SustainableFoodPackagingTechnology

Editedby

AthanassiaAthanassiou

Editor

Dr.AthanassiaAthanassiou

ItalianInstituteofTechnology

SmartMaterials

ViaMorego,30 16163Genova Italy

CoverImages

©AndreiMayatnik/Shutterstock, ©NelliSyrotynska/Shutterstock

Allbookspublishedby WILEY-VCH arecarefullyproduced.Nevertheless, authors,editors,andpublisherdonot warranttheinformationcontainedin thesebooks,includingthisbook,to befreeoferrors.Readersareadvised tokeepinmindthatstatements,data, illustrations,proceduraldetailsorother itemsmayinadvertentlybeinaccurate.

LibraryofCongressCardNo.: appliedfor

BritishLibraryCataloguing-in-Publication Data

Acataloguerecordforthisbookis availablefromtheBritishLibrary.

Bibliographicinformationpublishedby theDeutscheNationalbibliothek TheDeutscheNationalbibliotheklists thispublicationintheDeutsche Nationalbibliografie;detailed bibliographicdataareavailableonthe Internetat <http://dnb.d-nb.de>

©2021WILEY-VCHGmbH, Boschstr.12,69469Weinheim, Germany

Allrightsreserved(includingthoseof translationintootherlanguages).No partofthisbookmaybereproducedin anyform–byphotoprinting, microfilm,oranyothermeans–nor transmittedortranslatedintoa machinelanguagewithoutwritten permissionfromthepublishers. Registerednames,trademarks,etc.used inthisbook,evenwhennotspecifically markedassuch,arenottobe consideredunprotectedbylaw.

PrintISBN: 978-3-527-34556-4

ePDFISBN: 978-3-527-82006-1

ePubISBN: 978-3-527-82008-5

oBookISBN: 978-3-527-82007-8

Typesetting SPiGlobal,Chennai,India PrintingandBinding

Printedonacid-freepaper 10987654321

Contents

Preface xiii

PartIReviewonBiopolymersforFoodProtection 1

1EmergingTrendsinBiopolymersforFoodPackaging 3

SergioTorres-Giner,KellyJ.Figueroa-Lopez,BeatrizMelendez-Rodriguez, CristinaPrieto,MariaPardo-Figuerez,andJoseM.Lagaron

1.1IntroductiontoPolymersinPackaging 3

1.2ClassificationofBiopolymers 4

1.3FoodPackagingMaterialsBasedonBiopolymers 7

1.3.1Polylactide 7

1.3.2Polyhydroxyalkanoates 8

1.3.3Poly(butyleneadipate-co-terephthalate) 9

1.3.4PolybutyleneSuccinate 10

1.3.5Bio-basedPolyethylene 11

1.3.6Bio-basedPolyethyleneTerephthalate 13

1.3.7Poly(ethylenefuranoate) 14

1.3.8Poly(ε-caprolactone) 15

1.3.9ThermoplasticStarch 15

1.3.10CelluloseandDerivatives 17

1.3.11Proteins 17

1.3.11.1Gelatin 18

1.3.11.2WheatGluten 18

1.3.11.3SoyProtein 20

1.3.11.4CornZein 20

1.3.11.5MilkProteins 21

1.4ConcludingRemarks 21 References 24

2BiopolymersDerivedfromMarineSourcesforFoodPackaging Applications 35 JoneUranga,IratxeZarandona,MireiaAndonegi,PedroGuerrero,and KorodelaCaba

2.1Introduction 35

2.2FishGelatinFilmsandCoating 37

2.2.1CollagenandGelatinExtraction 37

2.2.2PreparationandCharacterizationofFishGelatinFilmsand Coatings 39

2.2.3FoodShelfLifeExtensionUsingFishGelatinFilms andCoatings 40

2.3ChitosanFilmsandCoatings 42

2.3.1ChitinandChitosanExtraction 42

2.3.2PreparationandCharacterizationofChitosanFilms andCoatings 43

2.3.3FoodShelfLifeExtensionUsingChitosanFilmsandCoatings 44

2.4FuturePerspectivesandConcludingRemarks 46 References 46

3EdibleBiopolymersforFoodPreservation 57 ElisabettaRuggeri,SilviaFarè,LuigiDeNardo,andBenedettoMarelli

3.1Introduction 57

3.2Polysaccharides 61

3.2.1Alginate 63

3.2.2Carrageenans 63

3.2.3Cellulose 67

3.2.4Chitosan 69

3.2.5Pectin 70

3.2.6Pullulan 71

3.2.7Starch 71

3.3Proteins 72

3.3.1Casein 73

3.3.2Collagen 74

3.3.3Gelatin 74

3.3.4WheatGluten 75

3.3.5WheyProtein 75

3.3.6SilkFibroin 76

3.3.7Zein 77

3.4Lipids 78

3.4.1Beeswax 80

3.4.2CandelillaWax 80

3.4.3CarnaubaWax 81

3.4.4Shellac 81

3.5EdibleCompositeMaterials 82

3.6ActiveCoatings 85

3.6.1AntimicrobialAgents 85

3.6.2AntioxidantAgents 85

3.7MaterialsSelectionandApplication 86

3.8Conclusions 87 References 88

PartIIFoodPackagingBasedonIndividualBiopolymersand theirComposites 107

4PolylacticAcid(PLA)andItsComposites:AnEco-friendly SolutionforPackaging 109

SwatiSharma

4.1Introduction 109

4.2SynthesisofPLAandItsProperties 110

4.3PropertiesRequiredforFoodPackaging 111

4.3.1BarrierProperties 111

4.3.2OpticalProperties 113

4.3.3MechanicalProperties 114

4.3.4ThermalProperties 114

4.3.5AntibacterialProperties 115

4.4GeneralReinforcementsforPLA 116

4.4.1NaturalFibers 116

4.4.2SyntheticFibers 121

4.4.3FunctionalFillers 122

4.4.3.1Clay/PLAComposites 122

4.4.3.2Metal-oxide/PLAComposites 123

4.5BiodegradabilityofPLA 123

4.6ConclusionsandFutureProspects 124 References 124

5GreenandSustainablePackagingMaterialsUsing ThermoplasticStarch 133

AnshuA.SinghandMariaE.Genovese

5.1SustainabilityandPackaging:TowardaGreenerFuture 134

5.1.1ThePlasticThreat 134

5.1.2TheCallforSustainability 135

5.1.3BiomaterialsforSustainablePackaging 135

5.2ThermoplasticStarch 137

5.2.1Starch:PhysicochemicalProperties,Processing,Applications 137

5.2.2FromStarchtoThermoplasticStarch 141

5.2.3PlasticizersofStarch 142

5.2.4ProcessingofThermoplasticStarch 143

5.3ThermoplasticStarch-BasedMaterialsinPackaging 145

5.3.1TechnicalandLegalRequirementsforPackagingMaterials 145

5.3.2CompositesofTPSwithFillers 146

5.3.3CompositesofThermoplasticStarchwithPolysaccharides 147

5.3.4CompositesofThermoplasticStarchwithPolyesters 149

5.3.5CompositeofTPSBasedonChemicalModification 152

5.3.6CommercialPackagingMaterialsBasedonThermoplastic Starch 152

5.4Conclusions 153 References 155

6Cutin-InspiredPolymersandPlantCuticle-likeCompositesas SustainableFoodPackagingMaterials 161 SusanaGuzmán-Puyol,AntonioHeredia,JoséA.Heredia-Guerrero,and JoséJ.Benítez

6.1Introduction 161

6.1.1BioplasticsasRealisticAlternativestoPetroleum-Based Plastics 161

6.1.2ThePlantCuticleandCutin:TheNaturalFoodPackagingofthePlant Kingdom 166

6.1.3AComparisonofCutinwithCommercialPlasticsand Bioplastics 169

6.1.4TomatoPomaceistheMainandMostSustainableCutinRenewable Resource 172

6.1.5TowardaSustainableIndustrialProductionofCutin-Inspired Commodities 173

6.2SynthesisofCutin-InspiredPolyesters 173

6.2.1TheInfluenceoftheMonomerArchitectureinthePhysicaland ChemicalPropertiesofCutin-InspiredPolyhydroxyesters 173

6.2.2TheEffectofOxidationintheStructureandPropertiesof Cutin-InspiredFattyPolyhydroxyesters 177

6.2.3Surfacevs.BulkProperties 180

6.3Cutin-BasedandCutin-likeCoatingsandComposites 183

6.3.1Cutin-InspiredCoatingsonMetalSubstrates 183

6.3.2PlantCuticle-likeFilmComposites 186

6.4ConcludingRemarks 188 Acknowledgments 189 References 189

7ZeininFoodPackaging 199 IlkerS.Bayer

7.1Introduction 199

7.2SolventCastZeinFilms 202

7.3ChemicalCharacteristicsofSolvent-CastZeinFilms 206

7.4ExtrusionofZein 209

7.5ZeinLaminateswithVariousPackagingFilms 212

7.6ZeinBlendFilmswithOtherBiopolymers 214

7.7OutlookandFutureDirections 217

7.8Conclusions 219 References 220

PartIIIBiocompositesofCelluloseandBiopolymersin FoodPackaging 225

8Cellulose-ReinforcedBiocompositesBasedonPHBandPHBV forFoodPackagingApplications 227

EstefaniaL.Sanchez-Safont,LuisCabedo,andJoseGamez-Perez

8.1IntroductiontoBioplastics 227

8.2PHBandPHBV:aSWOT(Strength,Weakness,Opportunity,and Threat)Analysis 229

8.2.1Polyhydroxyalkanoates(PHA):Poly-3-hydroxybutyrate(PHB)and Poly-3-hydroxybutyrate-co-3-hydroxyvalerate(PHBV) 229

8.2.2PHBandPHBV:Strengths 231

8.2.3PHBandPHBV:Weaknesses 232

8.2.4PHBandPHBV:Opportunities 235

8.2.5PHBandPHBV:Threats 236

8.3CelluloseBiocomposites 236

8.3.1Structure,Composition,andGeneralPropertiesofLignocellulosic fibers 237

8.3.2LignocellulosicFibersinPolymerComposites 240

8.3.2.1FiberModification 241

8.3.2.2Fiber-matrixChemicalAnchor 242

8.4PHA/FiberComposites 242

8.4.1PHBandPHBV/CelluloseComposites:Achievementsand Limitations 242

8.4.2NewTrendsinPHBandPHBV/Cellulose-Reinforced Biocomposites 245

8.4.3ThePotentialUseofPHA-BasedCompositesintheFoodPackaging Sector 247

8.5Conclusions 248 References 250

9Poly-Paper:Cellulosic-FilledEco-compositeMaterialwith InnovativePropertiesforPackaging 263 RominaSanti,SilviaFarè,AlbertoCigada,andBarbaraDelCurto

9.1Introduction 263

9.2Materials 265

9.2.1Matrix 265

9.2.2Reinforcement 266

9.2.3CompositeFormulations 266

9.2.4ExtrusionProcess 267

9.3MechanicalProperties 268

9.4SuitableProcessesforPoly-Paper 268

9.4.1InjectionMolding 269

9.4.2Thermoforming 270

9.4.3Poly-PaperExpansion 270

9.5AdditionalPropertiesofPoly-Paper 272

x Contents

9.5.1ShapeMemoryForming 272

9.5.2Self-HealingbyWater 273

9.6End-of-Life 275

9.7Conclusions 277 References 278

10PaperandCardboardReinforcementbyImpregnationwith EnvironmentallyFriendlyHigh-PerformancePolymersforFood PackagingApplications 281 UttamC.PaulandJoséA.Heredia-Guerrero

10.1Introduction 281

10.2ImprovingtheBarrierPropertiesofPaperandCardboardby ImpregnationinCapstoneandECASolutions 282

10.2.1PreparationoftheSamples 283

10.2.2MorphologicalCharacterization 283

10.2.3ChemicalCharacterization 285

10.2.4BarrierProperties,Wettability,andWaterUptake 285

10.2.5MechanicalCharacterization 291

10.3Water,OilandGreaseResistanceofBiocompatibleCellulose FoodContainers 292

10.3.1PreparationoftheSamples 294

10.3.2MorphologicalAnalysis 295

10.3.3WaterandOilResistanceProperties 296

10.3.4Mechanical,GreaseResistance,andBarrierPropertiesof TreatedPaper 296

10.4Conclusions 300 References 300

11Nanocellulose-BasedMultidimensionalStructuresforFood PackagingTechnology 305 SaumyaChaturvedi,SadafAfrin,MohdS.Ansari,andZohebKarim 11.1Introduction 305

11.2NecessitiesinFoodPackagingIndustry 307

11.3AnOverviewofNC 308

11.4CelluloseFibrilsandCrystallineCellulose 308

11.5WhyNCforPackaging? 310

11.6EffectonNCsonNetworking 310

11.7MigrationProcessofMoleculesThroughNCDimensional Film 312

11.8ProcessingRoutesofNC-basedMultidimensionalStructuresfor Packaging 312

11.9CNFsforBarrierApplication 314

11.10CNCsforBarrierApplication 315

11.11Conclusion 316 References 317

PartIVNaturalPrinciplesinActiveandIntelligentFood PackagingforEnhancedProtectionandIndicationofFood SpoilangeorPollutantPresence 323

12SustainableAntimicrobialPackagingTechnologies 325 SelçukYildirimandBettinaRöcker

12.1Introduction 325

12.2AntimicrobialFoodPackaging 326

12.3NaturalAntimicrobialAgents 328

12.3.1PlantExtracts 328

12.3.2OrganicAcids,TheirSaltsandAnhydrides 335

12.3.3Bacteriocins 336

12.3.4Enzymes 337

12.3.5Chitosan 338

12.4ConclusionsandPerspectives 340 References 341

13ActiveAntioxidantAdditivesinSustainableFood Packaging 349 Thi-NgaTran

13.1Introduction 349

13.2AntioxidantCapacitiesofPlant-BasedFoodPackagingMaterials 352

13.2.1AntioxidantNaturalExtractsinFoodPackaging 353

13.2.2AntioxidantRawMaterialsDerivedfromFoodWastesand Agro-Industryby-Products 359

13.3ConclusionsandFuturePerspectives 361 References 363

14NaturalandBiocompatibleOpticalIndicatorsforFood SpoilageDetection 369

MariaE.Genovese,JasimZia,andDespinaFragouli

14.1FoodSpoilage 370

14.1.1FoodSpoilage:ANever-endingChallenge 370

14.1.2MicrobialSpoilage 370

14.1.3PhysicalandChemicalSpoilage 372

14.1.4FactorsDeterminingFoodSpoilage 372

14.2FoodSpoilageDetection 372

14.2.1ConventionalMethodsandTechnologiesfortheDetectionof FoodSpoilage 372

14.2.2OnPackageandonSiteSensingTechnologies:ANewStrategyfor FoodSpoilageDetection 373

14.3NaturalandBiocompatibleOpticalIndicatorsforFoodSpoilage 379

14.3.1OpticalandColorimetricDetection 379

14.3.2NaturalandBiocompatibleIndicators 379

14.3.3DetectionofpH,Acids,andAmines 380

14.3.4DetectionofOxygen 386

14.3.5DetectionofCarbonDioxide 387

14.3.6DetectionofBacteria 388

14.4ConcludingRemarksandFuturePerspectives 388 References 389

PartVTechnologicalDevelopmentsintheEngineeringof BiocompositeMaterialsforFoodPackagingApplications 395

15BiopolymersinMultilayerFilmsforLong-LastingProtective FoodPackaging:AReview 397 IlkerS.Bayer

15.1Introduction 397

15.2BiopolymerCoatingsandLaminatesonCommonOil-Derived PackagingPolymers 399

15.3MultilayerFilmsBasedonProteins 405

15.4MultilayerFilmsBasedonPolysaccharides 409

15.5CoatingsonBiopolyesters 415

15.6SummaryandOutlook 418 References 420

Index 427

Preface

Therecouldnotbeaclearerandatthesametimeshockingdemonstrationof ournon-sustainablewayoflivingthantherecentCOVID-19pandemic,which startedinlate2019inWuhan,China,expandingallovertheworldinjustfew months.Theoccurrenceandtheextremelyrapidexpansionareconnectedto humandietaryshiftstowardconsumptionofanimalproductsneverusedbefore duetoincreasingnutritiondemand,extraordinarypopulationdensities,and unprecedentedenvironmentalpollution.Thepandemic,itsfastspread,andits consequencesallovertheplanetinaveryshortperiodmadeevidentthatwe arelivinginaclosedsystem,interconnectedinwaysthatareoutofourcontrol andwehavetofacetheglobalproblemswithcommonstrategies.Sustainable livinghasbecomeessential,andaglobalsustainableconsciousnessmustbe formedandimmediatedecisionsandactionsneedtobetakentowardthis direction.

Sustainabilityshouldberadicallyestablishedinourlifestyle,habits,and actions.Themassiveuseofplasticsandtheiruncontrolleddisposalinthelast fourdecadesarehabitsthatneedtobechangedimmediately.Theuncontrolled productionanduseofplastichavebroughttheplanet’spollutiontolevelsnever seenbefore.Onlyin2018,359millionmetrictonsofplasticwereproduced globally,whileatotalofabout9.2billionmetrictonswereproducedbetween 1950and2017.Fromallthisplasticeverproduced,itisestimatedthatabout 9%hasbeenrecycled,12%incinerated,andtheremaining79%hasendedupin landfillsortheenvironment.Forexample,itisestimatedthat4.8to12.7million metrictonsofplasticenterthemarineenvironmenteveryyear[1].Photographs ofanimalsandfishsuffocatingintheirhabitatsduetodumpedplastics,orof extendedareasfullofplasticgarbage,especiallyfromdevelopingcountriesthat havebecomethewastedisposalfieldsforthedevelopedones,aswellasstudies onhowtoxicchemicalsreleasedfromwronglydisposedplasticscompromise ourhealtharereachingusdaily.

Themostimportantsourceofbadlydisposedplasticwasteispackaging.In 2017,around15millionmetrictonsofplasticpackagingwastewasgenerated onlyintheEuropeanUnion.Inthegeneralpackagingsector,foodpackaginghas themostimportantplasticdemand.PlasticfoodpackagingproductioninEurope is8.2milliontonsperyear,includedinthe20.5milliontonsperyearproduction forthegeneralpackagingsectorandinthe51.2milliontonsperyearofthetotal Europeanplasticdemand[2].Itsshortlifetimeandfrequentcontaminationfrom

foodmakesitthemostvoluminous,wronglydisposed,plasticwaste.Forthis reason,theintroductionofbiodegradable-compostableplasticpackaging,either frompetrochemicalsourcesorpreferablyfromnaturalrenewableresources,has becomemandatoryandattractsagreatdealofresearchandindustrialinterest.This,incombinationwiththevariousgovernmentalstringentrequirements andincentivesrelatedtoplasticreductionthroughouttheplanet,makessustainablefoodpackaginganemergingapplicationareathatexpectantlywillfindits waytothemarketsubstitutingthecurrentlyusedrecalcitrantplasticpackaging solutions.

Thisbookdealsexactlywiththisrapidlyemergingresearchandapplication fieldofSustainableFoodPackaging.ItstartswithPartI“ReviewonBiopolymers forFoodProtection.”Thispartofthebookpresentsreviewchapters1,2,and3 onthemostrelevantbiopolymersthatslowlyfindtheirwaytothefoodpackagingmarket,butalsoonbiopolymersthatarenotyetindustrialized(eitherdue tohighcostsofextractionandtransformationinpackagingmaterialsordueto lackofinvestment),buthaveagreatpotentialduetotheiruniqueproperties.In particular,Chapter1“EmergingTrendsinBiopolymersforFoodPackaging,”by SergioTorres-Gineretal.,startswithadetailedandcomprehensiveintroductiontothedifferenttypesofbiopolymers,andtheirclassificationaccordingto theiroriginandbiodegradabilitycharacteristics.Thechaptercontinueswiththe presentationofthemostimportantbiopolymersthatarecurrentlyavailableand describestheirorigin,chemistry,synthesis/extraction,and/orchemicalmodificationmethods.Italsopositionsthesebiopolymersinthecurrentplasticmarket anddescribestheirprospects,advantages,anddisadvantagesinthesectoroffood packaging.Intheirconcludingremarks,theauthorsgiveanexpertpointofview onwherethebioplasticeffortsforfoodpackagingshouldbedirectedinorderto haveanimportantpositivefutureenvironmentalimpact.Chapter2“Biopolymers DerivedfromMarineSourcesforFoodPackagingApplications,”byJoneUranga etal.,presentsthetwomostimportantbiopolymersforfoodpackaging,originatingfrommarinebiomass,fishgelatinandchitosan.Regardinggelatin,thechapter describestheextractionmethodsofcollagenbyfishwastebiomass,andthesubsequentproductiongelatinbypartialhydrolysisofcollagen.Theauthorscontinue withapresentationofthemethodsofdevelopmentofgelatincoatingsandfilms asfoodpackagingandtheirimpactonthefoodshelflifeextension.Regarding chitosan,theauthorsfirstanalyzetheextractionmethodsofchitinbymarine biomass,suchascrustaceanshellsandsquidpens,beforeitstransformationto chitosanbydeacetylation.Finally,thedevelopment,properties,andeffectonthe packagedfoodlifeextensionareanalyzedforthevariouschitosancoatingsand filmspresentedintheliteratureasfoodpackagingsolutions.Chapter3“Edible BiopolymersforFoodConservation,”byElisabettaRuggerietal.,describesthe innovativeideaofnaturalpolymericprotectivecoatingsorfilmsforfoodpreservationandfreshnessextensionthatcanbeconsumedtogetherwiththefood, accompaniedbythevariousregulationsthatwouldcoversuchuse.Theauthors analyzethevariousbiopolymersthatcanbetransformedintoediblepackaging, classifyingthemaspolysaccharides,proteins,lipids,andtheirmixtures.They presentthevariouswaysofdevelopmentofthefilmsforwrappingorofthecoatingsapplieddirectlyontothefood,theirproperties,andthepossibilitytoact

Preface xv asmatricesforfunctionaladditives,likeantimicrobialandantioxidantagents. Finally,theauthorsprovideinformationonthepossiblelimitationsandonthe futureperspectivesofnaturalediblefoodpackaging.

ThebookcontinueswithPartII“FoodPackaging-BasedonIndividual BiopolymersandTheirComposites,”wherethemostpromisingbiopolymers andtheircompositesforthefoodpackagingsectorarepresentedseparately. PartIIdescribesboththebiopolymersthathavealreadyfoundtheirwaytothe markettogetherwiththeirfuturechallenges,andthebiopolymersthatarenot yetinthemarketbutduetotheiruniquepropertieshaveagoodpotentiality. Indeed,Chapter4“Polylacticacid(PLA)andItsComposites:AnEco-friendly SolutionforPackaging,”bySwatiSharma,describesresearchadvancement relatedtofoodpackagingbasedonPLAanditscomposites,indisputablythe mostavailableandpromisingbiopolymercurrentlypresentinthemarket.The chapterstartswiththesyntheticroutesofPLAandcontinueswiththedescriptionofitsphysicalproperties,emphasizingtheonesessentialforfoodpackaging materials.Subsequently,theauthorpresentsareviewonthevariousfillers,i.e. syntheticandnaturalfibersornanoparticles,thathavebeenusedtoenhance therelevantpropertiesofPLA,andclosesthechapterwiththecurrentusesin themarketandthefutureperspectivesofthisexceptionalbiopolymer.Chapter 5“GreenandSustainablePackagingMaterialsusingThermoplasticStarch,”by AnshuAnjaliSinghandMariaErminiaGenovese,isdedicatedtobiocomposites basedonthermoplasticstarch,abiopolymerwithgreatpotentialityforfood packagingduetoitsabundance,biodegradability,andlowprice,thathasalready founditswaytothemarket.Althoughthechapterisdedicatedtoaspecific biopolymer,theauthorsmakeananalyticalintroductiontotheplasticthreat thathasmadevitaltheneedofsustainablepolymersespeciallyinthefood packagingsector,andpresentthevariouscategoriesofbiopolymersavailable forthispurposeemphasizingonstarch.Theycontinuewiththepresentationof researchstudiesonthermoplasticstarchcompositesdevelopedforpackaging applicationsunderliningtheirmostrelevantproperties,suchasmechanical properties,gasandvaporpermeabilityandbiodegradability,theirprocessing methods,theirpossibledrawbacks,whiletheyalsopresentthecommercially availablepackagingsolutions.Finally,theyconcludewiththechallengesto beaddressedandthefuturedevelopmentsneededforstarch,itscomposites, anditsderivativesinfoodpackaging.Chapter6“Cutin-inspiredPolymers andPlantCuticle-likeCompositesasSustainableFoodPackagingMaterials,” bySusanaGuzman-Puyoletal.,presentstheuniquebiopolymercutin,the maincomponentofcuticle,whichconstitutestheoutersurfacesofplantsand servesasaprotectivelayerfromtheenvironment.Theauthorsintroducethe dramaticeffectofplasticstotheenvironmentandthealternativebio-based andbiodegradablebiopolymers.Theycontinuewiththedescriptionofplant cuticle,itsnaturalrole,itsstructureanditscomposition,wheretheprinciple componentcutinisintroduced.Aquantitativecomparisonofthephysical propertiesofcutinandvariousbiodegradablebiopolymersrevealsthestrong andweakpointsoftheformer,andthewaystoobtaincutinfromitsmain resource,thetomatopomace,aredescribed.Theauthorsalsopresentscalable techniquesforthesynthesisofcutin-inspiredpolyestersandmethodstotune

Preface theirproperties.Finally,themethodstofabricatecutin-inspiredcoatingsand cuticle-likecompositesasprotectivepackagingforfoodarepresented.Chapter 7“ZeininFoodPackaging,”byIlkerS.Bayer,givesanexhaustivepresentationof theproteinbiopolymer,zein,highlypromisingforfoodpackagingmainlydue toitsfilm-formingcapabilityandhydrophobicproperties.Itsorigin,molecular structure,andgeneralpropertiesarefirstintroduced.Thefocusofthechapter isonthefabricationmethodsofzein-basedfilmsandtheircharacterization asfoodpackagingmaterials.Thepresentedmethodsaresolventcasting,melt extrusion,solventormeltblendingwithbiopolymers,andlamination,either withotherbio-polymersorpetroleum-basedpolymericfilms.Theauthorcloses thechapterwiththefutureperspectivesandhispointofviewonthedirections thatzeindevelopmentshouldfollowinordertobeavalidcandidateforthefood packagingindustry.

PartIIIofthebookisdedicatedtothemostabundantnaturalpolymerofour planet,thecellulose,andisentitled“BiocompositesofCelluloseandBiopolymersinFoodPackaging.”Itpresentssustainablecompositesofbiopolymers withcelluloseinvariousforms,withexceptionalproperties,competitiveto theconventionalnonbiodegradableplastics,forthefoodpackagingmarket.In particular,Chapter8“Cellulose-reinforcedBiocompositesBasedonpolyhydroxybutyrate(PHB)andpoly(3-hydroxybutyrate-co-3-hydroxyvalerate)PHBV forFoodPackagingApplications,”byEstefaniaLidonSanchez-Safontetal., dealswiththemicrobialpolymerspolyhydroxyalkanoates(PHAs)anddiscusses howcellulosefiberscanimprovetheirpropertiestomakethemcompetitive forthefoodpackagingmarket.Specifically,theauthorsanalyzeseparately,first thestrengths,weaknesses,opportunities,andthreats(SWOT)oftwobacterial biopolymers,PHBandPHBV,andsubsequentlythepropertiesoflignocellulose fibersthatmakethemidealcandidatesasreinforcingfillersincomposites. Next,theyreviewtheresearchthathasbeendonesofaronthecombination ofPHBandPHBVwithvariouslignocellulosefibersandtheypresentthegreat potentialityofsuchcompositesasfoodpackagingmaterials,indicatingtheweak pointstobeovercome.Chapter9“Poly-Paper:Cellulosic-filledEco-composite MaterialwithInnovativePropertiesforPackaging,”byRominaSantietal., focusesonaveryinterestingpatentedmaterial,madeofcellulosemicrofibers inthesustainable,water-solublepoly(vinylalcohol)(PVA)matrix,withthe namePoly-Paper.Poly-papercanbeveryversatileintermsofmanufacturing processesandfinalproperties,andassuch,canfindmanywaystoenterintothe packagingmarket.Indeed,itcanbeprocessedbyextrusion,injectionmolding, andthermoforming,whileattheendoflifecanreenterinthepaperrecycling chain.Chapter10“PaperandCardboardReinforcementbyImpregnationwith EnvironmentallyFriendlyHigh-performancePolymersforFoodPackaging Applications,”byUttamC.PaulandJoséA.Heredia-Guerrero,describestheir researchonadifferentapproachtocellulose-basedfoodpackaging.Cellulose isnotpresentasmicroornanofillerinapolymer,butintheformofanintact substrate,likepaperorcardboard,impregnatedwithenvironmentallysafe, biocompatiblepolymersandcomposites,inordertoattainpropertiesthatcan expandandreinforceitspositioninginthefoodpackagingmarket,without compromisingitsbiodegradablenature.Thetreatmentofferstothecellulose

Preface xvii substrateswaterandoilresistance,resistancetomoisture,andmechanical reinforcement,allpropertiesthatcelluloselacksintrinsically,soitcanbea viablesolutiontoincreaseitsrequestinthesustainablefoodpackagingmarket. ThebookcontinueswithChapter11“Nanocellulose-BasedMultidimensional StructuresforFoodPackagingTechnology,”bySaumyaChaturvedietal.,which dealswithnanocellulose-basedfoodpackagingsolutions.Theauthorspresent anoverviewofthedifferentkindsofnanocellulose,whichincludefibrilsorcrystalliteswithatleastonedimensioninthenanoscalerange,andtheirproperties dependingontheorigin,i.e.plantsorbacteria,andtheisolationmethods.The chapterproceedswiththewaysthatnanocellulose,aloneorcombinedwith polymers,formsvariouscompactstructuresthatcanbeusedforpackaging. Finally,theauthorsfocusontwotypesonnanocellulose,thecellulosenanofibers andthecellulosenanocrystals,emphasizingtheirdifferencesandreporting theresearchthatwasdonesofarontheirfreestandingfilmseitheraloneoras polymerfillers,comparingthemwithconversionalplasticsfilmsusedinthe foodpackagingsector.

AbookonSustainableFoodpackagingcouldnotbecompletewithout PartIVdedicatedto“NaturalPrinciplesinActiveandIntelligentFoodPackagingforEnhancedProtectionandIndicationofFoodSpoilageorPollutant Presence,”sincesustainabilityiscloselyrelatedtotheextensionoftheshelflifeof foodandthepreventionoffoodwaste.Wastingfoodiseconomicallynonviable, notethical,anddrainsthealreadyverylimitednaturalresources.Chapter 12“SustainableAntimicrobialPackagingTechnologies,”byYildirimSelçuk andBettinaRöcker,presentsadvancementsintheuseofbioactivesubstances combinedwithinbiopolymersfromrenewableresourcesasprotectivefood packagingwithantimicrobialactionagainstfoodbornepathogensandspoilage microorganisms.Theauthorsintroducetheconceptofactivepackaging,its differentcategories,andspecificactions,withadedicatedsectiononthe antimicrobialactivepackaging,itsclasses,researchadvances,andregulations. Then,theyanalyzeseparatelythemoststudiednaturalantimicrobialagents, i.e.essentialoilsandphenoliccompounds;organicacids,theirsaltsandanhydrides;bacteriocinsandenzymes;andtheantimicrobialpolymerchitosan, withreferencesoftheiruseasactiveadditivesinpackagingoffoodsystems. Theauthorsconcludetheirchapterwiththestrategiesneededforasuccessful andrapidintroductionofactivesustainableantibacterialpackaginginthefood packagingindustry.Chapter13“ActiveAntioxidantAdditivesinSustainable FoodPackaging,”byThiNgaTran,dealsalsowithactivepackagingbutin thiscasewithantioxidantactivity.Theauthorstartswithanintroductionto theurgentneedofasignificantreductionoffoodlossesandwastes,andhow protectionfromoxidation,usingpackagingsystemsofbiopolymerscombined withnaturalantioxidantsubstances,couldhelp.Thechaptercontinueswitha detailedanalysisofthevariousantioxidantmoleculesextractedbyplants,their combinationwithbiopolymersintoactivefoodpackaging,andtheproperties oftheobtainedpackagingsystems,including,ofcourse,theirantioxidant activity.Aparticularmentionismadetothepossibilityofusingrawdried plantspowders,evenfromagriculturalby-products,asantioxidantfillersinto biopolymersforthedevelopmentofactivesustainablefoodpackaging,avoiding

Preface

theextractioncosts.PartIVofthebookendswithChapter14“Naturaland BiocompatibleOpticalIndicatorsforFoodSpoilageDetection,”byMariaE. Genoveseetal.,whichpresentsanotherveryinterestingapproachinfoodwaste prevention.Theauthorsdescribepackagingmaterialswithincorporatednatural orbiocompatiblemoleculesthatchangetheirmolecularstructure,andthus theiropticalproperties,inthepresenceoffoodspoilage.Consequently,whena specificfoodspoilageby-productispresent,theactivepackagingchangesone ormoreopticalproperties(i.e.color,spectralabsorption,fluorescence)enabling areal-timeanddirectnakedeyespoilagedetection.Theauthorsintroducethe factorsdeterminingfoodspoilage,andanalyzethoroughlytheconventional methods,aswellasthemostrecentportabletechnologiesforon-siteand on-packagedetectionofthespoilage,togetherwiththefunctioningprinciples ofthesetechnologies.Then,theauthorsfocusonthedescriptionofthevarious functionalcomponentsusedfortheopticalandcolorimetricspoilageindication usuallyembeddedinapolymeric,mostoftimesnaturalrenewable,support,as wellasthespecificspoilageby-producttheycandetect.Aparticularemphasis isgivenonthesensingpotentialofnaturaldyesandpigmentsextractedfrom plants,i.e.curcuminandanthocyanins,aswellastheirsyntheticcounterparts, duetotheireco-friendlynature.

ThebookcloseswithPartV“TechnologicalDevelopmentsintheEngineering ofBiocompositeMaterialsforFoodPackagingApplications,”whereChapter15 “BiopolymersinMultilayerFilmsforLongLastingProtectiveFoodPackaging: AReview,”byIlkerS.Bayer,presentsthepossibilitiesthattechnologyprovides totakeadvantageofthevariousbiopolymersandcompositescombiningthem inuniquesolutionsforfoodpackaging.Apartfrommeltextrusion,injection molding,blowmolding,andthermoforming,alltechniquesusedbroadlyinthe plasticindustryandmentionedinthevariouschaptersofthisbook,Chapter 15describesthewaysofmakingmultilayerfilmsthatcancombinetheunique propertiesofthevariousbiopolymerlayersintoonematerial.Thechapter reviewsbothmultilayerlaminatesofbiopolymerswithconventionaloil-derived polymersandallsustainablelaminates,basedonproteins,polysaccharides, orbiopolyesters.Theauthorconcludesthatmultilayerlaminatesofcarefully chosenbiopolymersandbiocompositescouldbetheidealmaterialsforfood packagingsincetheycombinesustainabilitywithoptimizeddesiredproperties duetotheiruniqueconstruction.

Genova,Italy 29September2020

References

1 Jambeck,J.R.,Geyer,R.,Wilcox,C.etal.(2015).Plasticwasteinputsfrom landintotheocean. Science:768–771.

2 Datafortheyear2018FromINGEconomicsDepartmentandhttps://www .statista.com/statistics/282732/global-production-of-plastics-since-1950.

AthanassiaAthanassiou

ReviewonBiopolymersforFoodProtection

EmergingTrendsinBiopolymersforFoodPackaging

SergioTorres-Giner,KellyJ.Figueroa-Lopez,BeatrizMelendez-Rodriguez, CristinaPrieto,MariaPardo-Figuerez,andJoseM.Lagaron

NovelMaterialsandNanotechnologyGroup,FoodSafetyandPreservationDepartment,Instituteof AgrochemistryandFoodTechnology(IATA),SpanishCouncilforScientificResearch(CSIC),CalleCatedrático AgustínEscardinoBenlloch7,Paterna46980,Spain

1.1IntroductiontoPolymersinPackaging

AccordingtotheFoodandAgricultureOrganizationoftheUnitedNations (FAO),approximatelyone-thirdofallfoodproducedgloballyislostorwasted [1].Foodwasteisproducedthroughoutthewholefoodvaluechain,fromthe householdtomanufacturing,distribution,retail,andfoodserviceactivities. Takingintoconsiderationthelimitednaturalresourcesavailable,itismore effectivetoreducefoodwastethantoincreasefoodproduction.Forthis reason,severaleffortshavebeenputforthedevelopmentofmoreeffective foodpackagingstrategies[2,3].Packagingitemshavebecomeessentialto protectfoodfromdifferentenvironmentalconditions.Dependingonthetype offood,thepackagingarticlecanbecustomizedtopreventorinhibitmicrobial growth,avoidfooddecompositionbyremovingtheentranceoflight,oxygen, andmoisture,oreventopreventspoilagefromsmallinsects.Additionally,novel packagingitemscanbemonitoredtogiveinformationaboutthequalityof thepackagedfood,ultimatelydiminishingfoodwasteduringdistributionand transport[4].

Commonmaterialsutilizedforfoodpackagingincludeglass,paper,metal,and plastic.Thelatterarenowadaysmorefrequentlyusedsincetheyhavealargeavailabilityatarelativelylowcostandcandisplaygoodcharacteristicsforpackaging items,suchasmechanicalstrength,barrierproperties,andtransparency[4,5]. Themostcommonlyusedpetrochemicalmaterialsforpackagingapplications canbedividedintovariousfamilies:

• Polyolefinsandsubstitutesofolefins,suchaslow-densitypolyethylene(LDPE) andlinearlow-densitypolyethylene(LLDPE),polypropylene(PP),polystyrene (PS),orientedpolystyrene(OPS),polyvinylalcohol(PVOH),polyvinylchloride (PVC),andpolyvinylidenechloride(PVDC).Polyolefinsarefrequentlyusedin reusablebags,papercups,andstand-uppouches,whilesubstitutesofolefins suchasPVCarepopularlyusedinclingfilmsandinsomeprepackagedmeals.

SustainableFoodPackagingTechnology, FirstEdition.EditedbyAthanassiaAthanassiou. ©2021WILEY-VCHGmbH.Published2021byWILEY-VCHGmbH.

1EmergingTrendsinBiopolymersforFoodPackaging

• Copolymersofethylene,suchasethylene-vinylacetate(EVA)and ethylene-vinylalcohol(EVOH),aretypicallyusedtomakelidfilmsfor traysandbarrierinterlayers.

• Polyesters,suchaspolyethyleneterephthalate(PET)andotheraliphaticand aromaticpolyesters,aremainlyusedtomakewaterbottles.

• Polyamides(PAs)arecommonlyemployedinfilmsortraysforfoodproducts thatareverysensitivetooxygen.

Mostofthesematerialsaremadebycondensationoradditionpolymerization ofmonomersofhydrocarbonorhydrocarbon-likerawmaterials,whichmeans thatduetotheirfossil-basednatureandhighchemicalstability,theyarenot biodegradableandwillaccumulateinlandfillsovertheyears,causinganegative impactontheenvironment.Althoughseveralrecyclingstrategiesarecurrently beingcarriedout,packagingmaterialsareoftencontaminatedwithleftoverfood, makingrecyclingeconomicallyinconvenientandthusunviable.In2010,primary plasticproductionwas270milliontons,yetplasticwastewas275milliontons sinceplasticsproducedinpreviousyearsenteredthewastestream,wherethesectorofpackagingwasthehighestproducerofplastics,thatis,146millionin2015. Thishasledtoanincreaseinthenumberofcampaignsrequestingtheremovalof single-useplastics,withtheEuropeanparliamentaimingtobansingle-useplastic cutlery,cottonbuds,straws,andstirrersby2021.Suchenvironmentalawarenessandimplementationofstringentenvironmentalregulationsareleadingto researchforalternativestofoodpackagingmaterialsand,thus,effortsarebeing directed,atbothacademicandindustriallevels,attheuseofbioplasticsinavarietyofconsumerproducts.

1.2ClassificationofBiopolymers

Theabove-describedenvironmentalissues,togetherwiththescarcityofoil sources,arethemaindriversbehindtheinterestforthedevelopmentofnew materialsforfoodpackagingapplications.Althoughbioplasticsonlyaccount for1%oftheapproximately350milliontonsofplasticsproducedannually, beingmostlyappliedaspackagingmaterials[6,7],includinghigh-performance thermoplasticmaterialsandfoams,theyrepresentanimportantpartofthe Bioeconomyandwillundoubtedlyshapethefutureoftheplasticindustry[8].As aresult,theuseofbiopolymersinpackaginghasincreasedconsiderablyoverthe pastfewyearsduetotheirsustainablefeedstock,biodegradability,andsimilar processingcharacteristicsasexistingthermoplastics[9].

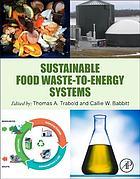

Biopolymerscompriseofawholefamilyofmaterialswithdifferentpropertiesandapplications.Theyincludepolymerswitha“bio-based”originand “biodegradable”polymersorpolymersfeaturingbothproperties.Bio-based polymersrefertoanykindofpolymerthatisproducedfromrenewable resources,whichincludebothnaturallyoccurringpolymersandsynthetic polymersproducedbymeansofmonomersobtainedfrombiologicalsources [10].Naturallyoccurringpolymersarebiomacromolecules,thatis,molecules oflargemolecularweights(M W )producedinnaturebylivingorganismsand

Bio-based polyolefins:

Bio-based polyethylene (bio-PE)

Bio-based polypropylene (bio-PP)

Bio-based polyamides:

Polyamide 1010 (PA1010), polyamide 11 (PA11), polyamide 1012 (PA1012), etc.

Others:

Bio-based polyethylene terephatalate (bio-PET)

Poly(ethylene furanoate) (PEF)

Bio-based polyurethane (bio-PU)

Renewable resources

Bioplastics

e.g. bio-PE, PA1010, bioPET

e.g. PE, PP, PAs, PET

Commodity plastics:

Polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC), polystyrene (PS), etc.

Engineering plastics:

Polyamides (PAs), polyethylene terephthalate (PET), polybutylene terephthalate (PBT), polycarbonate (PC), etc.

High-performance plastics: Poly(ether ether ketone) (PEEK), etc.

Bioplastics

e.g. PLA, PHB, TPS, cellulose

Bioplastics

e.g.

PCL, PBS, PBAT, PVOH

Petrochemical resources

Aliphatic polyesters: Polylactide (PLA)

Poly(3-hydroxybutyrate) (PHB)

Poly(3-hydroxybutyrate-co-3-hydroxyvalerate) (PHBV)

Poly(3-hydroxybutyrate-co-4-hydroxybutyrate) [P(3HB-co-4HB)]

Proteins:

Wheat gluten (WG), soy protein (SP), keratin, casein, zein, etc.

Polysaccharides: Thermoplastic starch (TPS), cellulose, chitin, chitosan, pectin, etc

Aliphatic polyesters:

Poly(ε-caprolactone) (PCL)

Polyglycolic acid (PGA)

Polybutylene succinate (PBS)

Poly(butylene succinate-co-adipate) (PBSA)

Aromatic polyesters:

Poly(butylene adipate-co-terephthalate) (PBAT)

Others: Polyvinyl alcohol (PVOH)

Figure1.1 Classificationofbiopolymerswidelyusedinpackaging. plants.Biodegradablepolymersaredefinedasthosepolymermaterialswhose physicalandchemicalpropertiesundergodeteriorationandcompletelydegrade, whenexposedtotheenzymaticactionofmicroorganisms,tocarbondioxide (aerobicprocess),methane(anaerobicprocess),water(aerobicandanaerobic processes),inorganiccompounds,andbiomass[11].Bio-basedpolymerscanbe biodegradablebutnotallbiodegradablepolymersarebio-based.Additionally, somesyntheticbiodegradablepolymerscouldbeinanearfuturepartiallyorfully developedfrombio-basedmonomers.Bio-basedpolymersoffertheadvantage ofconservationoffossilresourcesbyusingbiomassthatregenerates(annually) andtheuniquepotentialofcarbonneutralitywhereasbiodegradabilityisan add-onpropertyofcertaintypesofpolymersthatoffersadditionalmeansof recoveryattheendofaproduct’slife[12,13].

Figure1.1summarizestheclassificationofbiopolymersgroupedaccordingto theiroriginandbiodegradabilitycharacteristics.Onthetoprightofthefigure, bio-basedandbiodegradablepolymersaregathered.Natureproducesover170 billionmetrictonsperyearofbiomass,yetonly3–4%ofthismaterialisbeing usedbyhumansforfoodandnonfoodpurposes[14].Biomassderivedcarbohydratesarethemostabundantrenewableresourcesavailable,representing approximately75%ofthisbiomass,whicharecurrentlyregardedasthebasisfor thegreenchemistryofthefuture.Mostofthesebiopolymersaremainlymade fromcarbohydrate-richplantssuchascornorsugarcane,thatis,theso-called foodcrops,whicharealsocurrentlyreferredtoasthe“firstgenerationfeedstock” ofbioplastics.Thiscurrentlyrepresentsthemostefficientfeedstockfortheproductionofbioplastics,asitrequirestheleastamountoflandtogrowandproduce thehighestyields.Biomassderivedpolyesterssuchaspolylactide(PLA)andthermoplasticstarch(TPS)areamongthemostpromisingbiodegradablepolymers andtheycontributetoupto65%ofthefamilyofthistypeofbiopolymers.

Thesamedurabilitypropertiesthathavemadetraditionalpetroleumderived plasticsidealformanyapplications,suchasthosefoundinpackaging,areleading toterriblewaste-disposalproblemsasthesematerialsareresistanttomicrobial degradationandplasticsaccumulateintheenvironment.Forthisreason,some biodegradablepolymers,yetbasedonpetrochemicalpolymers,havebeendevelopedinthelastfewyears.Themostfrequentlystudiedpolymersareincluded inthebottom-rightgroup,whicharealiphaticoraliphatic–aromaticpolyesters sinceneataromaticpolyestersbasedonterephthalicacidaregenerallyinsensitivetohydrolyticdegradationandtoenzymaticormicrobialattackduetotheir highstability.Indeed,thebiodegradationrateincreasesrapidlywhentheconcentrationofterephthalicacidbecomeslowerthan55mol%.Thesepetrochemical biodegradablepolymerscanfindseveralusesinbothflexibleandrigidpackaging applications.

Bio-basedbutnotbiodegradablepolymers,whichareshownatthetop-leftof thefigure,currentlyofferimportantcontributionsbyreducingthedependence onfossilfuelsandthroughtherelatedpositiveenvironmentalimpact,thatis, reducedcarbondioxideemissions.Newapproachesgotowardthecomplete orpartialsubstitutionofconventionalplasticsbyrenewableresourcessuchas biomass[15].Conventionalpolymersfromfeedstockroutesarebeingexplored forwell-knownapplications,includingthepackagingindustry[16].These aregenerallybasedonmonomersderivedfromagriculturalandfood-based resourcessuchascorn,potatoes,andothercarbohydratefeedstock.Thenew branchofthese“greenpolymers”reflectsthe“biorefinery”concept[17].The monomerstoproducethesebio-basedpolymerscanbeobtainedfromnatural resources,forexamplecatalyticdehydrationofbioethanolobtainedbymicrobial fermentation.Althoughthesebiopolymersarenotbiodegradable,theyhavethe sameprocessingandperformanceasconventionalpolymersmadefromnatural gasoroilfeedstocks.Suchdevelopmentshaverecentlyledtothenewparadigm forsustainablefoodpackaging:“Bio-basedbutnotbiodegradable”[18].Thisis furtherevidencedbytherecentdevelopmentoffullybio-basedpolyethylene terephthalate(bio-PET),wheretheethyleneglycolandtheterephthalicacidare bothderivedfromplant-basedsugarsandagriculturalresidues.

Thediscussionabouttheuseofbiomassforindustrialpurposesisstilloften linkedtothequestionaboutwhethertheconversionofpotentialfoodandfeed intomaterialsisethicallyjustifiable.Althoughthesurfacerequiredtogrow sufficientfeedstockforcurrentbioplasticsproductionisonlyabout0.01%ofthe globalagriculturalareaofatotalof5billionhectares(bioplastics),thebioplastics industryisalsoresearchingtheuseofnonfoodcropsandagriculturalresidues, theso-called“secondgenerationfeedstock,”withaviewtoitsfurtheruse. Innovativetechnologiesarefocusingonnonedibleby-productsasthesource forbioplastics,whichincludeslargeamountsofcellulosicby-productsand wastessuchasstraw,cornstover,orbagasse.Thisleavessignificantpotential forusingbiotechnologicalprocessestocreateplatformchemicalsforindustrial purposes,amongthemtheproductionofbioplastics.Therefore,thetrendforthe developmentofnextgenerationofbioplasticsiscurrentlyledbytheemergence ofconventionalpolymersmadefromrenewableandnonfoodsources.

1.3FoodPackagingMaterialsBasedonBiopolymers

Thedevelopmentofdifferentkindsofpackagingmaterialsfrombiopolymershas seenanincreaseinthelastfewyears[19].Theuseofbiopolymersinfoodpackagingcanprovidephysicalprotectionduringstorageandtransportation,andcreate properphysicochemicalconditionsformaintainingqualityandsafetyandfor extendingtheshelflifeoffood[20].AllsubsectionsinSection1.3summarize themostimportanttrendsinbiopolymersforfoodpackagingapplications.

1.3.1Polylactide

ThecommercializationofPLAbeganin1990thoughitwasknownsince1845. PLAismostlyobtainedfrombacterialfermentationofcarbohydratesthatcan comefromrenewableresourcessuchascornorsugar.Fermentationturnsthe sugarintolacticacid,whichisthebuildingblockforPLA,butmostindustrial applicationsmakeuseofitsdimerlactide.NatureWorksLLC(previouslyCargill DowLLC)and,morerecently,Corbion(formerPuracBioplastics)arethemajor suppliersofPLAwithaproductioncapacityofover100ktonsperyear,in whichthisbiopolymerisproducedinacontinuousefficientsyntheticprocess viaring-openingpolymerization(ROP)ofthelactidedimer[21].Therearetwo opticalforms:l-lactide,thenaturalisomer,andd-lactide,thesyntheticone[22]. Theproductionofthedifferentisomersdependsonthemicrobialstrainused duringthefermentationprocess.Thepolymercrystallinityandthepropertiesof PLAcansignificantlyvarydependingontheratioandstereochemicalnatureof themonomer[23].

Nowadays,PLAisoneofthemostresearchedandcommercializedbiopolymersanditisseenasapotentialsubstituteforconventionalpolymersas packagingmaterialssinceitisbio-basedandcompostable[24].Ithassimilar propertiestotraditionalpolymerssuchasPET,PS,andpolycarbonate(PC) [25].Themostrelevantcharacteristicsofthisbiopolymerarehighrigidity, goodtransparency,heatsealability,printability,andmeltprocessability.Also, itcanbeprocessedonlarge-scaleproductionlinessuchasinjectionmolding, blowmolding,thermoforming,andextrusion[26].Itisclassifiedasgenerally recognizedassafe(GRAS)bytheUnitedStatesFoodandDrugAdministration (FDA)andissafeforallfoodpackagingapplications[27].However,italso haslimitingpropertiesforitsuseinpackagingapplications.Forexample,its lowglasstransitiontemperature(T g )limitsitsutilizationabove55 ∘ Cand italsoshowslowtoughnessandductility[28].Nevertheless,thesenarrow circumstancescanbeimprovedbyvaryingtheratioofl/disomers,modifying itsstereochemistry,ormixingwithotherpolymersandfillerstoimprovethe mechanicalandthermomechanicalproperties[29].

Inthefieldoffoodpackaging,PLAisidealforfreshproductsandthosethat donotrequireprotectionagainstoxygen,butalsoitcanbeusedinfoodtrays, bottles,candywraps,andcups[30].Accordingly,itshighpermeationtowater makesitsuitableforsomepackagingapplicationssuchasextensionofthelife periodoffreshfruitandbread.Somecoatingsareusedasakindofbarrierlayer

Figure1.2 Commercialfoodpackagingarticlesmadeofpolylactide(PLA):(a)Coffeecapsules. (b)Yogurtcups.Source:CourtesyofDanone(Paris,France).

toreducepermeabilityofthisbiopolymer[31,32].Figure1.2showssomecommercialpackagingarticlesmadeofPLAtocontainfoodproducts.

1.3.2Polyhydroxyalkanoates

Polyhydroxyalkanoates(PHAs)currentlyrepresentoneofthemostimportant alternativestofossilderivedpolymersintheframeoftheCircularEconomy[33], showingthehighestpotentialtoreplacepolyolefinsinpackagingapplications duetotheirbiocompatibilityandphysicalproperties[34].PHAsareafamily ofbiopolyesterssynthesizedbyawiderangeofmicroorganismsascarbonstoragematerial.Althoughtheyhavesuitablecharacteristicssuchasbiodegradability,thermoplasticity,andsimilarmechanicalstrengthandwaterresistanceto otherpolymerssuchasPPandPS[35],theirproductionisexpensiveduetothe highcostsofthefermentationanddownstreamprocesses.Theuseofindustrial by-productsandwasteormixedmicrobialcultures(MMCs)representsaviable optiontoreducetheproductioncostsofPHAs[36].

AmongPHAs,themostwidelystudiedandfirstbacterialmemberof thisfamilyidentifiedwaspoly(3-hydroxybutyrate)(PHB).Thisisotactic homopolyesterisbiodegradablenotonlyincompostingconditionsbutalso inotherenvironmentssuchasmarinewateranditpresentssimilarthermal andmechanicalpropertieswithsomepetrochemicalpolymers.However, itsuseislimitedduetoitspoorimpact-strengthresistanceandanarrow processingtemperaturewindow[37].Toimprovetheseshortcomings,its copolymerssuchaspoly(3-hydroxybutyrate-co-3-hydroxyvalerate)(PHBV)and poly(3-hydroxybutyrate-co-4-hydroxybutyrate)[P(3HB-co-4HB)]havebeen explored.Particularly,PHBVisagoodcandidatesinceithasamuchlower crystallinityandmeltingtemperature,decreasedstiffnessandbrittleness,and

Figure1.3 Biodegradablefoodtraymadeofpoly(3-hydroxybutyrate)(PHB)obtainedby injectionmolding.

higherductility.The T g ofthesePHAcopolymersvariesfrom 40to5 ∘ C,and themeltingtemperature(T m )alsorangefrom50to180 ∘ C,dependingontheir chemicalcomposition[38].

Biomer(Krailling,Germany)andTiananBiologicMaterials(Ningbo,China) arethemainproducersofmicrobialPHBandPHBV,respectively.PHAs canbeprocessedbycommonmethodssuchasextrusion,injectionmolding, thermoforming,filmblowing,andsoon[39].Thesematerialsaresuitablefor verydifferentareasoffoodandcosmeticpackaging,forinstanceblow-molded bottles,milkcartons,cosmeticcontainers,femininehygieneproducts,adhesives, papercoatings,waxes,paints,andsoon[40].Figure1.3depicts,asanexample, atraymadeofPHA.Moreover,theuseofnanofillersoractivesubstances,such asantimicrobialand/orantioxidantsubstances,incorporatedintoaPHA-based packagingmaterialcanchangethepackedfoodconditionextendingtheshelflife andimprovingtheprotectionand/orsensoryproperties,addinganextravalue tothefinalproduct[41,42].

1.3.3Poly(butyleneadipate-co-terephthalate)

Poly(butyleneadipate-co-terephtalate)(PBAT)isabiodegradablealiphatic–aromaticcopolymer,synthetizedbythereactionsofthemonomer1,4-butanediol, adipicacid,andterephthalicacid.Itisbiocompatibleandbiodegradable,being degradedinafewweeksbylipasesfrom Pseudomonascepacia and Candida cylindracea [43].Also,itishighlyamorphous,ithashighductilityandthermomechanicalpropertiescomparablewithLDPE,andiscompostable[44,45]. Despitethesesuitablecharacteristics,PBATshowsahighpermeabilitytowater, thatis,apoorwaterbarrierproperty,andfailstoachievethemechanicalstrength requiredforsomeapplications[46].Differentapproacheshavebeenconsidered toovercomethesedisadvantages,suchassurfacemodifications,useofpolymer blends,andreinforcementbyfillers[47].Forinstance,blendsofPBATwith PLAcanresultinabiodegradablearticlewithbalancedmechanicalproperties, thoughtheuseofachainextenderoracross-linkingagenttoenhancethe interfacialadhesionisusuallynecessary[48].Also,theuseofnanocomposites basedonPBATandlayeredsilicateshaveyieldedmaterialswithimproved mechanicalproperties[49].

PBATfilmscanbepreparedusingcastfilmextrusion,blownfilmextrusion, thermo-compression,andsolventcastingmethods[50]andtheycanbeusedfor agriculture,foodpackaging,wasteandcompostbags,amongothers[51].PBATis soldcommerciallybythetradenamesofEcoflex® byBASF(Ludwigshafen,Germany),EasterBio® fromEastmanChemical(Kingsport,USA),andOrigo-Bi® fromNovamont(Novara,Italy).Itisallowedforfoodpackagingapplicationsby theFDA[52,53]andtheincorporationofantimicrobialsubstancesforactivefood packaginghasrecentlyshownverypromisingresultstoenhancefoodsafety[54].

1.3.4PolybutyleneSuccinate

Polybutylenesuccinate(PBS)isabiodegradableandcompostablealiphatic polyesterproducedbypolycondensationofsuccinicacidand1,4-butanediol. PBSwasexclusivelyderivedfrompetroleum-basedmonomers,butsincemore recentlythemonomerscanalsobeobtainedbythebacterialfermentationroute toproducefullybio-basedpolybutylenesuccinate(bio-PBS)[29,55].Sofar succinicacidhasbeenmainlyproducedbyelectrochemicalsynthesisdueto thehighyield,lowcost,highpurityofthefinalproduct,andveryloworno wasteformation[56].However,theproductionofsuccinicacidbybacterial fermentationusesrenewableresourcesandconsumeslessenergycompared tochemicalprocess.Forthisreason,companiessuchasCorbion(Geleen, theNetherlands)andBASFareworkingonthescalingupofaneconomically feasiblebio-basedsuccinateproductionprocess,despitethefactthattheseprocesseshavetraditionallysufferedfrompoorproductivityandhighdownstream processingcosts.Otherexamplesarethedevelopmentofabiomass-derived succinicacidproductionbyMitsubishiChemical(Tokyo,Japan)incollaboration withAjinomoto(Tokyo,Japan)tocommercializebio-PBSorthedevelopment ofacommerciallyfeasiblefermentationprocessfortheproductionofsuccinic acid,1,4-butanediol,andthesubsequentproductionofPBSbyDSM(Heerlen, theNetherlands)andRoquette(Lestrem,France).Myriant(Quincy,USA)and Bioamber(Plymouth,USA)havealsodevelopedafermentationtechnology toproducethemonomers[57,58].Thus,in2015,theannualproduction capacityofbio-basedsuccinicacidreached200000tons[59].Inthecaseof 1,4-butanediol,conventionalproductionprocessesusefossilfuelfeedstocks, suchasacetyleneandformaldehyde.Nevertheless,thebio-basedprocessto obtainthediolinvolvestheuseofglucosefromrenewableresourcestoproduce succinicacidfollowedbyachemicalreductiontoproducebutanediol[29]. PBSwithexcellentmechanicalpropertiesandprocessingcapabilitiescanbe thenproducedfromtherenewablemonomersbytransesterification,direct polymerization,andcondensationpolymerizationreactionsfollowedbychain extensionandlipase-catalyzedsynthesis.

PBSisasemicrystallinealiphaticpolyesterwithagoodmeltprocessabilityand balancedmechanicalproperties,closelycomparabletothoseofPP.Itistougher thanPLAanditshowssimilarthermalbehaviorthanLDPEandameltingpoint lowerthanthatofPLA[29,60].Itsthermalandmechanicalpropertieshighly dependonthecrystalstructureandthedegreeofcrystallinity[61].The T g and T m areapproximately 32and115 ∘ C,respectively.Intermsofmechanical

1.3FoodPackagingMaterialsBasedonBiopolymers 11 properties,PBShasagoodtensileandimpactstrengthwithmoderaterigidity andhardness[29].PBShasawideprocessingwindow,whichmakestheresin suitableforextrusion,injectionmolding,thermoforming,fiberspinning,and filmblowing.PBShasbeenemployedasfilm,infoaming,andinfoodpackaging containers[60].However,therelativelypoormechanicalflexibilityofPBSlimits theapplicationsof100%PBS-basedproducts.Thisissuecanbeovercomeby blendingPBSwithotherbiopolymersandfillerstoimprovethemechanical propertiestosuittherequiredapplicationandbiodegradationrate[62–65].The developmentofPBScopolymerscanalsoleadtobiopolymerswithadecreased degreeofcrystallinity,depressedheatdistortiontemperature,andimproved elongation[56,66].Copolymerizationisachievedbyaddingathirdmonomer suchassebacicacid,adipicacid,terephthalicacid,succinicacidwithsubstituted sidegroups,1,3-propanediol,andothersubstitutedglycols,whichcanbealso producedfromrenewableresources.Poly(butylenesuccinate-co-terephthalate) (PBST)andpoly(butylenesuccinate-co-adipate)(PBSA)arethemostemployed copolymers,PBSAbeingthemostcommonforflexiblepackagingapplications. Additionally,theflexibilityofthePBSbackboneandthepresenceofreadily hydrolyzableesterbonds,whicharepronetocatalyticdegradationbymicroorganismsorenzymes,promoterapiddegradationprocessofthePBScopolyesters [67].SomestudieshaveevaluatedthebiodegradabilityofbiodegradablepolymersinthematurecompostsoilandfoundthatthebiodegradabilityofPBS wasslowerthanthatofPBSAincompostsoil[68].However,theresultsof enzymatichydrolysisaswellasenvironmentaldegradationofPBSarehighly dependentontheenvironment,thecompositionofthePBSgrade,andits compound[55].

1.3.5Bio-basedPolyethylene

Bio-basedpolyethylene(bio-PE),alsocalled“microbial”or“green”polyethylene, canbeproducedbythecatalyticdehydrationofbioethanolobtainedbymicrobialfermentation,followedbynormalpolymerizationtoproducepolyethylene (PE)[69,70].Bio-PEisnotbiodegradableandhasthesamepropertiesasPE madefromnaturalgasoroilfeedstocks[29].ConventionalPEismanufactured bypolymerizationofethyleneunderpressure,temperature,inthepresenceof acatalyst.Traditionally,ethyleneisproducedthroughsteamcrackingofnaphthaorheavyoilsorethanoldehydration.However,theconceptofproducing PEfrombioethanolisnotparticularlynew.Inthe1980s,Braskem(SãoPaulo, Brazil)hadalreadymadebio-PEfrombioethanol,however,thelimitationsof thebiotechnologyprocessesmadethetechnologyunattractiveatthattime[71]. Currently,bio-PEproducedonanindustrialscalefrombioethanolisderived fromrenewablefeedstocks,includingsugarcaneandbeet,starchcropssuchas maize,wood,wheat,corn,andotherplantwastesthroughmicrobialstrainand biologicalfermentationprocess.Inatypicalprocess,extractedsugarcanejuice withhighsucrosecontentisanaerobicallyfermentedtoproduceethanol.Atthe endofthefermentationprocess,ethanolisdistilledinordertoremovewater

Figure1.4 Schematicflowdiagramoftheproductionofbio-basedpolyethylene(bio-PE)from sugarcaneviafermentationintoethanolandsubsequentdehydrationintoethylene.Source: FromKoopmans[73].©2013,JohnWiley&Sons.

andtoyieldanazeotropicmixtureofhydrousethanol.Ethanolisthendehydratedathightemperaturesoverasolidcatalysttoproduceethyleneand,subsequently,bio-PE[69,72].Figure1.4showsaschematicflowdiagramofthebio-PE production.

Braskemisthelargestproducerofbio-PE,mainlybio-basedhigh-density polyethylene(bio-HDPE),with52%marketshare,withanannualproduction capacityof200000tonsperyearmadefromethanolobtainedfromsugarcane [71]andthisisthefirstcertifiedbio-PEintheworld.Similarly,Braskemis developingotherbio-basedpolymerssuchasbio-basedpolyvinylchloride (bio-PVP),bio-basedpolypropylene(bio-PP),andtheircopolymerswithsimilar industrialtechnologies.Braskem’scurrentbio-basedPEgradesaremainly targetedtowardfoodpackaging,cosmetics,personalcare,automotiveparts,and toys.DowChemical(Midland,USA)incooperationwithCrystalsev(SãoPaulo, Brazil)isthesecondlargestproducerofbio-PE,having12%marketshare.Solvay (Brussels,Belgium),anotherproducerofbio-PE,has10%shareinthecurrent market.However,Solvayisaleaderintheproductionofbio-PVCwithsimilar industrialtechnologies.ChinaPetrochemicalCorporation(Pekin,China)also planstosetupproductionfacilitiesinChinatoproducebio-PEfrombioethanol [74].LyondellBasell(Rotterdam,TheNetherlands)andNeste(Espoo,Finland) haverecentlyannouncedthefirstparallelproductionofbio-PPandbio-based low-densitypolyethylene(bio-LDPE)atacommercialscale,beingmarketed underthetradenamesCirculenandCirculenPlus[75].

Bio-PEcanreplaceallthepackagingapplicationsofcurrentfossilderivedPE becauseofitslowprice,goodlifetimeperformance,andespeciallyrecyclability [75].Thepriceofbio-PEiscurrentlyabout50%higherascomparedwith petrochemicalPE,butitwilltakeadvantagefromthescale-economy.Current upcomingapplicationsbymultinationalsincludeyogurtcupsproducedby Danone(Paris,France),fruitjuicebottlesbyOdwalla(Atlanta,USA),and plasticcapsandclosuresforasepticpaperboardcartonsbyTetraPak(Lund, Sweden)[76].

1.3.6Bio-basedPolyethyleneTerephthalate

PETisacopolymerofmonoethyleneglycol(MEG)andterephthalicacid,and oneofthemoststudiedpolymerstobetransformedincommercialbio-based plastics,whichcanbederivedfromplant-basedsugarsandagriculturalresidues. Thisinterestgavelifetoatechnologicalcollaborationbetweenseveralcompanies,suchasCoca-Cola(Atlanta,USA),Ford(Detroit,USA),Heinz(Sharpsburg, USA),Nike(Eugene,USA),DanoneandProcter&Gamble(Cincinnati,USA), Avantium(Geleen,theNetherlands),andMicromidas(SanJose,CA),todevelop commercialprocessesfortheproductionofbio-PET.Thesourceofpetrochemicalterephthalicacidisprimarilyfromtheoxidationof p-xylene,obtainedfrom thecatalyticreformingofnaphtha.Morethan98%ofthe p-xyleneproduced globallyisconvertedtoterephthalicacidandtheglobaldemandforpurified terephthalicacidisexpectedtoexceed60milliontonsby2020,beingmost ofitusedforPETproduction.Asaresultofthiscost-competitivedemand, bio-basedterephthalicacidmadeatequalpurityandcostasthepetroleum derivedterephthalicacidwouldhaveaclearmarketadvantageaswellasalower pricevolatilityduetothenon-dependenceonpetrochemical p-xylene[77]. However,bio-PETiscurrentlyproducedfromplant-basedmonoethyleneglycol (bio-MEG)whereasterephthalicacidisstillderivedfrompetroleum.Toyota Tsusho(Nagoya,Japan)andChinaManmadeFibersCorporation(Taipei,China) jointlyfoundedacompanyinNovember2010thatmanufacturesbio-MEGmade fromplantderivedbioethanol[78].OthercompaniessuchasSCGChemicals (Bangkok,Thailand)alsoproducebio-MEGfromresiduesofagriculturalactivitiesincludingmolasses,hay,andbagasse[79].Thefirstpartiallybio-PETproduct wascommercializedbyTheCoca-ColaCompany(Atlanta,USA)underthetrade nameofPlantBottleTM ,wherea30wt%ofbio-MEGwasusedfortheproduction ofbio-PET(Company).Atthemoment,someresearchersareworkingonthe synthesisofbio-basedterephthalicacidtoobtainfullybio-PET.Thisprocess isbasedonanintegratedmethodtoconvertforestresiduestoisobutanol[80], whichcanbeprocessedinto p-xylene[81],theprecursorofterephthalicacid. Althoughthe100%bio-basedbottlewasreleasedinMilaninJune2015,the so-calledPlantBottleTM ,showninFigure1.5,hasnotreachedyetthepriceparity toequalthepriceofproducingcurrentCoca-ColaPETbottles[82].PepsiCo (NewYork,USA)alsoannouncedtheuseofaPETbottlemadeentirelywith renewableresourcescomingfromwastecarbohydratebiomassobtainedfromthe foodindustrysuchasorangepeels,oathulls,cornhusks,andpotatoscraps[83].

Similartobio-PE,bio-PETisnotbiodegradablebutithasthesameproperties asconventionalPETmadefromnaturalgasoroilfeedstocks.Currentpartially bio-PETisusedtomakeanumberofproductsincludingdrinkingwaterandsoda bottles,makingthemenvironmentallyfriendlyandanewpackagingalternative. Productsmadefrombio-PEThavethesamequalitiesasregularPETinits distinctivefunctions,weight,appearance,anditcanalsoberecycledandreused [79].Thismaterialcanberecycled,incinerated,orlandfilled,butitcanalsobe intendedfordisposalbycomposting,whereitundergoessoildegradationtoCO2 andwater[9].Enzymatichydrolysisofaromatic/aliphaticpolyesterswasfirst demonstratedinthe1990sforPETwithseveralesterases,lipases,andespecially

Figure1.5 Imageofthe PlantBottleTM madeupto30%from biomassand100%recyclable.

Source:CourtesyoftheCoca-Cola Company(Atlanta,USA).

cutinases[84,85].Nevertheless,PEThydrolysisbyenzymesisarelativelyslow process,sincethebiocatalystsarespecializedtoattacknaturalpolyesterssuch ascutinandwerenotdesignedbynaturefordegradingmanmadesynthetic polyestersinthefirstinstance[85].

1.3.7Poly(ethylenefuranoate)

Apotentialgreensubstituteforterephthalicacidis2,5-furandicarboxylic acid(FDCA),whichisabio-basedbuildingblockthatcanbepolymerized withbio-MEGtoformanew100%bio-basedpolyestercalledpoly(ethylene furanoate)(PEF)[85].PEFcanbesynthesizedbypolycondensation,ROP,and solid-statepolymerization.Polycondensationisthemostcommerciallyrelevant methodbutitresultsinlongexposuretimestohighprocessingtemperatures, around200 ∘ C,whichincreasestheproductioncostand,evenmoreimportantly, leadstothermaldegradationanddiscolorationofthebiopolymer.Solid-state polymerization(SSP)isamilderprocess,thoughabottle-gradePEFhasnot beenachievedyet[86].SSPinvolvesheatingofthestartingpartiallycrystalline polyesteratatemperaturebetweenits T g and T m ,whichisusedmainlyforPET manufacturingtogetoveritsrelativelylow M W [87].ThecompanyAvantium isdevelopingPEFusingbio-MEGandFDCAcomingfromthedehydrationof carbohydrates[77].In2016,itwasannouncedanewtechnologyinvolvinga highlyefficientseparationtechnologyandcatalystthatwouldresultineconomicallyfeasibleproductionofFDCAstartingfrom2016.Theplannedindustrial productioncapacityisestimatedtoexceed300000tonsperyearwhilethe companyhasestablishedcollaborationswithmajorendusersfromthefoodand beverageindustry[84].