https://ebookmass.com/product/bio-based-nanoemulsions-foragri-food-applications-kamel-a-abd-elsalam/

Instant digital products (PDF, ePub, MOBI) ready for you

Download now and discover formats that fit your needs...

Carbon Nanomaterials for Agri-food and Environmental Applications 1st Edition Kamel A. Abd-Elsalam (Editor)

https://ebookmass.com/product/carbon-nanomaterials-for-agri-food-andenvironmental-applications-1st-edition-kamel-a-abd-elsalam-editor/

ebookmass.com

Agri-Waste and Microbes for Production of Sustainable Nanomaterials Kamel A. Abd-Elsalam

https://ebookmass.com/product/agri-waste-and-microbes-for-productionof-sustainable-nanomaterials-kamel-a-abd-elsalam/

ebookmass.com

Multifunctional hybrid nanomaterials for sustainable agrifood and ecosystems Abd-Elsalam

https://ebookmass.com/product/multifunctional-hybrid-nanomaterialsfor-sustainable-agri-food-and-ecosystems-abd-elsalam/

ebookmass.com

Joe Higgins Search 01-Search Through The Ashes Irene Hill

https://ebookmass.com/product/joe-higgins-search-01-search-throughthe-ashes-irene-hill/

ebookmass.com

Voids in Materials: From

Unavoidable Defects to Designed Cellular Materials 2nd Edition Gary M. Gladysz https://ebookmass.com/product/voids-in-materials-from-unavoidabledefects-to-designed-cellular-materials-2nd-edition-gary-m-gladysz/

ebookmass.com

The Enemy You Gnocchi Catherine Bruns https://ebookmass.com/product/the-enemy-you-gnocchi-catherine-bruns/

ebookmass.com

Signing Naturally Units 7-12 eBook

https://ebookmass.com/product/signing-naturally-units-7-12-ebook/

ebookmass.com

Big Data Analytics and Machine Intelligence in Biomedical and Health Informatics Sunil Kuma Dhal

https://ebookmass.com/product/big-data-analytics-and-machineintelligence-in-biomedical-and-health-informatics-sunil-kuma-dhal/

ebookmass.com

Sir Lancelot 1958 TV Series Big Little Book Big Little Books

https://ebookmass.com/product/sir-lancelot-1958-tv-series-big-littlebook-big-little-books/

ebookmass.com

Diabetes Secrets 1st Edition Michael T. Mcdermott Md Author

https://ebookmass.com/product/diabetes-secrets-1st-edition-michael-tmcdermott-md-author/

ebookmass.com

BIO-BASED NANOEMULSIONS FORAGRI-FOOD APPLICATIONS SeriesEditor

KAMEL A.ABD-ELSALAM

Editedby

KAMEL A.ABD-ELSALAM

ResearchProfessor,PlantPathologyResearchInstitute,AgriculturalResearchCenter(ARC),Giza,Egypt

KASI MURUGAN

MemberSyndicate,ProfessorandHead,DepartmentofBiotechnology,ManonmaniamSundaranarUniversity,Tirunelveli,India

Elsevier Radarweg29,POBox211,1000AEAmsterdam,Netherlands TheBoulevard,LangfordLane,Kidlington,OxfordOX51GB,UnitedKingdom 50HampshireStreet,5thFloor,Cambridge,MA02139,UnitedStates

Copyright©2022ElsevierInc.Allrightsreserved.

Nopartofthispublicationmaybereproducedortransmittedinanyformorbyanymeans,electronicor mechanical,includingphotocopying,recording,oranyinformationstorageandretrievalsystem,without permissioninwritingfromthepublisher.Detailsonhowtoseekpermission,furtherinformationaboutthe Publisher’spermissionspoliciesandourarrangementswithorganizationssuchastheCopyrightClearance CenterandtheCopyrightLicensingAgency,canbefoundatourwebsite: www.elsevier.com/permissions

ThisbookandtheindividualcontributionscontainedinitareprotectedundercopyrightbythePublisher(other thanasmaybenotedherein).

Notices

Knowledgeandbestpracticeinthisfieldareconstantlychanging.Asnewresearchandexperiencebroadenour understanding,changesinresearchmethods,professionalpractices,ormedicaltreatmentmaybecome necessary.

Practitionersandresearchersmustalwaysrelyontheirownexperienceandknowledgeinevaluatingandusing anyinformation,methods,compounds,orexperimentsdescribedherein.Inusingsuchinformationormethods theyshouldbemindfuloftheirownsafetyandthesafetyofothers,includingpartiesforwhomtheyhavea professionalresponsibility.

Tothefullestextentofthelaw,neitherthePublishernortheauthors,contributors,oreditors,assumeanyliability foranyinjuryand/ordamagetopersonsorpropertyasamatterofproductsliability,negligenceorotherwise,or fromanyuseoroperationofanymethods,products,instructions,orideascontainedinthematerialherein.

ISBN:978-0-323-89846-1

ForinformationonallElsevierpublications visitourwebsiteat https://www.elsevier.com/books-and-journals

Publisher: NikkiP.Levy

AcquisitionsEditor: NancyJ.Maragioglio

EditorialProjectManager: AndreaR.Dulberger

ProductionProjectManager: SwapnaSrinivasan

CoverDesigner: GregHarris

TypesetbySTRAIVE,India

Contributors SoleimanAbbasi FoodColloidsandRheologyLaboratory, DepartmentofFoodScienceandTechnology,Facultyof Agriculture,TarbiatModaresUniversity,Tehran,Iran

KamelA.Abd-Elsalam PlantPathologyResearchInstitute, AgriculturalResearchCenter(ARC),Giza,Egypt

Cristo ´ balNoeAguilar-Gonzalez CandelillaResearchGroup, DepartmentofResearch(DIA-UAdeC),SchoolofChemistry, AutonomousUniversityofCoahuila,Saltillo,Coahuila, Mexico

ZulfiqarAhmad DepartmentofFoodScienceandTechnology, FacultyofAgricultureandEnvironment,TheIslamia UniversityofBahawalpur,Bahawalpur,Pakistan

AnwaarAhmed InstituteofFoodandNutritional Sciences,PMAS-AridAgricultureUniversity,Rawalpindi, Pakistan

FarahK.Ahmed BiotechnologyEnglishProgram,Facultyof Agriculture,DepartmentofBiotechnology,CairoUniversity, Giza,Egypt;DepartmentofBiotechnology,Biofilm&BioprocessLaboratory,ManonmaniamSundaranarUniversity, Tirunelveli,TamilNadu,India

EmanF.Al-Amrousi FatsandOilsDepartment,National ResearchCentre,Cairo,Egypt

NaifAbdullahAl-Dhabi AddiriyahChairforEnvironmental Studies,DepartmentofBotanyandMicrobiology, CollegeofScience,KingSaudUniversity,Riyadh, SaudiArabia

RobertoArredondo-Valdes NanobioscienceResearchGroup, PostgraduatePrograminFoodScienceandTechnology, FacultyofChemicalSciencesoftheAutonomousUniversity ofCoahuila,Saltillo,Coahuila,Mexico

SadiaZ.Bajwa NanobiotechnologyGroup,IndustrialBiotechnologyDivision,NationalInstituteforBiotechnologyand GeneticEngineering(NIBGE),ConstituentCollegeofPakistanInstituteofEngineeringandAppliedSciences(PIEAS), Faisalabad,Pakistan

SenthilkumarBalakrishnan DivisionofBiologicalSciences, TamilNaduSateCouncilforScienceandTechnology, Chennai,TamilNadu,India

CynthiaLizethBarrera-Martı´nez ResearchCenterforthe ConservationofBiodiversityandEcologyofCoahuila (CICBEC),DepartmentofResearch(CICBEC-UAdeC), DirectionoftheResearchandPostgraduate,Autonomous UniversityofCoahuila,Saltillo,Coahuila,Mexico

FranciscoJ.Blancas-Benitez NationalTechnologyofMexico/ TechnologicalInstituteofTepic,IntegralLaboratoryonFood ScienceResearch,Tepic,Mexico

GuilhermeCarneiro DepartmentofPharmacy,Facultyof BiologicalandHealthSciences,FederalUniversityofJequitinhonhaandMucuriValleys,Diamantina,MinasGerais, Brazil

Mo ´ nicaCha ´ vez-Gonza ´ lez NanobioscienceResearchGroup, PostgraduatePrograminFoodScienceandTechnology, FacultyofChemicalSciencesoftheAutonomousUniversity ofCoahuila,Saltillo,Coahuila,Mexico

V.Chayapathy DepartmentofElectricalandElectronicEngineering,RVCollegeofEngineering,Bangalore,Karnataka, India

PoojaChouhan DepartmentofMolecularBiologyandBiotechnology,RajasthanCollegeofAgriculture,Maharana PratapUniversityofAgricultureandTechnology,Udaipur, Rajasthan,India

SofiaSantosDonaireChura DepartmentofPharmacy,Faculty ofBiologicalandHealthSciences,FederalUniversityof JequitinhonhaandMucuriValleys,Diamantina,MinasGerais,Brazil

MiguelA ´ ngelDeLeo ´ n-Zapata ResearchCenterfortheConservationofBiodiversityandEcologyofCoahuila(CICBEC), DepartmentofResearch(CICBEC-UAdeC),Directionofthe ResearchandPostgraduate,AutonomousUniversityof Coahuila,Saltillo,Coahuila,Mexico

AmandaLelisdeSouza LaboratoryofGreenMaterials,InstituteofScienceandTechnology,FederalUniversityofJequitinhonhaandMucuriValleys,Diamantina,MinasGerais, Brazil

KhaidemArunaDevi DepartmentofMolecularBiologyand Biotechnology,RajasthanCollegeofAgriculture,Maharana Pratap UniversityofAgricultureandTechnology,Udaipur, Rajasthan,India

SindhuPriyaDhas DepartmentofBiotechnology,JayaCollege ofArtsandScience,Chennai,India

SenbagamDuraisamy DepartmentofMarineBiotechnology, BharathidasanUniversity,Tiruchirappalli,TamilNadu, India

AmalA.M.Elgharbawy InternationalInstituteforHalal ResearchandTraining(INHART);BioenvironmentalEngineeringResearchCentre(BERC),DepartmentofBiotechnologyEngineering,InternationalIslamicUniversityMalaysia, KualaLumpur,Malaysia

BrunaLorenaFigueiredo LaboratoryofGreenMaterials, InstituteofScienceandTechnology,FederalUniversityof JequitinhonhaandMucuriValleys,Diamantina,MinasGerais,Brazil

JessicadeMatosFonseca DepartmentofChemicalandFood Engineering,FederalUniversityofSantaCatarina,Florianópolis,SantaCatarina,Brazil

JoseDanielGarcı´a-Garcı ´ a NanobioscienceResearchGroup, PostgraduatePrograminFoodScienceandTechnology, FacultyofChemicalSciencesoftheAutonomousUniversity ofCoahuila,Saltillo,Coahuila,Mexico

RamsesR.Gonza ´ lez-Estrada NationalTechnologyofMexico/ TechnologicalInstituteofTepic,IntegralLaboratoryonFood ScienceResearch,Tepic,Mexico

MayelaGovea-Salas NanobioscienceResearchGroup,PostgraduatePrograminFoodScienceandTechnology,Faculty ofChemicalSciencesoftheAutonomousUniversityofCoahuila,Saltillo,Coahuila,Mexico

PraveenKumarGupta DepartmentofBiotechnology,RV CollegeofEngineering,Bangalore,Karnataka,India

PorfirioGutierrez-Martinez NationalTechnologyofMexico/ TechnologicalInstituteofTepic,IntegralLaboratoryonFood ScienceResearch,Tepic,Mexico

AyatF.Hashim FatsandOilsDepartment,NationalResearch Centre,Cairo,Egypt

JuanA.Herrera-Gonza ´ lez NationalTechnologyofMexico/ TechnologicalInstituteofTepic,IntegralLaboratoryonFood ScienceResearch,Tepic;ExperimentalFieldsUruapan, NationalInstituteforForestry,AgricultureandLivestock Research,Uruapan,Michoacan,Mexico

SamarSayedIbrahim PestsandPlantProtectionDepartment, NationalResearchCentre,Cairo,Egypt

AnnaIlyina NanobioscienceResearchGroup,Postgraduate PrograminFoodScienceandTechnology,FacultyofChemicalSciencesoftheAutonomousUniversityofCoahuila, Saltillo,Coahuila,Mexico

FarwahJameel NanobiotechnologyGroup,IndustrialBiotechnologyDivision,NationalInstituteforBiotechnologyand GeneticEngineering(NIBGE),ConstituentCollegeofPakistanInstituteofEngineeringandAppliedSciences(PIEAS), Faisalabad,Pakistan

JosefJampı´lek DepartmentofAnalyticalChemistry,Facultyof NaturalSciences,ComeniusUniversity,Bratislava,Slovakia; InstituteofNeuroimmunology,SlovakAcademyofSciences, Bratislava,Slovakia

B.Jayanthi DepartmentofBiotechnology,SonaCollegeof ArtsandScience,Salem,TamilNadu,India

P.Karthik CentreforFoodNanotechnology(CFN),DepartmentofFoodTechnology,FacultyofEngineering,Karpagam AcademyofHigherEducation(DeemedtobeUniversity), Coimbatore,India

PonmuruganKaruppiah AddiriyahChairforEnvironmental Studies,DepartmentofBotanyandMicrobiology,Collegeof Science,KingSaudUniversity,Riyadh,SaudiArabia

E.Keshamma DepartmentofBiochemistry,Maharani'sScience CollegeforWomen,Bengaluru,Karnataka,India

WaheedS.Khan NanobiotechnologyGroup,IndustrialBiotechnologyDivision,NationalInstituteforBiotechnologyand GeneticEngineering(NIBGE),ConstituentCollegeof

PakistanInstituteofEngineeringandAppliedSciences (PIEAS),Faisalabad,Pakistan

AleksandarZ ˇ .Kostic UniversityofBelgrade,FacultyofAgriculture,DepartmentofFoodTechnologyandBiochemsitry, Belgrade,Serbia

Katarı´naKra ´ lova ´ InstituteofChemistry,FacultyofNatural Sciences,ComeniusUniversity,Bratislava,Slovakia

EsmerayKuley FacultyofFisheries,DepartmentofSeafood ProcessingTechnology,CukurovaUniversity,Adana,Turkey

AnbarasuKumarasamy DepartmentofMarineBiotechnology, Bharathidasan University,Tiruchirappalli,TamilNadu,India

ElanInakyLaredo-Alcala ´ ResearchCenterfortheConservationofBiodiversityandEcologyofCoahuila(CICBEC), DepartmentofResearch(CICBEC-UAdeC),Directionofthe ResearchandPostgraduate,AutonomousUniversityof Coahuila,Saltillo,Coahuila,Mexico

AmandaTibaesLopes LaboratoryofGreenMaterials,Institute ofScienceandTechnology,FederalUniversityofJequitinhonhaandMucuriValleys,Diamantina,MinasGerais, Brazil

AhmedMadni NanobiotechnologyGroup,IndustrialBiotechnologyDivision,NationalInstituteforBiotechnologyand GeneticEngineering(NIBGE),ConstituentCollegeofPakistanInstituteofEngineeringandAppliedSciences(PIEAS), Faisalabad,Pakistan

NiloufarMahmoudi DepartmentofAgroBiotechnology,Peoples'FriendshipUniversityofRussia(RUDNUniversity), Moscow,Russia

TanuMalik DepartmentofFoodTechnologyandNutrition, LovelyProfessionalUniversity,Phagwara,India

JoseLuisMartı´nez-Herna ´ ndez NanobioscienceResearch Group,PostgraduatePrograminFoodScienceandTechnology,FacultyofChemicalSciencesoftheAutonomous UniversityofCoahuila,Saltillo,Coahuila,Mexico

TahirMehmood DepartmentofFoodScienceandTechnology, FacultyofAgricultureandEnvironment,TheIslamiaUniversityofBahawalpur,Bahawalpur,Pakistan

NormaPaolaMelendez-Renterı´a ResearchCenterfortheConservationofBiodiversityandEcologyofCoahuila(CICBEC), DepartmentofResearch(CICBEC-UAdeC),Directionofthe ResearchandPostgraduate,AutonomousUniversityof Coahuila,Saltillo,Coahuila,Mexico

LeticiaA.Menchaca-Castro NanobioscienceResearchGroup, PostgraduatePrograminFoodScienceandTechnology, FacultyofChemicalSciencesoftheAutonomousUniversity ofCoahuila,Saltillo,Coahuila,Mexico

MarianoMichelon SchoolofChemistryandFood,Federal UniversityofRioGrande,RioGrande,RioGrandedoSul, Brazil

DanijelD.Milincic UniversityofBelgrade,FacultyofAgriculture,DepartmentofFoodTechnologyandBiochemsitry, Belgrade,Serbia

SamiaM.M.Mohafrash PesticideChemistryDepartment, ChemicalIndustriesResearchInstitute,NationalResearch Centre(NRC),Giza,Egypt

AlcileneRodriguesMonteiro DepartmentofChemicaland FoodEngineering,FederalUniversityofSantaCatarina, Florianópolis,SantaCatarina,Brazil

CristinaMoreno-Herna ´ ndez NationalTechnologyofMexico/ TechnologicalInstituteofTepic,IntegralLaboratoryonFood ScienceResearch,Tepic,Mexico

Abdel-TawabH.Mossa PesticideChemistryDepartment, ChemicalIndustriesResearchInstitute,NationalResearch Centre(NRC),Giza,Egypt

PrathabanMunisamy DepartmentofMicrobiology,PondicherryUniversity,Pondicherry,India

KasiMurugan BiotechnologyEnglishProgram,Facultyof Agriculture,DepartmentofBiotechnology,CairoUniversity, Giza,Egypt;DepartmentofBiotechnology,Biofilm&BioprocessLaboratory,ManonmaniamSundaranarUniversity, Tirunelveli,TamilNadu,India

AbdorrezaMohammadiNafchi DepartmentofFoodTechnology,SchoolofIndustrialTechnology,Penang,Malaysia

R.Nagarajan DepartmentofChemicalEngineering,Indian InstituteofTechnologyMadras,Chennai,India

YousefNaserzadeh DepartmentofAgroBiotechnology,Peoples'FriendshipUniversityofRussia(RUDNUniversity), Moscow,Russia

SharmilaDeviNatarajan DepartmentofMicrobiology,KarpagamAcademyofHigherEducation,Coimbatore,Tamil Nadu,India

ErikaNava-Reyna NationalCentersforDisciplinaryInvestigationinWater,Plant,SoilandAtmosphereRelationship (CENIDRASPA),GomezPalacio,Durango,Mexico

ViktorA.Nedovic UniversityofBelgrade,FacultyofAgriculture,DepartmentofFoodTechnologyandBiochemsitry, Belgrade,Serbia

MohammadNejatian DepartmentofFoodScienceandTechnology,SchoolofNutritionScienceandFoodTechnology; ResearchCenterofOilsandFats,KermanshahUniversityof MedicalSciences,Kermanshah,Iran

M.JoyceNirmala DepartmentofChemicalEngineering, IndianInstituteofTechnologyMadras,Chennai,India

YesimOzogul FacultyofFisheries,DepartmentofSeafood ProcessingTechnology,CukurovaUniversity,Adana, Turkey

SandraPacios-Michelena NanobioscienceResearchGroup, PostgraduatePrograminFoodScienceandTechnology, FacultyofChemicalSciencesoftheAutonomousUniversity ofCoahuila,Saltillo,Coahuila,Mexico

AjayPal DepartmentofBiochemistry,CollegeofBasicSciencesandHumanities,ChaudharyCharanSinghHaryana AgriculturalUniversity,Hisar,Haryana,India

J.Pavithra CentreforFoodNanotechnology(CFN),DepartmentofFoodTechnology,FacultyofEngineering,Karpagam AcademyofHigherEducation(DeemedtobeUniversity), Coimbatore,India

FrancieleMariaPelissari LaboratoryofGreenMaterials,InstituteofScienceandTechnology,FederalUniversityofJequitinhonhaandMucuriValleys,Diamantina,MinasGerais,Brazil

MirjanaB.Pes ˇ ic UniversityofBelgrade,FacultyofAgriculture,DepartmentofFoodTechnologyandBiochemsitry, Belgrade,Serbia

ChidambaramPrahalathan DepartmentofBiochemistry, BharathidasanUniversity,Tiruchirappalli,TamilNadu,India

DamyantiPrajapati DepartmentofMolecularBiologyand Biotechnology,RajasthanCollegeofAgriculture,Maharana PratapUniversityofAgricultureandTechnology,Udaipur, Rajasthan,India

UppadaSumanthRaj DepartmentofChemicalEngineering, IndianInstituteofTechnologyMadras,Chennai,India

AmuthaRaju DepartmentofBiotechnology,PeriyarUniversityPGExtensionCentre,Dharmapuri,TamilNadu,India

SurelysRamos-Bell NationalTechnologyofMexico/TechnologicalInstituteofTepic,IntegralLaboratoryonFoodScience Research,Tepic,Mexico

RodolfoRamos-Gonza ´ lez CONACYT-AutonomousUniversity ofCoahuila,PostgraduatePrograminFoodScienceand Technology,FacultyofChemicalSciencesoftheAutonomous UniversityofCoahuila,Saltillo,Coahuila,Mexico

Suriyaprabha Rangaraj DepartmentofBiotechnology,Sona CollegeofArtsandScience,Salem,TamilNadu,India

R.Rathika PG&ResearchDepartmentofBiotechnology, MahendraArts&ScienceCollege(Autonomous),Namakkal, TamilNadu,India

MythiliRavichandran DepartmentofMicrobiology,VivekanandhaArtsandScienceCollegeforWomen,Sankari; DepartmentofMicrobiology,K.S.RangasamyCollegeofArts andScience,Tiruchengode,TamilNadu,India

AsmaRehman NanobiotechnologyGroup,IndustrialBiotechnologyDivision,NationalInstituteforBiotechnologyand GeneticEngineering(NIBGE),ConstituentCollegeofPakistanInstituteofEngineeringandAppliedSciences(PIEAS), Faisalabad,Pakistan

MuhammadAdilRehman DepartmentofFoodScienceand Technology,FacultyofAgricultureandEnvironment,The IslamiaUniversityofBahawalpur,Bahawalpur,Pakistan

Toma ´ sRivas-Garcı´a CONACYT-ChapingoAutonomous University,Texcoco,Mexico

VinodSaharan DepartmentofMolecularBiologyandBiotechnology,RajasthanCollegeofAgriculture,Maharana PratapUniversityofAgricultureandTechnology,Udaipur, Rajasthan,India

UrvashiSahu FoodProtectantsandInfestationControl Department,CSIR-CentralFoodTechnologicalResearch Institute,Mysore;AcademyofScientificandInnovative Research(AcSIR),Ghaziabad,India

PadamataShaliniSai ChemicalEngineeringDepartment, NationalInstituteofTechnologyWarangal,Hanamkonda, Telangana,India

NarasaSaikrishna DepartmentofChemicalEngineering, IndianInstituteofTechnologyMadras,Chennai,India

AnaSalevic UniversityofBelgrade,FacultyofAgriculture, DepartmentofFoodTechnologyandBiochemsitry,Belgrade, Serbia

HamzahMohdSalleh InternationalInstituteforHalalResearch andTraining(INHART),InternationalIslamicUniversity Malaysia,KualaLumpur,Malaysia

SumathiC.Samiappan DepartmentofChemistryandBiosciences,SrinivasaRamanujanCentre,SASTRAUniversity, Kumbakonam,TamilNadu,India

JorgeA.Sa ´ nchez-Burgos NationalTechnologyofMexico/ TechnologicalInstituteofTepic,IntegralLaboratoryonFood ScienceResearch,Tepic,Mexico

A.SaravanaRaj DepartmentofChemicalEngineering,Vel TechHighTechDr.RangarajanDr.SakunthalaEngineering College,Chennai,India

PatriciaSegura-Ceniseros NanobioscienceResearchGroup, PostgraduatePrograminFoodScienceandTechnology, FacultyofChemicalSciencesoftheAutonomousUniversity ofCoahuila,Saltillo,Coahuila,Mexico

T.Selvankumar PG&ResearchDepartmentofBiotechnology, MahendraArts&ScienceCollege(Autonomous),Namakkal, TamilNadu,India

Faiz-ul-HassanShah DepartmentofFoodScienceand Technology,FacultyofAgricultureandEnvironment, TheIslamiaUniversityofBahawalpur,Bahawalpur, Pakistan

SanjanaSubramanya DepartmentofBiotechnology,RV CollegeofEngineering,Bangalore,Karnataka,India

KausthubhSumanth DepartmentofBiotechnology,RV CollegeofEngineering,Bangalore,Karnataka,India

Letı´ciaMoraisCostaTeixeira LaboratoryofGreenMaterials, InstituteofScienceandTechnology,FederalUniversityof JequitinhonhaandMucuriValleys,Diamantina,MinasGerais,Brazil

R.Thirumalaisamy DepartmentofBiotechnology, SonaCollegeofArtsandScience,Salem,TamilNadu, India

ThallesCantonTrevisol DepartmentofChemicalandFood Engineering,FederalUniversityofSantaCatarina, Florianópolis,SantaCatarina,Brazil

Germa ´ nAyalaValencia DepartmentofChemicalandFood Engineering,FederalUniversityofSantaCatarina, Florianópolis,SantaCatarina,Brazil

AlejandraVargas-Segura FacultyofDentistryofthe AutonomousUniversityofCoahuila,Saltillo,Coahuila, Mexico

S.EzhilVendan FoodProtectantsandInfestationControl Department,CSIR-CentralFoodTechnologicalResearch Institute,Mysore;AcademyofScientificandInnovative Research(AcSIR),Ghaziabad,India

HaticeYazgan FacultyofCeyhanVeterinaryMedicine, DepartmentofFoodHygieneandTechnology,Cukurova University,Adana,Turkey

Preface Agricultural,food,andpharmaceuticalresearchershavebeenworkingondevelopingdeliverysystemsthatcan encapsulate,protect,anddeliverbiologicallyactivenaturalchemicalsofvariousstructuresandfunctions.Natural nanoemulsionsarewidelyrecognizedasthemosteffectivedeliveryvehiclesfornaturalnutraceuticalsandphytochemicals,withseveralagro-fooduses.Thisemergingnanoemulsiontechnologyprovidesanewdimensiontothe developmentofnext-generationagrochemicals,functionalfoods,foodpreservatives,andotherproducts.

Inits26chapters,thecurrentvolume, “Bio-BasedNanoemulsionsforAgri-FoodApplications, ” showcasesthe know-how,discoveries,andrewardingfindingsofgreenandfood-gradenanoemulsionsappliedintheagricultural andfoodindustries.Thegoalofthisbookistoprovideessentialandcomprehensiveinformationontheoverview, concept,techniques,recentadvances,andissuesintheformulationanduseofnovelgreen/food-gradenanoemulsions inagriculturalandfoodtechnology.Theuseofgreen/food-gradenanoemulsionproductionmethods,components (plant/microbialproducts,biosurfactants,cosurfactants,emulsifiers,ligandtargets,andbioactive/functionalingredients),andsophisticatedinstruments/analyticalmethodsfornanoemulsioncharacterizationwillbeheavilyemphasized.Webelievethatthebookisup-to-date,andanswersasignificantneedintheagro-foodbusinessbyinvestigating current,evolvingtechnology.

Thebook ’s26chaptershavebeenwrittenbydistinguishedscholarsfromBrazil,India,Iran,theCzechRepublic, Malaysia,Mexico,Russia,Serbia,andTurkey.Researchersinthefieldsofenvironmentalscience,foodscience,and farmsciencemaybetheprimaryaudienceforthisbook;however,students,postgraduates,andresearchersinawide rangeoffieldsrelatedtofood,agriculture,andtheenvironmentwillalsobenefitfromitscontents.Inthisbook,three partsdiscussthegrowingroleofgreen/food-gradenanoemulsionsinagri-foodapplications:food-gradenanoemulsionformulation,production,andcharacterizationmethods;greennanoemulsionbioactivecomponentencapsulation techniques;nanoinsecticides/nanopesticides,antifungalandmycotoxininhibitorynanoemulsions;postharvestdiseasemanagement;foodspoilagecausatives/pathogensmanagement;ediblecompositesforfoodpackaging;biological destinyandtoxicityofnanoemulsionformulations;vitamin-basedediblenanoemulsions;deliveryvehiclesofnatural antioxidantsandnutraceuticals;andorganoleptic/sensoryfactors.

Researchersneedthoroughsummariestocomplementtheiractivestudiesandsupporttheirmainfindings,suchas bookreviewsorreviewarticles.Thispublicationwillmaketheseareasofexpertisemoreeasilyaccessibleinternationallybybringingthemtogether.Wetrulyfeelthatwehavepresentedafair,intriguing,andforward-thinkingperspectiveontheissue,notjustforseasonedacademics,butalsoforindustrydecision-makersandpeopleenteringthefield withlittleknowledge.

Firstandforemost,wewanttoexpressourappreciationtoElsevierstaff,particularlyMeganBall(ExecutiveEditor), AndreaDulberger(EditorialProjectManager),andDineshN.,fortheircooperationandeffortsinassistingusinreachingthisgoal.Weexpressourgratitudetoallofthereviewerswhotookthetimetothoroughlyexamineeachchapter. Wealsoexpressourgratitudetoourfamiliesfortheirunwaveringsupportandencouragement.

KamelA.Abd-Elsalam ResearchProfessor,PlantPathologyResearchInstitute,AgriculturalResearchCenter(ARC), Giza,Egypt

KasiMurugan MemberSyndicate,ProfessorandHead,DepartmentofBiotechnology, ManonmaniamSundaranarUniversity,Tirunelveli,India

Sustainablenanoemulsionsforagri-food applications:Todayandfuturetrends KasiMurugana andKamelA.Abd-Elsalam b

aDepartmentofBiotechnology,ManonmaniamSundaranarUniversity,Tirunelveli,TamilNadu,India

bPlantPathologyResearchInstitute,AgriculturalResearchCenter(ARC),Giza,Egypt

1.Introduction

Thediscoveryofnewapplicationsofnanotechnologyhasgainedmomentuminrecentyears,anditsacceptancein variousfields,includingchemistry,food,medicine,etc.,hasbeenemphasized.However,despitetheeffortbeing made,theenormouspotentialofmanynanomaterialsremainsuntapped.Untilthelate1980s,industrialization wasseenasthecentralpillarofeconomicdevelopmentandincreasedproductivity.Knowledgeandresearchfrom therecentlyemergingfieldsofbiotechnologyandlifesciences,includingthebio-basedeconomyanditsextendedcirculareconomyconcepts,helpstotransferandcontributeknowledge,transforminglifesciencesintoanew,sustainable, andenvironmentallyfriendlyeconomy.Thisbio-basedeconomyinvolvesagriculture,chemistry,theenvironment, food,andhealth,aswellasvarioussocioeconomicsectors.However,forittobedevelopedsuccessfully,itisimperativetoidentifythemostpromisingbio-basedproductssuchasfood,feed,value-addedrawmaterialsandchemicals, andbasechemicals.Thisplatformwillenhancetheoverallprocesseconomyandreducetheimpactontheenvironment(Pantetal.,2019).

Researchintonanotechnologyanditsapplicationinotherfieldsaregainingconstantmomentum.Duetotheecofriendlypropertiesofnanotechnology,itisbeingconsideredasanalternativetotraditionalpesticideformulationsto prevent,neutralize,orkillinsects.However,whilenanotechnologymightbeconsideredasaferpestcontroloption, enoughstudieshaveshownthatnanoparticlesaretoxictoanimalsandhumans,aswellaspresentingdangersinthe globalfoodsupply,tomakethemunsuitableforuseasinsecticides.Publicsafetyconcernsaboutagriculturalnanoparticleshavebeenraisedbytherapidandunprotectedlarge-scaledeploymentofnanoparticlesinagriculturebecause oftheiruseintheproductionandconservationofpesticides.Cropmanagementiscost-effective.Beyondthepossible benefits,nanoparticlesraiseimportantquestionsaboutthepotentialdifficultiestheypresent.Thedevelopmentofa comprehensiveregulatoryframeworkisnecessarytoaddressthesafetyissuesofnanoparticles;however,onlyahandfulofgovernmentshavebeguntoprioritizenanoregulation.TheremustberegulationsinplacefortheuseofnanotechnologyinanagriculturalandbiodiversecountrylikeIndia.

Undoubtedly,thepopularityofnanotechnologyinawiderangeofindustrieshasincreasedinrecentyears,includingchemistry,foodscience,andthemedicalfield.Theuniquephysicochemicalpropertiesofnanotechnologycould openupawiderangeofnewapplicationsinbiotechnologyandtheagriculturalindustries.However,despitetheeffort beingmade,aconsiderableproportionofthepotentialofnanomaterialsremainsuntapped(Mishraetal.,2019).Nonetheless,nanotechnologyhasopenedupnewhorizonsinanumberofareas,includinganimalhusbandry,theenvironment,foodpackaging,andindustrialapplications,makingitthemostfascinatingindustrialphenomenonofthe modernera.Ithasemergedasthetechnologyofchoice,risingtothechallengeofmakingtechnologymoresustainable, ecofriendly,andprecise.

Nano-sizedemulsionspromisemanypotentialapplicationsindifferentfieldsandattractinterestfromdifferent agriculturalandfoodsectors.Nanoemulsionsarelong-termkineticallyandthermodynamicallystabledispersionsystemsconsistingofnanometer-sizeddispersedliquiddropletsinacontinuousphaseliquid.Improvementsintheir

formulationallowthecreationofadvancednanoemulsionswithdesiredfunctionalityinadditiontocontrolledphysicalproperties(Rubio-Riosetal.,2019).Themainfeaturesofnanoemulsionsincludehighsolubility,largesurfacearea, lowviscosity,transparentortranslucentappearance,andneutralagglomeration,flocculation,anddepositionwith highkineticstability.Thedesirablephysicalpropertiesandchemicalcompositionofnanoemulsionsoffermanyapplicationopportunities,andasaresult,thefieldofnanoemulsiontechnologyiscontinuouslyexpanding.

Nanoemulsionsrequireforcedenergyinputfrommechanicaldevicesorthechemicalpotentialofthecompound becausethesenonequilibriumsystemscannotbeformedspontaneously.However,nanoemulsionshaveapplications inmanyindustries,includingcosmetics,food,andpharmaceuticals.Theycanbeproducedinvariousforms,suchas aerosols,creams,gels,foams,liquids,andsprays(Rubio-Riosetal.,2019).Therefore,thewideapplicabilityofbionanoemulsions,theiracceptanceinvariousfields,andtheireco-friendlynaturemakethemidealproductsfortheprocessesandnatural,environmentallyfriendly,andsustainableproductsdemandedbyactorsinagricultureandthe foodindustry.

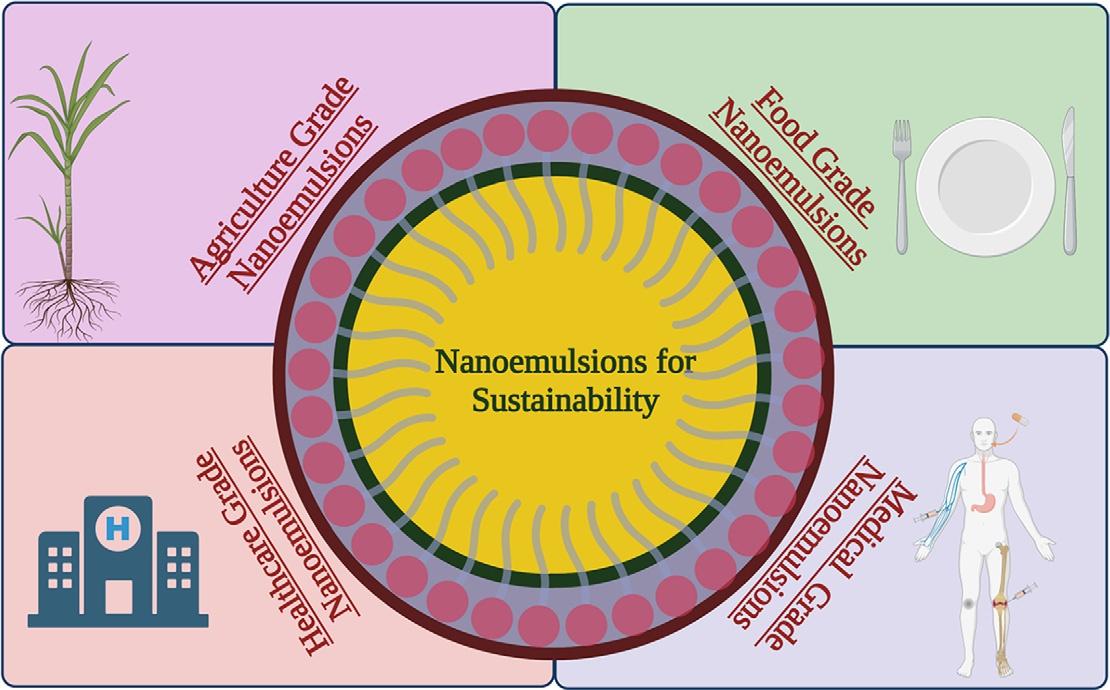

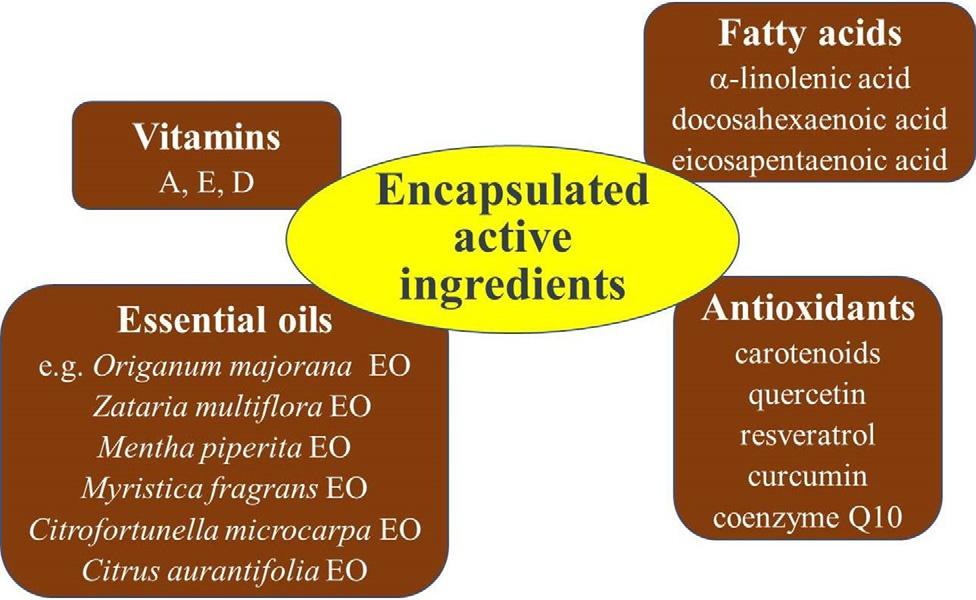

Today,allstakeholders,especiallyconsumers,inallindustriesareincreasinglyinterestedinnaturallyderivedmaterials,processes,andproducts.Therefore,anythinghavingabiologicaloriginattractsmorethanitschemicalorigin counterpartsinourdailylife.Moreimportantly,thesebio-basedproductsandprocessesareconsideredsafer,more environmentallyfriendly,uselessenergy,andoperateprimarilyundersustainabledevelopmentprinciples.Recently developednanotechnologyisnotanexemptionfromthis.Nanoemulsionsarelong-termkineticandthermodynamicallystabledispersionsystemsformedfromnano-phaseliquiddropletsdispersedinacontinuousphaseliquid. Improvementsinhowthey’remadeallowfornewnanoemulsionformulationstobemadethathavetherightfunctionalityandalsotherightphysicalpropertiesforspecificapplications(Rubio-Riosetal.,2019).Ananoemulsionisan artificialproduct,andevidencefornaturallyoccurringnanoemulsionsisnotavailable(Singhaetal.,2016).Inthisscenario,compilinginformationonstrategiesofbio-basednanoemulsionformulations,processoptimization,andthe developmentofapplicationordeliverysystemsisvitalforthesustainabledevelopmentoftheagricultureandfood sector.Asinotherfields,bio-basednanoemulsiondevelopmenthasattractedinterestamongthevariousinvestorsin foodandagriculture.Variousfunctionalpropertybioproductsarebeingstudiedasingredientsforimprovingthefunctionalityandapplicationofnanoemulsions(Fig.1).

Nanometer-sized-dropletemulsionstypicallycomprisingoil,surfactant,andwaterarecallednanoemulsions. Thesenanoemulsionsarealsoreferredtobyvarioustermsintheliteratureasemulsoids,miniemulsions,ultrafine emulsions,unstablemicroemulsions,submicrometeremulsions,etc.,whosedropletsizeisonthenanometricscale (Moralesetal.,2003).Thesizeofthedropletsvariescharacteristicallyuptoanupperlimitof500nm,depending ontheauthors.Thesenanoemulsionsareconceivablycategorizedintotwogroupsbasedonthedropletsize: (<300nm)transparentortranslucentand( 500nm)milky.Threetypesofnanoemulsionshavebeenformulatedsince theirfirstpreparationinthe1940s,viz.oil-in-water(o/w),water-in-oil(w/o),andbicontinuousormultipleemulsions. Oildropletsaredispersedwithinawaterphaseino/w,whereaswaterdropletsaredispersedinanoilphaseinw/o (Romesetal.,2021).Bicontinuousnanoemulsioncomprisesoilandwatermicrodomainsinterspersedwithinthesystem.Water-in-oil-in-water(w/o/w)compriseslargeoildropletscontainingaqueousphasedispersedwaterdroplets, whereasoil-in-water-in-oil(o/w/o)haswaterdropletscontainingoilphasedispersedoildropletsandbelongstothe

multipleemulsionsystemstype.Theo/wemulsionsareusedforthedeliveryofhydrophobicactivesubstances, whereasthew/oemulsionsareusedforthedeliveryofhydrophiliccompounds(AswathanarayanandVittal,2019).

Briefly,nanoemulsionsarecompositionsofnanoparticlespreparedusingapolymerizablemonomerasthedispersedphaseinwhichthenanoemulsionsactasnanoreactants(Cho,2011).Thesenanoemulsionsareconsideredto beathermodynamicallystableisotropicsystemsincetwoimmiscibleliquidsarenotcombinedtoformasinglephase withthehelpofsurfactantsandemulsifyingagentslikecosurfactantsandmechanicalorphysiochemicalenergyinputs (Azmietal.,2019).Thebasicpropertiesofnanoemulsions,includingopticalclarity,goodphysicalstability,andhigh bioavailability,areusedinanumberoffoodsandbeverages(KomaikoandMcClements,2016).Atwo-phasedispersion nanoemulsionoftwoimmiscibleliquidswithoilandwatercanbestabilizedbyanemulsifier;theyarestabilizeddropletsofwater-in-oil(W/O),oil-in-water(O/W),andmultiplewater-in-oil-in-water(W/O/W)nanoemulsions.

Manyattractivephysicalpropertiesofnanoemulsionsmakethemidealforagro-foodapplications;theseincludethe following:

(1) nanosize,highsurfacearea,andfreeenergyallowsnanoemulsionstoquicklypenetrateandspreadoverapplied surfaces;

(2) theappearanceoftransparent(<300nm)andmilky( 500nm)formsisappealing;

(3) creaming,coalescence,flocculation,andsedimentationeventsallowforlongshelflife;

(4) tunablerheologyviadispersedphaseallowsforvolumefractionanddropletsizeadjustments;

(5) thispavesthewayforlipophiliccompoundsolubilizationandprotectscompoundsfromoxidativeandlight degradation;

(6) thisallowsforvariousformulations,suchascream,liquid,spray,etc.,whichnecessitateslessenergyconsumption thancoveringorevenvolatilecompounds,anditimprovesthebioavailabilityofcompounds.

Renewablecomponentsofplantoriginhavebeenexploredmostlyforcreatingbio-basednanoemulsionsinnovel ways,resultinginmanyefficientproductspreviouslyunavailableonthemarket.Themajorityofthesecomponents arelipophilicand,asaresult,arephysicallyandchemicallyunstableinthepresenceofoxygen,light,andhighorlow temperature.Theyare,however,poorlysolubleinwater,whichreducestheirbiologicalactivityandlimitstheirapplicationinanaqueousmedium.Becausethesecomponentsarebiocompatible,biodegradable,antimicrobial,antioxidant, andsoon,theycanbeusedinawiderangeofagriculturalandfoodapplications,buttheydon’tworkaswellastheycould becauseoftheseefficiency-reducingfactors.Manysuccessstoriesofnanoemulsionformulationstrategiespromiseto overcometheselimitations.Forexample,agricultural,food,andmedicalapplicationsofLamiaceaefamilyplants’ essentialoilmajorcomponent,Thymol(2-isopropyl-5-methylphenol),nanoformulationpreparationhelpsovercomeits application-limitingproblems.Thethymolnanoemulsions,whichcomprisethymol’sentrappedconversionintonanodropletswithasuitablesurfactant,arestablephysicallyandchemicallyintheaqueousmedium.Thiscouldmakethem moreeffectiveandhaveawiderrangeofbiologicalactivitiesifyoulookatitfromabiologicalpointofview(Kumarietal., 2018).Ifyoulookatthesesmalldropletspassingthroughbiologicalsurfaces,theywillbeabsorbedefficiently.

Deliverytechnologiescapableofencapsulatingandprotectingnaturalsubstancesofvariousstructuresandactivities arethesubjectofrecentagriculturalandfoodresearch.Manyagro-foodapplicationscanbenefitfromnanoemulsions, whicharetheidealdeliverymethodfornatural-originnutraceuticalsandphytochemicals.Anewgenerationofagrochemicals,functionalfoods,foodpreservatives,etc.maybeproduceduniquelyusingthisevolvingnanoemulsiontechnology.Inaddition,greenandfood-gradenanoemulsionsandtheirapplicationsinagricultureandthefoodbusinessare discussedindepthinthisbook, “Bio-BasedNanoemulsionsforAgri-FoodApplications.” Thesenanoemulsionsmaybe usedinfoodtechnologyandagriculture,andthisbookseekstogiveafulloverviewoftheideas,methodologies,and currentbreakthroughsandproblemsinformulationandapplication.Fornanoemulsioncharacterization,alotofattentionwillbepaidtogreen/food-gradenanoemulsionmanufacturingmethodsaswellasthecomponentsemployed(biosurfactants,cosurfactants,emulsifiers,targetligands,andbioactive/functionalcompounds).Bio-basednanoemulsions areperfectfornatural,environmentallyfriendly,andsustainableprocessesandproductsbecauseoftheirwideapplicability,acceptabilityinawiderangeofindustries,andeco-friendlynature.Nanoemulsionsuseinagricultureandfood applicationshasgrownexponentiallybecausetheyprovideextremelyeffectiveanswerstoawiderangeofcomplex issues.Whenitcomestotoday’smostimportantissuesintheagro-foodindustry,wethinkthisbookisimportant.

2.Trendsinbio-basednanoemulsionformulation AsstatedintheIntroduction,renewable,bio-basednanoemulsionsderivedfromplantshaveproducedmanyproductspreviouslyunavailableonthemarket,utilizingcomponentsthatarelipophilic,meaningtheyarephysicallyand chemicallyunstableinthepresenceofoxygen,light,andtemperature.However,despitetheirbiocompatible,

biodegradable,antimicrobial,andantioxidantqualities,theyarepoorlysolubleinwater,whichreducestheirbiologicalactivityandlimitstheirapplicationviaaqueousmedia,and,therefore,theirwiderapplicationintheagricultural andfoodsectors.Nevertheless,variousnanoemulsionformulationstrategiesarebeingdevelopedtoovercomethese limitations(Kumarietal.,2018).Suchstrategiesfocusonimprovementsintheformulationsofnanoemulsions(which, aspreviouslystated,arekineticandthermodynamicallyunstabledispersionsformedfromthedispersedphaseof nano-sizeddropletsinacontinuousphaseliquid)toproducethedesiredfunctionalityinadditiontocontrolledphysicalproperties(Rubio-Riosetal.,2019).Mostofthetime,nanoparticlesareusedtoencapsulateantimicrobialagents them,whichmakesthemeasiertospreadinwater,moreresistanttoenvironmentalconditions,andmoreeffective, withacontrolledrelease(McClementsetal.,2021).

3.Emulsifiers Nanoemulsionformulationsrequiremoreefficientemulsifierstofacilitateformationandimprovethekineticstabilityofthenanoemulsions.Thesecommonlyusedsurfactantmoleculesstabilizeandprotectdropletsbyreducing surfacetensionaswellasincreasingnanoemulsionkineticstability,theyalsopreventcollisionandagglomeration betweendroplets(AswathanarayanandVittal,2019).Mostemulsifiersareamphotericmoleculesbecausetheyhave bothhydrophilicandhydrophobicgroups(McClementsetal.,2021).Inrecentyears,thedevelopmentofbio-based materialswithlowerenvironmentalimpacthasattractedincreasinginterest(Rubio-Riosetal.,2019).Manyplantcompounds,includingsoyorpeaprotein,gumArabicormodifiedstarchpolysaccharide,soyorsunflowerlecithin,phospholipids,andquillaja-likesurfactantsaponins,areplant-basedemulsifiersthatareemployedtoproduce nanoemulsions.

SyntheticsurfactantsarealsofrequentlyusedaloneorcombinedwithTweenandSpans-likeingredients (McClementsetal.,2021).Mostcommonly,surfactants,mainlyamphiphilicsurfactants,areusedasemulsifiers;on theotherhand,proteinsandlipidsareusedtoformulatenanoemulsions.Tweens,Spans,egg,soy,ordairylecithin, wheyproteinisolate,caseinate,gumArabic,andmodifiedstarchesareexamplesoftheemulsifiersused(Rubio-Rios etal.,2019).Legumeproteinspossessseveraldesirablefunctionalcharacteristicsneededforfoodapplication,viz. abundance,inexpensiveness,sustainability,andlowallergenicity.Manyproteinsofpulsesexhibitefficientsurfaceactivemoleculesthatcanactasnanoemulsions,formingandstabilizingeffectiveemulsifiers forexample,common globulinlegumeproteinsvicilinandlegumin. Gumusetal.(2017) showedthatpea,lentil,andfababeanproteinscould actaseffectiveemulsifiersduringalgaenanoemulsionformulation.Theessentialaminoacid-richsoyproteinsarea mixtureofsurface-activeglobularproteinsthatcanbeutilizedforbioactiveagentencapsulationandnanoemulsion formulation.Soybeanproteinswerefoundtobesuccessfulforperillaoilnanoemulsionfabrication.Likewise,sesame proteinhasbeenshowntobeaneffectiveemulsifierforfishoilnanoemulsionformulation(McClementsetal.,2021). ThefoodindustryusesgelatinandTween20emulsifierstoincreasecitral’sstabilityandpreventitsdegradationunder acidicconditions(AswathanarayanandVittal,2019).Nanoemulsificationorencapsulationofplantnutraceuticalsand otherphytochemicalsmakesthemmiscibleinwaterandcanhelpthemacquireatastepreferabletoconsumersor changeabadtaste.

4.Stabilizers Ostwaldripening,flocculation,coalescence,andgravitationalseparationcausesnanoemulsionbreakdown,i.e., revertingtoseparateaqueousandoilphases.Thenanoemulsionbreakdowncouldbepreventedbystabilizeragents, whichdistributethemselvesontheparticlesandformeitheramonolayerormultilayersandnanoemulsionsofsolid particulates.Emulsifiers,weightingagents,ripeningretarders,andtexturemodifiersarethestabilizersused (AswathanarayanandVittal,2019).Weightingagentsimpedethegravitationalforceandreducebothsedimentation andcreaming.Duetotheirdensity,weighingingredientslikeesteranddammargumareutilizedintheformulationof oil/wateremulsions.Ripeningretardersavoidripeningbyactinghydrophobically.

Similartonormalripeningretarders,long-chaintriacylglycerolsandmineraloilsstopsmalleroilmoleculesfrom enteringtheaqueousphasetocreatebiggermolecules.Lowwatersolubilityincreasesmixingentropy,whichhelps counteractthewavyeffectsofcurvature.Thereareavarietyofwaysinwhichtexturemodifiersaffecttheaqueous phase,includingthickeningandeventheformationofgels.Theoildroplets’ movementpreventionimpartscreaminess andthicknesstotheaqueousphase.Biopolymerslikegums,vegetableproteins,andpolysaccharidesareexamplesof commonlyusedtexturemodifiersasfood-gradestabilizersfornanoemulsionpreparationthathavereceivedincreased

interestinrecentyears.Thepickeringparticle’sdenselayerformationattheoilandwaterinterfaceandtheprevention ofdropletflocculationandcoalescencebystericmechanismmakepickeringstabilizationsuperiortoconventional surfactant-stabilizednanoemulsions.Manyflavonoids,polysaccharides,andproteins,likefood-gradeparticles,were investigatedtopreparePickeringnanoemulsions(AswathanarayanandVittal,2019).Thehighlyhydrophobicnature ofoilanditsseparationfromthefinalproductmakesoilincorporationandadditionintothefoodsystemsacolossal challenge.Althoughseveralmethods,includingamorphoussolidform,liposomes,meltextrusion,nanocarriers,solid dispersions,etc.,havebeensuggestedforoiladditioninfoodsystems,nonewassuitableforall(Mohammed etal.,2020).

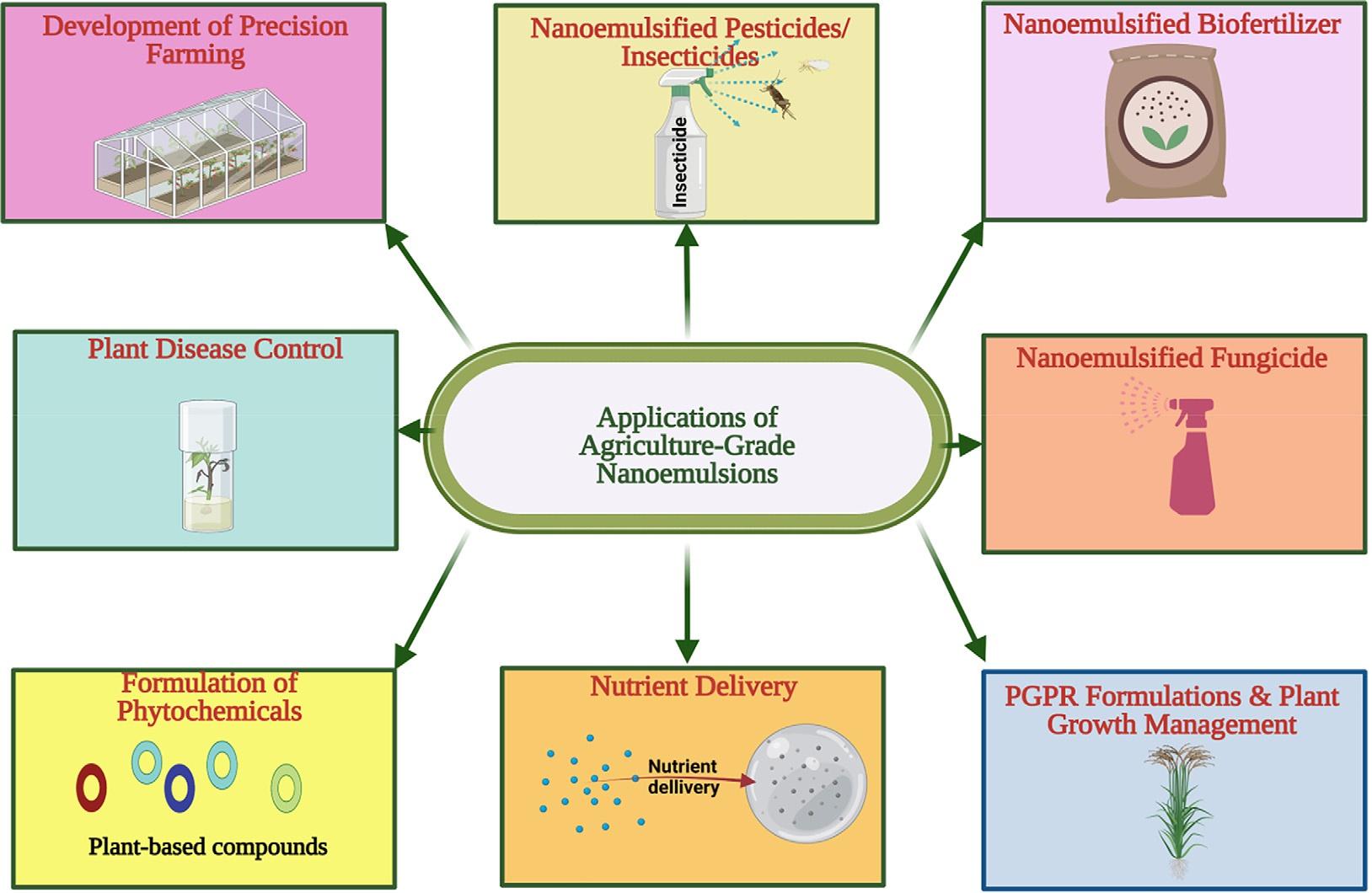

5.Agriculturalapplicationsofnanoemulsions Nanoemulsionsvastlyexpandtheagriculturalandfoodapplicationsofnanotechnologybyprovidingextremely effectivesolutionstoawiderangeofcomplexchallenges.Nanoemulsionresearchanduseinvariousindustries, includingagriculture(Fig.2),hasbeensteadilyincreasing.Byintroducingmodernagriculturaltechniques,precision farmingmethods,fertilizers,pesticides,hybridtypes,andsoon,thegreenrevolutionhasenhancedfoodproduction andsustainability.However,theunjustifiedcontinualuseoffertilizersandpesticideshasdamagedsoilhealthbydrasticallyloweringnativeactivemicrobialcountsinthesoilandmakingitunsuitableforcropcultivation.Pests,onthe otherhand,becomemoreresistanttopesticidesandtheirdosageswhenexposedtothem.Thismeansthatnewpesticideformulationsmustbedeveloped,andpesticidedosesmustberaised,inordertoefficientlyemployexistingpesticides.Pesticidecontaminationinagriculturalproduceoccursasaresultofpesticidesprayingonfoodcrops,resulting inunfavorablehealthconsequences.Theunjustifiableanduncontrolleddeploymentofsyntheticagrochemicalsfor cropandproductprotectioninrecentyearshasraisedseriousworriesaboutenvironmentalpollutionandincreases inphytopathogenicmicroorganismresistance.Agriculturalresearchisnowfocusedongeneratingbio-basedornonsyntheticbiocides(Kumarietal.,2018).Inaddition,thenanoencapsulationofconventionalfertilizers,herbicides,weedicides,andpesticides,aswellastheirbio-basednanoemulsionformulation,wouldaidinthegradualandsustained releaseofnutrientsandotheragrochemicals,deliveringtheappropriateamountrequiredbyplants.Oil-solublephytochemicals’ bioactivity,solubility,andstabilityareallimprovedbynanoencapsulation.

FIG.2 Pictorialrepresentationofpotentapplicationsofbio-basednanoemulsionsforsustainableagriculture.

6.Nanoemulsion-enabledpesticides Animalpestscausearound15%–18%ofcroploss,whileweedsandmicrobialdiseasescause34%and16%loss, respectively.Fungalpathogenscauseapproximately70%–80%yieldloss.Thecurrentplantdiseasecontrolstrategies dependheavilyonagrochemicalsthatcauseadverseeffectsbothonhumanbeingsandontheenvironment(Kutawa etal.,2021).Ofthepesticides,chemicals,andbiologicalmixturestypicallyfoundinagriculture,hygiene,andforestry applicationstopreventorkillpests(includingdiseases,insects,andweeds)andfornonagriculturalpurposes,mostare water-insolubleanddirectusageisnotpossible.Theyareprocessedintoliquidandsolidformulationsforpractical applications.However,inmanycases,solidformulationeffectivenessisunsatisfactoryduetothelargesizeoftheparticlesandtheirpooradhesion.Inaddition,conventionalpesticides,theirformulations,andtheirresidueshaveraised foodandenvironmentalconcerns.

Asanalternativetowater-insolublepesticides,emuls ifiableconcentrate(EC),oil/wateremulsion(EW),and microemulsion(ME)liquiddeliverysystemprocessingexhibi tsexcellentefficacy.Innanoemulsions,thepesticides aredissolvedanddispersedinsidewaterdropletsprotectedfromcoalescencebythesurroundingadsorbingsurfactant ’sinterfacefilm.Thesenanoemulsionsareoffinedrople tswithuniformdistributionandhighstabilityformulatedusingsimpleproductionprocessing.Theyexhibitexcellentdeposition,expansion,andpenetrationoninsect bodiesandplantfoliagesurfaces.This nanoemulsionimprovesthepesticides ’ utilizationratethroughrainscouring reduction,extendingthecontrolperiod,preventingac tiveingredientsdegradati on,andincreasingtarget absorption.

Thus,thenanoemulsionformulationofpesticidesprovidesaneffective,safe,andeco-friendlywaytousethem. Therefore,currently,thepesticideindustry’sresearchanddevelopmentfocusesondifferentpesticidenanoformulationsdesignedforeffectivecontroloffieldpestswithlessenvironmentalrisk(Fengetal.,2020).Environmentalpollutionproblemslikeprolongeddegradation,residuesinthefoodchain,lessefficientdiseasemanagement,and syntheticpesticides’ attributabletoxiceffectspersistinmodernagriculture.Inmanycountries,theantibioticsavailable foragriculturearenotallinuseduetothemoderateorsignificantresistancethatpathogenshavedevelopedbecauseof longperiodsofchemicalbreakdownandcontaminationintheenvironment.Theseconstraintscauseaconsiderable hindranceinachievingsustainableagriculturalproductioninmanyagriculturalsystems.Hence,thereisanurgent needforalternatenaturalpesticidesmadefromplant-basedrawmaterials.

Thenanoemulsionapproachrepresentsasolutiontothelowwatersolubilityandhighsensitivitytooxygen,moisture,heat,andlightproblems(Adamuetal.,2021)ofplantbioactiveessentialoils,extracts,andtheircompounds.The nanoemulsionapproachfacilitatesthedesign,fabrication,andapplicationstrategiesforwater-insolublepesticides, enhancingtheiractivityandloweringtheirtoxicityandenvironmentalpollutioneffects.Pesticideformulationrequires solventsandadjuvantsaswellasactiveingredientsinmanycases.Thesesolventsandtheadjuvant ’stoxiccharacteristicsmayincreasethetoxicityofformulationsmorethantheactiveingredient(Díaz-Blancasetal.,2016).Hence,the bio-basednanoemulsionsmayhavetheadvantageofprovidingatoxicity-reducedfinalproduct.Furthermore,these nanocarrierformulationsrelyontheirnanosize(10–200nm)-specificproperties,providingsubstantialsurface-volume ratio,whichdeterminestherationalebehindtheiruse,sincethisensures:

(1) increasedinteractionswithtargetedpestsevenatlowdoseapplications, (2) pesticidewastereduction, (3) waterretentionenhancement;and (4) watersolubilityimprovement(UrRahimetal.,2021).

Manyattemptshavebeenmadetodeveloprevolutionarynanoemulsionswithnontoxicplant-basedalkanolamides,alcohols,amines,esters,fattyacids,oils,andsurfactantsfrommanyplantsourcestosatisfythegrowingnumberofEarth-consciousconsumerswhodemandhealthy,environmentallyfriendly,andsafeagro-products.An agriculturalandbiodiversecountrylikeIndiamustsetupnormsofusefornanoregulationandbringnanotechnology intothesafetechnologynet.Inrecentyears,theuncontrolleduseofcrop-andproduce-protectingsyntheticagrochemicalshasbecomeacauseofsevereconcernsregardingenvironmentalcontaminationandphytopathogenicmicrobes’ resistance.Nowadays,agricultureresearchfocusesondevelopingbio-basedornonsyntheticbiocides(Kumarietal., 2018).Nanoencapsulationimprovesthebioactivity,solubility,andstabilityofoil-solublephytochemicals.

Fertilizersrepresentavitalindirectenergyinputforsoilfertilitymaintenance,yieldincrease,andharvestquality improvement,whichincreasesglobalconsumptioneveryyear.However,theirlowefficiencyinreachingtheplantand washingoffbyrainandirrigationwatercausessubstantialeconomiclosstofarmers,wasteofenergy,andsevereenvironmentalpollution(Rashidzadehetal.,2014).Hence,thereisanurgentneedtoaddressthesechallengesinproviding sustainableagricultureandensuringtheworld’sfoodsecurity.Basedonthecurrentrateofgrowth,theglobal

populationisestimatedtoreach9.6billionin2050and11.2billionsoonerthan2100.Hence,anincreaseinagri-food productionofatleast50%willbenecessarytoguaranteeglobalfoodsecurityaccordingtothesustainabledevelopmentgoals2030agenda(UrRahimetal.,2021).Theseshortcomingscanbeovercomebyusingslow-releasefertilizers (Rashidzadehetal.,2014),nanopesticides,andnanofertilisers(UrRahimetal.,2021).Reducingtheenvironmental impactwillalsoensuresustainableplantprotection.

Manynanoemulsionformulationshavebeenexploredforcropprotectionandfertilization,whichalsoimproves sustainability,andthefoodsystem’sresilience.Nonetheless,theassociatedharmfuleffectsandriskstonontarget plants,plant-beneficialmicrobes,andotherplant-associatedbeneficialinsectandmicroorganismactivitiesarenot fullyunderstood.Hence,itisnecessarytoaddressthepotentialorprovenadverseeffectsofthesenanomaterialswhen putintooperationthroughfoliarorsoilroutes.

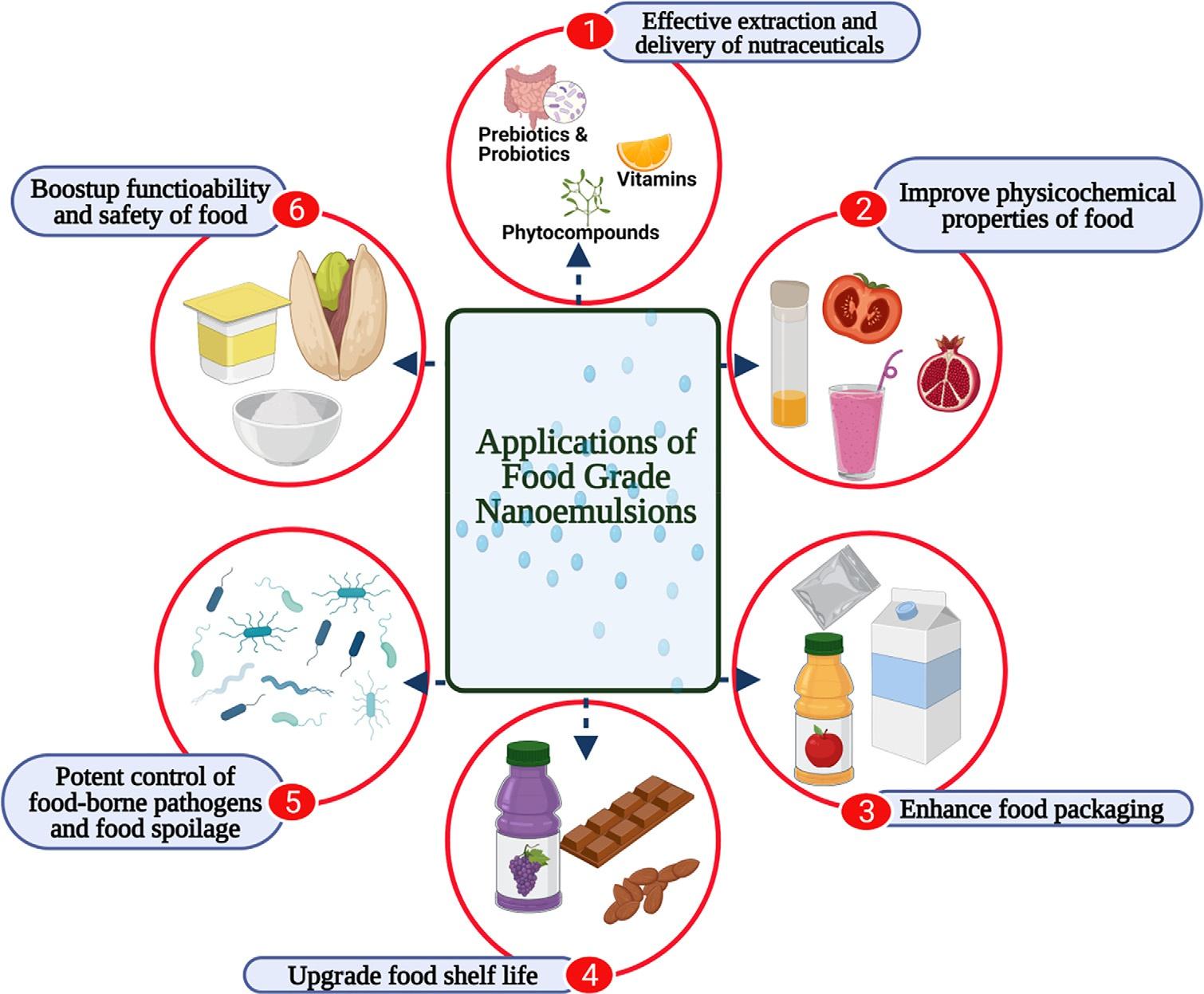

7.Foodapplicationsofnanoemulsions Traditionalemulsionsofferfewerpotentialbenefitsforfoodandbeverageproduct-specificusesthannanoemulsions,whichcanbeusedascarriersoflipophilicbioactiveconstituents,antioxidants,drugs,flavoringagents,andpreservatives,expandingthefoodindustry’suseofnanotechnology.Thefoodindustrywantstopreparelegally acceptable,label-friendly,andeconomicallyviableingredient-containingnanoemulsions(Thiruvengadametal., 2018).Thecurrentlydevelopedbio-basednanoemulsionsandtheirpromisingapplicationswouldhelptomeetthe foodandbeverageindustry’srequirements.

8.Nanoemulsionsinthefoodindustry Moststandardpreservationtechniques,suchasthermalprocessing,whichincreasethefoodproduct’ssafety,quality,andshelf-life,alsocompromisesfoodqualitybycausingundesirablechanges,lossofessentialnutrientsincluding vitamins,andinvolveshighenergycostsandvaluableresourceutilization.Theperceivedenvironmentalandhealth benefitshaveincreasedinterestinnaturalpreservativesforfoodqualityandsafetymaintenanceapplications.Avast arrayofnaturalsubstances,includingphytochemicalsofvariousbotanicalorigins,suchasbasil(Ocimumbasilicum), blackpepper(Pipernigrum),cannabis(Cannabissativa),citronella(Cymbopogonnardus),clove(Syzygiumaromaticum ), eucalyptus(Eucalyptusglobulus),androsemary(Salviarosmarinus),andthoseplants’ essentialoilsarestudiedfortheir foodpreservativepotentialandutilization.Severalplantcompounds,including(1)phenolsandpolyphenolsincludingsimplephenolsandphenolicacid,flavonoid,quinine,tannin,andcoumarins,(2)flavonoidscomprisinganthocyanidins,catechins(flavan-3-ols),flavones,isoflavones,flavanones,(3)alkaloidswithcodeine,colchicine,hordenine, N-methyltyramine,morphine,sanguinarine,andquinine,(4)gallotanninlikehydrolyzabletannins,(5)catechinconsistofcondensedtannins,(6)coumarinscomprisingaegelinol,agasyllin,chalepinandimperatorin,(7)albumin-like proteins,(8)proteinsandantimicrobialpeptideswithcyclotides,defensin,heveins,hionin,hispidulin, α-hairpinin, lipidtransferprotein,lunatusin,knottin,thionein:alpha-1-purothionin,puroindolines,and(9)terpenoidsandthyme, oregano,cloveandorangeessentialoilsandtheircomponentssuchasthymol,carvacrol,eugenol,limonene,andcinnamonareknowntoexertaneffectiveantimicrobialactivityonfoodspoilagecausativesandhence,haveafoodpreservativenature.

Mainly,plant-basedantimicrobialsarebeingwidelyemployedforpreventingorprotectingagainstmicrobialspoilage,therebyimprovingthesafety,quality,andshelf-lifeoffood.Onthewhole,plantsarethoughttobeagoodsource ofnaturalantimicrobialagentsthatcanbeusedtokeepfoodsafe.Thisiswhyresearchersallovertheworldareworkingtofind,identify,andusetheseagents.Ontheotherhand,severalnaturalantimicrobialshavechemicalinstability, poordispersibility,andunacceptableflavorprofilesthatrestricttheirwidespreadutilization(McClementsetal.,2021). Nnoemulsion,likeothertechnologiesthatmakeiteasiertohandle,use,andincreasethepotencyofantimicrobials,gets aroundtheseproblems.Tobeeffective,whetherbio-basedornot,theselectedantimicrobialcompoundshouldinteract intensivelyonlywiththeintendedtarget,whereasitshouldhaveonlyminimalinteractionswithnonspecifictargetsin ordertoexhibitincreasedpotencyandreducedeleteriouseffects.Thephasepartitioningingredientsinteractionlike foodmatrixeffectsalternaturalantimicrobials’ efficacyandreducemicrobialinteractions.Ediblecolloidaldelivery systemencapsulationofantimicrobialswouldhelpovercometheseeffects,asevidencedbytheworksofvarious researchers(McClementsetal.,2021).Forexample,nanoemulsionscontaininglimoninandeugenolhaveeffective antifungalactivityagainst Penicilliumitalicum,andmaybeusedasasubstituteforinhibitingbluemoldincitrusfruits, see Fig.3 (Lietal.,2021).

FIG.3 After5days,achallengeassaywasperformedoncitrusfruits thathadbeentreatedwith Penicilliumitalicum.Eachgroup(eightfruits perreplication, n ¼ 3)receiveda10Lnanoemulsion(320g/mL)injectionintoeachcut,whereasthecontrolgroupreceivedsterilewater. ReprintedfromLi,Y.,Zhao,R.,Li,Y.andZhou,Z.,(2021): Limonin EnhancestheAntifungalActivityofEugenolNanoemulsionagainst PenicilliumItalicum InVitro and InVivo Tests.Microorganisms,9(5), 969.Thisarticleisanopen-accessarticledistributedunderthetermsandconditionsoftheCreativeCommonsAttribution(CCBY)license(https:// creativecommons.org/licenses/by/4.0/).

9.Organolepticsensorycharacteristicsimprovement Color,flavor,andtexturearecriticalqualityattributesoffoodsconsumersusefortheirquickassessment.These organolepticcharacteristicsoffoodplayanimportantroleinconsumeracceptanceandpreferenceamongthose whoareusedtorejectingoff-flavor,off-color,andpoor-texturefoods.Thebio-basednanoemulsionshelprestore theoriginalorganolepticpropertiesoffoodlostduringpostharvesttreatmentofrawmaterialsandfurtherfoodprocessing.Thesebio-basednanoemulsionsoftenimproveoraddconsumer-preferredcolor,flavor,andtexture,aswellas organolepticproperties,andhelpmeetregulatoryauthorities’ stringentstandardsandregulations.

10.Flavors Food’sflavorsandcoloringagentsgenerallyhavealdehyde,ketone,andesterfunctionalgroupsthatmakeoxidativeandphotolyticdegradationsusceptible.Nanoemulsionencapsulationoftheseingredientscouldpreventthese deleteriouseffectsandenhancetheirshelflife.Thefoodandcosmeticsflavoraromaticcompound α, β-unsaturated aldehydecitral’snanoemulsionpreparationincreasesitsstabilityandpreventsitsdegradativeoff-flavorcompound production.Theo/wnanoemulsionofcitralplus β-carotene,tanshinone,andblackteaextractnaturalantioxidants showhighchemicalstabilityinstorage.Theantioxidantsencapsulationdecreases α,p-dimethylstyrene, p-methylacetophenone,andoff-flavorcompoundformation.Likewise,ubiquinol-10(Q10H2)andcitralo/wnanoemulsionsystemsexhibitgoodchemicalstability.The ZatariamultifloraBoiss nanoemulsion-immersedfreshwaterrainbowtroutshowedpreservationofsensoryattributesandincreasedshelflife(AswathanarayanandVittal,2019).

11.Color FoodindustriesusevitaminAprecursor β-Carotene,whichisalsoanaturalcolorantandanantioxidant.However, itissusceptibletoeasydegradationbyheat,light,andoxygen.Emulsification-evaporationtechniquepreparation β-carotenenanodispersionsexhibitedincreasedstability.ThenonionicemulsifierPGEs(Polyglycerolestersoffatty acids)O/W β-carotenenanodispersionsdisplayedbetterphysicochemicalpropertiesandphysicalstability.PGEdecaglycerolmonolaurateused β-carotenenanodispersionsandshowedhighstability.The β-carotenestarchcaseinnanodispersionspreparedbysolventdisplacementtechniqueexhibitedphysicalbarrierandcaseinantioxidantactivity withhighstabilityagainstoxidationdespitetheirlargeparticlesize.Themodifiedstarchanditsemulsifiedspraydriedpowdersexhibitedbetterstoragestability.Thestarchcaseinateandchitosanepigallocatechin-3-gallate conjugate-coated β-carotenenanoemulsionshaveimprovedphysicochemicalproperties.Thecantaloupemelonextractedcarotenoidsnanoemulsionsshowedimprovedwatersolubilityandcolorstability.Theporcinegelatinencapsulatedo/wcarotenoidnanoemulsionsshowedcarotenoids’ increasedwatersolubility.Theyogurtprepared withthesenanoemulsionsasanaturalcoloringagentwasstablefor60days(AswathanarayanandVittal,2019).

12.Bioavailabilityenhancementandfunctionalfoodpreparation Antioxidant,anticancer,andantiobesityfunctionalpropertiesofnanoemulsionsshownanincrement.Grapeskins, blueberries,andraspberries’ naturalpolyphenolresveratrol’sspontaneousemulsificationencapsulationimprovesits chemicalstability,counteringUV-lightdegradation.Cholecalciferol(vitaminD)o/wediblenanoemulsionswereused fordairyemulsionfortification(AswathanarayanandVittal,2019).Sodiumcaseinate, β-cyclodextrin,andTween 20emulsifiersstabilizedkenafseedoil.Theo/wnanoemulsionwasstableevenafter8weeksofstorageat4°Cand showedantioxidantactivitymaintenancewithahighpercentageofvitaminEandphytosterolretention.Astaxanthin, thelight-sensitivedietarysupplementnanoemulsionformulation,photostabilizespigments,makingthemsuitablefor foodapplications.Theastaxanthinchitosanandcarrageenan-coatednanoemulsionsprotectitfromUVlightand photodegradation.Thelipophilicbioactivecompounds’ nanoemulsionformulationimprovestheirbioaccessibility. Thechitosanandalginate-preparedcurcuminnanoemulsionsshowedimprovedantioxidantcapacityinvitrodigestionandbetterlipiddigestibilitycontrolemployingfreefattyacids.Therefore,thesenanoemulsionscouldbeapplied toobesity-targetingfunctionalfoodfortification(AswathanarayanandVittal,2019).

13.Foodprocessing Manynativeandprocessedfoodproductsareemulsionsormighthaveundergoneemulsificationprocessing. Hence,emulsiontechnologyhasbecomeaprominentevergreenareaoffoodprocessingresearchanddevelopment. Nanoemulsionsarethelatestadditiontothearrayoffoodemulsionsutilizedforsustainablefoodprocessing.They protectthefunctionalingredientsfromenzymaticreactions,oxidation,temperature,andpHvariations(Singhaetal., 2016).Anumberofnanoemulsionproductshavebeenpatentedbyleadingfoodindustries.Forexample,Nestlepatenteditspolysorbatesandmicelle-formingemulsionsforfrozenfoods’ rapidanduniformthawingbymicrowave. Unilevericecreamnanoemulsionsreducetheiricecreamfatcontentfrom16%to1%(Aswathanarayanand Vittal,2019).

14.Otherfoodapplications Biopolymerfilmsandcoatingsincorporatingbioactivecompoundsareusedforfoodpackaging.Abiopolymer matrixunderliesthemonodispersityandstabilityofnanoemulsiondropletsinthesefilmsandcoatings.Furthermore, thecontinuousincreaseinphaseviscosityreducesthedroplets’ coalescence.Theantibacterialfeatureofthecinnamaldehydeandcloveessentialoilnanoemulsionswithpectinbiopolymerbestowsedibilitywithlowwaterandvapor permeability.Cloveandoreganoessentialoilnanoemulsionsmightpotentiallybeusedtomakecelluloseanditsderivativeediblefilms.Chitosanisalsoutilizedtomakenanoemulsionantimicrobialactivecoatingsandfilmsusingbergamotoil,carvacrol,mandarinoil,andlemonoil.Sodiumalginateisusedtomakeessentialoilintegratedfilmswith lemongrass,thyme,andsage.Itwasalsousefulformakingfilmscontainingcornoilnanoemulsionsthatweretiny, stable,andlesssize-dispersed.Theantioxidantactivefilmsofcanolaoilandgingeressentialoilnanoemulsionswere madewithporcinegelatin.Itwasdiscoveredtobeusefulintheproductionofrutin-encapsulatedsoybeanoilfilms. Nanoemulsionsof Zatariamultiflora essentialoilantimicrobialfilmsaremadeusingbasilseedgums.

Themandarinessentialoilnanoemulsion-immersedchitosan-coatedgreenbeansshowedthesynergisticeffectsof γ andUVirradiationandozonizedwatertreatmenton Listeriainnocua growth.Methylcellulose-and-clovebudororeganoessentialoilnanoemulsions-immersedslicedpiecesofbreadshowedreductioninspoilagemoldsandincreased shelflife.Alginate-basedediblecoatingsoflemongrassessentialoilnanoemulsionshowedinhibitionof E.coli and naturalfloragrowthonfresh-cutFujiapplesforseveralweeks.Therosemary,laurel,thyme,andsagenanoemulsion immersionhasshownreducedpsychrotrophicandEnterobacteriaceaemembersgrowthonrainbowtroutfilets.Thymolnanoemulsioncoatingpreventedcherrytomatoesspoilagebymoldslike Botrytiscinerea.Thymolnanoemulsionincorporatedquinoaproteinandchitosanediblecoatinginhibitedfungalgrowthoncherrytomatoes.Likewise,anise oil-loadednanoemulsionssignificantlyinhibitedthefoodbornepathogenslike E.coli O157:H7and L.monocytogenes growth.Weighingadditiveslikeesteranddammargumareusedinthecreationofoil/wateremulsionsbecauseof theirdensity.Ripeningretardersworkbyactinghydrophobicallytopreventripening.Long-chaintriacylglycerolsand mineraloils,likeotherripeningretarders,preventsmalleroilmoleculesfromenteringtheaqueousphasetoform largermolecules.Lowwatersolubilityboostsmixingentropy,whichhelpsalleviatecurvature’swavyeffects.Texture

modifiersaltertheaqueousphaseinanumberofways,includingthickeningandeventheproductionofgels.Asa result,biobasednanoemulsionsareexpectedtohaveawiderangeofusesinthefoodindustryinthenearfuture (Fig.4).

15.Futuretrends Despitethevastpotential,onlyasmallnumberofbioactivesubstancesincorporatingnanoemulsionshavebeen commerciallystudiedinagricultureandfood,becausebio-basednanoemulsions ’ immensepromisecanonlyberealizediftheirlimitationsareovercome.Nanoemulsificationhasbeenproveninseveralinvitroexperimentstopreserve bioactivechemicalswhilealsoincreasingbioavailability.However,justafewresearcheshavedemonstratedthehealth advantages.Despitethefactthatbio-basednanoemulsionsmeetsustainabilitygoals,whichareanimportantaspectof companyplans,stakeholdersareinterestedtolearnabouttheeffectsofthesenanoformulationsonthemselvesandthe environment.Furthermore,themajorityofthestudiesavailablearelargelyfocusedonassessingtheuseofhigh-or low-energynanoemulsionformulationmethodologies,aswellasoptimizingprocessingparametersandchemicals employed,whereasresearchonmanufacturingcostreductionisscarce.Forexample,addressingthefoodindustry applicativenanoemulsionssignificantchallengesviz.needfor(1)developingfood-gradesurfactants,stabilizers,cosolvents,oilphasesystemsforediblenanoemulsionformulation,(2)scalableemulsificationtechnologiesorexisting emulsificationtechnologiesupgradation,(3)emulsificationprocessesoptimizationforreducingproductioncost andintendeduse(4)foodnanoemulsioncharacterizationforquantifyingtheirfunctionalityandtoxicity(Singha etal.,2016)canleadtotheircommercialization,i.e.,commercialfoodproductsincorporation,foodpacking,aningredientinfoodprocessinglikeotherwidespreadapplicationsinsustainablefoodmanufacturingandmarketing. Bioactivecompoundsandfunctionalfoodingredientnanoemulsionshaveexcellentpotentialforfoodindustry applications.However,mostofthesenanoformulations’ safety,potentialtoxicity,andbiologicalfatearenot completelyunderstood.Nanoemulsion-baseddeliverysystemsandediblecoatingscouldundoubtedlyimprove thefunctionalitiesoffoodandincreasequalityandshelflife.However,thewidespreadapplicationofthesefood-grade

FIG.4 Thebio-basednanoemulsions’ proposeddiversifiedapplicationsinthefoodsector.

nanoemulsionsrequirescommerciallyfeasibleproductioncostsandfoodindustrysafetystandardscompliance. Therefore,optimizingbioactivityofencapsulatedcomponentsisessentialforscalingupproduction.Thesafetyoffood andpackagingshouldbeassuredthroughtheuseofnanoemulsion-baseddeliverysystems,accordingtoanewreport (AswathanarayanandVittal,2019).Theagri-foodsectorisfacingmanychallengesthatcouldbeaddressedthrough patentsforcommercialpreparationsandnanomulsions.

References Adamu,A.,Ahmad,K.,Siddiqui,Y.,Ismail,I.S.,Asib,N.,BashirKutawa,A.,Adzmi,F.,Ismail,M.R.,Berahim,Z.,2021.Gingeressentialoils-loaded nanoemulsions:apotentialstrategytomanagebacterialleafblightdiseaseandenhancedriceyield.Molecules(Basel)26(13),3902.

Aswathanarayan,J.B.,Vittal,R.R.,2019.Nanoemulsionsandtheirpotentialapplicationsinfoodindustry.Front.Sustain.FoodSyst.3,95.

Azmi,N.A.N.,Elgharbawy,A.A.M.,Motlagh,S.R.,Samsudin,N.,Salleh,H.M.,2019.Nanoemulsions:factoryforfood,pharmaceuticalandcosmetics.Processes7,1–34.

Cho,W.G.,2011.Nanoemulsions:anovelvehicleforcosmetics.J.Soc.Cosmet.Sci.Korea37,1–21.

Díaz-Blancas,V.,Medina,D.I.,Padilla-Ortega,E.,Bortolini-Zavala,R.,Olvera-Romero,M.,Luna-Bárcenas,G.,2016.Nanoemulsionformulationsof fungicidetebuconazoleforagriculturalapplications.Molecules(Basel,Switzerland)21(10),1271.

Feng,J.,Chen,W.,Liu,Q.,Chen,Z.,Yang,J.,Yang,W.,2020.Developmentofabamectin-loadednanoemulsionanditsinsecticidalactivityand cytotoxicity.PestManag.Sci.76,4192–4201.

Gumus,C.E.,Decker,E.A.,McClements,D.J.,2017.Formationandstabilityof ω-3oilemulsion-baseddeliverysystemsusingplantproteinsasemulsifiers:lentil,pea,andfababeanproteins.FoodBiophys.12,186–197. Komaiko,J.S.,McClements,D.J.,2016.Formationoffood-gradenanoemulsionsusinglow-energypreparationmethods:areviewofavailable methods.Compr.Rev.FoodSci.FoodSaf.15,331–352.

Kumari,S.,Kumaraswamy,R.V.,Choudhary,R.C.,Sharma,S.S.,Pal,A.,Raliya,R.,Biswas,P.,Saharan,V.,2018.Thymolnanoemulsionexhibits potentialantibacterialactivityagainstbacterialpustulediseaseandgrowthpromotoryeffectonsoybean.Sci.Rep.8,6650.

Kutawa,A.B.,Ahmad,K.,Ali,A.,Hussein,M.Z.,AbdulWahab,M.A.,Adamu,A.,Ismaila,A.A.,Gunasena,M.T.,Rahman,M.Z.,Hossain,M.I., 2021.Trendsinnanotechnologyanditspotentialitiestocontrolplantpathogenicfungi:areview.Biology10,881.

Li,Y.,Zhao,R.,Li,Y.,Zhou,Z.,2021.Limoninenhancestheantifungalactivityofeugenolnanoemulsionagainst Penicilliumitalicuminvitro and in vivo tests.Microorganisms9(5),969.

McClements,D.J.,Das,A.K.,Dhar,P.,Nanda,P.K.,Chatterjee,N.,2021.Nanoemulsion-basedtechnologiesfordeliveringnaturalplant-basedantimicrobialsinfoods.Front.Sustain.FoodSyst.5,643208.

Mishra,M.,Dashora,K.,Srivastava,A.,Fasake,V.D.,Nag,R.H.,2019.Prospects,challengesandneedforregulationofnanotechnologywithspecial referencetoIndia.Ecotoxicol.Environ.Saf.171,677–682.

Mohammed,N.K.,Muhialdin,B.J.,MeorHussin,A.S.,2020.Characterizationofnanoemulsionof Nigellasativa oilanditsapplicationinicecream. FoodSci.Nutr.8,2608–2618.

Morales,D.,Gutierrez,J.M.,García-Celma,M.J.,Solans,Y.C.,2003.Astudyoftherelationbetweenbicontinuousmicroemulsionsandoil/water nano-emulsionformation.Langmuir19,7196–7200.

Pant,D.,Misra,S.,Nizami,A.S.,Rehan,M.,vanLeeuwen,R.,Tabacchioni,S.,Goel,R.,Sarma,P.,Bakker,R.,Sharma,N.,Kwant,K.,Diels,L.,Elst, K., 2019.TowardsthedevelopmentofabiobasedeconomyinEuropeandIndia.Crit.Rev.Biotechnol.39,779–799.

Rashidzadeh,A.,Olad,A.,Salari,D.,Reyhanitabar,A.,2014.Onthepreparationandswellingpropertiesofhydrogelnanocompositebasedon sodiumalginate-g-poly(acrylicacid-co-acrylamide)/Clinoptiloliteanditsapplicationasslow-releasefertilizer.J.Polym.Res.21,344.

Romes,N.B.,AbdulWahab,R.,AbdulHamid,M.,Oyewusi,H.A.,Huda,N.,Kobun,R.,2021.Thermodynamicstability,in-vitropermeability,and in-silicomolecularmodelingoftheoptimal Elaeisguineensis leavesextractwater-in-oilnanoemulsion.Sci.Rep.11,20851.

Rubio-Rios,A.,Rosales-Marines,L.,Solanilla-Duque,J.F.,Reyes-Acosta,Y.K.,Salazar-Sanchez,M.R.,Rodriguez-Herrera,R.,Farias-Cepeda,L., 2019.Biobasednanoemulsions:concept,formulation,andapplications.In:Prasad,R.,Kumar,V.,Kumar,M.,Choudhary,D.(Eds.),NanobiotechnologyinBioformulations.NanotechnologyintheLifeSciences.Springer,Cham,pp.1–31.

Singha,S.,Bhattacharya,B.,Basu,S.,2016.Processtechnologyofnanoemulsionsinfoodprocessing.In:Grumezescu,A.M.(Ed.),Nanotechnologyin theAgri-FoodIndustry,Encapsulations.APAcademicPress,pp.831–871.

Thiruvengadam,M.,Rajakumar,G.,Chung,I.M.,2018.Nanotechnology:currentusesandfutureapplicationsinthefoodindustry.3Biotech8,74. UrRahim,H.,Qaswar,M.,Uddin,M.,Giannini,C.,Herrera,M.L.,Rea,G.,2021.Nano-enablematerialspromotingsustainabilityandresiliencein modernagriculture.Nanomaterials(Basel)11,2068.

2 Greenandfood-gradenanoemulsion: Anovelnutraceuticalandphytochemical deliveryconcept JosefJampı´leka,b andKatarı´naKra ova aDepartmentofAnalyticalChemistry,FacultyofNaturalSciences,ComeniusUniversity,Bratislava,Slovakia bInstituteof Neuroimmunology,SlovakAcademyofSciences,Bratislava,Slovakia cInstituteofChemistry,FacultyofNaturalSciences, ComeniusUniversity,Bratislava,Slovakia

1.Introduction Emulsionsaretwo-phase(heterogeneous)systemsconsistingofatleasttwoimmiscibleorsparinglymiscibleliquids,usuallyofdifferentdensitiesandpolarities.Theemulsionisthuscomposedofadispersingmediumandadispersedcomponent,whichisusuallyintheformofsmalldroplets.Theformationofemulsionsiscalledemulsification. Toformanemulsion,itisnecessarytoapplyaforcethatallowsoneliquidtodisperseintoanother.Thiscanbedone, forexample,bymixingwithdifferentintensities.Thesizeofthedroplets(inthecaseofconventionalemulsions,itisin therangeof10–0.1 μm)dependsonthedegreeofhomogenizationandthenatureoftheindividualliquids.Stabilizers (emulsifiers)arealsopresentinsuchadispersionsystemtopreventthesystemfromdisintegrating.Thedispersed liquidisreferredtoastheinternalordiscontinuousphasewhilethedispersionmediumisreferredtoastheexternal orcontinuousphase.Emulsionsaredividedaccordingtothepolarityofthedispersionmediumandthedispersed substanceintooil-in-water(O/W)andwater-in-oil(W/O)emulsions.Mixedemulsionscanalsobeformed,namely water-in-oil-inwater(W/O/W)andoil-in-water-inoil(O/W/O).AdirectO/Wemulsion(anemulsionofthefirst type)consistsofanorganicnonpolarcompound(oil)dispersedinapolarsolvent(usuallywateroranaqueous solution),suchasmilkorcream.TheinvertedW/Oemulsion(anemulsionofthesecondtype)isrepresentedbydropletsofanaqueousphasedispersedinanorganicphase(morepolarliquidinalesspolarliquid),suchasmargarine ( JafariandMcClements,2018; NielloudandMarti-Mestres,2000; Sarker,2013).

Accordingtotheconcentrationofthedispersionfraction,emulsionscanbedividedintodilute,concentrated,and gel-likeones.Indiluteemulsions,thedispersioncontentoccupiesamaximumof2%ofthetotalvolumeandthedropletdiameterisclosetothesizeofcolloidalparticles(i.e.,1–500nm,mostoften100nm).Inconcentratedmonodisperse emulsions,theconcentrationofthedispersionfractioncanreachamaximumof74%byvolume(whichcorrespondsto thetightestgeometricarrangementofsphericalundeformedparticles).Polydisperseemulsions,wheresmalldropscan fillthespacesbetweenlargeones,canbemadeevenmoreconcentrated.Inhighlyconcentratedemulsions(gelemulsions),thedropletsofthedispersioncomponentaredeformedandseparatedfromoneanotherbythinlayersof dispersionmediumandemulsifier(Guptaetal.,2016; JafariandMcClements,2018; NielloudandMarti-Mestres, 2000; Sarker,2013).Anemulsifierisaspecificstabilizingmoleculethathasoneendthatishydrophilicwhiletheother ishydrophobic.Itpreventsreaggregationoffatglobulesbybindingtotheoil-waterphaseinterface(hydrophilicpart ofthemoleculetowardwaterandthehydrophobicparttowardoil)andtheemulsionisthusmorestabilizedthan withoutthepresenceofanemulsifier(NielloudandMarti-Mestres,2000; Sarker,2013).Specialtypesofemulsions include,inadditiontotheabove-mentioneddoubleemulsions(W/O/WandO/W/O),microemulsions(MEs) andnanoemulsions(NEs).Amicroemulsion,accordingtotheInternationalUnionofPureandAppliedChemistry

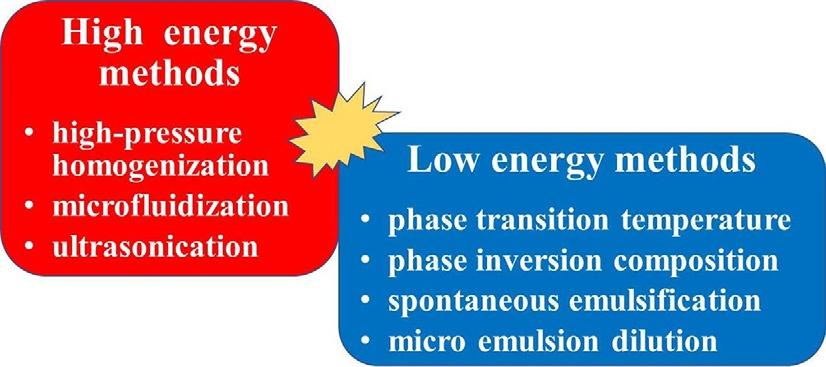

(IUPAC)definition,is “anisotropicandthermodynamicallystablesystemwithadisperseddomaindiameterinthe rangeofabout1to100nm,usually10to50nm”;theterm “oil” referstoanywater-insolubleliquid(Slomkowskietal., 2011).MEsarecomposedofmicelleswithahighsolubilizationcontent.Theyareformedspontaneously(requiring minimumenergyforformation)athighsurfactantconcentrationsandhighsolubilitycontentinthemicelleinthepresenceoftheso-calledcosurfactant(e.g.,medium-chainalcohol),whichcausesafurtherreductionoftheinterfacialtension.ThepropertiesofMEdonotdependonthemethodofpreparation.Unlikeconventionalemulsions,whichare typicallyopaqueormilkywhiteandthermodynamicallyunstable,MEsaretransparent,isotropicsingle-phasemixturesoftwoimmiscibleliquidsstabilizedbysurfactantsthatarealsothermodynamicallystable(Guptaetal.,2016; JafariandMcClements,2018; Shethetal.,2020; Tartaroetal.,2020).TheUSNationalNanotechnologyInitiativedefines nanoparticles(NPs)asbeingintherangeof1–100nm(NationalNanotechnologyInitiative,2018).Accordingtothis definition,NEsareemulsionswithaparticlesizeoflessthan100nm.However,ithasbeenshownthatthepropertiesof emulsionsdonotchangeimmediatelyafterexceeding100nm.Accordingtoanotherdefinition,theparticlesizeofthe NEsisintherangeof20–200nmandischaracterizedbyanarrowparticlesizedistribution.Usually,theaverageparticlesizeisintherangeof100–500nm,andtheterm “submicronemulsions” isusedasasynonymforNEs.NEsare oftenreferredtoastransparentandareresistanttosedimentation.IncontrasttoMEs,whicharethermodynamically stable,bothconventionalemulsions(macroemulsions)andnanoemulsionsarethermodynamicallyunstable(Gupta etal.,2016; Kumaretal.,2019; Rehmanetal.,2017; Shahetal.,2010).Thepreparationofnanoemulsionsrequiresa supplyofenergy.Thisenergycanbesuppliedeithermechanicallyorchemically.Theamountofenergysupplied toformemulsionsvaries.TheNEpreparationmethodsaredividedintolow-energyandhigh-energyemulsifications, withtheformerbeingincreasinglyimportant.Inthelow-energypreparationofemulsions(alsocalledspontaneous emulsificationorself-emulsification),theemulsionformsspontaneouslyaftertheadditionofoilandsurfactantto water,duetothereductionofsurfacetensionaftertheadditionofthesurfactant.Thisemulsionpreparationdistinguishesbetweendifferenttechniquessuchasphasetransitiontemperature,phaseinversioncomposition,spontaneous emulsification,andmicroemulsiondilution.High-energyemulsificationmethodsrequiretheuseofmechanical devicessuchasahigh-pressurehomogenizer,amicrofluidizer,oranultrasonicgenerator.Accordingly,high-pressure homogenization,microfluidization,andultrasonicationaredistinguished(DasguptaandRanjan,2018; Fengetal., 2020a,2021; Ghazyetal.,2021; Guptaetal.,2016; Heetal.,2021; JafariandMcClements,2018; Komaikoand McClements,2016; Kumaretal.,2019; Rehmanetal.,2017; Shethetal.,2020; Vermaetal.,2021)(see Fig.1).

NEshavealargertotalsurfaceareaandgreaterfreeenergythanmacroemulsionsand,therefore,areusedasefficienttransportsystems.Theycanbepreparedinvariousforms,suchasfoams,creams,liquids,orsprays.Theyare preferablypreparedwiththehelpofsurfactantsthatareapprovedforhumanconsumption(thegenerallyregardedas safe,seeGRASlist)(GRAS,2020),sotheyarenottoxicorirritatinganddonotharmhumanoranimalhealth (AswathanarayanandVittal,2019; DasguptaandRanjan,2018; Espitiaetal.,2019; Guptaetal.,2016; Jafariand McClements,2018; SalemandEzzat,2018).Ontheotherhand,theoveruseofsurfactantsappliedtostabilizeNEs canresultinthetoxicityoffinalfoodproducts(Dasguptaetal.,2019).NEspreparedusingbiocompatibleandbiodegradableconstituentscouldbeusedinmedicineandthefoodindustryfortheencapsulationofbioactiveingredients (especiallybioactivelipophiliccompounds);anotheradvantageistheirsustainedandcontrolledrelease.Thus,using encapsulation,notonlycantheapparentsolubilityofbioactiveingredientsinwaterbesignificantlyincreased,but alsotheirbioavailabilityandphysicochemicalstabilitycanbeimprovedwhilethestimulatedspecific/modified releaseofbioactiveingredientscanbeachieved.Inadditiontodrugdeliverynanosystems,NEshavepotential applicationsinthefoodindustryforthedeliveryofnutraceuticals,dyes,flavors,andantimicrobials(see Fig.2). Food-gradeNEformulationsofactiveingredientscanbeusedtodevelopbiodegradablecoatingsandpackagingfilms toincreasethequality,functionalproperties,nutritionalvalue,andshelf-lifeoffoods(Aswathanarayanand Vittal,2019; Chaijanetal.,2021; DasguptaandRanjan,2018; Espitiaetal.,2019; Flores-Andradeetal.,2021;

FIG.1 Themostcommonmethodsofpreparingnanoemulsions.

Gasa-Falconetal.,2021; JampílekandKrál ˇ ová,2017,2018a,b,2019a,b,c,2020a,b; Jampíleketal.,2019a,b,c; Jietal., 2021; Krishnamoorthyetal.,2021; Liuetal.,2021; Mirandaetal.,2021; SalemandEzzat,2018; Zeinalzadeganetal., 2021; Zhangetal.,2021).

Forexample,concentratedemulsifiedsystems,whichweredevelopedtobefurtherdilutedand/orincorporatedin beveragesascarriersofwater-insolubleingredients,areknownasbeverageemulsions.Thereductionofdropletsize accompaniedbytheincreasingsurfaceareaofNEscontributestotheimprovedreleaseofnutrientsorflavoroilsand increasestheirfunctionality(Molet-Rodriguezetal.,2018). TaheriandJafari(2019) discussedtheuseofgumsserving aswallmaterialsforthenanoencapsulationoffoodingredientsinNEsandothernanostructuressuchasNPs,nanocomplexes,andnanofibers.Strategiesrelatedtotheuseofnanosizedformulations,includingNEs,fortheimproved efficiencyofnutraceuticalsweresummarizedby Alietal.(2019).Acomprehensivereviewpaperfocusedonthe fabrication,stability,anduseoffood-gradeNEsintheencapsulationofbioactiveingredientswaspresentedby Liu etal.(2019) and PlacháandJampílek(2021).Acriticalreviewthatfocusedonthesynthesisprocedures,applications, andfuturepotentialofNEsinvariousfieldswaspresentedby Naseemaetal.(2021).Theapplicationoffoodhydrocolloidsasfunctionalingredientstocontrollipiddigestionandbioavailability,whichcanmodifythepharmacokinetics andbioavailabilityofoil-solublevitamins,hydrophobicnutraceuticals,andhealthylipids,wascomprehensively discussedby McClements(2021)

Thischapterisfocusedonthecurrentfindingsrelatedtotheapplicationoffood-gradenanoemulsions.Thesearea usefulclassofnanocarrierscomposedofbiocompatibleandbiodegradablevehiclesthatprotectbioactivecomponents, modifybioavailability,andallowtheadvanceddeliveryofbioactiveingredientsinfoodproducts.Attentionispaidto encapsulatedvitamins,antioxidants,omega-3fattyacids,phytochemicals,andothernutraceuticals/dietarysupplementsoringredientsusedforfoodfortificationtomeetthestatusoffoodsforspecialmedicalpurposesand,ofcourse, ediblecoatingsandsmartpackagingmaterials,whichareusedtoextendshelf-lifeandimprovethequalityoffood.

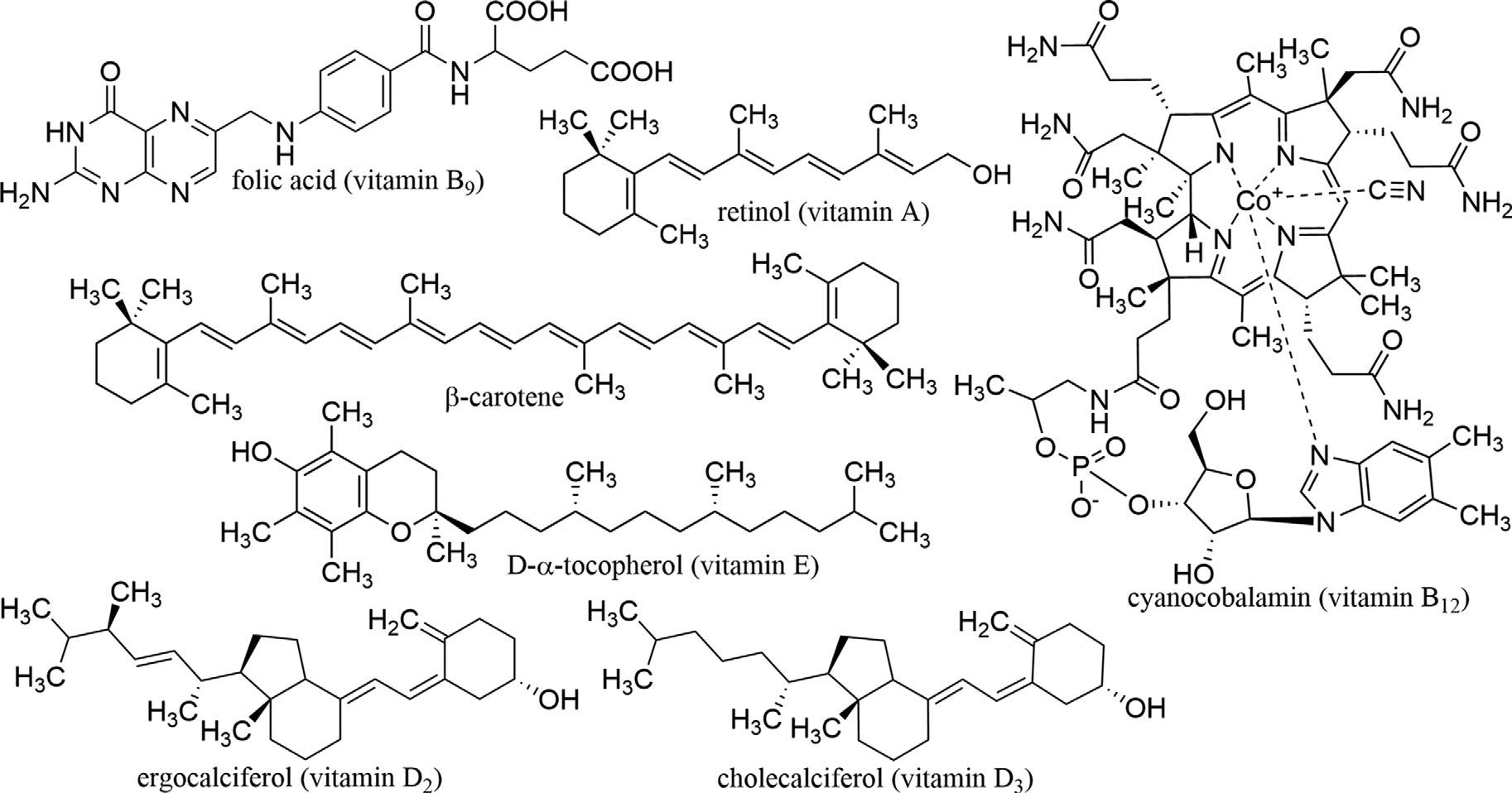

2.Vitamins Vitamins(Fig.3)arelowmolecularweightorganiccompoundsnecessaryforlife.Withafewexceptions,thehuman bodyisnotabletoproducevitaminsandmustthereforeobtainthemthroughdiet.Vitaminsactascatalystsforbiochemicalreactions(cofactorsformanyenzymes).Thereare13basictypesofvitamins,andtheycanbedividedinto water-solubleandfat-solublevitamins.Vitaminsarenecessarytomaintainmanybodilyfunctionsandcanstrengthen andmaintainimmuneresponses.Vitamindeficiencyleadstoavitaminosis,whichismanifestedbyvariousdisorders ofbodyfunctionsorevenseriousdiseases.Ontheotherhand,anexcessofvitaminsisalsoundesirable.Hypervitaminosiscanoccurwithfat-solublevitaminsbecausethebodycangetridofexcesswater-solublevitaminsthrough urinaryexcretion.TheriskiesthypervitaminosisiswithvitaminA,wheretherearecasesoffatalpoisoningorpoisoningwithlifelongconsequences(Zemplenietal.,2014; Jampíleketal.,2019a).Somevitaminsortheirprovitaminshave significantantioxidanteffectsandareusedasexcipients,antioxidants,increasingthestabilityofothercompounds ( Jampíleketal.,2019a; JampílekandKrál ˇ ová,2020b).Strategiesrelatedtoimprovethepreparation,stability,andbioavailabilityofNEdeliverysystemssuitabletoencapsulate,protect,anddelivernonpolarnutraceuticalssuchaslipophilicvitaminsandantioxidantswerereviewedby ChoiandMcClements(2020).

FIG.2 Frequentlyencapsulatednutraceuticalsandantioxidantsinfood-gradenanoemulsions.

2.1VitaminsB9 andB12 Folicacid,knownalsoasvitaminB9,isanimportantwater-solubleBvitamin. Assadpouretal.(2016) prepared doubleemulsionscontaininganinternalW/ONE/MEwithfolicacidoccurringinthewaterphaseandreemulsified withinanaqueousphaseofpectin-wheyproteinconcentrate(WPC)complex.Theencapsulationefficiency(EE)offolic acidwas99.0%inanoptimizedNEformulationwith1.0%pectin,4.0%WPC,15%dispersedphase,pH6,andapolyglycerolpolyricinoleatesurfactant.ThemostpronouncedeffectonEEwasshownbythedispersedphasecontentof doubleemulsions,whichwasaboutsevenfoldhigherthanthatofthesurfactant. α-Lipoicacidandcyanocobalamin (vitaminB12)coloadedNEsshowedsuperbEE(93.80%for α-lipoicacidand110.65%forvitaminB12)andstabilityat differenttemperaturesandpHvalues(Cobanetal.,2021).