EpoxyComposites

Fabrication,CharacterizationandApplications

Editedby

JyotishkumarParameswaranpillai

HarikrishnanPulikkalparambil

SanjayM.Rangappa SuchartSiengchin

Editors

Dr.JyotishkumarParameswaranpillai

KingMongkut’sUniversityof TechnologyNorthBangkok(KMUTNB) DepartmentofMaterialsandProduction Engineering

1518Pracharaj1

WongsawangRoad,Bangsue 10800Bangkok Thailand

Mr.HarikrishnanPulikkalparambil

KingMongkut’sUniversityof TechnologyNorthBangkok(KMUTNB) DepartmentofMaterialsandProduction Engineering 1518Pracharaj1

WongsawangRoad,Bangsue 10800Bangkok Thailand

Dr.SanjayM.Rangappa

KingMongkut’sUniversityof TechnologyNorthBangkok DepartmentofMaterialsandProduction Engineering 1518Pracharaj1

WongsawangRoad,Bangsue 10800Bangkok Thailand

Prof.SuchartSiengchin

KingMongkut’sUniversityof TechnologyNorthBangkok DepartmentofMaterialsandProduction Engineering 1518Pracharaj1

WongsawangRoad,Bangsue 10800Bangkok Thailand

CoverImage: ©IgorKrutov/AlamyStock

Allbookspublishedby Wiley-VCH arecarefullyproduced.Nevertheless, authors,editors,andpublisherdonot warranttheinformationcontainedin thesebooks,includingthisbook,to befreeoferrors.Readersareadvised tokeepinmindthatstatements,data, illustrations,proceduraldetailsorother itemsmayinadvertentlybeinaccurate. LibraryofCongressCardNo.: appliedfor

BritishLibraryCataloguing-in-Publication Data

Acataloguerecordforthisbookis availablefromtheBritishLibrary.

Bibliographicinformationpublishedby theDeutscheNationalbibliothek TheDeutscheNationalbibliotheklists thispublicationintheDeutsche Nationalbibliografie;detailed bibliographicdataareavailableonthe Internetat <http://dnb.d-nb.de>

©2021WILEY-VCHGmbH,Boschstr. 12,69469Weinheim,Germany

Allrightsreserved(includingthoseof translationintootherlanguages).No partofthisbookmaybereproducedin anyform–byphotoprinting, microfilm,oranyothermeans–nor transmittedortranslatedintoa machinelanguagewithoutwritten permissionfromthepublishers. Registerednames,trademarks,etc. usedinthisbook,evenwhennot specificallymarkedassuch,arenotto beconsideredunprotectedbylaw.

PrintISBN: 978-3-527-34678-3

ePDFISBN: 978-3-527-82406-9

ePubISBN: 978-3-527-82407-6

oBookISBN: 978-3-527-82408-3

Typesetting SPiGlobal,Chennai,India

Printedonacid-freepaper 10987654321

Contents

1IntroductiontoEpoxyComposites 1 HarikrishnanPulikkalparambil,SanjayMavinkereRangappa,Suchart Siengchin,andJyotishkumarParameswaranpillai

1.1Introduction 1

1.2ManufacturingMethodsforFabricationofEpoxyComposites 2

1.3ExperimentalTechniquesfortheCharacterizationofEpoxy Composites 3

1.4PropertiesofEpoxyComposites 6

1.4.1MechanicalProperties 6

1.4.2DielectricProperties 9

1.4.3Water/MoistureAbsorption 9

1.4.4Morphology 11

1.5Conclusion 13 References 13

2SynthesisandManufacturingofEpoxyComposites 23 TurupP.MohanandK.Kanny

2.1Introduction 23

2.2HistoryofEpoxyResin 23

2.3TypesofEpoxyResins 24

2.3.1Bisphenol-AEpoxyResin 24

2.3.2Bisphenol-FEpoxyResin 24

2.3.3PhenolNovolacEpoxyResin 25

2.3.4CycloaliphaticEpoxyResin 26

2.3.5EpoxyResinDiluents 26

2.3.6GlycidylamineEpoxyResin 27

2.4Curing 27

2.4.1CuringAgents 27

2.4.1.1PolyadditionReactions(ActiveHydrogenCompounds) 28

2.4.1.2PolyamideandPolyamine 28

2.4.1.3SecondaryandTertiaryAmines 30

2.4.2AnionicandCationicInitiators 31

2.4.2.1Imidazole(AnionicPolymerizing) 31

2.4.2.2Polymercaptan 31

2.4.2.3Anhydrides 32

2.4.2.4Canhydrides 32

2.4.2.5AlicyclicAnhydrides 32

2.4.2.6AliphaticAnhydrides 32

2.4.3LatentCuringAgents 32

2.4.3.1Light-CuringandUltraviolet-CuringAgents 33

2.4.3.2BoronTrifluoride–AmineComplex 33

2.4.3.3Dicyandiamide 33

2.4.3.4Organic-AcidHydrazide 33

2.4.4CuringConditions 34

2.4.4.1Bisphenol-AEpoxyResin 34

2.4.4.2Bisphenol-FEpoxyResin 34

2.4.4.3PhenolNovolacEpoxyResin 34

2.4.4.4CycloaliphaticEpoxyResin 34

2.4.4.5GlycidylamineEpoxyResin 34

2.5ReactionMechanisms 34

2.5.1Bisphenol-AEpoxyResin 34

2.5.2Bisphenol-FEpoxyResin 35

2.5.3PhenolNovolacEpoxyResin 35

2.5.4CycloaliphaticEpoxyResin 35

2.5.5EpoxyResinDiluents 36

2.6SafetyandEnvironmentalFactorsofEpoxyResins 36

2.6.1Bisphenol-AEpoxyResin,Bisphenol-FEpoxyResin,Glycidylamine EpoxyResin,EpoxyResinDiluents 36

2.6.1.1HealthRisks 36

2.6.1.2EnvironmentalIssues 36

2.6.2PhenolNovolacEpoxyResin 36

2.6.2.1HealthRisks 36

2.6.2.2EnvironmentalIssues 36

2.6.3CycloaliphaticEpoxyResin 37

2.6.3.1HealthRisks 37

2.6.3.2EnvironmentalIssues 37

2.7ManufacturingofEpoxyComposites 37

2.7.1OpenMolding 37

2.7.1.1HandLay-Up 38

2.7.1.2Spray-Up 39

2.7.1.3FilamentWinding 40

2.7.2ClosedMolding 41

2.7.2.1ReinforcedReactionInjectionMolding(RRIM) 41

2.7.2.2Vacuum-AssistedResinTransferMoldingProcess(VARTM) 43

2.7.2.3LightResinTransferMolding(LRTM) 44

2.7.2.4VacuumInfusionProcess(VIP) 45

2.7.2.5PultrusionProcess 46

2.7.2.6VacuumBagMolding(WetBagging) 47

2.7.2.7CentrifugalCasting 48

2.7.3NaturalFiberReinforcedEpoxyComposites 49

2.7.3.1ManufacturingofNaturalFiberReinforcedEpoxyComposites 49

2.8PreparingofParticulateFilledEpoxyComposites 51

2.8.1ParticleReinforcedEpoxyComposites 51

2.8.2Nanoparticle-FilledEpoxyComposite 51

2.8.2.1Method1 52

2.8.2.2Method2 52

2.9FuturisticProcessingofEpoxy-BasedComposites 52

2.9.1FastCuringPowderAdhesiveEpoxyResin 52

2.9.23DPrinting 53

2.9.3AdhesiveMethod 53

2.9.4UltrasonicFabricationMethodforEpoxyResin/SbSINanowire Composites 54

2.9.5Electron-Beam(E-Beam)Curing 54

2.9.6AutomatedFiberPlacement(AFP)EpoxyResinComposite 54

2.10Conclusion 54 References 55

3Micro-andNanoscaleStructureFormationinEpoxy-Clay Nanocomposites 61

SenoJose,V.K.Smitha,SanjayM.Rangappa,SenthilkumarKrishnasamy, DebabrataNandi,SuchartSiengchin,andJyotishkumarParameswaranpillai

3.1Introduction 61

3.2MicroandNanoscaleStructuresofPolymer/ClayNanocomposites 62

3.3EvolutionofEpoxy-ClayNanocompositeStructure 65

3.4MechanismofNanocompositeFormation 67

3.5ConclusionandFutureOutlook 72 References 73

4LongFiber-ReinforcedEpoxyComposites 83 AyeshaKausar

4.1Introduction 83

4.2LongFiberFillers 84

4.3LongFiber-ReinforcedEpoxyComposite 84

4.3.1EpoxyandLongGlassFiberComposite 84

4.3.2EpoxyandLongCarbonFiberComposite 87

4.3.3EpoxyandNaturalFiberComposite 90

4.4Applications,FutureProspective,andSummary 90 References 92

5Eco-FriendlyEpoxy-BasedComposites 97 VivekMishraandAlokAgrawal

5.1Introduction 97

5.2PhysicalBehaviorofNaturalFiber/Filler-ReinforcedEpoxy Composites 100

5.3MechanicalPropertiesoftheEpoxy-BasedComposites 103

5.3.1TensileProperties 104

5.3.2ImpactProperties 106

5.4ThermalBehaviorofNaturalFiber/Filler-ReinforcedEpoxy Composites 108

5.5WearBehaviorofNaturalFiber/Filler-ReinforcedEpoxy Composites 115

5.5.1ErosiveWear 115

5.5.2AdhesiveWear 115

5.5.3AbrasiveWear 116

5.6BioepoxyComposites 118

5.7Conclusion 119 References 119

6ProcessingofEpoxyCompositesBasedonCarbon Nanomaterials 125

LourdesRamos-Galicia,JuventinoLópez-Barroso,JulioAlejandro Rodríguez-González,CarlosVelasco-Santos,CarlosRubio-González, andAnaLauraMartínez-Hernández

6.1Introduction 125

6.2EpoxyNanocompositesReinforcedwith1Dand2DCarbonMaterials, MechanicalandThermomechanicalPerformance 126

6.3TracingofCureReaction 136

6.3.11DCarbonNanostructuresInfluenceovertheEpoxyCureReaction 137

6.3.2Influenceof2DCarbonNanostructuresOvertheCureReaction 139

6.3.33DHybridCarbonNanostructuresoverCureReactionofEpoxy Nanocomposites 143

6.4ImprovedMechanicalPropertiesofCarbonFiberReinforcedPolymers (Epoxy)throughtheIncorporationofCarbonNanostructures 146

6.4.1CFRPs(BasedEpoxy)ModifiedwithCarbonNanotubes 147

6.4.2CFRPs(BasedEpoxy)ModifiedwithGraphene-BasedMaterials 154

6.4.3CFRPs(BasedEpoxy)ModifiedwithHybrids(CarbonNanotubesand Graphene) 158

6.5ConcludingRemarks 160 References 161

7ThermalStabilityandFlameRetardancyofEpoxy Composites 177

MohamedismailFathimaRigana,TharakanSimiAnne,SadhasivamBalaji, ShanmugamChandrasekar,andMuthusamySarojadevi

7.1Introduction 177

7.2EffectsofMicroFillersonThermalPropertiesofEpoxyResin 178

7.2.1Epoxy/GlassFiberComposites 178

7.2.1.1Bis(4-cyanato-3,5-dimethylphenyl)NaphthylMethane/Epoxy/Glass FiberComposites 178

7.2.1.2Epoxy(DGEBA)Resin + CSE(ChlorinatedSoyOil)–BasedEpoxy/Glass FiberComposites 179

7.2.1.3Novolac-TypeEpoxyandIsocyanate-ModifiedEpoxy/GlassFiber Composites 182

7.2.2Epoxy/NaturalFiberComposites 182

7.2.2.1Epoxy(DER331)/KenafFiberComposites 182

7.2.2.2Epoxy(Ampreg26)/Phormiumtenax Composites 185

7.2.3Epoxy/NaturalFiberHybridComposites 186

7.2.3.1Epoxy(AralditeM)/Jute–GlassFiberHybridComposites 186

7.2.3.2Epoxy/FlaxandSisal–GlassFiberComposites 186

7.2.3.3Epoxy(DER331)/MH(MagnesiumHydroxide)-KenafFiber Composites 187

7.3EffectofNanofillersonThermalPropertiesofEpoxyResin 188

7.3.1Epoxy/ClayNanocomposites 188

7.3.1.1Epoxy(DGEBA)/ClayNanocomposites 188

7.3.1.2Epoxy(E51)/D-clay(Na+ -MMT)Nanocomposites 189

7.3.1.3Epoxy(DGEBA)/CloisiteNa+,Cloisite10A,Cloisite15,Cloisite93A Nanocomposites 190

7.3.1.4OrganoPhosphorusEpoxy/ClayNanocomposite 190

7.3.1.5Epoxy(DGEBA)/DNA-ModifiedMMTClayNanocomposites 191

7.3.2Epoxy/CNFNanocomposites 192

7.3.2.1Epoxy(SC-15)/CarbonNanoFiber(PR-24)Nanocomposites 192

7.3.3Epoxy/CNTNanocomposites 194

7.3.3.1CNT/EpoxyNanocomposites 194

7.3.4Epoxy/CelluloseNanofiberNanocomposites 196

7.3.4.1Epoxy(D.E.R.331)/CelluloseNanofiberNanocomposites 196

7.3.5Epoxy/SphericalMetalOxideNanocomposites 196

7.3.5.1Epoxy(Epon862)/CoreshellFe@FeONanocomposites 196

7.3.5.2Epoxy(Epon862)/Polyaniline-StabilizedSilicaNanoComposites 199

7.3.6EpoxyBasedHybridNanocomposites 201

7.3.6.1Epoxy(DGEBA)/CNT/OMPOSS/APPHybridNanocomposite 201

7.3.6.2Acrylonitrile–Butadiene–Styrene/BrominatedEpoxy–Antimony Oxide/OrganoMontmorillonite(ABS/BER-AO/OMT) Nanocomposites 202

7.3.6.3Epoxy/Ag@Cu–Ag@rGONanocomposite-BasedConductive Adhesives 203

7.3.6.4Epoxy/HM-SiO2 @CeO2 /NiONanocomposites 203

7.3.6.5Epoxy(Araldite)/Microsilica/NanoaluminaNanocomposites 204

7.4Epoxy-BasedHybridMicroandNanocomposites 204

7.4.1Epoxy(LY556)–Closite25AOMMT/GlassfiberMicroNano Composite 204

7.4.2Epoxy/GlassFiber(GE)Composites,Epoxy/GlassFiber/FGO Nanocomposites 205

x Contents

7.4.3Epoxy/GlassFiber(GE)CompositesandEpoxy/Glassfiber/NanoAl2 O3 Nanocomposites 205

7.4.4Epoxy/CF/DWCNT-NH2 Micro-Nanocomposites 206

7.4.5Epoxy/CarbonFiberComposites,Epoxy/CarbonNanotube Membrane/CarbonNanofiber(CNF)PaperMicro-Nanocomposites 207

7.5Conclusions 211

Acknowledgments 212 References 212

8SpectroscopyandX-rayScatteringStudiesofEpoxy Composites 217 P.PoornimaVijayan

8.1Introduction 217

8.2InsituCureMonitoring 218

8.3CharacterizationofInterfaceinFiber-ReinforcedEpoxy Composites 225

8.4DeterminationofResidualStressDevelopedDuringCure 228

8.5StressTransmissionStudiesinParticulateFilledEpoxyComposite 231

8.6WaterDiffusionStudies 232

8.7MorphologicalAnalysisinEpoxyComposites 233

8.8Conclusion 236 References 236

9WaterAbsorptionStudiesinEpoxyNanocomposites 241 BejoyFrancis

9.1Introduction 241

9.2FactorsAffectingWaterAbsorption 242

9.3EffectofWaterAbsorptiononMechanicalProperties 247

9.4EffectofWaterAbsorptiononDynamicMechanicalProperties 251

9.5EffectofWaterAbsorptiononThermomechanicalProperties 253

9.6EffectofWaterAbsorptiononDielectricProperties 254

9.7Conclusion 255 References 255

10FractureSurfaceandMechanicalPropertiesofEpoxy Composites 259 MehdiNaderiandFarnazEbrahimi

10.1Introduction 259

10.2Morphology 266

10.2.1DispersionandInterfacialAdhesion 266

10.2.2FractureSurfaceMorphology 273

10.3MechanicalProperties 278

10.3.1Stress–StrainBehavior 278

10.3.2FractureToughness 281

10.3.3ImpactProperties 282

10.3.4DynamicMechanicalProperties 284

10.3.5LapShearProperties 288

10.4ConclusionsandOutlooks 290 References 292

11DielectricandConductivityStudiesofEpoxyComposites 299

AnastasiosC.PatsidisandGeorgiosC.Psarras

11.1Introduction 299

11.2ExperimentalTechniquesandDataInterpretation 300

11.2.1ExperimentalTechniques 300

11.2.2DielectricandConductivityDataInterpretation 300

11.3ElectricalPropertiesofEpoxyResins 302

11.4Epoxy/NonconductiveReinforcingPhaseComposites 306

11.4.1Epoxy/NonconductiveFillerMicro-composites 306

11.4.2Epoxy/NonconductiveFillerNanocomposites 312

11.5Epoxy/ConductiveReinforcingPhaseComposites 317

11.5.1Epoxy/ConductiveFillerMicro-composites 317

11.5.2Epoxy/ConductiveFillerNanocomposites 325

11.6Epoxy-BasedHybridComposites–TargetingMultifunctionality 332

11.7ConclusionsandFutureTrends 343 References 343

12SmartEpoxyComposites 349

RezaEslami-FarsaniandHosseinEbrahimnezhad-Khaljiri

12.1Introduction 349

12.2ShapeMemoryEpoxyPolymersandtheirComposites 350

12.2.1TheCreationofShapeMemoryBehaviorintoEpoxy 350

12.2.2ShapeMemoryBehaviorinEpoxy-BasedNanocomposites 354

12.2.3ShapeMemoryBehaviorinEpoxy-BasedCompositeStructures 358

12.2.4ShapeMemoryWiresintheEpoxyComposites 360

12.3SmartEpoxyCompositeCoating 360

12.3.1Carbon-BasedNanomaterials–EpoxyCoating 364

12.3.2Clay-BasedNanomaterials–EpoxyCoating 365

12.3.3Silica-BasedNanomaterials–EpoxyCoating 366

12.3.4LayeredDoubleHydroxide-BasedNanomaterials–EpoxyCoating 367

12.3.5OtherNanoparticles–EpoxyCoating 367

12.3.6PolymerMicro-/Nanocontainer–EpoxyCoating 368

12.4Self-HealingEpoxyPolymersandtheirComposites 371

12.4.1Self-HealingBehavior 371

12.4.2IntrinsicHealingSystem 372

12.4.3VascularHealingSystem 375

12.4.4MicrocapsuleHealingSystem 377

12.5FutureTrends 380

12.6Conclusion 380

References 381

xii Contents

13ProjectsUsingCompositeEpoxyMaterials:Applications, RecyclingMethods,EnvironmentalIssues,Safety,andFuture Directions 395 AlencarBravoandDarliVieira

13.1IntroductionandContextofECMProjects 395

13.2DifferentApplicationsforECMs 397

13.3SafetyandEnvironmentalIssuesofECMProjects 400

13.4RecyclingOptionsforECMsandPollutionMitigationby EarlyDesign 405

13.5TheFutureforECMProjectsandConclusions 410 References 412

Index 421

1.4PropertiesofEpoxyComposites

1.4.1MechanicalProperties

Themechanicalpropertiesofepoxycompositesareanimportanttopicinshapingits efficientuseinanyapplicationarea.Thefactorsthataffectthemechanicalproperties

Table1.2 CharacteristicbandsofDGEBA.

Band(cm 1 )FTIRpeakassignment

≈3500O–Hstretching

3057C–Hstretchingvibrationsoftheoxiranering 2965–2873C–Hstretchingvibrationsinepoxyresin

1608C=Cstretchingvibrationsofaromaticrings

1509C–Cstretchingvibrationsofaromaticrings

1036C–O–Cstretchingvibrationsofethers

915C–Ostretchingvibrationsofoxiranegroup 831C–O–Cstretchingvibrationsofoxiranegroup 772CH2 rocking

Source:MaríaGonzálezetal.[73].IntechOpen.CCBY3.0.

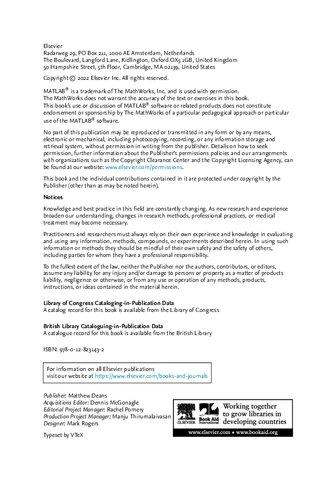

offiller-reinforcedepoxycompositesarevolumefractionoffiller,filleraspectratio, fillerorientation,andfiller–matrixinterfacialadhesion[74].Themechanicalpropertiesofnaturalfibercompositescanbeimprovedwhenitisusedalongwithsynthetic fibers[75].Inotherwords,thehybridizationofnaturalfiberandsyntheticfiber leadstoimprovedmechanicalpropertiesduetothesynergeticeffectsofboththe fibers.Fioreetal.[76]studiedtheeffectofalkali(NaOH)treatmentonkenaffibers. Theyreportedthatthealkalitreatmentresultedinimprovedmechanicalstrengthby reducingthepolymerchainmobilityandenhancingthestresstransfer.However,the immersiontimeinNaOHhadanunfavorableeffectonthemechanicalproperties. Theparticlesizeoffillersmayalsoaffectthemechanicalproperties.Forexample, Wangetal.[77]showedtheeffectofparticlesizeofgraphenenanoplateletsonthe mechanicalpropertiesofepoxycomposites.Moderateincreaseinstrengthandmodulusisobservedwhensmallerparticlesareused.Ontheotherhand,largerparticles improvethemodulusremarkablybutreducethestrength.Thisisduetothereinforcementeffectoflargerparticles,buttheyhavepoorinterfacialinteractionwith theepoxymatrix.Inaninterestingwork,Gojnyetal.[24]schematicallydescribed severalmechanismsduringthefailureofCNT-modifiedepoxymatrixasshownin Figure1.1.ThedifferentfailuresoccurringontheCNTsduringtheapplicationof tensileforcearepullout,breakage,pulloutofinnertube,andbridgingorpartial debondingattheinterfaces.

Theimpactstrength/resistanceofacompositeistheenergyneededtobreakany material.Inotherwords,theimpactstrengthofamaterialisitsabilitytoresistthe appliedstressathighspeed.Manyfactorssuchasvoids,sharpedgesoffillers,filler agglomeration,andweakfiller–epoxyinterfacemayleadtostressconcentratedareas thatmaycausefailuresintheformofcracksbytheapplicationofappliedstress [78,79].Onewaytoimprovetheimpactstrengthisbytheadditionofdispersantsor couplingagents[80].Theadditionofdispersantsreducesfilleragglomerationthat couldotherwiseactasastressconcentrationpoint.DevendraandRangaswamy[81]

(a)(b)(c)(d)(e)

Figure1.1 Schematicrepresentationoffailuretypesinepoxy/CNTcomposites:(a) undamagedCNT,(b)CNTpullout,(c)CNTbreakage(verygoodCNT–epoxyinteraction),(d) telescopicpulloutdamagingoutertubeandpulloutdamaginginnertube,and(e)bridging andpartialdebondingatinterface.Source:Gojnyetal.[24].©2005,Elsevier.

reportedthatthefillercontenthigherthanoptimumhasanadverseeffectonthe impactresistanceofacompositeduetoagglomerationoffillers.

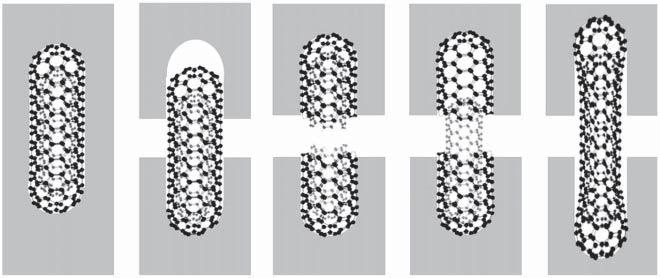

Theinterfacialshearstress(IFSS)measuresthedegreeofinterfacialstrength betweenthefillerandtheepoxymatrix.Wangetal.[82]studiedIFSSmeasurementsofAgnanoparticlesandgrapheneoxide(GO)-depositedCF-reinforcedepoxy composites.TheauthorsreportedthattheIFSSimprovedfrom46.8to87.1MPafor theepoxycomposites.ThepresenceofAgnanoparticleswasobservedtoincrease thesurfaceroughnessofthefiberandthematrix,whichprovidesbetterinterlocking betweenthefiberandthematrix.WhiletheincorporationofGOgreatlyimproves thewettabilityandinterfacialadhesionbetweentheCFandpolymermatrixthat leadstoimprovedshearstrength(Figure1.2).Godaraetal.[83]studiedtheeffectof CNTsontheIFSSofglassfiber-reinforcedepoxycomposites.Itwasobservedthat CNTsimprovetheIFSSirrespectiveofitslocationinthecomposites.However,as

Figure1.2 SchemeshowingfailuremodeofuntreatedCF-modifiedepoxy,CF/Ag-modified epoxy,andCF/Ag/GO-modifiedepoxy.Source:Wangetal.[82].©2017,Elsevier.

Figure1.3 Schematicrepresentation ofCNTsondifferentlocationsinthe compositeanditseffectonIFSS.

Source:Godaraetal.[83].©2010, Elsevier.

showninFigure1.3,themaximumimprovementofIFSSisobservedforcomposites withCNTsonthesurfaceoftheglassfiber.

1.4.2DielectricProperties

Thedielectricconstantandthedissipationfactorarethetwoimportantparameters inmeasuringthedielectricproperties[84].Thedielectricconstantmeasuresthe abilityofthematerialtostorecharge,whilethedissipationfactoristheenergydissipatedbyadielectric.Thesearemeasuredasafunctionoffrequencyofalternating currentbyplacingthecompositematerialbetweentheplatesofacondenserand measuringtheimpedance[85,86].Thedielectricconstantofepoxyresinisvery low(<10)tobeusefulinpracticalapplications[87].Incorporatinganadequate amountoffillersmayimprovethedielectricpropertiestosomeextent.However, higherloadingmayaffectthemechanicalpropertiesofthecomposite[88–90].Inan interestingwork,SinghaandThomas[91]studiedthedielectricpropertiesofinorganicfiller(TiO2 ,ZnO,andAI2 O3 )-incorporatedepoxycomposites.Itwasobserved thatthepermittivityandtandeltavaluesofthenanocompositeswerelowerthan thoseofthemicro-compositesandunfilledcomposites.Inanotherwork,Kuoetal. [92]preparedepoxycompositesusingself-synthesizedbariumtitanate(BaTiO3 ), commercialBaTiO3 ,andPb(Mg1/3 Nb2/3 )O3 ceramicparticles.Itwasobservedthat theself-synthesizedceramicparticleBaTiO3 exhibitsadielectricconstantof44 comparedto27and24forcommercialBaTiO3 andPb(Mg1/3 Nb2/3 )O3 composites. Thisisduetothelargeceramicaggregatesformedintheepoxycompositesby self-synthesizedBaTiO3 .Inanotherstudy,Wanetal.[93]reportedthedielectric propertiesofDGEBA–RGO/epoxycomposites,whereDGEBA–RGOwasprepared bygraftingDGEBAmoleculesonreducedgrapheneoxide(RGO)sheets.The DGEBA–RGO/epoxycompositesshowedanimproveddielectricconstantof ∼32. ThiswasattributedtobettercompatibilityarisingduetograftingofDGEBAandthe bettercontactofRGOsheetsmakingapathwayforsuppressingthedielectricloss effectively.Inoneoftheworks,Jlassietal.[94]reportedthataverysmallamount ofdiazonium-modifiedclay-polyanilinenanofiller(B-DPA/PANI)intheepoxy matrixcanimprovethetensilestrength(0.1wt%)anddielectricconstantwiththe incorporationaslowas0.5wt%.Thisisduetothegooddispersionofthenanofiller intheepoxymatrix.

1.4.3Water/MoistureAbsorption

Waterabsorptionofamaterialmaybedefinedasthepercentageofwateruptakein agivenunittimeataspecifictemperature.Itiscalculatedbymeasuringthechange

1IntroductiontoEpoxyComposites

inweightwithrespecttoitsoriginalweightafteragiventime.Theweightgainedat saturationisthefinalweight.

Wateruptake (%)= Initialweightofsample-Finalweightofsample Initialweightofsample × 100

Therateofwateruptakecanbemeasuredbycalculatingthediffusioncoefficientof thecomposites[95].Thefollowingequationcanbeusedtocalculatethecoefficient ofdiffusion:

Oneofthemainlimitationsofepoxyresinanditscompositesisitshighwater absorption.Thewateruptakemayadverselyaffectthe T g ,modulus,strength,and toughnessduetothedegradationoftheepoxythermoset[73].Italsogeneratesinternalstressesduetoswellingandcausesdelaminationofthefillerorotherdefects incomposites.Ingeneral,themainconcernwithnaturalfibercompositesistheir highmoistureintakeduetothepresenceofhydroxylgroupsinthefiber,which reducesthecompatibilitybetweenthefiberandtheepoxymatrix[96].Infact,the fiber–matrixinterfacialstrengthmaybereduced,whichinturnwilldecreasethe mechanicalperformancesofthecomposites.Infewstudies,itwasobservedthat thehybridizationoffibersinthecompositemayimprovethemechanicalandwater absorptionproperties[97–99].Forexample,Maslindaetal.[100]studiedtheeffect ofwaterabsorptiononthemechanicalpropertiesofwovenkenaf,jute,andhemp fiber-basedhybridepoxycomposites.Theauthorsreportedthatthemechanicaland water-resistantpropertiesofthecompositeswereimprovedwithhybridization.

Thewaterabsorptionisobservedtobehigherfornaturalfiber-reinforcedcompositeswhencomparedtosyntheticfiber-reinforcedcomposites[101,102].Therefore,thehybridizationofnaturalfiberandsyntheticfiberreducesthewateruptake tremendously.SanjayandYogesha[102]studiedthewaterabsorptionbehaviorof jute,kenaf,andE-glasswovenfiber-reinforcedepoxycompositeswithdifferentlayeringsequences.Theauthorsreportedareductioninwaterabsorptionbehaviorwith thehybridizationofnaturalandsyntheticfibers.Venkateshwaranetal.[103]studiedthewaterabsorptionrateofsisalandbananafibercomposites.Theyobserveda reductionintherateofwaterabsorptionafterhybridizingthesisalfiber(50%)with bananafiber.

Thewettingoffibersorfillersplaysanimportantroleinreducingthewater absorptionbecausewettingimprovestheadhesionofthefillerwithmatrix [104,105].Theadditionofasmallamountofnanoclay(c.3–5wt%)inepoxy compositesexhibitsimprovedbarrierproperties[106,107].Beckeretal.[108] studiedwaterabsorptioninnanoclay-filledtetrafunctionaltetraglycidyldiamino diphenylmethane(TGDDM)andDGEBAresinsystems.Itwasevidentfromthe resultsthatnanoclay-filledcompositesshowedlowerwaterabsorptionwhen comparedtoneatepoxyresin.However,therateofdiffusionwiththechangein nanoclayconcentrationisobservedtobeunaffected.Inaninterestingwork,Mohan andKanny[109]reportedthewaterbarrierpropertiesofsisalfiber-modifiedepoxy compositesandnanoclay-filledsisalfiber-reinforcedepoxycomposites.Afterwater

D =π( kh 4Mn )2

1.4PropertiesofEpoxyComposites 11 absorption,thetensileandwearpropertiesofsisalfibercompositesdetrimentally decreased.However,aftertheadditionofnanoclaytosisalfibercomposites,the tensileandwearpropertiesareleastaffected.Thisisduetothebarrierpropertyof nanoclaythatstopsthewaterfromenteringthecomposites.

1.4.4Morphology

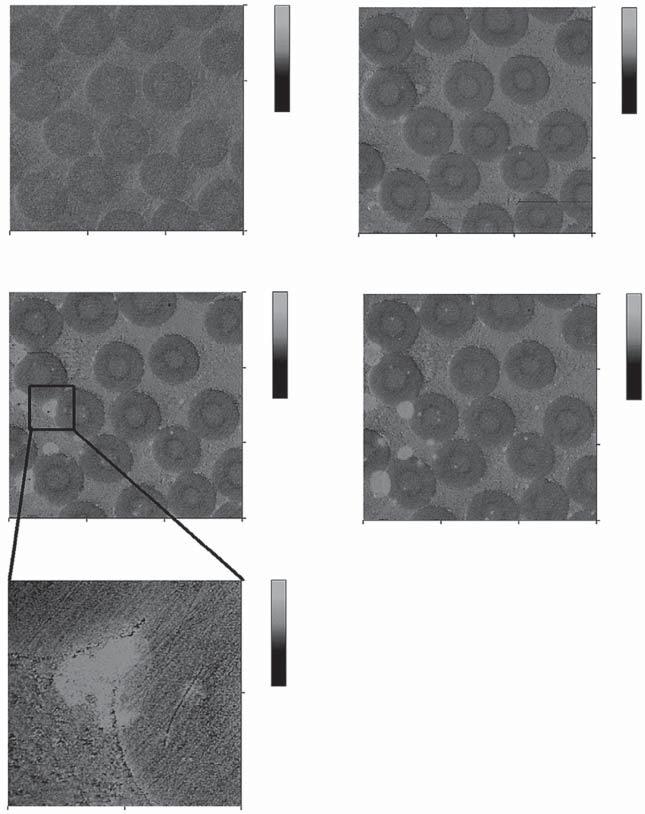

Themorphologyofcompositesplaysanimportantroleinidentifyingthefailure mechanisms.Forexample,electronmicroscopeisusedtoanalyzetheexistence ofvoids,agglomeration,anddispersionoffillers[110,111].Inaninteresting study,Sabaetal.[111]preparedhybridepoxycompositescontainingkenafandoil palmemptyfruitbunchfiber(OPEFB)fillersthatshowedimprovedmechanical properties.Themorphologystudyrevealedthattheadditionof3%OPEFBfiller intoepoxy/kenafcompositeswasobservedtoimprovetheinterfacialbonding betweenthefiberandmatrix.Also,theadditionofOPEFBfiberreducesvoid contents,fiberpullout,andfiberprotrudingandtearingonthecomposites.Oksmanetal.[112]studiedthemorphologyofunidirectionalsisal/epoxycomposites. Figure1.4a,bshowsscanningelectronmicroscopy(SEM)imagesoffractured surfaceofsisal/epoxycomposites.Here,thefiberpulloutandimprintsarevisible. Figure1.4c,dshowstheopticalmicroscopyimagesofthecomposites.Thefigures showfiberdistributionandhorseshoe-shapedtechnicalfibers.Atomicforce microscopy(AFM)isalsoapowerfultooltocharacterizesurfacemorphologyand

Figure1.4 (aandb)SEMimageofsisal/epoxyfracturesurfaceshowsfiberpulloutsand imprintofthefiberonepoxysurface,(candd)opticalmicroscopyofsisal/epoxycomposites showshorseshoestructureandvoidsinthefiber–epoxyinterface.Source:Oksmanetal. [112],ReproducedwithpermissionfromWiley,LicenseNumber:4847180686936.

(a)

(b)(d)

(c)

Figure1.5 AFMimageshowingdebondingoccurredduringhygroscopictreatmentsof carbonfiber-reinforcedcomposite.Source:WangandHahn[114],Reproducedwith permissionfromElsevier,LicenseNumber:4847180982493.

thicknessofnanosizedfillersinepoxycomposites.GeorgeandVerpoest[113] characterizedtheuntreatedandsilane-treatedfiberusingAFMandobservedthat thesurfaceofthetreatedfibersisrougherthanthatoftheuntreatedfibers.In anotherwork,WangandHahn[114]studiedtheeffectofhygrothermalprocesses ontheinterfacialpropertiesofCF-reinforcedepoxycomposites.TheAFMwas usedtoinvestigatethedebondingoffibers.Figure1.5showstheAFMimageof debondinginhygroscopictreatedcompositesatdifferenttimeintervals.

1.5Conclusion

Inthischapter,anoverviewofthemanufacturing,characterization,andproperties oftheepoxycompositesisbrieflydiscussed.Itisworthtopointoutthattheapplicationsofepoxycompositesarewidelyacceptedinallareasofmanufacturingindustriessuchasautomotive,aerospace,construction,oilandgas,andmarineowingto theirexcellentheatandsolventresistance,highthermomechanicalproperties,high specificstrength,goodadhesiveness,lightweight,andlowcost.Epoxycomposites alsofindapplicationsinprintedcircuitboards(PCBs),electromagneticshielding (EMI),supercapacitors,etc.Thehighperformanceofthecompositesisgenerally achievedbytheincorporationoffibers,organicfillers,andinorganicfillers.Furthermore,theadditionofthermoplasticcopolymersmayphaseseparateintodifferent phasemorphologieswhichmaytailortheperformanceoftheepoxycomposites.

References

1 Basheer,B.V.,George,J.J.,Siengchin,S.,andParameswaranpillai,J.(2020). Polymergraftedcarbonnanotubes–synthesis,properties,andapplications:a review. Nano-Structures&Nano-Objects 22:100429.

2 Masuelli,M.A.(2013).Introductionoffibre-reinforcedpolymers–polymers andcomposites:concepts,propertiesandprocesses.In: FiberReinforcedPolymers–TheTechnologyAppliedforConcreteRepair .Rijeka,Croatia:IntechOpen.

3 Campbell,F.C.(2010).Introductiontocompositematerials. StructuralCompositeMaterials 1:1–29.

4 Cantwell,W.J.andMorton,J.(1991).Theimpactresistanceofcompositematerials–areview. Composites 22(5):347–362.

5 Rahman,R.andPutra,S.Z.(2019).Tensilepropertiesofnaturalandsynthetic fiber-reinforcedpolymercomposites.In: MechanicalandPhysicalTestingof Biocomposites,Fibre-ReinforcedCompositesandHybridComposites,81–102. WoodheadPublishing,Cambridge,UK.

6 Jin,F.L.,Li,X.,andPark,S.J.(2015).Synthesisandapplicationofepoxyresins: areview. JournalofIndustrialandEngineeringChemistry 29:1–1.

7 Gu,H.,Ma,C.,Gu,J.etal.(2016).Anoverviewofmultifunctionalepoxy nanocomposites. JournalofMaterialsChemistryC 4(25):5890–5906.

8 Stenko,M.S.andChawalwala,A.J.(2001).Thinpolysulfideepoxybridgedeck overlays. TransportationRresearchRrecord 1749(1):64–67.

9 Vijayan,P.P.,Puglia,D.,Jyotishkumar,P.etal.(2012).Effectofnanoclayand carboxyl-terminated(butadiene-co-acrylonitrile)(CTBN)rubberonthereactioninducedphaseseparationandcurekineticsofanepoxy/cyclicanhydride system. JournalofMaterialsScience 47(13):5241–5253.

10 Kausar,A.(2017).Polyurethane/epoxyinterpenetratingpolymernetwork.In: AspectsofPolyurethanes,27.Rijeka,Croatia:IntechOpen.

1IntroductiontoEpoxyComposites

11 Hodd,K.(1989).Epoxyresins.In: ComprehensivePolymerScienceandSupplements,vol.5(eds.V.PercecandC.Pugh),667–699.Oxford:Pergamon Press.

12 Abdellaoui,H.,Raji,M.,Bouhfid,R.,andelkacemQaiss,A.(2019Jan1). Investigationofthedeformationbehaviorofepoxy-basedcompositematerials. In: FailureAnalysisinBiocomposites,Fibre-ReinforcedCompositesandHybrid Composites,29–49.Cambridge,UK:WoodheadPublishing.

13 Paluvai,N.R.,Mohanty,S.,andNayak,S.K.(2014).Synthesisandmodifications ofepoxyresinsandtheircomposites:areview. Polymer-PlasticsTechnologyand Engineering 53(16):1723–1758.

14 Satyanarayana,K.G.,Sukumaran,K.,Mukherjee,P.S.etal.(1990).Natural fibre-polymercomposites. CementandConcreteComposites 12(2):117–136.

15 Satyanarayana,K.G.,Sukumaran,K.,Kulkarni,A.G.etal.(1986).Fabrication andpropertiesofnaturalfibre-reinforcedpolyestercomposites. Composites 17 (4):329–333.

16 Gowda,T.M.,Naidu,A.C.,andChhaya,R.(1999).Somemechanicalproperties ofuntreatedjutefabric-reinforcedpolyestercomposites. CompositesPartA: AppliedScienceandManufacturing 30(3):277–284.

17 Ashik,K.P.andSharma,R.S.(2015).Areviewonmechanicalpropertiesof naturalfiberreinforcedhybridpolymercomposites. JournalofMineralsand MaterialsCharacterizationandEngineering 3(05):420.

18 Vijay,R.,Singaravelu,D.L.,Vinod,A.etal.(2019).Characterizationofrawand alkalitreatednewnaturalcellulosicfibersfromTridaxprocumbens. InternationalJournalofBiologicalMacromolecules 125:99–108.

19 Yorseng,K.,Sanjay,M.R.,Tengsuthiwat,J.etal.(2019).InformationinUnited StatesPatentsonworksrelatedto‘NaturalFibers’:2000–2018.CurrentMaterialsScience:Formerly:RecentPatentson. MaterialsScience 12(1):4–76.

20 Sanjay,M.R.,Siengchin,S.,Parameswaranpillai,J.etal.(2019).Acomprehensivereviewoftechniquesfornaturalfibersasreinforcementincomposites: preparation,processingandcharacterization. CarbohydratePolymers 207: 108–121.

21 Khan,A.,Vijay,R.,Singaravelu,D.L.etal.(2020).Extractionandcharacterizationofvetivergrass(Chrysopogonzizanioides)andkenaffiber(Hibiscus cannabinus)asreinforcementmaterialsforepoxybasedcompositestructures. JournalofMaterialsResearchandTechnology 9(1):773–778.

22 Madhu,P.,Sanjay,M.R.,Senthamaraikannan,P.etal.(2019).YogeshaB.A reviewonsynthesisandcharacterizationofcommerciallyavailablenatural fibers:Part-I. JournalofNaturalFibers 16(8):1132–1144.

23 Abdellaoui,H.,Bouhfid,R.,andelKacemQaiss,A.(2016).Clay,naturalfibers andthermosetresinbasedhybridcomposites:preparation,characterizationand mechanicalproperties.In: Nanoclayreinforcedpolymercomposites,225–246. Singapore:Springer.

24 Gojny,F.H.,Wichmann,M.H.,Fiedler,B.,andSchulte,K.(2005).Influence ofdifferentcarbonnanotubesonthemechanicalpropertiesofepoxymatrix

References 15 composites–acomparativestudy. CompositesScienceandTechnology 65(15–16): 2300–2313.

25 Fiore,V.,Scalici,T.,DiBella,G.,andValenza,A.(2015).Areviewonbasalt fibreanditscomposites. CompositesPartB:Engineering 74:74–94.

26 Summerscales,J.,Virk,A.,andHall,W.(2013).Areviewofbastfibresand theircomposites:Part3–Modelling. CompositesPartA:AppliedScienceand Manufacturing 44:132–139.

27 Mishra,V.andBiswas,S.(2013).Physicalandmechanicalpropertiesof bi-directionaljutefiberepoxycomposites. ProcediaEngineering. 51:561–566.

28 Ramesh,M.,Atreya,T.S.,Aswin,U.S.etal.(2014).Processingandmechanical propertyevaluationofbananafiberreinforcedpolymercomposites. Procedia Engineering 97:563–572.

29 Harshe,R.(2015).Areviewonadvancedout-of-autoclavecompositesprocessing. JournaloftheIndianInstituteofScience 95(3):207–220.

30 Hsiao,K.T.andHeider,D.(2012Jan1).Vacuumassistedresintransfermolding(VARTM)inpolymermatrixcomposites.In: ManufacturingTechniques forPolymerMatrixComposites(PMCs),310–347.Cambridge,UK:Woodhead Publishing.

31 Schmachtenberg,E.,ZurHeide,J.S.,andTöpker,J.(2005).Applicationofultrasonicsfortheprocesscontrolofresintransfermoulding(RTM). PolymerTesting 24(3):330–338.

32 Ouarhim,W.,Zari,N.,Bouhfid,R.,andelkacemQaiss,A.(2019Jan1). Mechanicalperformanceofnaturalfibers–basedthermosettingcomposites.In: MechanicalandPhysicalTestingofBiocomposites,Fibre-ReinforcedComposites andHybridComposites,43–60.Cambridge,UK:WoodheadPublishing.

33 Kong,I.,Tshai,K.Y.,andHoque,M.E.(2015).Manufacturingofnatural fibre-reinforcedpolymercompositesbysolventcastingmethod.In: ManufacturingofnaturalFibreReinforcedPolymerComposites,331–349.Cham: Springer.

34 Eckold,G.C.(1994).Designandmanufactureofcompositestructures. WoodheadPublishingSeriesinCompositesScienceandEngineering:251–304.

35 deAndradeSilva,F.,Chawla,N.,anddeToledoFilho,R.D.(2008).Tensile behaviorofhighperformancenatural(sisal)fibers. CompositesScienceand Technology 68(15-16):3438–3443.

36 Rong,M.Z.,Zhang,M.Q.,Liu,Y.etal.(2001).Theeffectoffibertreatmenton themechanicalpropertiesofunidirectionalsisal-reinforcedepoxycomposites. CompositesScienceandTechnology 61(10):1437–1447.

37 Chachad,Y.R.,Roux,J.A.,Vaughan,J.G.,andArafat,E.(1995). Three-dimensionalcharacterizationofpultrudedfiberglass-epoxycomposite materials. JournalofReinforcedPlasticsandComposites 14(5):495–512.

38 Santos,L.S.,Biscaia,E.C.Jr.,,Pagano,R.L.,andCalado,V.M.(2012). CFD-optimizationalgorithmtooptimizetheenergytransportinpultruded polymercomposites. BrazilianJournalofChemicalEngineering 29(3):559–566.

1IntroductiontoEpoxyComposites

39 Belaadi,A.,Bezazi,A.,Maache,M.,andScarpa,F.(2014).Fatigueinsisalfiber reinforcedpolyestercomposites:hysteresisandenergydissipation. Procedia Engineering 74:325–328.

40 Shen,F.C.(1995).Afilament-woundstructuretechnologyoverview. Materials ChemistryandPhysics 42(2):96–100.

41 Cheng,X.andWiggins,J.S.(2017).Noveltechniquesforthepreparationof differentepoxy/thermoplasticblends.In: HandbookofEpoxyBlends (eds.J. Parameswaranpillai,N.Hameed,J.PionteckandE.Woo),459–486.Cham: Springer.

42 Fenouillot,F.andPerier-Camby,H.(2004).Formationofafibrillarmorphology ofcrosslinkedepoxyinapolystyrenecontinuousphasebyreactiveextrusion. PolymerEngineeringandScience 44(4):625–637.

43 Olowojoba,G.B.andFraunhofer,P.(2013). AssessmentofDispersionEvolutionofCarbonNanotubesinShear-mixedEpoxySuspensionsbyInterfacial PolarizationMeasurement.FraunhoferVerlag:Stuttgart,Germany.

44 Chang,L.,Friedrich,K.,Ye,L.,andToro,P.(2009).Evaluationandvisualizationofthepercolatingnetworksinmulti-wallcarbonnanotube/epoxy composites. JournalofMaterialsScience 44(15):4003–4012.

45 Gojny,F.H.,Wichmann,M.H.,Köpke,U.etal.(2004).Carbon nanotube-reinforcedepoxy-composites:enhancedstiffnessandfracturetoughnessatlownanotubecontent. CompositesScienceandTechnology 64(15): 2363–2371.

46 Rumeau,N.,Threlfall,D.,andWilmet,A.(2009). ResonantAcoustic® Mixing–ProcessingandFormulationChallengesforCostEffectiveManufacturing France,Saint-Médard-en-Jalles:ROXEL.

47 Parameswaranpillai,J.,George,A.,Pionteck,J.,andThomas,S.(2013).Investigationofcurereaction,rheology,volumeshrinkageandthermomechanical propertiesofnano-TiO2 filledepoxy/DDScomposites. JournalofPolymers 5: 2013.

48 Jyotishkumar,P.,Logakis,E.,George,S.M.etal.(2013).Preparationandpropertiesofmultiwalledcarbonnanotube/epoxy-aminecomposites. Journalof AppliedPolymerScience 127(4):3063–3073.

49 Hameed,N.,Dumée,L.F.,Allioux,F.M.etal.(2018).Graphenebasedroom temperatureflexiblenanocompositesfrompermanentlycross-linkednetworks. ScientificReports 8(1):1–8.

50 Yorseng,K.,Rangappa,S.M.,Pulikkalparambil,H.etal.(2020).Acceleratedweatheringstudiesofkenaf/sisalfiberfabricreinforcedfullybiobased hybridbioepoxycompositesforsemi-structuralapplications:morphology, thermo-mechanical,waterabsorptionbehaviorandsurfacehydrophobicity. ConstructionandBuildingMaterials 235:117464.

51 Ivanov,E.,Kotsilkova,R.,Krusteva,E.etal.(2011).Effectsofprocessingconditionsonrheological,thermal,andelectricalpropertiesofmultiwallcarbon nanotube/epoxyresincomposites. JournalofPolymerSciencePartB:Polymer Physics 49(6):431–442.

52 Song,Y.S.andYoun,J.R.(2005).Influenceofdispersionstatesofcarbon nanotubesonphysicalpropertiesofepoxynanocomposites. Carbon 43(7): 1378–1385.

53 Kim,J.A.,Seong,D.G.,Kang,T.J.,andYoun,J.R.(2006).Effectsofsurface modificationonrheologicalandmechanicalpropertiesofCNT/epoxycomposites. Carbon 44(10):1898–1905.

54 Park,S.J.,Bae,K.M.,andSeo,M.K.(2010).Astudyonrheologicalbehaviorof MWCNTs/epoxycomposites. JournalofIndustrialandEngineeringChemistry 16 (3):337–339.

55 Zhu,J.,Wei,S.,Yadav,A.,andGuo,Z.(2010).Rheologicalbehaviorsand electricalconductivityofepoxyresinnanocompositessuspendedwithin-situ stabilizedcarbonnanofibers. Polymer 51(12):2643–2651.

56 Ferry,J.D.(1980). ViscoelasticPropertiesofPolymers.NewYork:JohnWiley& Sons.

57 Matykiewicz,D.,Barczewski,M.,andSterzy ´ nski,T.(2015Oct1).Morphologyandthermomechanicalpropertiesofepoxycompositeshighlyfilledwith wastebulkmoldingcompounds(BMC). JournalofPolymerEngineering 35(8): 805–811.

58 Chateauminois,A.,Chabert,B.,Soulier,J.P.,andVincent,L.(1995Aug). Dynamicmechanicalanalysisofepoxycompositesplasticizedbywater:artifact andreality. PolymerComposites 16(4):288–296.

59 Xian,G.andKarbhari,V.M.(2007).DMTAbasedinvestigationofhygrothermal ageingofanepoxysystemusedinrehabilitation. JournalofAppliedPolymer Science 104(2):1084–1094.

60 Groenewoud,W.M.(2001).Differentialscanningcalorimetry.In: CharacterisationofPolymersbyThermalAnalysis,10–60.Amsterdam,Netherlands:Elsevier Science.

61 Xie,H.,Liu,B.,Sun,Q.etal.(2005).Curekineticstudyofcarbon nanofibers/epoxycompositesbyisothermalDSC. JournalofAppliedPolymer Science 96(2):329–335.

62 Ricky,H.,Jessop,J.L.P.,Peters,F.E.,andKessler,M.R.(2013).Curekinetics characterizationandmonitoringofanepoxyresinusingDSC,Ramanspectroscopy,andDEA. CompositesPartA:AppliedScienceandManufacturing 49: 100–108.

63 Gojny,F.H.andSchulte,K.(2004).Functionalisationeffectonthe thermo-mechanicalbehaviourofmulti-wallcarbonnanotube/epoxy-composites. CompositesScienceandTechnology 64(15):2303–2308.

64 Kang,S.,Hong,S.I.,Choe,C.R.etal.(2001).Preparationandcharacterization ofepoxycompositesfilledwithfunctionalizednanosilicaparticlesobtainedvia sol–gelprocess. Polymer 42(3):879–887.

65 Groenewoud,W.M.(2001).Thermogravimetry.In: CharacterisationofPolymers byThermalAnalysis,61–76.Amsterdam,Netherlands:Science.

66 Carrier,M.,Loppinet-Serani,A.,Denux,D.etal.(2011).Thermogravimetricanalysisasanewmethodtodeterminethelignocellulosiccompositionof biomass. BiomassandBioenergy 35:298–307.

1IntroductiontoEpoxyComposites

67 Lupoi,J.S.,Singh,S.,Parthasarathi,R.etal.(2015).Recentinnovationsin analyticalmethodsforthequalitativeandquantitativeassessmentoflignin. RenewableandSustainableEnergyReviews 49:871–906.

68 Yee,R.Y.andStephens,T.S.(1996).ATGAtechniquefordetermininggraphite fibercontentinepoxycomposites. ThermochimicaActa 272:191–199.

69 Zhang,Z.,Wang,C.,Huang,G.etal.(2018).Thermaldegradationbehaviors andreactionmechanismofcarbonfibre-epoxycompositefromhydrogentank byTG-FTIR. JournalofHazardousMaterials 357:73–80.

70 Chen,Z.,Zhu,Q.,Wang,X.etal.(2015).PyrolysisbehaviorsandkineticstudiesonEucalyptusresiduesusingthermogravimetricanalysis. EnergyConversion andManagement 105:251–259.

71 Gao,N.,Li,A.,Quan,C.etal.(2013).TG–FTIRandPy–GC/MSanalysison pyrolysisandcombustionofpinesawdust. JournalofAnalyticalandApplied Pyrolysis 100:26–32.

72 Zhao,S.,Zhu,L.,Gao,L.,andLi,D.(2018).Limitationsformicroplastic quantificationintheoceanandrecommendationsforimprovementandstandardization.In: Microplasticcontaminationinaquaticenvironments,27–49. Amsterdam:ElsevierInc.

73 González,G.M.,Cabanelas,J.C.,andBaselga,J.(2012).ApplicationsofFTIRon epoxyresins-identification,monitoringthecuringprocess,phaseseparationand wateruptake.In: InfraredSpectroscopy-MaterialsScience,EngineeringandTechnology,261–284.IntechOpen.

74 Kahraman,R.,Abbasi,S.,andAbu-Sharkh,B.(2005).Influenceofepolene G-3003asacouplingagentonthemechanicalbehaviorofpal-fiberpolypropylenecomposites. InternationalJournalofPolymericMaterials 54(6):483–503.

75 Sanjay,M.R.,Arpitha,G.R.,andYogesha,B.(2015).Studyonmechanicalpropertiesofnatural-glassfibrereinforcedpolymerhybridcomposites:areview. MaterialsToday:Proceedings 2(4–5):2959–2967.

76 Fiore,V.,DiBella,G.,andValenza,A.(2015).Theeffectofalkalinetreatmentonmechanicalpropertiesofkenaffibersandtheirepoxycomposites. CompositesPartB:Engineering 68:14–21.

77 Wang,F.,Drzal,L.T.,Qin,Y.,andHuang,Z.(2015).Mechanicalpropertiesand thermalconductivityofgraphenenanoplatelet/epoxycomposites. Journalof MaterialsScience 50(3):1082–1093.

78 DeArmitt,C.(2011Jan1).Functionalfillersforplastics.In: AppliedPlastics EngineeringHandbook,455–468.Waltham,USA:WilliamAndrewPublishing.

79 Jyotishkumar,P.,Pionteck,J.,Moldenaers,P.,andThomas,S.(2013).PreparationandpropertiesofTiO2 -filledpoly(acrylonitrile-butadiene-styrene)/epoxy hybridcomposites. JournalofAppliedPolymerScience 127(4):3159–3168.

80 DeArmitt,C.andRothon,R.(2017Jan1).Dispersantsandcouplingagents. In: AppliedPlasticsEngineeringHandbook,501–516.Waltham,USA:William AndrewPublishing.

81 Devendra,K.andRangaswamy,T.(2013).StrengthcharacterizationofE-glass fiberreinforcedepoxycompositeswithfillermaterials. JournalofMineralsand MaterialsCharacterizationandEngineering 1(6):353–357.

82 Wang,C.,Zhao,M.,Li,J.etal.(2017).Silvernanoparticles/grapheneoxide decoratedcarbonfibersynergisticreinforcementinepoxy-basedcomposites. Polymer 131:263–271.

83 Godara,A.,Gorbatikh,L.,Kalinka,G.etal.(2010).Interfacialshearstrength ofaglassfiber/epoxybondingincompositesmodifiedwithcarbonnanotubes. CompositesScienceandTechnology 70(9):1346–1352.

84 Qing-Hua,L.andZheng,F.(2018).Polyimidesforelectronicapplications.In: AdvancedPolyimideMaterials:Synthesis,CharacterizationandApplications (ed. S.Yang),195–255.Amsterdam:Elsevier.

85 Varshneya,A.K.andMauro,J.C.Dielectricproperties.In: Fundamentalsof InorganicGlasses,3e,vol.2019,425–442.Amsterdam:Elsevier.

86 Morton,W.E.andHearle,J.W.S.Dielectricproperties.In: PhysicalProperties ofTextileFibres,4e,vol.2008,625–642.Cambridge,UK:WoodheadPublishing SeriesinTextiles.

87 Zhang,L.B.,Wang,J.Q.,Wang,H.G.etal.(2012).Preparation,mechanical andthermalpropertiesoffunctionalizedgraphene/polyimidenanocomposites. CompositesPartA:AppliedScienceandManufacturing 43(9):1537–1545.

88 Wang,Z.,Zhou,W.,Sui,X.etal.(2018).DielectricstudiesofAlnanoparticle reinforcedepoxyresincomposites. PolymerComposites 39(3):887–894.

89 Shang,J.,Zhang,Y.,Yu,L.etal.(2013).Fabricationandenhanceddielectric propertiesofgraphene–polyvinylidenefluoridefunctionalhybridfilmswitha polyanilineinterlayer. JournalofMaterialsChemistryA 1(3):884–890.

90 Xie,P.,Li,Y.,andQiu,J.(2014).Preparationanddielectricbehaviorof polyvinylidenefluoridecompositefilledwithmodifiedgraphitenanoplatelet. JournalofAppliedPolymerScience 131(24):40229.

91 Singha,S.andThomas,M.J.(2008).Dielectricpropertiesofepoxynanocomposites. IEEETransactionsonDielectricsandElectricalInsulation 15(1):12–23.

92 Kuo,D.H.,Chang,C.C.,Su,T.Y.etal.(2004).Dielectricpropertiesofthree ceramic/epoxycomposites. MaterialsChemistryandPhysics 85(1):201–206.

93 Wan,Y.J.,Yang,W.H.,Yu,S.H.etal.(2016).Covalentpolymerfunctionalization ofgrapheneforimproveddielectricpropertiesandthermalstabilityofepoxy composites. CompositesScienceandTechnology 122:27–35.

94 Jlassi,K.,Chandran,S.,Poothanari,M.A.etal.(2016).Clay/polyanilinehybrid throughdiazoniumchemistry:conductivenanofillerwithunusualeffectson interfacialpropertiesofepoxynanocomposites. Langmuir 32(14):3514–3524.

95 Pulikkalparambil,H.,Parameswaranpillai,J.,George,J.J.etal.(2017).Physicalandthermo-mechanicalpropertiesofbionanoreinforcedpoly(butylene adipate-co-terephthalate),hemp/CNF/Ag-NPscomposites.AIMS. Materials Science 4(3):814–831.

96 JA,M.H.,Majid,M.A.,Afendi,M.etal.(2016).Effectsofwaterabsorptionon Napiergrassfibre/polyestercomposites. CompositeStructures 144:138–146.

97 Braga,R.A.andMagalhaes,P.A.Jr.,(2015).Analysisofthemechanicaland thermalpropertiesofjuteandglassfiberasreinforcementepoxyhybridcomposites. MaterialsScienceandEngineering:C 56:269–273.