Karl Fink

Visit to download the full and correct content document: https://ebookmass.com/product/plastics-process-analysis-instrumentation-and-control -johannes-karl-fink/

More products digital (pdf, epub, mobi) instant download maybe you interests ...

Fundamentals of Industrial Instrumentation and Process Control, Second Edition William C Dunn

https://ebookmass.com/product/fundamentals-of-industrialinstrumentation-and-process-control-second-edition-william-cdunn/

Process Control Instrumentation Technology 8th Edition

Curtis D. Johnson

https://ebookmass.com/product/process-control-instrumentationtechnology-8th-edition-curtis-d-johnson/

Instrumentation And Control Systems Reddy

https://ebookmass.com/product/instrumentation-and-controlsystems-reddy/

Instrumentation and Control Systems William Bolton

https://ebookmass.com/product/instrumentation-and-controlsystems-william-bolton/

Instrumentation, Measurement and Analysis 4th Edition

Chaudhary Nakra

https://ebookmass.com/product/instrumentation-measurement-andanalysis-4th-edition-chaudhary-nakra/

Industrial Automated Systems: Instrumentation and Motion Control 1st Edition – Ebook PDF Version

https://ebookmass.com/product/industrial-automated-systemsinstrumentation-and-motion-control-1st-edition-ebook-pdf-version/

Process

Control 4th Edition Sohrab Rohani (Ed.)

https://ebookmass.com/product/process-control-4th-edition-sohrabrohani-ed/

Advanced Chemical Process Control 1st Edition Morten Hovd

https://ebookmass.com/product/advanced-chemical-processcontrol-1st-edition-morten-hovd/

Process

Control: Modeling,

Design,

and

Simulation

2nd Edition B. Wayne Bequette

https://ebookmass.com/product/process-control-modeling-designand-simulation-2nd-edition-b-wayne-bequette/

100CummingsCenter,Suite541J

Beverly,MA01915-6106

PublishersatScrivener

MartinScrivener(martin@scrivenerpublishing.com)

PhillipCarmical(pcarmical@scrivenerpublishing.com)

JohannesKarlFink

MontanuniversitätLeoben,Austria

Copyright © 2021byScrivenerPublishingLLC.Allrightsreserved.

Co-publishedbyJohnWiley&Sons,Inc.,Hoboken,NewJersey,and ScrivenerPublishingLLC,Salem,Massachusetts. PublishedsimultaneouslyinCanada

Nopartofthispublicationmaybereproduced,storedinaretrievalsystem,ortransmittedinanyformorbyanymeans,electronic,mechanical,photocopying,recording,scanning,orotherwise,exceptaspermittedunderSection107or108ofthe1976UnitedStatesCopyrightAct, withouteitherthepriorwrittenpermissionofthePublisher,orauthorizationthroughpaymentoftheappropriateper-copyfeetotheCopyright ClearanceCenter,Inc.,222RosewoodDrive,Danvers,MA01923,(978) 750-8400,fax(978)750-4470,oronthewebatwww.copyright.com. RequeststothePublisherforpermissionshouldbeaddressedtothe PermissionsDepartment,JohnWiley&Sons,Inc.,111RiverStreet, Hoboken,NJ07030,(201)748-6011,fax(201)748-6008,oronlineat http://www.wiley.com/go/permission.

LimitofLiability/DisclaimerofWarranty:Whilethepublisherandauthor haveusedtheirbesteffortsinpreparingthisbook,theymakenorepresentationsorwarrantieswithrespecttotheaccuracyorcompletenessof thecontentsofthisbookandspecificallydisclaimanyimpliedwarranties ofmerchantabilityorfitnessforaparticularpurpose.Nowarrantymay becreatedorextendedbysalesrepresentativesorwrittensalesmaterials.Theadviceandstrategiescontainedhereinmaynotbesuitablefor yoursituation.Youshouldconsultwithaprofessionalwhereappropriate.Neitherthepublishernorauthorshallbeliableforany lossofprofit oranyothercommercialdamages,includingbutnotlimitedtospecial, incidental,consequential,orotherdamages.

Forgeneralinformationonourotherproductsandservicesorfortechnical support,pleasecontactourCustomerCareDepartmentwithintheUnited Statesat(800)762-2974,outsidetheUnitedStatesat(317) 572-3993orfax (317)572-4002.

Wileyalsopublishesitsbooksinavarietyofelectronicformats.Some contentthatappearsinprintmaynotbeavailableinelectronicformats.FormoreinformationaboutWileyproducts,visitourwebsite atwww.wiley.com.

FormoreinformationaboutScrivenerproductspleasevisit www.scrivenerpublishing.com.

CoverdesignbyRussellRichardson

Preface

Thisbookfocusesonplasticsprocessanalysis,instrumentation,and control.Here,thesubjectofprocessanalysis,instrumentationand controlformodernmanufacturingintheplasticsindustryaredetailed.

Processanalysisisthestartingpointsinceplasticsprocessingis differentfromprocessingofmetals,ceramics,andothermaterials. Plasticsmaterialsshowuniquebehaviorintermsofheattransfer, fluidflow,viscoelasticbehavior,andadependenceoftheprevious time,temperatureandshearhistorywhichdetermineshowthematerialrespondsduringprocessinganditsenduse.Manyofthe manufacturingprocessesarecontinuousorcyclicalinnature.The systemsareflowsystemsinwhichtheprocessvariables,suchas time,temperature,position,meltandhydraulicpressure, mustbe controlledtoachieveasatisfactoryproductwhichistypicallyspecifiedbycriticaldimensionsandphysicalpropertieswhichvarywith theprocessingconditions.Instrumentationhastobeselectedsothat itsurvivestheharshmanufacturingenvironmentofhighpressures, temperaturesandshearrates,andyetithastohaveafastresponse tomeasuretheprocessdynamics.Manytimesthemeasurements havetobeinanon-contactmodesoasnottodisturbthemeltor thefinishedproduct.Plasticsresinsarereactivesystems. Theresins willdegradeiftheprocessconditionsarenotcontrolled.Analysis oftheprocessallowsonetostrategizehowtominimizedegradation andoptimizeend-useproperties.

Themaingoalofthebookistocoverthefieldofautomaticprocess controlandinstrumentationforplasticsprocessingandalsothenew topicsofstatisticalprocesscontrolandprocessmonitoring,which arerequiredtodocumentgoodmanufacturingpractices.

Thetextfocusesontheliteratureofthepastdecade.Beyond education,thisbookwillservetheneedsofindustryengineersand

specialistswhohaveonlyapassingknowledgeoftheplasticsand compositesindustriesbutneedtoknowmore.

HowtoUseThisBook

Utmostcarehasbeentakentopresentreliabledata.Becauseofthe vastvarietyofmaterialpresentedhere,however,thetextcannotbe completeinallaspects,anditisrecommendedthatthereaderstudy theoriginalliteratureformorecompleteinformation.

ThereadershouldbeawarethatmostlyUSpatentshavebeen citedwhereavailable,butnotthecorrespondingequivalentpatents inothercountries.Forthisreason,theauthorcannotassumeresponsibilityforthecompleteness,validityorconsequencesofthe useofthematerialpresentedherein.Everyattempthasbeen made toidentifytrademarks;however,thereweresomethattheauthor wasunabletolocate.

Index

Therearethreeindices:anindexofacronyms,anindexofchemicals,andageneralindex.Intheindexofchemicals,compounds thatoccurextensively,e.g.,“acetone,”arenotincludedatevery occurrence,butratherwhentheyappearinanimportantcontext.

Acknowledgements

Iamindebtedtoouruniversitylibrarians,Dr.ChristianHasenhüttl, MargitKeshmiri,FriedrichScheer,ChristianSlamenik,Renate Tschabuschnig,andElisabethGroßforsupportinliteratureacquisition.Ialsowanttoexpressmygratitudetoallthescientistswho havecarefullypublishedtheirresultsconcerningthetopicsdealt withherein.Thisbookcouldnothavebeenotherwisecompiled.

Last,butnotleast,Iwanttothankthepublisher,MartinScrivener, forhisabidinginterestandhelpinthepreparationofthetext.Inaddition,mythanksgotoJeanMarkovic,whomadethefinalcopyedit withutmostcare.

JohannesFink

Leoben,10thNovember2020

1.1SubjectsoftheBook....................1 1.2SpecialIssues.......................2 1.3InjectionMolding.....................3

1.3.1CostEstimationinInjectionMolding.....3

1.3.2CostPredictionModels.............4

1.4MiniatureMoldingProcesses..............6

1.5ComputerDeterminationofWeldLinesinInjection Molding..........................6

1.6ExtrusionBlowMolding.................8

1.6.1RapidThermalCyclingMolding........8

1.6.2RapidHeatCycleMolding...........8

1.6.3InjectionMolding:Heating...........16

1.7MicrocellularInjectionMolding.............22 1.8MoldCooling.......................23

1.9MicrocellularFoamProcessingSystem.........27

1.9.1Gas-AssistedInjectionMolding.........27

1.9.2Water-AssistedInjectionMolding.......32

1.10MoldingMachineforGranules.............32

1.15.1MarinePollution.................43

1.15.3Recycling.....................45

References............................57

2ProcessAnalysis 65

2.1ConceptsandStrategies.................66

2.1.1Chemometrics...................67

2.1.2SafetyRisks....................68

2.1.3FeedbackProcedures...............68

2.2LinearSystems......................68

2.2.1SimpleFirst-OrderSystems...........68

2.2.2FractionalOrderSystems............69

2.2.3NonlinearSystemsandLinearization.....69

2.2.4CharacteristicsofSystems............75

2.2.5ControllersandControllerSettings.......84

2.3Twin-ScrewExtrusion..................91 References............................92

3ExamplesofProcessAnalysis99

3.1GreenhouseGasBalance.................99

3.1.1Poly(ethylenefurandicarboxylate).......99

3.1.2PolyesterBinder.................100

3.2InjectionMoldingTechnology..............101

3.2.1ModuleforCADModelingofthePart.....103

3.2.2ModuleforNumericalSimulationofInjection MoldingProcess.................104

3.2.3ModuleforCalculationofParameters ofInjectionMoldingandMoldDesign CalculationandSelection............105

3.2.4ModuleforMoldModeling...........106

3.2.5ExamplesofTesting...............107

3.2.6MoldingAirCooling...............108

3.2.7CavityPressure..................109

3.2.8PlasticsExtruderDynamics...........110

3.2.9HistoryofMathematicalModeling.......110

3.2.10CurrentPhysicalComponentsConcept....112

3.2.11ProcessStages...................112

3.2.12DataEnvelopmentAnalysis...........116

3.2.13TaguchiMethod..................118

3.2.14TaitModel.....................119

3.2.15Phan-Thien-TannerModel............121

3.2.16ProductQualityPrognosis............121

3.2.17ProductionPredictiveControl.........122

3.2.18ParameterOptimizationforEnergySaving..123

3.2.19MultilayerControlSystem............124

3.2.20SmoothedParticleHydrodynamicsMethod.125

3.2.21Temperature-DependentAdaptiveControl..126

3.2.22Micro-InjectionMolding.............128

3.2.23ImmisciblePolymerBlends...........131

3.2.24ResinInjectionMolding.............133

3.2.25FoamInjectionMolding.............137

3.2.26Self-OptimizingInjectionMoldingProcess..138

3.2.27MachineSetup..................140

3.3ShrinkageinInjectionMolding.............146

3.3.1FactorsthatAffecttheShrinkage........146

3.3.2EffectofaCoolingSystem............147

3.3.3InfluenceofMoldingConditionsonthe ShrinkageandRoundness............148

3.3.4ShearViscosity..................148

3.3.5 In-Situ ShrinkageSensor.............149

3.3.6SemicrystallinePolymer.............151

3.3.7ThermoplasticElastomers............151

3.3.8ReprocessingofABS...............153

3.3.9SequentialSimplexAlgorithmwithAutomotive VentiductGrid..................155

3.3.10Taguchi,ANOVA,CAE,andNeuralNetwork Methods......................156

3.4RecyclingbyExtrusion..................166

3.4.1MultipleIn-LineExtruders...........166

3.4.2MixedPost-ConsumerPlasticWaste......167

3.4.3Poly(methylmethacrylate)...........168

3.4.4Poly(ethyleneterephthalate)..........169

3.4.5Poly(lacticacid)..................169

3.4.6ExpandedPoly(styrene).............169

3.5BatchWashingofRecycledFilms............171

3.5.1RecyclingofPoly(styrene)Waste........171

3.5.2TextileFinishing.................172

3.5.3RemovingScrapfromContainers.......173

3.5.4AdsorptionIsothermsandDesorptionRates.175

3.6Self-PurgingMicrowavePyrolysis...........176

3.7PurgingandPlasticizationinInjectionMolding....177

3.7.1AutomaticPurging................177

3.8HotRunnerSystems...................179

3.8.1HotRunnerMoldwithRunnerPipe......180

3.8.2HotRunnerSysteminPlasticsMoldingTools183

3.8.3ManufacturingandAssemblingofHot RunnerSystems..................184

3.9BlownFilmExtrusionandThicknessControl.....185

3.10ResidenceTimeDistributionforBiomassPyrolysis..186

3.11ReactiveExtrusion....................187 References............................187

4ProcessInstrumentation201

4.1In-MoldMeasurement..................201 4.2Temperature........................202

4.2.1SoftActuator...................202

4.2.2Thermocouples..................202

4.2.3ResistanceTemperatureDetectors.......206

4.2.4ThinFilmMiniatureTemperatureSensors..214

4.2.5NeuralNetworks.................214

4.3PositionTransducers...................215

4.3.1RotaryPositionTransducer...........215

4.3.2LinearVariableDifferentialTransformers...216

4.3.3OpticalEncoders.................218

4.3.4ThicknessGauges.................218

4.4CompositionofMatter..................222

4.4.1IRInterferometerforMultilayerFilm.....222

4.4.2X-RayDiffraction.................225

4.4.3IonMobility-MassSpectrometry........226

4.4.4TestforIceAdhesionStrength.........226

4.4.5PiezoelectricCoaxialFilamentSensors.....228

4.4.6InstrumentationforImpactTesting.......228

4.4.7TreatmentofTitaniumSurfaces.........229

4.4.8SpatialDifferentiationofSub-Micrometer Domains......................230

4.5MedicalIssues.......................231

4.5.1EndoscopicPlasticSurgicalProcedures....231

4.5.2MedicalCatheters................231

4.5.3MultichannelPlasticJoint............237

4.5.4TransluminalEndoscopicSurgery.......238

4.5.5Wire-ActuatedUniversal-JointWrists.....238

4.5.6MusculoskeletalDisorders...........239 References............................240

5ActuatorsandFinalControlElements245

5.1ServoValves........................245

5.1.1NozzleAssemblyforaServoValve......245

5.2ServoMotors........................248

5.2.1HydraulicSystem.................248

5.2.2FunctionallyGradedMaterials.........248

5.3SolenoidValves......................251

5.3.1DesignVerificationMethodology........251

5.3.2SmallSolenoidValve...............252

5.3.3High-SpeedSolenoidValve...........252

5.3.4NumericalSimulation..............252

5.4Heaters...........................253

5.4.1ConductionHeaters...............253

5.4.2RadiantHeaters..................255

5.4.3HeaterControls..................255

5.5DriveMotorsandMotorSpeedControlforExtrusion256

5.5.1Single-DriveMotor................256

5.5.2LinearInductionMotor.............256

5.5.3MotorPowerConsumptioninSingle-Screw Extrusion.....................257

5.5.4DualMotorMulti-Head3DPrinter.......258 References............................258

6AnalysisofMeltProcessingSystems261

6.1ProcessParameterDeterminationofPlasticInjection Molding..........................261

6.1.1Case-BasedReasoningMethod.........261

6.1.2Knowledge-BasedReasoningMethod.....264

6.1.3Rule-BasedReasoningMethod.........265

6.1.4FuzzyReasoningMethod............266

6.2ProcessParameterDeterminationofPlasticInjection MoldingofLCDs.....................267

6.3ProcessingHistory....................267

6.3.1FlowDefects....................267

6.3.2Biocomposites...................269

6.3.33DPrinting....................271

6.3.4SemiconductingPolymerBlends........272

6.3.5VanGurp-PalmenPlot..............272

6.3.6NanocrystalComposites.............273

6.3.7Melt-Mastication.................274

6.3.8CrystalNucleationinNanocomposites....275

6.4ShearHistory.......................276

6.5ExtrusionProductControl................278

6.5.1BranchedStructures...............278

6.5.2BigAreaAdditiveManufacturing.......279

6.5.3Single-ScrewExtrusionControl.........280

6.5.4BlownFilm....................284

6.5.5ChillRollCastFilm................285

6.5.6Sheet........................292

6.5.7Profiles.......................294

6.5.8PipeandTubing.................297

6.5.9AutomaticScreenChangers...........303

6.6ExtrusionBlowMoldingParisonControl.......306

6.7InjectionMolding.....................310

6.7.1RamVelocityControl...............310

6.7.2PressureControl.................313

6.7.3Gas-AssistedControl...............319

6.7.4SystemDiagnostics................322

6.7.5StatisticalProcessandQualityControl.....328

6.8Thermoforming......................329

6.8.1TwinSheetThermoforming...........329

6.8.2RotaryThermoforming.............330

6.8.3ProcessModelforThermoforming.......331

6.9Rotomolding........................332

6.9.1PolymerCompositionsforRotomolding...334

6.10Compounders.......................348

6.10.1HistoryofCompounding............348

6.10.2TypesofCompounders.............348

6.10.3SpecialApplications...............350 References............................352

7.2.1DryingTemperatures...............364

7.2.2MoistureContent.................366

7.2.3ResinDryers....................366 7.2.4PelletDryers....................369

1 GeneralAspects

1.1SubjectsoftheBook

Thisbookintroducesthesubjectofprocessanalysis,instrumentationandcontrolformodernmanufacturingintheplasticsindustry. Processanalysisisthestartingpointsinceplasticsprocessingis differentfromprocessingofmetals,ceramics,andothermaterials. Plasticsmaterialsshowanuniquebehaviorintermsofheattransfer, fluidflow,viscoelasticbehavior,andadependenceontheprevious time,temperatureandshearhistorywhichdetermineshowthematerialrespondsduringprocessinganditsenduse.

Manyofthemanufacturingprocessesarecontinuousorcyclicalin nature.Thesystemsareflowsystemsinwhichtheprocessvariables, suchastime,temperature,position,meltandhydraulicpressure, mustbecontrolledtoachieveasatisfactoryproduct,which istypicallyspecifiedbycriticaldimensionsandphysicalpropertieswhich varywiththeprocessingconditions.Instrumentationhastobeselectedsothatitsurvivestheharshmanufacturingenvironmentof highpressures,temperaturesandshearratesandyetithastohave afastresponsetomeasuretheprocessdynamics.Manytimesthe measurementshavetobeinanon-contactmodesoasnottodisturb themeltorthefinishedproduct.Plasticsresinsarereactivesystems. Theresinswilldegradeiftheprocessconditionsarenotcontrolled. Analysisoftheprocessallowsonetostrategizehowtominimize degradationandoptimizeenduseproperties.

Linearsystemsinwhichthereexistsaone-to-onerelationship betweentheinputvariableandtheoutputresponsearetheeasiest

2Plastics Process Analysis,Instrumentation, and Control

toanalyzeandcontrol.Plasticsontheotherhandshowanonlinear dependenceonpart/productcoolingwhichvarieswiththesquare ofthepartthickness,laminarflowwhichvarieswiththecubeof thewallthicknessandmechanicalstrength/stiffnesswhichvaries withthecubeofwallthickness.Also,wallthicknessinfluencesthe crystallization,shrinkage,morphologyandcriticaldimensionsof theproduct.

Inordertomakecorrectionstotheprocess,actuators,also known asfinalcontrolelements,mustintroduceenergytothesystem.This hardwareisintheformofservovalves,solenoidvalves,servo motors,heaters,andblowers.Thesizing,responsetime,ruggedness andlinearitymustbeconsidered.Alltheabovehardwarehastobe assembledintoasystemandprogrammedwithasuitablealgorithm tocarryoutautomaticcontrol.Thecontrolconfigurationand the algorithmaredictatedbythesystemitself.Commoncontrol modes arefeedbacksetpointcontrolwhichiscommoninextrusion, servo controlwhichiscommonininjectionmoldingandblowmolding cyclicalprocesses,andcombinationsandvariationsthereof.

1.2SpecialIssues

Asimplified,practical,andinnovativeapproachtounderstandthe designandmanufactureofplasticproductsintheWorldofPlastics hasbeenpresented(1).

Theinformationdefinesandfocusesonpast,current,andfuture technicaltrends.Thishandbookreviewsmorethan20,000different subjects.

Variousplasticmaterialsandtheirbehaviorpatternswere reviewed.Examplesareprovidedofdifferentplasticproductsand criticalfactorsrelatingtothemthatrangefrommeetingperformance requirementsindifferentenvironmentstoreducingcostsandtargetingforzerodefects(1).

1.3InjectionMolding

1.3.1CostEstimationinInjectionMolding

Costandperformanceestimationarefrequentlyusedattheearly stagesofproductdevelopmenttodeterminethefeasibility anddrive criticaldesigndecisions.Earlycostestimationhasbeenhampered bytheunavailabilityanduncertaintyofinformation.

Here,costestimateswerederivedfromacomplexitymetricas definedbythenumberofdimensionsthatuniquelydefinethepart geometry(2).

Thecostdriversofmanufacturinganinjectionmoldedplastic part Cpart areexpressedinEq.1.1.

Thematerialcostcontribution, Cmat,isverysignificant,typically 50%to80%ofthetotalpartcost.Toolingandprocessingcostsare alsosignificantcostdrivers.Theprocessingcost, Cproc,isdependent onthehourlyratechargedfortheusageoftheinjectionmolding machineaswellastheprocessingyield, yproc,whichistheratioof goodpartstothetotalnumberofpartsproduced.Thetoolingcost, Ctool,isamortizedovertheestimatedproductionquantity N forthe lifeofthetool.

Eq.1.2isanexpressionfortheassembledproductcost.

The m partsthatconstitutetheproductincludebothinjection moldedandstandardpurchasedparts.Thecostoftheassembly is theproductoftheassemblyshophourlyrate, Rassy,andthetotaltime requiredtoassemblethe m partsconstitutingtheproduct.Thus,the assemblycostdecreasesaspart-count m decreases.Theoverhead costperproduct COH includesboththeshopandtheadministrative overheads.

Dimensionalityandothercriticaldesignvariablescanbeautomaticallyassessedwithinmoderncomputer-aideddesignsystems throughouttheproductdevelopmentprocesstoprovidecontinual feedbackregardingtooling,process,andmaterialcosts(2).

4Plastics Process Analysis,Instrumentation, and Control

Thecomplexity-basedmodelsweredevelopedandtestedwith empiricaldataforthirtyinjectionmoldedpartsfromdifferentsuppliersandwasfoundtohaveahighlysignificantcorrelation with moldcostsandtoolingleadtimes.Modelsforestimatingmaterial andprocessingcostsandyieldattheearlystagesofdesignarealso developed.Thedevelopedmethodsenablereal-timeevaluationof theeffectsofaproductdesignonitstoolingcost,toolingleadtime, processingcosts,andyieldattheearlystagesofdesign(2).

1.3.2CostPredictionModels

Withtherecentevolutionofadditivemanufacturing,accuratecost predictionmodelsareofincreasingimportancetoassistdecisionmakingduringproductdevelopmenttasks(3).Estimatingthecost isachallengingtaskinthatitrequiresavastamountofmanufacturingknowledgeinwhichmanyaspects,fromdesigntoproduction, needtobesynchronized.Asaresult,variousadditivemanufacturingcostmodelshavebeendeveloped.

Thestateoftheartinproductcostestimationcoveringvarious techniquesanddevelopedmethodologieshasbeenreviewed(4). Theoverallworkcanbecategorizedintoqualitativeandquantitativetechniques.Thequalitativetechniquesarefurthersubdivided intointuitiveandanalogicaltechniques,andthequantitativeones intoparametricandanalyticaltechniques.Also,theimportanceof costestimationintheearlyphasesofthedesigncycleisdiscussed inthereview(4).Thecostclassificationtechniquesaresummarized inTable1.1.

Also,morerecently,anoverviewwaspresentedofthecosting modelsbeingdevelopedandutilizedassociatedwiththeadditive manufacturingproductdevelopmentphases(3).Here,itwas observedthatthecontextsandviewsdescribedduringthedevelopmentofthemodelswereoftentargetedatspecificapplicationsas wellastechnologiesandwereclassifiedinmanyways.Accordingly, differentaspectsofthecostestimationclassificationtechniquewere detailedanddefinitionsofsomeofthekeyterminologieswerereported.

Since2006,atotaloftenreviewworksrelatedtocostinginadditivemanufacturingwerereportedinwhicheachdifferedsignif-

Table1.1 Costclassificationtechniques(3).

ClassificationtechniquesDefinition

Method-basedQualitative: Intuitive Basedontheexperienceofthe estimator

Qualitative: Analogy Basedonhistoricaldata.Acomparisonisoftenmadebetween oldpartsandnewpartsduring estimation

Quantitative: Parametric Basedonstatisticalregression expressionwherevariablesare referredtoascostdrivers

Quantitative: Analytical Basedonproductdecompositionintounits,operations,or activitiesthatrelatetohowto manufacturetheproduct

Task-basedDesign-orientedBasedondesign-relatedactivities Process-orientedBasedontheprocessofcommissioningtheproductdevelopmentactivitiescoveringproduction-relatedandpost-processing costs

Level-basedProcess-levelBasedontheproductioncost, whichinvolvesentireproduct developmentphases(preprocessing,productionand post-processing)

System-levelBasedonproductlifecyclethat coverssupplychain,operation managementandsystem-level services

6Plastics Process Analysis,Instrumentation, and Control icantlyintermsoftheirscope.TheseworksarecollectedinTable 1.2.

1.4MiniatureMoldingProcesses

Inachapterofamonograph,particularprocessingstrategiesand techniquesforinjectionmoldingofprecisionparts,thinwallparts, microstructuredparts,andmicropartshavebeendescribed (5).

Theimportanceofincorporatingsizeeffectsintothefillingsimulationofmicrocavitieshasbeendemonstrated.Thestandard injectionmoldingsimulationandspecialsimulationneedsforminiature moldingprocesseshavebeendiscussed(5).

1.5ComputerDeterminationofWeldLinesin InjectionMolding

Aweldlineisoneofthemostcommonlyseendefectsinaninjection moldingprocess.Itisthelinewheretwopolymermeltfronts weld together,orameltfrontsplitsandcomesbackandweldstogether duringthefillingstage(6).

Aweldlinegreatlyaffectstheappearanceandmechanicalpropertiesoffinalinjectionmoldedparts(7).

ThesurfaceoftheweldlinemaycontainsmallV-notchcracks, andthesecrack-likefeaturesareoftenvisibletothenaked eyeand thereforetheyareconsideredaestheticallyunacceptable inmany applications,especiallywhenusinghigh-glosspolymers. Moreimportantly,thepolymersattheweldlinedonotbondperfectly,and thiscancauseaweakareainamoldedpartwhichcancausebreakagewhenthepartisunderstress(8).

So,aweldlineisaestheticallyunpleasantandaffectsthemechanicalstrengthofinjectionmoldedparts(9).Variousstudies havebeen performedrelatedtotheoptimizationofweldlines.

Aweldlinecomputerdeterminationmethodbasedonfilling simulationwithsurfacemodelhasbeenproposed,fromwhich the positionsandlengthsoftheweldlinescanbepredicted.

Accordingtothecharacteristicsofthesurfacemodel,allweld linescanbeclassifiedintotwodifferenttypes.Initialweldingnode

Table1.2 Recentreviewarticlesandtheirtargetedscope(3).

YearScopeReference

2006Generichierarchicalcostestimationclassification (4)

2009Web-basedsystemforrapidprototypingand traditionalmanufacturing.Brieflyhighlighted thecostmodelsutilization (10)

2014Categorizedadditivemanufacturingcostsby theirprocessesandmaterials,whichwere subdividedintoill-structuredcosts,well-structuredcostsandproductenhancementsand quality (11)

2016In-depthdiscussionofcostmethodologyused inproductdevelopmentprocess.Noclassificationtechniqueproposed. (12)

2016Coveredindustrialsectorrelatedtothematerialsandmanagement.Brieflyreviewed additivemanufacturingcostingmodels (13)

2016Providedupdatedestimateofthevaluerelated tothesupplychain (14)

2016Describedcostmodelsasasubsetofdesignfor additivemanufacturing (15)

2017Focusedondefensesupportservicesandcategorizedthecostmodelsintointuitive,analogicalandanalyticalapproaches (16)

2017Focusedonoperationmanagementwherethe strengthsandweaknessesofthemodelswere discussed.Includedageneralreviewofadditivemanufacturing (17)

2019Providedabroaderreviewonadditivemanufacturingtechnologies,additivemanufacturing costmodels,sparepartdigitalizationand environmentaleffectsfortheaviationindustry (18)

8Plastics Process Analysis,Instrumentation, and Control

searchingandrevisionalgorithmsforthetwodifferenttypesof weldlinesweredeveloped.Startingfrominitialweldingnodes, weldlinesarethenextendedbyapre-extensionalgorithmandan extensionalgorithm.

Intheweldlineextensionalgorithm,135°issetasawelding anglethresholdforformingweldlines.Finally,theeffectsofcavity thickness,processparameters,andmeshdensitieshavebeeninvestigated.Moreover,moldflowsimulationresultsandrealparts inproductionhavebeenconductedtoverifytheproposeddeterminationmethod,whichdemonstratethattheproposedmethodis correctandeffectiveinactualproduction(9).

1.6ExtrusionBlowMolding

1.6.1RapidThermalCyclingMolding

Blowmoldedpartsmadefromengineeringresinsusuallypossess apoorsurfacequality,andthuscannotsatisfytherequirementof high-glossappearanceinsomeapplications.Forthisreason,arapid thermalcyclingextrusionblowmolding(RTCEBM)technology was developed.Theprocessprinciplewaspresentedanditsprocess procedureoptimizationwasalsoanalyzed(19).

Withtheaimofobtainingauniformtemperaturedistributionon boththemoldcavityandthecoresurfaces,atwo-stepoptimization methodbasedonasequentialquadraticprogrammingalgorithm wasproposedfordesigningtheheatingsysteminaRTCEBMmold. Itseffectivenesswasdemonstratedbyoptimizingtheelectric-heatingsystemfortheRTCEBMmoldofanautomotivespoiler.

Afteroptimization,themaximumcoresurfacetemperaturedifferenceisreducedby77%fromtheinitialvalueof22.06°Ctothe optimalvalueof5.05°C.Themoldingprocesscoordinationcould alsobeensured.So,aneffectivemethodhasbeenassessedtooptimizetheheatingsystemforthesemoldswithcavityandcoresides tobeheatedsimultaneously(19).

1.6.2RapidHeatCycleMolding

Rapidheatcyclemolding(RHCM)isanadvancedinjectionmoldingtechnologyforproducingspraying-freeplasticproductswith

excellentappearance(20).Rapidmoldheatingandcoolingisthe keytechniqueofRHCM.

Despitebeingwidelyusedinpractice,theregularrapidmold heatingandcoolingmethodsstillhavesomeobviousdefects.Thus, anewrapidmoldheatingandcoolingmethodhasbeendeveloped, characterizedbyelectricheatingandannularcooling.

Here,thetemperatureandpressureresponsesintheheating and coolingperiodswereexperimentallyinvestigated(20).The results ofthestudyshowedthatthetoolsurfacetemperatureincreases almostlinearlywiththeheatingtimeafterashortresponse time. Thelargertheheatingpowerorthesmallerthedistancefromheater totoolsurface,thefastertheheatingrate.

Theintroductionofairbubblesintotheworkingfluidcanremarkablyreducethepressuregrowthofworkingfluidwithoutaffecting theheatingrate.Intheinvestigatedrangeofflowrate,thecooling ratefirstincreasessignificantlywiththeflowrate,andthenreaches aplateau,whiletherunningpressureofworkingfluidincreases linearlywiththeflowrateinthewholerange.

Theoptimumflowrateisaround6.0 lmin 1,correspondingtoa Reynoldsnumberof6700(20).TheReynoldsnumberhelpstopredictflowpatternsindifferentfluidflowsituations.AtlowReynolds numbers,flowstendtobedominatedbylaminar(sheet-like)flow, whileathighReynoldsnumbersflowstendtobeturbulent(21).

Theheattransfercoefficientinthecoolingperiodincreases sharplyattheinitialstage,andthenreducesgradually,andfinally reachesaplateau.ThelargertheReynoldsnumber,thehigher the heattransfercoefficient.Inparticular,theheattransfercoefficient andtheReynoldsnumbershowalinearrelationshiponthedouble logarithmicscale.Finally,amathematicalmodelwasdevelopedfor predictingandcontrollingthetemperaturefluctuationrangeoftool surface(20).

1.6.2.1ReductionofWeldLines

RapidHeatCycleMolding. TheRHCMtechniquecangreatly improveweldlineswithoutprolongingthemoldingcycle.The effectsofcavitysurfacetemperatureinRHCMonthemechanical strengthofthespecimenwithandwithoutweldlinewereinvestigated(22,23).

10Plastics Process Analysis,Instrumentation, and Control

Sixkindsoftypicalplastics,includingpoly(styrene)(PS), poly(propylene)(PP),acrylonitrile-butadiene-styrene (ABS), ABS/poly(methylmethacrylate)(PMMA),ABS/PMMA/nano-CaCO3 andglassfiber-reinforcedPP,areusedinexperiments.Thespecimenswithandwithoutaweldlineareproducedwiththedifferent Tcs onthedevelopedelectric-heatingRHCMsystem.Tensiletests andnotchedIzodimpacttestsareconductedtocharacterize the mechanicalstrengthofthespecimensmoldedwithdifferentcavity surfacetemperatures.Simulations,differentialscanningcalorimetry(DSC),scanningelectronmicroscopy(SEM)andopticalmicroscopeareimplementedtoexplaintheimpactmechanismof Tcs on themechanicalproperties.

Thermalcyclingexperimentsareimplementedtoinvestigate cavitysurfacetemperatureresponseswithdifferentheatingandcoolingtimes.Accordingtotheexperimentalresults,amathematical modelwasdevelopedbyregressionanalysistopredictthehighest temperatureandthelowesttemperatureofthecavitysurfaceduring thermalcyclingoftheelectricheatingRHCMmold(23).

Thesimulatedcavitysurfacetemperatureresponseshoweda goodagreementwiththeexperimentalresults.Basedonsimulations,theinfluenceofthepowerdensityofthecartridgeheaters andthetemperatureofthecoolingwateronthethermalresponse ofthecavitysurfacecouldbeobtained.AhighcavitysurfacetemperatureduringthefillingstageinRHCMcansignificantlyimprove thesurfaceappearancebygreatlyimprovingthesurfaceglossand completelyeliminatingtheweldlineandjettingmark(23).

Weldless-TypeInjectionMoldApparatus.

Ageneralforming processofapolymerresinhasproblemssuchasanaesthetically poorappearanceduetoaweldlineformedbythemoltenresinin themoldandalowdegreeofsurfacegloss.

Tosolvetheseproblems,amoldheatingmethodcanbeused,in whichthemoldtemperatureissettobehigherthanthemelting pointofaformedpolymerresin.

However,ifthepolymerresinisformedbysettingthetemperatureofamoldtobehigherthanthemeltingpointofpolymerresin, aweldlineisnotformedwhileenhancingaestheticappearance, suchasgloss.Butahightemperatureofthemoldextendsthecool-

ingtime,andtheoverallformingcyclemaybeprolonged,thereby loweringthemanufacturingefficiency.

Inparticular,sincethepolymerresinisnotseparatedfrom the moldafterbeingcooledtolowerthanthemeltingpointthereof, deformationduetoshrinkagemaybecomemoreseverethanina conventionalmolding.

Toovercometheseproblems,aweldless-typeinjectionmold apparatushasbeendeveloped(24).Thisapparatusincludesanupper mold,alowermoldengagedtotheuppermoldtoformacavityfor injectionmoldingofproducts,aheatingunitformedononesideof thecavityofatleastoneoftheloweranduppermoldstoheata resin injectedintothecavity,afirstcoolingunitformedinatleastoneof theloweranduppermoldstopreventtheinjectionmoldfrombeing overheated,andasecondcoolingunitinstalledbetweenthe heating unittocoolanareasurroundingthecavityandaninjectionmolded product.

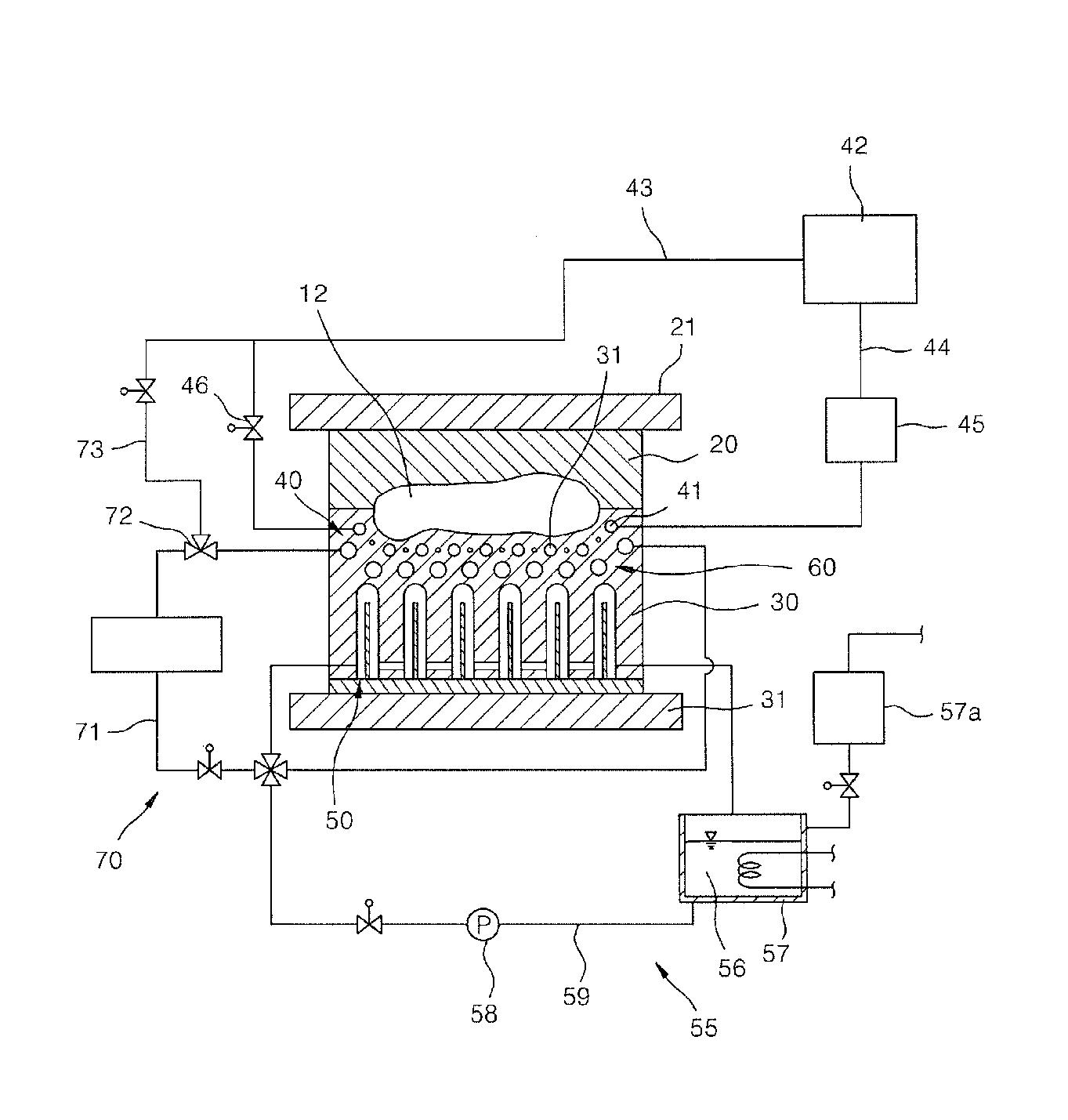

Aschematicdiagramofaweldless-typeinjectionmoldapparatus isshowninFigure1.1.

Thelowermold30includesaheatingunit40,afirstcoolingunit 50,andasecondcoolingunit60.

Thefirstcoolingunitmayincludeapluralityofverticalcooling flowsformedtoextendfromabottomsurfaceofthemoldtothe cavity,theverticalcoolingflowsmaybeconnectedtoeachother throughconnectionflows,andaninletandoutletmaybeformed onalateralsurfaceofthelowermoldtosupplyandejectcoolant.

Theheatingunit40isinstalledatasideadjacenttothecavity12 andheatsanareasurroundingthecavity12andaresininjectedinto thecavity12.Thefirstcoolingunit50isinstalledattheupperor lowermold20or30topreventtheupperorlowermold20or30 frombeingoverheatedduetorepeatedinjectionmoldingprocesses, andincludesaheat-blockingunitforpreventingheatfrombeing transferredtotheoutsideoftheupperorlowermold20or30. The secondcoolingunit60isinstalledbetweentheheatingunit 40and thefirstcoolingunit50andcoolsanareasurroundingthecavity12 andaninjectionmoldedproduct.

Thefirstcirculatingconduit43mayincludeafirstcontrolvalve 46installedtocontrolsteamtobesuppliedtothefirstfluidflows 41.Thesecondfluidflows51arespacedapredetermineddistance apartfromthebottomsurfaceofthelowermold30towardthe

Figure1.1 Weldless-typeinjectionmoldapparatus(24).

cavity12.Thesecondfluidflows51areconnectedtoeachother bycommunicationholes52.Inaddition,thesecondfluidflows 51aresealedbyablockingplate53engagedwiththelowermold 30.Theblockingplate53mayhavepartitioningplates54inserted intothesecondfluidflows51toelongateafluidflowtrackofthe secondfluidflows51.Here,eachofthepartitioningplates54may beshorterthaneachofthesecondfluidflows51.

Thefirstcoolingunit50includesafirstrefrigerantsupplyunit55 forcontinuouslysupplyingcoolanttothesecondfluidflows51. The firstrefrigerantsupplyunit55includesafirstrefrigerant tank57in whichrefrigerant56suchascoolantorcoolingoilisstored,afirst pump58connectingtherefrigeranttank57andthefirstfluidflow 51,andathirdcirculatingconduit59.Thefirstrefrigeranttank57is connectedtoamakeupwatertank57aforrefillingtherefrigerant56. Inaddition,arefrigerantcoolingsystemforcoolingtherefrigerant maybeinstalledinthefirstrefrigeranttank57.

Thethirdfluidflows61andthebranchconduit71maybeconnectedtoeachotherbythefirstcirculatingconduit43ofthe boiler 42andapurgeconduit73,sothattherefrigerantofthirdfluid flows 61maybeexhaustedwhenheatingiscarriedoutbytheheating unit 40.Thesecondcontrolvalve72maybeathree-wayvalveinstalled ataconnectionpartofthepurgeconduit73andthebranchconduit 71tosupplysteamorcoolant.

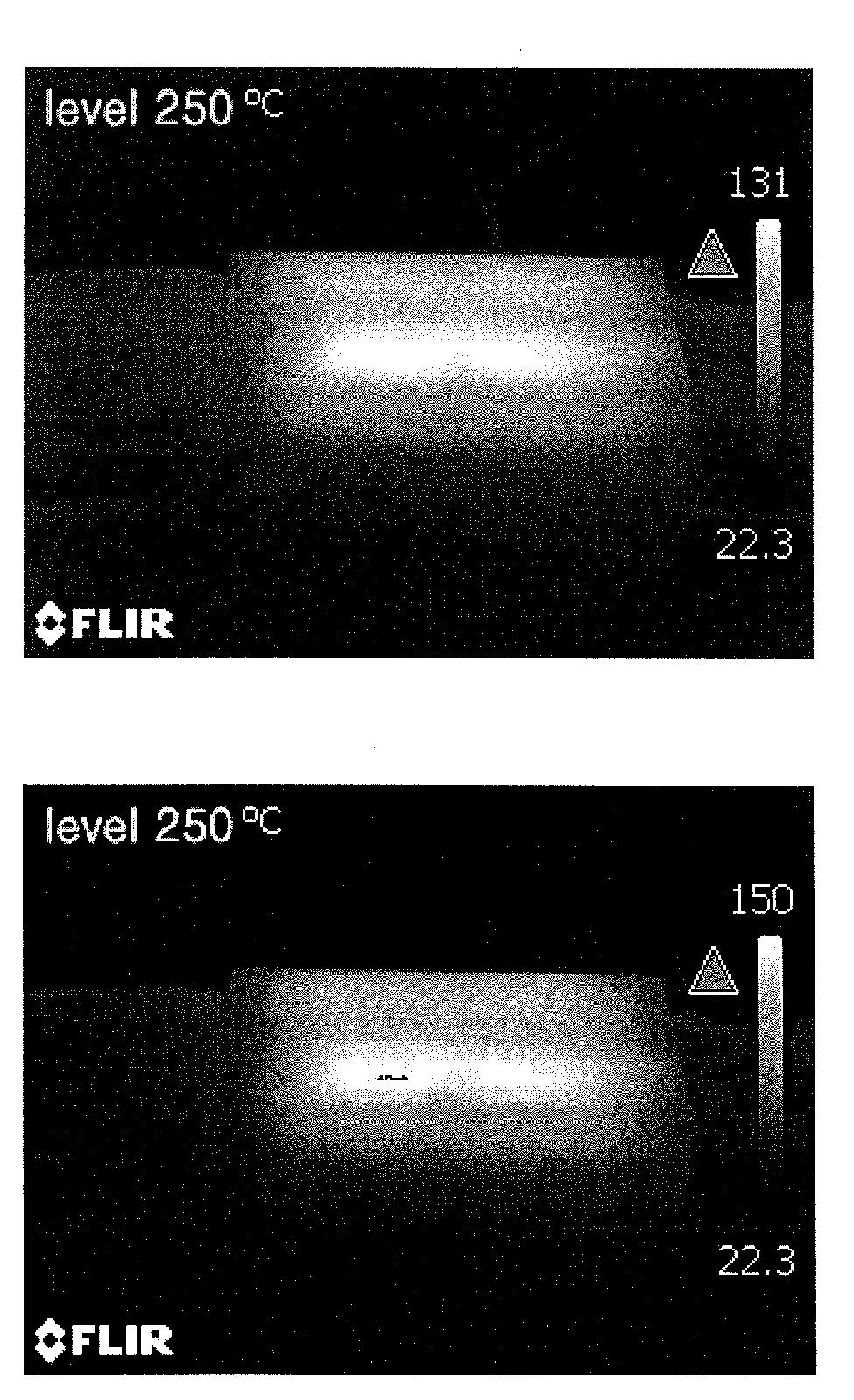

Imagesoftheuppermoldandthelowermoldduringinjection moldingwereobtainedusingaforward-lookinginfraredcamera. Thiscanillustratetheheatedstatesduringinjectionmolding,as showninFigure1.2.

AsevidentfromthephotographsinFigure1.2,heataccumulated aroundthecavity,whileheatdidnotaccumulateintheupper and lowermolds.Thatistosay,sinceheatisnottransferredtoalowerportionofthecavity,theheatcapacityfortheoverallinjection moldingprocessisnotsohigh.

Sinceheataccumulationispreventedinsuchamanner,acoolingandheatingtimeforinjectionmolding,specificallythe cooling time,canbereduced,therebyshorteningtheoverallcycletimerequiredforinjectionmoldingofaproduct,ultimatelyenhancingthe manufacturingefficiency(24).

Figure1.2 Heatedstatesduringinjectionmolding(24).