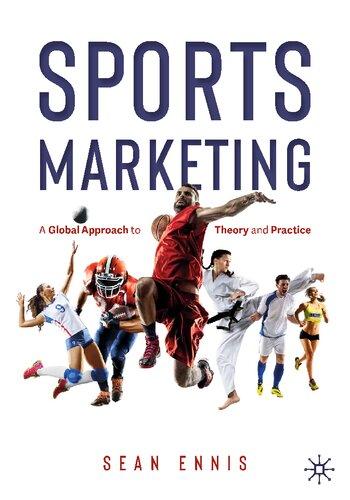

AThermo-Economic ApproachtoEnergyFrom Waste

ANANDRAMANATHAN

DepartmentofMechanicalEngineering,NationalInstituteof Technology,Tiruchirappalli,India

MEERASHERIFFABEGUMK.M.

DepartmentofChemicalEngineering,NationalInstituteof Technology,Tiruchirappalli,India

AMAROOLIMPIOPEREIRAJUNIOR

DepartmentofEnergyPlanning-PPE/COPPE,FederalUniversityof RiodeJaneiro-UFRJ,RiodeJaneiro,Brazil

CLAUDECOHEN

FacultyofEconomicsandAdministrativeJusticePost-graduation Program-PPGJA,FederalFluminenseUniversity-UFF,RiodeJaneiro, Brazil

Elsevier

Radarweg29,POBox211,1000AEAmsterdam,Netherlands

TheBoulevard,LangfordLane,Kidlington,OxfordOX51GB,UnitedKingdom 50HampshireStreet,5thFloor,Cambridge,MA02139,UnitedStates

Copyright©2022ElsevierInc.Allrightsreserved.

Nopartofthispublicationmaybereproducedortransmittedinanyformorbyanymeans, electronicormechanical,includingphotocopying,recording,oranyinformationstorageand retrievalsystem,withoutpermissioninwritingfromthepublisher.Detailsonhowtoseek permission,furtherinformationaboutthePublisher’spermissionspoliciesandourarrangements withorganizationssuchastheCopyrightClearanceCenterandtheCopyrightLicensingAgency, canbefoundatourwebsite: www.elsevier.com/permissions .

Thisbookandtheindividualcontributionscontainedinitareprotectedundercopyrightbythe Publisher(otherthanasmaybenotedherein).

Notices

Knowledgeandbestpracticeinthisfieldareconstantlychanging.Asnewresearchand experiencebroadenourunderstanding,changesinresearchmethods,professionalpractices,or medicaltreatmentmaybecomenecessary.

Practitionersandresearchersmustalwaysrelyontheirownexperienceandknowledgein evaluatingandusinganyinformation,methods,compounds,orexperimentsdescribedherein.In usingsuchinformationormethodstheyshouldbemindfuloftheirownsafetyandthesafetyof others,includingpartiesforwhomtheyhaveaprofessionalresponsibility.

Tothefullestextentofthelaw,neitherthePublishernortheauthors,contributors,oreditors, assumeanyliabilityforanyinjuryand/ordamagetopersonsorpropertyasamatterofproducts liability,negligenceorotherwise,orfromanyuseoroperationofanymethods,products, instructions,orideascontainedinthematerialherein.

BritishLibraryCataloguing-in-PublicationData

AcataloguerecordforthisbookisavailablefromtheBritishLibrary

LibraryofCongressCataloging-in-PublicationData

AcatalogrecordforthisbookisavailablefromtheLibraryofCongress

ISBN:978-0-12-824357-2

ForInformationonallElsevierpublications

visitourwebsiteat https://www.elsevier.com/books-and-journals

Publisher: CandiceJanco

AcquisitionsEditor: PeterAdamson

EditorialProjectManager: ChrisHockaday

ProductionProjectManager: DebasishGhosh

CoverDesigner: MarkRogers

TypesetbyMPSLimited,Chennai,India

Abouttheauthors xi

Preface xiii

Acronymsandabbreviationsxv

1.Pyrolysisofwastebiomass:towardsustainabledevelopment1

1.1 Introduction 1

1.2 Componentoflignocellulosicbiomasses2

1.2.1 Cellulose3

1.2.2 Hemicellulose4

1.2.3 Lignin 4

1.2.4 Ash 5

1.2.5 Extractives5

1.3 Typesofpyrolysis5

1.3.1 Slowpyrolysis7

1.3.2 Intermediatepyrolysis7

1.3.3 Fastpyrolysis7

1.4 Mechanismofpyrolysis8

1.4.1 Mechanismofcellulosepyrolysis8

1.4.2 Mechanismofhemicellulosepyrolysis9

1.4.3 Mechanismofligninpyrolysis9

1.5 Reactorconfigurations10

1.5.1 Fluidized-bedreactor10

1.5.2 Circulatingfluidized-bedreactor11

1.5.3 Ablativeplatereactor11

1.5.4 Auger/screwreactor13

1.5.5 Rotatingconereactor14

1.5.6 Cyclone/vortexreactor14

1.6 Upgradationtechniquesforpyrolyzedbio-oil15

1.6.1 Physicalupgradationofcrudebio-oil16

1.6.2 Chemicalupgradationofbio-oil17

1.6.3 Catalyticalupgradationofbio-oil19

1.7 Energyrecoveryforheatingorprocessapplications25

1.8 Conclusion 26 References 27

2.Biomasspyrolysissystembasedonlifecycleassessmentand Aspenplusanalysisandkineticmodeling35

2.1 Introduction35

2.2 CurrentIndianscenarioofwaste-to-energyconversiontechnologies36

2.3 Frombiomasstobiofuelthroughpyrolysis38

2.4 Lifecycleassessmentmethodologyforpyrolysis-basedbio-oilproduction39

2.4.1 StepsfollowedforstudyingLCA41

2.4.2 SettingrequireforLCA42

2.4.3 Inventorydatacollection44

2.4.4 Analysisoflifecycleinventory46

2.4.5 ImpactassessmentofLCA46

2.4.6 Sensitivityanalysis48

2.5 Aspenplusapproachtobiomasspyrolysissystem49

2.6 Kineticsofbiomasspyrolysis51

2.7 Isoconversionaltechniques54

2.8 Otherkineticmodels55

2.9 Applicationofbiomasspyrolysisproducts56

2.9.1 Bio-oilapplications57

2.9.2 Biocharapplication60

2.10 Conclusions 63

3.BiomassgasificationintegratedwithFischer Tropschreactor: techno-economicapproach73

3.1 Introduction 73

3.2 SurplusbiomassavailableinIndia78

3.2.1 Conflictingapplicationsforcropresiduebiomass78

3.2.2 Biomass79

3.2.3 Challengesinbiomassutilization80

3.2.4 Biomasstoenergyconversionprocesses80

3.3 Pretreatmentofbiomass81

3.3.1 Torrefaction82

3.3.2 Typesofpretreatment84

3.4 Kineticsofbiomassgasificationforsyngasgeneration87

3.4.1 Gasificationmechanism89

3.4.2 Syngasconditioning94

3.5 GasificationintegratedwithFischer Tropschreactor95

3.5.1 Bioenergypotentialcalculationsandestimation96

3.5.2 Fischer Tropschsynthesis96

3.5.3 Fischer Tropschcatalysts97

3.5.4 Fischer Tropschmechanism97

3.5.5 BiofuelsynthesisfromFischer Tropschreactor98

3.6 Techno-economicanalysisofFischer Tropschreactorwithbiomassgasification100

3.7 Conclusion 101 References 101

4.Energyrecoveryfrombiomassthroughgasificationtechnology107

4.1 Introduction107

4.2 Thermochemicalconversion108

4.2.1 Combustion108

4.2.2 Pyrolysis108

4.2.3 Gasification109

4.2.4 Principlesofanaerobicdigestion110

4.3 Productionanduseofaquaticbiomass111

4.3.1 Potentialofbiomasswaste111

4.4 Lignocellulosebiomasspretreatment112

4.4.1 Physicalmethods112

4.4.2 Chemicalmethods113

4.4.3 Biologicalpretreatment114

4.5 Bioconversionanddownstreamprocessingofbiomass-derivedmolecules’ conversiontochemicals114

4.6 Energyrecoveryforheatingorprocessapplications115

4.6.1 Steamcycle115

4.6.2 Engine115

4.6.3 Gasturbine116

4.6.4 Biogas116

4.7 Conversionoflignocellulosicbiomass derivedintermediatesligninbiorefinery biogasfromwastebiomass116

4.7.1 Hydrolysis117

4.7.2 Acidogenesis117

4.7.3 Acetogenesis117

4.7.4 Methanogenesis117

4.8 Parametersaffectinganaerobicdigestionprocess117

4.8.1 Temperature118

4.8.2 Solidtowatercontent118

4.8.3 pHlevel118

4.8.4 Retentionperiod118

4.8.5 Organicloadingrate119

4.8.6 C/Nratio119

4.9 Theconceptofgasificationanditstypesofreactors119

4.9.1 Fixedbedgasification120

4.9.2 Updraftgasifier122

4.9.3 Downdraftgasifier122

4.9.4 Cross-flowgasifier122

4.9.5 Fluidizedbedgasification122

4.9.6 Bubblingfluidizedbedgasification123

4.10 Lifecycleanalysisofgasificationprocess124

4.10.1 Scopeofanalysisanddefinition124

4.10.2 Boundarysystemandanalysisofrelatedlegislation124

4.10.3 Properselectionofenvironmentalperformanceindicators124

4.10.4 Inventoryanalysis124

4.10.5 Environmentalimpactassessment126

4.10.6 Lifecycleassessment126

4.11 Aspenplusapproachtothebiomassgasificationsystem126

4.12 Conclusion128 References 129

5.LifeCycleAssessmentappliedtowaste-to-energytechnologies133

5.1 Introduction133

5.2 Whatislifecycleassessment?134

5.2.1 Historicaldevelopment135

5.2.2 ApplicationsofLCA136

5.2.3 StepsandproceduresforanLCAstudy138

5.2.4 Definitionoftheobjectiveandscope138

5.2.5 Analysisofthelifecycleinventory139

5.2.6 Lifecycleimpactassessment139

5.2.7 Interpretation140

5.3 UseofLCAtoanalyzewaste-to-energytechnologies141

5.3.1 Mainapplications141

5.4 HighlightsinLCAstudiesforwaste-to-energytechnologies142

5.4.1 Functionalunit142

5.4.2 Typeofresidue143

5.4.3 Formofenergyuse144

5.4.4 Energyrecovery144

5.4.5 Sensitivityanduncertaintyanalyses144

5.5 Mainresultsfoundintheliterature145

5.6 Conclusion 146 References 147

6.Wastedisposalinselectedfavelas(slums)ofRiodeJaneiro149

6.1 Historicalbackground149

6.1.1 Somenumbersaboutsubnormalclusters150

6.1.2 ThefavelaofCatumbi151

6.2 Surveyandstudyofsolidwastein37slumsandinCatumbi153

6.3 Finalconsiderations165 References 168

7.Transesterificationprocessofbiodieselproductionfromnonedible vegetableoilsourcesusingcatalystsfromwastesources171

7.1 Introduction171

7.2 Biodieselproductionasanalternativesourceofenergy172

7.3 Transesterification:reactionandmechanism173

7.4 Catalysts 174

7.4.1 Chemicalcatalysts174

7.4.2 Biochemicalcatalysts177

7.4.3 Impactonkineticsoftransesterificationandmodeling177

7.5 Hydrocarbonfeedstocksforbiodiesel182

7.5.1 Edibleoils182

7.5.2 Nonedibleoils182

7.6 Variousnoveltechnologiesforbiodieselproduction182

7.6.1 Ultrasonic-assistedbiodieselproduction183

7.6.2 Microreactivetransesterification184

7.6.3 Microwave-assistedbiodieselproduction185

7.6.4 Reactivedistilledtransesterification185

7.6.5 Supercriticaltechnologyofbiodieselproduction(noncatalytic)187

7.7 Techno-economicanalysisofbiodieselproduction187

7.7.1 One-timecosts188

7.7.2 Rawmaterialandoperatingcost188

7.7.3 Fixedcostandmaintenancecost189

7.7.4 Costcalculationwithrespecttoproductionrate189

7.8 Perspectivesandconclusion190 References 190 Index 195

Thispageintentionallyleftblank

Abouttheauthors

Dr.AnandRamanathan isanassociateprofessorinthe DepartmentofMechanicalEngineeringattheNational InstituteofTechnology,Trichy.Areaofspecializationinvolves internalcombustionengines,alternativefuels,waste-to-energy conversion,emissioncontrol,andfuelcells.Heistherecipient oftheAustralianEndeavourFellowandworkedonsolarfuels atAustralianNationalUniversityatCanberra,Australia,from JulytoOctober2015.HehasreceivedvarioussponsoredprojectsfromGTRE-DRDO,DST-SERB,DST-YSS,DSTUKERI,MHRD,andBRICS.HehasreceivedIndo-Brazil collaboratedprojectintheareaofthethermochemicalconversionprocesswithlife cycleassessmentundertheSPARCscheme.Hehascontributedseveralpaperpublicationsinrenownedinternationaljournals.HehasfiledsevenIndianpatents.Hehas alsocontributed12bookchaptersinarenownedpublication(ElsevierandSpringer), andinvolvedinprofessionallyrelatedactivitiesandadministrativeresponsibilitiesto servethecommunity.

Dr.MeeraSheriffaBegumK.M. graduatedfromAnna University,Chennai.Shehasgotindustrialexperienceat “ChennaiPetroleumCorporationLtd” (formerlyMadras RefineriesLtd)atR&Ddivisionas “MRLResearchFellow” from1991to1995.Sheiscurrentlyaprofessoratthe DepartmentofChemicalEngineering.Shehasreceivedmany bestpaperawardsininternationalconferences,grantedtwo patents,publishedseveralpublicationsinrenownedinternationaljournals,andcoauthoredthreechemicalengineering textbookspublishedbyPHI,India.Shehascontributed research,sponsored,andconsultancyprojectstowardsustainable environmentandenergyfundedbyMHRD,DSTandCSIR,andSPARC,and undertakenresearchtrainingatNUS,Singapore,throughTEQIP.Shehasexecuted industrialconsultancyprojectsforwastewatertreatmentinTrichyDistilleries,dairy industry,textileindustry,andTamilNaduPaper,Ltd,usingfunctionalmaterials towardsustainabilityand,also,blendedbiodieseldevelopmentanditsexecutionon SouthernRailways.

Prof.AmaroOlimpioPereiraJunior isaneconomist,PhD inenergyplanningfromtheFederalUniversityofRiode Janeiro.HeworkedasatechnicaladvisoroftheEnergyand EnvironmentDepartmentatEnergyResearchCompany (EPE),inBrazil,isavisitingprofessoratUniversityPierre Mendès-FranceinGrenoble,France,andattheUniversityof TexasatAustin,Texas.HealsoworkedasResearchFellowat CIRED(CentreInternationaldeRecherchesur l’EnvironementetDévélopement),France.Currently,heisan associatedprofessoroftheEnergyPlanningProgramofthe InstituteofGraduateStudiesinEngineeringatFederalUniversityofRiodeJaneiro (PPE/COPPE/UFRJ),aresearcheratCentroClima,andamemberofthepermanent technicalcommitteeatLIFE.Heisanauthorofbooks,bookchapters,andseveral papersininternationaljournals.

Prof.ClaudeCohen obtainedherPhDinenergyplanning fromtheEnergyPlanningProgramatTheFederalUniversity ofRiodeJaneiro-PPE/UFRJandaMaster'sdegreein DevelopmentEconomicsfromtheUniversityofParisX Nanterre.SheiscurrentlyanassociateprofessorattheFaculty ofEconomicsatFederalFluminenseUniversity-UFF,apermanentprofessorattheAdministrativeJusticePostgraduate ProgramofFederalFluminenseUniversity-PPGJA/UFF,and thecoordinatoroftheInnovation,Environmentand SustainabilityResearchCenterofFederalFluminenseUniversity -NIMAS/UFF.Shehasexperienceineconomics,withemphasisonenvironmental andenergyeconomics,workingmainlyonthefollowingthemes:sustainabledevelopment,climatechange,energyconsumptionpatterns,energyconsumptioninfavelas, entrepreneurshipandsustainableinnovation.Sheistheauthorofbookchapters,and severalpapersininternationaljournals.

Preface

Theauthorsofthisbookhavebeenencouragedintheirwritingbylong-termsystematicattemptstoconnectresearchanddevelopmentachievementswithreal-world applications.Thewaste-to-energystrategyisahottopicthatdeservestobeexplored. Peoplearecommittedtocreatevarioussortsofwastesuntiltheworld'seconomicconditionimprovestoareasonablelevel.Inthisregard,theconversionofwasteresources intovalue-addedproductscombinedwithalifecycleassessmenttoevaluatetheactual environmentalimpactonthermochemicalconversionprocesses.

TheauthorswouldliketothankSchemeforPromotionofAcademicandResearch Collaboration,SPARC-MHRD(ProjectNoSPARC/2018-2019/P965/SL)forprovidingvaluableresourcesandsupportforthesuccessfulcompletionofthisbook.

Manyindustrypersonsandacademicexpertssupportedusinreviewingdraftchaptersthroughouttheproductionofthisneweditionandcreatednewgraphics.We wouldliketospecificallyacknowledgethefollowingpeoples:Mr.M.Dineshkumar, Mr.R.MuthuDineshKumar,Mr.G.Vigneshwaran,Mr.GuilhermeRodrigues Lima,andMrs.GiovannaFerrazzoNaspoliniwhohascontributednovelideas,useful data,andstatisticsforpreparingthisbook.

Theinspirationforthisbookistocoverwaste-to-energyconversiontechniques fromtheinitialconcepttothefinalproductbasedonrecentresultsoflong-termplanning.Thelifecycleassessmenttechniqueaidsinthedesignanddevelopmentofan eco-friendlyprocessthatminimizesgreenhousegasemissions.Wasteprocessinghas thepotentialtobecomeasourceofenergythatmaybeusedtogeneratepower, cooking,andtransportfuelsorinfuelcellapplications.

Webelievethatthisbookwillgiveenoughinformationontheactionthatmust befollowedtoimplementthewaste-to-energyprojectinthefuture.

AnandRamanathan1,MeeraSheriffaBegumK.M.2,AmaroOlimpioPereira Junior3 andClaudeCohen4

1DepartmentofMechanicalEngineering,NationalInstituteofTechnology, Tiruchirappalli,India

2DepartmentofChemicalEngineering,NationalInstituteofTechnology,Tiruchirappalli,India

3DepartmentofEnergyPlanning-PPE/COPPE,FederalUniversityofRiodeJaneiroUFRJ,RiodeJaneiro,Brazil

4FacultyofEconomicsandAdministrativeJusticePost-graduationProgram-PPGJA, FederalFluminenseUniversity-UFF,RiodeJaneiro,Brazil

Thispageintentionallyleftblank

Pyrolysisofwastebiomass:toward sustainabledevelopment

1.1Introduction

Inthenext20yearsextensiveconsumptionofpetroleumresourceswillriseataconstant rateof1.6%peryear [1].Sincetheirdepletionrateishigherthantheirregeneration rate,petroleumresourcesareregardedasvaluablenaturalresources.Excessiveuseof petroleumproductsresultsinharmfulpollutants,suchasnitrogenoxides,sulfurdioxide, andcarbondioxideemissions,whicharecausingamajorenvironmentalissue [2].Due totheburningoffossilfuels,greenhousegases,suchascarbondioxide,areemittedinto theatmospherecausingglobalwarming [3].Accordingtothesurvey,itisreportedthat petroleum-basedresourcesworldwidewillgetexhaustedafter2042,whichdoesnot dependonthegrowthofpetroleumoilconsumption [4].Thelimitationsofpetroleum resourcesareprimarilytoblamefortheseissues.Manynewprojectshaverecentlybegun tofindneweco-friendlyenergyresourcesforfuturegenerationstoreduceemissionsand minimizetheenergycrisis [3].Renewableenergysuppliesnotonlyeliminateharmful environmentaleffectsbutalsoeliminaterelianceonpetroleumresources [5].Infact,the recentrequirementforrenewablefuelsisproducedfromstarch-basedresources,competingwithotherediblefeedstocks [6].Ideally,biofuelsobtainedfromlignocellulosebiomass,suchasgrass,woods,agriculturalresidue,andenergycrops,arepreferredto competewithalreadyexistingenergysources [7].Thelignocellulosicbiomassavail abundantly,anditisconsideredarenewableresource.Globally,itisestimatedthatlignocellulosicbiomassof220billiontonsproduced [4].Ascomparedtopetroleum resources,lignocellulosicbiomassisconsideredacarbon-neutralresourceandalsohelps tomitigateglobalwarming [8].Ineconomicview,lignocellulosebiomassfeedstockis moreinexpensiveincontrastwithediblebiomass,suchascornstarch [9].Hence,appropriatetechnologyimplementationwillhelptoproducelargeandbetterqualitybiofuels [3].Biochemicalconversiontechnologiesusinglignocelluloseasrawmaterialarenot economicalandcost-effective.Nevertheless,thermochemicalconversiontechniquesare costeconomical [10].Pyrolysisisthemostfeasibleandcost-effectivewaytogenerate liquidfuelfrombiomassofallthermochemicalconversiontechnologies [11].Inpyrolysis,degradationofbiomassinaninertatmosphereatanelevatedtemperatureof 400 C 600 Coccurs.

Themainproductofpyrolysisisbiomass,alsoknownasbio-oil,whichcanbe obtainedbycondensinghotpyrolysisvapors.Duringthepyrolysisofbiomass,dueto thelargenumberofprimaryandsecondaryreactions,acondensablemixtureofchemicalsisformedaspyrolysisoil.Thepyrolysisoiliscomplexmixtureofabout300 oxygenatedcompounds [12,13].Pyrolysisoilmainlycomprisesthreeimportantgroups ofcompounds,suchaslignin-derivedcompounds,carbonylcompounds,andsugarderivedcompounds.Higherwatercontent(around15 30wt.%)presentinthepyrolysisoilresultsinlowercalorificvalues [14,15].Thelargequantityofcarboxylicacid makesthepyrolysisoilwithlowerpHvaluesaround2 2.5 [16].Theinstabilityof pyrolysisoilisassociatedwithmoreoxygeninnature;itprovidesprimaryvariation betweenpyrolysisoilandhydrocarbon(HC)fuels [14,17].Becauseoftheseunfavorableproperties,suchashigherreactivity,higheracidity,higherviscosity,andlower heatingvalues [14].Intoday’senginesystem,useofbio-oilastransportfuelisnotpossible.Itisimportanttoincreasethequalityofpyrolysisoiltomakeitcomparableto HCfuel [18].Effortstoremovethehigheroxygencontentinpyrolysisoilusingsome importantupgradationtechnologiesarerequired [14].Differentinvestigationshave beenconductedtoacquirethisobjectivethroughvariousupgradationtechnologies. Amongothertechniques,hydrodeoxygenationandcatalyticcrackingarewidely exploredasupgradationtechniques [19].Inthepyrolysisprocess,theinclusionofa solidacidcatalystwithouttheuseofhydrogeninanambientpressureenvironmentis knownascatalyticcracking [20].Hydrodeoxygenationofpyrolysisoilproduces desiredHCsinapressurizedenvironmentusingmetalcatalysts [21].

1.2Componentoflignocellulosicbiomasses

Tounderstandthemechanismsofcatalyticcopyrolysis,itisrequiredtohavesome basicknowledgeaboutthecharacteristicsoflignocellulosicbiomass.Thereforethissectionwillbededicatedtoasummaryofthepropertiesofthesame.Itisknownfrom pastresearchthatlignocellulosicbiomassesarethetypesofcomplexbiopolymer.The majorconstituentsincludecomplexcellulose,lignin,andhemicellulose.

Normally,byweight,thebiomasscontainsapproximately45%ofcellulose,25% ofhemicellulose,and25%oflignin [6].Celluloseprimarilyactsasastructuralframe forthelignocellulosecellwalls.Bynature, celluloseisastraightchainedsaccharide polymerofglucosewithastrong β-1,4-glycosidebond [22] .Owingtotheinclusion ofanumberofhydroxylgroupswithinthe polymerchains,cellulosealsodemonstratestheexistenceofs everalhydrogenbonds [23].Thefundamentalstructureof celluloseisconsideredtobemadeupofse veralamorphousandcrystallineareas [24] . Inadditiontothis,manyfiberslikestrandsofcellulosearefurtherlinkedbyhemicelluloseand/orpectinan dhaveacoatingoflignin [23] .Whencomparedtocellulose,hemicellulosehaslargelydifferentpropertiesinthatitismoreamorphousin

structureandalsohasarandomheterogeneoustypecomposition.Hemicellulose polymersareconstitutedbymultiplepentose s(suchasarabinoseandxylose),hexoses (fucose,rhamnose,galactose,andglucoseamongothers),anduronicacids(suchas methylglucuronicacid,galacturonicacid,andglucuronicacid) [6].Theformation ofasystemofcellulosemicrofibrilsandligninispromotedbythepresenceofmany short,branchedhemicellulosechains,which inturncausestheresultinglignocellulosematrixtobeextremelystiff [23] .

Intermsofphysicalproperties,ligninwasfoundtobeinsolubleinwaterandhas neutralopticalproperties.Itisalsothesecondabundantorganiccompositionin nature.Complexaromaticandhydrophobicamorphousbiopolymersofpropyl-phenol groupsarethemainconstituents [7].Coniferyl, p-coumaryl,andsinapylalcoholsare thethreebasicphenol-containingcomponents.Itismadeofthreebasicphenolcontainingcomponents:sinapylalcohols, p-coumaryl,andconiferyl [25].Theseunits arelinkedtogetherbyC C(β-5,5 5, β-1,and β β linkages)andC O(β-O-4, α-O-4,and4-O-5linkages) [26].Anotherimportantfunctionofligninisthelinking betweencelluloseandhemicellulose.Thisisachievedtogivethecellwallsarigidand inflexiblethree-dimensionalstructure.Ligninwasalsofoundtostorecloseto40%of thetotalenergyoflignocellulosicbiomasses.Thismaybeattributedtoahighcarbon content [25].Normally,softwoodusuallycontainsahigherfractionofligninascomparedtohardwoodandotheragriculturalresidues [23]

Themostabundantnonediblebiomassislignocellulosicbiomass.Accordingtoestimates,sustainablelignocellulosicbiomassof220billiondrytonsisgeneratedannually aroundtheworld.InAmericaalone,lignocellulosicbiomassesof1.3billiondrytons areproducedannually,whichis50%ofthecarbonconsumptionintheformofgasolineanddieselmaybesubstituted.Incontrasttopetroleumfuelsources,lignocellulosic biomassisoftenviewedasacarbon-neutralsource.Thismeansthatitisextremely usefulinthereductionoftheeffectsofglobalwarmings.Intermsofthefinancialperspective,makinguseoflignocellulosicbiomassasastartingpointtomanufacturebiofuelsismuchcheaperthanusingcorrespondingediblebiomassesandpetroleum sources.Asaresult,tohaveanefficientproductionoflargequantitiesofbiofuelsfrom lignocellulosicbiomasses,itisnecessarytomakeuseoftheappropriatetechniquesand technologies.

1.2.1Cellulose

Celluloseplaysanimportantpartinthestructuralstrengthofthecellwallsingreen plantsandalgae.Itisalsoknowntobeamongthemostplentifulpolymersoforganic nature.Thebasicstructurecanbedefinedasastraightchainsaccharideofrepeating pyranoseunits,whicharejoinedbymeansofacetyllinkage(β,1 4-glycosidebonds). Owingtoitslengthystraightchainedstructure,celluloseisnoteasilysolubleinwater.

Multiplechainsofcellulosepolymersarefurtherlinkedtoformstrandlikefibers. Theseareinterlinkedbyhydrogenbondstoformmicrofibrilsofcellulose.These extensivemicrofibrilsaremeshedinanintertwinedmanner,whichisthereasonfor therigidityofcellwalls.Cellulosefibersarecoatedwithhemicelluloseandlignin fibers.Theinterconnectionofthethreehydroxylgroupsinthepyranoseringscauses hydrogenbondstoformbothwithinthemoleculeandbetweentwoneighboring molecules.Thepresenceoftheseextensivehydrogenbondsisoneoftheprimaryreasonsforthecrystallineshapeofcellulose,whichpromotesitshighstrengthandchemicalinertness [27 29].

1.2.2Hemicellulose

Hemicellulosesareheterogenoussaccharidechains,constitutedbyvariousmonomers, suchasarabinoseandgalactose.Someotherconstituentsincludexylose,glucose,and mannose.Thesemonomerslinktogethertoformmanypolysaccharidestructures,such asglucuronoxylanandxyloglucan.InAngiospermicplants,thebasicconstituentof hemicelluloseisusuallyxylan,whileglucomannanconstituteshemicelluloseingymnosperms [30].Hemicellulosehasalesserextentofpolymerformationascomparedto cellulose,witheachmoleculeofhemicellulosecontaininganywherebetween50and 200monomers.Theabundanceinnaturehemicellulosesfallbehindcellulose,constitutingupto30%oforganicmatterinplants.Hemicellulosesalsoexhibitamorphous characteristicsincontrasttocrystallinecellulosesand,asaresult,areeasilysolublein diluteacidsandbasesbyhydrolysis [31].

1.2.3Lignin

Researchhasrevealedthatligninmaybeuptoone-thirdoftheorganicconstituents ofwoodandothertracheophyteplants [32].Intermsofstructure,ligninhasanextensivelybranched3-Dstructureofphenylgroupslinedtopropane,withthemajorityof bondsbeingthearyl-alkyletherbonds.Basedontheamountofmethoxylgroupsin theconstituentunitcellsofphenylpropane,theycanbesubdividedintosyringyl, guaiacyl,and p-hydroxyphenylunits.Whilelignincontainsavarietyoflinkages,such asester,carbon-to-carbon,andether,thepredominantlyoccurringbonds,asdiscussed above,aretheetherbondsbetweenanaromaticringandaphenylpropanesidechain (α-O-4, β-O-4, γ-O-4).Thesebondsalsooccurbetweentwobenzenerings,oralso betweentwophenylpropanechains(α-O-β0, α-O-γ0).Carbon-to-carbonbondsare thenextmostconcentratedlinkages,withavarietyoflinkagetypes,suchas5 5, β-5, or α-β0amongothers.Theesterbonds,whicharerelativelyfewinnumberand foundmostlyinsoftandherbaceousplants,makeupthemajorityoftheremaining bonds [32].Similartohemicellulose,ligninalsotendstodisplayastrongrepulsion towardwater,partlyduetoitsaromaticnature.Ligninusuallyoccursinthegaps

betweencellulosesandhemicellulosesandaccountsforthestrengthandinflexibilityof biomass [31].Furtherstudiesshowthatlignincontentalsovariesbythetypeofplant andtheclimatestheygrow.Ligninconstitutesaboutone-thirdoftheorganiccontent insoftwoods.Thisnumberreducestoabout25%intemperatehardwoodsand30%in tropical-zonehardwoods;thecompressionwoodcontainsthehighestlignincontent withupto40%,whereasintensionreactionwoodsinangiosperms,lignincontent dropstoatmost20% [33].

1.2.4Ash

Mineralsandotherinorganiccompounds,suchassulfur,sodium,silicon,potassium, phosphorus,magnesium,chlorine,calcium,andothers,canbefoundinanybiomass. Inadditiontothis,biomassesmaycontaintracesofheaviermetals,suchascobaltand nickel [34].Itisverydifficulttoquantifytheamountofinorganiccontentforevery typesofbiomassduetothesmallcontentandwidevariations;however,thegeneral trendthatisobservedisthewastesfromfarmingactivitieshaveahighermineralcontentthanbiomassesobtainedfromwoodsources [35].

1.2.5Extractives

Inadditiontotheabove-mentionedconstituents,biomassestendtocontainalarge quantityofextractives.Thesearecomponentsthatmaybereadilyremovedusingnonreactingsolvent(water,alcohol,etc.)andaremainlyformedasaby-productofthe metabolismprocessesofaplant.Primarymetabolicextractivesareusuallysimplecompounds,suchasorganicacids,fats,andsugars.Incontrast,secondarymetabolicbyproductsaremuchmorecomplexinnature.Thiscomplexitylendstheadvantageof beingusedintaxonomicalnomenclature,astheby-productsareuniquetotheenzyme reactionsthatproducethem.Somecommonlyoccurringsecondaryextractivesare coumarins,monoterpenes,andacetogens [36].Eventhoughextractivesusuallyconstitutelessthanone-tenthofthetotalbiomass,theyplayanintegralroleinincreasing theheatingvalueofbiomasswiththeirhighlyvolatilenature.Asaresult,thereisno majorthermaldifferencebetweentheoriginbiomassandthefinalresidueswhenphenoliccompoundsareformedbylignindecomposition [37 39].

1.3Typesofpyrolysis

Biomasspyrolysiswascategorizedasslow,medium,orfastpyrolysisbasedontheheatingrate.Slowpyrolysisoccurswhenthetimetakentoheatthebiomassinthepyrolysisprocessismuchlongerthanthepyrolysisreactiontime.Therearesomeother alternativesbasedonthepressureandmediumatwhichpyrolysisprocessiscarried out.Basedontheoperatingcharacteristics,eachpyrolysisprocesshasitsown

applicationsandoutputproducts.Theheatingrateatwhichheatenergyistransmitted intothesubstancedetermineswhetheritisfastorslowpyrolysis.Bothfastpyrolysis andslowpyrolysisareconductedinaninertatmosphere.Pyrolysisisusuallyclassified intothreebroadtypesbasedontheconditionstheseprocessesoperateinslow,intermediateormedium,andfast.Productyieldandoilcharacterizationfromtheliquid productsoffastpyrolysisandslowpyrolysisofeucalyptusmallee [40] arepresentedin

Table1.1.Eachofthesedifferentparametersmayleadtovariationsintheoutput product.Below,eachprocessisspecifiedindetail.

Table1.1 Productyieldsandoilcharacterizationfromtheliquidproductsoffastpyrolysisand slowpyrolysisofeucalyptusmallee [40]

(Slowpyrolysisoilfromacetonecondenseranddryice)

Viscosity(cP)1.41.11.853.8 pH2.32.52.42.4

Watercontent(%)45.948.243.820.8

Charcontent(%)0.020.030.030.04

Elementalanalysis(%)

C28.1328.0027.3943.9

H9.389.389.557.4

N0.03 0.07

Obydifference62.562.763.148.6

HHV(MJ/kg)6.86.47.114.4

(SlowpyrolysisoilfromEP-heavyorganicfraction)

Watercontent(%)8.611.37.8 pH2.82.62.6

Elementalanalysis(%)

C54.853.7555.30

H7.147.417.23

N0.100.130.16

Obydifference38.038.7237.32

HHV(MJ/kg)21.320.421.8

HHV,Higherheatingvalue.

1.3.1Slowpyrolysis

Thistypeofpyrolysisisusuallycharacterizedbyanextremelyslowrateofheating,thereby leadingtoalowprocesstemperature.Theprocesscontinuesforhoursordaysduetothe highresidencetimeofsolids.Slowpyrolysisusuallyproducesmorecharthanliquidproduct. Thistechniqueispreferredinbiomasseswithhighmoisturecontent,asthetolerancetoward moistureisveryhigh.Italsohasthelowestliquidyieldamongallthreetypesofpyrolysis [41].Sometermsassociatedwithslowpyrolysisarecarbonizationandtorrefaction.Toproducecoalfrombiomass,thecarbonizationprocessisused,whiletorrefactionisusedto removehighlyvolatileorganicmatterfrombiomass.Theresultanttorrifiedbiomassis extremelylightandinsolubleinwaterandcontainsanextremelyhighconcentrationof energyperunitmass.Torrefactionoccurs inanarrowandverylowtemperaturearound 200 C 300 C.Meanwhile,carbonizationoccursat veryhighandbroadtemperaturerange. Addedtothisadvantage,ithasanextendedshelflifemakingitidealforstorage [42 45]

1.3.2Intermediatepyrolysis

Intermediatepyrolysistakesplaceinatemperaturerangeofapproximately300 C 500 C. Productsofintermediatepyrolysisarecharacterizedbyalowtarcontentandlowviscous properties.Althoughthisreactionprovidesareducedyieldofliquefiableproduct,theadvantageremainsthatproductsofintermediatepyrolysisaremoreversatileintermsofdecompositionreactionsthatmaybeadopted.Asaresult,theprocessmaybestreamlinedasperthe needs,witharangeoffeedsizesbeingacceptedinthistypeofreaction [35,36,46].The intermediatepyrolysisleadstoverylessformationoftar;itisduetocontrolledchemical reactioninsteadofheterogeneouschemicalreaction.Thenon-condensablegasresidence timeismoredependentonreactortype,woodybiomasspyrolysisbyintermediatepyrolysis generatemoreliquidfractionaround55%ascomparedto75%.However,itisapplicable onlyforwoodybiomasspyrolysisanditvarieswithotherbiogenicfeedstocks [47].Though intermediatepyrolysisprocessrecentlyovercomestheproblemassociatedwiththefastpyrolysisprocess.Theformationofhigh-leveltarandpersistentfoulingofliquidswithhigher amountsofcharandashareprimarydifficultiesfacedinthequickpyrolysisprocess,asare biomassconditioningandlowermoisturecontent.Becauseofthepropertiesofthereaction mixture,whichtendstoobstructfiltersinashortperiodoftime,filtersusedtolimitthis normallyfail.Slowpyrolysisisalsonotaviableoptionbecauseitsignificantlyreducesthe organicphaseyieldandisusedtomanufacturemoresolidproductslikecharcoal.

1.3.3Fastpyrolysis

Fastpyrolysisisthebestchoicewhenoilisrequiredtobethedesiredproduct.Asthename suggests,thisreactionadoptsafastdecompositionofbiomasstoproducevapors,whichare againrapidlybroughttoliquidformtoreducethetendencyofsecondarydecomposition. Forfastpyrolysis,thevaporresidencetimeisofsecondormillisecond.Fastpyrolysis