3DAND4DPRINTING OFPOLYMER NANOCOMPOSITE MATERIALS

Processes,Applications, andChallenges

Editedby

KISHORKUMARSADASIVUNI

CenterforAdvancedMaterials,QatarUniversity,Doha,Qatar

KALIMDESHMUKH

NewTechnologies ResearchCenter,UniversityofWestBohemia, Pilsen,CzechRepublic

MARIAMALALIALMAADEED

QatarUniversity,Doha,Qatar

Elsevier

Radarweg29,POBox211,1000AEAmsterdam,Netherlands

TheBoulevard,LangfordLane,Kidlington,OxfordOX51GB,UnitedKingdom 50HampshireStreet,5thFloor,Cambridge,MA02139,UnitedStates

© 2020ElsevierInc.Allrightsreserved.

Nopartofthispublicationmaybereproducedortransmittedinanyformorbyanymeans,electronicor mechanical,includingphotocopying,recording,oranyinformationstorageandretrievalsystem,without permissioninwritingfromthepublisher.Detailsonhowtoseekpermission,furtherinformationabout thePublisher’spermissionspoliciesandourarrangementswithorganizationssuchastheCopyright ClearanceCenterandtheCopyrightLicensingAgency,canbefoundatourwebsite: www.elsevier.com/ permissions.

ThisbookandtheindividualcontributionscontainedinitareprotectedundercopyrightbythePublisher (otherthanasmaybenotedherein).

Notices

Knowledgeandbestpracticeinthisfieldareconstantlychanging.Asnewresearchandexperience broadenourunderstanding,changesinresearchmethods,professionalpractices,ormedicaltreatment maybecomenecessary.

Practitionersandresearchersmustalwaysrelyontheirownexperienceandknowledgeinevaluatingand usinganyinformation,methods,compounds,orexperimentsdescribedherein.Inusingsuch informationormethodstheyshouldbemindfuloftheirownsafetyandthesafetyofothers,including partiesforwhomtheyhaveaprofessionalresponsibility.

Tothefullestextentofthelaw,neitherthePublishernortheauthors,contributors,oreditors,assumeany liabilityforanyinjuryand/ordamagetopersonsorpropertyasamatterofproductsliability,negligenceor otherwise,orfromanyuseoroperationofanymethods,products,instructions,orideascontainedinthe materialherein.

LibraryofCongressCataloging-in-PublicationData

AcatalogrecordforthisbookisavailablefromtheLibraryofCongress

BritishLibraryCataloguing-in-PublicationData

AcataloguerecordforthisbookisavailablefromtheBritishLibrary

ISBN:978-0-12-816805-9

ForinformationonallElsevierpublications visitourwebsiteat https://www.elsevier.com/books-and-journals

Publisher: MatthewDeans

AcquisitionEditor: EdwardPayne

EditorialProjectManager: EmmaHayes

ProductionProjectManager:SelvarajRaviraj

CoverDesigner: MatthewLimbert

TypesetbySPiGlobal,India

Contributors

ShwetaAgarwala

DepartmentofEngineering,AarhusUniversity,Aarhus,Denmark

M.BasheerAhamed DepartmentofPhysics,B.S.AbdurRahmanCrescentInstituteofScienceandTechnology, Chennai,India

MariamAlAliAlMaadeed MaterialsScienceandTechnologyProgram,QatarUniversity,Doha,Qatar

V.Bertana

DepartmentofAppliedScienceandTechnology,PolitecnicodiTorino,Torino,Italy

RameshGuptaBurela MechanicalEngineeringDepartment,ShivNadarUniversity,GreaterNoida,India

F.Catania

DepartmentofAppliedScienceandTechnology,PolitecnicodiTorino,Torino,Italy

XuelongChen

SchoolofMechanical&AerospaceEngineering,NanyangTechnologicalUniversity,Singapore, Singapore

M.Cocuzza

DepartmentofAppliedScienceandTechnology,PolitecnicodiTorino,Torino;CNR-IMEM, ParcoAreadelleScienze,Parma,Italy

KalimDeshmukh

NewTechnologies—ResearchCenter,UniversityofWestBohemia,Pilsen,CzechRepublic

VishweshDikshit

SingaporeCentrefor3DPrinting,SchoolofMechanicalandAerospaceEngineering,Nanyang TechnologicalUniversity,Singapore,Singapore

S.Ferrero

DepartmentofAppliedScienceandTechnology,PolitecnicodiTorino,Torino,Italy

JonathanKennethGoh

SchoolofElectricalandElectronicEngineering,SingaporePolytechnic,Singapore,Singapore

KuanEngJohnsonGoh

InstituteofMaterialsResearchandEngineering,AgencyforScience,TechnologyandResearch (A*STAR);DepartmentofPhysics,NationalUniversityofSingapore,Singapore,Singapore

GuoLiangGoh

SingaporeCentrefor3DPrinting,SchoolofMechanicalandAerospaceEngineering,Nanyang TechnologicalUniversity,Singapore,Singapore

GuoDongGoh

SingaporeCentrefor3DPrinting,SchoolofMechanicalandAerospaceEngineering,Nanyang TechnologicalUniversity,Singapore,Singapore

ChristopherJ.Hansen

DepartmentofMechanicalEngineering,UniversityofMassachusettsLowell,Lowell,MA, UnitedStates

LewisR.Hart

DepartmentofChemistry,UniversityofReading,Reading,UnitedKingdom

DineshkumarHarursampath

AerospaceEngineeringDepartment,IndianInstituteofScience,Bengaluru,India

WayneHayes

DepartmentofChemistry,UniversityofReading,Reading,UnitedKingdom

YinfengHe

FacultyofEngineering,TheUniversityofNottingham,Nottingham,UnitedKingdom

MohammadTalalHoukan

DepartmentofMechanicalandIndustrialEngineering,QatarUniversity,Doha,Qatar

DerekIrvine

FacultyofEngineering,TheUniversityofNottingham,Nottingham,UnitedKingdom

AtharvJoshi

DepartmentofMaterialsScience&Engineering,NationalUniversityofSingapore,Singapore, Singapore

V.A.Kalyaev

SkolkovoInstituteofScienceandTechnology,Moscow,Russia

JagathNarayanaKamineni

MechanicalEngineeringDepartment,ShivNadarUniversity,GreaterNoida,India

A.M.Korsunsky

MBLEM,DepartmentofEngineeringScience,UniversityofOxford,Oxford,UnitedKingdom; SkolkovoInstituteofScienceandTechnology,Moscow,Russia

Toma ´ s ˇ Kova ´ rı´k

NewTechnologies—ResearchCenter,UniversityofWestBohemia,Pilsen,CzechRepublic

Toma ´ s ˇ Krenek

NewTechnologies—ResearchCenter,UniversityofWestBohemia,Pilsen,CzechRepublic

SijunLiu

AdvancedRheologyInstitute,DepartmentofPolymerScienceandEngineering,ShanghaiJiao TongUniversity,Shanghai,PRChina

AqibMuzaffar DepartmentofPhysics,B.S.AbdurRahmanCrescentInstituteofScienceandTechnology, Chennai,India

WiwatNuansing SchoolofPhysics,InstituteofScience;CenterofExcellentonAdvancedFunctionalMaterials (CoE-AFM),SuranareeUniversityofTechnology,NakhonRatchasima,Thailand

S.K.KhadheerPasha DepartmentofPhysics,VIT-APUniversity,Amaravati,India

C.F.Pirri

DepartmentofAppliedScienceandTechnology,PolitecnicodiTorino,Torino,Italy

NorbertRadacsi TheSchoolofEngineering,InstituteforMaterialsandProcesses,TheUniversityofEdinburgh, Edinburgh,UnitedKingdom

LauraRuiz-Cantu FacultyofEngineering,TheUniversityofNottingham,Nottingham,UnitedKingdom

KishorKumarSadasivuni CenterforAdvancedMaterials,QatarUniversity,Doha,Qatar

EhabSaleh UniversityofLeeds,Leeds,UnitedKingdom

A.I.Salimon

SkolkovoInstituteofScienceandTechnology;NationalUniversityofScienceandTechnology “MISiS”,Moscow,Russia

L.Scaltrito DepartmentofAppliedScienceandTechnology,PolitecnicodiTorino,Torino,Italy

F.S.Senatov NationalUniversityofScienceandTechnology“MISiS”,Moscow,Russia

SudipKumarSinha

DepartmentofMetallurgicalEngineering,NITRaipur,Raipur,India

FangWang

MOEKeyLaboratoryofMacromolecularSynthesisandFunctionalization,Departmentof PolymerScienceandEngineering,ZhejiangUniversity,Hangzhou,China

RickyWildman

FacultyofEngineering,TheUniversityofNottingham,Nottingham,UnitedKingdom

ZhenXu

MOEKeyLaboratoryofMacromolecularSynthesisandFunctionalization,Departmentof PolymerScienceandEngineering,ZhejiangUniversity,Hangzhou,China

JinXuan

DepartmentofChemicalEngineering,LoughboroughUniversity,Loughborough,United Kingdom

WaiYeeYeong

SingaporeCentrefor3DPrinting,SchoolofMechanicalandAerospaceEngineering,Nanyang TechnologicalUniversity,Singapore,Singapore

AdiletZhakeyev

DepartmentofChemicalEngineering,LoughboroughUniversity,Loughborough,United Kingdom

LiZhang

State-KeyLaboratoryofChemicalEngineering,SchoolofMechanicalandPowerEngineering, EastChinaUniversityofScienceandTechnology,Shanghai,China

YileiZhang

DepartmentofMechanicalEngineering,UniversityofCanterbury,Christchurch,NewZealand

ZuoxinZhou

FacultyofEngineering,TheUniversityofNottingham,Nottingham,UnitedKingdom

JianxiongZhu

DepartmentofMechanicalEngineering,KoreaAdvancedInstituteofScienceandTechnology (KAIST),Daejeon,RepublicofKorea

Preface

3D/4Dprintingoradditivemanufacturing(AM)isaprocessofjoiningmaterialstomake 3Dobjectsofcomplexgeometriesusingcomputersoftwareandcomputer-aideddesign (CAD).3D/4Dprintingallowslargerdesignflexibilityandlowcost,whichenableselevatedperformanceandhelpedinthetransformationofthedigitalworld.Polymersareby farthemostutilizedmaterialsfor3Dprinting.Awiderangeofpolymersthatareusedin 3Dprintingarethermoplastics,thermosets,elastomers,functionalpolymers,andcomposites.4Dprintinghasbecomeanewandexcitingbranchof3Dprinting.Unlike 3Dprinting,4Dprintingallowstheprintedparttochangeitsshapeandfunctionwith timeinresponsetochangeinexternalconditionssuchastemperature,humidity,pH, electricity,andlight.Smartmaterialsthatrespondtoexternalstimuliaregoodcandidates for4Dprinting.Usingthisbook,thereaderwillgainaconsolidatedviewofthepotential applicationsof3D/4Dprintinginaerospaceandarchitecturalindustry,theelectronic industryaswellasartandbiomedicalfields,dependinguponthechoiceofworthy& suitablepolymermaterial.3Dand4Dprintingofpolymercompositesfilledwithconductingnanofillerssuchascarbonnanotubes(CNTs),graphene,carbonblack,carbon fibers,andmetaloxidenanoparticlesallowthedevelopmentofobjectshavingmultifunctionalpropertiessuchasgoodelectricalandthermalconductivity,mechanicalstrength andstiffness,etc.atrelativelylowcost.

Thisbookaimsatprovidingathoroughandclearunderstandingofthefundamentals of3Dand4Dprintingprocessesandtherecentdevelopmentsinpolymer nanocomposites-basednovelmaterialsforprintingapplications.Thecommon3Dprintingtechniquessuchasfuseddepositionmodeling(FDM),selectivelasersintering(SLS), selectivelasermelting(SLM),electronbeammelting(EBM),inkjet3Dprinting(3DP), stereolithography(SLA),and3Dplottinghavebeendiscussedindetail.Both3Dand4D printingtechniqueshaveaseriousimpactonoursocietyanddailylifeandhavemuch moreinvolvementinthegrowingtechnology.Thecurrentbookprovidesadetaileddiscussiononthephysicsandchemistrybehindthisimportantareaofscience,whichwillbe appealingtotheresearchersallovertheworldhavinginterestinthedevelopmentof polymer-based3Dand4Dprintingmaterials.Thecontentisanticipatedtobuildonfrom whathasbeenlearnedinanelementary(core)courseonpolymerprocessingandthe developmentofadvancedpolymernanocompositesystemsfor3Daswellas4Dprinting andthemajormechanismsinvolvedinthedevicetechnologyaswellasmaterial processing.

Acknowledgment

ThisworkwassupportedbytheUREPgrant#UREP23-116-2-041fromtheQatar NationalResearchFund(amemberofQatarFoundation).Thestatementsmadeherein aresolelytheresponsibilityoftheauthors.

Introductionto3Dand4Dprinting technology:Stateoftheartandrecent trends

KalimDeshmukha,MohammadTalalHoukanb,MariamAlAliAlMaadeedc, KishorKumarSadasivunid

aNewTechnologies—ResearchCenter,UniversityofWestBohemia,Pilsen,CzechRepublic bDepartmentofMechanicalandIndustrialEngineering,QatarUniversity,Doha,Qatar cMaterialsScienceandTechnologyProgram,QatarUniversity,Doha,Qatar dCenterforAdvancedMaterials,QatarUniversity,Doha,Qatar

1Introduction

Three-dimensional(3D)printingisafabricationmethodologyusedforprinting3D objectsonthebasisofcontrolledlayerdepositionofprintablematerialuntilafinalstructureisachieved [1,2].Sincetheprintingof3Dstructureisachievedasaresultoflayered deposition,thistechniqueisalsoknownasadditivemanufacturing.3Dprintingisquite oppositetosubtractivemanufacturingfabricationprinciplewherein3Dstructureiscreatedonthebasisofmaterialremovalfromasolidblockofmaterial.Thestructureinsubtractivemanufacturingiscarvedusingprocesseslikedrilling,sawing,milling,broaching, etc. [3–5].3Dprintingisoftentermedasrapidprototyping;however,itisnoteworthy thatrapidprototypinginvolvesbothadditiveandsubtractivemanufacturing.Theseadditiveandsubtractivemanufacturingtechnologiesareutilizedonthebasisoffactorslike choiceofprintablematerial,structuralcomplexity,cost,andthequantityofstructures. Infact,thecomplexityinstructuralgeometryofanobjectprimarilydifferentiatesthetwo 3Dfabricationtechniques.Thecomplexdesignscomprisingsolidandhollowpartscan befabricatedbymeansofadditivemanufacturingduetosimultaneousprintingofhollow andsolidpartsoftheobjectfollowingalayer-wisedeposition [6].Ontheotherhand,the deliberativechoiceofmaterialforsimplerdesignsplaysavitalroleinthestructureconfinement.Thefabricationofplastic-orpolymer-basedobjectsismainlyattainedusing additivemanufacturing,whereasthe3Dstructuresobtainedfrommaterialslikewood, metal,orrocks,etc.areattainedbysubtractivemanufacturing [7].Each3Dfabrication techniqueoffersitsownadvantagesanddisadvantages.Forinstance,subtractive manufacturingtechniqueismorecosteffective,convenient,andusefulforproduction ofnumberofobjectswithinshortertimeinterval.Contrarytothatadditive

manufacturingisefficient,producingleastwasteandlargeenergy.Hence,itusesless energy-demandingmachinery [8].

Inthepast30years,3Dprintingtechnologyhasbeenamongrapidlyemergingtechnologies.However,contemplatingitsenormouspotential,itisheavilyunderutilized.Its potentialincost-effectiveandtime-efficientprintingof3Dmaterialspresentsanenticing proposition.Inthatregard,thenewadvancementin3Dprintinghasbeenthecenterof attentionincreatingobjectshavingthecapabilitytoaltertheirshapesoncetheyare removedfrom3Dprinter [9].Thistechnologicaladvancementhascommencedanew erainprintingandisreferredtoasfour-dimension(4D)printing.Themainobjective behind4Dprintingistheself-assemblingpropertyofthe3D-printedobjectonexposure tocertainstimuliintheformofheat,pressure,moisture,chemicalreactions,etc.Insimplewords,4Dprintingcanbedefinedasarevolutionarytechnologyanalogousto3D printingwithadditionoftimedimension,thatis,bytheinclusionoftimeframeto 3Dprinting,theconceptof4Dprintingevolves [10].Theadditionoffourthdimension to3Dprintingenablespreprogrammingofobjectswithrespecttotheirresponseagainst variousstimuli [11,12].4Dprintingmarksafuturisticapproachinprintingtechnology withanincrediblepotential.4Dprintingprovidesapossibilityofdesigninganytransformableshapefromavarietyofmaterialsexhibitingshape-transformingfeatures.With 4Dprinting,thecreationofdynamicallyself-assemblingandtransformingobjectscanbe usedindifferentindustrialsectorsforalargenumberofapplications.

Themanufacturingandprintingadvancements,especially3Dand4D,arethestateof-the-arttechnologieswithgreatscopeinvariousfieldssuchasautomobiles,medical implants,electronics,aerospace,androbotics [13–17].Theapplicabilityofthese manufacturingtechnologiesinsuchfieldisduetodimensionalaccuracy.3Dprinting technologyhasundergonevariouschanges,whenitcomestoprintablematerials(polymerstometals).Ithasplayedapivotalroleinpreciseadditivemanufacturingofobjects withinshortertimespans.Withadventof3Dand4Dprinting,theadditivemanufacturinghasgonetoanextlevelofmanufacturingwitheasierproductdevelopmentandproduction.Additivemanufacturinginhealthcaresectorhasbeenmostprominentduetoits versatileapplicabilityindifferenthealthcaredepartments.Theprocessofselectivelaser sintering(SLS)isoneofthemostimportantandpopularprocessesinpharmaceuticals andhealthcare(dentistryandorthopedics) [18–20].Inthesefields,theprocessparameters andvariablessignificantlyinfluenceandcontroltheproductoutcome.Theoutcomeof themanufacturingisdescribedonthebasisofthemechanicalandgeometricalproperties ofthepartsproduced.Theendproductsofthemanufacturingprocessmustinhibitthe adequatestrengthtoensuretherequirementsforparticularapplications.Inrecentyears, therehasbeenanincreasingtrendtoreducethedesigningandmanufacturingtimeleadingtoadvancementsinrapidprototyping(both3Dand4Dprinting).Thetechnological advancementshavemanyattractivefeatureslikereductionindesigntimeand manufacturingtime,freedomfromjigsandfixtures,etc.Theseadvancementsinmodern 2 3Dand4Dprintingofpolymernanocompositematerials

3 Introductionto3Dand4Dprintingtechnology:Stateoftheartandrecenttrends

timeshavemade3Dand4Dprintingtechnologydesirableforautomobileindustry,biomedicalengineering,jewelry,andmanufacturingofintricateobjects [21,22].Additionally,3Dand4Dprintingmanufacturingtechnologiesreducestoolingandminimizesthe wastages.Theseprintingtechnologieshavealsoshowngreatpossibilitiesandrapid growthinthefieldofspaceandaeronautics.

In3Dor4Dproductionofobjects,loweringmanufacturingcostshavebeencriticalin highlycompetitiveenvironment.Themainadvantageof3Dand4Dprinting,especially additivemanufacturing,hasbeeninloweringthecostofprintableobjects,cyclictime reduction,simplersupplychains,andperformanceimprovements,therebyallowing designingfreedom [23].Thelatestdevelopmentinprintingtechnologyhasbeenthe activitiestoimprovethesurfaceconditionandcontroloptimizationoftheprintable parts.Inparticular,4Dprintingtechnologyisprovingtobeanexcitingandemerging technologyforcreationofdynamicdevices [24,25].4Dprintingprovidesthe optionofcombiningsmartsensingandactuatingmaterialsinordertooffernovel,convenient,andversatilemethodsforproductionofcustom-designedsensors,actuators, self-assemblingstructures,androbotics [26,27].Thischapterprovidesanintroductory ideaabout3Dand4Dprintingtechnologies,particularlyadditivemanufacturingwith recenttrends.

2Designingperspectiveandeffectofprocessingparameters in3Dand4Dprinting

Both3Dand4Dprintingtechnologiesexpeditefreedomofdesigningtheprintable objectsastheirprimeandinterestingfeature.However,itisnecessarytoensurethereliabilityandqualityoftheproduct,whichcanbeachievedviafollowingasetofdesigning rulesatthepreprintingstage.Therulesfordesigningincludedesigningbasedonnumericalchainsforadditivemanufacturing,especiallyforthin-walledmetallicpartsinlaser manufacturing.Thisruleminimizesthegapbetweenthecomputer-aideddesign (CAD)andthemanufacturedpart.Theruleconsistsofproductoptimizationsatthelevel ofpartorientation,productfunctionalization,andmanufacturingpath [28,29].Inthe veryfirststepofoptimization,thatistheoptimizationofpartitself,thedesignationis assignedtotheareaselectedfortheproductdesign.Thesecondoptimization(functional optimization)determinestheinitialgeometryofparts,whilethefinaloptimizationdeterminesthemanufacturingpath.Thisruleprescribesamethodologybywhichgeneration ofprintingprogramoccursalongwithfinalcomputer-aideddesignmodel.Theforemost designingrulesindirectmanufacturingprovidesthefreedomofdesigningofthetechnicalparts,whichareapplicablefor3Daswellas4Dprinting [30].Thisrulebenefits multipleuserswithaccessibledesignsparticularlyinfuseddeposition,lasersintering, andmeltingmethods.Thegeometricalfreedomsavailedin3Dand4Dprintingprovide significantimprovementsinfunctionalityofseriesofproducts,therebysubstitutionof

conventionalpartsinadditivemanufacturing [31,32].Forbetterresults,itisessentialto fulfillfollowingcriteriaforeffectiveproductdesigningin3Dand4Dprinting:

•Integrateddesigning

•Lightweightmaterials

•Individualization

•Overallproductefficiency

Thesecriteriadeterminethesuccessoftheprintedobjectaswellasprovidetheneedfor improvementseconomicallyandtechnologically.Economically,thecostinvestedinthe productdesignandprocessingcanberecoveredbyloweringmanufacturingcostsorby utilizationofgeometricfreedominproductredesigningduringproductlifetime.

Theoptimizationofprocessingparametersin3Dand4Dprocessinghasopenednew windowinprintingtechnology.Likewise,theimplementationofoptimizedlaserassistedadditivemanufacturingtomicrolevelfollowingalayer-by-layermanufacturing ofnickel-basedsuperalloyshasbeenreportedbyBietal. [33].Theoptimizationinprocessingparametershasledtoeliminationofdefectscausedbypoorweldability,which resultsincrackingandporosity.Themicrolaser-assistedadditivemanufacturingallowed crack-freedepositionwithapplicationofminimumheatinput.Thegrainrefinementfollowedbyheattreatmentresultsinimprovementofthetensilestrengthalongwiththe requiredstandardsinaerospaceindustry.TheuseofhybridadditivemanufacturingtechniqueforfabricationofTC11titaniumsamplealloyhasbeenreportedbyZhuetal. [34]

Thesamplefabricatedbylaseradditivemanufacturingwasstudiedforhardnessandtensile strengthandtheresultsrevealedthetypicalzonesinthefabricatedsample,forexample, additivemanufacturedzone,bondingzone,andwroughtsubstratezones.Thesample displayedbasketwavemicrostructure,whichistheprimecauseofyieldingsuperiortensilestrength.Inanotherreport,wheremeansofadditivemanufacturingwasusedbyLi etal. [35],thetemperaturefieldsinAlSi10Mgusingselectivelasermeltingsinteringwere usedinordertostudytheconsequencesoflaserpower,scanspeed,andcoolingrate. Theirresultsrevealedthattheelevationincoolingratewhenlaserpowerwasincreased withanincreaseinscanspeed,therewasonlysignificantriseincoolingrate.Theresults providedtheoptimalconditionsfor3Dprocessingofthematerialafterrepetitionofdifferentconditionsandcombinationstoproducefullydenselayerswithdesiredlayerthicknessinthefinalfabricatedproduct.

2.1Challengingprospects

Consideringthe3Dand4Dprintingtechnology,thereareenormouschallengesinthe formofdesigning,manufacturing,etc.,whicharelistedbrieflyinthissection.

2.1.1Designingchallenges

Thedesigningaspectconsidering3Dand4Dprintingbeginswithdevelopmentoftrained engineers,whichwouldtenderthecapabilitytointegratetheoptionsofferedbyadditive manufacturing [36].Toattainthis,itisnecessarytosetastandardizationofdesigningrules.

5 Introductionto3Dand4Dprintingtechnology:Stateoftheartandrecenttrends

Thecurrentdesigningtoolsdonotyieldtheoutcomeof3Dand4Dtoitsfullestcapabilities consideringthepotentialofthesetechnologies.Thereforeitstillrequiresalotofworkto incorporatethetopologicaloptimizationsinthedesigningtools.

2.1.2Manufacturingchallenges

Afterdesigningfixations,propertrainingistobeprovidedtofuturemachinedesignersto meettheincreasingdimensionalneedsinordertoincreasethemanufacturingpotentialof theobjectsbyusing3Dand4Dprintingtechnology [37].Inadditiontothat,itisessential toestablishqualitystandardsfortheprintablematerialstoensuretheproductreliability andreproducibility.Itisalsoimportanttodevelopnewmaterialsfortheseprinting technologies.

2.1.3Qualificationandvalidation

Theconventionalmethodsofqualificationcannotbereadilyappliedtothe3Dand4D printingtechnologies,assamplemonitoringofthefinalproductdoesnotonlydependon theyieldmintproducts.Toensurebetterqualityoftheprintedsamples,itisnecessaryto developnon-destructiveinspectionmethodstoestablishproductqualityviareal-time monitoring [38].Theoptimizationandqualificationof3Dand4Dprintingmethods isthusveryessentialtoproducequalityproductswithminimalornodefectslikecracks, porosity,etc.Inadditiontothat,theestablishmentofacceptabledefectrangeneedstobe developedconsideringthedesigningrules.

Thenewprintingtechnologiesarenowconsideredtobethemeansofrealtimeproduction.However,toachievetheintendedbenefitsfromthesetechnologiesaspertheir potential,certainchallengesstillneedtobeaddressed.Totacklethesechallenges,it requiresalotofresearchanddevelopmenttoeffectivelyusethesetechnologiesinvariety offieldsandapplications.Thesetechnologies,withrespecttotheirusage,arestillyoung andrequiregreatdealofresearchtowidenitsusage.Thesetechnologieshavethetendencytoimpactanineradicableimprintonthefutureofdesigningandmanufacturing, therebyradicallychangingtheprintinghabitsintheupcomingyears.Theadvantagesand challengesof3Dadditivemanufacturingaresummarizedin Table1[39]

33Dprintingtechnology

The3Dprintingprocessinvolvesfewsteps,whichareinitiallybasedonCADmodeling followedbyitsconversionintostereolithographicfile [40].Afterfileformation,the printablesurfaceisslicedintothelogicalseriesoftriangles,eachoneofwhichrepresents partofthe3Dproductsurfacemodel.Thefileonexecutioncutsthemodelintothin cross-sectionallayersallowingthe3Dmodeltobeprinted [41] Fig.1 demonstratesdifferenttypesof3Dprintingtechnologiescurrentlyavailableinthemarketwhereas differentresearchfieldsinwhich3Dand4Dprintingtechniqueshavebeencurrently usedareshownin Fig.2.

AdvantagesChallenges

• Customizedproductsfromsmallbatches areeconomicallyattractiveascompared withthetraditionalmassproduction methods

• Possibilitytoproduce3DCADmodels directlymeaningthattoolsandmoldsare notrequired.Hence,noswitchovercosts

• Canbedesignedintheformofdigitalfiles, whichcanbesharedeasilyinorderto facilitatethemodificationandcustomizationofcomponentsandproducts

• Materialcanbesavedduetotheadditive natureoftheprocess.Thewastematerials (powder,resin),whicharenotusedduring manufacturingcanbereused

• Possibilitytoachievenovelandcomplex structuressuchaslatticesandfree-form enclosedstructuresandchannels

• Verylowporosityoffinalproducts

• Theinventoryriskcanbereducedby makingtoorderwithnounsoldfinished goods.Improvingtherevenueflowby payingforgoodspriortotheir manufacturing

• Duetothedistribution,thedirectinteractionbetweenlocalconsumerorclient andproducerispossible

• Productioncostandspeed

• Changingthewayandapproachofusing additivemanufacturing

• Toremovetheperceptionthatadditive manufacturingisonlyforrapidprototyping andnotfordirectcomponentandproduct development

• Todevelopandstandardizenewmaterials

• Tovalidatethemechanicalandthermal propertiesofexistingmaterialsandadditive manufacturingtechnologies

• Todevelopmultimaterialandmulticolor systems

• Toimprovemanufacturingefficiencyby automationofadditivemanufacturingsystemsandprocess

• Postprocessingisrequiredduetothestairsteppingeffectthatarisesfromincrementallyplacingonelayerontopofanotherfor producingfinishinglayers

• Torecyclethesupportstructurematerials byminimizingtheneedthroughagood build-uporientation

• Issuessuchasintellectualpropertyrights andnonlinearcollaborationwithilldefinedrolesandresponsibilities

• Designersandengineerswithdeficitskills inadditivemanufacturing.

3.1.1Binderjetting

Thecreationof3Dobjectbycombinationofpowderedmaterialbymeansofjetdepositionofbindingagentistermedasbinderjetting.Thematerialsprintedbythistechnologyaremetals,polymers,andceramics.ThedevelopersofthistechnologyareVoxelJet (Germany),exOne(USA),and3DSystem(USA).

3.1.2Materialjetting

Materialjettingistheprocessofbuildingpartsbysettlingdownsmalldropletsofthefilament.Thesesmalldropletsarethencarvedasperthedesigninstructionsgeneratedby exposingthefilamentdropstolightUVradiationstoattainahighresolutioninheightof

Fig.1 Differenttypesof3Dprintingtechnologies. 7

layerofabout16 μm.Thematerialssuitableforthistypeoffeedingmechanismsarephotopolymerandwax.Thetechnologywasdevelopedby3Dsystem(USA)Stratasys(USA) andLUXeXcel(Netherlands).

3.1.3Directenergydeposition

Thistechnologyusesfocusedthermalenergytofuse/joinmaterialontothesubstrateby directdepositionforcreating3D/4Dstructures.Thematerialsusedforthistypeofprintingareintheformofpowdersandwires.ThistechnologywasdevelopedbyIrepaLaser (France),Trumpf(Germany),NRC-IMI(Canada),andDM3D(USA).

4D printed parts can be sent to space and programmed to self assemble into an object at the desired location.

Construction/architecture

Materials that could be programmed to adapt and change shape in response to environment or situation. Example: Pipes that expand when demand increases.

Medical

Ongoing research on developing a nano robot built from DNA strands in the form of a clamshell basket, with double-helix’’ locks’’ that are only opened when the robot comes into contact with specific cells.

Industry application will be explored with cost of technology more suited for industrial applications.

Holds to revamp manufacturing introducing a new field of environmental manufacturing in which ambient sources of energy, water or even light will be used as impetuses to self assemble.

Fig.2 Anoverviewofongoingresearchon3Dand4Dprinting.

3.1.4Powderbedfusion

Inthistechnology,the3Dor4Dstructures(usingtimedimension)arecreatedtofuse regionsofapowderbedbyusingthermalenergy.Thematerialsusedinthistechnology arepolymers,ceramics,andmetals.ThistechnologywasdevelopedbyMatsuura Machinery(Japan),PhoenixSystem(France).EOS(Germany),ARCAM(Sweden), Renishaw(UK),and3Dsystem(US).Powderbedfusiontechnologyusesthefollowing processesincreationof3Dand4Dprintedobjects.

• Directmetallasersintering

Thisprocesscreatesobjectsbymeltingandfusingtheprintingmaterialinaninertgas chamberusingahighlyfocusedbeamoflaser.

• Electronbeammelting

Inthisprocess,theproductsarefabricatedusingahigh-intensityelectronbeaminside vacuummeltingthepowderplacedinsideit.Thisisfollowedbycoolingthesubstance togiveitafinalshape.

3D printing

• Selectiveheatsintering

Thistechniqueusesheatingofthermalprintheadforlayer-wisedepositionofthermoplasticpowder.Theheatingcuresthethermoplasticpowdertoattaina3D structure.

• Selectivelasermelting

Theprocessuseslasertomeltthemetalpowderformingapoolofmeltinsideaninert gaschamber.Themeltisthenrolledrepeatedlyintheformoflayerstoyieldthefinal product.

• Selectivelasersintering

Thisprocessissimilartothelasermeltingwhereinabeamoflaserisusedtosinterthe materialpowder.Thesinteredpowderisthenrolledinalayer-wisemanner.The majorpointofdifferenceamongthetwoprocessesisthatinlasermeltingthepowder isheatedabovemeltingpoint,whileasinsinteringprocesstheprintablematerialis heatedbelowmeltingpointuntilthepowderedparticlesfusewitheachother.

3.1.5Lightphotopolymerization

Thistechniqueuseslightincreationof3Dstructures.The3Dpartsarecreatedusinglight toselectivelycuremateriallayersinavatofphotopolymer.Thematerialsusedinthis techniqueareceramicsandphotopolymers,andthistechnologywasdevelopedbyLithoz (Australia),EncisionTEC(Germany),DWSSri(Italy),and3Dsystem(US).Thistechniqueuseseitherstereolithographyordigitallightprocessingindevelopmentof3D structures.

• Stereolithography

Inthisprocess,aliquidphotopolymerismeltedonexposuretoUVradiationsemitted fromalasersource.Thereactionoflaserbeamwiththephotopolymercausesthe solidificationoftheresintoform3Dobjects.

• Digitallightprocessing

ThistechniqueprojectslayersoftheobjectfromtheCADimageintothevatofphotopolymer,whichonreactionwiththeprojectionlightcuresandhardensthedesired 3Dpart.

3.1.6Extrusion

Thisprocesscreates3Dobjectsbydepositingmaterialviaheatednozzletoformlayer, whichhardensinstantlytoallowdepositionofnextlayer.Theprocessisrepeatedseveral timesuntildesiredshapeofobjectisattainedandthisprocessisalsoknownasfused depositionmethod.Mainlypolymericmaterialsareusedinthistypeofprintingandthis technologywasdevelopedbyDeltaMicrofactory(China),3Dsystems(US),and Stratasys(US).

3.1.7Sheetlamination

Thisprocesscreates3Dstructuresbytrimmingsheetsofprintablematerialandthenbindingtheminlayers.Thematerialsusedinthisprocessareceramics,metallicsheets,and hybridmaterials.ThedevelopersforthistechnologyareCAM-LEM(US)andFabrisonic (US).Thetechniqueincorporatesultrasonicadditivemanufacturingandlaminated manufacturing.

• Ultrasonicadditivemanufacturing

Thisprocessusesthesheetlaminationprocesstojointhinmetallicsheetstoform objects.ThemetallicsheetsarejoinedtogetherbyultrasonicweldingandCNCmill isusedtotrimtheexcessmaterial.

• Laminatedobjectmanufacturing

Thisprocessisalsolayer-by-layeradditiveprintingtechnologywhereinlayersarebound toeachotherusingadhesivepaper,metal,orplastic,whichisleasttoxic.Thesheetsof materialarecutintodesiredshapebyalasercutterandthengluedtogether.

4Classificationofmaterialsusedin3Dand4Dprinting

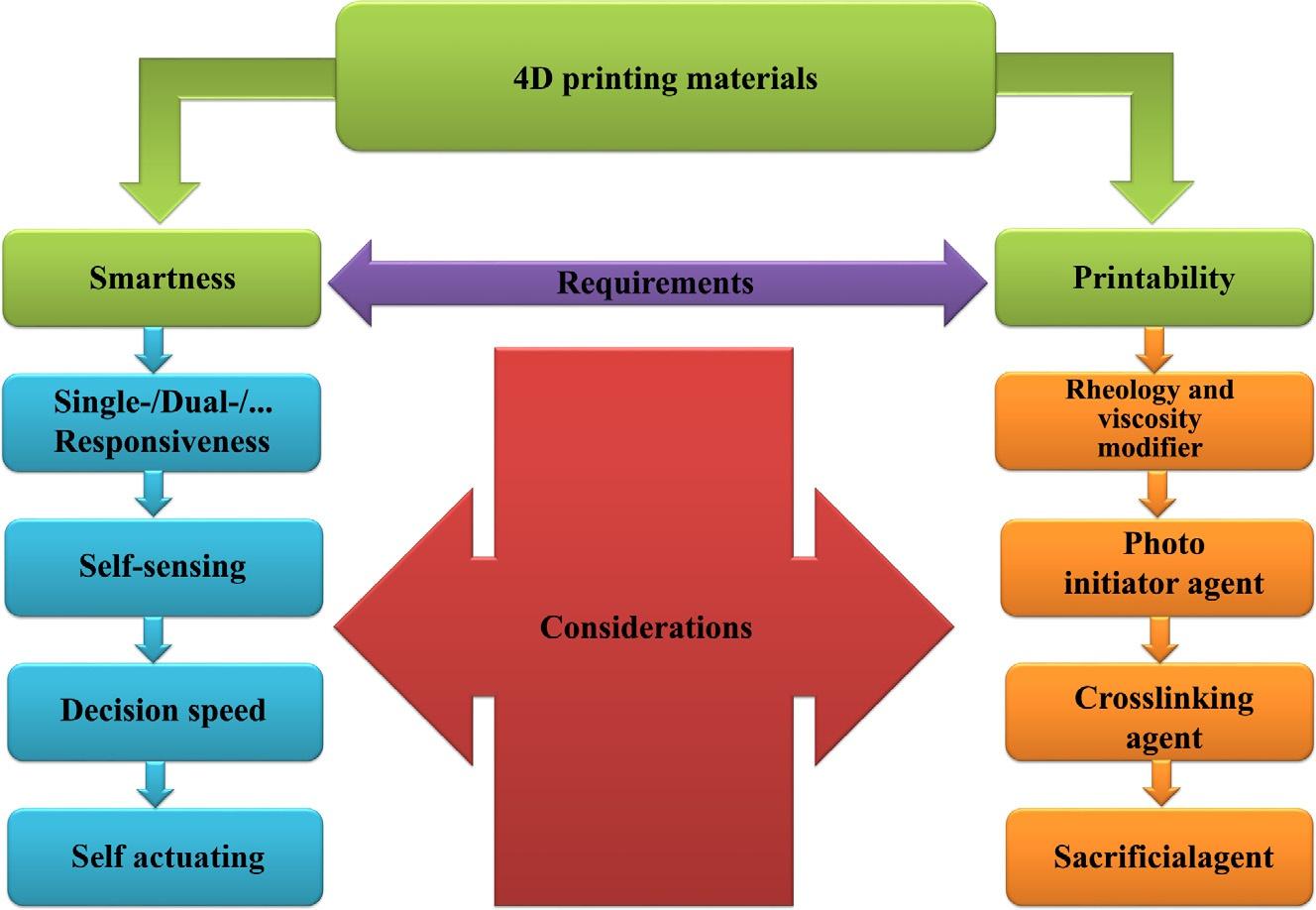

Thematerialsusedin3Dand4Dprintingtechnologiesareclassifiedaspowdermaterials, wirefilaments,printablewaxes,andliquidmaterials.Thesearelistedbrieflyinnextsection. Fig.3 givesanoverviewofmaterials,whicharerequiredfor3D/4Dprinting.

Fig.3 Considerationofmaterialsrequiredfor3D/4Dprinting.

4.1Powdermaterials

Thepowdermaterialsareprintedbyfusing,melting,orbyusingsuitablebindingmaterialsorwatercoloradditives,whereasthepowderismixtureofplasterandpolymersand alsowoodfilament.Thewoodfilamentsarecomposedofgroundwoodmaterialwith polymerslikepolylacticacid(PLA)orsomeplastic.Inareport,spoolsofwoodfilament wereprintedusingextrudernozzleofdiameter0.6mmwithoutdefects [42]

4.2Wirefilamentmaterials

Wirefilamentsmaterialsaremainlypolymeric materials,and,amongthem,acrylonitrilebutadienestyrene(ABS)isthemostaffordableone.Thedifferentwirefilamentmaterialswith theirpropertiesaresummarizedin Table2.ABSisaversatilematerialandcanbeeasilysanded orhybridizedwithacetone.ThehybridizedABSeasilystickstogethertoyield3Dstructures

Table2 Summaryofwirefilament–basedmaterials

ABSItcanbesanded,and bymixingABSwith acetone,itcanbe easilygluedtogether orsmoothedtoa glass-likefinish (petroleum)

PLABiodegradable plastictypically madefromcornor potatoes(produced fromplantstarch)

TPEFlexible,rubber-like materialsofdifferent varieties

PVAPVAisaspecial plasticthatiswatersoluble,Excellent filmformation, Highbonding power, Goodbarrier properties (petroleum)

Strong Slightlyflexible Heatresistant

CThepropertiesofa softrubber,making itevenmoreflexible andelasticthansoft PLAfilament

withsmoothglassyfinish [43].ABScanevenbearmostviolentheatwarpingandshrinkage, whichincreasesitsmanifolddemandsintheprintingplatforms.Thestructuresprintedfrom ABScantoleratehighertemperaturesduetoitshigherglasstransitiontemperatures.

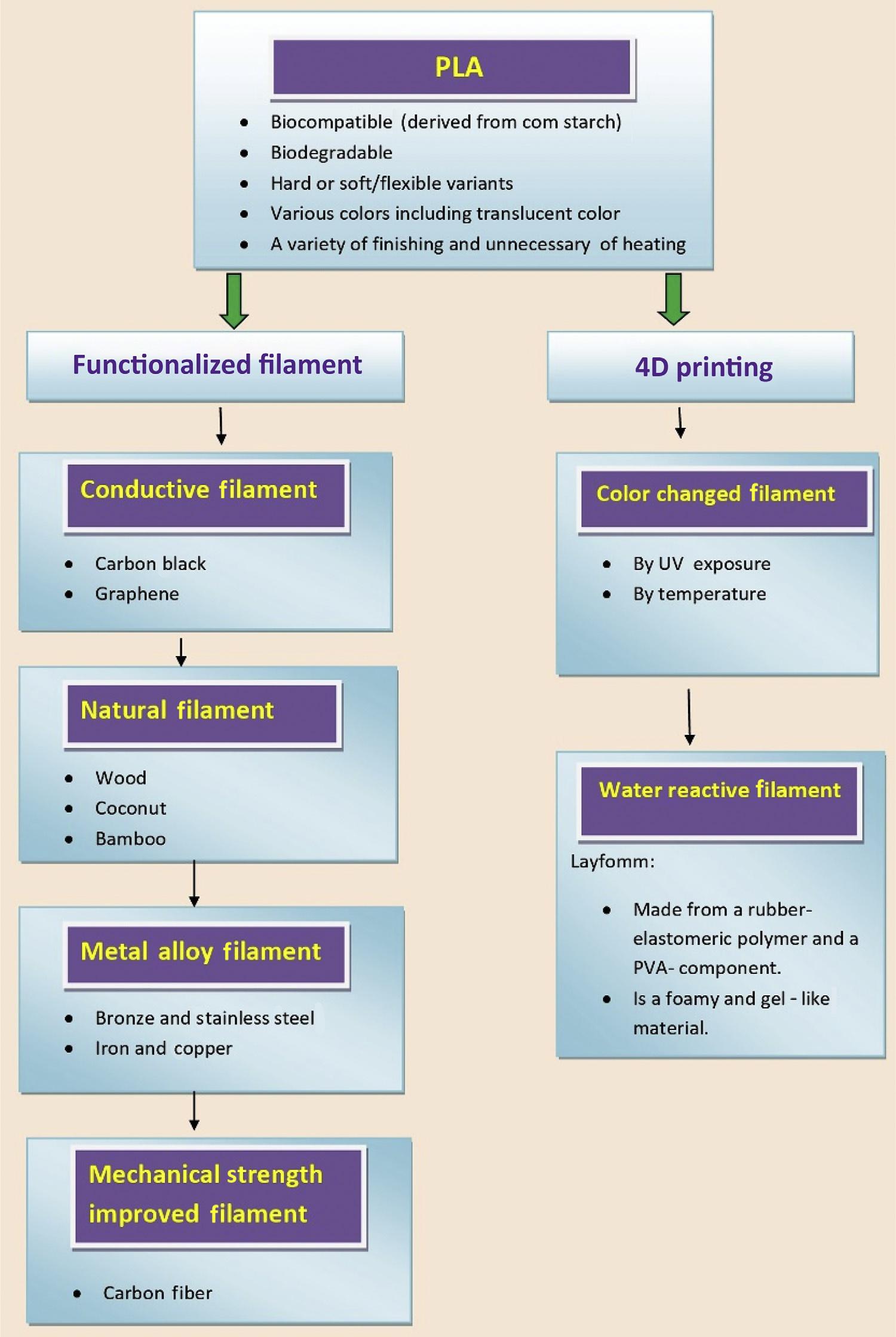

PLAisanotherpolymericmaterialsuitablefor3D/4Dprinting. Fig.4 showsPLAbaseddifferentfilamentmaterialsusedfor3D/4Dprintingapplication.PLAisabiodegradableplastic,whichcanbemadeaccessiblethroughnaturalmeans.Itisstifferthan ABSanddoesnotrequireheatingofprintingbedwhileprinting,butheatwarpingof PLAduringcoolingcanbeimprovedbyusingheatedbed [44].Thermoplasticelastomers (TPE)areasoft,flexible,andrubber-likematerial.Theseelastomersareprintedusing extrusionmethod,withrigidconstructedfilamentsduetoextensiveflexibilityofthe materials [45].Theprintingoftheseelastomersrequiresextrudertobemaintainedatidler pressureanditspositionhastobeprecisetoavoidfilamentsquashing.Polyvinylalcohol (PVA)isaspecialtypeofplasticusedasasupportingmaterialinextruderprinting.Dueto itswatersolubility,itisextremelyproblematictobeusedinhigh-humidityenvironment. Therefore,itisbestsuitedassupportingprintingmaterial,especiallywithABS [46]

4.3Printablewaxes

Thewaxesshowtendencytobe3D/4Dprintedusingthermojetprinter.Theprinteruses waxescomposedofthermoplasticsmadefromamides,hydrocarbons,andesters [42].

4.4Liquidmaterials

Liquidmaterialsusedin3Dand4Dprintinguseinkjet-basedprintertechnology.The inkjetprintersforsuchprintinguseUV-curableresinscomposedofthermosettingplastics andhavedifferentcharacteristicsthanthosethermoplasticsusedinextrusionprintinglike thetensilestrengthandglasstransitiontemperature [42].

53Dprintersoftwareandhardware

Theprintingof3Dobjectsthrough3Dprintersrequiresspecialtypeofsoftwareasshown in Fig.5.TheuseofsoftwareinphysicalprototypeoperatesthroughCAD.The computer-aidedmanufacturing(CAM)unitalsoreferredtoassliderconvertsthe CADmodelintosetofspecificmechanicalinstructionsforprintingrobot.Theprinter controllingsoftwaresendstheinstruction,whichtransmitsthefedinstructionstothe printertoprovidereal-timeinterface [42]

The3Dprintingofobjectsviafilamentof3Dprintertakesplacethroughseriesof commandscalledasG-code.Thehardware-softwareinterfaceandtheflowofG-codes inthereal-timeprintingthroughUSBportisshownin Fig.6.Therunningsoftware interpretstheG-codeataspecifictimeintervalandtransmitsthesametotheprinter forexecution.Theinformationstatusissentbacktothehostcomputerthrough USB.TheinterpretationofG-codeinsomecasesisdoneonhostcomputerwhilesendingthecontrolstotheprinter.

Fig.4 PLA-baseddifferentfilamentmaterialsusedfor3D/4Dprinting.

Softwarehierarchyusedin3Dprinting.

Autodesk 123D Tinkercard

Skechup ZBrush Sculptures OpenSCAD Modelbuilder Grasshopper Blender 3ds max Maya Modo Mudbox

Fig.6 Hardwareandsoftwarecontrolin3Dprinting.

6Evolutionof4Dprintingtechnology

4Dprintinghasbeenoneoftherecentapproachesinprintingtechnology.The 4D-printedobjectshavetheabilitytobetransformedintodesiredstructurewithreferencetotime [47].4Dprintingtechnologyhasevolvedtoincorporateembeddedwiring orconductingpartsintospecializedsubmissivecomponents.Once3Dprintingofthe objectisdone,theprintedpartsarestimulatedoractivatedusinganexternalstimulus. Thistypeofprintingapproachhasgreatpotentialinthefieldofrobotics,aerospace,furniture,andconstructionofbuildings [48].Theother4Dprintingapproachescomprise incorporatingcompositematerialshavingtheshapemorphingandcapabilitiesoftransformingintodifferentshapeswithrespecttovariousphysicalmechanismsandheat

Fig.5

CAD software

activation [49].Also,availablereportsclearlydemonstratetheself-foldingabilitiesof4D printablematerialsonexposuretolight [50].

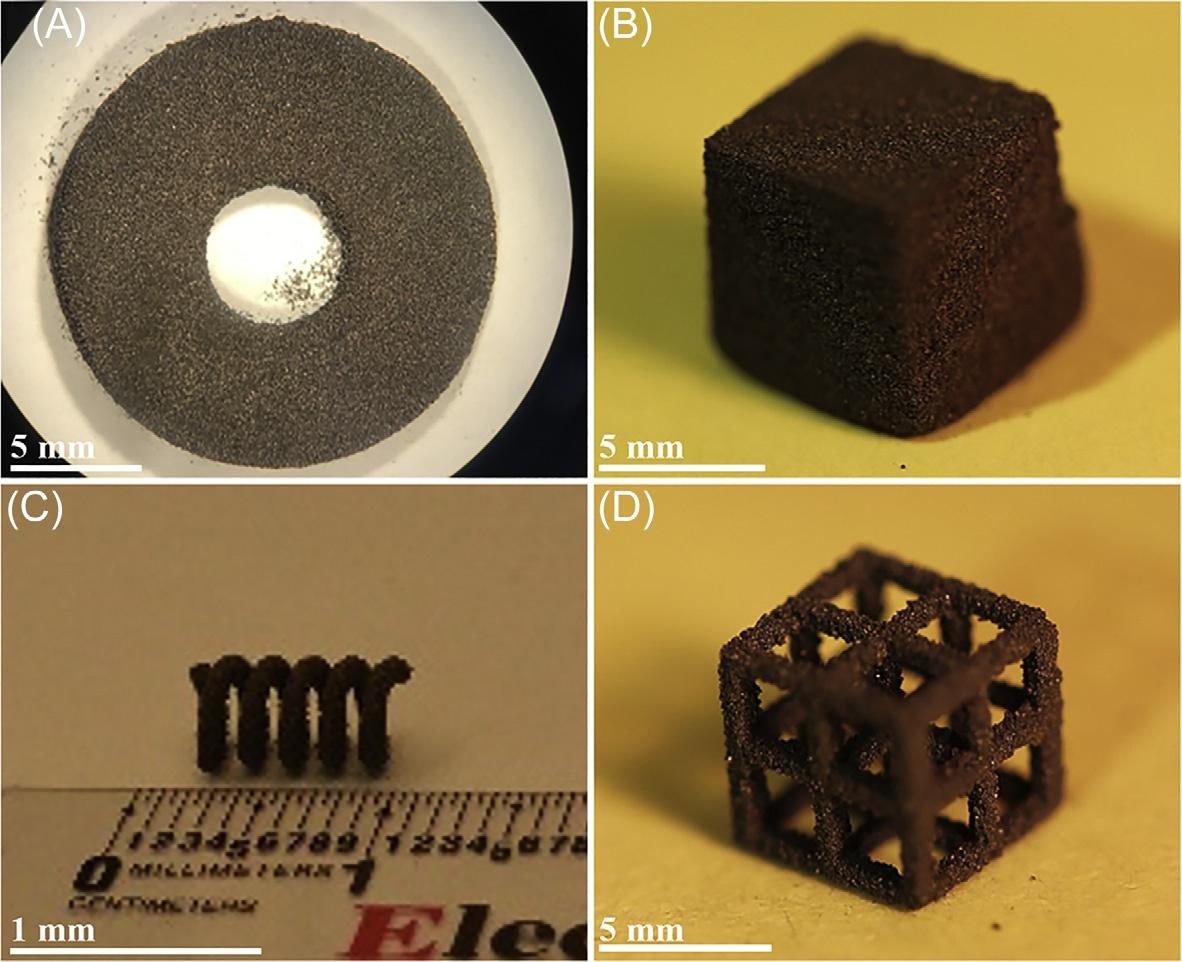

Caputoetal. [51] adapted3Dprintingrouteforproducingsinterednet-shapedpart fromNi-Mn-Gapowders.The4Dpartswerecreatedbythepredictablechangein3D printedpartsconfiguredasafunctionoftimeasaresultofshapememoryeffect.Netshapedporousstructureswithgoodmechanicalstrengthwereproducedbybinderjetting ofNi-Mn-Gapowdersfollowedbycuringandsintering.After3Dprinting,theprinted partswereremovedfromtheprinterandheatedto463Kfor4h.After4h,thebinderwas completelycuredandtheprintedpartswereremovedfromtheprintbed [51] Fig.7 showsseveralstructuresobtainedfromNi-Mn-Gapowderusing3Dprintingaftercuring. Fig.8 representsseveralsinteredparts.Thesinteringtimewas8hforbothsparkerodedandball-milledpowders.

Recently,Dingetal. [52] demonstrated4Dprintingofprogrammable1Dcomposite rodthatcanchangeinto3Dstructuresveryrapidlyuponheatingandretainthe3Dconfigurationwhencooled.Thecompositerodsconsistedofaglassypolymerandan

Fig.7 Net-shaped3DprintedpartsobtainedfromsparkerodedNi-Mn-Gapowdersin(A)liquid nitrogen(B)liquidargon(C)and(D)Ni-Mn-Gapowdersobtainedbyballmilling. (Reproducedwith permissionfromRef.M.P.Caputo,A.E.Berkowitz,A.Armstrong,P.Mullner,C.V.Solomen.4Dprinting ofnetshapedpartsmadefromNi-Mn-Gamagneticshapememoryalloys.Addit.Manuf.21(2018) 579–588.M.P.Caputo,A.E.Berkowitz,A.Armstrong,P.,Mullner,C.V.Solomen.4Dprintingofnet shapedpartsmadefromNi-Mn-Gamagneticshapememoryalloys.Add.Manuf.21(2018)579-588. Copyright2018,ElsevierLtd.)

3Dand4Dprintingofpolymernanocompositematerials

Fig.8 4Dprintingofsinterednet-shapedpartsmadefromball-milledNi-Mn-Gapowders. (Reproduced withpermissionfromM.P.Caputo,A.E.Berkowitz,A.Armstrong,P.Mullner,C.V.Solomen,4Dprintingofnet shapedpartsmadefromNi-Mn-Gamagneticshapememoryalloys,Addit.Manuf.21(2018)579–588. Copyright2018,ElsevierLtd.)

elastomer,whichwerebondedtogetherasaresultofmanufacturingprocess.Thiswaslater programmedwithacompressivestressduringtheprintingprocess [52].Thedetailedinformationwasobtainedaboutthebasicdeformationmodesofdirect4Dprintedcomposite rods,bendingandtwisting,andtheirdependenceondesignparameterssuchaslayerfractionofcompositesandthecross-sectiontwistalongtheaxisoftherod. Fig.9 showsa3D cubicframethatselfassemblesbyheating1Dcompositerodinsuchawaythateachofthe sixcubefacesrepresentsacircularringinthefinalconfiguration [52].Thecolorofthe glassypolymerwasusedforeasyvisualizationofeachofthesixcubefaces.Thecombinationoftheexperimentsandthesimulationsrevealedthecharacteristicsparametersthatcan beusedtodesign1Dcompositerods,whichcanyielddesired3Dstructures [52].

Inanotherstudy,Mulakkaletal. [53],developedacellulose-hydrogelcompositeink foradditivemanufacturingdemonstratingthephysicalcharacteristicssuchasstability, swellingpotentialandrheologyofcellulosehydrogelgelcomposites,anditssuitability for4Dprinting.Theadditionofcarboxymethylcellulose(CMC)hydrocolloidswithcellulosepulpfibersresultedinaninkwithgoodfiberdispersionwithinthehydrogel.The montmorillonite(MMT)claywasaddedtoincreasethestoragestabilityofthecomposite inkandtohavepositiveeffectontheextrusionprocess.Theinkwasusedfor3Dprinting demonstratingthefabricationofcomplexstructure,whichiscapableofmorphing accordingtothedesignedrules,whicharepredeterminedinresponsetohydration ordehydration(Fig.10).Thesetupoftheprinterandextruderisshownin