

11.4.4 Miscellaneous:differentapproaches247

11.5 Boneappositionstimulationinducedbysurfacepropertiesofbiomaterials248

11.6 Newtrendsinbiomaterialsdevelopment:bioinspiredstratifiedscaffolds252

11.7 Outlooksandperspectives254

Acknowledgments256

References 256

12.Toxicologicaleffectofbiopolymersandtheirapplications265 GagandeepKaur,VaneetKumar,Saruchi,AjayKumarMishraandShivaniMishra

12.1 Introduction265

12.2 Classificationofbiopolymers266

12.3 Propertiesofbiopolymers267

12.4 Relativeproperties267

12.5 Synthesizingproperties268

12.6 Componentproperties268

12.7 Synthesisofbiopolymers268

12.8 Starch

12.9 Cellulose

12.10 ChitinandChitosan270

12.11 Gelatin

12.12 Polylacticacid272

12.13 Poly(vinylalcohol)273

12.14 Polyurethanes273

12.15 Poly(hydroxyalkanoates)274

12.16 Poly(ε-caprolactone)274

12.17 Toxicologicaleffectofbiopolymers275

12.18 Applicationsofbiopolymers275

12.19 Synthesisofnanomaterials276

12.20 Synthesisofnanocarriers277

12.21 Biomedicalfield278

12.22 Adsorbentsforenvironmentalremediation278

12.23 Agriculturaldomain279

12.24 Foodindustry279

12.25 Conclusion280

Listofcontributors HeidiAbrahamse

LaserResearchCentre,UniversityofJohannesburg,Johannesburg,SouthAfrica

StefaniaAkromah

DepartmentofMaterialsEngineering,CollegeofEngineering,KwameNkrumah,University ofScienceandTechnology,Kumasi,Ghana

BapunBarik

DepartmentofChemistry,NationalInstituteofTechnology,Rourkela,India

UdayBhan

DepartmentofPetroleumEngineeringandEarthSciences,UniversityofPetroleumand EnergyStudies,Bidholi,Dehradun,India

PabloR.Bonelli

UniversityofBuenosAires,FacultyofExactandNaturalSciences,DepartmentofIndustries, InstituteofFoodTechnologyandChemicalProcesses,NationalCouncilforScientificand TechnicalResearch,UniversityCity,BuenosAires,Argentina

NaveenBunekar

DepartmentofChemistry,ChungYuanChristianUniversity,TaoyuanCity,Taiwan

AnaL.Cukierman

UniversityofBuenosAires,FacultyofExactandNaturalSciences,DepartmentofIndustries, InstituteofFoodTechnologyandChemicalProcesses,NationalCouncilforScientificand TechnicalResearch,UniversityCity,BuenosAires,Argentina;UniversityofBuenosAires, FacultyofPharmacyandBiochemistry,DepartmentofPharmaceuticalTechnology,Buenos Aires,Argentina

PriyabratDash

DepartmentofChemistry,NationalInstituteofTechnology,Rourkela,India;Centerfor Nanomaterials,NationalInstituteofTechnology,Rourkela,India

SathishSundarDhilipKumar

LaserResearchCentre,UniversityofJohannesburg,Johannesburg,SouthAfrica

DerrickS.Dlamini

StateKeyLaboratoryofSeparationMembranesandMembraneProcesses/NationalCenterfor InternationalJointResearchonMembraneScienceandTechnology,Tianjin,P.R.China; SchoolofMaterialsScienceandEngineering,TianjinPolytechnicUniversity,Tianjin, P.R.China;AcademyofNanotechnologyandWasteWaterInnovations,Johannesburg,South Africa

NoeliaL.D’Elía

INQUISUR-CONICET,DepartmentofChemistry,UniversidadNacionaldelSur, B8000CPB,BahíaBlanca,Argentina

Geetanjali

DepartmentofChemistry,KiroriMalCollege,UniversityofDelhi,Delhi,India

LalitGoswami

CenterfortheEnvironment,IndianInstituteofTechnologyGuwahati,Guwahati,India

ShivaniGoswami

DepartmentofBiotechnology,BrahmanandCollege,ChhatrapatiShahuJiMaharajUniversity, Kanpur,India

A.NoelGravina

INQUISUR-CONICET,DepartmentofChemistry,UniversidadNacionaldelSur, B8000CPB,BahíaBlanca,Argentina

NidhiRaniGupta

DepartmentofChemistry,MultaniMalModiCollege,Patiala,India

RamK.Gupta

DepartmentofChemistry,KansasPolymerResearchCenter,PittsburgStateUniversity, Pittsburg,KSUnitedStates

RajeevJindal

DepartmentofChemistry,Dr.BRAmbedkarNationalInstituteofTechnology,Jalandhar, India

BalbirSinghKaith

DepartmentofChemistry,Dr.BRAmbedkarNationalInstituteofTechnology,Jalandhar, India

GagandeepKaur

DepartmentofChemistry,SriGuruTegBahadurKhalsaCollege,SriAnandpurSahib, India

VaneetKumar

DepartmentofAppliedSciences,C.T.InstituteofEngineering,ManagementandTechnology, Jalandhar,India

VinitKumar

DepartmentofElectricalandElectronicEngineering,VisvesvarayaTechnologyUniversity, Belgaum,India

AnamikaKushwaha

DepartmentofBiotechnology,MotilalNehruNationalInstituteofTechnologyAllahabad, Prayagraj,India

JianxinLi

StateKeyLaboratoryofSeparationMembranesandMembraneProcesses/NationalCenterfor InternationalJointResearchonMembraneScienceandTechnology,Tianjin,P.R.China; SchoolofMaterialsScienceandEngineering,TianjinPolytechnicUniversity,Tianjin, P.R.China;AcademyofNanotechnologyandWasteWaterInnovations,Johannesburg,South Africa

BenediniLuciano

INQUISUR-UNS,NationalUniversityoftheSouth,BuenosAires,Argentina;Department ofBiology,BiochemistryandPharmacy,NationalUniversityoftheSouth,BuenosAires, Argentina

BanalataMaji

DepartmentofChemistry,NationalInstituteofTechnology,Rourkela,India

BhekieB.Mamba

StateKeyLaboratoryofSeparationMembranesandMembraneProcesses/NationalCenterfor InternationalJointResearchonMembraneScienceandTechnology,Tianjin,P.R.China; SchoolofMaterialsScienceandEngineering,Tianjin PolytechnicUniversity,Tianjin,P.R.China; AcademyofNanotechnologyandWasteWater Innovations,Johannesburg,SouthAfrica

ChristineMatindi

StateKeyLaboratoryofSeparationMembranesandMembraneProcesses/NationalCenterfor InternationalJointResearchonMembraneScienceandTechnology,Tianjin,P.R.China;School ofMaterialsScienceandEngineering,Tianjin PolytechnicUniversity,Tianjin,P.R.China

KwadwoMensah-Darkwa

DepartmentofMaterialsEngineering,CollegeofEngineering,KwameNkrumah,University ofScienceandTechnology,Kumasi,Ghana

PaulaV.Messina

INQUISUR-CONICET,DepartmentofChemistry,UniversidadNacionaldelSur, B8000CPB,BahíaBlanca,Argentina

AjayKumarMishra

AcademyofNanotechnologyandWasteWaterInnovations,Johannesburg,SouthAfrica

ShivaniMishra

AcademyofNanotechnologyandWasteWaterInnovations,Johannesburg,SouthAfrica

BezawadaSridharReddy

DepartmentofChemistry,IndianInstituteofPetroleumandEnergy,Visakhapatnam,India

DebasishSarkar

DepartmentofCeramicEngineering,NationalInstituteofTechnology,Rourkela,India; CenterforNanomaterials,NationalInstituteofTechnology,Rourkela,India

JavierSartuqui

INQUISUR-CONICET,DepartmentofChemistry,UniversidadNacionaldelSur, B8000CPB,BahíaBlanca,Argentina

Saruchi

DepartmentofBiotechnology,C.T.InstituteofEngineering,ManagementandTechnology, Jalandhar,India

RachnaSharma

DepartmentofChemistry,Dr.BRAmbedkarNationalInstituteofTechnology,Jalandhar, India

RamSingh

DepartmentofAppliedChemistry,DelhiTechnologicalUniversity,Delhi,India

JusticeM.Thwala

DepartmentofChemistry,FacultyofScienceandEngineering,UniversityofEswatini, Kwaluseni,KingdomofEswatini

KumudMalikaTripathi

DepartmentofChemistry,IndianInstituteofPetroleumandEnergy,Visakhapatnam,India

TsungYenTsai

MasterPrograminNanotechnology&CenterforNanotechnology,ChungYuanChristian University,TaoyuanCity,Taiwan

GcinaD.Vilakati

DepartmentofChemistry,FacultyofScienceandEngineering,UniversityofEswatini, Kwaluseni,KingdomofEswatini

Cellulose-basednanomaterialsfor textileapplications BapunBarik1,BanalataMaji1,DebasishSarkar2,3,AjayKumarMishra4 and PriyabratDash1,3

1DepartmentofChemistry,NationalInstituteofTechnology,Rourkela,India

2DepartmentofCeramicEngineering,NationalInstituteofTechnology,Rourkela,India

3CenterforNanomaterials,NationalInstituteofTechnology,Rourkela,India

4AcademyofNanotechnologyandWasteWaterInnovations,Johannesburg,SouthAfrica

1.1Introduction Developmentofqualitytextilethreadtowardmanufacturinghighvalue-addedclothesand fabricshasbeenaprominentresearchfieldforseveralyears(Mishraetal.,2018;Stokke etal.,2013).Textileindustryplaysasignificantroleintheeconomicdevelopmentofa countrybyenhancinggrossproductionindomesticlevel(Khalijietal.,2013).Textile industriesdemandseveralfabricmaterials,whichincludewoolen,cotton,andsynthetic fibers(Haraguchietal.,2017).Conversely,thesetextileindustriesgeneratehugeamount ofwastewater,whichcausesenvironmentalpollutionaggressively.Thetextileprocesses likedyeing,bleaching,printingetc.generatehighvolumeoftoxicwastewithheavy nitrogencontent,acidity,suspendedsolids,heavymetals,dyesetc.Generally,thesetextile contaminantscancauseseverehealthimpact inhuman,animals,andplantsbydegrading waterqualitiesinaquaticecosystem(Ütebayetal.,2019).Consequently,materialswith leastbyproductgenerationhavealwaysindemandintextileindustries.So,tomeetthe heavydemandofconsumersforlow-weightandenergy-efficientaswellassustainable materials,largescaleindustrieshaveextensivelyfocusedondevelopingnovelmaterials derivedfromthenaturalrenewableresources(Yousefetal.,2020).Materialssatisfying environmentalsafetyandreusabilitywithenhancedactivityhavealsoresultedinan enhancedinterest.Noticeably,therequirementtoexplorealternativesmaterialsofnonrenewableresourcesismajorlyfocusedonproducingadvancedproductsfromvariousbioderivedmaterialssuchascellulose,chitosan,nature-derivedpolymericfibersetc.(Väisänen etal.,2017).Celluloseandchitosanareimmenselypopularforthesynthesisofmodified nanostructureswithenhancedpotentialapplications.Chitosanisadeacetylatedformof chitin,whichisabiodegradable,biocompatible,nontoxic,andrenewableaminefunctionalizedpolysaccharide(Kumar,2000).It’suniquestructuralintegration,multidimensional properties,andextensiveheteroatomfunctionalizationhavemadeitapreferablecandidate

Bio-BasedNanomaterials DOI: https://doi.org/10.1016/B978-0-323-85148-0.00009-9

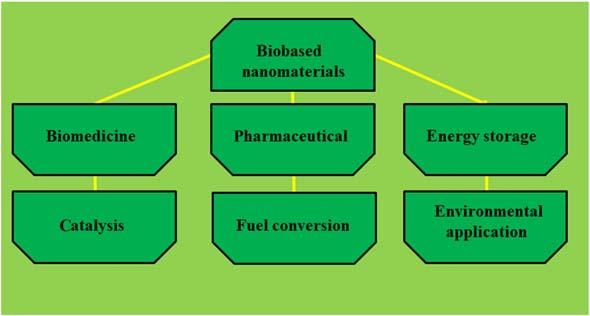

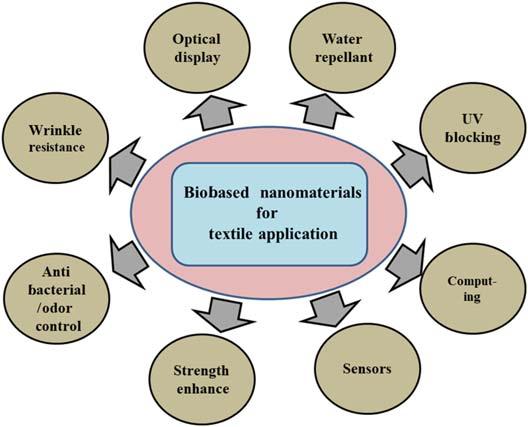

asasurface-basedactivematerial.Onasimilarnote,celluloseisanotherbiopolymerabundantlyavailableinnatureandalsousedasanovelandsustainablepolymericmaterialfor severaldomesticandindustrialapplications(Royetal.,2009). Fig.1.1 showsthevarious potentialapplicationsofbio-basednanomaterials.Itpossessessustainablestructural, mechanical,andopticalproperties.Moreover,improvedfunctionality,highstrength,and biocompatibilityfurtherbenefitbothchitosanandcellulose-basedmaterialsinpractical applications.Butlimitationslikelowadsorptioncapacityandhydrophilicnaturerestrict themfromlargescaleandindividualapplication.

Inthisdirection,derivativesofcelluloseandchitosanfamilies,nanocelluloseand nanochitosan(NCH)weresynthesizedviacontrolledacidhydrolysis(Siróand Plackett,2010;Yuetal.,2020).Theyhaveemergedasmostpreferablebiobased nanomaterialsduetotheirtunablesize,uniformmorphology,higherdispersibility, superiorsurfacechemistry,andimprovedphysicochemicalproperties.Thehigh surface-to-volumeratioandthermalstabilitymakebothNanochitosan(NCS)and NCHnanomaterialappropriatecandidateforlarge-scaleapplications(Mishraetal., 2018b).Theresearchcommunitieshaveextensivelystudiedaboutnaturalfibersfor theirwiderangeapplicationsandfuturepotentialsofthesebiobasednanomaterialsand theirderivatives.Naturalfibersarebiobasednanomaterialsderiveddirectlyfromthe agriculturalsources.Forexample,naturalfibersarederivedfromjute,banana,hemp, bamboo,woodetc.Thesenaturalfibersprovidenumerousadvantagessuchaslow density,biodegradabilityandcost-effectiveness.Additionally,theyhavelowtoxicity, highertensilestrength,improvedelasticity,betterperformanceandenhancedenergy consumptioncapacity(Ramamoorthyetal.,2015).

Recently,severalNCSandNCH-basednanofibersaredesignedfortextileapplications.Inthischapter,wewillprovideadetailedoverviewoftherecentprogressin

thefieldofbiobasednanomaterialsfortextileapplicationwithanobleviewpointof restorationofaquaticecosystem.

1.2Biomaterialsanditssources Theproductionofbiobasednanomaterialshasincreasedrapidlyasamoreefficient, renewable,andenvironmentfriendlysustainablematerial.Withduecredittothe nanoscience,nanostructuresoftherawbioderivedmaterialsarealsofabricatedandutilized. Celluloseandchitosanaretwoveryabundantbiopolymersreadilyavailableinnature. Cellulosecanbeisolatedfromvariousnaturalsourcessuchaswoods,aquaticanimals,biomass,agriculturalcropandfruitwaste,fungi,andalgae(Rajinipriyaetal.,2018).The compositionandstabilityofcellulosearehighlydependentontheirsource.Ingeneral, celluloseisknownasanaturalpolysaccharidefirstderivedfromwoodin1838bytreatmentwithHNO3.Naturally,itcontainsmicrofibrilsofdiameterrangingfrom3to35 nmowingtoitssource.Itsstructureiscomprisedoflinearpolymericchainswithmonomerscalled β-1,4-D-glucose.Theaveragedegreeofpolymerizationforcelluloseisupto 20,000whereasforwood,itisapprox.10,000units.Withincreasingdemandofecofriendlymaterials,cellulosederivedfromagriculturalcropsandfruitsaremorepreferred (Sinquefieldetal.,2020).Thisisbecausegenerationofrawcellulosebecomeseasier,environmentalfriendlywithlowcost.Agriculturalsourcesofcelluloseareatremendous resourceastheyareecofriendly,inexpensive,easilyavailable,reusable,andhavetunable mechanicalproperties.Moreover,thisagriculturalsourcedcellulosecanproduceabundant amountofnaturalfibers.Agriculturewastefiberscanbeobtainedfromcottonstalk,pineappleleaf,bananaleaf,ricestraw,jute,hemp,crophusk,garlicstraw,vegetablepeel,fruit skin,etc.(Esaetal.,2014).So,agriculturalcellulosehasmultitudeapplicationsinvarious industrialsectorssuchastextiles,paper,compositefabrication,architecture,furniture,and medicine.

Similarly,chitosanisanotherbioderivednaturalbiopolymer,whichisderivedfrom chitin.Skeletonofshrimpwastesandfungusbiomassaregenerallythemostpreferred sourceofchitosan(Kumaretal.,2004).Deacetylationofchitininalkalinemediumproducesthebiopolyaminosaccaridechitosan.Chitinisamajorbiopolymerfoundincrab, shrimp,lobster,jellyfish,coral,someyeasts, andinthecellwallsoffungi.Inrecentyears, researchonchitosanhasenhancedduetoitsbiocompatibility,biodegradability,andenvironmentalsafety(Banoetal.,2017).Ithashighlyinfluentialantimicrobialactivity,film formationcapacity,chelating,andsurfaceadsorptioncharacteristics.Chitosaniscomposed ofpoly-(1,4)-2-amino-2-deoxyD-glucopyranosewithextensiveaminoandhydroxyl functionalizationasactivesites(Islametal.,2017).Chitosanutilizationinvariousapplicationsisdependentonitsviscosityandmolecularweight.Inareport,Shimojohandhis coworkersreportedthathighmolecularweight chitosanhasbetteractivityasfoodadditive comparedtothatwithlowmolecularweightchitosan(Seyfarthetal.,2008).Additionally,

thepolycationicnatureofchitosanmakesitmoresuitableasflocculatingagentaswellas chelatingagentforheavymetals.Thecrustaceousindustrywastesaretheprimesourceof chitosanandcanbeobtainedwithminimumexpenditure.OthersourceslikeFilamentous fungicanprovidebothchitosanandchitinat largescalewhichcanbesynthesizedunder controlledenvironment(Ghormadeetal.,2017).Allthesourcesofchitosancanbecomparedbutallpropertiesofchitosandependonthedegreeofacetylation,homogeneityof molecularweight,viscosityandamountofchargedistribution.Optimizationofthebasic structureofchitosancanexploretheopportunityoffindingnewclassofchitosanderivativeswithabroadrangeimprovedproperties andapplications.Amongthem,designingof nanostructureswithbioderivedchitosanforpotentialapplicationsinseverallargescale industriesisthemostadvancedformofit. Chitosanhasbeenprovedasanontoxicfor consumptioneitherasfoodordrugsectors(Ghormadeetal.,2017).So,researchersare moreinterestedintheproductionofnanochitosan.Moreover,theirantimicrobialproperty furtherincreasesitsdemandinthefabricationofhigh-qualitynanofibersandcomposites fordiversifiedapplications.

1.3Chitosan,cellulose,banana,andjutefiberderivativesandtheir

advantages Totacklethemanmadeclimaticdisasters,biopolymermaterialsarebestalternativematerialsforgreenerworld.Extractedfromliving organisms,thepolymericbiomoleculeshave significantenvironmentalsuitability.Amongallbiopolymers,celluloseandchitosanalong withtheirderivativeshavethemostinteresting multipurposecharacteristics,whichgained significantinterestamongtheresearchersinpresenttime(Oliveraetal.,2016).Celluloseis themostabundantorganicpolymeronEarth.Celluloseisanorganiccompoundwithformula(C6H10O5)n.Itisapolysaccharideconsistingofalinearchainofhundredtomany thousandsof β (1-4)linkedD-glucoseunitsAsanimportantstructuralcomponentof primarycellwallofgreenplants,cellulosehasgaineditsreputation(CichoszandMasek, 2019).Likecellulose,chitosanisthesecondmostabundantorganicpolymerfoundon Earth.Chitosanisacopolymerof2-glucosamineandN-acetyl-2-glucosamine.Itis obtainedbydeacetylationofchitininhotalkali(Kurita,1998).Tilldate,thesehavebeen provedasasuccessfulmaterialasbiologicaladhesive,biofilm,Antioxidant,Foodpackaging,Antibacterial,coating,biosensors,surfaceconditioner,bioadsorbentandcatalyst.But therisinginterestincelluloseandchitosannanofibersinthetextileindustryisundeniable whichmaybeduetoitssuperiorsustainabilityandlow-costmechanicalproperties. Naturalfibersareobtainedfromvarioussourcesbutagriculturalsourcesarebestasthey aremadeupof60% 70%purecellulose,10% 20%hemicellulose,5% 15%ligninand around2%ofwaxesandpectin(Muthukumaretal.,2020).Bananafiberisanaturalfruit fiberextractedfromthesuperimposedleavesofbananaplantwhichhasverylimiteduse exceptasacattlefeed.Itisfrom Musa family(Pothanetal.,2003).CanaryIslandsof

Europearethemajorproducerofbanana.Theverypreciousbananafibersaregenerally isolatedfromthepseudo-stemsofbananaplantafterripeningofthefruit.So,oneofthe primebenefitsofthesefibersincomparedwithnaturallyobtainedfibersistheiragricultural sourceisalwayseco-friendly.Bananafiberspossessleasttoxicitytohumans,instruments andtheenvironment,whichcanberealisticalternativesofotherlessfavoredsynthetic fibers.Severalstudieshavealsobeendoneforthefabricationofbananafibers,someof themwithlongfibersandothersarewovenfibers(VenkateshwaranandElayaperumal, 2010).Thesestudiesshowthatspecificmechanicalpropertiesofbananafibercomposites aresimilartothosereinforcedwithglassfiber,althoughmechanicalpropertiesunder humidconditionsshowanimportantdecreaseforthenaturalfibercompositesbecauseof theirwatervaporabsorption.Anothercellulosebasedfibersourceisjutewhosecomposite materialsaregainingattentionforduetotheireasyavailabilityandcheapproductioncost (Alvesetal.,2010).Jutetakesonly2 3monthstogrowwithaheightof12 15ftinthe rettingprocess,theinnerandouterstemgetseparated.Theouterpartiskeptseparatelyto formfiber.Thesejutefibersarefurtherprocessedtomanufacturehighqualitylifestyleproducts(MishraandBiswas,2013).However,thesebioderivedfibershavehighmechanical strength,excellentthermalstability,renewabilityetc.

1.4Nanochitosan,nanocellulose,andnaturalfibers Inlate1950s,firsttimeacolloidalsuspensionofcellulosewasreportedbyRanbyandhis group(Habibietal.,2010).Theyobtaineditbycontrolledandpreciseadditionof H2SO4 tofabricatecellulosenanofibers.Inanotherwork,Nickesonetal.observedthat thecellulosenanofibersaredegradedtoa maximumlimitafterwhichthevolumeof nanofibersremainsconstant.Whenfurthercharacterized byTransmissionelectronmicroscopetheyrevealedthepresenceofaggregatedneedleshapedparticlesofcrystalline nature(Miaoetal.,2016).Consequently,commercializationofNCSwasachievedby largescalesynthesisviahydrochloricacidassisteddegradationofcelluloseobtainedfrom woodenpulpsfollowedbyultrasonication.Chemicalinactivity,ultrastability,andphysiologicalinertnessalongwithtremendoussurfacebindingproperties,NCSbroughtasignificantchanceformultipurposeapplicationsSinceitsdiscovery,severalimprovementsin themechanicalaswellassurfacepropertiesofnanomaterialswithNCSandNCSderivativeshavebeenpartofsubstantialresearchduetothegrowinginterestinfabrication materialsderivedfromrenewableresources.NCSsarealsoreferredasnanocrystals,nanowhiskers,nanoparticles,andnanofibers(Meloetal.,2020).Butnanofibershavethemost versatileandwiderangeofapplications.MethodsforseparationofCNsandtheir morphologies,characterization,modification,self-assembly,andapplicationswillbe reviewed.Inbasicprocessofisolationof cellulosefibersincludeacidhydrolysis. Preferentially,moredisorderedandleast-crystallinepartsoftherawcellulosearehydrolyzedwhereasthehighercrystallinepartsremainintactduetomoreresistancetoacid

attack.Theacidtreatmentremovesthemicrofibrilsattheloosedefectsandfiberlike nanocellulosestructuresareproduced.Generally,acidhydrolysisinducesminimizesthe degreeofpolymerizationwhichisdirectlyrelatedtothenanofibersizealongthelongitudinaldirectionofcellulosechain.Thisconceptofhypothesiswassupposedasthedisorderedorparacrystallinedomainsofcellulose aregenerallyspreadthroughthemicrofibers leadingtomoresusceptibleacidattack.Thisprocessresultsintheformationofhomogeneouscrystallinenanofibersafteracidhydrolysis. Table1.1 showsthecomparisondataof differentbiobasedcompositeswithvarioussyntheticprocedure.Moreover,allthesespeculationswerefurtherconfirmedfromseveralcharacterizationtoolssuchasX-raydiffraction(XRD)study,electronmicroscopy,smallangleXRDandneutrondiffraction analysis(Sunetal.,2016).Inrecenttime,anotherbiopolymericabundantpolysaccharide chitosanhavebeenintroducedandvastlystudied.Chitosancanbeusedinseveralaspects suchassupportforforeignnanoparticles,enhancingcompositestabilityandactivityand metalbinder.Buttheinherentsoleuseofchitosanhasbeenrestrictedduetoitslackof efficiencyandthermalstability.So,nanoformofchitosanhasbeendevelopedwhichcan bemoreeffectivefordesiredapplicationsdue totheirenhancedsurfacearea,nanosized, uniformdistribution,biodegradability,andhigherfunctionalitydistribution(Huangetal., 2009).Thesepropertiesfavornanochitosaninnumerousapplications,includingsensors, carrierforproteinmolecules,drugdeliverysystems,textile,adsorption,degradation,and catalysis.ThereareseveralmethodsadoptedbyseveralresearchersforfabricationofNCS (Yangetal.,2010).Amongthemmethodslikecoagulation/precipitation,emulsiondropletcoalescencemethod,cross-linkingviacovalentbonds,andionicbondsaremore favored.ButNCHmanufacturedbyionotropic-gelationmethodaremorestable,nontoxic,andsolventfree.NCHpossessalltheinherentproperties ofchitosanalongwith generalcharacteristicsofnanosizedfiberssuchassurfaceactivityeffect,grainsizeeffect

Table1.1 Biobasedcompositessynthesisprocedure.

MaterialSynthesisprocessReference

ChitosanEnzymatic deproteinization

Younesetal.(2012)

NanofibrillatedcelluloseEnzymehydrolysis Pääkköetal.(2007)

CellulosenanofibrilsTEMPO-mediated oxidation JiangandHsieh(2013)

CellulosefibersHigh-intensity ultrasonication

WangandCheng(2009)

CellulosenanofibrilsMicrofluidization Leeetal.(2009) Chitosan/magneticmaghemite (γ-Fe2O3)nanoparticles Solutioncastingmethod PratiwiandPutri(2019)

ZnO/Ce-ZnObased nanoflowers/chitosan

Microwave-irradiation method Saadetal.(2020)

andquantumsizeeffect(ChenandHsieh,2011).Also,ithastremendousphysicochemicalandbioactiveproperties.Ionic-gelationprocessincludesthedeacetylationofrawchitosanwith2%aceticacidsolutionfollowedbytheadditionoftripolyphosphateor ammoniumheptamolybdatetoformawhitesolution.Again,bymultipleringingwith distilledwater,excesstripolyphosphateorammoniumheptamolybdatewereeliminated andthedesiredNCHwasobtainedbyvigorous centrifugationat16,000rpmfollowed bydryinginCO2 atmosphere(Nguyenetal.,2017).Again,BertholdandhisgrouppreparedNCHusingNa2SO4 asaprecipitationagent.Theprocessincludestheadditionof Tween80withrawchitosaninCH3COOFsolutiondropwisefollowedbyultrasonication.Similarly,inanothermethodTianetal.improvisedthemethodofprecipitationandfoundchitosannanoparticlesof600 800-nm.Ohyaetal.cross-linkedthe aminogroupsofchitosanwithglutaraldehydeandemulsifieditwithwater-in-oilemulsifierwhichresultedinsynthesisof5-fluorouracilchitosanparticlesofaverageparticlesize 0.8 0.1mm(Houetal.,2011).NCHhasbeenveryfrequentlyusedforcontrolled releaseofdrugforgenetransferinhumanandanimalorgans(Huangetal.,2009). Moreover,ithasawidevarietyofapplicationintextileindustrywhichcanenhancethe fabricstrengthandwashabilityofthetextile withanadditionalbenefitofantibacterial ability.

1.5Applicationsofbiobasednanomaterials Theprogressofbiobasednanomaterialshasmarkedanessentialmilestoneinmodern civilization.Afterinventionandgainingpopularity,biobasednanoparticlesandnanofibersareconsideredastheneweramaterialsforouradvancedtechnology-basedhuman society.Therapidandunprecedentedprogressinmaterialworldisgreatlydependenton thedesignofbioderivedmaterialswithhigheractivityandphasestability.Batteries, machines,computers,vehicles,memorydevices,displaypanels,solarcells,andsensory devicesarethefundamentalpartofourdailylife,whicharemadeupofadvanced metals,ceramics,orplastics.Theadvancementoftechnologyhasbroughtrevolutionary conversiontotheenvironmentandhumans.Consequently,thisresultsinseriousenvironmentandhealthhazardsduetoproductionofenormousamountofsecondarywaste. Theevolutionoftechnologyhassuggestedthatthebioderivedmaterialssuchascellulose,chitosanandothernaturalfibersarethemostpreferredalternativesfortheceramic, metallicandplasticmaterials.Thesebiobasedmaterialsprovideuniquecombination propertiessuchassurfacechemistry,transparency,highelasticity,anisotropy,andlow thermalexpansion.Thebiobasedmaterialshavebeenaddressedformanymultipurpose applicationssuchasfuelconversion,energystorage,catalysis,biomedicine,pharmaceutical,environmentalapplicationandindustrialapplications.Amongthem,industrialapplicationsofbiobasedmaterialshavebeenstudiedforlongtimeperiodandstillgaining moreattention.Here,wewillbediscussingparticularlythetextileapplicationsofmost

popularnanosizedcelluloseandchitosan.Owingtotherequirementofhighqualityand antibacterialpropertyoftextilefabrics,thesebioderivednanoformsofchitosanandcellulosecansatisfythepurposeinbestway.Moreover,theenvironmentfriendlinessand nontoxicitytohumanskinhavefurtherproveditssuitabilityfortextileindustry.

1.5.1Textileapplicationsofnanochitosan Chitosanisapolycationicnaturalpolysaccharide,whichpossessesmanybeneficialpropertieslikeantifungal,antibacterial,antiacid,nontoxicandtotalbiodegradableandsuperb filmformingcapacity.Thenanoformofchitosaniscomprisedofalltheseinherentpropertiesalongwithnanosizedeffectandquantumsizeeffect.Inthisprospective,nanochitosanhasbeenusedforseveralapplicationssuchascosmetics,food,biomedical,paper, wastewatertreatment,agriculture,andindustries.Also,theseuniquecharacteristicsare veryadvantageousfortextileapplications. Fig.1.2 Showsthepotentialusageofbiobased nanomaterialsfortextileapplications.Intextileindustriesnanochitosancanbeusedas fibersandintheprocessofdyeingaswellasfinishing.Recently,nanochitosanhave demonstratedversatileapplicationintextilestoenhancethefunctionalcoatingswhich meansdurability,softnessoffabrics,UVprotection,breathability,fireandwaterresistance,antimicrobial,antifungal,self-cleaningpropertiesoffabrics,yarnandfiber. Chitosanhasalargeimpactonproductionoftextilewithantimicrobial,hemostatic, moisturecontrolling,nonallergic,deodorizing,andantithrombogenicpropertiestoward wounddressingbandages,fabricswithscents,activedrugcarrier,andsutures.Thesurfacequalityandmorphologyofthefiberwasanalyzedwithscanningelectron

Figure1.2 Schematicillustrationoftextileapplicationsofbiobasednanomaterials.

microscope.Duringthedyeingprocessintextileindustries,numeroustoxiccoloring agentslikedirect,anionic,reactive,andazoicdyesareutilized.Theconventionaldyeing processproducelargeamountofwastewaterwhichcandegradetheaquaticlifeaswell asenvironmentbycontaminatingwithtoxicchemicalsandmacromolecules.Inthis direction,Iqhrammullahetal.reportedthePb(II)adsorptionpropertiesofNCHcombinedpolyurethane-polypropyleneglycolfromtextileeffluents(Iqhrammullahetal., 2020).Thekineticandbatchadsorptionstudiesrevealedthattheternaryblendwas foundtobethermallystableandcrystallineinnaturewhichishighlyefficienttoremove metalionsfromtextilewastewater.Hadavifarandhiscoworkerspreparednanochitosan fromshrimpshellsandincorporateditwithsodiumtriphosphatetoremovemalachite greendyefromaqueouswastewater.Themaximumadsorptioncapacitywasfoundto be317.73mgg 1 fromLangmuirisotherm(Salamatetal.,2019).Theadsorbentwas suitableforindustrialwastewaterbecauseofthelowcost,ecofriendlynatureandminimizedsecondarycontaminationpossibility.Nanochitosanwithexcellentchelationpropertycanbeusedintheprocessingofwatertechnologyinthefiltrationprocess.Chitosan helpsinremovingheavymetals,oils,andphosphorousfromtheaqueousmedium. Moreover,chitosancanminimizetheturbidityofwaterupto99%whenemployed alongwithsandfiltrationprocess(ThakurandThakur,2016).

Severalstudieswerereportedrevealingthesuitabilityofnanochitosanontheevolutionofcottonfabric.Chattopadhyayetal.analyzedthenanochitosantreatedcotton fibersviascanningelectronmicroscopewhichfoundthenonglossyandswollensurface morphology(ChattopadhyayandInamdar,2013).Theyalsooptimizedthesurface propertiesbychangingtheparticlesizes.Agreaterextentofpenetrationintothefiber structurewasachievedwithsmallersizenanochitosanparticles.Thearticlealso reportedtheenhancedfabricstrengthduetoincorporationofnanochitosanwhichfurtherincreasedwithdecreaseinparticlesizes.Furthermore,theextensive functionalization-NH2 and OHofchitosancancrosslinkwiththefibermoleculesto improvethestrengthofcompositefiber.Theauthorsconcludedthatsmallerparticle sizesofnanochitosanprovidehighersurfaceareaandfabricqualityduetobettercrosslinking.Again,theabsorbencyofthenanochitosanwasfoundtobegreatlyminimized duetoreductioninparticlesize.Thenanochitosanparticlesformathinlayeroverand belowthefabricsurfacewhichcanrolloutthewaterdropletslikelotusleaf.Results alsodepictedthatconventionaldyeuptakecapacityofcottoncanbeimprovedby combiningitwithnanochitosan.Thenanochitosanwithenhancedsurfaceareaand smallerparticlesizeprovidehighernumberofactivesitetothedyemoleculesto attach.Inacidicmediumtheaminogroupsgetprotonatedandthecationicsurface weresuitableforanionicgroupsofdirectdyes.Also,thisbringsbetterfiber-dyecomplexformationimprovingthefastnesstowashing(ThakurandThakur,2016).

Nanochitosanalsoprovidesenhancedantimicrobialpropertiestocottonfibers. Nanochitosanmodifiedwithsilvernanoparticlescanbeveryeffectivetofurther

Table1.2 Nanochitosan-basedcompositesforTextileapplication.

Sl.noMaterialSynthesisprocessApplicationReference

1Chitosan-basedhydrogels/ HCPpolymer

Modified Davankov procedure

2NanochitosanLow-molecularweight chitosan treatment

3Chitosan-methacrylicacid nanoparticles

4Nanochitosan-reinforced unfoldedsoyprotein

5Manganese-peroxidase immobilized glutaraldehydeactivated chitosanbeads

6Ethylene-diamine modifiedchitosan

7O-acrylamidomethyl-N[(2-hydroxy-3trimethylammonium) propyl]chitosan chloride

8Chitosan-poly (Nisopropylamide) particles

Polymerization process

Ultrasonic treatment

Crosslinking method

Dropwise addition method

Pad-dry-cure method

Removalofdye deLunaetal., (2017)

Usedaswoolfabric finishingtreatment Yangetal. (2010)

Antibacterialactivity oftreatedcotton fabrics

Hebeishetal. (2013)

Usedasasustainable textilebioadhesive forindustry. Xuetal. (2020)

Detoxificationand decolorizationof textileeffluent Bilaletal. (2016)

Removalofanionic dyeeosin

Huangetal. (2011)

Usedasdurable antimicrobial textilefinish Limand Hudson (2004)

Pad-dry-cure method

Durableantibacterial finishoncotton fabric Yeetal. (2006)

improvetheantimicrobialaswellastheantifungalnatureofthecottonfiber.Ata verylowerconcentration,silvernanoparticlesareprovedtobebetterantibacterial agentsthanotherpopularmetals(lead,mercury,copper,etc.)(Alietal.,2011).So, thefabriccanbeefficientlytreatedwithnanochitosaninitiallyfollowedbylownanosilvertreatmentintwobathprocess.Thenanochitosanandsilvertreatedsamplesof cottonalsopossesshigherfabricstrength.Acomparisondataofdifferentnanochitosan basedcompositeswithdifferentsyntheticprocedurefortextileapplicationsisdisplayed in Table1.2.

1.5.2Textileapplicationsofnanocellulose Thegreatinterestofdesigningmoresustainableandenvironmentalfriendlytextilematerialshasfocusedmoreonrenewableresources.In thiscontext,nanocellulosehasattracted greatdealofattentionduetoitslowthermal expansion,cheapness,lowweight,tensile

stiffness(2 6GPa),andstringmodulus(140 150GPa).Ithasbeenderivedfromseveral agriculturalandindustrialwasteslike,ricestraw,husk,bagasseofsugarcaneetc.Ingeneral, textileindustriesnaturalfibersarewidelyusedasmoderntextilematerialsduetovariation instaplelength.Chattopadhyayetal.isolatedcellulosenanowhiskersfromindustrial byproductrayonfiber.Theyanalyzedthesizedependentthermalandphysicalproperties ofpolyesterfabricappliedwithnanocelluloseparticles(ChattopadhyayandPatel,2016). Furthermore,theyshowcasedthehighercolorstrengthintermsof K/S value(23.84)of thenanocelluloseanchoredfabricstowarddyeingwithdirectdye.Theimprovedcolor strengthalongwithsuperiorresistancetowardsoapingisachievedduetotwopathcoating withnanocellulose.Finally,theauthorsdemonstratedtheimprovedabsorbencyandair permeabilityofthepolyesterfabricduetocoatingwithnanocellulose.Liyanapathiranage etal.demonstratednanofibrillatedcellulose dyeingmethodtotackletheincreasingenvironmentalpollutionresultedby currenttextiledyeingprocess(Liyanapathiranageetal., 2020).Theposttreatmentprocesswithpolycarbxylicacidformscross-linkednanofibrillated cellulosefibersbyesterificationoverthecottonfabric.Theincorporationofnanofibrillated celluloseenhancedthedyefixationby30%andalsominimizesthefastnessduetowashing upto60%.Notably,theyimprovedthefabricqualitywithoutdisturbingthestiffnessand breathabilityoftheinherent fabric.Additionally,theytestedthemoderntextilemethod foraseriesofreactivedyecoveringtheentirevisiblespectrum.Anotherreportsuggested byShaheenandhiscoworkerspresentednanocellulose-polypyrrolecompositefordevelopmentofanovelconductivetextilematerialthroughcoating overcottonfabric (Hebeishetal.,2016).Itwasrevealedinthestudythattheincorporationof nanocellulose-polypyrrolecompositeboostedthemechanicalandelectricalpropertiesof thecottonfabric.Theyalsosuggestedthatwithincreaseinthedoseofnanocellulosesignificantlyaffectsthemechanicalpropertieswhereasincreaseinpolypyrroleamount enhancedtheconductivityofthecottonfabric.Theconductivefabricwasdesignedfor thepurposeoffiltering,de-electrifyingclothes,ceilingmaterials,anddust/bacteriafree clothes.In2016Minkoetal.filedapatentwhereheshowedtheutilizationofnanocellulosefibersfortextiledyeing application.Theyfoundthatthedyednanocellulosegelpreparedfromwoodpulpcanbeappliedoverfabricsortextileseliminatingtherequirement ofwater(Minkoetal.,2016).Inthiscase,nanocellulose hasbeenemployedasabinding agentaswellasacarrierfordyemolecules.Thebindingcapacityofthedyestotextiles throughnanosizedcelluloseparticleswasveryhighcomparedtothewetprocessusedfor dyeing.Theycreditedthelargesurfacearea andextensiveamountofsurfacefunctional groupsofnanocellulosebehindthestronginteractionwithdyemolecules.Saremietal. studiedtheadhesivepropertiesandstabilityofnanocellulosewhencoatedoverpolymer fabricssuchascotton,polyethyleneterephthalate(PET)andnylon6,6(Saremietal., 2020).Theauthorsdepositedcellulosenanofibersandnanoparticlesoverthesurfaceofthe polymerictextiles.Thesampleswerecharacterizedwithellipsometry,atomicforcemicroscopy,andT-peeladhesiontests.Bothwetanddrytestrevealedthehigheradhesionof