BiologicalTreatment ofMicrobialCorrosion OpportunitiesandChallenges

REZAJAVAHERDASHTI,PhD

Director

ParsCorrosion

Perth,Australia

KIANAALASVAND,PhD

ParsCorrosion

Perth,Australia

BIOLOGICALTREATMENTOFMICROBIALCORROSIONISBN:978-0-12-816108-1

Copyright 2019ElsevierInc.Allrightsreserved.

Nopartofthispublicationmaybereproducedortransmittedinanyformorbyanymeans,electronicor mechanical,includingphotocopying,recording,oranyinformationstorageandretrievalsystem,without permissioninwritingfromthepublisher.Detailsonhowtoseekpermission,furtherinformationabout thePublisher’spermissionspoliciesandourarrangementswithorganizationssuchastheCopyright ClearanceCenterandtheCopyrightLicensingAgency,canbefoundatourwebsite: www.elsevier.com/ permissions

ThisbookandtheindividualcontributionscontainedinitareprotectedundercopyrightbythePublisher (otherthanasmaybenotedherein).

Notices

Practitionersandresearchersmustalwaysrelyontheirownexperienceandknowledgeinevaluating andusinganyinformation,methods,compoundsorexperimentsdescribedherein.Becauseofrapid advancesinthemedicalsciences,inparticular,independentverificationofdiagnosesanddrug dosagesshouldbemade.Tothefullestextentofthelaw,noresponsibilityisassumedbyElsevier, authors,editorsorcontributorsforanyinjuryand/ordamagetopersonsorpropertyasamatterof productsliability,negligenceorotherwise,orfromanyuseoroperationofanymethods,products, instructions,orideascontainedinthematerialherein.

Publisher: MatthewDeans

AcquisitionEditor: ChristinaGifford

EditorialProjectManager: PeterAdamson

ProductionProjectManager: KiruthikaGovindaraju

CoverDesigner: AlanStudholme

Preface

Corrosion,ingeneral,andmicrobialcorrosion(MIC),in particular,areverysignificantissuesthatdoharmto human-madeassetsandstructures.Industry-wise,itis almostallindustriesthatsufferfromMICandmay includeoilandgas,pipeline,waterandwastewater treatment,chemicalplants,portsandjetties,ships,to nameafew.

Itmaysoundsurprisingtothereaderthatalthough MICissorecognized,thereareprofessionalswhotakeit lightlyandsimplythinkthatbythewaystheyhavebeen usingsofar,itispossibletocureandcontrolMIC.

Apartfromafewexemplaryuniversitiesandresearch institutesthathavelargelycontributedto fi llingthegap betweenindustryandacademiawithrespecttoMIC researchandengineering,amajorityoftechnological thinktanks andthereforeresearchers arenotyet awareofMICandhowsuchacomplexphenomena mustbeaddressedandevenpredictedproperly:ifwe acceptthatsoftwaresarebasedonmathematical models,lackofspeci fi callypreparedsoftwaresforMIC isitselfagoodindicationofhowpoorlymathematics hasbeenusedtolookatthisforgottencorrosionprocess.Totacklethisweakness,wehavesuggesteda mathematicalmodelbasedonfuzzylogicthatwe previouslyusedwithsuccessforcorrosion-related bacteria(CRB)topredicttheircorrosiveactions.This modelingnowaimstohighlighthowpathogenic bacteriacanalsobetreatedlikewise.

Inadditiontobeingintrinsicallycomplexbecauseof accommodatingvariousinteractionsbetweenliving thingsandnonlivingthings,microbialcorrosionalso suffersfrominadequateandsometimeswrongterminologythathasbeeninusefordecadesinitsliterature: anexampleofwrongtermsusedinMICstudiesisthe term “biofilm,” wehavesuggestedtheterm “Temenos” forthatandwehaveexplainedourreasonsforthis suggestionalthoughwehavestillused “biofilm” in majorityofthematerialgiveninthisbook.

Inthisbook,followingfocusingon “corrosioncontrol” and “corrosionprevention,” forthe firsttime,we coinedtheterms “ZugzwangEffect” and “MythEffect” andexplainedtheirimportanceespeciallyfroma microbialcorrosionmanagementpointofview.

Thesetwotermsaremeanttoaddmoremeaningtowhat industrydoeswithregardtorecognition,treatment,and monitoringofmicrobialcorrosion.

Inadditiontotheaboveinnovationsinthisbook,we believethatthemaininnovationisstillinitstitle:sofar inallindustries,MIChasbeentriedtobecontrolledby theaidofmechanical-physical(forexample,coatingsor pigging),electrical(cathodicprotection),andchemical (useofbiocides)means.Thisbookwilltalkabouta possibilitythattherecanexistyetanothermeansthatis biological.Inotherwords,howbacteriaagainstbacteria canbeusedtocontrolMIC.

Wedohopethatwiththeseinnovativepointsinthis book,ourreadersfromengineerstoresearcherswill find itveryuseful,practical,andquestion-making.Ifafter readingthisbook,thereaderhascomeupwithsome questionstobeansweredinhis/herhead,webelievethat wehavereachedourgoals.

Thestructureofthebookisthatithastwosectionsin sixchapters.The firstsectionthatcontainsthreechapters hasbeenauthoredbyDr.RezaJavaherdashti.Thesecond sectionthatcontainsthreechaptershasbeenwrittenand preparedbyDr.KianaAlasvand.

Wewouldliketodedicatethisbooktoourbeloved ones,HelyaandHannahJavaherdashti,Tahmoures Alasvand,andMahinSoleimani.

Letusclosethischapterwithaversefromagreatman, theIranianmathematician,astronomer,andpoet,Omar Khayyamwhosaid:

NeverdidIgiveupfromlearning/Tomeremainedunrevealed rarelysecretsoftheUniverseSpentIseventy-twoyearsofmylife inthinking/whatIgotasaresultwasthatIknewnothing

RezaJavaherdashti,PhD KianaAlasvand,PhD

Contents

1 WhyCorrosionandParticularlyMicrobial CorrosionAreImportant?, 1

TheDefinitionofEngineeringImportanceasa Functionof “Risk” and “Cost” , 1

WhataretheRisksandCostsofCorrosionand MicrobialCorrosion, 2 EconomicalCosts, 2 EcologicCosts, 3 HowcanRisks,DefinedasaFunctionof LikelihoodandConsequences,beRelatedto MicrobialCorrosion?, 6 References, 9

2 ABriefIntroductiontoCorrosion Engineering, 11 Introduction, 11

TheThermodynamicsofCorrosionandIts ImportanceinDealingWithItinIndustries, 11 SomeBasicConceptsofCorrosion, 15 EssentialitiesforCorrosion, 15 “Series” and “Parallel” CorrosionProcess Patterns, 16

ACombinationofaConcreteSlabandaSteel Rod, 16

HowisCorrosionTreated?, 17 ApplicationofCathodicProtectionMethods, 18 MaterialsSelection, 19 ApplicationofCoatings, 20 DesignFactor, 21 ChemicalTreatment, 22 ClosingRemarks, 23 References, 24

3 AnIntroductiontoMicrobial Corrosion, 25

HowAreMicrobialCorrosion,inTermsofBeingan ElectrochemicalProcess,andMicrobiology Related?, 25 WhatIsMICandWhatAretheFourBasic CharacteristicsofIt?, 25

MICasanElectrochemicalProcess, 25 DiversityofOrganismsInvolvedinMicrobial Corrosion, 26

SuitableEnvironmentforMICtoOccur, 27 Biofilm,ATrueConceptWithaWrong Name, 27

IntroducingSomeBacteriaThatAreRelatedto Corrosion(Corrosion-Related Bacteria ¼ CRB), 30

Sulfate-ReducingBacteria, 32

Iron-OxidizingBacteria, 33

Iron-ReducingBacteria, 34

Acid-ProducingBacteria Nonorganic Producers, 34

Acid-ProducingBacteria OrganicAcid Producers, 34

PossibleRoleofMagneticBacteriainInducing Corrosion, 35

UseofMathematicsinMicrobiology:Fuzzy ModelingforDistinguishingCRBand PathogenicBacteria, 36 EightFundamentalAssumptions, 37 GeneralMethodology, 37 CRBFuzzyModeling, 38

DefiningMembershipFunctionforCRB, 38 PBFuzzyModeling, 39 PhysicoelectrostaticFactors, 40 MechanicalFactors, 40 FuzzyCompositeFunctionsforPB, 41 Discussion, 41 Summary, 42

HowIsMICRecognized?AShortReviewof Culture-DependentandCulture-Independent MethodsandTheirProsandCons, 42 Culture-DependentMethods, 42 Culture-IndependentMethods, 45

“ZugzwangEffect” inMIC, 46

“MythsEffect” inRecognitionandTreatment ofMIC, 52 JavaherdashtiModelforCM-MIC, 55

ClosingRemarks, 67

References, 67

4 AnIntroductiontoMicrobiologyfor Nonmicrobiologists, 71 Introduction, 71

CellandMacromolecules, 71

AminoAcids, 71

FattyAcids, 73

Monosaccharides(orSimpleSugar), 74

Nucleotide, 74

ClassificationofOrganisms, 78

BacterialCellArchitecture, 81

Appendages, 81

CellEnvelope, 83

CytoplasmicRegion, 85

MicrobialGeneticMaterial, 86

MicrobialMetabolism, 86

ReproductionofMicroorganism, 87

MicrobialGrowth, 88

DormancyinBacteria, 89

PhysicalandChemicalRequirementforBacterial Growth, 89

BacterialSignalingPathways, 90

Quorum-SensingSignaling, 90

CyclicDinucleotideSignaling, 91

BacterialLocomotion, 91 Biofilm, 92

InhibitionofMicrobes, 93

MicrobialInteraction, 94 References, 96

5 BiologicTreatmentofCorrosion, 101

Introduction, 101

CorrosionInhibitionbyPredatory Microorganisms, 101

CorrosionInhibitionbyPredatoryBacteria, 101 CorrosionInhibitionbyPredatoryPhages, 107 CorrosionInhibitionbyNitrate-Reducing Bacteria, 113

CorrosionInhibitionbyRegenerativeBiofilm, 116

CorrosionInhibitionThroughtheRemovalof CorrosiveAgents, 118

CorrosionInhibitionThroughaProtective Layer, 119

CorrosionInhibitionThroughAntimicrobial ProducingBiofilm, 119

CorrosionInhibitionWithBiologicallyProduced CorrosionInhibitor, 120

CorrosionInhibitionWithBiosurfactant, 120 CorrosionInhibitionbyBiosynthesized Nanoparticles, 122

CorrosionInhibitionbyHydrophobicBiofilm, 123 CorrosionInhibitionbyMicrobialAntifreeze Protein, 125

InhibitionofCorrosionbyTargetingSignaling Molecule, 127

CorrosionInhibitionbyQuorumSensing Inhibitors, 127

InhibitionofCorrosionbyTargeting c-di-GMP, 130

CorrosionInhibitionbyMicrobialFootprint, 130 CorrosionInhibitionbyMicrobialCellSurface Display, 132 References, 133

6 FuturePerspectiveofBiological InhibitionofCorrosion, 145 References, 148

INDEX, 151

WhyCorrosionandParticularly MicrobialCorrosionAreImportant?

THEDEFINITIONOFENGINEERING IMPORTANCEASAFUNCTIONOF “RISK” AND “COST”

Anythingcanbespecifiedwithtwovariables:its importance(therolethatitplaysinourlives) andthecostofbeingatthisstatus.Arathertrivial examplecouldbeourpets:therolethatthese lovelycreaturesmayplayinthelivesofmanyof usishardtodeny.Ontheotherhand,thecost forlookingafterthemisa figurethatmany won ’t(can’t)afford.Ofcourseherewedon’t meaneconomyforkeepingapet,Iamsure manyofushaveexperiencedtheratherbitter feelingwhenwehaveread “NoDogsAllowed” signsoreventhetraumathatmaybefeltwhena lovedpetisnotwithusanymore.Allthesecan makesomething,fromapettocorrosion,become importantforus.

However,theimportanceofanythingisrather arelativemeasure:somethingthatmaybeimportantforsomeonemaynotbeimportantfor anotherperson.Engineeringimportance,onthe otherhand,isanotherstory.Infact,engineering importancebecauseofitsverynaturecannot varyfrompersontoperson.Ithasaclear,mathematicalde finitionthatcanbestatedasbelow:

EngineeringImportance ¼ Cost Risk

Eachofthesetermshasitsownnonvarying, de finitivemeaningasweshallexplainbelowin amoment.However,wehavetoaddaverysignificantpointheretoo:ifengineeringimportanceof somethingisimportant,noexcuseisacceptable forignoringit.Althoughthisstatementmay soundobvious,ourreallifeexperienceshows thatinmanycasesinindustries,theengineering importanceofcorrosionistakennotwiththe gravityitdeserves.

Whenitcomestocorrosion,we,asH.H.Uhlig did,cancategorizecorrosionlossesasbelow:

1.Wasteofenergyandmaterials

2.Economicalloss

a.Directloss

b.Indirectloss

i.Shutdown

ii.Lossofefficiency

iii.Productcontamination

iv.Overdesign

Wewillverybrieflyjusttoucheconomicecologicaspectsofcorrosionloss.However,this isnottobeunderstoodthatotheraspectsofcorrosionlosscanbeignored.Take,forexample,the overdesignthatwillbeimposedtocompensate forcorrosion.

Assumethatwehavea32-inchpipelinewitha lengthof10km.Ifthethicknessofthepipeis 5mm,theinternalvolumeofthepipewillbe 5064.0m3.However,ifwecouldmanageto decreasethisoverdesignto3mm,theinternal volumewillbeincreasedto5114.0m3,inother wordstheinternalvolumewillbeincreasedby morethan90%.

Theaboveshowsthattheoverdesigningtobe protectedagainstcorrosionisnotanengineering solution.Inadditiontodecreasingtheuseful volumeofthepipe,overdesigningcanindirectly addupmoreintothepollution:overdesignasa measureofprotectionagainstcorrosionwilladd intothe “embeddedenergy ” (EmE).Embedded energyisde finedas “theenergyconsumedbyallof theprocessesassociatedwiththeproductionofastructurefromtheacquisitionofnaturalresourcestoproduct delivery. ”2 Therefore,whenwedooverdesign,we areaugmentingtheenergyrequiredtomakethe part(inourexample,the10-km,32-inchpipe).

Thisaugmentedenergywillconsumeupmoreenergyfromextractionandrefiningofthemetalto meltingandshapinganddeformation.Just multiplythis figurebythetotallengthofpipelines usedaroundtheworldandthosethatare designednottoposeanycorrosionriskby applyingoverdesign.

Theexampleabovecanbetakenasastandalonecaseofhowcorrosioncanaffectourlives andenergysources.Below,wewillbrie flyintroducesomeeconomic-ecologicdisadvantagesof corrosion.

WHATARETHERISKSANDCOSTSOF CORROSIONANDMICROBIAL CORROSION

Wewillstartwithwhatwemeanby “cost” inthe definitionofengineeringimportance.Inthe contextofthischapter,costwillmeananything thatwillincreasethelikelihoodofcreatingahazardtoourinvestment.Whenwebuildapower plantorarefinery,forexample,wedoitby consideringifthisinvestmentisfeasibleenough forus.Inotherwords,westudytheitemsrequired toensureusthatwearenot “wastingourmoney.” Oneimportantparameterhereisthecostthatis imposedonourinvestment thatis,thepower plantorre fineryorpipelinegridwemake.The costherecanbecategorizedintotwosets:the intrinsiccostsassociatedwiththepassoftime andeffectofelementsonourinvestment(that canroughlybeaddressedas “depreciation” factor) andthecoststhatourinvestmentmayimposeon thesurroundingenvironment(ecologiccosts).We willdescribethedepreciationunder “economic costs,” bearinginmindthatdepreciationinits very financialmeaningdoesnotincludecorrosion properly,aswewilldiscussitbelow.

EconomicalCosts

Wheneverwedoaninvestment,wearealso obligedtothinkhowlongthisinvestmentwill last.Especiallyiftheinvestmentisinaphysical form(forinstance,buildingupapowerplant,a refinery,orthelike),wearealsointerestedto knowhowlongwecanexpectthisinvestment willlastaswellasafterwhatperiodintime,this

investmentwillstarttobecomeeconomically feasible.Allphysicalassetswehaveinindustry areexposedtotheelementsandthuswillgo throughaprocessknownbyeconomistsas “erosion ”:thevalueofyourinitialinvestment willdepreciatebymanyfactorssuchas “ wear andtear.” Ifwecanassumeacertainrateofannual depreciation/wearandtearforaphysicalasset, thenitwillbepossibletoalsocalculatefrom whatpointintimetheassetwillstarttobecome economicallyfeasible(thispointintimeisthe “break-evenpoint”).

However,thereareatleasttwoshortcomingsin sucheconomicalconsiderations:

1.Wearandtear asthenamealsoimplies can onlycontainphysicalformsofcorrosionsuch asbutnotlimitedtoerosion-corrosionor perhapsrusting(inironandsteelalloys).The termisnotinclusiveofchemical,electrochemical,andbiologicfactorsthatcanaffect corrosionandbringittothe finalstageof havinglostitsmechanicalintegrityand strength.

2.Althoughthedepreciationratemaybe assumedcertain,constantvalueforeachyear, asitisnotconsideringthewiderconceptof corrosion,theactualdepreciationratestobe imposedonthematerialwillbemuchhigher thanwhatisexpectedonthepaper.Themain reasonbehindintensifyingdeprecationratesis corrosion.

Havingsaidtheabove,itisnowevidentthatas longasthereisnomutualunderstandingbetween corrosionexpertsandeconomists,whatisbeing reportedas “costofcorrosion ” mustbetakenas theveryminimumvaluesthatcouldhavebeen surveyedandcalculated.

Whatisveryinterestingaboutthecountries mentionedin Table1.1 isthatbypropermanagementofcostofcorrosion,theyhavemanagedto lowerthiscost.Perhapsthemoststrikingexample inthisregardwillbeKuwait:in1995thecostof corrosionhasbeen5.2%ofitsGDP.Thiscostof corrosionhadactuallybeeninheritedfrom anotherstudythathadbeendoneforthiscountry in1987,yieldingthesame figureof5.2%GDPfor thecostofcorrosion.3 However,byseriously

TABLE1.1

Japan19993.9trillionYen (Uhlig), 5.3trillionYen (Hoar) 0.77(Uhlig), 1.02(Hoar) 9.7trillionYen (input/output) 1.88(input/ output)

workingonloweringthiscost,anotherstudyon thecostofcorrosioninKuwaitin2011revealed thatthiscosthadbeendecreasedtothesplendid figureof1.7%GDP.3 Now,ifweconsiderthat thecostofMICisnormally20%4 to40%5 of thetotalcostofcorrosion,thenitiseasytocalculatetheshareofcostbecauseofMICinacountry’ s economy.Javaherdashti 6 hasreviewedsome examplesofMICcostsinvariousindustriesand countries.

EcologicCosts

TounderstandthelinkbetweenMICandenvironment,onehasto firstunderstandthelinkbetween corrosionandenvironmentbecausewithout appreciatingtheexistenceofsuchalink,there willnomeaninginmentioningtheecologic importanceofMIC.First,wehavetode fine whatwemeanby “corrosioneffect” and “ corrosionimpact” 2

• Corrosioneffects addressthosenaturalcauses ofcorrosionthatcanbeexpressedby corrosion-relatedterminologyandwithina corrosion-relatedcontext.

• Corrosionimpacts willaddressthosenatural resultsofcorrosionthatcanbeexpressedina quantitativewayintermsofeconomicalcosts andmeasurableecologic/communityrisks.

Tounderstandtheinteractionbetweencorrosionandenvironment,wewilldefinetwotypes ofecologicimpactsofcorrosion 2 :

1.Impactsconcerningthecorrosionofaparticularsysteminagivenindustry(corrosionof systemimpacts [CSIs])

2.Impactsconcerninguseofcorrosioncountermeasuresonagivensysteminagivenindustry (counter-corrosionimpacts [CCIs])

Asanexample,althoughinaparticularcaseof apipelineexplosion,the effect couldbestress corrosioncracking(SCC),the impacts couldrange fromthehighcostofmaterialandlabortoserious ecologicdimensionssuchasleakageofthetoxic fluidinthepipelineintothesurroundingenvironments,thuscausingpollution.

OneimportantaspectofCSIsisthealgorithm bywhichthisimpactcanbeevaluated.Theevaluationprocedure(algorithm)forCSIsisasfollows:

1.Amaterialsapproachtowardthesystemof interest.Inotherwords,whatarethematerials fromwhichthesystemhasbeen manufactured.

2.Standardsthathavebeenusedin manufacturingandcorrosionmanagementof thesystemsuchasmaterialsselection,hydrotesting,coatingselectioncriteria,etc.

3.Possiblecorrosionmechanismsandscenarios thatmaybeexpectedinthesystemofinterest. Inthisregard,thethreefactorsbelowmustbe takenintoconsideration:

a.Themanufacturingstandardsandproceduresformakingthesystem.Forinstance, theweldingorhydrotestproceduresthat mayhavebeenapplied.

b.Corrosionmanagementmeasures, whetherthesystemisundercathodic protection,whethercoatinghasbeen appliedetc.,andwhethertheyhavebeen appliedinaccordancewiththestandards andcodes.Anexampleisthatalthough weldingmayhavebeenapplied,butithas notbeeninaccordancewiththerelevant codes.

c.Theworkingconditionsdictatedbythe industry.

4.Allpossiblecorrosionscenarios(whether seriesorparallelcorrosionscenarios)mustbe thoughtofandlisted.

Althoughinnextchapterswewillexplainmore whatwemeanby “series” and “parallel” corrosion scenarios,itisessentialtotouchthebasishere brieflyaboutthesetwoimportantconcepts.Itis becausewithouthavingasoundunderstanding aboutthepossiblecorrosionmechanismand/or scenariosinacorrosionsystem,itistoohard(if notimpossible)tobeabletodefinethepossible rootcauseofthefailurethatmayhaveresulted inaleaking “incident” that,becauseofitsenvironmentallydestructivenature,hasbeenturnedinto an “accident.”

Undernatural,normalworkingconditions,itis veryraretofacewithcorrosioncasesinagiven systemwhereonlyonespecificcorrosionprocess isthemaintrouble-makingissue.Thepointis thattherearecompetingcorrosionpossibilities thatbecauseofmanyreasonsonemayappearto bethecardinalprocess.Thiswillnotexcludethe possibilityofothercorrosionprocesses,andthereforewehavetotakecareofknowingallpossible corrosionprocessesthatcanbeassumedtoexist inthegivensystemofinterest.

Letustrytosuperimposethefoursteps mentionedaboveaboutCSIsforagivensystem ofinterest.Supposethatthesystemofinterestis

ahydrant,thatistosay,a firewaterring.a Toevaluatecorrosionofsystemimpacts(CSIs)algorithm,wewillfollowthefollowingsteps:

1.Whatisthematerialofthering?Ifitisa nonmetallicmaterialsuchascompositematerials,thentheriskofcorrosionishighlyunlikely.However,ifitismadeofametallic materialsuchascarbonsteel,thentheriskof corrosionwillexist.Althoughitisnotanengineeringpracticetomaketheseringsfrom stainlesssteelortitaniumalloys,bymaking thesematerialsthemanufacturingmaterialof thering,theriskofcorrosion,andMICwould behighlyreduced.

2.Iftheringhasweldedpartsisalsoaquestionto beanswered.Firewaterringsneitherarenot shortpipesnorareseamless.Therefore,they canalwaysbeclassi fiedasweldedsteels.They arenotinternallycoatednoraresubjectedto hydrotesting.Therefore,theonlystandards thatmustbetakenintoconsiderationwillbe codesandstandardsrelatedtoweldingand postweldingtreatment.

3.a.Istheweldingappliedinthewayitwas supposedtobe?Precommissioninginspectionsaswellasinspectionsapplied becauseoffailuresmayprovetobegood meanstoanswertothisquestion.Bearin mindthatfromanecologic-corrosionpoint ofview,themainguidelinefortheoperatorswillbe “prevention” andthen “control ” ofthepollution.

b.Istheringunderanycathodicprotection? Doesithaveanylining?Isthewatertreated withbiocidesbasedonapresurvey,the resultofwhichhaveshowntheCRB/CRAb thatmayhavebeenpresentinthewater?Is therearoutineprocedurebywhichparameterssuchasTDS(totaldissolved solids)aswellasthenumberandtypeof theCRBandCRAarebeingmonitored?

aAmoredetailedcorrosionmanagementapproachfora firewaterringistobepresentedinChapter3toexplain “Javaherdashticorrosionmanagementmodel.” bInthefollowingchapters,wewillexplainwhatwe meanbyCRB(corrosion-relatedbacteria)andCRA (corrosion-relatedArchaea).

c.Theworkingconditionsofthe firewaterare thatitismostofthetimestagnantandat ambienttemperatures.The flowrateofthe waterislessthan1.5m/smostofthetime.

4.Therecanexistseveralcorrosionscenariosthat inessencecouldbeunderdepositcorrosion causedbythedifferentialaerationcells, galvaniccorrosionbetweentheparentmaterial andtheweld,andMIC.Ofthesecorrosion scenarios,MICwillbethemostimportantone thatcancontributetounderdepositcorrosion asaseriesofcorrosionscenario(byproducing morebiofilm,moreanaerobic/aerobicspots maybecreated,leadingintointensified underdepositcorrosion.Withthesametoken, MICcanactasaparallelcorrosionscenarioto thegalvaniccorrosionthatmaybeexpected: theanode/cathodethusproducedbyinappropriatematerialsandwithintheconductive waterthatwillbeactingasanelectrolytewill continuetoaffecttheseriousnessofcorrosion; meanwhile,MICisproceedingwithitsown mechanisms).

Asseenfromtheabove,theCSIsofthe firewaterringcanbeevaluatedinthisway.Thecountermeasuresthatcanbeappliedtocontrolcorrosion couldthemselveshaveenvironmentalimpacts,

Corrosion Effects:

Technical Explanations using Corrosion Terminology

Environmental Impacts due to the corrosion of a system of interest

thusgivingrisetoCCIs(¼ countercorrosion impacts).Forexample,evenseeming “ green ” countercorrosionpracticessuchascathodicprotectioncouldhavedetrimentalimpactson environment.7

Fig.1.1 schematicallydescribestheinterrelationshipbetweenCSJsandCCIs2:

Fig.1.2 showsdischargeofhydrotestwater8 as reportedtooneofus(Javaherdashti)intothe openseas.ThewaterwithadarkercolorthatisbeingdischargedfromthroughapipecontainsCRB aswellastoxicgasessuchashydrogensulfide.The waterhadbeenleftasaresultofhydrotestinthe pipeforsomemonths.Thedarkwaterandwhy ithadbeenformedisasubjectof “corrosioneffects” becausetounderstandwhytheseawater thathadbeenusedasthehydrotestwaterhad becomesocorrosive,oneneedstoknowthe maincorrosionscenariosthatgovernposthydrotestcorrosionandalsothatwhyMICistheprevailingone.Ontheotherhand,asthiswaterthat entersintotheseadoeshavecontaminating agentsinit,thewaterisalsoacaseofCSI:this contaminationinthedischargedwatercould havedetrimentalimpactsontheecologyofthe sea,evenifitislocal.Thismeansthatbecauseof thecorrosionthusgenerated,animpacthas

Corrosion Impacts: Economical Costs and measureable Ecological/community Risks

Environmental Impacts due to anticorrosion measures

FIG.1.1 HowCSIandCCIareconnectedtoexpandthemeaningofcorrosionimpact.

FIG.1.2 Dischargeofhydrotestwater(darkwaterfromthepipe)intotheopensea(collectionof Dr.RezaJavaherdashti).

beencreatedthathasthepotentialofinducing risksofecologicnaturetothemarineecosystem. However,thehydrotestwateralsocontaineda cocktailofchemicals(corrosioninhibitors,biocides,oxygenscavengers)whoseenvironmental impactswerenotsurveyedandstudiedduring thetimeDr.Javaherdashtiwasworkingasacorrosionconsultanttothisproject.Thismeansthatthe hydrotestwatercouldalsohavethecapabilityfor beingcalledasCCI,aswedon’tknowabouthow thechemicalcocktailcouldhavehadadverseimpactsontheecology.

Theexampleshownin Fig.1.2 canclearlyshow thatacasecouldhavevariousaspectswhen lookedatfromdifferentviewpoints,andtherefore corrosionandenvironmentcouldbetightly entangledissuesthatitcouldnotbeeasytoseparatethemfromeachother.Anotherexampleof possibleecologicimpactsofcorrosionhasbeen givenelsewhere.9 Javaherdashti6 hasreported caseswhereMIChasbeenidentifiedasthemain causeofthecatastrophe.However,wewantto onceagainemphasizeonthefactthatevaluation ofecologicaspectsofcorrosionespeciallyMICis amultidisciplinarytaskanditrequiresawelldocumentedapproach.Justreportingthatsuch andsuchdisasterhappenedbecauseofMICis notmakingthatuse.Whatmakesitcountisto definethecauseandeffectandtrytoconcentrate oncorrosioneffectsaswellascorrosionimpacts inthesecases.

HowcanRisks,DefinedasaFunctionof LikelihoodandConsequences,be RelatedtoMicrobialCorrosion?

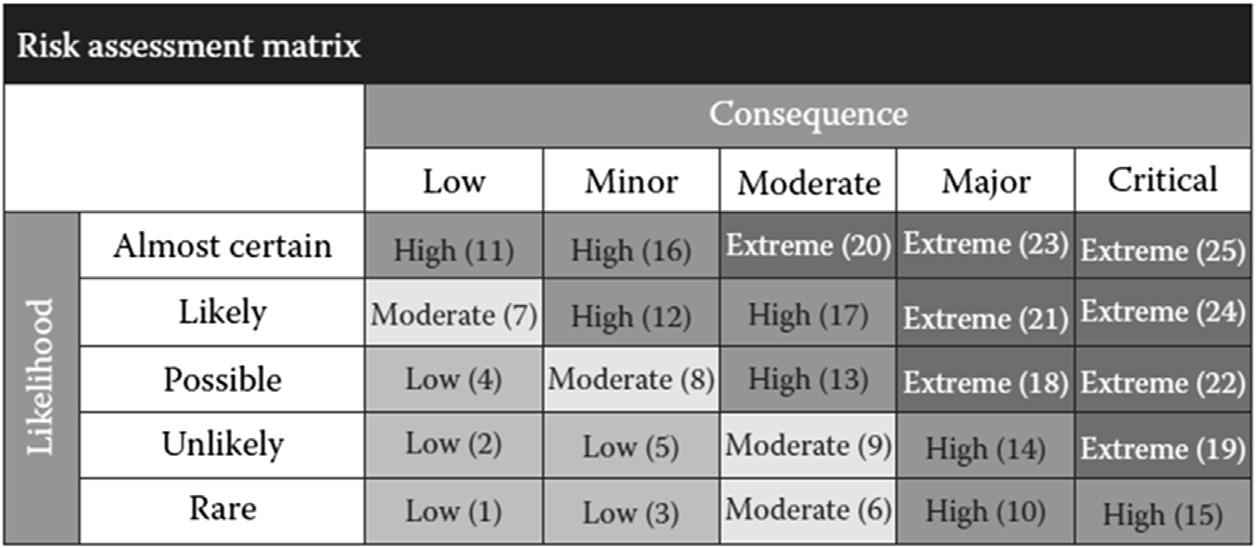

Averycommonsourceofindustrialmanagersnot beingabletoseethatMICdisastercomingisto mixup “likelihoodofMIC” with “riskofMIC” . Themainreasonforthis,ouryearsofexperience withvariousindustriesaroundtheworld,isthat althoughriskisawell-knownconceptinHSE (health,safety,andenvironment),itisnota familiarmattertocorrosionprofessionalsso muchsothattheyhavenotbeenabletoproperly communicatethiswiththeirmanagers.Although weacceptthattherecanbeexceptionstothe ruleandmanyoftheseexceptionsmayindeed betooevidenttodeny,wecanseeitfromthe never-endinglistofincidentsthatcouldotherwise besimplypreventedortoalargeextent controlled,similartothosereported.10 Tostart with,itwillbegoodifwelookatthemainstructureofariskmatrix(Fig.1.3):

Therearethreeelementsinariskmatrixthat mustbetakenintoconsideration:

a.Theelementoflikelihood

b.Theelementofconsequences

c.Theelementofriskclassi fication

“Likelihood” isthemaintaskofacorrosionengineer:hehastoassessifacorrosion(andforthat matter,anMIC)hazardisnearby,andifyes,how closeitis.Normally,onewayofsaying “howclose

thecorrosiondangeris” willbebyapplyingcorrosionassessmentandmonitoringtechniques.One wayofdoingitis,thatis,byplacingametallic couponofthesamematerialofthesystemofinterestintheactualworkingconditionsand observingthathowmuchofitsinitialweight willbelostbecauseofcorrosioninagiventime length.Thismethodisaddressedas “weightloss corrosionrateassessment”.Thisisamimicof theactualcorrosionscenariosinactionandreportstheoutputasafunctionofmasslossand time,ameasurethatisreportedas “corrosion rate.” Todemonstratehowcorrosionratecanbe ausefultoolinthiscontext,wecanthinkofa pipelinewhosethicknessis,say,2mm.Ifweight lossmeasurementscameupwithacorrosion rateof1mm/year,thismeansthat,onthe average,itcanbeexpectedtolose50%ofthe thicknessofthepipein1yearandprovidedthat norehabilitatingmeasuresareprovided,the wholepipewithin2yearsofoperation.

Althoughthesetechniques(andothertechniquesthatarewidelyavailableincorrosionengineeringtomimiccorrosionandgiveestimations abouttheso-called “remaininglife” ofthestructure”)areallinuseinindustriesnowadays,we havetobeverycautiousabouttheirlimitations too.Forinstance,theassumptionbehindusing couponsinweightlossstudiesisthatthecorrosive environmentwillbecorrodingthematerialina uniformmanner(uniformcorrosion)rather thanacceleratingcorrosionatonespot(localized corrosion).Wewillbrieflyexplainuniformand localizedcorrosioninthenextchapterbutfor

thetimebeingitissuf ficienttojustsaythatthe assumptionofexistinga “uniformlycorroding environment” isnotnecessarilytrueeverywhere andinmostcasesofcorrosion,andparticularly inthecasesofMIC,themajorityofcorrosion morphologyresembleslocalizedcorrosioninthe formoflocalminisculeholes(i.e.,pitting)that willlatercoalescenttoformlargerpitsoreven cracksandbyloweringtheeffectivesurfaceto carrytheload,themechanicalstabilityofthematerialwilldecline,leadingintofailure.Thedata fromweightlossstudyarenotofanyuseasindividualdata,itisthetrendtheymakethatwillgive ustheinformationwewillneedtomakeajudgmentabouthowasystemisrespondingtothe threatofcorrosion.Inotherwords,ifthecollectionofdatapointswillmakeanever-increasing trend,thatmaybethestartoftheend. Fig.1.4 willschematicallyshowthepossiblesituations thatmayexistinanimaginarysystemofinterest formonitoringcorrosioninit:

Althoughthelikelihoodcanbemeasured quantitativelyintheliteratureofcorrosionaswe mentionedabovewiththeexampleofweigh lossmethod,theconsequencesmaybeinterpretedasoflimitedknowledgetoa field,corrosionengineer.Infact,whatcanbeseenin practiceisthatthecorrosionengineercanestimate theimmediateoutcomeofapotentialcorrosion hazardsuchasleakagefromapipethatmaycause productiondelayorevenexplosion.Theassessmentoftheaftermathissues,thatis,theextent ofCSIs,oftenremainsuncategorizedandnonquantifiedtoacorrosionengineerworkingina

FIG.1.3 Howariskmatrixmaylooklike.

Another random document with no related content on Scribd: