3DandCircuitIntegrationofMEMS

Editedby MasayoshiEsashi

Editor

Prof.MasayoshiEsashi TohokuUniversity MicroSystemIntegrationCenter 519-1176Aramaki-Aza-Aoba Aoba-ku 980-0845Sendai Japan

Allbookspublishedby Wiley-VCH arecarefully produced.Nevertheless,authors,editors,and publisherdonotwarranttheinformationcontained inthesebooks,includingthisbook,tobefreeof errors.Readersareadvisedtokeepinmindthat statements,data,illustrations,proceduraldetailsor otheritemsmayinadvertentlybeinaccurate.

LibraryofCongressCardNo.: appliedfor

BritishLibraryCataloguing-in-PublicationData Acataloguerecordforthisbookisavailablefromthe BritishLibrary.

Bibliographicinformationpublishedbythe DeutscheNationalbibliothek TheDeutscheNationalbibliothekliststhis publicationintheDeutscheNationalbibliografie; detailedbibliographicdataareavailableonthe Internetat <http://dnb.d-nb.de>.

©2021WILEY-VCH,Boschstr.12,69469Weinheim, Germany

Allrightsreserved(includingthoseoftranslation intootherlanguages).Nopartofthisbookmaybe reproducedinanyform–byphotoprinting, microfilm,oranyothermeans–nortransmittedor translatedintoamachinelanguagewithoutwritten permissionfromthepublishers.Registerednames, trademarks,etc.usedinthisbook,evenwhennot specificallymarkedassuch,arenottobeconsidered unprotectedbylaw.

PrintISBN: 978-3-527-34647-9

ePDFISBN: 978-3-527-82325-3

ePubISBN: 978-3-527-82324-6

oBookISBN: 978-3-527-82323-9

Typesetting SPiGlobal,Chennai,India

Printedonacid-freepaper

10987654321

Contents

PartIIntroduction 1

1Overview 3 MasayoshiEsashi References 10

PartIISystemonChip 13

2BulkMicromachining 15

XinxinLiandHengYang

2.1ProcessBasisofBulkMicromachiningTechnologies 16

2.2BulkMicromachiningBasedonWaferBonding 20

2.2.1SOIMEMS 20

2.2.2CavitySOITechnology 27

2.2.3SilicononGlassProcesses:DissolvedWaferProcess(DWP) 29

2.3Single-WaferSingle-SideProcesses 34

2.3.1Single-CrystalReactiveEtchingandMetallizationProcess (SCREAM) 34

2.3.2SacrificialBulkMicromachining(SBM) 38

2.3.3SilicononNothing(SON) 40 References 45

3EnhancedBulkMicromachiningBasedonMISProcess 49 XinxinLiandHengYang

3.1RepeatingMISCycleforMultilayer3DstructuresorMulti-sensor Integration 49

3.1.1PressureSensorswithPS3 Structure 49

3.1.2P+GIntegratedSensors 52

3.2PressureSensorFabrication–FromMISUpdatedtoTUB 54

3.3ExtensionofMISProcessforVariousAdvancedMEMSDevices 58 References 58

4EpitaxialPolySiSurfaceMicromachining 61 MasayoshiEsashi

4.1ProcessConditionofEpi-polySi 61

4.2MEMSDevicesUsingEpi-polySi 61 References 67

5Poly-SiGeSurfaceMicromachining 69 CarrieW.Low,SergioF.Almeida,EmmanuelP.Quévy,andRogerT.Howe

5.1Introduction 69

5.1.1SiGeApplicationsinICandMEMS 70

5.1.2DesiredSiGePropertiesforMEMS 70

5.2SiGeDeposition 70

5.2.1DepositionMethods 70

5.2.2MaterialPropertiesComparison 71

5.2.3CostAnalysis 72

5.3LPCVDPolycrystallineSiGe 73

5.3.1VerticalFurnace 73

5.3.2ParticleControl 75

5.3.3ProcessMonitoringandMaintenance 75

5.3.4In-lineMetrologyforFilmThicknessandGeContent 76

5.3.5ProcessSpaceMapping 77

5.4CMEMS®Process 78

5.4.1CMOSInterfaceChallenges 79

5.4.2CMEMSProcessFlow 80

5.4.2.1TopMetalModule 80

5.4.2.2PlugModule 84

5.4.2.3StructuralSiGeModule 85

5.4.2.4SlitModule 85

5.4.2.5StructureModule 85

5.4.2.6SpacerModule 85

5.4.2.7ElectrodeModule 85

5.4.2.8PadModule 86

5.4.3Release 86

5.4.4Al–GeBondingforMicrocaps 87

5.5Poly-SiGeApplications 88

5.5.1ResonatorforElectronicTiming 88

5.5.2Nano-electro-mechanicalSwitches 92 References 94

6MetalSurfaceMicromachining 99 MinoruSasaki

6.1BackgroundofSurfaceMicromachining 99

6.2StaticDevice 100

6.3StaticStructureFixedaftertheSingleMovement 101

6.4DynamicDevice 103

6.4.1MEMSSwitch 103

6.4.2DigitalMicromirrorDevice 104

6.5Summary 111 References 111

7HeterogeneouslyIntegratedAluminumNitrideMEMS ResonatorsandFilters 113 EnesCalayir,SrinivasMerugu,JaewungLee,NavabSingh,andGianluca Piazza

7.1OverviewofIntegratedAluminumNitrideMEMS 113

7.2HeterogeneousIntegrationofAluminumNitrideMEMSResonatorswith CMOSCircuits 114

7.2.1AluminumNitrideMEMSProcessFlow 115

7.2.2EncapsulationofAluminumNitrideMEMSResonatorsandFilters 116

7.2.3RedistributionLayersonTopofEncapsulatedAluminumNitride MEMS 118

7.2.4SelectedIndividualResonatorandFilterFrequencyResponses 119

7.2.5Flip-chipBondingofAluminumNitrideMEMSwithCMOS 121

7.3HeterogeneouslyIntegratedSelf-HealingFilters 123

7.3.1ApplicationofStatisticalElementSelection(SES)toAlNMEMSFilters withCMOSCircuits 123

7.3.2Measurementof3DHybridIntegratedChipStack 124 References 127

8MEMSUsingCMOSWafer

131

WeileunFang,Sheng-ShianLi,YiChiu,andMing-HuangLi

8.1Introduction:CMOSMEMSArchitecturesandAdvantages 131

8.2ProcessModulesforCMOSMEMS 139

8.2.1ProcessModulesforThinFilms 140

8.2.1.1MetalSacrificial 140

8.2.1.2OxideSacrificial 142

8.2.1.3TiN-composite(TiN-C) 143

8.2.2ProcessModulesfortheSubstrate 145

8.2.2.1SF6 andXeF2 (DryIsotropic) 145

8.2.2.2KOHandTMAH(WetAnisotropic) 146

8.2.2.3RIEandDRIE(Front-sideRIE,BacksideDRIE) 146

8.3The2P4MCMOSPlatform(0.35 μm) 148

8.3.1Accelerometer 148

8.3.2PressureSensor 149

8.3.3Resonators 150

8.3.4Others 152

8.4The1P6MCMOSPlatform(0.18 μm) 154

8.4.1TactileSensors 154

8.4.2IRSensor 156

8.4.3Resonators 158

8.4.4Others 160

8.5CMOSMEMSwithAdd-onMaterials 164

8.5.1GasandHumiditySensors 164

8.5.1.1MetalOxide 164

8.5.1.2Polymer 170

8.5.2BiochemicalSensors 173

8.5.3PressureandAcousticSensors 175

8.5.3.1MicrofluidicStructures 178

8.6MonolithicIntegrationofCircuitsandSensors 180

8.6.1Multi-sensorIntegration 180

8.6.1.1GasSensors 180

8.6.1.2PhysicalSensors 181

8.6.2ReadoutCircuitIntegration 183

8.6.2.1ResistiveSensors 183

8.6.2.2CapacitiveSensors 184

8.6.2.3InductiveSensors 188

8.6.2.4ResonantSensors 190

8.7IssuesandConcerns 191

8.7.1ResidualStresses,CTEMismatch,andCreepofThinFilms 192

8.7.1.1InitialDeformation–ResidualStress 192

8.7.1.2ThermalDeformation–ThermalExpansionCoefficientMismatch 195

8.7.1.3Long-timeStability–Creep 197

8.7.2QualityFactor,MaterialsLoss,andTemperatureStability 199

8.7.2.1AnchorLoss 201

8.7.2.2ThermoelasticDamping(TED) 201

8.7.2.3MaterialandInterfaceLoss 201

8.7.3DielectricCharging 203

8.7.4NonlinearityandPhaseNoiseinOscillators 204

8.8ConcludingRemarks 205 References 207

9WaferTransfer 221

MasayoshiEsashi

9.1Introduction 221

9.2FilmTransfer 223

9.3DeviceTransfer(via-last) 228

9.4DeviceTransfer(Via-First) 231

9.5ChipLevelTransfer 236 References 241

10PiezoelectricMEMS 243

TTakeshiKobayashi(AIST)

10.1Introduction 243

10.1.1Fundamental 243

10.1.2PZTThinFilmsPropertyasanActuator 244

10.1.3PZTThinFilmCompositionandOrientation 246

10.2PZTThinFilmDeposition 246

10.2.1Sputtering 246

10.2.2Sol–Gel 248

10.2.2.1OrientationControl 248

10.2.2.2ThickFilmDeposition 249

10.2.3ElectrodeMaterialsandLifetimeofPZTThinFilms 250

10.3PZT–MEMSFabricationProcess 251

10.3.1CantileverandMicroscanner 251

10.3.2Poling 254 References 255

PartIIIBonding,SealingandInterconnection 257

11AnodicBonding 259

MasayoshiEsashi

11.1Principle 259

11.2Distortion 262

11.3InfluenceofAnodicBondingtoCircuits 263

11.4AnodicBondingwithVariousMaterials,StructuresandConditions 265

11.4.1VariousCombinations 265

11.4.2AnodicBondingwithIntermediateThinFilms 269

11.4.3VariationofAnodicBonding 271

11.4.4GlassReflowProcess 274 References 276

12DirectBonding 279

HidekiTakagi

12.1WaferDirectBonding 279

12.2HydrophilicWaferBonding 279

12.3SurfaceActivatedBondingatRoomTemperature 283 References 286

13MetalBonding 289

JoergFroemel

13.1SolidLiquidInterdiffusionBonding(SLID) 290

13.1.1Au/InandCu/In 291

13.1.2Au/GaandCu/Ga 294

13.1.3Au/SnandCu/Sn 297

13.1.4VoidFormation 297

13.2MetalThermocompressionBonding 298

13.2.1.1InterfaceFormation 299

13.2.1.2GrainReorientation 299

13.2.1.3GrainGrowth 300

13.3EutecticBonding 301

x Contents

13.3.1Au/Si 302

13.3.2Al/Ge 302

13.3.3Au/Sn 304 References 304

14ReactiveBonding 309

KlausVogel,SilviaHertel,ChristianHofmann,MathiasWeiser,MaikWiemer, ThomasOtto,andHaraldKuhn

14.1Motivation 309

14.2FundamentalsofReactiveBonding 309

14.3MaterialSystems 311

14.4StateoftheArt 312

14.5DepositionConceptsofReactiveMaterialSystems 313

14.5.1PhysicalVaporDeposition 313

14.5.1.1ConclusionPhysicalVaporDepositionandPatterning 315

14.5.2ElectrochemicalDepositionofReactiveMaterialSystems 315

14.5.2.1DualBathTechnology 316

14.5.2.2SingleBathTechnology 318

14.5.2.3ConclusionDBTandSBT 319

14.5.3VerticalReactiveMaterialSystemsWith1DPeriodicity 319

14.5.3.1Dimensioning 320

14.5.3.2Fabrication 321

14.5.3.3Conclusion 323

14.6BondingWithRMS 323

14.7Conclusion 326 References 326

15PolymerBonding 331

XiaojingWangandFrankNiklaus

15.1Introduction 331

15.2MaterialsforPolymerWaferBonding 332

15.2.1PolymerAdhesionMechanisms 332

15.2.2PropertiesofPolymersforWaferBonding 335

15.2.3PolymersUsedinWaferBonding 337

15.3PolymerWaferBondingTechnology 341

15.3.1ProcessParametersinPolymerWaferBonding 341

15.3.2LocalizedPolymerWaferBonding 348

15.4PreciseWafer-to-WaferAlignmentinPolymerWaferBonding 350

15.5PracticalExamplesofPolymerWaferBondingProcesses 351

15.6SummaryandConclusions 354 References 354

16SolderingbyLocalHeating 361

Yu-TingChengandLiweiLin

16.1SolderinginMEMSPackaging 361

16.2LaserSoldering 362

16.3ResistiveHeatingandSoldering 365

16.4InductiveHeatingandSoldering 368

16.5OtherLocalizedSolderingProcesses 370

16.5.1Self-propagativeReactionHeating 370

16.5.2UltrasonicFrictionalHeating 371 References 374

17Packaging,Sealing,andInterconnection 377

MasayoshiEsashi

17.1WaferLevelPackaging 377

17.2Sealing 378

17.2.1ReactionSealing 378

17.2.2DepositionSealing(ShellPackaging) 380

17.2.3MetalCompressionSealing 385

17.3Interconnection 388

17.3.1VerticalFeedthroughInterconnection 388

17.3.1.1ThroughGlassvia(TGV)Interconnection 388

17.3.1.2ThroughSivia(TSiV)Interconnection 393

17.3.2LateralFeedthroughInterconnection 395

17.3.3InterconnectionbyElectroplating 401 References 404

18VacuumPackaging 409

MasayoshiEsashi

18.1ProblemsofVacuumPackaging 409

18.2VacuumPackagingbyAnodicBonding 409

18.3PackagingbyAnodicBondingwithControlledCavityPressure 414

18.4VacuumPackagingbyMetalBonding 416

18.5VacuumPackagingbyDeposition 417

18.6HermeticityTesting 417 References 420

19BuriedChannelsinMonolithicSi 423

KazusukeMaenaka

19.1BuriedChannel/CavityinLSIandMEMS 423

19.2MonolithicSONTechnologyandRelatedTechnologies 425

19.3ApplicationsofSON 435 References 439

20Through-substrateVias 443

ZhyaoWang

20.1ConfigurationsofTSVs 444

20.1.1SolidTSVs 444

20.1.2HollowTSVs 445

20.1.3Air-gapTSVs 445

20.2TSVApplicationsinMEMS 445

20.2.1SignalConductiontotheWaferBackside 446

20.2.2CMOS-MEMS3DIntegration 446

20.2.3MEMSandCMOS2.5DIntegration 447

20.2.4Wafer-levelVacuumPackaging 448

20.2.5OtherApplications 450

20.3ConsiderationsforTSVinMEMS 450

20.4FundamentalTSVFabricationTechnologies 450

20.4.1DeepHoleEtching 451

20.4.1.1DeepReactiveIonEtching 451

20.4.1.2LaserAblation 452

20.4.2InsulatorFormation 454

20.4.2.1SiliconDioxideInsulators 454

20.4.2.2PolymerInsulators 455

20.4.2.3Air-gaps 455

20.4.3ConductorFormation 455

20.4.3.1Polysilicon 456

20.4.3.2SingleCrystallineSilicon 456

20.4.3.3Tungsten 457

20.4.3.4Copper 457

20.4.3.5OtherConductorMaterials 459

20.5PolysiliconTSVs 460

20.5.1SolidPolysiliconTSVs 460

20.5.2Air-gapPolysiliconTSVs 463

20.6SiliconTSVs 464

20.6.1SolidSiliconTSVs 465

20.6.2Air-gapSiliconTSVs 467

20.7MetalTSVs 469

20.7.1SolidMetalTSVs 470

20.7.2HollowMetalTSVs 474

20.7.3Air-gapMetalTSVs 480 References 481

Index 493

PartI Introduction

Overview

MasayoshiEsashi

TohokuUniversity,MicroSystemIntegrationCenter(μSIC),519-1176Aramaki-Aza-Aoba,Aoba-ku,Sendai 980-0845,Japan

Micro-electromechanicalsystems(MEMS)havebeenusedforversatilecomponents assensorsandarecalledmicrosystems.Thistechnologyisbasedonadvancedarts ofmicrofabricationdevelopedforintegratedcircuit(IC)onaSi(silicon)wafer.The microfabricationusespatterningwithphotolithographybywhichmanypatterns onaphotomaskaretransferredonthesurfaceoftheSiwafer.Thisbatchtransfer enablestofabricate10billiontransistorsonachipbyusingthelatesttechnology, whichcorrespondstoonetrilliontransistorsona12in.(300mm)diameterSiwafer. Wecanfabricatethick(2.5dimensional)structuresbyextendingthemicrofabricationwithetchinganddeposition.Theextendedtechnologiesofmicrofabricationis calledmicromachining.TheMEMSthathaveversatilecomponentsandcircuitson achipplayimportantrolesinadvancedsystemsforuserinterface,wirelesscommunication,Internetofthings(IoT),andsoon.Thisbook 3DandCircuitIntegration ofMEMS dealswithvariousconfigurationsofMEMSasshowninFigure1.1.There aretwokindsofMEMS.Oneismonolithictypecalledsystemonchip(SoC)MEMS andtheotherishybridtypecalledsysteminpackage(SiP)MEMS.TheformerSoC MEMSmeansthatMEMSandcircuitscanbefabricatedonthesamechip.This willbeexplainedfromChapter2toChapter10.TheSoCMEMSreducesinterconnectioncomplexityandenablesarrayedactivematrixMEMS;ontheotherhandit reducesthefreedomofMEMSprocessesbecauseofrestrictionssuchasthermalbudgetlimitedbythecircuits.ThelatterSiPMEMSmeansthatMEMSandcircuitsare fabricatedondifferentchipsandassembledinapackageaswillbediscussedlater usingFigure1.5.

ThebulkmicromachininginFigure1.1willbedescribedinChapter2,whichuses etchingofthebulkSiwafertomakeMEMSstructures.Thesurfacemicromachining inFigure1.1isshowninFigure1.2a.Sacrificiallayerisdepositedandpatterned followedbythedepositionandpatterningofstructurallayer.Thesacrificiallayeris selectivelyetchedout,andtheremainedstructurallayerisusedforthecomponents ofMEMS.

3DandCircuitIntegrationofMEMS, FirstEdition.EditedbyMasayoshiEsashi. ©2021WILEY-VCHGmbH.Published2021byWILEY-VCHGmbH.

MEMS systems

System on chip (SoC) MEMS

Bulk micromachining (Chapter 2)

Extended bulk micromachining(Chapter 3)

Surface micromachining

(Epitaxial) Poly-Si surface micromachining (Chapter 4)

Poly SiGe surface micromachining (Chapter 5)

Metal surface micromachining (Chapter 6)

MEMS using AIN thin film (Chapter 7)

MEMS using CMOS water (Chapter 8)

Wafer transfer (Chapter 9)

Piezoelectric MEMS (Chapter 10)

System in package (SiP) MEMS

Figure1.1 VariousconfigurationsofMEMS.

Sacrificial layer

Structural layer

LSI wafer

Interconnection layers

LSI wafer

Carrier wafer

LSI wafer

Film transfer

LSI wafer

Device transfer

wafer

Sacrificial layer

Structural layer (a) (b) (c)

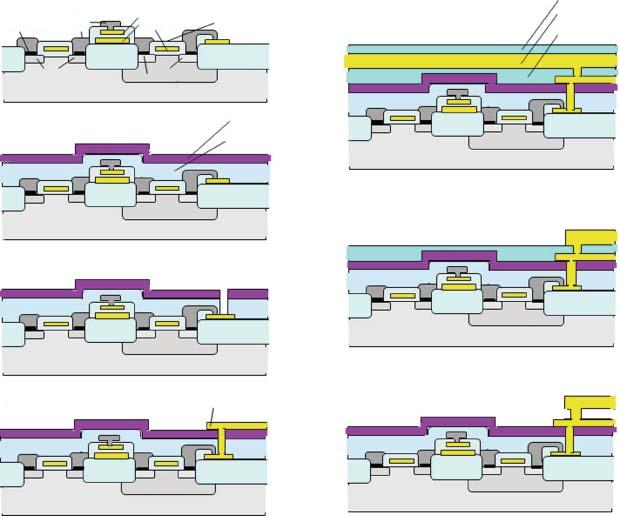

Figure1.2 VariousSoCMEMSbyLSIfirstapproach(a)Surfacemicromachining (depositionbased)(chap.4,5,6and7),(b)MEMSusingCMOSwafer(chap.8),(c)Wafer transfer(chap.9and10).

MEMSbythesurfacemicromachiningintegratedwithn-channelMOS (NMOS)FETandcomplementarymetaloxidesemiconductor(CMOS)circuitsare pioneeredbyProf.R.T.HoweandProf.R.S.MullerintheUniversityofCalifornia, Berkeley,UnitedStates.Thefabricationprocessofthesewillbeexplainedlater inFigure1.3andFigure1.4,respectively.Inrecentyearslarge-scaleintegration (LSI)usesstandardizedprocessesinfoundriesandtheprocessisnotflexible.For

1. LOCOS NMOS process

Poly Si n-Si p-Si

2. Si3N4 deposition and patterning

3. PSG/CVD SiO2 deposition and patterning

CVD SiO2

Poly Si (drive electrode)

SiO2 (field oxide)

P+ -Si

Si3N4 (etch stop layer)

PSG/CVD SiO2 (sacrificial spacer layer)

4. Poly Si CVD, phosphorous doping, RTA(1150 °C, 3 min), and patterning

Poly Si (1 µm)

5. Au deposition patterning and sacrificial PSG etching in HF Au (bonding pad)

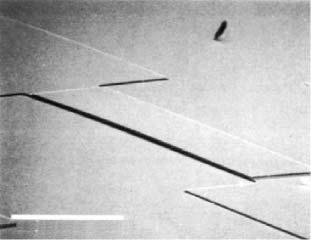

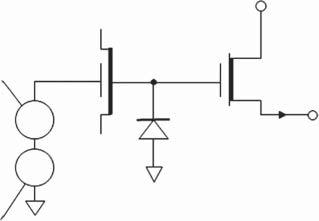

Figure1.3 NMOSintegratedpolySiresonantmicrostructure(SoCMEMS).(a)Fabrication process(b)Photographsofmicrostructure(c)CircuitwithNMOSFETandresonator.Source: Puttyetal.[1].©1989,Elsevier.

Depletion mode n-channel MOSFET

(Continued )

Resonant microbridge

AC drive voltage To detection circuit

Diode clamp

DC polarization voltage (c)

1. CMOS with W metallization

TiN/TiSi2 W poly Si PSG

n-Si n+ p well P+

2. LTO (SiO2) nad Si3N4 CVDSi3N4 (200 nm) LTO (300 nm)

5. PSG, poly Si, and PSG CVD

PSG (0.5 µm) poly Si (2 µm) PSG (1 µm)

3. Patterning, Si3N4, and LTO etching

4. Doped poly Si CVD poly Si (350 nm)

6. Rapid thermal annealing (1000°C, 1 min), patterning, PSG, and poly Si etching)

7. Sacrificial etching of PSG in buffered HF

Figure1.4 Fabricationprocessofsurface-micromachinedpolySimicrostructures integratedwithCMOScircuit.Source:BasedonYunetal.[2];Bustilloetal.[3].

thisreason,LSIfirstapproachiscommonlyusedasshowninFigure1.2.Thisis requirednottocontaminatetheLSIproductionlineaswell.

PolycrystallineSi(polySi)surfacemicromachiningusespolySiasthestructural layer.ThesurfacemicromachiningusingepitaxialpolySi(epi-polySi)willbe explainedinChapter3.ThepolySihasagoodmechanicalpropertyasamaterialfor spring,movingelement,etc.andcanbeusedforsensorsoractuatorsasresonators. Hightemperaturearound600 ∘ CisrequiredtodepositthepolySibychemicalvapor deposition(CVD).Theco-fabricatedIChastostandthistemperature.Resonant

Figure1.3

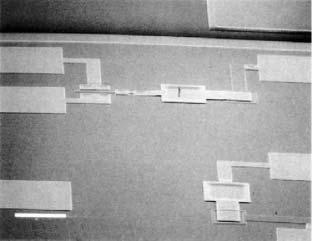

microstructuresmadeofpolySiwereintegratedwithdepletiontypeNMOSfield effecttransistor(FET)[4].ThefabricationprocessisshowninFigure1.3a[1,4].The NMOSFETsthathavepolySigatearefabricatedusingconventionallocaloxidation ofSi(LOCOS)technology.ThepolySilayerforthegateoftheFETisalsoused asadriveelectrodefortheresonator(1in(a)).Si3 N4 isdepositedandpatterned (etchedafterphotoresistpatterning)forthepurposeofetchstoplayerneededfor theetchingofthesacrificiallayer(2in(a)).Phosphosilicateglass(PSG)andSiO2 aredepositedbytheCVDforthepurposeofsacrificialspacerlayer(3in(a)).Poly Siisdepositedat600 ∘ Canddopedwithphosphorousbyionimplantation.Itis patternedafterrapidthermalannealing(RTA)at1150 ∘ Cforthreeminutes.The RTAisneededtocontrolthestressofthepolySi(4in(a)).Au(gold)isdepositedand patternedforbondingpads,andfinallythePSGsacrificiallayerisetchedoutinHF (hydrofluoricacid)tomakepolySimicrocantileverfortheresonator(5in(a)).The AuisusedonbehalfofconventionalAl(aluminum)becausetheAuisnotetched inHF.Photographsofthechipsurfaceandtheself-suspendedpolySicantilever fabricatedareshowninFigure1.3b.CircuitwiththeNMOSFETandtheresonator (resonantmicrobridge)areillustratedinFigure1.3c.Thecircuitforcapacitance detectionhastobemonolithicallyintegratedwiththeMEMSmicrostructurein ordertominimizetheinfluenceofstraycapacitance.

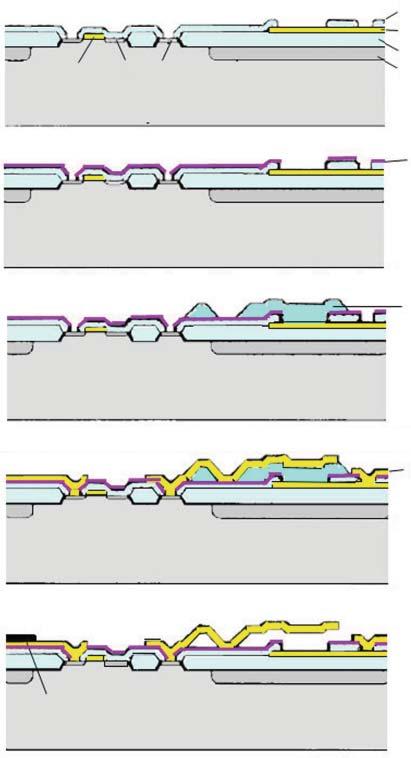

Thesurface-micromachinedpolySimicrostructureswereintegratedwithCMOS circuitaswell,beingcalledmodularintegrationofCMOSwithmicrostructures (MICS)[2,3].ThefabricationprocessisshowninFigure1.4.ThepolySisurface micromachiningrequires600 ∘ Cfordeposition,andthethermalbudgetrequires metallizationdifferentfromconventionalAl.W(tungsten)andTiN/TiSi2 wereused forthemetallizationanddiffusionbarrieratthemetal/siliconcontacts,respectively, tostandthehightemperatureprocess(1inthefigure).Low-temperatureoxide (LTO)(SiO2 )andSi3 N4 aredepositedbyCVD(2inthefigure),andtheSi3 N4 and theLTOarepatterned(3inthefigure).DopedpolySiisdepositedandpatterned (4inthefigure).PSG,polySi,and2nd PSGaredepositedbyCVD(5inthefigure). RTAismadeandthePSGandthepolySiarepatterned(6inthefigure).Movable polySimicrostructuresareformedbysacrificialetchingofthePSGinbufferedHF (7inthefigure).

ThethicknessofthepolySiislimitedtolessthan2 μmbecauseofitsstress,which causesabendingofthewafer.Ontheotherhand,low-stressepi-polySithatmakes alayerthicknessof20 μmormorepossiblewasdevelopedinFraunhoferInstitute forSiliconTechnologies(ISIT)inGermanyandUppsalaUniversityinSweden[5]. Surfacemicromachiningusingtheepi-polySihasbeenusedforcapacitivesensorsas accelerometerandgyroscope.Thelateralcapacitanceofmicromechanicalstructure canbeincreasedbecauseofthethickepi-polySilayer.Thecapacitancedetection circuitsneednottobemonolithicallyintegratedfortheSoCMEMS.Theepi-polySi surfacemicromachiningwillbeexplainedinChapter4.

ThepolySiGesurfacemicromachiningcategorizedinFigure1.1wasdevelopedto achievelowdepositiontemperature(410 ∘ C)[6].ThiswillbeexplainedinChapter5. Ge(germanium)isusedasthesacrificiallayerbecauseitcanbeetchedoutselectivelyinH2 O2 (hydrogenperoxide).

MetalsurfacemicromachiningwasdevelopedforthepurposeofmirrorarrayfabricatedonaCMOSLSI.Metalscanbedepositedbysputteringorevaporation.Since itdoesn’trequirehightemperature,thermaldamagetotheCMOSLSIisnotaproblemandphotoresistcanbeusedasasacrificiallayer.Thedurabilitywasimproved byusingamorphousmetal.Themirrorarrayhasbeenusedsuccessfullyforvideo projectorsandothersystemsaswillbeexplainedinChapter6.

TheothersurfacemicromachiningisaMEMSusingAlN(aluminumnitride).The AlNisapiezoelectricmaterialandcanbedepositedatlowtemperaturebyreactive sputtering.ThisenablesSoCMEMSthathavesurfacemicromachinedstructures havingpiezoelectricmaterialonacircuit.ThiswillbeexplainedinChapter7.

TheMEMSusingCMOSLSIwaferinFigure1.1istheSOCMEMSandschematicallyshowninFigure1.2b.ThemultilayersforinterconnectiononaCMOSwafer andthebulkSiareusedastheMEMSstructure,andtheSiundertheMEMSstructurecanbeunder-etchedifnecessary.ThiswillbeexplainedinChapter8.

WafertransfermethodsshowninFigure1.2cwillbeexplainedinChapter9.There aretwoways.Oneisfilmtransferinwhichstructurallayeronthecarrierwaferis transferredonanLSIwafer,andMEMSarefabricatedontheLSIwafer.Theotheris devicetransferinwhichMEMSarefabricatedonthecarrierwaferandtransferred ontheLSIwaferbyusingbumporothermethods.TheMEMSareleftontheLSI waferbyetchingoutthecarrierwaferorthetemporarybondinglayer,otherwise bydebonding(laserlift-off)theMEMSfromthecarrierwafer.Theadvantageofthe wafertransfermethodisthatthestructurallayerorMEMSarenotfabricatedonthe LSIwaferbutonthecarrierwafer,andhencethefabricationprocesshasflexibility. Hightemperatureprocesscanbeappliedonthecarrierwafer.

SomepiezoelectricmaterialsuchasPZT(leadzirconatetitanate)requireshigh temperature(700 ∘ C)fordepositionbysputtering.Thewafertransfermethodcanbe appliedforthefabricationoftheSoCMEMSwiththePZT.ThepiezoelectricMEMS willbedescribedinChapter10.

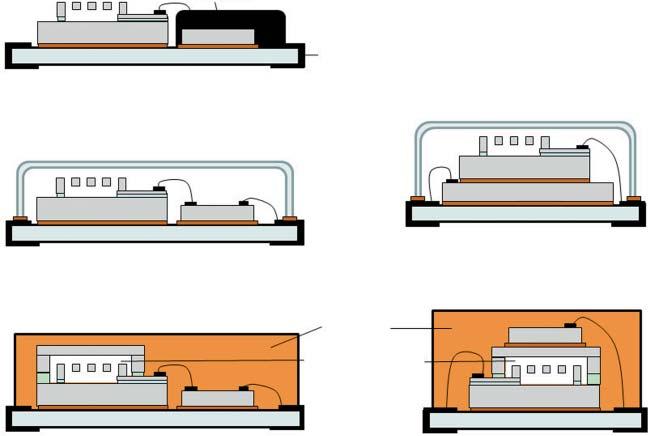

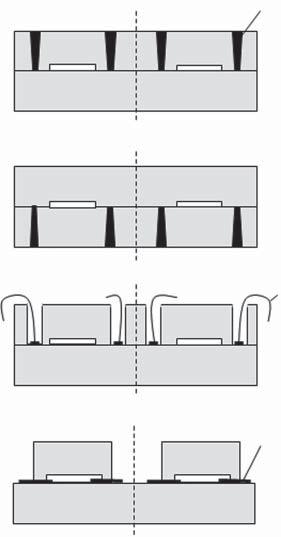

MonolithicSoCMEMShavebeendiscussedearlier.Theotherapproachisahybrid typecalledSiPMEMS.MEMSchipsandLSIchipscanbeconnectedwitheach otherasshowninFigure1.5.MEMSthathavetobeexposedasmicrophoneuse side-by-sideconfigurationwithLSIasshownininFigure1.5a.Theside-by-sideconfigurationofMEMSchipandLSIchip(Figure1.5b)andthestackedconfiguration ofMEMSchiponLSIchip(Figure1.5c)areplacedinacanorceramicpackage.The side-by-sideconfigurationofpackagedMEMSchipandLSIchip(Figure1.5d)and thestackedconfigurationofLSIchiponpackagedMEMSchip(Figure1.5e)canbe moldedwithpolymer.AnadvantageofthehybridapproachisthateachMEMSand LSIscanbefabricatedseparatelyusingoptimizedprocesses.

UnpackagedMEMSchipscan’tbemoldedwithresinbecausethesehavemoving elementsonthem.PackagingisneededforMEMSandespeciallyawaferlevelpackagingplaysimportantrolesinMEMS[7].Bonding,sealing,andinterconnection arerequiredfortheMEMSprocessandthepackaging.ThepackagedMEMSchip showninFigure1.5d,eusesglassfrit(solderglassandlow-melting-pointglass)for thebondingandsealing.ThiswillbeexplainedusingFigure4.6(Chapter4)and Figure17.35(Chapter17).SuchelementarytechnologiesfortheMEMSpackaging

Figure1.5 SiPMEMS(a)Side-by-sidehybridconfigurationofexposedMEMSchipand polymercoatedLSIchip,(b)Side-by-sidehybridconfigurationofMEMSchipandLSIchipin canorceramicpackage,(c)StackedhybridconfigurationofMEMSchiponLSIchipincanor ceramicpackage,(d)Side-bysidehybridconfigurationofpackagedMEMSchipandLSIchip withpolymermolding,(e)StackedconfigurationofLSIchiponpackagedMEMSchipwith polymermolding.

Figure1.6 Elementary technologiesforMEMS packaging. Bonding

Anodic bonding (Chapter 11)

Direct bonding (Chapter 12)

Metal bonding (Chapter 13)

Reactive bonding (Chapter 14)

Polymer bonding (Chapter 15)

Sealing and interconnection

Soldering by local heating (Chapter 16)

Packaging, sealing and interconnection (Chapter 17)

Vacuum packaging (Chapter 18)

Buried channel in monolithic Si (Chapter 19)

Through-substrate-vias (Chapter 20)

Figure1.7 Interconnectionmethods fromthepackagedMEMS (a)Through-substrate-vias(cap), (b)Through-substrate-vias (bottom),(c)Wire-bondedthrough-Si vias,(d)Lateralfeedthrough.

listedinFigure1.6willbeexplainedfromChapter11toChapter20ofthisbook.Five bondingmethodswillbeexplainedasfollows.Theseareanodicbonding(Chapter 10),directbonding(Chapter11),metalbonding(Chapter13),reactivebonding (Chapter14),andpolymerbonding(Chapter15).Sealingandinterconnection methodsexplainedaresolderingbylocalheating(Chapter16),packaging,sealing, andinterconnection(Chapter17),vacuumpackaging(Chapter18),buriedchannel inmonolithicSi(Chapter19),andthrough-substratevias(TSV)(Chapter20). InterconnectionmethodsfromthepackagedMEMSarecategorizedinFigure1.7. TheTSVinFigure1.7a,bwillbeexplainedinSection17.3.1andChapter20.The technologycalledwire-bondedthrough-Siviasin(c)willbeshowninSection 20.4.3.5[8].Thelateralfeedthroughinterconnectionin(d)willbediscussedin Section17.3.2.

References

1 Putty,M.W.,Chang,S.–C.,Howe,R.T.etal.(1989).Processintegrationforactive polysiliconresonantmicrostructures. Sens.Actuators 20:143–151.

2 Yun,W.,Howe,R.T.,andGray,P.R.(1992).Surfacemicromachined,digitally force-balancedaccelerometerwithintegratedCMOSdetectioncircuitry.IEEE Solid-StateSensorandActuatorWorkshop,HiltonHeadIsland,USA(22–15June 1992),126–131.

Bonding wire

3 Bustillo,J.M.,Fedder,G.K.,Nguyen,C.T.–C.,andHowe,R.T.(1994).Process technologyforthemodularintegrationofCMOSandpolysiliconmicrostructures. Microsyst.Technol. 1(1):30–41.

4 Howe,R.T.andMuller,R.S.(1984).Integratedresonant-microbridgevaporsensor. IEEEIEDM84,SanFrancisco,USA(9–12December1984),213–217.

5 Kirsten,M.,Wenk,B.,Ericson,F.,andSchweitz,J.A.(1995).Depositionofthick dopedpolysiliconfilmswithlowstressinanepitaxialreactorforsurfacemicromachiningapplications. ThinSolidFilms 259(2):181–187.

6 Takeuchi,H.,Quévy,E.,Bhave,S.A.etal.(2004).Ge-bladedamasceneprocessfor post-CMOSintegrationofnano-mechanicalresonators. IEEEElectronDeviceLett. 25(8):529–531.

7 Esashi,M.(2008).WaferlevelpackagingofMEMS. J.Micromech.Microeng. 18(7): 073001(13pp).

8 Fischer,A.C.,Grange,M.,Roxhed,N.etal.(2011).Wire-bondedthrough-silicon viaswithlowcapacitivesubstratecoupling. J.Micromech.Microeng. 21:085035 (8pp).

PartII

SystemonChip