AnIntroductiontoMetallic GlassesandAmorphous Metals

ZbigniewH.Stachurski

GangWang

XiaohuaTan

Elsevier

Radarweg29,POBox211,1000AEAmsterdam,Netherlands TheBoulevard,LangfordLane,Kidlington,OxfordOX51GB,UnitedKingdom 50HampshireStreet,5thFloor,Cambridge,MA02139,UnitedStates

Copyright©2021HigherEducationPress.PublishedbyElsevierInc.Allrightsreserved.

MATLAB® isatrademarkofTheMathWorks,Inc.andisusedwithpermission. TheMathWorksdoesnotwarranttheaccuracyofthetextorexercisesinthisbook. Thisbook’suseordiscussionofMATLAB® softwareorrelatedproductsdoesnotconstituteendorsementorsponsorshipby TheMathWorksofaparticularpedagogicalapproachorparticularuseoftheMATLAB® software.

Nopartofthispublicationmaybereproducedortransmittedinanyformorbyanymeans,electronicormechanical, includingphotocopying,recording,oranyinformationstorageandretrievalsystem,withoutpermissioninwritingfromthe publisher.Detailsonhowtoseekpermission,furtherinformationaboutthePublisher’spermissionspoliciesandour arrangementswithorganizationssuchastheCopyrightClearanceCenterandtheCopyrightLicensingAgency,canbefound atourwebsite: www.elsevier.com/permissions.

ThisbookandtheindividualcontributionscontainedinitareprotectedundercopyrightbythePublisher(otherthanasmay benotedherein).

Notices

Knowledgeandbestpracticeinthisfieldareconstantlychanging.Asnewresearchandexperiencebroadenour understanding,changesinresearchmethods,professionalpractices,ormedicaltreatmentmaybecomenecessary.

Practitionersandresearchersmustalwaysrelyontheirownexperienceandknowledgeinevaluatingandusingany information,methods,compounds,orexperimentsdescribedherein.Inusingsuchinformationormethodstheyshouldbe mindfuloftheirownsafetyandthesafetyofothers,includingpartiesforwhomtheyhaveaprofessionalresponsibility.

Tothefullestextentofthelaw,neitherthePublishernortheauthors,contributors,oreditors,assumeanyliabilityforany injuryand/ordamagetopersonsorpropertyasamatterofproductsliability,negligenceorotherwise,orfromanyuseor operationofanymethods,products,instructions,orideascontainedinthematerialherein.

LibraryofCongressCataloging-in-PublicationData

AcatalogrecordforthisbookisavailablefromtheLibraryofCongress

BritishLibraryCataloguing-in-PublicationData

AcataloguerecordforthisbookisavailablefromtheBritishLibrary

ISBN:978-0-12-819418-8

ForinformationonallElsevierpublications visitourwebsiteat https://www.elsevier.com/books-and-journals

Publisher: GlynJones

EditorialProjectManager: NaomiRobertson

ProductionProjectManager: NirmalaArumugam

Designer: MatthewLimbert

TypesetbyVTeX

Affineandnon-affinedeformation

StrainmeasuredbytheVoronoimethod(atomiclevel)...

StrainmeasuredbytheX-raymethod:crystallinesolids..

StrainmeasuredbytheX-raymethod:amorphoussolids.

Deformationinbulkmetallicglass

ElasticmodulusbytheX-raymethod..

DeformationinZr55 Al10 Ni5 Cu30 metallicglass...

DeformationinZr46.5 Cu45 Al7 Ti1.5 metallicglass..

DeformationinZr64 Cu16 Ni10 Al10 metallicglassundercooling

Deformationinthinfilmmetallicglass. .............................210

StructuralevolutioninZr50 Cu50 metallicglassduringcompression

StructuralevolutioninZr64.13 Cu15.75 Ni10.12 Al10 duringheating...........213

Changesinatomicstructurerevealedbyradialdistribution

Introduction

AristotlestatedatthebeginningofhisbookonMetaphysicsthat“allmen,bytheirnature,desireto know.”AristotlewasanancientGreekphilosopher(384–322BCE)andascientistborninthecity ofStagira,Chalkidiki,inthenorthofClassicalGreece.Allpeoplenaturallyarecuriousandacquire knowledgeforpracticalusageaswellasfordisseminatingknowledge.Anindicationofthisisour esteemforthesenses;forapartfromtheirusewevaluethemfortheirownsake,andmostofall,the senseofsight.Notonlywithaviewtoaction,butevenwhennoactioniscontemplated,weprefer sight,generallyspeaking,toalltheothersenses.Thereasonofthisisthatofallthesensessightbest helpsustoknowthings,andrevealsmanydistinctions.

Anotherphilosopher,XiangLiu,inWesternHanDynastyofancientChinasaid:“Seeingisbetter thanhearing,andpracticeisbetterthanseeing.”

Itisfrommemorythatpeopleacquireexperiencebecausenumerousmemoriesofthesamething eventuallyproducetheeffectofasingleexperience.Experienceseemsverysimilartoscienceandart, butactuallyitisthroughexperiencethatmenacquirescienceandart.

(a)TheGreatPyramidofGiza(ca.3000BCE);(b)abronzevaseofChina(ca.1300BCE);and(c)ironaxefrom Sweden(ca.1500ago).

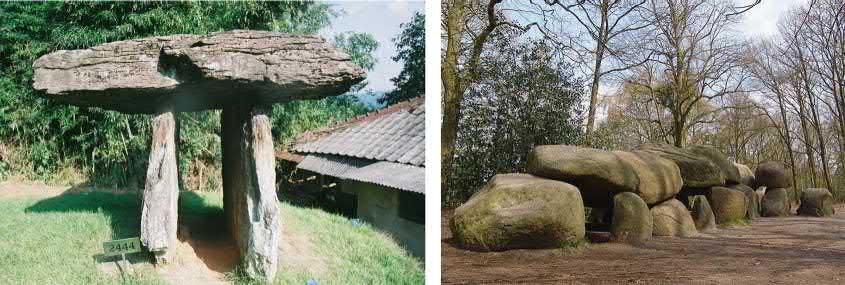

Archaeologistsinvestigatehistoricandprehistoricsitesandphysicalartifactsfoundatthesitesto understandhumanactivitiesinthepast.Inthisprocesstheyrevealtheadvancementsofvariousaspects ofhumanlifeandreconstructhistoryofhumancivilizations.Asaresultoftheirextensivestudies,they havedefinedthelongspanofhumancivilizationintothreeerasdistinguishedbytheuseofmaterials aslistedbelow,andwithexamplesillustratedin Fig. 1.1:

AnIntroductiontoMetallicGlassesandAmorphousMetals. https://doi.org/10.1016/B978-0-12-819418-8.00005-X Copyright©2021HigherEducationPress.PublishedbyElsevierInc.Allrightsreserved.

FIGURE1.1

•TheStoneAge–prehistorytoca.3000BCE

•TheBronzeAge–approximately3000–1000BCE

•TheIronAge–approximately1000BCE–CE1000

Inmoderntimes,theperiodfrom1850to2000issometimesreferredtobydifferentnames:

•theAgeofSteel, •ortheAgeofPlastics, •ortheAgeofNanomaterials.

Perhapsmanydecadesfromnow,thisperiodoftimewillbereferredtoasTheAgeofNewMaterials, towhichmetallicglassesbelong.High-techcompanies,suchasSpaceX,OrbitalSciencesCorporation, orXCORAerospace,arerapidlydevelopingtransportationsystemsforexplorationoftheneighboring planets.Itismorethanlikelythatmetallicglasseswillplayasignificantroleintheseendeavors.Of course,itmayevenbecalledtheAgeofQuantumComputingorsomethingelse.

Anaccumulatedknowledge,whichcomprisesskills,art,techniques,andskillfulshapingandconstruction,constitutesanaccumulatedknow-howthatinvolves experience (skillsandfamiliarity)and requires holdinginmemory anamountofinformation(i.e.,anumberoffacts,orsimplyinformation). Notethat know-how issufficienttorepeattheactivityasmanytimesasrequired.Forexample,large man-madestonestructuresbegintoappeararound10,000yearsago.Suitablyshapedrockswereselectedforthepurpose,withtimbertrunksusedasrollers,andropesusedasslingsandforhoisting.In today’sterms,theconstructionofthestonestructurewouldbecalled civilengineering.However,from thisexperiencethemoreobservantindividualswouldholdinmemorynotonlytheeffortoflaborand theknow-howoftheconstruction,butalsosuchfactsashardnessandsurfacesmoothnessoftherock forlowerfriction,thestrengthofropeforpullingandliftingandthehardnessandresistancetosplitting oftreetrunksforrollingapplications.Allofthesearepropertiesofthematerialsusedintheengineering activitythatwouldberetainedinmemoryandinduecoursebecomeknowledgeofmaterials.

Thelongestexperiencewithmaterialswasthatwithstoneandwood,ofwhichstoneistheeverlastingasisevidentin Fig. 1.2.Smeltingandshapingofironfollowedtheexperienceandknow-how ofmakingbronzefromanearlierage,andwentonforcenturieswithoutsignificantadvances,until themiddleofthe19thcenturywhentheconfluenceoftwomajorfactorsrevolutionizedironsmelting intosteelmaking,supersedingtheageoldprocess.Thisnewmethodofsteelmaking,anditswide application,hadapronouncedeffectonourcivilizationinthemodernera.

Thefirstmajorcontributingfactorwastheexpansionofmanufacturingandconstruction,createdby demandsoftheindustrialrevolutioninthedevelopingworld,andhencetheneedforlargequantitiesof strongmaterialsformachinery,construction,andcivilengineeringconnectingcontinentsbyrailroads.

Thesecondessentialfactorwasthediscoverybychemists(metallurgists)that“pigiron”contained toomuchcarbondissolvedinit,whichhadtoberemovedbylengthyandcostlyreprocessingtogive amoreuseful“wrought”iron.Priortothattime,thecrudeironmaterialwasproducedintheblast furnace,usingrawmineralssuchasironore,lime,cokeforfuel,andotheringredients.Theproductof thisprocess,thepigiron,hadaveryhighcontentofcarbon,between4%and5%,togetherwithsilica andotherimpuritieswhichrendereditbrittleandnotofmuchusedirectly.(Thetraditionalmolds wereformedinsand,withacentralchannelbranchingintomanyindividualingotsatrightangles, resemblingalitterofsucklingpiglets,hencethenamepigiron).Chemistrywasdevelopingintoa powerfulscience,equippedwithanalyticaltoolsandtheoreticalunderstandingofthegas,liquid,and

Megalithicman-madestructuresfromtheStoneAge:(a)SinglechambertombinKorea(ca.the9thmillennium BCE);(b)StonestructuresinthemunicipalityofBorger-Odoorn,Netherlands(ca.the4thmillenniumBCE).

solidstate.Chemicalelementswerebeingdiscoveredandidentifiedatarapidrate.Alreadyin1722, RenéAntoineFerchaultdeRéaumurdemonstratedthatironwastransformedintosteelthroughthe absorptionofsomesubstance,laterfoundtobecarbon,forwhichA.L.Lavoisierproposedthename “carbon”in1789fromtheLatinwordfor“charcoal.”In1774,J.Priestleyfoundthatairisamixture ofgases,oneofwhichwasthehighlyreactivegashecalled“dephlogisticatedair,”lateridentifiedas oxygen,whichhadgreataffinityforcarbon.

In1856,theEnglishmanHenryBessemerbecameawareofthesignificanceoftheseeminglyunsaturateddemandforsteel,andsuddenlyrealizedthatcarboncouldbeburnedoutofthemolteniron byair.Hetookoutapatentonmakingsteeldirectlybyblowingairthroughthemoltenironmixture. Bytheturnofthecentury,largecompaniesweresetupintheUSAandEuropetomanufacturesteel bytheBessemermethod.Lateron,oxygensteelmakingeventuallyreplacedtheopenhearthfurnace. Oxygenwasliquefiedinastableformforthefirsttimein1883byPolishscientistsfromJagiellonian University,ZygmuntWróblewskiandKarolOlszewski.

Today,steel(togetherwithconcrete)isthemostwidelyusedmaterialintheworld.

Similarcircumstancesoccurredinthemiddleof20thcenturywithrespecttothediscoveryand developmentofmetallicglasses–thenewmaterials.Themostimportantapplicationofmetallicglasses isinthefieldofmagneticandferromagneticdevices.Theexceedinglylowmagnetizationlossofthese materialsisusedtoagoodadvantageinhighefficiencytransformersatlowfrequencypowerlines. Alsoelectronicsurveillancedevices(suchastheftcontrolpassiveIDtags)oftenusemetallicglasses becauseofthesespecialmagneticproperties.

Itisimportanttobringtonoticethefactthatamorphoussolids,otherthanmetallicglasses,are widelyused:silicaglassinwindows,inopticaldevices,andinopticalfibersfortelecommunication.

Glassy(amorphous)solidshavebeenpositivelyidentifiedintermsoftheiramorphousatomicstructureatthebeginningofthe20thcenturywiththeaidofX-raydiffractionstudies.Thefirststructure ofanamorphoussolid,namelythatofplainsilicaglass,wasidentifiedbyanX-rayscatteringstudy

FIGURE1.2

by(Warren, 1934)andmorerecentlycorroboratedbytheso-calledfluctuatingelectronmicroscopy. Chemistshadsomepriorideasaboutrandomnetworksandchainmoleculesasisknownfromthe worksofZachariasen(1932)andStaudinger(1933).Thetechnologyofprocessingofglassesandtheir manifoldusesareveryadvancedandextensive,yetthereisnoadequateunderlyingtheoryofamorphousstructureasforcrystallinesolids.Whatisgenerallyknownandacceptedatthisstageisthat amorphoussolidsdonotpossessasaruleanycrystallinity,andthattheatomicarrangementsareconsideredtoberandom,havingnolong-rangeorderasincrystals.Insomecircumstancestheyarecalled “frozenliquids.”

Theunderstandingoftheatomic-scalestructureofsolids(fromwhichmoderntechnologyand societybenefitsogreatly)hascomeabouttoalargedegreebecauseofthedevelopmentofthemethods ofgeometryandX-raycrystallography.FromthefirstdiscoveryofthediffractionofX-raysbyacrystal by(Friedrichetal., 1913)and(Bragg, 1913),tothepresentdaywhenstructuresoflargemoleculesare determinedroutinely,crystallographyhasdevelopedfromsmallbeginningstobecomeanenormously successfulandpowerfultoolforthestudyofatomicarrangementsinsolids.

TheothercontributingfactortowardsdiscoveringmetallicglasseswastheadvancementofMaterialsScience,especiallyinthefieldofplasticityofmetalsandmetallicalloys.Theoryofdislocations withintheorderedcrystallinestructure,andverificationoftheirexistencebyelectronmicroscopy,providedasoundbasisforaclearunderstandingoftheplasticityofmetals,especiallyofpuremetals,in termsofdislocations’motioninthepolycrystallinestructure.Soonafter,thestrengtheningmechanisms ofstrainhardening,precipitations,andalloyingwereidentified.Itwasconcludedthatmakingmetallic alloyswithsmallerandsmallergrainsizeleadstostep-wiseimprovementsinstrength.Eventually,in thelimitingcaseofzerograinsize,anamorphousstructurewasenvisioned,possessingmechanical strengthapproachingthatofthetheoreticalstrengthofmaterials.

Inthemid-20thcentury,thealloysystemofgold–silicon(Au–Si)waswellstudied,andwasknown tohaveahexagonalclose-packedcrystallinestructureinsolidifiedalloys.Interestingly,theAu–Si alloysystemshowsadeepeutecticatacompositionofapproximately20%atomicweightofSiin Au,withalowmeltingpointof636K,comparedtothemeltingpointofAuof1337K,and1687K forSi.Thiseutecticmelt,whenrapidlyquenchedonaspinningcopperwheel,solidifiedintothin ribbon-likeobjects,andappearedtohavenocrystallinityonthebasisofX-raydiffractionpatternof the“quenched”Au80 Si20 composition.Thiswasthefirstcaseofametallicamorphousalloyreportedin thescientificliterature.Veryhighcoolingrateshadtobeemployed,oftheorderof106 K/s,toproduce smallamountsoflongamorphousmetalofapproximately0.1 × 10mmincross-section,hencethe description“ribbon-like”metallicglasses.

Thefirstbulkmetallicglass(BMG),withcentimeterdimension,wastheternaryPd–Cu–Sialloy preparedbyChenetal.in1974.Asimplesuction-castingmethodwasusedtoformrodsofthemetallic glassatacoolingrateof103 K/s.In1982,TurnbullandcoworkerssuccessfullypreparedthePd–Ni–P BMGusingboronoxidefluxingmethodtopurifythemeltandtoeliminateheterogeneousnucleation. Theexperimentsshowedthataglasstransitiontemperature, Tg ≈ 2/3 Tm ,wasachievedwhenheterogeneousnucleationwassuppressed.Theingotwasofcentimetersize,solidifiedatcoolingratesofthe orderof10K/s.AlthoughtheformationofPd-basedBMGisanexcitingachievement,however,due tothehighcostofpalladiummetal,theexperimentswereonlyfollowedinacademiccircles,andthe interestfadedaftersomeyears.

Inthelate1980s,InoueandhiscoworkersinTohokuUniversityofJapansucceededinfinding newmulti-componentalloysystemsconsistingmainlyofcommonmetallicelementswithlowercrit-

Table1.1Propertiesofmetallicglasses(fromAshbyandGreer,2006).

Attributes

Attractiveproperties

general theabsenceofmicrostructuralfeaturessuchasgrainandphase boundariesallowscomponentswithfeaturesofnear-atomicscale mechanical highhardness,givinggoodwearandabrasionresistance highyieldstrength,veryhighfracturetoughness lowmechanicaldamping(lowdissipationlosses) thermal forsomemetallicglasses, Tg Tc ,allowingprocessingassuper-cooled liquid(thermo-plasticforming:injectionmolding,hotpressing,etc.)

Tg –glasstransitiontemperature, Tc –crystallizationtemperature electrical resistivityisalmostindependentoftemperature magnetic highmagneticpermeability chemical highcorrosionresistance processing lowsolidificationshrinkageandnograinstructuregive highprecisionandfinishincastings aesthetics veryhighsurfacepolishduetolackofmicrostructure durability highhardnessandcorrosionresistancegivesdurability

icalcoolingrates.Havingsystematicallyinvestigatedternaryalloysofrare-earthmaterialswithAl andferrousmetals,theyobservedexceptionalglassformingabilityintherare-earth-basedalloys,for example,La–Al–NiandLa–Al–Cu,bycastingthealloys’meltinwater-cooledCumolds.

Bytheearly2000s,manyhundredsofBMGshavebeenproducedaroundtheworld.Theinterest inamorphousmetallicmaterialsisevidencedbyaUSAcompany,LiquidMetal,whichintroducedthe firstcommercialamorphousalloy,Zr-basedVitreloy,in2003.TheVitreloyBMGhasbeenusedin sporting,medical,andindustrialproducts.

Metallicglassesseemunusual.Theyarehardandbrittlelikeglass,butnottransparent;theyhave thesofteningpointlikeglasswellbelowtheircrystallinemeltingpoint,yet,unlikeopticalglasses,they donotconductlight,butaregoodconductorsofelectricity.Indeed,metallicglassesarelikemetals andglasses,exhibitingsomepropertiescommontoboth.Theypossesthecharacteristicsofthetwo typesofmaterialsbecausethearrangementofatomsinmetallicglassesissimilartothoseinorganic andinorganicglasses,yetthechemistryandelectronicstructureisthatofmetals.Themainaimof thistextbookistodescribemetallicglassesintermsoftheirphysicalcharacteristics,theirusesand applications,themethodsoftheirmanufacture,andtheirinneratomicstructure.

Thechallengesofstudyinganddevelopingmetallicglassesarenumerous,carryingexcitementof newdiscoveriesandnewapplications,basedontheirinherentadvantagesshownin Tables 1.1 and 1.2.

Itcanbesaidwithahighdegreeofcertaintythatpetrolanddieselmotorcarshavelimitedlifeas theyarereachingtheirpeakinperformanceandefficiency,butcontinuetocontributesignificantlytothe environmentalpollution.Theywillgraduallydisappearfromourliveslikesteamenginesandsailing shipsofearliertimes.Electricmotorsarefarsuperiortoreciprocatingpistonengines,andtherefore,are thefutureofallourtransportationandmechanicalmovementactions.Theuseofelectricmotorsare presentlylimitedonlybythesupplyofhighcapacitybatteries.Metallicglassesareexcellentcandidates forelectricmotorapplications,andgreatadvancesintheiruseanddesignareanticipated.Imaginethe futurewithoutairpollutingcarsandtrucks.

Infact,theveryfirstmotorcarhadanelectricmotor(foracommercialexample,see Fig. 1.3)–it wasthelackofadequatebatteriesthatstalleditsprogress.FranceandtheGreatBritainwerethefirst

Table1.2Currentandpotentialapplicationsofmetallicglasses(Wangetal., 2004).

Property Primaryapplications Secondaryapplications

highstrength machinesanddevices

highhardness cuttingtools wearresistantmedicaldevices

highfracturetoughness diematerials

highreflectionratio opticalprecisionmaterials

highfrequencypermeability highmagnetostrictivematerials

highwearresistance medicaldevices

alloftheabove spaceapplications

FIGURE1.3

An1901advertisementforacommercialelectriccar.

nationstosupportthewidespreaddevelopmentofelectricvehiclesinthe1890s.FerdinandPorsche’s designandconstructionofanall-wheeldriveelectriccarinGermanywaspoweredbyanelectricmotor ineachhub,andhassetseveralspeedrecordsatthetime.Electricvehicleshaveanumberofsignificant advantagesovertheirpresentdaycompetitors.Mostimportantly,theydonothavethevibration,smell, andnoiseassociatedwithgasolineanddieselcars.Theyalsodonotrequiregearchanges.Iftheir batteriesarechargedfromrenewableenergysources,theireffectonairpollutionisclosetozeroby comparisonwithtoday’scars.

(Forcomparison,electricmotorsaretypically95%efficientintransforminginputenergyintorotationalenergy,whereasinternalcombustionenginesareonly35%efficientatbest–therestofthe fuel’scalorificvaluedissipatesasairfriction,andescapesasheatandexhaustgasses.Theefficiency ofsteamlocomotivesofthepastwasaslowas10%.)

Intelligentreflectionsontherelationshipbetweentheobservedpropertiesandperformanceofmaterialsleadtoenhancedpersonal knowledge,withsocialadvantagetopeoplecarryingoutengineering

activity.Thelevelofknowledgedependsontheabilitytoconceptualizetherelationshipsbetweenthe elementsoftheinformation,andanabilitytomanipulatetheconceptsandfactstoderivethelifeadvantage,whichleadsto understanding.(Knowledgemaybethoughtofasthedatabasecollectedby Facebook,whereasunderstandingisanalogoustothealgorithmwhichcharacterizeseachpersonon thedatabasebytheinformationheld.)Thus,scienceisabranchofknowledgedealingwithabodyof truthfulfactsarrangedtorevealgenerallaws,gainedthroughobservationandexperimentation.

MaterialsScience,abranchofthePhysicsofSolidState,isbasedontheknowledgeandunderstandingofthefollowingfundamentalrelationship:

atomic/molecularstructure → material’sproperties thatis,thechemistryandstructureofsolidsgovernsthebehaviorofthesolidmaterials.

TheuseofthisrelationshipforappliedpracticalendsisthefieldofMaterialsEngineering.An importantrelationshipexistsbetweenthemethodsandconditionsofprocessingofmaterialsandtheir finalmicrostructure.

processingofmaterials → material’smicrostructures

ThebasisofthefirstrelationshipcanbetracedbackinhistorytotheancientGreece,whenLeccipus ofMiletusandDemocritusofAbdera(inancientGreece)proposedthatmatteriscomposedofatoms (indivisiblevolume –derivedfromGreek).Furthermore,theyhypothesizedthatatomshaveshapesthat makethempossessandexhibitproperties,suchasacidity,sweetness,stickiness,andsmoothness,and allowthemtobondtomakeupothermatter.

Inthetworelationshipsabove,theterm“atomic/molecularstructure”referstothearrangementof atomsinthesolidmaterial,and“property”referstothephysical,chemical,electrical,mechanical, andotherpropertiesofmaterialsthatwemakeuseofinparticularapplications.Themetallicglasses connectthe“amorphous”structurewith“metallic”bonding;theyarethusexpectedtopossessunique propertiesthatdonotexistinothermaterials.

Indeed,itistheaimofthisbooktoprovidedeepinsightintotheserelationships,aswellasto consolidatetheexistingknowledgeonmetallicglassesandrelatedsubjects.Thehopeoftheauthorsis thatthistextbookprovidesmuchoftheinformationthestudentreaderissearchingfor,andfurthermore, thatitpointsthereadersaccuratelyandefficientlytoothersourceswheremoreinformationcanbe foundsothatdeeppersonalknowledgecanbeacquiredandenriched.

References

Bragg,W.L.,1913.Thediffractionofshortelectromagneticwavesbyacrystal.ProceedingsoftheCambridge PhilosophicalSociety17,43–57.

Friedrich,W.,Knipping,P.,Laue,M.,1913.X-raydiffractionfromsinglecrystals.AnnalsofPhysics346(10), 971–988.

Wang,W.H.,Dong,C.,Shek,C.H.,2004.Bulkmetallicglasses.MaterialsScience&Engineering.R,Reports44, 45–89.

Warren,B.E.,1934.X-raydeterminationofthestructureofglass.JournaloftheAmericanChemicalSociety17, 249–254.

Makingofmetallicglassesand applications

Applicationsofmetallicglasses

Aerospaceandbeyond

2.1

Metallicglasses(MGs)areconsideredasanovelclassofmaterials,differentfromcrystallinemetallic alloys.Overthepastdecades,experimentalandtheoreticalresearchershavedevotedtimeandeffortto understandandcharacterizethenatureofamorphoussolids.Metallicglassespossessexcellentproperties,andareregardedaspotentialmaterialsinmechanical,chemical,magnetic,andopticalengineering.

VariousmetallicglassyalloysbasedonZr-,Fe-,Ce-,Ti-,andMg-elementsattractgreatinterest forapplicationsinmedicine,electricalengineering,aeronautics,andastronautics.Therelevantresearch workhasbeenconductedinthefieldofspaceresearchanddevicesinaerospacevehicles,including protectiveshieldsandvariousaerospacecomponentssuchascompliantmechanisms,gears,magnetoelectriccomponents,solarwindcollectorplates,etc.

SpaceenvironmentissodifferentandcomplexcomparedthatontheEarth’ssurfacethatthe aerospacevehiclesaresubjectedtoextremeconditions:temperatureaslowas 200◦ C,extremehumidityanddesertenvironmentbeforelaunch,ultravioletexposure,ionirradiation,anddebrisstriking, whichdemandexceptionalpropertiesofthemetallicglassyalloysappliedinaerospace.Thestructural evolutionandperformanceofMGsatcryogenictemperatureshavebeenstudied,andaductile–brittle transitionwasobservedgoingfromlowertohighertemperatures,andvice-versa.TheionirradiationresistanceofMGshasalsobeeninvestigatedunderdifferentionsources.Therewasnosignificant damageobservedonTa38 Ni62 MGsurfaceirradiatedbyHe2+ ions.However,thermallyinducedpartial crystallizationoccurredunderprolongedexposureat360◦ CforCu60 Zr20 Hf10 Ti10 MG,whichmeans thatthisalloyisnotsuitableforirradiationenvironmentsforextendedperiodsoftime.Recently,a novelhigh-temperatureIr35 Ni20 Ta40 B5 MGalloyhasbeendevelopedbycombinatorialmethods,and itisexpectedthatitwillbeappliedinaerospaceunderbothhighandcryogenictemperatures.

Coldweldingoccursunderhighvacuum(i.e.,inaerospace)betweentheatomicallycleanmetal surfaces,evenwithoutheatapplied,andunderstaticcontact,causedbythemutualdiffusionofatoms

AnIntroductiontoMetallicGlassesandAmorphousMetals. https://doi.org/10.1016/B978-0-12-819418-8.00006-1 Copyright©2021HigherEducationPress.PublishedbyElsevierInc.Allrightsreserved.

10Chapter2 Makingofmetallicglassesandapplications atthecontactingsurfaces.Theservicelifeofthecomponentsduringstaticordynamicapplications wouldbeharmedbythestick–slipadhesivewear,andfrictionalwearduetothecoldweld.AnMoS2 compositemembranewaspreparedbychemicalplatingand/orelectroplatingmethodonthesurface ofanNi–Pamorphousalloyandanaluminiumalloymovingpart.Theadhesion(friction)coefficient betweenthecompositemembraneandtheMGwaslowerthan10 4 ,whilethatbetweenthetwoMG surfaceswasabout10 2 .AccordingtotheQ/WHJ21-93principle,theNi–P–MoS2 compositemembraneiswellsuitedforpreventingthecold-weldingeffect.

Protectiveshield

Withagrowingexplorationoftheouterspace,moreandmoremissionsarelaunchedbyNationalAeronauticsandSpaceAdministration(NASA),theEuropeanSpaceAgency(ESA),theJapanAerospace ExplorationAgency(JAXA),andtheChinaNationalSpaceAdministration(CNSA).Thespacevehicles,suchastheunmannedroboticspaceprobes,InternationalSpaceStation(ISS),spaceshuttles, andotherspacecraftwithhumansaboard,arethreatenedbythespacedebris,thenumberofwhichincreasesdaily.UntilJanuary2019,thenumberofdebriswasestimatedtobe34000forparticleslarger than10cminsize,900000for1to10cminsize,andmorethan128millionfor1mmto1cminsize, respectively.Thehugepopulationofspacedebrisinthesizerangefrom1mmto1cmisaseriousrisk tothespacecraft,fargreaterthanthatofmicrometeoroids.

Theso-called“Whippleprotectivestructure”developedbyFredWhipple(anAmericanastronomer)wasadoptedandisbeingassembledinspacecraftbymanyaerospaceagencies,inwhich thematerialoftheoutershieldisofparamountimportancetoprotectthemaincraftduringmicrometeoroidsandorbitaldebris(MMOD)impacts.Incontrasttomonolithicshieldingoftheearlyspacecraft, Whippleshieldsconsistofarelativelythinouterbumperspacedsomedistancefromthemainspacecraftwall.Thebumperisnotexpectedtostoptheincomingparticleorevenremovemuchofitsenergy, butrathertobreakitupanddisperseit,dividingtheoriginalparticleenergyamongmanyfragments thatfanoutbetweenthebumperandtheouterspacecraftwall.

Theidealmaterialforprotectiveshieldisrequiredtohavehighhardnessinordertobeabletobreak uptheparticles,andlowdensitytominimizetheweight.Anotherdesiredpropertyisalowmelting point,sothatthedebriswouldevaporateittopreventgenerationofcollisiondebrisduringanMMOD impact.Analuminiumalloyisthematerialusedcurrentlyinthespacecraftprotectiveshieldbecauseof therelativelylowpriceandadequateperformance.AresearchgroupfromNASAreportedimpressive testresultsformetallicglassesduringhyper-velocityimpact(HVI)tests.

Inthefirsttrial,Zr36 6 Ti31 4 Nb7 Cu5 9 Be19 1 MGcompositewasadoptedforconstructingthecellularstructuresandsubjectedtoimpactwithvelocitiesrangingfrom0.8to3.0km/s,usingaluminium sphereswithadiameterof3.17mmastheimpactingparticles.Singlelayersmadefromthesame materialwereimpactedbythealuminiumprojectiles,andtheresultswerecontrastedwiththoseof amulti-facetedegg-boxstructure.Theresultsshowedthatthethicknessrequiredforthefacesheets wasgreaterthanthatintheegg-boxstructuretopreventpenetration.ThecorrugatedpanelscoulddiffusethedebrisproducedbythebumperduringanMMODimpactmoresignificantlycomparedtothe single-wallshield.Inthistrial,MGswererepeatedlycastatlowcostintoacomplexhoneycomb(eggbox)structure.TheconstructionofasinglehoneycombstructurebyweldingisdifficultusingMGs. AmethodforjoiningMGcompositescanusecapacitivedischarge.Duringtheprocess,MGsshowa near-constantelectricalresistivityasafunctionoftemperatureresultingfromtherandomatomicarrangements.Thematrixofthepanelcanbeheatedtoapproximately700◦ Cin10millisecondswhen

compositepanelsareplacedbetweentwocopperelectrodeplatesanddischargedbyacapacitor.The nodesofeachpanelwouldfuseandconnectintoasinglepiecebyapplyingaforgingloadduring discharge.Thetechniqueallowsthefabricationofacellularstructuredescribedinthepatent,whichis well-suitedforspacecraftshieldsormilitaryvehicledoorpanelswithhighest-strengthandmostenergy absorption.

InthesecondtestseriesforZr41 2 Ti13 8 Cu12 5 Ni10 Be22 5 andZr36 6 Ti31 4 Nb7 Cu5 9 Be19 1 MGs, compositesweredesignedtoestimatetheballisticlimitforbulkMGsandtheircompositesandto investigatespallingbehavioratvelocitiesfrom0.8to2.8km/s.TheresultsshowedexcellentcombinationsofhardnessandtoughnessofMGsforuseasshields.Comparedtoasingleshieldstructure, multi-layershieldsaremoreeffectiveindiffusingtheimpactenergy.

Forthethirdseries,theWhippleshieldsincorporatedlayersofFe65 Si15 B20 MGandwereassessed atvelocitiesof6.97–7.05km/sthroughHVItests.ThiscompositionMGhasalowglass-formingability andcanbeproducedinaribbonwhichisonly23µmthick.Ashieldcomprising21cmsquaresheets stackedtogetherfromindividualribbonlayersallowedtheWhipplestructuretomaintainthesameareal densityastheactualISSmodulebaseline.Intheresults,theprojectilepenetratedthebaselinesample butdidnotpenetratetheshieldwithintermediatelayersofMGsundertheidenticalconditionswitha baselineWhippleshieldcurrentlyusedontheISS.ItisclaimedthatthisMGcanbeareplacementfor thefabriclayersintheWhippleshieldarchitecture.

AnothergroupconductedtheHVItestsusingFe77 Si14 B9 MGfilmcoatedontheLY12Alaluminiumalloytobeusedasthefrontbumperofatwo-layerWhippleshieldwithvelocitiesranging from3.44to5.70km/s.TheMGfilmwasfabricatedbythethermalspraycoatingtechniquetodeposit athicknessof0.15mm.CombiningtherigidsubstrateprovidedbyaluminiumandthehardFeMG film,thereinforcedbumpershowedbetterperformancethanthetraditionalone,whichmaybedueto thehigherdensity,lowerspecificheat,andnotsohighmeltingtemperatureoftheFe-basedamorphous alloy.However,thedensityenhancedbyMGfilmontheAlsubstrateislimited.Anotheradvantage ofMGinthiscaseisthathighershockpressurescanbegeneratedinthereinforcedbumpertoinduce ahighertemperatureriseintheprojectile,whichwillpromoteprojectilefragmentationandprovide betterprotectionperformancecomparedtothetraditionalone.

Inanotherdevelopment,bulkZr51 Ti5 Ni10 Cu25 Al9 MGwasfabricatedbycoppermoldcastingwith asizeof3.5mm × 45mm × 45mm.TheHVIexperimentswereconductedusingatwo-stagegas gunwithseveralvelocitiesoftheprojectiles,rangingfrom1.40to4.27km/s.Afterthehyper-velocity tests,damagemorphologyofthefrontbumpwasanalyzed.

Applicationascompliantmechanisms

Variousmechanismsareusedinaerospaceequipmentasrequiredbecauseoftheirexcellentability toapplyforce,translationandrotationmovement,inkinematicpairs,gears,linkages,andflexurecompliantmechanisms.Thesemechanismshavestrictrequirementsofdimensionalaccuracy,high strength,andelasticity,aswellaslowwearandlowcoefficientofthermalexpansion.Especially single-piecemechanismsarepreferredtoreducetheassemblingtoleranceandenhancestability.MGs combinetheadvantagesofhighstrength,highelasticity,andgoodprocessability.Twotypicalmetallic glasses,i.e.,Zr41 2 Ti13 8 Ni10 Cu12 5 Be22 5 andZr44 Ti11 Ni10 Cu10 Be25 ,areusedtofabricatebistable compliantmechanisms.Sometraditionalmaterials,suchasthebestperformanceTi-6Al-4Valloy amongthecrystallinematerials,arealsoadoptedtobecontrastedinexperiments.Itisdemonstrated

12Chapter2

Makingofmetallicglassesandapplications thatdevicesmadefromMGscanprovidealargersafetyfactorforsimilarly-sizedcompliantmechanisms,ortheycanbefabricatedtohavemuchsmallersizesbecauseofhigherstrengthcomparedto theTi-6Al-4Valloy.Duringthefabricationprocess,MGscanbemeltedandinjectedintoacomplex moldatalowtemperaturewithoutpost-processing(polishing)procedurewhichalsolowerstheproductioncosts.Forthedesignchallenge,MGsexhibitbettermanufacturabilitywithoutpost-machining toovercometheproblemofthermalexpansionmismatchandpreciseassembly.Somepatentshave beenappliedinthisfieldrecently.

Ball-and-conelocatorsarestandardlatchingmechanismswithadeployablestructureforaerospace vehicles,inwhichthepreferredmaterialshouldhavelowdensityandhighperformance,highhardness andductility,lowmeltingpoint,tolerancetocryogeniccircumstanceandcryogenic-thermalcycling, andbecompatiblewithflight-gradeepoxymaterial.TheperformanceofTi-basedMGsandtheircompositeswasstudiedthroughpush-outtests,four-pointbending,andcryogenic–thermalcyclingtests. ItwasshownthatthelocatorinsetsusingTi44 Zr20 Cu5 V5 Al7 Be19 MGwouldbe39.5%lighterwhen comparedto440stainlesssteel,indicatingthegreatestpotentialtoreplacethistraditionalsteelmaterial.AcompositionofTi40 Zr20 Cu10 Be30 isyetanotheralternativetoconsiderbecauseofitshigh glass-formingabilityandattractivemechanicalproperties.

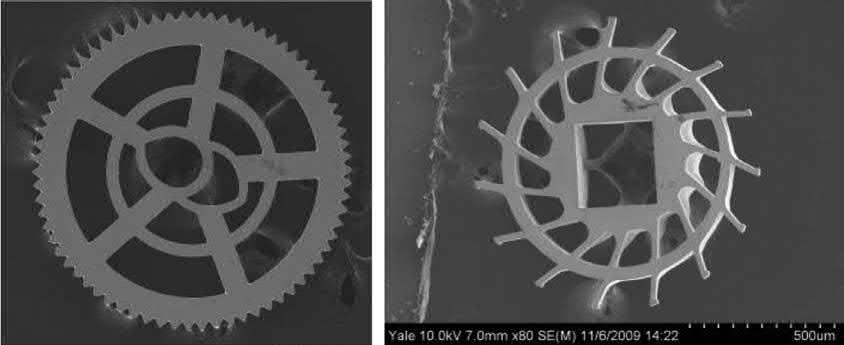

Applicationasgears

Unlikethetraditionalsteelmaterials,metallicglassesbecomemoreductile(lessbrittle)inextreme cold,whichmakesthemmoreappropriateforrobotsworkinginspaceoronicyplanets.TheresearchersandengineersfromNASAJetPropulsionLaboratory(JPL)designedatesttoestimatethe potentialbenefitofmetallicglassincreatingroboticgearsforspacecomparedtoceramicsandsteels. Agearisessentialintheprecisionroboticsandrequiredwhentherobotsperforminspacemissions. ResultsfromJPLshowthatthegearsmadefrommetallicglasscantransmithightorqueandsmooth turningwithoutlubricantevenattemperaturesaslowas76K.Amongvariousmetallicglasses,CuZrbasedCu43 Zr43 Al7 Be7 MGexhibitsexcellentwear-resistancewitha60%improvementthrougha superiormethodofgear-to-geartestingcomparedtohigh-performancesteelVascomaxC300whichis usedcurrentlybyNASAonMarsroverCuriosity.Itisindicatedthatthenatureoftoughnessismore importantthanhardnesswhenconsideringgearwear,whichiscontrarytotraditionalclaims.Inthis test,theMGsgearwasfabricatedbyanet-shapedcastingwithoutpost-machining,whichcanimprove thewear-performanceandlifetimeofMGgearbutwithasuperiorsurfacequalitytothatofelectric dischargemachinedgears.Somepatentshavebeenappliedforinthisfieldrecently.Examplesofgears manufacturedfrommetallicglassesareshownin Fig. 2.1.1.

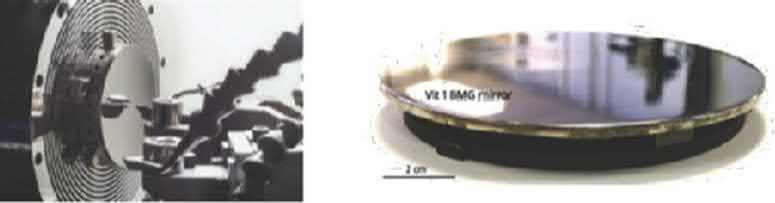

Applicationasmirrors

Metallicglassesweremanufacturedintomirrorsforpossessingtheabilityofcastingintoboththe mirrorsurfaceandbacking,allinonestep.Duetotheexcellentscratchresistanceandpotentiallylow costoffabrication,metallicglassesareinvaluableinspaceapplications.

AnotherapplicationformetallicmirrorsisinITER(“TheWay”inLatin)asoneofthemostambitiousenergyprojectsintheworldtoday.InSouthernFrance,35nationsarecollaboratingtobuildthe world’slargesttokamak,amagneticfusiondevicethathasbeendesignedtoprovethefeasibilityof fusion.AsimilarprojectisunderwayintheUSA.TheobjectiveoftheITERprogramistounderstand andcontrolnuclearfusion.

FIGURE2.1.1

Gearsmanufacturedformetallicglasses.

TwoITERrequirementsonshuttersareunprecedentedoncontemporarymachines.First,plasmanearcomponentsmustwithstandsignificantneutronfluxesoftheorderof1014 s 1 cm 2 withenergies upto14MeV,leadingtovolumetricheatingandmaterialdegradation.Second,accessibilityformaintenanceandreplacementisverylimitedformultiplereasons,requiringthelifetimeofshuttersbe ≥ 20 years.

MetalmirrorsareforeseenforopticaldiagnosticsystemsofITER.However,thesemirrors,subjectedtointenseirradiationbyX-rays,gammarays,neutrons,andchargedparticlesofwideenergy ranges,quicklyloosetheoriginalopticalpropertiesduetosputtering,erosion,deposition,accumulationofgasses,creationofdefects,ionimplantation,etc.Therefore,theselectionofthemirrormaterials reliesprimarilyontheresistancetodegradationthroughplasmaexposures.Amongthemaincandidate mirrormaterialsarehigh-Zmetalslikemolybdenum,tungsten,andrhodium.Laboratoryandtokamakexperimentsshowedthatpolycrystallinemetallicmirrorscouldnotsustaintheirreflectivities undererosion-dominatedconditionsduetotheincreaseinsurfaceroughness.Single-crystalmaterials suchasmolybdenumandtungstenlargelyovercometheheterogeneouserosionproblemofdifferentlyorientatedgrainsandcanpreservetheiropticalpropertiesundererosionconditionsforlongerperiods oftimeasconfirmedbylaboratorytests.

Amorphousalloys,ormetallicglasses,arehomogeneousstructureswithoutgrainboundariesthat maywellresistheterogeneoussputteringanderosions.Bulkamorphousalloyshavelargeglassformingabilitiesandhighstrengthsinsharpcontrasttotraditionalamorphousalloys.Forinstance, bulkamorphousalloyZr41 2 Ti13 8 Cu12 5 Ni10 Be22 5 wasshowntohaverelativeslowdecreaseinspecularreflectivity. Fig. 2.1.2 showsaspacemirrormadefromtheabovemetallicglassalloy.

FIGURE2.1.2

SpacemirrormadefromZr-basedmetallicglass(VitreloyI).

Applicationtocorrosionresistance

Tooptimizetheperformanceandcostswhileminimizingtheweightofthecomponentsinaerospace vehicles,afiber–metallaminateisusedincommercialaircraft,madeupofalternatinglayersoffiberreinforcedpolymer,i.e.,glassfiber-reinforcedepoxyandaluminiummetallicalloy.Thecombination betweencarbonfibercompositeandaluminiumisnotfeasiblebecauseofgalvaniccorrosioninducedat thecontactofthetwomaterialswhensubjectedtodifferentelectricalpotential.Theisotropicstructure andabsenceofcrystalboundariesinmetallicglassesassistcorrosionresistance.IthasbeendemonstratedthatametallicglassreplacingAlexhibitssuperiorcorrosionresistance(approximately20times better)aswellasgoodmechanicalperformance,especiallytheretentionofelasticbehaviortohigher strains,duetotheincorporationofalternativecomponentmaterials.

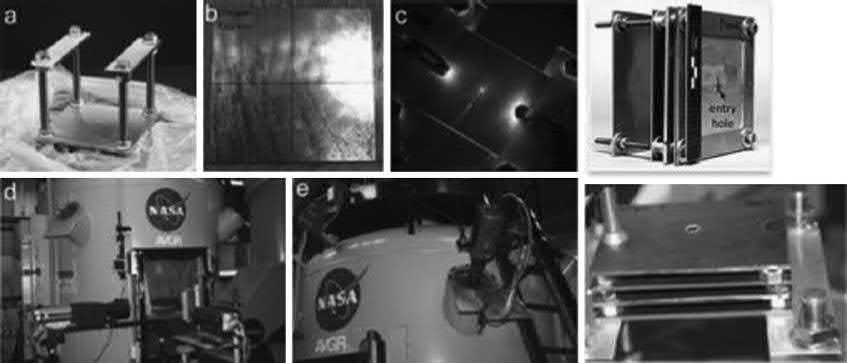

Applicationtosolarwindcollection

Metallicglasseswerefabricatedintotargetstobeexposedtosolarcorpuscularradiationwiththeaim toexploretheactivityofsolarwind,asconductedbyNASAontheGenesisDiscoveryMission.Itis consideredthatmetallicglassespossessvariousexpectedadvantagesthatmeetthedemandsforsolar windcollection.Duetotheisotropicstructureandabsenceofcrystallattice,fractionationandlossof solarwindalongthepreferreddiffusionpathsoncrystalplanesiseliminated.Furthermore,homogeneousetchingallowsthehighresolutiondepthprofilingoftheisotopiccompositionandtheamount ofimplantedsolarnoblegases.Thisdatademonstratesthecompositionalinformationaboutthesolar windandpotentialvariationsasafunctionofenergyoftheradiation.However,itwasalsonotedthat metallicglassisnotperfectlysuitablefortheprecisedeterminationoftheisotopicandelementalcompositionofbulksolarwindnoblegasesasaconsequenceofcorrectionsforlightelementscompared toahighproportionofheavyelementsintheglass. Fig. 2.1.3 showsasolarwindcollectiondevice,of theNASAspacemission,comprisinghexagonalcollectorsmadefromsiliconandotherpurematerials, includingmetallicglass.Otherexamplesofusingmetallicglassesforspaceapplicationsareshownin Fig. 2.1.4.

FIGURE2.1.3

In2004,NASA’s“Genesis”solarwindcollectiondevice.

Applicationasmagneticsensors

Magneticsensorsworkindeepaerospaceexplorationtodetecttheambientmagneticfieldvectoraccuratelyandtodiscriminatethesourcesofstraymagneticfieldsproducedbymechanical,electrical, andelectronicsystemsonaerospacevehicles.Amorphousgiantmagnetoimpedance(GMI)sensors areusedinassembledspacemagneticinstruments.Ontheotherhand,amorphousGMIsensorsare ideallyusedforthecontrolofthegearspeedandprecisedeterminationofthegear-toothpositionin aircraftenginesduetotheultrahighsensitivityandsmallsize.Co-/Fe-basedamorphousribbonsare theidealmaterialsduetotheexcellentsoftmagneticproperties,i.e.,highsaturatedmagnetization, lowcoercivity,highmagneticpermeability,andgoodmechanicalproperties.Whenaerospacevehiclesareworking,somefunctionalcomponents(i.e.,traveling-wavetube,rubidiumclock)areaffected easilybyamagneticfield.Thusmagneticshieldingisnecessarytoprotectthosecomponents.The amorphous/nano-crystallinesoftmagneticmaterialsareapromisingcandidateforuseasshielding materials,inwhichFeNi-/Co-basedamorphousalloysshowbettershieldingeffectiveness.

NASA’sGenesisspacecraftisthefirstmissiontocollectandreturnsamplesofthesolarwind— fastmovingparticlesfromtheSun.Adiskmadeofauniqueformulationofbulkmetallicglasswas createdspeciallyforGenesisinacollaborativeeffortwiththeHowmetCorporation.Thesurfacesof metallicglasseswillbedissolvedevenly,allowingthecapturedionstobereleasedinequallayersby sophisticatedacidetchingtechniques.

Inthe1990s,ametallicglass(Metglass®)wasdevelopedintoalightweightsearch-coilantenna orsensorincludingamulti-turnelectromagneticinductioncoilwoundonaspooltypecoilform.The limitationsoflightweight,size,andlocationareconstrainedbysurvivalinhighstresstypicallyused inspace.Thoughthedensityofametallicglassisabouttwicethatofferrite,only7%asmuchof themetallicglassmaterialisneededforaconfigurationofequaleffectiveness.Theamorphousribbon VITROVAC6025(typicalcomposition,Co66 Fe4 Mo2 Si16 B12 )wasusedinthevectormagnetometer sensoronboardtheAstrid-2satellitemadeasacompactring-coretomapthemagneticfield.Themissions“NewMillenniumProgramme”werelaunchedbyNASAtoestablishtheEarth’smagnetosphere, whereanetworkofnano-satellitesensorsweredesignedin2003forthispurpose.

Spaceapplicationsofmetallicglasses.

TheCo67 Fe3 Cr3 B12 Si15 amorphousalloywasusedtoinvestigatethemodelingofhysteresisloops ofultrahighpermeabilityalloysforspaceapplication.Aring-shapedcorewithasmallcross-section, with400sensingwindings,wasstudiedtoensurehighmeasurementsignal,whichindicatestheJiles–Athertonmodelissuitableformodelingtheultrasoftamorphousalloy.Itwasannouncedthatthisresult isappliedin“SmallExplorerforAdvancedMissions”and“DigitalMagnetometerforMicrosatellites Lemi-020”projectswhichaimtolowerthenoisethroughthedesignanddevelopmentofmagnetic fluxgatesensors.

Applicationassuper-conductingsensor

AprogramwasdevisedbyNASAtomeasureabroadelectromagneticspectrumatsub-millimeterand far-infraredwavelengths.Thus,anactivelycooledanddirectradiationdetectorwithhighsensitivity wasrequired,whichcanaccomplishthetaskssuchasX-raydetectionformedicalimaging,chemicalanalysisforMaterialsScienceatX-raywavelengths,andradiationdetectorsfornuclearforensics. Comparedtothetraditionalstate-of-the-artdetector,super-conductingmetallicglasstransition-edge sensorsCu35 Ti65 andCu60 Zr40 exhibitvariousadvantages,includingimprovedenergyresolution, lowerexcessnoise.Anamorphousalloymayalsobeaself-absorberofradiation(with4dand5dtransitionmetaladditionstoalloy(s)).Itcanpreciselycontrolsuper-conductingtransitiontemperature, Tc , havesimplifieddetectorarchitecture,aswellasmechanicallyandchemicallyrobustdesign.

Ti-basedmetallicglasses,whenmadeintothinpipes,havehightensilestrengthof2100MPa, elasticelongationof2%,andhighcorrosionresistance.Usingtheseproperties,aTi–Zr–Cu–Ni–Sn metallicglasswasusedtoimprovethesensitivityofaCoriolisflowmeter.Thisflowmeterisabout 28–53timesmoresensitivethanconventionalmeters,whichcanbeappliedinfossil-fuel,chemical, environmental,semiconductor,andmedicalscienceindustry.

FIGURE2.1.4