https://ebookmass.com/product/applications-in-design-andsimulation-of-sustainable-chemical-processes-1st-edition-

Instant digital products (PDF, ePub, MOBI) ready for you

Download now and discover formats that fit your needs...

Towards Sustainable Chemical Processes: Applications of Sustainability Assessment and Analysis, Design and Optimization, and Hybridization and Modularization 1st Edition Jingzheng Ren

https://ebookmass.com/product/towards-sustainable-chemical-processesapplications-of-sustainability-assessment-and-analysis-design-andoptimization-and-hybridization-and-modularization-1st-editionjingzheng-ren/ ebookmass.com

Energy Sources. Fundamentals of Chemical Conversion Processes and Applications 1st Edition Balasubramanian Viswanathan

https://ebookmass.com/product/energy-sources-fundamentals-of-chemicalconversion-processes-and-applications-1st-edition-balasubramanianviswanathan/

ebookmass.com

Chemical Engineering Process Simulation 1st Edition Nishanth G. Chemmangattuvalappil

https://ebookmass.com/product/chemical-engineering-processsimulation-1st-edition-nishanth-g-chemmangattuvalappil/

ebookmass.com

The Oxford History of Poetry in English, Volume 3: Medieval Poetry, 1400-1500 Julia Boffey

https://ebookmass.com/product/the-oxford-history-of-poetry-in-englishvolume-3-medieval-poetry-1400-1500-julia-boffey/

ebookmass.com

European Glacial Landscapes : Maximum Extent of Glaciations 1st Edition David Palacios

https://ebookmass.com/product/european-glacial-landscapes-maximumextent-of-glaciations-1st-edition-david-palacios/

ebookmass.com

Beavers: Ecology, Behaviour, Conservation, and Management Frank Rosell

https://ebookmass.com/product/beavers-ecology-behaviour-conservationand-management-frank-rosell/

ebookmass.com

Nanocomposites N B Singh

https://ebookmass.com/product/nanocomposites-n-b-singh/

ebookmass.com

PowerPoint For Dummies, Office 2021 Edition Doug Lowe

https://ebookmass.com/product/powerpoint-for-dummiesoffice-2021-edition-doug-lowe/

ebookmass.com

Silicon Containing Hybrid Copolymers: Synthesis, Properties, and Applications Zibiao Li

https://ebookmass.com/product/silicon-containing-hybrid-copolymerssynthesis-properties-and-applications-zibiao-li/

ebookmass.com

The Siberian World John P. Ziker https://ebookmass.com/product/the-siberian-world-john-p-ziker/

ebookmass.com

APPLICATIONSIN DESIGNAND SIMULATIONOF SUSTAINABLE CHEMICALPROCESSES ALEXANDREC.DIMIAN COSTINSORINBILDEA ANTONA.KISS Elsevier Radarweg29,POBox211,1000AEAmsterdam,Netherlands TheBoulevard,LangfordLane,Kidlington,OxfordOX51GB,UnitedKingdom 50HampshireStreet,5thFloor,Cambridge,MA02139,UnitedStates

Copyright 2019ElsevierB.V.Allrightsreserved.

Nopartofthispublicationmaybereproducedortransmittedinanyformorbyany means,electronicormechanical,includingphotocopying,recording,orany informationstorageandretrievalsystem,withoutpermissioninwritingfromthe publisher.Detailsonhowtoseekpermission,furtherinformationaboutthe Publisher’spermissionspoliciesandourarrangementswithorganizationssuchasthe CopyrightClearanceCenterandtheCopyrightLicensingAgency,canbefoundatour website: www.elsevier.com/permissions .

Thisbookandtheindividualcontributionscontainedinitareprotectedunder copyrightbythePublisher(otherthanasmaybenotedherein).

Notices Knowledgeandbestpracticeinthis fieldareconstantlychanging.Asnewresearchand experiencebroadenourunderstanding,changesinresearchmethods,professional practices,ormedicaltreatmentmaybecomenecessary.

Practitionersandresearchersmustalwaysrelyontheirownexperienceandknowledge inevaluatingandusinganyinformation,methods,compounds,orexperiments describedherein.Inusingsuchinformationormethodstheyshouldbemindfulof theirownsafetyandthesafetyofothers,includingpartiesforwhomtheyhavea professionalresponsibility.

Tothefullestextentofthelaw,neitherthePublishernortheauthors,contributors,or editors,assumeanyliabilityforanyinjuryand/ordamagetopersonsorpropertyasa matterofproductsliability,negligenceorotherwise,orfromanyuseoroperationof anymethods,products,instructions,orideascontainedinthematerialherein.

LibraryofCongressCataloging-in-PublicationData

AcatalogrecordforthisbookisavailablefromtheLibraryofCongress

BritishLibraryCataloguing-in-PublicationData

AcataloguerecordforthisbookisavailablefromtheBritishLibrary

ISBN:978-0-444-63876-2

ForinformationonallElsevierpublicationsvisitourwebsite at https://www.elsevier.com/books-and-journals

Publisher: SusanDennis

AcquisitionEditor: KostasKIMarinakis

EditorialProjectManager: ReddingMorse

ProductionProjectManager: JamesSelvam

CoverDesigner: MilesHitchen

TypesetbyTNQTechnologies

PREFACE Man’syesterdaymayne’erbelikehismorrow;Noughtmayendure butMutability.

PercyByssheShelley(1792 1822).

SustainableProcessTechnologyisthemajorchangethat chemicalprocessindustrieswillundergointhenextyearsand overalongerperspective.Thestrategicgoalisaneffective transitionfromfossilresources,coal,oil,andgastorenewable rawmaterials,mainlybasedonbiomassandrecycledwaste.The integratedbiorefinerybecomesthenewindustrialconceptfor manufacturingbiofuels,biochemicals,consumerproducts,food productsforhumansandanimalsandforsupplyingenergy,at bestfromlocalavailableresources.Biobuildingblocksallow constructingacompleteofferofchemicalproductsinawaythat iscomparableorsuperiortotraditionalroutesstartingfrom fossilmaterials.Challengesforresearchanddevelopmentof sustainabletechnologiesemerge,butthesearealsoopportunitiesforinnovation.

Thepurposeofthisbookiscoachingandtrainingonhowto createconceptualflowsheetsforsustainableprocessesby employingsystematicprocessdesignmethodsandpowerful simulationtools.Boostingthecreativityisthefinalobjectiveand theaddedvalueforthereader.Forthisreason,thebookstarts withasectiondevotedtokeyfeaturesoftheSustainableProcess TechnologyandtoProcessSystemsEngineeringapproach. Fifteenrepresentativecasestudiesarepresentedafterward.The goalistodeveloporiginalprocessflowsheetsandnottoreproduceexistingtechnologies.Accordingly,eachcasestudybrings elementsofnovelty,invitingthereadertodeepenortoextend theapproachtosimilarapplications.

Eachprojectstartsfromthefundamentalknowledgeabout chemistry,thermodynamics,andreactionkinetics,considering theimpactonhealth,safety,andenvironmentaswell.Aconceptualflowsheetisdevelopedbyapplyingasystemicmethodology(processsynthesis).Severalalternativesaregenerated,from whichthemostsuitableoneisrefinedbyimplementingenergy saving,processintegration,optimization,andplantwidecontrol.

Computersimulationisemployedintensivelyfordataanalysis, investigatingthefeasibilityofalternatives,sizingtheequipment, andperformingtheenergyandeconomicstudies.Theresultsare theinputofasustainabilityanalysisthatsuppliesthekeyprocess performanceintermsofmaterialintensity,energyrequirements, emissionsandecologicalfootprint,andcapitalandoperation costs.Theresultsmaybecomparedwithflowsheetsandperformanceindicesofindustriallicensedprocesses.Inmostcases,the technicalsolutionsproposedinthisbookareoriginalbeingthe objectofpeer-evaluatedpublications.

Chapter1 Sustainableprocesstechnology presentsthebiorefineryconceptandthekeybuildingblocksproducedfrom renewablerawmaterials,asbiomass,oil,proteins,andbio-based syngas.Themostimportantaremethanolandethanol,which maybeconvertedtoC2andC3olefins,whichtogetherwiththe glycerolandbutanolderivativesmaycoveralltheproducts availabletodayfromC2 C4petrochemicals.Otherimportant biobuildingblocksavailablebythefermentationofsugars,as lacticacid,3-hydroxipropanol,succinicacid,sorbitol,adipic acid,andfurandicarboxylicacid,etc.,ensuretheemergenceof newecologicalbiochemicals,namelybiodegradablepolymers. Thechapterpresentsalsothechallengesforprocessdesignand simulationraisedbybiorefineries.

Chapter2 ProcessSystemsEngineeringapproach presents thesystematicconceptualprocesssynthesisappliedinthebook. ThisisbasedontheseminalHierarchicalApproachupgradedby theauthors’experience.Thus,theecologicalissuesareintroducedearlyattheInput/Outputlevel.Thebasicflowsheet architectureisdeterminedatthelevelofReactor/Separations/ Recycles.Hereothersystemicissuesmaybeanalyzed,asEnergy Integrationaroundthereactors,andPlantwideControlstrategy. Thedevelopmentoftheseparationisdrivenbyasystematic task-orientedmethodology.

Chapter3 Methanol focusesonmethanolasamajorcommodity andenergycarrier.Today,significantresearcheffortisdevotedto thedevelopmentoftechnologiesformethanolsynthesisbysyngas andCO2 hydrogenation.Thechapterdealswithmethanol manufacturingfromsynthesisgas(obtainedfrommethane,biogas, coal,orbiomass).Anewgreeneralternativeprocessbasedoncarbondioxidehydrogenationisalsoexplored.Despitebeingamature technology,newdevelopmentsarestillemergingbecauseofnew catalystsandtomoreefficientreactordesign.

Chapter4 OlefinsbyMTOprocess dealswiththeconceptual designofenergyefficientandcost-effectivemanufacturingof

olefinsfrommethanol.Theinnovativesolutionconsistsinfull recoveryoftheenergygeneratedbyreaction.Mechanicalvapor compressionisemployedforupgradingthetemperature/ enthalpyprofileofthecondensingwater/hydrocarbonmixture. Theenergyreleasedinreactorisusedinacombinedheatand powercycle.Theolefinseparationandpurificationtakeplacein acompactschemeoffivecolumns,integratedwiththereaction sectionforenergysaving.Heatpumpisimplementedforpropylenepurification.Operationandcapitalcostsareminimised becausetheprocessmayfullycovertheenergyneedsand employaminimumnumberofunits.

Chapter5 Propylenebyolefinmetathesis investigatesviable solutionsforconversionoflow-valueby-productstohigh-value olefins,asthedemandforpropyleneisofincreasinginterest.The chapterconsiderstheolefinmetathesis,aprocesswhichuses 2-butene(aby-productfromfluidcatalyticcrackingunit)asfeedstockforobtainingmorevaluableolefins.Severalprocessalternativesaregeneratedandevaluatedinahierarchicalapproach,with thegoalofdeterminingtheprocessflowsheetwhichreturnsthe highestrevenueforafixedflowrateofrawmaterials.

Chapter6 Isobutenedimerization dealswithaprocessthat yieldsahigh-octanenumberolefinicgasoline.Twooptionsare presented:Reactor/Separation/Recycle(RSR)andreactive distillation(RD).Thesearecomparedintermsofspecificenergy andcatalystrequirements.TheRSRappearstobemoreattractivethantheRDprocess,asitallowsboththereactorandthe separationunitstooperateclosetotheiroptimalconditions.The RDprocessoperatesintheoverlappingwindowofprocess conditionsforreactionanddistillationandthussuffersfromthis inherenttrade-off.

Chapter7 Castoroilbiorefinery convertsthisvaluable resourceinspecialbiodieselandhigh-valuechemicals.The centralbuildingblockisthemethylricinoleateesterproduced bytransesterificationwithmethanol.Thetechnologymakesuse ofatwo-stepprocessbasedonhomogeneousbasecatalysis, employingagitatedmulticompartmentreactor.Methylricinoleateesterisconvertedbypyrolysistoheptaldehyde,which findsmanyapplicationsincosmetics,and u -amino-undecylenic acid,amonomerforhigh-valuepolyamides.Theprocessinvolvescomplexchemistryandspecies,forwhichproperties estimationfromstructurewasapplied.Theflowsheetdevelopmentusessystematicmethodsandcomputersimulation,kinetic modelingofreactors,andthermodynamicassessmentofseparations.Particularattentionisgiventosavingenergyaspects.

Themanufacturingofcommoditybiodieselhasasynergetic effectwiththeproductionofhigh-valuebiochemicals.

Chapter8 Bioethanolandbiobutanol arebioalcoholsproducedbytheactionofmicroorganismsandenzymesthroughthe fermentationofsugars,starches,orcellulose.Akeyproblemin theproductionistheenergy-intensivedownstreamprocessingof thedilutedmixtureobtainedbyfermentation.Thischapter examinestheprocessesformanufacturingbioethanolandbiobutanol,withemphasisontheseparationandpurificationasthe finalcostlystepsintheprocess.Theoptimizationofdistillationbasedprocessesiscarriedoutandusedasacomparisonbasisfor moreadvancedseparationprocesses(dividing-wallcolumnand heatpumpsassisteddistillation).

Chapter9 Biodiesel presentstheconceptualdesignoftwo manufacturingprocesses.Specifictechnologyissuesaredevelopedregardingfeedpretreatment,purification,andseparation methodsarediscussed.Thefirstcasestudyconsidersbiodiesel manufacturingfromrapeseed(canola)oilusingheterogeneous catalysisandtwo-steptransesterificationwithintermediate glycerolseparation.Thesimulationusesdetailedreaction kineticsinviewoffulfillingtheproductspecifications.Atowertypereactorandanovelvariable-timereactorarecompared. Thesecondprocessdealswithbiodieselfromusedcookingoil usinghomogeneousalkalicatalysis.Alternativesforesterification offreefattyacidswithmethanolarecompared:batchreactor withhomogeneouscatalysisandreactiveabsorptionusingsolid catalysts,thelastbringingsubstantialadvantages.Moreover,a process-intensificationmethodbasedonreactivedistillationis appliedfortransesterification.

Chapter10 Dimethylether (DME)focusesonthesimplest ether,whichisausefulprecursortootherorganiccompounds andagreenaerosolpropellant.RecentlyDMEhasbeen consideredascandidatefornonconventionalcleanertransportationfuels,namelyinScandinaviancountries.Thischapter handlesconceptualprocessdesignissuesofaclassicreaction/ separation/recycleprocessbasedonadiabaticreactor,aswellas ofseveralprocessintensificationalternatives,withafocusona novelcatalyticdistillationprocess.Thekeydesignparameters areidentifiedandsteadystateoptimization(minimizingthe annualcosts)isperformedinAspenPlus.Acombinedprocess (gas-phasereactorandreactivedistillation)isalsopresentedas anoptionforrevampingexistingDMEprocessesbasedon methanoldehydration.

Chapter11 Fueladditives presentsseveralalternativesfor convertingglycerolintomorevaluableproducts,asglycerolis obtainedinlargequantitiesasaby-productfrombiodiesel production.Thus,etherificationwithisobuteneortert-butanol leadstoglycerolethers,whichcanbeusedasfueladditives. Moreover,reactionwithaldehydesandketonesleadstoacetals andketals oxygenatedcompoundswhich,besidesimproving thepropertiesoffuels,haveapplicationsassurfactantsand disinfectantsorincosmeticandpharmaceuticalindustries.

Chapter12 Styrene dealswithconceptualdesignofaprocess basedonethylbenzenedehydrogenationinadiabatictypereactors.High-performancecatalystisemployed.Thetechnology makesuseofsuperheatedsteamasinert,requiringalarge amountofenergy.Aninnovativesolutionisproposedthatgives aspectacularenergysaving.Theideaisrunningthewater evaporationforsteamgenerationundervacuumfollowedby mechanicalvaporcompression(MVR)forrestoringthepressure. Thischangeallowsinstallingafeed-effluent-heat-exchanger (FEHE)inanevaporation/condensationzonethatconcentrates 57%fromenergysaving.AnefficientnetworkoffiveFEHEunits diminishestheutilityconsumptionby70%withrespecttothe basecase.Theeconomicanalysisdemonstratesthatthecostof energyrequiredbythereactionsectiondominatesthecostof separations.Despitetheinvestmentincompressor,theMVR alternativebringsareductionintotalannualcostby30%.

Chapter13 Aceticacidfrommethanol developstheconceptualdesignofasustainableprocessusingrhodium/iridium catalyst.Theemphasisissetonenergyefficiencybyoptimizing thereactorcoolinginrelationwiththeseparationsystem.Inthe homogeneousprocesstheseparationsectionconsistsofthree columns,whilethereactionsectionmaycoverabout45%from theheatneededintheseparationsection.Ifheterogeneous catalystisemployed,theseparationisreducedtoasequenceof twocolumns.Moreover,theenergyrequirementsmaybe reducedby75%ifheatpumpisappliedtoaceticacidpurification.Theeconomicanalysisallowstheestimationofcapitaland operationcosts,aswellastheproductpricefor20%returnon investment.Thecasestudyalsoshowshowtocalculate comprehensivesustainabilitymetricsforprocessdesign.

Chapter14 Acrylicacidfromglycerol dealswiththeconceptualdesignofasustainableprocess,sincetherenewableraw materialisavailableinlargeamountsandatlowcostfrom biodieselmanufacturing.Thechemistryinvolvestwosteps: dehydrationofglyceroltoacroleinandfurtheroxidationof

acroleintoacrylicacid.Heteropolyacidsandzeolitescatalysts havegoodperformance,butaregenerationmethodmustbe includedinthereactordesign.Thestudyexaminesthreealternatives:bubblingfluidizedbed,circulatingturbulentfluidized bed,andcirculatingfluidizedbed.Twoalternativesforseparatingtheacrylicacid aceticacid watermixturearedeveloped, usingazeotropicdistillationandliquid liquidextraction.The exothermalreactiongivesgoodoptionsforenergysavingbyheat integration.Thecapitalcostsaredominatedbyreactors.The sustainabilityanalysisindicatesthattheprocessisaviablegreen alternativetothepetrochemicalmethods.

Chapter15 Acrylicesters considersthedesign,plantwide control,andeconomicevaluationofseveralprocessesforhigher acrylatesproduction,usingsolidcatalysts.Threereaction/ separation/recycle(RSR)processalternativesfor2ethylhexylacrylateareconsidered.Eachemploysafixedbed reactorwithAmberlyst70ascatalystandstandardseparation equipment.Thealternativeusingdistillationasfirstseparation stephasbettereconomicindicatorsduetobetteruseoftheraw materials,comparedtoalternativeswhereasimpleflashora decanterareused.Thereactivedistillation(RD)technologyallowsgreatreductionofthecapitalandoperatingcosts.Then,the productionofn-butylacrylateisaddressed.Inthiscase,thelow relativevolatilityofacrylicacidandn-butylacrylateclearlyfavorsRDoverconventionalRSRprocesses.Dynamicsimulations showthat,inallcases,thecontrolstructurecanachievelarge throughputchangesandcopeswellwiththecontaminationwith waterofbothfreshreactants.

Chapter16 Dimethylcarbonate focusesonaneco-friendly versatilechemicalthatiswidelyemployedasagreensolvent, methylation,andcarbonylationagentandpotentiallyasafuel additive.Thechapterdescribestwoprocessesfordimethylcarbonate(DMC)synthesis,whichavoidthedisadvantagesofthe traditionalmethanolphosgenationroute.Thedirectsynthesis frommethanolandcarbondioxideisanenvironmentallyinterestingprocess.Membranereactorsaresuggestedasawayof overcomingtheequilibriumlimitationsbycontinuousremoval ofwaterfromreactionproduct.Thesamerawmaterialscanbe alsousedinamorecomplexroute.Thus,DMCisobtainedbythe transesterificationreactionbetweenpropylenecarbonate(PC) andmethanol,whereoperationatanexcessofPCavoidsthe costlyseparationofthemethanol DMCazeotrope.Thereaction ofthepropyleneglycolby-productwithurealeadstoPC

(recycled)andammonia(convertedtoureabyreactionwith carbondioxide).

Chapter17 Polyesters exploresvariousconfigurationsofa reactivedistillation(RD)processforpolyestersproduction.RDis agreatprocessintensificationtechniquethatcandrastically enhancetheunsaturatedpolyesterssynthesis.Multi-product simulationswereusedtofindtheoperationalparametersand transitiontimefordifferentgradesofpolyestersmadeinthe sameequipment.Theresultsoftherigoroussimulationscarried outinAspenCustomModelerrevealthatthebestsetuphasthe reactivestrippingsectionasapackedortrayedbubblecolumn andthereactiverectifyingsectionasapackedcolumn.With respecttothefeedpolicy,thefeedingofmonoesterstotheRD columnsignificantlyintensifiesthepolyesterprocessas comparedtoananhydridereactantfedtothecolumn.Furthermore,theproducttransitiontimeinthisconfigurationisalso significantlyreducedascomparedtotheotherconfigurations.

Weareawarethatsomeerrorsmightstillbepresent,despite allofoureffortsintherevisionandthevaluablesupportof Elsevier.Weareopentoanyremarksandcriticalsuggestionsand thereforegratefulinadvanceforfeedbackfromourreaders.

Theauthorsacknowledgethecontributiontothisbookof manycolleaguesandstudentsfromtheUniversitiesofAmsterdam,Delft,Eindhoven,Twente,andManchesterwheretheauthorshavespentalargepartfromtheirscientificandteaching activities.Weexpressalsoourgratitudetothecolleaguesand studentsfromtheUniversityPolitehnicaofBucharest,where computersimulationisusedfordecadestoteachChemical Engineeringsubjects.Theauthorsexpresstheirappreciationto companyAspenTechformakingavailabletoacademiaan outstandingsimulationtechnologysoftware.

Andlastbutnottheleastweexpressourgratitudeandloveto ourfamiliesfortheircontinuoussupportandunderstanding.

AlexandreC.Dimian,CostinS.Bildea,AntonA.Kiss

1 SUSTAINABLEPROCESS TECHNOLOGY CHAPTEROUTLINE 1.1Introduction4

1.2SustainableDevelopment5

1.3RenewableVersusFossilRawMaterials7

1.3.1Biomass8

1.4BiorefineryConcept11

1.5ChemicalsFromBiomass14

1.5.1ChemicalsFromC1BiobuildingBlocks15

1.5.2ChemicalsFromC2BiobuildingBlocks16

1.5.3ChemicalsFromC3BiobuildingBlocks17

1.5.4ChemicalsFromC4BiobuildingBlocks18

1.5.5ChemicalsFromC5BiobuildingBlocks19

1.5.6ChemicalsFromC6BiobuildingBlocks21

1.5.7OtherChemicalProductsObtainedFromBiomass22

1.6Biofuels23

1.6.1EconomicSignificance23

1.6.2SustainabilityIssues25

1.6.3Biodiesel28

1.6.4Bioethanol29

1.6.5OtherBiofuels30

1.7Biopolymers31

1.8ProcessDesignIssues32

1.8.1ScreeningofAlternatives32

1.8.2FeedstockPretreatment32

1.8.3ChemicalReactors34

1.8.4SeparationProcesses34

1.8.5ProcessIntensification35

1.9EconomicChallenges36

1.10Conclusions38 References39

1.1Introduction Thisintroductorychapterpresentstheperspectiveoffundamentalchangesinchemicalprocessindustries(CPI)generated bythetransitionfromfossiltorenewablerawmaterialsandthe requirementsofsustainabledevelopment.Theimpactofraw materialsonprocesstechnologyandprocessdesignissignificant, consideringthattheirweightinthe finalcostofchemicalproductsistypicallyfrom60%to80%.Rebuildingthechemicalindustriesonnewfeedstockbaseswillaccelerateconsiderablyinthe nextyears.Theanswertovariouschallengesispromotingthe innovation.Usingrenewablerawmaterialsbootsthediscovery ofnew “green” chemistriesandcatalysts.Sustainabletechnology requiresfocusingtheprocessdesignontheminimizationofmaterialsandenergyconsumptions,thereductionofwaste,toxic materialsand greenhousegases (GHG)toprotectthehealth andtheenvironment.

Chemistryandchemicalengineeringshouldworktogether tobringinnovativesolutions,beginningwithinitialstagesofprojects.Traditionally,theprocessdesignofanewprocessstarted whentheresearchonchemistrywas(almost)completed.It followedvariousscale-upstagesfromlaboratorytoindustrial process,includingseveraldemonstrationandpilotplants.Computerprocesssimulationradicallychangedthissituation.The powerofmodelingimbeddedinthe flowsheetingsoftwareallows investigatingtheinfluenceofnumerousfactorsontheprocess design,inmanycasesclosetothephysicalreality.Evenwhen thedetailedmodelingofsomeunitsisnotaccurate,thesimulationcanofferapreciousglobalviewoftheprocessbehavior. The systemsapproach focusesonthefunctionsofunitsandtheirinteractionsratheronthedetaileddesign(Dimianetal.,2014).Onthis basis,themanagementcantakedecisionsregardingthefeasibility ofthedesign,theavailabilityofhardware,andtheincurredcosts andrisks.

Today,processsimulationisthekeytoolinchemicalprocess design.Startingfromagivenchemistryandpropertydata, thedesignercandevelopaconceptual flowsheet,determine materialandenergybalances,evaluatetherisksonhealth,safety andenvironment,aswellastheeconomicfeasibilityintermsof operation(OPEX)andcapitalcosts(CAPEX).Thisisthegoalof thepresentbook:teachhowtoproducerealistic flowsheetsby usingadvancedprocesssimulationtoolsavailabletodaytoalarge populationofstudentsandprofessionals.

However,switchingfromfossiltorenewablerawmaterials willtakesometime.Thedevelopmentofradicallyinnovative

processesneedstimeandsubstantial financialinvestments, especiallyinbiotechnology.Inthenexttwodecades,thefossil resourceswillcontinuetoensurealargepartoffuelsand basechemicals.Themanufacturingof drop-inchemicalsfrom biosources,whichcanreplacepartiallyfossilcounterparts,can preservetheabilityofusingexistingplantsandprocesses,asfor example,theuseofole finsformanufacturingtraditional polymers.

1.2SustainableDevelopment Followingawide-agreeddefinition(Brundtland,1987), “Sustainabledevelopment meetstheneedsofthepresentwithoutcompromisingtheabilityoffuturegenerationstomeettheirownneeds.” Notethatthisde finitiondoesnotneglectthepresentbecausethe movetothisparadigmmuststartnow. Fig.1.1 illustratesthesustainabledevelopmentconceptasabalancedstatethatregards threemaindomainsofhumanactivities:economy,environment, andsociety.Thisconceptreflectsasystemicviewpoint,inwhich thesustainabilitystateisaccomplishedonlywhenthethreecomponentsaresimultaneouslyconsidered,byincludingpositiveand negativeinteractions.Thus,achievingthe eco-efficiency ofproductsintermsofeconomicandenvironmentalperformancesis notsufficientwithoutintegratingthe socio-efficiency,suchas

Social Responsibility

Socioefficiency

Sustainable Development

Environment Protec on Eco-social balance

Economic Efficiency

Ecoefficienc y

Figure1.1 Sustainabledevelopmentasacompromiseofthreeconstituent parts:environmental,socialresponsibility,andeconomicefficiency.

jobscreation,decentrevenues,etc.,andthe eco-socialbalance, suchasprotectingthelifeandenvironmentquality.Forexample, theprojectforimplementingabiore fineryplantshouldconsider askeygoals,besidesprofitability,theopportunitytoputmore valueonlocalbiomassresourcesandtocreatenewjobs,but withoutdamagingtheenvironmentandthelandscape.

Sustainabledevelopmentistheparadigmthatwilldrivethe progressinCPIforthenextdecades.InEurope,theSusChem initiative(www.suschem.org)hasbeenlaunchedasacommon platformforguidingthefutureR&Dactions,aswellasthe industrialinvestments.AroadmapcalledSPIRE(Sustainable ProcessIndustrythroughResourcesandEnergyEfficiency) de finesthestrategy(upto2030)ofapublic privatepartnership (www.spire2030.eu).Thisdocumentprescribesthemostpromisingresearchactivitiesandinnovativetechnologiesforachieving thesustainabilitygoals.Emphasisisputonagradualswitching fromfossiltorenewablerawmaterials,bypromotingtheuseof biomassandthevalorizationofwaste,residuestreams,and recycledmaterials.

Togetherwithchemicalengineering,thechemistryplaysa centralroleindevelopinginnovativeprocesses,inwhichcatalysis andbiocatalysisarekeydriversforconvertingthematerialresourceswithhigheryieldsandlowerenergyconsumption.The impressiveprogressinthelastyearsin “greenchemistry” isa valuablesupportforthecasestudiesandprojectsproposedin thisbook.Amongthepublicationsinthis field,werecommend themonographseditedby Cavanietal.(2009) and deJongand vanOmmen(2015).

Theprinciplesofsustainabilityanalysiswereoutlinedin Chapter17ofourbook(Dimianetal.,2014).Theseincludetopics aslifecycleassessment(LCA),eco-efficiencyanalysis,socioefficiencyanalysis,andmetricsfordesignprojects.Thereaderis alsoencouragedtoreferChapter16ofthesamebook,wherea numberofcomputationaltoolsforhandlinghealth,safety,and environmenttopicsaredescribed.

Theincreasinginterestintheuseofrenewablerawmaterials, namelyofbiomass,forproducingfuelsandchemicalsisreflected bythelargenumberofbooksandmonographspublished recently.Referencescanbefoundfurtherinthischapter.These worksaddresspredominantlychemistryandtechnologyaspects, butconceptualprocessdesign(theinventionof flowsheets)is treatedonlyoccasionally.Thepresentbookaimstocompensate thisdrawback.Usefulcase-studiescanbefoundalsoinapreviousbook(DimianandBildea,2008).

1.3RenewableVersusFossilRaw Materials Inthecontextofthe finiteavailabilityoffossilrawmaterials, namelycoal,oil,andnaturalgas,theuseof renewablerawmaterials,especiallyof biomass,becomesacrucialissueforthefuture ofCPI.Thefossilreservesareconcentratedinfewplaces,andasa consequence,theybecomefocalpointsofgeopoliticalconflicts. Incontrast,thebiomassisabundantandmoreevenlydistributed overtheplanet.Forcountrieshavingonlylimitedfossilresources, incorporatingbiomassintheindustrialprofilecancontributeto preservetheenergeticindependenceandbringnewopportunities forchemicalindustry,namelyinthe fieldofhighervalue products.

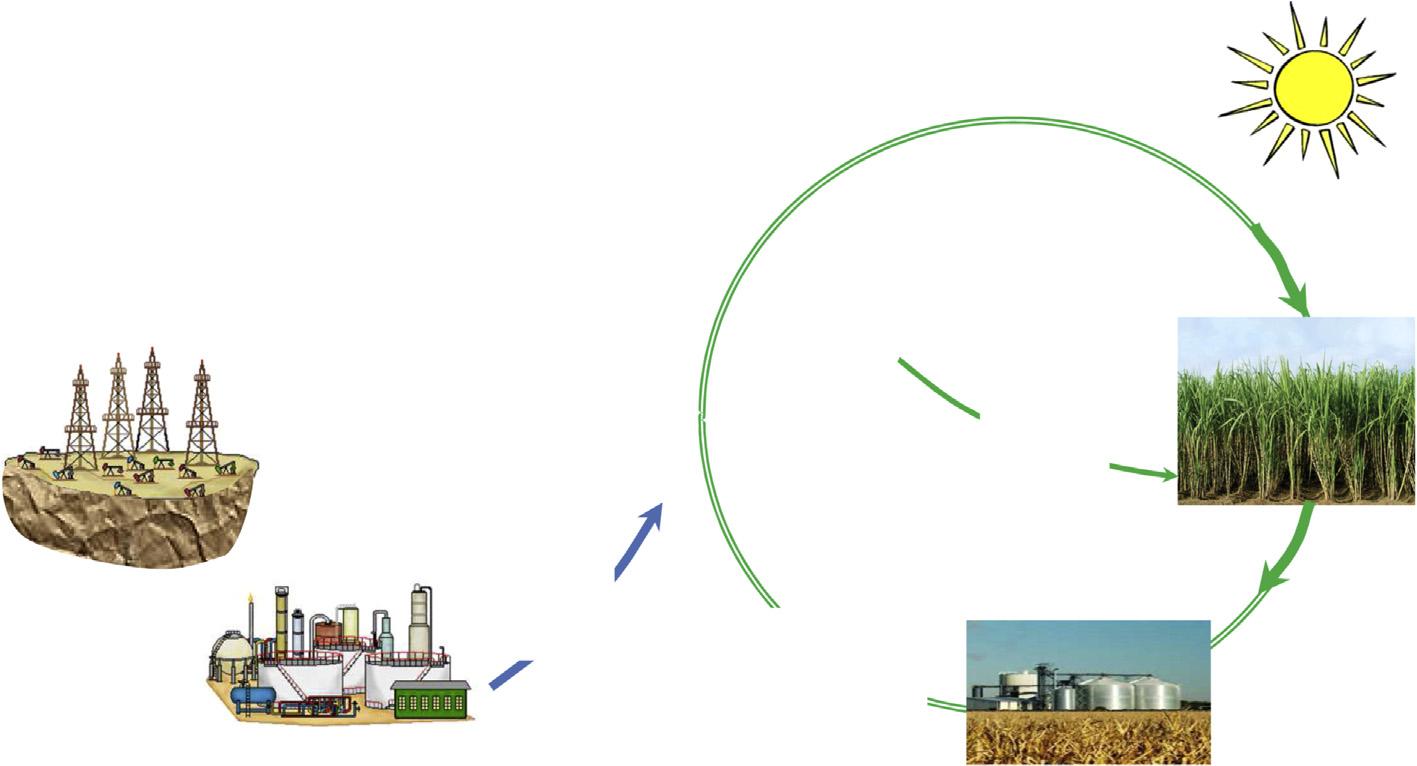

Fig.1.2 presentsthetoday’sproblemofresources.Thefeedstockforenergyandpetro-refineryplantsisbasedessentiallyon theuseof fossilreserves,namelycoal,oil,andnaturalgas.These industriesdeliverusefulfuels,chemicals,andenergyforensuring thefundamentalneedsofthesociety,e.g.,forindustryandagriculture,food,transportation,heating,etc.Theoutputofthese activitiesresultsintheairpollutionbyGHG, particlematters (PM), toxicgases suchasNOx andSO2,aswellasin soilandwater pollution bywaste.Puttinginanutshell,thelimitedfossil

Figure1.2 Fossilresourcesversusrenewablerawmaterials.

resourcesareexhaustedirreversiblyandinexorably.In2015,the totalworldhydrocarbonproductionwasabout7.8Btoe/y(billionstonsoilequivalent/year),fromwhich4.6wasoiland3.20 gas,respectively(BPStatisticalReview,2016).Theexhaustionof oilandgasresourcesistheobjectofaharshdebateviathemodel ofthe “peakofreserves.” Recently,thesuccessoftheshalegasin theUnitedStatesfueledthiscontroversy.However,itisquiteclear thatthefossilreserveswillbeexhaustedinashorthistoricaltime. Asveryprecious,thehydrocarbonresourcesshouldbepreserved forthenextgenerations.Followingtheabovereport,theratioof world’sreservetoproductionin2015wasabout50.7yearsfor oiland52.8yearsforgas.Consideringthemassiveriseofworld’s populationandthelegitimateneedsforbetterlife,itisobvious thatthedevelopmentbasedonlyonfossilresourcesisnotbearableatmediumandlongerterms.

Instead,anotherapproachshouldbeconsidered,basedon renewableresources and circulareconomy,whichmeansrecycling usedproductsandwaste.Thebiomassisthenaturalenergy carrierfromthesuntotheterrestriallife.Attheoriginoffossilresourcesisstillthebiomass,whichwasconvertedinhydrocarbons byprocessesthatoccurredinthedeepgroundduringseveral geologicalperiods!Modernchemicaltechnologymustsolvethe challengingtaskofreplacingfossilhydrocarbonprocessingby biomassconversionintosimilarornewproducts.Themodern technologyconceptisthe biorefinery,whichsuppliesfuelschemicalsandenergyforsatisfyingtheneedsofthesociety.Theimplementationofthisdevelopmentmodelimpliestheavailabilityof advancedtechnologiesfortheminimizationofenergeticandmaterialresources,aswellasforrecyclingthewastefromagriculture, industry,ordomesticactivities.Newgreenchemistriesshouldbe invented,andsustainableprocessdesignshouldbegeneralized.

1.3.1Biomass Biomassdesignatesmaterialsderivedpredominantlyfromplants, whichmaybeusedasfeedstockinagricultureorindustry.From chemicalcompositionviewpoint,biomassisamixtureofcomplexorganicmoleculescontainingforthemostpartcarbon, hydrogen,andoxygen,withsmallamountsofnitrogenand sulfur,aswellaswithtracesofotherelementsincludingmetals. Inthemostcases,thebiomasscompositionisapproximately carbon47% 53%,hydrogen5.9% 6.1%,andoxygen41% 45% (ECsugarplatformreport,2015).Thepresenceofalargeamount ofoxygeninbiomassmakesasignificantdifferencetofossilhydrocarbons.Whenusedasfuel,biomassislessefficient,butmore

suitedforgettinghighervaluechemicalsandbioproductsas containingalreadyfunctionalmoleculargroups.

Thebiomassusedasindustrialfeedstockcanbesuppliedby agriculture,forestry,andaquaculture,aswellasresultingfrom variouswastematerials.Thebiomasscanbeclassifiedasfollows:

1. Agriculturalfeedstock

• Sugarcrops(sugarcane,sugarbeet,cassava)

• Starchcrops(wheat,maize,potatoes)

• Oilcrops(rapeseed,soy)

2. Dedicatedenergycrops

• Shortrotationcoppice(poplar,willow,eucalyptus)

• High-yieldperennialgrass(miscanthus,switchgrass)

• Nonedibleoilplants(Jatropha,Camelina,sorghum)

3. Lignocellulosicwastematerial

• Forestrywood

• Agriculturalby-products(straw,cornstraw)

• Industrialby-products(bagasse,paperpulp)

4. Algalcropsfromlandandseafarming

Thefeedstockorigindeterminestheso-called biofuelgeneration,aspresentedin Fig.1.3.The first-generation (1G) biofuels makeuseofagriculturalresources,andasaconsequence,they canenterinantagonismwiththefoodchain(ediblefeedstock). Thus,1G bioethanol isproducedfromstarch(corn)andsugar (sugarcane,sugarbeet)sources,while1G biodiesel ismanufacturedasfattyacidmethylesters(FAME)fromvegetableoils, namelyrapeseed(canola),soya,andpalm.However,themerit ofthe1Gfuelswasopeninganewchapterinthechemical technology,bysettingthebasesoflarge-scalebiofuelsandbiochemicalsbasedonrenewablerawmaterials.Inparticular,the

Figure1.3 Relationbetweenbiomassfeedstockandgenerationoffuels.

bioethanolmanufacturing,nowagloballeadingchemical, broughtsubstantialprogressinthefermentationtechnology, includingthedevelopmentofefficientenzymesandreactionsystems.TheFAMEbiodieseltechnologyevolvedfromsimplebatch tomoresophisticatedsolidcatalystprocesses,withtheadvantage ofsupplyingsubstantialamountsofglycerol,whichfortodayisan importantfeedstockforgettinghighervaluechemicals.Thus,the developmentofcost-efficienttechnologiesforbiofuelsenables thedevelopmentofinnovativetechnologiesforproducingmore valuablechemicalproducts.

Whileearlybiofuelswerebasedoneasyextractablesugarsand vegetableoils,the second-generation (2G) biofuels takeadvantage from low-valuenonediblebiomass asdedicatedenergycrops grownonnonarablelandandwasteoflignocellulosicorlipidnature.Inaddition,thereisnoconnectionwiththefoodchain. However,thetechnologyof2Gbiofuelsisdemandinginterms ofequipment,enzymes,andchemicals.

Furtherprogressinsustainabilityisexpectedfromthe thirdgeneration (3G) biofuels basedonveryhigh-yield algalcrops. ThealgaeculturescanbefeddirectlywithconcentratedCO2 streamsresultingfromindustrialprocesses,suchasfromcoal powerplantsandfromfermentationofsugars.Theresearchof industrialalgalfarmingisinrapidexpansion,andtheresultsare veryspectacular.Algaecanproducetriglyceridessimilartothose originatingfromplants,butwithayieldhigherbyanorderof magnitude.Morerecently,algalculturescanproducedirectly varioushydrocarbonmolecules,includinglightolefins.

Theemergenceof1Gbiofuelsraisedstrongpolemics,mainly becauseofdivertingfarmlandfromthefoodsupplychainand thusincreasingtheprices,especiallyinthedevelopingcountries (seealsothepage “foodversusfuel” inWikipedia).Itisagreed todaythattheeffectofbiofuelsonthefoodchainshouldbe weak,mainlybecauseofthelimitationofsurfacesallowedfor energycrops,ingeneralatfewpercentagefromthetotalfarmland.Inthesametime,theadventofbiofuelsincitedtosubstantialimprovementsinfarmingtechnology,bothincultivationand harvesting.Thus,afterdataofAmericanfarmers(NCGA,2015), theyieldofcornroseby70%between1980and2015,hittingarecordof167.5bushel/acreor167.5 25.4/0.4047 ¼ 10,514kg/ha. Theyieldofconversionofcorntobioethanolcouldriseto2.8 gallon/bushelor2.8 3.785 1000/25.4 ¼ 417L/ton.Thiscould increaseby20%byemployinghighlyfermentablestarchhybrids. Thevegetablecakeordistiller’sgrainsobtainedafterethanol fermentationprocessareemployedforfeedinglivestock,such ascattle,pigs,andpoultry,whilethecornstovermaybeused

forsupplyingenergyinprocessingand/orasfeedstockforalignocellulosicbiore finery.Foratypicalyieldof10tonnesdrybiomass perhectareandtakingintoaccountanethanolyieldof300L/ tonne,itwouldbringasupplementof3000L/ha.Thus,thetotal bioethanolyieldfromthewholecornplantcouldreachmore than8000L/ha.NotethatwholeUSbioethanolproductionfrom cornin2015(31Mtpy)hasbeenobtainedbyincreasingthe cropproductivityandnotthefarmingsurface.Inthisway,the manufactureofbiofuelscancontributetoensuregoodandstable revenuesforfarmers.Usingonly1.4%ofthearableland,Brazil hasmanagedtoreplacealmost42%ofthegasolinewithethanol (www.sugarcane.com).

Thecultivationofagriculturecropsforbiofuelsisnotablein countrieshavinglargesurfacesforagriculture,suchastheUnited States(cornandwheat),BrazilandIndia(sugarcane),Malaysia andIndonesia(palmoil),andArgentina(soy).Itcanbenoted that nonedibleplants,suchasJatrophaandCamelina,canbe grownwithgoodyieldforproducingbiodieselindeveloping countries,easingthepressureofimportinghigh-priceoil.Europe hasonlylimitedfarmlandsurfacesforbiofuels,typicallycultivatedwithrapeseedandsugarbeet,althoughsomeextensions couldbeenvisagedinEasternEurope.

Inthe2Gbiofuels,thelignocellulosicfeedstock(LCF)consists inenergeticcropscultivatedonlow-valuesoils,by-productsfrom firstprocessing,asbagassefromsugarcane,strawfromwheat, cornstover,aswellasmunicipalorindustrialwaste.From chemistryviewpoint,LCFcontains,ingeneral,threemainuseful components:cellulose,hemicellulose,andlignin. Table1.1 gives therelativecompositionforsomerepresentativerawmaterials.

1.4BiorefineryConcept Thereisnotonlyananalogybetweentheconceptsofpetro-and biore finerybutalsofundamentaldifferences.Aclassicpetrorefinerydealsprimarilywithprocessing oilandgasfeedstock for supplying fuels fortransportationandheating,aswellas energy (steamandelectricity).Inamuchmoreefficientproduction mode, petrochemicalcomplex, therefineryoutletcanbeconvertedto petrochemicalbuildingblocks,whichareprimaryole fins andaromatics(BTX),bythermochemicalenergy intensiveprocesses.Thesemoleculesarerelativelylimitedforapplications. Furthermore,morereactivecompoundsareobtainedbyinserting organicfunctionalgroups,forexample,alcohols,acids,halogens, amines,etc.,byspendingconsiderableamountsofenergy,andby

Table1.1TypicalCompositionofBiomassinWt%. BiomassCellulose(%)Hemicellulose(%)Lignin(%)

Softwood35 4025 3027 30

Hardwood45 5020 2520 25

Wheatstraw33 4020 2515 20

Cornstraw35 4117 2810 17

Switchgrass30 5010 405 20

usingsophisticatedprocesses.Inthisway,alargevarietyofmoleculesforvariousapplicationsareobtained,suchasintermediatesforchemicalsynthesis,polymers,rubbers,solvents,etc.As anorderofmagnitude,90%fromglobalrefineryoutputisdirected tofuels’ market,whileonly10%isconvertedtopetrochemical products(WorldPetroleumCouncil,2013).

Abiorefineryhasanaloguefunctions,butthistimestarting from biomass asfeedstock.Abiorefinerysuppliesinthe first placefuels,chemicals,andenergy,butmayalsodeliverfoodproductsforlivestockandhumans,andalargevarietyofhighvalueaddedproducts,suchasbiopolymers.Inviewingofmanufacturing chemicals,thebiomassprocessingconsistsofgeneratingina first stagespecific biobuildingblocks.Itshouldbestressedthatthese aremuchmoresuitablefortheorganicsynthesisthanthepetrochemicalcounterpartsbecausemostofthemincorporatealready ready-for-synthesisfunctionalgroups.Moreover,thebiobuilding blocksaregotbybiochemicalprocessestakingplacenearambient temperatureswithrelativelylow-energyrequirements.However, theefficientproductionofbiobuildingblocksrequiresadvanced biotechnologiesandenzymes,aswellasinnovativeseparation methods.Themanufacturingofbiofuelswasthemainincentive forconstructingbiorefineries,startingwiththeyear2000.The plantsproducingbiochemicalsfollowed,andnowthedevelopmentisinfastprogress.

Fig.1.4 presentstheessentialfeaturesofabiorefinery(Dimian, 2007).Inthe firststep,thebiomassissubmittedto preprocessing, fromwhichsome primaryproducts aredirectlyobtained.For example, pyrolysisoil obtainedbytreatmentatelevatedtemperatureleadstovaluablechemicals,suchasalcohols,esters,phenols, andcomplexorganicmolecules,whichotherwisewouldrequire

complicatedorganicsynthesis.Afterpreprocessing,theconditionedbiomassissenttodedicated technologyplatforms tobe convertedintodesiredproducts.Theplatformsaredetermined primarilybythecompositionalcharacteristicofthefeedstock andthechemistryroutes,aswellasbythetechnologyusedfor conversion(thermochemical,biochemical,chemical).

BiorefineryistodayacentralissueforthefutureofCPI.There areseveralmonographsdevotedtothissubject,fromwhichwe mention Kammetal.(2006),Dembiras(2010),Arestaetal. (2012,2015), Waldron(2016).Theconceptofbiore finerywasthe objectofaninternationalworkofsystematizationhostedbythe InternationalEnergyAgency(IEA)asBioenergyTask42(deJong etal.,2012).Several technologyplatforms havebeenidentified asfollows:

• Biogas:CH4 fromanaerobicdigestion.

• Syngas:mixofCOandH2 frombiomassgasi fication.

• Hydrogenbymethanesteamreforming,waterelectrolysis,and fermentation.

• C6sugars:hydrolysisofsucrose,starch,cellulose,and hemicelluloses.

• C5sugars:hydrolysisofhemicellulose.

• Lignin:processingoflignocellulosicbiomass.

• Pyrolysisoil.

• Lipids(triglycerides)fromoilcrops,cultureofalgae,wasteoils andfats.

• Organicjuiceasliquidafterpressingwetbiomass.

• Electricityandheattobeusedinternallyorsoldtothegrid. Themostefficientuseofbiomassisbyan integratedbiorefinery complexthatconsistsofcouplingthemanufacturingof

Figure1.4 Biorefineryconcept.

Figure1.5 Alignocellulosicbiorefineryformanufacturingfuels,chemicals,and polymers.

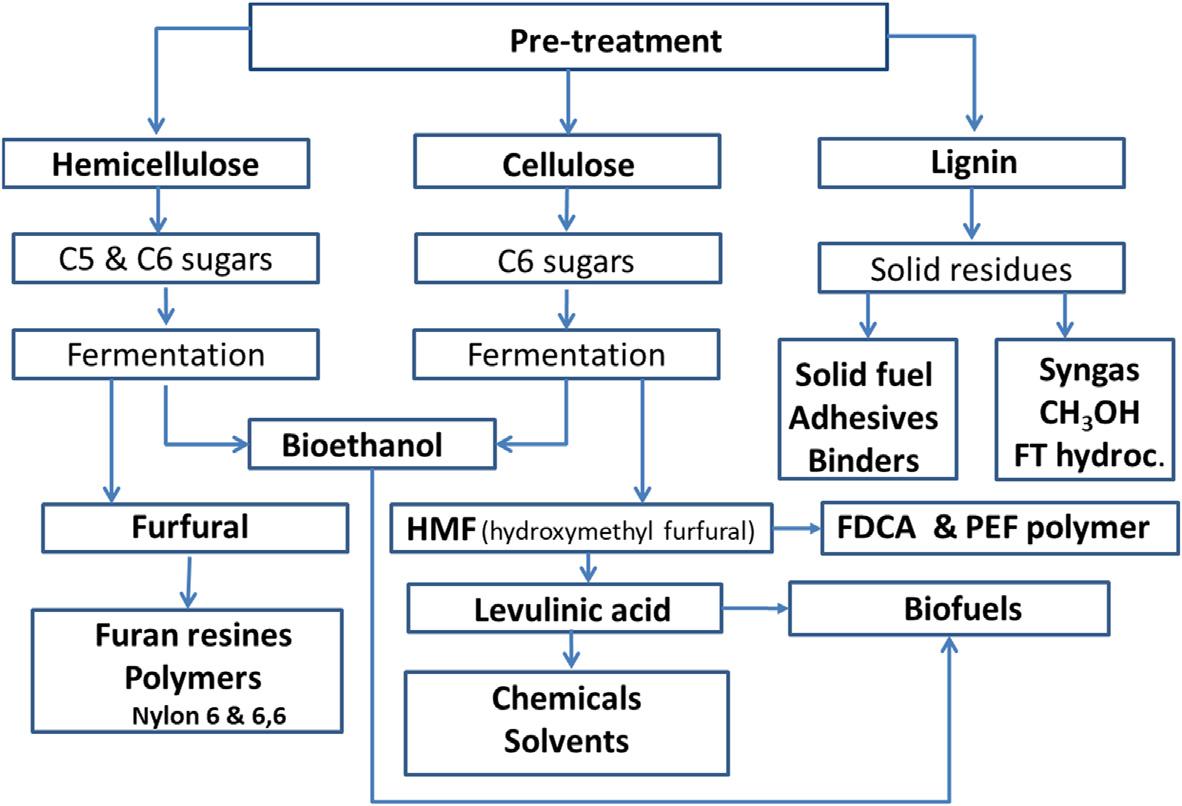

biofuelsandbiochemicals,analoguetoanintegratedrefineryand petrochemicalcomplex.Thegoalisgettingoptimaleconomicefficiencybythevalorizationofhigh-volumelow-valuebiofuels withlow-volumehigh-valuebiochemicals. Fig.1.5 showssuch anintegratedbiore finerybasedontheprocessingofLCFbiomass. Alargevarietyofproductscanbeobtained,fromcommodityfuels tovaluableresinsandbiopolymers.

1.5ChemicalsFromBiomass Fig.1.6 presentsthemainbiobuildingblockstogetherwithraw materialsandtechnologicalplatforms,aswellaskeybiochemical products.Thesearerangedintheorderofcarbonnumbersfrom C1toC6.Itcanbeobservedthatthebiobuildingblocksmake possiblethesynthesisofalargevarietyofbasicchemicalsand polymersmanufacturedtodayfromfossilmaterials.Moreover, theyareuniqueresourcesforsomehigh-valueecologicalchemicals,namelybiodegradablepolymers.However,amajordrawbackofbiobuildingblocksislimitedavailabilityofaromatics (BTX).Thisisalong-termchallengeforbiotechnology.

Thenextsectionswillpresentbrieflysomeimportantvaluable chemicalsthatcanbeproducedfromrenewableresources.More informationcanbefoundinspecializedmonographs,aspublishedby SenguptaandPike(2013) and ClarkandDeswarte(2015).

Figure1.6 Buildingblocksfororganicsynthesisinbiorefineries.

1.5.1ChemicalsFromC1BiobuildingBlocks Asshownin Fig.1.7,thesynthesisofchemicalsstartingfromC1 biobuildingblockscanbeorganizedaround methane and methanol. Themainsourceofmethaneisthe biogas,whichcanbeobtainedbyanaerobicdigestionofmunicipalsolidwaste.Methanol ismanufacturedfrom syngas,whichinturnisobtainedfrom biomassbythermalprocessing,aswellasfrombiogasbysteam reforming.Syngascanbeconvertedfurthertovarious hydrocarbonspecies,includinggasolineanddieselfuels,by employing Fischer Tropschtechnologies.Stateoftheartof

Figure1.7 C1buildingblocksstartingfromsyngas.

Fischer Tropschtechnologiescanbefoundinthemonographof DeClerk(2011) ,aswellinthepartIIIofthemultiauthorbookon biomassconversioneditedby deJongandvanOmmen(2015). Syngascanrecoverthecarbonpracticallyfromeverycarbonated source,forexample,frommunicipalsolidwaste(MWS).Another importantsourceinthefuturewillbethelignin,whichisobtained assubproductfromlignocellulosicbiore fineriesandpapermills. However,gettingsustainablehydrogenforsyngasischallenging, asmethanereformingremainsthebesthydrogensource.

MethanolisthemostvaluableC1chemical.Thebookby Olah etal.(2009) presentsanoverviewofthemanufacturingprocesses, bothclassicalandinnovative,aswellasnumerousapplications. Methanolcanbeproducedfrombothfossil(namelycoaland methane)andrenewablematerials,namelyfromsyngasand recentlybythehydrogenationofcarbondioxidefromindustrial exhausts.Chapter3dealswiththemethanolmanufacturingby bothmethods.Theconversionofmethanoltogasolineisknown forabout30years,buttodaythemostpromisingisthe methanol-to-olefintechnology.TheconceptualdesignofasustainableMTOprocessishandledintheChapter4.Severalplants havebeencommissionedsofarinChinaforethyleneandpropyleneproduction.

1.5.2ChemicalsFromC2BiobuildingBlocks ThemainC2biobuildingblocksare ethanol and aceticacid (Fig.1.8).Ethanolcanbeconvertedeasilyto ethylene andfurther toavarietyofintermediates,suchasethyleneoxide,ethyleneglycol,etc.,followingtheclassicalpetrochemicalroutes.Bioethylene maybecost-competitivewithpetro-ethylenewhenlow-costbioethanolisavailable,asatpresentlyfromBraziliansugarcane.For othersources,thepricewouldbe1.3 2 higher.Fastprogressis expectedinthenextyearswhenthelignocellulosicbiorefineries willarrivetomaturity(IRENA,2013).Moreover,forprocesses whereethyleneisonlypartiallyresponsiblefortherawmaterials cost,suchasvinylchloridemonomerandvinylacetatemonomer, thebioethylenecanofferprofitablealternativesolutions,avoiding theneedofanoilrefineryenvironment.

Figure1.8 C2biobuildingblocks.

Aceticacidcanbeproducedbythefermentationofethanol. Todaythemostefficientmethodisbythecarbonylationofmethanol,whichistheobjectofChapter12.Othervaluablechemicals canbefurtherobtained,suchasaceticacidestersandmonomers,includingvinylacetate(DimianandBildea,2008)and methylmethacrylate.

1.5.3ChemicalsFromC3BiobuildingBlocks ThemostimportantC3biobuildingblocksareglycerol,propanediol,acrylicacid,lacticacid,andacetone.Glycerolisavailabletoday atlowpriceandinlargeamountsfrombiodieselmanufacturing, butitcanbeproducedalsobytheenzymaticfermentationof glucose.Glycerolcanbeemployedasdrop-infeedstockforproducingtraditionalpetrochemicals,suchasepichlorohydrinandpropyleneoxide. Fig.1.9 showsthatothervaluablechemicalsmay beobtainedfromglycerol,suchasacrylicacidandmethionine byacrolein(Dumesicetal.,2006),propyleneglycolbyhydrogenation(Dasarietal.,2005),and1,3-propanediolbymicrobialconversion.Forthelast,aprocessbasedoncornstarchfermentationis commercializedbyDuPontformanufacturingSoronapolyester fibers.Acrylicacidcanbeobtainedalsobythedehydration of3-hydroxypropionicacid,whichisinturnobtainedbythe fermentationofstarch(deJongetal.,2012).Chapter13develops theconceptualdesignofaninnovativeprocessbasedonthedehydrationofglycerol,whileChapter15continuesitsvalorisationas esters.