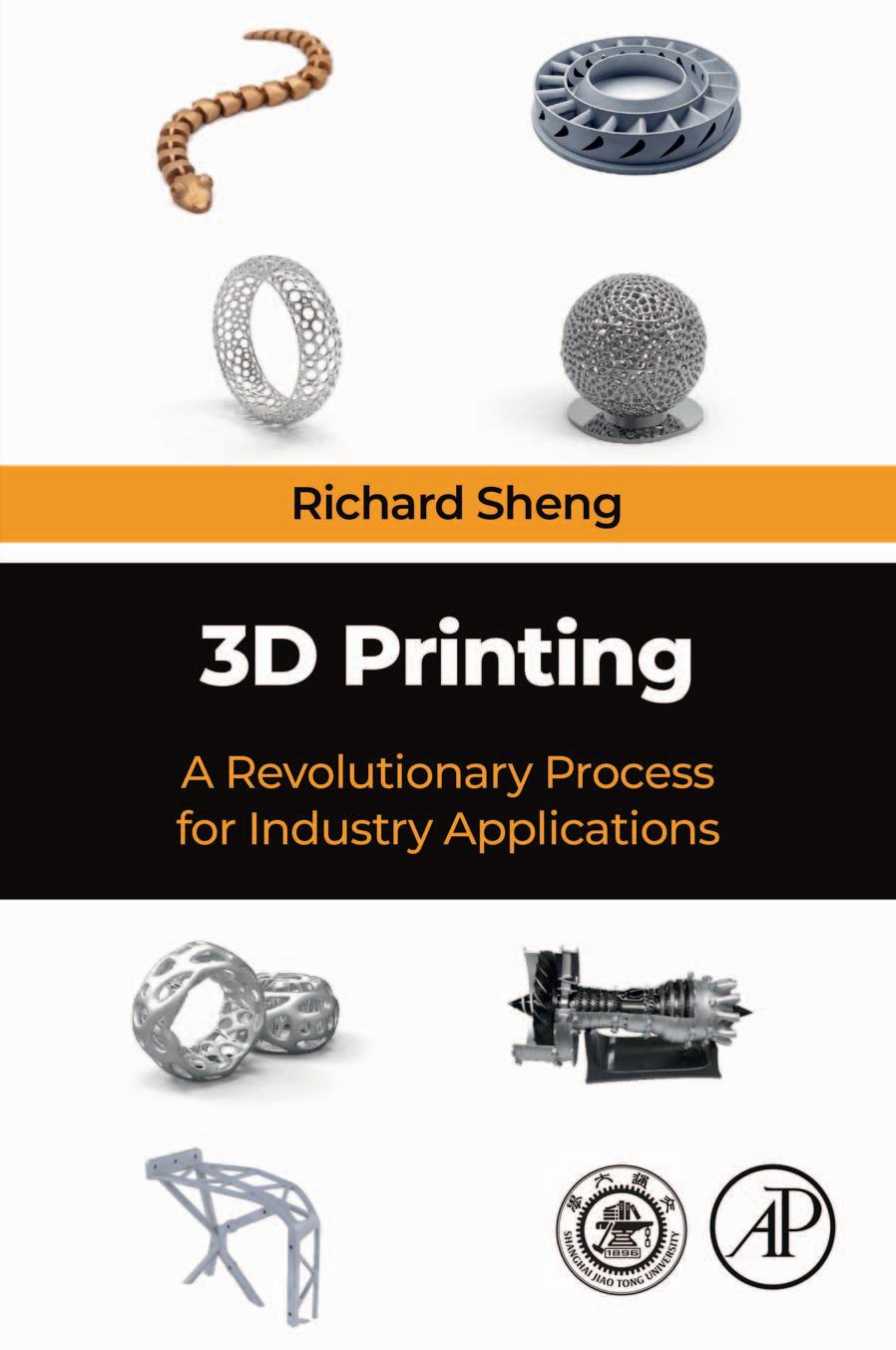

3DPRINTING AREVOLUTIONARY PROCESSFORINDUSTRY APPLICATIONS

RICHARDSHENG

JiaotongUniversity,Shanghai,China

WebsterUniversity,Shanghai,China

SAEInternational,Shanghai,China

AcademicPressisanimprintofElsevier 125LondonWall,LondonEC2Y5AS,UnitedKingdom 525BStreet,Suite1650,SanDiego,CA92101,UnitedStates 50HampshireStreet,5thFloor,Cambridge,MA02139,UnitedStates TheBoulevard,LangfordLane,Kidlington,OxfordOX51GB,UnitedKingdom

© 2022ShangaiJiaoTongUniversityPress.PublishedbyElsevierInc.Allrightsreserved.

Nopartofthispublicationmaybereproducedortransmittedinanyformorbyanymeans, electronicormechanical,includingphotocopying,recording,oranyinformationstorage andretrievalsystem,withoutpermissioninwritingfromthepublisher.Detailsonhowto seekpermission,furtherinformationaboutthePublisher’spermissionspoliciesandour arrangementswithorganizationssuchastheCopyrightClearanceCenterandtheCopyright LicensingAgency,canbefoundatourwebsite: www.elsevier.com/permissions .

Thisbookandtheindividualcontributionscontainedinitareprotectedundercopyrightby thePublisher(otherthanasmaybenotedherein).

Notices

Knowledgeandbestpracticeinthis fieldareconstantlychanging.Asnewresearchand experiencebroadenourunderstanding,changesinresearchmethods,professional practices,ormedicaltreatmentmaybecomenecessary.

Practitionersandresearchersmustalwaysrelyontheirownexperienceandknowledgein evaluatingandusinganyinformation,methods,compounds,orexperimentsdescribed herein.Inusingsuchinformationormethodstheyshouldbemindfuloftheirownsafety andthesafetyofothers,includingpartiesforwhomtheyhaveaprofessionalresponsibility.

Tothefullestextentofthelaw,neitherthePublishernortheauthors,contributors,or editors,assumeanyliabilityforanyinjuryand/ordamagetopersonsorpropertyasa matterofproductsliability,negligenceorotherwise,orfromanyuseoroperationofany methods,products,instructions,orideascontainedinthematerialherein.

ISBN:978-0-323-99463-7

ForinformationonallAcademicPresspublicationsvisitour websiteat https://www.elsevier.com/books-and-journals

Publisher: MatthewDeans

AcquisitionsEditor: GlynJones

EditorialProjectManager: NaomiRobertson

ProductionProjectManager: SojanP.Pazhayattil

CoverDesigner: GregHarris

TypesetbyTNQTechnologies

2.3-Dprintingintheaerospaceindustry3

2.1 What3

2.2 When7

2.3 Where8

2.4 Keybenefitsofadditivetechnologiesforaerospacemanufacturing9

2.5 Why9

2.6 How10

2.7 Who10

2.8 3-Dbioprintinginspace11

2.9 Constructionofstructuresusing3-Dprinting11

2.10 Conclusion12 References12

3.3-Dprintingofairplaneparts13

3.1 3-Dprintingairplaneparts13

3.2 Advantages14

3.3 Airplaneparts15

3.4 What17

3.5 Where17

3.6 Who18

3.7 Why18

3.8 When18

3.9 How18 References19 Furtherreading20

4.3-Dprintingintheautoindustry21

4.1 When:sincewhenhas3-Dprintingbeenusedintheautoindustry21

4.2 How:howhas3-Dprintingimpactedtheracingworld?22

4.3 What:whatarethebenefitsof3-Dmaterialsandtechnologies?23

4.4 Why:whyshouldautomotivecompaniesuse3-Dtechnology?25

4.5 Where:whereis3-Dprintingbeingused?26

4.6 Who:whoisgettingthebenefitfrom3-Dtechnology?27 References29 Furtherreading29

5.3-Dprintinginthechemicalindustry31

5.1 Introduction31

5.2 What32

5.3 When33

5.4 Who33

5.5 Where34

5.6 How35 References38

6.3-Dprintingintheconstructionindustry39

7.3-Dprintingindentalcare47

7.1 3-DIntroduction47

7.2 Howhavedentistsused3-Dprinters?50

7.3 Capabilitiesof3-Dprintingindentistry51

7.4 Benefitsof3-Dprintingindentistry54

7.5 Useof3-Dprintingtechnologyinendodonticsandperiodontics55

7.6 Advantagesof3-Dprintingtechnologyindentistry55

7.7 Disadvantagesof3-Dprintingtechnologyindentistry55 References57

8.3-Dprintinginthedroneindustry59

8.1 What59 8.2 Why61

8.3 Where62

12.3-Dprintinginthefootwearindustry103

13.16 Who119 13.17 ThecaseofEricMoger119 13.18 ThecaseofKaibaGionfriddo119 References120 Furtherreading120

14.3-Dprintinginthehearingaidindustry121

14.1 Introduction121

14.2 What122 14.3 Where124

14.4 Who124

14.5 Why125

14.6 When128

14.7 How128

14.8 Conclusion129 References129 Furtherreading130

15.3-Dprintinginthemaritimeindustry131

15.1 What131

15.2 Prototypes,interiors,spareparts,tools132

15.3 Largeshippartsfromindustrial3-Dprinters132

15.4 When133

15.5 Where133

15.6 Who135

15.7 Why136

15.8 How137 References139

16.3-Dprintinginthemechanicsindustry141

16.1 What141

16.2 Why142 16.3 Where143

16.4 When143

16.5 Who146

16.6 How147 References149

17.3-Dprintinginthemovieindustry151

17.1 Introduction151 17.2 What151 17.3 Why152 17.4 When153 17.5 Who154 17.6 Where155 17.7 How155

17.8 Typesofglassesfor3-D158

17.9 Passive3-Dglasses(anaglyphlenses)158 References159

18.3-Dprintinginthetoolanddieindustries161

18.1 How161 18.2 Who162 18.3 Why163 18.4 When164 18.5 Where165

18.6 Advantagesof3-Dprintingintoolmanufacturing168 18.7 What169 References170

19.3-Dprintinginthetoyindustry171

19.1 What171 19.2 When172 19.3 Where173 19.4 Who174

19.5 How175

19.6 3-Dprintingstillfacesmanytechnicalchallenges177 References178

20.Summaryandconclusion179

20.1 Summary179 20.2 Conclusion179

Preface

Themainpurposeofthisbookistointroducetheimportanceof3-D printing/additivemanufacturingandhowthistechnologyisimpacting ourdailylives.3-Dprinting/additivemanufacturingisoneofthemost revolutionaryinventionsofthe21stcentury.The3-Dprinterisafascinatingpieceofequipmentasitprintsreal-lifethree-dimensionalobjects insteadofjustprintingsomewordsorimagesonapieceofpaper.3-D printing/additivemanufacturingmakessolidobjectsfromadigital file. Anobjectisprintedusinganadditiveprocess,whichcreatesanobjectby layingdownlayersofmaterialsuntiltheobjectis finallycreated.A3-D printerproducescomplexshapeswhileusinglessmaterialascomparedto traditionalmanufacturingprocesses.3-Dprinterscanbeusedtoprintany object,irrespectiveoftheirmaterial.Nowadays,throughtechnicaladvancements,3-Dprintersarebeingusedtocreateobjectsfortransport, buildings,humanorgans,etc.Thereisagreatdealofsoftwareusedin3-D printing.Theycanbefromindustrialgradetoopensource.Thepurposeof thisbookistodirectlyapplyintellectualinsightstouse3-Dprinting/additivemanufacturingtechnologytosolveourindustrialproblems.

My30plusyearsofexperienceacrossmanydifferent fieldshelpsto provideuniqueperspectivesonsolvingproblemsthatwewillbechallenged withandhelpreaderstogainanunderstandingofhowthisisdone.Iama verymotivatedself-learnerandamlookingforwardtosharingmypast challengeswithyou,andIonlyhopethatyouarejustasexcitedtoreadmy bookasIwaswhenIstartedwritingit.

3-Dprinting/additivemanufacturingtechnologyisofinteresttome becauseitfocusesoncreatingcomplexsystemsthatcrossmultipleengineeringdisciplines.EverydayasachiefengineeratTheBoeingCompany, GE,andCOMAC,Iworkonsystemsfromawidearrayofdisciplinesthat havebeenbroughttogethertobuildenormouslycomplexdefensesystems. ThisbookwillhelptoprovidetheskillsthataChiefEngineershould possessandenableyoutoaddressmanufacturingproblemsthatyouwillbe challengedbyeverysingleday.

Byreadingthisbook,youwillbeableto:

• Learnhowsomelargecompanieshaveadopted3-Dprinting/additive manufacturingtechnologyfordesigningandproducingcomplexparts fordifferentindustries.

• Determineallessential3-Dprinting/additivemanufacturingsuppliers forsupportingdifferentindustries.

• Learnhowsomecompanieshavealreadyconvertedtheirtraditional design/productionprocessto3-Dprinting/additivemanufacturing technology.

• Acquirethelifecyclestrategyusing3-Dprinting/additivemanufacturing.

• Identifyalltheinfluencesofthecostdriversforusing3-Dprinting/additivemanufacturingindifferentindustries.

3-Dprintingintheaerospace industry

Contents

2.1 What3

2.2 When7

2.3 Where8

2.4 Keybenefitsofadditivetechnologiesforaerospacemanufacturing9

2.5 Why9

2.6 How10

2.7 Who10

2.8 3-Dbioprintinginspace11

2.9 Constructionofstructuresusing3-Dprinting11

2.10 Conclusion12 References12

2.1What

A3-Dprinterisadevicethatusesthemethodoflayer-by-layercreationof aphysical(solid)objectusingadigital3-Dmodel.3-Dprintingcanbe carriedoutusingvariousmaterials:plastic,metal,stemcells,andevenfood components.Therearemany3-Dprintingtechnologiescurrentlyavailable, andnewonesareconstantlyappearing.Therearetwomaintechnologies forforminglayers:laserandinkjet.Themostcommonlyusedarelaser stereolithographyandselectivelasersintering.

3-Dprintingcanbeusedinspaceinthefollowingpromisingareas (Attaran,2017):

1. 3-Dprintersforcreatingsparepartsandtoolsonboardthespaceship. TheAmericanspaceagencyNASAandMadeinSpacesentthe first 3-DprintertotheInternationalSpaceStation(ISS)inthefallof2014 fortheproductionofvariousparts,including:spareparts,instruments, andscientificequipment.Theprinterisabletomakemodelslayerby

3DPrinting

ISBN978-0-323-99463-7

https://doi.org/10.1016/B978-0-323-99463-7.00002-5

layerfrompolymersandothermaterials.3-Dmodelsforcreatingobjectsareplacedinthedevice’smemoryortransmittedfromEarthif necessary.

Thisnewtechnologyisassociatedwithgrandioseprospectsinoptimizingworkinspace:fromthesimplestthings,suchasthreedimensionalprintingofbrokenparts,totheindependentcreationof robots,navigationsystems,spacesuits,andresearchequipment.

2. 3-Dprintersforcreatinglarge-sizedstructuresinspace.

NASA,undertheNIACprogram,in2013allocatedTethersUnlimited,Inc.(TUI)$500,000tofurtherdevelopSpiderFab’sautomatedassemblytechnologyinspace.

ThetechnologyisbasedontheTrusselator adevicethatisakind ofcrossbetweena3-Dprinterandaknittingmachine.Thedeviceis currentlybeingsuccessfullytestedinthelaboratory.

Ononesideofthecylindricalbodythereisaspoolwiththread(the deviceusesplasticasrawmaterial,forexample,carbon fiber),andonthe otherthereisanextruderthroughwhichthreemainpipesofafuture formorotherstructureareextruded.Thetrussisstrengthenedbywindingitwithathread,andasaresult,arobotaboutameterlongcancreate atrusstensofmeterslong.

Arobottracerusingamanipulatorandaspecialweldingmachine willbeabletoconnecttheoriginaltrussesintolargecomplexstructures andcoverthemwithsolarpanels,reflective films,andperformother operations,dependingontheobjectivesofthemission.Thereare differenttypesoftracer,forexample,itcanproduceroundorsquare pipesofdifferentdiametersandthicknesses.

SpiderFabrobotsareequippedwithanextruderthatextrudesthe finishedplasticpipewithdrum-containersoflargecapacitywithraw materials,andmanipulatorsforassemblingthestructure.

Thistechnologymakesitpossibletomanufacture,inspace,very large,severalkilometerslong,spacecraftframes,antennatrusses,basic structuresofsolarpowerplants,hugetelescopes,etc.

Currently,thereisahugesurplusofstructuresbeingsentintospace margintowithstandtheoverloadatlaunch.Usually,inspace,such heavy-dutystructuresarenotneeded,butaverylargesizeisneeded, forexample,fortelescopesandinterferometers.SpiderFabdevicesallow suchstructurestobebuilt:lightweight,large-sized,andwithalowlife cyclecost.

AllnecessarypartsoftheSpiderFaborbitalproductioncomplexcan belaunchedintospaceusingexistinglaunchvehicles.Infact,evenwith currenttechnologies,SpiderFaballowsforbreakthroughprojects,such asbuildingspacestationsbeyondtheorbitoftheMoonorsolarpower plantswithacapacityofhundredsofmegawatts.Atthesametime,the costofstructuresproducedusingSpiderFabwillberelativelysmall.One exampleoftheuseofSpiderFabistheconstructionofaspaceradiotelescopeworth$200millionwithanantennadiameterofmorethan 100m.Astronomerstodaycanonlydreamofsuchaninstrument,but SpiderFabtechnologycouldmakethisdreamarealityinthecoming decades.

3. 3-Dprintersfortheconstructionofobjectsonotherplanets,for exampleontheMoon,includingfromimprovisedmaterials.

In2011,NASApublisheditsdesignfortheconstructionofalunar basewiththeparticipationofalargenumberofrobots(excavators,bulldozers,shredders,etc.).

NowtheEuropeanSpaceAgencyhasproposedanalternativeprojectfor3-Dprintingthelunarbase,usinglocalsoilasabuildingmaterial.

TheD-ShapeprintermanufacturedbytheBritishcompanyMonoliteisusedforprinting.OntheMoon,theprinterwillbeabletousethe localsoil,regolith,asamaterial.

Regolithisaloose,unevenlygrainedclastic-dustylayerseveralmetersdeep,consistingoffragmentsofigneousrocks,minerals,glass,and meteorites,thatiswellsuitedforconstruction.

Shownhereisa1.5-tonbuildingblockmadebyaD-Shapeprinter asademonstration.Thematerialusedforprintingis99.8%similarto regolith,obtainedfrombasaltrocksfromavolcanoincentralItaly.

TheBoeing787Dreamlinerreportedlyuses303-Dprintedparts,a recordintheindustry.What’smore,itwasrecentlyannouncedthat GeneralElectricisinvesting$50millionto3-Dprintfuelnozzlesfor thenextgenerationofLEAPjetengines.Themainreasonforthe growinginterestoftheaerospaceindustryin3-Dprintingtechnologies istheabilitytoproducesignificantlylighterparts.AccordingtorepresentativesofAmericanAirlines,byreducingtheweightoftheaircraft by500g,morethan40,000litersoffuelaresavedannually.

(Sharke,P.(2017).Howpracticalis3-Dmetalprinting? MechanicalEngineering, 139(10), 44 49.)

VivekSaxena,vicepresidentofaerospaceatICFInternational,a technicalconsulting firm,claimsthat3-Dprintingtechnologycurrently accountsforapproximately0.0002%ofglobalproduction.Specifically fortheaerospaceindustry,3-Dprintinghasa0.002%shareofthe $150billionmarket.However,Saxenaagreeswithmanyexpertsthat themarketfor3-D-printedpartswillreach$2billionoverthenext decade.Withthesepromisingprospects,potentialusesfor3-Dprinting lookevenmorepromising.The fivemostpromisingaerospaceapplicationsusingthesetechnologiesaredescribedbelow.

Consideringthatrelativelysmallaircraftpartsarealreadybeing3-D printed,Boeingalsoconsidersitpossibletocreateanentirewingusing thismethod.Atthisstageinthedevelopmentof3-Dprinting,theproductionoflarge-sizedobjectsisassociatedwithanumberoflimitations, sincewithanincreaseinsize,internalstressincreases,whichcancause distortion.However,thelatestdevelopmentfromBAESystemsallows reinforcedmetalpartstobecreatedbyexposingeachlayertoultrasonic waves.Thishelpstoreducestress,therebymakingitpossibleinthe futureto3-Dprintlargeobjectssuchasaircraftwings.

Inadditionto3-Dprintingfuelnozzles,GeneralElectricisalso activelydevelopingtheabilityto3-Dprintpartsoftheworld’slargest jetengine,theGE9X,forthenextgenerationofBoeing777Xpassengeraircraft.3-Dprintingtechnologiescanalsoproveusefulindevelopingexperimentalprototypesforperformancetestingwithout havingtospendlargesumsofmoneyonnumericalcontrolequipment. AnewjointprojectbetweenAutodeskandStratasys,inwhichalife-size turbopropenginewas3-Dprinted,showedhowpromisingtheuseof 3-Dprintingisintheproductionofjetengineparts.

Currently,NASA’sspacecraftcontainsabout703-Dprintedparts, buttheyaremadeonearth,whichmakesthemverycomplicatedsupply chainsandextendedtimeframes.Manufacturingtherequiredpartsin spacewouldsignificantlyreducecostsandsimplifyplanning,without havingtosendarocketwiththerightpartsandtools.3-Dprinting ofpartsinspaceiscurrentlybeingdevelopedbyresearchgroupssuch asMadeinSpaceandLunarBuildings.WorkingwithNASA,Made inSpaceisconductingzero-gravityexperimentstotestwhether3-D printingcouldbeusedontheISStoproducethenecessarypartsand tools.

BAESystemsrecentlyannouncedthat2040ofitsnewaircraftengineeringconceptsincludeequipmentdesignedtocreateunmanneddevicesusinga3-Dprinteronboard.Theideaisthattheaircraftarriving atthesceneoftheaccidentassessesthesituationandreportsthedatato thecontrolcenter.Theinformationisthentransmittedtoon-board3Dprinters,whichprintouttheunmannedaerialvehiclesneededinthis situation.Thesedronescanmonitorthesituationorevenconduct rescueoperations.Althoughtheconceptisstillindevelopment,BAE Systemshasalreadyinvestedover$180millioninthisresearch(Khan etal.,2020).

2.2When

Inhis1955shortstory ANecessaryThing,RobertShakesleydescribeda configuratorthattwoastronautstookwiththemonaninterstellarexpeditiontoprinteverythingtheymightneedinspace,fromshippartstoapple strudelfordessert.Alittlemorethanhalfacenturyhaspassed,andalthough realityhasnotsurpassedthiswriter’simagination,ithascomeclosetoit.

NASAisdevelopinga3-Dprinterforprintingsparepartsdirectlyonthe ISS.Indeed,thedevelopmentof3-Dprintersinthenearfuturecould significantlyaffectthespaceindustryingeneralandtheprospectsforthe developmentofindividualdesignbureausinparticular.

2.3Where

NASAexpectstouse3-Dprintingtechnologyasaservicetorapidlycreate preliminaryprototypes. “3-Dprintingallowsyoutomoreaccurately conveytheconceptofthemission.Wecanliterallyseewhatotherdevelopersarethinking,” explainsTomSonderstrom,headofITatNASA’ s JetPropulsionLaboratory.Using3-DPlatformAsAService(PaaS),engineerswillbeabletoreceivepeercomments,designalternatives,and final prototypeapproval.Inaddition,thistechnologycouldhelpattractexternal specialistswithoriginalideas,whichwillsignificantlyreduceboththe developmenttimeandcosts.

Additivetechnologies,whichseemedlikescience fictionafewdecades ago,arenowsuccessfullyusedinavarietyof fields.Oneofthemost promisingmarketsfortheirapplicationistheaerospaceindustry,forwhich theproblemofreducingproductionandtimecostsisespeciallyacute.In addition,thisindustryisdevelopingrapidlyduetorevolutionaryscientific andtechnologicalachievements. Thecapabilitiesof3-Dtechnology are changingsomassivelythatmanufacturerswillhavetorethinktheirbusiness models.Newstrategiesarejustemerging,butindustrygiants,suchas NASA,SpaceX,Airbus,andBoeing,arealreadyinvestingbillionsin3-D printing prototypes,tooling,andenginepartsforaircraftandspacecraft.

2.4Keybenefitsofadditivetechnologiesfor aerospacemanufacturing

• Flexibility:3Dprintersareusedtocreatecomponentswithcomplex geometriesthatcannotbemanufacturedusingtraditionalmanufacturing processes.Wecanconfidentlytalkaboutthecreationinthefutureof moreandmoreperfectdesigns.Materialsusedin3Dprinting(alloys, composites,polyamides,etc.)makeitpossibletomanufactureunique products.

• Additivetechnologiesaresuccessfullysolvingakeyproblemforthe industry reducingtheweightofaircraft.A3Dprinteristheideal toolformakingtopologicallyoptimizedcomponentsthatincrease payloadandreducefuelcosts.

• Developingnewandupgradingexistingproductstakeslesstimeand significantly shortenstheproductioncycle

• Costeffective:forhighlyspecializedtasks,a3-Dprinterallowsforthe useoffewerparts,materials,andaccessories,whiledramaticallyreducing thecostofsmall-scalecomponents.Withthedevelopmentoftechnology,thecostofthe finishedproductisfalling,andthepricesofprinters havedroppedbyanorderofmagnitudeoverthepastfewyears.Accordingtoforecasts,thecostofconsumableswillalsodecrease.

• Finally,additivetechnologiesinsomecasesmakeitpossibleto minimizewaste (comparedtotraditionalprocesses)andimprovetheenvironmentalfriendlinessandenergyefficiencyofaircraft.

2.5Why

Thepossibilitiesof3Dprintingwillexpandwiththedevelopmentof software.Withthehelpofmodernsoftware,itwillbepossiblenotonlyto quicklycreateacomplexmodelbutalsotoautomatetheproduction process.Interactivemodelswillmakeitpossibletotrackandcorrectthe slightestshortcomingsinrealtime,calculatethesafetyandefficiencyofall operations,andhelpintheunderstandingofhowtheequipmentwill behaveinemergencysituations.Thankstoadvancedsoftwaretechnologies, suppliers,manufacturers,anddesignerswillworkinsingleinformation spaceand,infact,communicateinauniversal3-Dlanguage.Today,most ofthetestsarecarriedoutinrealconditions,butinthecomingdecades, softwarewillbeabletosolveincreasingnumbersofproblems.

2.6How

Additivetechnologiesareaninevitablechoiceforacompetitiveenterprise. Today,mostcompaniesthatimplementthemseektoreduceproduction costsandproductdevelopmenttimewithoutchangingthesupplychain andassortment.Inthemediumterm,astrategywillcometothefore, involvingthedevelopmentofmorecomplex,aswellasnew,highly functionalproducts,whichwillleadtochangesinthesupplychain.Finally, inthelongterm,companieswillbeabletosignificantlyimprovemanufacturabilitywhileeliminatingmiddlemenfromthesupplychain.Allofthis willenabletheuseofradicallynew,moreefficient businessmodels.

2.7Who

Astronautsinorbitoftencannotprovidethemselveswitheverythingthey needandareforcedtowaitforthecargothatarrivesattheISSduring scheduled flights.Unfortunately,duringthistime,thecrewisnotprotected againstaccidentsorbreakdownsofimportantsystems.Experimentswith3Dprintinginspaceofferthepotentialtoprinttherequiredpartsifany shouldfailinspace.Thisisveryimportantforfuture flightstoMarsand otherplanets,as,foralongtime,thecolonistswillnotbeabletoreceive helpfromEarth.Therefore,intheupcomingexpeditions,itisextremely importanttouseallavailableopportunitiesforthemanufactureofproducts onboardshipsandspacestations.

SuchexperimentshavebeenconductedontheISSsince2014.Itwas thenthattheMadeinSpaceZeroG3-Dprinterwasdeliveredtothe Americansegmentofthestation.The firstprintingtookplaceon November24,2014,andmarkedanewerainthedevelopmentof3-D technology.Theprintedobjectwasapartoftheprinteritself,thebezel oftheprinthead,whichsymbolizestheabilitytoonedayprinta3-D printerinspaceona3-Dprinter.In2016,anotherMadeinSpace printercalledtheAdditiveManufacturingFacility(AMF)wasdeliveredto theISS(Junetal.,2017).

Sincethen,printingtestsontheISShavebeentakingplaceregularly. OneofthelatestideaswastheinnovativeplanoftheCanadiancompany 3D4MD,whichinvolvedprintingmedicaldevices,suchassplintsor surgicalinstruments,ontheISS.Tocreatedevicessuchasindividual splintsforfractured fingers,3D4MDdeveloperscoulduse,forexample,

measurementstakenduringthepreparationofspacesuitsandcreateamodel onEarth.The3DmodelcanthenbesenttotheISS,wherethetirewillbe 3Dprinted(Leeetal.,2020).

Unabletoconductexperimentsinspace,otherpowersorganizeexperimentsonearth.AdevelopmentteaminChinarecentlysuccessfully testedthe firstZeroGravity3Dprinter.Manydifficulttestswerecarried outintheFrenchcityofBordeaux.

2.83-Dbioprintinginspace

Itisknownthatinopenspacethereiselectromagneticandsolarradiation, whichhasadestructiveeffectonbiologicaltissues.Inorderforanastronaut tobeabletoendureallthehardshipsoftheir flight,theprotectionofthe spacecraftaloneisnotsufficient itisnecessarytothinkabouthigh-quality medicalcare,andifthisdoesnothelp,thenorgansmayneedtobe replaced.

ThatiswhytheAmericanUnitedRocketandSpaceCorporationhas agreedonanexperimentontheuseofa3-DbioprinterontheISS.Itwas developedbytheUnitedStateslaboratory3-DBioprintingSolutions, whichspecializesinbioprintingtechnologies.Scientistshopethatamagneticbioprinterwillallowthecreationoftissuesandorgansinspace.The 3DbioprinterwascompletedanddeliveredtotheISSin2018.

2.9Constructionofstructuresusing3-Dprinting

Oneofthemostbasicproblemsintheconstructionofbuildingson extraterrestrialobjectsisthelimitedamountorlackofbuildingmaterial. Theonlyavailablerawmaterialsthatdonotneedtobetransportedfrom Eartharelocalgeologicalrocks.Itisnotsurprisingthatscientistsaresolving theproblemofusingthemintheconstructionofbuildings.

Forexample,engineersatNorthwesternUniversityintheUnitedStates havefoundawaytousequalitymaterialsinsituationswhereresourcesare limited.Thisisanadditivemanufacturingprocessfromspecialmaterialsthat mimicthelunarandMartianregolith.Thesearestrongandresilientmaterialsthatareproducedusingpowderedsubstancesthatresemblerocks fromthesurfacesoftheMoonandMars.

ItislikelythatthistechnologywillbeusedinthecolonizationofMars. Duetoextremetemperaturesandhighradiationonthesurfaceofthe “red planet,” the firstcolonizerswillneedreliableshelters.NASAexperts

proposecreatinga “dome” oficefromthesurfaceofMarsusing3-D printing,coveredwithatransparentmembranemadeof fluoroplastic-40. Oneofthemainadvantagesofawater-baseddwellingisthatsuchwalls provideprotectionfromcosmicradiationbutdonotimpedethepenetrationoflight thiscreatessomecomfort.Inaddition,othercriteriawere takenintoaccountwhenchoosingthemostappropriatematerials their strengthandreliability,andtheirabilitytowithstandthedifficultconditions ofMars(Hoffman&Volpe,2018).

TheEuropeanSpaceAgency(ESA)isdevelopinginthesamedirection andhasalreadyachievedsomeresults.ScientistsattheAustrianUniversity ofAppliedSciencesinWienerNeustadtmanagedto3-Dprintasmall needleandacornerwallmadeofJSC-Mars-1Amaterialthatmimics Martiansoil.

2.10Conclusion

Inadditiontoseriousresearch,therearealsosomequiteunexpected projects.Forexample,expertsfromtheESAhavediscussedsavingthesouls ofthe firstlunarcolonistsandplannedtobuildatempleontheMoonusing 3-Dprinting.Thisbuilding,withthepoeticnameoftheTempleofEternal Light,willbelocatedatthecenteroftheresidentialcomplexforthe first lunarsettlersandwillcombineaprayerplaceandanobservatory.The designersbelievethatthetemplesontheMoonwillhelprevivethelost connectionofmankindwithspace.

References

Attaran,M.(2017).Theriseof3-Dprinting:Theadvantagesofadditivemanufacturingover traditionalmanufacturing. BusinessHorizons,60(5),677 688. Hoffman,W.,&Volpe,T.A.(2018).Internetofnuclearthings:Managingtheproliferation risksof3-Dprintingtechnology. BulletinoftheAtomicScientists,74(2),102 113. Jun,S.Y.,Sanz-Izquierdo,B.,Parker,E.A.,Bird,D.,&McClelland,A.(2017). Manufacturingconsiderationsinthe3-Dprintingoffractalantennas. IEEETransactions onComponents,PackagingandManufacturingTechnology,7(11),1891 1898. Khan,M.S.(2018). 3-Dprintingintransportation:Alreadyinaction (Vol.314).TRNews. Khan,M.S.,Sanchez,F.,&Zhou,H.(2020).3-Dprintingofconcrete:Beyondhorizons. CementandConcreteResearch,133,106070. Lee,L.,Burnett,A.M.,Panos,J.G.,Paudel,P.,Keys,D.,Ansari,H.M.,&Yu,M.(2020). 3-Dprintedspectacles:Potential,challengesandthefuture. ClinicalandExperimental Optometry,103(5),590 596.

Sharke,P.(2017).Howpracticalis3-Dmetalprinting? MechanicalEngineering,139(10), 44 49.