inSynthesisGas:Methods,Technologies andApplications,Volume3:SyngasProductsand UsagesMohammadRezaRahimpour

https://ebookmass.com/product/advances-in-synthesis-gasmethods-technologies-and-applications-volume-3-syngasproducts-and-usages-mohammad-reza-rahimpour/

Instant digital products (PDF, ePub, MOBI) ready for you

Download now and discover formats that fit your needs...

Advances in Synthesis Gas: Methods, Technologies and Applications, Volume 1: Syngas Production and Preparation

Mohammad Reza Rahimpour

https://ebookmass.com/product/advances-in-synthesis-gas-methodstechnologies-and-applications-volume-1-syngas-production-andpreparation-mohammad-reza-rahimpour/ ebookmass.com

Advances in Synthesis Gas: Methods, Technologies and Applications, Volume 2: Syngas Purification and Separation

Mohammad Reza Rahimpour

https://ebookmass.com/product/advances-in-synthesis-gas-methodstechnologies-and-applications-volume-2-syngas-purification-andseparation-mohammad-reza-rahimpour/ ebookmass.com

Advances in Synthesis Gas: Methods, Technologies and Applications, Volume 4: Syngas Process Modelling and Apparatus Simulation Mohammad Reza Rahimpour

https://ebookmass.com/product/advances-in-synthesis-gas-methodstechnologies-and-applications-volume-4-syngas-process-modelling-andapparatus-simulation-mohammad-reza-rahimpour/ ebookmass.com

Chemistry for today Ninth ed Spencer L. Seager

https://ebookmass.com/product/chemistry-for-today-ninth-ed-spencer-lseager/

ebookmass.com

Vincent & Sien Silvia Kwon

https://ebookmass.com/product/vincent-sien-silvia-kwon/

ebookmass.com

Tall, Dark, and Dirty: A Bossy Billionaire Novel A.M. Hargrove

https://ebookmass.com/product/tall-dark-and-dirty-a-bossy-billionairenovel-a-m-hargrove/

ebookmass.com

How International Law Works in Times of Crisis George Ulrich (Editor)

https://ebookmass.com/product/how-international-law-works-in-times-ofcrisis-george-ulrich-editor/

ebookmass.com

Programming for Problem Solving E Balagurusamy

https://ebookmass.com/product/programming-for-problem-solving-ebalagurusamy/

ebookmass.com

(eTextbook PDF) for Peak Performance: Success in College and Beyond 10th Edition

https://ebookmass.com/product/etextbook-pdf-for-peak-performancesuccess-in-college-and-beyond-10th-edition/

ebookmass.com

Liquid-Liquid and Solid-Liquid Extractors 1st Edition

Jean-Paul Duroudier

https://ebookmass.com/product/liquid-liquid-and-solid-liquidextractors-1st-edition-jean-paul-duroudier/

ebookmass.com

AdvancesinSynthesisGas: Methods,Technologies andApplications

Volume3:SyngasProductsandUsages

Editedby

MohammadRezaRahimpour DepartmentofChemicalEngineering,ShirazUniversity,Shiraz,Iran

MohammadAminMakarem MethanolInstitute,ShirazUniversity,Shiraz,Iran

MaryamMeshksar DepartmentofChemicalEngineering,ShirazUniversity,Shiraz,Iran

Contributors

MitraAbbaspour DepartmentofChemicalEngineering,ShirazUniversity,Shiraz,Iran

AmrAbdalla DepartmentofChemicalandPetroleumEngineering,UniversityofCalgary,Calgary, AB,Canada

WaqarAhmad DepartmentofChemicalandBiologicalEngineering,MonashUniversity,Clayton, VIC,Australia

ChayeneGonc ¸ alvesAnchieta PaulScherrerInstitut,Villigen,Switzerland

PrakashAryal DepartmentofChemicalandBiologicalEngineering,MonashUniversity,Clayton, VIC,Australia

NooshinAsadi DepartmentofChemicalandBiologicalEngineering,MonashUniversity,Clayton, VIC,Australia

KorooshAsghari DepartmentofChemicalandPetroleumEngineering,UniversityofCalgary, Calgary,AB,Canada

ElisabeteMoreiraAssaf UniversityofSa ˜ oPaulo,Sa ˜ oCarlosInstituteofChemistry,Sa ˜ oCarlos, Sa ˜ oPaulo,Brazil

JoseMansurAssaf FederalUniversityofSaoCarlos,ChemicalEngineeringDepartment,SaoCarlos, SaoPaulo,Brazil

ManuelBailera DepartmentofMechanicalEngineering,UniversidaddeZaragoza,CampusRı´o Ebro,Bldg.Betancourt,Zaragoza,Spain;GraduateSchoolofCreativeScienceandEngineering, WasedaUniversity,Tokyo,Japan

CarlosGilbertoTemoltzinCaballero MonterreyInstituteofTechnologyandHigherEducation, Puebla,Mexico

JoaoSousaCardoso PolytechnicInstituteofPortalegre,Portalegre;InstitutoSuperiorTecnico, UniversityofLisbon,Lisbon,Portugal

JoseAntonioMayoralChavando PolytechnicInstituteofPortalegre,Portalegre,Portugal

SilviodeOliveiraJunior DepartmentofMechanicalEngineering,PolytechnicSchoolofUniversity ofSa ˜ oPaulo,Sa ˜ oPaulo,Brazil

MeireEllenGoreteRibeiroDomingos DepartmentofChemicalEngineering,PolytechnicSchoolof UniversityofSa ˜ oPaulo,Sa ˜ oPaulo,Brazil

MoisesTelesdosSantos DepartmentofChemicalEngineering,PolytechnicSchoolofUniversityof Sa ˜ oPaulo,Sa ˜ oPaulo,Brazil

SwaritDwivedi DepartmentofChemicalandBiologicalEngineering,MonashUniversity,Clayton, VIC,Australia

DanielaEusebio PolytechnicInstituteofPortalegre,Portalegre,Portugal

AzharuddinFarooqui DepartmentofChemicalandPetroleumEngineering,UniversityofCalgary, Calgary,AB,Canada

CarlaFerna ´ ndez-Blanco ChemicalEngineeringLaboratory,FacultyofSciencesandCentrefor AdvancedScientificResearch(CICA),UniversityofLaCorun ˜ a,LaCorun ˜ a,Spain

DanielA.Flo ´ rez-Orrego DepartmentofMechanicalEngineering,PolytechnicSchoolofUniversity ofSa ˜ oPaulo,Sa ˜ oPaulo,Brazil;FacultyofMinas,NationalUniversityofColombia,SchoolofProcesses andEnergy,Medellin,Colombia;DepartmentofMechanicalEngineering, EcolePolytechnique FederaledeLausanne,Switzerland

ForooghMohseniGhalehGhazi DepartmentofChemicalEngineering,ShirazUniversity,Shiraz, Iran

AshwinHatwar DepartmentofChemicalandBiologicalEngineering,MonashUniversity,Clayton, VIC,Australia

FatemehKhodaparastKazeroonian DepartmentofChemicalEngineering,ShirazUniversity, Shiraz,Iran

ChristianKennes ChemicalEngineeringLaboratory,FacultyofSciencesandCentreforAdvanced ScientificResearch(CICA),UniversityofLaCorun ˜ a,LaCorun ˜ a,Spain

DavidM.Kennes-Veiga CRETUS,DepartmentofChemicalEngineering,Universityof SantiagodeCompostela,SantiagodeCompostela,Spain

HadisehKhosravani DepartmentofChemicalEngineering,ShirazUniversity,Shiraz,Iran

AnandaValleziPaladinoLino FederalUniversityofSa ˜ oCarlos,ChemicalEngineeringDepartment, Sa ˜ oCarlos,Sa ˜ oPaulo,Brazil

PilarLisbona DepartmentofMechanicalEngineering,UniversidaddeZaragoza,CampusRı´oEbro, Bldg.Betancourt,Zaragoza,Spain

NaderMahinpey DepartmentofChemicalandPetroleumEngineering,UniversityofCalgary, Calgary,AB,Canada

MohammadAminMakarem MethanolInstitute,ShirazUniversity,Shiraz,Iran

TayebehMarzoughi DepartmentofChemicalEngineering,ShirazUniversity,Shiraz,Iran

MaryamMeshksar DepartmentofChemicalEngineering;MethanolInstitute,ShirazUniversity, Shiraz,Iran

RafaelNogueiraNakashima DepartmentofMechanicalEngineering,PolytechnicSchoolof UniversityofSaoPaulo,SaoPaulo,Brazil

VirginiaPerez CentrefortheDevelopmentofRenewableEnergy-CentreforEnergy,Environment andTechnologyResearch(CEDER-CIEMAT),Soria,Spain

ElhamRahimpour ShirazUniversityofMedicalSciences,Shiraz,Iran

HamidRezaRahimpour DepartmentofChemicalEngineering,ShirazUniversity,Shiraz,Iran

MohammadRezaRahimpour DepartmentofChemicalEngineering,ShirazUniversity,Shiraz,Iran

TayebeRoostaie DepartmentofChemicalEngineering;MethanolInstitute,ShirazUniversity, Shiraz,Iran

SoniaSepahi DepartmentofChemicalEngineering,ShirazUniversity,Shiraz,Iran

MohammadJavadShahbazi DepartmentofChemicalEngineering,ShirazUniversity,Shiraz,Iran

NazaninAbrishamiShirazi GraduateFacultyofEnvironment,UniversityofTehran,Tehran,Iran

ValterSilva PolytechnicInstituteofPortalegre,Portalegre;CentreforEnvironmentalandMarine Studies(CESAM),DepartmentofEnvironmentandPlanning,UniversityofAveiro,Aveiro,Portugal

AnahitaSoleimani DepartmentofNano-ChemicalEngineering,FacultyofAdvancedTechnologies, ShirazUniversity,Shiraz,Iran

AkshatTanksale DepartmentofChemicalandBiologicalEngineering,MonashUniversity,Clayton, VIC,Australia

Luı´sA.C.Tarelho CentreforEnvironmentalandMarineStudies(CESAM),Departmentof EnvironmentandPlanning,UniversityofAveiro,Aveiro,Portugal

Marı´aC.Veiga ChemicalEngineeringLaboratory,FacultyofSciencesandCentreforAdvanced ScientificResearch(CICA),UniversityofLaCoruna,LaCoruna,Spain ShabnamYousefi DepartmentofChemicalEngineering,ShirazUniversity,Shiraz,Iran

Elsevier

Radarweg29,POBox211,1000AEAmsterdam,Netherlands

TheBoulevard,LangfordLane,Kidlington,OxfordOX51GB,UnitedKingdom 50HampshireStreet,5thFloor,Cambridge,MA02139,UnitedStates

Copyright©2023ElsevierInc.Allrightsreserved.

Nopartofthispublicationmaybereproducedortransmittedinanyformorbyanymeans,electronicor mechanical,includingphotocopying,recording,oranyinformationstorageandretrievalsystem,without permissioninwritingfromthepublisher.Detailsonhowtoseekpermission,furtherinformationaboutthe Publisher’spermissionspoliciesandourarrangementswithorganizationssuchastheCopyrightClearance CenterandtheCopyrightLicensingAgency,canbefoundatourwebsite: www.elsevier.com/permissions.

ThisbookandtheindividualcontributionscontainedinitareprotectedundercopyrightbythePublisher (otherthanasmaybenotedherein).

Notices

Knowledgeandbestpracticeinthisfieldareconstantlychanging.Asnewresearchandexperiencebroadenour understanding,changesinresearchmethods,professionalpractices,ormedicaltreatmentmaybecome necessary.

Practitionersandresearchersmustalwaysrelyontheirownexperienceandknowledgeinevaluatingandusing anyinformation,methods,compounds,orexperimentsdescribedherein.Inusingsuchinformationormethods theyshouldbemindfuloftheirownsafetyandthesafetyofothers,includingpartiesforwhomtheyhavea professionalresponsibility.

Tothefullestextentofthelaw,neitherthePublishernortheauthors,contributors,oreditors,assumeanyliability foranyinjuryand/ordamagetopersonsorpropertyasamatterofproductsliability,negligenceorotherwise,or fromanyuseoroperationofanymethods,products,instructions,orideascontainedinthematerialherein.

ISBN:978-0-323-91878-7

ForinformationonallElsevierpublications visitourwebsiteat https://www.elsevier.com/books-and-journals

Publisher: SusanDennis

AcquisitionsEditor: AnitaKoch

EditorialProjectManager: ZsereenaRoseMampusti

ProductionProjectManager: SruthiSatheesh

CoverDesigner: MarkRogers

TypesetbySTRAIVE,India

Preface

Vol.3:Syngasproductsandusages

Synthesisgas(syngas)anditsproductssuchashydrogenareindispensableinchemical,oil,and energyindustries.Theyareimportantbuildingblocksandserveasfeedstockfortheproduction ofmanychemicalcompoundssuchasammoniaandmethanol.Hydrogenisexpectedtobecome acommonenergycarriernolaterthanthemiddleofthe21stcenturysinceitoffersconsiderable energydensityandreleasesnegligiblepollutants.Itisalsoutilizedinpetroleumrefineriesfor producingcleantransportationfuels,anditsconsumptionisexpectedtoincreasedramatically inthenearfutureasrefineriesneedtointensifyproductioncapacities.Manypublicationshave hithertofocusedonsyngasproductionandpurificationmethods,aswellasitsapplicationsin industrialproductionunits.Despitethefactthatextendedstudieshavebeenundertaken,thereis stillroomforimprovement.Thefourvolumesofthisbookseriesexplaintheconventionaland state-of-the-arttechnologiesfortheproduction,purification,andconversionofsyngas meticulously.

Thedevelopmentofdifferenttechnologiesfortransformingsyngasorthemajoringredients intovalue-addedproductssuchashydrogen,ammonia,ethanol,andmethanolhasattractedthe attentionofresearchersinbothacademicandindustrialcommunities.Thankstotheir undeniablesignificance,manystudieshavebeenhithertodevotedtothedevelopmentofthese processesandthereisawealthofinformationontheconventionaltechnologies,whichshould becollectedinacomprehensivecontribution.However,theprogressthatisbeingmadeata breakneckpaceshouldnotbeoverlooked.Forthisgoaltobeachieved,thisengagingtext touchesonthedetailsofdifferentproductsofsyngas,aswellastheiroperatingconditionsand challenges,andwouldthusserveasaconnectionbetweenthescientistsinresearchlaboratories andtheoperatorsinindustrialplants.

Todoso,thebookisdividedintothreesectionsofchemicalandenergyproductionsfrom syngaswithrelatedchallenges.Thefirstsectionincludesapplicationsandutilizationofsyngas forproducingavastvarietyofchemicalmaterialssuchashydrogen,methanol,ethanol, methane,ammonia,aceticacid,fuelgas,andbiofuel,whilethesecondaddressespower generationinfuelcellseithersolelyorpowerandheatgenerationintandem,aswellasiron reductionindetail.Inthethirdsection,theenvironmentalchallengesofsyngasanditsfuture prospectsandindustrialoutlookarepresented.

Theeditorsfeelobligedtosincerelyappreciatetheauthorsofthechaptersfortheir contributions,hardwork,andgreatassistanceinthisproject.Furthermore,theauthors,aswell astheeditors,aregratefultoalltheElsevierstafffortheirinvaluableandirreplaceable step-by-stepassistanceinpreparingthisbook.

MohammadRezaRahimpour

MohammadAminMakarem

MaryamMeshksar

ReviewerAcknowledgments

Theeditorsfeelobligedtoappreciatethededicatedreviewers(listedbelow)whowereinvolved inreviewingandcommentingonthesubmittedchaptersandwhosecooperationandinsightful commentswereveryhelpfulinimprovingthequalityofthechaptersandbooksinthisseries.

Dr.MohammadHadiSedaghat

SchoolofMechanicalEngineering,ShirazUniversity,Shiraz,Iran

Dr.AliBakhtyari

ChemicalEngineeringDepartment,ShirazUniversity,Shiraz,Iran

Dr.JavadHekayati DepartmentofChemicalEngineering,ShirazUniversity,Shiraz,Iran

Ms.ParvinKiani

DepartmentofChemicalEngineering,ShirazUniversity,Shiraz,Iran

Ms.SamiraZafarnak DepartmentofChemicalEngineering,ShirazUniversity,Shiraz,Iran

AbouttheEditors

Prof.MohammadRezaRahimpour isaprofessorin ChemicalEngineeringatShirazUniversity,Iran.Hereceived hisPhDinChemicalEngineeringfromShirazUniversityin cooperationwiththeUniversityofSydney,Australia,in 1988.Hestartedhisindependentcareerasassistantprofessor atShirazUniversityinSeptember1998.Prof.Rahimpourwas aresearchassociateattheUniversityofCalifornia,Davis, from2012to2017.DuringhisstintattheUniversityof California,hedevelopeddifferentreactionnetworksand catalyticprocessessuchasthermalandplasmareactorsfor upgradingligninbio-oiltobiofuelwiththecollaborationof UCDAVIS.HehasbeenachairoftheDepartmentof ChemicalEngineeringatShirazUniversityfrom2005to2009andfrom2015to2020.Prof. Rahimpourleadsaresearchgroupinfuelprocessingtechnologyfocusedonthecatalytic conversionoffossilfuelssuchasnaturalgasandrenewablefuelssuchasbio-oilsderived fromlignintovaluableenergysources.Heprovidesyoungdistinguishedscholarsfrom developingcountrieswithperfecteducationalopportunitiesinbothexperimentalmethodsand theoreticaltoolstoundertakein-depthresearchinthevariousfieldsofchemicalengineering includingcarboncapture,chemicallooping,membraneseparation,storageandutilization technologies,noveltechnologiesfornaturalgasconversion,andimprovingtheenergy efficiencyintheproductionanduseofnaturalgasinindustries.

Dr.MohammadAminMakarem isaresearchassociateat MethanolInstitute,ShirazUniversity.Hisresearchinterests arefocusedongasseparationandpurification,nanofluids, microfluidics,catalystsynthesis,reactordesign,andgreen energy.Inthegasseparationfield,hisfocusisonexperimental andtheoreticalinvestigationandoptimizationofthepressure swingadsorptionprocess,andinthegaspurificationfield,heis workingonnoveltechnologiessuchasmicrochannels. Recently,hehasinvestigatedmethodsofsynthesizing bio-templatenanomaterialsandcatalysts.Hehascollaborated inwritingandeditingvariousbooksandbookchaptersfor famouspublisherssuchasElsevier,Springer,andWiley,in additiontoguesteditingjournalspecialissues.

MaryamMeshksar isaresearchassociateatShiraz University.Herresearchisfocusedongasseparation,clean energy,andcatalystsynthesis.Inthegasseparationfield,sheis workingonmembraneseparationprocesses,andintheclean energyfield,shehasworkedondifferentreforming-based processesforsyngasproductionfrommethaneexperimentally. Shehasalsosynthesizednovelcatalystsfortheseprocesses, whichhavebeentestedforthefirsttime.Shehasreviewed noveltechnologieslikemicrochannelsforenergy production.Recently,shehaswrittenvariousbookchaptersfor famouspublisherssuchasElsevier,Springer,andWiley.

Introductiontosyngasproductsand applications

HadisehKhosravania,MaryamMeshksara,b,HamidRezaRahimpoura,and MohammadRezaRahimpoura

aDepartmentofChemicalEngineering,ShirazUniversity,Shiraz,Iran bMethanolInstitute,Shiraz University,Shiraz,Iran

1.Introduction

Theextremeuseoffossilfuelsduetothefastindustrialdevelopment,aswellaspopulation increment,hascreatedmanyenvironmentalproblemslikeincreasedglobalwarminggases concentrationintotheatmosphere(CO2,CH4,etc.) [1].Recently,theincreasedrateofCO2 concentration(1.5ppm/year)forcedtheinternationalsocietytodecreasetheconcentrationof greenhousegasesbyloweringtheirproductionsorconsumingtheminotherplants [2–4].Forthis purpose,manyapproacheshavebeenreviewedbybiologicalandchemicalresearchers [5,6].

Synthesisgasasanimportantintermediateorfeedstockinmanymanufacturesorprocessescan bemadefromadiversityofsourcescontainingnaturalgas(NG),coal,oxygen,carbondioxide, ornearlyeachhydrocarbonfeedstock [7].Fromsuchmentionedrawmaterials,NGisthemost commonandthelowestpricedoneforsyngasproduction [8–10].Methaneisthemost importantconstituentofNG,whichmainsourceisreservesofoilandgas,aswellaslandfill gas.Asaresultofabout20%ofglobalwarmingcausedbyCH4 emissionintotheatmosphere, thedevelopmentoftechnologiesforconvertingmethaneintovaluableproductsisessential [11,12].Differentconvectionalprocessesexistforproducingsyngasfrommethane,listedas steamreforming,dryreforming,partialoxidation,inadditiontothenewtechnologieslikethe plasmaprocess [13–16].Assyntheticgasgenerationisveryendothermic,itneedshigh temperaturesandis,therefore,costly [17].In Table1,thesummariesofdifferentsyngas producingprocessesusedinammoniaplantsregardingtheirenergyconsumptionandcosts [18].Byloweringtheactivationenergyofthedesiredreactionsinthesyngasproduction processes,thecatalystplaysakeyroleinincreasingreactionkineticsandachievingamaximum yieldofsyngasproduction.Severaleffortshavebeendonetodevelopcatalyticsystemsthat haveenhancedresilienceforcokeformationandcheaperprecursors.Theseattemptsinclude AdvancesinSynthesisGas:Methods,TechnologiesandApplications. https://doi.org/10.1016/B978-0-323-91878-7.00014-9 Copyright # 2023ElsevierInc.Allrightsreserved. 3

Table1Relativeplantinvestmentcostandenergyconsumptionforvariousfeedstockusedfor syngasproductionforammoniasynthesis [18].

aDependsontheefficiencyoftheelectricitygeneration.

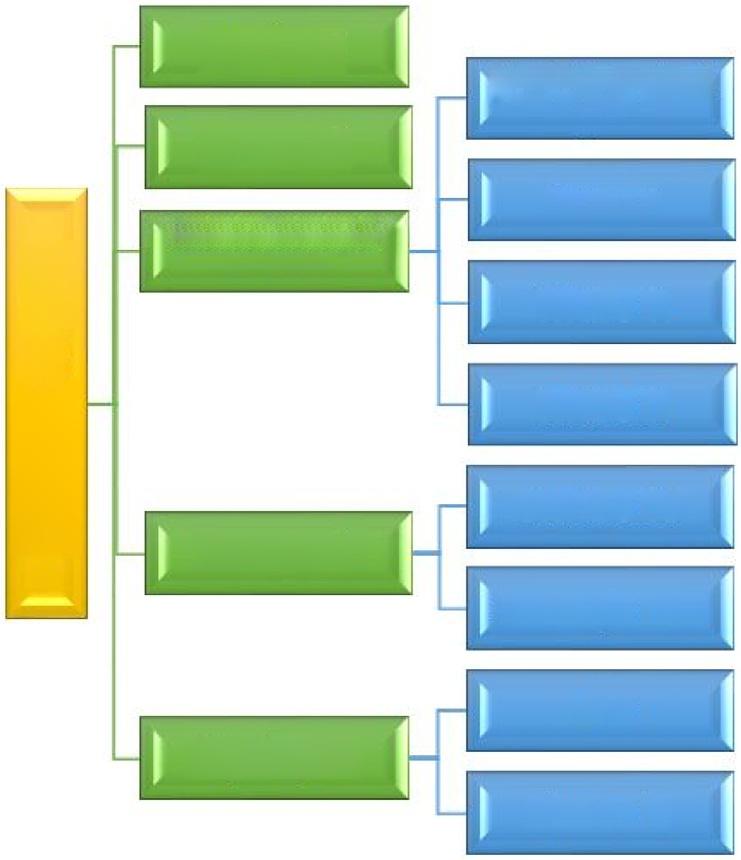

Fig.1 Examplesofchemicalsmadefromsynthesisgas [7].

thealterationofsynthesisconditionsandmethodsinadditiontoapplyingmixedsupport approachesandbimetalliccatalysts [11,19].

Syntheticgasmayproduceabroadrangeofenvironmentallyfriendlychemicalsandfuels, whichconventionaluseshavebeensteadilyincreasing. Fig.1 liststhemostimportant chemicalsproducedfromsyngas.Syntheticgasisagreatsourceofhydrogenthatcanbeusedto makealmostallchemicalsfromhydrogenlikeammonia [3,4].In1910,HaberandBosch developedamethodforproducingammoniafromN2 andH2, andthefirstindustrialammonia

Fuel gas

Town gas

Fischer-Tropsch liquids

Synthesis gas

Synthetic natural

Introductiontosyngasproductsandapplications5

synthesisplantwasbuiltin1913 [20].Besides,themethanol—anotherproductofsyngas—has exhibitedtremendousdevelopmentforsynthesizingmethylethersusedasoctaneboostersin vehiclefuels,despiteremainingthesecond-largestconsumerofsynthesisgas.Fisher-Tropish synthesisisstillthethird-largestconsumerofsyntheticgasinwhichkerosene,naphtha,waxes, etc.,arethemainproducts [7].Inthefollowing,eachapplicationofsyngasisintroducedand discussedinmoredetail.

2.Chemicalsfromsynthesisgas

Asmentioned,differentchemicalsareproducedfromsyntheticgas,whichareintroducedinthe followingsectionswiththeirproductionmethodsindetail.

2.1Hydrogen

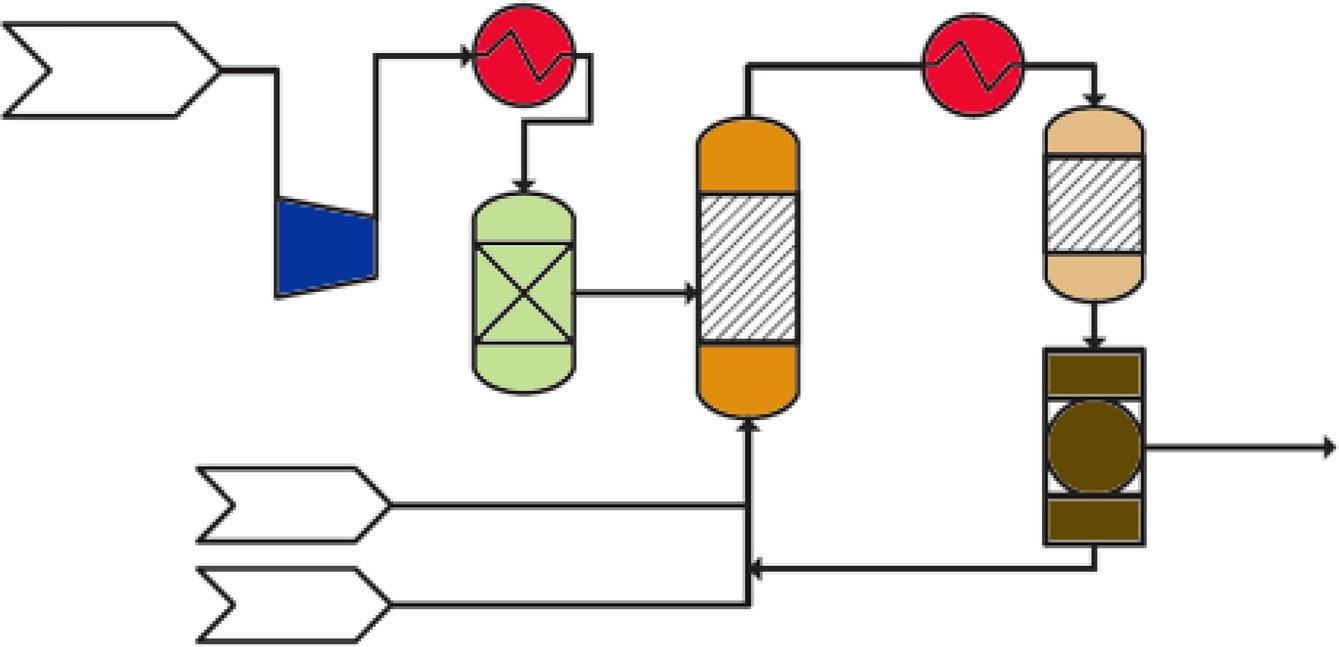

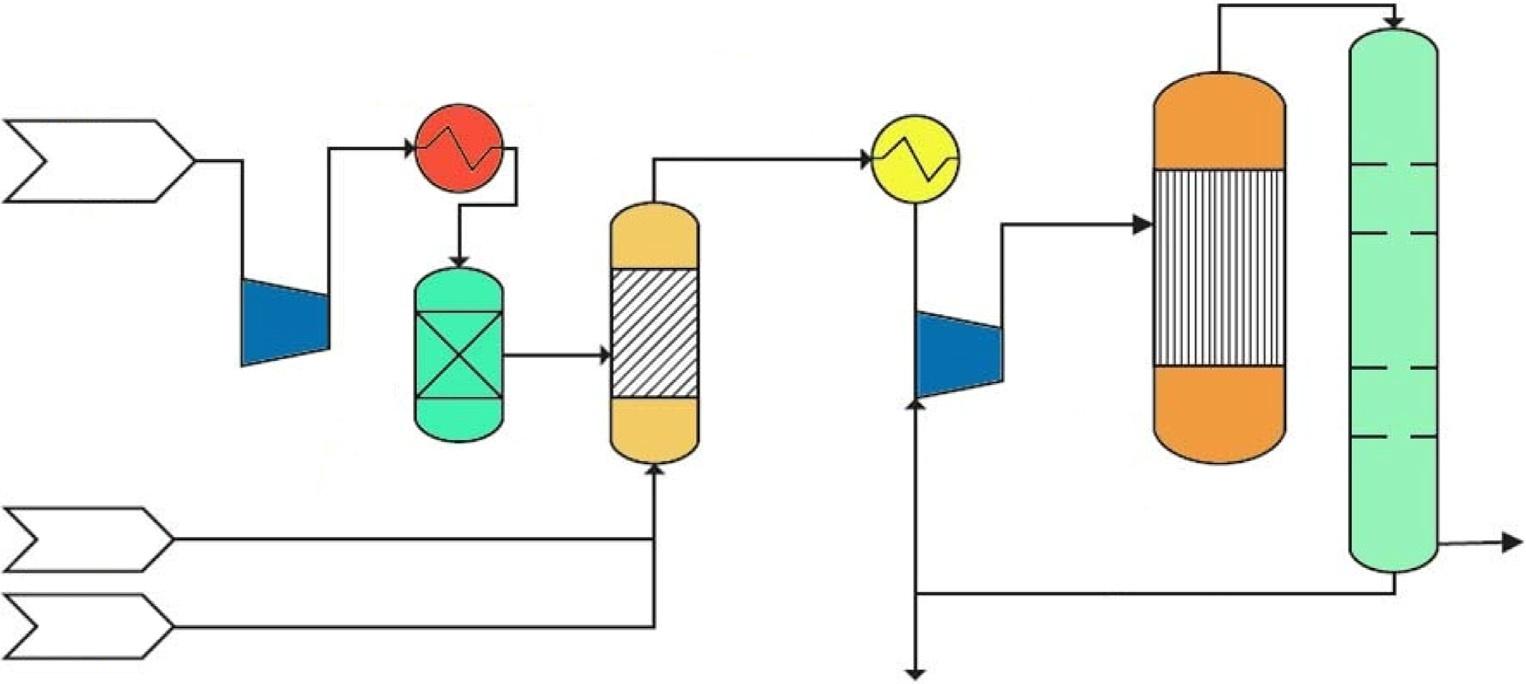

Hydrogenislargelyusedintheproductionofammoniaandmethanol,aswellasin petroleumrefining.Itcanbealsobeutilizedtogenerateenergyorbeappliedasa transportationfuel.Inadditiontovarioushydrogenapplicationslistedin Table2 ,its differentproducingmethodsarealsomentioned.Amongdifferentprocesseslisted previouslyforhydrogenproduction,80%–85%ofhydrogenneededindifferentfactories comesfromSMR(steammethanereforming),whichisshownin Fig.2[21].Different separatingmethodscanbeusedforproducinghigh-purityH2 fromsyngas,suchaspressure swingadsorption(PSA)andmembrane-basedt echnologies,eachofwhichisdiscussedin moredetailinthefollowing.

2.1.1Swingadsorptiontechnologies

PSA,themostmaturecyclicadsorptiontechnology,hasbeenwidelyappliedforgas separationandpurification.Theadsorption-desorptioncycleisachievedbythedropin solidadsorptioncapacitywithdecreasingpressure.PSAprocesseshavebeensuccessfully appliedinseveralprocessestoseparatevariousgasmixtures,suchasCO2 capture, olefin-paraffinseparation,methanerecovery,NGupgrading,andairseparation.PSAhas becomethemostwidespreadtechnologyusedtoproducehigh-purityH 2 fromagas mixture.Currently,PSAtechniquesareusedinover85%ofglobalH 2 plantsfor high-purityH 2 production [22] .

Thistechnologycanbearrangedintosingleormulticolumnarrangementsthatdependonthe numberofadsorbers.MulticolumnPSAunitshaving4–12parallelcolumnsarefrequentlyused forindustrialapplications,asforlarge-scaleplants,continuousoperationisdesired. Fig.3 showsatypicaldouble-bedPSAsetup:oneadsorbingwhiletheotherregenerates [20].

ForseparatingH2 fromsyngas,high-pressuresyngasisfedintothePSAabsorber,andits impuritiesmainlyconsistofCO,CO2,CH4,andN2 areselectivelyadsorbedonthesurfacesof

Table2Differentapplicationsandproducingmethodsofhydrogen [7].

Hydrogenapplications

Naphthahydrotreater:

• Hydrogenisusedtodesulfurizenaphthafromatmosphericdistillation;thenaphthamustbehydrotreated beforebeingsenttoacatalyticreformerunit.

Distillatehydrotreater:

• Afteratmosphericorvacuumdistillation,desulfurizesthedistillates;insomeunits,aromaticsare hydrogenatedtocycloparaffinsoralkanes.

Hydrodesulfurization:

• AsafeedforClausplants,sulfurcompoundsarehydrogenatedtohydrogensulphideH2S.

Hydroisomerization:

• Toimprovetheproduct’scharacteristics,normal(straight-chain)paraffinistransformedintoisoparaffins (e.g.,octanenumber).

Hydrocracker:

• Hydrogenisusedtoconvertheavyfractionsintohighervalue,lowerboilingproducts.

Hydrogenproduction

Catalyticreformer:

• Hydrogenisproducedasaby-productoftheconversionofnaphtha-boilingrangemoleculesintohigher octanereformate.

Steam-methanereformer:

• Hydrogenisproducedforthehydrocrackerorthehydrotreaters.

Steamreformingofhydrocarboncompoundswithagreatermolecularweight:

• Otherthanmethane,itproduceshydrogenfromlow-boilinghydrocarbonderivatives.

Off-gasesfromrefineriescanberecovered:

• Hydrogenintherangeof50%(v/v)iscommoninprocessgas.

Gasificationofpetroleumresidua:

• Gasificationunitsproducesynthesisgas,whichcanberecovered.

Gasificationofpetroleumcoke:

• Ingasificationunits,synthesisgasisrecovered.

Partialoxidationprocesses:

• Producesynthesisgasfromwhichhydrogencanbeextracted,similartothegasificationprocess.

theadsorbingbed.Therefore,theproductofthefirstcolumnishighpurityH2.Adsorption typicallyoccursatrelativelyhighpressure(20–50bar)andupto50–60°Ctemperature [23].In continuousadsorption,thesyngasfeedstreamisswitchedtoanotherbedbyreachingthe adsorbentscapacitytoitssaturationamount.Then,thesaturatedadsorbentsarerecoveredvia depressurizationaidedthroughapurge-gassupplyforreleasingthetrappedimpuritiesinto

adsorbents.Thesereleasedgasesarecalledoff-gas.PartoftheH2 feed-stream(usuallyupto 20%)maybelostintheoff-gas,dependingontheoperatingcondition.Off-gasiscommonly partiallyburntinthereformerorappliedasaheatsource,avoidingunnecessaryemissions.The COcontentinthetail-gasimprovesthereformerflamestabilityandenhancesthereforming equilibrium [14].

DespitegoodadvantagesofPSAtechnology,includingrelativelysimpleoperation,notable performanceatambienttemperatures,highregenerationefficiency,equipmentcompactness, andlowenergyintensity,ithassomedrawbackslistedashighsyngaslossesinthebedafter purginginthedepressurizationstep,lowH 2 recoveries,andlimitedimpuritiessorptioninto theadsorbents [2].Therefore,acompleterecoveryofH2 bycouplingPSAwithother separationtechnologiesishighlydemanded.Membranetechnologiesoffersignificant advantagesforH 2 purificationwiththeirtypicallyhighrecoveryrates,facileoperation,and energyefficiency [4].Therefore,byusingmembranereactorsinthesyngasproducingunit, thenumberofstageswillbereducedasbothpurificationandproductionstepsoccur simultaneouslyatthesametime.

2.1.2Membrane-basedtechnologies

Membranesactasaphysicalbarrierthatallowmassspeciesselectivetransport,whichare widelyappliedforpurificationandseparationinmanyindustries.Membranesaredividedinto threecategories:inorganic,organic,andhybridsoforganic/inorganicmembranes.Inorganic membranescanbeclassifiedintoceramicandmetallicconstituents,whileorganiconesare

Pre-heater Syngas (H2, CO, CO2)

Fig.2

SchematicofSMRforH2 production [20]

Fig.3

TypicalPSAdouble-bedarrangementforH2 recovery [22]

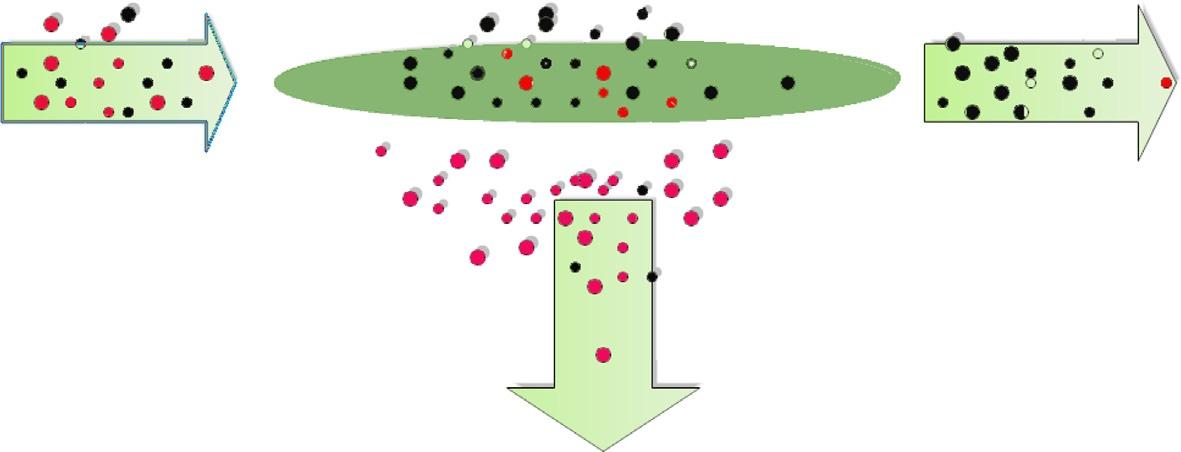

dividedintobiologicalandpolymericmembranes.Membraneperformanceintheseparation processisshownin Fig.4,inwhichthedrivingforceistheconcentrationoffeedstockspeciesor pressuregradient [24].

Thecriterionforselectingamembraneisbasedonitsapplication.Importantpropertiesof membranesincludingmechanicalintegrityanddurability,aswellasseparationselectivityand productivity,mustbebalancedagainsttheircost [25].However,permeance(permeationrate) andselectivityarethemainpropertiesofmembranes.

Pt-basedmembranes,denseceramicmembranes,andmicroporousmembranesarethreemajor typesofH2 separatingmembranesinwhichtheresearchershaveprimarilyfocusedonsolving

Syngas

Column Adsorbing

Pure Gas

Valve close

Column Regenaration

Open

Membraneperformanceforseparatinggasescomponents [24]

theirmajorchallenges,includingmaximizinghydrogenfluxandselectivity,aswellas minimizingmembranecostandmembranefailurecreatedbythechemicalinteractionsor thermalcycling [26].Thecharacteristicsandoperatingconditionsofthesethreemembranesare summarizedin Table3.Thegenericdrawbackofthesemembranesisrecoveryofhydrogenat lowpressure,whichisappropriateforfuelcellapplications,forprocesseswherehigh-pressure hydrogenisrequired,H2 needstobecompressedbeforebeingapplied.However,the pressurizationofhydrogenisdifficultandneedshighcostsasithassmallmolecularsizes.

MorecompleteCOtoH2 shiftisrequiredinasinglereactorforremovinghydrogenina membranereactor.Thisreactionisexothermic,soH2-membranesneedheatremovaltoprevent catalystdeactivationcausedbycokeformationorsinteringathightemperatures.Thisisa significantchallengeoffixed-bedreactorsasinthesesystems,hotspotsareformedbecauseof gasesmixinglessthanidealandnaturalheatflowintothereactor [20].

2.2Methanolproduction

Methanol,alsoknownasmethylalcoholormethylhydratewiththeformulaCH3OH,isthe simplestalcohol.Itisacolorless,light,volatile,flammable,andtoxicmaterial.Methanol consistsofamethylgrouplinkedtoapolarhydroxylgroupandisapolarchemical,thusis completelysolubleinwaterandorganicsolventsandonlyslightlysolubleinfatandoil [27]. Methanolhasamolecularweightof32.04,anoctanenumberof113,anditsdensityisabout halfthatofgasoline.Itcanbeusedasatransportationfuelintheroleofadditivetogasoline. Combining10%methanolwith90%gasolinecancauseanoctanenumberupto130.Any additionalpercentageofmethanoltofueladvancestheperformanceofinternalcombustion engines(ICE)andreducesthepollutantssuchashydrocarbons,NOx,SOx,and particulates [23].

Methanol,asthesecondmostcommonsynthesisgasproductafterhydrogen,canbeconsumed asasolvent,chemicalfuel,aswellasbeingappliedasarawmaterialindifferentindustrieslike formaldehyde,methyltert-butylether(MTBE),aceticacid,dimethylether(DME),methyl,

Fig.4

Table3CharacteristicsofH2 membranes [20]. Dense ceramic membrane Ceramic membraneMicroporousmembraneMetallicmembrane

Materials Silica, perovskite MixedofPd withdense ceramic Zeolites,silicaonceramicPd,Pd-Ag,orPd-Cuon ceramicorstainlesssteel

Operating tempeature (°C)

H2 flux (ft3H2/ ft2membrane × 100psi)

Chemical stability HighMedium tolerantto feedstream impurities

Hightoleranttosulfur, carbonatesathigh temperaturesareformedby thereactionofsome membraneswithCO2

Low,reductioninH2 flux athightemperatures,Pd alloyismoreefiicient

Low,COandsulfurare twomajorpoisonsofPd, sidereactionsand defectionsareoccurred byalloys

Cost LowMediumLowHigh(forpurePd)to medium(foralloys)

vinylacetates,methylmethacrylate(MMA),methylamines,melamineresin,ethylene,and propyleneproduction.Asmethanolhasanimportanteffectonenergy-relatedconversionand therateofenergyrequirementhasbeenincreased,thedevelopmentofmethanol-synthesizing industrieswithlowercostsisanurgentnecessityinthefuture.

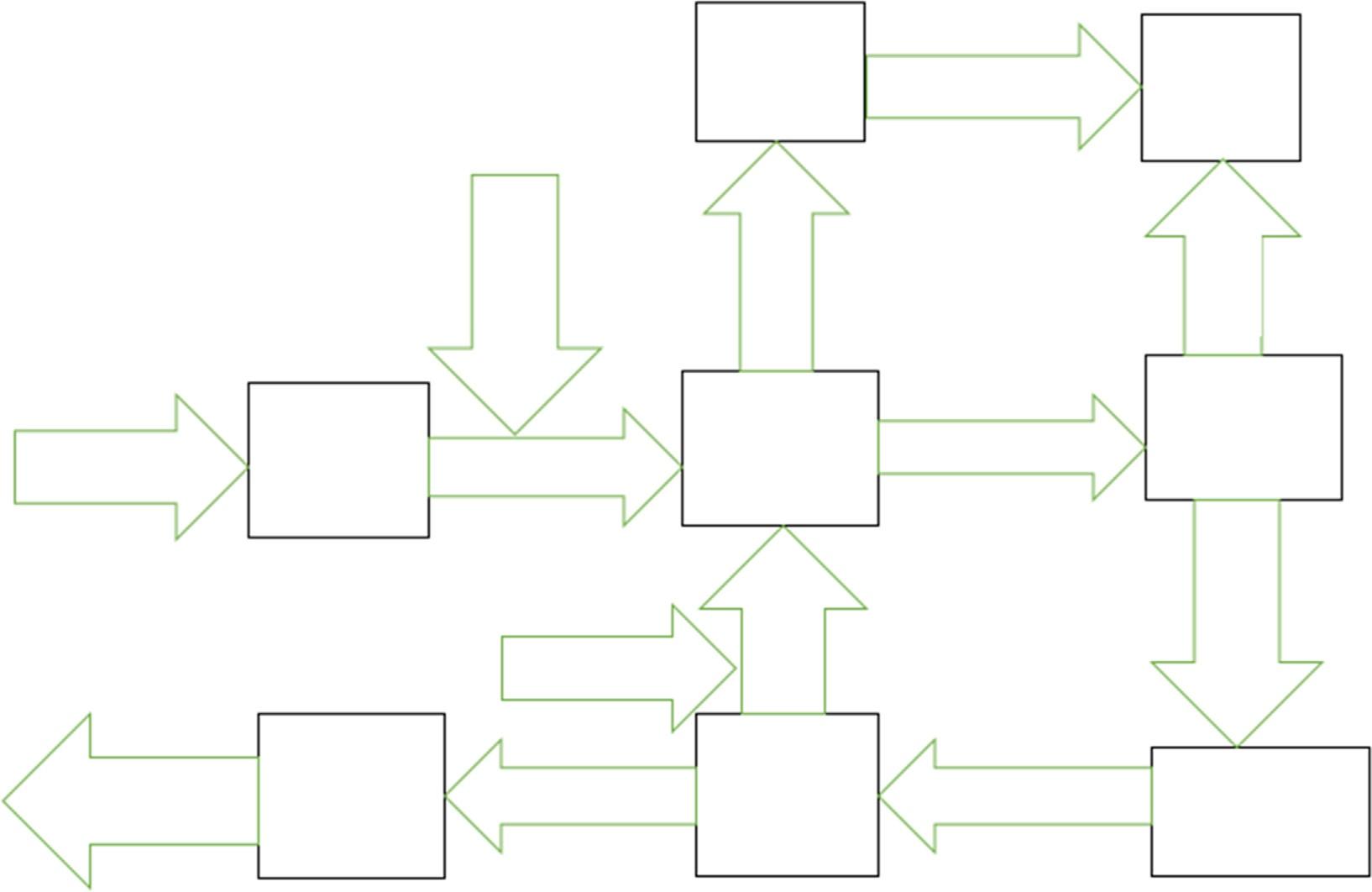

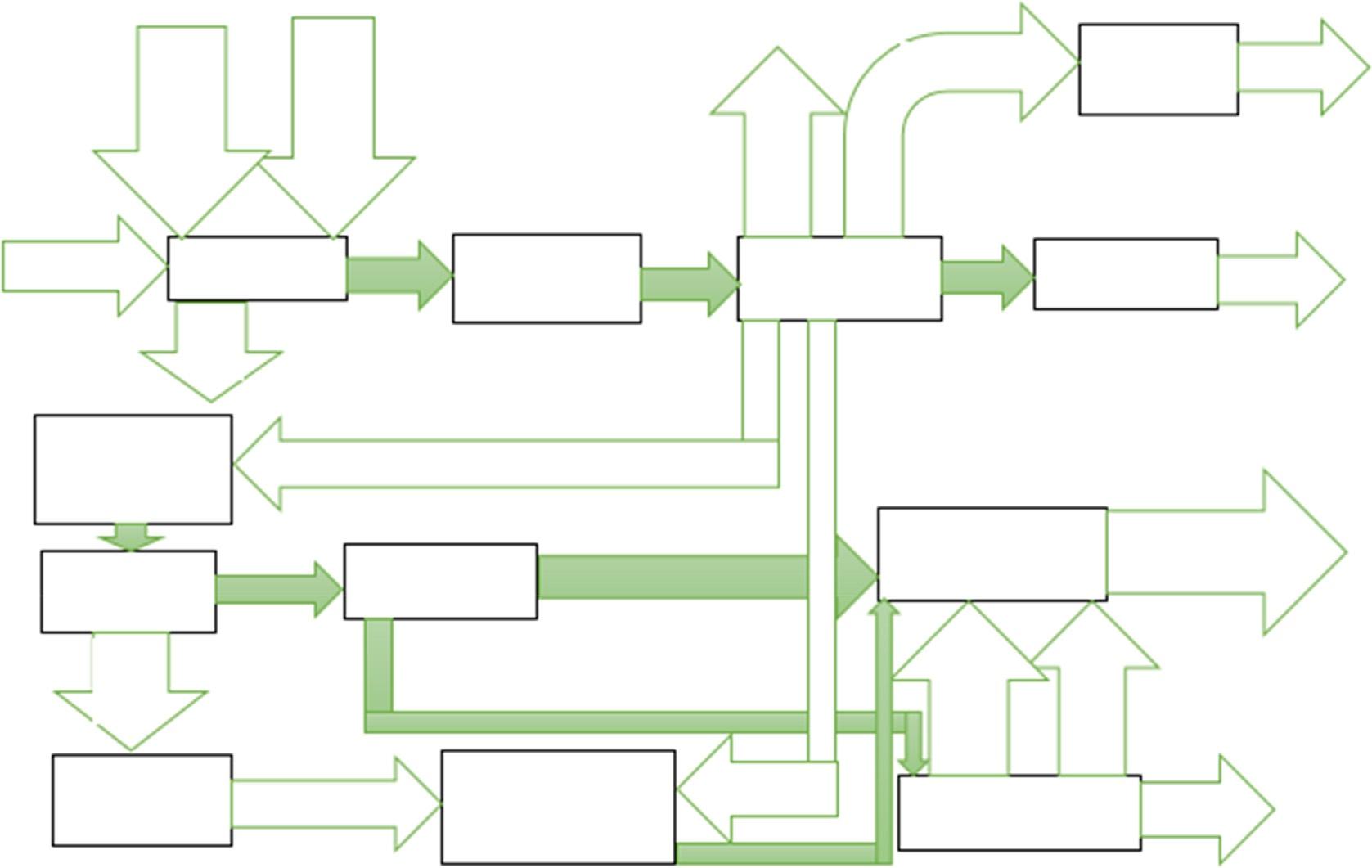

Methanolsynthesisprocedurecanbesummarizedinthreestepsasfollows,whichdetailsare illustratedin Fig.5:

• Synthesisgasproduction

• Methanolsynthesis

• Productseparation/purification

Aspreviouslymentioned,synthesisgascanbeobtainedbyNGorliquidhydrocarbons reformingorcoalorbiomassgasification.Themostwidelyusedrouteforsyngasproductionis steamreformingofNG,commonlyreferredtomethanesteamreforming(MSR),bywhich morethan75%ofsyngasareproduced [29].Inthefollowing,methanolsynthesisplantsare discussedinmoredetail.

Fig.5

Stepsintheconventionalmethanolproductionprocess [28]

2.2.1Methanolsynthesisplant

Methanolsynthesisisoriginallyahigh-pressureprocess,initiallyworkedundertemperature 320–450°Candpressure250–350bar,whichwasfirstdevelopedin1923 [30].Intheprocess, ZnO/Cr2O3 catalystswerewidelyusedduetotheiruniquecharacteristics,includinghigh temperatureandmechanicalresistance.Thehigh-operatingpressurebalancesoutthe decrementinmoles.Ashigh-pressureprocessesrequirehighinvestmentinoperatingcostsand factorydesign,low-pressureprocessesreceivedmuchattention.Thelow-pressureprocess worksattemperatureof200–300°Candpressureof50–100bar.Despitetheadvantagesof workingatequilibriumconditionswhichoperateatlowtemperatures,theactivityofthe catalystsdecreasesintensively.Byincreasingthereactiontemperature,thecatalystactivityis enhanced,resultinginacatalystdeactivationbycokedeposition [31].Therefore,the optimizationofreactiontemperatureandalsoitspressureisanimportantissueinthisprocess. Thelow-pressureprocesswastheonlyprocessemployedinthemarketby1999.Accordingto thistechnologyemployment,syngasshouldbewashed,compressed,andheatedbeforebeing usedasarawmaterialofthemethanolsynthesisprocess.Thisfreshfeedismixedwithrecycled unreactedsyngasandsenttoamethanolconverterwherethefollowingreactionsaretaken place [32]:

COreduction(Eq. 1)isanexothermalprocesslimitedbyequilibriumandfavoredatlow temperaturesinthegasphase.Toachieveareasonableindustrialconversionrate,theuseofan appropriatecatalystandoperatingconditionisessential [33].Theappliedcatalystinthe low-pressuremethanolsynthesisprocessisbasedoncopperoxide,zincoxide,andalumina (CuO/ZnO/Al2O3).Theselectivityofthiscatalysttowardmethanolisquitehigh.However,the selectivityperpassconversionislowforcommercialplants,necessitatingproductrecycling. Fig.6 showsatypicalmethanolsynthesissection.

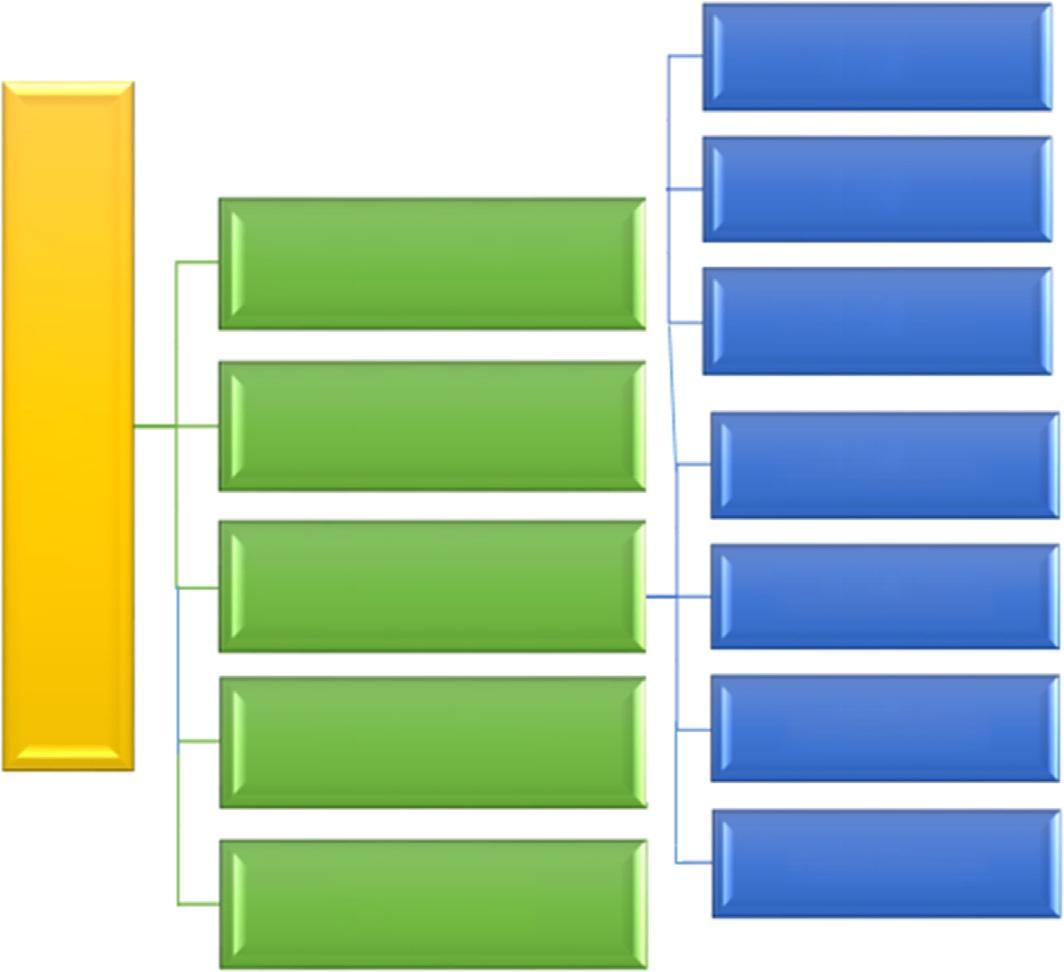

2.2.2Separationandpurificationsection

Theproducedmethanolisnotpure,andtheimpurities,includingdissolvedgases,hydrogen, andwater,mustberemovedbeforetheproducedmethanolisapplied.However,theamountof lateralcurrentpresentinthesynthesizedmethanolislowundernormaloperatingconditions. Therefore,severaldistillationcolumnsareneededtoseparatelow-boilingimpuritiesfrom methanol.Thephysicallydissolvedgasesareflashedoffinaflashvessel [34].Aftertheflash vesselisdistilledinatwo-stagesystem,thestabilizedmethanolisfirstunderpressureand secondatatmosphericpressuretoobtainaspecificpurification.Afterward,thehigherboiling pointcomponentsareremovedinadistillationcolumn.Theprocessflowsheetofsucha methanolpurificationplantisshownin Fig.7.

Steam/Reformed

Gas Reboiler

Steam/Reformed

Gas Reboiler Crude Methanol

Atwo-stagemethanoldistillationprocessflowdiagram [35].

2.2.3Methanoltogasoline

Althoughmethanolcanbeusedasatransportationfuel,currentneeds(withoutengine modifications)dictateconvertingthemethanoltoimmediatelyusablegasoline [36].The conversionofmethanoltogasoline(MTG)isbasedonappropriatecatalysts,including zeolite-basedones.Thetechnologyofproducinggasolinefromcoalviamethanolinterstage productioninvolvescoalgasificationbythereactionofoxygenandsteamunderpressurein whichthecompositionofthesynthesisgasproducedisadjustedbyashiftreaction(which convertscarbonmonoxideandsteamtohydrogenandcarbondioxide)(Fig.8).Afterward,the producedsyngasispurifiedandthenconvertedtomethanol.Thecrudeintermediatemethanol, whichcontainsabout15%water,isthenfedtotheM-Gasolineunitandconvertedtothe gasolineend-productinatwo-stagefixed-bedconversionprocess.

Inordertoconvertmethanoldirectlytohigh-octanegasoline,theMobilMTGprocesshasbeen developedinwhichbothfluidized-bedandfixed-bedreactorshavebeenused(Fig.9).Inthis process,methanolisfirstdewateredtoproducedimethylether,andthenfurtherdewatering withaZSM-5catalystendstoaseriesofC5+ hydrocarbonproduction.Zeolitecatalystshavean importantroleincontrollingthedistributionofhydrocarbonproductsduetotheirspecific geometryandsizepores.Therefore,moleculeswithlargersizesthanzeoliteporescannotbe madeinthisprocess.Aftervaporization,themethanolfeedstockisfedtothefirstconverterfor

Fig.7

Senthesis

Fig.8 M-Gasolineprocess [37].

Fig.9 TheMobilMTGprocess [36].

convertingtodimethylether,H2O,andunreactedmethanolmixtureatoperatingconditionsof 300psiand300°C.ThisreactioncanbeseeninEq. (4)[37]

Afterthat,thefirst-stageproductismixedwitharecycledstreamandsenttoasecond-stage converter.Whilethetemperatureattheentranceisaround345°C,theoutflowtemperatureis around400°C,whichisfilledwithacatalystforgasolinecomponentsproduction.Severalchain stepsoccurherefractionationofarawproduct,alkylationoflightends,hydrationofa recovered,andblendingproductsforproducinggasoline. Fig.9 illustratesthemethanolto gasolineprocessinwhichvaporizedmethanolfirstmovesupwardfromacatalyticbedata pressureof25psiandatemperatureof415°C,andthenconvertedtowaterandhydrocarbons. Afterthereaction,thecatalystisremovedfromtheproductsatthetopofthereactor,thenthe overheadproductiscondensedandseparatedfromwaterandsmallquantitiesofcoke(Fig.10). Thecatalyst’sselectivityisanessentialfactorintheM-gasolineprocessforhavinghigh-octane gasoline.ThisselectivityishigherthanthatofthetraditionalFTcatalystsastheselectivityof Mobilcatalystsisabout85%,whereasFTcatalystshavea50%selectivity [37].

Methanol + ether (0.2)

Gasoline(CS+)(60)