Building materials in a circular economy: The case of wood waste as CO2-sink in bio concrete Lucas Rosse Caldas

https://ebookmass.com/product/building-materialsin-a-circular-economy-the-case-of-wood-waste-asco2-sink-in-bio-concrete-lucas-rosse-caldas/

More products digital (pdf, epub, mobi) instant download maybe you interests ...

Waste Valorisation: Waste Streams in a Circular Economy

Carol Sze Ki Lin

https://ebookmass.com/product/waste-valorisation-waste-streamsin-a-circular-economy-carol-sze-ki-lin/

Circular Economy: From Waste Reduction to Value Creation Karen Delchet-Cochet

https://ebookmass.com/product/circular-economy-from-wastereduction-to-value-creation-karen-delchet-cochet/

Waste-to-Resource System Design for Low-Carbon Circular Economy Siming You

https://ebookmass.com/product/waste-to-resource-system-designfor-low-carbon-circular-economy-siming-you/

Stakeholder Engagement in a Sustainable Circular Economy: Theoretical and Practical Perspectives Johanna Kujala

https://ebookmass.com/product/stakeholder-engagement-in-asustainable-circular-economy-theoretical-and-practicalperspectives-johanna-kujala/

Practising corporate social responsibility in Malaysia a case study in an emerging economy Hui

https://ebookmass.com/product/practising-corporate-socialresponsibility-in-malaysia-a-case-study-in-an-emerging-economyhui/

Advanced Materials from Recycled Waste Sarika Verma

https://ebookmass.com/product/advanced-materials-from-recycledwaste-sarika-verma/

Building Honor in Academics: Case Studies in Academic Integrity

Valerie P. Denney

https://ebookmass.com/product/building-honor-in-academics-casestudies-in-academic-integrity-valerie-p-denney/

Biomass, Biofuels, Biochemicals: Circular Bioeconomy: Technologies for Waste Remediation Sunita Varjani

https://ebookmass.com/product/biomass-biofuels-biochemicalscircular-bioeconomy-technologies-for-waste-remediation-sunitavarjani/

Minorities and State-Building in the Middle East: The Case of Jordan 1st Edition Paolo Maggiolini

https://ebookmass.com/product/minorities-and-state-building-inthe-middle-east-the-case-of-jordan-1st-edition-paolo-maggiolini/

Full length article

Contents lists available at ScienceDirect

Resources, Conservation & Recycling

journal homepage: www.elsevier.com/locate/resconrec

Building materials in a circular economy: The case of wood waste as CO2-sink in bio concrete

Lucas Rosse Caldas a, d, * , Anna Bernstad Saraiva a , Andr´ e F.P. Lucena b ,

M’hamed Yassin Da Gloria a , Andrea Souza Santos c , Romildo Dias Toledo Filho a

a Civil Engineering Program, COPPE, Universidade Federal do Rio de Janeiro, UFRJ, Cidade Universitaria, Ilha do Fundao, CEP 21941-972 Rio de Janeiro, RJ, Brazil

b Energy Planning Program, COPPE, Universidade Federal do Rio de Janeiro, UFRJ, Cidade Universitaria, Ilha do Fundao, CEP: 21941-972 Rio de Janeiro, RJ, Brazil

c Transport Engineering Program, Universidade Federal do Rio de Janeiro, UFRJ, Cidade Universit´ aria, Ilha do Fundao, CEP 21941-972 Rio de Janeiro, RJ, Brazil

d Programa de P´ os-Graduaçao em Arquitetura (PROARQ), Universidade Federal do Rio de Janeiro (UFRJ), Cidade Universit´ aria, Ilha do Fundao, CEP 21941-901, Rio de Janeiro, RJ, Brazil

ARTICLE INFO

Keywords:

Circular economy

Life cycle assessment (lca)

Biogenic carbon

Climate change

Bio-concrete Transportation

ABSTRACT

This paper aims to assess greenhouse gases’ (GHG) emissions in the life cycle of wood bio-concretes (WBC) production when recycled wood shavings (WS) are used as a circular economy (CE) strategy. Two WBC were evaluated, one with a higher content of WS (WBC–HC) and another with a lower content (WBC-LC). Different WS recycling and transportation scenarios were evaluated. The Life Cycle Assessment (LCA) methodology was used, considering a cradle-to-gate scope, comparing two methods for calculation of GHG emissions: IPCC GWP100 and GWPbio. The transport analysis was carried out considering the WBC production in 26 Brazilian cities, according to different locations where waste WS are generated. In order to increase the robustness of the study, a sensitivity analysis was performed for: types of WS allocation, the origin of WS (waste x virgin materials), transportation efficiency, and electricity grid matrix. We verified that the waste WS content increase in WBC resulted in climate change mitigation for all cases and scenarios (when the biogenic carbon is considered). However, this benefit can vary according to WS availability and transport efficiency. Therefore, transportation must deserve special attention for the CE evaluation. When the GWPbio method is used and CO2 capture during the eucalypt growth is accounted for, the GHG emissions of WBC production can be very low (15 kgCO2-eq/m3). We conclude that recycling wood waste to use in WBC can be considered a good CO2 sink and a pathway for the low-carbon and circular construction industry.

1. Introduction

Circular economy (CE) is gradually attracting attention from scientific and policy communities to support the development of products with higher amounts of reused or recovered materials in order to maximize the efficiency in resource use. In tropical and subtropical countries, that are commonly developing countries, plant (or bio-based) residues are generated in large quantities in agricultural and forestry activities and, in some cases, they are just burned without any energy recovery. In addition, it is a common practice that the burning process occurs in open spaces, resulting in environmental and human health impacts (Luhar et al., 2019).

It is expected that a major part of the global construction demand

will be centered in emerging economies, such as Asia, Africa, and South and Central America (UN Environment and International Energy Agency, 2017). Brazil and other developing countries have interesting features for the development of a CE, especially in the building sector, with its expected growth in the next years to attend the national housing deficit (Pinheiro, 2016). Thus, the construction of thousands of new homes can be seen as an opportunity for reusing or recycling bio-based waste, which is a promising strategy for the bio-material cascading process (Jarre et al., 2020). Additionally, buildings can be viewed as an important carbon stock in cities (Chen et al., 2020), so the use of bio-based building materials that come from waste can play an critical role in climate change mitigation.

However, in this CE strategy, the recovery of waste as raw materials

* Corresponding author. Faculdade de Arquitetura e Urbanismo (UFRJ), Departamento de Estruturas, Departamento de Estruturas. Pr´ edio da Reitoria/FAU, Av Pedro Calmon, 550. Cidade Universitaria, Ilha do Fundao 21941485 - Rio de Janeiro, RJ - Brasil - Caixa-postal: 21941485.

E-mail address: lucas.caldas@fau.ufrj.br (L.R. Caldas).

https://doi.org/10.1016/j.resconrec.2020.105346

Received 28 August 2020; Received in revised form 6 December 2020; Accepted 6 December 2020

Availableonline26December2020 0921-3449/©2020ElsevierB.V.Allrightsreserved.

can be limited depending on their availability and the kind of treatment needed. Although some studies point out that the main limitations for the diffusion of CE are regulatory and policy barriers (Ghisellini et al., 2018; Shi et al., 2019), from a technical perspective, the reuse/recycling of waste can be limited mainly by recycling processes, local availability and high transportation costs (Goswein et al., 2018). Thus, these aspects must be quantified and evaluated in order to assess the environmental feasibility of waste reuse and to estimate whether the use of virgin sources is more advantageous.

Life Cycle Assessment (LCA) can be a very useful tool to measure environmental impacts, especially climate change and greenhouse gasses (GHG) emissions mitigation. It is considered a robust way to quantify and evaluate the potential environmental impacts of products, processes, and services throughout their life cycle and has been widely used in the construction sector (Cabeza et al., 2014; Rock et al., 2019).

In the last years, the use of LCA has started to gain attention in evaluating CE strategies applied to the construction sector to assess benefits in terms of climate change mitigation strategies. There is a special interest in the use of recycled Construction and Demolition Waste (CDW) (L ´ opez Ruiz et al., 2020). Gallego-Schmid et al. (2020) reviewed the literature related to the CE in the construction sector in terms of climate change mitigation and concluded that although closing the loops can be a good strategy in terms of GHG emissions’ reduction, it is highly dependent on the type and efficiency of the recycling process and transportation distances. Foster (2020) proposes a framework to apply the CE principles for the adaptive reuse of cultural heritage buildings to reduce environmental impacts. The framework was structured considering a cradle-to-grave perspective, similar to an LCA study. However, in the literature, there are just a few examples of recovered bio-based waste for use in construction materials, which points out to a scientific gap.

In Brazil, bio-based waste commonly comes from industrialized wooden products such as particleboards, panels, laminated floors, furniture, construction formworks, etc. It is estimated that more than 10 million tons of wood waste are generated annually, 63% of which is burned, many times without energy recovery (Indústria Brasileira de ´ Arvores, 2019). Therefore, the use of wood waste for other purposes, such as CE with wood cascading (Jarre et al., 2020), should be encouraged.

Concrete is the predominant material in the building sector in most countries (Meyer, 2009) due to its availability, low cost, good performance, and durability. Concrete production has received special attention in LCA and CE studies, investigating mainly the use of waste for replacing cement or aggregates, for example, using CDW (Colangelo et al., 2020; Pantini et al., 2019; Santos et al., 2019; Zhang et al., 2019) or other industrial wastes (Arrigoni et al., 2020; Goswein et al., 2018;

Hossain et al., 2018; Nakic, 2018; Turk et al., 2015). Most studies point out that the replacement of some concrete components, especially the Portland cement, reduces environmental impacts, including global warming.

Da Gloria and Toledo Filho (2016) presented an alternative type of concrete using wood shavings’ (WS) waste as aggregates instead of mineral (sand, gravel, etc.), here called wood bio-concrete (WBC). When bio-based aggregates are mixed with cementitious materials, it is possible to produce lightweight concrete with good thermal and acoustical properties (Amziane and Sonebi, 2016; Jami et al., 2019).

The most well-studied bio-concrete, in terms of LCA, is the hempcrete (Arehart et al., 2020; Ip and Miller, 2012; Pittau et al., 2018; Ruggieri et al., 2017; Sinka et al., 2018a) that is already used in commercial applications in some European countries (France, United Kingdom, etc.) and the US (Sinka et al., 2018). However, hemp is a virgin source of biomass, and WS can be considered one of the most available bio-wastes in different countries. Most LCA studies about WS recycling are focused on the production of particleboards (Hossain and Poon, 2018) or other wooden products (Ng et al., 2014). There are very few studies with a focus on alternative bio-concretes, and even less with a focus on LCA. (Rosse Caldas et al., 2020) evaluated the use of bamboo bio-concrete as an alternative for buildings’ climate change impacts reduction in Brazil due to its lower carbon footprint and good thermal performance. Caldas et al. (2020) verified that the use of Supplementary Cementitious Materials (SCM), in this case, fly ash and metakaolin, in WBC production, improves both mechanical and environmental performance. Both studies show that bio-concretes made of waste can be an interesting alternative, mainly in developing countries. However, aspects related to the circularity of materials were not evaluated in-depth.

There is a literature gap related to the environmental impacts’ study of the WS’ recycling process and transportation for use in bio-concretes. This is especially so when considering longer distances, e.g., more than 1000 km, which can be the case of continental dimension countries. Most studies in existing literature consider the European countries’ context. In terms of wood supply chains, Klein et al. (2016) evaluated the German case. Garcia and Hora (2017) assessed the transportation GHG emissions’ impact in different European countries (Germany, United Kingdom, Italy, and Finland). In both studies, transportation showed to be a limitation for the wood waste recovery, even when evaluating small distances, limited to 250 km.

In this context, some research questions emerge: (1) Can wood waste be considered a CO2-sink when used for the production of WBC? (2) Does the WS recycling and treatment process have an important influence on WBC production in terms of mitigation of GHG emissions? (3) Does transportation have a significant influence on the life cycle GHG emissions impacts when recycled or reused waste is used to produce

Table. 1

Wood bio-concrete mixtures composition (kg/m3).

Mixture Cement (kg/ m3) Metakaolin (kg/ m3) Fly ash (kg/m3) Wood shavings (kg/ m3)

VMA – Viscosity modificatory additive.

WBC? (4) Is it better to use distant recycled WS or local virgin sources for WBC production in terms of GHG emissions?

In order to answer these questions, the objective of this article is to quantify the WBC’s life cycle GHG emissions when WS are used as raw material (WBC) to assess its role as low carbon and circular economy alternative in the construction sector, using a Brazilian case study. In addition, the WS-WBC potential as a strategy for storing CO2 is evaluated. Two climate change impact methods were employed, and different aspects were evaluated by sensitivity analysis to improve the robustness of the evaluation.

The novelty of this is study is related to the integration of the evaluation of change mitigation and CE in an innovative building material, the WBC, considering stages of recycling, treatment, and transportation of WS for WBC production in the context of a continental and developing country, since bio-concretes are receiving special attention in different countries as an alternative for GHG reduction in the concrete industry (Amziane and Sonebi, 2016; Jami et al., 2019). In addition, our study brings new guidelines for circular bio-concretes design and GHG emissions life cycle evaluation.

2. Materials and methods

This study combined experimental data collected in a laboratory and emissions modeling (using an attributional LCA). As such, the methods are divided into (1) Characterization of WBC and (2) LCA.

2.1. Characterization of wood bio-concrete mixtures

Two WBC (Fig. 1) mixes were compared. They were manufactured using recycled and treated WS (collected from a wooden panel factory in Rio de Janeiro) and different cementitious materials: Brazilian Portland

m3)

cement of high early strength, metakaolin and fly ash, mixed with chemical additives, calcium chloride (CaCl2) and viscosity modification additive (VMA), and water. In the laboratory, diverse mixtures were tested until reaching the same values of compressive strength, around 5 MPa, in order to have a fair functional comparison while increasing the WS content. This value is considered as a minimum in order to attend structural applications for concrete masonry (ABNT, 2014). In the end, two mixtures of WBC were evaluated, with low content (WBC-LC – 140 kg/m3) and high content (WBC–HC – 247 kg/m3) of WS, as presented in Table 1

2.2. Life cycle assessment

2.2.1. Definition of objective, scope, and functional unit

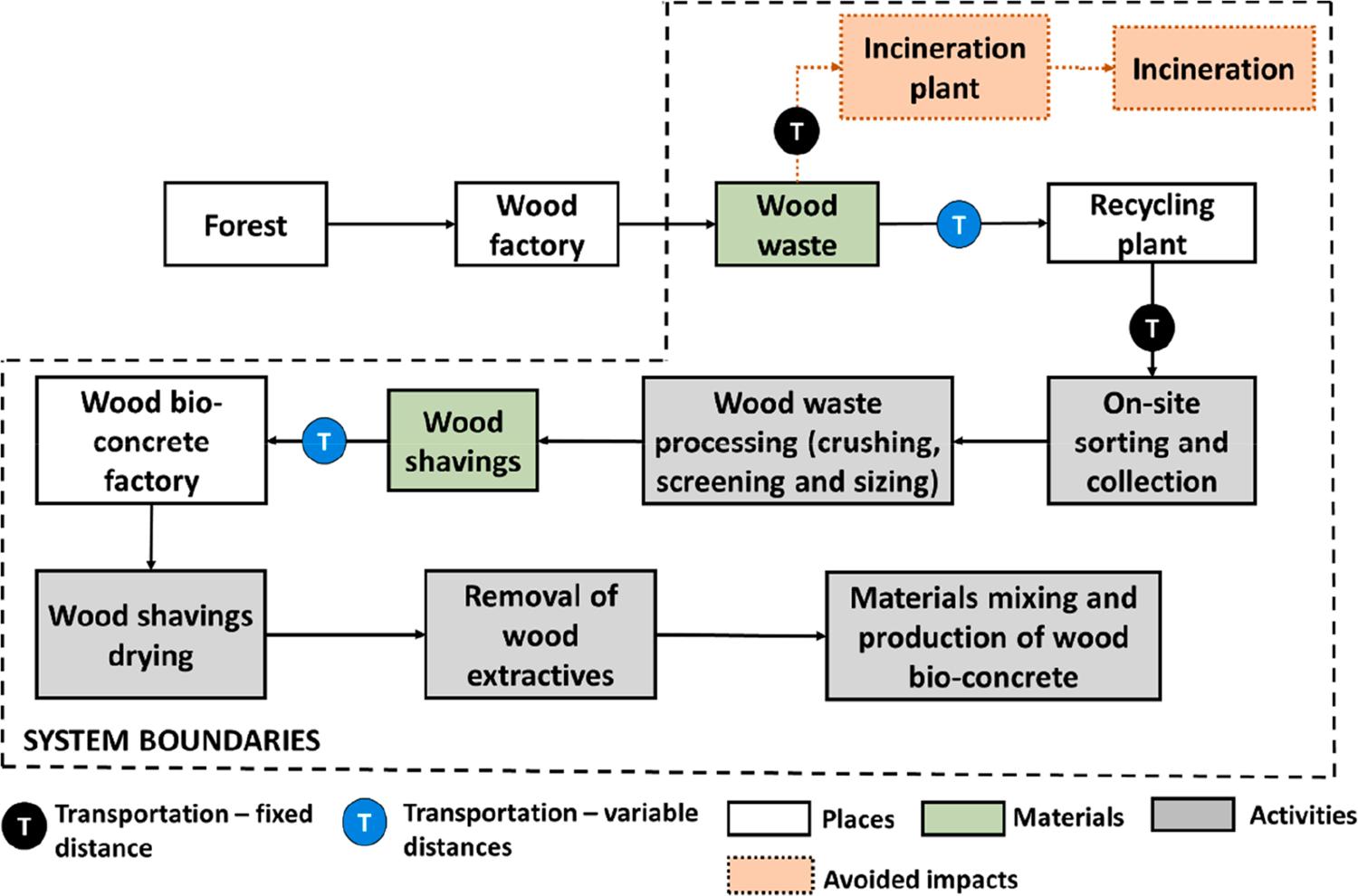

The objective of this LCA study was to compare different WBC mixtures, with a focus on the content, origin, recycling, treatment, and transportation of WS in order to find directives for CE in terms of mitigation of life cycle GHG emissions. For the scope definition, the standard EN 15,978:2011 (CEN, 2011) was used, considering the following stages and modules: raw materials supply (A1) – cement, metakaolin, fly ash, wood shavings, and chemical additives production; raw materials transportation to WBC factory (A2); WBC manufacturing (A3); and benefits (D) due to avoided impacts related to the end-of-life (EoL) of WS. The functional unit was set to 1 m3 of WBC with a minimum compressive strength of 5 MPa.

2.2.2. Life cycle inventory

The life cycle inventory (LCI) was performed based on laboratory data, literature, and the Ecoinvent database v. 3.3. The original activities of Ecoinvent had the electricity dataset changed to an Ecoinvent process representing the Brazilian electricity grid matrix, using the year 2014 as

reference. GHG emissions were accounted for at all stages. It is important to say that the year 2014 was an atypical year, with higher GHG emissions for the grid matrix, due to the drought crisis in Brazil. However, this year was used because it was the data already available in Ecoinvent, and it can be considered a conservative assumption.

A high initial resistance cement, CPV, with 90% of clinker, 5% of crushed limestone, and 5% of gypsum, was considered, as CPV is normally used in Brazil. The average thermal energy consumption and electricity used in Brazilian cement plants for clinker and cement production were used, according to WBCS (2019) and Energia (2018).

A kaolin extraction and calcination process using charcoal as an energy source, based on Henrique et al. (2014), were considered for metakaolin in the study. Fly ash is considered as waste, entering the system without environmental burden, considering merely the treatment normally performed to use as an SCM. Data from Chen et al. (2010) was used to model this process, after adaptation, to address the Brazilian electric energy mix for the year 2014.

Since WS are generated as waste in commercial production of wooden products without any economic value, it was considered that they do not cause environmental impacts in their acquisition besides the recycling and treatment stages presented in Fig. 2 These stages include screening, homogenization, and washing at 80 ◦ C for the removal of wood extractives (the use of 0.15 kWh of electricity and 10 L of water per kg of dry WS was measured in the laboratory). The detailed LCI for WBC treatment is presented in Appendix A1 (Table A1). For the benefits (D), it was considered the avoided GHG emissions of the WS incineration process, including transportation to the incineration plant. Data from Ecoinvent v.3.3 was used and presented in Appendix A1 (Table A2).

The amount of carbon content in WS was quantified through elementary analyses of Carbon, Hydrogen, and Nitrogen (CHN), and we found a 53% value of WS dry mass. However, this value can change according to different factors, especially the type of wood. In order to account for this uncertainty, the amount of CO2 absorbed and stored in WS was calculated, considering three values (47%, 50%, and 53%). A similar assumption was used by Pittau et al. (2018). We assumed that the WS come from Eucalyptus, considering sustainable forest management, with a rotation period of 10 years (Ríos, 2009). We used the method developed by Guest et al. (2012) that defines a GWPbio index. We considered that the biogenic CO2 is stored indefinitely (more than 100 years) since the WBC’s cementitious materials tend to mineralize the

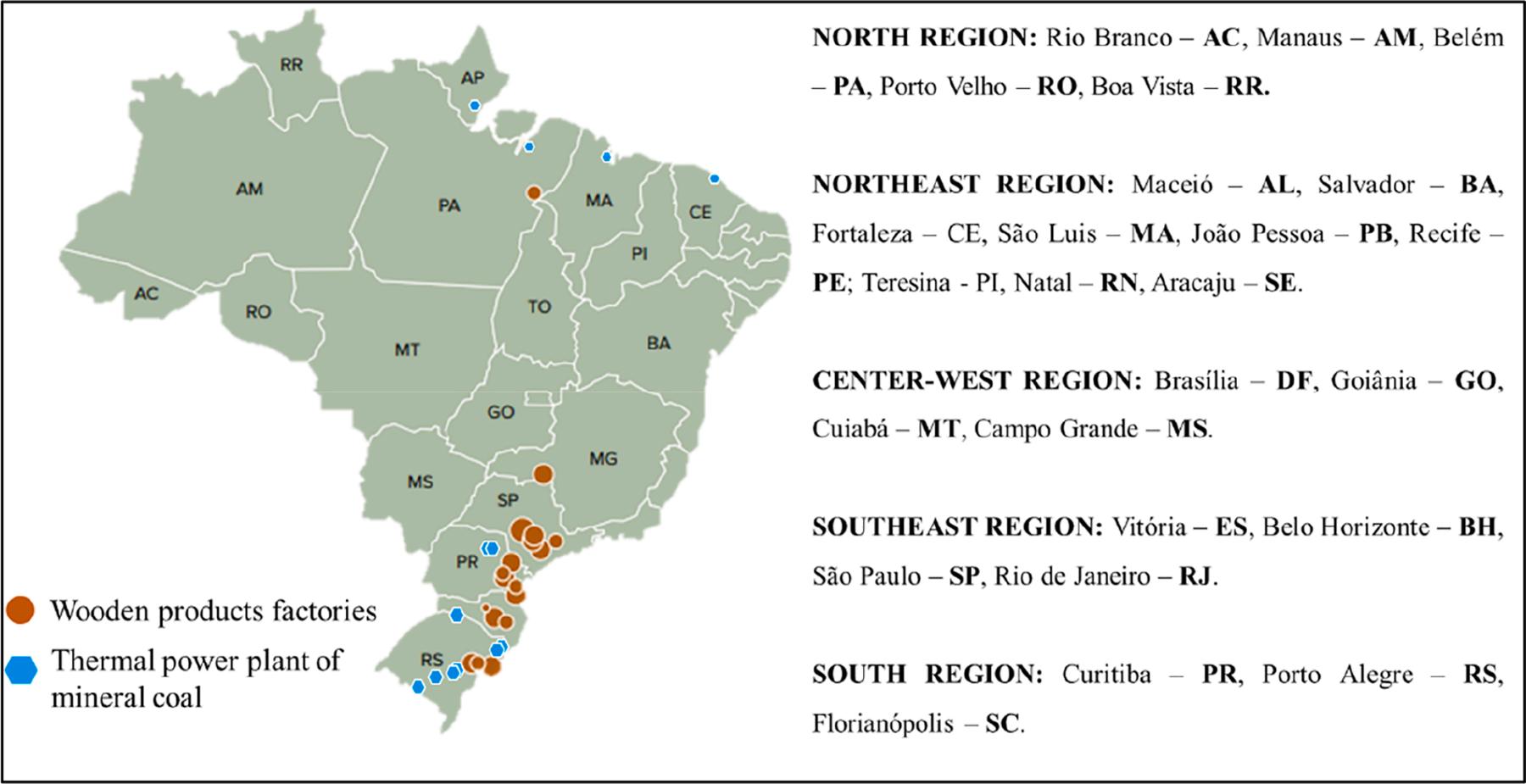

WS, which was the same approach performed by Pittau et al. (2018) and Ruggieri et al. (2017). Assuming the ten-year rotation period and that the CO2 will be stored for more than 100 years in the anthroposphere, we found the GWPbio factor of 0.96 presented by Guest et al. (2012) Brazil is a country with continental dimensions, which could influence transportation distances of building materials. Thus, different distances for the transportation of raw materials (A2) were assumed, considering the geographical distribution of industrialized wooden product factories and thermal coal power plants for WS and fly ash, respectively. Both of them can be considered as constrained available materials since they come as waste from other industrial processes and are concentrated in specific regions of Brazil (most of them in the South and Southeast), according to Fig. 3. Then, the following assumptions were made for the transportation stage:

• Wood shavings and fly ash (constrained available materials): distances calculated according to map in Fig. 3, presented in Appendix A2 (Table A3).

• Cement, metakaolin, calcium chloride, and VMA additive (other materials): we assumed three constant values for transportation distances (minimum, average, and maximum), presented in Appendix A2 (Table A4).

• Transportation of wood shavings to incineration plant (avoided GHG emissions) and from recycling plant to on-site sorting and collection – 50 km.

For all cases, the road modal with EURO 3 and 10–20 tones was adopted from the Ecoinvent database, considering that Brazilian trucks for building materials transportation normally have these characteristics (Caldas and Sposto, 2017). The distances were measured by using Google Maps (Developers, 2018), and the shortest distances between the factories and the site locations were adopted. The cities selected were the twenty-six Brazilian state capitals, divided by region, as presented in Fig. 3.

2.2.3.

Life cycle impact assessment

Two different GWP methods were evaluated to increase the robustness of the results: (1) The GWPbio by Guest et al. (2012) and the IPCC GWP100 (Stocker, 2013) method. These methods were employed in order to see the biogenic carbon influence in the total GHG emissions of

Table. 2

Summary of items evaluated in the sensitivity analysis.

Sensitivity analysis items Description of alternatives

GHG emissions from the production of wood shavings and fly ash

No allocation (Baseline scenario). Mass and economic allocation.

Electricity used for wood shavings recycling and treatment Cleaner source – Brazil (Baseline scenario). GHG intensive electricity grid matrix –China.

Transportation efficiency Truck capacity and way of return (empty or loaded). 100% carried and carried in return (Baseline scenario). 50% carried and empty return (worst scenario).

Origin of wood shavings Waste wood shavings (Baseline scenario). Virgin wood shavings.

Table. 3

Allocation coefficients and comparison with literature.

Material Wood shavings (WS) Fly Ash (FA)

Type of allocation Mass Economic Mass Economic

Hossain et al. (2018)

Seto et al. (2017)

Chen et al. (2010)

WBC, since, in the IPCC method, the biogenic carbon is considered neutral, while it is regarded as a sink using GWPbio

2.2.4.

Sensitivity analysis

A sensitivity analysis was made for four premises adopted in this study, according to Table 2 We chose items that have an important influence in terms of CE, according to Garcia and Hora (2017) and Jarre et al. (2020)

Firstly, mass and economic allocation were considered. For WS, we adopted the production of particleboards produced in Brazil, and for FA, the electricity produced by bituminous coal. For both cases was used data from Ecoinvent v.3.3. Detailed data for the allocation process is presented in Appendix A3 (Tables A5 and A6). The coefficients of mass (Wm) and economic allocation (W$) of the total impacts of waste materials (W), WS, and FA, are calculated through Eq. (1) and (2), respectively, according to Hossain et al. (2018)

Where Wm is the coefficient allocation of emissions that are allocated in WS and FA in mass, mW is the mass of WS or FA and, mP is the mass of the main product. W$ is the coefficient allocation of emissions that are allocated in WS and FA in R$ (Brazilian currency). $P is the market value of the main product (particleboard or electricity generated by coal), and $W is the price of WS and FA. The W$ for WS is null since WS do not have economic value. We found the coefficients presented in Table 3, where FA values are consistent with the literature.

The second item evaluated in the sensitivity analysis is the electricity grid matrix used in the WS recycling and treatment process. We considered a cleaner source (from the Brazil grid matrix) compared with a source with a higher share of fossil fuels (from the China grid matrix), using the Ecoinvent v. 3.3 database. It should be pointed out that this choice was made to extrapolate the evaluation carried out here, considering data from another country with continental dimensions, but with a very different electricity grid matrix (with higher GHG emissions). The evaluation of different countries’ electricity grid matrix, especially ones with considerable differences, is a common practice in LCA studies, e.g., the study of Escamilla et al. (2016), as a way to see how these differences impact the final results, and as a way to improve the scientific contribution of the research, not intending to get a very local and specific study.

Assuming transportation is an important aspect for CE and considering that in Brazil and other developing countries, the transportation of building materials is many times inefficient, different scenarios were built considering the capacity and whether trucks return empty or loaded, using Ecoinvent database v. 3.3 as presented in Appendix A1.

As a last sensitivity analysis, we considered different sources of WS: the first one from waste (the WS that were previously evaluated) and the second from virgin sources. This sensitivity analysis aims to assess the extent to which the use of waste WS, instead of virgin WS, is beneficial in terms of GHG emissions. We considered that the WS from a virgin source come from adequate forest management, where the tree is managed, cut, collected, processed for the production of wood aggregates (chipping, flaking, and screening), and dried, according to data of Hossain and Poon (2018), adapted to the Brazilian context (in terms of electricity and transportation). Additional data was used for the forest activities (plantation, fertilization, maintenance, etc.) based on Ferro et al. (2018) that evaluated the production of oriented strand boards in Brazil.

The premises for the sensitivity analyses resulted in 0.34 kgCO2-eq/ kg (for Brazilian electricity) and 0.58 kgCO2-eq/kg (for Chinese

4.

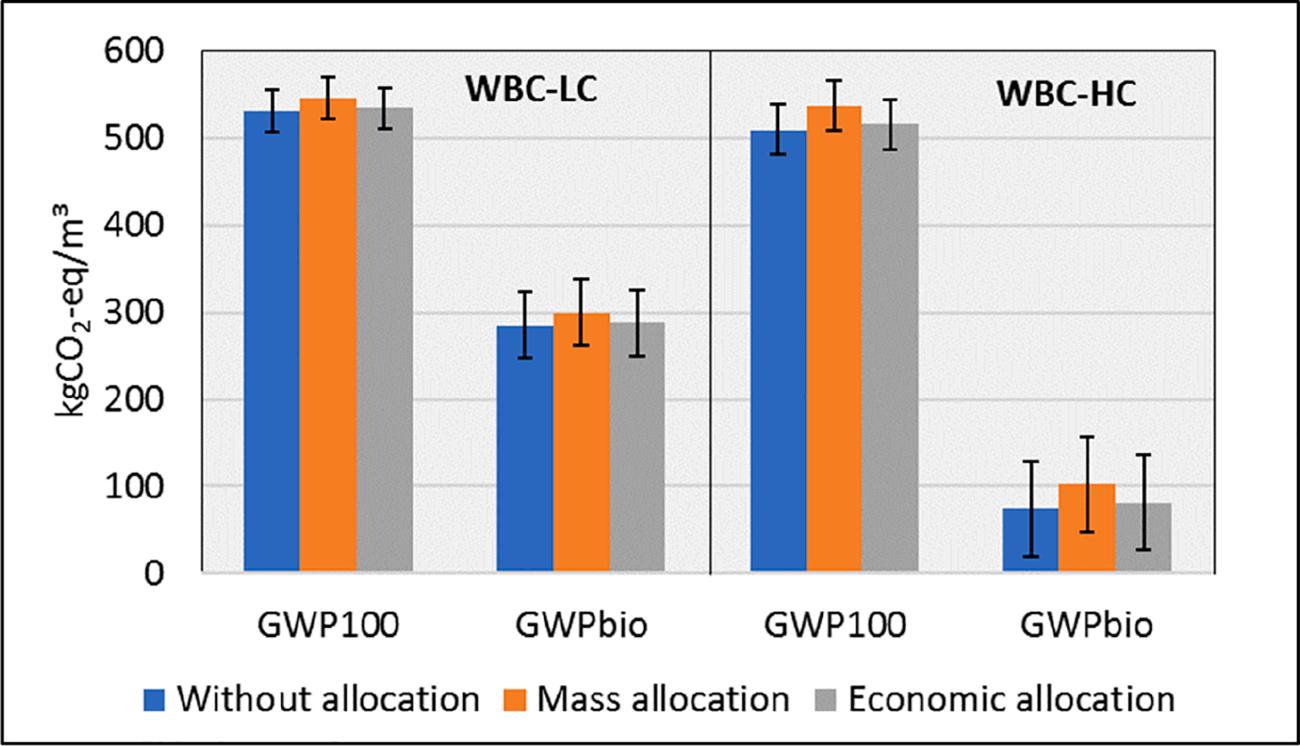

WBC mixtures, GWP methods, and types of allocation (WBC – Wood bio-concrete. LC - Low wood shavings content. HC - High wood

content. The error bars represent the standard deviation due to transportation scenarios and biogenic carbon (When the GWPbio method is used).

electricity) of virgin WS, compared to 0.09 kgCO2-eq/kg (for Brazilian electricity) and 0.31 kgCO2-eq/kg (for Chinese electricity) of waste WS. All the data used is presented in Appendix A1. New modeling was performed for WBC-LC and WBC–HC, considering the best (100% default) and worst (50% empty) scenarios for transportation efficiency. For virgin WS, we assumed three different transportation distances: 50 km, 200 km, and 400 km.

3. Results and discussion

This section divided the results and their related discussions into the following subsections, according to questions raised in the Introduction section: (3.1) Total GHG emissions evaluation, (3.2) GHG emissions profile evaluation, (3.3) Evaluation of the transport contribution to overall GHG emissions, and (3.4) Comparison of GHG emissions between recycled and virgin wood shavings.

3.1. Total GHG emissions evaluation

The GHG emissions results for the production of WBC using recycled WS, under the different premises for the sensitivity analyses (allocation), are presented in Fig. 4

There are considerable differences between the two methods for life cycle emissions calculation. When the GWP100 method was used, the CO2 captured during the eucalyptus growth was not accounted for. Not considering this capture increases the GHG emissions of bio-concretes

drastically, reaching more than 500 kgCO2-eq/m3 (see Fig. 4 for WBCLC and WBC–HC) for both WBC mixtures. On the other hand, when the biogenic CO2 is accounted for, it is possible to produce low carbon WBC with GHG emissions with just 15 kgCO2-eq/m3 for WBC–HC (see Fig. 4 at the bottom of the error blue bar) for the cases with and without economic allocation. These results answer the first question and show that wood waste can be considered a CO2-sink when it is used for WBC production. Caldas et al. (2017) evaluated other bio-concretes using bamboo and rice husk aggregates, with 133 kgCO2-eq/m3 and 387 kgCO2-eq/m3, respectively, even accounting for the biogenic carbon. However, for these bio-concretes, just Portland cement is employed as a binder, while for WBC, fly ash and metakaolin are used, replacing the cement, which helps to justify the low GHG emissions. Expressive differences between GWP methods have been verified already by Guest et al. (2012) The carbon content present in the biomass has an important impact on the results. In this case study, three values were used (47%, 50%, and 53%), and the difference between the highest and smallest value reached 5-fold times for GWPbio-WBC–HC, as can be seen by the bigger error bars in Fig. 4.

Aspects related to methodological choices are very relevant for the GHG emission results. Firstly, the question of sequestration of biogenic carbon is a polemic issue, already discussed by several authors (Guest et al., 2012; Fouquet et al., 2015; Penaloza et al., 2016; Pittau et al., 2018). In our study, the sequestration of biogenic carbon had a great influence on the final results, especially for the WBC–HC. Yet another issue that can influence the results, although it was not investigated in

the present study, is the consideration of land use, which is rarely considered in LCA or carbon footprint studies. Several standards and methods do not address these two aspects clearly (Negishi et al., 2019; Dolezal et al., 2017;Tellnes et al., 2017).

Another point for discussion in the literature related to biogenic carbon is the end-of-life of bio-based materials. For example, for wooden or bamboo materials, if they are burned with or without energy recovery, the accounting of biogenic carbon will have different impacts in terms of GHG emission contribution, as already shown by Fouquet et al. (2015) and Pittau et al. (2018) However, in the case of WBC that is an inorganic material, the WS and consequently the stored CO2 tend to be locked indefinitely, acting as a CO2 sink. Thus, we suggest that negative quantification should be assumed. Negative quantification has previously been proposed for similar bio-concretes, such as hempcrete (Pittau et al., 2018; Ruggieri et al., 2017) and bamboo bio-concrete (Caldas et al., 2019). The new version of EN 15,804 (2019) tried to align with the European Union Product Environmental Footprint (PEF) that made the accounting of biogenic carbon and EoL stages mandatory in Environmental Product Declarations (EPD). One of the justifications for this modification is the possibility of measuring all benefits of circular and bio-based materials (Durao et al., 2020).

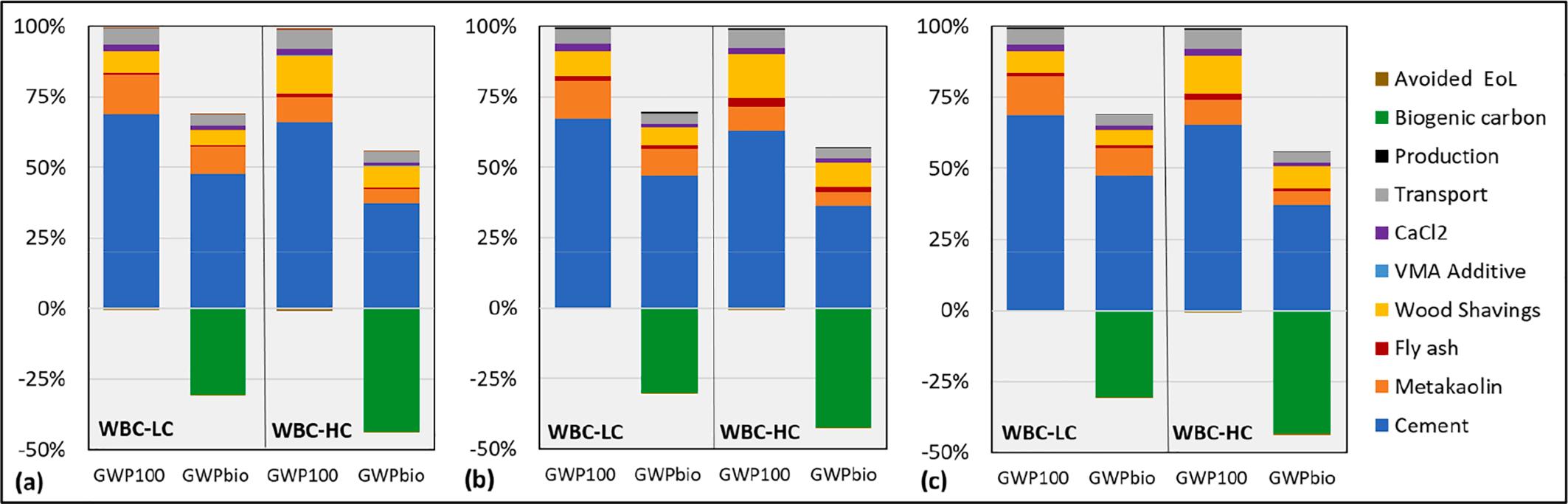

3.2. GHG emissions profile evaluation

The GHG emissions profile for the production of WBC using recycled WS, under the different premises for the sensitivity analyses (allocation and electricity), is presented in Figs. 5 and 6

The cement was the highest emission material due to the production of clinker by calcination of calcium carbonate and the use of fossil fuels. Hossain and Poon (2018) found that the cement contributes to 57% of GHG emissions of cement-based particleboard production in Hong Kong. Metakaolin comes in second place due to kaolin extraction and calcination (considered here as charcoal). Caldas et al. (2019) also find that the Portland cement and metakaolin result in the highest GHG-emissions from bamboo bio-concrete production in Brazil. The fly ash, CaCl2, and mixing water had small participation (less than 10%) in the life cycle GHG emissions. The first one is related to the minimal impacts of fly ash (even considering the allocation in mass or economic), and for CaCl2, principally due to the small amount used in WBC. The contribution of avoided impacts related to the incineration process and transportation of WS was irrelevant (less than 0.5%).

In terms of avoided impacts, waste reuse or recycling will avoid endof-life impacts, which is an important aspect regarding CE. In this study, the chosen EoL process (incineration) showed an insignificant contribution to emissions, according to the data used. However, it is important to mention that wood waste can be used for energy generation (e.g., electricity production), replacing fossil fuels. More GHG-intensive electricity matrixes, such as China’s, tend to have the greatest benefit in terms of emissions reduction from energy productions by wood-

burning, as shown by Escamilla et al. (2016). In this sense, there is a concrete opportunity cost related to different uses of wood waste. The opportunity cost is commonly strongly context-derived, and there could be situations where the use of wood for energy generation can be more advantageous than the use in bio-concretes in terms of climate change mitigation. Thus, it would be interesting to assess the impacts or benefits associated with this kind of use on a larger scale, employing LCA with a consequential approach. Future and more detailed research dedicated to these two topics should be evaluated.

In terms of the allocation of GHG emissions in waste materials, WS and FA, it did not have a substantial influence on the final results for most cases (less than 10%), for both types (mass and economic), except for the case of WBC–HC, using GWPbio that reached 37%. It occurred due to the strong influence of biogenic carbon for this mixture that has a higher content of WS and FA. However, even with the increase of GHG emissions due to allocation and for the GWP100 method, the WBC–HC mixture presented better results than the WBC-LC. As presented in Appendix A4 – Figs. A1 and A2, we evaluated the increase of life cycle GHG emissions when allocation coefficients (mass and economic) are changed to 20% and 50% for FA and WS. In these cases, the WBC–HC, using GWPbio, reached average values of 205 kgCO2-eq /m3 and 150 kgCO2-eq/m3 for mass and economic allocation for 50% allocation coefficients, respectively.

The use of different bases for allocation (comparing economic and mass allocation) demonstrated a significant influence on the results in the cases where it has coefficients larger than 20%. However, there are other forms to include the impacts of multifunctional processes, such as system expansion, which can lead to different results. The economic allocation is particularly affected by the market price fluctuation, and it generally has smaller allocation coefficients when compared to mass allocation since the price of waste and co-products is typically much smaller the that of the main product, as can be viewed in different studies that evaluated the impact of allocation in the construction sector (Chen et al., 2010; Hossain et al., 2018). It must be noted that in the scenario without allocation, the WS enter as zero-burden, and when the allocation (mass or economic) is considered, just part of the impacts are allocated to WS, and the rest, to the main product (wood). However, the benefits of CO2 capture are 100% allocated in the WS when WS are used for WBC production. This choice can be justified by the assumption that if WBC were not produced, the WS would probably be burned, and the stored CO2 would return to the atmosphere.

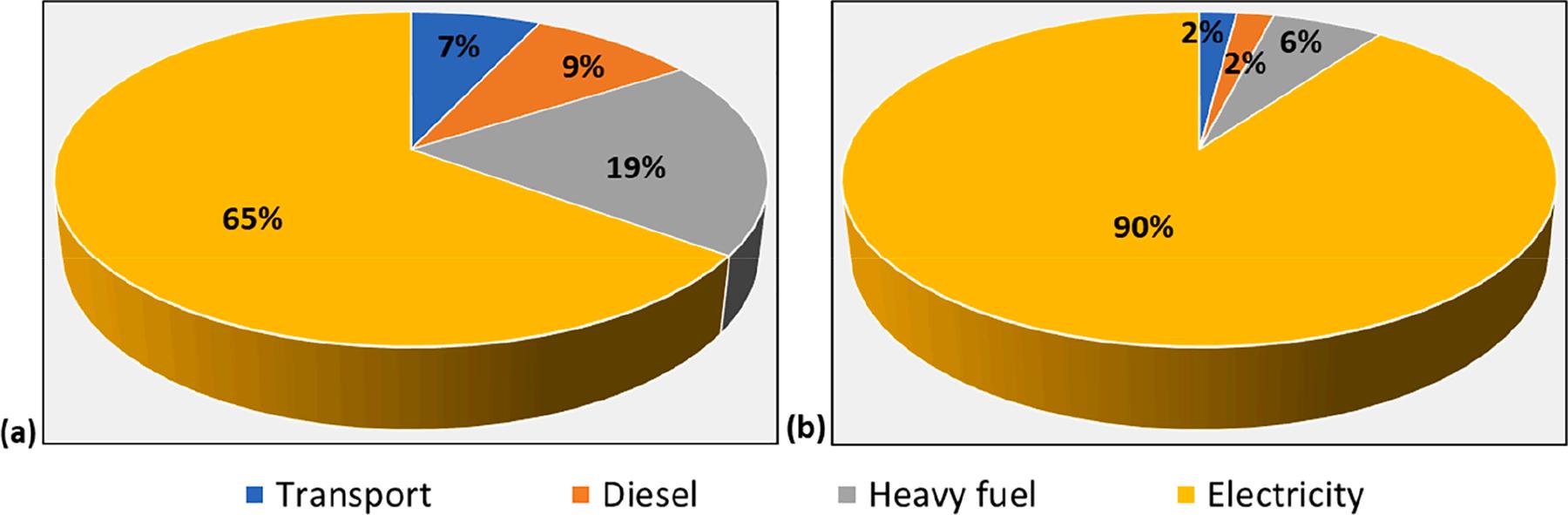

Answering the second question, we can see that the WS recycling and treatment do not have a considerable influence on the GHG emissions of WBC (reaching 5% for Brazilian electricity and 15% for the Chinese scenario), even when a high amount of WS is used (WBC–HC) or when a different method (GWP100 and GWPbio) or electricity grid matrix (Brazil and China) is used. Only when the allocation impacts of WS and FA are considerably high (more than 20%) that the impacts of recycled waste start to become important in the total life cycle GHG emissions, as

presented in Appendix A4 – Figs. A3 and A4. From these findings, we can conclude that the GHG emissions for WS recycling and treatment are not an obstacle for WBC production, and based just on this requirement, it can be a good option from the CE point of view. Electricity is the factor that most influenced the life cycle GHG emissions of WS (see Fig. 7), especially for a country with a GHG-intensive electricity grid matrix, as the case of the Chinese scenario.

3.3. Evaluation of the transport contribution to overall GHG emissions

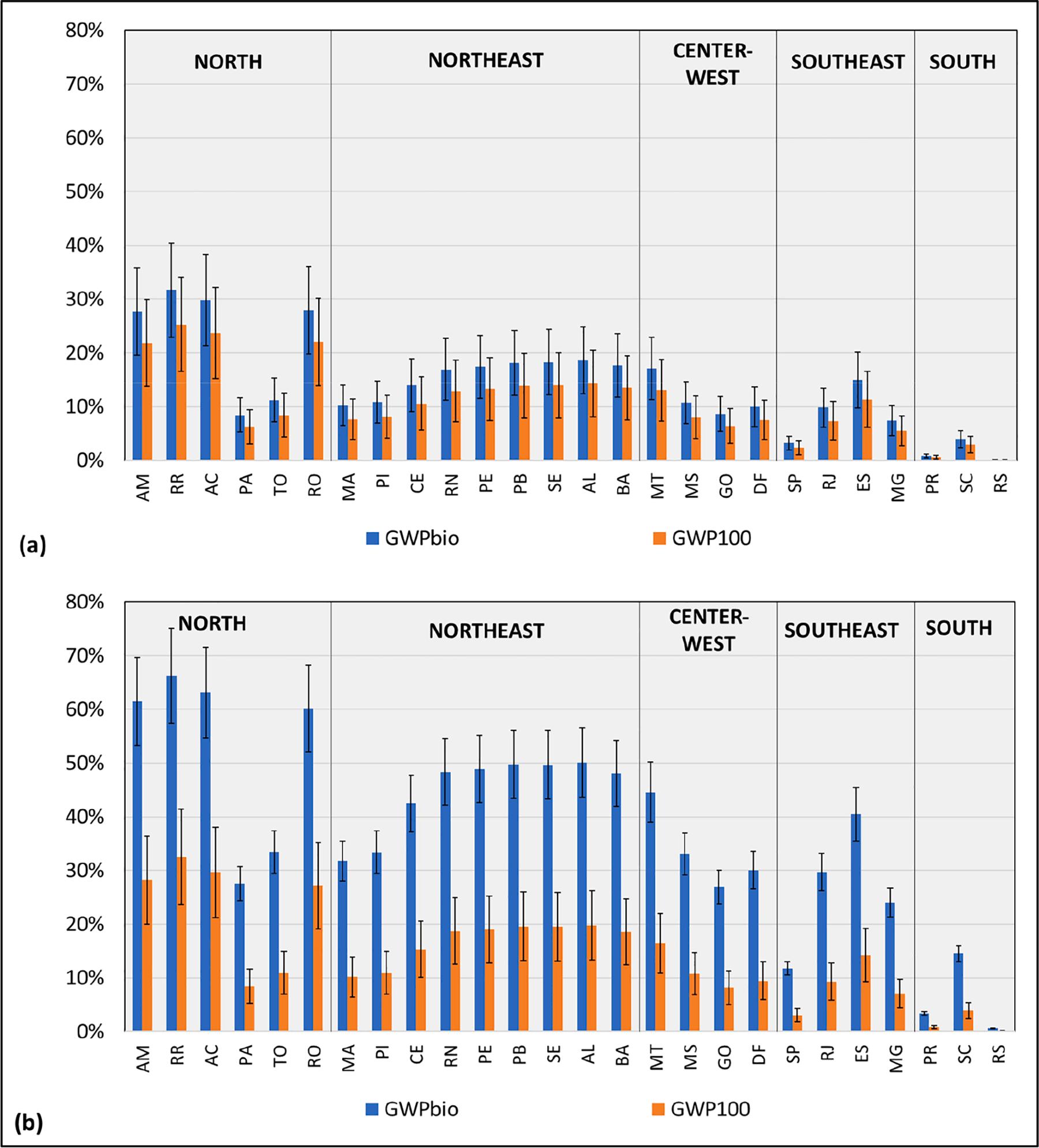

In Figs. 8 and 9, we present the GHG emissions and the contribution of transportation impact, respectively, in terms of different locations for WBC-LC and WBC–HC and different methods, GWPbio (blue bars) and GWP100 (orange bars).

When we look at the Brazilian territory, we see that North (AM, RR,

AC, and RO - represented by the fist cluster in Figs. 8 and 9) and Northeast (PI, CE, RN, PE, PB, SE, AL, and BA - represented by the second cluster in Figs. 8 and 9) regions are the places where the WBC will have the highest GHG emissions, which confirms the findings by Caldas and Sposto (2017). These authors pointed out that longer distances are necessary to transport some building materials (concrete and ceramic blocks) since Brazil has very different degrees of technological development. The most developed regions, in terms of industrial development, are concentrated in the Southeast and South regions, similar to our findings here. In this sense, the production of WBC using WS in these locations will result in lower GHG emissions. The cities located in the South region (PR, SC, and RS) presented the lowest transportation impact, which is also related to the location of wood factories and the higher availability of fly ash in this region. Therefore, we can see here that the South and Southeast regions are the places more

shavings content. The error bars represent the standard deviation due to transportation scenarios. Each cluster represents a Brazilian region.

suitable for the development of industrial-scale production of WBC in terms of a CE.

When the biogenic carbon is considered, in the GWPbio method (blue bars), as a negative emission of CO2-eq, the increase in WS content decreases the contribution to GHG emissions (see Fig. 8), and the relative transportation impact increases (see Fig. 9), especially for the WBC–HC (see Figs. 8b and 9b).

The increase of WS content showed to be a good strategy to reduce the life cycle GHG emissions of WBC if the GWP method considers the accounting of biogenic carbon, e.g., GWPbio, even if an allocation is considered for WS. It is important to note that this occurs even when the WS is obtained from remote locations (further than 3000 km for an efficient transportation scenario, e.g., RR, RO, and AM locations – the North region). The WBC–HC performed better for all locations and scenarios when compared with the WBC-LC for the GWPbio method

(indicated by blue bars in Fig. 8), however, with big differences between the locations. The greatest difference between them (WBC-LC and WBC–HC), for GHG emissions (in Fig. 8), occurred for the GWPbio method in RS (South region), that reached 279% (truck loaded with 100% of capacity and returning loaded), and the smallest difference occurred for RR (North region) for the worst transportation scenario (truck loaded with 50% of capacity and returning empty) that reached just 1%.

Then, answering the third question, transportation has a significant influence on the life cycle GHG emissions impacts of the WBC, thus in terms of the circular building products’ design that pretends to employ recycled or reused waste, the transportation can be a limiting factor per Klein et al. (2016) and Garcia and Hora (2017). However, for the cases of continental countries (e.g., Brazil), this influence is much greater. For the case of bio-based materials that can archive neutral or negative

Table. 4

Maximum delivery distance (in km) and variation among the scenarios (in parentheses) of recycled WS considering different sources of virgin wood shavings (50 km, 200 km, and 400 km) for GWPbio and GWP100 methods.

GWPbio

Bioconcretes Transportation scenario Virgin wood shavings (distance 50 km)

Virgin wood shavings (distance 200 km)

Virgin wood shavings (distance 400 km)

WBC - LC 100 % default 1792 km ( 16.6%) 1945 km ( 9.5%) 2149 km (best scenario)

50% empty 704 km ( 67.2%) 857 km ( 60.1%)

GWP100

Bioconcretes Transportation scenario Virgin wood shavings (distance 50 km) Virgin wood shavings (distance 200 km) Virgin wood shavings (distance 400 km)

WBC - LC 100 % default 1796 km ( 16.7%) 1962 km ( 9.0%) 2157 km (best scenario)

50% empty 715 km ( 66.9%) 863 km ( 60.0%) 1070 km ( 50.4%)

WBC - HC 100 % default 1822 km ( 16.8%) 1986 km ( 9.3%) 2189 km (best scenario)

50% empty 736 km ( 66.4%) 885 km ( 59.6%) 1086 km ( 50.3%)

carbon footprint, it can turn out a trade-off, losing the benefits related to the carbon storage. Finally, transportation efficiency, especially in terms of carried capacity and type of return (empty or loaded), also showed a big influence on results.

3.4. Comparison of GHG emissions between recycled and virgin wood shavings

In the section, the maximum transportation distances of recycled WS are evaluated when compared to virgin WS (considering they are transported from distances of 50 km, 200 km and 400 km), as presented in Table 4, considering WBC-LC and WBC–HC (for Brazilian electricity), and different transportation scenarios (100% default and 50% empty), and the GWP methods (GWPbio and GWP100). The percentage values presented in parentheses show the variation concerning the best scenario for transporting recycled wood shavings, which, in this case, is the transportation of virgin aggregates over a 400 km distance, considering the best transport efficiency scenario (100% default).

We can see that the scenarios with the use of recycled WS tend to be better even when considering long transportation distances and least transport efficiency scenarios (50% empty) and virgins WS coming from

a near location (50 km), with distances greater than 700 km, for GWPbio and GWP100 methods. The transportation efficiency influence is notable, almost 2.5 times greater for better efficiency scenarios. For a scenario of high transport efficiency (100% default), the use of recycled WS from distant locations (more than 1700 km) is still feasible from the point of view of the GHG emissions, considering the data used in the modeling.

Comparing the impact of WS origin, the recycled option is almost three times less impactful, considering the data used in this modeling. Most of the impact of virgin WS comes from the forest activities (for Brazilian electricity case – Fig. 10a), followed by electricity consumption for wood debarking, chipping, and screening process. When Chinese electricity is used instead of Brazilian, the share of electricity increases considerably (Fig. 10b) due to the higher GHG emissions related mainly to the big participation of coal generation in that country. Thus, by these findings, we can answer the fourth question that the use of recycled WS tend to be more advantageous in terms of GHG emissions when compared to virgin sources for WBC production, and this is a good alternative from the CE point of view, even considering long distances for waste WS.

The comparison between the virgin and recycled WS showed that electricity consumption is an important emissions source, even for the Brazilian electricity grid matrix. In a scenario with the efficiency improvement of the WS production process and/or renewable electricity production use, the application of virgin aggregate tends to become more competitive, especially in the Northern and Northeastern regions in Brazil, where transportation impacts are significant. However, this statement must be carefully interpreted. It is valid only if adequate forest and land use management are practiced, which is rarely the case in developing countries, such as Brazil.

4. Conclusions

In this study, the life cycle GHG emissions of two mixtures of wood bio-concretes (WBC) with different contents of wood shavings (WS) were evaluated under different scenarios, considering two methods for assessing biogenic CO2-emissions (GWPbio and GWP100). Based on our research and the premises adopted in the modeling, we want to highlight the main findings:

• The increase of WS content in WBC leads to a radical decrease in life cycle GHG emissions when the biogenic carbon is accounted for (in GWPbio method).

• For WBC production it is better to use waste WS than virgin sources due to lower GHG emissions in processing and omission of emissions in forest-related activities of the first alternative – adopting a zeroburden assumption for used waste WS.

• It is better to transport waste WS for more than 1700 km than to use virgin sources, assuming efficient transportation.

• If adopting the allocation of environmental burdens to waste WS, the mass allocation can increase the life cycle GHG emissions of WBC production, reaching an increment of 37% when the GWPbio method is used.

• The electricity consumption for the WS recycling and treatment process can have an important role in life cycle GHG emissions, especially in countries with a GHG intensive matrix, e.g., China.

• WS transportation distances can be a critical aspect for the development of a circular bio-concrete, especially for a scenario with low efficiency of transportation (considering the capacity and if the truck returns empty or carried).

We conclude that wood waste can be considered a CO2 sink when used to produce WBC and can be an interesting strategy for the production of low carbon and circular materials in the concrete industry.

In addition, it is important to describe the main limitations of this study: firstly, some of the used databases are not adapted to the Brazilian context and can influence the final results; secondly, the type of modeling of biogenic carbon used here does not consider that some aspects, e.g., land use, were outside of the scope of the research; other kinds of allocation, such as system expansion, can also change the results. These limitations could be explored in future evaluations of other environmental impacts for WBC production and possible trade-offs.

Authorship contributions

Please indicate the specific contributions made by each author (list the authors’ initials followed by their surnames). The name of each author must appear at least once in each of the three categories below.

Category 1 Conception and design of study: L. R. Caldas, A.B. Saraiva, A. Lucena, R. D. Toledo Filho. acquisition of data: L. R. Caldas, M. Y. da Gloria. analysis and/or interpretation of data: L. R. Caldas, A.B. Saraiva, A. Lucena, M. Y. da Gloria, A. S. Santos, R. D. Toledo Filho.

Category 2 Drafting the manuscript: L. R. Caldas, A.B. Saraiva, A. Lucena. revising the manuscript critically for important intellectual content: L. R. Caldas, A.B. Saraiva, A. Lucena, M. Y. da Gloria, A. S. Santos, R. D. Toledo Filho.

Category 3 Approval of the version of the manuscript to be published (the names of all authors must be listed): L. R. Caldas, A.B. Saraiva, A. Lucena, M. Y. da Gloria, A. S. Santos, R. D. Toledo Filho.

Funding

We want to acknowledge the financial support from CNPq (National Council of Scientific and Technological Development - Brazil).

Declaration of Competing Interest

None.

Acknowledgments

We would like to acknowledge researchers Francesco Pittau and Guillaume Habert from ETH Zürich, Institut für Bau- und Infrastrukturmanagement, Chair of Sustainable Construction, for the previous discussion about the theme of LCA and bio-concretes. We want to thank the reviewers for their constructive comments that helped to improve the quality of the paper. Finally, we want to thank Katerina Dimitrova for the language review.

Supplementary materials

Supplementary material associated with this article can be found, in the online version, at doi:10.1016/j.resconrec.2020.105346

References

ABNT, 2014. NBR 6136. Rio de Janeiro, Brazil

Amziane, S., Sonebi, M., 2016. Overview on bio-based building material made with plant aggregate Overview on bio-based building material made with plant aggregate 31–38. RILEM Technical Letters, v. 1.

Arehart, J.H., Nelson, W.S., Srubar, W.V., 2020. On the theoretical carbon storage and carbon sequestration potential of hempcrete. J. Clean. Prod. 266, 121846 https:// doi.org/10.1016/j.jclepro.2020.121846

Arrigoni, A., Panesar, D.K., Duhamel, M., Opher, T., Saxe, S., Posen, I.D., MacLean, H.L., 2020. Life cycle greenhouse gas emissions of concrete containing supplementary cementitious materials: cut-off vs. substitution. J. Clean. Prod. 263, 121465 https:// doi.org/10.1016/j.jclepro.2020.121465

Cabeza, L.F., Rincon, L., Vilarino, V., Perez, G., Castell, A., 2014. Life cycle assessment (LCA) and life cycle energy analysis (LCEA) of buildings and the building sector : a review. Renew. Sustain. Energy Rev. 29, 394–416. https://doi.org/10.1016/j. rser.2013.08.037

Caldas, L.R., Gloria, M.Y., Santos, D.O.J., Andreola, V.M., Pepe, M., Toledo Filho, R.D., 2017. Carbon footprint of bamboo particles, rice husk and wood shavings-cement composites. 2nd Int. Conf. Bio-Based Build. Mater. RILEM 499–506

Caldas, L., Pittau, F., Andreola, V., Habert, G., Saraiva, A., Filho, R.T., 2019. In: Amziane, S. (Ed.). RILEM, pp. 593–599. Ed.

Caldas, L.R., Da Gloria, M.Y.R., Pittau, F., Andreola, V.M., Habert, G., Toledo Filho, R.D., 2020. Environmental impact assessment of wood bio-concretes: evaluation of the influence of different supplementary cementitious materials. Constr. Build. Mater., 121146 https://doi.org/10.1016/j.conbuildmat.2020.121146

Caldas, L.R., Sposto, R.M., 2017. Emissoes de CO 2 referentes ao transporte de materiais de construçao no Brasil: estudo comparativo entre blocos estruturais cer ˆ amicos e de concreto. Ambient. Construído 17, 91–108.

CEN, 2011. BS EN 15978:2011. Sustainability of construction works. Assessment of environmental performance of buildings. Calculation method. Pages: 64 ISBN: 978 0 580 77403 4.

Chen, C., Habert, G., Bouzidi, Y., Jullien, A., Ventura, A., 2010. Resources, Conservation and Recycling LCA allocation procedure used as an incitative method for waste recycling : an application to mineral additions in concrete. Resources, Conserv. Recycl 54, 1231–1240. https://doi.org/10.1016/j.resconrec.2010.04.001

Chen, S., Chen, B., Feng, K., Liu, Z., Fromer, N., Tan, X., Alsaedi, A., Hayat, T., Weisz, H., Schellnhuber, H.J., Hubacek, K., 2020. Physical and virtual carbon metabolism of global cities. Nat. Commun. 11, 1–11. https://doi.org/10.1038/s41467-019-137573

Colangelo, F., Navarro, T.G., Farina, I., Petrillo, A., 2020. Comparative LCA of concrete with recycled aggregates: a circular economy mindset in Europe. Int. J. Life Cycle Assess. 25, 1790–1804. https://doi.org/10.1007/s11367-020-01798-6

Gloria, Da, Mohammed, Toledo Filho, R, 2016. Influence of the wood shavings/cement ratio on the thermo-mechanical properties of lightweight wood shavings-cement based composites. In: 6th Amazon & Pacific Green Materials Congress Conference. Cali, pp. 365–374

Developers, G., 2018. Google maps documentation [WWW Document].

Dolezal, F., Hill, C.A.S., Escamilla, E.Z., 2017. i Forest. 10.3832/ifor2386-010.

Durao, V., Silvestre, J.D., Mateus, R., de Brito, J., 2020. Assessment and communication of the environmental performance of construction products in Europe: comparison between PEF and EN 15804 compliant EPD schemes. Resour. Conserv. Recycl. 156, 104703 https://doi.org/10.1016/j.resconrec.2020.104703.

Escamilla, E.Z., Habert, G., Wohlmuth, E., 2016. When CO 2 counts : sustainability assessment of industrialized bamboo as an alternative for social housing programs in the Philippines. Build. Environ. 103, 44–53. https://doi.org/10.1016/j. buildenv.2016.04.003

Ferro, F.S., Silva, D.A.L., Rocco Lahr, F.A., Argenton, M., Gonzalez-García, S., 2018. Environmental aspects of oriented strand boards production. A Brazilian case study. J. Clean. Prod. 183, 710–719. https://doi.org/10.1016/j.jclepro.2018.02.174

Foster, G., 2020. Circular economy strategies for adaptive reuse of cultural heritage buildings to reduce environmental impacts. Resour. Conserv. Recycl. 152, 104507 https://doi.org/10.1016/j.resconrec.2019.104507

Fouquet, M., Levasseur, A., Margni, M., Lebert, A., Lasvaux, S., Souyri, B., Buhe, C., Woloszyn, M., 2015. Methodological challenges and developments in LCA of low energy buildings: Application to biogenic carbon and global warming assessment. Build. Environ 90, 51–59

Fouquet, M., Levasseur, A., Margni, M., Lebert, A., Lasvaux, S., Souyri, B., Buh´ e, C., Woloszyn, M., 2015a. Methodological challenges and developments in LCA of low energy buildings: application to biogenic carbon and global warming assessment. Build. Environ. 90, 51–59. https://doi.org/10.1016/j.buildenv.2015.03.022

Gallego-Schmid, A., Chen, H.M., Sharmina, M., Mendoza, J.M.F., 2020. Links between circular economy and climate change mitigation in the built environment. J. Clean. Prod. 260, 121115 https://doi.org/10.1016/j.jclepro.2020.121115

Garcia, C.A., Hora, G., 2017. State-of-the-art of waste wood supply chain in Germany and selected European countries. Waste Manag 70, 189–197. https://doi.org/10.1016/j. wasman.2017.09.025.

Ghisellini, P., Ripa, M., Ulgiati, S., 2018. Exploring environmental and economic costs and benefits of a circular economy approach to the construction and demolition sector. A literature review. J. Clean. Prod. 178, 618–643. https://doi.org/10.1016/j. jclepro.2017.11.207

Goswein, V., Gonçalves, A.B., Silvestre, J.D., Freire, F., Habert, G., Kurda, R., 2018. Transportation matters – Does it? GIS-based comparative environmental assessment of concrete mixes with cement, fly ash, natural and recycled aggregates. Resour. Conserv. Recycl. 137, 1–10. https://doi.org/10.1016/j.resconrec.2018.05.021

Guest, G., Cherubini, F., Strømman, A.H., 2012. Global Warming Potential of Carbon Dioxide Emissions from Biomass Stored in the Anthroposphere and Used for Bioenergy at End of Life 17. 10.1111/j.1530-9290.2012.00507.x.

Henrique, P., Borges, R., Pacheco, L.S., 2014. Estudo comparativo da analise de ciclo de vida de concretos geopolimericos e de concretos a base de cimento Portland composto (CP II). Ambient Construído 14, 153–168

Hossain, M.U., Poon, C.S., 2018. Comparative LCA of wood waste management strategies generated from building construction activities. J. Clean. Prod. 177, 387–397. https://doi.org/10.1016/j.jclepro.2017.12.233

Hossain, M.U., Poon, C.S., Dong, Y.H., Xuan, D., 2018. Evaluation of environmental impact distribution methods for supplementary cementitious materials. Renew. Sustain. Energy Rev. 82, 597–608. https://doi.org/10.1016/j.rser.2017.09.048

Indústria Brasileira de Arvores, 2019. Anu´ ario Estatístico da IBA 2019. Ano Base 2018 Ip, K., Miller, A., 2012. Life cycle greenhouse gas emissions of hemp-lime wall constructions in the UK. Resour. Conserv. Recycl. 69, 1–9. https://doi.org/10.1016/ j.resconrec.2012.09.001

Jami, T., Karade, S.R., Singh, L.P., 2019. A review of the properties of hemp concrete for green building applications. J. Clean. Prod. 239, 117852 https://doi.org/10.1016/j. jclepro.2019.117852

Jarre, M., Petit-Boix, A., Priefer, C., Meyer, R., Leipold, S., 2020. Transforming the biobased sector towards a circular economy - What can we learn from wood cascading? For. Policy Econ 110, 101872. https://doi.org/10.1016/j.forpol.2019.01.017

Klein, D., Wolf, C., Schulz, C., Weber-Blaschke, G., 2016. Environmental impacts of various biomass supply chains for the provision of raw wood in Bavaria, Germany, with focus on climate change. Sci. Total Environ. 539, 45–60. https://doi.org/ 10.1016/j.scitotenv.2015.08.087

Lopez Ruiz, L.A., Roca Ramon, X, Gasso Domingo, S, 2020. The circular economy in the construction and demolition waste sector – A review and an integrative model approach. J. Clean. Prod. 248. https://doi.org/10.1016/j.jclepro.2019.119238

Luhar, S., Cheng, T.W., Luhar, I., 2019. Incorporation of natural waste from agricultural and aquacultural farming as supplementary materials with green concrete: a review. Compos. Part B Eng. 175, 107076 https://doi.org/10.1016/j. compositesb.2019.107076

Meyer, C., 2009. Cement & Concrete Composites The greening of the concrete industry. Cem. Concr. Compos. 31, 601–605. https://doi.org/10.1016/j. cemconcomp.2008.12.010

Nakic, D., 2018. Environmental evaluation of concrete with sewage sludge ash based on. LCA. Sustain. Prod. Consum. 16, 193–201. https://doi.org/10.1016/j. spc.2018.08.003.

Negishi, K., Lebert, A., Almeida, D., Chevalier, J., Tiruta-Barna, L., 2019. Evaluating climate change pathways through a building’s lifecycle based on Dynamic Life Cycle Assessment. Build. Environ. 164, 106377 https://doi.org/10.1016/j. buildenv.2019.106377

Ng, R., Shi, C.W.P., Tan, H.X., Song, B., 2014. Avoided impact quantification from recycling of wood waste in Singapore: an assessment of pallet made from technical wood versus virgin softwood. J. Clean. Prod. 65, 447–457. https://doi.org/10.1016/ j.jclepro.2013.07.053

Pantini, S., Giurato, M., Rigamonti, L., 2019. A LCA study to investigate resourceefficient strategies for managing post-consumer gypsum waste in Lombardy region (Italy). Resour. Conserv. Recycl. 147, 157–168. https://doi.org/10.1016/j. resconrec.2019.04.019

Penaloza, D., Erlandsson, M., Falk, A., 2016. Exploring the climate impact effects of increased use of bio-based materials in buildings 125, 219–226. 10.1016/j. conbuildmat.2016.08.041.

Pittau, F., Krause, F., Lumia, G., Habert, G., 2018. Fast-growing bio-based materials as an opportunity for storing carbon in exterior walls. Build. Environ. 129, 117–129. https://doi.org/10.1016/j.buildenv.2017.12.006

Ríos, H.C., 2009. Bambu – Guadua: Guadua Angustifolia Kunth, Bosques Naturales En Colombia y Plantaciones Comerciales en M´ exico, 1aed. ed

Rock, M., Ruschi Mendes Saade, M., Balouktsi, M., Nygaard, F., Birgisdottir, H., Frischknecht, R., Habert, G., Lützkendorf, T., 2019. Embodied GHG emissions of buildings – The hidden challenge for e ff ective climate change mitigation. Appl. Energy 258, 114107. https://doi.org/10.1016/j.apenergy.2019.114107

Rosse Caldas, L, Bernstad Saraiva, A, Andreola, V.M., Dias Toledo Filho, R., 2020. Bamboo bio-concrete as an alternative for buildings’ climate change mitigation and adaptation. Constr. Build. Mater. 263, 120652 https://doi.org/10.1016/j. conbuildmat.2020.120652

Ruggieri, G., Arrigoni, A., Pelosato, R., Meli, P., Sabbadini, S., Dotelli, G., 2017. Life Cycle Assessment of Natural Building materials : the Role of carbonation, Mixture Components and Transport in the Environmental Impacts of Hempcrete Blocks 149, pp. 1051–1061. https://doi.org/10.1016/j.jclepro.2017.02.161

Sinka, M., Van den Heede, P., De Belie, N., Bajare, D., Sahmenko, G., Korjakins, A., 2018. Comparative life cycle assessment of magnesium binders as an alternative for hemp concrete. Resour. Conserv. Recycl 133, 288–299. https://doi.org/10.1016/j. resconrec.2018.02.024

Santos, S., da Silva, P.R., de Brito, J., 2019. Self-compacting concrete with recycled aggregates – A literature review. J. Build. Eng. 22, 349–371. https://doi.org/ 10.1016/j.jobe.2019.01.001

Seto, K.E., Churchill, C.J., Panesar, D.K., 2017. Influence of fly ash allocation approaches on the life cycle assessment of cement-based materials. J. Clean. Prod. 157, 65–75. https://doi.org/10.1016/j.jclepro.2017.04.093

Shi, J., Zhou, J., Zhu, Q., 2019. Barriers of a closed-loop cartridge remanufacturing supply chain for urban waste recovery governance in China. J. Clean. Prod. 212, 1544–1553. https://doi.org/10.1016/j.jclepro.2018.12.114

Sinka, M., Korjakins, A., Bajare, D., Zimele, Z., Sahmenko, G., 2018a. Bio-based construction panels for low carbon development. Energy Procedia 147, 220–226. https://doi.org/10.1016/j.egypro.2018.07.063

Tellnes, L.G.F., Ganne-Chedeville, C., Dias, A., Dolezal, F., Hill, C., Escamilla, E.Z., 2017. Comparative assessment for biogenic carbon accounting methods in carbon footprint of products: a review study for construction materials based on forest products. i Forest Biogeosciences and Forestry. 248 10, 815–823. https://doi.org/10.3832/ ifor2386-010

Turk, J., Cotic, Z., Mladenovic, A., Sajna, A., 2015. Environmental evaluation of green concretes versus conventional concrete by means of LCA. Waste Manag 45, 194–205. https://doi.org/10.1016/j.wasman.2015.06.035

UN Environment and International Energy Agency, 2017. Towards a zero-emission, efficient, and resilient buildings and construction sector.

Zhang, Y., Luo, W., Wang, J., Wang, Y., Xu, Y., Xiao, J., 2019. A review of life cycle assessment of recycled aggregate concrete. Constr. Build. Mater. 209, 115–125. https://doi.org/10.1016/j.conbuildmat.2019.03.078

Another random document with no related content on Scribd: