https://ebookmass.com/product/a-guide-to-hazardidentification-methods-2nd-edition-crawley/

Instant digital products (PDF, ePub, MOBI) ready for you

Download now and discover formats that fit your needs...

A Practical Approach To Hazard Identification For Operations And Maintenance Workers 1st Edition Ccps

https://ebookmass.com/product/a-practical-approach-to-hazardidentification-for-operations-and-maintenance-workers-1st-editionccps/ ebookmass.com

Larone's Medically Important Fungi: A Guide to Identification, 7th Edition Lars F. Westblade

https://ebookmass.com/product/larones-medically-important-fungi-aguide-to-identification-7th-edition-lars-f-westblade/

ebookmass.com

A Beginners Guide to Python 3 Programming 2nd Edition John Hunt

https://ebookmass.com/product/a-beginners-guide-topython-3-programming-2nd-edition-john-hunt/

ebookmass.com

John Webster: The Shape and Development of His Theology: The Shape and Development of His Theology Jordan Senner

https://ebookmass.com/product/john-webster-the-shape-and-developmentof-his-theology-the-shape-and-development-of-his-theology-jordansenner/ ebookmass.com

You're a Mean One, Matthew Prince (Boy Meets Boy 2) 1st Edition Timothy Janovsky

https://ebookmass.com/product/youre-a-mean-one-matthew-prince-boymeets-boy-2-1st-edition-timothy-janovsky-3/

ebookmass.com

Loving: A Second Chance Romantic Comedy (Unleashed Romance, Book 10) Kylie Gilmore

https://ebookmass.com/product/loving-a-second-chance-romantic-comedyunleashed-romance-book-10-kylie-gilmore/

ebookmass.com

Neon Gods Katee Robert

https://ebookmass.com/product/neon-gods-katee-robert-5/

ebookmass.com

Tight Hold (Vegas Aces: The Tight End Book 2) Lisa Suzanne

https://ebookmass.com/product/tight-hold-vegas-aces-the-tight-endbook-2-lisa-suzanne/

ebookmass.com

Operations Management 10th Edition Nigel Slack

https://ebookmass.com/product/operations-management-10th-editionnigel-slack/

ebookmass.com

Therese M Donovan

https://ebookmass.com/product/bayesian-statistics-for-beginners-astep-by-step-approach-therese-m-donovan/

ebookmass.com

AGuidetoHazard IdentificationMethods

SecondEdition

FrankCrawley

Elsevier

Radarweg29,POBox211,1000AEAmsterdam,Netherlands TheBoulevard,LangfordLane,Kidlington,OxfordOX51GB,UnitedKingdom 50HampshireStreet,5thFloor,Cambridge,MA02139,UnitedStates

©2020ElsevierInc.Allrightsreserved.

Nopartofthispublicationmaybereproducedortransmittedinanyformorbyanymeans,electronicor mechanical,includingphotocopying,recording,oranyinformationstorageandretrievalsystem,without permissioninwritingfromthepublisher.Detailsonhowtoseekpermission,furtherinformationaboutthe Publisher’spermissionspoliciesandourarrangementswithorganizationssuchastheCopyrightClearance CenterandtheCopyrightLicensingAgency,canbefoundatourwebsite: www.elsevier.com/permissions

ThisbookandtheindividualcontributionscontainedinitareprotectedundercopyrightbythePublisher(other thanasmaybenotedherein).

Notices

Knowledgeandbestpracticeinthisfieldareconstantlychanging.Asnewresearchandexperiencebroadenour understanding,changesinresearchmethods,professionalpractices,ormedicaltreatmentmaybecome necessary.

Practitionersandresearchersmustalwaysrelyontheirownexperienceandknowledgeinevaluatingandusing anyinformation,methods,compounds,orexperimentsdescribedherein.Inusingsuchinformationormethods theyshouldbemindfuloftheirownsafetyandthesafetyofothers,includingpartiesforwhomtheyhavea professionalresponsibility.

Tothefullestextentofthelaw,neitherthePublishernortheauthors,contributors,oreditors,assumeanyliability foranyinjuryand/ordamagetopersonsorpropertyasamatterofproductsliability,negligenceorotherwise,or fromanyuseoroperationofanymethods,products,instructions,orideascontainedinthematerialherein.

LibraryofCongressCataloging-in-PublicationData

AcatalogrecordforthisbookisavailablefromtheLibraryofCongress

BritishLibraryCataloguing-in-PublicationData

AcataloguerecordforthisbookisavailablefromtheBritishLibrary ISBN:978-0-12-819543-7

ForinformationonallElsevierpublications visitourwebsiteat https://www.elsevier.com/books-and-journals

Publisher: SusanDennis

AcquisitionsEditor: KostasKIMarinakis

EditorialProjectManager: AndreaDulberger

ProductionProjectManager: R.VijayBharath

CoverDesigner: VictoriaPearson

TypesetbySPiGlobal,India

Foreword

Iamdelightedtoprovideaforewordtothelatesteditionofthisimportantbook.Since thelasteditionwaspublished,Ihavebecomemuchmoreawareofhowimportantthe thinking,whichliesbehindthemethodologiesinhere,reallyisandhowmuchmorewe needtodotosharethisthinkingbeyondthedisciplinesofprocessandchemical engineering.

IChemE’shugelysuccessfulHazardsconferenceshavenowbecomearegularfeature aroundtheworldandin2020theUKwillcelebrateits30thHazardsconference.That meanswehaveahugebankofknowledge,whichhasbuiltupinourprofessionon howtoidentifyandmanageprocessrisksinasystematicway.Thetoolsandtechniques havebeenusedrepeatedlybygenerationsofchemicalengineers,theyhavebeen improveduponandnewapproacheshavealsobeenaddedtothetoolkitasresultofinnovativeideasandlessonswehavelearned.Itisgreattoseethisbookbeingupdatedto reflectthecurrentstateofknowledge.

Iamalsopleasedtoseetheauthorextendinghisreachtosharetheapplicabilityofthe methodologiesbeyondchemicalprocesssafety.In2017–18Iconductedanindependent reviewfortheUKGovernmentintoBuildingRegulationsandFireSafetyinhigh-risebuildingsfollowingthetragicfireatGrenfellTowerinWestLondon,whichclaimed72lives.In theprocessofgatheringevidenceforthisreview,itveryquicklybecameapparenttome thatmanyofthehabits,whicharesoingrainedinusaschemicalengineers,arenotso commoninotherengineeringdisciplines.

Whilstourfocushasbeenonhowtodesignandoperatechemicalprocessessafely,we havebeendevelopingmethods,whichcanequallybeappliedtomanyotherdynamicand complexsystems—includingmultiple-occupancyhigh-risebuildings.Systemdesignand managementofchangethroughoutthelifecyclearejustasimportantintheseareasasin chemicalprocessesandtheconsequencesoffailuretotakethatdisciplinedapproachcan becatastrophic.

Wemustensurethatchemicalengineerstodaymaintaintheirfocusonandcompetenceinprocessandsystemsafety,butwemustdomorethanthat.Wemustpassthat knowledgeontofuturegenerationsofchemicalengineersthroughbooks,conferences, andothermeansofcommunicationandeducationifitistotrulybepartofwhowe areandwhatwedotodeliverinherentlysaferprocesses.Wemustalsotakeourknowledge

tootherengineeringdisciplinesandshareitfreelywiththem.Wehaveanimportantjobto do—andahugeopportunitytomakeadifference—inhelpingotherstoseethevalueand thebenefitsoflookingatsystemsandprocessesthroughthelensesofhazardidentificationandriskreduction.

Ihopethisbookistrulywidelyread.

DameJudithHackitt

Acknowledgements

Thiseditionbuildsuponandextendsthefirsteditionpublishedin2003,whichreceived contributionsandsupportfrommanyindividualsandcompanies,whichwereacknowledgedtherein.OnceagainIhavereceivedsuggestions,reviewsofmydraftsandgeneral assistancefrommanypresentandformercolleagues.Inparticular,Iwishtoexpress thankstoRichardGowland,KenFirst,BrianTyler.

However,thefinalselectionofmaterialanditspresentationistheresponsibilityofthe authoralone.

Theauthorwishestothankthefollowingforpermissiontocopyphotosandtext:

• Picturesin Chapter15 suppliedbycourtesyofDNVGL(SpadeadamResearch& Testing).

• IChemEforthere-useofvarioustextsfromtheFirsteditionanddrawingsasnoted.

• DSScottforthepermissiontocopytheRiskCube.

Disclaimer

Theauthorandcollaboratorshavewrittenthisguideingoodfaithanddonotacceptany legalresponsibilityformisuseormisinterpretationofthetext. Itisaguidetouseandnotthedefinitivedocument.Theresponsibilityfortheselection andaccuracyanddetailofanystudylieswiththeuserorathirdpartywhomightcarryout theworkontheirbehalf.Themethodsshouldalwaysbeselectedwithduethoughttothe needandthefinaloutcomeofthestudy.Theuserorthirdpartyshouldensurethatthey havereceivedadequatetrainingandexperienceintheiruse.

Acronymsandabbreviations

ActualMPPD ActualMaximumProbablePropertyDamage

AIChemE AmericanInstituteofChemicalEngineers

ACOP ApprovedCodeofPractice

ALARP aslowasreasonablypracticable

ACMH AdvisoryCommitteeonMajorHazards

BI businessinterruption

BoD BasisofDesign

CEI DowChemicalExposureIndex

CHA ChemicalHazardAnalysis

CCF CommonCauseFailure

CMF CommonModeFailure

CIMAH ControlofIndustrialMajorHazards

COMAH ControlofMajorAccidentHazards

COSHH ControlofSubstancesHazardoustoHealthRegulations2002,amendment2003

DIERS DesignInstituteforEmergencyReliefSystems—AIChE

ERPG EmergencyResponsePlanningGuideline

ESD EmergencyShutdown(system)

EPSC EuropeanProcessSafetyCentre

ETA eventtreeanalysis

F&EI DowFireandExplosionIndex

FDT fractionaldeadtime

FEED Front-EndEngineeringDesign

FTA faulttreeanalysis

FME(C)A failuremodeandeffect(criticality)analysis

HASWA HealthandSafetyatWorkAct1974

HAZID hazardidentification(method)

HAZOP hazardandoperability(study)

HIPS High-IntegrityProtectionSystem

HS hazardstudy(0–7in Chapter3)

HSE HealthandSafetyExecutive

IChemE InstitutionofChemicalEngineers

IPC IntegratedPollutionControl

IPL IndependentProtectionLayer

IPPC IntegratedPollutionandPreventionControl

LFL lowerflammablelimit(sometimesalsoexplosivelimit)

LOPA LayerofProtectionAnalysis

MAPP MajorAccidentPreventionPolicy

MF MaterialFactor

MoC ManagementofChange

MPDO MaximumProbableDaysOutage

MPPD MaximumProbablePropertyDamage

NISHH NotificationofInstallationsHandlingHazardousSubstances(NIHSS)Regulations1982

NPSH NetPositiveSuctionHead

PFD ProbabilityofFailureonDemand(akaProbabilityofFailuretoDanger)

PHA processhazardanalysis

PHR processhazardreview

P&ID pipingandinstrumentationdiagram

PPE personalprotectionequipment

PtW PermittoWork

RR relativeranking

RAST riskassessmentscreeningtool

RIDDOR ReportingofInjuries,DiseasesandDangerousOccurrencesRegulations2013

SEP SurfaceEmissivePower

SHE Safety,Health&Environment

SIL SafetyIntegrityLevel

SIS SafetyInstrumented(interlock)System

SMS safetymanagementsystems

UFL upperflammablelimit(sometimesalsoexplosivelimit)

VCE vapourcloudexplosion

SIunits

M mega m milli

p pico

F Farads

J Joules

Pa Pascals

W Watts

Regulatoryframework

1.1Overview

Societyissubjecttorulesandthereisnodifferenceforindustry.Thischaptergivesabrief reviewoftherulesorRegulationsbywhichtheChemicalIndustrymustoperateandlinks theseintothevariouschapterswithinthisMonograph.ItconcentratesontheUnited Kingdom,workingwithintheEuropeanUnionsystem.

Therearemanyaccountscoveringtherulesofdifferentnon-EuropeanUniondifferent NationsorStates.Thesemustbeunderstoodfullyandfollowed.Therefore,eachnationor statewithinanationmustusetherulesappropriatetothatnationorstate.

1.2Background

ThedevelopmentofchemicalandpetrochemicalmanufacturinginthepostSecondWorld Warerahasledtoaglobalexpansionofproductionandstoragefacilities.Forexample,the sizeofolefinplantsbetween1948and1968wasdoublingevery7or8years,whilethesite footprinthadhardlychanged.Newprocessessuchasthedirectoxidationofethylene withpureoxygenweredevelopedandmanynovelprocesses,particularlyinthepharmaceuticalindustry,werebroughton-line.Thesefacilitiesintroducednewhazardsinto communitiesandneighbourhoodswhichrequiredregulation.

Ingeneralthehistoriclegalframeworkwasreactive,notanticipative,althoughnewer frameworkshavetendedtobemoreanticipative.

Thefirst‘SafetyActs’gobackover150yearswiththeregulationofchemicalprocess safetybecomingmoreestablishedsincethe1970s.Variousreasonsexistforthepromulgationofthedifferentregulationswithoneofthemaininitiatorsofnewregulations

orchangesinexistingregulationsbeingtheoccurrenceofmajoraccidentswith seriousconsequenceseitherforthesafetyofemployees,theneighbourhoodorthe environment.

WithinUnitedKingdomtherearesomedifferencesofapproachtoregulationwithin thecomponentcountriesoftheUnitedKingdomasaresultofancientActspassedmany yearsago [1,2,3,4].ThusintheUnitedKingdomthereisEnvironmentalAgency,whilstin ScotlandthereistheScottishEnvironmentalProtectionAgency(SEPA).

Itisself-evidentthattheregulationsrequiretobepolicedrequiringaRegulatoror CompetentAuthoritywithmeansofenforcementsuppliedbyoverarchingActs.

BackgroundinUnitedKingdom

TheregulationofmajoraccidenthazardswithintheUnitedKingdomhasitsrootswithin thereportoftheRobens’Committeein1972 [5].Thisidentifiedthat‘majorhazards’associatedwithtechnologypresentaparticularproblem,andrecommendedcomprehensive provisionstodealwithtoxic,explosiveandflammablesubstancesbeadopted.Tothisend thecreationofamajorhazardsbranchwithinthenewinspectorate(i.e.Healthand SafetyExecutive)wasrecommended,aswastheestablishmentofaStandingAdvisory CommitteeonMajorHazards(ACMH).TheACMHbeinggiventheremittoidentifytypes ofinstallationswhichhavethepotentialtoposeamajorhazardandtoadviceonmeasures ofcontrol.OneoftherecommendationsofACMH(ACMHIII)was‘LandUsePlanning’. HoweverbeforetheresultingregulationfromtheRobens’Report,theHealthandSafety atWorkAct [6] couldtakeeffect,oneoftheworstaccidentsinBritishchemicalprocessing history,theexplosionandfireatFlixborough,occurredon1June1974.

ThesequenceofmajorRegulationswithintheUnitedKingdomunderHASWAhas been:

• 1978ThepublicationoftheHazardousInstallations(NotificationandSurvey Regulations) [7] asaconsultativedocumentinlinewiththeHealthandSafety Commission’sdutytoconsultunderthetermsoftheHASAWAct.

• 1983NotificationofInstallationsHandlingHazardousSubstances(NIHSS) Regulations1982 [8].

• 1984RIDDORRegulations(ReportingofInjuries,DeathsandDangerousOccurrences Regulations).

• 1984ControlofIndustrialMajorAccidentHazards(CIMAH)Regulations(1984) [9] implementingEECDirective82/501/EEC.

InmanywaystheUnitedKingdomhasledtheEuropeanUnioninProcessSafetyanduses astructureatfourlevels:

TheAct

TheRegulation—orStatutoryInstrument(empoweredbytheAct)

TheApprovedCodeofPractice(whatisexpected) GuidanceNotes

EvolutionEuropeanUnion

FollowinganaccidentatachemicalfacilityinItalyacloudofca.10tonnesofchemicals, includinganestimated1–2kgTCDD(dioxane),wasreleasedovertheneighbouringtown, Seveso.ThenameofthetownhasbeenadoptedforthemajorEuropeanUnionregulations.Hence‘SevesoDirective1’andtwoupdatesfollowingfurtherincidents.Theconcept oftwotiersofapplicationwaskeptinbothSevesoIIandthecurrentSevesoIIIDirective. MemberStateswererequiredtoensurethatthelower-tierestablishmentsprovide notificationtothecompetentauthorities,fulfilthegeneraldutyofsafeoperationto preventmajoraccidentsandthattheoperatorestablishedamajoraccidentprevention policy(MAPP).TheMAPPwasthebasisforthemanagementofsafetyatSevesoIII establishments.

ThedangeroussubstancesintheSevesoIIDirectivewereprimarilycoveredinten genericcategoriesrelatedtoacutetoxic,flammable,explosiveorenvironmentalhazard properties.InadditiontheCommissionproposedaverymuchshorterlistofnamedsubstancesthanincludedintheoriginalSevesoDirective.Thesearegenerallysubstances, whichhaveaverywidespreaduseinlargequantities,aresubstancesofparticularconcern orareofparticulareconomicimportancewhereaverylowthresholdlevelwouldcausean extremelylargenumberofsitestobecoveredbytheDirective.

1.3FeaturesofSevesoIIIDirective

TheSevesoIIIDirective [10] placesrequirementsontheMemberStatesoftheEuropean Uniontosetnationalregulationsforoperatorsandforthecompetentauthoritieswhich enforcethenationallegislationandimplementtherequirementsoftheDirective.The requirementsmaybedescribedasfollows:

Scopeanddefinitions:ApplicationoftheDirectiveisto‘establishments’inwhich sufficientquantitiesofdangeroussubstancesarepresentormaybepresent.This mayinvolveaddingthevariouscomponents inamultiprocesssite.Activities,which areexcludedfromthescope,arethosecoveringmilitaryinstallationsandfacilities; hazardsduetoionisingradiation;thetransportationofdangerouschemicalsandtheir immediateactivities,marshallingyards,docks,wharves;wastelandfillsites(excluding tailingspondsanddams);mineralextractionactivities;offshoremineralandhydrocarbonextraction.

Generalrequirements:Operatorsaretoberequiredtoshowthattheyhavetakenall measuresnecessarytopreventtheoccurrenceofmajoraccidentsandtolimittheireffects tomanandtheenvironment.Further,anoperatorshouldbeabletoprovetothecompetentauthorities,atanytime,thatthesemeasureshavebeentaken.(See Chapters3–5, 7, 15, 16, 17 and 19.)

Notification :Operatorsaretoberequiredtonotifythecompetentauthoritiesof theirexistence,thehazardoussubstancesi nvolved,theactivity,thepersonincharge oftheestablishment.Thisinformationistobeprovidedpriortocommencingthe

activityandwithanysignificantchange,incl udingclosureoftheestablishment(seethe ‘SafetyReport’later).

MajorAccidentPreventionPolicy(MAPP): Theoperatoristoberequiredtoprovidea writtendocumentsettingoutthepolicyforthepreventionofmajoraccidentsandto ensurethatitisproperlyimplementedandguaranteedahighlevelofprotectionfor manandtheenvironmentbyappropriatemeans,structuresandmanagementsystems. Thesemeanscanbereviewedorexaminedbythemethodsoutlinedin Chapters3–5 andinparticularTaskAnalysis(Chapter6).Audits(Chapter17)thengivesguidanceon examinationoftheseforweaknessesorsystematicdriftinstandard.

SafetyManagementSystem(SMS): TheoperatorisrequiredtoestablishaSafetyManagementSysteminaccordancewithappropriateAnnexoftheDirective.TheSMSshould beproportionatetothehazardsandrisksoftheactivitiesoftheestablishmentand adaptedtothecomplexityoftheestablishment’sorganisationalstructure.TheMajorAccidentPreventionPolicyisanintegratedelementoftheSMS.ThisgivestheSMSastructure similarinformtothatofenvironmentalmanagementsystemsaccordingtoISO14001or qualitymanagementsystemsaccordingtoISO9001.[ThisMonographdoesnotcover managementsystemsexplicitly,buttheyarepartoftheanalysisinHazardStudies (Chapter3),HAZOP(Chapter4),HAZID(Chapter5),TaskAnalysis(Chapter6),Risk Assessment(Chapter15)andVulnerability(Chapter16)].

SafetyReport: Theoperatorofanupper-tierestablishmentisrequiredtoproducea SafetyReport,whichisacoredocumentationoftechnical,organisationalandmanagementmeasurestoensurethesafeoperationoftheestablishment.TheSafetyReportis tohavethepurposesof:

(a) demonstratingthatamajor-accidentpreventionpolicyandasafetymanagement systemforimplementingithavebeenputintoeffectinaccordancewiththe informationsetoutinAnnexIII;

(b) demonstratingthatmajor-accidenthazardshavebeenidentifiedandthatthe necessarymeasureshavebeentakentopreventsuchaccidentsand/ortolimittheir consequencesformanandtheenvironment;

(c) demonstratingthatadequatesafetyandreliabilityhavebeenincorporatedintothe design,construction,operationandmaintenanceofanyinstallation,storagefacility, equipmentandinfrastructureconnectedwithitsoperationwhicharelinkedtomajoraccidenthazardsinsidetheestablishment;

(d) demonstratingthatinternalemergencyplanshavebeendrawnupandsupplying informationtoenabletheexternalplantobedrawnupinordertotakethenecessary measuresintheeventofamajoraccident;

(e) providingsufficientinformationtothecompetentauthoritiestoenabledecisionsto bemadeintermsofthesiteofnewactivitiesordevelopmentsaroundexisting establishments.

TheminimumcontentsoftheSafetyReportarelistedinAnnexIIoftheDirective.Itmust howevercontainanup-to-dateinventoryofdangeroussubstancesintheestablishment.

TheSafetyReportisnotadocument,whichisfinalisedinonego.Itshouldbea‘living document’.Thismeansthataregularreviewprocessshouldbeestablished,whichensures thatthatdescriptionswithintheSafetyReportarekeptuptodate.TheDirectiverequires thattheSafetyReportshouldbeamendedasnecessaryasaresultofalterations(material orsignificantchange)totheestablishmentastheresultof:

(a) newtechnicalknowledgefollowing‘nearmisses’ormajoraccidents.

(b) aregularreviewprocess,whichshouldtakeplaceatleasteveryfiveyears.[SeePHR (Chapter19)andotherreferencestorepeatingstudiesregularlysuchasHAZOP (Chapter4)].

(c) asignificantchangeintheprocessandinventory.

Inthecaseof‘TopTierProcesses’theSafetyCaseshouldberesubmittedevery5years.The factthatacompetentauthorityhasacceptedaSafetyReportdoesnotabsolveanoperator ofanyresponsibilityforthesafeoperationoftheestablishment,norisitastatementthat theestablishmentcannothaveamajoraccident.

TheSafetyReportistobesubmittedtotheCompetentAuthorityandthis,inturn,isto giveitsopiniononthereport,withinareasonabletime.Practicehasshownthatthismay rangefrom:‘acceptanceofthereportassubmitted’;through‘acceptancewithamendments’;to‘rejectionofthereport’.(‘Acceptedbutnotnecessarilyacceptablehasbeen quotedbytheRegulator’.)

On-siteandoff-siteemergencyplanning: Emergencyplanningisdividedbetween thoseactivitiestobecarriedoutbytheoperat or,on-site,andthoseactivitieswhichfall withintheresponsibilitiesoftheemergencyplanningauthorities,off-site.Themeasures shouldbeco-ordinated,whichrequiresthattheoperatorprovidestheemergencyplanningauthoritieswiththenecessaryinformationtocarryouttheexternalemergency planning.Theplansmustalsobedevelopedinconsultationwiththosewhomaybe potentiallyaffected.Thereforethedrawingupandtestingofinternalemergencyplans mustinvolvetheemployees,includinglong-t ermsubcontractors.Externalemergency plansshouldbedrawnupinconsultationwiththepublic.Theminimumcontentsof theemergencyplansaregivenintheappropriateAnnexoftheDirective.TheuseofRisk Assessment(Chapter15)andVulnerability(Chapter16)willassistinthedevelopmentof theseplans.

Informationtothepublic: TheDirectiverequiresthatMemberStatesensurethat informationisprovidedtothepublicandhe ldinapermanentlyaccessibleelectronic formabouteveryestablishment.MinimumcontentislistedintheappropriateAnnex oftheDirective.Thereisnostipulationastowheretheinformationistobeheld;thus, itispossiblefortheinformationtobeprovidedonasinglenationalportaloronthe internetsitesofestablishmentsorcorporati ons.Inadditionforupper-tierestablishmentsinformationonsafetymeasuresandtherequiredbehaviourintheeventofa majoraccidentistobesuppliedtothosewhomaybeaffected.Thatis,theinformation istobesuppliedtoallpersonsandtoallestablishmentsservingthepublicwithoutthem requestingit.ThepracticalapplicationofthisrequirementintheMemberStatesvaries

fromtheinformationbeingsuppliedbytheau thoritiestotheinformationbeingsuppliedbytheoperatoroftheestablishmentoragroupofestablishmentswhicharein closeproximity.Whicheverapproachischosen,thereneedstobeaclosecooperation betweentheoperatorsandtheauthorities.Thereneedstobeacleardefinitionofthe neighbourhood,whichistobeencompassedbytheinformationandalsohowtheneighbourhoodshouldbewarnedintheeventofanemergency.Itshouldbeclearwhetherthe operatorortheauthoritiestriggerthea larmsignalandhowthethirdpartiesshould respond.

Reportingofmajoraccidents: MemberStatesarerequiredtoensurethatintheevent ofamajoraccidenttheoperatornotifiestheauthoritiesassoonaspracticableandbythe mostappropriatemeans.Thenotificationshallcoverthecircumstancesoftheaccident, thedangeroussubstancesinvolved,thenecessarydataforassessingtheeffectsoftheaccidentandtheemergencymeasurestaken.Furthertheoperatorshallinformtheauthorities ofthemeasuresthatareenvisagedtodealwiththeeffectsoftheaccidentandtoprevent therecurrenceoftheaccident.Theinformationshallbeupdatedbytheoperatorinthe eventthatadditionalfactsorinformationbecomeavailable.

Thecompetentauthorityshallberequiredtoensurethaturgent,medium-orlongtermmeasuresaretakentodealwiththeaccident.Theauthorityshallcollectthenecessaryinformationforafullanalysisoftheaccident.Itshallalsoensurethattheoperator takesthenecessaryremedialmeasurestodealwiththeaccidentandmakerecommendationsonfuturepreventativemeasures.

Inspectionofestablishmentsbypublicauthorities: TheMemberStatesarerequired toensurethatthecompetentauthoritiesestablishaninspectionsystemtoassessthetechnical,organisationalandmanagementspecificaspectsofthesafetyoftheestablishment. Thisinvolvesassessingtherelevantdocumentationaswellascarryingoutanon-site inspectionoftheestablishment.TheDirectiverequiresthattheinspectionsofupper-tier establishmentsarecarriedoutannuallyunlessthecompetentauthorityhasestablisheda programmeofinspectionsbasedonasystematicappraisalofthemajoraccidenthazards oftheestablishment.Followingtheinspection,areportshallbepreparedandfollowedup withthemanagementoftheestablishment.

TheDirectivedoesnotmakespecificdemandsontheintensityoftheinspectionby thecompetentauthorities.Experienceshows thatlarge,complexestablishmentscannot beinspectedintheirentiretyinoneon-siteinspectionvisit.Inadditionitshouldbe recognisedthataninspectiondoesnotincreaseineffectivenesswithincreasinglength andthatgeneralimpressions,targetedinsp ectionsofindividualaspectstogetherwith spotchecksandinterviewsleadtothebestresults.Keyforasuccessfulon-sitevisitis goodpreparationbeforehand,togetherwithatransparentdocumentationofthose aspects,whichhavebeenassessedandthefindingsoftheinspection(see Chapter17).Theresultsneedtobefollowedupwiththemanagementoftheestablishmentandshouldincludeatimetableforthe implementationofthenecessarymeasures (see Chapter17).

Land-useplanning

RequirementsonmemberstatestoprovideinformationtotheCommission:Forthe CommissiontobeabletoenforcetheDirectiveaswellastobeabletofollowitsapplicationanddeveloptheregulationsinanappropriatemanner,itisdependentoninformation providedbytheMemberStates.TheMemberStatesarerequiredtoprovideinformation relatingtothefollowingaspects:

(a) theimplementationoftheDirectivewithinthenationallegalsystemsandstructures.

(b) a3-yearreportoftheimplementationoftheDirectiveaccordingtoaquestionnaire, whichisprovidedaccordingtoaprocedureonthestandardisingandrationalisingof reports.

(c) acatalogueoftheestablishmentsfallingundertheDirectivewithintheMemberState.

(d) areasonedlistoftheexceptionsfromtheprovisionofinformationwithintheSafety Report.

(e) informationonthosemajoraccidentswhichhaveoccurredintheMemberState.This informationistobeprovidedaccordingtoanagreedformatandismadepublic, exceptforthosedatawhicharedeclaredasconfidential,intheonlinedatabase ‘eMARS’.

Otherareas

ThereareclosesimilaritiesbetweenUnitedKingdomandEuropeanRegulationsin Canada,AustraliaandNewZealand.

Othernationshavetheirownrules,soitisessentialthattherulesofthatnation(or StateinUSA)arefollowedtothefull.

TheOffshoreOilandGasindustryhassomedifferentrules,includingthesecurityof theSafeHaven(TemporaryRefuge)againstfireandsmokeingressaswellasthemeans ofescapefromtheinstallationaswellasthesiteofafire.The‘totalrisk’mustalsoinclude helicoptertransitsfromtheheliporttotheinstallationaswellasshippingcollisionand structuralfailureoftheinstallation.Thesedonotapplyonshore.

Thehelicoptertransitispotentiallyasignificantelementinthetotalrisktooffshore employees.

Appendix

Furthermaterialmaybefoundat:

aicheme.org ‘RegulationsandResourcespage’. J.BessermanandR.A.Mentzer,Reviewofglobalsafetyregulations,J.LossPrev.Proc. Ind.50(2017)165–183. http://www.hse.gov.uk/pubns/hse49.pdf. https://www.hse.gov.uk/pubns/hsc13.pdf.

References

[1] ThePlanning(HazardousSubstances)Regulations2015,2015.SINo.627.

[2] TheTownandCountryPlanning(HazardousSubstances)(Scotland)Regulations2015,2015.SSINo 181.

[3] ThePlanning(HazardousSubstances)(Wales)Regulations2015,2015.No.1597(W.196).

[4] ThePlanning(HazardousSubstances)(No.2)Regulations(NorthernIreland),2015.SRofNI2015No. 344StatutoryInstruments(Regulations)OwnedandEnforcedbyHSE.

[5] L.Robens,SafetyandHealthatWork,ReportoftheCommittee1970-72,HMSOCmnd.5034,1972.

[6]HealthandSafetyatWorkAct1974.

[7]HazardousInstallations(NotificationandSurveyRegulations)Regulations1978.

[8]NotificationofInstallationsHandlingHazardousSubstances(NIHSS)Regulations1982.

[9]ControlofIndustrialMajorAccidentHazards(CIMAH)Regulations1984.

[10]Directive2012/18/EUoftheEuropeanParliamentandoftheCouncilof4July2012onthecontrolof major-accidenthazardsinvolvingdangeroussubstances,amendingandsubsequentlyrepealing CouncilDirective96/82/EC,Off.J.Eur.Union197(2012)1–37. http://data.europa.eu/eli/dir/ 2012/18/oj

AguidetoHazardIdentification Methods

Chapteroutline

2.1HazardIdentification

HazardIdentificationisfundamentaltothesafedesignandoperationofanysystem,beit aprocessplantoranyotherfacility.Thetoolsusedvaryaccordingtothesituationbutthey areallrigorous,systematicanddependtoagreaterorlesserextentontheknowledgeof teammembersthatwillusuallycontainsomeformofexpertise.

Thisbookprovidesaselectionguidethatattemptstointroduce,describeandillustrate themostcommonlyusedmethods,andthentodirectthereadertomoredetailedreferenceswherefullerguidancemaybefoundonthespecificmethod.Itdoesnotprovidea fulllistingofalloftheavailablemethod.Theselectioninthe1steditionwasbasedonan analysisofthemorecommonmethodsusedbyEPSCMembers:newandmoremodern methodshavebeenaddedinthisedition.Itshouldbenotedthattheauthorfoundthata generalmethodmighthavesomeverysmall,industry-specific,featuresorchangesand thenbeknownbyadifferentname.Thedescriptionsgivenhereforeachmethodare genericandnon-industryspecific,sothatthemethodscanbeusedbydifferentindustries withminor,casespecificvariations.Inthedescriptionsitwillbeseenthatamethodmay sometimesuseanadaptedpartofanothermethod.Thistooistobeexpectedasmost methodswillincludethebestpartsofother,triedandtestedmethods.Theusershould reviewthemethodsandchosetheonemostappropriatetothattask.

ThemethodsselectedbytheEPSCmembersincludesomethatareontheboundary betweenidentificationandassessment.Theseinclude:

• FaultTreeAnalysis(FTA)

• EventTreeAnalysis(ETA)

• FailureModesEffects(andCriticality)Analysis(FME(C)A)

Thesemethodscanbeusedbothanalyticallyandquantitatively.Inthefirstmodetheycan beusedasaninvestigativetool,butitisinthesecondmodethattheyhavemostuse.

Eachmethodisdescribedunderthefollowingheadings:

• Definition

• Description

• Resourcerequirements(bothpersonnelanddocumentation)

• Timing(againstthePHAtimeframe)

• Advantages,disadvantagesanduncertainties

• References

• Illustratedexample(ifneeded)

HazardIdentificationshouldberegardedasasetoftoolsthatareusedattheappropriate timeduringaparticularprojectdevelopment(Chapter3).Thetimingofuseisnotalways criticaland,otherthanpossiblyforHAZOPstudy,theremaybeseveralpointsinaproject whereamethodcanprofitablybeused.Alsoitshouldberecognisedthata‘project’could beamaintenancetask,amodificationoralargeconstructionproject.Theidentification methodscanbeconsideredforanyofthese,theonlydifferencesbeinginthedepth,the effortandtherecording.Whilecertainmethodshavemoreapplicationtotheprocess industry,fromwheretheyevolved,themethodscanbeofvalueinanytaskinanyEngineeringorSciencefield.Themethodsshouldalwaysbeselectedwithduethoughttothe needandthefinaloutcomeofthestudy.

Theappendicesinthisbookprovidethreeexamplesshowingwhichofthemethods anditisintendedthattheyshouldbeeasilyunderstood.Full,realexampleswouldbe muchmorecomplexanddetailedandcannotbeusedinanintroductorydocumentsuch asthis.Theyalsogiveamoredetailedillustrationoftheinterplayofthevariousmethods andshowhowtheycan,andoftendo,interacttoproducethebestresults.Whereworked examplesaregiveninthemethoddescriptionsinthemaintexttheyareintendedtohelp explainthedetailedworkingofthatmethod.

AlloftheillustrativeexamplesgiveninthisMonographaredeliberatelyrelativelysimple,requiringlittleornospecificpriorknowledgeandthereforeshouldbeeasilyunderstood.Full,realexampleswouldbemuchmorecomplexanddetailedandcannotbeused inanintroductorydocumentsuchasthis.

Table2.1 showstheusualtimingsforeachoftheselectedmethodsbasedonthestandardstagesofaproject.Asdescribedin Chapter4,anadditionaltwospecialisedstages, number0and7,havebeenincludedtotheoriginalsetof6.Inthetablethemostlikely timeofuseforamethodisshownbyanX:alesslikelytimeisshownby(X).Definitions oftheabbreviationsaregivenintheappropriatechapters.

NotethatHAZOPisshownasapossibilityatprojectstage2,astheremaybesome desiretocarryouta‘preliminary’HAZOPonapipingandinstrumentationdiagram (P&ID)asitisbeingdeveloped.

Noindexisprovidedforthisbookasastandardisedformathasbeenusedinthe descriptionofeachoftheselectedmethodsandthepartsofeachdescriptionarefully detailedonthecontendpages.

Table2.1 HazardIdentificationMethodandindicativeproject(lifecycle)phase(order ascontents).

Projectlifecyclestages,0–7(asidentifiedin Chapter3) Methodused01234567

HazardStudiesXXXXXXXX HAZOP(X)XX HAZIDXXXX TaskAnalysis(X)X(X)X LOPAXX(X)

RelativeRankingXX(X)(X) RiskAnalysisScreeningTool(RAST)XX(X)X CheckListsXXXXXXXX

Therearenowmany‘HazardIdentificationMethods’.Theoldesttwoareprobably ‘Checklists’and‘Whatif?’Thenextoldestisprobably‘HazardandOperabilityStudies’ (nowknownasHAZOP),whichwastrialrunin1968andevolvedfromMethodStudy.Since thennewmethodshaveevolved,somearevariationsonother,older,methodssuchthat thereisthepossibilityofconfusioninthemindsofpotentialusers.Thismonographisa selectionofthemorecommonlyusedmethodsgivingthestrengthsandweaknessesofeach andhow/whereitmightbeused.Eachhasanillustrativeexampleoftheuseinreality.Itis onlyaguideandisnotthedefinitivedocumentoneachmethodbutshouldgivesufficient informationforEngineersandScientiststobeabletochosewhichonemightbeappropriate inaspecificcaseandtobeabletoassessthedetailandqualityofanyworkcarriedoutbya secondpartystudy.Inlinewiththedisclaimeritistheresponsibilityofanypotentialuserto seektrainingandguidancefromatrainedpractitionerbeforeusinganyspecificmethod.

Thegeneralhierarchyofrisk-reducingmeasuresisasfollows:

• Prevention,

• Detection,

• Control,

• Mitigation,

• Emergencyresponse.

Itisnotpossibletowriteamonographsuchasthissoastocovereverytopicsoithashad tobeselectiveandleanstowards‘detection—atdesign’.Inthecaseofprevention,mitigationandemergencyresponsesomeguidanceisgivenunderRiskAssessment(Chapter15) andVulnerability(Chapter16).

Thereisonefinaltool,whichiscalledProcessHazardReview(Chapter19).Thisis carriedoutonanexistingprocessandexaminesthehistoryandexperienceoftheoperationsstaff.Itisnotusedinthedevelopmentofaprojectbutisusefulforanexisting process.

TaskAnalysis maybecarriedoutthroughoutaproject.Theareasshownareindicative. ItmaybeusedduringtheStudies2and3processtodesignthemaintenanceoftheequipmentandatStudy7tofacilitatedemolition.Itwillbeusedduringallphasesofoperation includingshutdownandstartup.

Audits canbecarriedoutonanyphaseofthedevelopmentoftheproject,buttheyare probablymoreusefulduringthesteady-stateoperationalphaseoftheprojectexamining thedriftofManagementSystemsfromrecognisedstandards.

Notethat HAZOP isshownasapossibilityatstagetwooftheSafetyStudies—Process HazardAnalysis,astheremaybesomedesiretocarryouta‘preliminary’HAZOPona P&IDasitisbeingdeveloped.

Groundrules

ItisatimelywarningthatmoreandmoreoftheHAZOP/HAZIDstudiesarecarriedoutby Facilitatorswhoare‘contracted’.Toooftentheyarechosenforparticularskillsandenter thestudytotallycold.Thescope,termsofreferenceandgroundrulesshouldbeagreed withtheclientpriortothestudy.

Therearecleargroundrulesbeforeexecutinganystudy.Theseare:

TheScope shouldcovertheboundariesofthestudy,includewhatistobedoneand whatistobeexcluded.Itshouldbethatresultofadialoguebetweentheclientandthe Facilitatorandshouldwhereappropriatecoverthe‘matrix’.Itshouldcoverwhoshould carryouttheactionsandwhethertheyshouldberankedinpriority.Thescopeshouldalso addresstheresponsibilitiesforrestudyparticularlyfollowingaHAZOPwheretheremay bematerialchangesinthedrawings.

TheTermsofReference shouldcoverthedeliverydateandwhereappropriatethereferencespoints,forexampleinanAuditagainstwhatshouldtheactionsbemeasured.

ReportingandWorksheets Itisimportantthatthereisastandardformofworksheetsor reports.Thiswillgreatlyassistintheauditingofanystudywheretheauditorwillknow whereandwhattolookforinthefinalreport.

Interlinking

ManyHazardIdentificationMethodscross-linkwithothersorhaveevolvedfromanother. Thiswillbemoreobviouswhenthelinksareshown.Thishasbeendrawnoutinthethree examplesinAppendices.

InadditionitshouldberecognisedthatsomeHazardIdentificationMethodsare appropriatetoaspecifictask.Thatmeansthatthecorrectmethodshouldbeusedso astooptimisetheuseofresourcesforthemaximumreturns.

Thesetopicsarecoveredinmoredetailinthechaptersindicated.

TheLegalStructure (Chapter1)isderivedfromhistoriceventsleadingtoActsorRegulationsandtheneedtocarryoutadetailedassessmentofasituation.

HazardStudies (Chapter3),alsoknownasProcessHazardAnalysis,evolvedinthelate 1960sfollowinganupsetonachemicalplantresultinginthereleaseofchlorine.Itisthe systematicanalysisofthedevelopmentofaprojectfrominceptiontodemolition.Ithasa structure,whichcanbeadaptedforuseinTaskAnalysis,writingaprocedure,orchecking thedevelopmentofaproject.WithinthiscouldbethemethodologiescalledHAZOP, HAZIDandAudits.

HAZOP (Chapter4)isastructuredanalysisofaP&ID.Itreliesonthecorrectselectionof ‘guidewords’ and ‘parameters’.Theresultantmatrixisverymuchbasedonpastworldwide experience.ItevolvedfromMethodStudy.InsomerespectsithassimilaritiestoFailure ModesandEffectsAnalysis.Onceagaintheactionsmustberankedinorderofpriority.

HAZID (Chapter5)isastructuredanalysis,whichagainreliesonadetailedunderstandingofthesystemsbeinganalysedandtheprocessarchitecture.Originallyitwas called‘Three-DimensionalHAZOP’inthe1980s.Insomewaysitcanbethoughtofas asystematicallyderived checklist ofscenarios.Oncedefinedeachhastobesubjectto QuantifiedRiskAssessment.

TaskAnalysis (Chapter6)istheanalysisofaroutineorinfrequentoperationandhas someoftheelementsofhazardstudieswithinitsuchassequenceandpriority.Itisprobablybestthoughtofasachecklistmethodasitrelieson‘experience’.

LOPA (Chapter7)isasimplifiedformofRiskAssessment,whichhaspre-defined conditionalprobabilitiesandfailureratedata.Itprovidesfortheexaminationofmajor eventsandgivesclearindicationsoftheneedforadditionalprotectivemeasures.

RelativeRanking (Chapter8)isbasedonpre-preparedtools,whichhavebuiltinto themasetofparametersderivedfromthepastworldexperience.Thisallowsanelement offilteringoftheoptionsbeforetheprojecthasevolvedtoofar.

TheRiskAssessmentScreeningtool(RAST) (Chapter9)hassomelinkstoLOPA (Chapter7)andagainitisbasedonanaccumulationofworldexperienceanddata.

Checklists (Chapter10)areanaidememoireandareagainbasedonhistoricevents. Thesecanbeusedinthedevelopmentofaprocedureortaskanalysis.Theyalsorelatetoa formofHAZID.

Whatif? (Chapter11)hassomeelementsofHAZOP,whichiscausedriven(whatifthere isnoflow?),andHAZID,whichiseffectdriven(whatifthereisamajorreleaseofmaterial Xhere?)

TheonetoolwheretheoutcomeofafailureisassessedinlessdetailisprobablyFailure ModesandEffectsAnalysis (Chapter12),whichusessubjectiveassessmentskills.Insome respectsitissimilartoHAZOPbutisappliedtoapieceofhardware.

FaultTreeAnalysis (Chapter13)usesclearlydefinedlogicofeitherafrequencyorprobability,whichinvolvesadditionandmultiplicationtodefinethecombinationofeventsto definethe‘topevent’ortheeventofconcern.Itcanbe‘topdown’(startwiththefinal event)or‘bottomup’(createthelogic,whichwillcreatethefinalevent).Therulesarewell definedandtheinputdatacanbederivedfromreliabilitystudies.

EventtreeAnalysis (Chapter14)usesonlyprobabilitydatawhicharemultiplied.Itis oftenusedwithFaultTrees.

QuantifiedRiskAssessment (Chapter15)feedsoffvulnerabilityandconsequence models.ItalsousesmethodssuchasFaultTreeandEventTreeanalysis.

Vulnerability (Chapter16)completesthelinktoRiskAssessmentanddefinesthepossibleinjury/damagescenarios

Audits (Chapter17)areastructuredanalysisofthecorporatehealth,beitfinancial and/orsafety,andattempttoidentifythesystematicerosioninstandards.

BowTie (Chapter18)hassomelinksintoHAZOPaswellasFaultandEventTrees.Itisa morevisible(andmoreunderstandable)representationofcausationandmitigationthan FaultTreesandLOPA.The‘threats’useamoredetailedanalysisofthepotentialcauses andexaminessomeofthehumanfactorsinmoredetailthanQuantifiedRiskAssessment. ItalsohaslinkstoAudits.

Thenext(four)methodsarefreestandingandevolvedfromtheneedtoexaminehighriskapplicationssuchaNuclearPower:

Riskassessmentistheonelink,whichiscommontoallmethods.Havingidentifiedthe hazardorpotentialhazarditmustberanked.Somerisk-rankingmethodsarebetterthan others.AsatrivialexampleafullQuantifiedRiskAssessment(QRA; Chapter15)isnotjustifiedforatrivialcaseorroutineoperation.Theassessmentmethodsare:

1. Quantitative wheretheriskisgivenbothmagnitudeandfrequencyusingtoolsuchas Fault TreeandEventTreeanalysisandphenomenology.Theerrorbandsareabouta halforderofmagnitude.

2. Semi-quantitative wheretheriskbothmagnitudeandfrequencyisderivedfrom predetermineddatasets.TypicallythisappliestoLayerofProtectionAnalysis and RankingTools.Theerrorbandscanbeuptoanorderofmagnitude.

3. Qualitative wheretheriskisbasedonexperienceandjudgement.Theerrorbandsare relativelylowastherisksarelowbydefinition.TypicallythismayapplytoTask Analysis.

QuantitativeRiskAssessmentwillinevitablytakeinformationfromhumanandhardware vulnerabilitydata(Chapter16).Thismaybeofaphysicalorapsychologicalnaturefor humans.Likewiseforequipmentthedatawillbeestablishedintabularformat.Thephenomenologyisbasedonexperimentallyverifiedmodelssuchasgas(andwherenecessary liquid)dispersion,thermalradiationandblastfromexplosions.Finallytheassessment musthaveasetofagreedcriteriabywhichtheriskcanbeassessed.

3.1Introduction

ThetopicreferredtohereasHazardStudies,usingtheoriginalICIintent(1),hasseveral othernames.Commononesinclude‘HazardStudies1–6’,ProcessSafetyReviews,Project HazardStudiesandProjectSHEReviews.Confusingly,PHAhasalsobeenusedasan abbreviationforPreliminaryHazardAnalysis.

3.2Definition

HazardStudiesareasystematicanalysisofaproject,bothprocessandcontrol,byselected teamsofexperiencedpersonnel,atdefinedphasesduringitsdevelopment,toensurethat thesafetystandardsbuiltintotheprojectsatisfycorporateandnationalstandardsaswell astheproject,corporateandnationalcriteria.

3.3Description

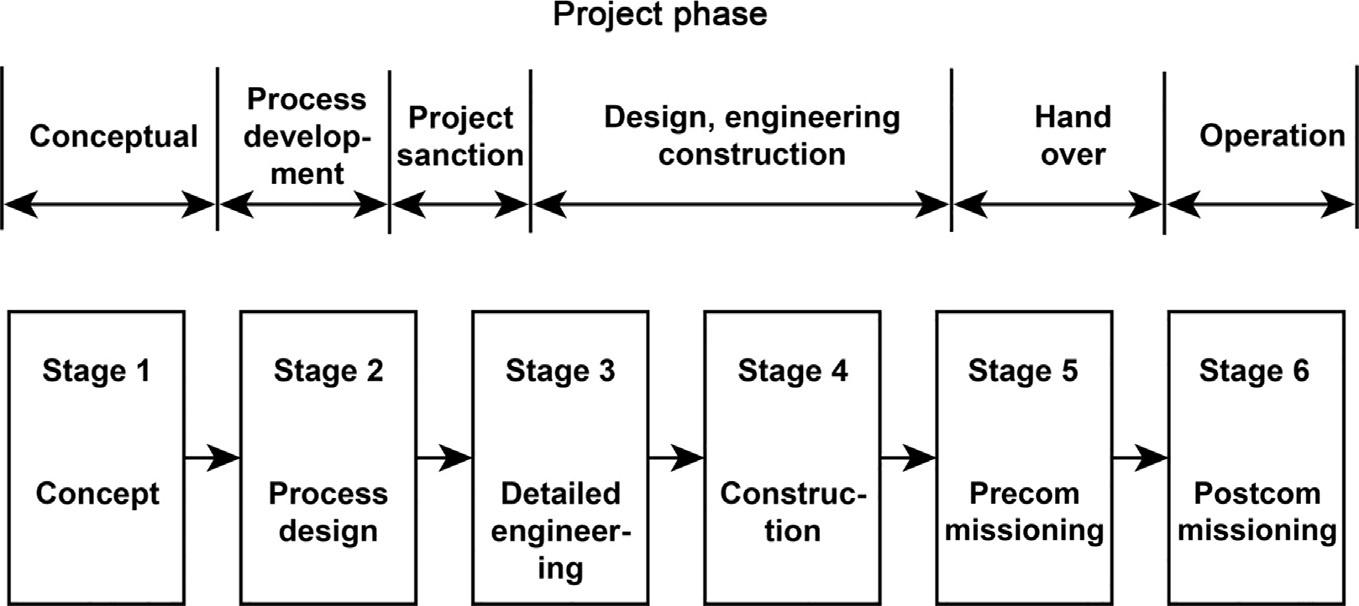

Themostcommonsetofstudies,carriedoutasappropriateduringtheprojectlifecycle, are:

(1) conceptualdesign

(2) front-endengineering(FEED)design—process

(3) detailedengineeringdesign

(4) constructiondesignverification

(5) precommissioningsafetyreview

(6) post-start-up

ThenumbersarethosereferredtointhetraditionalSafetyStudies,asfirstdevelopedby ICIintheearly1970s [1].‘HazardStudies’hasbeenusedinhistext.Itisdescribedby Swann [2] andadaptedbymanyothercompanies.Thecompositionoftheteamand thedocumentationchangesfromstudytostudyastheprojectdevelopsandthedetail becomesmorefixed.Descriptionsofstudies1–6havebeengivenintheliterature [3] with oneaccountinsomedepthalthoughspecificallyforthepharmaceuticalindustry [4].

Inrecentyears,ithasbeencustomarytoaddtwoextrastudies.These,numberedto leavethetraditionalstudynumbers1–6unchanged,are:

(0)inherentlysafer/lessharmfultotheenvironment (7)decommissioninganddemolition

Itisimportanttorecognisethatthesestudiesformacontinuumand,toadegree,flowinto oneanother.Eachlooksbackattheoutcomesoftheprecedingstudyandwillfeedintothe followingstudy.Thetimingisimportantsothateachanalysisisinplaceforthecorrect phaseoftheprojectbutisnotcarriedouttooearly,whenthedefinitionmaystillbeincomplete,ortoolate,whentheoptionsforchangemaybelimited.Thetimingofstages1–6ina normalprojectlifecycleisshownin Fig.3.1.Obviouslystudy0inherencyprecedesstudy1 anddemolitionorabandonmentfollowsstudy6.

FIG.3.1 Sequenceorhazardstudiesinaproject.

Itisimportanttorealisethatsanctionwillbegrantedinbetweenstudies2and3.This valueisusually 10%.Ifsignificantissuesarenotidentifiedbeforesanction,thereisa graveriskofcostoverrunand/orprojectdelays.

Study0:Inherentsafety

Thisstudyiscarriedoutasthedesignoptionsarebeingidentified;itsaimistoexamine andtoapplywherepossibletheprinciplesofinherentlysafedesign [5].Theteamwillbe smallandthestudywillonlylastabout1day.Memberswillincludeaprojectrepresentativetogetherwithaprocessengineer,chemist,safetyengineerandatechnologyexpert. Ideallytherewouldhavebeenacarefulreviewofthehistoryofthattypeofprocess,includingasearchofaccidentdatabases.

Theinherentlysaferprocessstartswithguidewords,typically:

• Intensify

• Attenuate

• Simplify

• Getitrightfirsttime

• Change

• Substitute

• Eliminate

Intensify:Concentratetheprocessinasmaller,higherpressurereactorandreducethe workinginventoryortotalleakpotential.Anexamplemightbeahigh-pressurecatalytic reactor,whichissignificantlysmallerthantheconventionallowpressurereactor.Another mightbetheuseofalinearreactorinsteadofacontinuouslystirredbackmixedreactor. Anothermightbetheuseof‘green-field’equipment,whichhasbytheverynatureofthe designaverylowinventory;someofthemoderncompactheatexchangerswouldfitinto thisheading.Theendpointisthatwhilethepeakoutflowfromahole(lossofcontainment)maybehigherthetotaloutflowwillbesignificantlylower.

Attenuate:Reducetheworkingpressure/temperaturesuchthattheleakrate—should itoccur—islessorlesslikelytoignite/explode.Anexamplemightbetheuseofrefrigeratedstorageofcryogenicsinsteadof‘green-field’storage.Onceagaintheuseofacatalyst lendstoinherency.

Simplify:Thisisself-evident

Getitrightfirsttime:Avoidtheneedforlast-minutechangeorevenrecognisingthe wholespectrumofconditions,whichmayapplytochoosingthecorrectmaterialsforfabricationandthechoiceofdesignpressureforequipment.Itcanalsomean‘de-clutter’the processandavoidasurfeitof‘add-onsafetyfeatures’,whichdolittleforSHEorefficiency butcreateoperationalproblems.

Change:Whiletheconceptofchangeissimple,itdoesrequireabitofthought!Considerthe‘change’inalayoutsuchastosegregateflammablematerialsfromsourcesof ignitionorthepositioningofavalvesuchthataccessisenhanced—thelayoutoraccess