https://ebookmass.com/product/additive-manufacturing-for-

Instant digital products (PDF, ePub, MOBI) ready for you

Download now and discover formats that fit your needs...

Titanium for Consumer Applications: Real-World Use of Titanium Francis Froes

https://ebookmass.com/product/titanium-for-consumer-applications-realworld-use-of-titanium-francis-froes/

ebookmass.com

Fundamentals of Additive Manufacturing for the Practitioner Sheku Kamara

https://ebookmass.com/product/fundamentals-of-additive-manufacturingfor-the-practitioner-sheku-kamara/

ebookmass.com

Metal Additive Manufacturing Ehsan Toyserkani

https://ebookmass.com/product/metal-additive-manufacturing-ehsantoyserkani/

ebookmass.com

Immobility and Medicine: Exploring Stillness, Waiting and the In-Between 1st ed. Edition Cecilia Vindrola-Padros

https://ebookmass.com/product/immobility-and-medicine-exploringstillness-waiting-and-the-in-between-1st-ed-edition-cecilia-vindrolapadros/ ebookmass.com

Water - Energy - Food Nexus Narratives and Resource Securities Tafadzwa Mabhaudhi

https://ebookmass.com/product/water-energy-food-nexus-narratives-andresource-securities-tafadzwa-mabhaudhi/

ebookmass.com

Enhanced photo-Fenton degradation of tetracycline hydrochloride by 2, 5-dioxido-1, 4-benzenedicarboxylatefunctionalized MIL-100(Fe) Mingyu Li

https://ebookmass.com/product/enhanced-photo-fenton-degradation-oftetracycline-hydrochloride-by-2-5-dioxido-1-4-benzenedicarboxylatefunctionalized-mil-100fe-mingyu-li/ ebookmass.com

Shards of Earth Adrian Tchaikovsky

https://ebookmass.com/product/shards-of-earth-adrian-tchaikovsky/

ebookmass.com

Future Energy Options from a Systems Perspective Nick King

https://ebookmass.com/product/future-energy-options-from-a-systemsperspective-nick-king/

ebookmass.com

Syntactic Features and the Limits of Syntactic Change Jóhannes Gísli Jónsson And Thórhallur Eythórsson

https://ebookmass.com/product/syntactic-features-and-the-limits-ofsyntactic-change-johannes-gisli-jonsson-and-thorhallur-eythorsson/ ebookmass.com

The Oxford Textbook of Clinical Research Ethics Reprint Edition

https://ebookmass.com/product/the-oxford-textbook-of-clinicalresearch-ethics-reprint-edition/

ebookmass.com

AdditiveManufacturingforthe AerospaceIndustry AdditiveManufacturing fortheAerospace Industry Editedby FrancisFroes

RodneyBoyer

Elsevier

Radarweg29,POBox211,1000AEAmsterdam,Netherlands TheBoulevard,LangfordLane,Kidlington,OxfordOX51GB,UnitedKingdom 50HampshireStreet,5thFloor,Cambridge,MA02139,UnitedStates

Copyright © 2019ElsevierInc.Allrightsreserved.

Nopartofthispublicationmaybereproducedortransmittedinanyformorbyanymeans,electronicor mechanical,includingphotocopying,recording,oranyinformationstorageandretrievalsystem,without permissioninwritingfromthepublisher.Detailsonhowtoseekpermission,furtherinformationaboutthe Publisher’spermissionspoliciesandourarrangementswithorganizationssuchastheCopyrightClearance CenterandtheCopyrightLicensingAgency,canbefoundatourwebsite: www.elsevier.com/permissions

ThisbookandtheindividualcontributionscontainedinitareprotectedundercopyrightbythePublisher (otherthanasmaybenotedherein).

Notices

Knowledgeandbestpracticeinthisfieldareconstantlychanging.Asnewresearchandexperiencebroaden ourunderstanding,changesinresearchmethods,professionalpractices,ormedicaltreatmentmaybecome necessary.

Practitionersandresearchersmustalwaysrelyontheirownexperienceandknowledgeinevaluatingand usinganyinformation,methods,compounds,orexperimentsdescribedherein.Inusingsuchinformationor methodstheyshouldbemindfuloftheirownsafetyandthesafetyofothers,includingpartiesforwhom theyhaveaprofessionalresponsibility.

Tothefullestextentofthelaw,neitherthePublishernortheauthors,contributors,oreditors,assumeany liabilityforanyinjuryand/ordamagetopersonsorpropertyasamatterofproductsliability,negligenceor otherwise,orfromanyuseoroperationofanymethods,products,instructions,orideascontainedinthe materialherein.

BritishLibraryCataloguing-in-PublicationData

AcataloguerecordforthisbookisavailablefromtheBritishLibrary

LibraryofCongressCataloging-in-PublicationData

AcatalogrecordforthisbookisavailablefromtheLibraryofCongress

ISBN:978-0-12-814062-8

ForInformationonallElsevierpublications visitourwebsiteat https://www.elsevier.com/books-and-journals

Publisher: MatthewDeans

AcquisitionEditor: ChristinaGifford

EditorialProjectManager: AndraeAkeh

ProductionProjectManager: KameshRamajogi

CoverDesigner: MatthewLimbert

TypesetbyMPSLimited,Chennai,India

ListofContributors ThomasK.Ales DepartmentofMaterialsScienceandEngineering,IowaState University,Ames,IA,UnitedStates

LeonardJ.Bond CenterforNondestructiveEvaluation,AppliedSciences ComplexII,IowaStateUniversity,Ames,IA,UnitedStates;Departmentof MechanicalEngineering,IowaStateUniversity,Ames,IA,United States;DepartmentofAerospaceEngineering,IowaStateUniversity,Ames,IA, UnitedStates

RodneyBoyer SchoolofMaterialsScienceandEngineering,Universityof ShanghaiforScienceandTechnology,Shanghai,P.R.China;RBTiConsulting, Bellevue,WA,UnitedStates

ShengCao MonashCentreforAdditiveManufacturing(MCAM),Monash University,NottingHill,VIC,Australia;SchoolofMaterialsScienceand Engineering,UniversityofShanghaiforScienceandTechnology,Shanghai,P.R. China

WeiChen AVICManufacturingTechnologyInstitute,Beijing,P.R.China

ZhuoerChen DepartmentofMechanicalandAerospaceEngineering,Monash University,Clayton,VIC,Australia;MonashCentreforAdditiveManufacturing (MCAM),MonashUniversity,NottingHill,VIC,Australia

SergeiA.Chizhik PresidiumoftheNationalAcademyofSciencesofBelarus, Minsk,RepublicofBelarus;A.V.LykovHeatandMassTransferInstituteofthe NationalAcademyofSciencesofBelarus,Minsk,RepublicofBelarus

PeterC.Collins DepartmentofMaterialsScienceandEngineering,IowaState University,Ames,IA,UnitedStates

ChrisH.J.Davies DepartmentofMechanicalandAerospaceEngineering,Monash University,Clayton,VIC,Australia;MonashCentreforAdditiveManufacturing (MCAM),MonashUniversity,NottingHill,VIC,Australia

AgustinDiaz REMSurfaceEngineering,Brenham,TX,UnitedStates

B.Dutta DM3DTechnology,AuburnHills,MI,UnitedStates

FrancisFroes LightMetalsIndustry,Tacoma,WA,UnitedStates;Advanced MaterialsIndustries,Tacoma,WA,UnitedStates

LawrenceGasman SmarTechMarketsPublishingCrozet,Virginia,UnitedStates

ShishkovskyIgor CenterforDesign,ManufacturingandMaterials,Skolkovo InstituteofScienceandTechnology,Moscow,Russia

OrestIvasishin G.V.KurdyumovInstituteforMetalPhysics,Kyiv,Ukraine

QingboJia DepartmentofMaterialsScienceandEngineering,MonashUniversity, Clayton,VIC,Australia;MonashCentreforAdditiveManufacturing(MCAM), MonashUniversity,NottingHill,VIC,Australia

ManishKamal ArconicInc.,ArconicFasteningSystems,Carson,CA,United States

MikhailL.Kheifetz PresidiumoftheNationalAcademyofSciencesofBelarus, Minsk,RepublicofBelarus;StateScientificandProductionAssociation hhCenterii oftheNationalAcademyofSciencesofBelarus,Minsk,RepublicofBelarus

LucasW.Koester CenterforNondestructiveEvaluation,AppliedSciences ComplexII,IowaStateUniversity,Ames,IA,UnitedStates

DmytroKovalchuk JSCNVOChervonaHvilya,Kyiv,Ukraine

AnjaLoesser EOSNorthAmericaInc

ZhiqiangLi AVICManufacturingTechnologyInstitute,Beijing,P.R.China

BrainW.Martin DepartmentofMaterialsScienceandEngineering,IowaState University,Ames,IA,UnitedStates

KevinMinet EOSFinlandOy

ThomasF.Murphy HoeganaesSpecialtyMetalPowdersLLC,Cinnaminson,NJ, UnitedStates

JoelC.Najmon DepartmentofMechanicalandEnergyEngineering,Indiana University PurdueUniversityIndianapolis,Indianapolis,IN,UnitedStates

TsuyoshiNakagawa JAXASafetyandMissionAssurance,Tokyo,Japan

M.B.Novikova All-RussiaInstituteofLightAlloys,JSC,Moscow,Russia

EricOtt GeneralElectricAdditive,WestChester,OH,UnitedStates

I.S.Polkin All-RussiaInstituteofLightAlloys,JSC,Moscow,Russia

BehrangPoorganji GeneralElectricAdditive,WestChester,OH,UnitedStates

SajjadRaeisi DepartmentofMechanicalandEnergyEngineering,Indiana University PurdueUniversityIndianapolis,Indianapolis,IN,UnitedStates

NikoRaitanen EOSFinlandOy

JeremyH.Rao DepartmentofMaterialsScienceandEngineering,Monash University,Clayton,VIC,Australia;MonashCentreforAdditiveManufacturing (MCAM),MonashUniversity,NottingHill,VIC,Australia

GregoryRizza ArconicInc.,ArconicFasteningSystems,Carson,CA,United States

MatthewR.Rolchigo DepartmentofMaterialsScienceandEngineering,Iowa StateUniversity,Ames,IA,UnitedStates

PaulRometsch DepartmentofMaterialsScienceandEngineering,Monash University,Clayton,VIC,Australia;MonashCentreforAdditiveManufacturing (MCAM),MonashUniversity,NottingHill,VIC,Australia;RioTintoArvida ResearchandDevelopmentCentre,Jonquie ` re,QC,Canada

RichardRussell NASAEngineeringandSafetyCenter,KennedySpaceCenter, FL,UnitedStates

AnkitSaharan EOSNorthAmericaInc

HectorSandoval LockheedMartinMissilesandFireControl,GrandPrairie,TX, UnitedStates

ChristopherT.Schade HoeganaesSpecialtyMetalPowdersLLC,Cinnaminson, NJ,UnitedStates

MohsenSeifi ASTMInternational,Washington,DC,UnitedStates

NimaShamsaei NationalCenterforAdditiveManufacturingExcellence,Auburn University,Auburn,AL,UnitedStates

S.V.Skvortsova MoscowAviationInstitute(NationalResearchUniversity), Moscow,Russia

HosseinTaheri CenterforNondestructiveEvaluation,AppliedSciencesComplex II,IowaStateUniversity,Ames,IA,UnitedStates;DepartmentofMechanical Engineering,IowaStateUniversity,Ames,IA,UnitedStates

AndresTovar DepartmentofMechanicalandEnergyEngineering,Indiana University PurdueUniversityIndianapolis,Indianapolis,IN,UnitedStates

G.A.Turichin St.PetersburgStateMaritimeTechnicalUniversity,St.Petersburg, Russia

PetrA.Vityaz PresidiumoftheNationalAcademyofSciencesofBelarus,Minsk, RepublicofBelarus;JointInstituteofMechanicalEngineeringoftheNational AcademyofSciencesofBelarus,Minsk,RepublicofBelarus

JessWaller NASA-JohnsonSpaceCenterWhiteSandsTestFacility,LasCruces, NM,UnitedStates

DouglasWells NASAMarshallSpaceFlightCenter,Huntsville,AL,UnitedStates

JamesC.Withers ATS-MER,LLC,Tucson,AZ,UnitedStates

XinhuaWu DepartmentofMaterialsScienceandEngineering,Monash University,Clayton,VIC,Australia;MonashCentreforAdditiveManufacturing (MCAM),MonashUniversity,NottingHill,VIC,Australia

KunV.Yang DepartmentofMaterialsScienceandEngineering,Monash University,Clayton,VIC,Australia;MonashCentreforAdditiveManufacturing (MCAM),MonashUniversity,NottingHill,VIC,Australia;CSIRO Manufacturing,Clayton,VIC,Australia

Introductiontoaerospace materialsrequirementsandthe roleofadditivemanufacturing FrancisFroes1,RodneyBoyer2,3 andB.Dutta4 1AdvancedMaterialsIndustries,Tacoma,WA,UnitedStates, 2SchoolofMaterials ScienceandEngineering,UniversityofShanghaiforScienceandTechnology,Shanghai, P.R.China, 3RBTiConsulting,Bellevue,WA,UnitedStates, 4DM3DTechnology,Auburn Hills,MI,UnitedStates

1.1Aerospacematerialsandtheirrequirements Aerospacematerials arefrequentlymetalalloys,althoughtheyalsoincludepolymericbasedmaterials,thathaveeitherbeendevelopedfor,orhavecometoprominencethrough,theiruseforaerospacepurposes.Aerospaceusesoftenrequire exceptionalperformance,strengthorheatresistance,evenatthecostofconsiderableexpenseintheirfabricationorconventionalmachining.Othersarechosenfor theirlong-termreliabilityinthissafety-consciousfield,particularlyfortheirresistancetofatigueloading.Thefieldofmaterialsengineeringisanimportantone withinaerospaceengineering.Itspracticeisdefinedbytheinternationalstandards bodiesthatmaintainstandardsforthematerialsandprocessesinvolved,suchas ASTM,AMSorcompanyspecifications(Table1.1 showsspecificationsforadditivemanufacturing[AM]).Generally,notalotofinformationiscontainedin companyspecs,butwiththecontrolsrequired,acompanyspecwillbemandatory duetothecomplexityoftheprocess,wherethecustomerwillwanttoknowalot moredetailsthanwillevergetintoapublicspecduetoprotectionofproprietary information.Afurtherrequirementisobserverobservationoffabricationof acceptablequality,includingmicrostructures(Fig.1.1).

1.2Additivemanufacturing Inpublicationsoverthepastfewyears [1 5], thecostoffabricatingvarioustitanium precursorsandmillproductshasbeendiscussed(veryrecentlythepriceofTiO2 has risento$2.00perpoundandTiCl4 to$0.55perpound)andithasbeenpointedout thatthecostofextractionisasmallfractionofthetotalcostofacomponentfabricatedbythecastandwrought(ingotmetallurgy)approach.Toreachafinalcomponent,themillproductsmustbemachined,oftenwithveryhighbuy-to-flyratios

https://doi.org/10.1016/B978-0-12-814062-8.00001-7

2AdditiveManufacturingfortheAerospaceIndustry

Table1.1 Specificationsreleasedandin-workforadditivemanufacturing(AM) components

Specificationno.SpecificationtitleStatus

AMS4998Titaniumalloypowder,Ti 6Al 4VReleased—1977

AMS4999Titaniumalloylaserdepositedproducts, Ti 6Al 4V,annealed Released—2002

AMS7000Additivemanufactureofaerospaceparts fromNi-basesuperalloy625vialaser powderbedprocess

AMS7001Nibase625superalloypowderforusein laserpowderbedmanufacturingof aerospaceparts

AMS7002Processrequirementsforproductionof powderfeedstockforuseinlaserpowder bedadditivemanufacturingofaerospace parts

Inwork

Inwork

Inwork

AMS7003LaserpowderbedfusionprocessInwork

AMS7004Titaniumalloypreformsfromhigh depositionrateadditivemanufacturing onsubstrateTi 6Al 4Vstressrelieved

AS9100Qualitymanagementsystems— requirementsforaviation,space,and defenseorganizations

Inwork

Issued1997, CurrentRev.D, 2016

TheAS(AerospaceStandards)areutilizedfordetailswithregardtoqualitymanagementsystems.Theydonotcover specificmaterialrequirementssuchasproperties,inspection,etc.

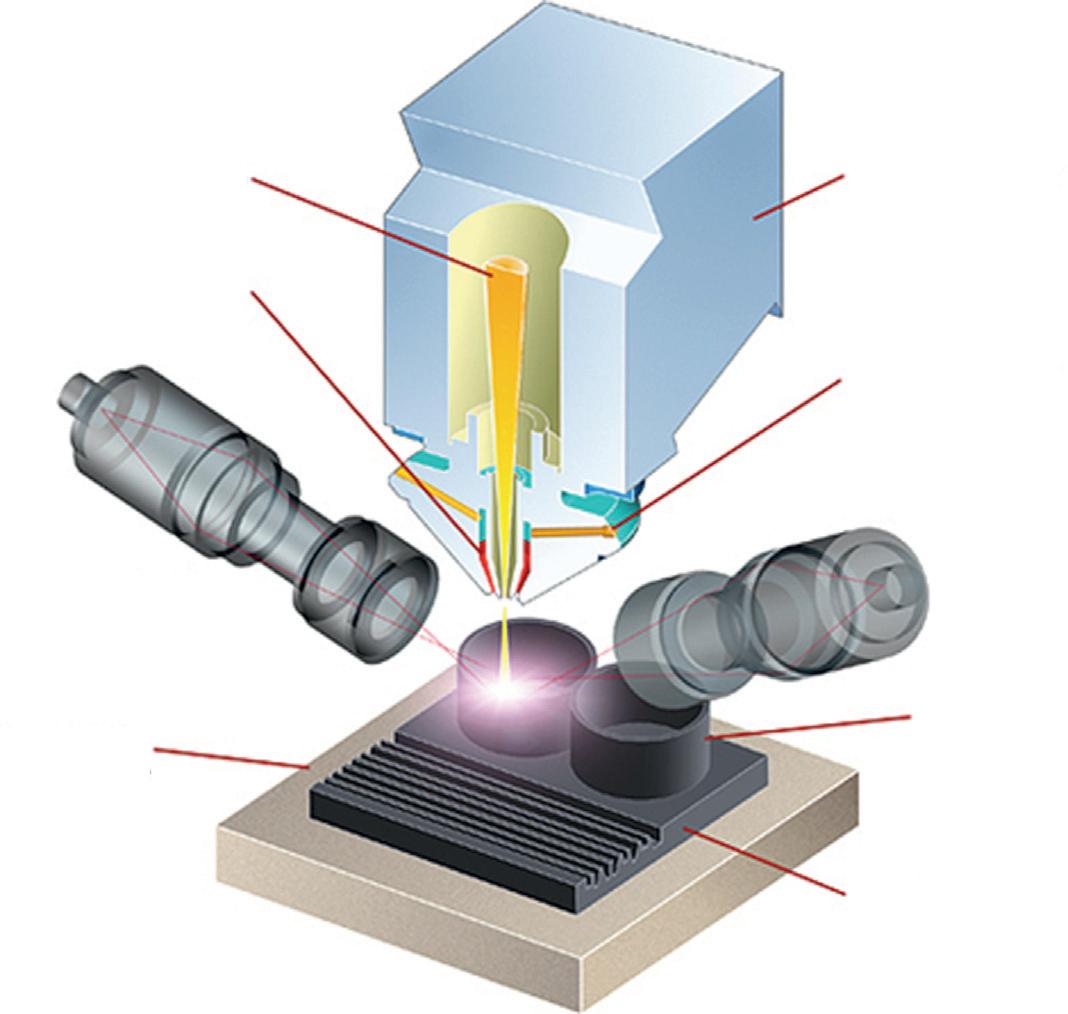

(whichcanreachashighas40:1).Thegenerallyacceptedcostofmachiningacomponentisthatitdoublesthecostofthecomponent.ThefeedstockforAMcanbea wireorapowder.Usingpowder,therearetwobasicapproachestoAM:powderbed fusion(PBF)anddirectenergydeposition(DED), Figs.1.1and1.2.ThePBF

Schematicshowingpowderbedfusiontechnology.

Figure1.1

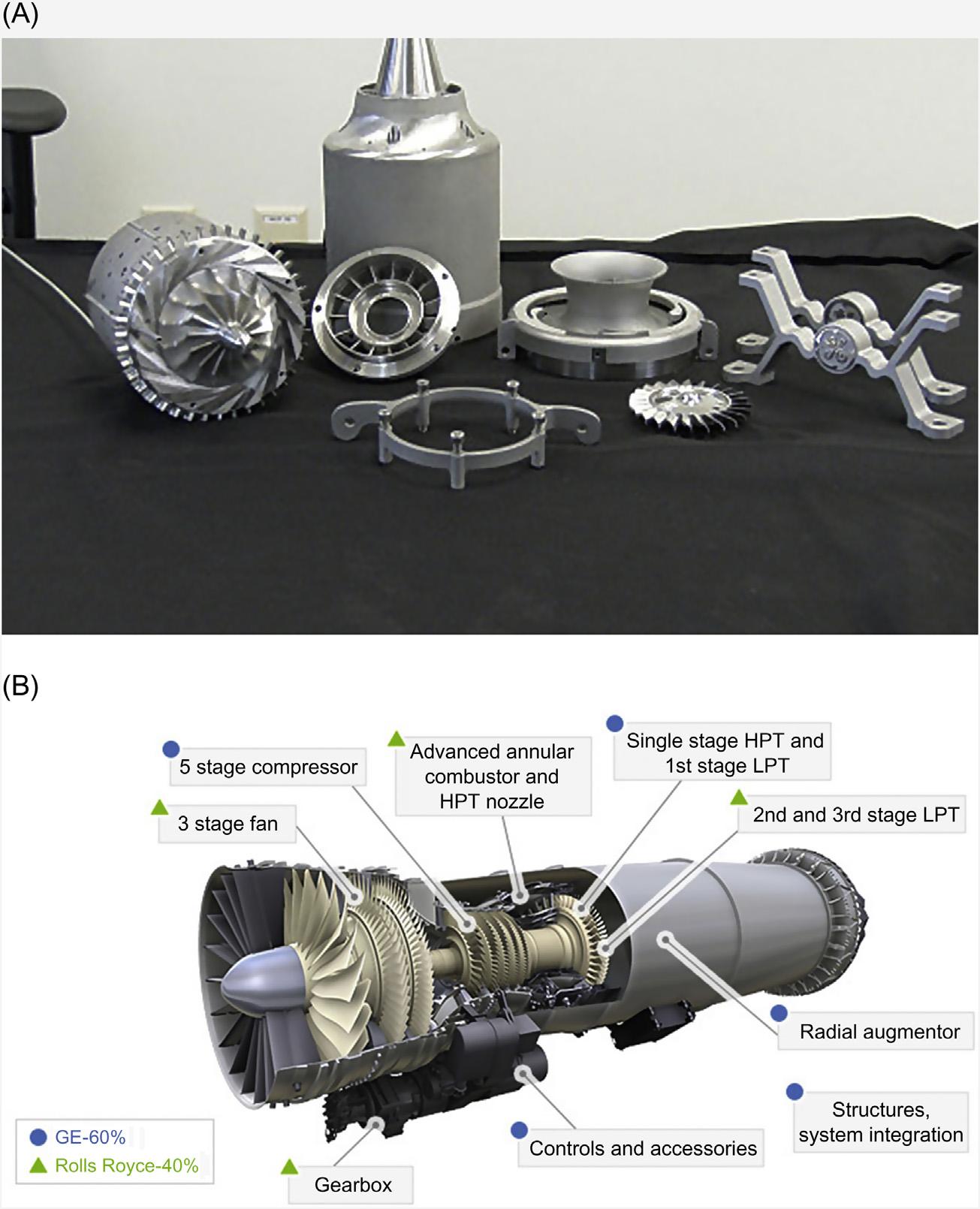

techniqueallowsthefabricationofcomplexfeatures,hollowcoolingpassages,high precisionparts,andsinglemetalbuilds.TheDEDapproachallowslargebuildenvelopes,highdepositionrates,multiplematerials,andadditionofmaterialtoexisting components.Mechanicalpropertiesareatleastatingotmetallurgylevels(including fracturetoughness).ExamplesofAMmanufacturedpartsandpartswhichcouldbe AMfabricatedinanadvancedengineareshownin Fig.1.3.

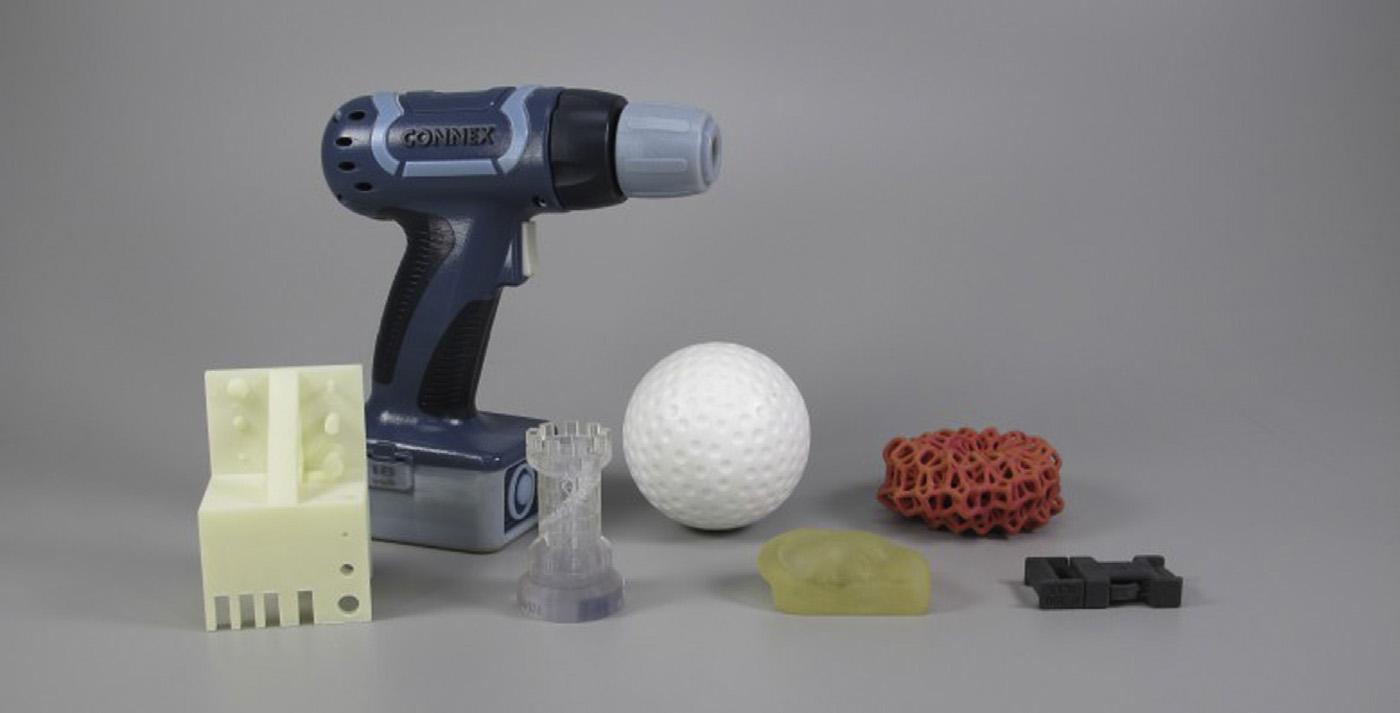

1.3Additivemanufacturingfabricationofvarioustypes ofmaterials TheAMtechniquehasbeenappliedtometals,ceramics,andpolymericmaterials (Figs.1.3 1.5)

AftertheAMbuild,ceramicpartsareporousand,ifdesired,canbeinfiltrated orfiredinapostprocessstep.Thismethodisusedforfineartceramics.Theprimaryadvantagesfor3-Dprinting,especiallybinderjetting(binderjettingisanAM processinwhichaliquidbindingagentisselectivelydepositedtojoinpowder particles.Layersofmaterialarethenbondedtoformanobject,forexamplebyhot isostaticpressing)arelowcost,highspeed,scalability,easeofbuildingpartsin

Figure1.2 SchematicshowingDMDtechnology. DMD,Directmetaldeposition.

Figure1.3 (A)Examplesofmetallicpartsfabricatedbyadditivemanufacturing.(B)The propulsionsystemfortheF-35lightening,whichcontainsasubstantialnumberof componentsthatcanbefabricatedbyadditivemanufacturing.

multiplematerials,andversatilityforusewithceramicmaterials.Originally evolvedfromsystemsthatusedthermoplastics,thebinderjettingmethodhasbeen modifiedtoacceptceramicslurriesorceramicpowdersinwaxorliquidbindercarriers.Materialjettinghassignificantchallenges,includinggettingmaterialstoflow throughnozzlesatreasonablespeedswithoutclogging.Workisongoingtoimprove therheologyofmaterialsystemsforceramicmaterials,suchasaluminaandzirconia.Thismethodpromisesgoodsurfacefinishesandhightolerancesforpartsthat canbeprintedandthenfiredtohighdensity.PBForiginatedwithselectivelaser

Figure1.4 Examplesofceramicpartsfabricatedbytheadditivemanufacturingtechnique.

Figure1.5 Examplesofpolymericmaterialsfabricatedbyadditivemanufacturing. 5 Introductiontoaerospacematerialsrequirementsandtheroleofadditivemanufacturing

sintering(SLS).SLSusesapowderbedlayerinabuildbox,similartothebinder jetmethod,butitisplacedinasystemthatbringsthepowdertoanelevatedtemperatureandthenexposesselectareastoalaserbeam.Thiscauseslocalizedsinteringoftheceramicpowder.Theparthassufficientstrengthforhandling,but requiresaconventionalpostprocessfiringtoachievefulldensity.AllPBFmethods sharecertaincharacteristics,includingoneormorethermalsourcesforinducing

6AdditiveManufacturingfortheAerospaceIndustry

fusionorsinteringbetweenparticles,amethodforprescribingfusioninaregionof eachlayer,andmechanismsforaddingandsmoothingpowderlayers.Electron beammeltinghasbecomeapopularapproachtoPBFasitisfast,efficient,andcan providefullydenseparts.Thedownsideforceramicsisthatthepowderbedneeds tobeelectricallyconductive.Directedenergydepositionisalsoatechniquethatis bettersuitedtometals.Polymerizationisusedforpolymersthatcanbeloadedwith ceramicpowders.

Polymericpartsrangefromepoxy-based,ABS(acrylonitrilebutadenestyrenea lightweightthermoplasticpolymerresinofthepolyesterfamily),wax,polystyrene, ceramic,andnylon.Allthesystemsfollowtheprinciplesofbuildinglayerbylayer, butvaryinhowthematerialsareapplied(e.g.,asafinepowder,liquidpolymer,or moltenplastic)andhowtheyarecured(e.g.,bymeltingwithalaseroractivating UVresinwithalaser).Thematerialmostcommonlyusedinnonimplantablemedical applicationsisnylon12.

1.4Contentsofthisbook InthisbookanattemptwasmadetocontactallthemajorAMfabricatorsandaerospaceuser(airframes,engines,andmissile)world-widetofullycoverallthesignificantactivityintheAMinaerospacefield.Notalltheorganizationscontacted expressedaninterestinparticipatinginthisbook.Howeveritisconsideredthat enoughinformationhasbeengatheredtogivethereaderacomprehensiveviewof thefield.OnerumorwhichwasdispelledisthattheUSAFisverynegativeonAM, theyarenot.Readthe40articleswhichfollowthisintroductiontogetabroadview oftheuseofAMinaerospaceapplications.

References [1] B.Dutta,F.H.(Sam)Froes,Additivemanufacturingoftitaniumalloys,Adv.Mater.Proc. (2014)18 23.

[2] B.Dutta,F.H.(Sam)Froes,Chapter24:theadditivemanufacturingoftitaniumalloys, in:M.Qian,F.H.(Sam)Froes(Eds.),TitaniumPowderMetallurgy,ButterworthHeinemann,2015.

[3]F.H.(Sam)Froes,B.Dutta,Theadditivemanufacturingoftitaniumalloys,in: ProceedingsoftheWorldConferenceonTitanium,SanDiego,CA,2015.

[4]B.Dutta,F.H.Froes,Additivemanufactureroftitaniumalloys,in:A.Badiru(Ed.), AdditiveManufacturingHandbook:ProductDevelopmentfortheDefenseIndustry, 2016.

[5] B.Dutta,F.H.Froes,BookAdditiveManufacturingofTitaniumAlloys,Elsevier Publishing,Amsterdam,2016.

Reviewofadditivemanufacturing technologiesandapplicationsin theaerospaceindustry JoelC.Najmon,SajjadRaeisiandAndresTovar DepartmentofMechanicalandEnergyEngineering,IndianaUniversity Purdue

UniversityIndianapolis,Indianapolis,IN,UnitedStates

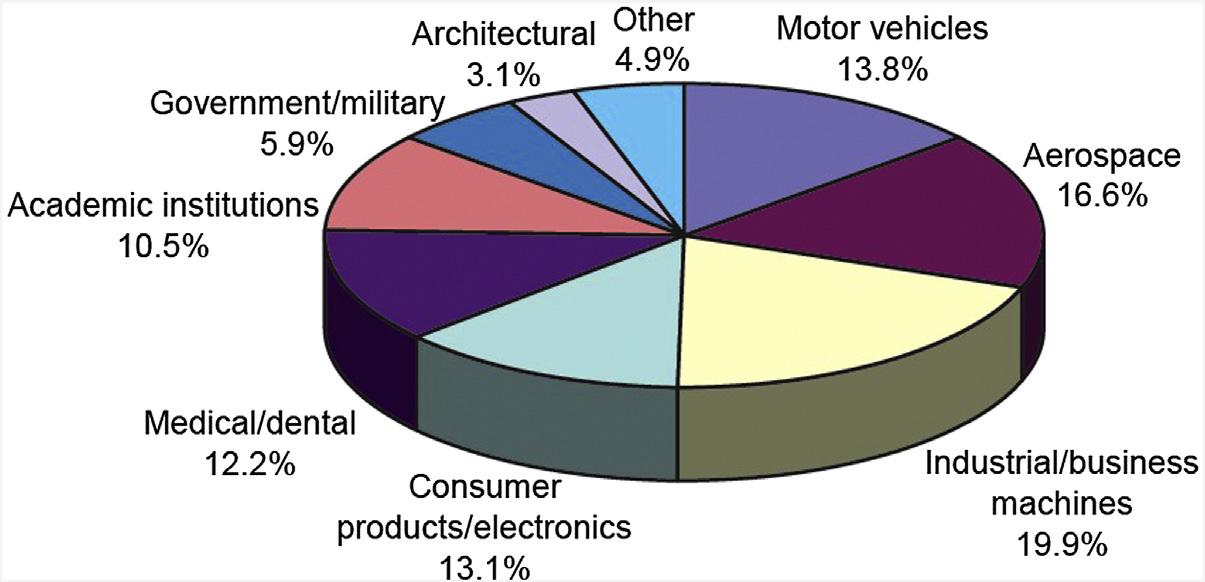

2.1Aerospacerequirementsandopportunitiesfor additivemanufacturing 2 Additivemanufacturing(AM)isbeingestablishedasafabricationtechnologythat bringsrevenuetotheaerospaceindustrythroughoutitssupplychainandrepair operations [1].Forthelast10years,theaerospaceindustryhasbeenoneofthetop sectorsleadingtheAMmarket(Figs.2.1and2.2).Today,18.2%oftherevenuein theAMindustryisreceivedfromtheaerospaceindustry.Theaerospacesectoris alsothefastestgrowingsector,showinganannualincreaseof1.6%in2016,followedbymotorvehicleswithagrowthof1.0%.TherevenuesfromtheAMare estimatedat$2.7billionin2016(growthof12.9%withrespectto2015)and areexpectedtosurpass$100billionwithinthenexttwodecades,mostlyinthe aerospaceindustry [3]

ThemarketforAMpartsinaerospacecanbedividedintometallicandnonmetallic(mostlypolymer)components,whicharegenerallyrelatedtocriticalandnoncriticalaircraftparts,respectively.BoeingandBellHelicopterstartedusing polymerAMpartsfornonstructuralcomponentsinthemid-1990s.InMarch2015, Boeingfabricatedmorethan200uniquepartsfor10differentaircraftusingAM technologies.Bythattime,morethan20,000nonmetallicAMpartswereinstalled inairplanes [1].Today,BoeinghasinstalledtensofthousandsofAMpartson16 commercialandmilitaryaircraft [4].In2017,BoeingstartedusingatleastfourAM titanium-alloypartstoproduceits787Dreamlineraircraftwithnear-futureplansto manufacturealmost1000partsviaAMtosave$2 3millionperairplane [5]. AirbusisalsoamainplayerinAM.IthasinstalledAMmetalbracketsandbleed pipesontheAirbusA320neoandtheA350XWBtestaircraft [6].Italsohasa multiyearcooperativeresearchagreementwithArconictoproducelarge-scaleAM airframecomponents(1minlength) [7].NASA,theEuropeanSpaceAgency,and SpaceXareexploringtheuseofAMigniters,injectors,andcombustionchambers ontheirrocketengines.HoneywellAerospace,LockheedMartin,andNorthrop GrummanarealsoimportantusersofAM.Theuniquedesignrequirementsfrom

8AdditiveManufacturingfortheAerospaceIndustry

Figure2.1 Additivemanufacturingmarketsharebyindustryin2016.

Source: Wohlers,A.,WohlersReport2016.3DPrintingandAdditiveManufacturingStateof theIndustry.AnnualWorldwideProgressReport.2016:AssociatesWohlers.WohlersReport 2016.WohlersAssociates,Inc. [2].

Figure2.2 Additivemanufacturingmarketsharebyindustryin2017.

Source: Wohlers,A.,WohlersReport2017.3DPrintingandAdditiveManufacturingStateof theIndustry.AnnualWorldwideProgressReport.2017:AssociatesWohlers.WohlersReport 2017.WohlersAssociates,Inc. [4]

theaerospaceindustryandcapabilitiesofAMtechnologiesarediscussedinthis section.

2.1.1Designrequirements Theaerospaceindustryisconstantlydemandinglightweightaircraftcomponents withahighstrength-to-weightratiotoimprovefuelefficiency,reduceemissions, andrespondtosafetyandreliabilityrequirements [8].Tothisend,aerospace designersstrivetominimizetheamountofmaterialusedineverycomponent,

whichresultsinincreaseddesigncomplexitywithrespecttothestructure,function, andproperty [9].AMallowsthefabricationofpartswithvirtuallyanyshape(freeformfabrication).

2.1.1.1Structuraldesign

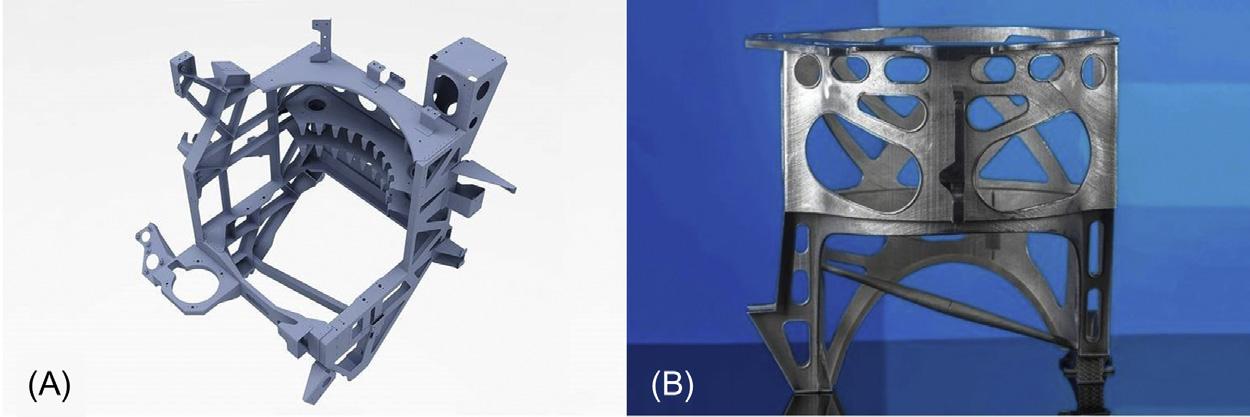

Structurallycomplexdesignsarecharacterizedbynontraditional(freeform,organiclike)externalshapesthatprovidehighmechanicalperformancewithminimum mass.AMallowsthefabricationofpartswithcomplexdesignswithsomeconstraints,dependingonthespecificAMtechnology [10].Framedesignsareexampleswheretopologyoptimizationisused.Complexaircraftstructurescanbealso designedtomaximizeinternalspace(packingratio) [11].Whencomparedwithtraditionalmanufacturingprocesses,likeinjectionmoldingormilling,AMissignificantlymoreversatileduetoitslayer-by-layerfabricationprocess [12].Thisallows fortheoptimizationandmanufacturingoflightweight,strong,androbustparts [13].

Structuralcomplexityalsodescribesthemultiscaleinternalhierarchicalarchitecturesoflattice/cellulararrays(mechanicalmetamaterials) [14 16].Suchcomplex structurescanbeobtainedwithuseoftopologyoptimizationalgorithms [17 23] Commercialsoftwarethatcanprovidelatticematerialstooptimizedesignsincludes Netfabb,Within,Materialise,andSimpleware,aswellastopologyoptimization toolssuchasOptiStruct,Genesis,andMeshify.Thesolutionoftopologyoptimizationproblemsinvolvesmultiphysicssimulationsandmultiscaledesignmethodsto findthebestcompromisedsolutionamongmultipleobjectives [24].Withtheuseof thesesoftwaretools,aerospacedesignershavetheabilitytoreducematerialand weightwhilemakingthedesignsuitableforAM.Thesetoolsalsoallowtheability toretainorincreasethepart’smechanicalperformanceandreducemanufacturing cost.Lightweightpartscandeliversubstantialcostsavingsfromthefabricationproceduretotheendoftheairplane’slife [25].

2.1.1.2Functionalcomplexity Functionalcomplexityreferstotheabilityofpartstointegratemultiplefunctions (multifunctionalparts),includingfunctionsthataretraditionallynotassignedtothe part,forexample,heatdissipation,electricalcircuitry,flexibility,capillaritytoa load-bearingcomponent.Examplesinaerospaceincludestructuralcomponentsthat alsoactasconduits,suchasairfoilsandturbinebladeswithembeddedcooling channels [26,27].

Functionalcomplexityalsodefinesfunctionsthataredifficulttoachievebya singlecomponent.Anexampleisthedesignoftheswirlerinsideajetenginethat forcescombustionproductstorecirculateinsidethechamber,generatingahighly turbulentflow.Sinceincreasingtheturbulencecanreducethechamberpressure, theswirlergeometrymustbedesignedpreciselytodeliverthedesiredturbulence suitablytomixtheinjectedfuelandtheairflow [28].Suchacomplexfunctionis difficulttoachievewithoutthefreeformfabricationcapabilitiesofAM.

2.1.1.3Propertyrequirements Finally,behavioralcomplexitydescribeschangesinthematerialpropertiesacross thecomponent.Thisincludesmultimaterialdesignsandfunctionallygradedmaterials(FGMs).FGMscanbefabricatedbylocalmicrostructuremodificationsfrom thermally-inducedtransformations [29 33] orbychangesinthearchitectureofthe cellular/latticestructure [34 36].

Theabilitytotailormechanicalpropertiesisparticularlyrelevanttoadditive metaltechnologies(AMTs),likedirectedenergydeposition(DED)andpowderbed fusion(PBF) [37].InPBF,thepowdergrainsizeanddistributioncanbevariedto changethedensityandcorrespondingproperties [38,39].Theprocessingparameters canbevariedtotailorthequalityofthepart’shardness,fatiguestrength,surface microstructure,andsurfacefinish [39,40].Thisallowsforthemanufacturingof metalpartswithlocalcontrolofresidualstressconcentrations [41].

2.1.2Manufacturingcapabilitiesandbenefits Theincreasedcomplexityofthestructure,function,andpropertyofanaerospace componententailsfabricationchallengesandhighercosts [42].Traditionally,the designissimplifiedformanufacturingandassemblyoperationsattheexpenseof partperformance.AM,however,allowsfreeformfabricationandreducesassembly throughpartconsolidation.Italsoreducesmaterialwasteandallowstheuseofpremiummaterialsthataredifficulttoprocesswithothermanufacturingtechniques. Unlikeconventionalmanufacturing,AMreducesoreveneliminatestheneedfor tooling,whichallowstheproductionofsmallproductionrunsandpartsthatrequire quickturnaroundtime.ThebenefitsofAMfortheaerospaceindustryarediscussed inthissection.

2.1.2.1Partconsolidation Traditionally,complexaerospacecomponentscontainmultiplesimplepartsthatare joinedtogetherusingdifferenttypesoffasteners(welds,bolts,andbrazes). However,suchassembliesofferlowerreliabilityandrequiregreaterinspection, tooling,andsustainmentcostswhencomparedtoasinglepart [43].Inaddition, geometricerrorsandundesiredmisalignmentsordeformationsmayexceedallowabletolerancesinaerospacecomponents [44]

PartconsolidationcanbeattainedusingAM.Thisenablesfeatureintegrationas wellasincreasedreliabilityandperformance [45].WhenacomplexpartisfabricatedonasingleAMmachine,thepartinventoryisreducedandtheeconomiesof scaleassociatedwithlargecentralizedfactoriesarealsoreduced [1].Decreasingthe numberofpartsinanassemblyreduces(1)thenumberoftoolsheldininventory, (2)thecostsassociatedwithdocumentation,inspection,andproduction,(3)the assemblylinefootprint,and(4)theoverallmanufacturingcosts.

GEAviationhasreportedareductionfrom855partsproducedusingconventionalmanufacturingintoadozenpartsusingAMtechnologies.Thesimplified 10AdditiveManufacturingfortheAerospaceIndustry

designreducedweight,improvedfuelefficiencyupto20%,andachieved10% morepower.Abearingsupportandsumpwereredesignedtoconsolidate80parts intoone.Also,a20-partnozzlewasconsolidatedintoasingleAMunitandthe weightwasreducedby25% [46].Similarly,Airbusreduceda126-parthydraulic housingtanktoasingleAMpart [47] (Fig.2.3).

2.1.2.2Materialeconomy Asignificantcontributortothehighfabricationcostofaerospacecomponentsisthe buy-to-flyratio,whichisdefinedastheweightratiobetweentherawmaterialand theweightofthefinalcomponent.Aerospacecomponentswithlargevolume envelope-to-volumeratios(e.g.,thin-walledstructuresandturbineblades)have buy-to-flyratiosashighas20 40:1 [48],whichmakesCNCtoolplanningtime consumingandimpracticalduetothemassiveamountofwastematerial.Inthese cases,thematerialuseandthemanufacturingcostcanbesignificantlyimproved withAMfreeformfabricationcapabilitiesandreducethebuy-to-flyratiocloserto 1:1.ForPBFprocesses,theamountofwasteproducedisaround5%comparedto thatoftraditionalmilling,whichcanproduceupto95%waste [12,49].Reducing thematerialwasteandthepartweightalsohasasignificantpositiveeffectonthe environment [50,51]

Theaerospaceindustryconstantlydemandspremiummetals,suchastitanium alloys,aluminumalloys,nickel-basedsuperalloys,andspecialsteels.Titanium alloys,forexample,provideoutstandingcharacteristics,likehighstrength-toweightratio,awiderangeofoperatingtemperatures,highcorrosionresistance,and compositecompatibility.However,titaniumalloysarehighlylimitedbytheirrelativelyhighcostcomparedtoothermaterials [52] andtheirpoormachinability [53] AgrowingnumberofpremiummaterialsareavailableinAMtechnologies,includingtitanium.Forinstance,GEAvioAeroisproducinglow-pressureturbineblades intitaniumaluminide(TiAl)usingAM [54].Today,NorskTitaniumownsthe world’slargesttitaniumAMfacilityandsuppliesaerospace-gradeAMstructural titaniumcomponents,approvedbytheFederalAviationAdministration(FAA)of theUnitedStates,tocompanieslikeBoeing.

Figure2.3 (A)AMhydraulicreservoirrackfromAirbusconsolidating126parts.(B) Consolidateddesignintoonepart. AM,Additivemanufacturing. Source: PhotocopyrightAirbus HermannJansen.

12AdditiveManufacturingfortheAerospaceIndustry

2.1.2.3Smallproductionrunsandturnaroundtime Incomparisontoconventionalmanufacturingprocesses,AMtendtobemore expensiveforlargeproductionruns;however,therelativelyhighinvestmentcosts offixturesandtoolsareavoidedorconsiderablyreducedinAM [12].Therefore, AMismorecosteffectiveforcustomizedpartsandsmallproductionruns,which arecommonintheaerospaceindustry.

Sinceaircrafthavelifespansofover30years,maintainingandreplacinglegacy partsandtoolingmayinvolvehighinventorycosts [55].AMenablestheproduction oftestandreplacementpartsondemandforrapidshipmentandinstallation [56] Thisminimizesdowntimeandassociatedcosts.AccordingtoAirbus,theturnaroundfortestorreplacementpartswasaslowas2weeksin2014.Finally,AM allowspartstobemanufacturedatdecentralizedlocations.Thislowerstransportationandstoragecosts.Thissimplificationinsupplychainsalsoleadstoareduction inmaintenance-baseddowntimeandturnaroundtime [57].

2.2Additivemanufacturingtechnologies TheAmericanSocietyforTestingandMaterialsInternationalCommitteeF42classifiesAMtechnologiesintosevencategories:binderjetting,DED,materialextrusion,materialjetting,PBF,sheetlamination,andvatphotopolymerization [58]. Accordingtothematerial,AMtechnologiesinaerospacecanbeclassifiedinto AMTsandadditivenonmetaltechnologies.Thesetechnologiesaredescribedinthis section.

2.2.1Additivemetaltechnologies ThetwomostcommonAMTsforaerospaceapplicationsareDEDandPBF. WidespreadDEDtechnologiesintheaerospaceindustryincludelasermetaldeposition(LMD),laserengineeringnet-shaping(LENS),electronbeamwelding(EBW), electronbeamfree-formfabrication(EBF3),andwirearcAM(WAAM).

PBFtechnologiesincludedirectmetallasersintering(DMLS),selectivelaser melting(SLM),andelectronbeammelting(EBM).OtherrelevantAMTsforaerospaceapplicationsincludebinderjettingandsupersonicparticledeposition(SPD), alsoknownascoldspray(Table2.1).Thissectiondescribesthemostrelevant AMTstotheaerospaceindustry.

2.2.1.1Directedenergydeposition DEDtechnologyworksbymeltingmaterialthatisfedtoalocalsiteonthebuild layer,usuallyoccurringwithinaninertgasatmosphere [1,59].Whilethiscanbe usedfornonmetalmaterials,itispredominatelyusedwithmetalsandmetalalloys [1,60 62].Feedstockusuallycomesintheformofpowderorwireandismelted withafocusedenergysource,suchaslaserbeams,electronbeams,andarcs [1,48]

Reviewofadditivemanufacturingtechnologiesandapplicationsintheaerospaceindustry

Table2.1 Additivemetaltechnologiesintheaerospaceindustry AMTs

DirectedenergydepositionPowderbedfusionOther

● LMD/LENS

● EBW/EBF3

● WAAM

● DMLS

● SLM ● EBM

● Binderjetting

● SPD/coldspray

LMD,Lasermetaldeposition; LENS,laserengineeringnet-shaping; EBF3,electronbeamfree-formfabrication; EBW,electronbeamwelding; WAAM,wirearcAM; DMLS,directmetallasersintering; SLM,selectivelaser melting; EBM,electronbeammelting; SPD,supersonicparticledeposition; AMTs,additivemetaltechnologies.

DEDprocessesbuildupthe3Dpart,layerbylayer;however,thetechnology canbeimplementedinamultiaxialmachineandprovide3Dpositioning [1].This allowsmanufacturingofcomplexpartswithouttheneedofsupportstructures.Due toincreasedversatilityinorientation,DEDtechnologiesareidealforcomponent repairofturbineblades,enginecombustionchambers,compressors,airfoils,and blisks [1,62,63].Turbineairfoilshavebeenrepairedtowithin0.030mmaccuracy oftheoriginalbladeandshownthatforarepairvolumeof10%,thereisaatleasta 45%improvementinthecarbonfootprintanda36%totalenergysavings [64].The mechanicalpropertiesofanAMpartproducedbywire-fedlaserandarcbeam depositionprocessesrelyheavilyonprocessparameters,loaddirection,andpost build-upheattreatment;however,bothprocessesproducedpartswithcomparable propertiesandaresuitableforaerospaceapplications [60]

2.2.1.2Powderbedfusion PBFtechnologiesworkbylocallymeltingmetalpowderonasubstratetoform layers.Afteranewlayerisformed,alevelingrollerdistributesanewlayerofpowder.Un-meltedpowderisreusableandbecomesthesupportforsuccessivelayers, reducingtheneedforsupportstructures [1,59].Toavoidpowderoxidation,SLM andDMLSoccurinaninertgasatmosphere,whileEBMoccursinavacuum [65,66].Consequently,therequirementofavacuummakesEBMattractivefor outerspacemanufacturing [59,67].ComparedtoDEDprocesses,PBFprocesses havetheabilitytocreateinternalpassagesand,typically,producehigher-fidelity buildfeatures [68].Titaniumalloy(Ti 6Al 4V)hasbeentypicallyusedinthe fabricationofAMpartsviaEBMtechnology [69 74].Topologyoptimized Ti 6Al 4VbracketsweremanufacturedwithanArcamQ10PlusEBMsystem, demonstratingthatgeometryandmicrostructurearedependentonthebuildtimeor cross-sectionalareaofeachlayer [74]

2.2.1.3Otherrelevantadditivemetaltechnologies

BinderjettingisusedforquickandreliablerapidprototypingofmetalAMparts, suchasimpellersandturbineblades [75,76].Itisalsousedforrapidtoolinginthe

14AdditiveManufacturingfortheAerospaceIndustry

fabricationofAMsandcoresandmoldstoproducelargemetalparts.Typicalmetals usedarealuminumandcopperalloys,grayandductileiron,andmagnesium.Binder jettingAMofsandcoresandmoldsallowstheremovalofpatternsusedinindirect rapidtoolingandsimplifiesthestepsinvolvedinthecreationoflowvolumeproductionparts [77].Applicationsofdirectrapidtoolingthroughmetalbinderjetting includecomplexgearcasesandcovers,fueltanks,transmissionhousings,componentsrequiringdraftfreewalls,lightweightengineparts,andstructuralhinges [78].

SPD,orcoldspray,worksthroughtheconsolidationofsupersonic,microsized, metalparticlesontoasuitablesubstrateuponimpact(ballisticimpingement).This technologyisalsosuitableforceramicandpolymerpowders [79].Theparticlesare acceleratedwithaspraygunfittedwithaconvergent-divergentrocketnozzleusinga heatedhigh-pressuregas(heliumornitrogen).Sincethemetalpowderisnotsignificantlyheatedduringthisprocess,withconsolidationoccurringinthesolidform,the risksofoxidation,residualstressaccumulation,andchangesinthepowder’smicrostructureareavoided [79].SPDhasbeenutilizedforrepairingandenhancingtheairworthinessandintegrityofagingaircraftstructures [80 82].Nitrogen-basedSPD hasbeenshownlimitedparticledeformationresultinginhighdegreesofporosity, whilehelium-basedSPDhadsubstantiallymoremicrostructuraldeformationwith verylittleporosity [83].Aircraftthatareoftenexposedtosaltspray,likenavyrescue/patrolhelicopters,shouldberepairedandtreatedwithhelium-basedSPD [55].

2.2.2Additivenonmetaltechnologies Additivenonmetaltechnologiesmostrelevanttotheaerospaceindustryinclude: selectivelasersintering(SLS),stereolithography(SLA),fuseddepositionmodeling (FDM),andPolyJet [84] (Table2.2).Thissectionpresentsthemaincharacteristics ofthesetechnologiesandtheirrelevancetotheaerospaceindustry.

2.2.2.1Selectivelasersintering SLSisaPBFprocessthattypicallyusesalaserenergysourcetomeltpolymer powders [59].Ithastheabilitytoproducelargepartswithgoodmechanical strengthatarelativelylowcost [91].Foraerospaceapplications,SLSisprimarily usedforrapidprototypingofnonfunctionalpartsanddirectdigitalmanufacturing (DDM)ofnoncriticalcomponents [92].Glass-fillednylonisusedinSLSfabricationofenginecompartmentsthatrequireheatresistance,forexample,tarmacnozzlebezel [85].Nylon12isusedinSLSproducedpartsthatrequireflexibility,such asductsandbellowdirectorsforairflow [86] (Fig.2.4).Ithasbeenshownthatthe percentcrystallinityofSLSnylon-12partsisdependentonthedegreeoftheparticlemelt,totheextentthatsufficientlydifferentpercentcrystallinitypartvolumes canbetreatedasdifferentmaterials [93].Thisopensupthepossibilityofproducing FGMpartswithSLS.SLSpartsproducedwithacrylicstyreneandpolyamide (nylon)shownearlythesamemechanicalpropertiesasplasticinjectedcounterparts [94,95].Inmostapplications,SLSisknowntobecosteffectivefortheproduction ofsmallvolumepartsforaircraft [59]

Table2.2 Additivenonmetaltechnologiesintheaerospaceindustry

Additivenonmetaltechnologies

ApplicationExamplepartRequirementsRecommended

Engine compartment

Tarmacnozzle bezel [85]

AirductsAirflowducting [86]

FullsizepanelsSeatbacksand entrydoors [84]

Castedmetal parts Bracketsand doorhandles [87]

LightsHeadlight prototypes [84]

BezelsDashboard interface [84]

UAVWingsand fuselage [88]

Prototypesand tools

Heatresistant functional parts

Flexibleducts andbellow directors

Largepartswith smooth surfacefinish

Castmetalparts using3Dprinted patterns

Fullytransparent, high-detail models

End-usecustom screenbezels

Highstrength, lightweight, durability

Cameracase prototypeand tooltoinstall wiring [89]

Cabin accessories Doorhandle covers [90]

nylon

SLSNylon12

SLAStandardresin

PolyJet Castableresinor wax

PolyJet Clearresin

Rigidity, dimensional stability

Customizable androbust handles

SLS,Selectivelasersintering; SLA,stereolithography; FDM,fuseddepositionmodeling.

Source:AdaptedfromB.Artley,Aerospace3DPrintingApplications,in:D.Hubs(Ed.). ,https://www.3dhubs.com/knowledge-base/ aerospace-3d-printing-applications. [84]

2.2.2.2Stereolithography SLA,alsoknownasvatphotopolymerization,isamethodofcreating3Dobjects usingalight-emittingdevice(laserordigitallightprocessing)thatilluminatesand curesaliquidphotopolymerresin(thermosettingplastic)layerbylayer [96].SLA hastheabilitytoproducefinefeaturesandprovidegoodsurfacefinishwithminimumstairsteppingeffect [91].Severalphotopolymerresinscanbeutilizedwith SLA:standard(rigid,opaque),castable,andclear,aswellasflexible,hightemperature,anddental,amongothers [97].High-fidelityrapidprototypesfortesting,verification,anddesignofaeroelasticairfoilshavebeenproducedwithlow-stiffness resins,wheremodelsimilaritybetweenprototypeswashighlydesired [98].Cabin accessoriessuchasconsolecontrolpartswithfunctionalknobsaswellasfullsize

Figure2.4 Airductsforlaminarflowmadewithpolyamide12(PA2200)fromEOS [86]

panels,seatbacks,andentrydoorshavebeenproducedwithSLAstandardresin [84].Castableandhigh-temperatureSLAresinsareusedtofabricatemoldpatterns (indirectrapidtooling)andinjectionmolds(directrapidtooling),respectively. Prototypesofhighly-detailed,fullytransparentaircraftheadlightsareproducedwith SLAclearresins [84]

2.2.2.3PolyJet PolyJet,alsoknownasmaterialjetting,usesinkjetprintingtechnologytojetliquid photopolymerdropletsontoabuildsubstrateandthencureitwithUVlight.Ithas theabilitytofabricatepartswithfinefeaturesandgoodsurfacefinish,whileexhibitinglittlestairsteppingeffect [91].SomePolyJetsystemsalsoboasttheabilityto producemultimaterialpartsthroughFGM,allowingawiderangeofmaterialpropertiesselection [99].TheroleofPolyJetintheaerospaceindustryincludesrapid prototyping,indirectrapidtooling(moldpatternfabrication),andDDM.Material jettingoccursthroughtwoprocesses:dropondemand(DOD)andcontinuousinkjet (CIJ).TheDODprocessoffershighpartresolutionattheexpenseofbuildtime, makingitfavorableforapplicationsrequiringafinesurfacefinish,suchasprototypelightfittingsandintricatewingdesignprototypes(bat-likeornithopter,lattice structurewingstruts) [100,101].TheCIJprocessofferfasterbuildtimesatlower partresolutionsandisbettersuitedfornoncritical,nonmetallicpartfabrication,like interfacebezels [102].

2.2.2.4Fuseddepositionmodeling FDM,alsoknownasmaterialextrusion,iscurrentlythemostpopularAMtechnologyonthemarket [103].Itallowsthefabricationofdurablecomponentsmadeof

high-strengththermoplasticssuchasULTEM,polycarbonate,polyphenylsulfone, polylacticacid,andacrylonitrilebutadienestyrene(ABS) [104].FDMsystemsare widelyversatileinapplications,rangingfromquickandinexpensiverapidprototypingtotoughandrigidpartssuitableforend-use.Theaerospaceindustryhasbeen substitutingtraditionallymetalpartswithsufficientlystrongFDM-producedpartsto reduceweightandturnaroundtimeforpartrepairs [105].Approximately70 production-gradethermoplasticparts,arebeingimplementedinNASA’sMarsrover becausetheyarelightweight,yetdurableenoughtowithstandtherigorsofspace [106].Forprototypeapplicationsthatdonotrequirehighresolutionandsurfacefinish,FDMtechnologyisidealbecauseitiseconomicalanddoesnotrequirechemicalpostprocessing [107].StratasysandAuroraFlightSciencesfabricatedthelargest andfastestAMunmannedaerialvehicle(UAV)usingFDM.Lowweightandhigh strengthareachievedusingULTEM9085asthebuildmaterialinadditiontoaddinganinternalhoneycombstructuretotheinternalwingdesign.

2.3Additivemanufacturingapplications AMtechnologiesforaerospaceapplicationsusuallyfallunderoneofthefollowing categories:DDM,rapidtooling,rapidprototyping,andrepair. Table2.3 showsa breakdownofAMtechnologiesintometalandnonmetalapplicationcategories.DDM referstotheproductionofpartstobeutilizedintheaircraft.Suchpartscanbecritical componentsrequiredfortheoperation(e.g.,nozzles,combustionchambers)and

Table2.3 Metalandnonmetaladditivemanufacturingtechnologieswithselectaerospace examples

ApplicationAM technology

Metal

Nonmetal

DDM,Directdigitalmanufacturing; DED,directedenergydeposition; PBF,powderbedfusion; SLS,selectivelaser sintering; SLA,stereolithography; FDM,fuseddepositionmodeling; UAV,unmannedaerialvehicle. 17

● DDM(direct metalpart fabrication)

● Rapidtooling

● Repair

● DDM(fixtures and accessories)

● Rapid prototyping

● Rapidtooling

● DED

● PBF

● Cold spray

● Binder jetting

● SLS

● SLA

● PolyJet

● FDM

● Helicopterenginecombustion chamberfabrication(DED) [108]

● Bliskairfoilrepair(DED) [109]

● Satelliteantennabracket(PBF) [110]

● Lapjointreinforcement(SPD) [81]

● RatchetwrenchprintedbyNASA onInternationalSpaceStation (SLS) [111]

● UAVwingdesign(PolyJet) [91]

● Boeing777-300ERdoorhandle (FDM) [90]

● Cameracaseprototyping(FDM) [89]

noncriticalparts(e.g.,brackets,fixtures,andaccessories).Rapidtoolingreferstothe fabricationoftoolsandpatternsrequiredforthefabricationofthefinalpart.Itcanbe classifiedintodirectrapidtooling(e.g.,moldsanddies)andindirectrapidtooling (e.g.,moldpatterns).Rapidprototypingreferstothefabricationofnonfunctionalparts, usuallyusingnonmetaltechnologies.Finally,repairentailstherepairandreinforcementofmetallicpartsandjointsusuallythroughDEDandcoldsprayprocesses.

2.3.1Directdigitalmanufacturing 2.3.1.1Directmetalpartfabrication

DEDsystemsfromcompanieslikeTWI(TheWeldingInstitute)andEOSGmbH (Electro-OpticalSystems)arebeingusedtofabricatecomplexandoverhanging metalstructuresasthemultiaxisorientationsystemscanorientthepartsothatjuttingstructuresarebuiltoffofexistinglayers.TWI’sfive-axisLMDsystemhas beenusedintheproductionofanIN718helicopterenginecombustionchamber, featuringanoverhangingflange [108] (Fig.2.5).RUAGSwitzerlandhasusedAM withtopologyoptimizationtoreducetheweightoftheSentinelsatellites’antenna bracketby40% [110].Theoptimizedbracketismadeofaluminumalloy, AlSi10Mg,manufacturedwiththeEOSM400,anSLMAMsystem.Boeing’s787 Dreamlinerisnowusingfouradditivemanufacturedtitaniumpartsthatwilleventuallyreduceitsproductioncostsbyupto$3million [5].

Multipartassemblieshavebeenconsolidatedintoasinglecomplexpartusing EOS’sM290DMLSsystem.TheArianeGroupwasabletoreducea248-partupper stagepropulsionmoduletoasinglepartthroughDMLS [112].Vectoflowused DMLStofabricateacompact,one-piece,flowmeasurementdevice,designedto withstandtheseverestressesofaircraftinthesubsonicandsupersonicrange [113]. GEhasusedArcam’sEBMQ20plustoproduceTi 6Al 4Vturbinebladesand structuralairframecomponents [114].Aliquidoxygenflangehasbeenadditively manufactured,inlieuoftraditionalmanufacturingmeans,foruseontheupperstage ofUnitedLaunchAllianceLaunchVehicles [42].

Figure2.5 TWI’sfive-axisLMDprintermanufacturinganIN718helicopterengine combustionchamber. LMD,Lasermetaldeposition.

Source: C.Hauser,CaseStudy:LaserPowderMetalDepositionManufacturingofComplex RealParts.2014,TWI.ImageCourtesyofTWILtd. 18AdditiveManufacturingfortheAerospaceIndustry

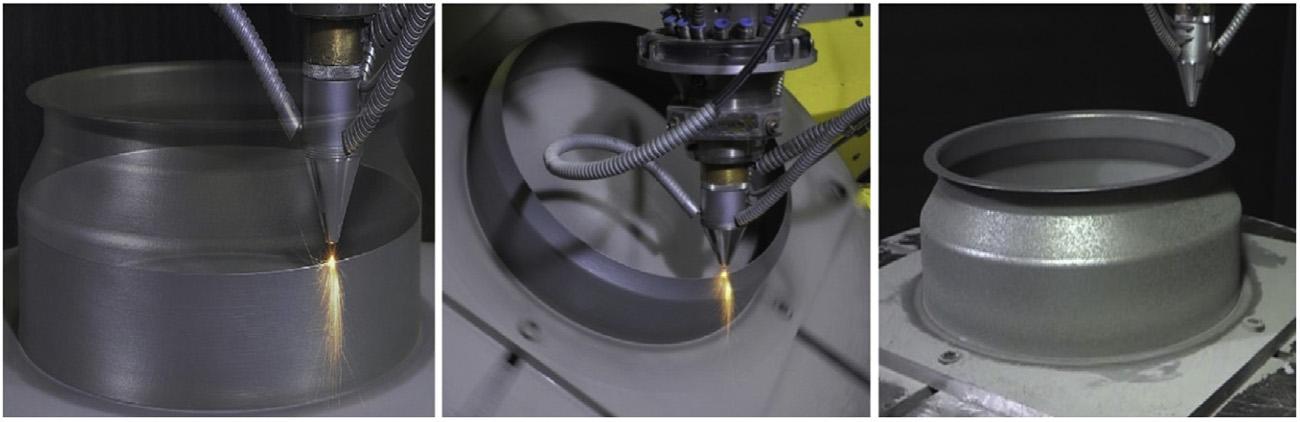

Postprocessingnecessitiescanbeaddressedthroughhybridmanufacturing [115] Hybridmanufacturingisthecombinationofadditiveandsubtractivemanufacturing intoasinglesystem [116].AMbuildsupthemetalpart,whiletraditionalsubtractivemanufacturing(CNCmilling)isusedforspotmillingandsurfacefinishing. Thiscombinedprocesssimplifiespartfabricationbyreducingthenumberofproductionsteps.Severalcompaniesareintroducinghybridmanufacturingsystems (HybridManufacturingTechnologies’AmbitSeries7andELB-Schliff’smillGrind) totheaerospaceindustryforpartfabricationandrepair.ELB-Schliff’smillGrindis theworld’sfirsthybridmanufacturingfeaturinggrindingforin-processrepairof aerospacecomponents [117]

2.3.1.2Fixturesandaccessories While,mostmechanicalandstructuralcomponentsofaircraftaremadeofmetal,fixtureandinterioraccessoriesareoftenmadefromnonmetalstosaveweightandcost. ChinaEasternAirlinesusedFDMtomanufacturemisprintedseatsignsonitsBoeing 777aircraft,anexpensiveandtime-consumingfix [118].NorthropGrummanutilize SLAtofabricaterepairkitsforspecificaircraftrepairssimplifyingteardownproceduresandreducingmaintenance-relateddowntime [119].Similarly,MoogAircraft GrouphasadoptedFDMtomanufacturecomponentmaintenancemanualfixturesfor internalinspection [120].AMofthesepartshaveotherbenefits,likeassemblypart consolidation.AdvancedAerialsuses3Dsystems’SLStechnologytofabricatetough partsforitsunmannedvehiclesystems [121].HoneywellalsousedSLSforthe manufacturingofcontrolpodcasingsonitsRQ-16T-HawkUAV [122].

2.3.2Rapidtooling Rapidtoolingdescribesanymold-makingprocessthatcancreatetoolsquicklyand withminimumdirectlabor [123].Generally,AMrapidtoolingprocessesfallunder indirectordirectrapidtooling.IndirectrapidtoolingistheuseofAMmethodsto produceatemporarypartmodel.Areverseceramicorsandmoldiscreatedfrom thismodelformetalpartcasting.Onesubprocessofindirectrapidtoolingisreconfigurabletooling [124].Reconfigurabletoolingallowsthereuseofmoldsthrough theuseofstate-changingmaterialsformoldcreation.Thissubprocesshasbeen usedtoproducesplashesandtoolsofwingshapesforaircraftinthefieldwithout theneedfordisassembly [124].AirbususedindirectrapidtoolingtocreatestructuraldoorhingesfortheAirbusA320 [1].Withdirectrapidtooling,moldsand insertsaremadedirectlywithAMprocesses.Thus,directrapidtoolingdoesnot requireasmanystepsasindirectrapidtoolingandhasthepotentialtopreserve overallpartdensitymoreeffectively [124]

2.3.3Rapidprototyping Rapidprototypingallowsforrealizationa ndverificationofcomputersimulation modelsofaerospacepartsandaircraft. Prototypesareusefulforidentifying