TribologyofGraphene:SimulationMethods, PreparationMethods,andTheirApplications OleksiyV.Penkov

https://ebookmass.com/product/tribology-of-graphenesimulation-methods-preparation-methods-and-theirapplications-oleksiy-v-penkov/

Instant digital products (PDF, ePub, MOBI) ready for you

Download now and discover formats that fit your needs...

Electric Motor Drives and their Applications with Simulation Practices V Indragandhi & V. Subramaniyaswamy & R Selvamathi

https://ebookmass.com/product/electric-motor-drives-and-theirapplications-with-simulation-practices-v-indragandhi-vsubramaniyaswamy-r-selvamathi/ ebookmass.com

Two-Dimensional Materials for Nonlinear Optics: Fundamentals, Preparation Methods, and Applications Qiang Wang

https://ebookmass.com/product/two-dimensional-materials-for-nonlinearoptics-fundamentals-preparation-methods-and-applications-qiang-wang/

ebookmass.com

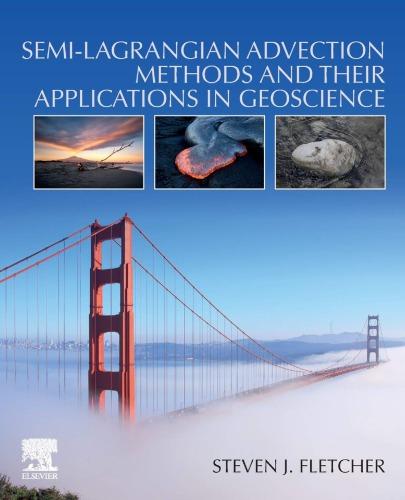

Semi-Lagrangian Advection Methods and Their Applications in Geoscience 1st Edition Steven J. Fletcher

https://ebookmass.com/product/semi-lagrangian-advection-methods-andtheir-applications-in-geoscience-1st-edition-steven-j-fletcher/

ebookmass.com

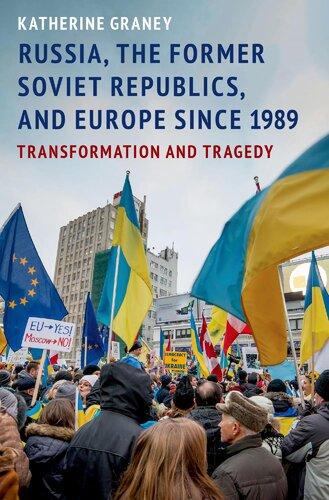

Russia, the Former Soviet Republics, and Europe Since 1989: Transformation and Tragedy Katherine Graney

https://ebookmass.com/product/russia-the-former-soviet-republics-andeurope-since-1989-transformation-and-tragedy-katherine-graney/ ebookmass.com

Monster Girl Awakened : Academy of Magic Book Two (Academy Of Magic Books 2) Anne Hall

https://ebookmass.com/product/monster-girl-awakened-academy-of-magicbook-two-academy-of-magic-books-2-anne-hall/

ebookmass.com

Analytics Enabled Decision Making Vinod Sharma

https://ebookmass.com/product/analytics-enabled-decision-making-vinodsharma/

ebookmass.com

Circuit Design and Simulation Quick Start Guide: Create Schematics and Layout Electronic Components Ashraf

Almadhoun

https://ebookmass.com/product/circuit-design-and-simulation-quickstart-guide-create-schematics-and-layout-electronic-components-ashrafalmadhoun/

ebookmass.com

Literature, Music and Cosmopolitanism: Culture as Migration 1st Edition Robert Fraser (Auth.)

https://ebookmass.com/product/literature-music-and-cosmopolitanismculture-as-migration-1st-edition-robert-fraser-auth/

ebookmass.com

Political Conversations in Late Republican Rome Cristina Rosillo-López

https://ebookmass.com/product/political-conversations-in-laterepublican-rome-cristina-rosillo-lopez/

ebookmass.com

Diagnostic Imaging: Chest 3rd Edition Melissa L. RosadoDe-Christenson

https://ebookmass.com/product/diagnostic-imaging-chest-3rd-editionmelissa-l-rosado-de-christenson/

ebookmass.com

TRIBOLOGYOF GRAPHENE

TRIBOLOGYOF GRAPHENE SimulationMethods,

PreparationMethods, andtheirApplications

OLEKSIYV.PENKOV

ZJU-UIUCInstitute,InternationalCampus, ZhejiangUniversity

Elsevier

Radarweg29,POBox211,1000AEAmsterdam,Netherlands TheBoulevard,LangfordLane,Kidlington,OxfordOX51GB,UnitedKingdom 50HampshireStreet,5thFloor,Cambridge,MA02139,UnitedStates ©2020ElsevierInc.Allrightsreserved.

Nopartofthispublicationmaybereproducedortransmittedinanyformorbyanymeans, electronicormechanical,includingphotocopying,recording,oranyinformationstorageandretrieval system,withoutpermissioninwritingfromthepublisher.Detailsonhowtoseekpermission, furtherinformationaboutthePublisher’spermissionspoliciesandourarrangementswith organizationssuchastheCopyrightClearanceCenterandtheCopyrightLicensingAgency,canbe foundatourwebsite: www.elsevier.com/permissions.

Thisbookandtheindividualcontributionscontainedinitareprotectedundercopyrightbythe Publisher(otherthanasmaybenotedherein).

Notices

Knowledgeandbestpracticeinthisfieldareconstantlychanging.Asnewresearchandexperience broadenourunderstanding,changesinresearchmethods,professionalpractices,ormedical treatmentmaybecomenecessary.

Practitionersandresearchersmustalwaysrelyontheirownexperienceandknowledgeinevaluating andusinganyinformation,methods,compounds,orexperimentsdescribedherein.Inusingsuch informationormethodstheyshouldbemindfuloftheirownsafetyandthesafetyofothers,including partiesforwhomtheyhaveaprofessionalresponsibility.

Tothefullestextentofthelaw,neitherthePublishernortheauthors,contributors,oreditors,assume anyliabilityforanyinjuryand/ordamagetopersonsorpropertyasamatterofproductsliability, negligenceorotherwise,orfromanyuseoroperationofanymethods,products,instructions,orideas containedinthematerialherein.

LibraryofCongressCataloging-in-PublicationData

AcatalogrecordforthisbookisavailablefromtheLibraryofCongress BritishLibraryCataloguing-in-PublicationData

AcataloguerecordforthisbookisavailablefromtheBritishLibrary ISBN:978-0-12-818641-1

ForinformationonallElsevierpublications visitourwebsiteat https://www.elsevier.com/books-and-journals

Publisher: MatthewDeans

AcquisitionEditor: DennisMcGonagle

EditorialProjectManager: JohnLeonard

ProductionProjectManager: NirmalaArumugam

CoverDesigner: MarkRogers

TypesetbySPiGlobal,India

AbouttheAuthor

OleksiyV.Penkov iscurrentlyanassociateprofessorattheZhejiangUniversity/theUniversityofIllinoisatUrbana-ChampaignInstitute,Haining, China.HereceivedhisB.S.andM.S.degreesfromtheNationalTechnical University“KhPI”(Ukraine).In2007,hereceivedhisdoctoratedegreein physicsandmathematics,withaspecialtyinsolid-statephysics.Sincethen, hestayedinKoreaasapostdocandresearchprofessor.During2011–19,he wasaresearchprofessorattheCenterforNano-Wear,YonseiUniversity. HejoinedtheZJU-UIUCInstitutein2019.Hisresearchinterestscover severalareasofphysics,materialsscience,andmechanicalengineeringsuch asnano-layeredcoatings,tribology,andsurfaceengineering.

Preface

Frictionandwearareubiquitousfeaturesofmechanicalsystemshavingcontactbetweenmovingcomponents.Thesephenomenaareresponsiblenot onlyforthedegradationofmechanicaldurabilityandefficiencyduetoprogressivelossofmaterial,butalsoforexcessiveenergyconsumption.So,itis notsurprisingthatsignificanteffortshavebeendevotedtothecreationof effectivemethodsofcontroloftribologicalproperties.Oneofthe approachesistouseanothermaterialintheformofacoatingonslidingcomponentsthatprovideslowfrictionandwear.Thefabricationofintegral mechanicalcomponentsusingsuchmaterialsinthebulkformcouldbe complicatedandnotcosteffective,orevenimpossible.Acombinationof differentmaterialsforthebulkandsurfaceishighlyattractivebecauseit allowstailoringdifferentphysicalandmechanicalproperties.Inotherwords, surfacemodificationbycoatingscanprovideauniquecombinationofpropertiesandmultifunctionalityandoffersuperiortribologicalfeatures.

Tribologicalbehaviorisessentialonallscalesofmechanicalapplications, fromthenanotothemacro.Itplaysavitalroleintheperformanceofultraprecisionmechanicalsystemssuchasmicroelectromechanicalsystems (MEMS).DuetothesmallsizeandtighttoleranceofMEMSdevices,the effectivenessofmechanicalcomponentssuchasswitches,gears,andactuatorsisstronglydependentontheirfrictionalbehaviorwhilethewearresistancedeterminesthemechanicalandcommercialviabilityofthedevice. Furthermore,classicalmethodsforreducingfrictionwithlubricatingfluids cannotbeemployedinmicrosystemsbecauseofsignificantsurfacetension effects.Therefore,thetribologicalpropertiesofthecomponentsmustbe optimizedunderdryslidingconditionstoallowthedevelopmentofreliable microdevices.Differenttypesofthincoatingssuchassoftmetals,organic compoundssuchasself-assembledmonolayers,bilayerandmultilayerhard coatings,diamond-likecarbonfilms,andnanostructuredcoatingscanbe usedtoreducefrictionandwearinmicrodevices.

Nonetheless,despitereportsofnumerousproposedcoatings,auniversal methodforreducingthefrictionandwearofthesedeviceshasnotyetbeen identified.Thus,thediscoveryandinvestigationofnewmaterialsfornanoandmicrotribologicalapplicationsarestillongoing.Onesuchnewmaterial demonstratinghighpotentialfortribologicalpropertiesisgraphene.During thelastdecades,graphenehasattractedmuchattentioninthematerials

communityduetoitsexceptionalfeatures.Inadditiontoitsuniqueelectrical properties,themechanicalpropertiesofgraphenearealsoimpressive.Graphenehashighlevelsofstiffness,strength,andthermalconductivityandis alsoimpermeabletogas.Thecombinationoftheremarkablemechanical, thermal,chemical,andelectricalpropertiesofgraphenesheetsandtheirrelativelylowproductioncostdistinguishesthemfromothermaterialsusedfor nanoelectromechanicalapplications.Thus,graphenehasbeenconsidereda promisingmaterialforapplicationsinnanoelectronicsandminiaturized devices.

Moreover,duetoitssuperiorstrength,graphenehasexcellentpotential foruseasanultrathinprotectivecoatingforvariousmacroscalecomponents exposedtocontactstress.Graphenederivativessuchasfunctionalizationgraphenehaveopenednewperspectivesforuseinindustrialtribologicalapplicationsduetotheirrelativelylowprice.

Besidessolidlubrication,graphenematerialscanbeusedforthe improvementofvarioustypesofcompositematerialsfrompolymersto ceramics.Theyalsodemonstratedtheirperformanceasnanoadditivesfor differentkindsoflubricantssuchaswater,oils,greases,andionicliquids. Aminimalamountofgrapheneadditivecanenhancethedurabilityofcompositematerialsandtheperformanceoflubricants.

Inthisbook,advancementsmadeinthefabricationandapplicationsof graphenematerialsforthereductionoffrictionandweararereviewed.The aimistoprovideacomprehensiveoverviewofvarioustypesofgraphenebasedmaterialsfortribologicalapplicationsandgainabetterunderstanding oftheiradvantagesandlimitations. OleksiyV.Penkov

Acknowledgments

Firstandforemost,IwouldliketoexpressmysinceregratitudetoProf. Dae-EunKim(DepartmentofMechanicalEngineering,YonseiUniversity),whointroducedmetotribology.Hemotivatedmetowritemyfirst reviewpaper(TribologyofGraphene:AReview),whichfinallyevolvedinto thisbook.

Iamincrediblythankfultomyteachers,advisors,andformercolleagues fromtheNationalTechnicalUniversity“KharkivPolytechnicInstitute,” andespeciallytheX-rayopticslab.Thankallofyouforbringingmeto science.

Iacknowledgehundredsofresearcherscitedinthisbook.Thisbook wouldnotbepossiblewithouttheirfantastictheoreticalandexperimental work.

Imustalsorecordanotherspecialtributetomyfamily.Myparents,thank youforyourloveandconstantsupportasIsatisfymyowncuriosity.Mywife Evgeniya,thankyouforyourunfailinglove,sacrifice,andencouragement torealizemydreamaswellasyourconsiderationinmyeverydaylife.

OrganizationoftheBook

Thisbookisorganizedintoeightchapters,eachofwhichhasalistof references.

Chapter1 introducesthestructureofgrapheneanditsderivatives,basic definitions,andnomenclature.In Chapter2,theresultsofcomputersimulationsofthemechanicalandtribologicalperformanceofgraphenearediscussed. Chapter3 providesabriefoverviewofthepreparationand characterizationmethodsforgraphene,itsderivatives,andgraphene-based composites. Chapter4 evaluatesthetribologicalperformanceofgraphene fromthenano-tothemacroscale. Chapter5 discussesthepossibilityof replacinggraphenewithcheaperderivativesindifferenttribologicalapplications. Chapter6 isanoverviewoftheutilizationofgraphenereinforcementforimprovementofcompositematerials. Chapter7 discussesthe performanceofgraphene-basednano-additivesinlubricants,including water,oils,greases,andionicliquids. Chapter8 summarizestheoverallcontentofthebookanddiscussesthefuturedirectioninthetribologyof graphene.

Abbreviations

AFM atomicforcemicroscopy

AIREBO adaptiveintermolecularreactiveempiricalbondorderpotential

APCVD atmospheric-pressurechemicalvapordeposition

CMS computermodelingandsimulation

CNT carbonnanotube

CQD carbonquantumdots

CVD chemicalvapordeposition

DFT densityfunctionaltheory

DLC diamond-likecarbon

DV divacancy

EHL elastohydrodynamiclubrication

EHT epoxy-hydroxyl-terminatedrGO

EPD electrophoreticdeposition

ESCA electronspectroscopyforchemicalanalysis

ESD electrodynamicsprayingdeposition

FEM finiteelementsmethod

FG fluorinatedgraphene

fG functionalizedgraphene

fGO functionalizedgrapheneoxide

FTIR Fouriertransforminfraredspectroscopy

GIC graphiteintercalationcompound

GNP graphenenanoplatelet

GNR graphenenanoribbons

GNS graphenenanosheets

GO grapheneoxide

GONR grapheneoxidenanoribbons

HAADF high-angleannulardark-fieldimaging

HIP hotisostaticpressing

HOFG hydroxyl-functionalizedgraphene

HOPG highlyorderedpyrolyticgraphite

HRTEM high-resolutiontransmissionelectronmicroscopy

HT hydroxyl-terminatedrGO

IL ionicliquid

ISS internalshearstrength

LPCVD low-pressurechemicalvapordeposition

LST lasersurfacetexturing

MC MonteCarlo

MD moleculardynamics

MEMS/NEMS microelectromechanicalsystems/nanoelectromechanicalsystems

MG multilayergraphene

xviii Abbreviations

ML machinelearning

MSM molecularstructuralmechanics

NDP nanodiamondparticles

OFGR oxyfluorinatedgraphene

oWNC oxidizedwood-derivednanocarbon

PECVD plasma-enhancedchemicalvapordeposition

PGO pristinegraphiteoxide

PLD pulsedlaserdeposition

QCM Quartzcrystalmicrobalance

QC quantumchemistry

REBO reactiveempiricalbondorderpotential

rGO reducedgrapheneoxide

SAM self-assemblymonolayers

SEM scanningelectronmicroscopy

SPS sparkplasmasintering

STEM scanningtransmissionelectronmicroscope

STM scanningtunnelingmicroscopy

SW Stone-Walesdefect

TEM transmissionelectronmicroscopy

XPS X-rayphotoelectronspectroscopy

XRD X-raydiffractometry

Chemicalabbreviations

APS 3-aminopropyltriethoxysilane

APTES 3-aminopropyltriethoxysilane

APTMS 3-aminopropyltrimethoxysilan

BLG β-lactoglobulin

BMIMI 1-butyl-3-methylimidazoliumiodide

BScB bis(salicylate)borate

DDA dodecylamine

DDP alkylphosphate

DMF N,N-dimethylformamide

EC ethylcellulose

EMIM 1-ethyl-3-methylimidazolium

EP epoxy

ETA ethanolamine

GPTS 3-glycidoxypropyl-trimethoxysilane

HBPE hyperbranchedpolyamine-ester

MAC multiply-alkylatedcyclopentane

MC monomercastednylon

NBR acrylnitrilebutadienerubber

NMP N-methylpyrrolidone

ODA octa-decylamine

OHMimBScB 3-(hydroxypropyl)-3-methylimidazoliumbis(salicylate)borate

OL oleate

OTA octylamine

OTS hydroxylatedoctadecyltrichlorosilane

PAO polyalphaolephin

PA polyamide

PDA polydopamine

PDMS polydimethylsiloxane

PEEK poly(ether-etherketone)

PEG poly(ethyleneglycol)

PEI polyethyleneimine

PET polyethyleneterephthalate

PFDTS perfluorodecyltrichlorosilane

PFPE perfluoropolyether

PF phenol-formaldehyde

PI polyimide

PMMA poly(methylmethacrylate)

PPS polyphenylenesulfide

PSS poly(sodium4-styrenesulfonate)

PTFE poly(difluoromethylene)

PTFE polytetrafluoroethylene

PU polyurethane

PVC poly(vinylchloride)

PVDF polyvinylidenedifluoride

PVP poly(vinylpyrrolidone)

PWF polytetrafluoroethylenewax

SDBS sodiumdodecylbenzenesulfonate

TFSI bis(trifluoromethylsulfonyl)imide

UHMWPE ultrahighmolecularweightpolyethylene

ZDDP zinccialkylcithiophosphatelubricantadditives

Introductiontographene

1.1Introductiontographenestructure

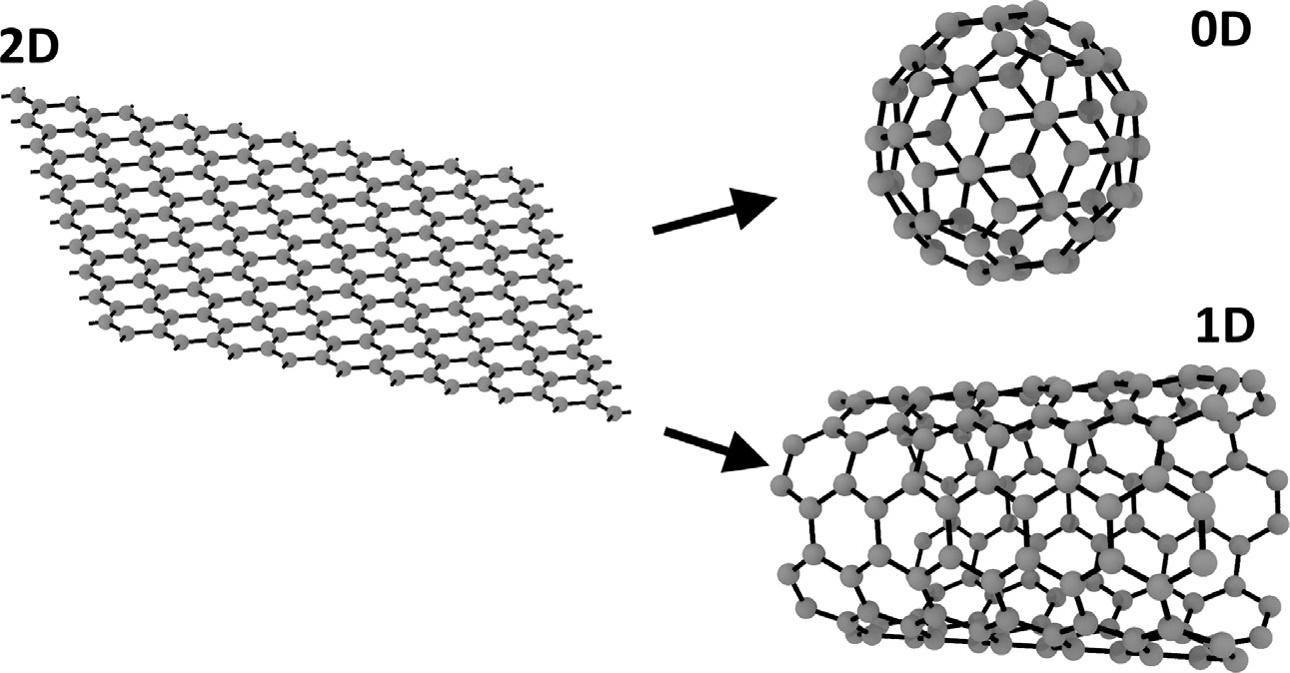

Carbonisoneofthemostessentialmaterialsfororganiclife,and“graphene” isthenameofoneofthecarbonallotropes.Theword“graphene”consistsof theprefix“graph,”whichcomesfromgraphite,andthesuffix“ene,”which representsthecarbon/carbondoublebonds [1].Ingeneral,theword “graphene”referstoamonolayerofsp2-hybridizedcarbonatomspacked intoatwo-dimensional(2D)honeycombstructurethatispartiallyfilledwith π-orbitalsaboveandbelowthemonolayer [2].Thegraphenemonolayeris atomicallyflatwiththeVanderWaalsthicknessof 0.34nm.Thismonolayerrepresentsabuildingblockforallothergraphiticmaterials.Graphene canexistnotonlyintheformofthesinglemonolayer(sheet)butalsointhe multilayerformwhereseveralsheetsarestackedtogether,formingathreedimensional(3D)structure(Fig.1.1).Besidetheformingof3Dgraphite, graphenecanbewrappedupintozero-dimensional(0D)fullerenesorrolled intoone-dimensional(1D)nanotubes(Fig.1.2) [3]

Initially,itwasassumedthatgraphenecouldnotbestandalonebecauseof thepredictedthermodynamicinstabilityof2Dcrystals [2].Nonetheless,the theoreticalpredictionsaboutthismaterialbecamerealin2004whenitwas demonstratedthatisolated2Dstructurescannotonlybestableatroomtemperatureandintheair,butalsomaintainmacroscopiccontinuity [4].

Grapheneisafundamentalelementofalargegroupof2Dand3Dcarbon formsthatincludesmaterialswithverydifferentproperties,lateralsizes,and numberoflayers.Theterm“graphene”canbeprefixedby“bilayer,”“fewlayer,”or“multilayer.”Thisclassificationisessentialbecausetheproperties

TribologyofGraphene

2020ElsevierInc. https://doi.org/10.1016/B978-0-12-818641-1.00001-0

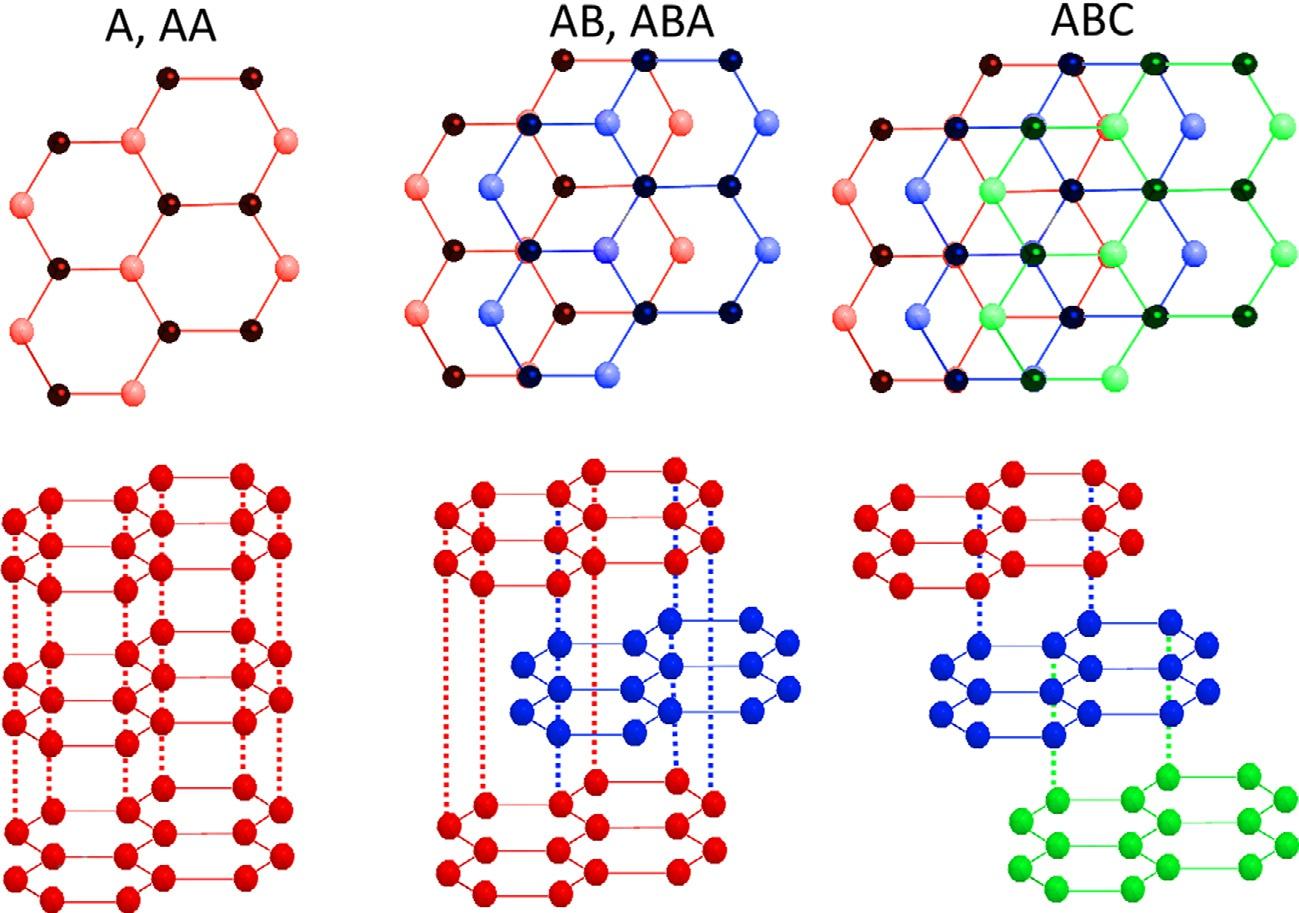

Fig.1.1 Formationof3Dgraphenefroma2Dbuildingblock threecommongraphite structureswithdifferentgraphenestackingarrangements:hexagonalstacking(AA), Bernalstacking(AB),andrhombohedralstacking(ABC).

Fig.1.2 A2Dgraphenesheetisthebaseforotherallotropes:0D(fullerene)and1D (carbonnanotube).

ofmono-,bi-andmultilayergraphenedifferfromthepropertiesofgraphite andeachother [1,2].Besides,differentnamescanbeusedforthesamestructures.Forexample,“multilayernanosheet”hasthesamemeaningas“fewlayernanoplate.”Themostcommonlyusedterminologyofgrapheneis summarizedin Table1.1

Table1.1 Nomenclatureofgraphenematerialsbasedontheirdimensions.

Parameter

Aspectratio A (length/width)Lateralsize D (nm) Range 1

Numberoflayers n

NomenclatureSingle-layer; monolayer Few-layer; multilayer GraphiteNanoMicro - Flake - Sheet - Plate - Platelet - Ribbon

Therearethreepossiblestackingconfigurationsoffew-layergraphene (Fig.1.1):Bernal(AB),hexagonal(AA),andrhombohedral(ABC) [5,6]. Thesestackingconfigurationsdifferintherelativeorientationofthegraphenelayerstacksthatmaybecrucialforsomeapplications.Forinstance, thestackingordersignificantlyaffectedtheelectronicstructureoffew-layer graphene [5].Amongthepossiblestackingconfigurations,theBernalconfigurationhastheloweststackingenergy [7].Thisconfigurationisformedby stackingtwographenesheetsrotatedby60degreesrelativetoeachother aroundthez-axis.Inthiscase,the3Dunitcellhasfouratoms,andathird basisvectorperpendiculartothegraphenelayerstacksis0.6672and 0.6708nmat4.2and297K,respectively [8].

InthecaseofAA-stackedgraphene,allcarbonatomsineverysheethave thesamexandycoordinates(Fig.1.1).IntheABCstructure,halftheatoms arelocateddirectlybelowatomsintheadjacentlayeranddirectlyabovethe hexagonalringcenterswhiletheotherhalfoftheatomsaredirectlyabove atomsanddirectlybelowhexagonalringcenters [9].EventhoughtheBernal stackingisthemostcommonconfigurationinsingle-crystalgraphite,itwas foundthat15%oftheexfoliatedmultilayergrapheneiscomposedof micrometer-sizeddomainsofrhombohedralstacking,ratherthantheusual Bernalstacking [10].Stackingordermaybecrucialforthemechanical behaviorofseveral-layergraphene,especiallyonthemacroscopiclevel. Forinstance,differentlengthsoftheupperandlowerlayersofgraphene inthecaseofABstackingledtoastressconcentrationattheboundaryof theshortlayersofgraphene [11]

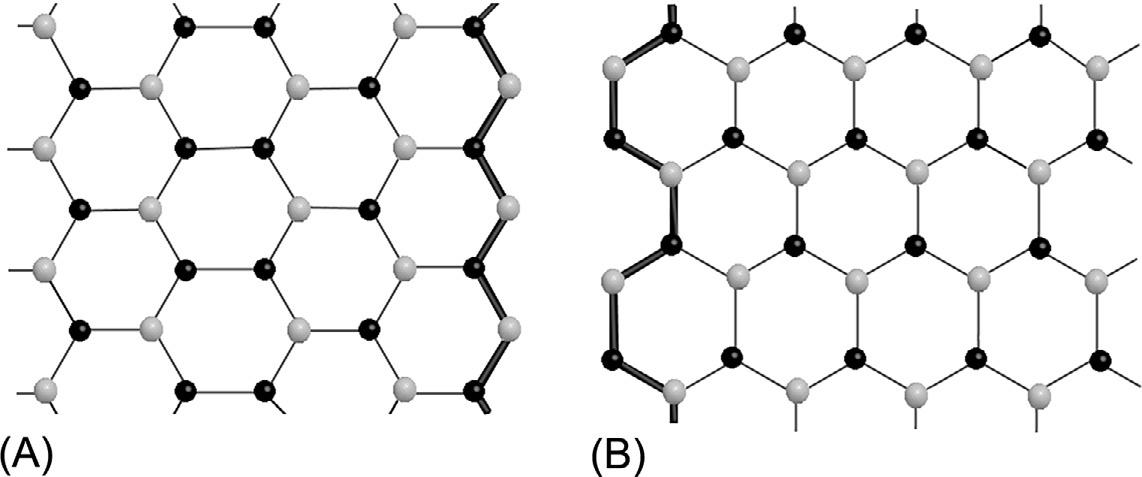

Manypropertiesofgrapheneareaffectedbychiralityororientation. Becausegraphenehasahexagonallattice,therearetwotypesofedges,called zigzagandarmchair(Fig.1.3).Zigzagandarmchairedgesalsocouldbedrawn

Fig.1.3 Twotypesofedgesingraphene:(A)zigzagand(B)armchair.Theedgesare indicatedbyboldlines.

as“lateral”and“longitudinal”edges [12].Inthecaseofnanoribbons,“zigzag graphene”and“armchairgraphene”definitionscanbeused.Here,thename isdefinedbytheedgetypealongthelongestdimensionofananoribbon.

1.2Defectsingraphene

Varioustypesofstructuraldefectsmayappearduringthesynthesisofgraphene.Becausesp2-hybridizedcarbonatomscanrearrangethemselvesinto variouspolygonsandformdifferentstructures,theformationofnonhexagonalringsmayoccur [13].Suchnonhexagonalstructurescouldbeconsideredasstructuraldefectsoftheidealhexagonallattice.Dependingontheir configuration,nonhexagonalringscouldproducecurvatureofthegraphene sheetorleaveitflatifthearrangementofpolygonssatisfiescertainsymmetry rules.Suchbehaviorisattributedonlyto2Dstructuresandcouldnotbe foundinbulkcrystals [13].

Severalexperimentalstudiesreportedtheexistenceofeithernativeor physicallyintroducedstructuraldefectsingraphene.Thepresenceofdefects isessentialforthemechanicalandtribologicalpropertiesofgraphene materials.Defectsingraphenestructure arereferredtoasintrinsicorextrinsic,dependingontheirnature.Intrinsicdefectsresultedintheformof perturbationoftheoriginalcrystalstr ucturewithoutthepresenceofforeign atoms.Foreignatomsaredenotedasimpuritiesandconstituteextrinsic defects [14].Duetothereduceddimensionalityofgraphene,thenumber ofpossibledefectsisreducedincomparisonto3Dmaterials.The0Dpoint defectsingraphenearesimilartooneofthebulkcrystals,linedefectsare different,and3Ddefectsdonotexist.Graphenedefectshavecertain mobilityinthegrapheneplane.The migrationmobilityofvarioustypes ofdefectsisgovernedbytheiractivatio nenergyandexponentiallyincreases withtemperature [14].

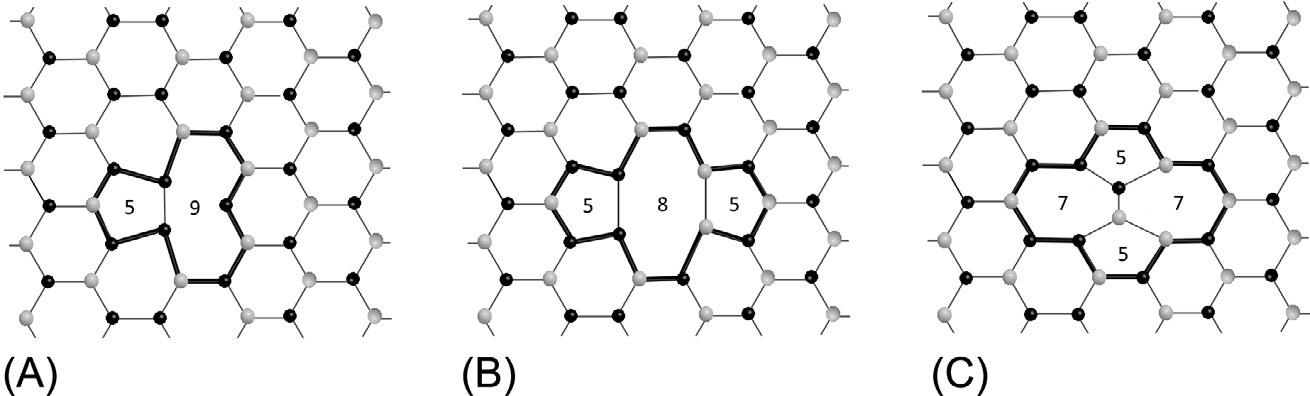

Severalpointdefectsofgraphenesuchasmono-anddi-vacancies,adatoms,andStone-Wales(SW)defectsareknown.Defectsingrapheneare illustratedin Fig.1.4.Themonovacancyisthemissinglatticeatom;this isthesimplestpointdefectinagraphenestructure(Fig.1.4A).Theformationofthemonovacancyledtothecreationofnine-andfive-membered rings,alsocalledthe5-9cluster.Theformationenergyofthemonovacancy isabout7.5eV [15].Duetohavingadanglingbond,themonovacancyis highlyreactiveandcanbequicklydemolished.

Divacancy(DV)ingraphenehasnodanglingbond(Fig.1.4B).Dueto thelowerenergyofformation,itismuchmorestableandlessreactive [16].

Fig.1.4 Schematicsofpointdefectsingraphene.(A)mono-vacancy;(B)di-vacancy;and (C)Stone-Waledefect(SW);theboundaryofdefectsisindicatedbyboldlines.

Itcouldbeformedbythecoalescenceoftwomonovacanciesorbythe removingoftwoneighboringatoms.Thus,twopentagonsandoneoctagon arebuiltinsteadoffourhexagons,forminga5-8-5cluster [14].Theformationenergyofthedivacancyisveryclosetooneofthemonovacancies [15]. Butbecauseoftwomissingatoms,theenergyperatomwouldbesignificantlylower,makingtheformationofDVthermodynamicallypreferable [13].Besidethe5-8-5configuration,thereareseveralotherwaysforagraphenelatticetoaccommodatetwomissingatoms.Moreover,thisconfigurationisnotenergeticallypreferred.Otherarrangementssuchas555-777or 5555-6-7777havelowerformationenergy [14]

Theeliminationofmorethantwoatomsmaycausetheformationofa largerandmorecomplexconfigurationofdefects.Becauseanevennumber ofmissingatomsallowsthefullrecombinationofdanglingbonds,such defectsareenergeticallypreferableoverdefectshavinganoddnumberof missingatomsduetotheremainingoftheopenbond [14].Theformation oflargeholeswithunsaturatedbondsismorelikelyinthecaseofsimulations removingalargenumberofatoms.

Oneoftheexceptionalpropertiesofgraphenelatticeistheabilitytoreorderbyestablishingnonhexagonalringswithoutmissingatoms [14].ThesimplestexampleofsuchrearrangementistheformationoftheSWdefect (Fig.1.4C).Itformsduetoachangeofconnectivityoftwo π-bondedcarbon atoms,whichledtoa90degreein-planerotationofthebond [17].Fourhexagonsaretransformedintotwopentagonsandtwoheptagons,forminga so-called5-7-7-5cluster.Thus,theformationoftheSWdefectdoesnot involveanyremovedoraddedatom,andnodanglingbondsareintroduced [14].Theformationenergyofthe5-7-7-5defectisabout5eV [18]

Theformationofinterstitialatomsasoccurredinbulkcrystalsisnotpossibleingraphenebecauseaddinganatomtoanyin-planepositionsuchasthe

centerofahexagonwouldrequireexcessivelyhighenergy.Thus,ingraphene,adatomsarelocatedinthethirddimension.Theenergeticallypreferredpositionwouldbethetopofacarbon-carbonbond(thebridge configuration).Theformationofsuchastructureledtothechangingof hybridization.Duetotheappearanceofsomesp3 hybridization,theformationoftwocovalentbondsbetweentheadatomandtheunderlyingatomsin thegrapheneplanetakesplace [14]

One-dimensionaldefectssuchasdislocationsandgrainboundarieswere observedinseveralexperimentalstudiesofgraphene.Generally,these defectsaretiltboundariesseparatingtwodomainswithdifferentlatticeorientations.Suchdefectscouldbeimaginedasalineofpointdefectswithor withoutdanglingbonds [14].Theformationoflinedefectscanoccurinthe caseofsimultaneousnucleationofgraphenelayersindifferentlocationsfollowedbytheircoalescence.Thisprocessissimilartothecreationofgrain boundariesinbulkcrystals.

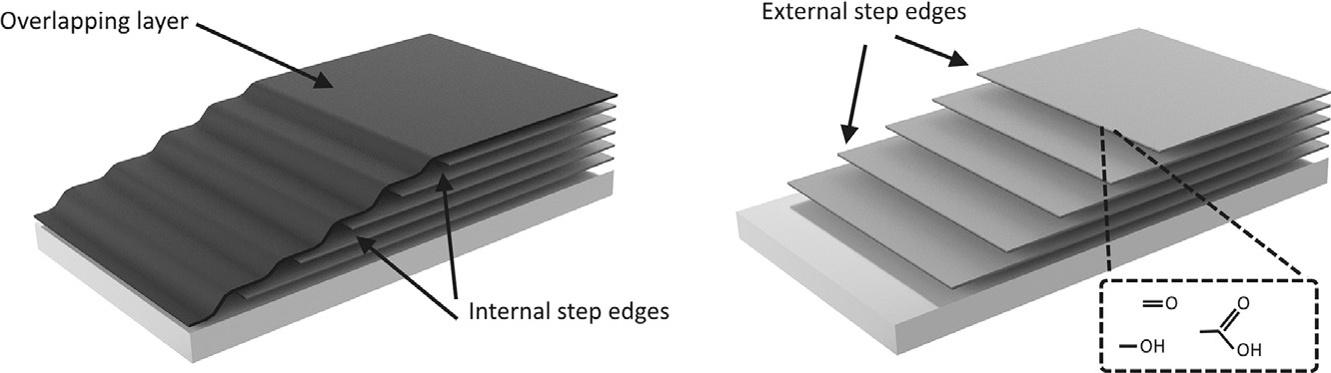

Thepresenceofatomic-scalestepsisaubiquitousfeatureofmultilayer graphene.Therearetwotypesofstepedges(Fig.1.5).Thefirsttypeisinternalorcoveredsteps,whichformedduringthegraphenegrowth (Section3.3).Thesecondtypeisexternal(uncovered)stepsusuallycreated duringthemechanicalcleavageofHOPG(Section3.1).Thepresenceof danglingbondsontheexposededgesmakesthemchemicallyactive. Ahigherworkfunctionwasobservedontheexternalstepscomparedwith otherinternalstepsduetostepdipolesandadsorbates [19]

1.3Derivativesofgraphene

Significantattentionwasfirstpaidtopristinegraphenebecauseofitsunique electronicproperties.Thismadegrapheneamodelsystemfortheobservationofanovelquantumphenomenonandthebuildingblockforfuture nanoelectronicdevices [3].Nevertheless,fromapracticalpointofview,

Fig.1.5 Coveredanduncoveredstepedgesofgraphene.

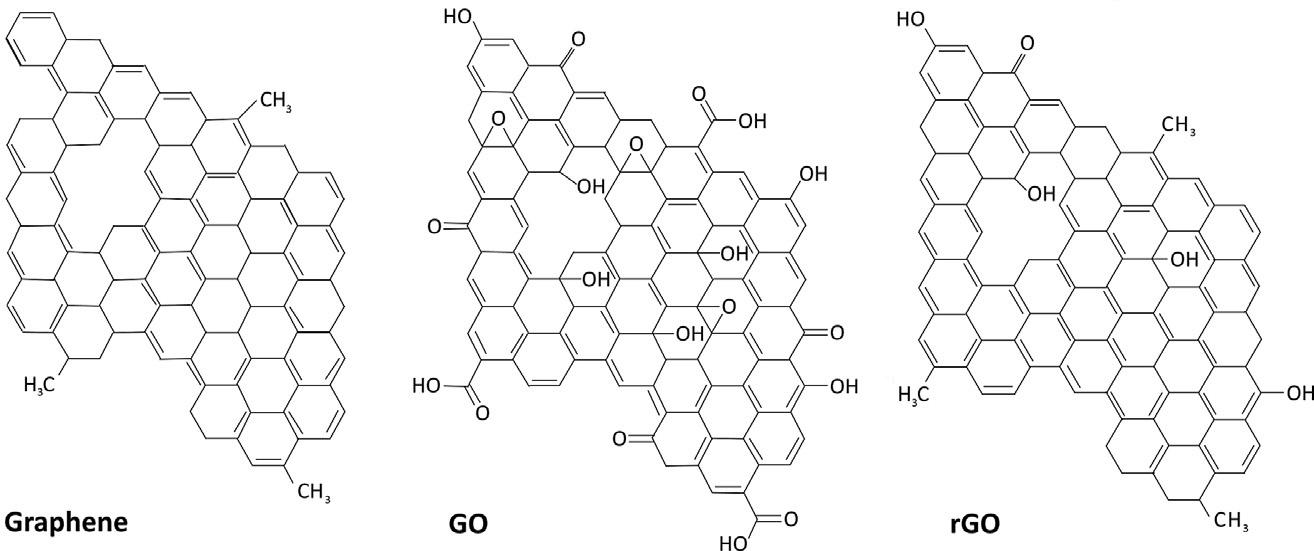

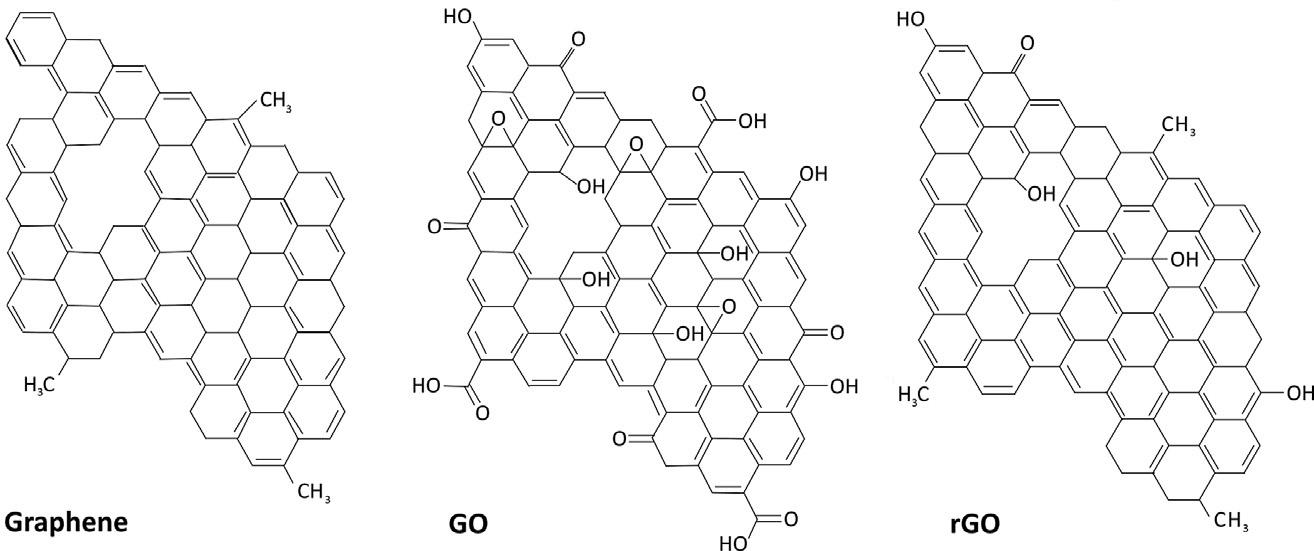

industrialapplicationsarerequiredtoproducegrapheneinsignificantlylarge quantiles.Oneoftheapproachestoincreasetheproductionrateofgraphene isfabricationbythereductionofgrapheneoxide(GO)becauseitdemonstratedthepotentialofcost-effective,large-scaleproductionofgraphenebasedmaterials [20].Sinceitwasfirstsynthesizedinthenineteenthcentury, GOhasbeenapopulargraphenederivative.GOisasingle-carbonmonolayerwithrandomlydistributedaromaticregions(sp2 carbonatoms)and oxygenatedaliphaticdomains(sp3 carbonatoms)containingcarbonyl,carboxyl,epoxy,andhydroxylfunctionalgroups(Fig.1.6).Thepresenceofthe functionalgroupsmakesGOhydrophilic [21].

GOissynthesizedbytheoxidationofgraphiteinthepresenceofastrong acidandanoxidizingagent.Theoxidationprocessleadstoapartialdisruptioninthesp2 hybridizedstructureofgraphiteandtoanincreaseofthedistancebetweenitscarbonlayers,leadingtofinalseparationtosheetsthatarea singlecarbonatomthick [21].Grapheneoxidesheetsarethickerthangrapheneduetothedisplacementofsp3 hybridizedcarbonatomsslightlyabove andbelowtheoriginalgrapheneplaneandthepresenceofcovalentlybound oxygenatoms [3].Theleveloftheoxidationcanbevarieddependingonthe method,thereactionconditions,andthegraphiteprecursor.Although extensiveresearchhasbeendonetorevealthechemicalstructureofGO, severalmodelsofthisprocessarestillbeingdebatedintheliterature [20] Reducedgrapheneoxide(rGO)isalsoa2Dsingle-atom-thickmaterial. Itislikegraphene,butithasextracarbonringdomains,defects,andremainingoxygen-containinggroups(-OH,-COOH,etc.)onthesurface (Fig.1.6).TheinitialgoalofreducingGOwastofabricategraphenematerialscomparabletothestructureandpropertiesofpuregrapheneachieved bymechanicalexfoliation.

Fig.1.6 Comparisonofthechemicalstructuresofgraphene,GO,andrGO.

1.4Mechanicalpropertiesofgraphene

Themechanicalpropertiesofgraphenearethemainreasonthatitisaprimarytribologicalmaterialofthefuture.Ithasthehigheststrengthandelastic modulusaftercarbonnanotubes.Theexceptionalmechanicalpropertiesof graphenearebasedonthestabilityofsp2 bondsformingthehexagonallattice.Thatallowsagraphenesheettoopposein-planedeformations [22].For thefirsttime,themechanicalpropertiesoffree-standingmonolayergrapheneweremeasuredbyLeeetal.usingthenanoindentationmodeof AFM [23].Itwasdemonstratedthatthemonolayergraphenemembrane hadaYoung’smodulusof 1TPa.Hoverer,differentstiffnessvalueswere obtainedinsomereports.Thisdifferencewasattributedtotheunrecordable crumplingofgraphenesheetsthatmayoriginatefrompointdefectsor unevenstressattheboundaries [22].Thetransferprocessusedafterthe CVDprocessalmostalwayscauseswrinklinganddamage,whichalso mayreducethemechanicalproperties.TheshearmodulusofCVD-grown monolayergraphene(Section3.3)wasmeasuredbyLuietal. [24].Avalueof 280GPawasobtained.

Defect-freemonolayergraphenewasconsideredbyHoneetal.tobethe mostdurablematerialevertested [23].Hoverer,themechanicalproperties ofgraphenecanbesignificantlyaffectedbydefects [25].Dependingonthe typeandconcentrationofdefects,suchasvacancytypeorsp3-type,the strengthandstiffnessofgraphenecanbereducedsignificantly,aswas observedforvacancies.Intheopposite,themechanicalpropertieswere maintainedevenathigherdensitiesofsp3-typedefects.

References

[1]A.Bianco,H.M.Cheng,T.Enoki,Y.Gogotsi,R.H.Hurt,N.Koratkar,T.Kyotani, M.Monthioux,C.R.Park,J.M.Tascon,J.Zhang,Allinthegraphenefamily—a recommendednomenclaturefortwo-dimensionalcarbonmaterials,Carbon 65(2013)1, https://doi.org/10.1016/j.carbon.2013.08.038

[2]A.K.Geim,K.S.Novoselov,Theriseofgraphene,Nat.Mater.6(2007)183, https:// doi.org/10.1038/nmat1849 .

[3]V.Singh,D.Joung,L.Zhai,S.Das,S.I.Khondaker,S.Seal,Graphenebasedmaterials: past,presentandfuture,Prog.Mater.Sci.56(2011)1178, https://doi.org/10.1016/ j.pmatsci.2011.03.003

[4]K.S.Novoselov,D.Jiang,F.Schedin,T.J.Booth,V.V.Khotkevich,S.V.Morozov, A.K.Geim,Two-dimensionalatomiccrystals,PNAS102(2005)10451, https://doi. org/10.1073/pnas.0502848102

[5]K.F.Mak,J.Shan,T.F.Heinz,Electronicstructureoffew-layergraphene:experimentaldemonstrationofstrongdependenceonstackingsequence,Phys.Rev.Lett. 104(2010)1, https://doi.org/10.1103/PhysRevLett.104.176404

[6]B.Partoens,F.M.Peeters,Fromgraphenetographite:electronicstructurearoundthe Kpoint,Phys.Rev.B74(2006)1, https://doi.org/10.1103/PhysRevB.74.075404 .

[7]R.R.Haering,Bandstructureofrhombohedralgraphite,Can.J.Phys.36(1958)352, https://doi.org/10.1139/p58-036

[8]N.Ferralis,ProbingmechanicalpropertiesofgraphenewithRamanspectroscopy, J.Mater.Sci.45(2010)5135, https://doi.org/10.1007/s10853-010-4673-3

[9]C.L.Lu,C.P.Chang,Y.C.Huang,J.H.Ho,C.C.Hwang,M.F.Lin,ElectronicpropertiesofAA-andABC-stackedfew-layergraphites,J.Phys.Soc.Jpn.76(2007)1, https://doi.org/10.1143/JPSJ.76.024701

[10]H.L.Chun,Z.Li,Z.Chen,P.V.Klimov,L.E.Brus,T.F.Heinz,Imagingstacking orderinfew-layergraphene,NanoLett.11(2011)164, https://doi.org/10.1021/ nl1032827

[11]W.Dou,C.Xu,J.Guo,H.Du,W.Qiu,T.Xue,Y.Kang,Q.Zhang,Interfacial mechanicalpropertiesofdouble-layergraphenewithconsiderationoftheeffectof stackingmode,ACSAppl.Mater.Interfaces10(2018)44941, https://doi.org/ 10.1021/acsami.8b18982

[12]H.Zhang,T.Chang,Edgeorientationdependentnanoscalefriction,Nanoscale 10(2018)2447, https://doi.org/10.1039/C7NR07839K .

[13]L.Liu,M.Qing,Y.Wang,S.Chen,Defectsingraphene:generation,healing,andtheir effectsonthepropertiesofgraphene:areview,J.Mater.Sci.Technol.31(2015)599, https://doi.org/10.1016/j.jmst.2014.11.019 .

[14]F.Banhart,J.Kotakoski,A.V.Krasheninnikov,Structuraldefectsingraphene,ACS Nano5(2011)26, https://doi.org/10.1021/nn102598m

[15]A.A.El-Barbary,R.H.Telling,C.P.Ewels,M.I.Heggie,P.R.Briddon,Structureand energeticsofthevacancyingraphite,Phys.Rev.B68(2003)144107, https://doi.org/ 10.1103/PhysRevB.68.144107.

[16]Z.Sahan,S.Berber,Divacancyingraphenenano-ribbons,Phys.E.106(2019)239, https://doi.org/10.1016/j.physe.2018.09.029

[17]A.J.Stone,D.J.Wales,TheoreticalstudiesoficosahedralC60andsomerelatedspecies, Chem.Phys.Lett.128(1986)501, https://doi.org/10.1016/0009-2614(86)80661-3

[18] J.Ma,D.Alfe,A.Michaelides,Stone-Walesdefectsingrapheneandotherplanarsp2bondedmaterials,Phys.Rev.B80(2009)033407.

[19]H.Lee,H.B.Lee,S.Kwon,M.Salmeron,J.Y.Park,Internalandexternalatomicsteps ingraphiteexhibitdramaticallydifferentphysicalandchemicalproperties,ACSNano 9(2015)3814, https://doi.org/10.1021/nn506755p

[20]S.Park,R.S.Ruoff,Chemicalmethodsfortheproductionofgraphenes,Nat.Nanotechnol.4(2009)217, https://doi.org/10.1038/nnano.2009.58 .

[21]M.Ionita,G.M.Vlasceanu,A.A.Watzlawek,S.I.Voicu,J.S.Burns,H.Iovu,Graphene andfunctionalizedgraphene:extraordinaryprospectsfornanobiocompositematerials, Compos.PartB121(2017)34, https://doi.org/10.1016/j.compositesb.2017.03.031

[22]D.G.Papageorgiou,I.A.Kinloch,R.J.Young,Mechanicalpropertiesofgrapheneand graphene-basednanocomposites,Prog.Mater.Sci.90(2017)75, https://doi.org/ 10.1016/j.pmatsci.2017.07.004

[23]C.Lee,X.Wei,J.W.Kysar,J.Hone,Measurementoftheelasticpropertiesandintrinsic strengthofmonolayergraphene,Science321(2008)385, https://doi.org/10.1126/ science.1157996

[24]F.Scarpa,Shearmodulusofmonolayergraphenepreparedbychemicalvapordeposition,NanoLett.12(2012)1013, https://doi.org/10.1021/nl204196v

[25]A.Zandiatashbar,G.H.Lee,J.A.Sung,S.Lee,N.Mathew,M.Terrones,T.Hayashi, C.R.Picu,J.Hone,N.Koratkar,Effectofdefectsontheintrinsicstrengthandstiffness ofgraphene,Nat.Commun.5(2014)1, https://doi.org/10.1038/ncomms4186

CHAPTER2

Computersimulations andtheoreticalpredictions

2.1Simulationofmechanicalproperties

Foralongtime,graphenewasjustanidealmodelobject.Avarietyofcomputermodelingandsimulation(CMS)methodssuchasMonteCarlo(MC), moleculardynamics(MD),andquantumchemistry(QC)havebeenutilized fortheinvestigationofvariouscharacteristicsofgraphene,includingthermal conductivityandexpansion,surfacediffusion,andelasticmodulus [1].In general,CMSisapracticalapproachthatusescomputermodelstoinvestigatenotonlytheinteractionprocessbetweendifferentmaterials,butalso structuraltransformationsthatoccurredduringthisinteractionprocess [2].Theavailabilityofsimulationmethodsisespeciallycrucialforgraphene, whereexperimentsencounteredmanylimitationscausedbythenanoscale oftribologicalsystems.Butitshouldbenotedherethatduetothenatureof CMS,thescaleofsimulationsisusuallylimitedtoatenthsofnanometers. ThisisbecauseCMSmethodsdealwithindividualatomsandmolecules, andtheincreasingsizeofthemodelrequiressignificantcomputational resources.Inthecaseofsimulationoftribologicalphenomena,anotherlimitingfactorappears,whichisarequirementtohaveanadequatemodelto describeaninteractionbetweenindividualatomsofdifferentelements. Forinstance,inthetypicalMDsimulation,eachparticleisconsideredas

asingleentity,andtheinteractionsbetweenvariousparticlesaremodeled usingtheirreactionstopotentialfunctionsderivedfromclassicalphysics [2].Availablepotentialsdefinedavarietyofmaterialsthatcanbeusedinsimulations.Moreover,usingvariousreactivepotentialscouldgivesignificantly differentresultseveninsimilarmodels.

Historically,earlytheoreticalstudiesofgrapheneweremostlyfocusedon thesimulationofelectricalorthermalproperties.Later,manysystematic piecesofresearchwereperformedonthemechanicalpropertiesofgraphene. Forinstance,Young’smoduluswascalculatedusingvariousapproachesand simulationmethodssuchasMDandabinitioDFT [2].Dependingonthe reactivepotentialsusedinMDsimulations,thevaluesofYoung’smodulus reportedbyotherresearcherswereintherangefrom0.86to1.24TPa [3–5].Suchadifferencecanbeattributedtoseveralfactors.Thefirstfactor isaselectionofthereactivepotential.Forexample,AIREBO,Tersoff,Brenner,orbond-orderTersoff-Brennerpotentialswereusedindifferentstudies. Thesecondfactoristhesizeofasimulatedspecimen.Forinstance,increasing thespecimensizefrom0.1to0.35nmledtoanincreaseofYoung’smodulus from0.65to1.05Tpa,anditssaturation [6].Similarbehaviorwasobservedby Haoetal.forgraphenenanoribbons [4].Whenrelativelylargespecimens wereused(morethan2nm),themechanicalpropertieswerefoundtobe independentofthespecimensize [5].Thus,themodelusedinCMSshould belargeenoughtoavoidtheeffectsofitssize.

Manysimulationsdemonstratedasignificantdifferenceinthemechanical propertiesofgraphenedependingonthedirectionofdeformation.For instance,thezigzaggraphenestructurehada30%higherstrengthand60% higherfracturestrainthanthearmchairstructure [3].GaoandPeng [7] also reportedsimilarfailuremechanismsanddifferentmechanicalpropertiesofzigzagandarmchairgraphene.TheirMDsimulationshowedthatbothzigzag andarmchairgraphenebegantobreakattheoutermostcarbonatomiclayers.

Furthermore,Young’smoduluswasfoundtobeaffectedbytemperature.Raisingthetemperaturefrom100to500KincreasedtheYoung’s modulusofmonolayergraphenefrom0.94to1.1TPa [6].Dewapriya etal.alsoreportedthatYoung’smoduluswasslightlyaffectedbytemperatureintherangeof1–300K [8].Theyreportedvaluesof0.9and1.12TPa forarmchairandzigzagconfigurations,respectively.Thesmalldifferencein thetemperaturebehavioroftheYoung’smodulusofgrapheneagaincould beattributedtousingdifferentreactivepotentials.

Besidestheeffectsofchiralityandtemperature,themechanical propertiesofgrapheneareaffectedbythepresenceofstructuraldefects.

Thepresenceofdefectssignificantlyreducedthefailurestrainandthe inherentstrengthofsingle-layergraphenewhileithadasmalleffecton theYoung’smodulus [9].Theimpactofvariousdefectsonmechanical propertieswascarefullyassessedbyZandiatashbaretal. [10].Inthiswork, differenttypesofdefectshavingarangeofsizesweremodeledinasingle graphenesheetusingMDsimulation.Itwasdemonstratedthatboththe elasticmodulusandstrengthwerealmostinsensitivetodefects.Also,it wasconfirmedthatgraphenecanbecovalentlybondedtoapolymeric matrixwithoutlosingitsreinforcingproperties,whichisveryimportant forthedesignofgraphene-basedpolymers.

Asimulationofdefectsingrapheneusingamolecularstructuralmechanics(MSM)approachshowedthatSWdefectscausedasmallereffecton mechanicalpropertiesincomparisonwithvacancies [11].MSMisa continuum-basedmodelingtechniqueinwhichC Ccovalentbondswere replacedwithenergeticallyequivalentbeamelements.Aninvestigationof 100 100nm2 graphenesheetsrevealedthatmono-anddivacancyreduced theaxialstiffnessofgraphenesignificantly.Inthecaseofmonovacancy,it wasdroppedby 60%atthedefectconcentrationaround12%.Divacancies causedanevenhigherreductionofthestiffness.Moreover,vacancies—and especiallydivacancies—ledtoasignificantdeteriorationofmechanicalproperties.TheeffectofSWdefectswaslesssignificant.Thesameconcentration ofSWdefectsreducedtheaxialstiffnessbyseveralpercent.

ThefractureofgraphenesheetshavingSWdefectswasalsoinvestigated atdifferenttemperaturesusingMD [12].Itwasalsodemonstratedthatthe structuraldefectsandvacanciesingraphenecouldleadtoasignificantreductioninstrength.Inparticular,introducingfourvacancydefectsintoa 5 5nm2 graphenesheetcausedadecreaseoffracturestrengthfrom100 to60GPa.SWdefectscauseda 50%loweringoffracturestrength.Besides, itwasdemonstratedthatthefracturestrengthofgraphenewasdependenton temperatureandloadingdirection.Raisingthetemperaturefrom300to 900Kledtoa 20%dropofthefracturestrength.

Inthestudiesdiscussedabove,relativelysimplestretchingofgraphene wassimulated.FurtheradvancesinthedevelopmentofCMSmethods allowedperformingmorecomplicatedbutalsomorerealisticsimulations. Forexample,simulationoftheindentationofsuspendedgraphenemembraneswithatipbecameavailable.Kimetal. [13] performedasimulation ofsingle-andmultilayergraphenemembraneswitharoundedSitiphavinga diameterof5nm(Fig.2.1).Thewidthofthecirculargraphenelayerwas 17nm,whichallowedavoidingthesizeeffectmentionedabove.Itwas