Stratégique Gerry Johnson Et All.

https://ebookmass.com/product/strategique-gerry-johnson-et-all/

ebookmass.com

Garfield (Griffin Brothers Book 3) Kathi S. Barton

https://ebookmass.com/product/garfield-griffin-brothers-book-3-kathis-barton/

ebookmass.com

The Challenge Danielle Steel

https://ebookmass.com/product/the-challenge-danielle-steel/

ebookmass.com

Curriculum Leadership: Strategies for Development and Implementation 5th Edition, (Ebook PDF)

https://ebookmass.com/product/curriculum-leadership-strategies-fordevelopment-and-implementation-5th-edition-ebook-pdf/

ebookmass.com

Easy Algebra Step-by-Step, Third Edition Sandra Luna Mccune

https://ebookmass.com/product/easy-algebra-step-by-step-third-editionsandra-luna-mccune/

ebookmass.com

Using IBM SPSS Statistics: An Interactive Hands On Approach 3rd Edition, (Ebook PDF)

https://ebookmass.com/product/using-ibm-spss-statistics-aninteractive-hands-on-approach-3rd-edition-ebook-pdf/

ebookmass.com

FullLengthArticle

journalhomepage: www.elsevier.com/locate/fuel

AstudyofusingE10andE85underdirectdualfuelstratification(DDFS) strategy:Exploringtheeffectsofthereactivity-stratificationanddiffusionlimitedinjectiononemissionsandperformanceinanE10/dieselDDFS engine

SaeidShirvania,⁎,SasanShirvania,AmirH.Shamekhia,RolfD.Reitzb

a MechanicalEngineeringDepartment,K.N.ToosiUniversityofTechnology,No.7,PardisSt.,MollaSadraAve.,VanakSq.,Tehran,P.O.Box19395-1999,Iran

b EngineResearchCenter,UniversityofWisconsin,Madison,Madison,WI,USA

ARTICLEINFO

Keywords:

DDFS

E10/dieselDDFS

E85/dieselDDFS,LTC

CFDsimulation

ABSTRACT

OnepromisingpathwaytodirectlycontrolcombustionisDirectDualFuelStratification(DDFS).DDFShas comparablethermalefficiencytoRCCI,acceptablelevelsofemissions,andlowercyclicvariation.Theprimary drawbackofDDFSissootproductionowingtothediffusion-limitednatureofthenear-TDCinjection.Inthis paper,E10(10%ethanolingasolinebyvolume)andE85werestudiedasalternativefuelstogasolinetotackle sootformation.Inthefirststep,E10andE85werecompared,andthebestalternativetogasolinewaschosen basedonemissionsandperformance.E10reducedsootby40%,andE85eradicatedsootcompletely.However, E85had25timeshigherNOX thangasoline.Next,dieselenergyfractionanditsstartofinjection(SOI2)were swepttoexplorethedomainofthereactivitycontrolledregime.ItwasfoundthatforSOI2sbefore−80°ATDC, theregimewaspremixed,andforSOI2safter−40°ATDC,theregimewasdiffusion-limited.Dieselenergy fractions,morethan11%,yieldedunintendedcombustion.Then,theenergyfractionandinjectiontimingofthe near-TDCinjection(SOI3)wassweptandstudied.Thebestdomainforbothinjectorswasdiscoveredbasedon theEURO6emissionmandate.Sprayanglesofbothinjectorsweresweptfrom50to80°,and55°fordiesel injectorand65°fortheE10injectorshowedthebestresultsregardingemissions,performance,andfuelconsumption.Finally,theeffectsoftheinjectionpressureofSOI3onemissionsandperformancewerestudied.The suitabledomainforinjectionpressurewaschosenbasedonEURO6.

1.Introduction

ThedemandforICEsarose,andhumankindapproachedtwocrises, firstenvironmentalpollution,andsecond,thegrowthinfuelcostand extensiveenergyconsumption.Theinstabilityofcrudeoilpriceand regulationsmandateautomotiveindustriestodevelopenginetechnologyinordertodecreasefuelconsumptionandengineemissions. FromthestudyperformedbyPFFlynnetal. [1],itwasfoundthat ConventionalDieselCombustion(CDC)suppliesaveryrichmixture andwithadiffusion-limitedflame.Thisdiffusionflamecausesthe formationoftheParticulateMatter(PM)inrichzones,andhighlocal temperatureregionscontributetonitrogenoxides(NOX)formation.The levelsofPMandNOX inCDCisveryhigh,butbyutilizingaftertreatments,thereisapossibilitytoreachthehighstandardsofemission mandates.Aftertreatmentsneedtoreachastandardtemperatureto havedesirableconversionefficiency.Thecostofimplementationof

⁎ Correspondingauthor.

E-mailaddress: saeidshirvani@email.kntu.ac.ir (S.Shirvani).

https://doi.org/10.1016/j.fuel.2020.117870

theseaftertreatmentsandbeingafunctionofexhausttemperaturewere motivationstoreachmoreefficientandcleanercombustion.

LowTemperatureCombustion(LTC)isapathwaytoreachmore efficientandcleanercombustionthanCDC.Manystrategies,suchas HomogenousChargeCompressionIgnition(HCCI),PremixedCharge CompressionIgnition(PCCI),andReactivityControlledCompression Ignition(RCCI)areutilizedtoachieveLTC.LTCstrategiesresultin ultra-lowNOX andsoot,butahighamountofUnburnedHydrocarbon (UHC)andCOcomparedtoCDC.LTCstrategiesarecontrolledby chemicalkinetics;thus,thereislessauthorityovertherateandtiming ofheatrelease.Thatbeingsaid,theyareverysensitivetosmallchanges inboundaryconditions [2–4]

Onishietal. [5] designedanewtwo-strokeengineusingHCCI strategy.ThechallengingpointwashighloadoperationinHCCIcombustions.Asamatteroffact,controllingHCCIengineswasdifficult,and itwasfoundthatExhaustGasRecirculation(EGR)canbeapromising

Received20December2019;Receivedinrevisedform9April2020;Accepted13April2020

0016-2361/©2020ElsevierLtd.Allrightsreserved.

Nomenclature

AHRRApparentHeatReleaseRate

AMRAdaptiveMeshRefinement

ATDCAfterTopDeadCenter

BTDCBeforeTopDeadCenter

CADCrankAngleDegree

CDCConventionalDieselCombustion

CFDComputationalFluidDynamics

CRICommonRailInjector

DDFSDirectDualFuelStratification

DDMDiscreteDropletModel

DurDuration

E10/DE10/DieselDDFS

E85/DE85/DieselDDFS

ED Dieselenergyfraction

EE10 E10energyfractionfornear-TDCinjection

EGRExhaustGasRecirculation

EPAEnvironmentalProtectionAgency

EVCExhaustValveClosing

EVOExhaustValveOpening

FEFixedEmbedding

G/DGasoline/DieselDDFS

way.Severalyearslater,NajtandFoster [6] appliedHCCIstrategyina four-strokeengine,andtheyfoundthatbymeansofcontrollingintake temperatureandEGRrate,itispossibletocontrolHCCIcombustion. ShortcombustiondurationrelatedtoHCCIstrategyisanoticeable problemathighloadoperations,andsomenoisemetricssuchasPeak PressureRiseRate(PPRR)andRingingIntensity(RI)aresignificantly highathighloadoperations.HCCIalsohasitsowndrawbacks.Inthe HCCIcombustion,whenthechargeisperfectlyhomogenous,allregions undergoheatreleaseatthesametime.FromtheOttoperspective,this kindofheatadditionisideal,butextremepressureoscillationinHCCI causeenginedamageandnoise.Thereisalsoatrade-offbetween thermalefficiencyandnoise,whichlimitstheoperationofHCCIat differentloads.HCCIiskineticallycontrolled,anditssensitivityto boundaryconditionsisachallengeaswell [7,8]

Scholarshavefocusedonsomemethodstocontroltheheterogeneity ofthecombustionchambertocontrolignitiontimingandcombustion phasingofHCCI.Thisledtotheemergenceofsomepartiallypremixed strategieslikePCCI.In1996,thefirstPCCIenginewasmanufactured withaportfuelinjectorthatcouldachievebetterauthorityovercombustioncontrol,betterefficiency,andasignificantreductioninNOX andsootemissionscomparedtoCDC.ManyscholarsperformedexhaustiveresearchesonPCCI,andtheyfoundthatwithonefueland changingintaketemperature,chargestratification,EGRandfuel blending,thePCCIstrategyismorecontrollablethanHCCI [2,3,9–11]

In2006,Kalghatgietal. [12] performedaninvestigationtoovercomeHCCIlimitations.Theyfoundthattheuseoffuelwithhigher resistancetoauto-ignitioncomparedtodieselcouldextendcombustion durationwithouttheneedforEGR.Itwasreportedthattooearlyinjectiontimingsprovideawell-mixedchargeforcombustion,andthis method,namedPartiallyPremixedCombustion(PPC),ledtolower levelsofNOX andsoot.GasolinePPCwasfoundasanewmethodto controltheheatreleaseratebetterthandieselHCCI.However,this concepthadchallengesforaPPCenginefueledbygasolinewithan octanenumbergreaterthan90atlowloads.Inordertoachievebetter control,sparkassistancewasprovided,andadoubleinjectionstrategy wasusedtoreachbetterperformance,butNOX andsootwereatunacceptablelevels [13–17]

FromthestudiesthatcarriedoutbyYaoetal. [18],itwasfound thatinanHCCIengine,byutilizingtwofuelswithdifferentResearch OctaneNumbers(RON)suchas iso-octane(RON100)andn-heptane

HCCIHomogenousChargeCompressionIgnition

ICEInternalCombustionEngine

IMEPIndicatedMeanEffectivePressure

ISFCIndicatedSpecificFuelConsumption

IVCIntakeValveClosing IVOIntakeValveOpening KH-RTKelvinHelmholtz-RaleighTaylor LHVLowerHeatingValue

LTCLowTemperatureCombustion NOX NitrogenOxides

NTCNoTimeCounter

PCCIPremixedChargeCompressionIgnition

PMParticulateMatter

PPCPartiallyPremixedCombustion

PPRRPeakPressureRiseRate

RCCIReactivityControlledCompressionIgnition

RNGk-ε Re-NormalizationGroupk-ε

RONResearchOctaneNumber

SOI1StartOfInjectionforfirstgasolineinjection

SOI2StartOfInjectionfordieselfuel

SOI3StartOfInjectionfornear-TDCinjection

TDCTopDeadCenter

UHCUnburnedHydroCarbon

(RON0),itispossibletocontrolcombustionprocess,engineperformanceandemissionsatdifferentloads.In2006,Inagakietal. [19] introducedanewstrategyforcontrollingPCCIbyusingtwodifferent fuels(differentreactivity),andtoday,itisknownasReactivityControlledCompressionIgnition(RCCI).Infact,intheRCCI,bymeansof reactivitystratification,combustionstartsfromregionswithhighreactivityanditcontinuestootherregionswithlowerreactivity.Bythis method,scholarsmanagedtoextendcombustionduration,andoperatingrange.Inaddition,morecontrolovercombustionphasingwas achieved.

TheemissionsofRCCIaresignificantlylow,andatmanyloads, RCCIcanmeetEURO6emissionregulations.Moreover,itwasfound thatRCCIcanreachto60%grossthermalefficiencyunderoptimized conditions.RCCIisamorepromisingmethodcomparedtoHCCIand PPCbecauseithasasmootherheatreleaserate,lowerPPRR,andnoise levels.UsingdifferentratesofEGR,differentfractionsofgasoline,and injectiontimingledtomoreauthorityovercombustioncontrol.RCCI combustionoffersbettercontrolovercombustiondurationandcombustionphasingatmoderateloads,buttherearesignificantlimitations athigherloads.Inordertomaintainthecombustionphasingathigher loads,themassfractionofthelowreactivityfuelneedstobeincreased, andthistrendproceedsuntilthehighreactivityfuelwilldiminish. Hence,RCCIislimitedbytheresistanceofthelowreactivityfuel againstauto-ignition.Asaresult,controllingthetimingandrateofheat releasefordifferentLTCstrategiessuchasPPC,PCCI,andRCCIis difficultbecausetheyarekineticallycontrolledandofferlowauthority onthecombustion.Inaddition,thesestrategieshaveotherdrawbacks suchashighUHCandCOemissionscomparedtoconventionaldiesel combustion,andtheyhaveanarrowoperatingrangeandimpractical boundaryconditions [20–25]

Shimetal. [26] performedanexperimentalstudyonthecomparisonbetweenadvancedcombustiontechnologiessuchasHCCI,PCCI, RCCI,andCDC.ItwasreportedthatallstrategiescoulddecreaseNOX andPMsimultaneouslywiththeuseofaftertreatment.HCCIandPCCI hadsomechallengestomaintainthecombustionphasing,sotheEGR ratewasincreasedupto40%toservethepurpose.UHCandCO emissionsincreasedbyabout38timesinadvancedstrategiescompared toCDC.Inthedual-fuelPCCI,indicatedthermalefficiencywaspeaked at45.3%,andbyusingnaturalgas,CO2 emissionreducedby14.3%.

TohavemorecontrolovercombustionanddecreaseUHCandCO,

in2013and2014,LimandReitz [27,28] implementedadirectgasoline injectorinthecombustionchamberofanRCCIengine.Gasolinewas injectedinthecombustionchamberwithanarrowsprayangle,and thendieselwasinjectedwithawidesprayangle.Asaresult,UHCand COemissionsweredecreasedbyabout7%and27%.Inaddition, combustionefficiencyimprovedbythismethod.Theyadoptedthis methodandmanagedtoextendtheRCCIoperatingrangeto21bar grossIMEP.

In2015Wissinkimplementedtwodirectinjectorsinthecombustion chambertohavemoreauthorityoverthecombustionphasingandthe rateofheatreleasetoovercomeRCCIlimitations.Heintroducedanew strategycalledDirectDualFuelStratification(DDFS).Inthisstrategy, gasolineisinjecteddirectlyinthecombustionchamberat340°BTDCto makeapartiallyhomogenouscharge,andlikeRCCIstrategy,dieselfuel isinjecteddirectlyinthecombustionchamber40–60°BTDCtoprepare areactivitygradienttoachieveprecisecontrolovertheLow TemperatureHeatRelease(LTHR).AfterLTHR,anear-TDCinjection makesmorecontrolovertherateofheatrelease.DDFShascomparable efficiencytoRCCI,andemissionswereatacceptablelevels.Inaddition, pressureriserate,noiselevel,EGR,andcyclicvariationwereimproved inDDFScomparedtoRCCI.WissinkalsocomparedDDFSwithPPCand foundthatDDFShashigherefficiencybyabout15%.Onebigconcern oftheDDFSishighPMproductionduetothenatureofdiffusion-limitedflameofthenear-TDCinjection.Wissinkadoptedmanymethodsto reducePM,especiallyforhighloadoperations.PMreductionmethods thatheusedincludedpostinjection,increasinginjectionpressure,decreasinginjectiondurationorusinggasolineinsteadofdieselforthe near-TDCinjection.PostinjectiondecreasedPM,butitincreasedNOX. Thesamebehaviorwasobservedfortheincreasinginjectionpressure [29–32]

In2017,Loungetal. [33] performedanumericalinvestigationon theeffectsofinjectiontimingontheignitionof iso-octaneusingDDFS strategyandcomparedwithRCCI.Theyuseda2Ddirectnumerical simulation(2DDNS)withreducedchemistryofprimaryreferencefuel oxidization.TheyfoundthattheRCCIcombustionexhibitedshorter combustiondurationwithhighlypeakedheatreleaserate,whilethe DDFScombustionhadalowerpeakofheatreleaseandlongercombustionduration,whichwasattributedtothesequentialinjectionof isooctane.TheyreportedthattheDDFSstrategycanallowprecisecontrol overtherateofheatreleaseandcombustionphasingwhencompared withRCCI,andbyadjustingthenear-TDCinjectionandproperenergy fraction,thispurposecanbeserved.

In2020,Shirvanietal. [34] performedaninvestigationontheeffectsofpiston-profileonemissionsandperformanceunderDDFS strategy.Theyfoundthattwogeometricalparameters,includingthe ratiosofsquishvolumetoclearancevolume,andpistonareato chamberareahavesignificantimpactsonemissionformation.They investigatedthreeconventionalpistonprofiles,andthencombinedthe benefitsofthemandproposedanewpistonprofile,whichhassmall squishvolumeandomegatypespray-guideshapeonthepiston.This pistonissuitableforthecombustionchamberwithtwodirectinjectors usingtheDDFSstrategy.TheymanagedtoreduceNOX,soot,andCOby about17,2,and27%,respectively,withtheproposedpiston.

Duetoglobalenergydemands,energyconsumptionhasbeenincreased,whichiscombinedwithgreenhousegasandglobalwarming concerns.Biomassisrenewableandcanbeconsideredasanalternative tofossilfuels,whichissuitableforsatisfyingapartofenergydemands. Biomassisutilizedfordirectcombustioninpowerproduction,butit hassomedrawbacks.Insteadofusingbiomassfordirectcombustion, somegasificationtechniqueshaveshownsignificantheedbyalleviating theseverechangesinclimateandenergycrisis.Biomassgasification canreducehazardousgasessignificantlyandcansatisfyenergydemands.Syngascontainshydrogen(H2),methane(CH4),carbondioxide (CO2),carbonmonoxide(CO),andnitrogen(N2)andwatervapor. Someeminentscholarsperformedexperimentalandnumericalinvestigationsonbiomassandsyngasproductiontofinalizesyngas

productionforvariousapplications.H2 canbeusedasacleansourceof energy,andCH4 frombiomassgasificationcanbeusedeasilyinthe transportationindustryunderLTCstrategieslikeRCCI [35–37]

Anotherrenewablesourceofenergythatisveryattractiveforthe transportationindustryisalcoholfuelslikemethanolandethanol. AlcoholfuelscanreducethetradeoffbetweenNOX andsootinconventionaldieselcombustion.Ethanolisusedwidelyinmanycountries onalargescaleasarenewablefuelandasuitablealternativetofossil fuels.Therearetwocommonwaysofethanolproduction:ethylene hydrationandfermentation.Inthefirstway,ethanoliswidelyproducedforindustrialapplications.Ethyleneisreactedwithsteamandby usingsomechemicalssuchasphosphoricandsulfuricacids,andasa result,ethanolisproduced.Inthefermentationmethod,bioethanolis producedfromfoodcropssuchascorngrainandsugarcane,butitmay belimitedbecauseitmayleadtoatradeoffbetweenbioethanolproductionandfoodprovisions.Alcoholfuelshavesomeadvantages: higheroctanenumber,renewability,evaporativecoolingeffects,which leadstohighervolumetricefficiencyandlowercombustiontemperature,lowsulfurcontentcomparedtogasoline,andcontainingoxygen facilitatesfueloxidization [38,39]

EthanolcanbeusedwithpuregasolineinSparkIgnition(SI)enginesfordifferentcompressionratios.ItwasreportedthattheapplicationofalcoholinSIenginesunderoptimizedconditionscanenhance enginebrakethermalefficiencyandemissionswhencomparedwith baseline [40].Dieselenginesgenerallyhavehigherefficiencycompared togasolineengines,butthisefficiencyisatrade-offbetweensootand NOX.Infact,asimultaneousreductioninNOX andsootisdifficultin conventionaldieselcombustion.Manyscholarshavestudiedtheeffects ofusingethanolindieselenginesnotonlyasasubstitutionfordiesel butalsoforreducingNOX andsootsimultaneously [41–44].Fromthe studiesperformedbyscholarsontheeffectsofethanol/dieselblend properties,itwasfoundthat30%ethanolbyvolumeindieselnotonly haslittleeffectsonfuelatomizationbutalsoincreasesignitiondelay andimprovescombustionefficiency.Inaddition,NOX andsootlevels canbeimprovedundercertainconditions [45–48].Otherresearches wereperformedontheeffectsofdifferentalcoholfuelssuchasmethanolandbutanolindieselfuel.Itwasfoundthattheapplicationof alcoholfuelsincreasesfueloxidization,NOX,andthermalefficiency whileitsignificantlyreducessoot [49–51].

Lietal. [52] conductedamulti-objectiveoptimizationofmethanol/ dieselinadualfuelenginetofindthebaselinesofoptimizedRCCIand DDFSatlowloadoperatingconditions.Themodelwasvalidated againstexperimentaldataofalight-dutyRCCIengine,andthestrategy waschangednumericallyfromRCCItoDDFS.ItwasfoundthatDDFS hashigherthermalefficiency,lowerUHCandCO,andlowersensitivity toinitialconditionsatlowloads.Moreover,inRCCI,alargesprayincludedangleispreferred,whileinDDFS,asmallspray-includedangle ismoredesirableforfueloxidization.Longetal. [53] performedan experimentalinvestigationontheeffectsofdual-directinjectionina light-dutyengine.Itwasreportedthatdieselfueljet-injectioncould controlthecombustionphasingandignitiontimingrobustlyforfour operatingconditions.Advancingthenear-TDCinjectiontimingresulted inhighgrossthermalefficiencyandhighNOX emissions.Forprolonged near-TDCinjection,thereisatrade-offbetweenNOX andsootlikeCDC. Aspreviouslymentioned,theDDFSstrategyisapracticalpathway ininternalcombustionenginestoachieveultra-lowemissionsandhigh thermalefficiency.UnlikeRCCIandHCCI,whicharekineticallycontrolled,DDFShasgreatauthorityovertherateofheatreleaseand combustion.TheadvantagesoftheDDFSoutweighedthedisadvantages excepthighPMproduction.Onepracticalwaytoaddressthisproblem isusingfuelswithlowC/Hratio,oroxygenatedfuelssuchasethanol. Inthispaper,E85andE10werechosenasalternativestogasolineinthe gasoline/dieselDDFScombustion.Anumerical3D-CFDmodelwas developedandvalidatedagainstexperimentaldata.Tothebestofour knowledge,thereislittleinformationaboutusingethanolunderthe DDFSstrategytotacklePM.Acomparativestudywasperformed

betweenE10andE85asalternativestogasolineregardingemissions andperformancecriteria.Thepaperisacomprehensivestudyonthe effectsofdieselenergyfractionanditstimingonemissionsandperformance.Inaddition,theenergyfractionofthenear-TDCinjectionand itstimingwasswept,andthebestregionbasedontheEURO6emissions mandatewaschosen.TheDDFScombustioncanmeetEURO6without aftertreatment.Thecombustionchamberhastwodirectinjectors,and theirsprayangleswereswept,andthebestregionsforthesprayangles werealsochosen.Finally,theeffectsofinjectionpressureofthenearTDCinjectionwerestudied,andthesuitablerangeofinjectionpressure forDDFScombustionwaschosenbasedontheEURO6emissionsregulation.

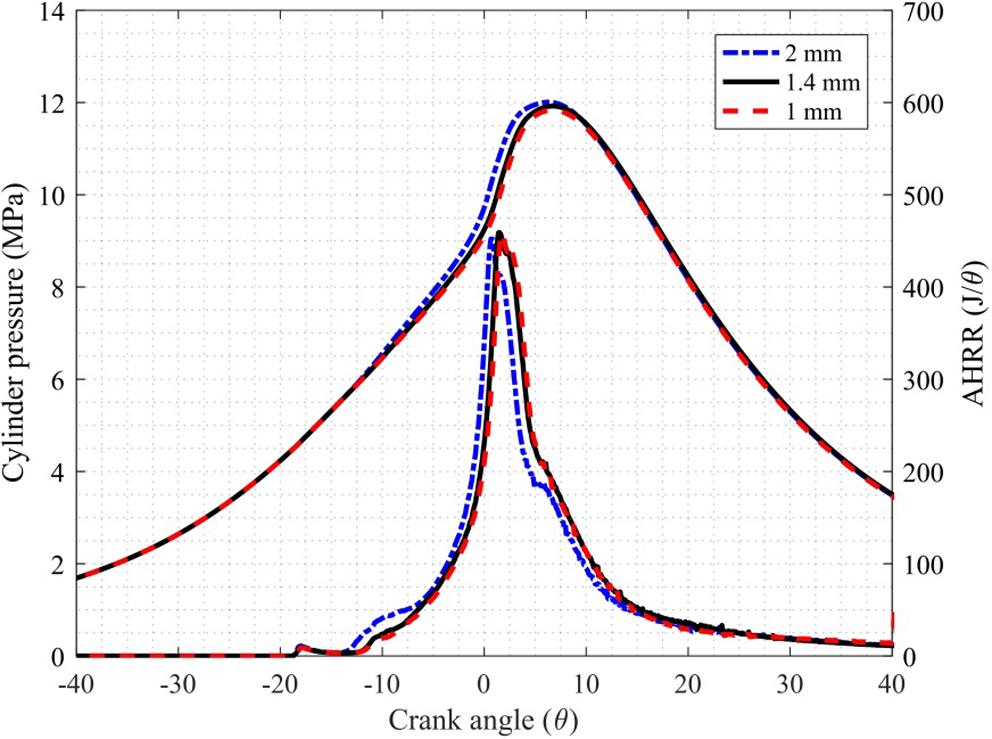

2.Computationalapproach

Inthisstudy,a3D-CFDmodelwasdevelopedandusedtosimulate DDFScombustionoftheCaterpillarsinglecylinderengine.Meshstudy wasperformedforthreemeshsizes:coarsemesh(2mm),mediummesh (1.4mm),andfinemesh(1mm).Thebestmeshsizewaschosenbased onmeshaccuracyandcomputationaltime.Experimentaltestswere performedbyWissinkandReitzattheUniversityofWisconsinMadison Lab [29,30].Theenginespecificationandoperatingconditionsofthe experimentsareoutlinedin Tables1and2,respectively.

2.1.Computationalmodel

Inthispaper,theCFDmodelwasemployedtosimulatetheDDFS combustionat9.41bargrossIMEPand1300rpm.Thissimulation considersclosed-cycleforcombustionsimulationfromIVC(143°BTDC) toEVO(130°ATDC).Thegasolinechargewasconsideredcompletely homogeneousatIVCforthesimulation.

ALagrangianapproachwasemployedtosimulatespraydynamics frominjectionuntilvaporization.Adropdragsub-model,whichthe dropdragcoefficientcanbechangeddynamicallywithflowconditions, wasusedintheCFDmodel [54].StandardDiscreteDropletModel (DDM)wasapplied,whichusesatechniqueforsimulatingthebehavior ofatomizedevaporatingliquidparcelsinthegaseousenvironment [55].TheKelvin-HelmholtzandRayleigh-Taylor(KH-RT)hybridmodel wereusedtosimulatesprayatomizationfortheprimaryandsecondary break-ups.Thismodeliscapableofbeingusedforbothdieselandgasolinespray,especiallyfortheDDFSstrategy [56].BothKHandRT instabilitieswereusedtopredictthesecondarybreakupofeachdroplet. O’Rourkesubmodelwasappliedforspraywallinteractionandwallfilm [57].TheNoTimeCounter(NTC)method,whichisfasterthanthe O’Rourkemodel,wasemployedtocalculatedropletcollisionsinLagrangianspraysimulation [58]

TheRe-NormalizationGroup(RNG)k-ε modelwasusedtosimulate turbulencetransport.Thismodelisusedforinternalcombustionengines,especiallyfordieselengines,whichhavecompressing-expanding flowsandspraycombustion [59].Detailedchemicalkineticsusing multi-zonemodelingwasusedinthispaper.Thismodelaccelerates combustionprocess,anditisappropriateforgasolineanddieselfuels andalsoformulti-componentfuels [60].Themulti-zonechemistry solverwasusedtospeedupcombustioncalculationsforgroupedcells withsimilarproperties.Tosimulateenginecombustion,areduced chemistrymechanismforgasoline/diesel,whichsimulatedieselasnheptaneandgasolineas iso-octanewith108speciesand435reactions [30,61].Inordertopredictthesootconcentration,Hiroyasusootmodel wasused,andtheextendedZeldovichprocedurewasappliedtopredict NOX emissions [62,63]

Fixedwallboundaryconditionswereusedfortheheadcylinderand cylinderwallwithasmoothwallassumption.TheLawoftheWall boundaryfortemperatureandvelocitywasappliedforallwall boundaries [64].Thebasegridsizeforglobalmeshwaschosen1.4mm basedongridindependencystudy.Somelocalrefinementsweredone forsomecriticalregionssuchasnozzles’regions,cylinderwall,head

cylinder,andcrevicevolume,whichisasourceofUHC.AsSenecal etal.recommendedin [65],theoptimumgridsizeforspraysimulation wasabout0.25mm;inthisstudy,appropriatemeshresolutionwas performedforspraytoreachthissize.Inthiscomputationalmodel,the minimumnumberofthegridforthecompressionstrokeatTDCwas about252,000,andfortheexpansionstroke,itwasabout960,000cells.

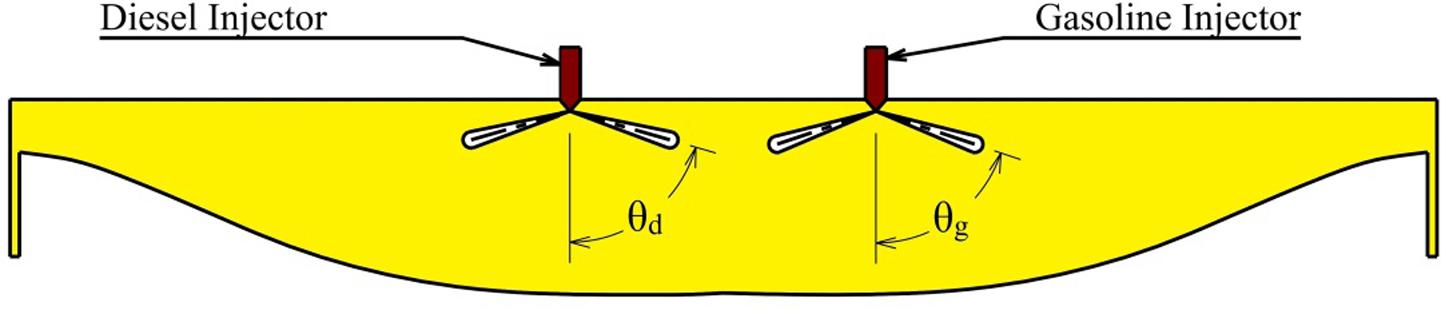

ToensurethattheCFDmodelisreliableforthegasoline/dieseland E85/dieselcombustion,themodelwasusedforotherloadsin Appendix.Thenumericalresultsshowedareliablemodelandenough accuracy.Thecombustionchamberhastwodirectinjectors,sothe wholecombustionchamberwasmodeled,and Fig.1 showstheprofile ofthecombustionchamberfortheDDFSenginewithcrevicevolumeat TDCaswellastheinjectors’positions.

2.2.Meshstudy

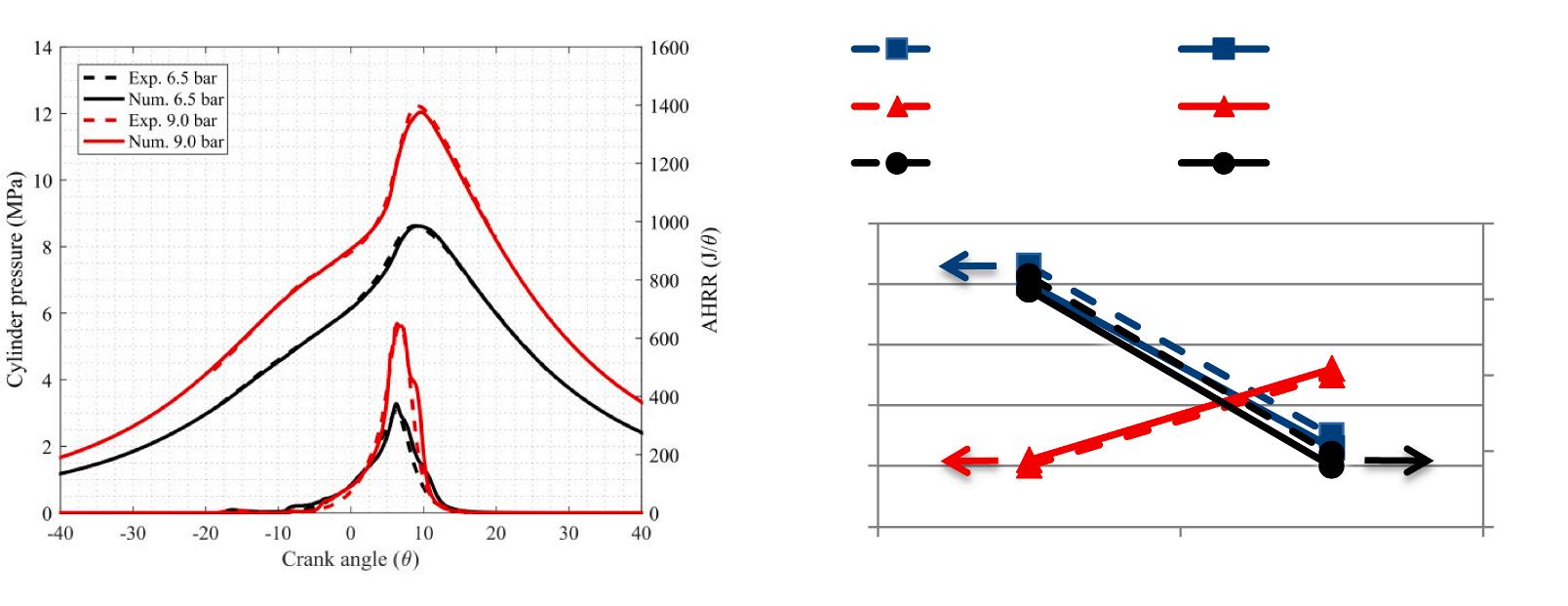

TheCFDcomputationalmodelofDDFScombustionwasvalidated againstexperimentaldatagivenin [29].Inordertoexamineitsaccuracy,meshindependencyofthenumericalmodelwasstudied. Fig.2 illustratesacomparisonbetweenthenumericalresultsandexperimentaldataforthreemeshsizes. Table3 showstheresultsofmesh independencystudyforemissions.Accordingto Fig.2 and Table3,the appropriatemeshsizebasedontheaccuracyandcomputationaltime wasconsidered1.4mm.

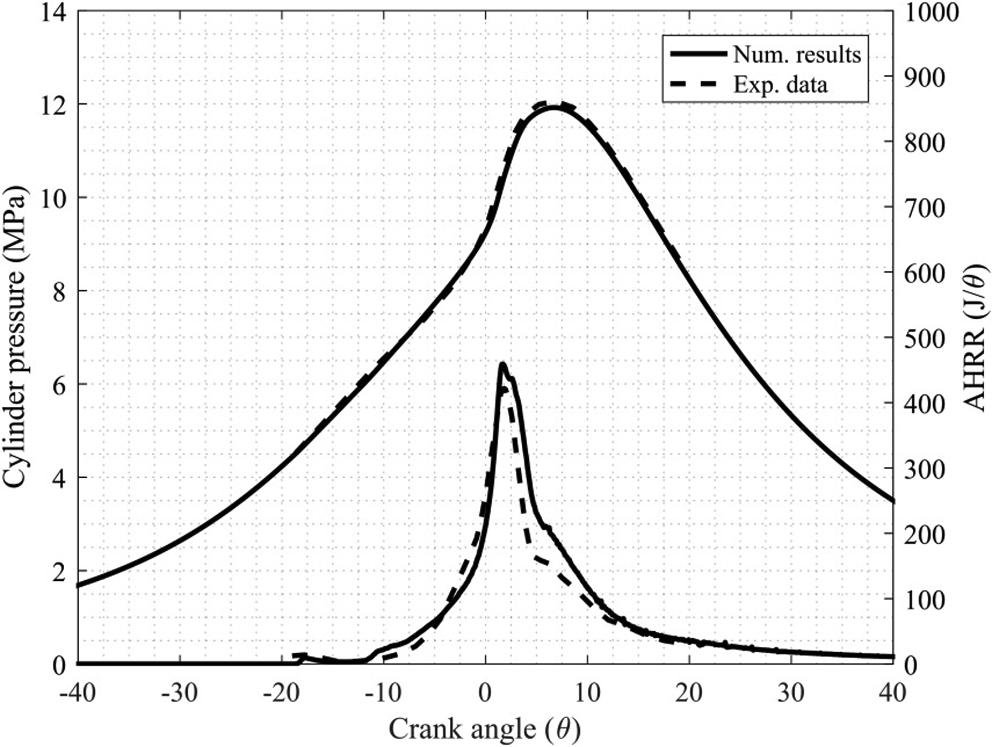

2.3.Modelvalidation

Thenumerical3D-CFDmodelwasvalidatedagainstexperimental dataand Fig.3 showsacomparisonofthecylinderpressureandAHRR betweennumericalresultsandexperimentaldata. Fig.4 depictsthe emissionsresultsofthenumericalmodelandexperimentaltests.

3.Resultsanddiscussion

Aspreviouslymentioned,theDDFSstrategyhassupremacyover RCCIexceptitsPMproductionowingtothenear-TDCinjection.In ordertodecreasethesootformation,andreducethetrade-offbetween NOX andsootindiffusion-limitedcombustion,itisproposedtouseE10

Table1

Enginegeometryanddirectinjectorspecificationsfortheexperimentalsetup (experimentaldatatakenfrom [29]).

EngineSpecifications

EngineType

Caterpillar3401ESingleCylinderOilTest Engine(SCOTE)

Pistontype Modified-piston(wideshallow)

Numberofvalvespercylinder 4 IVO(°ATDC)

Swirlratio

Compressionratio

Commonrailinjectorsname(CRI1)

Bodystyle BoschCRI2series

Nozzleangle(°) 148

Holediameter(μm) 141

Numberofholes 7

Commonrailinjectorsname(CRI2)

Bodystyle BoschCRI2series

Nozzleangle(°) 143

Holediameter(μm) 117

Numberofholes 10

Table2

ExperimentaloperatingconditionsusedfortheDDFSexperiments(experimentaldatatakenfrom [29]).

OperatingConditions

ComparisonofcylinderpressureandAHRRfordifferentmeshsizes usingDDFSstrategy.

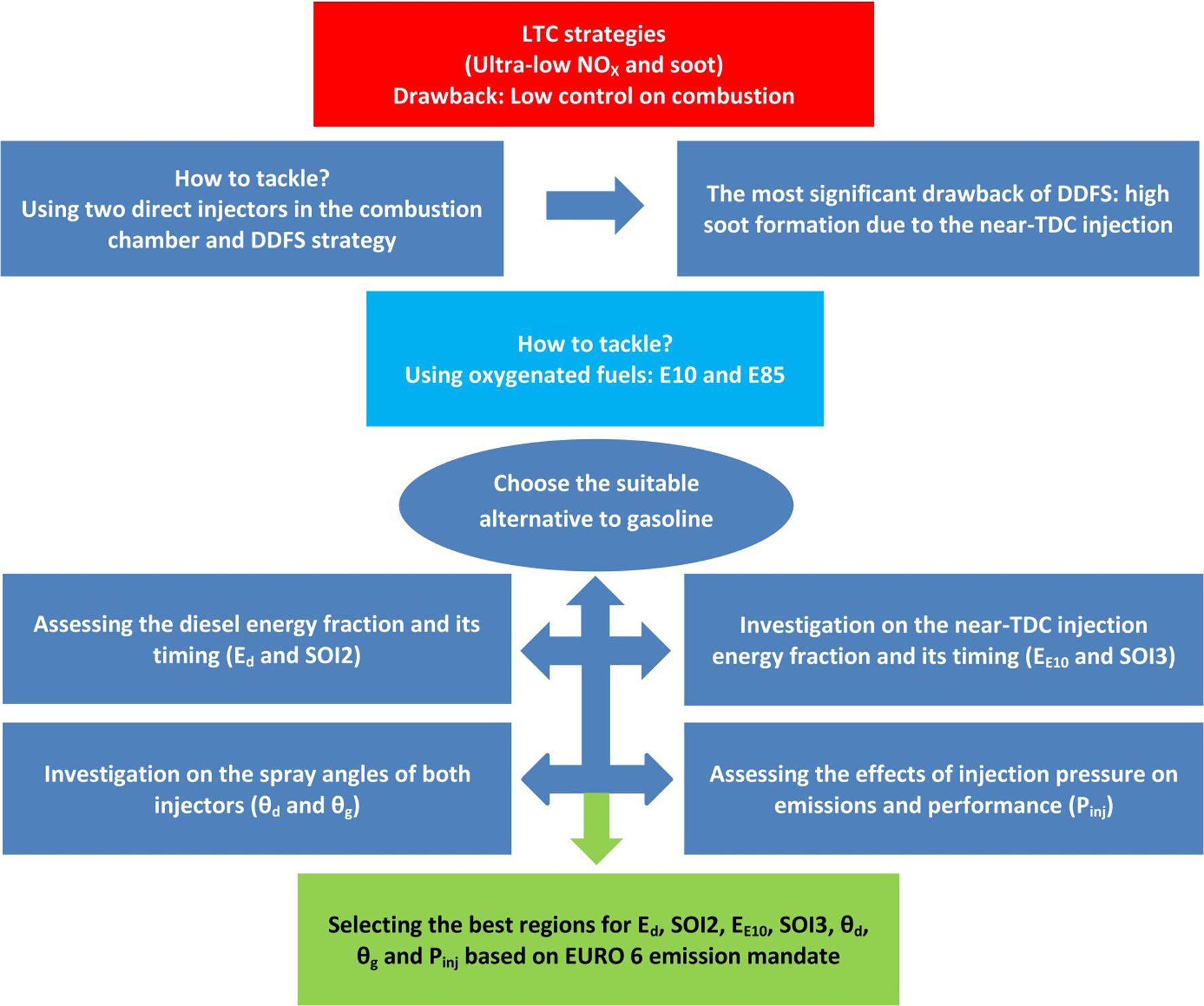

(10%ethanolingasolinebyvolume)andE85(85%ethanolingasoline byvolume)astwoconventionalalcoholfuels.Inthefirststep,gasoline wassubstitutedbyE10andE85,andacomparativestudywasperformedtoinvestigatetheireffectsonemissionsandperformance.Inthe secondstep,oneofthemwaschosen,andanumericalstudyonthe injectiontimingandsweepsofenergyfractionforSOI2andSOI3will bestudiedinthefollowingsections. Fig.5 showstheproblemformulationinthisstudy.

3.1.SubstitutionofgasolinewithE10andE85

Inthissection,theeffectsofusingE10andE85asthelowreactivity fuelsareinvestigated.In-cylinderenergyforGasoline/Diesel(G/D), E10/Diesel(E10/D),andE85/Diesel(E85/D)usingtheDDFSstrategy wasconsideredconstant.CA50fortheG/Dcasewasabout3.9°ATDC. Tomakeafaircomparison,energyfractionsfortheE10/DandE85/D wereconsideredconstantsimilartotheG/Dcase,andbychangingthe near-TDCStartOfInjection(SOI3),CA50waskeptconstantforall cases.

SimulationparametersfortheG/D,E10/D,andE85/Dcasesare providedin Table4.TheEGRratefortheE85/Dcasewasconsidered zeroowingtothefactthatE85hasahigheroctanenumberandithas coolingeffectsonthecombustionchamber.Ingeneral,for9.41bar IMEP,usingEGRinE85/Disunnecessaryaccordingtotheexperimentaltestsprovidedin [4,66,67].Dieselinjectionstrategy,including SOI2,dieselenergyfraction,andinjectionpressureanddurationwere consideredconstantinthissection.Thecoolingeffectsofethanolvaporizationinthefirstinjection(SOI1=-340°ATDC)onthecylinder temperaturewerecalculatedinAppendix,andTIVC forclosed-cycle simulationforeachcaseisprovidedin Table4

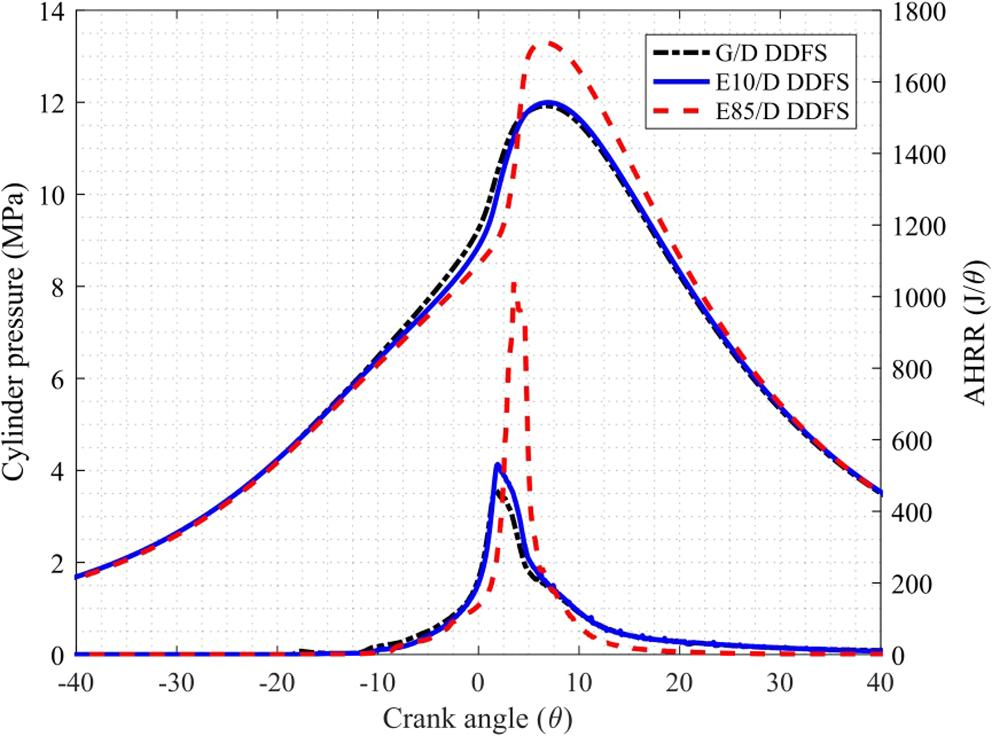

Fig.6 illustratesthecomparisonofcylinderpressureandAHRRfor allcases.DespitethesameEGRratefortheE10/Dcasecomparedtothe G/Dcase,thepeakofAHRRofthiscaseslightlyincreased.E10contains

oxygen,andoxygenmoleculesleadtofasterfueloxidizationandmore ratesofheatreleaseinashorterduration.Thus,thepeakofAHRR increased.IntheE85/Dcase,AHRRincreaseddramatically,anditresultedinadramaticincreaseinthecylinderpressure.ThePPRRofthe E85/Dcaseis21.6bar/degandmuchhigherthannormallevels,given in Table5

Emissions,grossIMEP,andGrossThermalEfficiency(GTE)are presentedin Table5.IntheE10/Dcase,NOX slightlyincreasedby about1.7%comparedtotheG/Dcase.However,sootsignificantly reducedbyabout40%.Thisreductioncanbeattributedtothefactthat oxygenmoleculesinE10acceleratefueloxidizationandpreventthe formationofsootandcarbonclusters.UHCandCOintheE10/Dcase reducedbyabout23.5%,38.6%,respectively.

NumerousstudieswereperformedontheeffectsofE85underthe RCCIstrategy;E85isabsolutelyhelpfulfortheRCCIstrategyowingto itshigheroctanenumberthangasolineandmakingahigherreactivity gradient.However,inthedirectinjectionnear-TDC,thisfuelresultsin asuddenandveryquickincreaseintherateofheatreleaseandNOX emissions.IntheE85/DDDFScase,NOX dramaticallyincreasedby approximately25ordersofmagnitudecomparedtotheG/Dcase.

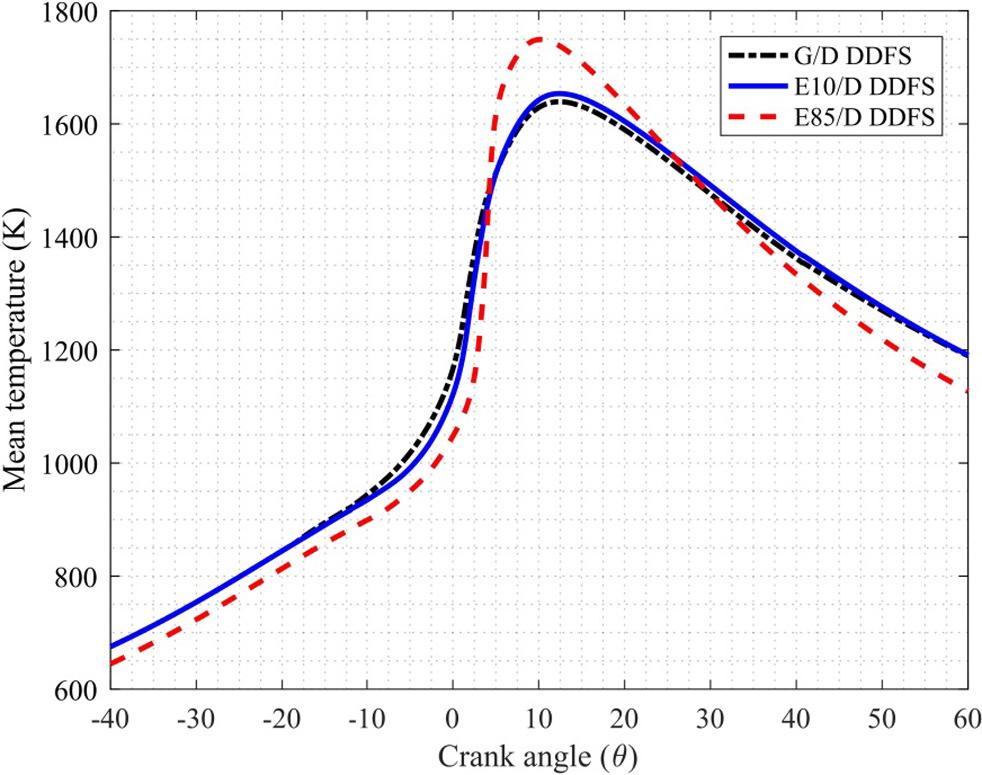

Asaresult,E10ismoresuitablethanE85forDDFScombustion. SootsignificantlyreducedintheE85/Dcase,andCOreducedbyabout 83.9%owingtothisfactthatE85hasfewercarbonsinitsstructure comparedtoE10andgasoline.UHCemissionintheE85/Dcasewas slightlyhigherthanE10/DcasebecauseofthecoolingeffectsofE85on thecombustionchamber,shownin Fig.7.Forconstantin-cylinder energyineachcase,thegrossIMEPincreasedforthealcoholcasesand resultedinhigherGTE.

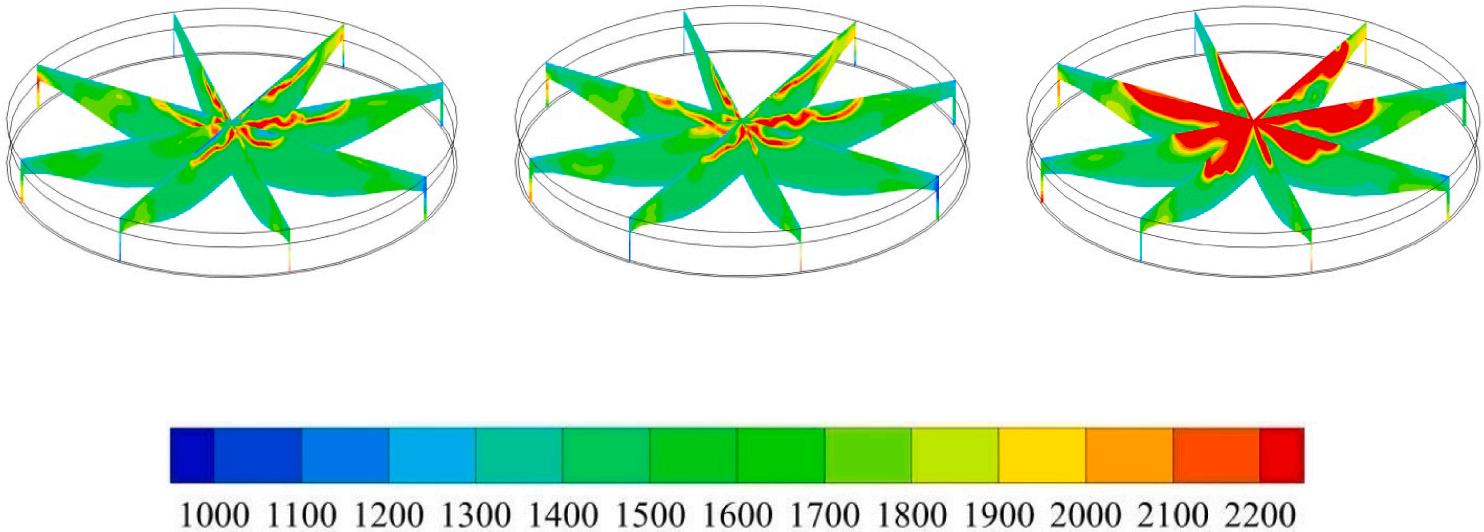

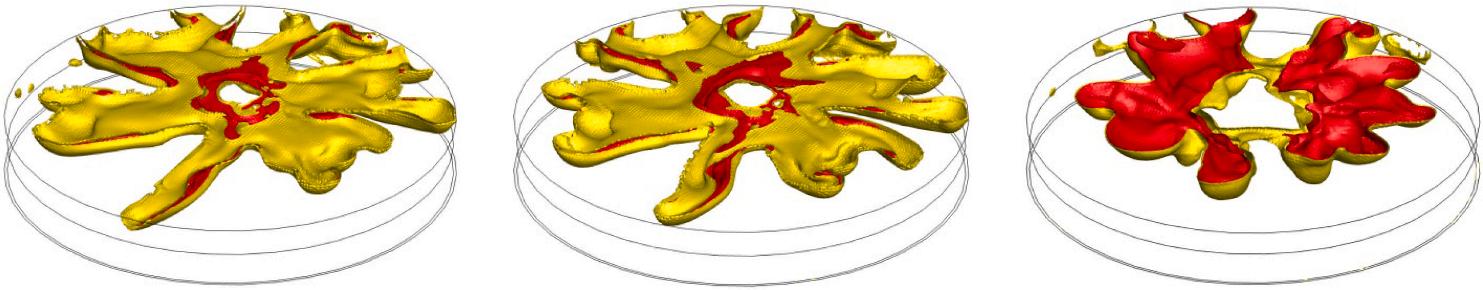

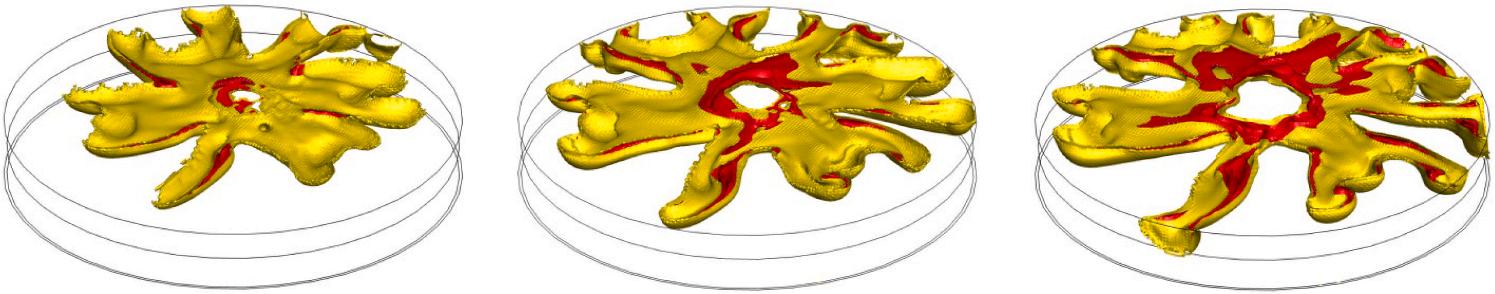

Fig.8 depictstemperaturecut-planesatsimilarcombustionphasing (CA50=3.9°ATDC)forallcases.Asitisevident,theE85/DDDFScase hasthehighestlocaltemperaturezoneswhichassociatewiththermal NOX formation.TheE85hasmuchmoreoxygenmoleculesthatresulted inhigherandfasterAHRR.Consequently,thesehightemperaturezones justifythehighamountofNOX andbetteroxidizationforsootinthe E85/DcasecomparedtotheE10/DandG/Dcases. Fig.9 shows isothermalsurfaces(2000and2200K)forallcases.TheeffectsofE85and

Fig.1. Pistongeometryprofilewiththecrevice volumeforthecombustionchamberatTDC.

Fig.2.

Table3

NumericalresultsofemissionsfordifferentmeshsizesusingDDFSstrategy(systemconfigurationisIntelCorei76700kwith32GBRAM).

Case basegridsize(dx,dy,dz)NOX(gr/kW-hr)Soot(gr/kW-hr)UHC(gr/kW-hr)CO(gr/kW-hr)Computationaltime

ComparisonofcylinderpressureandAHRRbetweennumericalresults andexperimentaldata.

E10ontheflameshapeareobviouslyshowninthisfigure.

Aspreviouslymentioned,improvedheatreleaserate,lesscyclic variation,comparablegrossthermalefficiencytoRCCI,lowerengine noiselevelsinhighloadoperations,andhighergreatpotentialheat recoveryfromdownstreamisachievableintheDDFSstrategy.The primarydrawbackoftheDDFSishighsootproductioncomparedto RCCIstrategy. Table6 presentsaqualitativecomparisonofemissions andotherperformanceparametersbetweenE10/DandE85/DcomparedtotheG/DasthebasecaseunderDDFSstrategy.Inthistable, zeroisnegligiblevariation,plusconveysanimprovement,andminus showsanaggravationforeachcasecomparedtoG/DDDFScase.

ThetableshowsthatE10isabetteralternativetogasolineforDDFS strategybecausenotonlysoot,UHC+CO,andGTEimproved,butalso NOX,ISFC,andPPRRhadnegligiblechanges.Asaresult,byusingE10, sootastheprimarydrawbackoftheDDFScanbereducedsignificantly upto40%atthisload.

TheE85alsoreducedsootproduction,butattheexpenseof25 timeshigherNOX.PPRRandfuelconsumptionaremuchhigherthan E10.Theheatrecoveryparameterinthistablepresentsanimportant conceptininternalcombustionengines.Inordertoreachhigherloads, itisnecessarytohavehighboostpressurefortheintakemanifold.

Generally,LTCstrategieshavealowerexhaustgastemperaturecomparedtoconventionaldieselcombustion,sotheapplicationofaftertreatmentandturbochargerischallenging.Inshort,DDFShasgreater potentialfordownstreamrecoverycomparedtoRCCIowingtothe near-TDCinjection.UsingE10hasnegligibleeffectsontheheatrecoveryparameter,butE85significantlydecreasestheexhaustmean temperature,whichisnotsuitablefortheheatrecoveryparameter.

3.2.DieselenergyfractionandSOI2sweepsforE10/dieselDDFS

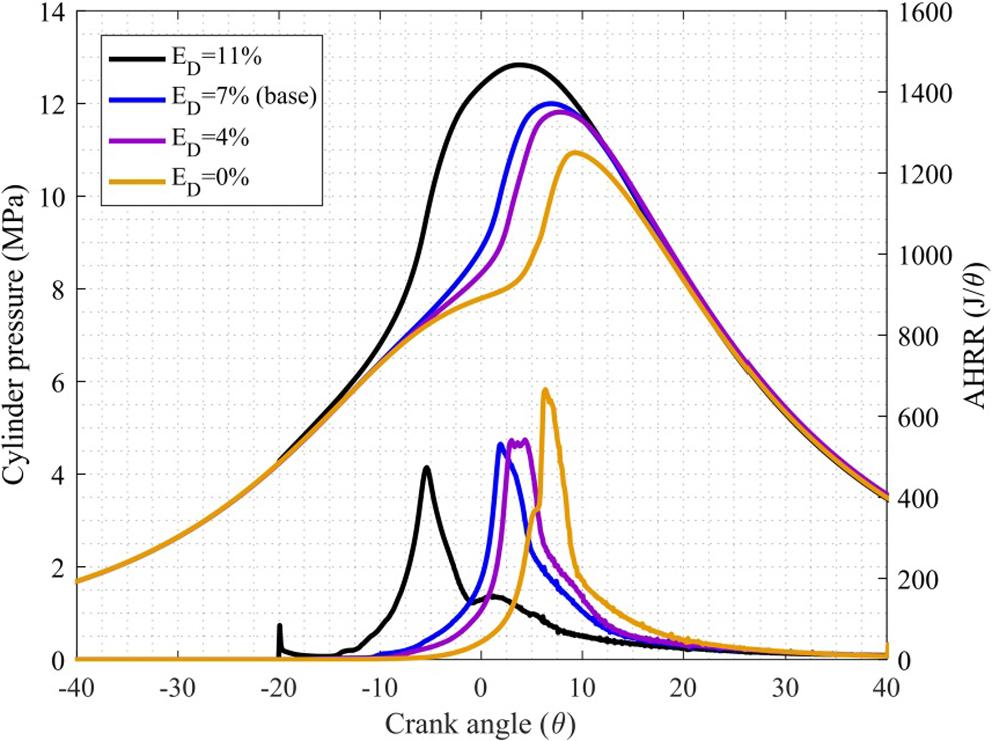

Inthissection,thedieselenergyfractionanditsstartofinjection (SOI2)wereswept.Asitisvisualizedin Fig.10,dieselfuelsupplies7% ofthetotalcylinderenergyat−60°ATDC.Dieselenergyfractionwas sweptfrom0to11%oftotalenergybysubtractingtheenergyfromthe firstinjectionat−340°ATDC.Then,thedieselstartofinjectionwas sweptfrom−100°ATDCto−30°ATDCtoinvestigateitseffectsonthe chargestratification.

Fig.11 showsthecylinderpressureandAHRRforthecasesof0%, 4%,7%,and11%dieselenergyfractions.AHRRandpeakofcylinder pressureadvancedasthefractionofdieselincreased.Asitisevident, forthe11%dieselenergyfraction,thepeakofAHRRoccurredbefore TDC,anditresultedinnegativework.Moreover,thepeakoflow temperatureheatrelease,inthiscase,wasratherhigh,whichmeans therewasdiffusion-limitedcombustionat20CADbeforeTDC.The dieselenergyfractionof11%andmagnitudesabove11%isnotsuitable forE10/DDDFScombustionatthisengineload.Astheamountofdiesel fueldecreases,thepeakofcylinderpressureandAHRRretard,andin the0%case,thestrategychangesfromDDFStoPPC.

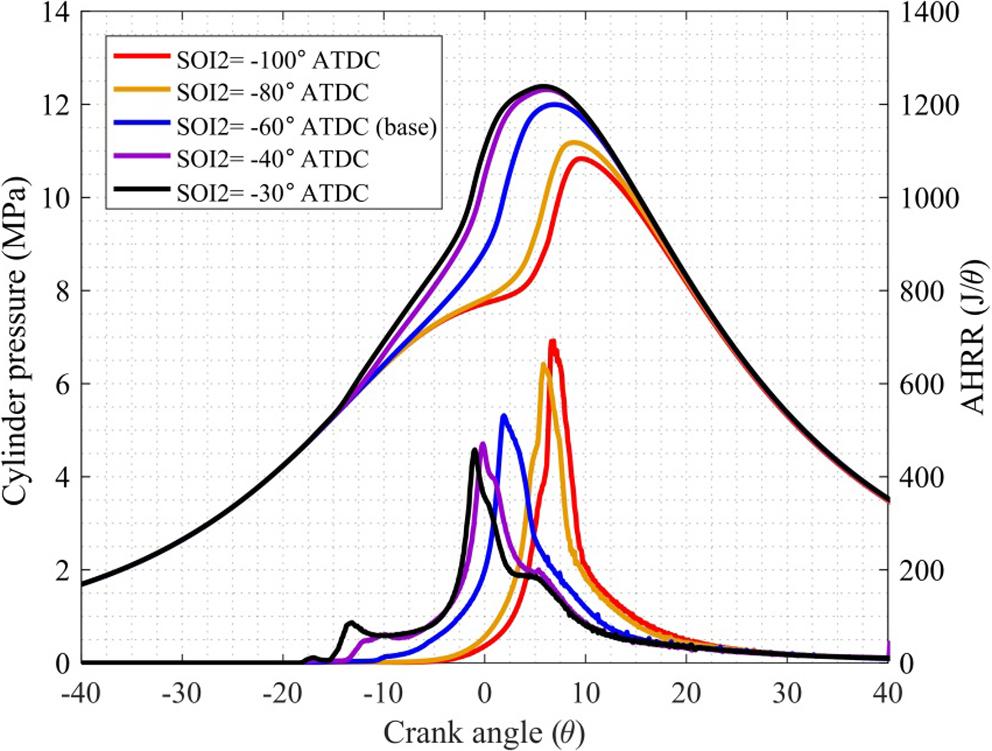

Fig.12 illustratesthecylinderpressureandAHRRtracesforE10/D DDFSwith7%dieselenergyfractionandwithasweepofdieselstartof injection(SOI2).ByadvancingSOI2,thecylinderpressuresandAHRRs retarded.Inaddition,thepeakofAHRRincreasedastheSOI2advanced.SOI2hadsignificanteffectsonthein-cylinderstratificationand reactivitygradient.Threeregimesoccurredbeforethelowtemperature heatreleasebychangingSOI2.Theseregimesarepremixed(PPC-like combustion),reactivitycontrolled,anddiffusion-limited.Asitisshown, thecasewithSOI2=-40°ATDC,hadasuddenincreaseinAHRRandit canbeconcludedforSOI2=-40°ATDC,andafterthat,theregimewas diffusion-limited.

ForthecaseswithadvancedSOI2,homogeneityincreased,andthe regimechangedintoapremixedregime(PPC-likeregime).Thecharacteristicofthisregimeisahighpeakofheatreleaserateand

data Num. results

Fig.4. Comparisonoftheemissionsbetweennumericalresultsandexperimentaldata.

Fig.3.

Table4

SimulationparametersfortheG/D,E10/D,andE85/DcasesusingDDFS strategy.

G/DDDFSE10/DDDFSE85/DDDFS

Injectorname

Injectionpressure(bar)

Fuel2

Injectorname

Injectionpressure(bar)1000

combustionbecomesretardedandresemblesPPCcombustion.Ascan beseenfromtheshapeofAHHR(start,end,andpeak)in Fig.12,reactivitystratification,whichisadjustedbySOI2,affectstherateofheat release,itsstart,end,andalsoemissionformation.Adjustingreactivity stratification,whichisabenefitofRCCI,makesitpossibletomanage andcontrolthecombustion.HavingthisbenefitfromRCCIisagreat characteristicofDDFS.Thesecondphaseofcombustioncontrolisthe near-TDCinjection.

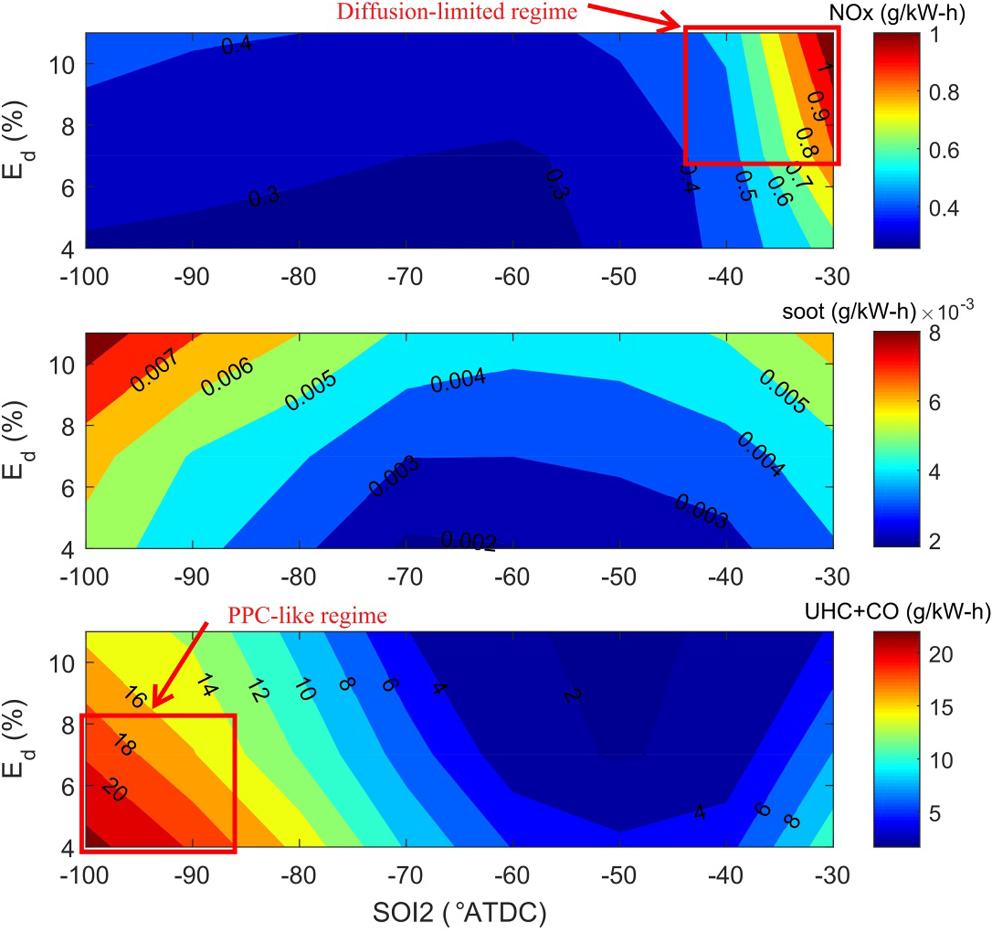

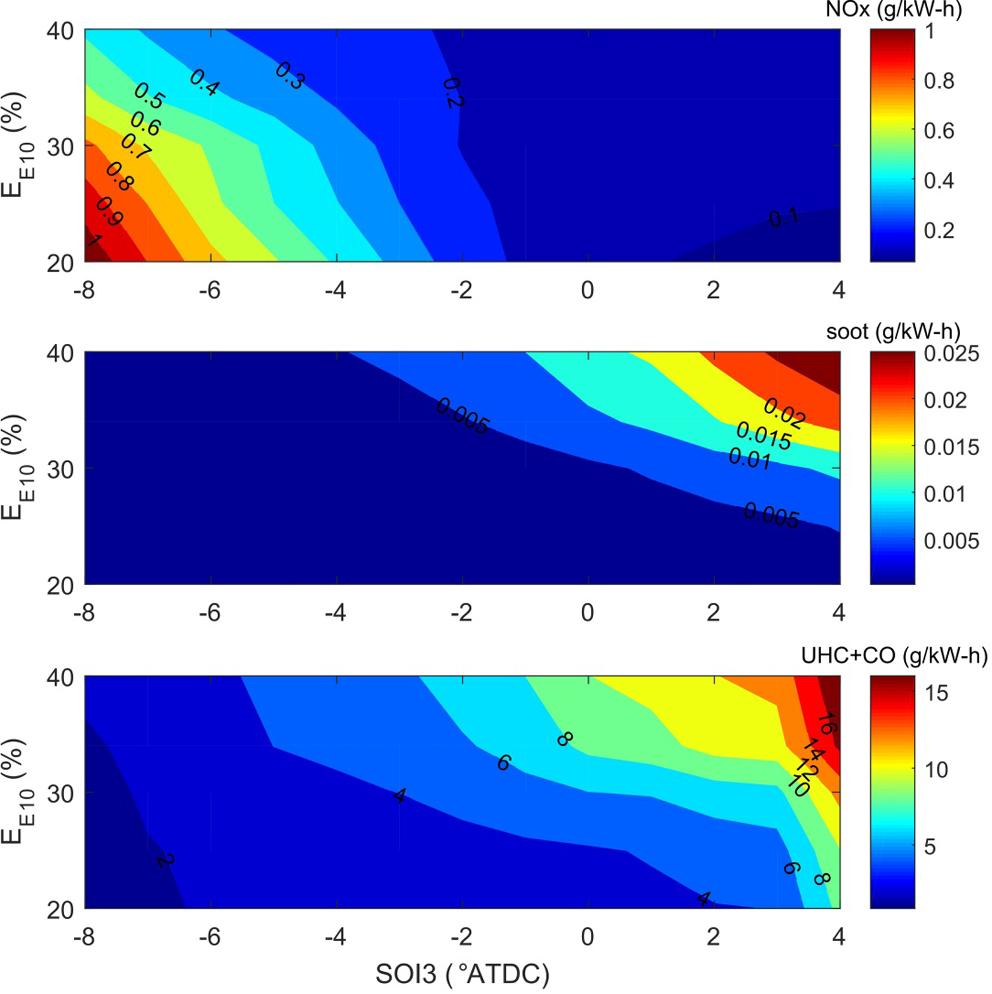

Fig.13 showsemissioncontoursfortheE10/Dcasewithsweepsof SOI2anddieselenergyfraction(Ed).TheupperlimitoftheEd was

Fig.6. ComparisonofcylinderpressureandAHRRforG/D,E10/D,andE85/D usingDDFSstrategy.

considered11%ofthetotalcylinderenergybecause,asitisshownin Fig.12,forthemagnitudesofEd higherthan11%,combustionbecame advanced,andAHRRpeakedbeforeTDC,whichwasnotsuitableand resultedinnegativework.Aspreviouslymentioned,threeregimesoccurredbysweepsofSOI2andEd.Diffusion-limitedandPPC-likeregimesaredemonstratedin Fig.13.ThecharacteristicofthediffusionlimitedregimeishighamountsofNOX andsootemissions,andthePPClikeregimehashighamountsofUHCandCO.ForSOI2sbetween−80

Fig.5. Problemformulationinthisstudy.

Table5

EmissionsandperformancefortheG/D,E10/D,andE85/DusingDDFSstrategy.

IMEP(bar)GTE(%)NOX (gr/kW-h)Soot(gr/kW-h)UHC(gr/kW-h)CO(gr/kW-h)CA50(°ATDC)PPRR(bar/deg)

Fig.7. ComparisonofmeantemperaturediagramsbetweenG/D,E10/D,and E85/DusingDDFSstrategy.

to−40°ATDC,theregimeisreactivity-controlled,whichisthebest regimeforDDFSthatcanbeobtainedbyadjustingSOI2anddiesel energyfraction.AstheEURO6emissionstandardis0.4g/kW-hand 0.01g/kW-hforNOX andsoot,respectively,thisenginecanmeet EURO6emissionmandatewithoutusingaftertreatmentsbyadopting E10asthelow-reactivityfuelusingDDFSstrategy.However,fortheEd above8%andSOI2safter−40°ATDC(diffusion-limitedregime),the enginecannotmeetEURO6forNOX.

Asitisillustratedin Fig.13,UHCandCOamountsareratherhighin PPC-likeregimeowingtohigherhomogeneityofthechargethatcan resultinincompletecombustioncomparedtothereactivity-controlled regime.Fromallemissionsperspective,thesuitableregionsfor choosingEd andSOI2are4to8%ofand−80to−40°ATDC(reactivity-controlledregime).

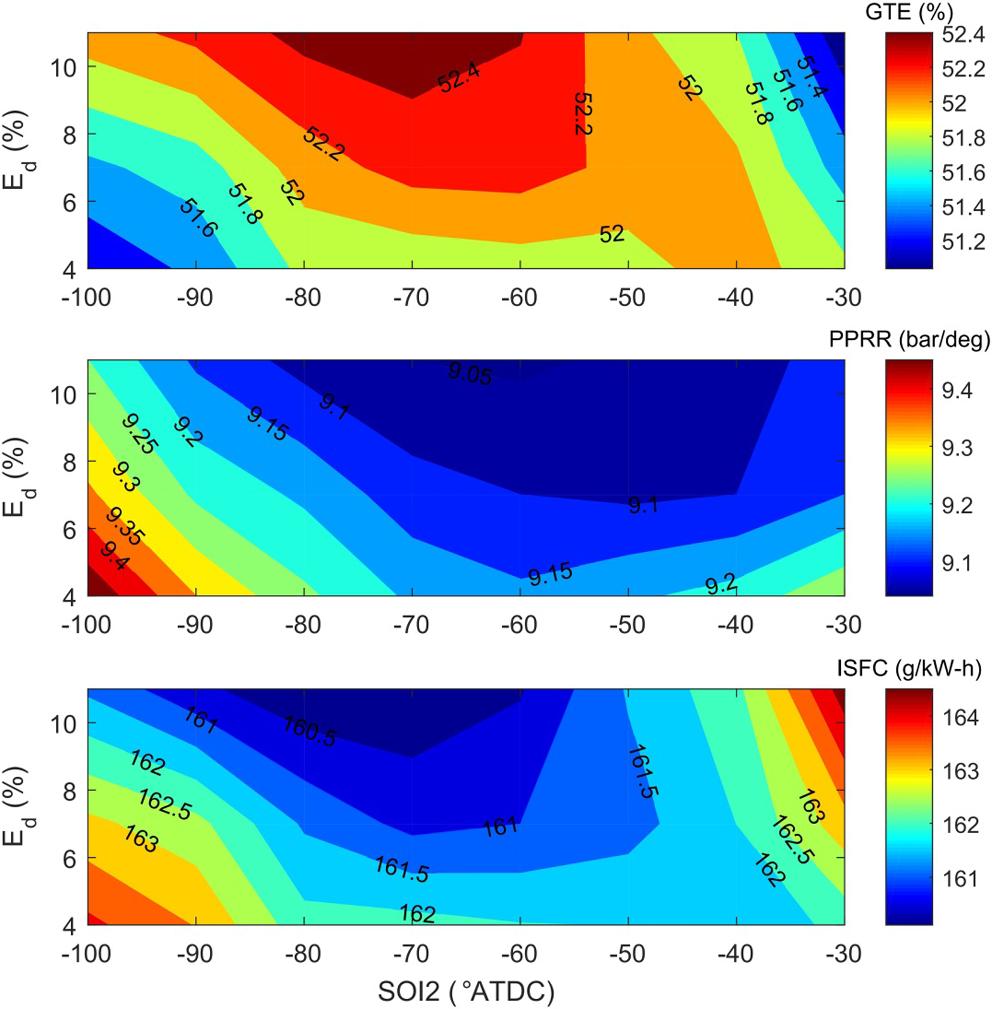

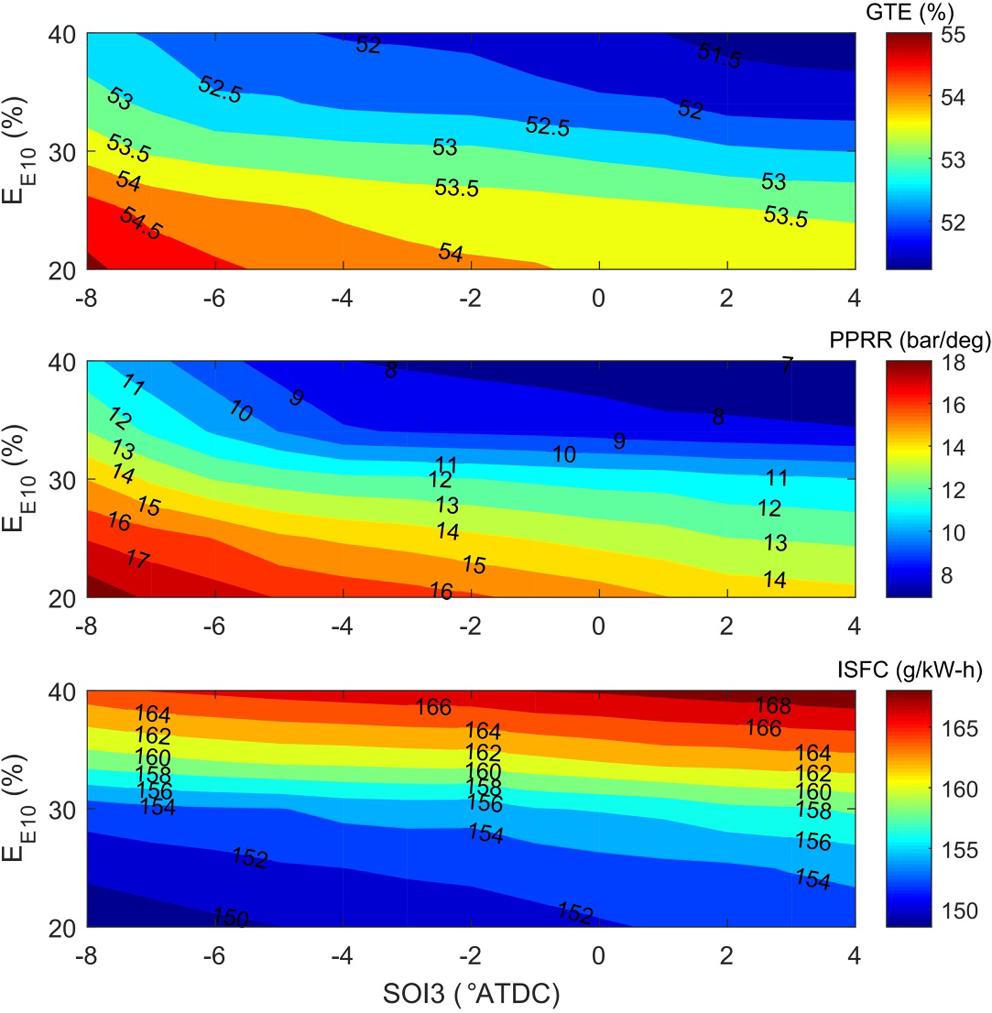

Fig.14 depictstheeffectsofSOI2,andEd sweepsonGTE,PPRR,and indicatedspecificfuelconsumption.ThePPC-likeregimehadhigher PPRRcomparedtootherregimes,whichindicateshighernoiselevels. Whentheamountofdieselfueldecreasedwithearlydieselinjection (SOI2=-100°ATDC),owingtohigherhomoginityofthecharge,PPRR increased.Ontheotherhand,thereactivity-controlledregime(SOI2

between−80to−40°ATDC)andthediffusion-limitedregime(-40to −30°ATDC)hadthelowestamountsofPPRR.Thereactivity-controlled regimehadthehighest.Inthisregion,ISFCwasatitsthelowestlevel.

Tosummarizethissection,reactivity-controlledregime(SOI2between−80to−40°ATDC),showsthebestresultsofemissions,GTE, PPRRandfuelconsumptionfortheE10/DDDFScombustion.ThisregionbenefitsfromtheRCCIconceptsanditscharacteristicsforbetter resultsofemissionsandperformanceandmoreauthorityovercombustion.

3.3.EnergyfractionandSOIsweepsfornear-TDCinjection

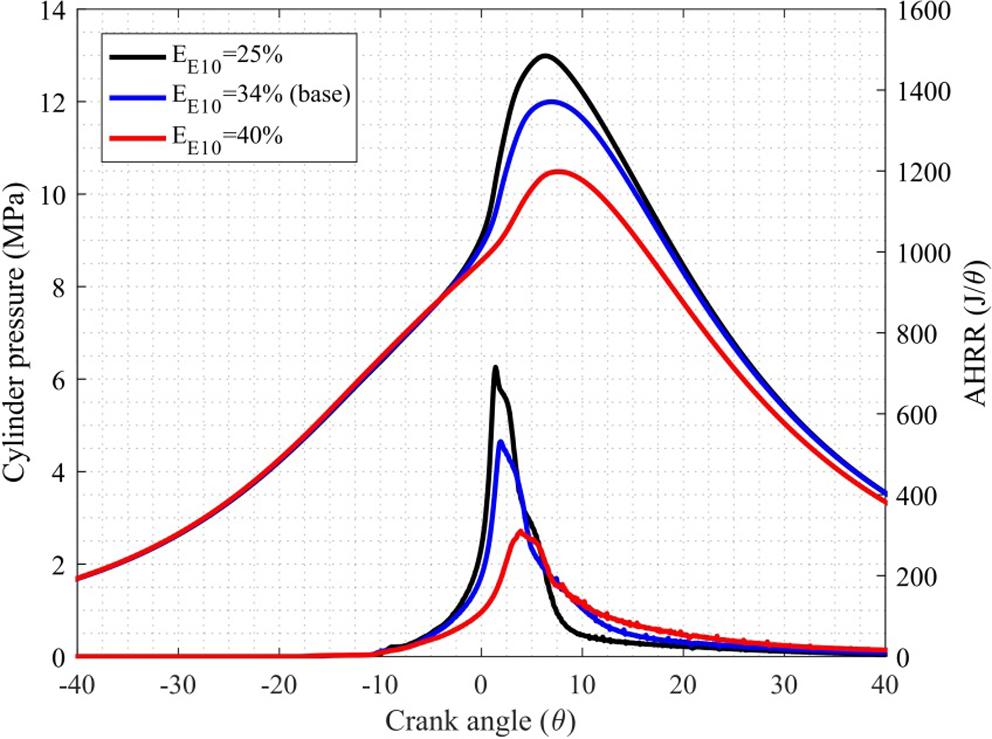

Inthissection,theenergyfractionandSOI3ofE10forthenear-TDC injectionwereswept.Energyfractionsweepswere20to40%ofthe totalcylinderenergybysubtractingfromthefirstE10injection. Fig.15 showscylinderpressureandAHRRtracesforenergyfactionsweepsat fixedSOI3=-4.5°ATDC.AHRRwasextendedbyincreasingthenearTDCenergyfraction.ThepeakofAHRRandcylinderpressuredrops, anditresultedinretardedcombustionphasing.Theoppositetrendis evidentbyreducingtheenergyfraction.

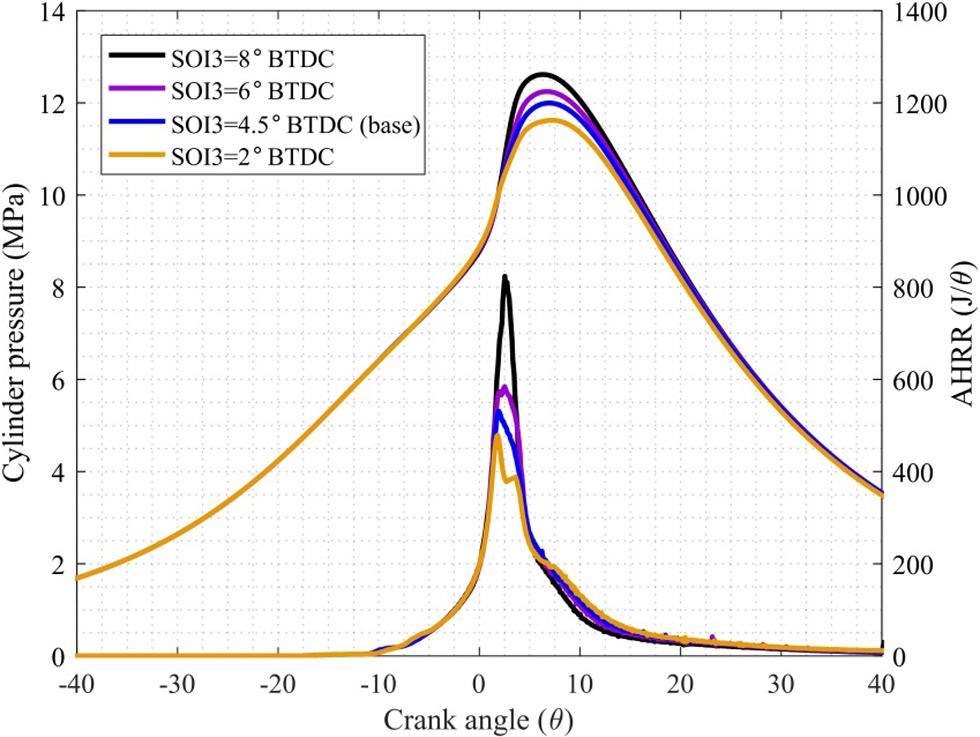

Fig.16 illustratesthesweepsofSOI3forafixedenergyfractionof 34%.SOI3wassweptfrom−8°ATDCto−2°ATDC.AsSOI3advanced, thepeakofcylinderpressureandAHRRincreased,thiswascombined withadvancedCA50.

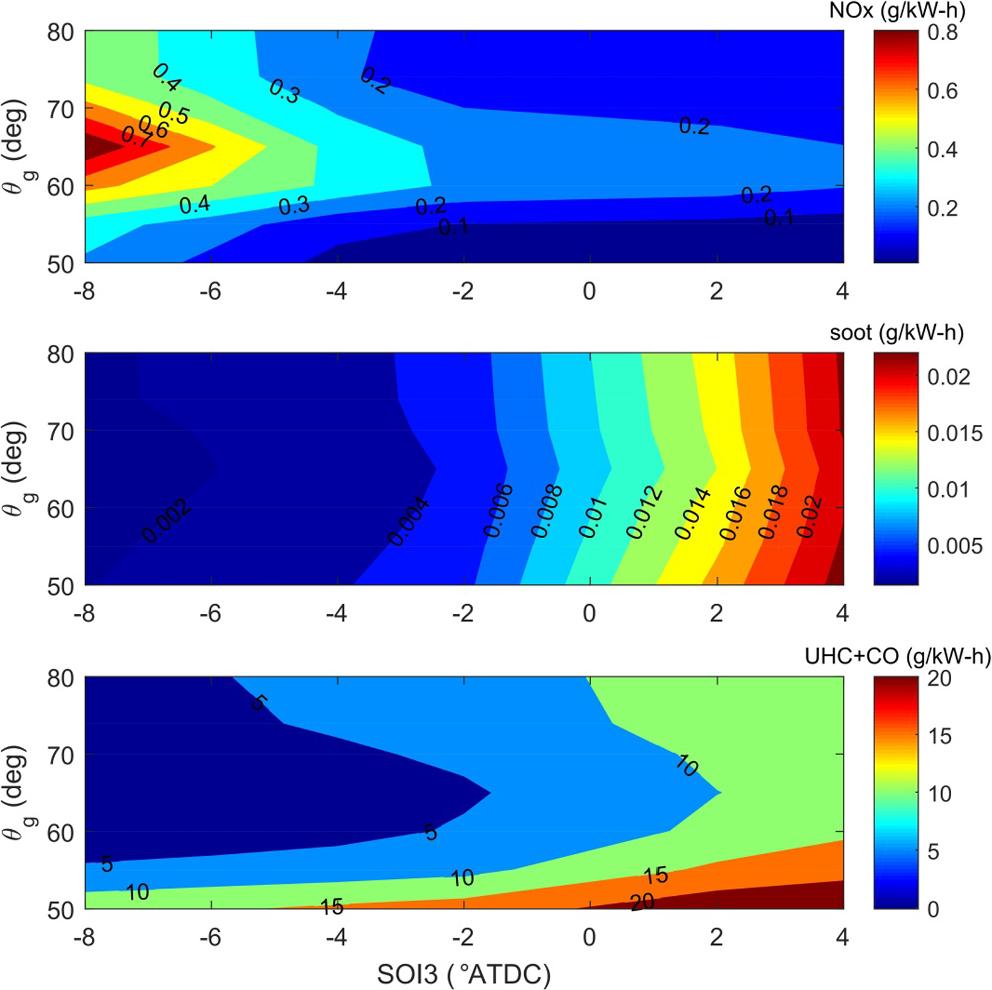

TheeffectsofE10energyfractionandSOI3sweepsonemissions andperformancearedepictedin Figs.17and18.Aspreviouslymentioned,advancingSOI3resultedinhighercylinderpressureandAHRR. Thus,thermalNOX increased,shownin Fig.17.Ontheotherhand,soot, UHC,andCOdecreasedbyadvancingSOI3owingtohighercylinder pressureandtemperatureandbetteroxidization.ByretardingSOI3, soot,UHCandCOincreasedowingtoincompletecombustion.Fromthe emissions’perspectiveandEURO6emissionmandate(NOX =0.4g/ kW-handsoot=0.01g/kW-h),suitableSOI3andE10energyfraction are−4to−2°ATDCand20to30%energyfraction,respectively,to meetthisstandardwithoutaftertreatmentintheE10/DDDFScombustion.

Fig.18 showstheeffectsofenergyfractionandSOI3ofthenearTDCinjection’ssweepsonoperatingemissionsandperformance.As previouslymentioned,advancedSOI3yieldedhighercylinderpressure, andhigherGTE,owingtohigheroutputwork.GTEincreasedbyadvancingSOI3,butattheexpenseofhigherenginenoiseandPPRR.

Fig.8. Temperaturecut-planesforG/D,E10/D,andE85/DatsimilarCA50(3.9°ATDC)usingDDFSstrategy.

Table6

G/D DDFS

E10/D DDFS

E85/D DDFS

Fig.9. Iso-thermalsurfaces(2000and2200K)forG/D,E10/D,andE85/Dat8°ATDCusingDDFSstrategy.

Qualitativecomparisonofemissions,grossthermalefficiency,ISFC,PPRR,and theheatrecoveryforE85/DandE10/DunderDDFSstrategy.

Case NOX SootUHC+COGTEISFCPPRRHeatrecovery

E10/DDDFS

E85/DDDFS–

Fig.10. VisualizationofenergyfractionandstartofinjectionforE10/DDDFS (basecase),andsweepsrange.

Fig.11. ComparisonofcylinderpressureandAHRRforE10/DDDFSwitha sweepofdieselenergyfractionatfixedSOI2=−60°ATDC.

RetardedSOI3andhighEE10 resultedinhighfuelconsumption.From theemission,GTEandfuelconsumptionperspectives,thesuitabledomainforchoosingSOI3andEE10,is−4to−2°ATDC,and20to30% E10energyfractionfortheE10/DDDFScombustion.

3.4.EffectsofdieselandE10sprayangles

Fig.12. ComparisonofcylinderpressureandAHRRforE10/DDDFSwitha sweepofSOI2atfixedED =7%.

Fig.13. EmissioncontoursforE10/DDDFSwithsweepsofdieselinjection (SOI2)anddieselenergyfraction(Ed)withfixedSOI3=−4.5°ATDCand EE10 =34%.

Asitisshownin Fig.1,thecombustionchamberhastwodirect injectorswithtwosprayanglesthatcanaffectemissionformation.In thissection,theeffectsofthedieselsprayangle(θd)andE10spray angle(θg)onemissionsandperformanceareinvestigated.Inthefirst step,θd wassweptbetween50and80°withfixeddieselenergyfraction andvariableSOI2.OtherfixedassumptionsareSOI3=-4.5°ATDCand EE10 =34%forthenear-TDCinjection.

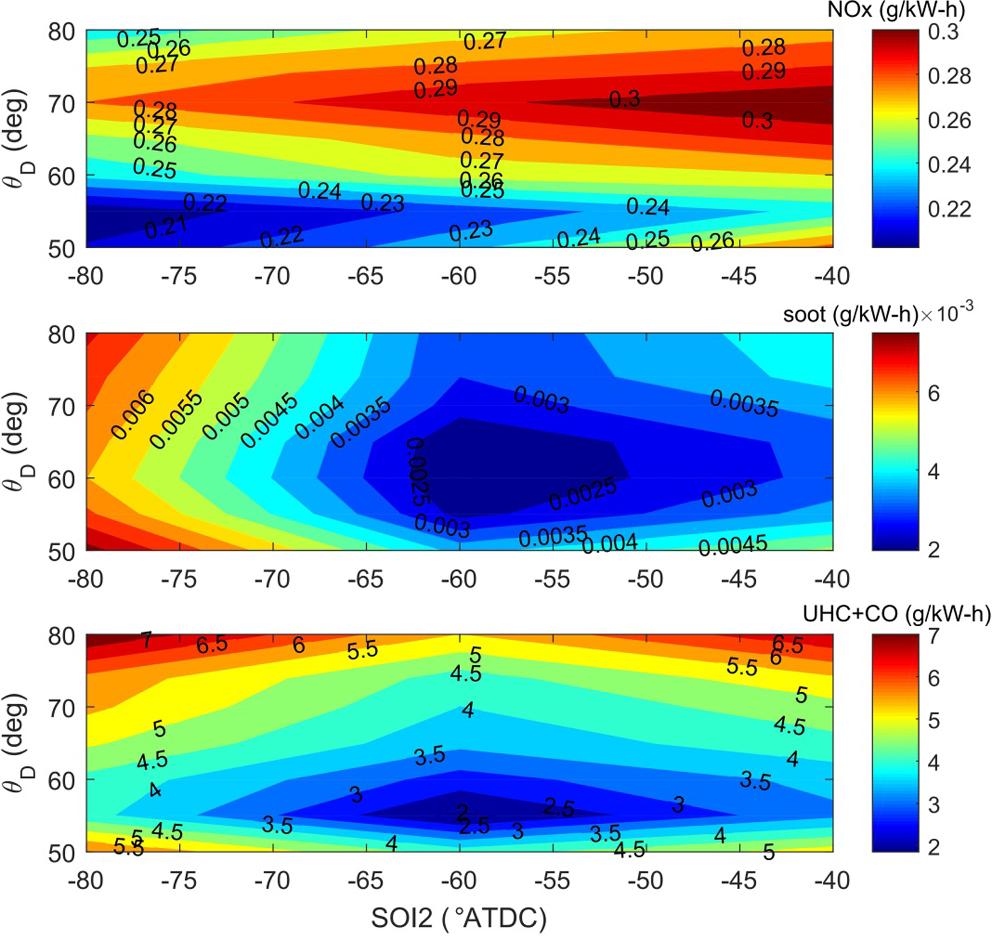

Fig.19 showsemissioncontoursforthesweepsofθd andSOI2.As previouslymentioned,thereactivity-controlledregimeoccurredbetweenSOI2=-80to−40°ATDC.Thus,inthissection,thesweepsof

Fig.14. PerformancecontoursforE10/DDDFSwithsweepsofdieselinjection (SOI2)anddieselenergyfraction(Ed)withfixedSOI3=-4.5°ATDCand EE10 =34%.

Fig.15. ComparisonofcylinderpressureandAHRRforE10/DDDFSwitha sweepenergyfractionoftheinjectionnearTDC(SOI3=−4.5°ATDC).

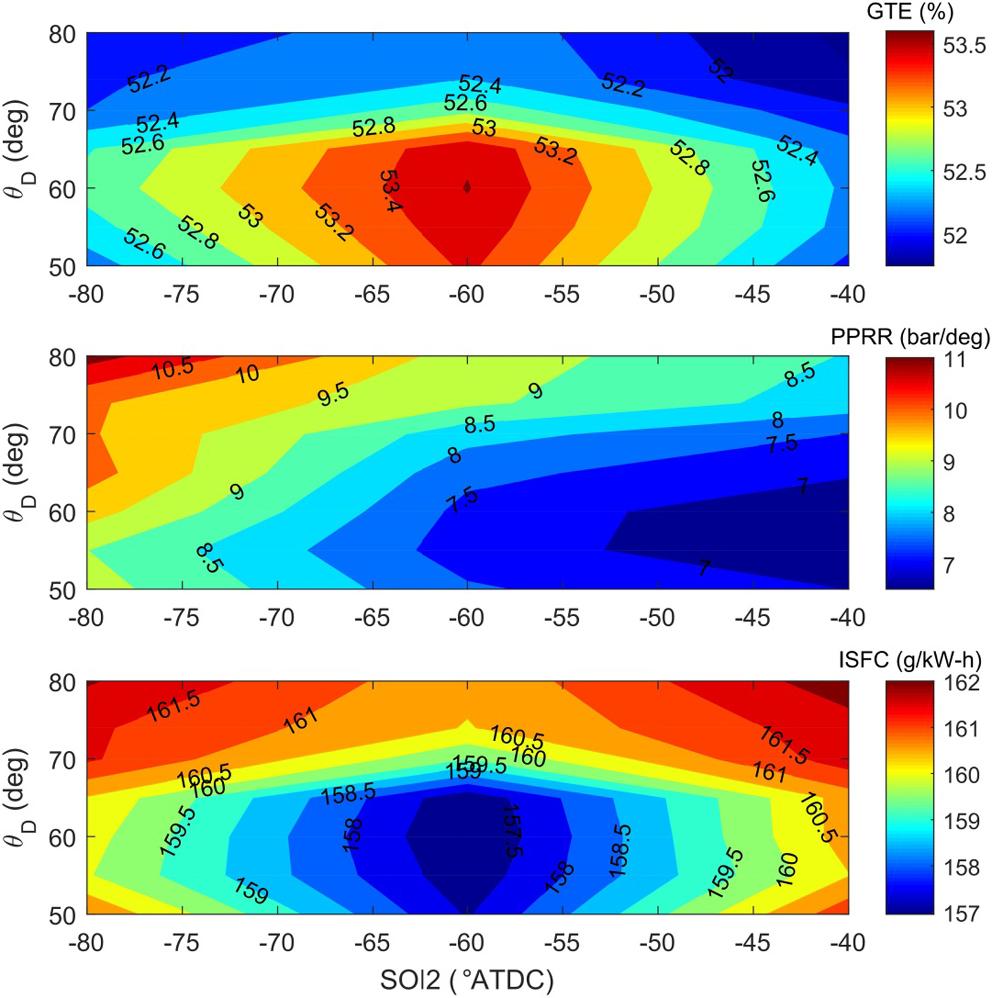

SOI2wasconsideredfor−80to−40°ATDC.Thehighestamountof NOX occurredforθd =70°,whileθd =55°hadthebestresultsforNOX θd =55°andSOI2between−65to−55°ATDCshowedthebestresults forUHC,COandsootemissions.Fromtheemission’sstandpoint,theθd between55and60°andSOI2between−65to−55°ATDC,aresuitable intervalstoachiveloweremissionsintheE10/DDDFScombustion.

Fig.20 showstheperformancecontoursforthesweepsofθd and SOI2.GTEhadthebestresultsfortheregionswhereUHCandCOhad thelowestamounts,indicatingthatUHCandCOoxidizationresultedin higheroutputworkandhigherGTE.Inaddition,fuelconsumptionhad thelowestmagnitudeinthisregion.Aspreviouslymentioned,the suitableintervalforchoosingθd andSOI2arebetween55and60°and −65to−55°ATDC.Thisregionsatisfiesbothemissionsandengine performance.PPRRhasacceptablelevelsforthisregion(lessthan 10bar/deg)andsatisfiestheenginenoise.

Inthesecondstep,theeffectsofthesprayangleofthenear-TDC injectionofE10(θg)onemissionsandperformanceareinvestigated.

Fig.16. ComparisonofcylinderpressureandAHRRforE10/DDDFSwitha sweepofthenear-TDCinjection(SOI3),atfixedenergyfractionof34%.

Fig.17. EmissioncontoursforE10/DDDFSwithsweepsofnear-TDCinjection (SOI3)andE10energyfraction(EE10)withfixedSOI2=−60°ATDCand Ed =7%.

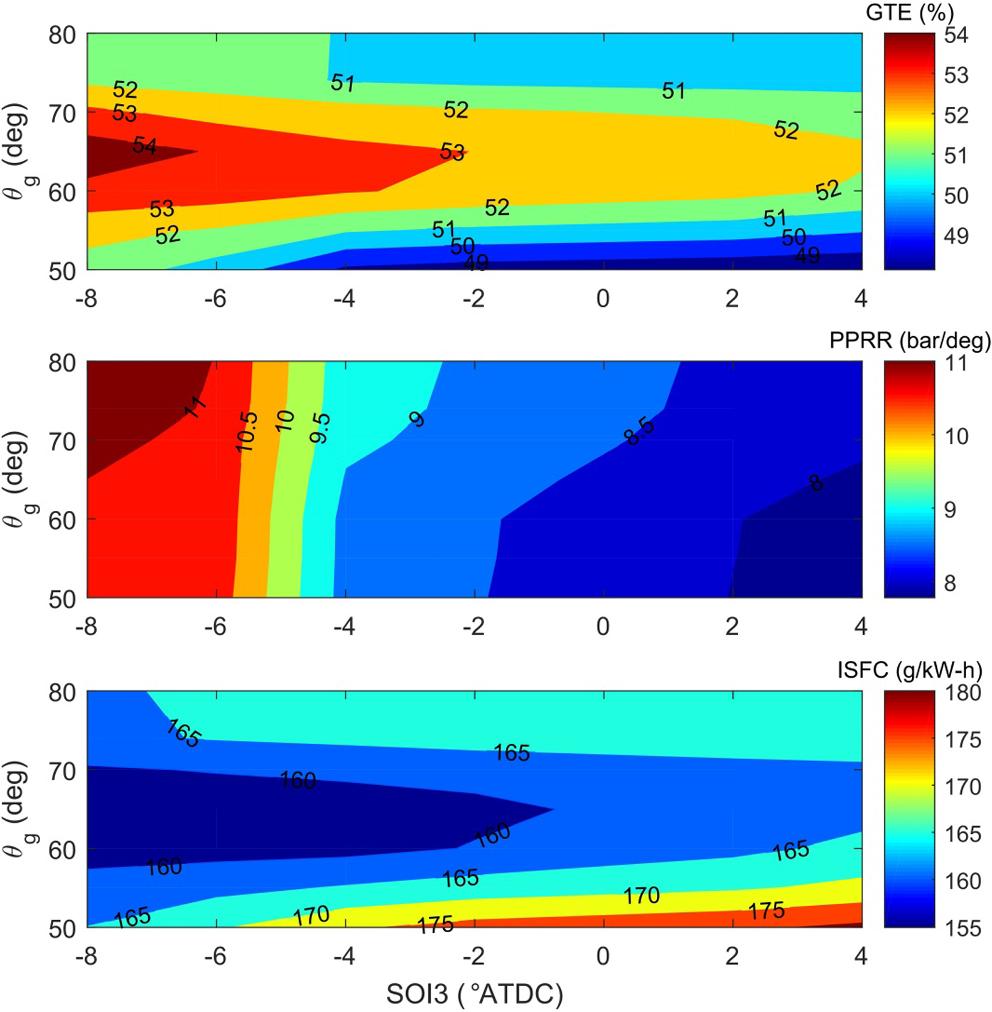

Figs.21and22 illustratetheemissionandperformancecontourswith sweepsofθg andSOI3fortheE10/DDDFScombustionwithfixed Ed =7%,SOI2=-60°ATDC,andEE10 =34%.ByadvancingSOI3to −8°ATDC,NOX significantlyincreased,andwhenθg isbetween60and 70°,NOX hadthehighestamountbyabouttwotimesthantheEURO6 emissionmandate.Fromallemissions’perspectives,SOI3between−4 to−2°ATDCandθg between60and70°havethebestresultsfor emissions.Inaddition,thisregionhasthebestresultforGTEandISFC shownin Fig.22.PPRRforthisregionislessthan10bar/deg,which meansacceptableenginenoiselevel.

Inbrief,dieselandE10sprayanglesaffectemissionformationsand engineperformance.Thestudyshowedthatformediumsprayangles forbothsprayanglesismorepreferableregardingemissionandperformancecriteria.Inshort,fordieselsprayangle(θd)between55and 60°anddieselstartofinjection(SOI2)between−65to−55°ATDC indicatedthebestresultsofemissionsandperformance.ForthenearTDCinjection,E10sprayanglebetween60and70°andnear-TDC

Fig.18. PerformancecontoursforE10/DDDFSwithsweepsofnear-TDCinjection(SOI3)andE10energyfraction(EE10)withfixedSOI2=−60°ATDC andEd =7%.

Fig.19. EmissioncontoursforE10/DDDFSwithsweepsofdieselsprayangle (θd)andSOI2withfixedEd =7%,SOI3=−4°ATDC,andEE10 =34%.

injectiontimingbetween−4to−2°ATDCshowedthebestresultsof emissionsandperformance.

3.5.EffectsofinjectionpressureofSOI3

Fig.20. PerformancecontoursforE10/DDDFSwithsweepsofdieselspray angle(θd)andSOI2withfixedEd =7%,SOI3=−4°ATDC,andEE10 =34%.

Fig.21. EmissioncontoursforE10/DDDFSwithsweepsofE10sprayangleof thenear-TDCinjection(θg)andSOI3withfixedEd =7%,SOI2=−60°ATDC, andEE10 =34%.

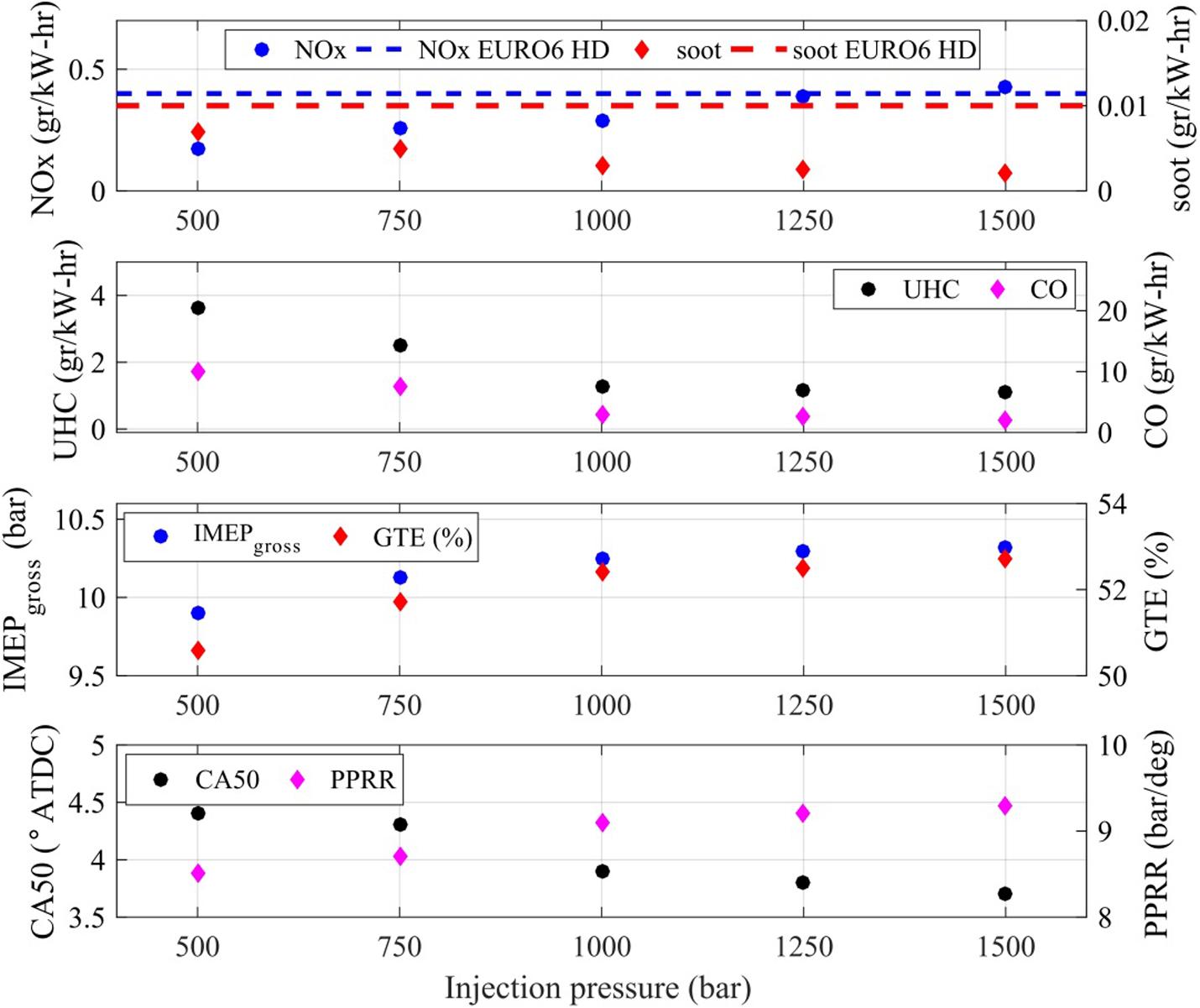

Fig.24 showsemissionsandperformanceforthirdinjectionpressuresweeps.Astheinjectionpressureincreased,NOX increaseddramaticallybyabout50%inthe1500barcasecomparedtothe1000bar (basecase).Ontheotherhand,nosignificantsootreductionwasobserved.NOX doesnotmeetEURO6HDforinjectionpressuresabove 1250bar.

Astheinjectionpressureincreased,UHCandCOdecreaseddramatically,owingtothebetterfuelatomizationandoxidization. Accordingtothisfigure,grossIMEPincreasedbyboostinginjection

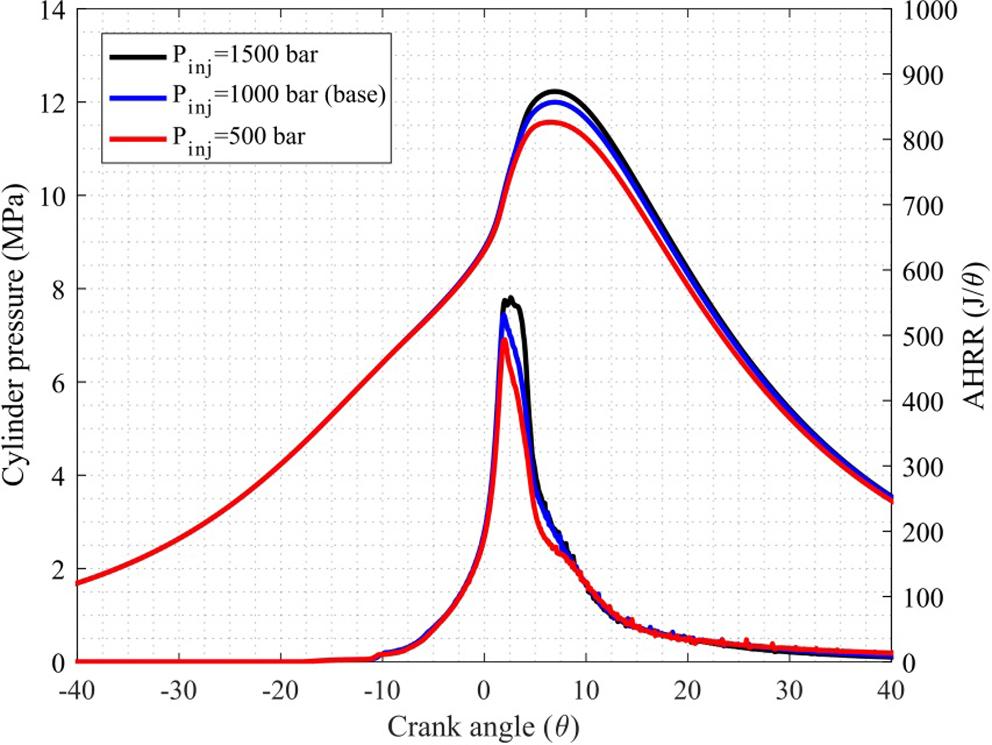

OneofthedrawbacksofDDFSstrategyissootproductionowingto thediffusion-limitednatureofthenear-TDCinjection.Inthissection, theeffectsoftheinjectionpressureofthethirdinjection(E10injection nearTDC)areinvestigated.Theinjectionpressurewasvariedfrom 500barto1500bar.Theincreaseininjectionpressureatomizesfuel properlyandleadstoafasterrateofheatreleaseandfacilitatessoot oxidization. Fig.23 illustratescylinderpressureandAHRRtracesfor 500,1000,and1500barinjectionpressure.ThepeakofAHRRand cylinderpressureincreasedastheinjectionpressureincreased.

Fig.22. PerformancecontoursforE10/DDDFSwithsweepsofE10sprayangle ofthenear-TDCinjection(θg)andSOI3withfixedEd =7%,SOI2=−60° ATDC,andEE10 =34%.

Fig.23. ComparisonofcylinderpressureandAHRRwithasweepofinjection pressureforthenear-TDCinjection.

pressure,butanegligiblechangeinGTE(about0.3%)wasobserved. HigherinjectionpressureadvancedCA50andledtohigherPPRRby about2%inthe1500barcasecomparedtothebasecase(1000bar).

Fig.25 depictsthe iso-thermalsurfacesfor500,1000,and1500bar injectionpressures.Higherinjectionpressureresultedinbetterflame penetrationandmorenumbersofhigh-temperaturezones.Thisfigure alsoshowsthedifferencesintheflameshapesasaresultofincreasing injectionpressure.

4.Conclusions

TheDirectDualFuelStratification(DDFS)strategyisanew pathwaythatbenefitsbothRCCIandPPCcombustionsimultaneously. DDFShasimprovedcontrolandmoreauthorityovertherateofheat release,comparablethermalefficiencytoRCCI,lesscyclicvariation, betterpotentialfordownstreamrecoverywhencomparedtoRCCIand etc.OneoftheprimarydrawbacksofDDFSishighsootproduction

owingtothediffusion-limitednatureofthenear-TDCinjection.One practicalapproachtowardsthisdrawbackistheuseofalcoholfuels (E10orE85)asalternativestogasoline.Inthispaper,a3D-CFDmodel wasdevelopedandvalidatedagainstexperimentaldatainordertosimulatethecombustionprocessofaheavy-dutyengineusingDDFS strategyat9.41bargrossIMEPand1300rpm.Themainresultsareas follows:

• Atthefirststep,E10andE85,astwoconventionalcandidatesas alternativestogasoline,werestudied.IntheE85/DDDFScase,NOX increaseddramaticallybyafactorof25times.PPRRalsoincreased dramaticallybyabout2.7timescomparedtotheG/DDDFScase. Owingtothesemaindrawbacks,E85wasnotagoodcandidateasan alternativetogasolineinDDFScombustion.Ontheotherhand,in theE10/DDDFScase,soot(theprimarydrawbackofDDFS)decreasedbyabout40%,whileNOX increasedonlylessthan2%.In general,E10wasasuitablealternativetogasolinefortheDDFS strategybecauseitnotonlyimprovedsoot,UHC,CO,andGTE,but alsoanegligiblechangeinfuelconsumption,NOX,andPPRRwas observed.

• Inordertoinvestigatetheroleofdieselenergyfractionanditsstart ofinjectiononfuelstratification,dieselenergyfractionwasswept from0%to11%,andalsoSOI2wassweptfrom−100°ATDCto −30°ATDC.Itwasfoundthat11%dieselenergyfractionandabove thismagnitudewasnotsuitableatthisengineloadbecausenotonly thepeakoflowtemperatureheatreleasewasratherhighwhichwas asignofdiffusion-limitedregime,butalsothepeakofAHRRoccurredbeforeTDC,whichresultedinnegativework.The0%diesel energyfractionwasnotsuitableaswellbecausethestrategyisno longerDDFSandchangesintoPPC.

• BysweepingSOI2anddieselenergyfraction(Ed),threeregimes werediscovered:PPC-like(partiallypremixed),reactivity-controlled,anddiffusion-limitedregimes.ThePPC-likeregimewasnot suitableowingtohighUHC,CO,andsootemissions.Thediffusionlimitedregimewasnotacceptableaswellduetothehighlevelsof NOX.Thereactivity-controlledregime(SOI2sbetween−80to−40° ATDC)wasthebestregimeregardingthebestresultsofemissions, thermalefficiency,andfuelconsumption.Inthisregion,ifEd was between4and6%,theE10/DDDFScombustioncanmeetthe EURO6emissionmandatewithoutaftertreatments.

• TheeffectsofSOIandenergyfractionsofthenear-TDCinjectionof theE10/DDDFScombustionwereinvestigated.SOI3wasswept from−8to4°ATDC,andEE10 wassweptfrom20to40%ofthetotal cylinderenergy.Itwasfoundthatthebestregionfromemission, performance,andfuelconsumptionperspectiveswasSOI3between −4to−2°ATDCandEE10 between20and30%.Inthisregion,the combustioncanmeetEURO6withoutaftertreatments.

• Asthesprayangleshavesignificanteffectsonemissionformation, thesprayanglesofbothinjectorsweresweptfrom50to80°.Itwas foundthatamediumsprayangleaboutθd =55°forthedieselinjectorhadthebestresultsforemissions.Thismagnitudealsoyielded thebestresultsforgrossthermalefficiencyandfuelconsumption. FortheE10injector(near-TDCinjection),θg between60and70° showedthebestresultsregardingemissionandperformance.

• Anotherpromisingwaytodecreasesootisanincreaseinnear-TDC injectionpressure.ThepeakofAHRRandcylinderpressureincreasedbyboostingtheinjectionpressure.Inaddition,CA50and thepeakofAHRRadvanced.Anincreaseintheinjectionpressure resultedinhighNOX fortheE10/DDDFScase(withED =7%). Above1250barinjectionpressures,NOX doesnotmeettheEURO6 standard.However,sootandCOemissionsdecreasedslightlyforthe injectionpressuresabove1000bar.Fromtheemissionsperspective, from750barto1250,barinjectionpressurehasacceptableresults. GrossthermalefficiencyandgrossIMEPreducedsignificantly,for lowinjectionpressures(near500bar).

Fig.24. EmissionsandperformanceofE10/DDDFSwithasweepofinjectionpressureforthenear-TDCinjection.

Fig.25. Iso-thermalsurfaces(2000and2200K)forE10/DDDFSwithasweepofinjectionpressureforthenear-TDCinjection.

Forfutureworks,itisproposedthatE10/DDDFScanbeoptimized forthisloadandotherloads.Inaddition,theeffectsofotheralcohol fuelscanbeinvestigatedaswell.DDFSisanovelstrategywithlotsof supremaciesoverRCCI,andduetoitsnear-TDCinjection,newpiston profilelikethoseconventionalonescanbeproposedforDDFSandinvestigated.

DDFShasarobustcontrolovertherateofheatreleasethanother LTCstrategies,andalsoitislesssensitivetoboundaryconditions;thus, itisasuitablestrategytobeusedinautomotiveindustries,especially forhybridcars,whichdemandhighthermalefficiencyandlowfuel consumption.

CRediTauthorshipcontributionstatement

SaeidShirvani: Conceptualization,Methodology,Software,

Appendix

Investigation,Validation,Visualization,Writing-originaldraft. Sasan Shirvani: Conceptualization,Methodology,Software,Investigation, Validation,Visualization,Writing-originaldraft. AmirH.Shamekhi: Supervision,Resources. RolfD.Reitz: Writing-review&editing.

DeclarationofCompetingInterest

Theauthorsdeclarethattheyhavenoknowncompetingfinancial interestsorpersonalrelationshipsthatcouldhaveappearedtoinfluencetheworkreportedinthispaper.

Inordertoshowthatthedeveloped3D-CFDmodelisreliablewith1.4mmmeshsize,theCFDmodelwasusedforotherdifferentloadsusing gasoline/diesel6.5and9.25bar(50%EGR)undertheRCCIstrategy,shownin Fig.A.1

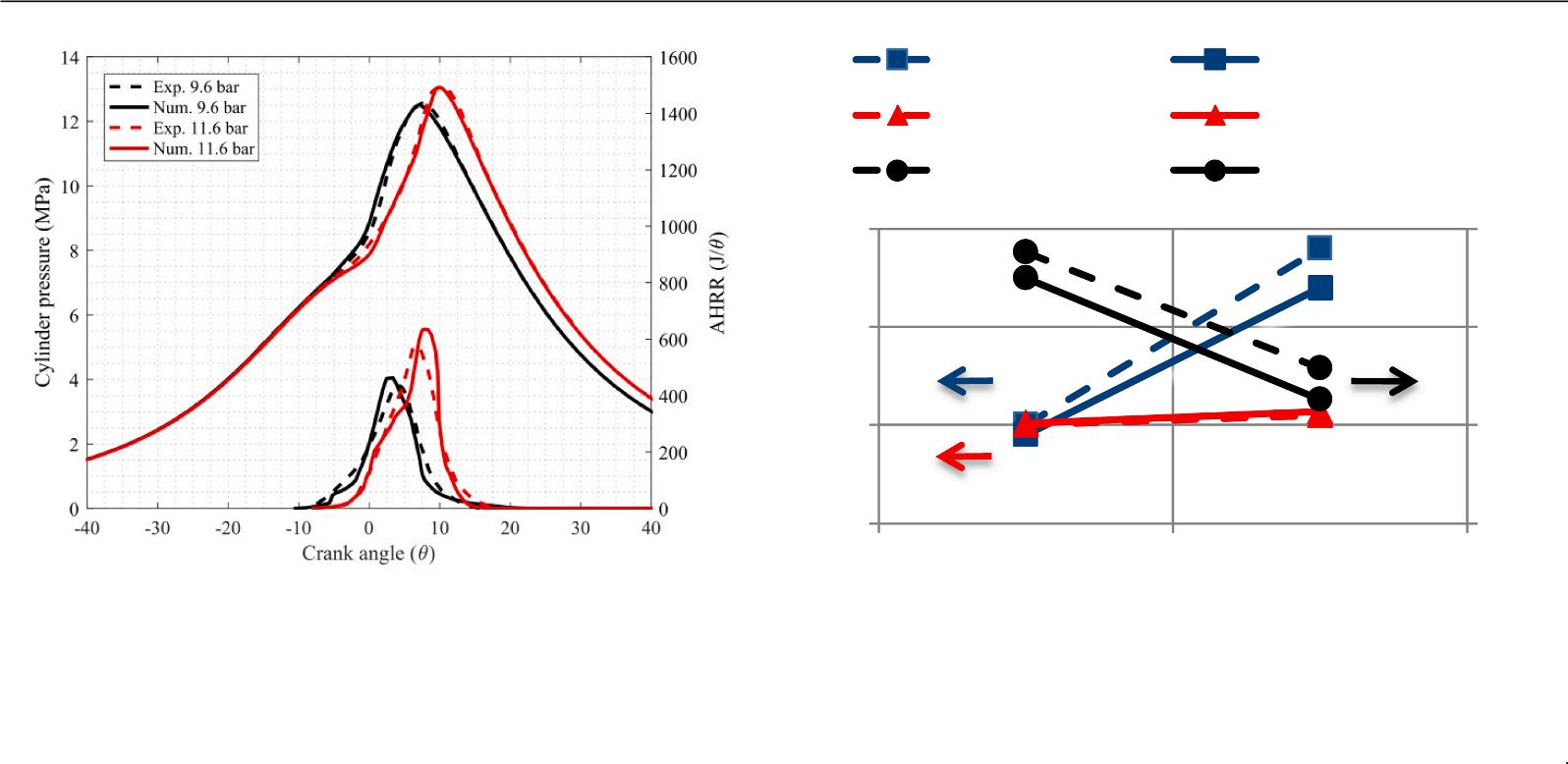

As Fig.A.2 shows,E85/dieselnumericalmodelwasusedfordifferentloads,including9.6and11.6.Accordingtheresultsinthisfigure,themodel isreliableforE85/Dcombustion.

500 bar

1000 bar (base case)

1500 bar

Exp. NOx Num. NOx

Exp. soot Num. soot

Exp. UHC+CONum. UHC+CO

G/D RCCI 6.5 bar and 9.25 bar gross IMEP (50% EGR) at 1 300 rpm (Exp. data was taken from [29, 68]).

Comparison of emissions in gr/kW-hr for experimental data and numerical results (Exp. data was taken from and [29, 68])

Fig.A1. Comparisonofcylinderpressure,AHRR,andemissionsbetweenthenumericalresultsandexperimentaldataforgasoline/dieselRCCIcombustion.

E85/D RCCI 9 6 bar and 11.6 bar, 1300 rpm and no EGR (Exp. data was taken from [4]).

Exp. NOx Num. NOx

Exp. soot×10Num. soot ×10

Exp. UHC+CONum. UHC+CO

Comparison of emissions in gr/kW-hr for experimental data and numerical results (Exp. data was taken from [4]).

Fig.A2. Comparisonofcylinderpressure,AHRR,andemissionsbetweenthenumericalresultsandexperimentaldataforE85/dieselRCCIcombustion.

Alloperatingparameterstocalculateengineperformanceareasfollows.Grossindicatedworkandgrossindicatedpowerpercyclearecalculated basedonEqs. (A.1)and(A.2),respectively.

= Work pdV gross 180 180

= × P Workn VN gross grossR d (A.2)

where;pispressureandVisvolume,Pispower, Vd isdisplacementvolumeand nR forthefour-strokeengineequals2,andNisenginespeed.Gross indicatedmeaneffectivePressure( IMEPgross )isobtainedfromEq. (A.3)[63]:

= IMEP Pn VN gross grossR d

FuelenergyisobtainedfromEq. (A.4),andgrossthermalefficiency(GTE)isasfollows:

=×+×+ EmLHVmLHVmLHV

== GTE Work E gross gross fuel

where; Efuel isthefuelenergy, m isthemassforeachspecies,andLHVisthelowerheatingvalue.Theadiabaticapparentheatreleaserateis calculatedbasedonEq. (A.6)[30]:

(A.1)

where; isthecrankangledegree,γistheratioofspecificheats.PPRRisanoisemetric,anditcanbedefinedasfollows:

= PPRR dp d max (A.7)

Inthispaper,ethanolisconsideredfullyevaporatedandhomogenousatIVC.Ethanolhasaconsiderableenthalpyofvaporizationanditcoolsthe combustionchamber.TheCFDsimulationisperformedbasedonclosed-cycleanditisassumedthatethanolisfullyevaporatedatIVC.Thefirst injectioninthismodelstartsat340°BTDCandoccursbeforethestartofsimulation143°BTDC(IVC).Sinceinjectionpressureishigh(about 1000bar),ethanolhasenoughtimetobecomefullyvaporized,andthecombustionchamberishotenoughintherealenginetomakeethanolfully vaporized.Moreover,theinjectorisawidesprayanglewithtennozzles,whichfacilitatesthevaporizationprocess.Thus,theamountoffuelatfirst injectionisconsideredfullyhomogenousforthestartofthesimulation.ThecoolingeffectsofethanolcanbecalculatedbasedonEqs. (A.8)and (A.9),and TableA.1 givesthephysicalpropertiesofethanoland iso-octane. TableA2 showsthecoolingeffectsofethanol(E10andE85)onthe combustionchamber.

=×× +×+×× +× QmcTTmhmcTTmh ( ) ( ) EthpEthboilinginitialEthfgEthGaspGasboilinginitialGasfgGas 1

==×× QQmcT airpair 12 ,

where, m ismassforeachspecies, cp isthespecificheatcapacity.

TableA1

Physicalpropertiesof iso-octaneandethanol(datatakenfrom [67]).

TableA2 Temperatevariationoftheethanolvaporizationeffect.

References

[1] FlynnPF,DurrettRP,HunterGL,zurLoyeAO,AkinyemiOC,DecJE,etal.Diesel combustion:anintegratedviewcombininglaserdiagnostics,chemicalkinetics,and empiricalvalidation.SAETechnicalPaper1999

[2] KokjohnSL,HansonRM,SplitterDA,ReitzRD.ExperimentsandmodelingofdualfuelHCCIandPCCIcombustionusingin-cylinderfuelblending.SAEIntJEngines 2010;2(2):24–39

[3] HansonRM,KokjohnSL,SplitterDA,ReitzRD.Anexperimentalinvestigationof fuelreactivitycontrolledPCCIcombustioninaheavy-dutyengine.SAEIntJ Engines2010;3(1):700–16

[4] SplitterD,HansonR,KokjohnS,ReitzRD.Reactivitycontrolledcompressionignition(RCCI)heavy-dutyengineoperationatmid-andhigh-loadswithconventional andalternativefuels.SAETechnicalPaper2011

[5] OnishiS,JoSH,ShodaK,JoPD,KatoS.Activethermo-atmospherecombustion (ATAC)—anewcombustionprocessforinternalcombustionengines.SAETrans 1979:1851–60

[6] NajtPM,FosterDE.Compression-ignitedhomogeneouschargecombustion.SAE Trans1983:964–79

[7] DecJE,YangY,DronniouN.BoostedHCCI-controllingpressure-riseratesforperformanceimprovementsusingpartialfuelstratificationwithconventionalgasoline. SAEIntJEngines2011;4(1):1169–89

[8] YunH,WermuthN,NajtP.HighloadHCCIoperationusingdifferentvalving strategiesinanaturally-aspiratedgasolineHCCIengine.SAEIntJEngines 2011;4(1):1190–201

[9] MarriottCD,ReitzRD.Experimentalinvestigationofdirectinjection-gasolinefor premixedcompressionignitedcombustionphasingcontrol.SAETechnicalPaper 2002

[10] MarriottCD,KongS-C,ReitzRD.Investigationofhydrocarbonemissionsfroma directinjection-gasolinepremixedchargecompressionignitedengine.SAE TechnicalPaper2002.

[11] AoyamaT,HattoriY.MizutaJi.SAETechnicalpaper:SatoY.Anexperimental studyonpremixed-chargecompressionignitiongasolineengine;1996

[13] LiuH,YaoM,ZhangB,ZhengZ.Effectsofinletpressureandoctanenumberson combustionandemissionsofahomogeneouschargecompressionignition(HCCI) engine.EnergyFuels2008;22(4):2207–15

[14] BenajesJ,GarcíaA,DomenechV,DurrettR.Aninvestigationofpartiallypremixed compressionignitioncombustionusinggasolineandsparkassistance.ApplTherm Eng2013;52(2):468–77

[15] BenajesJ,TormosB,GarciaA,Monsalve-SerranoJ.Impactofsparkassistanceand multipleinjectionsongasolinePPClightload.SAEIntJEngines 2014;7(4):1875–87

[16] BenajesJ,MolinaS,GarcíaA,Monsalve-SerranoJ,DurrettR.Performanceand engine-outemissionsevaluationofthedoubleinjectionstrategyappliedtothe gasolinepartiallypremixedcompressionignitionsparkassistedcombustionconcept.ApplEnergy2014;134:90–101

[17] BenajesJ,MolinaS,GarcíaA,Monsalve-SerranoJ,DurrettR.Conceptualmodel descriptionofthedoubleinjectionstrategyappliedtothegasolinepartiallypremixedcompressionignitioncombustionconceptwithsparkassistance.ApplEnergy 2014;129:1–9

[18] YaoM,ZhengZ,ZhangB,ChenZ.TheeffectofPRFfueloctanenumberonHCCI operation.SAETechnicalPaper2004

[19] InagakiK,FuyutoT,NishikawaK,NakakitaK,SakataI.Dual-fuelPCIcombustion controlledbyin-cylinderstratificationofignitability.SAETechnicalPaper2006

[20] LiY,JiaM,ChangY,FanW,XieM,WangT.Evaluationofthenecessityofexhaust gasrecirculationemploymentforamethanol/dieselreactivitycontrolledcompressionignitionengineoperatedatmediumloads.EnergyConversManage 2015;101:40–51

[21] LeermakersC,VandenBergeB,LuijtenC,SomersL,deGoeyL,AlbrechtB. Gasoline-dieseldualfuel:effectofinjectiontimingandfuelbalance.SAETechnical paper2011

[22] LiJ,YangW,AnH,ZhouD,YuW,WangJ,etal.Numericalinvestigationonthe effectofreactivitygradientinanRCCIenginefueledwithgasolineanddiesel. EnergyConversManage2015;92:342–52

[23] ZhouD,YangW,AnH,LiJ,ShuC.AnumericalstudyonRCCIenginefueledby biodiesel/methanol.EnergyConversManage2015;89:798–807

[12] KalghatgiGT,RisbergP, ÅngströmH-E.Advantagesoffuelswithhighresistanceto auto-ignitioninlate-injection,low-temperature,compressionignitioncombustion. SAETechnicalPaper2006

[24] KokjohnSL,HansonRM,SplitterD,ReitzR.Fuelreactivitycontrolledcompression ignition(RCCI):apathwaytocontrolledhigh-efficiencycleancombustion.IntJ EngineRes2011;12(3):209–26

[25] SplitterD,WissinkM,DelVescovoD,ReitzRD.RCCIengineoperationtowards60% thermalefficiency.SAETechnicalPaper2013

[26] ShimE,ParkH,BaeC.Comparisonsofadvancedcombustiontechnologies(HCCI, PCCI,anddual-fuelPCCI)onengineperformanceandemissioncharacteristicsina heavy-dutydieselengine.Fuel2020;262:116436

[27] LimJH,ReitzR.Improvinghighefficiencyreactivitycontrolledcompressionignitioncombustionwithdieselandgasolinedirectinjection.ProcInstMechEng,Part D:JAutomobileEng2013;227(1):17–30

[28] LimJH,ReitzRD.Highload(21barIMEP)dualfuelRCCIcombustionusingdual directinjection.JEngGasTurbinesPower2014;136(10)

[29] WissinkM,ReitzRD.Directdualfuelstratification,apathtocombinethebenefits ofRCCIandPPC.SAEIntJEngines2015;8(2):878–89

[30] WissinkML.Directinjectionfordualfuelstratification(DDFS):improvingthe controlofheatreleaseinadvancedICenginecombustionstrategies.TheUniversity ofWisconsin-Madison;2015

[31] WissinkM,ReitzR.Theroleofthediffusion-limitedinjectionindirectdualfuel stratification.IntJEngineRes2017;18(4):351–65.

[32] WissinkM,ReitzR.Exploringtheroleofreactivitygradientsindirectdualfuel stratification.SAEIntJEngines2016;9(2):1036–48

[33] LuongMB,SankaranR,YuGH,ChungSH,YooCS.Ontheeffectofinjectiontiming ontheignitionofleanPRF/air/EGRmixturesunderdirectdualfuelstratification conditions.CombustFlame2017;183:309–21

[34] ShirvaniS,ShirvaniS,ShamekhiA,ReitzR.Investigationoftheeffectsofthepiston bowlgeometriesofaheavydutyengineonperformanceandemissionsusingdirect dualfuelstratificationstrategy,andproposingtwonewpistonprofiles.SAE InternationalJEngines2020;13(3)

[35] HaiIU,SherF,ZarrenG,LiuH.Experimentalinvestigationoftararrestingtechniquesandtheirevaluationforproductsyngascleaningfrombubblingfluidizedbed gasifier.JCleanerProd2019;240:118239

[36] HaiIU,SherF,YaqoobA,LiuH.AssessmentofbiomassenergypotentialforSRC willowwoodchipsinapilotscalebubblingfluidizedbedgasifier.Fuel 2019;258:116143

[37] SherF,IqbalSZ,LiuH,ImranM,SnapeCE.Thermalandkineticanalysisofdiverse biomassfuelsunderdifferentreactionenvironment:Awayforwardtorenewable energysources.EnergyConversManage2020;203:112266

[38]PulkrabekWW.Engineeringfundamentalsoftheinternalcombustionengine.1997.

[39] ÇelebiY,AydınH.Anoverviewonthelightalcoholfuelsindieselengines.Fuel 2019;236:890–911

[40] BalkiMK,SayinC,SarıkayaM.Optimizationoftheoperatingparametersbasedon TaguchimethodinanSIengineusedpuregasoline,ethanolandmethanol.Fuel 2016;180:630–7.

[41] DemirbasA.Political,economicandenvironmentalimpactsofbiofuels:Areview. ApplEnergy2009;86:S108–17

[42] RakopoulosC,AntonopoulosK,RakopoulosD.Experimentalheatreleaseanalysis andemissionsofaHSDIdieselenginefueledwithethanol–dieselfuelblends. Energy2007;32(10):1791–808

[43] RakopoulosD,RakopoulosC,KakarasE,GiakoumisE.Effectsofethanol–dieselfuel blendsontheperformanceandexhaustemissionsofheavydutyDIdieselengine. EnergyConversManage2008;49(11):3155–62

[44] IshidaM,YamamotoS,UekiH,SakaguchiD.RemarkableimprovementofNOx–PM trade-offinadieselenginebymeansofbioethanolandEGR.Energy 2010;35(12):4572–81

[45] MoonS,TsujimuraT,OgumaM,ChenZ,HuangZ,SaitouT.Mixturecondition,

combustionandsootingcharacteristicsofethanol–dieselblendsindiffusionflames undervariousinjectionandambientconditions.Fuel2013;113:128–39

[46] Xing-caiL,Jian-GuangY,Wu-GaoZ,ZhenH.Effectofcetanenumberimproveron heatreleaserateandemissionsofhighspeeddieselenginefueledwithethanol–dieselblendfuel.Fuel2004;83(14–15):2013–20

[47] SayinC.Engineperformanceandexhaustgasemissionsofmethanolandethanol–dieselblends.Fuel2010;89(11):3410–5

[48] HulwanDB,JoshiSV.Performance,emissionandcombustioncharacteristicofa multicylinderDIdieselenginerunningondiesel–ethanol–biodieselblendsofhigh ethanolcontent.ApplEnergy2011;88(12):5042–55

[49] EmiroğluAO,ŞenM.Combustion,performanceandemissioncharacteristicsof variousalcoholblendsinasinglecylinderdieselengine.Fuel2018;212:34–40

[50] NingL,DuanQ,ChenZ,KouH,LiuB,YangB,etal.Acomparativestudyonthe combustionandemissionsofanon-roadcommonraildieselenginefueledwith primaryalcoholfuels(methanol,ethanol,andn-butanol)/dieseldualfuel.Fuel 2020;266:117034

[51] JamrozikA,TutakW,PyrcM,GrucaM,KočiškoM.Studyonco-combustionof dieselfuelwithoxygenatedalcoholsinacompressionignitiondual-fuelengine. Fuel2018;221:329–45

[52] LiY,JiaM,XuL,BaiX-S.Multiple-objectiveoptimizationofmethanol/dieseldualfuelengineatlowloads:Acomparisonofreactivitycontrolledcompressionignition (RCCI)anddirectdualfuelstratification(DDFS)strategies.Fuel2020;262:116673

[53] LongW,LiB,CaoJ,MengX,TianJ,CuiJ,etal.Effectsofdual-directinjection parametersonperformanceoffuelJetControlledCompressionIgnitionmodeona high-speedlightdutyengine.Fuel2019;235:658–69

[54] LiuAB,MatherD,ReitzRD.Modelingtheeffectsofdropdragandbreakuponfuel sprays.SAETrans1993:83–95

[55] DukowiczJK.Aparticle-fluidnumericalmodelforliquidsprays.JComputPhys 1980;35(2):229–53

[56] BealeJC,ReitzRD.ModelingsprayatomizationwiththeKelvin-Helmholtz/ Rayleigh-Taylorhybridmodel.AtomSprays1999;9(6):623–50

[57] O'RourkePJ,AmsdenA.Aspray/wallinteractionsubmodelfortheKIVA-3wallfilm model.SAETrans2000:281–98

[58] SchmidtDP,RutlandC.Anewdropletcollisionalgorithm.JComputPhys 2000;164(1):62–80

[59] HanZ,ReitzRD.TurbulencemodelingofinternalcombustionenginesusingRNG

ε models.CombustSciTechnol1995;106(4–6):267–95

[60] RajuM,WangM,DaiM,PiggottW,FlowersD.Accelerationofdetailedchemical kineticsusingmulti-zonemodelingforCFDininternalcombustionenginesimulations.SAETechnicalPaper2012

[61] RaY,ReitzRD.AreducedchemicalkineticmodelforICenginecombustionsimulationswithprimaryreferencefuels.CombustFlame2008;155(4):713–38

[62] HiroyasuH,KadotaT.Modelsforcombustionandformationofnitricoxideandsoot indirectinjectiondieselengines.SAETrans1976:513–26.

[63]HeywoodJB.Internalcombustionenginefundamentals.1988.

[64]BradshawP,HuangGP.Thelawofthewallinturbulentflow.Proceedingsofthe RoyalSocietyofLondonSeriesA:MathematicalandPhysicalSciences 1995;451(1941):165-88.

[65] SenecalP,PomraningE,RichardsK,SomS.Grid-convergentspraymodelsforinternalcombustionengineCFDsimulations.ASME,InternalCombustionEngine DivisionFallTechnicalConference.AmericanSocietyofMechanicalEngineers DigitalCollection;2012.p.697–710

[66] SplitterDA.Experimentalinvestigationoffuelreactivitycontrolledcombustionina heavy-dutyinternalcombustionengine.UniversityofWisconsin-Madison;2010

[67] DempseyAB.Dual-fuelreactivitycontrolledcompressionignition(RCCI)withalternativefuels.TheUniversityofWisconsin-Madison;2013

Other documents randomly have different content

something small and select of the function, and I’ll do all the rest.”

“In some way John and I will manage the money,” said Mr. Ward, slowly, and then catching a meaningful look in John’s eyes, he added with unwonted confidence: “Where there’s a will there’s a way. I want the Campbells’ visit to be a happy occasion. You are entitled to it, Margaret—you and Helen must get all the pleasure possible from meeting a woman of Mrs. Campbell’s large experience of life.”

“Mama will need a new frock,” said Helen, a remark which precipitated at once a lively debate with her mother as to which—if any item of her existing wardrobe would lend itself to the process of reconstruction. This question seemed susceptible of endless discussion, and was only ended by John’s firm declaration that there should be new raiment for both his mother and Helen.

“Father, we’ll show these upstarts from New York what real American women are like!”

“We shall be ruined!” cried Helen tragically, as she disappeared through the swing door with a pile of plates.

“Please, John, don’t do anything foolish,” his mother pleaded, but she smiled happily under the compulsion of his enthusiasm.

“Trust me for that!” he replied, laying his hands on her shoulders. “We’re all too humble; that’s what’s the matter with the Ward family. And for once I want you to step right out!”

He waved her into the sitting room and darted into the kitchen, where he threw off his coat and donned an apron.

III

“Crazy! You’ve gone plumb stark crazy!” said Helen, as she thrust her arms into the dishwater. “It’s cruel to raise mother’s hopes that way. You know well enough that as things are going we’re just about getting by, with the grocery bill two months behind and that eternal interest on the mortgage hanging over us like the well-known sword of Damocles.”

“The sword is in my hands!” declared John, balancing a plate on the tip of his finger. “How does that old tune go?

The Campbells are coming, tra la, tra la, The Campbells are coming, tra la!

There’s a bit of Scotch in us, and I feel my blood tingle to those blithe martial strains! What’s the rule for drying dishes, sis? Do you make ’em shine like a collar from a Chinese laundry, or is the dull domestic finish in better form?”

“If you break that plate I’ll poison your breakfast coffee! If I didn’t know you for a sober boy I’d think you’d been keeping tryst with a bootlegger! You don’t seem to understand that you sat there at the table spending money like Midas on a spree. You couldn’t borrow a cent if you tried!”

“Borrow!” he mocked. “I’m going to pull this thing off according to specifications, and I’m not going to borrow a cent. I expect to be refusing offers of money gently but firmly within a week. Observe my smoke, dearest one! Watch my fleet sail right up to the big dam in Sycamore River laden like the ships of Tarshish that brought gifts of silver and gold and ivory, apes and peacocks for Solomon’s delight!”

“You’re not calling the Campbells apes and peacocks!”

“Not on your life! All those rich treasures will be yours and mine, O Helen of Kernville! The Campbells are rich enough. We’re not going to embarrass them by piling any more wealth on ’em. But the magic of the name of Walter Scott Campbell, if properly invoked, manipulated and flaunted will put us all on the high road to fame and fortune.”

“You’ll break mama’s heart if you begin bragging about her acquaintance with this woman she hasn’t seen for a quarter of a century! She’s already warned you against vulgar boasting.”

“Keep mother busy planning for the care and entertainment of our guests! I’ll hold father steady. This being Thursday I’ve got time enough to plan the campaign before Sunday. I’ll lay down a barrage and throw myself upon the enemy. To the cheering strains of ‘The

Campbells are Coming!’ we’ll cross the valley of death and plant our flag on the battlements without a scratch or the loss of a man.”

By the time the kitchen was in order he had her laughing and quite won to his idea that it was perfectly legitimate to avail themselves fully of the great opportunity offered by the Campbells’ visit.

“Nothing undignified at all! The Campbells will never be conscious of my proceedings as they don’t read the Kernville papers and will linger only a day. By the way, it happens that Billy Townley, a fraternity brother of mine, has just been made city editor of the Journal and Billy and I used to pull some good stunts when we were together at the ’varsity. When I hiss the password in his ear and tell him I’ll need a little space daily for a few weeks he’ll go right down the line for me. And the boys on the Evening Sun are friends of mine, too. They have less space but they make up for it with bigger headlines.”

“You’re a dear boy, John, if you are crazy! I believe you can do most anything you tackle, and I’ll stand by you whether you land us in jail or in the poorhouse.”

“Bully for you, sis!” And then lowering his voice, “This chance may never come again! I’m going to wring every possible drop out of it even as you wring out that dish rag. By-the-way, if it isn’t impertinent, when did you see Ned last?”

“Not since the day you saw me walking with him—for the last time. But he telephoned this afternoon. He wanted to come up this evening.”

“Well, he’s of age and the curfew law can’t touch him. What was the answer?”

“I told him I wouldn’t be at home. I’m not going to have him calling here when his mother barely speaks to me! Ned didn’t say so, but I suspect she gave him a good scolding for taking me instead of Sally to the Seebrings’ dance.”

“How do you get that? If he didn’t tell you——!”

“Of course not! But Sally had to go with her mother and there were more girls than men; so Sally only had about half the dances and the rest of the time sat on the sidelines with her mother and Mrs. Kirby. I caught a look now and then that was quite suggestive of murder in the first degree.”

“Helen,” said John, lifting his eyes dreamily to the ceiling, “I’ll wager a diamond tiara against one of your delicious buckwheat cakes that you and I will get an invitation to the Kirby party.”

“Taken! The cards went out yesterday. I met some of the girls downtown this morning, and they were buzzing about it.”

“Let ’em buzz! Ours will probably come special delivery with a note of explanation that in copying the list or something of the kind we were regrettably omitted. And let me see,” he went on, rubbing his chin reflectively, “I rather think Ned will ask you to go to the party with him. It occurs to me that old man Shepherd owns some land he’s trying to sell to the Transcontinental, and the railway people are shy of it because it’s below the flood line on our perverse river. Yes; I think we may jar the Shepherds a little too.”

“Why, John!” she laughed as she hung up her apron, “you almost persuade me that you’ve already got free swing at the Campbell boodle!”

“I look at it this way, Helen. We can all spend our own money; it’s getting the benefit of other people’s money that requires genius. I must now step down to the public library and to the Journal office to get some dope on the Campbells. Also I’ll have to sneak mother’s photograph of Mrs. Campbell out of the house. A few illustrations will give tone to our publicity stuff.”

“Be bold, John, but not too bold!”

“‘The Campbells are coming, tra la!’” he sang mockingly, and spiking her hands, hummed the air and danced back and forth across the kitchen. “By jing, that tune’s wonderful for the toddle!” he cried exultantly. “We’ll make all Kernville step to it.”

IV

“The point we want to hammer in is that we—the Ward family—are the only people in Sycamore county who are in touch with the Campbell power, social and financial,” John elucidated to his friend Townley. “Modest, retiring to the point of utter self-effacement as we, the Wards, are, no other family in the community has ever been honored by a visit from so big a bunch of assets. And when it comes to social prominence their coming will link Kernville right on to Newport where old Walter Scott Campbell owns one of the lordliest villas. Here’s a picture of it I found in ‘Summer Homes of Great Americans.’ We’ll feed in the pictorial stuff from time to time, using this photograph of Mrs. Campbell mother keeps on the upright at home, and that cut of Walter Scott I dug out of your office graveyard. Your record shows you ran it the time the old money-devil was indicted under the Sherman law for conspiracy against the peace and dignity of the United States in a fiendish attempt to boost the price of bathtubs. The indictment was quashed as to the said Walter because he was laid up with whooping cough when the wicked attack on the free ablutions of the American people was planned or concocted, and he denied all responsibility for the acts of his proxy.”

“You’ve got to hand it to that lad,” said Townley ruminatively. “Anything you can do to put me in the way of a soft snap as private secretary for his majesty would be appreciated. I’ve had considerable experience in keeping my friends out of jail and I might be of use to him.”

John rose early on Sunday morning to inspect his handiwork in the section of the Journal devoted to the goings and comings, the entertainments past and prospective and the club activities of Kernville. Townley had eliminated the usual group of portraits of the brides of the week that Mrs. Walter Scott Campbell’s handsome countenance might be spread across three columns in the center of the page. The photograph of Mrs. Campbell had been admirably reproduced, and any one informed in such matters would know instantly that she was the sort of woman who looks well in evening

gowns and that her pearl necklace was of unquestionable authenticity.

The usual double column “lead” was devoted wholly to the announcement of the visit of the Walter Scott Campbells of New York and Newport to the Robert Fleming Wards of Kernville, with all biographical data necessary to establish the Campbells in the minds of intelligent readers as persons of indubitable eminence entitled to the most distinguished consideration in every part of the world. Mrs. Campbell, John had learned from “Distinguished American Women,” was a Mayflower descendant, a Colonial Dame and a Daughter of the Revolution, besides being a trustee of eighteen separate and distinct philanthropies, and all these matters were impressively set forth. Mr. Campbell’s clubs in town and country required ten lines for their recital. Any jubilation over the coming of so much magnificence was neatly concealed under the generalization that the horizon of Kernville was rapidly widening and that there was bound to be more and more communication between New York and Kernville. Mrs. Ward, the article concluded, had not yet decided in just what manner she would entertain for the Campbells, but the representative people of the city would undoubtedly have an opportunity to meet her guests.

“The first gun is fired!” John whispered, thrusting the paper through Helen’s bed-room door. “Read and ponder well!”

Mrs. Ward read the announcement aloud at the breakfast table as soberly as though it were a new constitution for her favorite club.

“That Miss Givens who does the society news for the Journal has more sense than I gave her credit for,” she said. “There isn’t a word in that piece that isn’t true. But that portrait of Ruth is a trifle too large; you ought to have warned them about that! When Tetrazzini sang here they didn’t print her picture half as big as that.”

“Well, mother, the Journal simply begged for a photograph. People of note don’t mind publicity. They simply eat it up!”

“Well, the article is really very nice,” said Mrs. Ward, “but I hope they won’t say anything more until the Campbells arrive.”

John, aware that several columns more bearing upon the Campbell visit were already in type in the Journal office, was grateful to Helen for changing the subject to a pertinent discussion of the proper shade of wall paper for the guest-room.

On Tuesday the Journal’s first page contained a news-article on the crying need of enlarged railway facilities, adroitly written to embody the hope of the transportation committee of the Chamber of Commerce, that when Mr. Walter Scott Campbell of the board of directors of the Transcontinental paid his expected visit to the city he would take steps to change the reactionary policy of the road’s operating department. The same article stated with apparent authority that Robert Fleming Ward, the well-known attorney, whose guest Mr. Campbell would be, had pledged himself to assist the mayor and the Chamber of Commerce to the utmost in urging Kernville’s needs upon the great capitalist.

“See here, John, you’ve got to be careful about this Campbell business!” Mr. Ward’s tone was severe. “I know without your telling me you inspired that piece in this morning’s paper. Campbell never saw me in his life and that article gives the impression that he and I are old cronies. It’s going to cause us all a lot of embarrassment. It won’t do!”

“Sorry if it bothers you, father; but there’s nothing untrue in that article. You’ll be the only man in town who can get Campbell’s ear. If he refuses to interest himself in a new freight house and that sort of thing, that’s his affair.”

The stenographer knocked to announce Mr. Pickett.

“Say to him,” replied John, indifferently, “that we are in conference but he can see us in just a moment.”

“Pickett!” exclaimed Ward, senior, as the door closed. “What on earth brings him here!”

“The Campbells are coming,” replied John with a grin. “Pickett’s president of the Water Power Company, and he wants to line us up to get Campbell interested in making a new bond deal.”

“Humph! If that’s what he wants I like his nerve. We don’t even speak when we meet.”

“You’ll be speaking now! Let’s go out and give him the glad hand of brotherly greeting.”

A little diffident at first, Wesley T. Pickett warmed under the spell of the Wards’ magnanimity.

“I’ve regretted very much our little differences——” he began.

“There’s no feeling on our side at all, Mr. Pickett,” John declared and his father, a little dazed, murmured his acquiescence in this view of the matter, and eyed with interest a formidable bundle of documents in Pickett’s hands.

“Fact is,” remarked Pickett, with a sheepish grin as he re-crossed his legs, “you were dead right on that matter of the pollution of the river. Swiggert probably did the best he could with our defense but you were right when you told me I’d save money and avoid arousing hostile feeling in the community by pleading guilty.”

“It’s always disagreeable to be obliged to tell a man he hasn’t a good case,” Ward announced.

“Well, I want you to know I respect you for your honesty. Swiggert encouraged me to think he might get us off on some technical defect in the statute, and it cost me a two thousand dollar fee to find he was wrong.”

“The point he raised was an interesting one,” Ward remarked mildly, “and he might have made it stick.”

“But he didn’t!” Pickett retorted a little savagely. “Now I got a matter I want the God’s truth about, absolutely. It’s a row I’ve got into with a few of my stockholders in the glass company. The fools got the idea of freezing me out! It’s all in these papers, and I want you to give it all the time it needs, but I want an opinion,—no more than you can get on a letter sheet. Swiggert uses too many words and I’ve got to have a yes or no.”

The thought of being frozen out caused Mr. Pickett to swell with indignation. He turned from father to son in an unvoiced but eloquent

appeal to be saved from so monstrous and impious an assault upon his dignity.

“Certainly, Mr Pickett,” said the senior Ward, accepting the papers. “We’ll be glad to take up the matter. It’s possible I may have to ask some questions——”