https://ebookmass.com/product/advanced-processingproperties-and-applications-of-starch-and-other-bio-basedpolymers-1st-edition-faris-m-al-oqla-editor/

Instant digital products (PDF, ePub, MOBI) ready for you

Download now and discover formats that fit your needs...

Starch-based materials in food packaging processing, characterization and applications Barbosa

https://ebookmass.com/product/starch-based-materials-in-foodpackaging-processing-characterization-and-applications-barbosa/

ebookmass.com

Applied Mechanics of Polymers. Properties, Processing, and Behavior George Youssef

https://ebookmass.com/product/applied-mechanics-of-polymersproperties-processing-and-behavior-george-youssef/

ebookmass.com

Biobased Polymers: Properties and Applications in Packaging Pratima Bajpai

https://ebookmass.com/product/biobased-polymers-properties-andapplications-in-packaging-pratima-bajpai/

ebookmass.com

Survey of Mathematics with Applications, A 10th Edition, (Ebook PDF)

https://ebookmass.com/product/survey-of-mathematics-withapplications-a-10th-edition-ebook-pdf/

ebookmass.com

Japan Prepares for Total War: The Search for Economic Security, 1919–1941 (Cornell Studies in Security Affairs) 1st Edition Barnhart

https://ebookmass.com/product/japan-prepares-for-total-war-the-searchfor-economic-security-1919-1941-cornell-studies-in-securityaffairs-1st-edition-barnhart/

ebookmass.com

Conflict of Laws: Cases and Materials (Aspen Casebook Series) 7th Edition, (Ebook PDF)

https://ebookmass.com/product/conflict-of-laws-cases-and-materialsaspen-casebook-series-7th-edition-ebook-pdf/

ebookmass.com

I Know: A Captive Mafia Romance Landry Hill

https://ebookmass.com/product/i-know-a-captive-mafia-romance-landryhill/

ebookmass.com

Maid For My BOSS: A Steamy Boss Romance, Dark Romance (Boss Series Book 1) (BOSS: Dark Romance) Mia Hill

https://ebookmass.com/product/maid-for-my-boss-a-steamy-boss-romancedark-romance-boss-series-book-1-boss-dark-romance-mia-hill/

ebookmass.com

Human-Centered AI Ben Shneiderman

https://ebookmass.com/product/human-centered-ai-ben-shneiderman-2/ ebookmass.com

Architecture of Advanced Numerical Analysis Systems: Designing a Scientific Computing System using OCaml 1st Edition Liang Wang

https://ebookmass.com/product/architecture-of-advanced-numericalanalysis-systems-designing-a-scientific-computing-system-usingocaml-1st-edition-liang-wang/

ebookmass.com

AdvancedProcessing, Properties,and ApplicationsofStarch

andOtherBio-Based

Polymers

Editedby

FARISM.AL-OQLA

DepartmentofMechanicalEngineering

FacultyofEngineering

TheHashemiteUniversity

Zarqa,Jordan

S.M.SAPUAN

AdvancedEngineeringMaterialsandComposites

ResearchCentre(AEMC)

DepartmentofMechanicalandManufacturingEngineering

UniversitiPutraMalaysia

Serdang,Selangor,Malaysia

LaboratoryofBiocompositeTechnology

InstituteofTropicalForestryandForestProducts

UniversitiPutraMalaysia

Serdang,Selangor,Malaysia

Elsevier

Radarweg29,POBox211,1000AEAmsterdam,Netherlands TheBoulevard,LangfordLane,Kidlington,OxfordOX51GB,UnitedKingdom 50HampshireStreet,5thFloor,Cambridge,MA02139,UnitedStates

Copyright 2020ElsevierInc.Allrightsreserved.

Nopartofthispublicationmaybereproducedortransmittedinanyformorbyanymeans,electronicor mechanical,includingphotocopying,recording,oranyinformationstorageandretrievalsystem,without permissioninwritingfromthepublisher.Detailsonhowtoseekpermission,furtherinformationaboutthe Publisher’spermissionspoliciesandourarrangementswithorganizationssuchastheCopyrightClearance CenterandtheCopyrightLicensingAgency,canbefoundatourwebsite: www.elsevier.com/permissions

ThisbookandtheindividualcontributionscontainedinitareprotectedundercopyrightbythePublisher(other thanasmaybenotedherein).

Notices

Knowledgeandbestpracticeinthis fieldareconstantlychanging.Asnewresearchandexperiencebroadenour understanding,changesinresearchmethods,professionalpractices,ormedicaltreatmentmaybecome necessary.

Practitionersandresearchersmustalwaysrelyontheirownexperienceandknowledgeinevaluatingandusing anyinformation,methods,compounds,orexperimentsdescribedherein.Inusingsuchinformationormethods theyshouldbemindfuloftheirownsafetyandthesafetyofothers,includingpartiesforwhomtheyhavea professionalresponsibility.

Tothefullestextentofthelaw,neitherthePublishernortheauthors,contributors,oreditors,assumeany liabilityforanyinjuryand/ordamagetopersonsorpropertyasamatterofproductsliability,negligenceor otherwise,orfromanyuseoroperationofanymethods,products,instructions,orideascontainedinthe materialherein.

LibraryofCongressCataloging-in-PublicationData

AcatalogrecordforthisbookisavailablefromtheLibraryofCongress

BritishLibraryCataloguing-in-PublicationData

AcataloguerecordforthisbookisavailablefromtheBritishLibrary

ISBN:978-0-12-819661-8

ForinformationonallElsevierpublicationsvisitourwebsiteat https://www.elsevier.com/books-and-journals

Publisher: MatthewDeans

AcquisitionsEditor: EdwardPayne

EditorialProjectManager: CharlotteRowley

ProductionProjectManager: KiruthikaGovindaraju

CoverDesigner: AlanStudholme

TypesetbyTNQTechnologies

ListofContributors

HairulAbral DepartmentofMechanicalEngineering AndalasUniversity Padang,SumateraBarat,Indonesia

H.A.Aisyah LaboratoryofBiocompositeTechnology InstituteofTropicalForestryandForestProducts UniversitiPutraMalaysia Serdang,Selangor,Malaysia

AmaniM.Al-Ghraibah Al-AhliyyaAmmanUniversity Amman,Jordan

FarisM.AL-Oqla DepartmentofMechanicalEngineering FacultyofEngineering TheHashemiteUniversity Zarqa,Jordan

MahaAl-Qudah PrimaryHealthCareCorporation(PHCC) Doha,Qatar

MochamadAsrofi LaboratoryofMaterialTesting DepartmentofMechanicalEngineering UniversityofJember Jember,EastJava,Indonesia

M.R.M.Asyraf DepartmentofAerospaceEngineering UniversitiPutraMalaysia Serdang,Selangor,Malaysia

M.S.N.Atikah DepartmentofChemicalandEnvironmental Engineering UniversitiPutraMalaysia Serdang,Selangor,Malaysia

M.N.M.Azlin InstituteofTropicalForestryandForestProducts UniversitiPutraMalaysia Serdang,Selangor,Malaysia SchoolofIndustrialTechnology DepartmentofTextileTechnology UniversitiTeknologi MARANegeriSembilan KualaPilahCampus KualaPilah,NegeriSembilan,Malaysia

ManikChandraBiswas DoctoralFellow FiberandPolymerScience TextileEngineering ChemistryandScience NCStateUniversity Raleigh,NC,UnitedStates

AhmedEdhirej AdvancedEngineeringMaterialsandComposites ResearchCentre DepartmentofMechanicalandManufacturing Engineering UniversitiPutraMalaysia Serdang,Selangor,Malaysia DepartmentofMechanicalandManufacturing Engineering SabhaUniversity Sabha,Libya MohdNorFaizNorrrahim ResearchCentreforChemicalDefence(CHEMDEF) UniversitiPertahananNasionalMalaysia KualaLumpur,Malaysia

OsamaO.Fares ElectricalEngineeringDepartment IsraUniversity Amman,Jordan

M.D.Hazrol

AdvancedEngineeringMaterialsandComposites ResearchCentre(AEMC) DepartmentofMechanicalandManufacturing Engineering, UniversitiPutraMalaysia Serdang,Selangor,Malaysia

MdEnamulHoque DepartmentofBiomedicalEngineering MilitaryInstituteofScienceandTechnology(MIST), MirpurCantonment,Dhaka,Bangladesh

M.R.M.Huzaifah

LaboratoryofBiocompositeTechnology InstituteofTropicalForestryandForestProducts UniversitiPutraMalaysia Serdang,Selangor,Malaysia

M.I.J.Ibrahim

AdvancedEngineeringMaterialsandComposites ResearchCentre DepartmentofMechanicalandManufacturing Engineering

UniversitiPutraMalaysia Serdang,Selangor,Malaysia DepartmentofMechanicalandManufacturing Engineering SabhaUniversity Sabha,Libya

LaboratoryofBiocompositeTechnology InstituteofTropicalForestryandForestProducts UniversitiPutraMalaysia Serdang,Selangor,Malaysia

RushdanIbrahim PulpandPaperBranch ForestResearchInstituteMalaysia Kepong,Selangor,Malaysia

R.A.Ilyas

BiocompositeTechnology & Design AdvancedEngineeringMaterialsandComposites ResearchCentre(AEMC) DepartmentofMechanicalandManufacturing Engineering UniversitiPutraMalaysia(UPM) Serdang,Selangor,Malaysia LaboratoryofBiocompositeTechnology InstituteofTropicalForestryandForestProducts UniversitiPutraMalaysia Serdang,Selangor,Malaysia

LatifahJasmani PulpandPaperBranch ForestResearchInstituteMalaysia Kepong,Selangor,Malaysia

RidhwanJumaidin FakultiTeknologiKejuruteraanMekanikaldan Pembuatan UniversitiTeknikalMalaysiaMelaka DurianTunggal,Melaka,Malaysia

AbudukeremuKadier

DepartmentofChemicalandProcessEngineering FacultyofEngineeringandBuiltEnvironment NationalUniversityofMalaysia(UKM) Bangi,Selangor,Malaysia ResearchCentreforSustainableProcessTechnology (CESPRO) FacultyofEngineeringandBuiltEnvironment NationalUniversityofMalaysia(UKM) Bangi,Selangor,Malaysia

MohdSahaidKalil DepartmentofChemicalandProcessEngineering FacultyofEngineeringandBuiltEnvironment NationalUniversityofMalaysia(UKM) Bangi,Selangor,Malaysia ResearchCentreforSustainableProcessTechnology (CESPRO) FacultyofEngineeringandBuiltEnvironment NationalUniversityofMalaysia(UKM) Bangi,Selangor,Malaysia

A.Khalina InstituteofTropicalForestryandForestProducts UniversitiPutraMalaysia Serdang,Selangor,Malaysia

SanthanaKrishnan CentreofEnvironmentalSustainabilityandWater Security(IPASA) ResearchInstituteofSustainableEnvironment(RISE) SchoolofCivilEngineering FacultyofEngineering UniversitiTeknologiMalaysia(UTM) JohorBahru,Johor,Malaysia

C.H.Lee

InstituteofTropicalForestryandForestProducts UniversitiPutraMalaysia Serdang,Selangor,Malaysia INTROP UniversitiPutraMalaysia Serdang,Selangor,Malaysia

S.H.Lee

InstituteofTropicalForestryandForestProducts UniversitiPutraMalaysia Serdang,Selangor,Malaysia

TariqMahbub DepartmentofMechanicalEngineering MilitaryInstituteofScienceandTechnology(MIST), MirpurCantonment,Dhaka,Bangladesh

SushmitaMajumder DepartmentofMaterialsandMetallurgical Engineering

BangladeshUniversityofEngineeringandTechnology (BUET),MirpurCantonment,Dhaka,Bangladesh

S.Misri

LaboratoryofBiocompositeTechnology InstituteofTropicalForestryandForestProducts UniversitiPutraMalaysia Serdang,Selangor,Malaysia

N.MohdNurazzi

BoardofTechnologists(MBOT) Futurise

PersiaranAPEC Cyberjaya,Selangor,Malaysia

SitiNuraishahMohdZainel FakultiTeknologiKejuruteraanMekanikaldan Pembuatan UniversitiTeknikalMalaysiaMelaka DurianTunggal,Melaka,Malaysia

A.Nazrin LaboratoryofBiocompositeTechnology InstituteofTropicalForestryandForestProducts UniversitiPutraMalaysia Serdang,Selangor,Malaysia

M.N.F.Norrahim ResearchCentreforChemicalDefence(CHEMDEF) UniversitiPertahananNasionalMalaysia SungaiBesi,KualaLumpur,Malaysia

MahmoudM.Rababah

DepartmentofMechanicalEngineering TheHashemiteUniversity

Zarqa,Jordan

TilottomaSaha DepartmentofMaterialsandMetallurgicalEngineering BangladeshUniversityofEngineeringandTechnology (BUET)

Dhaka,Bangladesh

S.M.Sapuan

AdvancedEngineeringMaterialsandComposites ResearchCentre(AEMC) DepartmentofMechanicalandManufacturing Engineering

UniversitiPutraMalaysia Serdang,Selangor,Malaysia LaboratoryofBiocompositeTechnology InstituteofTropicalForestryandForestProducts UniversitiPutraMalaysia Serdang,Selangor,Malaysia

NasmiHerlinaSari

DepartmentofMechanicalEngineering MataramUniversity Mataram,WestNusaTenggara,Indonesia

AhmedSharif

DepartmentofMaterialsandMetallurgicalEngineering BangladeshUniversityofEngineeringandTechnology (BUET)

Dhaka,Bangladesh

R.Syafiq LaboratoryofBiocompositeTechnology InstituteofTropicalForestryandForestProducts UniversitiPutraMalaysia Serdang,Selangor,Malaysia

EdiSyafri DepartmentofAgriculturalTechnology PoliteknikPertanian Payakumbuh,Sumatra,Indonesia

JarinTusnim

DepartmentofMaterialsandMetallurgicalEngineering BangladeshUniversityofEngineeringandTechnology (BUET)

Dhaka,Bangladesh

TengkuArisyahTengkuYasim-Anuar DepartmentofBioprocessTechnology FacultyofBiotechnologyandBiomolecularSciences UniversitiPutraMalaysia Serdang,Selangor,Malaysia

E.S.Zainudin

AdvancedEngineeringMaterialsandComposites ResearchCentre(AEMC) DepartmentofMechanicalandManufacturing Engineering FacultyofEngineering UniversitiPutraMalaysia Serdang,Selangor,Malaysia

M.Y.M.Zuhri

AdvancedEngineeringMaterialsandComposites ResearchCentre(AEMC) DepartmentofMechanicalandManufacturing Engineering FacultyofEngineering UniversitiPutraMalaysia Serdang,Selangor,Malaysia

BiopolymerCompositesand Sustainability

MAHMOUDM.RABABAH • FARISM.AL-OQLA

1 INTRODUCTION

Itisveryobviousthatplasticpollutionhasnegative impactontheenvironmentaswellastheclimate change.Unfortunately,thepollutionoccurredalong thewholeproductioncycleoftheplasticfromitsproductionusingthefossilfuelsuntilitsdisposalby burning.Besidetheplasticpollution,deforestation, greenhouseeffect,industrialpollution,andmanyother factorsareresponsibleincausingthenegativeimpact ontheenvironmentbyblowingmoregasestoairascarbondioxide,methane,SO2,nitrousoxide,andmany others(AL-Oqlaetal.,2016;Alaaeddinetal.,2019b).

Greenerplasticcompositescanbeobtainedof renewableresourcesinamoreecologicalresponsible manner.Thisisachievedusingthebiotechnology andwasimprovedusingthenanotechnology,which isapromisingapproachthatwouldgreatlyaffectthe valuechainsoftheplasticindustryworldwide.Some stepsarealreadyachievedindevelopingsustainable plastics.Infact,photodegradableplasticswitha balanceamountofbothantioxidantsandcatalysts aredeveloped.Thecatalystsinitiateacontrolleddegradationwhilemaintainingtheperformanceproperties oftheplastics.Thesephotodegradableplasticsarepossessingsimilarperformancepropertiestoconventional plasticsatclosecosts.However,atthemoment,they stillusefossilfuelsandtheyarenotabletofully degradetoH2OandCO2 inthesoil(Khabbazetal., 1999).Besides,photofragmentationmayoccurifno controlisperformedcausingalitterincrease. Degradablepolymersaredevelopedwithoutusing antioxidantorwithprooxidantsthathelpinaslow degradation.Comparingtophotodegradable polymers,degradablepolymerspossesssimilarperformanceproperties,coststructure,andproductionof otherdegradationproductsthanH2 OandCO2,such asalcohols,alkenes,esters,andketones(Jakubowicz, 2003).Therefore,developingsustainableplastics

frombiodegradableandrenewableresourcesisa demandinggoal.

Anamountof260billionboundsofplasticwere annuallyproducedintheworldattheendofthelast century,withanindustryvalueof1trilliondollars (HalleyandDorgan,2011).Thisamountissubjected toamassiveincreasebecauseofthehighdemanding duetothepopulationincreaseandthenewdeveloped consumers ’ habits.Greatamountofpetroleumis consumedforplasticproduction.However,asitis finite supply,itspriceswillincreasemoreandmore.Inaddition,theenvironmentalpollutioncausedfromproducing,using,anddisposingofplasticmaterialsisofagreat concernduetogreenhousegasesandtheglobal warmingeffects.Thedecayingofworldreservefrompetroleumandtheincreasingdemandsfromdeveloping countriessuchasChinaandIndiaarebothcausethe pricesofoiltoreachunprecedentedlevels.Thesehigh pricesdriveasimilarincreaseinpetroleum-basedplastics.Thisleadsforminingoflower-gradecrudeoilsuch astheCanadianheavyoil(Deffeyes,2008).Theheavy oilislesseconomicalandmoreenvironmentallyharmfulthanthelightoil.However,plasticscanbeofagreat assisttohumanitybyincreasingtheagricultural production,decreasingthefoodloses,reducingthe fuelconsumption,offeringlighterandcheaperalternativesformanyproducts,improvingthehealthcare,etc. Inotherwords,plasticmaterialsareessentialinour modernsocieties.Unfortunately,theenergyissues directlyimpacttheplasticsindustries.Whatwillbe theimpactonourdailylives,ourhealth,ourenvironment,andontheplasticindustryitself(morethan1 millionemployeesintheUnitedStatesalone)ifthesustainabletechnologiesdonotreachmaturitysosoonor iftheyarenotwidelyadopted?Developingappropriate methodsandapproachesforproducinggreencompositeshasbeenademandingpriorityforsometime. However,theevolvingeconomicalandtechnical

problemlimitspursuingsuchapproachesonlarge scales(AL-OqlaandSapuan,2014a,c).Eventhough theneedofdevelopingbioplasticandbiocomposite materialsisdemanding,suchmaterialsmust firstbe costcompetitive.

2 PLASTIC

2.1 OriginofPlastics

Thepolyethylenepolymerusedinplasticbagsproductionisderivedfrompetroleum.Petroleumisacomplex mixtureofcarbonandhydrogencompoundswith heavymetalsasnickelandvanadiumandothercomponentsassulfur.Aspetroleumcontainshighconcentrationofchlorinatedhydrocarbonsaswellasheavy metals,itistoxictoanimalsandplants.

Theprocessofextractionpetroleumiscomposedof fourstages: first,crudeoilisobtainedbydeepdrilling fromnaturalreservoirsbelowtheseaoroffshore.This crudeoilisshippedtotherefineries.Inthesecondstage, thecrudeoilisseparatedbyevaporation/condensation processatdifferenttemperatures.Inthethirdstage,the compoundsareyieldedtoconversionprocessinthe presenceofheat,pressure,andcatalyst(forinstance, platinum).Inthisprocess,theshapeofthecompounds anditsmolecularweightarechanged.Thecompounds obtainedfromtheprocessservesasfueltoautomobiles, factories,etc.Someofthesecompoundscanbedeliveredtofactoriesforupgrading(laststage)toproduce fertilizersanddifferentplasticproducts.Forinstance, ethyleneisupgradedfromtheserefinedcompounds andusedforplasticproducts.Ethyleneisexplosive, inflammable,toxic,andcarcinogenic.

Extractionpetroleumstages:Drilling / Separation / Conversion / Upgrading

Duringtherefiningstagesofthecrudeoiltobeconvertedtofuel,plastics,andotherpetro-basedproducts, manytypesofgasesareemittedtoair.Thesegasesare carryingharmfulcomponentslikecarbonmonoxide, hydrocarbons,sulfurdioxide,andnitrousoxide. Unfortunately,thesecomponentsremaininthe final petroleumcompoundsaftertheseparationprocess. Theireffectsonourenvironmentandontheecosystems arecatastrophicandcanleadtoacidrains,andunfortunately,theseeffectsareirreversible.

2.2 ApplicationsofPlastics

Plasticsbecomemoreandmoreveryessentialinour modernsocieties.Itisusedinawidevarietyofapplications,suchasinpackaging,automobileindustry,aerospace,agriculture,andhouseholdproducts,etc.Its availability, flexibility,durability,lightweight,and

mostimportantitscheappriceshelpplasticstodominateagreatportionofthecurrentproductionmarkets. Plasticsaremainlycategorizedintotwomaingroups: thermoplasticsandthermosets.Thermoplasticscanin generalbemeltedandrecycled,someexamplesofthermoplasticmaterialsarePE,PP,PS,polyethyleneterephthalate(PET),andpolyamide.Ontheotherside, thermosetshavecanneitherbemeltednorberecycled. Thisisbecausethepolymerchainsfortheseplasticsare connectedinstrongcross-linkbondsasthecasein epoxyresin,polyurethane,andunsaturatedpolyester. Asthepetro-basedplasticsdonotdegrade,theycause pollution.Thesolutiontothisistodevelopanduse biodegradablebioplasticsasalternativestotheconventionalplastics.Thesebioplasticswillrequireshorter timetodecomposeafterbeendisposed.Also,theycan fertilizethesoilinthecompostingprocess,wherethey canbemixwithsoilinordertodegradebythehelp ofbacteria.Thelifeofthebiodegradablebioplasticsbeginsfromrenewableresource,suchascelluloseand starch,andendseco-friendlycomparingwithpetrobasedplastics.

2.3 ChemicalPollutionfromPlastics

Greatportionofthechemicalpollutionoccursduring energygeneration;suchenergyisusedforgenerating electricity,miningindustry,transportation,etc.The pollutionstrikesourenvironmentthroughglobal warming,acidrains,andthroughproducingcarcinogenicsubstancesinairandallaround.Tonsofharmful gasesareblownintheatmosphereinmostoftheindustrialsectorsascoalmining,uraniumprocessing, petrochemicalindustry,etc.Thepollutionisexpected toincreasewiththeincreasepopulation,thedeveloped consumptionhabitsofpeople,andthegrowingandthe spreadingoftechnology.Directburningofplasticsin airspreadsveryharmfulandtoxicgasesintotheatmosphere.Someofthesegasesarealkanes,alkenes,and chlorinatedandaromatichydrocarbons(PAHs, PCDDs,andPCDFs).Infact,hugeamountofgases areaccumulatedinecosystem.Gaseslikecarbonmonoxide,nitrogenoxide,andvolatileparticulateswhen accumulatedinatmosphereformdarksmog.Inthe extrusionprocesseswherethemeltingtemperatureis reached(between150and300 ),manygasesareleaked totheecosystemduetotheattractionbetweenpolymersandtheadditives,longthermalexposure,oraging.

2.4 InitiativesAgainstPlasticsPollution

Somepeoplewhoareawareabouttheharmfulimpact ofusingconventionalplasticsinourdailylifearetrying toraisetheawarenessoftheirsocietiesbydistributing

eco-friendlybagsfabricatedfromnatural fibers(ALOqlaandSalit,2017;AL-OqlaandSapuan,2018a; Alaaeddinetal.,2019c).UnitedKingdomtooka pioneerstepandpreventedusingmicroplasticsinpersonalcareproductsaswellasincosmetics.Thisstep istaken,accordingtotheDepartmentofEnvironment, FoodandRuralAffairs,sincethemicroplasticsaremore harmfulthanthelarge-sizeplastics.Asthemicroplastics areinfinitesimal,theycannotberemovedorseparated fromtheecosystemeasily,andthus,theycaneasily reachthefoodchain.AstudentnamedJonssonfrom Icelandintroducednewbottlesbymixingpowdered agarwithwater.Thesebottleshelpindevelopingsustainableenvironmentandreplacetheconventionalbottlesmadenormallyfromplastics.Somecountriessuch asSriLankastartedtoenforcetheplasticmanufacturers toproducetheirproductswithcertainstandards.Some citiesfromallovertheworldarehappilydeclaringthat theircitiesareplastic-freezones.Mostofthesecities startedbybanningtheuseofplasticbagsand announcedadeadlinefortheiruse.

3 RENEWABLE-BASEDPLASTICS

Inthepast,renewable-basedplasticswerelackingthe sufficientpropertiesformanyapplicationsbesidetheir highcosts.Nowadays,greatsuccessesarebeing achievedinnewbioplasticmartialscommercially. Theseachievementsaredirectlyreflectedfromthesuccessfulapplicationsoftheindustrialbiotechnology.ExamplesincludeMirel(polyhydroxyalkanoates polymers)forinjection-moldedproducts,polylactides for flexible films,andcompostbags(AL-Oqlaetal., 2018a;AL-Oqlaetal.,2015c;AL-OqlaandSapuan, 2014b).Otherexamplesarethesoyoil-basedmaterials thatareproducedoncommercialscalebynumberof companiesinordertobeusedinurethanesindustries (AL-Oqlaetal.,2018b;Faresetal.,2019).

Moreover,manyglobalcompaniesareworkingon commercializingfurtherrenewable-basedplasticsas PBS(polybutylenesuccinate)foruseas flexible films inagriculturalandpackagingapplications.Besides, manyofthesoftdrinkmanufacturershaveconverted toutilizePETfromrenewableresources.Allthesecumulativesuccessesstronglyencourageinreplacingthe petroleumplasticsproducedinbillionsofpounds annually.Fortunately,generatingrenewable-based plasticsarebecomingmoreandmorepossible.Better understandingoftheimpactsofplasticsontheenvironmentalisnowpossiblethroughthelifecyclelife-cycle analysis(LCA)oftheseplastics.Inotherwords,the LCAstudiestheoverallimpactofthematerialalong

itslife(Blacketal.,2011).Improvementstrategiesfor theprocessesarealsointroducedandanalyzedfortheir impacts.Forexample,plantingcropswithlowwater andfertilizerneedsinmarginalregionscanreduce deforestationaswellasthepressuresonfoodsupplies. Similarly,thefastandwidedevelopingstepsinthe biotechnologicalindustryarefacilitatingtheconversion ofthebiomassintofuelorusefulchemicalsandare makingitveryfeasible.Finally,nanotechnologyis contributinginenhancingthematerialsperformance properties.

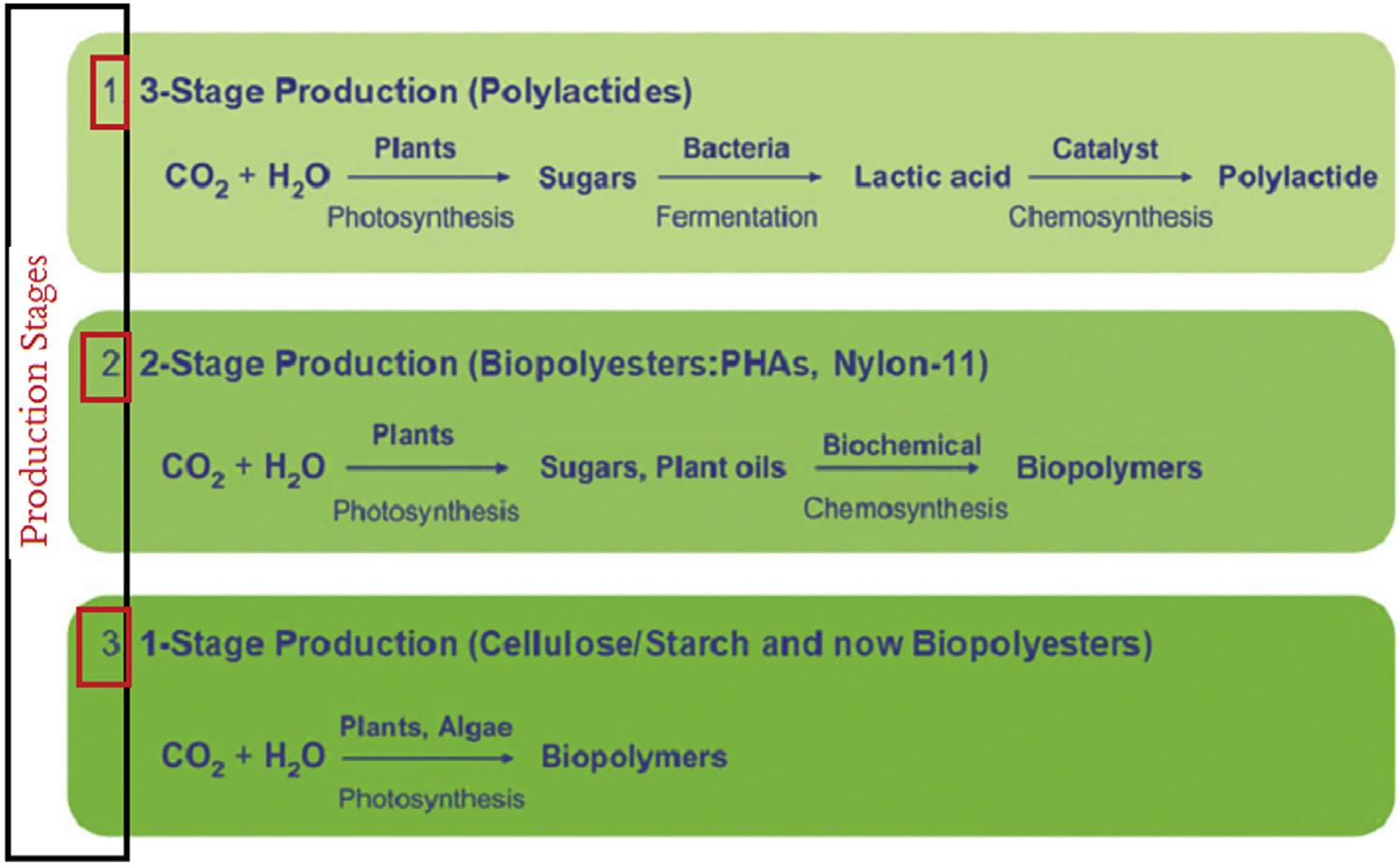

Bioplasticsareobtainedbymanystagesasdescribed intheschemeshownin Fig.1.1.Thenumberofthe chemicaltransformationsrequiredtoconvertfromthe rawbiomasstothe finalpolymeriscalledastage.For example,polylactidesisconsideredasthree-stagebioplastics:plantisconvertedintosugar,thenthesugar isfermentedtolacticacid,and finallythelacticacidis polymerized.Inatwo-stageprocess,theplantisdirectly fermentedandpolymerizedasthecasewithpolyhydroxybutyrates/polyhydroxyalkanoates.Another exampleoftwo-stagebioplasticsisthepolyaminoundecanoicacidknownasNylon-11:castoroilis first extractedandthenchemicallyconvertedtopolymers. Finally,inone-stagebioplastics,thebiomassitselfcontainsthetargetedpolymer.Mostofthecommonbiopolymers,suchasthenaturalrubber,starch,and cellulose,areobtainedinone-stage.

Thegeneticengineeringcontributestotheadvances inbiotechnologybymovinggenesoverspecies,for example,movingsomegenesfromthebacteriathat producePHAsintosugarcane.Directproductionof desiredpolymersfromsunlightandCO2 hasmany attractivebenefits.However,theLCAshould firstbeperformed.Besides,suchgeneticengineeringfacesmany ethical,social,environmental,andregulatoryissues.

4 STARCH-BASEDBIOPLASTICS

Starch-basedplasticshavemanyindustrialapplications infoodpackaging,injectionmolding,andas flexible films.Theyarecomposedofstarch,plasticizeragents, andadditives.Starch-basedplasticsareconsidered veryattractivechoicesintermsofeconomicalandsustainableaspectsduetothelowcost,theinherentbiodegradability,andthelargecontentoftherenewable resourcesinitscomposition.However,theyarewater sensitive,andtheyrevealpoorperformanceproperties insevereenvironmentalconditions(Iannottietal., 2018).Recentlydevelopedresearchesimprovedthewaterresistivityofthestarch-basedplasticswhilemaintainingtheirbiodegradability,andhence,their

Bioplasticsfeaturesbaseduponthenumberofbiochemicaltransformationsrequiredtoachievethe finalpolymer.

applicationswereextendedtonewaspects.Somegrades oftheseplasticsarecommerciallyproducedasshownin Fig.1.2

Blendingstarchwithsyntheticpolymerssuchas polyethyleneorethylenevinylacetatehasbeen extensivelyinvestigated.Theadvantagesoftheobtained plasticsarethelowcost,thegoodmechanicalproperties,thegoodpackagingproperties,andtheabilityto manufactureusingconventionalmachines.The disadvantagesoftheseplasticsarethenonrenewable syntheticcomponentsandthepartialdegradability (Alaaeddinetal.,2019a,d).

5 BIOPOLYESTERS

Regardlessofwhetherthepolyestersarecomposedof renewableresourcesorfromfossilresources,theyare oftendegradableastheesterbondscanbeeasilyhydrolyzed.PolyestersfromrenewablesourcesasPLAsand PHBsarenowcommerciallyavailable.Ontheother side,polyestersfromfossilresourcesarealsocommerciallyavailableasPBS.Itisnoteworthythatsignificant effortsarecurrentlypushingtoproducecommercial PBSfromrenewableresources.Therearewideand extensiveinvestigationsintheliteratureonincorporatingbiopolyesters,petroplastics,andotherbioplastics inpolymerblends(AL-OqlaandEl-Shekeil,2019; Alaaeddinetal.,2019c;Valerioetal.,2016).

6 BIOCOMPOSITESANDBIONANOCOMPOSITES

Significantattentionisalsoraisedfornatural fiberreinforcedcompositeslately.The fibersareobtainedfrom abaca, flax,jute,hemp,palm,kenaf,andmanymore plants(AL-Oqla,2017;AL-OqlaandSapuan,2018b; AL-Oqlaetal.,2015b).These fibersareusedtoproduce biocompositeswithmatricesofbioplasticorpetroplasticmaterials.Amongthese fibers,kenafisconsidered oneofthemostpromisingnatural fibersformanyreasons,includingthelowemissionofodor.Untilnow, biocompositesaremainlydevotedforsheetapplications,morespecificallyasinteriorpartsinautomobiles (AL-Oqlaetal.,2015a).Ontheotherside,nanocompositesarethepromisingkeytoovercomemanyofthe drawbacksofthebiocomposites.However,thereare stillmanychallengesintheirdevelopment(AL-Oqla andOmari,2017;AL-OqlaandSalit,2017;AL-Oqla etal.,2014;Sadrmaneshetal.,2019).Massiveresearch hasbeenconductedonnanoclayreinforcedbioplastics. Addingnanocelluloseorcarbonnanotubestobiopolymerscanimproveasetofthermalproperties.An increasingattentionispaidtousingnanocellulosein bio-basedmaterialsasitscostislessexpensivethan manyconventionalpetroplastics($0.20 $0.25/lb). Renewable-basedpolymersarepreferredoverpetroplastics.However,formanyapplicationssuchasin automobileindustry,andinbuildingconstructions,

FIG.1.1

theyareundesirableastheypossessfastdegradability (AL-Oqlaetal.,2018a;Aridietal.,2016a,b;Fares etal.,2019).Furthermore,asthepetroleumpricesare continuallyvibrating,andlately,theyarereachingunprecedentedlevels.Thereisastrongeconomicneedto searchforotheralternativestothetraditionalmaterials available(AL-OqlaandSapuan,2018a).

Extensiveeffortshavebeenspentinthelastfew yearsindevelopingsuchalternativesfromrenewable resources.TheUnitedStatesisleadingtheworldin this fi eldasitisthelargestproducerofethanolfrom biomass.Ethanol,inturn,isusedinproducingtwo importantnondegradablebioplastics:thesearethe biopolyethyleneandbio-PET.Theproduction pathwayofthebiopolyethyleneisusuallyachieved byseveralstepsas fi rst,ethanolisdehydratedto ethylene,andthen,ethyleneispolymerizedusing oneofmanyavailablemechanismswiththehelpof catalysts.Anotherexampleofdevelopingalternative productsfromrenewableresourcesisthebutylrubber (acopolymerofisopreneandisobutylene)thatwill soonbecommercialized.First,isobutanolisfermentedfromcellulosesugarorfromstarch.Then,isobutanolisconvertedintoisobutylene.Combiningthe derivedisobutyleneandtherenewableisopreneproducesthebutylrubber,whichiscalledthenatural/syntheticrubber.Onemoreexampleofdeveloping alternativeproductsfromrenewableresourcesisthe 3-hydroxypropionicacid(3-HP).Thismonomercan

bedehydratedtoproducerenewableacrylicacid (usedinpaintsandinsuperabsorbants),oritcanbe polymerizedtoproducebiopolyesterpoly(3-HP).Nylons,ontheotherhand,havedesirablepropertiesbesidetheirtoughness.However,theyshowrelatively highprices.Inthepast,Nylon-11hasbeenderived fromcastoroil.Nowadays,manyresearchersaretrying todevelopothergradesofNylonfromrenewableresources.Asanexample,Nylon-4cannowbederived frommonosodiumglutamate.Thebiotechnological industryiscon fi denttorevealneworganismswith engineeredmetabolismtoinnovatenewpathways forotherpolyamideprecursors.

7 SUSTAINABILITY

Inordertoenhancethepropertiesofplastics,chemical additivesarecommonlyused.unfortunately,theseadditiveshaveharmfulimpactontheenvironment.The microparticlesinplasticsusuallyreachtheecosystem bywind,water,animals,andorganisms.Hence,they combinewiththefoodchaincausinghazardoushealth problemsthatmayleadtoinjuriesorevendeathofthe organisms.Inordertolimitthebadeffectofplastics, newawaretrendsshouldbedevelopedinsocietiesaccordingthesustainableenvironment.Anexampleto thisisbyreplacingtheplasticbagscommonlyusedby bagsmadeofnatural fibers.Theharmfulcomponents intheplasticproductscancausemanycomplex

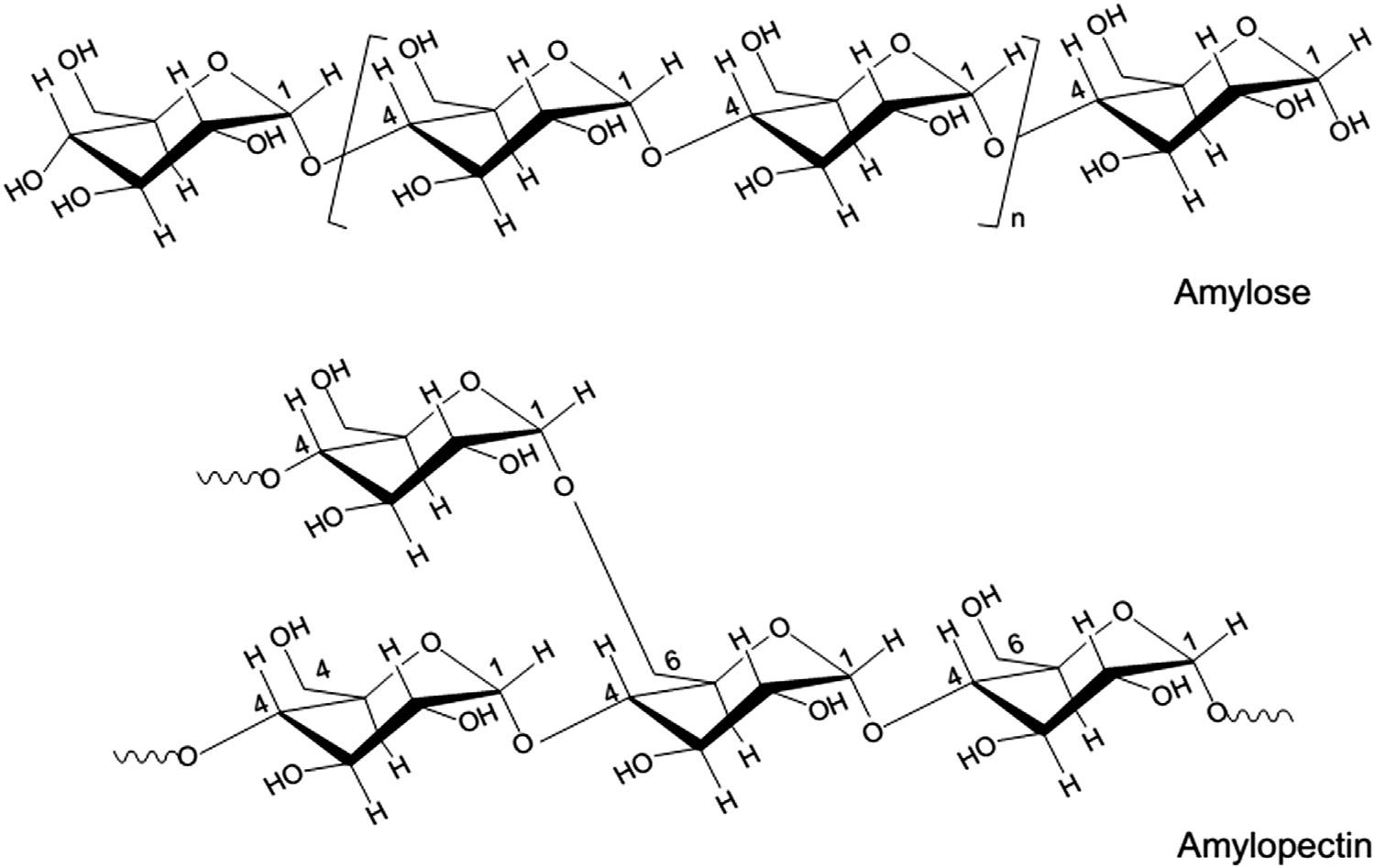

FIG.1.2 Starchchemicalstructureofbothamyloseandamylopectin.

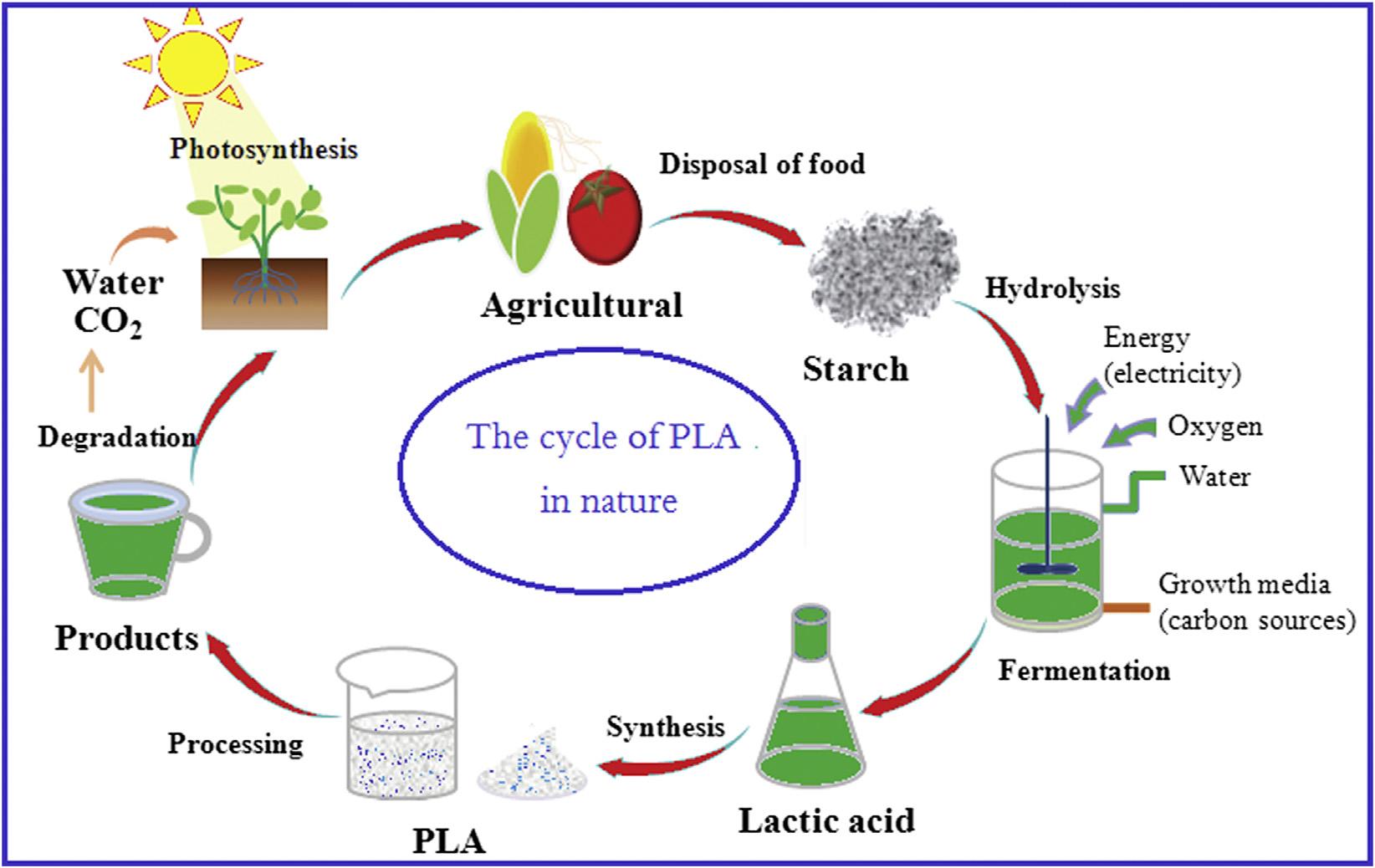

problemsasreducingthequalityofair,water,andthe wholesurrounding.Foraproducttobeclaimedthat itissustainable,itshouldfulfillalltherequirements ofhealthyenvironmentwithoutharmingthe ecosystem. Fig.1.3 highlightstheclosingloopofend lifeofbioplastics(PLAasanexample)toenhancethe sustainability.Forbioplastics,theplantsaregrownin farms,then,theyarepolymerizedandconvertedto theintendedproducts,andthen,theyaretransported tomarketsuntiltheyreachtheconsumers.Attheend ofthesebioplastics’ life,theyarecompostedorrecycled (degradationoccursfordegradablepolymers)without leavinganyharmfulortoxiccomponentsinthe environment.

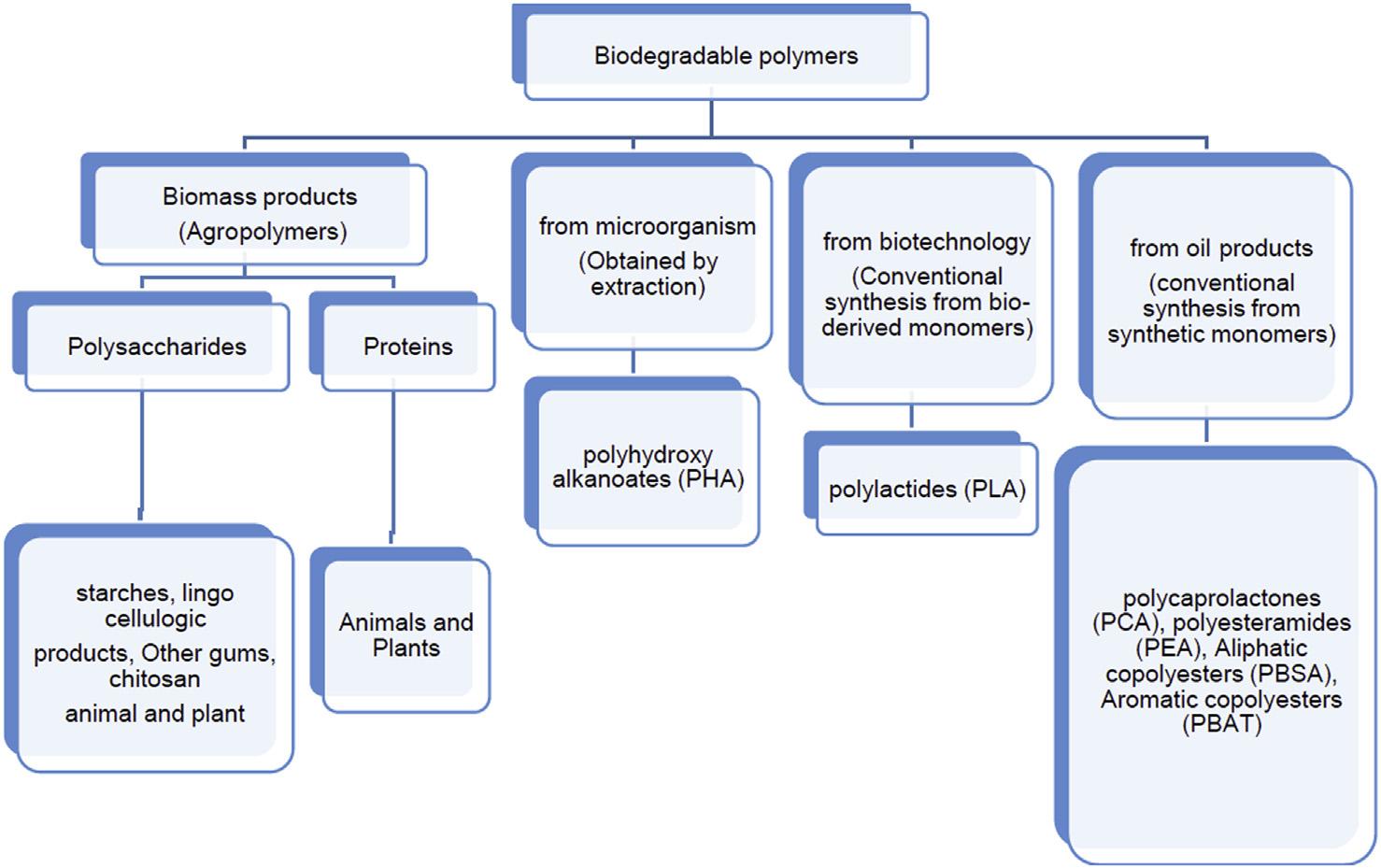

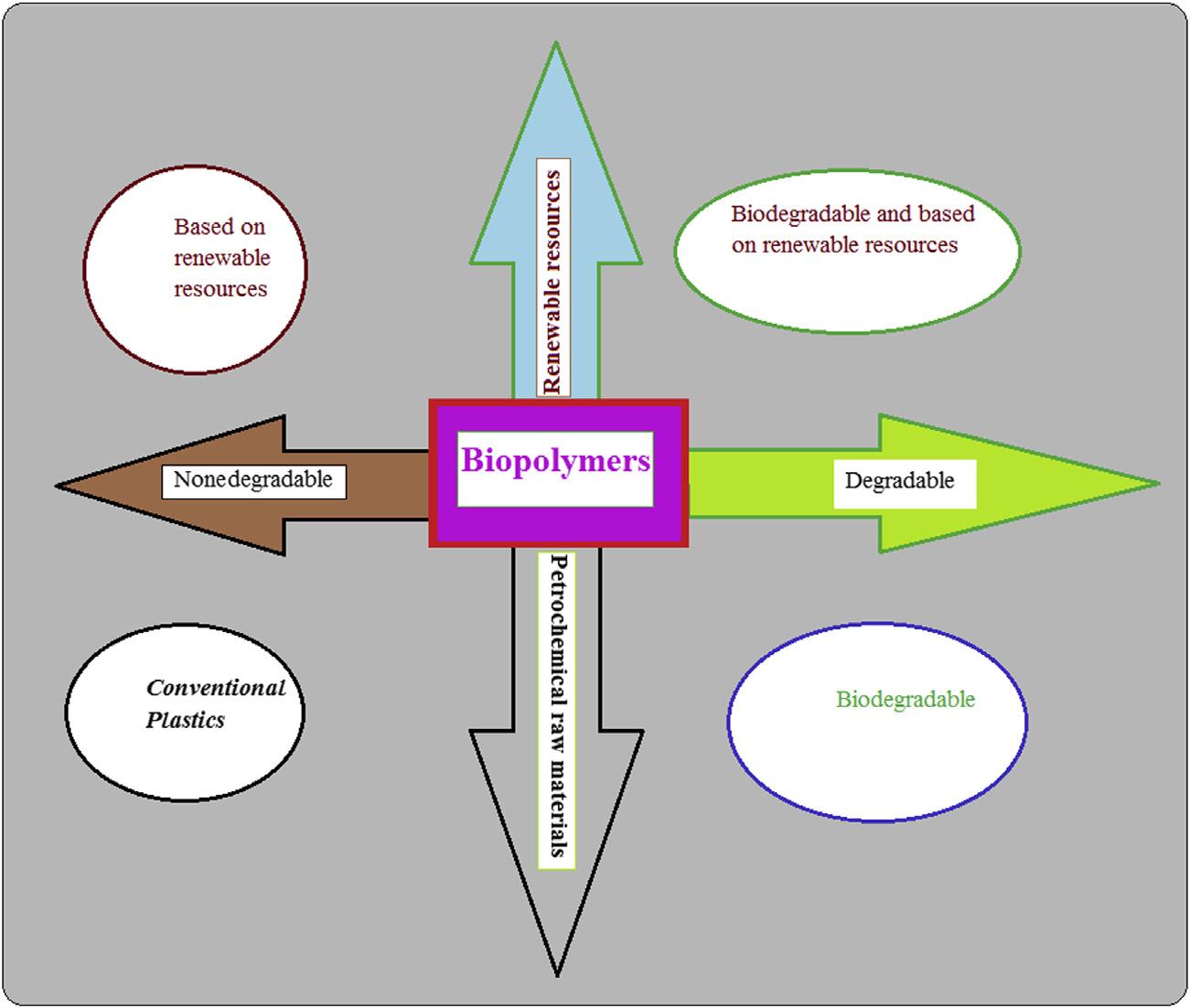

Butunfortunately,fossilfuelisrequiredduringthe manufacturingstepsofthebioplastic,aswellasduring transportingtheplantstothemanufacturersorthe final productstotheretailers.However,apartialsolutionto thisissuecomesfromthefactthatmanymanufacturers aremovingtowardusingcleanrenewableenergyin theirfactories.Bioplasticsarecategorizedaccordingto manyparameters:origin,composition,synthesisprocess,andapplication. Fig.1.4 demonstratestheclassificationsofbiodegradablepolymers,and Fig.1.5 illustratesthebioplasticsandthethreedistinct biopolymergroupswithrespecttodegradabilityand renewabilityaspects.

7.1 TypesofBioplasticstoDevelop SustainableIndustry

7.1.1 Starch-basedplastics

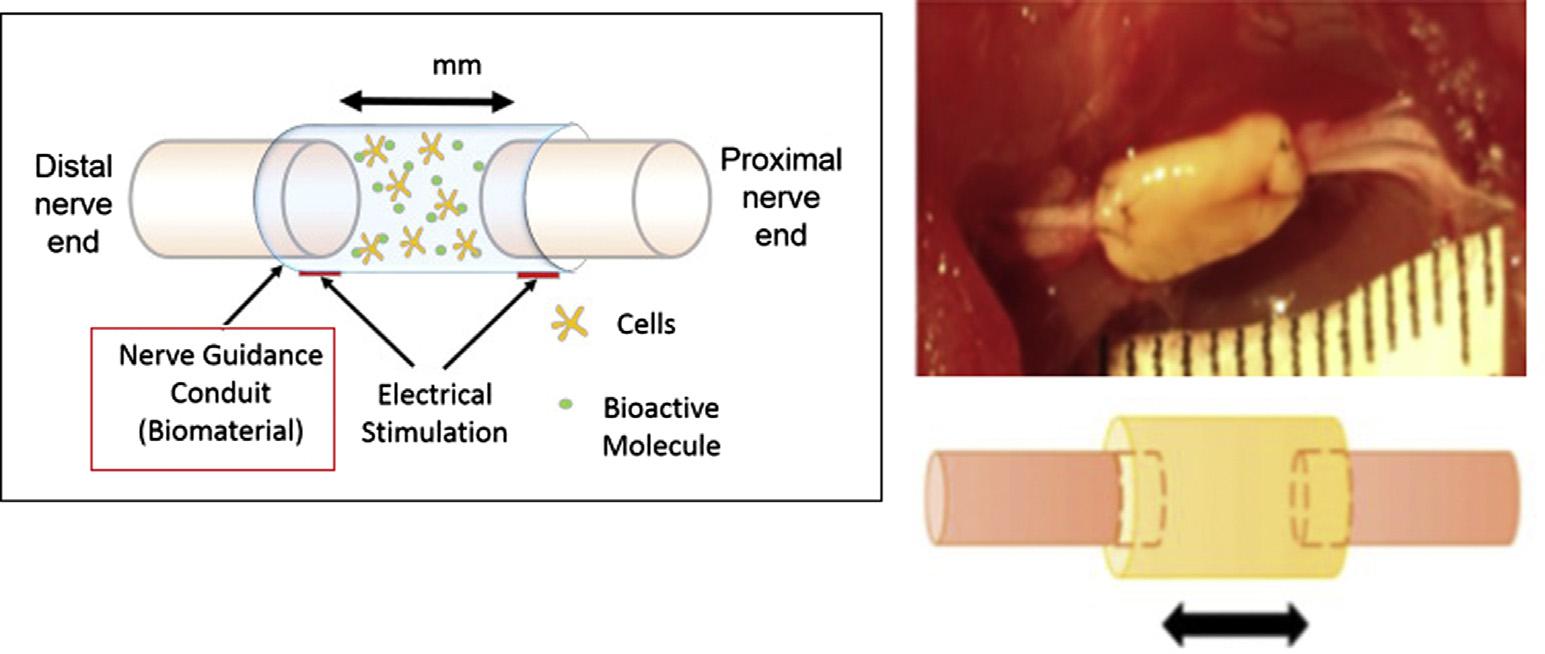

Starch-basedplasticsarethemostcommonlyused amongallotherbioplastics.Itisdominatingabout 50%ofthebioplasticmarket.Simplestarch-based plasticscanbeproducedathomewithsimpletools. Starchisgoodinabsorbinghumidity,andthus,it wasasuitablechoicefordrugcapsulesaswellas medicalapplications. Fig.1.6 isanillustrativediagramfortheapplicationsofbiopolymersinnerve repairing.

Additiveslikeglycerineandsorbitolcanworkas plasticiserand fl exibilizerwhenaddedtostarchto enhanceitsthermalcharacteristics.Thesethermal characteristicscanbetailoredtotherequiredneeds bycontrollingtheamountoftheadditivesinthe starch-basedplastic(calledthermoplasticalstarch). Starchiscommonlymixedwithbiodegradablepolyestersinordertoproducevarietiesofcompounds,such asstarch/polylacticacid,starch/Eco fl ex,orstarch/polycaprolactone.Thesecompoundsarecompostable,and theyareusedformanyapplications.Othercompoundsarealsodevelopedasstarch/polyole fi nblends. Theyarenotbiodegradable,buttheyreveallowercarbonfootprintcomparingtopetro-basedplasticsfor sameapplications.Starchischeap,renewable,and

FIG.1.3 Endoflifeofbioplasticstoenhancesustainability.

FIG.1.4 Biodegradablepolymers.

FIG.1.5 Illustrationofthebioplasticsandthethreedistinctbiopolymergroups.

availableinplentyamounts.Starch-basedplasticsare composedofcomplexblendswithcompostable plasticsaspolycaprolactone,polylacticacid,PBS, polyhydroxyalkanoates,andpolybutyleneadipate terephthalate.Thiscombinationwillenhancetheperformancepropertiesoftheplastic,aswellasimprove itswaterresistivity.Bioplastic fi lmsareproduced mainlyfromblendingstarchwithbiodegradablepolyesters;hence,these fi lmsarebiodegradableandcompostable.Theirapplicationsaremainlyinpackaging: foodpackagingasinbakeryorfruitandvegetable bagsandgoodspackagingwherebubble fi lmsare commonlyused.Newlydevelopedstarch-based fi lms bytheAgriculturalResearchServicescientistshave thepotentialtobeusedaspapers.

7.1.2 Cellulose-basedplastics

Thecellulose-basedbioplasticscommonlyusedarethe celluloseesters(includingcelluloseacetateandnitrocelluloseandtheirderivatives).Celluloseacetateis commonlyusedinpackagingblisters.Itispossibleto modifythecellulose-basedplasticstobecomethermoplasticmaterialssuchasthecelluloseacetate.However, thecelluloseacetateisexpensiverelativetoother plastics,aswellasitrequiresextensivemodi fications. Therefore,itsuseinpackagingisnotcommon.Onthe otherside,addingcellulosic fiberstostarchcanenhance itscharacteristicsasthemechanicalproperties,thewater resistance,andthegaspermeability.

7.1.3 Protein-basedplastics

Proteinsderivedfromdifferentsourceshavebeen alreadyusedinplasticstoformbiodegradablebioplastics.Forexample,soyproteinshavebeenusedin bioplasticssinceearly1900s.Fordcompanyhadused soy-basedplasticsintheirautomobileslongtimeago.

Therearesomechallengesinusingsoy-basedplastics duetotheircostandtheirwatersensitivity.However, thiscanbeovercomebyblendingsoyproteinwith someexistingbiodegradablepolyestersinorderto decreasethecostandimprovethewatersensitivity. Otherproteinsarebeinginvestigatedforpotential blending.Forexample,wheatglutenandcasein revealedverypotentialpropertiestobeusedasrawmaterialsforvarietiesofbioplastics.

7.2 EnvironmentalImpact

Cellulose,starch,sugar,wood,andmanyotherrenewableresourcescanbeusedassustainablealternatives tothefossilfuelresourcesintheplasticproduction. Thebioplasticsproducedfromtheserenewable resourcesaresustainableincomparisontotheconventionalplastics.However,theenvironmentalimpactof bioplasticsshouldbeinvestigated.Thisisconductedusingmanymetricssuchasthewaterandenergyusage, thebiodegradation,thedeforestation,etc.Theenvironmentalimpactsofbioplasticsarecategorizedasthe nonrenewableenergyusage,theeutrophication,the acidification,andtheclimatechange.Thenonrenewableenergyusageinbioplasticproductionislower thantherequiredenergyfortheconventionalplastics forthesameapplications.Theemissionofthegreenhousegasesissignificantlyreducedinbioplasticproduction.Hence,governmentsandorganizationscan increasethesustainabilityoftheenvironmentbyadoptingthebioplasticsinsteadoftheconventionalplastics, andbyapplyingsuitableregulationstoachievethis goal.Althoughtheenvironmentalimpactmetrics regardingenergyandgreenhousegasesencourageusing bioplasticsinsteadofconventionalplastics,othermetricsshouldalsobeinvestigated.Bioplasticshavehigher potentialsofeutrophicationthanconventionalplastics.

FIG.1.6 Illustrativediagramfortheapplicationsofbiopolymers-basedmaterialsfornerverepairing.

Eutrophicationisthewaterrichnessofnutrients.Itis consideredaseriousthreattowaterresourcesasit endsthelifeoftheaquaticorganisms,harmsthefreshwater,andcausesharmfulalgalblooms.Thereasonof theeutrophicationisthatduringproductionofthe biomass,phosphate,andnitrate filtrateintothefreshwaterreservoirs.Anothermetricistheacidi fication.In fact,thisenvironmentalimpactisnegativeinbioplasticsastheyincreasetheacidi fication.Thehigh harmfulincreasesofbothmetrics(acidificationand eutrophication)arenotonlyduringthebioplasticproductionbutalsoduringplantingandgrowingtheraw materialswherethechemicalfertilizersareused.

7.3 BiodegradationofBioplastics

Thebiodegradationinbioplasticsisoccurredbydepolymerizingthepolymericmaterialsusinginherentenzymes.Thebiodegradationstartsatthesolid/liquid interfacewheretheenzymesareincontactwiththe solidpolymers.Someconventionalplasticscanalso bebiodegradableiftheycontainbiodegradableadditives.Bioplasticsareabletobiodegradeunderextreme conditionsofheatandhydration.Thebiodegradation speedoftheseplasticsisalteredbytheenvironmental conditions,whereinthepresenceofsoilandcompost, thebiodegradationbecomesfasterandmoreefficientas richmicrobialdiversitywillexist.Theefficiencyofthe biodegradabilityincompostenvironmentscanbe increasedmorebyincreasingthetemperatureandby addingsolublesugar.Besideincreasingthebiodegradationefficiency,compostingisabletoincrediblyreduce theemissionofgreenhousegases.Ontheotherside, biodegradationinsoilenvironmentswillprovide higherdiversityofmicrobes;makingiteasierfor biodegradationtotakeplace.However,soilenvironmentstakelongertimetobiodegradethebioplastics andrequirehighertemperatures.Otherenvironments canincreasetheefficientlyofthebiodegradationas theaquaticenvironment.However,usingtheaquatic environmentsinordertobiodegradethebioplasticsis riskyandnotrecommended;itshouldbeavoidedas itharmsthefreshwaterandtheecosystemsandends thelifeoftheaquaticorganisms.Lastparameters affectingthebiodegradationspeedarethecomposition andthestructureofthebioplastics,andindeveloping thebioplastics,theresearchersputgreateffortstooptimizethebiodegradationspeedratetomeettheapplicationsneeds.

8 CONCLUSIONS

Thesocialandtheenvironmentaldemandsinone hand,aswellthelateachievementsofthebiotechnologyandthenanotechnologyontheother,are

dramaticallyaffectingourviewforplasticsandhow theyshouldbeproduced.Thesereasonsarepushingresearcherstoaccelerateinenhancingthebioplasticmaterialstohigherlevelsofperformanceandin commercializingtheirprocesses.Starch-basedplastics arethemostcommonlyusedamongallotherbioplastics.Theemissionofthegreenhousegasesissignificantlyreducedinbioplasticproduction.Hence, governmentsandorganizationscanincreasethesustainabilityoftheenvironmentbyadoptingthebioplasticsinsteadoftheconventionalplastics,andby applyingsuitableregulationstoachievethisgoal. Nowadays,greatsuccessesarebeingachievedinnew bioplasticmaterialscommercially.Theseachievements aredirectlyreflectedfromthesuccessfulapplications oftheindustrialbiotechnology.

REFERENCES

AL-Oqla,F.M.,2017.InvestigatingthemechanicalperformancedeteriorationofMediterraneancellulosiccypress andpine/polyethylenecomposites.Cellulose24, 2523 2530.

AL-Oqla,F.M.,El-Shekeil,Y.,2019.Investigatingandpredictingtheperformancedeteriorationsandtrendsofpolyurethanebio-compositesformorerealisticsustainabledesign possibilities.JournalofCleanerProduction.

AL-Oqla,F.M.,Omar,A.A.,Fares,O.,2018a.Evaluatingsustainableenergyharvestingsystemsforhumanimplantablesensors.InternationalJournalofElectronics105, 504 517.

AL-Oqla,F.M.,Omari,M.A.,2017.Sustainablebiocomposites: challenges,Potentialandbarriersfordevelopment.In: Jawaid,M.,Sapuan,S.M.,Alothman,O.Y.(Eds.),Green Biocomposites:ManufacturingandProperties.SpringerInternationalPublishing(Verlag),cham,switzerland, pp.13 29.

AL-Oqla,F.M.,Salit,M.S.,2017.MaterialsSelectionforNatural FiberComposites.WoodheadPublishing,Elsevier,Cambridge,USA.

AL-Oqla,F.M.,Sapuan,M.S.,Ishak,M.R.,Aziz,N.A.,2014. Combinedmulti-criteriaevaluationstagetechniqueasan agrowasteevaluationindicatorforpolymericcomposites: datepalm fibersasacasestudy.BioResources9, 4608 4621.

AL-Oqla,F.M.,Sapuan,M.S.,Ishak,M.R.,Nuraini,A.A.,2015a. Decisionmakingmodelforoptimalreinforcementconditionofnatural fibercomposites.FibersandPolymers16, 153 163.

AL-Oqla,F.M.,Sapuan,S.,2018.Investigatingtheinherent characteristic/performancedeteriorationinteractionsof natural fibersinbio-compositesforbetterutilizationof resources.JournalofPolymersandtheEnvironment26, 1290 1296.

AL-Oqla,F.M.,Sapuan,S.,2018b.Natural fibercomposites.In: Sapuan,S.M.,Ishak,M.R.,Sahari,J.,Sanyang,M.L.(Eds.), KenafFibersandComposites.CRCPress.

AL-Oqla,F.M.,Sapuan,S.,Anwer,T.,Jawaid,M.,Hoque,M., 2015b.Natural fiberreinforcedconductivepolymercompositesasfunctionalmaterials:areview.SyntheticMetals 206,42 54.

AL-Oqla,F.M.,Sapuan,S.,Fares,O.,2018b.Electrical Based ApplicationsofNaturalFiberVinylPolymerComposites, NaturalFibreReinforcedVinylEsterandVinylPolymer Composites.Elsevier,pp.349 367.

AL-Oqla,F.M.,Sapuan,S.,Ishak,M.,Nuraini,A.,2015c.Predictingthepotentialofagrowaste fibersforsustainable automotiveindustryusingadecisionmakingmodel.ComputersandElectronicsinAgriculture113,116 127.

AL-Oqla,F.M.,Sapuan,S.,Jawaid,M.,2016.Integrated mechanical-economic environmentalqualityofperformancefornatural fibersforpolymeric-basedcomposite materials.JournalofNaturalFibers13,651 659.

AL-Oqla,F.M.,Sapuan,S.M.,2014a.DatePalmFibersandNaturalComposites.In:PostgraduateSymposiumonCompositesScienceandTechnology2014&4thPostgraduate SeminaronNaturalFibreComposites2014,28/01/2014, Putrajaya,Selangor,Malaysia.

AL-Oqla,F.M.,Sapuan,S.M.,2014b.Enhancementselecting propernatural fibercompositesforindustrialapplications. In:PostgraduateSymposiumonCompositesScienceand Technology2014&4thPostgraduateSeminaronNatural FibreComposites2014,28/01/2014,Putrajaya,Selangor, Malaysia.

AL-Oqla,F.M.,Sapuan,S.M.,2014c.Natural fiberreinforced polymercompositesinindustrialapplications:feasibility ofdatepalm fibersforsustainableautomotiveindustry. JournalofCleanerProduction66,347 354.

Alaaeddin,M.,Sapuan,S.,Zuhri,M.,Zainudin,E.,AlOqla,F.M.,2019a.Photovoltaicapplications:statusand manufacturingprospects.RenewableandSustainableEnergyReviews102,318 332.

Alaaeddin,M.,Sapuan,S.,Zuhri,M.,Zainudin,E.,ALOqla,F.M.,2019b.Physicalandmechanicalpropertiesof polyvinylidene fluoride-Shortsugarpalm fiber nanocomposites.JournalofCleanerProduction235, 473 482.

Alaaeddin,M.,Sapuan,S.,Zuhri,M.,Zainudin,E.,ALOqla,F.M.,2019c.Polymermatrixmaterialsselectionfor shortsugarpalmcompositesusingintegratedmulticriteria evaluationmethod.CompositesPartB:Engineering 107342.

Alaaeddin,M.,Sapuan,S.,Zuhri,M.,Zainudin,E.,ALOqla,F.M.,2019d.Polyvinyl fluoride(PVF);itsproperties,

applications,andmanufacturingprospects.In:IOPConferenceSeries:MaterialsScienceandEngineering.IOPPublishing,p.012010.

Aridi,N.,Sapuan,S.,Zainudin,E.,AL-Oqla,F.M.,2016a. Investigatingmorphologicalandperformancedeteriorationofinjection-moldedricehusk polypropylene compositesduetovariousliquiduptakes.International JournalofPolymerAnalysisandCharacterization21, 675 685.

Aridi,N.,Sapuan,S.,Zainudin,E.,AL-Oqla,F.M.,2016b. Mechanicalandmorphologicalpropertiesofinjectionmoldedricehuskpolypropylenecomposites.InternationalJournalofPolymerAnalysisandCharacterization 21,305 313.

Black,M.,Whittaker,C.,Hosseini,S.,Diaz-Chavez,R., Woods,J.,Murphy,R.,2011.Lifecycleassessmentandsustainabilitymethodologiesforassessingindustrialcrops, processesandendproducts.IndustrialCropsandProducts 34,1332 1339.

Deffeyes,K.S.,2008.Hubbert’sPeak:TheImpendingWorld OilShortage,NewEdition.PrincetonUniversityPress. Fares,O.,AL-Oqla,F.M.,Hayajneh,M.T.,2019.Dielectric relaxationofmediterraneanlignocellulosic fibersforsustainablefunctionalbiomaterials.MaterialsChemistryand Physics.

Halley,P.,Dorgan,J.R.,2011.Next-generationbiopolymers: advancedfunctionalityandimprovedsustainability.MRS Bulletin36,687 691.

Iannotti,G.,Fair,N.,Tempesta,M.,Neibling,H.,Hsieh,F.H., Mueller,R.,2018.StudiesontheEnvironmentalDegradationofStarch-BasedPlastics,DegradableMaterials.CRC Press,pp.425 446.

Jakubowicz,I.,2003.Evaluationofdegradabilityofbiodegradablepolyethylene(PE).PolymerDegradationandStability 80,39 43.

Khabbaz,F.,Albertsson,A.-C.,Karlsson,S.,1999.Chemical andmorphologicalchangesofenvironmentallydegradable polyethylene filmsexposedtothermo-oxidation.Polymer DegradationandStability63,127 138.

Sadrmanesh,V.,Chen,Y.,Rahman,M.,AL-Oqla,F.M.,2019. Developingadecisionmakingmodeltoidentifythemost influentialparametersaffectingmechanicalextractionof bast fibers.JournalofCleanerProduction117891.

Valerio,O.,Pin,J.M.,Misra,M.,Mohanty,A.K.,2016.Synthesis ofglycerol-basedbiopolyestersastoughnessenhancersfor polylacticacidbioplasticthroughreactiveextrusion.ACS Omega1,1284 1295.

ProcessingofThermoplasticStarch

RIDHWANJUMAIDIN • SITINURAISHAHMOHDZAINEL • S.M.SAPUAN

1 INTRODUCTION

Duetoenvironmentandmanageabilityissues,thiscenturyhasseenexceptionalaccomplishmentsingreen innovationinthematerialscience fieldthroughthe improvementofbiocomposites(Joshietal.,2004). Society’sexpandingfamiliarityonthesignificanceof ecologicalsafeguardinghasdriventremendous measuresforexploringdevelopmentsofmorenatural materials.Theadvancementofelitematerialproduce usingnormalassetsispresentaroundtheworld.The improvementofregular fibercompositesisbecoming amoregenuineconsiderationduetotheirpromising properties.Abundantagriculturalwastemakesthem aneasysourceformaterialenhancement.Theenhancementofbio-basedpolymersasalternativematricesfor petroleum-derivedpolymersfurtherprovidesanother greenperspectiveforcomposites.Adaptingnatural fiber asthereinforcementappearasapracticalsolution, particularlyinautomotive,foodpackaging,infrastructure,andbuildingitemapplications(Scholtenetal., 2014).Amongbiopolymers,starchstandsoutasthe mostencouragingsinceitiseasilyaccessible,simple, abundant,sustainable,andbiodegradable.

2 BIOPOLYMERS

Biopolymersarepolymersthatoccurinnature.Starches andproteins,forinstance,arebiopolymers.Numerous biopolymersarenow financiallydeliveredatavast scale,despitethefactthattheywillnotbeusedoften forthecreationofplastics.Onlyasmallportionof deliveredbiopolymersareemployedinthecreationof plastics.Byutilizingthemmore,itwouldfundamentallydiminishourrelianceonfabricated,nonsustainableassets.Otherthanbeingaccessible,biopolymers haveafewmonetaryandecologicalpointsofinterest. Biopolymersdemonstrateanadvantageforhandling waste.Forinstance,replacingpolyethylenebya biopolymercouldhelpremoveplasticpiecesfoundin compost.Coalitionbetweensyntheticpolymers,

commonpolymers,andbiodegradablepolymerscan formnovelmaterialssincetheycanconsolidatethe processcapacitywithbiodegradationandutilization ofsustainablecrudematerials.Inanycase,customary polymerstypicallydisplayabnormalamountsofrecyclabilityandtherecyclingprocedurecanbeinfluenced bythepresentationofasystemcontainingcommon polymers(Peresetal.,2016).

2.1 CategorizationofBiopolymers

Biopolymerscanbeobtainedfrommicrobialframeworksextractedfromhigherlifeformssuchasplants orintegratedsyntheticallyfromessentialbiological buildings.Biopolymersaredevelopedforvariousapplicationsrangingfrompackaging,medical,pharmaceutical,etc.Apreviousstudy(Scholtenetal.,2014)had investigatedtheroleofbiopolymercompositesforemulsionsandgelsinfoodengineering.Biopolymersare furtherdevelopedforuseinclothingtextures,watertreatmentchemicals,modernplastics,sponges,biosensors, andeveninformationstockpilingcomponents.Thecategorizationofbiopolymersisprovidedin Table2.1.

Biopolymershavetheirownproperties.Theyareinexhaustible,maintainable,biodegradable,safe,nonimmunogenic,non-cancer-causing,nonthrombogenic,and carbon;forexample,chitin/chitosan.Chitinexistsinthe skeletalsystemofcreaturesandhasawhiteappearance (Asgharietal.,2017).Inexhaustibleresourcesareutilized progressivelyinthecreationofpolymers(specifically, monomers).Forexample,carbondioxide,terpenes, vegetableoils,andsugarscanbeappliedasfeedstocks forthefabricationofavarietyofmanageablematerials andproducts,includingelastomers,plastics,hydrogels, adaptablegadgets,resins,engineeringpolymers,and composites(Zhuetal.,2016).Biodegradablematerials areemployedaspartofbundling,farming,prescription, anddistinguishedareas.Asoflate,theenthusiasmfor biodegradablepolymersisrising.Therearetwoclasses ofbiodegradablepolymerspresent:engineeredandcharacteristicpolymers.Thesearepolymersmadefromstocks

TABLE2.1

CategorizationofBiopolymers.

Polyesters

Polysaccharides(lant/ Algal)

PolyhydroxyalkanoatesStarch(amylose/ amylopectin)

PolylacticacidCellulose

Proteins Agar

SilksAlginate

Collagen/GelatinCarrageenan

ElastinPectin

ResilinKonjac

AdhesivesVariousgums(e.g.,guar)

Polyaminoacids

Soy,zein,wheatgluten, casein

Polysaccharides(animal)

Chitin/chitosan

SerumalbuminHyaluronicacid

Polysaccharides (bacterial)

Lipids/Surfactants

XanthanAcetoglycerides,waxes, surfactants

DextranEmulsan

Gellan Polyphenols

LevanLignin

CurdlanTannin

PolygalactosamineHumicacid

Cellulose(bacterial) Specialtypolymers

Polysaccharides (fungal)

Shellac

PullulanPoly-g-glutamicacid

ElsinanNaturalrubber

YeastglucansSyntheticpolymersfrom naturalfatsandoils;nylon fromcastoroil

predominantresourceofcarbohydratesdevouredby humans,providingaround66%oftherequireddayto-daycalories.Itassumesacrucialpartinourregular dailyexistenceandisavitalplant-derivedmaterial generallyusedasfood(Riyajan,2015),inpackaging products,andinthemanufacturingofnonnourishment products.Itisnotonlyamajordietarycarbohydratebut isalsoemployedtomanufacturehouseholdproducts suchaspharmaceuticals,paper,andtextiles(Seung etal.,2015).Starchisthesecondlargestsourcefor biomass(inexhaustible)onthisplanet,providingan eco-friendlyapproachtoproduceenormousassortmentsofmaterialswhenmixedwithotherbiodegradablepolymers.Moreover,itisafamiliarpolymer accessibleinlargeamountsfromvarioussources(Pasquinietal.,2010).Thedegradationofstarchatnight distributescarbohydratestofuelrespirationandgrowth whenphotosynthesisisnonviable.

Starch,initslocalgranularshape,issometimesutilizedasnourishment.Initslocalstate,starchcomprises ofsemicrystallinegranulesthatareinsolubleinwater (Pasquinietal.,2010).Starch,forthemostpart,ispreparedbyheatwhichpromptsgelatinizationandsubsequentlycrumblesintoessentialsugarsegments, amylose,andamylopectin(Pasquinietal.,2010).Other refinementsofstarchincludetheutilizationofenzymatic orchemicaltreatments.High-control,low-frequencyultrasoundhandlinghastheadditionalcapabilityofhydrolyzingstarchparticles,withthebenefitofbeinga physicaltechnique(Kangetal.,2016).Todate,starch isgenerallyemployedasnourishment(Riyajan,2015), inbuildingmaterials(Teodoroetal.,2015),andinthe creationofpaper(Petersenetal.,2013).Itisaneasy, inexhaustibleasset(Riyajan,2015).

acquiredfromeitheroilassets(noninexhaustibleassets) ororganicassets(sustainableassets).

3 STARCH

Starchishydrophilicinnature(Zhangetal.,2014).Asa completelybiodegradablepolysaccharidethatisbiosynthesizedbynumerousplants,starchisoneofthe mostabundantrenewableresourcesknowntoman (MohammadiNafchietal.,2013).Starchisthe

Starchfundamentallyexistsasefficientgranulesin whichamylopectinexhibitsnonrandomappropriation oflinerchainsandacongregatearrangementofbranch linkages,givingrisetoahighdegreeofstructuralorganization.Starchisasemicrystallinepolymermadefrom directpolysaccharidemolecules(amylose)and stretchedparticles(amylopectin).Itisadistinctivepolymercharacterizedasaccessiblegranulematerial(Peres etal.,2016).Thepreserveddesignofamylopectinis inchargeofthesemicrystalline,water-insolublestarch granules.Starchgranulesarethemostimportantenergy reserveinplantsandcanbefoundintubers,cereals, roots,sorghum,andstemofaplant,i.e.,barley,wheat, oat,corn,sago,greenpea,cassava,sugarpalm,andpotato(Saharietal.,2014).

Starchgranulesconsistoftwomajortypesofpolysaccharides:amyloseandamylopectin.Eachdiffersin atomicmass,levelofexpansion,andchemicalproperties

(Baietal.,2017).Theminorcomponentssuchaslipid, protein,andphospholipidsarefoundatthestarch’ ssurfaceorconnectedwithpolysaccharidechains.

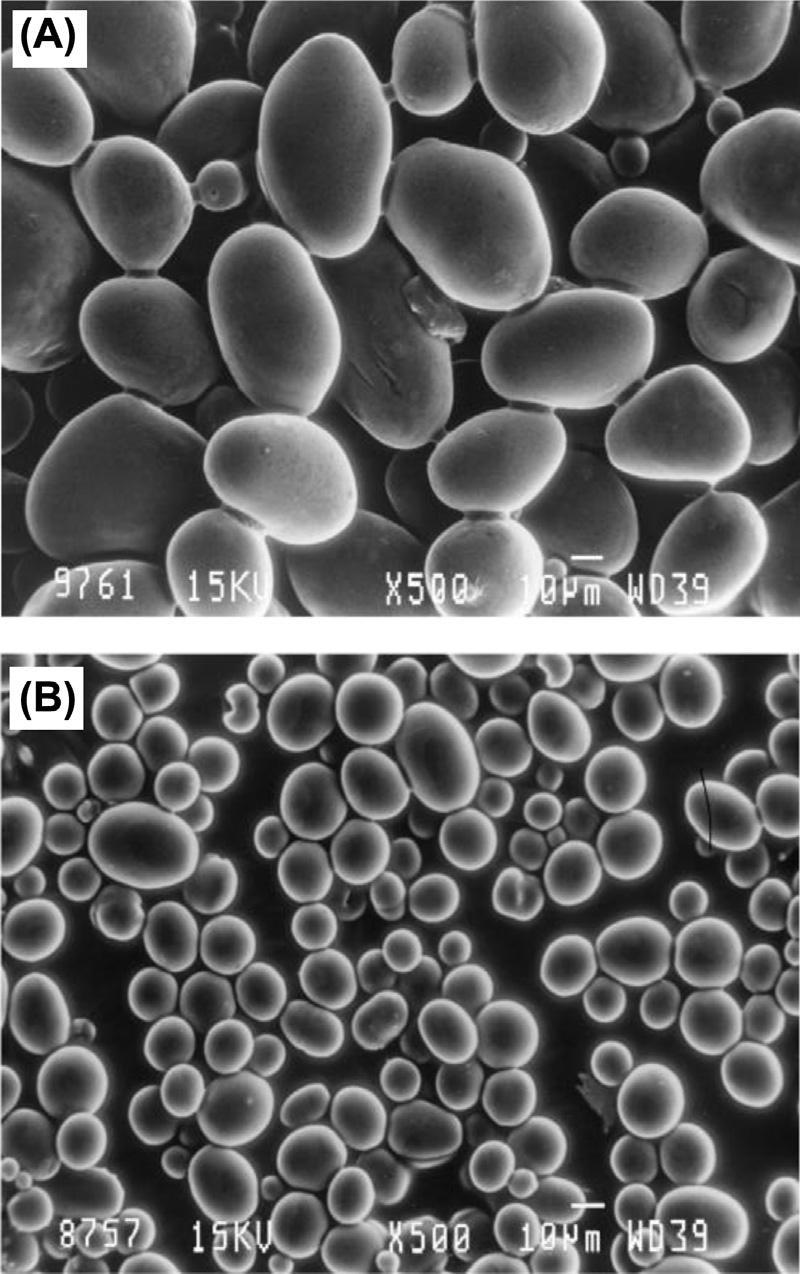

Forpotatostarch,theshapechangesfromovaltocircularasthewidthofthegranulesdiminishes.Potatoisa tuberousharvestthatcontainsahighmeasureofstarch andgenerallyutilizedaspartofthefoodindustry, materialindustry,adhesives,andpaperindustry.In addition,thestateofpotatostarchgranulesistypically representedaslenticularandtheirnormalsizecan changebetween5and100 mm(Baietal.,2017).Other thanthat,itcanbeappliedasthickeners,coating,gelling,bonding,anduniquecasingsfordrugrelease.In variousmechanicalapplications,potatostarchisused fornourishmentsolutions,operatorsforpaperandmaterials,biodegradableplastics,andpharmaceuticals. Fig.2.1 displaysthepotatostarchgranules.

Thegranulesizeofstarchcouldreflectthebiosyntheticage.Smallsizedgranulesareconsideredasprepubescentgranulesthatcannotdevelopintofull-estimate granules,whileextensivegranulesarecompletelydevelopedgranules(Wangetal.,2016).

3.1 ApplicationofStarch

Ingeneral,starchisacommonsourceofcarbohydrates forthehumandiet.Itisconsumedintheformofstaple foodssuchasrice,pasta,breads,cereals,andvegetables. Starchisalsousedinfoodpreparationprocessessuchas athickeningagentforgravy,puddings,etc(Jumaidin etal.,2018).Inthepharmaceuticalindustry,starchis employedasadrugexcipientthatexhibitstheslow releasecharacteristics(LeBailetal.,1999).Itisreported thathighamylosestarchdisplaysgoodswellingand drugreleasebehaviorwhenformedasatablet.Inpapermaking,starchisappliedtoenhancethestrengthofpaper.Itisalsousedforadhesivematerialsinthe manufacturingofglueandothertypesofadhesives. Starchisfurtherusedincosmetics,petfood,aquatic food,andclothing.

3.2 ThermoplasticStarch

Starchhasuniquecharacteristicswhereitcanbetransformedintothermoplasticswhensubjectedtohightemperature,shear,andwiththepresenceofaplasticizer.In general,theroleoftheplasticizeristodisruptstarch granulesbybreakingitsintermolecularandintramolecularhydrogenbonds.Thestarch-plasticizerinteractionis formedbyeliminatingthestarch-starchinteraction. Thisprocessisaccompaniedbypartialdepolymerization ofthestarchbackboneandadecreaseinthemeltingtemperatureofstarch(Stepto,2003).Theintroductionofa plasticizerandheatwithrawstarchistermedasplasticization.Theroleoftheplasticizeristoreducethe

brittlenessofstarchandincrease flexibilityforfutureapplications.Theuniquecharacteristicsofthermoplastic starchallowthisbiomaterialtomeltandhardenrepeatedly,makingitsuitableforvariousfabricationprocesses forconventionalplastics.Hence,thisfeaturecanbe includedinthepositiveattributesofthematerial,apart frombeingbiodegradableandrenewable.

3.3 ProcessingofThermoplasticStarch

Aspreviouslymentioned,starchrequiresthepresence ofheat,shear,andplasticizertotransformintothermoplasticstarch.Ingeneral,thereareseveraltypesofplasticizers:glycerol,sorbitol,fructose,urea,water,etc.Two mainprocessescanbeappliedtoproducethisgreen material.Hotpressandsolutioncastingarethemost commonmethodsemployedinreportedstudieson thermoplasticstarchdevelopment.

3.3.1 Hotpress

Thehotpressmethodreferstoaprocesswherethe starchmixtureispressedatacertaintemperature;the

(A) ThenativelargepotatostarchgranulesbySEM and (B) thenativesmallpotatostarchgranulesbySEM (Sandhuetal.,2015).

FIG.2.1

pressureisappliedbyusinghydraulicpressequipped withaheatingelement.Toemploythehotpress method,severalstagesmustbeaccomplished.Firstly, nativestarchshouldbemixedwithaplasticizeratapredeterminedratio,i.e.,20to30wt%.Apreviousstudy hadreportedthatmixingcanbeconductedinaplastic baguntilahomogeneousmixtureisattained(Lomelí Ramírezetal.,2011).Anotherstudyreportedthata mechanicalstirrercanbeusedtocompletethisprocess (Saharietal.,2013).Itwasalsomentionedthatahighspeedmixercanbeemployedtoensuregoodmixingis achievedatthisstage(Jumaidinetal.,2016).Thehomogenousstarch/plasticizermixturecanbehotpressed atcertaintemperatureranges,from130to180 Cwith pressurerangingbetween10and20tons.However, somestudiesdidreportusingthemelt-mixingprocess withapolymermelt-mixerbeforethehotpressing process(Lopezetal.,2014;Lópezetal.,2015;Salaberriaetal.,2014;TaghizadehandFavis,2013).The melt-mixingprocessisaccomplishedtoobtainearly plasticizationofthestarch,whileacquiringahomogeneousstarch/plasticizermixture.Thiscanbeachieved moreeasilyduringthemeltcondition.Theproduct frommelt-mixingwillbecrushedintosmallpellets beforeplacedontoasteelmoldforthehotpressingprocess.Here,thethermoplasticstarchwillpossesssimilar characteristicstoconventionalpolymer,i.e.,polypropyleneorpolyethylene.ThepressingofcrushedTPS pelletsmaybeconductedattemperaturesbetween 130and180 Cwithapressureof10 30tons,dependingonthestudy.Removalagentshouldbeappliedonto themold’ssurfaceinordertofacilitatetheremovalof samplesafterhotpressing.Sincethermoplasticstarch isknowntobemoisturesensitive,thesamplesobtained fromhotpressingshouldbecooleddowninadesiccatortoavoidmoistureabsorption,whichwillaffect themechanicalpropertiesofthematerial.Theadvantageofthehotpressingmethodistheabilitytoproduce arigidmaterialandproductthatisnotpossiblefor solutioncasting.Thelimitationofthisprocessisthe variationinthephysicalpropertiesoftheproductdue toanonhomogeneousstructure,void,cracks,etc., formedwhensamplesaresubjectedtohighpressure. Anaccurateamountoftherawmixtureisquitedifficult toobtainsincelowamountswillresultinunmelted samplesatthecorner,whileexcessiveamountswill resultinincreasinglythicksamples.Toaccomplish thisprocess,multipletrialsshouldbeconductedinordertoobtaintheidealtemperature,pressure,time,and amountofrawmaterialstobeplacedontothemold. Theseparametersarehighlydependentonthetypes ofstarch,plasticizer,anddimensionofthemold.

3.3.2 Solutioncasting

Solutioncastingisaprocessofproducingthermoplastic starchbyusingwatersolution,plasticizer,heat,andstirring.Ingeneral,thismethodisalsousedforothertypes ofbiopolymerssuchasagar,alginate,carrageenan,chitosan,chitin,etc.(Haciuetal.,2013;Pereiraetal.,2003; Wuetal.,2009).Theprocessofproducingthermoplasticstarchusingsolutioncastingisrelativelyeasier thanthehotpressingmethod.Ingeneral,ahotplate orwaterbath,aswellasdistilledwaterandmechanical/magneticstirrer,isrequired.Film-formingsolution thatconsistsofstarch,plasticizer,anddistilledwater shouldbepreparedforthisprocess.Priortoheating, theamountofstarchandplasticizershouldbeweighed accordingtothedesiredratiotoobtainthe film-forming solution.Edhirejetal.employeda film-formingsolutioncontaining5gofcassavastarch/100mLdistilled water(Edhirejetal.,2016).Fructosewasthenusedas theplasticizer,atconcentrationsof0.30g/gofdry starch.The film-formingsolutioncontainingallnecessarymaterialsisthenheatedto80 Cinathermal bathandkeptatthistemperaturefor20minunder constantstirring.Duringstirring,bubblestendto formwithinthesolution;however,accordingtoEdhirej etal.itcanberemovedbyplacingthe film-formingsolutionintoadesiccatorunderavacuum.Thesolution shouldbekeptinthevacuumdesiccatoruntilnobubblesarevisible.Theremovalofbubblesfromthesolutioniscrucialinordertoensureahomogeneous structureofthethermoplasticstarch.Theexistenceof bubblesmayleadtotheformationofavoidinthe final filmthatcouldinterferewiththemechanicalproperties oftheresultant film.

Thebubble-freesolutionwasthenpouredontocircularglassplateswith10cmdiameters.Next,the film-formingsolutionwasdriedat50 Cinanaircirculatingoven.Thedried filmswereslowlyremovedby peelingthe filmofffromtheplates.Theresultant film isthenkeptinazip-lockedplasticbagpriortocharacterization(Edhirejetal.,2016).

Solutioncastingisasimplemethodthatproduces thermoplasticstarchthatdoesnotrequireheavyequipment,i.e.,heatedhydraulicpress(hotpressmethod). Theadvantagesofthismethodisthatonlyminimum amountsof film-formingmaterialarerequiredto producethe film.Hence,multipleproductionscanbe carriedout,especiallyformaterialsthataredifficultto extractorhighincost(suchasnanoscalematerials). Sincethereisnopressureappliedduringthefabrication ofthe film,thestructureofanyadditionalmaterials (suchasnatural fiber)isnotsusceptibletodamageas inthehotpressmethod.However,thelimitationof

thismethodisthattheresultantproductisonlyinthe formofathin film.Hence,fabricationofothershapes isnotpossible,andthesamplescanonlyundergo tensiletestingforthecharacterizationofmechanical properties.Thermoplasticstarchproducedfromthehot pressmethodcanundergo flexuralandimpacttesting. The filmformedfromsolutioncastingisonlysuitable forexperimentalpurposesandisnotreadyforactual productionprocesses.Thehotpressmethodismuch moresimilartotheactualproductionprocessforconventionalplasticsandsimilardatacanbeappliedfor productionusingextrusionorinjectionmolding.

3.3.3 Injectionmolding

Injectionmoldingisatypeofmanufacturingprocess commonlyemployedforcreatingthermoplasticmaterialsinrapidproduction.Thismethodincludesinjectingmoltenmaterialsintoamold,whicharethen cooledandhardenedinsidethemoldcavity.Apart fromplastic,thismethodisemployedforglass,metals (knownasdie-casting),andelastomers.

Rosaetal.fabricatedthermoplasticcornstarchby usinginjectionmolding(RosaandAndrade,2004). Priortoinjectionmolding,thepreparationofaplasticizedmixtureisakeystepforthisprocess.Toobtain ahomogeneousmixture,Rosaetal.preparedaconstant weightofstarch,glycerol(15wt%),andwater(15wt %).ThismixturewasinjectionmoldedintoASTM D638-72TypeIspecimens,approximately2mmthick, usingaPicBoy15/42PetersenIrmaosMachine(Sao Paulo,Brazil).Thiswasprovidedwiththreeelectrically heatedzones,maintainedat130and145 Cfromthe feedzonetothedieend.Themixturesweremanually fedintothemachine,andtheinjectionpressurewas keptat113bar.Theinjectionmoldwascooledat 30 40 Cbyarefrigerationsystemandkeptclosedat 1275bar.

Injectionmoldingisthemostcommonprocessused fortheproductionofconventionalplastics.However, therearesomelimitationstothisprocessascompared withothers.Intermsofcost,injectionmoldingrequires high-endequipmentinorderfortheprocesstobecarriedout.Thisprocesswillrequirehugeamountsofmaterialstobeused,whichcanbeunlikelydependingon thematerialinvolved.

4 PROCESSINGOFTHERMOPLASTIC STARCHCOMPOSITES

Eventhoughthermoplasticstarchseemstobeapromisingmaterialforreplacingconventionalpetroleumbasedpolymers,therearesomelimitationspresentfor thismaterial,i.e.,poormechanicalproperties,low thermalstability,highmoisturesensitivity,andlow dimensionalstability.Theselimitationsrestrictthematerial’spotentialofbeingusedasanalternativeto conventionalplastics.Hence,variousstudieshave beencarriedouttoimprovethepropertiesofthermoplasticstarch.Thismodi ficationincludestheincorporationofnatural fibersatthemacro,micro,andnano levelsaswellasblendingTPSwithotherpolymers thathavebetterphysicalproperties.

Ibrahimetal.investigatedtheeffectofdatepalmand flax fiberonthebehaviorofthermoplasticstarchcomposites(Ibrahimetal.,2014),wherethermoplasticstarch compositeswerefabricatedusingthehotpressmethod. Priortothat,nativecornstarchwasmixedwith30wt %glycerinand20wt%distilledwateratatemperature between60and80 C.Itwasreportedthatthegelatinizationprocessofstarchcanbeenhancedwiththepresence ofwater,whichcouldimprovethetensilestrainofsampleswithoutsignificanteffectontensilestrength.Adding glycerinmayenhancetheprocessabilitywhilereducing

Anotherstudy(Avérous,2004)usedextrusionand injectionmoldingtofabricatethermoplasticwheat starch.Theauthorsfabricatedtwotypesofplasticized starchmatrix:TPS1andTPS2.TPS1waspreparedwith acombinationof70wt%starch,18wt%glycerol,and 12wt%water;whileTPS2waspreparedwith65wt% starchand35wt%glycerol.TheprocessingofTPS beganbyweighingthestarchandglycerol,followed bymixingathighspeed(2000rpm).Next,thestarch washeatedat170 Cfor45mininaventedovento allowglyceroldiffusionintothestarchgranulesas wellaswatervolatilizationfromthemixture.The mixturewasthencooledandbecameadryblend.The dryblendwasaddedwithwateratacertainformulation thatwasnotmentionedspecificallybytheauthors.The mixturewassubjectedtodispersioninamixer.Itthen underwenthigh-speedmixing(2500rpm)toobtain the finalmixture.Thepowderwasextrudedwithasinglescrewextruderandgranulated.Thepelletswere extrudedforthesecondtimeinordertoimprovedispersion.The finalpelletswereequilibratedat50%RHfor 8dayspriortotheinjectionmoldingprocess.Next,the injectionmoldingmachinewithaclampingforceof 50tonswasusedtomoldstandarddumbbells.The parametersfortheinjectionmoldingprocessareasfollows:screwbarreltemperature(100 130 C), moldtemperature(20 25 C),holdingpressure (1000bars),holdingtime(20s),andcoolingtime (10s).Theresultantdumbbell-shapedproductwas conditionedatatemperatureandhumidity-controlled room(23 C,54%RH)during2,4,or6weeks.

embrittlementbyinhibitingtheretrogradationprocedureafterprocessing.Thepreparationofcompositeswas accomplishedbyusingapositivetypemoldcoated withstericacidasthereleasingagent.Natural fiber (i.e.,datepalmand flax fiber)waschoppedanddistributedinthemold.Next,thermoplasticstarchwasemulsifiedinwaterwithTPS:waterratioof1:1,1:2,1:3,1:4, and1:8for0,20,40,50,60,and80wt% fibercontents, respectively.Thesampleswerepreheatedat140 3 C for30mininahydraulicpresstoremoveexcesswater fromtheemulsion.Thiswasfollowedbyhotpressing at5MPaand160 3 Cfor30minandthencooled atarateofabout2 C/min.The findingsindicatethat theincorporationofbothdatepalmand flax fiberdid improvethemechanicalpropertiesandthermalstability, whilereducingthewateruptake. Fig.2.2 showsthe treatedanduntreateddatepalm fiberandtheSEM micrographofstarchandthethermoplasticstarch.

Jumaidinetal.investigatedtheeffectofagaronthe thermal,mechanical,andmoistureabsorptionbehaviorsofthermoplasticsugarpalmstarch(Jumaidin

etal.,2016).Thecompositesweredevelopedbyusing acombinationofmelt-mixingandhotpressing methods.Priortotheirfabrication,sugarpalmstarch wasmanuallyextractedfromthesugarpalmtreebyusingextraction,washing,sedimentation,anddryingprocesses.TheTPSmatrixwaspreparedbyusing30wt% glycerolastheplasticizer.Themixturewasthenmixed usingahigh-speedmixerat3000rpmfor5min.The well-mixedsampleunderwentamelt-mixingprocess usingBrabenderplastographat140 Candrotorspeed of20rpmfor10min.Theresultantproductfromthe melt-mixingapproachwasgranulatedbyusingablade millwith2mmmeshtoproducesmallpellets.Lastly, thepelletswerepressedinamoldat140 Cfor 10minundertheloadof10tons.Thesameprocess wasadoptedforthecompositepreparationofagar (10,20,30,and40wt%)introducedduringthehighspeedmixingprocess.Theauthorsreportedthatthe incorporationofagardidimprovethethermalstability andmechanicalproperties,whileincreasingthemoistureuptakeandthicknessswellingofthecomposites.

FIG.2.2 Datepalm fibersandstarchSEMinvestigation: (A) rawdatepalm fibersarecoveredwithmuch lignin; (B) NaOH-treateddatepalm fiberswithcleansurfaceandprotruded fibrils; (C) overnight-stored plasticizedcornstarch;and (D) compressionmoldedthermoplasticstarchbyemulsiontechnique(Ibrahim etal.,2014).

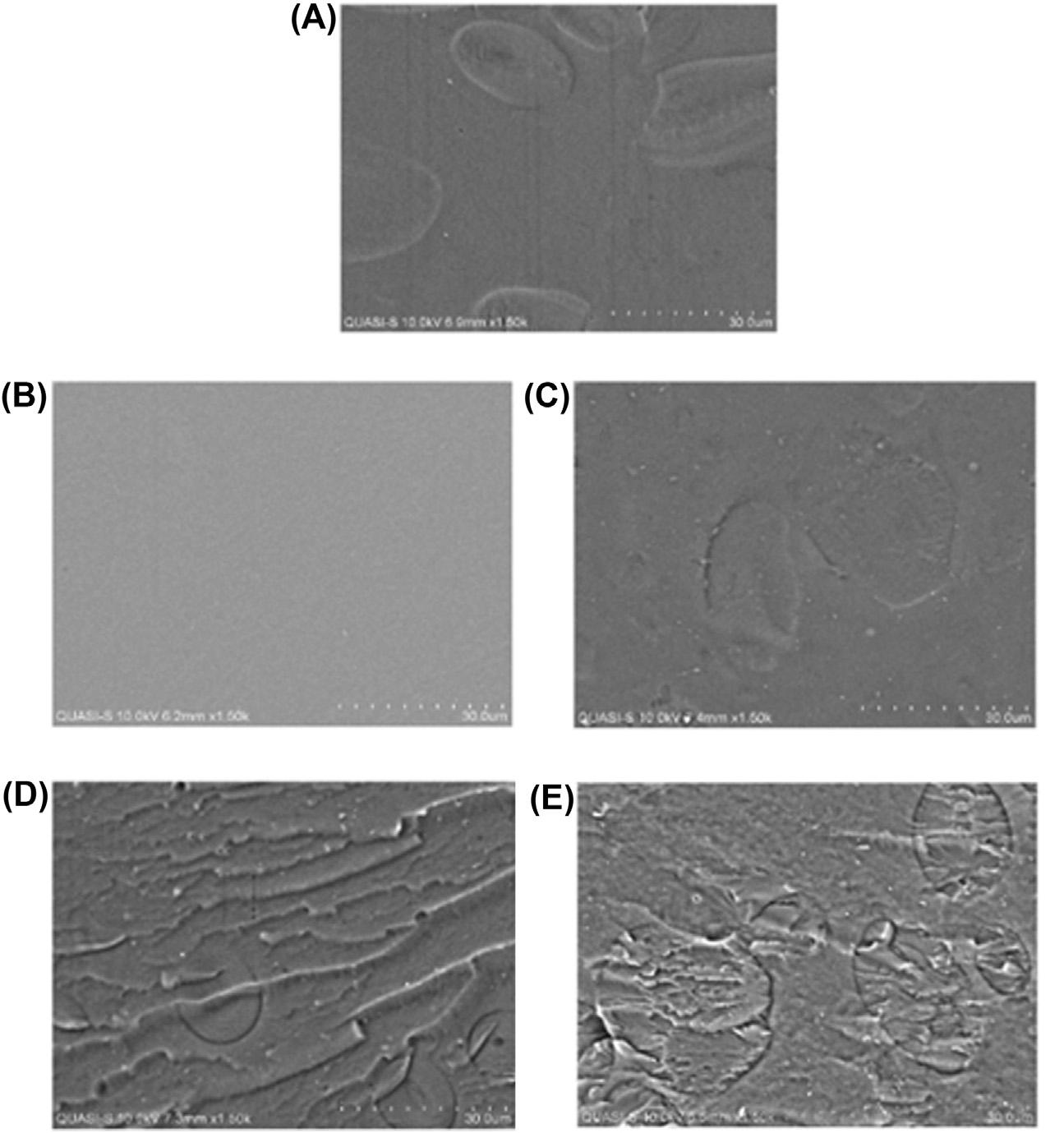

Fig.2.3 showstheSEMmicrographoffracturesurfaceof thermoplasticSPSblendedwithdifferentratioofagar (A)0wt%,(B)10wt%,(C)20wt%,(D)30wt%,and (E)40wt%.

Anotherrecentstudyhadreportedthedevelopment ofthermoplasticstarch/naturalkeratin fibercomposites for flame-retardantapplication(Rabeetal.,2019).In thisstudy,theauthorsusedthermoplasticstarch (namely,Mater-BiEF05B)procuredfromNovamont S.p.A(Novara,Italy).Thekeratin fiberswereobtained aswastefromthebeamhousestageofaMexicantannery, whilethecoconut fiberswereobtainedfromthehuskof coconutfruits.Thenatural fibersunderwentseveralprocedurespriortothemixingprocesswithTPS.TheTPS compositeswerepreparedbytheextrusionofTPSand fibermixtureinatwinscrewextruderL/D ¼ 32witha diameterof27.0mmandeightheatingzonesusinga counterrotatingintermeshingmode.Thetemperature profileforthecompoundingprocess(fromfeedtodie)

wereasfollows:130/135/135/140/145/150/145/ 140 C.Therotationalspeedofthetwinscrewswasset at120rpm.Theauthorsadoptedthedoubleextrusion method(repeated)inordertoensurebetterdispersion of fibersand flame-retardantproperties.Forthesecond extrusion,theTPSandcompositesweredriedat105 C inmodel30lowpressuredryerwith80psi (0.5516MPa)maintainedduringheating.Aftereach extrusionstep,thecompositesweregranulatedina7.5 HPgranulatorusingascreenwitha5mmmesh.The findingsindicatethattheincorporationof fiberdid improvethe flame-retardantpropertiesofthecomposites.Thiswasindicatedbythelowerheatreleaserate andtotalheatevolvedfromtheTPScomposites.

5 CONCLUSIONS

Ingeneral,thischapterhasshownthatthermoplastic starchisaversatilematerialthatcanbeprocessedusing

FIG.2.3 SEMmicrographoffracturesurfaceofthermoplasticSPSblendedwithdifferentratioofagar (A) 0wt%, (B) 10wt%, (C) 20wt%, (D) 30wt%,and (E) 40wt%.

variousmethods.TPScanbefabricatedusingexisting equipmentforthemanufacturingofcommercialplastic productsintheplasticindustry.Hence,thepromising characteristicsofTPSprovidegreatopportunitiesfor thismaterialtobecomeasustainablealternativetosyntheticnonbiodegradablepolymers.Morestudies regardingthefeasibilityofTPSforvariousapplications, especiallyforhighmoistureenvironment,mustbe exploredbyresearcherstofurtherenhancethereadiness ofTPSforwidercommercialapplications.

REFERENCES

Asghari,F.,Samiei,M.,Adibkia,K.,Akbarzadeh,A.,Davaran,S., 2017.Biodegradableandbiocompatiblepolymersfortissue engineeringapplication:areview.ArtificialCells,NanomedicineandBiotechnology45(2),185 192. https://doi.org/ 10.3109/21691401.2016.1146731

Avérous,L.,B.N.,2004.Biocompositesbasedonplasticizedstarch: thermalandmechanicalbehaviour.CarbohydratePolymers 56,111 122. https://doi.org/10.1016/j.carbpol.2003.11.015

Bai,W.,Hébraud,P.,Ashokkumar,M.,Hemar,Y.,2017.Investigationonthepittingofpotatostarchgranulesduringhigh frequencyultrasoundtreatment.UltrasonicsSonochemistry. https://doi.org/10.1016/j.ultsonch.2016.05.022

Edhirej,A.,Sapuan,S.M.,Jawaid,M.,Zahari,N.I.,2016.Preparationandcharacterizationofcassavastarch/peelcomposite film.PolymerComposites1 12. https://doi.org/10.1002/pc Haciu,D.,Saner,S.,Türdogru,O.,Ünal,U.,2013.Studyof antibacterialeffectsofaself-standingagarbased filmincorporatedwithZnO.FrontiersinScience3(3),96 101. https://doi.org/10.5923/j.fs.20130303.03.

Ibrahim,H.,Farag,M.,Megahed,H.,Mehanny,S.,2014.Characteristicsofstarch-basedbiodegradablecompositesreinforced withdatepalmand flax fibers.CarbohydratePolymers101, 11 19. https://doi.org/10.1016/j.carbpol.2013.08.051

Joshi,S.V.,Drzal,L.T.,Mohanty,A.K.,Arora,S.,2004.Arenatural fibercompositesenvironmentallysuperiortoglass fiberreinforcedcomposites?CompositesPartA:Applied ScienceandManufacturing. https://doi.org/10.1016/ j.compositesa.2003.09.016

Jumaidin,R.,Sapuan,S.M.,Jawaid,M.,Ishak,M.R.,Sahari,J., 2016.Characteristicsofthermoplasticsugarpalmstarch/ agarblend:thermal,tensile,andphysicalproperties.InternationalJournalofBiologicalMacromolecules89,575 581. https://doi.org/10.1016/j.ijbiomac.2016.05.028

Jumaidin,R.,Sapuan,S.M.,Jawaid,M.,Ishak,M.R.,Sahari,J., 2018.Starch:renewablesourceforthermoplastic.In: Mishra,M.(Ed.),EncyclopediaofPolymerApplications, firsted.Taylor&Francis,pp.2461 2489. https://doi.org/ 10.1201/9781351019422-120054068

Kang,N.,Zuo,Y.J.,Hilliou,L.,Ashokkumar,M.,Hemar,Y., 2016.Viscosityandhydrodynamicradiusrelationshipof high-powerultrasounddepolymerisedstarchpasteswith differentamylosecontent.FoodHydrocolloids52, 183 191. https://doi.org/10.1016/j.foodhyd.2015.06.017.

LeBail,P.,Morin,F.G.,Marchessault,R.H.,1999.Characterizationofacrosslinkedhighamylosestarchexcipient.InternationalJournalofBiologicalMacromolecules26,193 200. https://doi.org/10.1016/S0141-8130(99)00082-3

LomelíRamírez,M.G.,Satyanarayana,K.G.,Iwakiri,S.,De Muniz,G.B.,Tanobe,V.,Flores-Sahagun,T.S.,2011.Study ofthepropertiesofbiocomposites.PartI.Cassavastarchgreencoir fibersfromBrazil.CarbohydratePolymers86, 1712 1722. https://doi.org/10.1016/j.carbpol.2011.07.002.

Lopez,O.,Garcia,M.A.,Villar,M.A.,Gentili,a.,Rodriguez,M.S., Albertengo,L.,2014.Thermo-compressionofbiodegradable thermoplasticcornstarch filmscontainingchitinand chitosan.Lebensmittel-Wissenschaftund-TechnologieFoodScienceandTechnology57(1),106 115. https:// doi.org/10.1016/j.lwt.2014.01.024

López,O.V.,Ninago,M.D.,Lencina,M.M.S.,García,M.a., Andreucetti,N.a.,Ciolino,A.E.,Villar,M.a.,2015.Thermoplasticstarchplasticizedwithalginate glycerolmixtures: melt-processingevaluationand filmproperties.CarbohydratePolymers126,83 90. https://doi.org/10.1016/ j.carbpol.2015.03.030

MohammadiNafchi,A.,Moradpour,M.,Saeidi,M.,Alias,A.K., 2013.Thermoplasticstarches:properties,challenges,and prospects.Starch-Stärke65,61 72. https://doi.org/ 10.1002/star.201200201

Pasquini,D.,Teixeira,E.deM.,Curvelo,A.A.daS., Belgacem,M.N.,Dufresne,A.,2010.Extractionofcellulose whiskersfromcassavabagasseandtheirapplicationsas reinforcingagentinnaturalrubber.IndustrialCropsand Products. https://doi.org/10.1016/j.indcrop.2010.06.022.

Pereira,L.,Sousa,A.,Coelho,H.,Amado,A.M.,RibeiroClaro,P.J.A.,2003.UseofFTIR,FT-Ramanand13C-NMR spectroscopyforidentificationofsomeseaweed phycocolloids.BiomolecularEngineering20,223 228. https://doi.org/10.1016/S1389-0344(03)00058-3.

Peres,A.M.,Pires,R.R.,Oréfice,R.L.,2016.Evaluationoftheeffectofreprocessingonthestructureandpropertiesoflow densitypolyethylene/thermoplasticstarchblends.CarbohydratePolymers136,210 215. https://doi.org/10.1016/ j.carbpol.2015.09.047

Petersen,H.,Radosta,S.,Vorwerg,W.,Kießler,B.,2013. Cationicstarchadsorptionontocellulosicpulpinthepresenceofothercationicsyntheticadditives.ColloidsandSurfacesA:PhysicochemicalandEngineeringAspects433, 1 8. https://doi.org/10.1016/j.colsurfa.2013.04.060

Rabe,S.,Sanchez-Olivares,G.,Pérez-Chávez,R.,Schartel,B., 2019.Naturalkeratinandcoconut fibresfromindustrial wastesin flameretardedthermoplasticstarch biocomposites.Materials12(3),344. https://doi.org/ 10.3390/ma12030344

Riyajan,S.A.,2015.Robustandbiodegradablepolymerofcassavastarchandmodifiednaturalrubber.Carbohydrate Polymers. https://doi.org/10.1016/j.carbpol.2015.07.038

Rosa,R.C.R.S.,Andrade,C.T.,2004.Effectofchitinadditionon injection-moldedthermoplasticcornstarch.Journalof AppliedPolymerScience92,2706 2713. https://doi.org/ 10.1002/app.20292. 18

Sahari,J.,Sapuan,S.M.,Zainudin,E.S.,Maleque,M.A.,2013. Thermo-mechanicalbehaviorsofthermoplasticstarch derivedfromsugarpalmtree(Arengapinnata).CarbohydratePolymers92,1711 1716. https://doi.org/ 10.14233/ajchem.2014.15652

Sahari,J.,Salit,M.S.,Zainudin,E.S.,Maleque,M.A.,2014. DegradationcharacteristicsofSPF/SPSbiocomposites fabricationofSPF/SPSbiocomposites.FibresandTextiles inEasternEurope22(5107),96 98.

Salaberria,A.M.,Labidi,J.,Fernandes,S.C.M.,2014.Chitin nanocrystalsandnanofibersasnano-sized fillersintothermoplasticstarch-basedbiocompositesprocessedbymeltmixing.ChemicalEngineeringJournal256,356 364. https://doi.org/10.1016/j.cej.2014.07.009

Sandhu,K.S.,Sharma,L.,Kaur,M.,2015.Effectofgranulesize onphysicochemical,morphological,thermalandpasting propertiesofnativeand2-octenyl-1-ylsuccinylatedpotato starchpreparedbydryheatingunderdifferentpH conditions.Lebensmittel-Wissenschaftund-TechnologieFoodScienceandTechnology. https://doi.org/10.1016/ j.lwt.2014.11.004

Scholten,E.,Moschakis,T.,Biliaderis,C.G.,2014.Biopolymer compositesforengineeringfoodstructurestocontrolproductfunctionality.FoodStructure. https://doi.org/10.1016/ j.foostr.2013.11.001

Seung,D.,Soyk,S.,Coiro,M.,Maier,B.A.,Eicke,S., Zeeman,S.C.,2015.PROTEINTARGETINGTOSTARCH isrequiredforlocalisingGRANULE-BOUNDSTARCH SYNTHASEtostarchgranulesandfornormalamylose

synthesisinarabidopsis.PLoSBiology. https://doi.org/ 10.1371/journal.pbio.1002080

Stepto,R.F.T.,2003.Theprocessingofstarchasa thermoplastic.MacromolecularSymposia201,203 212. https://doi.org/10.1002/masy.200351123

Taghizadeh,A.,Favis,B.D.,2013.Carbonnanotubesinblends ofpolycaprolactone/thermoplasticstarch.Carbohydrate Polymers98(1),189 198. https://doi.org/10.1016/ j.carbpol.2013.05.024.

Teodoro,A.P.,Mali,S.,Romero,N.,deCarvalho,G.M.,2015. Cassavastarch filmscontainingacetylatedstarchnanoparticlesasreinforcement:physicalandmechanical characterization.CarbohydratePolymers126,9 16. https://doi.org/10.1016/j.carbpol.2015.03.021

Wang,C.,Tang,C.H.,Fu,X.,Huang,Q.,Zhang,B.,2016.Granularsizeofpotatostarchaffectsstructuralproperties,octenylsuccinicanhydridemodificationand flowability.Food Chemistry. https://doi.org/10.1016/j.foodchem.2016.06.006

Wu,Y.,Geng,F.,Chang,P.R.,Yu,J.,Ma,X.,2009.Effectofagar onthemicrostructureandperformanceofpotatostarch film.CarbohydratePolymers76(2),299 304. https:// doi.org/10.1016/j.carbpol.2008.10.031

Zhang,Y.,Rempel,C.,Liu,Q.,2014.Thermoplasticstarchprocessingandcharacteristics-areview.CriticalReviewsin FoodScienceandNutrition54(February),1353 1370. https://doi.org/10.1080/10408398.2011.636156

Zhu,Y.,Romain,C.,Williams,C.K.,2016.Sustainablepolymersfromrenewableresources.Nature540(7633), 354 362. https://doi.org/10.1038/nature21001.