OxideElectronics

Editedby AsimRay

BrunelUniversity London,UK

Thiseditionfirstpublished2021

©2021JohnWileyandSonsLtd

Allrightsreserved.Nopartofthispublicationmaybereproduced,storedinaretrievalsystem,ortransmitted,in anyformorbyanymeans,electronic,mechanical,photocopying,recordingorotherwise,exceptaspermittedby law.Adviceonhowtoobtainpermissiontoreusematerialfromthistitleisavailableathttp://www.wiley.com/go/ permissions.

TherightofAsimRaytobeidentifiedasauthoroftheeditorialmaterialinthisworkhasbeenassertedin accordancewithlaw.

RegisteredOffices

JohnWiley&Sons,Inc.,111RiverStreet,Hoboken,NJ07030,USA

JohnWiley&SonsLtd,TheAtrium,SouthernGate,Chichester,WestSussex,PO198SQ,UK

EditorialOffice

TheAtrium,SouthernGate,Chichester,WestSussex,PO198SQ,UK

Fordetailsofourglobaleditorialoffices,customerservices,andmoreinformationaboutWileyproductsvisitusat www.wiley.com.

Wileyalsopublishesitsbooksinavarietyofelectronicformatsandbyprint-on-demand.Somecontentthat appearsinstandardprintversionsofthisbookmaynotbeavailableinotherformats.

LimitofLiability/DisclaimerofWarranty

Inviewofongoingresearch,equipmentmodifications,changesingovernmentalregulations,andtheconstantflow ofinformationrelatingtotheuseofexperimentalreagents,equipment,anddevices,thereaderisurgedtoreview andevaluatetheinformationprovidedinthepackageinsertorinstructionsforeachchemical,pieceofequipment, reagent,ordevicefor,amongotherthings,anychangesintheinstructionsorindicationofusageandforadded warningsandprecautions.Whilethepublisherandauthorshaveusedtheirbesteffortsinpreparingthiswork,they makenorepresentationsorwarrantieswithrespecttotheaccuracyorcompletenessofthecontentsofthiswork andspecificallydisclaimallwarranties,includingwithoutlimitationanyimpliedwarrantiesofmerchantabilityor fitnessforaparticularpurpose.Nowarrantymaybecreatedorextendedbysalesrepresentatives,writtensales materialsorpromotionalstatementsforthiswork.Thefactthatanorganization,website,orproductisreferredto inthisworkasacitationand/orpotentialsourceoffurtherinformationdoesnotmeanthatthepublisherand authorsendorsetheinformationorservicestheorganization,website,orproductmayprovideorrecommendations itmaymake.Thisworkissoldwiththeunderstandingthatthepublisherisnotengagedinrenderingprofessional services.Theadviceandstrategiescontainedhereinmaynotbesuitableforyoursituation.Youshouldconsultwith aspecialistwhereappropriate.Further,readersshouldbeawarethatwebsiteslistedinthisworkmayhavechanged ordisappearedbetweenwhenthisworkwaswrittenandwhenitisread.Neitherthepublishernorauthorsshallbe liableforanylossofprofitoranyothercommercialdamages,includingbutnotlimitedtospecial,incidental, consequential,orotherdamages.

LibraryofCongressCataloging-in-PublicationData

Names:Ray,AsimK.,editor.

Title:Oxideelectronics/editedbyAsimRay,BrunelUniversity London,England,UnitedKingdom.

Description:Firstedition.|Hoboken,NJ,USA:JohnWileyandSons,Inc., 2021.|Series:Wileyseriesinmaterialsforelectronic& optoelectronicapplications|Includesbibliographicalreferencesand index.

Identifiers:LCCN2020051123(print)|LCCN2020051124(ebook)|ISBN 9781119529477(hardback)|ISBN9781119529484(adobepdf)|ISBN 9781119529507(epub)

Subjects:LCSH:Electronics–Materials.|Metallicoxides.| Oxides–Electricproperties.

Classification:LCCTK7871.O952021(print)|LCCTK7871(ebook)|DDC 621.381028/4–dc23

LCrecordavailableathttps://lccn.loc.gov/2020051123

LCebookrecordavailableathttps://lccn.loc.gov/2020051124

CoverDesign:Wiley

CoverImages:CourtesyofSubhasishBasuMajumder Setin10/12ptWarnockProbySPiGlobal,Chennai,India 10987654321

Contents

SeriesPreface xiii

Preface xv

ListofContributors xvii

1GrapheneOxideforElectronics1 FenghuaLiu,LifengZhang,LijianWang,BinyuanZhaoandWeipingWu

1.1Introduction1

1.2SynthesisandCharacterizationsofGrapheneOxide2

1.2.1ChemicalReductionofGrapheneOxide(GO)2

1.2.2MicrowaveMethod2

1.2.3PlasmaMethod3

1.2.4LaserMethod4

1.3EnergyHarvestApplicationsofGrapheneOxide5

1.3.1SolarCells5

1.3.2SolarThermalEnergyHarvestDevices7

1.4EnergyStorageApplicationsofGrapheneOxide7

1.4.1Supercapacitors7

1.4.2Batteries10

1.5ElectronicDeviceApplicationsofGrapheneOxide12

1.6LargeAreaElectronicsApplicationsofGrapheneOxide13 References16

2FlexibleandWearableGraphene-BasedE-Textiles21 NazmulKarim,ShailaAfroj,DamienLeechandAmrM.Abdelkader

2.1IntroductiontoWearableE-Textiles21

2.2SynthesisofGrapheneDerivatives22

2.2.1GrapheneOxide22

2.2.2ReducedGrapheneOxide24

2.3Graphene-BasedWearableE-Textiles25

2.3.1Graphene-BasedTextileFibres26

2.3.2Graphene-CoatedTextiles27

2.3.3Graphene-PrintedWearableE-Textiles28

2.3.3.1ScreenPrinting30

2.3.3.2InkjetPrinting30

2.4SurfacePre-andPost-TreatmentofSubstrates32

2.5Applications34

2.5.1Sensors34

2.5.2Supercapacitor36

2.5.3RechargeableBatteries38

2.5.4Optoelectronics39 2.6ChallengesandOutlook40 References41

3MagneticInteractionsintheCubicMottInsulatorsNiO,MnO,andCoOandthe RelatedOxidesCuOandFeO51 DavidJ.LockwoodandMichaelG.Cottam

3.1Introduction51

3.2Spin–SpinInteractions52

3.2.1MagneticOrderingBelow T N 52

3.2.2Magnetostriction53

3.2.3MagneticandElectronicExcitations54

3.3Spin–PhononInteractions59

3.3.1PhononandMagnonTemperatureDependences60

3.3.2PhononModeSplittingBelow T N 62

3.4OtherRelatedMaterials64

3.4.1CupricOxide64

3.4.2IronMonoxide65

3.5Conclusions68 Acknowledgments68 References68

4High-�� DielectricOxidesforElectronics75 TongZhang,XiaoyangZhang,YiYangandWeipingWu

4.1IntroductionofHigh-�� DielectricOxides75

4.1.1GroupIIIADielectricOxides77

4.1.2GroupIIIBHigh-�� DielectricOxides77

4.1.3GroupIVBHigh-�� DielectricOxides77

4.2TheDepositionofHigh-�� OxideDielectrics78

4.3High-�� DielectricOxidesforField-EffectTransistors80

4.3.1High-�� DielectricOxidesfortheMOSFETs80

4.3.2High-�� DielectricOxidesforTunnelField-EffectTransistors84

4.4High-�� DielectricOxidesforMemoryDevices85

4.4.1High-�� DielectricOxidesforDRAM85

4.4.2High-�� DielectricOxidesforReRAM87 References88

5LowTemperatureGrowthofGermaniumOxideNanowiresbyTemplateBased SelfAssemblyandtheirRamanCharacterization93 RaisaFabiha,AbigailCasey,GregoryTriplettandSupriyoBandyopadhyay 5.1Introduction93

5.2Synthesis93 5.3Characterization96 5.4RamanMeasurements96 5.5Conclusion98 References99

6ElectronicPhenomena,Electroforming,ResistiveSwitching,andDefect ConductionBandsinMetal-Insulator-MetalDiodes101 ThomasW.Hickmott

6.1Introduction101

6.2Experimental103

6.3Electroforming,Electroluminescence,andElectronEmission104

6.3.1ElectroformingofAl-Al2 O3 -AgDiodes104

6.3.2ElectroluminescencefromAl-Al2 O3 -AgDiodes104

6.3.3ElectronEmissionfromAl-Al2 O3 -AgDiodes105

6.3.4VCNR,EL,andEMinOtherInsulators107

6.3.5TemperatureDependenceofEM108

6.4ElectrodeEffectsinResistiveSwitchingofNb-Nb2 O5 -MetalDiodes109

6.4.1ResistiveSwitchinginNb-Nb2 O5 -MetalDiodes109

6.4.2ResistiveSwitchingatLowTemperatures109

6.4.3Structurein I-V CurvesofElectroformedNb-Nb2 O5 -Metal Diodes110

6.5Conduction,Electroluminescence,andPhotoconductivityBefore ElectroformingMIMDiodes112

6.5.1ConductioninNb-Nb2 O5 -AuDiodes112

6.5.2ElectroluminescenceinNb-Nb2 O5 -AuDiodes112

6.5.3ConductionandElectroluminescenceinMIMDiodeswith TiO2 andTa2 O5 115

6.5.4PhotoconductivityinMIMDiodes115 6.6Discussion118

6.6.1DefectConductionBandsinAmorphousAl2 O3 119

6.6.2DefectConductionBandsinAmorphousNb2 O5 121

6.6.3DefectConductionBandsinAmorphousInsulators123

6.7SummaryandConclusions125 References125

7LeadOxideasMaterialofChoiceforDirectConversionDetectors129 AllaReznikandOleksiiSemeniuk

7.1Introduction129

7.2CrystalStructureandElectronicPropertiesofPbO130

7.2.1CrystalStructureofTetragonalPbO(�� -PbO)131

7.2.2CrystalStructureofOrthorhombicPbO(�� -PbO)132

7.2.3ElectronicPropertiesof �� -and �� -PbO133

7.3DepositionProcessofPbOLayers135

7.4ChargeTransportMechanisminLeadOxide147

7.4.1ElectronTransportinpoly-PbO148 References151

8ZnOVaristors:FromGrainBoundariestoPowerApplications157 FelixGreuter

8.1Introduction157

8.2ManufacturingProcessofZnOVaristors160

8.3MicrostructureandGrainBoundaries162

8.4GrainBoundaryPotentialBarriers168

8.5The‘DoubleSchottkyBarrierDefectModel’174

8.6HotElectronEffectsControllingtheBreakdownRegion181

8.7HotElectronEffectsandDynamicResponse185

8.8FromSingleGrainBoundariestoMicrostructuresandVaristorDevices196

8.9AgeingandLong-TermStabilityofVaristorMaterials207

8.10EnergyAbsorptionCapabilityandHighCurrentImpulseStresses218

8.11SummaryandOutlook223 Acknowledgements226 References226

9FundamentalPropertiesandPowerElectronicDeviceProgressofGallium Oxide 235 XuanhuChen,ChennupatiJagadishandJiandongYe 9.1Introduction235

9.2ElectronicPropertiesandDefectsofGa2 O3 236

9.2.1BulkCrystals,Epitaxy,andn–typeDoping237

9.2.2ElectronicBandStructureandFeasibilityofp–typeDoping240

9.2.3DefectBehaviourinBulkCrystalsandEpitaxialFilms245

9.3BasicDeviceCharacteristics250

9.3.1Metal-SemiconductorContact250

9.3.1.1BarrierFormation250

9.3.1.2Image-ForceLowering252

9.3.1.3CarrierTransportandBreakdown254

9.3.2PhysicsofDeepDepletionGa2 O3 MOSFETs257

9.3.2.1Metal-Insulator-SemiconductorCapacitors257

9.3.2.2BasicDeviceCharacteristicsofDepletionMode MOSFETsBasedonGa2 O3 270

9.3.2.3ApproachestoEnhancement-Mode �� -Ga2 O3 MOSFETs280

9.3.3RelevantFigureofMeritinGa2 O3 282

9.4Ga2 O3 SchottkyRectifiers286

9.4.1EdgeTerminations287

9.4.2Ga2 O3 SchottkyRectifiers295

9.4.3Ga2 O3 p-nHeterojunctionDiodes301

9.5Ga2 O3 Transistors307

9.5.1OhmicContactstoGa2 O3 307

9.5.2DielectricMaterialsforGa2 O3 andMOSCaps308

9.5.3LateralGa2 O3 FETs313

9.5.4 �� -Ga2 O3 MODFETs324

9.5.5VerticalGa2 O3 MOSFETs330 9.6Summary335 References336

10EmergingTrends,Challenges,andApplicationsinSolid-StateLaserCooling353 JyothisThomas,LauroMaia,YannickLedemi,YounesMessaddeqandRaman Kashyap 10.1Introduction353 10.2Theory355

10.3ExperimentalDesignConsiderationsforCooling357

10.3.1ExperimentalSetupsUsedforSolid-stateLaserCooling357

10.3.1.1Crystals357

10.3.1.2Glasses358

10.3.1.3SilicaGlassOpticalFibres360

10.3.1.4SemiconductorNanoribbons361

10.3.2TechniquestoAnalyseBackgroundAbsorption(�� b )Coefficient361

10.3.3TemperatureMeasurementTechniquesinSolid-StateLaser Cooling362

10.3.3.1ThermalImaging362

10.3.3.2Photoluminescence(PL)Thermometry363

10.3.3.3TemperatureMeasurementUsingFibreBragg Gratings363

10.3.3.4Thermocouples364

10.3.3.5PhotothermalDeflectionSpectroscopy(PTDS)364

10.3.3.6InterferometricTechnique364

10.4LaserCoolingMaterialsandProperties365

10.4.1Crystals366

10.4.2Semiconductors368

10.4.3OpticalFibres370

10.4.4NanocrystallinePowders371

10.5OxyfluorideGlass-Ceramics:RecentDevelopmentsinSolid-State LaserCooling373

10.5.1Earth-DopedOxyfluoridePseudo-BinaryGlassesand Glass-CeramicsforOpticalRefrigeration375 10.5.1.1MaterialsandMethods376 10.5.1.2ResultsandDiscussion376 10.5.1.3SummaryonPseudo-BinaryOxyfluorideGlass Ceramics381 10.6OpticalCryocoolerDevices382 10.7FutureProspectsandConclusions386 Acknowledgements388 References388

11ElectrodeMaterialsforSodiumIonRechargeableBatteries397 TaniaMajumder,AnwesaMukherjee,DebasishDasandS.B.Majumder 11.1Introduction–ReviewoftheConstituentsUsedinNa–IonCells397 11.2CathodeMaterialsforNaIonRechargeableCells397 11.2.1TransitionMetalOxideswithLayeredStructure397 11.2.2PrussianBlueAnalogue398 11.2.3SodiumSuperionicConductors(NASICON)399 11.2.4OtherCathodes400 11.3CurrentCollectors,Binder,andElectrolyte400 11.4AnodeMaterialsforNaIonRechargeableCells401 11.4.1CarbonaceousMaterials401 11.4.2AlloyingTypeAnodes401 11.4.3ConversionTypeAnodes402 11.4.4OtherAnodes402

11.5OutstandingResearchIssuesandStatementoftheProblem402

11.6SynthesisandElectrochemicalCharacterizationofElectrodes404

11.6.1IlmeniteNiTiO3 asAnode404

11.6.1.1SynthesisandCharacterization404

11.6.2ElectrochemicalCharacterization404

11.6.3ElectrophoreticDepositionofNiTiO3 -BasedAnode406

11.6.4ElectrochemicalPerformanceofEPDGrownNTOAnodes408

11.7Na2 Ti3 O7 asAnode409

11.7.1SynthesisandCharacterization409

11.7.2ElectrochemicalCharacterizationofPristineNaTO410

11.7.3ElectrochemicalPerformanceofCarbon-CoatedNaTOAnode411

11.7.4ElectrochemicalPerformanceofNaTO/rGOCompositeAnode413 11.8PBAasCathode414

11.8.1NickelHexacyanoferrate(NiHCF)415

11.8.2IronHexacyanoferrate(FeHCF)417 11.9SummaryandConclusions418 Acknowledgement419 References419

12PerovskitesforPhotovoltaics423 HoomanMehdizadehRad,DavidOmpongandJaiSingh 12.1Introduction423 12.2DiffusionLength424

12.2.1Methodology425

12.2.2ResultsofSimulatedDiffusionLengthandDiscussions427 12.3Open-CircuitVoltage432

12.3.1ResultsofOpen-CircuitVoltageandDiscussions433

12.3.2BimolecularRecombination436 12.4InfluenceofDensityofTailStatesatInterfaces437 12.4.1Methods437

12.4.2ResultsofDensityofStatesandDiscussions441 12.5Conclusions444 References447

13AdvancedCharacterizationsofOxidesforOptoelectronicApplications453 U.Onwukwe,L.AnguilanoandP.Sermon

13.1ABriefHistoryofOptoelectronicDevices453

13.1.1Semiconductors454

13.1.1.1n-TypeExtrinsicSemiconductors455

13.1.1.2p-TypeExtrinsicSemiconductors456

13.2InteractionofSemiconductorsandtheOptoelectronicPhenomenon457

13.2.1DirectBandGapSemiconductors457

13.2.1.1IndirectBandGapSemiconductors458

13.2.2OxidesforOptoelectronics:Introduction459

13.2.3MajorTypesofMOforOptoelectronics460

13.2.3.1ITO460

13.2.3.2ZnO460

13.2.3.3AZO461

13.2.3.4IGZO461

13.2.3.5PerovskiteOxides462

13.2.3.6ReducedGrapheneOxide-MiscellaneousMaterials463

13.2.4MethodofPreparationofOptoelectronicStructures467

13.2.4.1Nanowires/Nanorods467

13.2.4.2ThinFilms467

13.2.4.3MixedMorphologiesFabrication468

13.3CharacterizationTechniquesandtheirUseforMetalOxide Optoelectronics470

13.3.1RutherfordBackscatteringSpectrometry(RBS)470

13.3.2Fourier-TransformInfra-Red(FTIR)471

13.3.2.1RamanSpectroscopy473

13.3.3ScanningElectronMicroscopy(SEM)475

13.3.4TransmissionElectronMicroscope(TEM)477

13.3.5LuminescenceTechniques480

13.3.6X-RayDiffraction482

13.4FacilitiesandCaseStudies484

13.4.1CaseStudyI–LeafBiotemplateDerivedTiO2 485 References488

14FutureTuningOptoelectronicOxidesfromtheInside:Sol-Gel(TiO2 )x -(SiO2 )100-x 497

M.P.Worsley,J.G.Leadley,R.M.A.MacGibbon,T.Salvesen,P.A.SermonandJ.M. Charnock

14.1IntroductionandBackground497

14.1.1PhotonsandWavetrains497

14.1.2OptoelectronicOxidesandDevices497

14.1.5AlkoxideandSol-GelRoutestoTiO2 -SiO2

14.1.6Miscibilityandthe%TiO2 (x)AddedinTiO2 -SiO2

14.1.7DopingofTiO2 -SiO2

14.1.8LocalStructureinTiO2 -SiO2

14.2Hypothesis503 14.3Experimental504

14.3.1Materials504

14.3.2Preparations504

14.3.3CharacterizationMethods504

14.4CharacterizationResults505

14.5DiscussiononFutureAutomatedCALPHADDesign,Dip-Coating Mechanical,andHigh-ThroughputScreeningofNovelOptoelectronic OxidesandDevices510

14.6ConclusionsonTiO2 -SiO2 Use510 Acknowledgements513 References513

15BinaryCalcia-AluminaThinFilms:SynthesisandPropertiesandApplications525 AsimK.Ray

15.1Introduction525

15.2StructuralandPhysicalPropertiesofC12A7526

15.2.1ThermalStability528

15.2.2IonicConductivityandMechanismsofOxide–IonMigration529

15.3AtomicandElectronicStructure530

15.3.1SynthesisofC12A7531

15.3.2SinglePowders531

15.3.3SingleCrystal532

15.3.4PolycrystallineBulk533

15.3.5ThinFilm535

15.3.6IonDopinginC12A7536

15.3.6.1HeatTreatmentinH2 Atmosphere537

15.3.6.2Thermoelectricity537

15.4OpticalProperties540

15.4.1Reflectivity541

15.4.2Luminescence542

15.5ApplicationsofC12A7543

15.6Summary545 Acknowledgements546 References546

16OxideCathodes553 IanAlberts

16.1HistoricalAspects553

16.1.1TheEdisonEffect555

16.1.2ArthurWehnelt555

16.1.3ThermionicEmissionResearchintheEarlyTwentiethCentury556

16.1.4OxideCathodesfortheCRT556

16.2PhysicsofThermionicEmission557

16.2.1DerivationoftheRichardson-DushmanEquation558

16.2.2SpaceChargeandtheChild-LangmuirLaw559

16.3OxideCathodeDevelopment560

16.3.1TheBarium-CoatedCathode561

16.3.2TheRiseandSubsequentFalloftheImpregnatedCathode562

16.3.3CermetCathodes565

16.3.4StateoftheArt565

16.4FutureTrendsandOngoingApplications567

16.4.1VacuumX-RayTubes568

16.4.2MilitaryTelecommunications568

16.4.3Klystrons570

16.4.4Gyrotron571

16.4.5ThermionicEnergyConversion571

16.4.6TriboelectricNanogenerators573

16.4.7FrontiersinThermionicResearch:VacuumNanoelectronics575

16.4.8FieldEmissionDisplays(FED)575 16.5Conclusion577 References577 Index 583

SeriesPreface

WileySeriesinMaterialsforElectronicandOptoelectronic Applications

Thisbookseriesisdevotedtotherapidlydevelopingclassofmaterialsusedforelectronicandoptoelectronicapplications.Itisdesignedtoprovidemuch-neededinformationonthefundamentalscientificprinciplesofthesematerials,togetherwithhow theseareemployedintechnologicalapplications.Thebooksareaimedat(postgraduate)students,researchers,andtechnologists,engagedinresearch,development,andthe studyofmaterialsinelectronicsandphotonics,andindustrialscientistsdevelopingnew materials,devices,andcircuitsfortheelectronic,optoelectronicand,communications industries.

Thedevelopmentofnewelectronicandoptoelectronicmaterialsdependsnotonlyon materialsengineeringatapracticallevel,butalsoonaclearunderstandingofthepropertiesofmaterials,andthefundamentalsciencebehindtheseproperties.Itisthepropertiesofamaterialthateventuallydetermineitsusefulnessinanapplication.Theseries thereforealsoincludessuchtitlesaselectricalconductioninsolids,opticalproperties, thermalproperties,andsoon,allwithapplicationsandexamplesofmaterialsinelectronicsandoptoelectronics.Thecharacterizationofmaterialsisalsocoveredwithinthe seriesinasmuchasitisimpossibletodevelopnewmaterialswithoutthepropercharacterizationoftheirstructureandproperties.Structure–propertyrelationshipshave alwaysbeenfundamentallyandintrinsicallyimportanttomaterialsscienceandengineering.

Materialsscienceiswellknownforbeingoneofthemostinterdisciplinarysciences. Itistheinterdisciplinaryaspectofmaterialssciencethathasledtomanyexcitingdiscoveries,newmaterialsandnewapplications.Itisnotunusualtofindscientistswith achemicalengineeringbackgroundworkingonmaterialsprojectswithapplicationsin electronics.Inselectingtitlesfortheseries,wehavetriedtomaintaintheinterdisciplinaryaspectofthefield,andhenceitsexcitementtoresearchersinthisfield.

ArthurWilloughby PeterCapper SafaKasap

Preface

Potentialapplicationsofoxideelectronicmaterialsarevast.Transparentelectronics, optoelectronics,magnetoelectronic,photonics,spintronics,thermoelectric,piezoelectric,resistiveswitching,powerharvesting,hydrogenstorage,andenvironmentalwaste managementhasstimulatedhugeinterests,bothacademicandindustrial,inoxideelectronics.Thevastwealthoffunctionalpropertiesofoxidesisfirstrootedintheextreme diversityofcharacterizingtechniques.Complextransitionmetaloxidesexhibitmanifoldphysicalpropertiescomprisinghigh-temperaturesuperconductivity,piezoelectricity,ferroelectricity,magnetism,multiferroicity,andresistiveswitching.Thefunctional propertiesofcomplexmetaloxidesareverysensitivetothedetailsofelectronicstructureandaretherebystronglyinfluencedbytheelementalcompositionandthepresence ofdefectsorlatticedistortions.Thenanoscaleformofoxidesprovidesanewdimension duetotheincreasedsurface-to-volumeratio.

Thishandbookcontains16chapters.Thesetopicshaveabroaderappealwithaview tosatisfyingthemultidisciplinaryneedofelectricalandelectronicengineers,physicists,andmaterialscientists.Theformatofthesechaptersissimilartooneanother. Forexample,eachbeginswithanabstractfollowedbyanintroductiontothetopic andaclearillustrationofcontentswithrelevantequationsandgraphicalillustrations. Chaptersendwithasummaryofthedescription.Eachchaptercontainsanadequate numberofsupportingreferences,pointingouttheadditionalcontributiontoexisting knowledge.Allchaptersareself-containedwithnooverlappingintheircontents.Difficultmathematicshasbeenavoidedasfaraspossibleindescribingthesciencewithin thechapters.Thehandbookishighlyinterdisciplinarysothatitschaptersarevaluable forreaderswithdifferentbackgrounds.

Iamverygratefultoalltheauthorsfortheirexcellentcontributions.Eachtopic ismultidisciplinary,Therefore,readerswithchemistrybackgroundsbutworkingin electricalengineeringwillmaybeinterestedinthishandbook.Similarly,physicists willbenefitfromthishandbookinordertoacquireknowledgeinmaterialsscience. Theauthors’cooperationindeliveringtheirmanuscriptsduringdifferentstagesof productionhasalsobeenverymuchappreciated.SincerethanksareduetoJenny CosshamandKatrinaMacedafortheirhelpoverseveralmonthsincommissioningthe contributionsandgettingthemreadyforproduction.

xvi Preface

ItismygreatpleasuretothankProfessorSafaKasapforhismanyhelpfulsuggestions. HeistheEditor-in-Chiefof MaterialsScience:MaterialsinElectronics.Hisadviceon theselectionofchaptersandtheirauthorshasbeenverymuchappreciated. Finally,theeditorwishestothankallthemembersoftheirfamily(Arunima,Raj, Madhurima,Rishabh,MayanandReuben).

AsimRay London,UK,August2016

ListofContributors

AmrM.Abdelkader DepartmentofDesignandEngineering BournemouthUniversity Dorset UK

ShailaAfroj CentreforFinePrintResearch TheUniversityofWestofEngland Bristol UK

U.Onwukwe,L.Anguilano CollegeofEngineering, DesignandPhysicalSciences BrunelUniversityLondon Uxbridge UK

IanAlberts DepartmentofNuclearMedicine Inselspital,BernUniversityHospital UniversityofBern Bern Switzerland and

LG.PhilipsDisplays Lancashire UK

SupriyoBandyopadhyay DepartmentofElectricalandComputer Engineering

VirginiaCommonwealthUniversity Richmond USA

AbigailCasey DepartmentofElectricalandComputer Engineering

VirginiaCommonwealthUniversity Richmond USA

J.M.Charnock NanomaterialsandApplications Laboratory CEDPS,BraggBuilding BrunelUniversity Uxbridge UK

XuanhuChen SchoolofElectronicScienceand Engineering NanjingUniversity Nanjing China

MichaelG.Cottam DepartmentofPhysicsandAstronomy WesternUniversity,London Ontario Canada

DebasishDas SchoolofNanoScienceandTechnology IndianInstituteofTechnology Kharagpur W.Bengal India

RaisaFabiha DepartmentofElectricalandComputer Engineering

VirginiaCommonwealthUniversity Richmond USA

FelixGreuter DepartmentofEnergy&Materials ABBCorporateResearch Baden-Daettwil Switzerland

ThomasW.Hickmott DepartmentofPhysics StateUniversityofNewYorkatAlbany Albany USA

ChennupatiJagadish DepartmentofElectronicMaterials EngineeringandARCCentreof ExcellenceonTransformative Meta-OpticalSystems ResearchSchoolofPhysics AustralianNationalUniversity,ACT Canberra Australia

NazmulKarim CentreforFinePrintResearch TheUniversityofWestofEngland Bristol UK

RamanKashyap DepartmentofEngineeringPhysics ÉcolePolytechniquedeMontréal Canada

J.G.Leadley NanomaterialsandApplications Laboratory

CEDPS,BraggBuilding BrunelUniversity Uxbridge UK

YannickLedemi DepartmentofElectricalEngineering ÉcolePolytechniquedeMontréal Canada

DamienLeech CentreforFinePrintResearch

TheUniversityofWestofEngland Bristol UK

FenghuaLiu ShanghaiInstituteofOpticsandFine Mechanics ChineseAcademyofSciences Shanghai China

DavidJ.Lockwood MetrologyResearchCentre NationalResearchCouncilCanada Ottawa,Ontario Canada

R.M.A.MacGibbon NanomaterialsandApplications Laboratory

CEDPS,BraggBuilding BrunelUniversity Uxbridge UK

LauroMaia InstitutodeFísica UniversidadeFederaldeGoiás Goiânia Brazil

S.B.Majumder MaterialsScienceCentre IndianInstituteofTechnology

Kharagpur

W.Bengal

India

TaniaMajumder MaterialsScienceCentre

IndianInstituteofTechnology

Kharagpur W.Bengal

India

HoomanMehdizadehRad CollegeofEngineering ITandEnvironment

CharlesDarwinUniversity

Darwin Australia

YounesMessaddeq Centred′ optique, PhotoniqueetLaser UniversitéLaval

Québec

Canada

AnwesaMukherjee MaterialsScienceCentre

IndianInstituteofTechnology

Kharagpur

W.Bengal

India

DavidOmpong CollegeofEngineering ITandEnvironment

CharlesDarwinUniversity

Darwin Australia

AsimK.Ray Design&PhysicalSciences CollegeofEngineering BrunelUniversity Uxbridge UK

AllaRez PhysicsDepartment LakeheadUniversity ThunderBay Canada and ThunderBayRegionalHealthResearch Institute ThunderBay Canada

T.Salvesen NanomaterialsandApplications Laboratory CEDPS,BraggBuilding BrunelUniversity Uxbridge UK

OleksiiSemeniuk RadiationMedicineProgram PrincessMargaretCancerCentre Toronto,ON Canada

JaiSingh CollegeofEngineering ITandEnvironment CharlesDarwinUniversity

Darwin Australia

P.Sermon CollegeofEngineering, DesignandPhysicalSciences BrunelUniversityLondon Uxbridge UK

xx ListofContributors

JyothisThomas

DepartmentofEngineeringPhysics ÉcolePolytechniquedeMontréal Canada

GregoryTriplett

DepartmentofElectricalandComputer Engineering

VirginiaCommonwealthUniversity Richmond USA

LijianWang SchoolofMaterialsScienceand Engineering

ShanghaiJiaoTongUniversity Shanghai China

M.P.Worsley NanomaterialsandApplications Laboratory CEDPS,BraggBuilding BrunelUniversity Uxbridge UK

WeipingWu

ShanghaiInstituteofOpticsandFine Mechanics

ChineseAcademyofSciences Shanghai China

YiYang SchoolofElectronicScienceand Engineering SoutheastUniversity

Nanjing,Jiangsu China

JiandongYe SchoolofElectronicScienceand Engineering

NanjingUniversity

Nanjing China

LifengZhang SchoolofMaterialsScienceand Engineering

ShaanxiUniversityofScienceand Technology

Xi’an,Shaanxi China

TongZhang SchoolofElectronicScienceand Engineering

SoutheastUniversity

Nanjing,Jiangsu China

XiaoyangZhang SchoolofElectronicScienceand Engineering

SoutheastUniversity

Nanjing,Jiangsu China

BinyuanZhao SchoolofMaterialsScienceand Engineering

ShanghaiJiaoTongUniversity

Shanghai China

GrapheneOxideforElectronics

FenghuaLiu 1 ,LifengZhang 2 ,LijianWang 3 ,BinyuanZhao 3 andWeipingWu 1

1 ShanghaiInstituteofOpticsandFineMechanics,ChineseAcademyofSciences,Shanghai,China

2 SchoolofMaterialsScienceandEngineering,ShaanxiUniversityofScienceandTechnology,Xi’an,Shaanxi,China

3 SchoolofMaterialsScienceandEngineering,ShanghaiJiaoTongUniversity,Shanghai,China

1.1Introduction

Graphene,asinglelayerorafewlayersofsp2 -hybridizedgraphiticcarbon,hasgenerated muchattentionbothinscientificandtechnologicalfieldsduetoitsuniquephysicaland chemicalproperties.Asaconductingsemimetal,graphenehasattractedlotsofinterestsfortheresearchandapplicationsofelectronics.Masspreparationofgraphenewith controllablesizeandeconomiccostisstillakeychallengeinitsapplicationtoelectronic devices.Differentsynthesismethodsofgrapheneleadedtoitsvariousproperties.Since thefirstsuccessfulpreparationofgrapheneusingthe‘scotchtape’method,aseriesof methodshavebeendevelopedforthesynthesisofgraphene[1].Asignificantproportion ofthegrapheneresearchhasbeenrealizedbythegrapheneoxide(GO)anditsreduced form,thereducedgrapheneoxide(rGO)astherawmaterials.

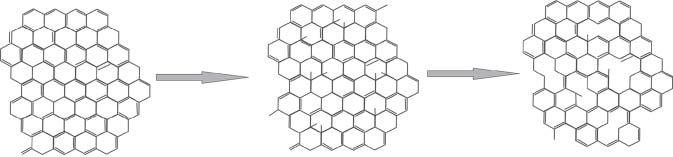

Graphiteoxideisacompoundofcarbon(C),oxygen(O),andhydrogen(H),andhas beensynthesizedbyHummers’methodin1958[2],usingthechemicalreactionbetween graphite,potassiumpermanganate(KMnO4 ),sodiumnitrate(Na2 NO3 ),andsulfuric acid(H2 SO4 ).Theone-molecule-thickorfew-layerversionofthesubstancegraphite oxideisknownasgrapheneoxide(GO).TheGOisnotconductivebutcanbereduced bychemicalreactions,thermaltreatment,ormanyothermethods,formingconductiverGO(Figure1.1)[3].Sofar,manymethodshavebeenwelldevelopedtosynthesis GOandrGO,includingthechemicalreduction,themicrowavemethod,theplasma method,thelasermethod,andthehydrothermalmethod.Othersynthesismethods, suchaschemicalvapourdeposition(CVD)method,arcdischargemethod,ballmilling approach,solvent-assistedexfoliation,etc.,werealsodevotedtodevelophigh-quality graphene,althoughthesesynthesismethodsallhavesometrade-offsintermsofhigh quality,highyield,andenvironmentalfriendliness.

Oxide (GO)Reduced Graphene Oxide (rGO)

Figure1.1 Thechemicalstructuresofgraphene,grapheneoxide(GO),thereducedgrapheneoxide (rGO)andtheconversionofgrapheneintoGOandrGOviaoxidation/reductionreactions.Source: Reprintedwithpermissionfromref. [3]Copyright2018,SpringerNature.

1.2SynthesisandCharacterizationsofGrapheneOxide

1.2.1ChemicalReductionofGrapheneOxide(GO)

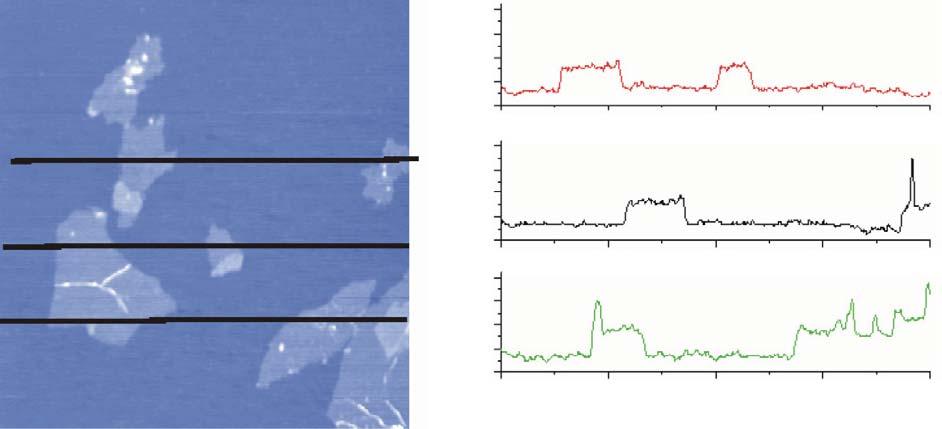

Chemicalreductionofgrapheneoxide(GO)isacommonmethodtolow-costsynthesizegraphene[4].ExfoliationofGOtoindividualGOsheets(Figure1.2)couldbe chemicallyreducedtorGO,using,forinstance,NaBH4 orhydrazine[5].However,the producthasproblems,suchasaggregationanddefects.Moreover,thegenerallyused reducingagents,suchashydrazineorNaBH4 ,aretoxic.However,itstillremaineda greatchallengetoreadilyandefficientlysynthesisofhigh-qualitygraphenewithhigher conductivityandlessdefects.Recently,someemergingmethodsofproducinggraphene, suchasmicrowavemethod,plasmamethod,andlasermethod,haveattractedalotof interest,whichwillbepresentedinthefollowingsections.

1.2.2MicrowaveMethod

Microwaveabsorbsheatenergythroughthemediumandconductsmicro-gradient heatingfrominsidethematerial,whichisconsideredasauniquemethodformaterial

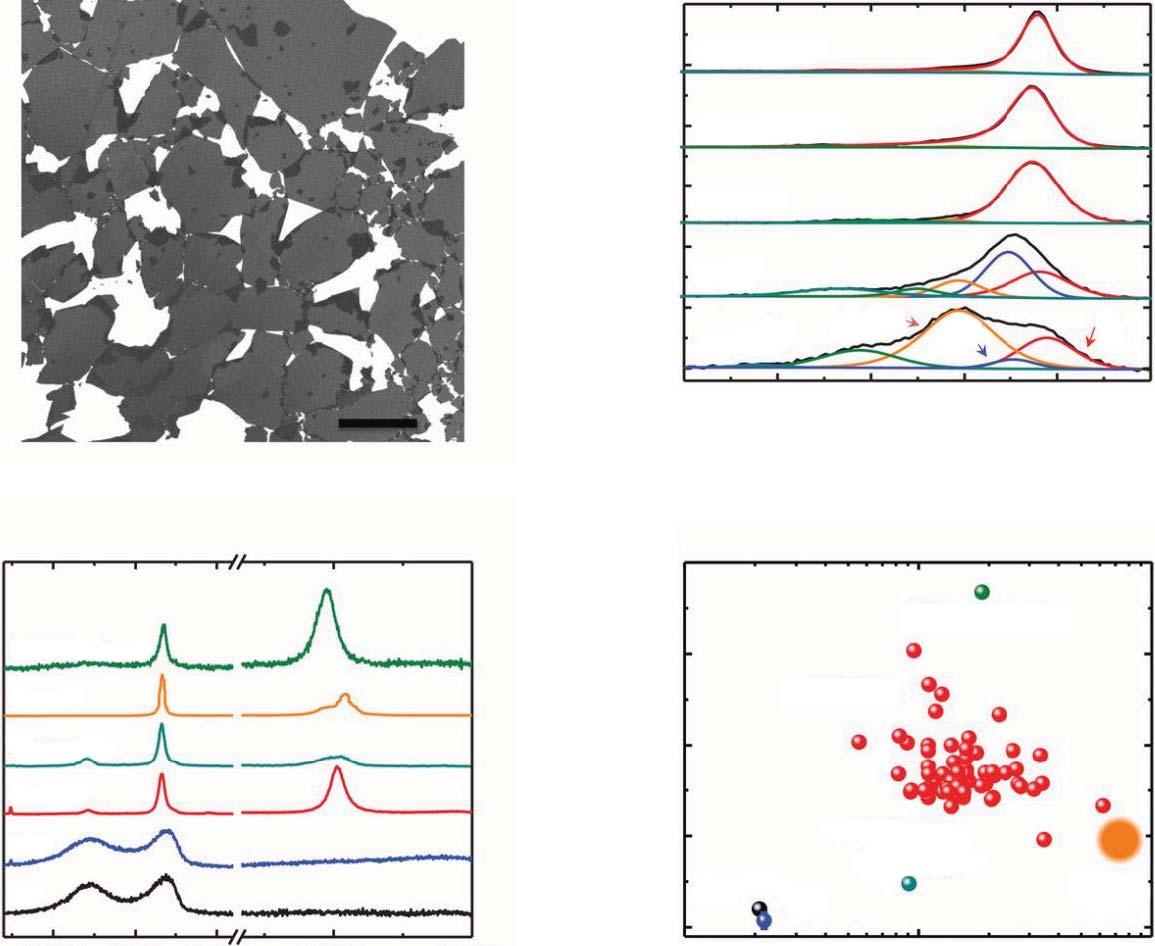

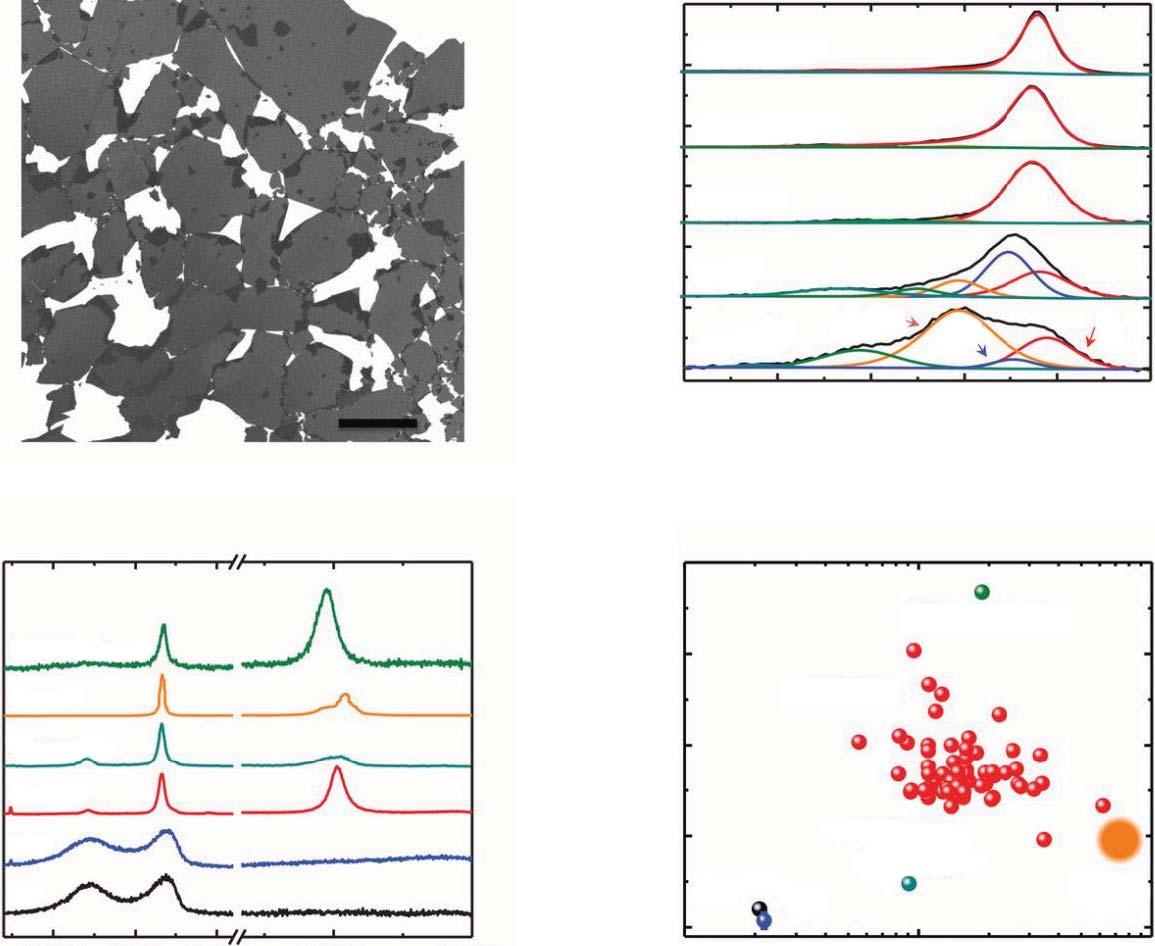

Figure1.2 AFMimageofexfoliatedgrapheneoxide(GO)sheetswiththreeheightprofilesacquiredin differentlocations.Source:Reprintedwithpermissionfromref.[5]Copyright2007ElsevierLtd.

3 synthesis.Thestrongmicrowaveabsorptioncapabilityofgrapheneoxide(GO)can quicklyremoveoxygen-containingfunctionalgroupsandfurtherexfoliatesGO.This featurehasafataltemptationforthepreparationofhigh-qualityandpollution-free graphene.Asearlyasin2011,microwavemethodwasemployedbyZhuetal.to exfoliateGO[6].ThroughthesubsequentactivationofKOH,theypreparedgraphene withahighspecificsurfacearea(SSA)valueof3100m2 g 1 andahighconductivityof 500Sm 1 .Anotherexampleofutilizationofmicrowavesistheexfoliationofgraphite inmolecularlyengineeredionicliquids[7].Itissupposedthatthecation–�� interactions canimprovetheaffinityofgraphenesurfaces.Theas-exfoliatedgrapheneexhibiteda highsingle-layerproportion.Besides, I D /I G valueof0.14andC/Oratioof30areclose tothevaluesofthegraphiteprecursor,indicatingtheexcellentstructuralintegrity. OneofthechallengesonproducingGOandrGOistheuseofthetoxicchemicals, suchassulfuricacidandhydrazinehydrate.Lotsofmethodshavebeendeveloped tosynthesizerGObygreenreductionmethods,usinghydroiodicacid(HI),citric acid,plantextracts,phytochemicals,oralternativelybythermalheatingintheinert atmosphere.In2016,Voiryetal.reportedonthefabricationofhigh-qualitygraphene throughthemicrowavereductionofGO[8].Thisresultattractedmuchinterestbecause theyusedaconventionalmicrowaveovenoperatedat1000Wtorapidlyandefficiently reduceGOnanosheetswith ∼50 μmsize(Figure1.3a).Thehigher-powermicrowave pulseslocallyandultra-fast-heatedGOuptoseveralthousanddegreestothoroughly eliminatetheoxygenfunctionalgroupsandreorderthegraphenebasalplane.The XPSresults(Figure1.3b)suggestthatmicrowave-reducedGO(MW-rGO)showsa negligiblein-planeoxygenconcentrationsof ∼4at.%.Thisoxygencontentismuch lowerthanthetheoreticalvalueofrGOannealedat1500K[9].TheRamanspectra ofMW-rGOandothercomparedsamplesareshowninFigure1.3c.Theas-prepared MW-rGOexhibitedhighlyorderedgraphene–likeRamanfeatureswithsharpand symmetrical2DandGpeaksandaverylow I D /I G ratio(<0.1).Itisalsofoundthat MW-rGOshowshigher I 2D /I G ratiosandlargergraphenedomainsizesascompared withrGOandsolution-exfoliatedflakes(Figure1.3d).Althoughmicrowavemethod haspotentialadvantagesintheefficientpreparationofhigh-qualitygraphene,itshould benotedthattheyieldissolowthatscale-upfabricationofhigh-qualitygraphene remainsagreatchallenge.

1.2.3PlasmaMethod

Plasmaetchingmaynotbeabletopreciselycontrolthemicrostructureoftheproduct attheatomiclevel,andevenmayentailundefinedstructuraldisordersordefectsofthe products.However,asasimpleandefficientmethod,plasmaetchingstillwaswidely usedforetchingofcarbonmaterials[10].Graphenewasoncepreparedbyunzipping ofcarbonnanotubes(CNTs)throughplasmaetchingwithpoly(methylmethacrylate) (PMMA)films[10].Herein,PMMAprotectsCNTsasanetchingmaskduringtheetchingprocess.ThetopsidewallsofCNTswereetchedfasterandremovedbytheplasma. For10secondsofAgron(Ar)plasmaetching,20%ofthestartingCNTswereconverted intosingle-orfew-layergraphenenanoribbons(GNRs)with ∼10–20nmwidthand 2nmheight.Pangetal.reportedonthepatternedGNsynthesizedbymeansofan oxygen-plasmaetchingapproachfromsolution-processedGOfilms[11].Theyused low-costaluminiumassacrificialmetalandprotectivemaskstoremovethegraphene

Figure1.3 (a)SEMofGOnanosheets.(b)High-resolutionXPSC1sspectraand(c)Ramanspectraof MW-rGOandothercomparedsamples.(d)Evolutionofthe I2D /IG ratioversusthecrystalsize(La).

Source:Reprintedwithpermissionfromref.[8]Copyright2016TheAmericanAssociationforthe AdvancementofScience(AAAS).

regionsnotcoveredbythealuminiumwhenthesamplewasexposedtooxygenplasma. Theyarguedthatoxygen-plasmaetchingofgraphenefilmwithsacrificialaluminium contactpatternsisaneffectivemethodforaccuratelycontrollingthesizeofgraphene electrodes.WangandcoworkersreportedthepreparationofgraphenefromtheGO usingaradiofrequency(RF)dielectricbarrierdischargeplasmasystemwithdifferent plasmagas,suchasO2 ,N2 ,andCH4 [12].

1.2.4LaserMethod

Thelasermethodforthefabricationofgraphenehasadvantagesovertheconventional methodsrequiringhighsynthesistemperatureortediouspost-treatments.Lasertechnologiesenabledtheprocesstobesimplerandmorecompatible.Althoughthistechnologystillfacestheproblemoflarge-scaleproduction,ithasbeendemonstratedto producehigh-qualitygraphene.El-Kadyetal.usedastandardLightScribeDVDopticaldrivetocarryoutthedirectlaserreductionofGOfilmstoGNwithhighelectrical conductivity(1738Sm 1 )andSSA(1520m2 g 1 ),whichcanbeuseddirectlyassupercapacitorelectrodeswithoutthebinderorcurrentcollectors[13].TheLightScribelaser

Figure1.4 (a)PreparationillustrationofLSGandSEMimagesofcross-sectionoftheproduct.Source: Reprintedwithpermissionfromref.[13]Copyright2012TheAmericanAssociationforthe AdvancementofScience(AAAS).Morphologycharacterizationsoflaser-inducedgraphene(LIG) derivedfrompine:(b)SEMimageofpristinepine,(c)SEM,(d)TEMand(e)high-resolutionTEMimages ofP-LIG-70.Thescalebarsare500 μm,500 μm,20nm,and4nm,respectively.Source:Reprintedwith permissionfromref.[14]Copyright2017TheWiley-VCH.(f)Schematicillustratingthepreparation processofsolid-stateflexibleMG-MSCs.Source:Reprintedwithpermissionfromref.[15]Copyright 2018Wiley-VCH.

wasabletosimultaneouslyreduceandexfoliatetheGOsheetstoformanopennetwork oflaser-scribedgraphene(LSG)(Figure1.4a).Thisnetworkstructurewithopenpores integratesthepositiveintermsofpreventingtheagglomerationofgraphenesheetsand facilitatingtheelectrolyteaccessibilitytoimprovetheionicdiffusion.

1.3EnergyHarvestApplicationsofGrapheneOxide

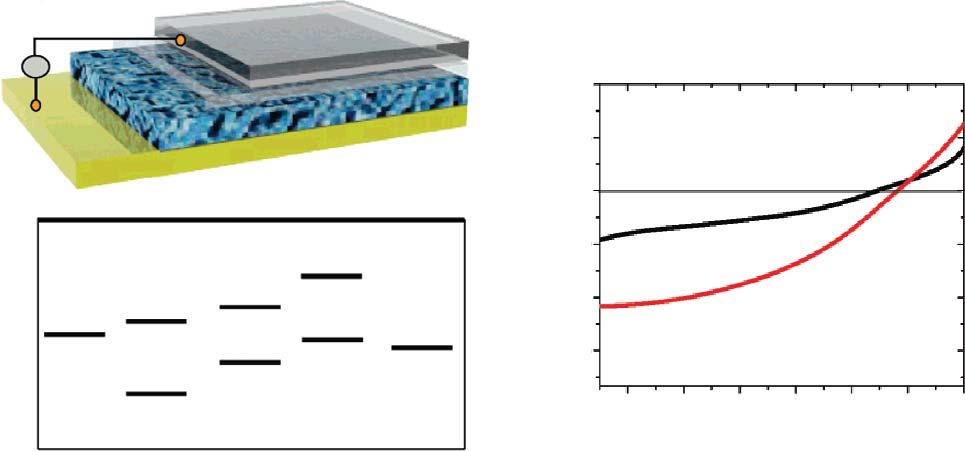

1.3.1SolarCells

Thesuperiorelectronicandopticalpropertiesofgraphenemadeitanidealcandidate forvariousenergyharvestdeviceapplications.GrapheneandrGOcouldbeusedasthe

Figure1.5 Illustrationandperformanceofsolarcellbasedongrapheneelectrodes.(a)Illustrationof dye-sensitizedsolarcellusinggraphenefilmaselectrode,thefourlayersfrombottomtotopareAu, dye-sensitizedheterojunction,compactTiO2 ,andgraphenefilm.(b)Theenergyleveldiagramof graphene/TiO2 /dye/spiro-OMeTAD/Audevice.(c)I-Vcurveofgraphene-basedcell(black)andthe FTO-basedcell(grey),illuminatedunderAMsolarlight(1sun).Source:Reprintedwithpermissionfrom ref.[16]Copyright2008TheAmericanChemicalSociety.

transparentelectrode,counterelectrode,orinterfacelayersinsolarcelldevices.Wang, Zhi,andMüllenreportedtheultra-thintransparentconductiveelectrodeofrGOfilms forthesolid-statedye-sensitizedsolarcells(DSSC;Figure1.5a).TheGOproducedby theHummersmethodwerepurifiedanddispersedinDIwater,the5–20-nm-thickGO filmsweredepositedonthesubstratebydipcoatingfollowedbythethermalreduction. ThesheetresistanceoftherGOwasabout1.8kΩ/sq,calculatedconductivitywasabout 550Scm 1 andatransparencyofmorethan70%over1000–3000nm.TheworkfunctionofrGOis4.42eV(Figure1.5b),closetothethatofFTOelectrode(4.4eV).When servedastheanode,thegraphene/TiO2 /dye/spiro-OMeTAD/AuDSSCdevicedemonstratedashort-circuitphotocurrentdensity(I sc )of1.01mAcm 2 withanopen-circuit voltage(V oc )of0.7V.Thecalculatedfillingfactor(FF)was0.36andthepowerconversionefficiencywas0.26%(Figure1.5c)[16].

Edaetal.reportedtheuseofrGOthinfilmspreparedbyvacuumfiltrationandtransferfortheorganicsolarcells[17].TheGOdispersionwasfilteredthrougha25-nm pore-sizemixedcelluloseestermembrane,thentheobtainedfilmsweretransferred ontothesubstrateandtheestermembranewasthenremovedbyacetonewashes.The GOwasreducedbythehydrazinevapourandlowtemperatureannealingat200 ∘ C.The sheetresistanceoftherGOfilmwasveryhigh,about70kΩ/sqwhenthetransmittance ofthefilmisapproximately65%.Theysuccessfullyreducedthesheetresistancenearly byafactorof5whenbydippinginthionylchloride(SOCl2 )for1hour.TheOPVdevices withtherGOfilmswereverylow,onlyabout0.1%duetotheverylargesheetresistance (ontheorderof105 ).

Wuetal.usedtheGOasthedualfunctionalinterfacemodifierforimprovingwettabilityandretardingrecombinationinindiumtinoxide(ITO)/GO/CH3 NH3 PbI3-x Clx / PCBM/ZnO/Alhybridperovskitesolarcells[18].TheGOservicedasthebuffer

1.4EnergyStorageApplicationsofGrapheneOxide 7

layerbetweentheperovskiteand2,2′ ,7,7′ -tetrakis-(N,N-di-p-methoxyphenyl-amine)9,9′ -spirobifluorene(Spiro-MeOTAD)holetransportlayer(HTL).Theopen-circuit voltage(V OC )andthefillfactor(FF)improvedandtheaverageefficiencygreatly increasedby45.5%,from10.0%to14.5%.Wangetal.fabricatedhighefficiency(up to15.6%)solarcellswithperovskitematerialsandthenanocompositesofsolvent exfoliatedgrapheneandTiO2 usinglowtemperaturesolutionprocesses(nohigher than150 ∘ C).Thegraphenenanoflakesprovidesuperiorcharge-collectioninthe nanocomposites[19].

1.3.2SolarThermalEnergyHarvestDevices

ThebroadbandopticalabsorptionpropertiesandthehighsurfaceofrGOmade itanidealcandidateforthesolarthermalenergyharvestandsolarthermalenergy ultilizations.Itoetal.reportedtheuseofgraphenegrownbyCVDforthesolarabsorber andtheheatlocalizationmaterialforsteamgeneration[20],high-energyconversion efficiencyof80%andfastwaterevaporationrateof1.50kgm 2 h 1 wereachieved.Hu etal.preparerGO-CNTaerogelsanddemonstratehighefficiency(83%)solarsteam generationunderonesun[20].Liuetal.designandpreparedthecarbon–carbon compositematerialsbasedonrGOandcarbonclothbyelectrochemistryreduction ofGO(Figure1.6a)[21].TherGO-carbonclothhasultra-highsolarabsorptionup to93–97%,thusaultra-highevaporationrate2.54kgm 2 h 1 wasachievedunder normalilluminationof1kWm 2 .Theconductingnatureofthesolaropticalabsorber layerallowstheuseoflow-voltageelectricityasanadditionalenergyinput.The flexiblecarboncompositingfilmcouldreach389 ∘ Cwithin10secondsatonly3.5V (Figure1.6b,c).TheelectricallypoweredJouleheatingboostedthesteamgeneration ratebyorderofmagnitude,settingtherecordhighvalueoftheinterfacialevaporation andsteamgenerationupto45.87kgm 2 h 1 .

GrapheneoxideandrGOhavealsobeenusedinotherenergyharvestdevices,such asthermalenergyharvesting[22],themechanicalenergyharvesting[23],theacoustic energy[24]harvesting,andsoon.Besidesusinggrapheneonitsown,itcanalsobe compositedorhybridwithothermaterialstoenhancetheperformanceoftheenergy harvestdevices.

1.4EnergyStorageApplicationsofGrapheneOxide

1.4.1Supercapacitors

Sinceitsfirstapplicationinsupercapacitorsin2008[25],graphenewithitshightheoreticalSSA(2630m2 g 1 ),excellentelectronicconductivity,highflexibility,andsurfacefunctionalizeddiversity,isregardedasapotentialcandidateforbothelectrical double-layercapacitance(EDLC)andpseudocapacitance-basedsupercapacitors.Ruoff etal.preparedtheactivatedgraphenebysimpleactivationwithKOHofmicrowave exfoliatedGO(MEGO)[6].TheMEGOhasultra-highsurfaceareaupto3100m2 g 1 , containingmicroporesandmesoporeswithsizesdistributedbetween ∼1nmand10nm. SupercapacitorsbasedontheMEGOshowedahighgravimetriccapacitanceof166Fg 1 andanexcellentenergydensityof ∼70Whkg 1 . Althoughgrapheneshowedexcellentpowerdensityandcyclicstability,theirspecific capacitancesstillhavealargegapcomparedtothetheoreticalvalueof550Fg 1 [20].

Figure1.6 ThepreparationofGO-CCandrGO-CCcomposites.(a)Theelectrochemicaldepositionof graphene.(b)Theschematicdiagramofelectrochemicaldepositionandjouleheatingprocessto obtainrGOoncarbonclothsamples.(c)TheschematicdiagramofrGO-CCcompositeheating elementstogeneratewatervapourwithlowvoltage.(d–g)Thephotographsandinfraredphotosof therGO-CC(flatandbending).Source:Reprintedwithpermissionfromref.[21]Copyright20202020 WILEY-VCHVerlagGmbH&Co.KGaA,Weinheim.

Thisiscausedbyintrinsicaggregationorre-stackingofgraphenenanosheets(GNSs) duetothestrongvanderWaalsforces,resultinginaseriouslyreducedelectrochemical property.Nevertheless,thishasnotaffectedpeople’senthusiasmfortheapplication ofgrapheneinsupercapacitorsoverthepastdecade.Inthissection,wewillfocus onthefollowingaspects:theemergingpreparationmethodsforgraphene,howto tunetheinterlayerspacingofgraphenetoachievebetterelectrochemicalproperties, three-dimensional(3D)porousgraphene,andgrapheneaerogels.

Itisgenerallyconsideredthatinvestigationofhowiontransportthroughcomplexlayeredgraphene-basedmembranesisdifficultbecauseoftherandomdistributionofmultiscalecomplexandimperfectnanoslitsornanochannelswithinthelayeredgraphenes. Usingalayeredgraphenegel(LGG)asatargetplatformpreparedfollowingthepreviouslyreported‘capillarycompression’method,Chengetal.demonstratedtheeffects oftuneableinterlayerspacingonthetransportpropertiesofionswithexperimentand simulation[26].Theexperimentallyestimatedinterlayerspacing(d exp )canbevaried intheregionofbelow10nm(Figure1.7aTop).Additionally,smallangleneutronscattering(SANS)measurementwascarriedouttoprobetherestackphenomenoninthe as-compressedLGGmembranes(Figure1.7a,bottom).

Figure1.7 (a)Top:SEMimagesoftheLGGmembraneswhencompressedto3.2nm(left)and0.5nm (right),respectively.Bottom:Smallangleneutronscattering(SANS)patternsofthemembraneswith d exp of3.9nm(left)and0.5nm(right),respectively.(b)Aschematicillustrationoftheformationof nanoslitsarray.(c)Reduced1DSANSdataoffsetfromtheabsoluteintensityscale.Theupperright insetistheslope F asafunctionof d exp .Source:Reprintedwithpermissionfromref.[26]Copyright 2016,TheAmericanAssociationfortheAdvancementofScience(AAAS).(d)Schematicdiagram illustratingtheproductionofEGM-GOfilms.(e)SchematicillustrationoftheASSCconfigurationand digitalphotosofthesolid-stateelectrolyte,theflexibleASSC,andtheASSCundervariousbending angles.(f)Cross-sectionalSEMimagesofrGOfilmand(g)EGM-rGO(50%EG)film.Scalebars,2 μm. Source:Reprintedwithpermissionfromref.[27]Copyright2020,NaturePublishingGroup.

Inordertoestablishaquantitativerelationshipamongthenanoconfinediontransport propertiesinrelationtothecomplexnanoporousstructureofthelayeredmembrane, theyconstructedarepresentativestructuralmodeltodescribethefluidiccontourscontainedintheLGGmembranes(Figure1.7b),inwhichtheheightofnanoslits(d ),thelateralsizeofindividualnanosheets(L),andthegapdistancebetweentheendsofthesheets (�� )arethekeygeometricalvariablesoftheproposedstructuralmodel.Thereduced1D SANScurvesinFigure1.7cfurtherconfirmedthatthenanospaceandtheporousstructureintheLGGmembranesremainslargelycontinuous.Theseresultsrevealednew insightsintotheiontransportphenomenaconfinedinagraphenenanochanneland providedasolidfoundationfortheapplicationofGNSsinsupercapacitors.

Recently,Lietal.preparedafreestandinggraphenelaminatefilmelectrodewithhighly efficientporeutilizationforcompactcapacitiveenergystorage[27].Theenhancement ofporeutilizationwasachievedbypreciselyadjustingtheinterlayerspacingofthisfilm