Counter-Revolution: Liberal Europe in Retreat Jan Zielonka

https://ebookmass.com/product/counter-revolution-liberal-europe-inretreat-jan-zielonka/

ebookmass.com

Mario Lavista: Mirrors of Sounds Ana R. Alonso-Minutti

https://ebookmass.com/product/mario-lavista-mirrors-of-sounds-ana-ralonso-minutti/

ebookmass.com

Whole Body Reset: 2 Books in 1: A Perfect Guide To Losing Weight in Your Midlife and Beyond + The Anti-inflammatory Diet to Detoxify your Body,100+ Delicious Recipes and Many Delicious Smoothies Stephanie Myller https://ebookmass.com/product/whole-body-reset-2-books-in-1-a-perfectguide-to-losing-weight-in-your-midlife-and-beyond-the-antiinflammatory-diet-to-detoxify-your-body100-delicious-recipes-and-manydelicious-smoothies-steph/ ebookmass.com

The United States and Contemporary China-Russia Relations : Theoretical Insights and Implications Brandon K. Yoder

https://ebookmass.com/product/the-united-states-and-contemporarychina-russia-relations-theoretical-insights-and-implications-brandonk-yoder/

ebookmass.com

Building the Literacy Block: Structuring the Ultimate ELA Workshop Bridget M. Spackman

https://ebookmass.com/product/building-the-literacy-block-structuringthe-ultimate-ela-workshop-bridget-m-spackman/

ebookmass.com

Sofie Bager-Charleson

https://ebookmass.com/product/supporting-research-in-counselling-andpsychotherapy-qualitative-quantitative-and-mixed-methods-researchsofie-bager-charleson/ ebookmass.com

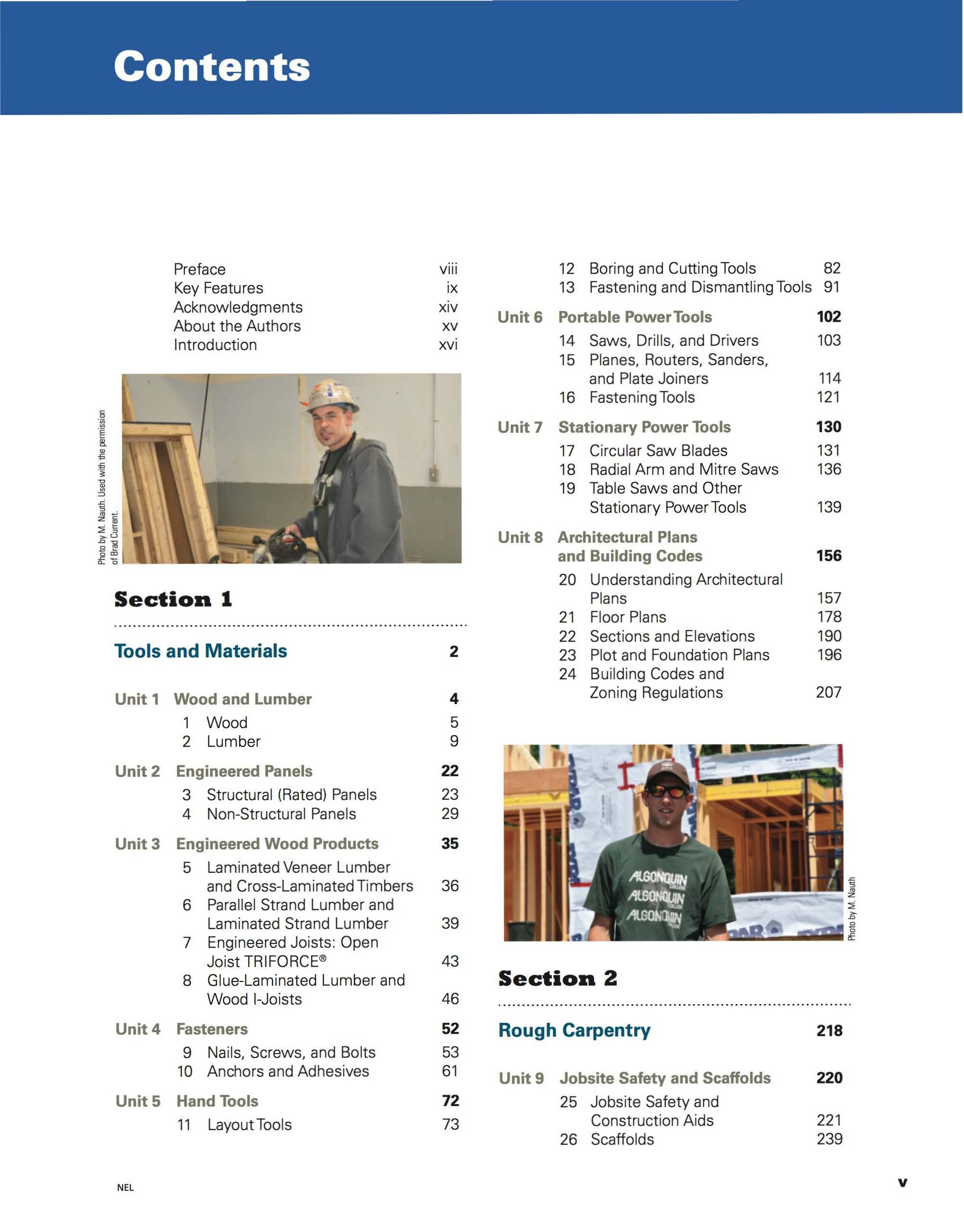

Section 4

elcome to Carpentry, Third Canadian Edition. This text is designed for students who are studying residential construction and who are pursuing careers in the trade either in post-secondary college programs, in apprenticeship programs, or at the senior high school level across Canada. The 2015 National Building Code of Canada is used as the point of reference. All measurements are given in both metric and imperial systems.

APPROACH

The core of the carpentry trade as practised in Canada is covered in four comprehensive sections: Tools and Materials, Rough Carpentry, Exterior Finish, and Interior Finish. Each section features step-by-step procedures for all stages of construction, important safety precautions, tips of the trade, and a look at anticipated future trends in the construction industry.

Section 1: Tools and Materials

This section describes how building materials from wood to engineered wood products to composites are shaped, produced, and applied in their various forms. The Canadian Plywood Association (CANPLY) is referenced. Wood !-joists are included in the discussion of engineered wood products. Information about cross-laminated timber (CLT) and its application in the construction industry has been added to the unit on engineered wood products. The latest fasteners and cordless tools and their batteries are described in their current use in the trade. The final unit on plans and codes has been revised to Canadian standards to provide the student with a basic understanding of how the building components come together to form a structure. The house plans used in Chapter 20 have been provided by Cardel Homes. The Ontario Building Code, 2012, is referenced, as well as the minimum requirements for occupancy.

Section 2: Rough Carpentry

The on-site work starts with locating the building, with the use of surveying instruments (automatic levels, theodolites, and total stations), in its exact

position on the building lot. The site is then excavated. Foundation work in concrete and other materials, waterproofing, drainage tile placement, backfilling, and other associated work then gets the structure above grade. The "clean" work is nextfloor framing, wall framing, and roof framing, using both new and old materials and methods. This unit has been expanded to emphasize the importance and the intricacies of roof work from both a mathematical and a geometric approach, including equal and unequal pitched hip roofs, dormer roofs, hexagonal and octagonal roofs, and gazebo roofs. Timber-frame construction is expanded with detailed drawings for timber joinery from Mohawk College in Hamilton, Ontario. Energy-efficient construction details (R-2000 Program, LEED ®Canada for Homes rating system, and ENERGY STAR®for New Homes initiative) are emphasized with respect to energy and resource conservation and healthy indoor air quality.

Section 3: Exterior Finish

Exterior finish as it pertains to the surroundings"fitting in" instead of sticking out is discussed in terms of the availability and durability of various materials. The installation of roof coverings, sidings, doors and windows, cornice work, decks, and fences is also covered in this section. Special attention is paid to first and second planes of protection, end dams, air leakage control, ventilation, and the insulation values of materials.

Section 4: Interior Finish

The section on interior finishes begins by discussing how drywall is applied to walls and ceilings. It then describes how other finishes are applied to these surfaces, as well as to floors. The hanging of interior doors is discussed, followed by the installation of various trim mouldings to windows, doors, walls, and ceilings. The section then covers how to construct a finished set of stairs with a balustrade. The book ends by explaining how to install manufactured cabinets and countertops and how to construct countertops, unit boxes, and drawers from various materials.

A Success Story opens each of the sections in the book, providing a look at the day -to-day job of a carpenter and the successes accomplished through dedication and education.

Safety Reminders and Cautions prominently feature the latest safety considerations s o that readers can avoid the dangers of certain procedures, tools , and equipment in order to

Step by Step Procedures walk readers through the key tasks associated with specific residential building tasks, including On the Job tips of the trade.

Visually intensive content featuring photorealistic drawings and full-colour jobsite photos, from live construction sites in geographically diverse locations in Canada, bridge the gap between the classroom and the jobsite.

THE THIRD CANADIAN EDITION

• • A full-colour design br i ngs the jobsite to lifeintegrating photo-realistic drawings drawn to scale and on-the-job photos from construction projects across Canada and the United States.

metric

conversions are

Measurements in the text are recorded in both and imperial. Some

approximate, such as 4 feet (1.2 m), whereas others are exact, especially in building code references, such as 7 inches (200 mm) for the maximum rise for a set of stairs to a dwelling unit. Safety information retains its prominence in the text, including a section titled "Safety at the Worksite" in the Introduction, unit-opening Safety Reminders to alert students to potentially dangerous situations on the job, and Cautions to

help prevent accidents when working with various tools of the trade.

• A section in the Introduction covers the critical soft skills required of successful and proficient carpenters. Coverage of important organizations, including the Carpenters' Union and Skills Canada, helps students keep up to date on industry expectations.

• A Success Story opens each of the four sections, highlighting a successful account of an individual working on carpentry jobs in different regions of the country, and providing insight into the industry.

• Structural and health and safety issues are aligned to the National Building Code of Canada (NBCC), 2015 edition.

New to this third Canadian edition are the following:

• New and revised drawings and photos on heavy concrete construction, including piles, precast, pre- and post-tensioning, fly-forms, slip forms, shoring, and more.

• A What's Wrong with This Picture? feature at the end of some units that includes an incorrect application or scenario as well as a corrected one.

• The Deconstruct This feature illustrates situations where a problem may or may not exist in the construction process, giving students the opportunity to consider what is right and wrong and to develop their critical thinking skills.

• An up-to-date Canadian path to obtaining training in preparation for taking the Inter- Provincial Red Seal Certificate of Qualification Exam.

• Improved coverage of stationary and portable power tools, the anti-kickback splitter and riving knife for the table saw, and setup for the

•

• JOinter.

• Expanded coverage of insulated concrete forms (ICF), monopour ICF, rebar vibrator, and power screed.

• Added information on stair building, stairwell opening, landings, and circular stairs.

• Correct installation of steel studs and new techniques and construction aids for the application of drywall.

• Expanded CAD drawings to illustrate the determination of lengths and angles of rafters and sheathing for hip roofs, including setting the top of ridge and the drop and backing bevel for the hip rafter.

• The use of construction geometry to start with the plan view of roofs and to "unfold" them to illustrate actual roof surface.

• Revisions to the chapter on unequal pitched roofs and intersecting roofs (including dormer roofs), as well as hexagonal and octagonal roof rafter lengths, side cut angles, and backing angles.

• A complete set of construction drawings for timber framing (from Mohawk College) and structural insulated panels (SIPs) installation methods.

• Updates to energy-efficient housing, which highlights building science and its important impact on current practices and products such as increased air sealing, reduced thermal bridging, acoustical sealants, and heat recovery ventilators.

• A revised chart on Canada's climate zones for windows, including degree days.

• Methods to reduce sound transmission within the building envelope complete with Building Code references.

• Revised treatment of composite decking, air-gap at ledgers, Fast- Tube concrete piers, guardrails, and code references.

• Added discussion of drywall butt joints, ceiling drywall, 54-inch panels, and paper-faced corner bead.

• Added discussion of ceramic tile un-coupling membrane and shower bases.

• New photos for mitre saw compound angles and jigsaw templates for cutting crown moulding.

• Added discussion of cork, bamboo, and engineered flooring and OSB tiles for basement floors.

• Up-to-date information on frameless kitchen cabinets, European hardware, and composite, granite, and wood-edged countertops.

INSTRUCTOR RESOURCES

The Nelson Education Teaching Advantage (NETA) program delivers research-based instructor resources that promote student engagement and higher-order thinking to enable the success of Canadian students and educators. Visit Nelson Education's Inspired

Instruction website at www.nelson.com/inspired to find out more about NETA.

The following instructor resources have been created for Carpentry, Third Canadian Edition. Access these ultimate tools for customizing lectures and presentations at www.nelson.com/instructor

NETA Test Bank

This resource was written by Tim Dorn, Okanagan College. It includes over 1500 multiple-choice questions written according to NETA guidelines for effective construction and the development of higher-order • questtons.

Rdl-Circle Assessment•

The NETA Test Bank is available in a new, cloudbased platform. Nelson Testing Powered by Cognero ® is a secure online testing system that allows instructors to author, edit, and manage test bank content from anywhere Internet access is available. No special installations or downloads are needed, and the desktop-inspired interface, with its drop-down menus and familiar, intuitive tools, allows instructors to create and manage tests with ease. Multiple test versions can be created in an instant, and content can be imported or exported into other systems. Tests can be delivered from a learning management system, the classroom, or wherever an instructor chooses. Nelson Testing Powered by Cognero for Carpentry, Third Canadian Edition, can also be accessed through www.nelson.com/instructor

NETA PowerPoint

Microsoft ® PowerPoint® lecture slides for every chapter have been created by Brad MacDonald, Mohawk College. There is an average of 25 slides per chapter, featuring an outline of the chapter, key figures, drawings, photos, tables, and procedures from Carpentry, Third Canadian Edition. NETA principles of clear design and engaging content have been incorporated throughout, making it simple for instructors to customize the deck for their courses.

Image Library

This resource consists of digital copies of figures, drawings, photographs, and procedures used in the book. Instructors may use these jpegs to customize the NETA PowerPoint or create their own PowerPoint presentations.

Videos

Instructors can enhance the classroom experience with the exciting and relevant videos provided directly to students through MindTap. These videos have been selected to accompany Carpentry, Third Canadian Edition.

NETA Instructor Guide

The Instructor's Guide to accompany Carpentry, Third Canadian Edition, has been prepared by Brad MacDonald, Mohawk College. This guide contains many helpful tools to facilitate effective classroom presentations of material comprehensive Lesson Plans, integrated PowerPoint® references and teaching tips, a review of important math, blueprint reading to help evaluate student knowledge at the start of the course, and Answers to Review Questions. A separate Note to the Instructor includes valuable information on effectively teaching construction students everything from learning styles to safety on the worksite is covered in this introduction to the course.

DayOne Slides

Day One--Prof InClass is a PowerPoint presentation that instructors can customize to orient students to the class and their text at the beginning of the course.

MindTap

Offering personalized paths of dynamic assignments and applications, MindTap is a digital learning solution that turns cookie cutter into cutting edge, apathy into engagement, and memorizers into higher-level thinkers. MindTap enables students to analyze and apply chapter concepts within relevant assignments, and allows instructors to measure skills and promote better outcomes with ease. A fully online learning solution, MindTap combines all student learning tools readings, multimedia, activities, and assessments into a single Learning Path that guides the student through the curriculum. Instructors personalize the experience by customizing the presentation of these learning tools to their students, even seamlessly introducing their own content into the Learning Path.

STUDENT ANCILLARIES

MindTap

1n a

Stay organized and efficient with MindTap a single destination with all the course material and study aids you need to succeed. Built-in apps leverage social media and the latest learning technology, including the following:

• ReadSpeaker will read the text to you.

• Flashcards are pre-populated to provide you with a jump start for review or you can create your own.

• You can highlight text and make notes in your MindTap Reader. Your notes will flow into Evernote, the electronic notebook app that you can access anywhere when it's time to study for the exam.

• Videos to apply the concepts you learn in class.

• Self-quizzing allows you to assess your understanding.

Visit www.nelson.com/student to start using MindTap. Enter the Online Access Code from the card included with your text. If a code card is not provided, you can purchase instant access at NELSONbrain.com

Workbook

A workbook that provides a wide range of practice problems to reinforce concepts learned in each chapter, as well as to prepare you for exams, is available for students. Question types include multiple choice, completion, and identification as well as critical math problems and soft skill activities. Instructors may assign these questions as homework to ensure full comprehension of the material.

he publisher and author of Carpentry, Third Canadian Edition, wish to sincerely thank those who contributed to this book. Our gratitude is extended to those reviewers who contributed to the revision: Hank Bangma, Thompson Rivers University; Barry Botham, St. Lawrence College; Donnie Brown, Holland College; Don Fishley, Durham College; Julie Lewis, George Brown College; Brad MacDonald, Mohawk College; and Ted Zak, University of the Fraser Valley.

We continue to benefit from the insightful comments of reviewers of previous editions: Hank Bangma, Thompson Rivers University; Chuck Barsony, Loyalist College; Jeff Chow, SIAST; Rick Dohl, BCIT; Tim Dorn, Okanagan College; Bruce Fergstad, Winnipeg Technical College; Murray Fleece, SIAST; Rob Gilchrist, Conestoga College; Steve Laing, Fanshawe College; Doug Laporte, George Brown College; Tom Newton, Camosun College; Rob Passmore, Canadore College; Dana Rushton, NSCC; AI Scott, Niagara College; and Kim Woodman, Georgian College. Their insights and recommendations were invaluable.

Special thanks to Kevin LeMay of Algonquin College, to Andris Balodis of Conestoga College, to Rick Dohl of the British Columbia Institute of Technology (BCIT), and to Greg Kenny of Algonquin College, for their significant input on necessary

additions and changes to the Canadian author's submissions.

Thanks also to Jeff Acciaccaferro from Mohawk College for his help with the chapter on timber framing, both with the content and with the photographs.

The supplemental package could not have been completed without the help of four talented instructors to Timothy Dorn for the Test Bank, to Brad MacDonald for the PowerPoint and the Instructor's Guide, to Kevin LeMay for MindTap, and to Kim Woodman for the Student Workbook, our many thanks.

And to the Nelson Education team, whose dedication to the project produced quality learning materials for aspiring carpenters everywhere Jackie Wood, publisher; Toula DiLeo, content development manager; Carrie McGregor, permissions coordinator; Christine Gilbert, production project manager; and Michael Kelly, copy editor thanks to you all!

A special thanks to all the many tradespeople who were willing to share their techniques and to pause in their tasks for pictures. Last and most, thanks to my wife, Barb, for her gracious support.

Michael Nauth

loyd Vogt is a sixth-generation carpenter/builder. He was raised in a family with a business devoted to all phases of home construction, and began working in the family business at age fifteen.

After completing a B.A. in chemistry from the State University of New York at Oneonta, Mr. Vogt returned to the field as a self-employed remodeller. In 1985, he began teaching in the Carpentry program at the State University of New York at Delhi in Delhi, New York (www.delhi.edu ). He has taught many courses, including Light Framing, Advanced

ichael Nauth was born in Guyana. His family immigrated to Canada in 1967. He finished high school in Scarborough, Ontario, and began working in construction in 1972, in both the residential and commercial sectors. He obtained his carpenter's licence in 1978 in Fort St. John, British Columbia. After moving to Ottawa, he started a residential construction company. He obtained his Ontario licence in the early 1990s. A few years later he passed the Inter-Provincial Certificate of Qualification Red Seal Exam.

Michael took training to teach in carpentry, receiving his diploma from McGill University in Montreal. He would later complete a B.Sc. in mathematics at Carleton University in Ottawa. He began teaching night school in carpentry at Algonquin College (Ottawa) in 1984; he was hired as a full-time professor of the Carpentry Apprenticeship programs. He is currently enrolled in the Master of Education in Educational Administration and Policy program at St. Francis Xavier University in Antigonish, Nova Scotia.

Framing, Math, Energy Efficient Construction, Finish Carpentry, Finish Masonry, and Estimating. Currently, Mr. Vogt is a professor in construction design-build management, bachelor's degree program at Delhi. Course responsibilities include Residential Construction, AutoCAD, Construction Seminar, and Physical Science Applications. He has served as a carpentry regional coordinator for SkillsUSA and postsecondary Skills-USA student advisor. He is currently a member of a local town planning board. He is available by e-mail at vogtfh@delhi.edu •

Michael has also served as a building supervisor, foreman, and board member with Habitat for Humanity National Capital. He has worked with Global Village in Honduras, Nicaragua, and Yukon assisting in the building of homes, the establishment of septic systems, and the delivery of potable water. He has coordinated and judged carpentry competitions for Skills Canada-Ontario and for the Carpenters' Union, Local 93. Besides several other construction textbooks, he has reviewed Canada Mortgage and Housing Corporation's Canadian Wood Frame House Construction, 2005 edition. He has worked as a carpenter and a trainer in Russia and is currently engaged by Canada Wood to assist with training needs and quality assurance of the residential construction industry in China.

Michael is the proud father of four sons: Aaron, Anthony, Jason, and Jonathan. They have all helped Dad in the summers on the construction site and have experienced, firsthand, the adrenaline rush, the addictive buzz, and the sweet sleep that follows an honest, hard day's work.

he history of carpentry goes back to 8000 B.C., when primitive people used stone axes to shape wood to build shelters. Stone Age Europeans built rectangular timber houses more than 100 feet (30m) long proving the existence of carpentry even at this early date. The Egyptians used copper woodworking tools as early as 4000 B.C. By 2000 B.C. they had developed bronze tools and were proficient in the drilling, dovetailing, mitring, and mortising of wood.

In the Roman Empire, two-wheeled chariots, called carpentum in Latin, were made of wood. A person who built such chariots was called a carpentarius, from which the English word carpenter is derived. Roman carpenters handled iron adzes, saws, rasps, awls, gouges, and planes.

During the Middle Ages, most carpenters were found in larger towns where work was plentiful. They would a lso travel with their tools to outlying villages or wherever there was a major construction project in progress. By this time, they had many efficient, steel-edged hand tools. During this period, skillful carpentry was required for the building of timber churches and castles.

In the twelfth century, carpenters banded together to form guilds. The members of the guild were divided into masters, journeymen, and apprentices. The master was a carpenter with much experience and knowledge who trained apprentices. The

apprentice lived with the master and was given food, clothing, and shelter and worked without pay. After five to nine years, the apprentice became a journeyman who worked and travelled for wages. Eventually, a journeyman could become a master. Guilds were the forerunners of the modern labour unions and associations.

Starting in the fifteenth century, carpenters used great skill in constructing the splendid buildings of the Renaissance period and afterward. With the introduction of the balloon frame in the early nineteenth century, more modern construction began to replace the slower mortise-and-tenon frame. In 1873, electric power was used for the first time to drive machine tools. The first electric hand drill was developed in 1917, and by 1925, electric portable saws were being used.

At present, many power tools are available to the carpenter to speed up the work. Although the scope of the carpenter's work has been reduced by the use of manufactured parts, some of the same skills carpenters used in years past are still needed for the intricate interior finish work in buildings.

Carpenters construct and repair structures and their parts using wood, plywood, and other building materials. They lay out, cut, fit, and fasten the materials to erect the framework and apply the finish. They build houses, factories, banks, schoo ls, hospitals, churches, bridges, dams, and other structures. In addition to new construction, a large part of the industry is engaged in the remodelling and repair of existing buildings.

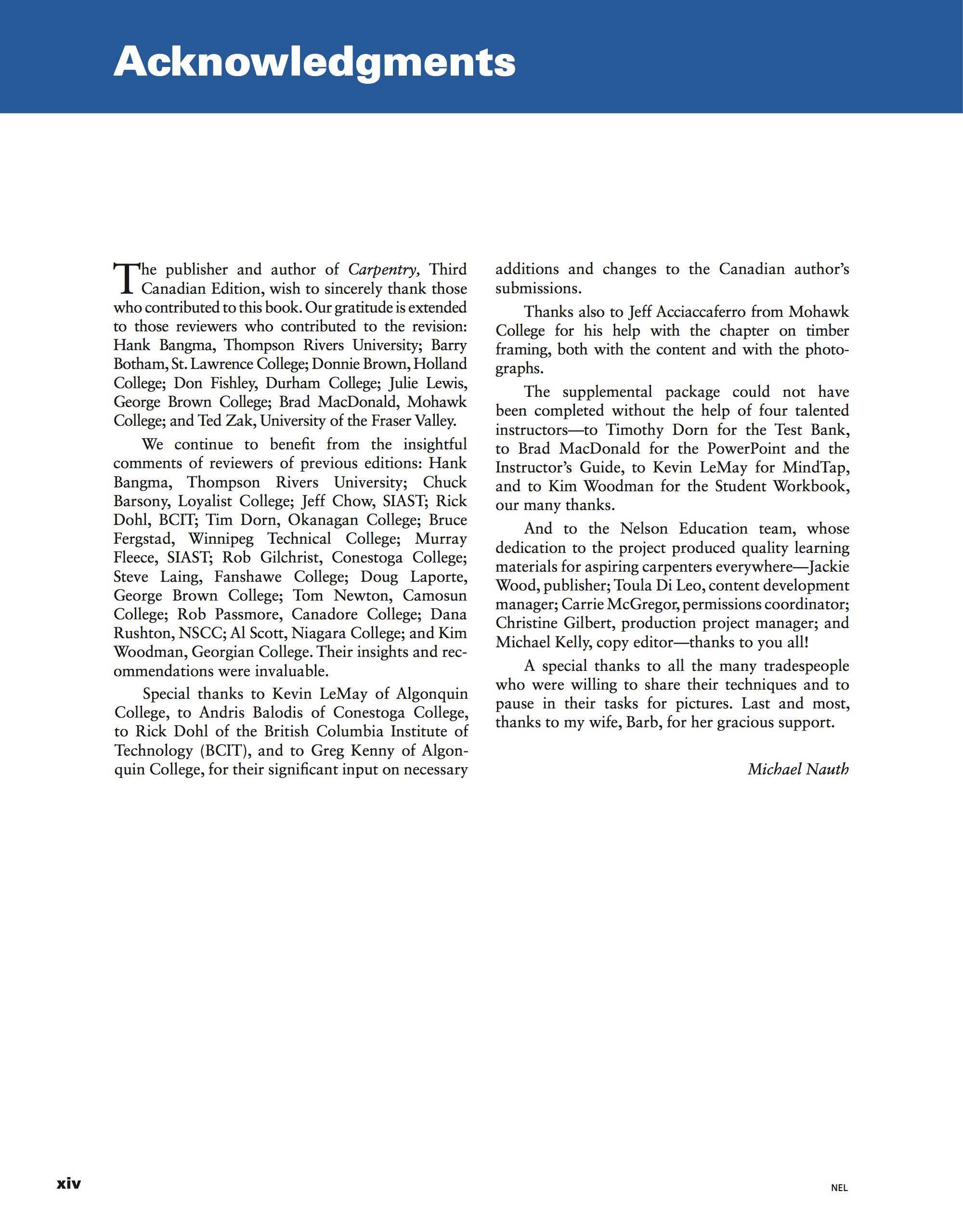

The majority of workers in the construction industry are carpenters (Figure I-1). They are the first trade workers on the job, laying out excavation and building lines. They take part in every phase of the construction, working below the ground, at ground level, or at great heights. They are the last to leave the job when they put the key in the lock.

SPECIALIZATION

In large cities, where there is a great volume of construction, carpenters tend to specialize in one area of the trade. They may be specialists in rough carpentry, who are called rough carpenters or framers (Figure 1-2).

FIGURE 1-1 Carpenters make up t he majority of wor kers in the cons t ruct ion industry

Rough carpentry does not mean that the workmanship is crude. They typically measure to within 1;1 6 inch (2 mm). Just as much care is taken in the rough work as in any other work. Rough carpentry will be covered eventually by the finish work or will be dismantled, as in the case of concrete form construction.

Finish carpenters specialize in applying exterior and interior finish, sometimes called trim (Figure 1-3 ). Many materials require the finish carpenter to measure to tolerances of 73 2 or Y 6 4 of an inch (1 or 0.5 mm). Other specialties are constructing concrete forms (Figure 1-4 ), laying finish flooring, building stairs, applying roofing (Figure 1-5 ), insulating, and installing suspended ce i lings.

In smaller communities, where the volume of construction is lighter, carpenters often perform tasks i n all areas of the trade from the rough to the finish. Such communities may have workers who perform

ca r pen t e r s choose t o do only roof ing wo r k .

all aspects of construction, including plumbing, electrical work, and excavating. The general carpenter needs a more complete knowledge of the trade than the specialist does.

REQUIREMENTS

Every occupation sets specific requirements for its workers. These include the skills necessary to perform each task and an attitude or mind-set the workers should have while on the job. Construction skills vary to fit the type of work being performed.

FIGURE 1-2 Some ca r pen t e r s specia li ze in framing

FIGURE 1-3 Carpenters may be specialis t s in applying

nt

ior trim.

FIGURE 1-4 Erecting concre t e formwork may be a special t y ------

FIGURE 1-5 Some

They tend to be clearly defined, and it is easy to determine whether a worker possesses these skills. The construction attitude is less tangible, but no less important. While work may continue if the workers have only the required skills, minor or severe slowdowns are inevitable if workers do not have the proper attitude.

Skill

Carpenters need to know how to use and maintain hand and power tools. They need to know the kinds, grades, and characteristics of the materials with which they work how each can be cut, shaped, and most satisfactorily joined. Carpenters must be familiar with the many different fasteners available and choose the most appropriate ones for each task.

Carpenters should know how to lay out and frame floors, walls, stairs, and roofs. They must know how to install windows and doors and how to apply numerous kinds of exterior and interior finish. They must use good judgment to decide on proper procedures to do the job at hand in the most efficient and safest manner.

Carpenters need to be in good physical condition, because much of the work is done by hand and sometimes requires great exertion. They must be able to lift large sheets of plywood, heavy wood timbers, and bundles of roof shingles; they also have to climb ladders and work on scaffolds.

Carpenters need reading and math skills. Much of construction begins as an idea put on paper. A carpenter must be able to interpret these ideas from the written form to create the desired structure. This is done by reading prints and using a ruler. The quantity of material needed must be estimated using math and geometry. Accurate measurements and calculations speed the construction process and reduce waste of materials.

Communication skills are also very important. Carpenters must communicate with many people during the construction process. Work to be done as determined by the owner or architect must be accurately understood, otherwise costly delays and expenses may result. Efficiency of work relies heavily on workers' understanding of what others are doing and what work must be done next. Communication is vital for a jobsite to be safe.

Attitude

The proper construction attitude is not as clearly defined as job skills. Regional variations and requirements will affect the expected jobsite attitude. For

example, in regions where heat is a concern, workers develop a steady rhythm to their work that survives the heat. In regions where winters are harsh, workers develop a faster style of work when the weather is warm, knowing they rna y have downtime in the winter. Other attitudes, such as having a good work ethic, are universal to all jobsites.

A good ethic is not easily defined in one sentence. It involves the person as a whole, the way he or she approaches life and work. A person with a good work ethic has respect and lets it show. Respect for the jobsite, co-workers, tools and materials, and themselves reveals care and concern for the construction process. Workers demonstrating this form of respect are safe and more pleasant to work alongside.

Workers with a good work ethic show up 15 minutes early, not a few minutes late. When finished with a task, they look for something else to do that promotes the job, even if it's using a broom. They perform their tasks as well as expected, up to the standard required for that application. They finish the task, not leaving something undone for someone else to fix. They are interested in learning, looking around at the work of others for ways to improve their own skills. They cooperate with other workers and tradespeople to make the jobsite a pleasant workplace. They are also honest with the material and their time, never cheating on the accepted method. They feel that nothing less than a first-class job is acceptable.

Jobsite humour makes work easier to do and more fun. Some tasks, by their very nature, are boring and unpleasant. Humour can make difficult jobs seem to get done faster. Unfortunately, humour has a bad side because humour for one person can be pain for another. Jobsite humour can be tasteless. It can single out a person, making him or her feel alienated. This type of humour can have severe effects on jobsite safety. Someone who feels like a victim will feel defensive and will not concentrate on what he or she is doing. During these times, unintended things can happen and someone may get hurt. Keep jobsite humour suitable for everyone present.

There is no replacement for teamwork on the jobsite. Someone once said, "Two people working together can outperform three people working alone." This is easily seen when one person holds material to be fastened or cut for another. But the difference between the team and individuals is more dramatic when each member of the team anticipates the next move of the other. For example, while holding a board that is being fastened, that person looks to see what else can be done. Is more

material needed? Does the horse or ladder have to be moved into a better position? Will there be another tool needed? How can the tool best be handed to the co-worker? It can be easy to miss this type of teamwork when it is done without words and without being asked.

Another way a team works better is in the mental energy used on the job. Two pairs of eyes working on one task can ward off errors and mistakes. Two minds can find the better, faster, safer method. Teamwork is a major reason why people stay in construction for a lifetime.

BUILDINGYOUR CAREER AS A CARPENTER

Across Canada, education and skills training fall under the jurisdiction of the provinces. This means that while there are various paths for apprentices to follow,

depending on the province, all must serve time on the job under the tutelage of a journeyperson and pass the same Inter- Provincial Certificate of Qualification Red Seal Exam with a minimum score of 70 percent.

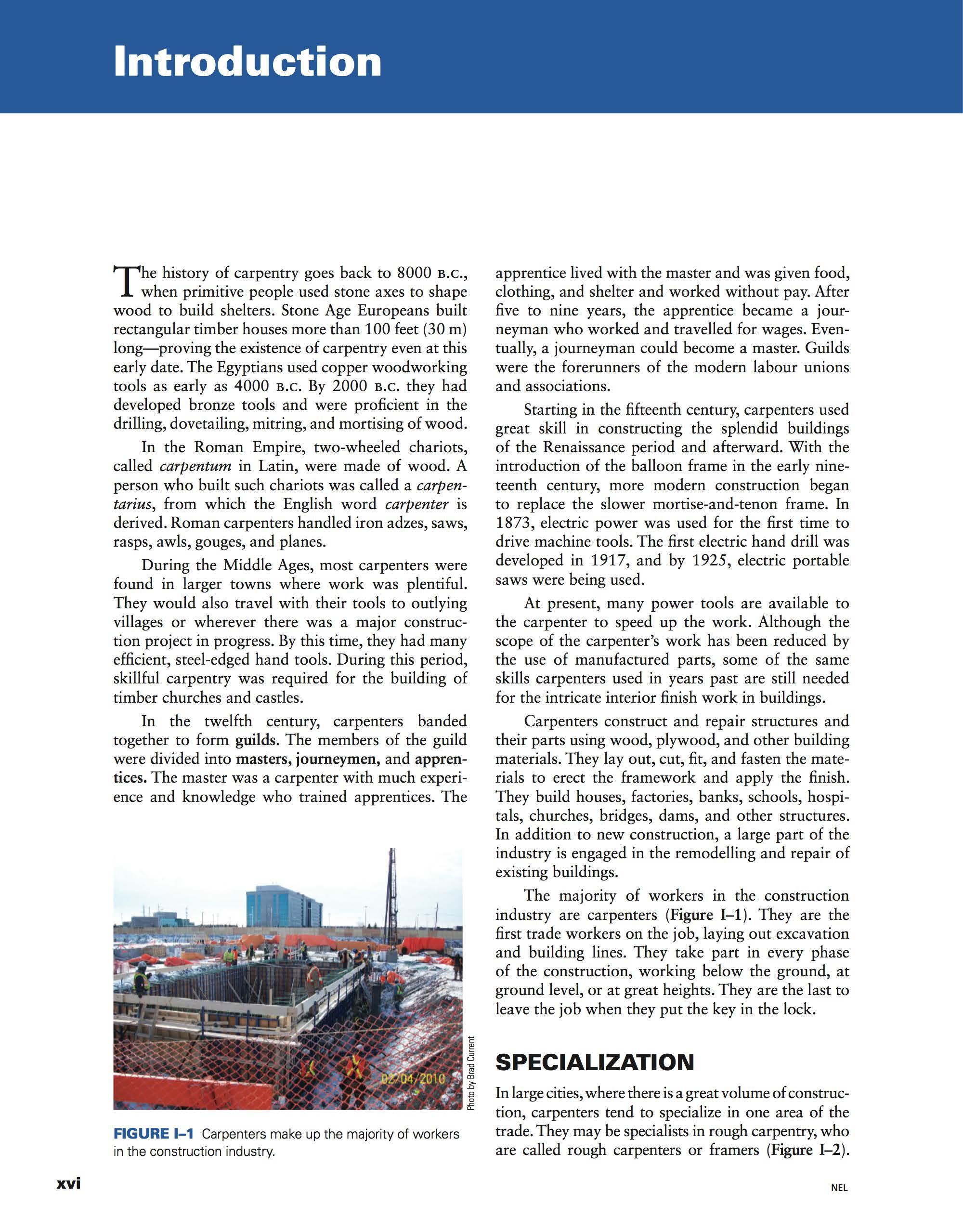

There are several paths toward the goal of journeyperson, but all of them require that the traveller achieve competence in both skill and knowledge. The first and most important path is that of apprenticeship (Figure I-6). The educational prerequisite for apprenticeship varies from grade 9 to grade 12 (minimum age 16). However, the Canadian Council of Directors of Apprenticeship (CCDA) advises that most employers require prospective apprentices to have grade 12 or the equivalent. Also, there is a provincially specified ratio of journeypersons to apprentices, in most cases 1:1.

To become an apprentice, the young worker must find a licensed employer who is willing to indenture him or her and then sign an agreement with that

APPRENTICESHIP AND TRAINING SYSTEM OF THE CARPENTRY TRADE

Canadian Construction Association Provincial Construction Association Local Construction Association General Contractors

United Brotherhood of Carpenters and Joiners of America

Carpenters' Union Provincial Apprenticeship (Advisory) Committee

Labour-Management and Provincial Ministry

Local Apprenticeship Committee

Labour-Management and Provincial Ministry

APPRENTICES

TRAINING DELIVERY AGENTS

Colleges, Institutes of Technology, Union Training Centres

Canadian Home Builders' Association Provincial Home Builders' Association Local Home Builders' Association Renovators' Council

FIGURE 1-6 Employers in commerc ial and res idential construc t ion indus t ry assoc iat ions work together w ith labour and government organ iza ti ons in appren t iceship programs.

employer and with the provincial ministry responsible for skills training. In Ontario, Carpentry Apprenticeship falls under the purview of the Ontario College of Trades. The apprentice's name then goes on a list, and he or she is called to go to school for the in-school portion of apprenticeship training. This type of training is called block release and can be in three or four blocks of six to eight weeks at a time. (Some of the Maritime provinces and Quebec have individualized learning packages rather than block release.) Usually, the apprentice takes a level of inschool training, works for a year, and then takes the next level. Human Resources and Skills Development Canada (HRSDC) is currently working with the provinces and territories to standardize the delivery of the in-school portion of apprenticeship training.

After the in-school training or the modularized training is complete, and all of the required on-the-job hours have been served, the apprentice is entitled to write the Certificate of Qualification Exam (C of Q) and obtain journeyperson status. Passing the Red Seal exam allows the carpenter to receive recognition and top dollar right across Canada.

Apprenticeship in-school training generally has a fee attached to it, though some provinces offer it as a free service. While attending school, the qualifying apprentice will receive Employment Insurance and in some cases travel and cost-ofliving allowances. To help offset the cost to the apprentice, the federal government has launched the Apprentice Incentive Grant (AIG) for Red Seal trades, which offers $1000 per level to apprentices who have successfully completed Ievell and level2 of the in -school portion of their training. There are also "loans for tools" and tax credits for apprentices. Upon successful completion of the Red Seal Exam, the "new" journeyperson receives a grant of $2000.

Another route to achieving journeyperson status is to complete pertinent postsecondary technician and technologist programs and receive credit for one or two levels of the in-school portion of apprenticeship training. This path provides novices with marketable skills to help them find employment with a company that will train them in the trade. This path costs more, but it also equips participants with "soft" skills relating to the construction industry, such as AutoCAD, surveying, business ethics, technical reporting, project planning, and accounting. Many employers find that individuals with this wellrounded background are valuable assets to their operations (Figure I-7).

A third way to get a carpenter's licence is referred to as the "Trade Qualifiers" way. This is intended for

older carpenters who have worked for many years on the job but who lack the financial or educational resources to go to school to get training. Having shown proof of the hours they have spent on the job, they are given the opportunity to take the C of Q exam. With sufficient preparation in trade calculations, safety training, and building code familiarization, many have succeeded. The C of Q is designed to test what the apprentice has learned on the job. Clearly, then, experience counts.

Many opportunities exist for the journeyperson carpenter. Advancement depends on dependability, skill, productivity, and ingenuity, among other characteristics. Carpentry foremen, construction superintendents, and general contractors usually rise from the ranks of the journeyperson carpenters. Many who start as apprentice carpenters eventually operate their own construction firms. A survey revealed that 90 percent of the top officials (presidents, vice presidents, owners, and partners) of construction companies who replied began their careers as apprentices. Many of the project managers, superintendents, and craft supervisors employed by these companies also began as apprentices.

National student organizations such as Skills Canada offer students training in leadership, teamwork, citizenship, and character development. The organization helps build and reinforce work attitudes, self-confidence, and communications skills for the future workforce. It emphasizes total quality at work, high ethical standards, superior work skills, and pride in the dignity of work. Skills Canada also promotes involvement in community service activities. Yearlong student activities culminate with skill competitions where local winners move up to regional, provincial, and then national and international levels.

FIGURE 1-7 Many opportun ities l ie ahead for the apprent ice carpen t er.

SAFETY ATTHE WORKSITE

Much of the work performed in construction carries risk with it. Although the risk will vary with the type of work, all construction workers, at some point, may be at risk of being maimed or killed on the job.

Tools are, by their very nature, dangerous to use. Each must be operated in a fashion suited to the design of the tool. Some tools can cause cuts, while others can kill. Safety cannot be taken for granted and must be built into the methods and processes being used for any particular task. Unusual situations leading to accidents can happen at any time. For example, a roofing carpenter can be thrown to the ground by a gust of wind, cleanup workers can be injured by falling objects from a scaffold, and trim carpenters can fall through a stairway opening that is under construction. Safety is like the air we breathe: It must be everywhere all of the time in order for workers to survive.

Jobsite safety is like team sportsmanship. Everyone on the team must work together and play by the same rules or someone is at risk of being injured. Safety is like silence: Just as everyone in a room must agree to be silent for silence to exist, so too everyone on the job must agree to be safe for safety to exist. One person can create a situation where dozens of workers will be at risk. All safety programs are successful only because workers join the team.

Safe Work Practices

Safe methods and practices learned correctly today will develop into habits that will become second nature for a lifetime. Always approach new tasks thoughtfully and carefully. If a new tool is being used, become familiar with its requirements. Adapt to the tool, because it cannot adapt to you. Always read and follow the directions associated with the tool or task. Read the manufacturer's recommendations for use and installation. Manufacturers clearly define the risks and recommended uses. Failure to follow their instructions is foolish and short-sighted. Always use the safety devices designed into a tool. They are there to protect the operator, not to make it harder to use the tool. Always remember where you are and the possible dangers of the worksite. Horseplay and practical jokes are distracting to everyone around. When horseplay happens, the work environment is less safe. Workers have suffered permanent back injuries while lifting an object too fast because someone touched them inappropriately. Respect is the key word to safety. Always listen and communicate fully. Think of possible ways for misunderstanding and clear them up. The only stupid question is the one not asked.

Safe Work Conditions

Safe work conditions are not hard to create, yet they can be easily neglected. Always maintain clear areas for working and walking. Store materials in an orderly fashion and dispose of waste materials as they are produced. If you stumble and struggle for a place to stand, then safety risks have increased. Always work to keep the area as dry as possible. Sweep water puddles away or make small trenches to divert the water. Keep electrical cords and tools dry. Always maintain tools and equipment according to manufacturer's recommendations. Equipment needs may include lubrication, cleaning, drying, or inspection. Always understand the risks associated with building materials. All workers are to have access to information on the hazards of materials they are working with through Material Safety Data Sheets (MSDSs). Read them. Always look for ways to keep fires from starting. Any possible heat source should be carefully studied and isolated from starting fires. Always be aware of the effect of air temperature on safety. Cold or frozen areas can be slippery to work on. Hot areas can have soft material that is easily marred. Always wear personal protective equipment. Eyes, ears, and airways should be protected when injury is possible. It is easier to understand why eyes are important to protect. Most of our perception of the world comes through our eyes. But ear, lung, and sinus damage often occurs slowly. Most times they do not show any effects for years. Personal protection is a personal responsibility.

Construction efficiency and jobsite safety require good listening skills. Listening to what is asked and performing that task efficiently is one form of good listening. It is just as important to listen to the sounds of the job. Most sounds are normal, some are not. A saw cutting wood, a mixer mixing mortar, a generator providing power, and the bangs, taps, and thuds of construction are examples of normal noises. As workers become acquainted and accustomed to these sounds, it is important for them to be able to tell when these sounds change. A change in sound can be an early warning signal that something is wrong. It could be that something is about to break or that someone is in trouble and needs assistance.

OCCUPATIONAL HEALTH AND SAFETY

The Canadian federal government states that all Canadians have the right to work in a safe and healthy environment. However, it is the provincial ministries and departments that have jurisdiction over jobsite safety. Each province has set regulations for health and safety practices on construction projects. Those

who contravene these regulations can be punished by fines, job shutdowns, and even jail time. Every construction worker is protected by the Workers' Compensation Act and the Workplace Safety and Insurance Board (WSIB). Contact your provincial government offices or go online to your provincial government's website for more information.

Provincial construction safety associations have been established to provide research information, education, and training in the field of occupational health and safety. It is the employer's responsibility to ensure a safe and healthy workplace and to provide training for employees. It is the employee's responsibility to follow the safety rules, especially when it comes to wearing properly fitted personal •

protective equipment.

SUMMARY

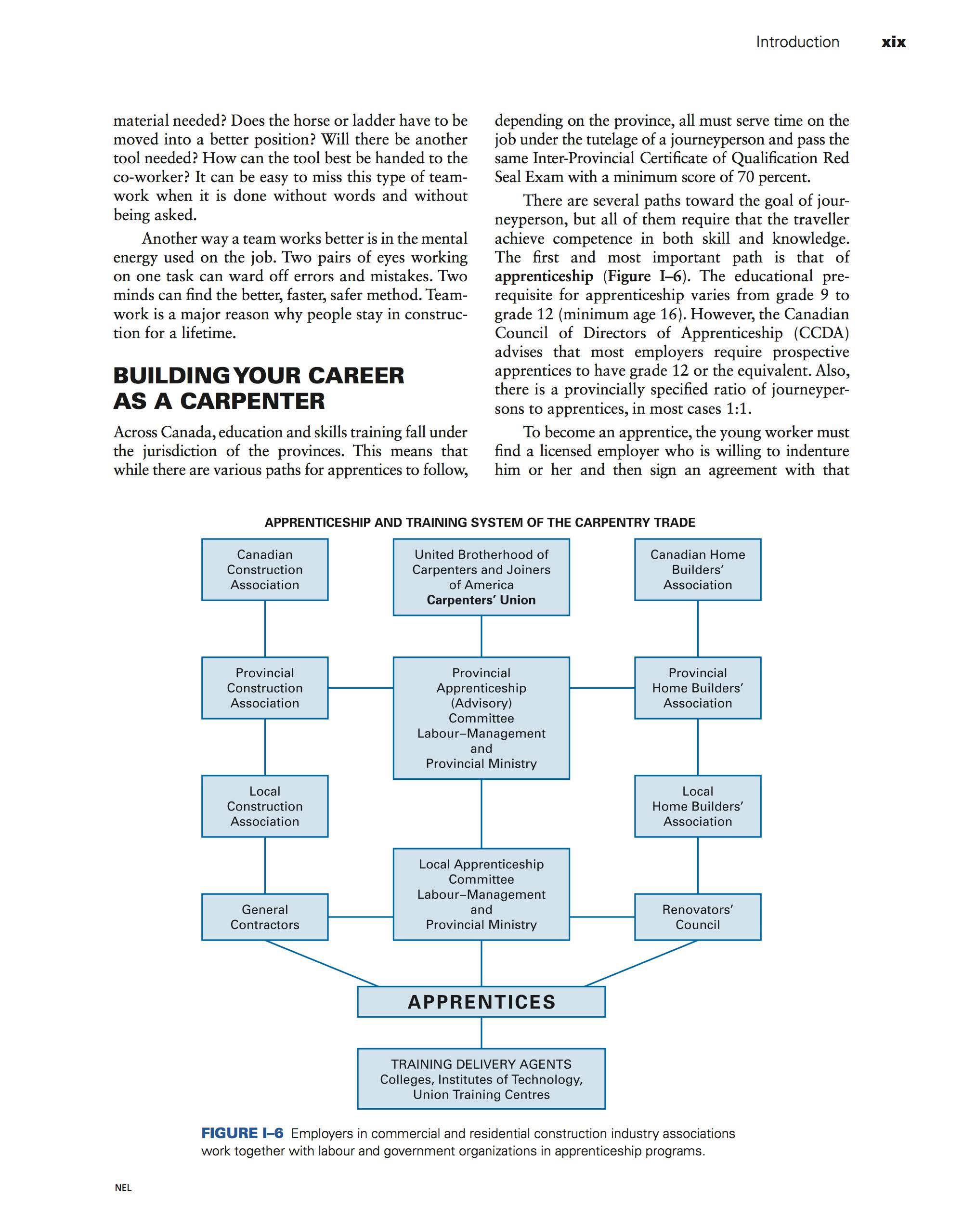

Carpentry is a trade in which a great deal of selfsatisfaction, pride, and dignity is associated with the work. It is an ancient trade and the largest of all trades in the building industry.

Skilled carpenters who have laboured to the best of their ability can take pride in their workmanship, whether the job was a rough concrete form or the finest finish in an elaborate staircase (Figure I-8). At the end of each working day, carpenters can stand back and actually see the results of their labour. As the years roll by, the buildings that carpenters' hands had a part in creating still can be viewed with pride in the community.

FIGURE 1-8 A ft er completing a comp lica t ed piece of wo rk, such as this intricate staircase , carpen t ers can take pride in and v iew the ir accomplishmen t.

Wood and Lumber

Engineered Panels

Engineered Wood Products

Fasteners

Hand Tools

Portable Power Tools

Stationary PowerTools

Architectural Plans and Building Codes •

Brad Current

Title: Red Seal journeyman carpenter and lead hand Company: United Brotherhood of Carpenters and Joiners of America, Local 93, Ottawa, Ontario

EDUCATION

Brad completed high school in 1996 in Lakefield, Ontario, and continued his education at Bishop's University in Lennoxville, Quebec. He majored in marketing and finance and graduated with a four-year B.B.A. degree.

He took his in-school apprenticeship training at Algonquin College, completing the basic level in 2005, the intermediate level in 2006, and the advanced level in 2007.

HISTORY

After graduating from Bishop's, Brad found employment in Montreal as a production manager in a clothing company. After two years he decided that working in an office was not what he wanted. He moved back to Ottawa and started working for a residential framing company. After a year in the residential sector, he moved to commercial work. At that point he was signed on by the Carpenters Union Local 93 and registered as an apprentice .

•

•

•

•

•

i ON THE JOB

•

• Brad's work experience has included residential

• framing, concrete

• formwork, scaffolding, rigging, and interior fit-up of

• light commercial buildings.

• : He has framed floors, walls,

• and roofs for homes in

• : Ottawa. His commercial

• • experience has ranged from erecting scaffolding

• for large towers and office

• buildings and bridges, to constructing concrete

• : forms for industrial and

•

• commercial buildings, to applying finishing trim and

• installing fixtures in office buildings As a result of

• his varied background, he

• was chosen to represent his Local at the 14th

• Annual Ontario Provincial

• Carpentry Contest in Port Hope.

• He completed the

• mandatory hours of on-the-job training and

• wrote and passed his

• : Inter-Provincial Red Seal

• Certificate of Qualification

• Exam in August 2007.

•

• • • • • : BEST ASPECTS

•

• Brad likes the physical,

• hands-on part of the job

• : and the adrenaline rush

• that comes with working

• at heights. He stays

: fit and i nc rea ses his

•

• strength by working out at the gym and playing

• rugby. He understands

• the team aspect of working in the trades -

• that is, working as a

• : cohesive unit to

• complete specified

• : tasks.

•

•

•

•

•

• : On the jobsite, he

• appreciates the fact

• : that there is a new task

•

• : every day and a constant

• change of scenery. Brad

• recently experienced

• another enjoyable part of his trade when he was

• : able to contribute as a

•

• : volunteer crew leader on

• the Habitat for Humanity

• : ''Women Build" in

•

• : Stittsville (near Ottawa).

•

•

CHALLENGES

•

• : Brad finds that his

• biggest challenge is to

• learn and retain all the

• knowledge and skills that

• a good carpenter requires. The work skills expected

• of a carpenter are

• : wide-ranging, and there

• are many different ways to

• approach the same task. Another challenge on the

• job is communication:

• among workers, and between worker and

• supervisor. Instructions

•

•

•

•

•

•

•

•

i must be clearly given and

• : clearly he ard

•

• Brad continues to grow

• in a leadership role. With the Carpenters Union,

• : he works in northern

• : Canada on reserves,

• hydro dams, and

• gold mines (1.5 m

• : thick concrete head

• frame) where he trains

• apprentices, labourers,

• : and even truck drivers.

• He is also teaching

• : Concrete Formwork at

• : Algonquin College where

• he integrates field trips

• to commercial projects

• with preparing fourthyear apprentices for the

• : Red Seal Certification

• : exam. Brad's ultimate

• goal is to be his own

• boss and operate his

• own business. He already has the business skills

• : that will make him an

• • : asset for managing a

• construction company.

WORDS OF ADVICE

• : Success in the trades

• : requires a commitment

• to the lllong haul," a

• strong and fit worker, and

• : mastery of arithmetic

• II Brains and brawn,"

• says Brad

Wood

The construction material most often associated with a carpenter is wood. Wood has properties that make it the first choice in many applications in home construction. Wood is easy to tool and work with, is pleasing to look at and smell, and has strength that will last a long time.

Lumber is manufactured from the renewable resources of the forest. Trees are harvested and sawn into lumber in many shapes and sizes, having a variety of characteristics. It is necessary to understand the nature of wood to get the best results from the use of it. With this knowledge, the carpenter is able to protect l umber from decay, select it for appropriate use, work it with proper tools, and join and fasten it to the best advantage.

Wood comes from many tree species having many different characteristics. A good carpenter knows the different applications for specific wood • species.

Lumber

After complet ing this unit, the student should be able to ach ieve the fol low ing :

• Name the parts of a tree trunk and state each part's function.

• Describe methods of cutt ing the log into lumber.

• Def i ne hardwood and softwood, give examples of some common kinds, and list their character istics

• Explain moisture content at var ious stages of seasoning, te ll how wood shrinks, and describe some common lumber defects.

• State the grades and sizes of lumber and compute board measure.

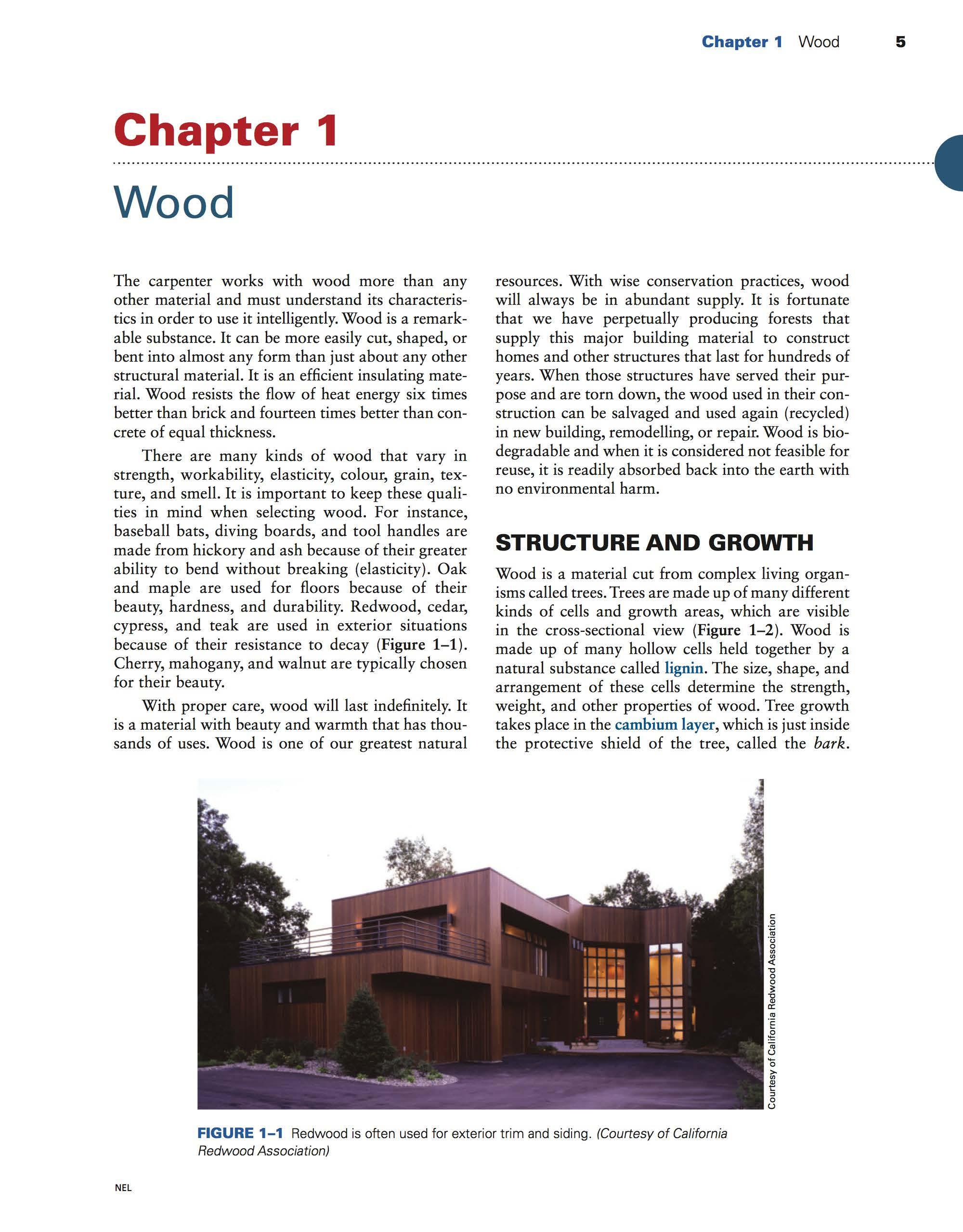

The carpenter works with wood more than any other material and must understand its characteristics in order to use it intelligently. Wood is a remarkable substance. It can be more easily cut, shaped, or bent into almost any form than just about any other structural material. It is an efficient insulating material. Wood resists the flow of heat energy six times better than brick and fourteen times better than concrete of equal thickness.

There are many kinds of wood that vary in strength, workability, elasticity, colour, grain, texture, and smell. It is important to keep these qualities in mind when selecting wood. For instance, baseball bats, diving boards, and tool handles are made from hickory and ash because of their greater ability to bend without breaking (elasticity). Oak and maple are used for floors because of their beauty, hardness, and durability. Redwood, cedar, cypress, and teak are used in exterior situations because of their resistance to decay (Figure 1-1). Cherry, mahogany, and walnut are typically chosen for their beauty.

With proper care, wood will last indefinitely. It is a material with beauty and warmth that has thousands of uses. Wood is one of our greatest natural

resources. With wise conservation practices, wood will always be in abundant supply. It is fortunate that we have perpetually producing forests that supply this major building material to construct homes and other structures that last for hundreds of years. When those structures have served their purpose and are torn down, the wood used in their construction can be salvaged and used again (recycled) in new building, remodelling, or repair. Wood is biodegradable and when it is considered not feasible for reuse, it is readily absorbed back into the earth with no environmental harm.

STRUCTURE AND GROWTH

Wood is a material cut from complex living organisms called trees. Trees are made up of many different kinds of cells and growth areas, which are visible in the cross-sectional view (Figure 1-2). Wood is made up of many hollow cells held together by a natural substance called lignin . The size, shape, and arrangement of these cells determine the strength, weight, and other properties of wood. Tree growth takes place in the cambium layer , which is just inside the protective shield of the tree, called the bark.

FIGURE 1-1 Redwood is oft en used f or exterior t rim and s iding. (Courtesy of California Redwood Association)

BARK

SAPWOOD (USUALLY LIGHTER COLOUR)

MEDULLARY RAYS

resistant to decay and is used extensively for outdoor furniture, patios, and exterior siding. Used for the same purposes, sapwood decays more quickly.

Each spring and summer, a tree adds new layers to its trunk. Wood grows rapidly in the spring; it is rather porous and light in colour. In summer, tree growth is slower; the wood is denser and darker, forming distinct rings. Because these rings are formed each year, they are called annular rings By counting the dark rings, the age of a tree can be determined. By studying the width .g of the rings, periods of abundant rainfall and sunshine or periods of slow growth can be discerned. Some trees, such as the Douglas fir, grow rapidly to great heights E and have very wide and pronounced annular rings.

ANNULAR RINGS

HEARTWOOD (USUALLY DARKER COLOUR)

FIGURE 1-2 A cross -sect ion of a tree show ing its st ruct ure. (Courtesy of Western Wood Products Association )

The tree's roots absorb water that passes upward through the sapwood to the leaves, where it is combined with carbon dioxide from the air. Sunlight causes these materials to change into food, which is then carried down and distributed toward the centre of the trunk through the medullary rays

As the tree grows outward from the pith (centre), the inner cells become inactive and turn into heartwood . This older section of the tree is the central part of the tree and usually is darker in colour and more durable than sapwood. The heartwood of cedar, cypress, and redwood, for instance, is extremely

Mahogany, which grows in a tropical climate where '0 the weather is more constant, has annular rings that do not contrast as much and sometimes are hardly visible.

HARDWOODS AND SOFTWOODS

Woods are classified as either hardwood or softwood There are different methods of classifying these woods. The most common method of classifying wood is by its source. Hardwood comes from deciduous trees that shed their leaves each year. Softwood is cut from coniferous , or cone-bearing, trees, commonly known as evergreens (Figure 1-3). In this method of classifying wood, some of the softwoods may actually be harder than the hardwoods. For instance, fir, a softwood, is harder and stronger than basswood, a hardwood. There are other methods of classifying hardwoods and softwoods, but this method is the one most widely used.

CAMBIUM LAYER

FIGURE 1-3 Softwood is from cone -b earing trees , hardwood from broad -leaf trees.

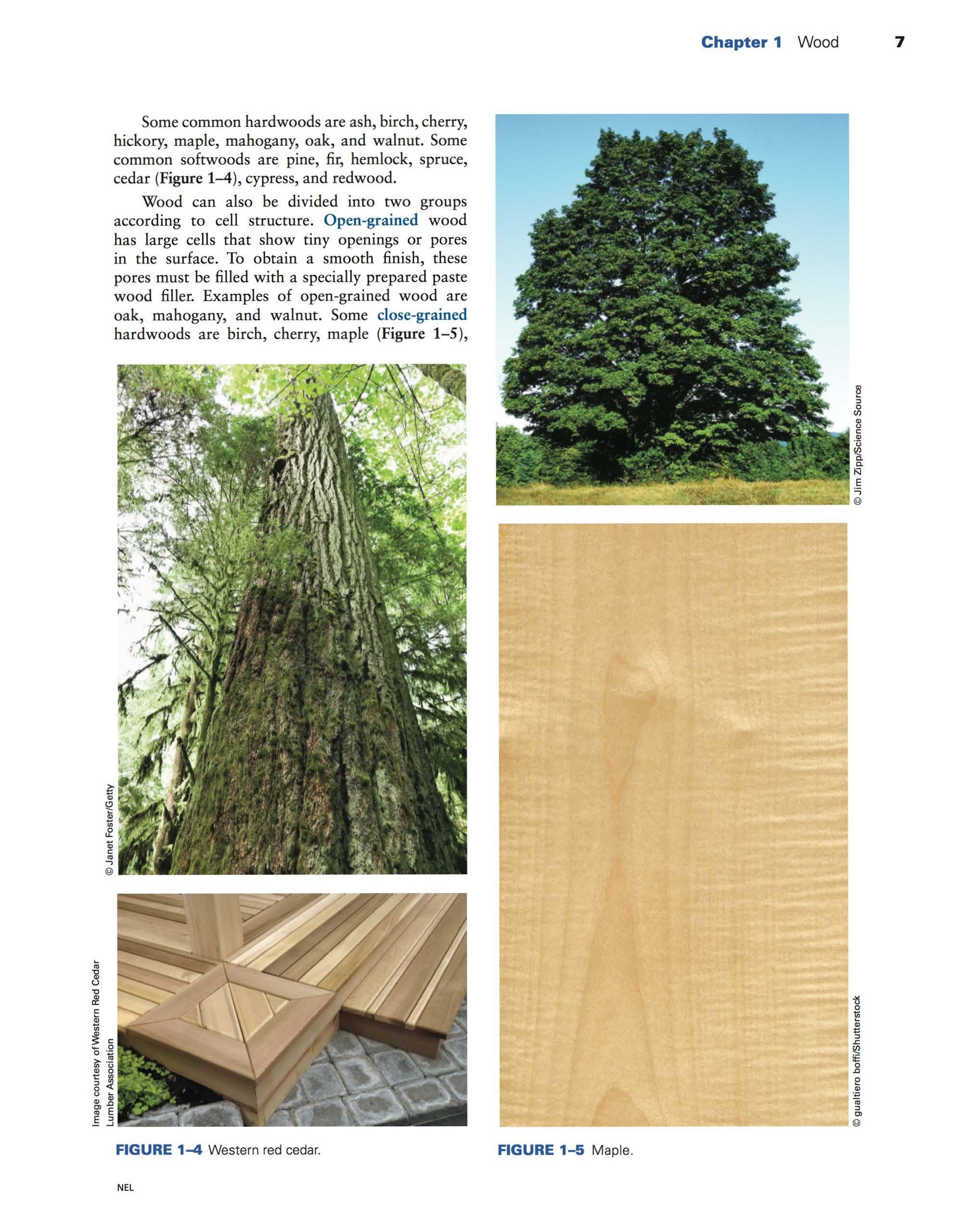

Some common hardwoods are ash, birch, cherry, hickory, maple, mahogany, oak, and walnut. Some common softwoods are pine, fir, hemlock, spruce, cedar (Figure 1-4 ), cypress, and redwood.

Wood can also be divided into two groups according to cell structure. Open-grained wood has large cells that show tiny openings or pores in the surface. To obtain a smooth finish, these pores must be filled with a specially prepared paste wood filler. Examples of open-grained wood are oak, mahogany, and walnut. Some dose-grained hardwoods are birch, cherry, maple (F igure 1-5 ),

FIGURE 1-4 Western red cedar.

FIGURE 1-5 Map l e.