Visit to download the full and correct content document: https://ebookmass.com/product/manufacturing-processes-for-engineering-materials-in -si-units-6th-ed-serope-kalpakjian/

More products digital (pdf, epub, mobi) instant download maybe you interests ...

Manufacturing Processes for Engineering Materials (5th Edition)-Solution Manual Serope Kalpakjian

https://ebookmass.com/product/manufacturing-processes-forengineering-materials-5th-edition-solution-manual-seropekalpakjian/

Manufacturing Engineering and Technology 7th Edition Serope Kalpakjian

https://ebookmass.com/product/manufacturing-engineering-andtechnology-7th-edition-serope-kalpakjian/

Shigley's Mechanical Engineering Design in SI Units (11th Ed.) 11th Edition Richard Budynas

https://ebookmass.com/product/shigleys-mechanical-engineeringdesign-in-si-units-11th-ed-11th-edition-richard-budynas/

Engineering Mechanics: Statics, SI Units, 15th Edition

Russell Hibbeler

https://ebookmass.com/product/engineering-mechanics-statics-siunits-15th-edition-russell-hibbeler/

Engineering Mechanics: Dynamics, SI Units 15th Edition

Russell Hibbeler

https://ebookmass.com/product/engineering-mechanics-dynamics-siunits-15th-edition-russell-hibbeler/

Thomas' Calculus in SI Units 14th Edition Hass

https://ebookmass.com/product/thomas-calculus-in-si-units-14thedition-hass/

Structural Analysis in SI Units 10th Edition Hibbeler

https://ebookmass.com/product/structural-analysis-in-siunits-10th-edition-hibbeler/

Introductory Chemistry, 7th Edition in SI Units Tro N.J.

https://ebookmass.com/product/introductory-chemistry-7th-editionin-si-units-tro-n-j/

Materials for Biomedical Engineering: Nanobiomaterials in Tissue Engineering 1st Edition Alina-Maria Holban

https://ebookmass.com/product/materials-for-biomedicalengineering-nanobiomaterials-in-tissue-engineering-1st-editionalina-maria-holban/

SIXTH EDITION IN SI

Serope Kalpakjian • Steven R. Schmid

Digital Resources for Students Your new textbook provides 12-month access to a companion Web site that includes several manufacturing videos.

Follow the instructions below to register for the companion Web site for Kalpakjian and Schmid’s Manufacturing Processes for Engineering Materials, Sixth Edition in SI Units.

1. Go to www.pearsonglobaleditions.com.

2. Enter the title of your textbook or browse by author name.

3. Click Companion Website.

4. Click Register and follow the on-screen instructions to create a login name and password.

ISSEPM-PRINK-WOVEN-SPITE-NADIR-RUNES Use the login name and password you created during registration to start using the online resources that accompany your textbook.

IMPORTANT: This prepaid subscription does not include access to the Pearson eText, which is available at www.plus.pearson.com for purchase.

This access code can only be used once. This subscription is valid for 12 months upon activation and is not transferable. If the access code has already been revealed it may no longer be valid.

For technical support, go to https://support.pearson.com/getsupport.

Manufacturing Processesfor Engineering Materials SIXTH EDITION INSIUNITS

SeropeKalpakjian

StevenR.Schmid

SIContributionsby K.S.VijaySekar

Product Management: Gargi Banerjee and K. K. Neelakantan

Content Strategy: Shabnam Dohutia, Aurko Mitra, and Shahana Bhattacharya

Product Marketing: Wendy Gordon, Ashish Jain, and Ellen Harris

Supplements: Bedasree Das

Production and Digital Studio: Vikram Medepalli, Naina Singh, and Niharika Thapa

Rights and Permissions: Rimpy Sharma and Akanksha Bhatti

Cover image: Shutterstock/sergua

Please contact https://support.pearson.com/getsupport/s/ with any queries on this content.

PearsonEducationLimited

KAO Two KAO Park Hockham Way Harlow CM17 9SR

United Kingdom

and Associated Companies throughout the world

VisitusontheWorldWideWebat: www.pearsonglobaleditions.com

© Pearson Education Limited 2023

The rights of Serope Kalpakjian and Steven R. Schmid to be identified as the authors of this work have been asserted by them in accordance with the Copyright, Designs and Patents Act 1988.

Authorized adaptation from the United States edition, entitledManufacturingProcessesforEngineeringMaterials, 6th Edition, ISBN 978-0-13-429055-3 by Serope Kalpakjian and Steven R. Schmid published by Pearson Education © 2017.

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted in any form or by any means, electronic, mechanical, photocopying, recording or otherwise, without either the prior written permission of the publisher or a license permitting restricted copying in the United Kingdom issued by the Copyright Licensing Agency Ltd, Saffron House, 6–10 Kirby Street, London EC1N 8TS. For information regarding permissions, request forms and the appropriate contacts within the Pearson Education Global Rights & Permissions department, please visit www.pearsoned.com/permissions/.

Many of the designations by manufacturers and seller to distinguish their products are claimed as trademarks. Where those designations appear in this book, and the publisher was aware of a trademark claim, the designations have been printed in initial caps or all caps.

The author and publisher of this book have used their best efforts in preparing this book. These efforts include the development, research, and testing of theories and programs to determine their effectiveness. The author and publisher make no warranty of any kind, expressed or implied, with regard to these programs or the documentation contained in this book. The author and publisher shall not be liable in any event for incidental or consequential damages with, or arising out of, the furnishing, performance, or use of these programs.

PEARSON and ALWAYS LEARNING are exclusive trademarks owned by Pearson Education, Inc. or its affiliates in the U.S. and/or other countries.

MATLAB® is a registered trademark of The MathWorks, Inc., 3 Apple Hill Drive, Natick, MA 01760-2098.

Unless otherwise indicated herein, any third-party trademarks that may appear in this work are the property of their respective owners and any references to third-party trademarks, logos or other trade dress are for demonstrative or descriptive purposes only. Such references are not intended to imply any sponsorship, endorsement, authorization, or promotion of Pearson’s products by the owners of such marks, or any relationship between the owner and Pearson Education, Inc. or its affiliates, authors, licensees, or distributors.

This eBook may be available as a standalone product or integrated with other Pearson digital products like MyLab and Mastering. This eBook may or may not include all assets that were part of the print version. The publisher reserves the right to remove any material in this eBook at any time.

ISBN 10 (print): 1-292-25438-6

ISBN 13 (print): 978-1-292-25438-8

ISBN 13 (uPDF eBook): 978-1-292-25441-8

British Library Cataloguing-in-Publication Data

A catalogue record for this book is available from the British Library

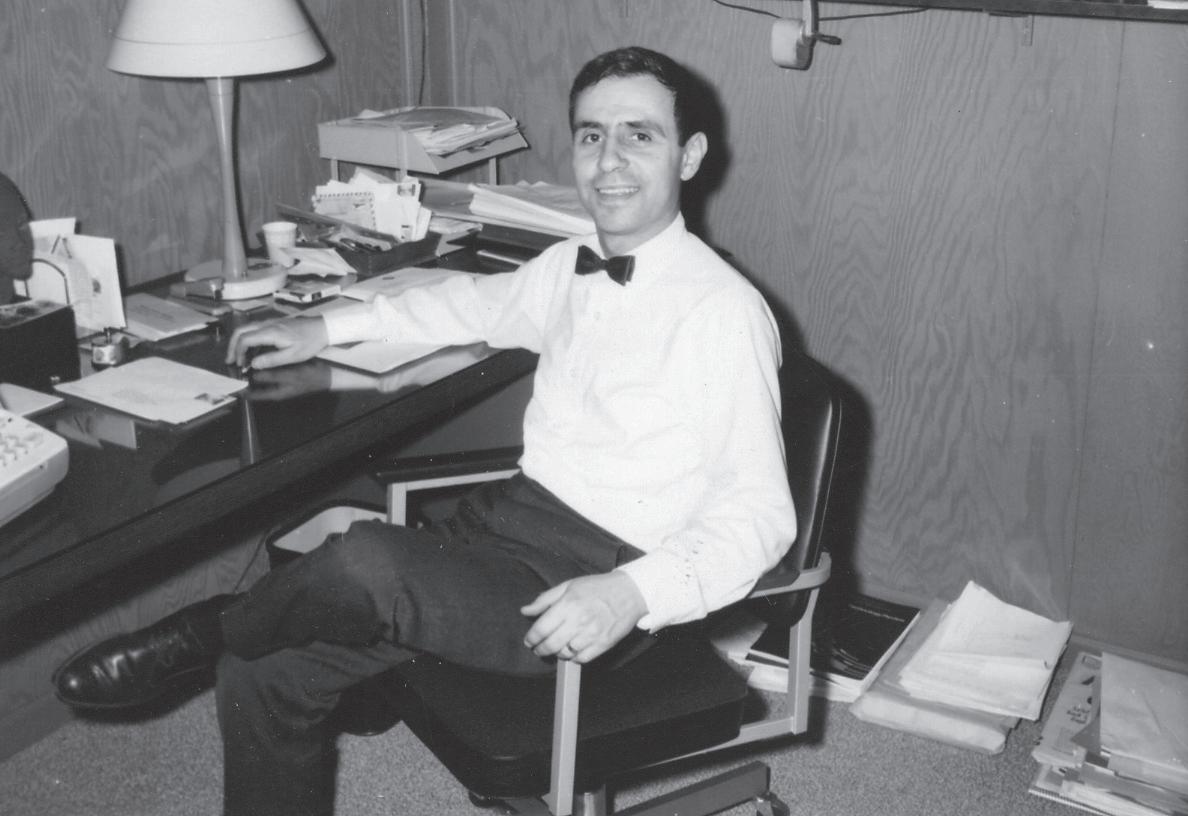

Dedication WhatcanbesaidaboutSeropeKalpakjian?

Heisagiantofmanufacturingresearch,publishing,andeducation. (“ButIamsosmall,”hewouldsay,“fartoosmalltobeagiant.”)

Hehaswrittentheworld’smostpopulartextbookforoverthreegenerationsandhashadmoreinfluenceontrainingengineersthananyone.He haswontheASMandSMEGoldMedals,indicatingthehighesteemthat professionalsocietiesholdforhim,yetheremainshumble.

Universallybeloved,Seropecanworkaroom,whetherit’sfilledwith engineers,scientists,philosophers,orpoets.(Nooneisperfect,hereminds us.)Everyoneishisfriend,justasheiseveryone’sfriend.

Heisaphenomenalspeaker.Iknowofnootherpersonthathasbeen askedtogivethecommencementaddressathisownuniversity.Hewas askedtogiveaFounder’sLectureatanNAMRCConference,andtoldhe couldspeakofwhateverhewished:hislifeasaprofessor,his40yearsof writing,hisdecadesofinnovativeteaching,hiscutting-edgeresearch;but heonlyhad30minutes.(“30minutes?I’lljustspeakslowly,”hesays.)

Heisadevotedhusbandandfather,interestedandinvolved.Hischildrenandgrandchildrenhaveexcelledinlife—thisisperhapsthegreatest measureofman.(“Ihatedthatheaskedmathquestionsatdinner,”complainshisdaughter—aprofessorattheUniversityofMichigan.)Always patientandcaring,heexcelledatadvisingstudentsandmentoringfaculty. Especiallycoauthors.Especiallyme.(“Bookauthorsmakemuchlessthan thosethatthrowaballforaliving,”helamented.)

Therearesomepeople,unfortunatelyaveryfew,thatyoumeetinyour lifethatyoutreasuretheircompanyandrealizethattheyaregenuinely great;peoplethathavealastinginfluenceonyourlife;peoplethatareyour life-longfriends.Therearesomepeoplethatyoucanholdasarole-model andnotbedisappointed.

That’sSerope.

Sincerely,

StevenSchmid

This page is intentionally left blank

AbouttheAuthors17 1 Introduction19

1.1WhatIsManufacturing?19

1.2ProductDesignandConcurrentEngineering25

1.3DesignforManufacture,Assembly,Disassembly,and Service28

1.4EnvironmentallyConsciousDesign,SustainableManufacturing,andProductLifeCycle30

1.5SelectingMaterials32

1.6SelectingManufacturingProcesses36

1.7Computer-IntegratedManufacturing40

1.8LeanProductionandAgileManufacturing42

1.9QualityAssuranceandTotalQualityManagement43

1.10ManufacturingCostsandGlobalCompetitiveness44

1.11GeneralTrendsinManufacturing46

2 FundamentalsoftheMechanicalBehavior ofMaterials48

2.1Introduction49

2.2Tension50

2.3Compression65

2.4Torsion68

2.5Bending70

2.6Hardness71

2.7Fatigue76

2.8Creep77

2.9Impact79

2.10ResidualStresses79

2.11YieldCriteria83

2.12WorkofDeformation90 Summary94Bibliography97Questions98 Problems100

3 StructureandManufacturingProperties ofMetals104 3.1Introduction104

3.2TheCrystalStructureofMetals105

3.3DeformationandStrengthofSingleCrystals107

3.4GrainsandGrainBoundaries113

3.5PlasticDeformationofPolycrystallineMetals116

3.6Recovery,Recrystallization,andGrainGrowth117

3.7Cold,Warm,andHotWorking119

3.8FailureandFracture119

3.9PhysicalProperties126

3.10GeneralPropertiesandApplicationsofFerrous Alloys131

3.11GeneralPropertiesandApplicationsofNonferrous MetalsandAlloys138 Summary152Bibliography153Questions154 Problems156

4

Tribology,Metrology,andProduct Quality157 4.1Introduction158

4.2SurfaceStructureandProperties158

4.3SurfaceTextureandRoughness160

4.4Tribology:Friction,Wear,andLubrication164

4.5SurfaceTreatments,Coatings,andCleaning176

4.6EngineeringMetrologyandInstrumentation189

4.7DimensionalTolerances195

4.8TestingandInspection196

4.9QualityAssurance199 Summary208Bibliography210Questions211 Problems212

5 CastingProcessesandHeat Treatment214 5.1Introduction214

5.2SolidificationofMetals215

5.3CastStructures222

5.4FluidFlowandHeatTransfer227

5.5MeltingPracticeandFurnaces235

5.6CastingAlloys237

5.7IngotCastingandContinuousCasting244

5.8Expendable-Mold,Permanent-PatternCasting Processes246

5.9Expendable-Mold,Expendable-PatternCasting Processes254

6 5.10Permanent-MoldCastingProcesses258

5.11HeatTreatment269

5.12DesignConsiderations280

5.13EconomicsofCasting289

Summary292Bibliography294Questions294 Problems296Design299

BulkDeformationProcesses302 6.1Introduction303

6.2Forging303

6.3Rolling328

6.4Extrusion349

6.5Rod,Wire,andTubeDrawing363

6.6Swaging373

6.7Die-ManufacturingMethods374

6.8DieFailures376

6.9EconomicsofBulkForming377

Summary380Bibliography383Questions383 Problems385Design390

7 SheetMetalProcesses391 7.1Introduction392

7.2SheetMetalCharacteristics392

7.3Shearing397

7.4BendingofSheetandPlate407

7.5MiscellaneousFormingProcesses420

7.6DeepDrawing437

7.7SheetMetalFormability448

7.8EquipmentforSheetMetalForming454

7.9DesignConsiderations455

7.10EconomicsofSheetMetalForming457

Summary460Bibliography462Questions462 Problems464Design466

8 MachiningProcesses468 8.1Introduction469

8.2MechanicsofChipFormation470

8.3ToolWearandFailure494

8.4SurfaceFinishandSurfaceIntegrity501

8.5Machinability504

8.6Cutting-ToolMaterials507

8.7CuttingFluids519

8.8High-SpeedMachining521

8.9CuttingProcessesandMachineToolsforProducing RoundShapes522

8.10CuttingProcessesandMachineToolsforProducing VariousShapes539

8.11MachiningandTurningCenters554

8.12VibrationandChatter560

8.13Machine-ToolStructures562

8.14DesignConsiderations563

8.15EconomicsofMachining565 Summary571Bibliography573Questions574 Problems578Design581

9 AbrasiveandOtherMaterialRemoval Processes583

9.1Introduction584

9.2Abrasives585

9.3BondedAbrasives587

9.4MechanicsofGrinding591

9.5Grinding-WheelWear598

9.6GrindingOperationsandMachines604

9.7FinishingOperations611

9.8Deburring616

9.9UltrasonicMachining617

9.10ChemicalMachining619

9.11ElectrochemicalMachining623

9.12ElectrochemicalGrinding625

9.13Electrical-DischargeMachining627

9.14High-Energy-BeamMachining633

9.15Water-Jet,AbrasiveWater-Jet,andAbrasive-Jet Machining636

9.16HybridMachiningSystems639

9.17DesignConsiderations640

9.18ProcessEconomics642 Summary646Bibliography648Questions648 Problems650Design652

10 PolymerProcessingandAdditive Manufacturing654

10.1Introduction655

10.2TheStructureofPolymers657

10.3Thermoplastics:BehaviorandProperties665

10.4Thermosets:BehaviorandProperties674

10.5Thermoplastics:GeneralCharacteristicsand Applications674

10.6Thermosets:GeneralCharacteristicsand Applications677

10.7High-TemperaturePolymers,ElectricallyConducting Polymers,andBiodegradablePlastics678

11 10.8Elastomers(Rubbers):GeneralCharacteristicsand Applications680

10.9ReinforcedPlastics681

10.10ProcessingofPlastics694

10.11ProcessingofPolymer-Matrix-ReinforcedPlastics715

10.12AdditiveManufacturing721

10.13DesignConsiderations737

10.14EconomicsofProcessingPlastics740

Summary744Bibliography747Questions747 Problems750Design752

PowderMetallurgyandProcessingof CeramicsandGlasses754 11.1Introduction755

11.2PowderMetallurgy755

11.3CompactionofMetalPowders761

11.4Sintering773

11.5SecondaryandFinishingOperations779

11.6DesignConsiderationsforPowderMetallurgy781

11.7EconomicsofPowderMetallurgy784

11.8Ceramics:Structure,Properties,andApplications786

11.9ShapingCeramics797

11.10Glasses:Structure,Properties,andApplications804

11.11FormingandShapingGlass806

11.12DesignConsiderationsforCeramicandGlass Products811

11.13GraphiteandDiamond811

11.14ProcessingMetal-MatrixandCeramic-Matrix Composites814

11.15ProcessingSuperconductors817

Summary819Bibliography821Questions822 Problems824Design825

12 JoiningandFasteningProcesses828 12.1Introduction828

12.2OxyfuelGasWelding831

12.3ArcWeldingProcesses:ConsumableElectrode833

12.4ArcWeldingProcesses:NonconsumableElectrode842

12.5HighEnergyBeamWelding845

12.6Cutting847

12.7TheFusionWeldedJoint849

12.8ColdWelding861

12.9UltrasonicWelding862

12.10FrictionWelding863

12.11ResistanceWelding866

13 12.12ExplosionWelding872

12.13DiffusionBonding873

12.14BrazingandSoldering875

12.15AdhesiveBonding883

12.16MechanicalFastening889

12.17JoiningNonmetallicMaterials891

12.18DesignConsiderationsinJoining894

12.19EconomicConsiderations898

Summary901Bibliography903Questions903 Problems906Design907

Micro-andNanomanufacturing909 13.1Introduction909

13.2CleanRooms914

13.3SemiconductorsandSilicon915

13.4CrystalGrowingandWaferPreparation917

13.5FilmsandFilmDeposition919

13.6Oxidation921

13.7Lithography923

13.8Etching931

13.9DiffusionandIonImplantation943

13.10MetallizationandTesting944

13.11WireBondingandPackaging947

13.12YieldandReliabilityofChips953

13.13PrintedCircuitBoards954

13.14Roll-to-RollPrintingofFlexibleElectronics956

13.15MicromachiningofMEMSDevices958

13.16LIGAandRelatedMicrofabricationProcesses969

13.17SolidFreeformFabricationofDevices976

13.18MesoscaleManufacturing976

13.19NanoscaleManufacturing977 Summary982Bibliography983Questions983 Problems985Design986

14 AutomationofManufacturingProcesses andOperations988 14.1Introduction988

14.2Automation990

14.3NumericalControl997

14.4ProgrammingforNumericalControl1003

14.5AdaptiveControl1004

14.6MaterialHandlingandMovement1008

14.7IndustrialRobots1010

14.8SensorTechnology1016

14.9FlexibleFixturing1020

14.10Assembly,Disassembly,andService1023

14.11DesignConsiderations1026

14.12EconomicConsiderations1029

Summary1030Bibliography1031Questions1032 Problems1033Design1034

15 Computer-IntegratedManufacturing Systems1035 15.1Introduction1035

15.2ManufacturingSystems1036

15.3Computer-IntegratedManufacturing1037

15.4Computer-AidedDesignandEngineering1040

15.5Computer-AidedManufacturing1047

15.6Computer-AidedProcessPlanning1047

15.7ComputerSimulationofManufacturingProcessesand Systems1050

15.8GroupTechnology1051

15.9CellularManufacturing1059

15.10FlexibleManufacturingSystems1061

15.11HolonicManufacturing1064

15.12Just-in-TimeProduction1065

15.13LeanManufacturing1067

15.14CommunicationsNetworksinManufacturing1069

15.15ArtificialIntelligenceinManufacturing1072 Summary1075Bibliography1076Questions1076 Problems1078Design1078

16 CompetitiveAspectsofProductDesign andManufacturing1079 16.1Introduction1079

16.2ProductDesignandRobustDesign1081

16.3ProductQualityasaManufacturingGoal1085

16.4Life-CycleAssessmentandSustainable Manufacturing1094

16.5EnergyConsumptioninManufacturing1096

16.6SelectionofMaterialsforProducts1100

16.7SubstitutionofMaterialsinProducts1104

16.8CapabilitiesofManufacturingProcesses1105

16.9SelectionofManufacturingProcesses1108

16.10ManufacturingCostsandCostReduction1110 Summary1114Bibliography1115Questions1115 Problems1116Design1117

AnswerstoSelectedProblems1119

This page is intentionally left blank

Preface Manufacturinghasundergonearebirthinitsdevelopmentandresearch activitiessincethemid-2000s.Withtherecognitionthatmanufacturing addsvaluetonationaleconomies,governmentsaroundtheworldhave beeninvestingintheirinfrastructure,andarenowpartneringwithindustry tobringnewmanufacturingcapabilitiestothemarketplace.

Inviewoftheadvancesmadeinallaspectsofmanufacturing,the authorshavecontinuedtopresentcomprehensive,balancedand,most importantly,up-to-datecoverageofthescience,engineering,andtechnologyofmanufacturingprocessesandoperations.Asintheprevious editions,thistextmaintainsthesamenumberofchapterswhilecontinuingtoemphasizetheinterdisciplinarynatureofallmanufacturing activities,includingthecomplexinteractionsamongmaterials,design,and manufacturingprocesses.

Everyattempthasbeenmadetomotivateandchallengestudentsto understandanddevelopanappreciationofthevitalimportanceofmanufacturinginthemodernglobaleconomy.Theextensivequestionsand problems,attheendofeachchapter,aredesignedtoencouragestudentstoexploreviablesolutionstoawidevarietyofchallenges,giving themanopportunitytoassessthecapabilitiesaswellaslimitationsof allmanufacturingprocessesandoperations.Thesechallengesincludeeconomicconsiderationsandthecompetitiveaspectsinaglobalmarketplace. Thenumerousexamplesandcasestudiesthroughoutthebookalsohelp givestudentsaperspectiveonthereal-worldapplicationsofthetopics describedinthebook.

What’sNewinThisEdition • Thetexthasbeenthoroughly updated withnumerousnewmaterials andillustrationsrelevanttoallaspectsofmanufacturing.

• Amajoradditiontothisrevisedtextistheintroductionof QRcodes Recognizingtheproliferationofsmartphonesandtablets,andthe inherentInternetbrowsingcapabilityinthesedevices,thereareQR codesthatprovideareadilyavailablevideoinsightintorealmanufacturingoperations.(PleasenotethatusersmustdownloadaQR codereaderontheirsmartdevice;dataandroamingchargesmayalso apply.)

• Eachchapternowbeginswitha listofvariables forthetopicscovered inthatchapter.

• Whereverappropriate, illustrationsandexamples havebeenreplaced toindicate recentadvances inmanufacturing.

• Thetextcontainsmorecross-referencestootherrelevantsections, tables,andillustrationsinthebook.

• TheQuestions,Problems,andDesignproblemsattheendofeach chapterhavebeensignificantly expanded.

• The Bibliographies attheendofeachchapterhavebeenthoroughly updated.

• A SolutionsManual,availableforusebyinstructors,hasbeen expanded;itnowprovides MATLABcode fornumerousproblems, allowinginstructorstoeasilychangetherelevantparameters.

Thefollowingaretheneworexpandedtopicsinthisedition:

Chapter Topics 1

2

3

4

5

6

7

8

9

10

11

12

13

Economicmultiplier;technologyreadinesslevel;acasestudy onthree-dimensionalprintingofguitars;expansionofgeneral trendsinmanufacturing.

Leebhardnesstest;expansionofflowstressdescription.

Advancedhigh-strengthsteels;thirdgenerationsteels;expansionofdiscussiononmagnesium,chromium,andrare-earth metals.

Environmental-friendlylubricants;validationofproductsand processes.

Stripcasting;moldablation;designofribsincastings;computer modelingofcasting;acasestudy.

Servopresses;electricallyassistedforging;theHall–Héroult process;acasestudyontheproductionofaluminumfoil.

Single-pointincrementalforming;ageforming;hotstamping.

Expansionoftool-conditionmonitoring;throughthecuttingtoolcooling.

Expansionoflasermachining;blue-arcmachining;lasermicrojet;hybridmachiningsystems.

Electricallyconductivepolymers;big-areaadditivemanufacturing;laser-engineerednetshaping;frictionstirmodeling;the MakerMovement;designforadditivemanufacturing.

Expansionofmetalinjectionmolding;dynamiccompactionof powders;combustionsynthesis;pseudo-isostaticpressing;roll densification;graphene.

Expansionoffrictionwelding;acasestudyonBlisks.

Wafer-scaleintegration;three-dimensionalcircuits;cleanrooms; immersionlithography;pitchsplitting;chiponboard;systemin-package;roll-to-rollprinting,includingsilvernanoparticles, inks,inkjetprinting,gravure,flexographic,andscreenprinting; theMolTunprocess;photonicintegratedcircuits.

14 Intelligentrobotsandcobots;smartsensors;sensorvalidation.

15 ERP,ERP-II,andMES;manufacturingcelldesign;expansion ofleanmanufacturing;developmentsincommunications;the InternetofThings;BigData;cloudstorage;cloudcomputing.

16

Energyconsumptioninmanufacturing;processenergydemand andeffectsofworkpiecematerials.

Acknowledgments Wegratefullyacknowledgebelowindividualsfortheircontributionsto varioussectionsinthebook,aswellasfortheirreviews,comments,and constructivesuggestionsinthisrevision.

Wearehappytopresentbelowaslistofthoseindividuals,inacademic institutionsaswellasinindustrialandresearchorganizationswho,inone wayoranother,havemadevariouscontributionstothisandtherecent editionsofthisbook.KentM.Kalpakjian,MicronTechnology,Inc.,was theoriginalauthorofthesectionsonthefabricationofmicroelectronic devices.

D.Adams

G.Boothroyd

D.Bourell

J.Cesarone

A.Cinar

D.A.Dornfeld

M.Dugger

D.R.Durham

M.Giordano

M.Hawkins

K.Jones

R.Kassing

K.Kozlovsky

K.M.Kulkarni

M.Madou

H.Malkani

M.Molnar

S.Mostovoy

C.Nair

P.G.Nash

J.Neidig

C.Petronis

M.Prygoski

R.Shivpuri

K.S.Smith

B.S.Thakkar

J.E.Wang

K.R.Williams

P.K.Wright

Wewouldalsoliketoacknowledgethededicationandcontinuedhelp andcooperationofoureditor,HollyStark,andErinAult,Content Producer.

Wearegratefultomanyorganizationsthatsupplieduswithnumerous illustrations,videos,andvariousmaterialsforthetext.Thesecontributionshavespecificallybeenacknowledgedthroughoutthetext.

SeropeKalpakjian StevenR.Schmid

AcknowledgmentsfortheGlobalEdition PearsonwouldliketoacknowledgeandthankthefollowingfortheGlobal Edition:

Contributor

K.S.VijaySekar graduatedfromtheUniversityofMadras,Chennai,with aBachelor’sinProductionEngineeringandaMaster’sinComputer-aided Design.HecompletedhisPhDinMechanicalEngineeringfromAnna University,Chennai,specializinginfiniteelementanalysisinmachining. Hehasovertwenty-fiveyearsofteachingexperienceandmorethanfifteenyearsofresearchexperience.Hisareasofresearchinterestinclude materials,materialsprocessing,andapplicationoffiniteelementsin manufacturing.

Atpresent,heisaprofessorandtheHeadoftheDepartmentofMechanicalEngineeringatSriSivasubramaniyaNadarCollegeofEngineering (SSNCE),Kalavakkam,TamilNadu,India.

Reviewers

K.Baxevanakis,LoughboroughUniversity Ü.Chatwin,UniversityofSussex X.Song,TheChineseUniversityofHongKong

AbouttheAuthors SeropeKalpakjian isprofessoremeritusofmechanicalandmaterials engineeringattheIllinoisInstituteofTechnology.Heistheauthorof MechanicalProcessingofMaterials andco-authorof Lubricantsand LubricationinMetalworkingOperations (withE.S.Nachtman);both ofthefirsteditionsofhistextbooks ManufacturingProcessesforEngineeringMaterials and ManufacturingEngineeringandTechnology have receivedtheM.EugeneMerchantManufacturingTextbookAward.He hasconductedresearchinvariousareasofmanufacturing,istheauthorof numeroustechnicalpapersandarticlesinhandbooksandencyclopedias, andhaseditedseveralconferenceproceedings.Healsohasbeeneditor andco-editorofvarioustechnicaljournalsandhasservedontheeditorial boardofEncyclopediaAmericana.

Amongotherawards,ProfessorKalpakjianhasreceivedtheForging IndustryEducationalandResearchFoundationBestPaperAward,the ExcellenceinTeachingAwardfromlIT,theASMECentennialMedallion, theInternationalEducationAwardfromSME,APersonoftheMillennium AwardfromlIT;theAlbertEastonWhiteOutstandingTeacherAward fromASMInternational,andthe2016SMEGoldMedal.TheOutstandingYoungManufacturingEngineerAward,bySME,in2001,wasnamed afterhim.ProfessorKalpakjianisaLifeFellowASME,FellowSME, FellowandLifeMemberASMInternational,FellowEmeritustheInternationalAcademyforProductionEngineering(CIRP),andisafounding memberandpastpresidentofNAMRI.HeisagraduateofRobertCollege(HighHonor,Istanbul),HarvardUniversity,andtheMassachusetts InstituteofTechnology.

StevenR.Schmid isprofessorofAerospaceandMechanicalEngineering attheUniversityofNotreDame,whereheteachesandconductsresearch inthegeneralareasofmanufacturing,machinedesign,andtribology. HereceivedhisB.S.degreefromIllinoisInstituteofTechnology(with Honors)andMaster’sandPh.D.degreesfromNorthwesternUniversity, allinmechanicalengineering.Hehasreceivednumerousawards,including theJohnT.ParsonsAwardfromSME,theNewkirkAwardfromASME, theKanebCenterTeachingAward(threetimes),andtheRuthandJoel SpiraAwardforExcellenceinTeaching.

ProfessorSchmidservedasthePresidentoftheNorthAmericanManufacturingResearchInstitution(NAMRI,2015–2016)andwasappointed thefirstAcademicFellowattheAdvancedManufacturingNational ProgramOffice,USDepartmentofCommerce,wherehehelpeddesign theNationalNetworkforManufacturingInnovation.Startingin2016,he willserveastheProgramDirectorfortheManufacturingMachinesand EquipmentprogramattheNationalScienceFoundation.Dr.Schmidisthe authorofover140technicalpapers,andhasco-authoredthetexts FundamentalsofMachineElements, FundamentalsofFluidFilmLubrication, and ManufacturingEngineeringandTechnology

This page is intentionally left blank

Theobjectivesofthischapterare:

• Definemanufacturinganddescribethetechnicalandeconomicconsiderations involvedinmanufacturingsuccessfulproducts.

• Explaintherelationshipsamongproductdesignandengineeringandfactorssuch asmaterialsandprocessesselectionandthevariouscostsinvolved.

• Describetheimportanttrendsinmodernmanufacturingandhowtheycanbe utilizedinahighlycompetitiveglobalmarketplacetominimizeproductioncosts.

1.1 WhatIsManufacturing? AsyoureadthisIntroduction,takeafewmomentstoinspectvarious objectsaroundyou:pencil,paperclip,laptopcomputer,bicycle,and smartphone.Youwillnotethattheseobjectshavebeentransformedfrom variousrawmaterialsintoindividualpartsandthenassembledintospecific products.Someobjects,suchasnails,bolts,andpaperclips,aremadeof onematerial;thevastmajorityofproductsare,however,madeofnumerouspartsfromawidevarietyofmaterials(Fig.1.1).Aball-pointpen,for example,consistsofaboutadozenparts,alawnmowerabout300parts, agrandpianoabout12,000parts,atypicalautomobileabout15,000 parts,andaBoeing787about2.3millionparts.Allareproducedbya combinationofprocesses,calledmanufacturing.

Manufacturing istheprocessofconvertingrawmaterialsintoproducts; itencompassesthedesignandmanufacturingofgoodsusingvariousproductionmethodsandtechniques.Manufacturingbeganduring5000to 4000 b.c. withtheproductionofvariousarticles,suchaspottery,knives andtools,fromwood,clay,stone,andmetal(Table1.1).Theword manufacturing isderivedfromtheLatin manu and factus,meaningmadeby hand;theword manufacture firstappearedin1567,andtheword manufacturing,in1683.Theword production isalsousedinterchangeablywith thewordmanufacturing.

FIGURE1.1 JohnDeeretractorshowingthevarietyofmaterialsandprocesses incorporated. Source: Shutterstock/NilsVersemann.

Manufacturingmayproduce discreteproducts,meaningindividual parts,suchasnails,rivets,bolts,andsteelballs.Ontheotherhand,wire, sheetmetal,tubing,andpipeare continuousproducts,thatmaythenbe cutintoindividualpiecesandthusbecomediscreteproducts.

Becauseamanufactureditemhasundergoneanumberofchanges wherebyrawmaterialhasbecomeaspecificandusefulproduct,ithas addedvalue,definedbyitsmonetaryworth.Clay,forexample,hasacertainvalueasmined;whentheclayisusedtomakeaceramicdinnerplate,a cuttingtool,oranelectricalinsulator,valueisaddedtotheclay.Similarly, awirecoathangerhasaddedvalueoverandabovethecostofapieceof wirefromwhichitismade.

Manufacturingisextremelyimportantfornationalandglobaleconomies.ConsiderFig.1.2,whichshowstheeconomicmultiplierofdifferentsectorsintheUSeconomy.Theeconomicmultiplierindicatesthe amountofgeneralactivityintheeconomygeneratedfromonedollar ofactivityinagivensector.Notethatmanufacturinghasamultiplier over1.5,andthatitishigherthananyothersectorintheeconomy.This higheconomicmultiplierhasanumberofimplications,including:

1. Thewealthofacountryiscloselytiedtothelevelofitsmanufacturing activity,especiallyinadvancedmanufacturingorhighvalue-added processes.

Economicmultiplierfor differentsectorsoftheUSEconomy. Source: USDept.ofCommerce.

2. Althoughtheemergenceofglobaleconomiesisoftenperceivedas detrimentalinthemedia,globaltradingleadstoanincreaseinthe wealthofeachparticipatingnation,duetotheeconomicmultipliereffect.However,totakeadvantageofthismultiplier,avibrant manufacturingsectorisessential.

3. NationswithlargeGrossDomesticProduct(GDP)growthhave theireconomicactivityconcentratedonhighvalue-addedproducts, suchasautomobiles,airplanes,medicaldevices,computers,electronics,andvariousmachinery.Otherproducts,suchasclothing, toys,andhand-heldtools,arelabor-intensiveandthusaregenerally concentratedincountrieswherelaborratesarelower.

4. Nationswherelaborratesarehighcanstillcompetebytheapplicationofautomationandbycontinuousimprovementsinworker productivity.

Manufacturingisacomplexactivity,involvingpeoplewhohaveabroad rangeofdisciplinesandskills,togetherwithawidevarietyofmachinery, equipment,andtoolswithvariouslevelsofautomationandcontrols,such ascomputers,robots,andmaterial-handlingequipment.Manufacturing activitiesmustberesponsivetoseveraldemandsandtrends:

1. Aproductmustfullymeet designrequirements, specifications,and standards

2. Itmustbemanufacturedbythemost economical and environmentallyfriendly methods.

3. Quality mustbe builtintotheproduct ateachstage,fromdesignto assembly,ratherthanrelyingonqualitytestingaftertheproductis made.

4. Inahighlycompetitiveandglobalenvironment,productionmethods mustbesufficiently flexible torespondtoconstantlychangingmarket demands,typesofproducts,productionratesandquantities,and ontimedelivery tothecustomer.

Economic multiplier in US Dollars

FIGURE1.2

Historicaldevelopmentofmaterialsandmanufacturingprocesses.

TABLE1.1

Tools,machining,

Formingand andmanufacturing

Joining systems

Toolsofstone,flint, wood,bone,ivory, compositetools

Corundum(alumina, emery)

Soldering(Cu-Au, Cu-Pb,Pb-Sn)

Hoemaking, hammeredaxes,tools forironmakingand carpentry

Riveting,brazing

Various

Metalsand materialsand

Dates casting composites shaping

Hammering

Earthenware, glazing,natural fibers

Stamping,jewelry

Improvedchisels, saws,files, woodworkinglathes

Forgeweldingof ironandsteel, gluing

Etchingofarmor

Sandpaper, windmill-drivensaw

Handlatheforwood

Boring,turning, screw-cuttinglathe, drillpress

Period

Before4000b.c. Gold,copper, meteoriciron

Coppercasting, stoneandmetal molds,lost-wax process,silver,lead, tin,bronze

4000–3000b.c.

Wirebyslittingsheet metal

Glassbeads,potter’s wheel,glassvessels

3000–2000b.c. Bronzecastingand drawing,goldleaf

2000–1000b.c. Wroughtiron,brass

Stampingofcoins

Glasspressingand blowing

1000–1b.c. Castiron,caststeel

RomanEmpire: ∼ 500b.c.to476a.d.

Greece: ∼ 1100b.c.to ∼ 146b.c.

Egypt: ∼ 3100b.c.to ∼ 300b.c.

Armor,coining, forging,steelswords

Wiredrawing,gold- andsilversmithwork

Waterpowerfor metalworking, rollingmillfor coinagestrips

Rolling(lead,gold, silver),shaperolling (lead)

Venetianglass

Crystalglass

Castplateglass,flint glass

Porcelain

1–1000a.d. Zinc,steel

Blastfurnace,type metals,castingof bells,pewter

Cast-ironcannon, tinplate

1000–1500

1500–1600

Permanent-mold casting,brassfrom copperandmetallic zinc

1600–1700

Renaissance:14thto16thcenturies

MiddleAges: ∼ 476to1492

Shaping,milling, copyinglathefor gunstocks,turretlathe, universalmilling machine,vitrified grindingwheel

Gearedlathe, automaticscrew machine,hobbing, high-speedsteeltools, aluminumoxide,and siliconcarbide (synthetic)

Oxyacetylene;arc, electrical-resistance, andthermitwelding

Extrusion(leadpipe), deepdrawing,rolling

Steamhammer,steel rolling,seamlesstube, steel-railrolling, continuousrolling, electroplating

Windowglassfrom slitcylinder,lightbulb, vulcanization,rubber processing,polyester, styrene,celluloid, rubberextrusion, molding

Malleablecastiron, cruciblesteel(ironbars androds)

Centrifugalcasting, Bessemerprocess, electrolyticaluminum, nickelsteel,babbitt, galvanizedsteel,powder metallurgy,open-hearth steel

Tuberolling,hot extrusion

Automaticbottle making,bakelite, borosilicateglass

Tungstencarbide,mass production,transfer machines

Coatedelectrodes

Tungstenwirefrom metalpowder

Developmentof plastics,casting, molding,polyvinyl chloride,cellulose acetate,polyethylene, glassfibers

Phosphateconversion coatings,totalquality control

Submergedarc welding

Extrusion(steel), swaging,powder metalsforengineering parts

Acrylics,synthetic rubber,epoxies, photosensitiveglass

Electricalandchemical machining,automatic control.

Gasmetalarc,gas tungstenarc,and electroslagwelding; explosionwelding

Coldextrusion(steel), explosiveforming, thermochemical processing

Acrylonitrile-butadiene- styrene,silicones, fluorocarbons, polyurethane,float glass,temperedglass, glassceramics

( continued )

1700–1800

1800–1900

1900–1920

Diecasting

1920–1940

Lost-waxprocessfor engineeringparts

1940–1950

Ceramicmold,nodular iron,semiconductors, continuouscasting

1950–1960

Historicaldevelopmentofmaterialsandmanufacturingprocesses( continued ).

TABLE1.1

Tools,machining,

Formingand andmanufacturing

Joining systems

Titaniumcarbide, syntheticdiamond, numericalcontrol, integratedcircuitchip

Plasma-arcand electron-beam welding,adhesive bonding

Cubicboronnitride, coatedtools,diamond turning,ultraprecision machining, computer-integrated manufacturing, industrialrobots, machiningandturning centers,flexible manufacturing systems,sensor technology, automatedinspection, computersimulation andoptimization

Laserbeam, diffusionbonding (alsocombined withsuperplastic forming), surface-mount soldering

Various

Metalsand materialsand

shaping

Hydroforming, hydrostatic extrusion, electroforming

casting composites

Acetals, polycarbonate,cold formingofplastics, reinforcedplastics, filamentwinding

Squeezecasting, single-crystalturbine blades

Dates

1960–1970

Period

Precisionforging, isothermalforging, superplastic forming,diesmade bycomputer-aided designand manufacturing, net-shapeforging andforming, computer simulation

Adhesives,composite materials, semiconductors, opticalfibers, structuralceramics, ceramic- matrixcomposites, biodegradable plastics,electrically- conducting polymers

Compactedgraphite, vacuumcasting, organically-bonded sand,automationof moldingandpouring, rapidsolidification, metal-matrix composites,semi-solid metalworking, amorphousmetals, shape-memoryalloys

1970–1990

Micro-and nanofabrication, LIGA,dryetching, linearmotordrives, artificialneural networks,SixSigma

Frictionstir welding,lead-free solders,laser butt-welded (tailored) sheet-metalblanks

Additive manufacturing, rapidtooling, environmentally- friendly metalworkingfluids

Nanophasematerials, metalfoams, high-temperature superconductors, machinableceramics, diamond-likecarbon

Rheocasting, computer-aideddesign ofmoldsanddies, rapidtooling

1990–2000

Digitalmanufacturing, three-dimensional computerchips, blue-arcmachining, softlithography, flexibleelectronics

Linearfriction welding

Singlepoint incremental forming,hot stamping, electricallyassisted forming

Carbonnanotubes, graphene

TRIPandTWIPsteels

2000–2010s

5. Newdevelopmentsin materials,productionmethods, and computerintegration ofbothtechnologicalandmanagerialactivitiesmust constantlybeevaluatedwithaviewtotheirtimelyandeconomic implementation.

6. Manufacturingactivitiesmustbeviewedasalarge system,each partofwhichisinterrelated.Suchsystemscanbemodeledinorder tostudytheeffectofvariousfactors,suchaschangesinmarket demand,productdesign,materials,costs,andproductionmethods, onproductqualityandcost.

7. Amanufacturermustworkwiththecustomerfortimelyfeedbackfor continuousproductimprovement

8. Globalsourcing ofcomponentsandproductsrequiresadherenceto qualitysystems,andthemanagementofglobalsupplychains.

9. Amanufacturingorganizationmustconstantlystrivefor higherproductivity,definedastheoptimumuseofallitsresources:materials, technology,machines,energy,capital,andlabor.

1.2 ProductDesignandConcurrentEngineering Productdesign isacriticalactivitybecauseithasbeenestimatedthat,generally,70to80%ofthecostofproductdevelopmentandmanufacture, aswellasenvironmentalimpactandenergyconsumption,aredetermined atthe initial stagesofproductdesign.Thedesignprocessforaparticular productfirstrequiresaclearunderstandingofthefunctionsandtheperformanceexpectedofthatproduct.Theproductmaybeneworitmay beanimprovedmodelofanexistingproduct.Themarketfortheproduct anditsanticipatedusesmustbedefinedclearly,withtheassistanceofsales personnel,marketanalysts,andothersintheorganization.

ProductdevelopmentgenerallyfollowstheflowoutlinedinTable1.2. TechnologyReadinessLevel (TRL)and ManufacturingReadinessLevel (MRL)aremeasuresofaproduct’sabilitytobeproduced,marketed,and sold.Inpractice,alltechnologiesmustprogressfromsomestartingpoint uptoaTRLandMRLof9.Anewscientificdiscoveryorproductidea beginsataTRLof1anditmayormaynoteverbesuitableforcommercial application.Newversionsofexistingproductsmaystartatsomehigher TRLorMRLlevel,buttheflowofdevelopmentisalwaysthesame.

Notethateachstageofaproductdevelopmentgenerallyrequiresdifferentskillsandresources.Demonstratinganewconceptinalaboratory environment(TRL3)anddemonstratingtheconceptinanewsystemina realenvironment(TRL7)areverydifferenttasks.Similarly,producinga laboratoryprototype(MRL4)isverydifferentfromdemonstratingmanufacturingstrategiesforproducingaproductatscale(MRL7),whichis alsoverydifferentfromhavingaproductionfacilityinplace.

AnotherproposedproductdevelopmentprocessisshowninFig.1.3; itstillhasageneralproductflow,frommarketanalysistodesignand tomanufacturing,butitcontainsdeliberateiterations.Also,whilenot shownexplicitly,itisrecognizedthatalldisciplinesareinvolvedinthe earlieststagesofproductdesign.Theyprogressconcurrently,sothat theiterations(which,bynature,occurfromdesignchangesordecisions

FIGURE1.3 General productflow,frommarket analysistosellingthe product,anddepicting concurrentengineering.

Source: AfterS.Pugh.

productionrelevantenvironment 6 System/subsystemmodelorprototype demonstrationinarelevantenvironment

subsysteminaproductionrelevantenvironment 7 Systemprototypedemonstrationinan operationalenvironment

8 Actualsystemcompletedandqualified throughtestanddemonstration

9 Actualsystemproventhroughsuccessful missionoperations

componentsinaproductionrepresentative environment

lowrateinitialproduction

placetobeginfullrateproduction

betweenalternatives)resultinlesswastedeffortandlosttime.Akeytothis approachisthewell-recognizedimportanceof communication amongand withindifferentdisciplines.Whiletheremustbecommunicationamong engineering,marketing,andservicefunctions,theremustalsobeavenues ofinteractionbetweenengineeringsub-disciplines,suchasdesignformanufacture,designforrecyclability,anddesignforsafety.

Concurrentengineering,alsocalled simultaneousengineering,isasystematicapproachintegratingthedesignandmanufactureofproductswith theviewtowardoptimizingallelementsinvolvedinthe lifecycle ofthe product(seeSection1.4).Thebasicgoalsofconcurrentengineeringareto minimizeproductdesignandengineeringchanges,aswellasthetimeand costsinvolvedintakingtheproductfromdesignconcepttoproduction andintroductionoftheproductintothemarketplace.

Althoughtheconceptofconcurrentengineeringappearstobelogical andefficient,itsimplementationcanrequireconsiderabletimeandeffort, especiallywhenthoseusingiteitherarenotabletoworkasateamor failtoappreciateitsrealbenefits.Forconcurrentengineeringtosucceed itmust:(a)havethefullsupportofanorganization’stopmanagement; (b)havemultifunctionalandinteractingworkteams,includingsupport groups;and(c)utilizeallavailablestate-of-the-arttechnologies.

Apowerfulandeffectivetool,particularlyforcomplexproductionsystems,is computersimulation inevaluatingtheperformanceoftheproduct andthedesignofthemanufacturingsystemtoproduceit.Computersimulationalsohelpsintheearlydetectionofdesignflaws,identifyingpossible problemsinaparticularproductionsystem,andoptimizingmanufacturing

linesforminimumproductcost.Severalcomputersimulationsoftware packages,usinganimatedgraphicsandwithvariouscapabilities,are widelyavailable.

Somestepsintheproductionprocesswillrequirea prototype,aphysical modeloftheproduct.Animportanttechniqueis additivemanufacturing (Section10.12),thatreliesonCAD/CAMandvariousmanufacturing techniques(typicallyusingpolymersormetalpowders)torapidlyproduceprototypesofapart.Thesetechniquesarenowadvancedtosuch anextentthattheycanbeusedforlow-volumeeconomicalproductionof actualparts.

Duringtheprototypestage,modificationsoftheoriginaldesign,the materialsselected,orproductionmethodsmaybenecessary.Afterthis phasehasbeencompleted,appropriateprocessplans,manufacturingmethods(Table1.3),equipment,andtoolingareselected,withthecooperation ofmanufacturingengineers,processplanners,andallthoseinvolved inproduction.

TABLE1.3 Shapesandsomecommonmethodsofproduction.

Shapeorfeature

Flatsurfaces

Partswithcavities

Partswithsharpfeatures

Thinhollowshapes

Tubularshapes

Tubularparts

Curvatureonthinsheets

Openingsinthinsheets

Crosssections

Squareedges

Smallholes

Surfacetextures

Detailedsurfacefeatures

Threadedparts

Verylargeparts

Verysmallparts

Note:

Productionmethoda

Rolling,planing,broaching,milling,shaping,grinding

Endmilling,electrical-dischargemachining,electrochemicalmachining,ultrasonic machining,blanking,casting,forging,extrusion,injectionmolding,metal injectionmolding

Permanent-moldcasting,machining,grinding,fabricatingb ,powdermetallurgy, coining

Slushcasting,electroforming,fabricating,filamentwinding,blowmolding,sheet forming,spinning

Extrusion,drawing,filamentwinding,rollforming,spinning,centrifugalcasting

Rubberforming,tubehydroforming,explosiveforming,spinning,blowmolding, sandcasting,filamentwinding

Stretchforming,peenforming,fabricating,thermoforming

Blanking,chemicalblanking,photochemicalblanking,lasermachining

Drawing,extrusion,shaving,turning,centerlessgrinding,swaging,rollforming

Fineblanking,machining,shaving,beltgrinding

Laserorelectron-beammachining,electrical-dischargemachining, electrochemicalmachining,chemicalblanking

Knurling,wirebrushing,grinding,beltgrinding,shotblasting,etching,laser texturing,injectionmolding,compressionmolding

Coining,investmentcasting,permanent-moldcasting,machining,injection molding,compressionmolding

Threadcutting,threadrolling,threadgrinding,injectionmolding

Casting,forging,fabricating,assembly

Investmentcasting,etching,powdermetallurgy,nanofabrication,LIGA, micromachining

a Rapidprototypingoperationscanproduceallofthesefeaturestosomedegree.

b ‘Fabricating’referstoassemblyfromseparatelymanufacturedcomponents.

CASESTUDY1.1 Three-DimensionalPrintingofGuitars ThedesignflexibilityofadditivemanufacturingisillustratedbythecustomguitarsproducedbyODD, Inc.TheseguitarsaredesignedinCADprograms,withfullartisticfreedomtopursueinnovative designs;thoseinFigure1.4areonlyaselectionofthemanyavailable.TheCADfileisthensent toathree-dimensionalprinter,usingtheselectivelasersinteringprocessandproducedfromnylon (DuraformPA).Asprinted,theguitarsarewhite.Theyarefirstdyedtoanewbasecolor,then subsequentlyhand-paintedandsprayedwithaclearsatinlacquer.Thecustomer-specifiedhardware (pickups,bridges,necks,tuningheads,etc.)arethenmountedtoproducetheelectricguitar.

FIGURE1.4 Guitarsproducedthroughadditivemanufacturing.(a)Spiderdesignbeing removedfromapowderbed.Notethatthesupportmaterial,or cake,hassomestrengthand needstobecarefullyremoved;(b)finishedSpiderguitars. Source: CourtesyofO.Diegel, MasseyUniversity,NewZealand.

1.3 DesignforManufacture,Assembly,Disassembly, andService Designandmanufacturingshouldneverbeviewedasseparatedisciplinesandactivities.Eachpartorcomponentofaproductmustbe designedsothatitnotonlymeetsdesignrequirementsandspecificationsbutalsosoitcanbemanufacturedeconomicallyandwithrelative ease.Thisbroadconcept,knownas designformanufacture (DFM),is acomprehensiveapproachtotheproductionofgoods.Itintegratesthe productdesignprocesswithmaterials,manufacturingmethods,process planning,assembly,testing,andqualityassurance.