TranscriticalCO2 HeatPump

FundamentalsandApplications

Xin-RongZhang DepartmentofEnergy&ResourcesEngineering CollegeofEngineering PekingUniversity Beijing,China

HiroshiYamaguchi EnergyConversionResearchCenter DoshishaUniversity Kyoto,Japan

Thiseditionfirstpublished2021year

©2021JohnWiley&SonsSingaporePte.Ltd

Allrightsreserved.Nopartofthispublicationmaybereproduced,storedinaretrievalsystem,or transmitted,inanyformorbyanymeans,electronic,mechanical,photocopying,recordingorotherwise, exceptaspermittedbylaw.Adviceonhowtoobtainpermissiontoreusematerialfromthistitleisavailable athttp://www.wiley.com/go/permissions.

TherightofXin-RongZhangandHiroshiYamaguchitobeidentifiedastheauthorofthisworkhasbeen assertedinaccordancewithlaw.

RegisteredOffices

JohnWiley&Sons,Inc.,111RiverStreet,Hoboken,NJ07030,USA

JohnWiley&SonsSingaporePte.Ltd,1FusionopolisWalk,#07-01SolarisSouthTower,Singapore138628

EditorialOffice

TheAtrium,SouthernGate,Chichester,WestSussex,PO198SQ,UK

Fordetailsofourglobaleditorialoffices,customerservices,andmoreinformationaboutWileyproducts visitusatwww.wiley.com.

Wileyalsopublishesitsbooksinavarietyofelectronicformatsandbyprint-on-demand.Somecontentthat appearsinstandardprintversionsofthisbookmaynotbeavailableinotherformats.

LimitofLiability/DisclaimerofWarranty

Whilethepublisherandauthorshaveusedtheirbesteffortsinpreparingthiswork,theymakeno representationsorwarrantieswithrespecttotheaccuracyorcompletenessofthecontentsofthisworkand specificallydisclaimallwarranties,includingwithoutlimitationanyimpliedwarrantiesofmerchantability orfitnessforaparticularpurpose.Nowarrantymaybecreatedorextendedbysalesrepresentatives,written salesmaterialsorpromotionalstatementsforthiswork.Thefactthatanorganization,website,orproduct isreferredtointhisworkasacitationand/orpotentialsourceoffurtherinformationdoesnotmeanthat thepublisherandauthorsendorsetheinformationorservicestheorganization,website,orproductmay provideorrecommendationsitmaymake.Thisworkissoldwiththeunderstandingthatthepublisheris notengagedinrenderingprofessionalservices.Theadviceandstrategiescontainedhereinmaynotbe suitableforyoursituation.Youshouldconsultwithaspecialistwhereappropriate.Further,readersshould beawarethatwebsiteslistedinthisworkmayhavechangedordisappearedbetweenwhenthisworkwas writtenandwhenitisread.Neitherthepublishernorauthorsshallbeliableforanylossofprofitorany othercommercialdamages,includingbutnotlimitedtospecial,incidental,consequential,orother damages.

LibraryofCongressCataloging-in-PublicationDataappliedfor 9781118380048(Hardback)

CoverDesignbyWiley

CoverImage:©NicoGarstmanPhotography/Shutterstock

Setin9.5/12.5ptSTIXTwoTextbySPiGlobal,Chennai,India 10987654321

Contents

ListofContributors xi

Preface xiii

1Introduction 1

Xin-RongZhang

1.1Background 1

1.1.1EnergyShortageandEnergy-SavingTechnology–HeatPump 1

1.1.2HeatPumpChallengesandNaturalRefrigerants 2

1.1.3OneoftheMostPotentialNaturalRefrigerants–CarbonDioxide(CO2 ) 3

1.1.4MotivationforThisBook 5

1.2Fundamentals 5

1.2.1OperatingProcessesoftheBasicTranscriticalCO2 Cycle 7

1.2.2CharacteristicsofTranscriticalCO2 Cycles 9

1.2.3ModificationsofTranscriticalCO2 Cycles 10

1.3Applications 11

1.4AGuidetoThisBook 14 References 14

2CurrentDevelopmentofCO2 HeatPump 17

HiroshiYamaguchiandXin-RongZhang

2.1Introduction 17

2.2CO2 Properties 20

2.3WorkingPrincipleofTranscriticalCO2 HeatPump 25

2.4ABriefHistoryofCO2 HeatPump 29

2.5CO2 CascadeHeatPumpSystem 30

2.6AdvancedCO2 HeatPumpSystemwithanEjector 36

Acknowledgments 38

Nomenclature 38

GreekLetters 39

Subscripts 39

Abbreviations 39 References 40

3FluidDynamicsandHeatTransferofSupercriticalCarbonDioxide Cooling 43

BrianM.Fronk

3.1SupercriticalProperties 43

3.2SupercriticalHeatTransferFluidMechanics 44

3.2.1Buoyancy,FlowAccelerationandOscillationsinNear-CriticalFlows 45

3.2.2OutlineofRemainderofChapter 47

3.3SupercriticalGasCoolingExperiments 48

3.3.1Single-TubeStudies 48

3.3.2Mini/MicrochannelStudies 50

3.3.3SummaryofExperimentallyObservedEffects 50

3.4SupercriticalCO2 HeatTransferCorrelations 53

3.4.1ConstantPropertyTurbulentCorrelations 54

3.4.2Krasnoschekovetal.(1970)Correlation 54

3.4.3GhajarandAsadi(1986)Correlation 55

3.4.4Pitlaetal.(2002)Correlation 56

3.4.5SonandPark(2006)Correlation 56

3.4.6OhandSon(2010)Correlation 56

3.4.7MicrochannelCorrelations 57

3.4.8ComparisonofCorrelations 58

3.5SupercriticalCO2 PressureDrop 58

3.6SupercriticalCO2 HeatTransferandPressureDropwithLubricants 60

3.6.1CO2 /LubricantPressureDropCorrelations 61

3.6.2CO2 /LubricantHeatTransferCorrelations 62

3.7SummaryandNeedforAdditionalResearch 62

3.7Nomenclature 63

3.7GreekSymbols 63

3.7Subscripts 64 References 64

4BoilingFlowandHeatTransferofCO2 inanEvaporator 73

HaruhikoYamasaki

4.1Introduction 73

4.2BoilingHeatTransferofLiquidCO2 inanEvaporator 76

4.3SublimationHeatTransferofDryIce-GasCO2 inan Evaporator/Sublimator 85 Acknowledgments 92 Nomenclature 92 GreekSymbols 93 Subscripts 93 References 93

5TheoreticalAnalysisoftheCO2 ExpansionProcess 99

AmmarM.Bahman,RileyB.Barta,EckhardA.GrollandDavideZiviani

5.1Introduction 99

5.2ThermodynamicAnalysisoftheExpansionProcessinTranscriticalCO2 Cycles 100

5.2.1ThermodynamicLosses 100

5.2.2EffectofExpansionProcess 102

5.2.3RealTranscriticalCO2 Expansion 108

5.3TheoryofEjector-ExpansionDevices 111

5.3.1One-DimensionalEjectorFlowModel 113

5.3.1.1CriticalTwo-PhaseFlowModel 114

5.3.1.2MotiveNozzleFlowModel 116

5.3.1.3SuctionNozzleFlowModel 116

5.3.1.4MixingSectionFlowModel 117

5.3.1.5DiffuserFlowModel 118

5.3.2EjectorEfficiencies 118

5.4ExpansionWorkRecoveryDevicesforTranscriticalCO2 Systems 119

5.4.1PositiveDisplacementExpanders 120

5.4.1.1ReciprocatingExpanders 120

5.4.1.2RollingPistonandRotaryVaneExpanders 121

5.4.1.3ScrollExpanders 122

5.4.1.4ScrewExpanders 125

5.4.2Turbine-TypeExpanders 127

Nomenclature 131 GreekSymbols 132 Subscripts 132 References 133

6TranscriticalCarbonDioxideCompressors 137 Xin-RongZhang

6.1Introduction 137

6.2SlidingVaneCO2 Compressor 138

6.3ScrewCO2 Compressor 140

6.4CO2 RollingRotorCompressor 141

6.4.1CO2 CompressorsDevelopedbytheCompany 141

6.4.2Two-StageRollingPistonCO2 Compressor 142

6.5SCO2 ScrollCompressor 143

6.6SCO2 Turbo-Compressor 145

6.6.1SCO2 Turbo-CompressorApplicationsandChallenges 145

6.6.2TheTwo-PhaseAxial-FlowTurbine 146

6.6.3ApplicationofTranscriticalTurbinetoCO2 RefrigerationSystems 148

6.7SCO2 PistonCompressor 149

6.7.1CO2 ChallengesfromaCompressorPerspective 149

6.7.1.1HighPolytropicExponentandDischargeTemperatures 150

6.7.1.2Lubricant 151

6.7.1.3DischargePlenum 151

6.7.1.4PistonsandCompressionRings 152

6.7.2DesignPressures 153

6.7.2.1Materials 154

6.7.2.2WallThicknessandEnvelopeShapes 155

6.7.2.3SafetyValves 155

6.7.3Performances 155

6.8FutureTrends 156

6.8.1Two-StageCompressor 156

6.8.2ExpanderandExpander–Compressor 159

6.9SomeKeyTechnicalProblemsofCO2 Compressor 160

6.9.1MechanicalStrength 160

6.9.2LubricantProblems 160

6.9.2.1MiscibilityofLubricantandCO2 160

6.9.2.2LubricantStability 161

6.9.2.3ChoiceofLubricant 161

6.9.3OilDilution 162

6.9.4LargePressureDifferences 162

6.9.4.1WristPin 162

6.9.4.2ConnectingRod 164

6.9.4.3Crankshaft 164

6.9.4.4Bearings 164

6.9.4.5ValvePlate 165

6.10ConclusionandPerspectives 165 Nomenclature 166 References 166

7CO2 Subcooling 171

RodrigoLlopis,DanielSánchez,LauraNebot-Andrés,JesúsCatalán-GilandRamón Cabello

7.1Introduction 171

7.2CO2 ThermodynamicPropertiesandApproach 175

7.2.1ThermodynamicPropertiesofCO2 175

7.2.2CO2 SubcoolingApproach 180

7.2.2.1SubcriticalCO2 Subcooling 182

7.2.2.2TranscriticalCO2 Subcooling 183

7.2.3BenefitsofSubcooling 184

7.2.3.1SecondLawApproach 185

7.2.3.2Capacity 186

7.2.3.3COP 187

7.2.3.4EnergyInput 188

7.2.4SubcoolingOptimization 188

7.3InternalHeatExchanger 189

7.3.1Introduction 189

7.3.2DescriptionandOperation 189

7.3.3RevisionofResearchofIHX 192

7.3.3.1PredictingMethods 192

7.3.3.2TheoreticalandExperimentalAnalysis 193

7.3.4ExperimentalAnalysis 197

7.3.4.1RefrigerantSystem 197

7.3.4.2ExperimentalResultsandDiscussion 198

7.4DedicatedMechanicalSubcooling 201

7.4.1OptimumParametersoftheDMSCycle 205

7.4.1.1SubcoolingDegree 205

7.4.1.2HeatRejectionPressure 207

7.4.2TheoreticalStudies 209

7.4.3ExperimentalStudies 210

7.5IntegratedMechanicalSubcooling 212

7.5.1OptimumParametersoftheIMSCycle 215

7.5.1.1SubcoolingDegree 215

7.5.1.2HeatRejectionPressure 216

7.5.2TheoreticalStudies 219

7.6Summary 219 Nomenclature 220 GreekSymbols 220 Subscripts 221 References 221

8HighTemperatureCO2 HeatPumpSystemandOptimization 229 LinChenandDipankarN.Basu

8.1Background 229

8.2BasicSystemDesign 230

8.2.1KeyFeaturesinHighTemperatureCO2 HeatPump 230

8.2.2OverallSystemDesign 231

8.2.3RealSystemConstruction 231

8.3HighTemperatureOperationandKeyEquipment 232

8.3.1BasicHighTemperatureCO2 HeatPumpOperations 232

8.3.1.1WaterSourceHeatPump 233

8.3.1.2AirSourceHeatPump 234

8.3.1.3GroundSourceHeatPump 234

8.3.1.4HybridHeatPump 234

8.3.2Compressors 234

8.3.3HeatExchanger/GasCooler 236

8.3.4Expander 238

8.4SystemOptimization 238

8.4.1BasicSystemComponentsOptimization 238

8.4.2DischargePressureOptimization 238

8.4.3SystemOptimization 239

8.5ApplicationsandChallenges 239

8.5.1HeatingandCooling 239

8.5.2OtherIndustrialSectors 240

8.5.3COPAnalysisandComparison 241

8.6CommercializedProductsbyHighTemperatureCO2 HeatPump 242

x Contents

8.7Summary 243

Acknowledgments 243

Nomenclature 244

GreekSymbols 244

Subscripts 244

References 245

9PerformanceAnalysisandOptimizationofaCO2 HeatPumpWater

HeatingSystem 249

RyoheiYokoyama

9.1Introduction 249

9.2SystemConfiguration 250

9.3SystemModeling 251

9.4NumericalSolution 252

9.5ConditionsforPerformanceAnalysisandOptimization 253

9.6PerformanceAnalysisUnderPeriodicallySteadyState 256

9.7PerformanceEnhancementbyExtractingTepidWater 261

9.8PerformanceAnalysisUnderUnsteadyState 266

9.9PerformanceEstimationUnderUnsteadyState 268

9.10PerformanceOptimizationUnderUnsteadyState 273

9.11OtherIssuesonPerformanceAnalysisandOptimization 278

Nomenclature 280

Subscripts 281

Abbreviations 281 References 281

10TranscriticalCO2 HeatPumpSpaceHeating 283 FengCaoandYulongSong

10.1AttemptsTowardSpaceHeatingUsedaTranscriticalCO2 HeatPump 283

10.2ThermodynamicAnalysisoftheSubcooler-BasedCO2 HeatPump 287

10.3ComparisonBetweentheSubcooler-BasedCO2 SystemandtheCascade Cycle 289

10.4OptimalDischargePressure 292

10.5OptimalMediumTemperature 295

10.6ConclusionandProspects 296 References 298

Index 299

ListofContributors

RileyB.Barta RayW.HerrickLaboratories

PurdueUniversity WestLafayette

USA

AmmarM.Bahman MechanicalEngineeringDepartment CollegeofEngineeringandPetroleum KuwaitUniversity Kuwaitw

DipankarN.Basu DepartmentofMechanicalEngineering IndianInstituteofTechnologyGuwahati Assam

India

LinChen InstituteofEngineeringThermophysics ChineseAcademyofSciences

Beijing China

FengCao SchoolofEnergyandPowerEngineering Xi’anJiaotongUniversity Xi’an

China

RamónCabello MechanicalEngineeringandConstruction Department JaumeIUniversity

Spain

JesúsCatalán-Gil MechanicalEngineeringandConstruction Department JaumeIUniversity

Spain BrianM.Fronk GeorgeW.WoodruffSchoolofMechanical Engineering

GeorgiaInstituteofTechnology

Atlanta USA

EckhardA.Groll RayW.HerrickLaboratories PurdueUniversity WestLafayette USA

RodrigoLlopis MechanicalEngineeringandConstruction Department

JaumeIUniversity

Spain

xii ListofContributors

LauraNebot-Andrés

MechanicalEngineeringandConstruction Department

JaumeIUniversity

Spain

DanielSánchez MechanicalEngineeringandConstruction Department

JaumeIUniversity

Spain

YulongSong SchoolofEnergyandPowerEngineering Xi’anJiaotongUniversity Xi’an

China

HiroshiYamaguchi EnergyConversionResearchCenter DoshishaUniversity

Kyoto Japan

HaruhikoYamasaki DepartmentofmechanicalEngineering OsakaPrefectureUniversity Osaka Japan

RyoheiYokoyama DepartmentofMechanicalEngineering OsakaPrefectureUniversity

Osaka Japan

DavideZiviani RayW.HerrickLaboratories PurdueUniversity WestLafayette USA

Xin-RongZhang Departmentofenergyandresources engineering Collegeofengineering PekingUniversity Beijing China

Preface

Withthesocialandeconomicdevelopments,heatpumpbecomesmoreandmoreimportant invariousenergyconversionfieldsduetoitshighenergyefficiency.However,itsworking fluidsfaceseriouschallengesduetoglobalwarmingandozonelayerdepletionsincetheend oftwentiethcentury.Carbondioxide(CO2 )isanaturalfluidandcanprovideanexcellent energyandenvironmentsolutionstoreplacefreonsubstances,suchaschlorofluorocarbons(CFCs)andhydrochlorofluorocarbons(HCFCs).Furthermore,forthepastdecade, researchershavestudiedandobtainedmoreandmoreknowledgeaboutsupercriticalfluid flowdynamicandheattransferandalsophasechangeflowandheattransfer.Thus,transcriticalthermodynamiccyclesusingcarbondioxideasworkingfluidaregainingmoreand moreattention.TranscriticalCO2 heatpumpcyclesownmanyuniqueadvantages,suchas ahigherCOPperformanceandhighertemperatureforthermalenergyprovided,etc.These naturaladvantagesofthetranscriticalCO2 cycleclearlyextendtheirapplicationstowider fieldsandprovidebetterenergyandenvironmentsolutionstooursociety.

ThisbookdoesnotaimtoprovideeveryaspectoftranscriticalCO2 heatpump.Butallthe keypointsrelatedtothetranscriticalCO2 heatpumpcyclesandsystemsareincluded.Both fundamentalknowledgeandapplicationareconsideredanddiscussedinthemaintextto helpthereadertobetterunderstandthetranscriticalCO2 heatpumpcyclesandsystems. Thefundamentalaspectsmainlyincludeflowdynamicandheattransferofsupercritical CO2 ,evaporativeflowandheattransferofCO2 liquid-gasfluid,theoreticalanalysisoftranscriticalCO2 compressionandexpansionprocesses,andsubcoolingmethods.Thebookalso providesseveralimportantapplicationsofthetranscriticalCO2 heatpumpcycles,suchas CO2 heatpumpwaterheaterandCO2 spaceheating.Thebookisexpectedtobehelpfulfor researchers,postgraduates,engineersandalsopolicymakers,etc.

Wethankthemanyhelpers,includingthefollowing,fortheircollectingofdocuments, reviewingofmanypublicationsandcheckingoftexts:Dr.QiuyunZheng,Mr.Guanbang Wang,Mr.ZhaoruiPeng,Ms.YisaiGao,Mr.XuegangLu,Mr.JunminYin,Mr.Bing Fang,Mr.YudongZhu.Otherswhohavemainlycontributedtosomechaptersarelisted separately.Wegreatlyappreciatethesecontributions.WealsorecognizetheeffortofMr. XingyuShangforthetextediting.Inaddition,thesupportoftheNationalKeyResearch

xiv Preface andDevelopmentProgram(2016YFD0400106)andthesupportfromBeijingEngineering ResearchCenterofCityHeataregratefullyacknowledged.Finally,asalways,wewelcome yourcomments,criticismsandsuggestions.

Xin-Rong(Ron.)Zhang xrzhang@pku.edu.cn PekingUniversity

HiroshiYamaguchi hyamaguc@mail.doshisha.ac.jp DoshishaUniversity

Introduction

Xin-RongZhang

DepartmentofEnergyandResourcesEngineering,CollegeofEngineering,PekingUniversity,Beijing,China

1.1Background

1.1.1EnergyShortageandEnergy-SavingTechnology–HeatPump

Withthefastdevelopmentofhumansocietyandtherapidexpansionofthehumanpopulation,worldwideenergyconsumptionhasgrownquicklyduringthelastseveraldecades.As fortheyearof2017,primaryenergy,almost13511.2milliontonsoilequivalent,wasconsumedaroundtheworld,anaveragegrowthrateof1.7%peryearintheperiod2006–2016. Amongtheprimaryenergysources,upto85%wasnon-renewable,suchasoil,naturalgas, andcoal.1 Hugeenergyconsumptionleadstoenergyshortagesaswellasincreasingcarbon emissions,thuscausingclimatechange.Finding,researchingandusingrenewableenergy andenergy-savingtechnologybecomeessentialandurgent.

Heatingisanenergy-intensiveprocessinresidences,industriesandcommercialareas, whichusuallyutilizesfossilfuelorelectricityasenergysources.Thankstothedevelopmentofrenewableandenergy-savingtechnologies,theprocesscanbemoreefficientbased onthenewways,andoneofthemostmaturetechnologiesisheatpump.Heatpumpis anenergy-efficientsystemwhichmovesheatfromlowtemperatureside(heatsource)to hightemperatureside(heatsink)withcompressorwork;itcansupplymoreheatcompared totraditionalheaterswithequalenergyinput,providingthepotentialofheatrecoveryto reduceprimaryenergyconsumption.Nowadays,heatpumpsareappliednotonlyassingleheatingsystems,suchasfordirectheating,spaceheating,andwaterheating,butalsoas multi-functionenergyconversationsystemslikesimultaneousheatingandcooling,product dryingandwasteheatrecovering,etc.Asfortheheatpumpmarket,itshowsconsiderable developmentinrecentdecades;aroundtheworld,forinstance,theworldheatpumpmarketincreasedby7.2%andalmosttwomillionunitsweresoldin2013.2 Therefore,heatpump becomesmoreandmoreindispensableinhumansociety.

1Thedatainthisparagraphcomefrom BPStatisticalReviewofWorldEnergy2018 2Referencedfrom Growthintheworldheatpumpmarket byBSRIAWorldwideMarketingIntelligence. www.bsria.co.uk/news/article/growth-in-the-world-heat-pump-market. TranscriticalCO2 HeatPump:FundamentalsandApplications, FirstEdition.Xin-RongZhangandHiroshiYamaguchi. ©2021JohnWiley&SonsSingaporePte.Ltd.Published2021byJohnWiley&SonsSingaporePte.Ltd.

1.1.2HeatPumpChallengesandNaturalRefrigerants

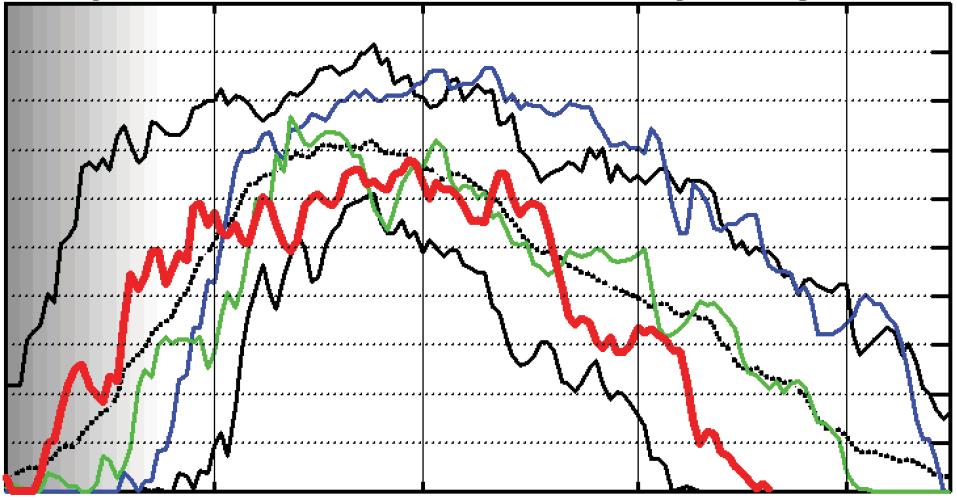

However,withthegrowingconcernsfortheenvironment,heatpumptechnologiesarefacingnewchallenges,especiallythechoiceanduseofrefrigerant.Refrigerantistheblood ofaheatpumpsystemwhichtransfersheatfromsourcestosinkswithphasechanging. Sincesyntheticrefrigerants(i.e.chlorofluorocarbons[CFCs])wereinventedandusedfrom the1930s,thiskindofnewrefrigerantwaswidelyusedanddominatedthemarketfor severaldecadeslaterduetoitsnon-toxic,non-flammableandhighefficiencyforthecorrespondingcycles,whilethesituationchangedinthe1970swhenpeoplestartedtonotice thatchlorineandbrominerelatedcompounds(CFCs,hydrochlorofluorocarbons[HCFCs]) causedozonedepletion,whichwasharmfultoearthlife[1].Oneofthemostremarkablephenomenaistheexistenceofozoneholes(Figure1.1showstheareaoftheozone holeinthesouthernhemisphere3 ).Hence,basedonozonelayerprotection,theMontreal Protocol(1987)[2]statedthescheduleofphasingoutofCFCsandHCFCs,thustheproductionandtheuseofsuchkindofrefrigerantswasrestricted.Thereplacementrefrigerants(hydrofluorocarbons[HFCs])thatwereproposedandpopularizedlater,wereregulatedaswell(KyotoProtocol,1997[3]),becausetheyemitstronggreenhousegaseswhich canenhanceglobalwarmingandcauserelatedenvironmentalissues(Figure1.2shows

2016 Southern Hemisphere Ozone Hole Area

NOAA S-NPP OMPS Current Year Compared Against Past 10 Years

Figure1.1 ThecurrenttrendofSouthernHemisphereOzoneHoleArea.Source:Referencedfrom NOAANationalWeatherServiceClimatePredictionCenter.3

3ReferencedfromNOAANationalWeatherServiceClimatePredictionCenter,USA.https://www.cpc .ncep.noaa.gov/products/stratosphere/sbuv2to/ozone_hole.shtml.

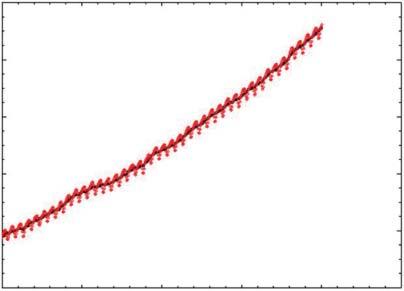

Figure1.2 Thecontentvariationofcarbondioxideinatmosphere(1980–2020).Source: ReferencedfromEarthSystemResearchLaboratory(ESRL)GlobalMonitoringDivision.4

thecontentvariationofCO2 intheatmosphere4 ).Withthepressingneedtosatisfythe existingenvironmentallawsandprotocols,researchingandusingnewrefrigerantswhich causenoharmtotheozonelayerandpreventglobalwarmingarecurrenttrends,especially forheatpump/refrigeration/air-conditionermanufacturers,refrigerantsuppliers,environmentalexperts,thermodynamicresearchersandgovernments.

Toaddresstheenvironmentalconcerns,theuseofnaturalrefrigerantshasgrownin recentyears.Naturalrefrigerants,ratherthanman-made,werewidelyusedfromthe1800s tothe1930suntiltheinventionofsyntheticrefrigerants.Withthedevelopmentofdesign andmanufacturingtechnology,theweaknessesoflow-efficiencyandlackofsafetywhich troubledpeopleintheearlyyearswereovercomegradually,sothattogetherwiththeadvantagesofenvironmentalfriendliness,naturalrefrigerantsarethusinrenaissancenow.

1.1.3OneoftheMostPotentialNaturalRefrigerants–CarbonDioxide(CO2 )

Asoneofthemainnaturalrefrigerants,carbondioxide(CO2 ,R744)gainsmoreattention nowadaysduetoitsenvironmentalfriendliness.AsforCO2 itself,ithasarelativelylow impactonclimatechangeandnoimpactonozone.Table1.1showsthepropertiesofsome commonrefrigerants,inwhichODP(ozonedepletionpotential)isanindextoreflectthe impactofrefrigerantontheozonelayer,andGWP(globalwarmingpotential)istomeasure thepotencyofagreenhousegascomparedtoCO2 overacertainperiod.Itcanbefound thattheODPofCO2 is0whichisthesameasthatofHFCsandtheGWPofCO2 isabout 0.01–0.7%tothatofCFCs,HCFCs,andHFCs,showinglessimpactonglobalwarmingwith thesamemass.AlthoughCO2 isthemajorgreenhousegasleadingtoclimatechangedue toitshighercontentintheatmospherecomparedtootherrefrigerants,thesubstitutionfor

4ReferencedfromEarthSystemResearchLaboratory(ESRL)GlobalMonitoringDivision,USA.https:// www.esrl.noaa.gov/gmd/ccgg/trends/gl_full.html#.

Table1.1 Propertiesofvariousrefrigerants.

CategoryCFCsHCFCsHFCsHCsNaturalrefrigerants

RefrigerantR12R22R134aR152aR290R717R744

ChemicalformulaCCl2

ODP10.0500000

GWP(100-yr)a 1020017601300138301

Flammability/toxicityN/NN/NN/NY/NY/NY/YN/N

Criticaltemperature(∘ C)112.096.0101.1113.396.7133.031.1

Criticalpressure(MPa)4.114.974.074.524.2511.427.38

a)GWPreferencesfromIPCC(InternationalPanelonClimateChange)FifthAssessmentReport. WorkingGroupIReport“ClimateChange2013:ThePhysicalScienceBasis.”Chapter8.Appendix8A.

highGWPrefrigerantsisstilleffectiveforgreenhousegasreductionsinceCO2 asarefrigerantcomesfromotherindustrialprocesses,thusthenetglobalwarmingimpactiszero[4]. Besidestheenvironmentaladvantages,CO2 alsohassatisfactorysafe,thermodynamic andeconomicproperties.

● Safety. CO2 isnon-toxicandnon-flammable,whichisdifferentfromothernaturalrefrigerantssuchasammonia(NH3 )andsulfurdioxide(SO2 ).

● Thermodynamicbenefits. CO2 hasarelativelylowcriticaltemperature(31.1 ∘ C)and highoperatingpressure(e.g.itscriticalpressureis7.38MPa,whichisonetotwotimes higherthanthecommonsyntheticrefrigerants).TheformercharacteristicallowstheCO2 heatpumptooperateasatranscriticalcycleeasily;thatistosaytheCO2 wouldtransfer heatpartlyabovethecriticaltemperatureandbeinsupercriticalstateintheheatrejection process.Comparedtoasystemwithrefrigerantoperatingasasubcriticalcycle,atranscriticalcyclehassomeuniquefeatures,likethesingle-phasegascoolingprocessthatoccurs whenitrejectsheat,whichisdifferentfromthecondensationprocessinsubcriticalcycles, andgascoolinghasalargertemperatureglidewhichfitsthewater/airheatingprocess better.Anothercharacteristic,highoperatingpressure,bringschallengestocomponent designandmanufacturebecauseitrequiresrobustcomponentsandastablecompressor. Thiscausedproblemsintheperiodbeforethe1930s,andthusrestrictedtheuseofthe CO2 cycleinhigherambientconditionsduetoextremelyhighpressure.However,the problemcanbesolvednowadayswiththedevelopmentofmaterialresearch,component designandmanufacture.

Besidesthethermodynamicpropertiesmentionedabove,CO2 alsohassomedifferent propertiescomparedwithconventionalrefrigerants.Itsvolumetriccapacityisquitelarge whichcontributestouseofsmallercomponentstoachieveamorecompactsystem[5], andthelargerslopeofvaporpressureversussaturationtemperatureresultsinsmaller temperaturechangewithagivenpressuredropwhichallowshighermassfluxinevaporation.Furthermore,thethermalconductivity(k)ofCO2 isrelativelyhighandthekof CO2 liquidandvaporisrespectively20%and60%higherthanthatofR134aliquidand vapor[6],indicatingbetterheattransfer.

● Economy. Carbondioxideiseconomicalasitisavailableintheairandalotofindustrial processes,leadingtolowcost.

Asforvaporcompressionheatpumps, cycleperformance isworthyofattentiondueto energyefficiency,compressionratio,etc.Intheearlyperiod(before1930s),CO2 wasmainly usedasarefrigerantinasubcriticalcycle,whilethecyclehadlowefficiencywhencondensationtemperatureincreasedduetothelowcriticaltemperature.SincetranscriticalCO2 heatpumpcycleswereproposedin1980s,energyefficiencyhasbeendemonstratedasbeing ascompetitiveasconventionalsyntheticrefrigerantcycles,especiallywhencomparedover seasonsandaddingsupplementaryheat[6].Asforthecompressionratiooftranscritical CO2 heatpumps,eventhoughithasarelativelyhighoperatingpressure,thepressureratio issmallerthanwithcommonrefrigerants.Forinstance,thecompressionratioofatranscriticalCO2 cycleisalmosthalfofthatofaR134acycle,thusimprovingthecompressor efficiencydirectly.

TranscriticalCO2 heatpumpscanbewidelyappliedinresidential,commercialandindustrialareas.InJapan,atranscriticalCO2 heatpumpwaterheaterhasalreadybeencommercializednamed“EcoCute”.Morethanthreemillionhavebeeninstalledsince2011[7]. Besides,theheatpumpalsohaspotentialtobeusedinspaceheating,automotiveairconditioningsystemsanddryingprocesses,indicatingitsvariousmultifunctionaluses.

1.1.4MotivationforThisBook

Basedontheforegoing,itshowsthattheCO2 heatpumpisofgreatsignificancetobe researchedandappliedduetoitsnatural,stable,environmentally-friendlyrefrigerantpropertiesandalsoitscompetitivecycleperformance.Thus,itisquiteimportanttostudyand understanditsthermodynamicmechanism,operatingcharacteristicsandsuitableapplicationsthroughasystematicmethodology,especiallyforpeoplewhohavegreatinterestin thistopic,suchascollegestudents,technicalstaffandrelatedresearchers.Afterdecadesof developmentinthisfield,itismatureandessentialtosummarizerelatedbasicfundamentalsandresearchresultsinoneprofessionalbook,suchasthisone.

ThisbookhasmainlybeendividedintotwopartstoillustrateCO2 heatpumps:fundamentalsandapplications.Inthischapter,simplifiedintroductionstothesetwoparts (Sections1.2and1.3)andalsoaclearguidetoeachchapter(Section1.4)willbeshown nexttoprovideabasicunderstandingforreaders.

1.2Fundamentals

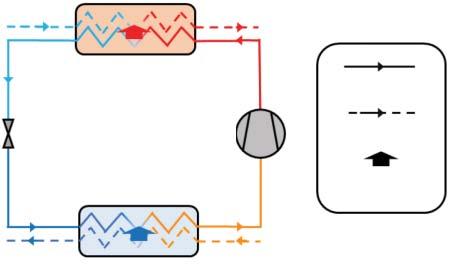

CommontranscriticalCO2 heatpumpsoperateontheprincipleofvaporcompression cycles,whichhavevariousconfigurationsafteryearsofdevelopment.Theoriginaland simplestcycleisshowninFigure1.3awhichcomprisesonegascooler,oneexpansion valve,onecompressorandoneevaporator,andwhichcanbemodifiedasaninternal heatexchangecycle,two-stagecycleorcyclewithexpander,etc.Thus,thisbasiccycle isconcentratedtoillustratethesciencemechanismsintranscriticalCO2 heatpumps. Inthissection,thefirstpartmainlydescribesthethermodynamicprocessesinthebasic

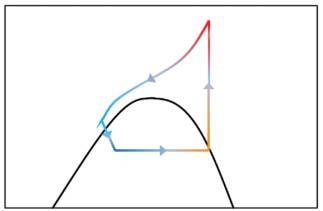

Figure1.3 (a)AschematicofthebasictranscriticalCO2 heatpumpcycle.(b)T-sdiagramofthecorrespondingcycle.

cycleandthecharacteristicsoftypicalprocesses.Thesecondpartintroducesperformance characteristicsforthewholecycle,andthelastpartgivesabriefoverviewofcycle modification.

1.2.1OperatingProcessesoftheBasicTranscriticalCO2 Cycle

ThebasiccycleanditscorrespondingT-sdiagramarerespectivelyshowninFigure1.3a andb.Thecycleiscomposedoffourprocessesasfollows:

1–2: Isentropiccompressionprocess.CO2 fromtheevaporatoriscompressedfromsaturated vaportosuper-heatedgasinsupercriticalstate.

2–3: Isobariccoolingprocess.ThesupercriticalCO2 entersthegascoolerandrejectsheat bygascoolingwithoutphasechange.

3–4: Adiabaticexpansionprocess.Thehigh-pressureCO2 isexpandedadiabaticallytolow pressureasvapor-liquidmixturethroughexpansionvalve.

4–1: Isobaricevaporationprocess.Two-phaseCO2 flowsintotheevaporatorandabsorbs heatfromoutsideheatsourceunderasubcriticalpressure.Itisthenevaporatedtoa saturatedvaporstateattheoutletoftheevaporatorandentersthecompressoragainto repeattheprocess1–2.

Eachprocessinthecycleshowsuniqueheattransferandflowcharacteristics,which attractedresearcherssomuchbecauseoftheirhelpwithcomponentdesignandcycleoptimization.Ageneralviewofthetwo-heatexchangeprocessissummarizedbelow:

● Heatrejectionprocess(2–3) isthemostparticularprocessintranscriticalcycles becauseheatisrejectedbysinglephasecoolinginsteadofcondensationasinconventionalsubcriticalcycles(therefore,theheatexchangeriscalledagascoolerinsteadofa condenser).

Forthisprocess,specialheattransferandflowcharacteristicscanbeobservedduetothe sharpchangesofthermodynamicandtransportproperties5 ofCO2 ,especiallywhenit worksintheregionnearpseudo-criticaltemperature(Tpc ).6 Inthenear-criticalregion, thefluidbehaveswithhighexpansionandlowthermaldiffusion,bringingnewfeatures influidflowandconvectivestructures,suchasapistoneffect(akindofthermalrelaxationprocess)inmicro-channels.Theseuniquemechanismsoffluidflowandheattransferplayanimportantroleintheheatrejectionprocessinheatpumps.

Researchhasfocusedontheuniquemechanismssincethe1960s,usuallyinthein-tube heating/coolingprocess,likeShitsman[8],Krasnoshchekov etal [9],ShiralkarandGriffith[10],Kurganov etal [11],Jiang etal [12],etc.Thesein-tuberesearchescontributedto thedevelopmentofcorrelations,andthedesign/optimization/control/operationofconventionalchannel/mini-channel/micro-channel7 gascoolers.

5Thethermodynamicpropertiesincludedensity(ρ)andspecificheat(Cp ),thetransportproperties includeviscosity(μ)andthermalconductivity(k).

6Thepseudo-criticaltemperature(Tpc )isdefinedasthetemperatureatwhichthespecificheat(Cp ) reachesapeakunderisobarcondition.

7AstheclassificationofchannelsgivenbyKandlikar[13]andKandlikarandGrande[14],thehydraulic diameters(Dh )ofconventionalchannels,mini-channels,andmicro-channelsarerespectivelyintherange of>3,0.2–3and0.01–0.2mm.

Becauseofthenon-uniformdistributionofpropertiesintubes,heattransferdeteriorationorenhancementwillbeobservedinspecificconditions,whichcanbeaffectedbyheat flux,massflowrate,inlettemperature,wallroughness,flowdirectionandtubediameter. Thefeatureofnon-uniformityleadstobuoyancyforceandflowaccelerationbringing uniquecharacteristicstothemechanismsbutalsodifficultieswithresearch.However, withthepresenceofnon-dimensionalparameters,buoyancyparameter Bo* andflow accelerationparameter KvT ,itbecomeshelpfulandconvenienttoestimatetheireffects onheattransferintheoreticalandpracticalanalysis.Thedevelopmentofheattransfer andpressuredropcorrelationsisquiteessentialforgascoolerdesign,whilethetraditionalsingle-phasecorrelationsarenotaccuratehereduetothevaryingproperties(This conclusionhasbeenverifiedbylotsofresearch).Itshouldbenotedthattheheattransfer correlationisnotthesameforheatingandcooling,asforthegascoolingprocess.Krasnoshchekov etal [9]firstcarriedouttheheattransfercorrelationthroughexperimental study.Thecorrelationconsideredthedifferencebetweenwalltemperaturepropertiesand bulktemperaturepropertieswhichreflectsthepropertyvariationinradialdirection,thus improvingtheaccuracy.Baskov etal [15],PetrovandPopov[16],Yoon etal [17],etc.also proposeddifferentcorrelationsadaptingtodifferentconditionsshowingrelativeaccuracy.Forpressuredropofthecoolingprocess,thecorrelationsproposedbyPetrovand Popov[16],etc.werewidelyused.

● In evaporator(4–1),CO2 vaporizesduringtheflowboilingprocess.ComparedtoconventionalHFCs,CO2 showsahigherheattransfercoefficientandalowerpressuredrop, indicatingbetteroverallperformance.

DuringtheboilingofCO2 ,theheattransfercoefficientdecreaseswithincreasingquality, andasharpdropoccursincriticalqualityatwhichpointdryoutphenomenonoccurs(i.e. theliquidfilmbreaksdown).Boilingheattransfercanbeaffectedbyheatflux,massflux andevaporationtemperature.Intheregionwithlowqualities,nucleateboilingdominatestheheattransferprocess,showingmoresensitivitytoheatfluxratherthanmass flux.Andafterdryoutathighqualities,convectiveboilingisthemajorheattransfer process,withtheheattransfercoefficientbeinginfluencedmorebymassflux.Further, thedryoutqualityismainlydeterminedbymassflux[18,19].Asforthepressuredrop characteristic,itincreaseswithincreasingmassfluxwhiledecreasingwithincreasing evaporationtemperature[17].

Flowpatternisanotherinterestingtopicfortwo-phaseflow.Duringtheboilingprocess, slugflowcanbeobservedatlowqualitiesandannularflowwithentrainmentofdroplets canbeobservedathighqualities[20].

Severalresearchershavefocusedontheeffectoflubricantonheattransfer,whichis essentialtobediscussedinvaporcompressioncycles.Rieberer[21]concludedthatheat transfercanbeinfluencedbycompressorlubricantandthenucleateheattransfermaybe weakened.Zhao etal [22]concludedthatthedecreaserateofheattransferduringboiling canbehigherwithincreasingconcentrationoflubricant.

Likethedevelopmentofcorrelationsinthegascoolingprocess,evaporationcorrelation isofthesameimportancetoevaporatordesignandoperation.Boilingflowcorrelations havebeendevelopedalotbutresultshaveshownthatgeneralizedcorrelationswerenot accurateforCO2, thereforecorrelationsforCO2 shouldbedevelopedspecifically[5].The

correlationspresentedbyJung etal [23],Cheng etal [24],Fang[25],etc.showedbetter predictabilityaftercomprehensivecomparison[26,27].

1.2.2CharacteristicsofTranscriticalCO2 Cycles

Basedontheuniquepropertiesforthenear-criticalCO2 resultingindifferentheatexchange processes,severalpeculiaritiesoftranscriticalCO2 heatpumpcyclescanberevealed.

● Thefirstcharacteristicisthelargetemperatureglideofheatrejection,whichis thetemperaturedifferencebetweenthegascoolerinletandoutlet.AsFigure1.4shows, thetemperatureprofileofgascoolingcanmatchtheheatedcurveofsecondaryfluid (Figure1.4b)betterthancondensationcondition(Figure1.4a)duetothelargertemperatureglide,implyinglessirreversiblelossesingascooler.Thus,thetranscriticalheatpump canoperatemoreeffectively.Inotherwords,transcriticalCO2 heatpumpsaremoresuitablethansubcriticalheatpumpsinheatingapplications.Further,betterperformance canbeobtainedwithlargertemperatureglidewhichcanbeoperatedbyreducingthe inlettemperatureofthesecondaryfluid[5].

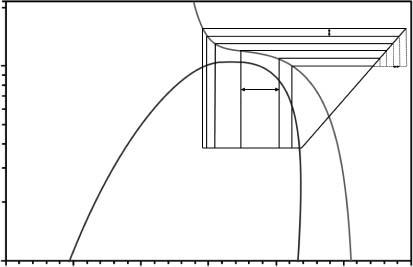

● Anothercharacteristicistheexistenceoftheoptimumhigh-sidepressure(heat rejectionpressure). Inthesupercriticalregion,temperatureandpressurearetwoindependentparameters,implyingthatthehigh-sidepressurecanbeadjustedwiththefixed coolingoutlettemperature;thus,itisimportanttocontrolhigh-sidepressuretogiveabetterperformance.Duetothespecialthermodynamicpropertiesinthesupercriticalregion, theoptimumhigh-sidepressurecanbeobtained.AsFigure1.5shows,withtheincrease ofhigh-sidepressure(��Prejection ),theheatingcapacityincreasesforagivengascooler outlettemperature.Theincreasedcapacity(��qheating )cancompensatetheincreasedcompressorwork(Δw)withthehigh-sidepressurenearthecriticalpressure,thereforethe coefficientofperformance(COP)increases.Withthemuchhigherpressure,theisotherm becomessteeper,leadingtoasmallerincreaseinheatingcapacitywiththesamepressure increment.Theincreasedcapacitycannotcompensatefortheincreasedcompressorwork anymore,hencetheCOPdecreasesandtheoptimalhigh-sidepressureexists.

Figure1.4 Temperatureprofilesofheatrejectionprocesses.(a)Condensationprocess,(b)gas coolingprocess.

Figure1.5 Thevariationofheatingcapacityandcompressorworkwiththeidenticalhigh-side pressureincrementillustratedintheP-hdiagramoftranscriticalcarbondioxideheatpumpcycle.

● IntranscriticalCO2 cycle,theeffectofevaporationtemperatureonheating capacityandCOPissmallerthanthatofotherconventionalsubcriticalcycles whichindicatesthetranscriticalCO2 heatpumpcansupplyheatmorestablyinconditionswithvaryingheatsourcetemperatures(forinstance,airsourcetranscritical CO2 heatpumpscanperformbetterwithvaryingambienttemperaturesoverayear). Therefore,whencomparedwithconventionalheatpumpsbyconsideringsupplementary heat,thetranscriticalCO2 heatpumpmayhavehigheroverallheatingCOP(i.e.theratio ofheatpumpheatingloadplussupplementaryheatingloadtothepowerinput)dueto thesmallerrequirementonsupplementaryheatingdevices[6].

1.2.3ModificationsofTranscriticalCO2 Cycles

BasedonthebasicCO2 cycle,severalmodificationstocyclescanbeobtainedbymodifying theexistingcomponents,addingotherdevicesordesigningnewcirculationsinordertoget betterperformance.

Heatexchangerslikegascoolersandevaporatorscanbemodifiedbyusingdifferent typesofheatexchangechannels,likethefinandtubetype,theshellandtubetype andthemicrochanneltype,leadingtodifferentresults.Forinstance,microchannel tubescanincreasetheheattransferarea,thusreducingtheheatexchangersize,and alsocanimproveheattransferperformance.Calculationsshowedthatthecapacityofa microchannelevaporatorwas33%higherthanthatoftheconventionalfin-and-tubetype [28].Besidesthechoiceoftype,theheatexchangerparameter(e.g.tubediameter,tube pitch,finspacing),channelarrangement(e.g.cross-flow,counter-flow),orientation(e.g. verticalflow,horizontalflow)andwallmaterial(e.g.stainlesssteel,copper,aluminum) alsohaveauniqueimpactonheattransferandcycleperformance,whichshouldbe modifiedcomprehensively.

Addingasuctionlineheatexchanger(SLHX)isacommonmethodofpreheatingthe vaporbeforecompressionandsubcoolsthecooledfluidattheoutletofthegascooler.This

operationcanimprovetheCOPby7%throughsimulationanalysis[5].Besides,addingcompressorsisanotherbasicmodificationwhichmakesthecyclerunasamulti-stagecycleto improvecompressorefficiencybyreducingthepressureratioofeachstage.Further,the arrangementofotherdeviceslikeflashtanksandintercoolerscancooltheexhaustedgas atoutletofthelow-pressurecompressor,thereforeenhancingenergyefficiency.

1.3Applications

AsmentionedinSection1.2,transcriticalCO2 heatpumpshavemoreadvantagesinheating comparedtosubcriticalheatpumps,especiallyforapplicationswhichneedalargetemperatureincrease.TranscriticalCO2 heatpumpshavethepotentialtobeappliedinvarious areassuchasresidentialheatingandcommercial-sizeheatingtosatisfythedemandofhot watersupplyorhotairsupply,andsometypeshavealreadybeenpopularizedonthemarket suchasresidentialCO2 heatpumpwaterheaters.Next,severalapplicationswillbelisted andbrieflyintroduced.

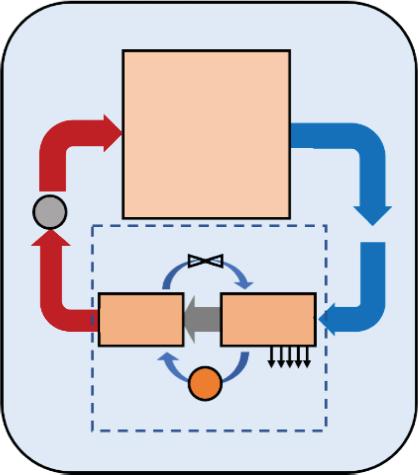

● TranscriticalCO2 heatpumpwaterheater (asshowninFigure1.7)hasattracted peoplesincethelate1980sduetoitsgoodperformanceinthesupplyofhightemperature waterwithgoodCOP,whichbenefitedfromwellmatchingintheheatrejectionprocess. ThiskindofwaterheaterwascommercializedinJapanandnamed“EcoCute”in2001.As Figure1.6shows,salesofEcoCuteinJapangrewrapidlyandthecumulativenumberof installedunitsexceededthreemillionby2011withmorethan400000soldeveryyearby theleadingcompanieslikeDenso,Sanyo,Sanden,andMitsubishiElectric[7].Basedon itsrapidgrowth,Japanestablishedstandardspecificationsforheatpumpwaterheaters anditistheonlycountryfortherefrigerantCO2 .Theleadingmanufacturerscontinueto innovateproductstomeetdifferentdemandssuchasmakingheatpumpsthatoperatein coldregions,[29]orenhancetheperformanceofkeycomponentslikecompressorsand gascoolers[7].ComparedtothematuremarketinJapan,theEuropeanmarketseems newandunderexploited.Besidesthedomesticwaterheatermarket,somecommercial

Figure1.6 ThemarketsizeofEco-cuteinJapanbeforetheyearof2013[7].

applicationsofCO2 heatpumpshavebeendevelopedinEuropetosupplyhotwaterfor hotels,restaurants,hospitals,andschools,andsomeexampleshavebeenconstructedin Ireland,France,Denmark,andSwitzerlandsince2012[30].

AsforthetranscriticalCO2 heatpumpwaterheater,thoughithasbeencommercialized successfully,itstillneedstoberesearched,optimized,anddeveloped.Ithasbeenfound thattheinletandoutletwatertemperatureandambienttemperaturecanaffecttheoptimaldischargepressureandheatingCOP.Forexample,ahigherambienttemperatureand alowerinletwatertemperatureleadtoahigheroverallCOP[31].Besidestheoptimizationofoperatingparameters,themodificationoftheoperatingcycleandthemanagement ofwaterstorageandheatingalsoneedtobecarefullyconsidered.

● Heatingforvehicles, especiallyinlowambienttemperatures,isacurrenttrenddue tothecompactstructureofCO2 heatpumps,environmentallyfriendlybenefitsand suitablethermodynamicpropertiesofcarbondioxide.Becauseofthefinitespacesin vehicles,compactheatingdeviceswithlargeheatingcapacityarerequired(Figure1.8).

Figure1.7 SchematicofEco-cuteproducts[7].

Figure1.8 Airoutletofacarairconditioningunit.

Figure1.9 TheschematicofaCO2 heatpumpdryer.

Meanwhile,regulationsintheEU,Japan,andtheUSaimtophaseoutHFCsinmobile airconditioningsystems[32],thusCO2 isconsideredasoneofthemostsuitable refrigerantsforsubstitution.

WhenusingCO2 heatpumpsinvehicles,ithasbeenproventhatthetemperaturecan increaserapidlyandtheheating-uptimecanbereducedby50%comparedtothatofthe conventionalheatcores[33].Modifyingtheheatpumpsystembyaddingexhaustheat recoveryandutilizingcabinreturnairwereeffectivewaystoadjustheatingcapacity; theformerimprovingcapacityby100%comparedtoconventionalheating[34]andthe latterreducingheatingloadthussavingelectricitypower[35].Further,heatingperformancecanbeinfluencedbyoutdoortemperature,outdoorairvelocity,indoortemperature,indoorairflowrate,CO2 chargevolumeandcompressorspeed[36],indicatingthat furtheroptimizationcanbeachievedforbetterenergyefficiency.

● TranscriticalCO2 heatpumpappliedindrying (asshowninFigure1.9)hasgreat potentialowingtothegoodmatchofgascoolingtotheairheatingprocess,therefore leadingtoahigherairtemperatureandalargermoistureextractionrate.Comparedwith conventionalrefrigerantsandconventionalheaters,CO2 heatpumpshavebeentested andhaveprovedcompetitive.Schmidt etal [37]concludedthatthehighercompressor efficiencycancompensateforthelargethrottlinglossesfortheCO2 cycle,resultinginan equivalentorevenbetterperformancecomparedwiththeR134acycle.Klocker etal [38] comparedtwoCO2 heatpumpprototypeswithtraditionalelectricalheatersfordrying experimentally,showingthateven53%ofenergycanbesaved.Moreover,inCO2 heat pumpdrying,theoptimizationofoperatingconditionsisquiteessential,suchasairtemperature,airflowrate,flowbypassratio,etc.,whichcaninfluenceboththeheatpump efficiencyanddryingperformance.

1.4AGuidetoThisBook

ThisbookisnotexpectedtoincludeeverythingrelatedtotranscriticalCO2 heatpump,but isexpectedtofocusonthemainpartsoftranscriticalCO2 heatpumpfromthetwoaspects offundamentalsandapplications.Chapter1providesbackgroundandmotivationforthe book.Chapter2presentsfundamentalconceptandworkingprinciplefortranscriticalCO2 heatpump.Chapters3–6coverthefundamentalsofthefourbasicprocessesoftranscriticalCO2 heatpump,cooling,evaporation,expansion,andcompression,respectively.Some designconceptsarealsoinvolved.Chapter7isspeciallyincludedtocoverthemostrelevant studyonsubcooledCO2 cyclesandaimstosolvethemaindrawbackoftranscriticalCO2 cycles.Chapters8–10focusonsomeimportantapplicationexamplesoftranscriticalCO2 heatpumpcycles.

Here,itshouldbementionedthatthebasicprincipleoftranscriticalCO2 heatpumpisnot onlyseeninChapter2,butalsoinotherchapters.Similarly,CO2 thermophysicalproperties arealsopresentedinsomedifferentchapters.However,theCO2 propertiesandprinciples areexplainedfromthedifferentviewsandrequirementsforthedifferentchapters,suchas fromthephasechange,fromthesubcooling,andfromthecycle.

References

1 Molina,M.J.andRowland,F.S.(1974).Stratosphericsinkforchlorofluoromethanes: chlorineatom-catalyseddestructionofozone. Nature 249(5460):810–812.

2 Protocol,M.(1987).Montrealprotocolonsubstancesthatdepletetheozonelayer.Washington,DC:USGovernmentPrintingOffice,26:128–136.

3 Protocol,K.(1997).UnitedNationsframeworkconventiononclimatechange.Kyoto Protocol,Kyoto,19:497.

4 Petter,N.(2002).CO2 heatpumpsystems. InternationalJournalofRefrigeration 25(4): 421–427.

5 Austin,B.T.andSumathy,K.(2011).Transcriticalcarbondioxideheatpumpsystems:a review. RenewableandSustainableEnergyReviews 15(8):4013–4029.

6 Kim,M.(2004).FundamentalprocessandsystemdesignissuesinCO2 vaporcompressionsystems. ProgressinEnergyandCombustionScience 30(2):119–174.

7 Zhang,J.-F.,Qin,Y.,andWang,C.-C.(2015).ReviewonCO2 heatpumpwaterheater forresidentialuseinJapan. RenewableandSustainableEnergyReviews 50:1383–1391.

8 Shitsman,M.E.(1963).Impairmentoftheheattransmissionatsupercriticalpressures. TeplofizikaVysokikhTemperatur 1(2):267–275.

9 Krasnoshchekov,E.A.,Kuraeva,I.V.,andProtopopov,V.S.(1970).Localheattransferof carbondioxideatsupercriticalpressureundercoolingconditions. TeplofizikaVysokikh Temperatur 7(5):922–930.

10 Shiralkar,B.S.andGriffith,P.(1969).Deteriorationinheattransfertofluidsatsupercriticalpressureandhighheatfluxes. ASMEJournalofHeatTransfer91(1):27–36.

11 Kurganov,V.A.andKaptilnyi,A.G.(1993).Flowstructureandturbulenttransportif asupercriticalpressurefluidinaverticalheatedtubeundertheconditionsofmixed

convection.Experimentaldata. InternationalJournalofHeatandMassTransfer 36(13): 3383–3392.

12 Jiang,P.X.,Ren,Z.P.,andWang,B.X.(1995).Convectiveheatandmasstransferof wateratsupercriticalpressuresunderheatingorcoolingconditionsinverticaltubes. InternationalJournalofThermalSciences 4:15–25.

13 Kandlikar,S.G.(2002).Fundamentalissuesrelatedtoflowboilinginminichannelsand microchannels. ExperimentalThermalandFluidScience 26(2–4):389–407.

14 Kandlikar,S.G.andGrande,W.J.(2003).Evolutionofmicrochannelflowpassages–thermohydraulicperformanceandfabricationtechnology. HeatTransfer Engineering 24(1):3–17.

15 Baskov,V.L.,Kuraeva,I.V.,andProtopopov,V.S.(1977).Heattransferwiththeturbulent flowofaliquidatsupercriticalpressureintubesundercoolingconditions. Teplofizika VysokikhTemperatur 15(1):96–102.

16 Petrov,N.E.andPopov,V.N.(1985).Heattransferandresistanceofcarbondioxide beingcooledinthesupercriticalregion. ThermalEngineering 32(3):131–134.

17 Yoon,S.H.,Cho,E.S.,Hwang,Y.W.etal.(2004).Characteristicsofevaporativeheat transferandpressuredropofcarbondioxideandcorrelationdevelopment. International JournalofRefrigeration 27:111–119.

18 Sun,Z.andGroll,E.(2000).CO2 flowboilinginhorizontaltubes.InternalreportNo. HL-2001-8,RayW.HerrickLaboratories,PurdueUniversity.

19 Yun,R.,Kim,Y.C.,Kim,M.S.,andChoi,Y.D.(2003).Boilingheattransferanddryout phenomenonofCO2 inahorizontalsmoothtube. InternationalJournalofHeatand MassTransfer 46:2353–2361.

20 Pettersen,J.(2002).FlowvaporizationofCO2 inmicrochanneltubes.PhDThesis. NorwegianUniversityofScienceandTechnology,Norway.

21 Rieberer,R.(1998).CO2 asworkingfluidforheatpump.PhDThesis.InstituteofThermalEngineering,GrazUniversity,Austria.

22 Zhao,Y.,Molki,M.,andOhadi,M.M.(2002).FlowboilingofCO2 withmiscibleoil inmicrochannels.TechnicalandSymposiumPapers4505,ASHREAWinterMeeting, Atlanticcity,USA.

23 Jung,D.S.,Radermacher,R.,McLinden,M.,andDidon,D.(1989).Astudyofflow boilingheattransferwithrefrigerantmixtures. InternationalJournalofHeatandMass Transfer 32:1751–1764.

24 Cheng,L.,Ribatski,G.,MorenoQuiben,Q.,andThome,J.R.(2008).Newprediction methodsforCO2 evaporationinsidetubes:partI–atwo-phaseflowpatternmapand aflowpatternbasedphenomenologicalmodelfortwo-phaseflowfrictionalpressure drops. InternationalJournalofHeatandMassTransfer 51:111–124.

25 Fang,X.D.(2013).Anewcorrelationofflowboilingheattransfercoefficientsforcarbon dioxide. InternationalJournalofHeatandMassTransfer 64:802–807.

26 Fang,X.D.,Zhou,Z.R.,andLi,D.K.(2013).Reviewofcorrelationsofflowboiling heattransfercoefficientsforcarbondioxide. InternationalJournalofRefrigeration 36: 2017–2039.

27 Mastrullo,R.,Mauro,A.W.,Rosato,A.,andVanoli,G.P.(2010).Carbondioxideheat transfercoefficientsandpressuredropsduringflowboiling:assessmentofpredictive methods. InternationalJournalofRefrigeration 33:1068–1085.

28 Yun,R.,Kim,Y.,andPark,C.(2007).Numericalanalysisonamicrochannelevaporator designedforCO2 air-conditioningsystems. AppliedThermalEngineering 27:1320–1326.

29 Vanaga,G.(2014).Verylatest“EcoCute”innovationsfromHVAC&RJapan.

30 Maratou,A.,Lira,J.T.,Jia,H.,andMasson,N.(2012).CO2 heatpumpsinEurope marketdynamics&legislativeopportunities.

31 Fernandez,N.,Hwang,Y.,andRadermacher,R.(2010).ComparisonofCO2 heatpump waterheaterperformancewithbaselinecycleandtwohighCOPcycles. International JournalofRefrigeration 33:635–644.

32 Andersen,S.Chowdhury,S.,Craig,T.etal.(2017).Comparativemanufacturing andownershipcostestimatesforsecondaryloopmobileAirconditioningsystems (SL-MACs).SAEInternational.

33 Hammer,H.(2000).Carbondioxide(R744)assupplementaryheatingdeviceSAE PhoenixForum2000.

34 Kim,S.C.,Kim,M.S.,Hwang,I.C.,andLim,T.W.(2007).HeatingperformanceenhancementofaCO2 heatpumpsystemrecoveringstackexhaustthermalenergyinfuelcell vehicles. InternationalJournalofRefrigeration 30(7):1215–1226.

35 Wang,D.,Yu,B.,Li,W.etal.(2018).HeatingperformanceevaluationofaCO2 heat pumpsystemforanelectricalvehicleatcoldambienttemperatures. AppliedThermal Engineering 142:656–664.

36 Wang,D.,Yu,B.,Hu,J.etal.(2018).HeatingperformancecharacteristicsofCO2heat pumpsystemforelectricalvehicleinacoldclimate. InternationalJournalofRefrigeration 85:27–41.

37 Schmidt,S.L.,Klöcker,K.,Flacke,N.,andSteimle,F.(1998).ApplyingtheCO2 transcriticalprocesstoadryingheatpump. InternationalJournalofRefrigeration 21: 202–211.

38 Klöcker,K.,Schmidt,E.L.,andSteimle,F.(2001).Carbondioxideasaworkingfluidin dryingheatpumps. InternationalJournalofRefrigeration 24:100–107.