AdvancesinAdditive Manufacturing: ArtificialIntelligence,

Nature-Inspired, andBiomanufacturing

Editedby

AjayKumar

DepartmentofMechanicalEngineering,SchoolofEngineering,JECRCUniversity,Jaipur, Rajasthan,India

RaviKantMittal

(RetiredProfessor)DepartmentofMechanicalEngineering,BirlaInstituteofTechnologyandScience, Pilani,Rajasthan

AbidHaleem

DepartmentofMechanicalEngineering,JamiaMilliaIslamia,NewDelhi,Delhi,India

SeriesEditor

MaQian

Elsevier

Radarweg29,POBox211,1000AEAmsterdam,Netherlands

TheBoulevard,LangfordLane,Kidlington,OxfordOX51GB,UnitedKingdom 50HampshireStreet,5thFloor,Cambridge,MA02139,UnitedStates

Copyright©2023ElsevierInc.Allrightsreserved.

Nopartofthispublicationmaybereproducedortransmittedinanyformorbyanymeans,electronicormechanical,including photocopying,recording,oranyinformationstorageandretrievalsystem,withoutpermissioninwritingfromthepublisher. Detailsonhowtoseekpermission,furtherinformationaboutthePublisher’spermissionspoliciesandourarrangements withorganizationssuchastheCopyrightClearanceCenterandtheCopyrightLicensingAgency,canbefoundatourwebsite: www.elsevier.com/permissions .

ThisbookandtheindividualcontributionscontainedinitareprotectedundercopyrightbythePublisher(otherthanasmaybe notedherein).

MATLABs isatrademarkofTheMathWorks,Inc.andisusedwithpermission.TheMathWorksdoesnotwarranttheaccuracyof thetextorexercisesinthisbook.Thisbook’suseordiscussionofMATLABs softwareorrelatedproductsdoesnotconstitute endorsementorsponsorshipbyTheMathWorksofaparticularpedagogicalapproachorparticularuseoftheMATLABs software. Notices

Knowledgeandbestpracticeinthisfieldareconstantlychanging.Asnewresearchandexperiencebroadenourunderstanding, changesinresearchmethods,professionalpractices,ormedicaltreatmentmaybecomenecessary.

Practitionersandresearchersmustalwaysrelyontheirownexperienceandknowledgeinevaluatingandusinganyinformation, methods,compounds,orexperimentsdescribedherein.Inusingsuchinformationormethodstheyshouldbemindfuloftheir ownsafetyandthesafetyofothers,includingpartiesforwhomtheyhaveaprofessionalresponsibility.

Tothefullestextentofthelaw,neitherthePublishernortheauthors,contributors,oreditors,assumeanyliabilityforanyinjury and/ordamagetopersonsorpropertyasamatterofproductsliability,negligenceorotherwise,orfromanyuseoroperationof anymethods,products,instructions,orideascontainedinthematerialherein.

ISBN:978-0-323-91834-3

ForInformationonallElsevierpublications visitourwebsiteat https://www.elsevier.com/books-and-journals

Publisher: MatthewDeans

AcquisitionsEditor: DennisMcGonagle

EditorialProjectManager: AprilGraceMorquin

ProductionProjectManager: SajanaDevasiPK

CoverDesigner: ChristianJ.Bilbow

TypesetbyMPSLimited,Chennai,India

PartI

Introduction

1.Introductiontoadditive manufacturingtechnologies3

RasheedatM.Mahamood,T-C.Jen,S.A.Akinlabi, SunirHassanandEstherT.Akinlabi

1.1Introduction3

1.2Briefhistoryofadditivemanufacturing4

1.3Classesofadditivemanufacturing4

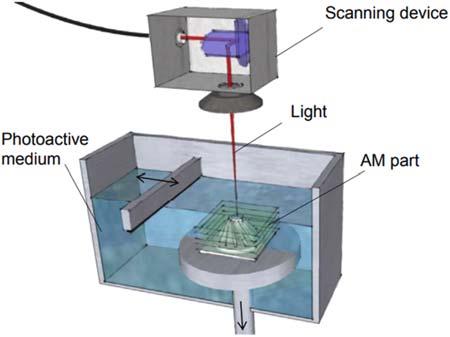

1.3.1Vatphotopolymerization4

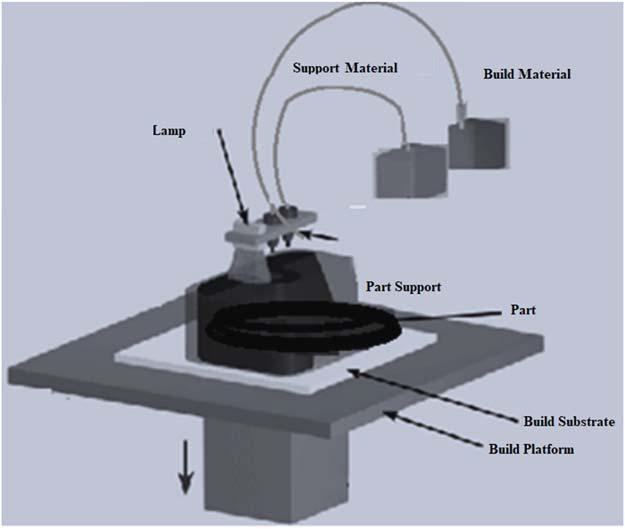

1.3.2Materialjetting5

1.3.3Binderjettingprocess5

1.3.4Materialextrusion6

1.3.5Sheetlamination6

1.3.6Powderbedfusion6

1.3.7Directedenergydeposition(DED)7

1.4Areasofapplicationofadditive manufacturing8

1.4.1Foodsandhousing9

1.4.2Healthcare10

1.4.3Automobilesandaerospace10

1.4.4Electronics10

1.4.5Consumersproductandjewelry10

1.5Summary11 References11 Furtherreading13

2.Trendsinadditivemanufacturing: anexploratorystudy15

MohdShoeb,LokeshKumar, AbidHaleemandMohdJavaid

2.1Introduction15

2.2Researchobjectivesofthechapter16

2.3Comparisonofadditivemanufacturing withtraditionalmanufacturingprocesses16

2.4Additivemanufacturing16

2.5Whatandwhyofadditivemanufacturing17

2.6Developmenttrendsinadditive manufacturing17

2.7Classificationofadditivemanufacturing methodsbasedonmaterialcharacteristics18

2.7.1Powder-basedadditive manufacturing18

2.7.2Liquid-basedadditive manufacturing19

2.7.3Solid-/filament-basedadditive manufacturing20

2.8Extensivecapabilitiesofadditive manufacturinginthecurrentscenario20

2.9Applicationareasofadditive manufacturing20

2.9.1Medicalmanufacturing21

2.9.2Aerospaceandautomotive manufacturing21

2.9.3Architecturalandjewelry manufacturing21

2.10Challengesbeingtakenupbyadditive manufacturing21

2.11Futureapplicationsandtechnologiesof additivemanufacturing23

2.12Conclusion23 References23 Furtherreading25

3.Addictivemanufacturinginthe

Health4.0era:asystematicreview27

VineetJain,PuneetaAjmera, SheetalKalraandSheetalYadav

3.1Backgroundandintroduction27

3.2Additivemanufacturingprocessand technologies28

3.3Applicationinthehealth-careindustry28

3.4Materialsandmethods29

3.4.1Informationsources29

3.4.2Searchstrategyandstudyselection30

3.4.3Datacollectionprocess30

3.5Results31

3.6Discussion37

3.6.1Globaladditivemanufacturing market38

3.6.2Advantagesofadditive manufacturingprocesses38

3.6.3Challengesofadditive manufacturingprocesses39

3.6.4Roleofadditivemanufacturing duringpandemicCOVID-1939 3.7Conclusion40 References40

4.Integrationofreverseengineering withadditivemanufacturing43

AjayKumar,ParveenKumar,HariSingh, AbidHaleemandRaviKantMittal

4.1Introduction43

4.2ConceptofRE44

4.3ProductdevelopmentbyREandAM45

4.4IntegratingREwithAM46

4.4.1IntegrationofREandAMby constructinga3DCADmodelfrom thepointcloudandobtainingan STLmodelfortheAMsystem46

4.4.2IntegratingREandAMbydirect generationofSTLmodelfilefrom pointcloud52

4.4.3IntegrationofREandAMbyDirect ConversionofDataPointsto SlicedFile53

4.5DatadigitizationtechniquesinRE55

4.5.1NoncontactdataacquisitionRE techniques56

4.6Summary63 References63

PartII

Additivemanufacturing technologies

5.Recentinnovativedevelopmentson additivemanufacturingtechnologies usingpolymers69

CarmenM.Gonza ´ lez-Henrı´quez, DanA.Pe ´ rez-Monje,FernandoE.Rodrı ´ guezUmanzor,MauricioA.Sarabia-Vallejosand JuanRodrı´guez-Herna ´ ndez

5.1AbriefintroductiontoAMtechnologies69

5.2AMmarketandinnovationopportunities70

5.3InnovativeAMtechnologies71

5.3.1AMbasedonFDMorfusedfilament fabrication71

5.3.2AMbasedonVAT photopolymerization:SLAor digitallightprocessing(DLP)77

5.3.3AMbasedonpowderbedfusion (PBF)orSLS83

5.4Conclusionsandfutureperspective84 Acknowledgments84 References84

6.Printingfileformatsforadditive manufacturingtechnologies87

AjayKumar,ParveenKumar,RaviKantMittaland HariSingh

6.1Introduction87

6.23Dmodelrepresentationdataformatsin additivemanufacturingtechniques88

6.2.1Standardtessellationlanguage format88

6.2.2Additivemanufacturingformat90

6.2.33Dmanufacturingformat92

6.2.4OBJformat92

6.2.5Virtualrealitymodelinglanguage format92

6.2.6JupiterTessellationformat93

6.2.7Extensible3Dformat93

6.2.8CubitalFacetListformat93

6.2.9Solidinterchangeformat93

6.2.10Surfacetrianglehintedformat94

6.3Comparisonof3Dmodelrepresentation dataformats94

6.4Slicedmodelrepresentationdata formatsinadditivemanufacturing95

6.4.1Commonlayerinterfaceformat96

6.4.2LayerexchangeASCIIformat96

6.4.3Stereolithographycontourformat96

6.4.4HewlettPackardGraphics Languageformat96

6.4.5Comparisonofslicedmodel representationdataformatsin additivemanufacturing96

6.5Otheradditivemanufacturinginterfaces97

6.5.1Layeredmanufacturinginterface98

6.5.2Rapidprototypinginterface98

6.5.3Voxel-basedmodelingmethod98

6.6Dataexchangestandardsutilizationin additivemanufacturing99

6.6.1StandardfortheExchangeof ProductModelstandard99

6.6.2Initialgraphicsexchange specificationstandard100

6.7Discussion100

6.8Summary101 References101

7.Additivemanufacturingtechniques usedforpreparationofscaffoldsin bonerepairandregeneration103 SudipDasguptaandYogendraPratapSingh

7.1Introduction103

7.2Scaffolddesign106

7.2.1Computer-aideddesign-based methods106

7.2.2Optimizationoftopology107

7.2.3Reversemodeling107

7.2.4Mathematicalmodeling107

7.3Additivemanufacturingtechniques108

7.3.1Selectivelasersintering108

7.3.2Selectivelasermelting110

7.3.3Extrusion-basedprinting111

7.3.4Fuseddepositionmodeling113

7.3.5Electronbeammelting114

7.3.6Stereolithography114

7.3.7Powderinkjetprinting116

7.3.8Electrospinning117

7.4Posttreatments118

7.4.1Heattreatment118

7.4.2Surfacetreatment119

7.4.3Coatings120

7.5Challengesandconclusions121 References121

8.Coldspraytechnology:aperspective ofnature-inspiredfeature processingandbiomanufacturing byaheatlessadditivemethod usingnanopowders129

RijaNirinaRaoelison

8.1Introduction:aheatlessadditivemethod fornature-inspired,bio-andnanofeatures129

8.2Coldsprayingprincipleandprocessing conditionsfornanopowders131

8.3Developmentofsuperhydrophobic propertiesusingthecoldsprayadditive method132

8.4Coldsprayadditivebiomanufacturing ofbiocompatiblecoatingforsurgical implant134

8.5Concludingremarksontheuseof CSasnature-inspiredand/or biomanufacturing137 References139

9.Preprocessingandpostprocessing inadditivemanufacturing141

AjayKumar,ParveenKumar,RaviKantMittaland HariSingh

9.1Introduction141

9.2Preprocessinginadditivemanufacturing142

9.2.1PreparationofCADmodel142

9.2.2ConversiontoSTLfile143

9.2.3DiagnosisofSTLfileerror146

9.2.4Partorientation149

9.2.5Generation/designofsupport151

9.2.6Typesofsupportstructure152

9.2.7Slicing153

9.2.8Generationoftoolpathpattern andinternalhatchingpattern155

9.3Postprocessinginadditivemanufacturing160

9.3.1Removalofsupportmaterial160

9.3.2Improvementinsurfacefinish161

9.3.3Improvementinaccuracy162

9.3.4Estheticimprovementofadditive manufacturingproducts162

9.3.5Modifyingpropertyofadditive manufacturingproducts162

9.4Summary162 References164

10.Computervisionbasedonline monitoringtechnique:partquality enhancementintheselectivelaser meltingprocess167

BrahmanshKaushikandS.AnandKumar

10.1Introduction167

10.2Experimentalmethods168

10.2.1Designofexperiment168

10.2.2Methodsandalgorithmsof analysis168

10.3Resultsanddiscussion170

10.3.1Edgedetectionanalysis170

10.3.2Greyscalepixelvalueanalysis182 10.3.3Layerclassification184

10.4Conclusions190

10.5Futurescopeandindustrial application192 References193

11.Fundamentalsofthermo-fluidmechanicalmodelinginadditive manufacturingprocesses195 AnshulYadav

11.1Introduction195

11.2Fundamentalsofthermalphenomena modeling196

11.2.1Generalclassificationofheated bodymodelsandheatsources models196

11.2.2Steady-statepointmovingheat source197

11.2.3Transitoryshiftingpointheat source198

11.2.4Semiellipticaltransientmoving heatsource198

11.2.5Doubleellipticaltransient movingheatsource199

11.2.6Uniformtransientmovingheat source200

11.3Mathematicaldescriptionof temperaturefield200

11.3.1Analyticalsolutionsoftheheat conductionequationforpoint source202

11.3.2Surfaceandvolumetricheat sourcemodels203

11.3.3Volumetricheatsourcemodels203

11.4Numericalmodelingofthethermal fieldconsideringsolid liquidchanges204

11.4.1Thermalandfluidflow modelingofthemoltenpool205

11.5Quantitativedescriptionofphase transformationsinsolidstate207

11.5.1Calculatingstructuralshares duringthesinglethermalcycle208

11.5.2Keyparametersindetermining thesolidificationstructure208

11.6Modelingstressandstrainsduring additivemanufacturing210

11.6.1Analyticalmodelingofresidual stressinadditivemanufacturing210

11.7Summary213 References213 PartIII

12.Materialsprocessedbyadditive manufacturingtechniques217 AjayKumar,ParveenKumar,

RaviKantMittalandVictorGambhir

12.1Introduction217

12.2MaterialsforAMtechnology218

12.2.1Polymers218

12.2.2Ceramics220

12.2.3Composites221 12.2.4Metals222

12.3BiomaterialsforAMtechnology223 12.3.1Metallicbiomaterials226 12.3.2Ceramicbiomaterials227 12.3.3Polymericbiomaterials227 12.3.4Compositebiomaterials228

12.4Smartmaterialsand4Dprinting perspectives228

12.5MaterialsprocessingissuesinAMand characterizationtechniques230

12.5.1Liquidmaterialsprocessingissues andtheircharacterization techniques231

12.5.2Solidmaterialsprocessingissues andtheircharacterization techniques231

12.5.3Powdermaterialsprocessing issuesandtheircharacteristic techniques231

12.6NewlydevelopedmaterialsforAM232

12.7Summary232 References232

13.Ceramic metalinterface:In-situ microstructuralcharacterization aidvacuumbrazingadditive manufacturingtechnology235

S.StalinandK.Kalaichelvan

13.1Introduction235

13.2Wettability236

13.3Wettingversusbrazing238

13.4Ceramic metalinterface: Microstructuralcharacterization240

13.5Effectofbrazingparametersonthe interfacialmicrostructureevolution242

13.6Ceramic metalinterface: Nanoindentationcharacterization245

13.7Ceramic metalinterface:Brazing mechanism247

13.8Conclusion248 References249

14.Processingchallengesinadditively manufacturedsinglecrystalalloys: aprocess structure property relationshipapproach253 RajkumarVelu,S.AnandKumarandRuban Whenish

14.1Introductionandbackground253

14.2ChallengesinthedepositionofSX structure254

14.2.1Influencinglaserprocessing parameters254

14.2.2Influencingofseedinglayer substrate255

14.2.3Influenceofthermalgradient255

14.3Suitablepre-andpostprocessing strategies257

14.3.1Preprocessingschemes257

14.3.2Influenceofpostprocessing schemes259

14.4Casestudy:remanufacturingof high-valuedcomponent261

14.5Conclusions261

14.6Futurescope262 References262 Furtherreading264

15.Transientthermalanalysisinfriction-stir additivemanufacturingofdissimilar wroughtaluminumalloys265

U.SudhakarandJ.Srinivas

15.1Introduction265

15.2Materialsandmodeling267

15.2.1Thermomechanicsoftheprocess268

15.3Finiteelementmodeling269

15.3.1Microstructureandhardness evaluation270

15.4Conclusion271 References271

16.Processingofbiomaterialsby additivemanufacturing273

MayurkumarA.MakhesanaandKaushikM.Patel

16.1Introductiontoadditivemanufacturing andbiomaterials273

16.1.1Introductionofadditive manufacturing273

16.1.2Additivetechnologyselection274

16.1.3Materialselection274

16.1.4Additivemanufacturingpolymers274

16.2Additivemanufacturingtechnologyfor biomaterials276

16.3Limitationsofadditivemanufacturing withbiomaterials277

16.4Furtherdevelopmentofadditive manufacturingapplications278 References278

17.Selectivelasermeltingoffunctionally gradedmaterial:currenttrendsand futureprospects281

AshishKumarMishra,KuldeepYadavand ArvindKumar

17.1Introduction281

17.2FGMsinnature282

17.3ClassificationofFGM283 17.4MathematicalrepresentationofFGMs andmodelsforpropertyprediction283

17.4.1Mori Tanakascheme284

17.4.2Voigtmodel284

17.4.3Powerlawgradation285 17.4.4Exponentiallawgradation285 17.4.5Sigmoidallawgradation285

17.5ApplicationsofFGMs286

17.6ManufacturingmethodsforFGMs286

17.6.1Legacymanufacturingmethods forFGMs286

17.6.2Stateoftheartofthelegacy manufacturingmethodsfor FGMs286

17.6.3Challengeswiththelegacy manufacturingmethodsfor FGMs287

17.7AMmethodsforFGMs288

17.8ManufacturingofSS316 AlSi10Mg FGM290

17.8.1Themotive290

17.8.2Attempt1:BuildingSS316L overAlSi10MgBase290

17.8.3Attempt2:Buildingthe AlSi10MgoverSS316L baseplate291

17.8.4Attempt3:In-house manufacturingofSS316L-IN718 FGMthroughSLM291

17.9Conclusion295

17.10FutureprospectsofFGM295 References296

18.Nondestructiveevaluationof additivelymanufacturedparts299

P.R.SreerajandSantoshKr.Mishra

18.1Introduction299

18.2DefectsassociatedwithAMparts300

18.2.1Cracking300

18.2.2Porosity301

18.2.3Inclusions301

18.2.4Voids302

18.2.5Lackoffusion302

18.2.6Delaminations302

18.2.7Residualstresses302

18.2.8Keyhole302

18.2.9Increasedsurfaceroughness302

18.3Challengesforimplementationof NDEinAM302

18.3.1Geometricalcomplexityofparts303

18.3.2Criticaldefects304

18.3.3Onlinemonitoring304

18.3.4Inspectionprocedures304

18.4ApplicationsofNDEinAM304

18.5TechnologiesinvolvedinNDEfor testingandinspectionofAMparts305

18.5.1Penetranttesting305

18.5.2Ultrasonictesting306

18.5.3Acousticemission306

18.5.4Opticalmethods306

18.5.5Radiographictechniques307

18.5.6Thermographictechniques307

18.5.7Electromagnetictechniques307

18.5.8Recommendationsandfuture work308

18.6Conclusion309 References310

PartIV

Learningsfromnature/inspirations fromnature

19.Bio-inspiredadvancementsin additivemanufacturing313

RubanWhenish,SelvamArivazhagan, RajkumarVeluandSAnandKumar

19.1Introduction313

19.2Historyandresearchmethodsof bio-inspiredstructures314

19.3Learninginnovativeprinciplesfrom nature315

19.4Bio-inspiredstructuresandmaterials foradditivemanufacturing316

19.5Additivemanufacturingmethodsfor bio-inspiredstructures317

19.6Mechanicalbehaviorofadditively manufacturedbio-inspiredstructures318

19.7Bio-inspiredstructuresandtheir applications(science,engineering,and medicine)319

19.8Futuredirectionandconclusionof bio-inspireddesign320 References321

20.Pathplanningandsimulationfor prototypingbio-inspiredcomplex shapes325 TadeleBelayTuli

20.1Introduction325 20.2Stateoftheart326

20.2.1Pathplanningfor3Dprinting326 20.2.2Robotsasthree-dimensional printingsystems327 20.3Pathplanningforthree-dimensional printing327

20.3.1Geometricalmeshgeneration andshapeoptimization327

20.3.2Slicingandgeometric reconstructionofthethreedimensionalmodels328

20.3.3Pathgenerationandplanning330

20.4Resultanddiscussion330 20.5Conclusionandfutureoutlook332 Acknowledgment332 References332

21.Substitutefororthognathicsurgery usingbioprintedbonescaffoldsin restoringosseousdefects335

SonamSehrawat,AjayKumarand MonaPrabhakar

21.1Introduction335

21.1.1Roleofadditivemanufacturing inreconstructivesurgery335

21.1.2Literaturegap336

21.1.3Motivation336

21.1.4Literaturereview336

21.1.5Objectives337

21.2Bonescaffoldsforreconstructive treatments337

21.2.1Boneasaspecializedtissue337

21.2.2Congenitalandtraumatic osseousdefects338

21.2.3Biologicalstimuliresponsive materials339

21.2.4Fabricationofbonescaffolds340

21.2.5Fabricationofbioprinted scaffoldsusingstereo lithographicfiles340

21.3Orthognathicsurgicalsubstitutes342

21.3.1Conventionalsurgeriesandtheir limitations342

21.3.2Geneticallydriventreatment: genetherapy343

21.3.3Bioprintedscaffoldsfor reconstructiveprocedures344

21.3.4State-of-the-artcomparison344

21.3.5Pointsfavoringadditive manufacturingandclinical successofbonescaffolds344

21.4Conclusionandfutureperspectives344

21.4.1Conclusion344

21.4.2Futureperspectives346 References346

22.Multiobjectiveprocessparameter optimizationinfusedfilament fabricationwithnature-inspired algorithms349

NitaYodoandArupDey

22.1Introduction349

22.2Methodologies350

22.2.1Responsesurfacemethod351

22.2.2Artificialneuralnetwork351

22.2.3Geneticalgorithm352

22.2.4NondominatedGAII352

22.2.5Particleswarmoptimization353

22.3Casestudy353

22.3.1Datacollection353

22.3.2Surrogatemodels353

22.3.3MPPOformulations354

22.3.4Optimizationresults355

22.3.5Resultsdiscussion355

22.4Discussionandfuturework357

22.5Conclusions358 References358

23.4Dprinting:Anexperimentalcase studyonprocessingofshape memorypolymerbyFDM/FFFfor natureinspiredstructures361

BijayaBikramSamal,AnitaJena, ShailendraKumarVarshneyand CheruvuSivaKumar

23.1Introduction361

23.2Mechanismofshapememoryeffectin thermoresponsiveshapememory polymer363

23.2.1Propertiesofshapememory polymers364

23.2.2Shapememoryeffectin polylactideacid365

23.3Programming/trainingconceptsin4D printing366

23.3.1Programming/trainingafter printing366

23.3.2Programming/trainingduring printing367

23.4Casestudy:PLA-SMPfor4Dprinting byFFFbasedondifferentprogramming conceptsandprocessparameters367

23.4.1Experimentaldetails367

23.4.2Resultsanddiscussions370

23.5Applicationsof4Dprintingtechnology375

23.6Conclusion376 References376

PartV Applications

24.Selectedbiomedicalapplications ofadditivemanufacturing techniques381 KishorePradeepandBidyutPal

24.1Introduction381 24.2Biomedicalapplicationsofadditive manufacturing384 24.2.1SpinalandorthopedicImplants384 24.2.2Dentistry391 24.2.3Bonetissueengineering394 24.2.4Medicaldevices:diagnostic andtherapeutictools396 24.2.5Otherapplications: pharmaceuticals397 24.3Limitationsandfuturepotentials (4Dand5Dprinting)397 24.4Conclusions399 Acknowledgment400 References400

25.State-of-the-artinadditive manufacturingofTi 6Al 4V: recentprogressandinsightsinto futuredevelopments405 NataliaB.GhisiC,HendAlqaydi, NujoodAlshehhi,NesmaT.Aboulkhairand AmalM.K.Esawi

25.1Laserpowderbedfusion:definition, importance,andindustrialrelevance405 25.2Titaniumalloysforlaserpowderbed fusion406 25.2.1Titaniumanditsalloys407

25.2.2Feedstockmaterialforlaser powerbedfusion409

25.3Process structure property relationships411

25.3.1ProcessabilityofTi 6Al 4V usinglaserpowerbedfusion411

25.3.2Metallurgyoflaserpowerbed fusionTi 6Al 4V412

25.3.3Mechanicalperformanceoflaser powerbedfusionTi 6Al 4V416

25.4Designfreedomcapabilities419

25.4.1Topologyoptimization420

25.4.2Latticestructures421

25.5Applicationsofadditivelymanufactured titaniumalloysinthebiomedical implantsindustry423

25.6Summaryandoutlook424 Acknowledgments426 References426

26.Materialselectionandprocessing challengeswithadditive manufacturinginbiomimicryfor biomedicalapplications431 DeepakGuptaandJayeshBellare

26.1Introduction431

26.2Nature-inspiredbiomedicalmaterials anddevices432

26.3Challengesinbiomimicrywithadditive manufacturingforbiomedical applications433

26.3.1Hardwarelimitations433

26.3.2Bio-inspiredgeometry434

26.3.3Bio-inspiredtissueengineering andbiofabrication434

26.3.4Multicriteriadecision-making437

26.4Futurescope443 References444

27.Designandoptimizationofartificial intelligencerobotarmprintable byametal-basedadditive manufacturingprocess449

M.Kumaran,V.SenthilkumarandT.Sathies

27.1Introduction449

27.2Productdesignanddevelopmentfor additivemanufacturing449

27.3Designforadditivemanufacturing450

27.4Methodologyanddesignforadditive manufacturingprojectdesign processforrobotparts451

27.5Generativedesignforadditive manufacturingrobotparts451

27.6Topologyoptimizationforadditive manufacturingofrobotparts453

27.7Robotarmmodelingtechniquesand simulationprocesses453

27.8Usingadditivetoolstosimulate additivemanufacturing454

27.9Experimentaloptimizationbasedon machineconfiguration454

27.10Partprintingbyametal-based additivemanufacturingprocess455

27.10.1Powderbedfusion455

27.10.2Directenergydeposition456

27.11Casestudy:usingadditive manufacturingtechnologyto manufactureroboticparts457

27.12Conclusion460 References460

28.Additivemanufacturingof customized,accessible,and affordablelowerlimbprosthetics inIndia:casestudy463

DheerajKumarAngajala,AnkitSahaiand RahulSwarupSharma

28.1Introduction463

28.1.1Demographyoflowerlimb amputeesinIndia463

28.1.2Low-costprosthetic manufacturersinIndia464

28.1.3Lowerlimbprosthetics464

28.2Traditionallowerlimbprosthetic manufacturingmethodsinIndia465

28.2.1Manufacturingprocess465

28.2.2Casestudy:BhagwanMahaveer ViklangSahayataSamiti (JaipurFoot)465

28.2.3Casestudy:HardayalViklang SevaKendra466

28.2.4Observationsinthecasestudies466

28.3Additivemanufacturingofprosthetic sockets468

28.3.1Introduction468

28.3.2Manufacturingprocess468

28.3.3Advantagesandchallenges470

28.4Casestudy:additivelymanufactured lowerlimbprostheticsockets470

28.4.13Dscanning470

28.4.2Socketmodeling470

28.4.3Materialcharacterization471

28.4.4Additivemanufacturing472

28.4.5Testing472

28.5Comparisonoftraditionallyand additivelymanufacturedlowerlimb prosthetics475

28.6Conclusion475 Acknowledgement476 References476

29.Currenttrendsofapplicationof additivemanufacturinginoral healthcaresystem479

AmitBhardwaj,AnuragBhatnagarandAjayKumar

29.1Introduction479

29.2Additivemanufacturingfororal healthcare480

29.2.1Three-dimensionalscaffoldsand periodontalregeneration480

29.2.2Additivemanufacturingfor dentaleducationalandtraining482

29.2.3Additivemanufacturingfor dentalimplantdesignand fabrication482

29.2.4Oralandmaxillofacialsurgeries andtreatingtraumaticinjuries usingcustomizedtechnology484

29.2.5Augmentationofalveolarbone485

29.2.6Prostheticfabrication486

29.3Challengesinadditivemanufacturing487

29.3.1Cost-effectiveness487

29.3.2Awareness488

29.3.3Materialavailability488

29.4Conclusionandfuturedirections488 References488

Index493

Thispageintentionallyleftblank

Listofcontributors

NesmaT.Aboulkhair AdvancedMaterialsResearch Centre,TechnologyInnovationInstitute(TII),Masdar City,AbuDhabi,UAE;CentreforAdditive Manufacturing(CfAM),FacultyofEngineering, UniversityofNottingham,Nottingham,United Kingdom

PuneetaAjmera DepartmentofPublicHealth,Schoolof AlliedHealthSciences,DelhiPharmaceuticalScience andResearchUniversity,NewDelhi,India

EstherT.Akinlabi DepartmentofMechanical EngineeringScience,UniversityofJohannesburg, AucklandParkKingswayCampus,Johannesburg, Guateng,SouthAfrica;PanAfricaUniversityforLife andEarthSciencesInstitute,Ibadan,OyoState, Nigeria

S.A.Akinlabi DepartmentofMechanicalEngineering, ButterworthCampus,WalterSisuluUniversity,East London,EasternCape,SouthAfrica

HendAlqaydi AdvancedMaterialsResearchCentre, TechnologyInnovationInstitute(TII),MasdarCity, AbuDhabi,UAE

NujoodAlshehhi AdvancedMaterialsResearchCentre, TechnologyInnovationInstitute(TII),MasdarCity, AbuDhabi,UAE

S.AnandKumar AdditiveManufacturingResearch Laboratory,DepartmentofMechanicalEngineering, IndianInstituteofTechnologyJammu,Jammu, JammuandKashmir,India

DheerajKumarAngajala AdditiveManufacturingLab, FacultyofEngineering,DayalbaghEducational Institute,Agra,UttarPradesh,India

SelvamArivazhagan DepartmentofMechanical Engineering,KPRInstituteofEngineeringand Technology,Coimbatore,TamilNadu,India

JayeshBellare DepartmentofChemicalEngineering, IndianInstituteofTechnologyBombay,Mumbai, Maharashtra,India

AmitBhardwaj DepartmentofPeriodontology,Faculty ofDentalSciences,SGTUniversity,Gurugram, Haryana,India

AnuragBhatnagar DepartmentofPeriodontology, FacultyofDentalSciences,SGTUniversity, Gurugram,Haryana,India

SudipDasgupta DepartmentofCeramicEngineering, NITRourkela,Rourkela,Odisha,India

ArupDey DepartmentofIndustrialandManufacturing Engineering,NorthDakotaStateUniversity,United States

AmalM.K.Esawi MechanicalEngineeringDepartment, SchoolofSciencesandEngineering,TheAmerican UniversityinCairo,NewCairo,Cairo,Egypt

VictorGambhir DepartmentofMechanical Engineering,SchoolofEngineering,JECRC University,Jaipur,Rajasthan,India

NataliaB.GhisiC AdvancedMaterialsResearch Centre,TechnologyInnovationInstitute(TII),Masdar City,AbuDhabi,UAE

CarmenM.Gonza ´ lez-Henrı´quez FacultyofNatural Science,Mathematics,andEnvironmentalStudies, DepartmentofChemistry,MetropolitanTechnological University,Santiago,Chile

DeepakGupta DepartmentofChemicalEngineering, IndianInstituteofTechnologyBombay,Mumbai, Maharashtra,India

AbidHaleem DepartmentofMechanicalEngineering, JamiaMilliaIslamia,NewDelhi,India

SunirHassan DepartmentofMechanicalEngineering, ButterworthCampus,WalterSisuluUniversity,East London,EasternCape,SouthAfrica

VineetJain DepartmentofMechanicalEngineering, MewatEngineeringCollege,Nuh,Haryana,India

MohdJavaid DepartmentofMechanicalEngineering, JamiaMilliaIslamia,NewDelhi,India

T-C.Jen DepartmentofMechanicalEngineeringScience, UniversityofJohannesburg,AucklandParkKingsway Campus,Johannesburg,Guateng,SouthAfrica

AnitaJena AdvancedTechnologyDevelopmentCentre, IndianInstituteofTechnology,Kharagpur,West Bengal,India

K.Kalaichelvan DepartmentofCeramicTechnology, ACTCampus,AnnaUniversity,Chennai,TamilNadu, India

SheetalKalra SchoolofPhysiotherapy,Delhi PharmaceuticalScienceandResearchUniversity,New Delhi,India

BrahmanshKaushik AdditiveManufacturingResearch Laboratory,DepartmentofMechanicalEngineering, IndianInstituteofTechnologyJammu,Jammu, JammuandKashmir,India

AjayKumar DepartmentofMechanicalEngineering, SchoolofEngineering,JECRCUniversity,Jaipur, Rajasthan,India

ArvindKumar DepartmentofMechanicalEngineering, IndianInstituteofTechnology,Kanpur,UttarPradesh, India

CheruvuSivaKumar DepartmentofMechanical Engineering,IndianInstituteofTechnology, Kharagpur,WestBengal,India

LokeshKumar DepartmentofMechanicalEngineering, JamiaMilliaIslamia,NewDelhi,India

ParveenKumar DepartmentofMechanicalEngineering, RawalInstituteofEngineeringandTechnology, Faridabad,Haryana,India

M.Kumaran DepartmentofProductionEngineering, NationalInstituteofTechnologyTiruchirappalli, Tiruchirappalli,TamilNadu,India

RasheedatM.Mahamood DepartmentofMaterialsand MetallurgicalEngineering,UniversityofIlorin,Ilorin, KwaraState,Nigeria;DepartmentofMechanical EngineeringScience,UniversityofJohannesburg, AucklandParkKingswayCampus,Johannesburg, Guateng,SouthAfrica

MayurkumarA.Makhesana MechanicalEngineering Department,InstituteofTechnology,Nirma University,Ahmedabad,Gujarat,India

AshishKumarMishra DepartmentofMechanical Engineering,IndianInstituteofTechnology,Kanpur, UttarPradesh,India

SantoshKr.Mishra DepartmentofProduction Engineering,NationalInstituteofTechnology Tiruchirappalli,Tiruchirappalli,TamilNadu,India

RaviKantMittal DepartmentofMechanical Engineering,BirlaInstituteofTechnologyand Science,Pilani,Rajasthan,India

BidyutPal DepartmentofMechanicalEngineering, IndianInstituteofEngineeringScienceand TechnologyShibpur,Howrah,WestBengal,India

KaushikM.Patel MechanicalEngineeringDepartment, InstituteofTechnology,NirmaUniversity, Ahmedabad,Gujarat,India

DanA.Pe ´ rez-Monje FacultyofNaturalScience, Mathematics,andEnvironmentalStudies,Department ofChemistry,MetropolitanTechnologicalUniversity, Santiago,Chile

MonaPrabhakar DepartmentofOrthodonticsand DentofacialOrthopedics,FacultyofDentalScience, ShreeGuruGobindSinghTricentenaryUniversity, Gurugram,Haryana,India

KishorePradeep DepartmentofMechanical Engineering,IndianInstituteofEngineeringScience andTechnologyShibpur,Howrah,WestBengal, India

RijaNirinaRaoelison Universite ´ deBourgogneFrancheComte ´ —UTBM,LaboratoireInterdisciplinaireCarnotde Bourgogne,UMR6303CNRS,Belfort,France

JuanRodrı´guez-Herna ´ ndez DepartmentofApplied MacromolecularChemistry,Polymer FunctionalizationGroup,InstituteofPolymerScience andTechnology–SpanishNationalResearchCouncil (ICTP-CSIC),Madrid,Spain

FernandoE.Rodrı´guez-Umanzor MaterialScienceand ProgressEngineering,MetropolitanTechnological University,Santiago,Chile

AnkitSahai AdditiveManufacturingLab,Facultyof Engineering,DayalbaghEducationalInstitute,Agra, UttarPradesh,India

BijayaBikramSamal AdvancedTechnology DevelopmentCentre,IndianInstituteofTechnology, Kharagpur,WestBengal,India

MauricioA.Sarabia-Vallejos FacultaddeIngenierı´ay Tecnologı´a,UniversidadSanSebastia ´ n,Sede Santiago,Santiago,Chile

T.Sathies DepartmentofProductionEngineering, NationalInstituteofTechnologyTiruchirappalli, Tiruchirappalli,TamilNadu,India

SonamSehrawat DepartmentofOrthodonticsand DentofacialOrthopedics,FacultyofDentalScience, ShreeGuruGobindSinghTricentenaryUniversity, Gurugram,Haryana,India

V.Senthilkumar DepartmentofProductionEngineering, NationalInstituteofTechnologyTiruchirappalli, Tiruchirappalli,TamilNadu,India

RahulSwarupSharma AdditiveManufacturingLab, FacultyofEngineering,DayalbaghEducational Institute,Agra,UttarPradesh,India

MohdShoeb DepartmentofMechanicalEngineering, JamiaMilliaIslamia,NewDelhi,India

HariSingh DepartmentofMechanicalEngineering, NationalInstituteofTechnology,Kurukshetra, Haryana,India

YogendraPratapSingh DepartmentofCeramic Engineering,NITRourkela,Rourkela,Odisha, India

P.R.Sreeraj DepartmentofProductionEngineering, NationalInstituteofTechnologyTiruchirappalli, Tiruchirappalli,TamilNadu,India

J.Srinivas NationalInstituteofTechnologyRourkela, Odisha,India

S.Stalin DepartmentofCeramicTechnology,ACT Campus,AnnaUniversity,Chennai,TamilNadu, India

U.Sudhakar SCSVMVKanchipuram,Tamilnadu,India

TadeleBelayTuli DepartmentofElectromechanical Engineering,CollegeofElectricalandMechanical Engineering,AASTU,AddisAbaba,Ethiopia; DepartmentofMechanicalEngineering,Universityof Siegen,Siegen,Germany

ShailendraKumarVarshney DepartmentofElectronics andElectricalCommunicationEngineering,Indian InstituteofTechnology,Kharagpur,WestBengal,India

RajkumarVelu DepartmentofMechanicalEngineering, IndianInstituteofTechnology,Jammu,Jammuand Kashmir,India;AdditiveManufacturingResearch Laboratory,IndianInstituteofTechnologyJammu, JammuandKashmir,India

RubanWhenish CentreforBiomaterials,Cellularand MolecularTheranostics,VelloreInstituteofTechnology, Vellore,TamilNadu,India; MannaChemicals&Drugs PrivateLimited,Chennai,TamilNadu,India

AnshulYadav CSIR–CentralSaltandMarineChemicals ResearchInstitute,Bhavnagar,Gujarat,India

KuldeepYadav DepartmentofMechanicalEngineering, IndianInstituteofTechnology,Kanpur,UttarPradesh, India

SheetalYadav DepartmentofHospitalManagement, SchoolofAlliedHealthSciences,DelhiPharmaceutical ScienceandResearchUniversity,NewDelhi,India

NitaYodo DepartmentofIndustrialandManufacturing Engineering,NorthDakotaStateUniversity,UnitedStates

Thispageintentionallyleftblank