Organic

Visit to download the full and correct content document: https://ebookmass.com/product/organic-electronics-for-electrochromic-materials-anddevices-1st-edition-hong-meng/

More products digital (pdf, epub, mobi) instant download maybe you interests ...

Composite Materials It Meng Low

https://ebookmass.com/product/composite-materials-it-meng-low/

Thermoelectric Materials and Devices Lidong Chen

https://ebookmass.com/product/thermoelectric-materials-anddevices-lidong-chen/

Quantum Materials, Devices, and Applications Mohamed Henini

https://ebookmass.com/product/quantum-materials-devices-andapplications-mohamed-henini/ Terahertz Biomedical and Healthcare Technologies: Materials to Devices 1st Edition Amit Banerjee (Editor)

https://ebookmass.com/product/terahertz-biomedical-andhealthcare-technologies-materials-to-devices-1st-edition-amitbanerjee-editor/

Quantum Physics of Semiconductor Materials and Devices

Debdeep Jena

https://ebookmass.com/product/quantum-physics-of-semiconductormaterials-and-devices-debdeep-jena/

Novel Electrochemical Energy Storage Devices: Materials, Architectures, and Future Trends 1st Edition Feng Li

https://ebookmass.com/product/novel-electrochemical-energystorage-devices-materials-architectures-and-future-trends-1stedition-feng-li/

Go Programming Language For Dummies 1st Edition WeiMeng Lee

https://ebookmass.com/product/go-programming-language-fordummies-1st-edition-wei-meng-lee/

Principles of Electronic Materials and Devices 4th

Edition Safa O. Kasap

https://ebookmass.com/product/principles-of-electronic-materialsand-devices-4th-edition-safa-o-kasap/

Lectures on Digital Design Principles (River Publishers

Electronic Materials, Circuits and Devices) 1st Edition

Pinaki Mazumder

https://ebookmass.com/product/lectures-on-digital-designprinciples-river-publishers-electronic-materials-circuits-anddevices-1st-edition-pinaki-mazumder/

OrganicElectronicsforElectrochromicMaterialsandDevices

HongMeng

Author

Prof.HongMeng PekingUniversity ShenzhenGraduateSchool

BuildingG306

LishuiRoad,NanshanDisctrict 518055Shenzhen China

CoverDesign:Wiley

CoverImage:©Andrew Goodsell/Shutterstock

Allbookspublishedby Wiley-VCH arecarefullyproduced.Nevertheless, authors,editors,andpublisherdonot warranttheinformationcontainedin thesebooks,includingthisbook,to befreeoferrors.Readersareadvised tokeepinmindthatstatements,data, illustrations,proceduraldetailsorother itemsmayinadvertentlybeinaccurate.

LibraryofCongressCardNo.: appliedfor

BritishLibraryCataloguing-in-Publication Data

Acataloguerecordforthisbookis availablefromtheBritishLibrary.

Bibliographicinformationpublishedby theDeutscheNationalbibliothek TheDeutscheNationalbibliotheklists thispublicationintheDeutsche Nationalbibliografie;detailed bibliographicdataareavailableonthe Internetat <http://dnb.d-nb.de>

©2021WILEY-VCHGmbH, Boschstr.12,69469Weinheim, Germany

Allrightsreserved(includingthoseof translationintootherlanguages).No partofthisbookmaybereproducedin anyform–byphotoprinting, microfilm,oranyothermeans–nor transmittedortranslatedintoa machinelanguagewithoutwritten permissionfromthepublishers. Registerednames,trademarks,etc. usedinthisbook,evenwhennot specificallymarkedassuch,arenotto beconsideredunprotectedbylaw.

PrintISBN: 978-3-527-34871-8

ePDFISBN: 978-3-527-83061-9

ePubISBN: 978-3-527-83062-6

oBookISBN: 978-3-527-83063-3

Typesetting SPiGlobal,Chennai,India PrintingandBinding

Printedonacid-freepaper

10987654321

Contents

Preface xiii AbouttheAuthor xiv

1Introduction 1

1.1GeneralIntroduction 1

1.2TheHistoryofElectrochromicMaterials 3

1.3TheKeyParametersofElectrochromism 5

1.3.1ElectrochromicContrast 5

1.3.2SwitchingTime 8

1.3.3ColorationEfficiency 9

1.3.4OpticalMemory 11

1.3.5Stability 12

1.4Conclusion 14 References 14

2AdvancesinPolymerElectrolytesforElectrochromic Applications 17

2.1Introduction 17

2.2RequirementsofPolymerElectrolytesinElectrochromic Applications 18

2.3TypesofPolymerElectrolytes 20

2.3.1GelPolymerElectrolytes(GPEs) 20

2.3.1.1PEO-/PEG-BasedElectrolytes 21

2.3.1.2PMMA-BasedPolymerElectrolytes 21

2.3.1.3PVDF-BasedPolymerElectrolytes 22

2.3.2Self-HealingPolymerElectrolytes 24

2.3.3Cross-LinkingPolymerElectrolytes(CPEs) 26

2.3.4CeramicPolymerElectrolytes 27

2.3.5IonicLiquidPolymerElectrolytes 30

2.3.6Gelatin-BasedPolymerElectrolytes 32

2.4ConclusionandFutureOutlook 33 References 40

3ElectrochromicSmallMolecules 49

3.1BackgroundofSmallMoleculeElectrochromic 49

3.2TechnologyDevelopmentofSmallMoleculeElectrochromic Materials 50

3.3Violene–CyanineHybrids(AIEPLOEC) 50

3.4TerephthalateDerivatives(MulticolorOEC) 56

3.4.1Conclusion 63

3.5IsophthalateDerivatives 64

3.5.1Conclusion 79

3.6MethylKetoneDerivatives 79

3.6.1Conclusion 84

3.7Diphenylacetylenes 84

3.8FluoranDyeDerivatives 85

3.9PH-ResponsiveMoleculeDerivatives 92

3.10TPADyeDerivatives 95

3.11HydrocarbonDerivatives-NIR-OEC 99

3.12ConclusionsandPerspective 101 References 101

4ViologenOEC 105

4.1TheIntroductionofOECandViologen 105

4.1.1GeneralIntroduction 105

4.1.2ResearchHistoryofViologen 105

4.1.2.1FirstStage(1930s–1970s) 107

4.1.2.2SecondStage(1970s–2000s) 107

4.1.2.3ThirdStage(2000s–2010s) 107

4.1.2.4FourthStage(2010s–Present) 108

4.1.3ElectrochromismandElectrochemistryofViologensandTheir Device 109

4.2DifferentStructuresofViologen-BasedElectrochromicMaterials 110

4.2.1SynthesisofViologens 110

4.2.1.1DirectSubstitutionReaction 110

4.2.1.2ZinckeReaction 110

4.2.1.3MethodsforSynthesizingBipyridine 110

4.2.2The1,1′ -SubstitutedViologen 111

4.2.2.1SimpleAlkyl 111

4.2.2.2AcidGroup 111

4.2.2.3EsterandNitrogenHeterocycle 112

4.2.2.4AsymmetricSubstitution 113

4.2.3ConjugateRingSystemExpansion 113

4.2.3.1Thiazolothiazole(TTz)Unit 113

4.2.3.2Perylenediimide(PDI)Unit 115

4.2.3.3PBEDOTPh 115

4.2.3.4HeteroatomsBridged 115

4.2.3.5BithiopheneBridged 118

4.2.4Viologen-BasedPolymer 119

4.2.4.1ViologenintheSideChain 120

4.2.4.2ViologenintheMainChain 122

4.3ViologenElectrochromicDevice 124

4.3.1DeviceStructure 124

4.3.1.1Five-LayerClassicStructure 124

4.3.1.2SimpleSandwichStructure 125

4.3.1.3CathodicAnodeSeparationStructure 125

4.3.1.4ReflectiveDeviceStructure 126

4.3.2Electrolyte 126

4.3.3RedoxMediator 126

4.3.4ConductiveMedium 128

4.3.5ProblemswithViologenCompound 128

4.3.5.1Dimerization 128

4.3.5.2AggregationandSolubility 131

4.3.5.3ResponseTime 131

4.3.5.4DrivingVoltage 131

4.3.5.5Conclusion 131

4.3.6ExamplesofViologen-BasedECD 132

4.4CompaniesOperatingintheFieldofViologenElectrochromism 132

4.4.1Gentex 132

4.4.2Essilor 134

4.4.3Haoruo 134

4.5Conclusion 134 References 135

5Metallohexacyanates 143

5.1Background 143

5.2TechnologyDevelopmentofPB 144

5.3CrystalStructure 144

5.4ElectrochromicMechanism 145

5.5Synthesis 147

5.6ElectrochromicDevices(ECDs) 150

5.7Nanocomposites 154

5.8PBAnalogs 160

5.9MultifunctionalApplications 170 References 175

6ElectrochromicConjugatedPolymers(ECPs) 183

6.1Introduction 183

6.1.1CommonCategoriesandOperationMechanism 183

6.1.2SyntheticMethods 186

6.2Thiophene-BasedConjugatedElectrochromicPolymers 190

6.2.1Introduction 190

6.2.2Color-TuningStrategiesforThiophene-BasedPolymers 191

6.2.2.1StericEffects 192

6.2.2.2SubstituentandElectronicEffects 193

6.2.3TypicalColoredPolymers 195

6.2.3.1YellowandOrange 196

6.2.3.2Red 198

6.2.3.3MagentaandPurple 199

6.2.3.4Black 202

6.2.3.5Multicolored 203

6.2.3.6AnodicallyColoringPolymers 205

6.2.4Water-or“GreenSolvents”-SolubleECPs 208

6.3Polypyrroles-BasedConjugatedElectrochromicPolymers 216

6.3.1Introduction 216

6.3.2ElectrochromicPropertiesofPolypyrroles(PPy) 218

6.3.3TuningofElectrochromicPropertiesofPolypyrrole(PPy) 218

6.3.3.1StructuralModification 218

6.3.3.23-and3,4-SubstitutedPolypyrroles 235

6.3.3.3Donor–AcceptorApproach 236

6.3.3.4TeraryleneSystems 237

6.4Polycarbazole-BasedConjugatedElectrochromicPolymers 237

6.4.1Introduction 237

6.4.2ElectrochromicPropertiesofPolycarbazoles(PCARB) 238

6.4.3ElectrochromicPropertiesofPolycarbazolesDerivatives 238

6.4.3.1LinearPolycarbazoleDerivatives 241

6.4.3.2Cross-LinkedPolycarbazolesDerivatives 249 References 260

7TA-BasedElectrochromicPolyimidesandPolyamides 269

7.1Introduction 269

7.1.1AromaticPolyimidesandPolyamides 269

7.1.2Triarylamine-BasedAromaticPolymers 270

7.1.3ElectrochemicalandElectrochromicBehaviorsofMVTriarylamine Systems 272

7.2DevelopmentofTA-BasedElectrochromicPolyimidesand Polyamides 272

7.2.1SideGroupEngineering 276

7.2.1.1IntroductionofProtectingGroups 276

7.2.1.2IntroductionofElectroactiveGroupstoAchieveColorTuningofEC Material 277

7.2.1.3IntroductionofSideGroupstoAchieveElectrofluorochromic Materials 278

7.2.1.4IntroductionofOtherFunctionalSideGroupstoAchieveMultiple FunctionsECMaterial 281

7.2.2BackboneModulation 283

7.2.2.1ExtendingthePolymerBackbonebyIntroducingMoreElectroactive Groups 283

7.2.2.2IntroductionofAmideLinkageintoPolyimideBackbone 285

7.2.2.3IntroductionofEtherLinkageintoPIs/PAsBackbone 285

7.2.2.4IntroductionofAlicyclicStructuresintoPIs/PAsBackbone 288

7.3Conclusions 290 References 290

8Metallo-SupermolecularPolymers 295

8.1Introduction 295

8.2SingleMetallicSystem 296

8.2.1Fe(II)-andRu(II)-BasedMetallo-SupramolecularPolymers 296

8.2.2CoII -BasedMetallo-SupramolecularPolymers 299

8.2.3ZnII -BasedMetallo-SupramolecularPolymers 301

8.2.4Cu-BasedMetallo-SupramolecularPolymers 305

8.2.5EuIII -BasedMetallo-SupramolecularPolymers 308

8.3Hetero-MetallicSystem 311

8.4TheFabricationMethodofMetallopolymerFilm 314

8.4.1Layer-by-LayerSelf-AssemblyandDip-CoatingMethods 314

8.4.2ElectropolymerizedConductingMetallopolymers 315

8.5Conclusion 323 References 323

9Metal-OrganicFramework(MOF)-andCovalentOrganic Framework(COF)-BasedElectrochromism(EC) 327

9.1Introduction 327

9.2CurrentStudiesinECMOFs 327

9.2.1TheOrganicLinkersinECMOFs 328

9.2.1.1NDI-BasedOrganicLinkers 328

9.2.1.2OtherOrganicLinkers 332

9.2.2TheTransportofElectrolyteIonsinECMOFs 335

9.2.3SpecialECMOFs 338

9.2.3.1PhotochromicandElectrochromicMulti-ResponsiveMOF 338

9.2.3.2MOF-BasedDouble-SidedECDeviceandOtherColor-Switching Mechanisms 339

9.2.3.3ECBaseon“Guest@MOF”CompositeSystem 340

9.3CurrentStudiesinECCOFs 341

9.4ConclusionandProspect 348 References 348

10Nanostructure-BasedElectrochromism 353

10.1Introduction 353

10.2CurrentStudiesofNanostructureinElectrochromism 354

10.2.1Non-ElectrochromicActiveMaterialsasaTemplateforECs 354

10.2.1.1PhotonicCrystalsasTemplatesforECs 354

10.2.1.2PlasmonicStructuresasTemplatesforECs 359

x Contents

10.2.2NanostructuredElectrochromicMaterialsinECs 365 10.3ConclusionandProspect 369 References 369

11OrganicElectroluminochromicMaterials 373

11.1Introduction 373

11.2ConventionalMechanismsofElectroluminochromism 375

11.2.1IntrinsicMechanism 375

11.2.2ElectronTransfer(ET)Mechanism 376

11.2.3EnergyTransfer(EnT)Mechanism 376

11.3ElectroluminochromicPerformanceParameters 376

11.3.1EmissionContrast 376

11.3.2SwitchingTime 377

11.3.3Long-TermStability/CycleLife 377

11.4ClassicalMaterials 378

11.4.1SmallMolecules 378

11.4.1.1SmallMolecularDyads 378

11.4.1.2Redox-ActiveMoietyandLuminophoresSystem 380

11.4.1.3ElectroactiveLuminophores 382

11.4.2TransitionMetalComplexes 386

11.4.3Polymers 387

11.4.3.1Non-ConjugatedPolymers 387

11.4.3.2ConjugatedPolymers 396

11.4.4NanocompositeFilms 407

11.5FuturePerspectivesandConclusion 408 References 408

12OrganicPhotoelectrochromicDevices 415

12.1Introduction 415

12.2StructureDesignofPECDs 417

12.2.1PowerSupplyforPECD 417

12.2.1.1DSSC-BasedPECD 418

12.2.1.2PSC-BasedPECD 423

12.2.1.3OPV-BasedPECD 423

12.2.2ElectrochromicMaterialsinPECD 425

12.2.2.1SmallMolecule 425

12.2.2.2ConductingPolymers 427

12.2.2.3Near-Infrared(NIR)ElectrochromicMaterials 433

12.2.3ElectrolytesinPECD 435

12.2.4SubstratesinPECD 435

12.3FuturePerspectivesandConclusion 436 References 436

13ApplicationofOECDevices 445

13.1SmartWindow 445

13.1.1TheStructureandWorkingMechanismofSmartWindows 445

13.1.2TheMaterialsforElectrochromicWindows 446

13.1.3Prospects 450

13.2DimmableRearviewMirror 450

13.3Sensors 451

13.3.1ApplicationofElectrochromicSensorsonFoodPreservation 451

13.3.2ApplicationinBio-Sensing 454

13.4TheApplicationofElectrochromicDeviceinDisplay 460

13.5OtherApplicationsofOEC 462 References 469

14CommercializedOECMaterialsandRelatedAnalysisof CompanyPatents 471

14.1GeneralIntroduction 471

14.2GentexCorporation 471

14.3RicohCompany,Ltd. 475

14.4CanonInc. 476

14.5BOETechnologyGroupCo.,Ltd.andOPPOGuangdongMobile CommunicationsCo.,Ltd. 477

14.6OtherImportantEnterprises 481

14.6.1NinboNinuoElectronicTechnologyCo.,Ltd. 481

14.6.2AmbilightInc. 483

14.6.3FurciferInc. 483

14.6.4ChangzhouSpectrumNewMaterialCo.Ltd. 484

14.7Conclusion 485 References 485

15MainChallengesfortheCommercializationofOEC 491

15.1Introduction 491

15.2TheLong-TermStabilityofOECMaterials 491

15.3TheMechanicalStabilityofOECDevices(Encapsulation Technology) 495

15.4Large-AreaProcessTechnology:SprayCoatingandRoll-to-Roll Processes 498

15.4.1InkjetPrinting 498

15.4.2SprayCoating 500

15.4.3Slot-DieCoating 500

15.4.4ScreenPrinting 501

15.5ConclusionsandPerspective 501 References 502

Index 505

Preface

Inrecentyears,withthedevelopmentofartificialintelligence,moreandmore industriesstrivetobe“smart.”Asanewgenerationofdisplaytechnology,organic electrochromic(OEC)devicesoffernumerousadvantagessuchasflexibility,full colors,wideoriginsofmaterials,fastswitchingtime,lowdrivingvoltage,and simpleconfiguration.Inaddition,thesedevicespossess“smart”characteristicsof multi-stimulationandmulti-response.Therefore,theOECindustryisemergingas apotentialdisplaycompetitorinthefieldofelectronicinformation.

Thisbookcoversmajortopicsrelatedtothephenomenonofelectrochromism, includingthehistoryoforganicelectrochromism,fundamentalprinciples,different typesofelectrochromicmaterials,developmentofdevicestructures,multifunctional devices,theircharacterizationsandapplications,andfutureprospectsofOECtechnology.Italsospotlightsrecentresearchprogressreportedbyacademicinstitutes andenterprises,anddiscussestheexistingchallengesinfurtherdevelopmentofthis area.

ThisbookprovidesacomprehensivereviewofOECmaterialsanddevices,and canbeusedasateachingreferenceforundergraduateandgraduatestudentsaswell asteachersinthefieldsoforganicchemistryandpolymerscienceetc.Also,this bookcanbeadoptedasacomprehensivereferenceforresearchersengagedinthe developmentofOECtechnologyenterpriseinthefieldofelectrochromism.

Shenzhen,PRChina 11November2020

HongMeng

AbouttheAuthor

Prof.Dr.HongMengobtainedhisBSinChemistryat SichuanUniversityin1988andMSdegreeinOrganic ChemistryfromPekingUniversityin1995.Hethenstudied PolymerScienceandEngineeringandacquiredhissecond MSdegreefromtheNationalUniversityofSingaporein 1997.AfterworkingattheInstituteofMaterialsScience andEngineering(IMRE)inSingaporefortwoyears,he wenttotheUnitedStatesin1999andcompletedhisPhD underthesupervisionofProf.FredWudlattheUniversity ofCalifornia,LosAngeles(UCLA),in2002.Prof.Dr.Mengworkedasaresearch consultantatBellLabs,LucentTechnologies,withDr.ZhenanBaoforoneyear.He thenjoinedDuPontExperimentalStation,CentralResearchandDevelopment,asa seniorresearchchemistin2002.In2012,hemovedbacktoChinaandworkedasthe CEOofalaserprintingindustryatLeputaiTechnologyCompany.In2014,hejoined theSchoolofAdvancedMaterialsatPekingUniversity,Shenzhenasachairprofessor.Hehasbeenengagedintheresearchanddevelopmentofsolid-stateorganic synthesis,organicsemiconductordeviceengineering,organicelectronics,andother relevantfields,especiallyorganiclight-emittingdiodes,organicelectrochromics, organicthin-filmtransistors,organicconductivepolymers,andnanotechnology.He haspublishedmorethan200articlesininternationallyrenownedjournals,participatedinthewritingofthreebookchaptersandco-editedtwobooksinthefieldof organicoptoelectronictechnology.Hehasobtainedmorethan150patentsforinventionsintheUnitedStatesandChina,amongwhich,severalpatentedproductshave beencommercialized.

Introduction

1.1GeneralIntroduction

Electrochromismisthephenomenonthatdescribestheoptical(absorbance/ transmittance/reflectance)changeinmaterialviaaredoxprocessinducedbyan externalvoltageorcurrent[1].Usuallytheelectrochromic(EC)materialsexhibit colorchangebetweenacoloredstateandcolorlessstateorbetweentwocolors, evenmulticolor.Innature,itsoriginisfromthechangeofoccupationnumberof material’sinternalelectronicstates.AsthecoreofECtechnology,theECmaterials havebuiltupmanycategoriesduringdecadesofdevelopment,forexample,accordingtothecolorationtype,itcouldbeclassifiedasanodicallycoloringmaterials (colorationuponoxidation)orcathodicallycoloringmaterials(colorationupon reduction)[2].Basedonthelightabsorptionregioninthesolarradiation,which consistsofthesethreeparts:ultraviolet(UV),visible(Vis),andnear-infrared radiation(NIR)lights(Figure1.1),itcouldbedividedintovisibleECmaterials (wavelength:380–780nm),whichcanbeseenbythehumaneyeandtherefore aresuitableforsmartwindowandindicatorapplications,andNIRECmaterials (wavelength:780–2500nm),whichhavegreatpotentialforthermalregulation technologiesandeveninnationaldefense-relatedapplications[3].Andonthe basisofmaterialsspecies,therearemainlyinorganic,organic,andhybridECmaterials[4,5](https://commons.wikimedia.org/wiki/File:Solar_spectrum_en.svg). InorganicECmaterialsaretransitionmetaloxides(TMOs)(WO3 ,NiO,TiO2 ,and PrussianBlue[PB]),organicECmaterialsincludingsmallmolecules(e.g.viologen), conjugatedpolymers(e.g.poly(pyrrole),poly(thiophene),andpoly(carbazole))and aromaticpolymers(e.g.polyimides[PIs]andpolyamides[PAs]),organic–inorganic hybridmaterialsreferringtometallo-supermolecularpolymers,andmetal–organic framework(MOF).Amongthem,inorganicmaterialsexhibitexcellentlong-term stabilitycomparedwithorganicones;however,consideringthestructurevariety, flexibility,andlow-costsolutionprocessability,organicECmaterialsaresuperior toinorganicmaterials.Theorganic–inorganichybridmaterialsaredesignedto combineadvantagesofbothorganicandinorganicmaterials.

ECmaterialsexhibitcolorchangesduringtheredoxprocess;thereforethe electrochromicdevices(ECDs)generallyconsistofthreeelements:electrodes,EC materials,andelectrolytesolution.Theelectrodesofferaconstantsupplyofelectric OrganicElectronicsforElectrochromicMaterialsandDevices, FirstEdition.HongMeng. ©2021WILEY-VCHGmbH.Published2021byWILEY-VCHGmbH.

Figure1.1 SolarirradiancespectrumaboveatmosphereandatthesurfaceoftheEarth. Source:Nick84:https://commons.wikimedia.org/wiki/File:Solar_spectrum_en.svg,Licensed underCCBY-SA3.0.

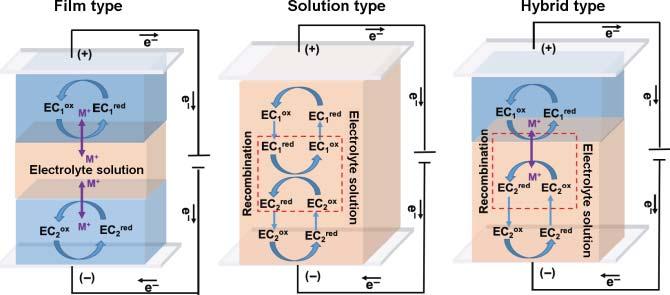

Figure1.2 Theschemeofthreetypesofelectrochromicdevices. current,andionsareconductedbytheelectrolytesolution.ThentheECmaterials undergoelectrochemicaloxidationand/orreduction,whichresultsinchangesin theopticalbandgapandcolors.AsshowninFigure1.2,atypicalECDhasfivelayers: twotransparentconductingoxide(TCO)layers,EClayer,ion-conductinglayer (electrolytesolution),ionstoragelayer.Particularly,theionstoragelayeractsasthe “counterelectrode”tostoreionsandkeepelectricchargebalance.Andaccordingto theexactstateofECmaterials,therearethreetypesofECD:filmtype(I),solution type(II),andhybridtype(III).TheTypeIECDisthemostcommon;manykindsof ECmaterialsaresuitableforthistypeincludingTMOs,conjugated/non-conjugated polymers,metallo-supermolecularpolymers,andMOF/covalentorganicframework(COF)materials,whichusingspin-coating,spray-coating,anddip-coating processestoformuniformfilms;thesefilmswon’tdissoluteinelectrolytesolutions. TypeIIECDrequiresthattheECmaterialshavegoodsolubilityinelectrolyte

1.2TheHistoryofElectrochromicMaterials 3 solutions.Thereforemanyorganicsmallmoleculessuchasviologen,terephthalate derivatives,andisophthalatederivativesareappropriateforthistypeofdevice. Meanwhilethefabricationmethodforthistypeofdeviceisthemostsimpleone. ItjustneedstodissolvetheelectrolyteandECmaterialinaspecificsolventand injectintothepreparedconductingcell.TypeIIIECDusesfilm-typeECmaterials asworkingelectrodeandsolution-typeECmaterialsasionstoragelayer.

1.2TheHistoryofElectrochromicMaterials

Theword“electrochromism”wasinventedbyJohnR.Plattin1960[6],inanalogy to“thermochromism”and“photochromism.”However,theECphenomenoncould betracedtothenineteenthcentury,asearlyas1815.Berzeliusobservedthecolor changeofpuretungstentrioxide(WO3 )duringthereductionwhenwarmedunder aflowofdryhydrogengas.Thenfrom1913to1957,somepatentsdescribedthe earliestformofECDbasedonWO3 [7,8].Thereforetheoriginsofelectrochromism arethenineteenthandtwentiethcenturies.Afterthen,electrochromismtechnology begantoundergorapiddevelopment,especiallytheexplorationofmanyclassesof ECmaterials.Asshowedinthetechnologyroadmap(Figure1.3),wesummarized severalgenerationsofECmaterialsduringlong-termdevelopment.

Thefirst-generationECmaterialisTMOs(e.g.WO3 ,NiO,andPB).Amongthem, WO3 playsanimportantroleintheelectrochromismfield;asthefirstfoundedEC material,ithasalreadyrealizedcommercializationinsmartwindowsapplication. PBwasdiscoveredasadyebyDiesbachin1704,andthentheelectrochemicalbehaviorandECperformanceofPBwasfirstlyreportedbyNeffat1978[9].Benefitted fromthestructurestabilityandreversibleredoxprocessofthoseinorganicTMOs, theelectrochromismbasedonthethin-filmTMOsarewidelyinvestigated,including

thedevelopmentofnewTMOsmaterials,introductionofnewnanostructures,and differentelementdoping.

Followingthefirst-generationTMOECmaterials,organicsmallmoleculeEC materialshaveemergedsince1970.Amongthem,viologenasthemostrepresentativesmallmoleculewasfirstdiscoveredbyMichaelisandHillin1932[10],and becauseofthevioletonthereduction,these1,1′ -disubstituted-4,4′ -bipyridinecompoundswerenamed“viologen.”Thenin1973,Shootmadeanewflatalphanumeric displayusingheptylviologen;thiscanberegardedasthebeginningoftheuseof viologenforelectrochromism[11].Afteracentury’sdevelopment,viologenalready hasbeensuccessfullycommercialized.Besidestheviologen,othersmallmolecules ECmaterialssuchasterephthalatederivatives,isophthalatederivatives,methyl ketonederivatives,andsomedyemoleculeshavealsoattractedmuchattentions fromscientistsduetotheirsimplestructureandlowcost.

Thethird-generationECmaterialsareconjugatedpolymers.In1983,Francis GarnierandcoworkersfirstlycharacterizedtheECpropertiesofaseriesof five-memberedheterocyclicpolymersincludingpoly(pyrrole),poly(thiophene), poly(3-methylthiophene),poly(3,4-dimethylthiophene),andpoly(2,2′ -dithiophene).

Sincethen,conjugatedpolymersweregivenrisetotherapidemergeasanewclass ofelectrochromism[12].Fiveyearslater,BertholdSchreckobservedtheelectrochromismphenomenonofpoly(carbazole),whichshowedacolorchange frompaleyellowishtogreentogetherwiththeconductivityenhancement[13]. Todate,theconjugatedpolymerECsystemhasbeenwelldeveloped,frombetterunderstandingsonmechanismstocompletedcolorpallettewithsolubleor electro-depositedpolymers,andevenfull-colordisplaysamplesorroll-to-roll fabricatedflexibledevices.

Later,inearly2000,triarylamine(TA)-basedaromaticpolymersespeciallythe PIsandPAshavedrawnconsiderableattentionfromtheresearchcommunity asthefourth-generationECmaterials.Thecorrelationbetweenelectrochemical propertiesandchemicalstructuresofdifferentaromaticPIswasfirstlydescribed in1990.Tenyearslater,ZhiyuanWangandcoworkers[14]reportedthefirstEC behaviorofpoly(ethernaphthalimide)s,whichshowedstepwisecolorationprocess, fromcolorlesstoredandtodarkbluecorrespondingtotheneutral,radicalanion, anddianionspecies,respectively.However,duetothehighrigidityofthePIs/PAs backboneandstrongintermolecularinteractions,thepoorprocessabilitylimitedthe developmentofPIsorPAsECmaterials.ThereforetheTAgroupswereintroduced tothePIs/PAsbackbonetoimprovethesolubilityofaromaticpolymers.Thefirst TA-basedpolyamidePAwassynthesizedin1990[15],andthefirstaromaticpolyimidesintegratinginterestingECpropertiescontainingTAgroupsweredisclosed in2005[16].Sincethen,Liou,Hsiaoand,othergroupshavedevelopednumerous TA-basedECPIs/PAs.MostofthePIs/PAsweresolutionprocessibleandthermally stablewithexcellentadhesionwithindiumtinoxide-coatedglasselectrodeandhad goodelectrochemicalstability.NowtheTPA-basedPIs/PAsareconsideredasgreat anodicECmaterialsduetoproperoxidationpotentials,electrochemicalstability, andthin-filmformability.

1.3TheKeyParametersofElectrochromism 5

Benefitingfromthebloomandrevolutionoforganicpolymers,metallo-supermolecularpolymersweredevelopedbyincorporatingmetalcentersintosynthetic polymerchains,asthefifth-generationECmaterials.Thefirstmetal-containing polymer,poly(vinyl-ferrocene),wasreportedinasearlyas1955[17].However, duetotheinsolubilityofthosemacromoleculesandthelimitationofcharacteristic technologiesintheearlyyears,themetallo-supermolecularpolymershaven’tbeen rapidlydevelopeduntilthemid-1990s[18].Sincethen,metallo-supermolecular polymersbegantobewidelyexploredinECfieldwiththeadvantagesofbeneficial propertiesofbothorganicandinorganicmaterials.Especially,becausethetransitionmetalcomplexesoftenexhibitwell-definedredoxeventsandintensecharge transfertransitionsintheNIRregion,metallo-supermolecularpolymersoftenshow potentialsinNIRECapplication.

Morerecently,withtheactiveresearchesonthecrystallineandporousMOFs andCOFs,thesixth-generationMOFs/COFsECmaterialshaveemerged.In2013, thefirstECpropertiesofMOFsusingnaphthalenediimide(NDI)asorganiclinker werereportedbyProfessorM.Dinca’sgroup[19].AndthefirstCOFsECmaterial usingtheTPAasbuildingblockwasrevealedbyYuwuZhongandDongWang andcoworkersin2019[20].Allinall,someessentialfeaturesofMOFs/COFsgive themadvantagesinEC,includingdesignableandprecisemolecularstructure, simpleself-assemblysynthesis,andporousstructurethatfacilitatetheelectrolyte ionstransport.However,thesenewECmaterialshaven’tbeenfullyrevealed;many effortsshouldbetakentoimprovethedeviceperformanceofMOFs/COFs-based electrochromism.

1.3TheKeyParametersofElectrochromism

InordertoelucidatetheECpropertiesofECmaterials,insituUV–Vis–NIRspectroelectrochemistry(SEC)measurementswereperformedonaspectrophotometer, combiningwithanelectrochemicalworkstationtoapplyandcontrolthepotential intheSECcell.ThisSECspectrumdynamicallyrecordstheabsorptionchangeof ECmaterialsduringdifferentappliedvoltage,whichreflectsthecolorchangeduringthewholeredoxprocess.Asanexample,theSECofablack-to-transmissiveEC materialisshowninFigure1.4.Bothabsorbancemodelandtransmittancemodel couldbeusedtocarryouttheSECmeasurement.

1.3.1ElectrochromicContrast

ECcontrast(Δ%T )ismeasuredasthepercenttransmittancechangeoftheEC materialataspecificwavelength[22]itisaprimaryparameterforcharacterizing theECmaterials.Itiscalculatedfromthedifferenceoflighttransmission(TM)in thebleachedandcoloredstateTMb andTMc atthespecifiedwavelength.Andthe transmittancevaluesaregenerallyrecordedupontheapplicationofsquare-wave potentialstepstotheelectroactivefilmplacedinthebeamofaspectrophotometer. EachcolorhasacharacteristicwavelengthasshowninFigure1.5b,suchasthe

(b)

Figure1.4 Thespectroelectrochemistry(SEC)ofablack-to-transmissiveECmaterial.(a) Absorbancemodeland(b)transmittancemodel.Source:ReproducedbypermissionLietal. [21].©2018,RoyalSocietyofChemistry.

wavelengthofbluecolorisrangingfrom455to490nm.Therefore,inmostcases, thecontrastinthecharacteristicwavelengthischosentoevaluatethedegreesof colorchange.Usuallytheabsorptionofthischaracteristicwavelengthalsoreaches itsmaximumvalue(��max ).Moreover,thereisevidencethathumaneyesaremost sensitivetogreenlightwithawavelengthof555nm[25].It’salsorecommendedto calculatethecontrastin555nmforcomparisonindifferentpublications.Specifically,acontrasttestexampleisshowninFigure1.5a,theTMb andTMc of ��max 425nmare1%and99%,respectively;thereforethe Δ%T iscalculatedas98%.For applicationssuchassmartwindows,inwhichthedifferencebetweenthebleached andcoloredstatesisexpectedtobethehighest,the Δ%T shouldbehigherthan 80%.ManyinorganicECmaterials,organicsmallmolecules,andPEDOTseries polymers,whichhaveahightransmittanceinthebleachedstate,canachievethis index.Especially,somereportedsmallmoleculeECmaterialsevenshow Δ%T exceed95%[23].

Figure1.5 (a)TheelectrochromiccontrastofasmallmoleculeECmaterial.Source:Jiang etal.[23],(b)sensitivityfunctionofthehumaneye V (��)andluminousefficacyvs wavelength.Source:FredSchubert[24].©2006,CambridgeUniversityPress.(c)The changeofthelightnessvaluesfromtheneutraltotheoxidizedstates.Source:Lietal.[21]. ©2018,RoyalSocietyofChemistry.

Meanwhile,forsomebroadabsorptionorcolor-to-colorlessECmaterials, measurementsontherelativeluminancechange(Δ%Y )duringanECswitch aremorerealisticforexhibitingtheoverallECcontrast,whichconveysmore informationontheperceptionoftransmittancetothehumaneye.Asanexample, aluminancechangecurveduringtheredoxprocessofblack-to-transmissiveEC materialsisshowninFigure1.5c.Thelightness L* value(from0(black)to100 (white))of37.5(blackstate)increasesto60(bleachstate);thereforethe Δ%Y is calculatedas22.5%.

Exceptfortheaforementionedmethodforelectrochemicalcontrastmeasurements,aphotopicallyweightedvaluecalledphotopiccontrastwasproposedby JavierPadillaetal.[26].Thephotopiccontrastalsoreflectsanoverallcontrast duringthewholevisibleregion,whichismoreconsistentwiththerealapplication condition.Itcanbecalculatedusingthefollowingequation:

where T photopic isthephotopictransmittance, T (��)isthespectraltransmittanceof thedevice, S(��)isthenormalizedspectralemittanceofa6000Kblackbody,and P(��)

isthenormalizedspectralresponseoftheeye. ��min and ��max definetheconsidered rangeofwavelengths.

1.3.2SwitchingTime

Inthecontextofelectrochromism,theswitchingtime(t)canbedefinedasthetime neededforECmaterialstoswitchfromoneredoxstatetotheother.Itisgenerallyfollowedbyasquarewavepotentialstepmethodcoupledwithopticalspectroscopy.Switchingtimedependsonseveralparameters,suchastheabilityofthe electrolytetoconductionsaswellastheeaseofintercalationanddeintercalationof ionsacrosstheECactivelayer,theelectricalresistancesofelectrolytes,andthetransparentconductingfilms.Usuallytheliquidelectrolytehasalowerresistancethan thesolidelectrolyte;thereforethehalfdeviceandtheliquidelectrolyteECDwill exhibitarapidswitchingthansolidECD.Meanwhile,thelargeareaECDsuchasthe largesmartwindowswillshowalowerswitchingcomparedwiththesmalllaboratorysamplesduetothelargerelectricalresistancesoftransparentconductingfilms. However,fastswitchingisnotrequiredinallapplications,suchastheswitchable windowtechnologies;theobviouscolorchangeprocesswillincreasethefunofuser experience.Conversely,thesub-secondmagnituderapidswitchingisparticularly desiredfordisplayapplications.

Usuallytheswitchingtimesareevaluatedatthe ��max or555nmtogetherwith theECcontrast.Thereforetherearetwokindsofswitchingtime.Oneiselectrochemicalswitchingtime,asshowninFigure1.6a,whichisthetimerequiredfor thecurrentdensitytochangeby90%or95%betweentwoconstantvoltages.Meanwhiletheswitchingtimeofoxidization(toxidization )andreduction(treduction )process canbeestimatedfromthiscurve.Theotherisopticalswitchingtime(Figure1.6b), whichdefinesthetimeneededforthetransmittancetochangeby90%or95%.Correspondingly,thecolorationswitchingtime(tcoloration )andbleachingswitchingtime (tbleaching )arerecordedinthismeasurement.Itisworthnotingthatthepulselength ofpotentialstephasinfluenceintransmittance.Ashorterpotentialstepwillachieve asmallercontrast,andlongerpotentialwillallowECmaterialstoreachstationary transmittancevalueinbothcolorationandbleachingstate.Butafteracertainlength, continuingincreasethepulselengthwon’tboostthecontrast.Thereforethepulse lengththatjustreachedthehighestcontrastareappliedtoswitchingtimeaswellas contrasttests.

However,theaforementionedmethodofswitchingtimeisanexperientialmeasurement,whichhasadifferenceinvariedresearchgroups,suchasthedifferent percentageoftransmittancechange(90%or95%).Therefore,itisdifficulttocompare switchingtimedatabetweendifferentresearchgroups.Inrecentyears,JavierPadilla andcoworkersproposedastandardmethodforcalculatingECswitchingtimes.They fittedthecontrastvaluesasafunctionofpulselengthtothefollowingexponential increasefunction:

��TM (t)= ��T Mmax (1 e t∕�� )

where ΔT max representsthefull-switchcontrastobtainedforlongpulselengths and �� isthetimeconstant.Ifswitchingtime t isequalto �� ,63.2%ofthemaximum

Figure1.6 Theswitching timeofECmaterials.

(a)Electrochemical switchingtime.Source: Lietal.[21].©2018,Royal SocietyofChemistry(b) Opticalswitchingtime. Source:Hsiaoetal.[27].

1.3TheKeyParametersofElectrochromism 9

transmittancechangeisreached.Atatimeof2.3�� ,90% ΔTMmax isswitched, identically95%and99%of ΔTMmax correspondingto3�� and4.6�� . Therefore,fornewECmaterials,thesamechronoabsorptometricresponses[28] shouldbemeasuredandfittedtotheaforementionedfunction.Fromthefittings,the maxvaluesof ΔTMmax (thecontrastcorrespondingtoafullswitch),thetimeconstant �� ,andthecorrespondingregressioncoefficient r 2 willbeobtained.Afterwards theswitchingtime t90% or t95% willbeeasilycalculated.Thismethodallowsaneasy directcomparisonbetweendifferentreportedvalues.

1.3.3ColorationEfficiency

Colorationefficiency(CE)playsafundamentalroleintheevaluationoftheefficiencyofchargeutilizationduringtheECprocesses.Itrelatestheoptical absorbancechangeofanECmaterialatagivenwavelength(ΔA)tothedensity ofinjected/ejectedelectrochemicalchargenecessarytoinduceafullswitch(Qd ). ThehigherCEvalueindicatesalargetransmittancechangewithasmallamount ofcharge,whichmakesmoreeffectiveuseoftheinjectedcharge.CEvaluecanbe

Figure1.7 Thecalculationof Qd .Source:Hsiaoetal.[27].

calculatedusingthefollowingequation:

= ��A Qd = log ( Tox Tneut ) Qd

where T ox and T neut arethetransmittancesintheoxidizedandneutralstates,respectively,and Qd representstheinjected/ejectedchargeperunitarea,whichcouldbe obtainedfromtheintegralareaofthecurrentdensitycurveduringvoltageswitching (Figure1.7).

Verysimilartothepreviousparameterscontrastandswitchingtime,theCEvalues arealsodifferentdependingontheselectivewavelength,asshowninFigure1.8. SeveralkindsofCEvalueofthesameECmaterialsareexhibited:inmostreportedliterature,theCEofcharacteristicwavelengthreachingthemaximumcontrast(��max ) iscalculated,whichisthemaximumCEvalue(CEmax ).Also,theCEvalueat555nm

TMVIS, bleached = 77% CEmax, at 767 nm = 188 cm2/C

cm2/C TMVIS, colored = 8%

at 550 nm = 66 cm2/C

=

Figure1.8 DifferenttypesofCEvalueofthesameECmaterials.Source:Kraft[25].

1.3TheKeyParametersofElectrochromism 11 iscalculatedforcomparisonindifferentpublishesbecauseofthehighestsensitivity ofhumaneyesat555nmaswellasthephotopicCEbasedonthephotopictransmittancementionedinthecontrastpart,whichconsideredthelighttransmission overthewavelengthrangebetween380and780nmnormalizedwiththespectral sensitivityofthehumaneye.Therefore,moreplotofCEvaluesshouldbeobtained ratherthansingle-valuedCEvalues,togivemoreinformationabouttheperformanceofECmaterials.

Inaddition,wheninsightfullyconsideringtheinjected/ejectedcharge Qd ,we canfinditinfacttoconsistofthreepart:faradaiccharge QF associatedwith doping/de-doping,capacitivecharge QC duetothecapacitivenatureoftheECD, andparasiticcharge QP associatedwithelectrolyte/impurityreactions.Among them,thefaradaicchargeisthesourceofredoxactivityleadingtochromicchange actually.Therefore,Fabrettoetal.reportedanewtechniqueformeasuringCEby extractingthefaradaicchargefromthetotalchargeandcalculatedtheonlyfaradaic charge-basedCEvalue[29].Aswediscussed,thetotalchargeflowissimplythe additionofthethreeindividualchargeflowsandisgivenby

Qd = QF + QC + QP

wheretheparasiticcurrentwasasmallcomponent(approximately <2%)compared withtheothertwoandthereforecanbeignored.Thenthetime–evolutiontotal currentflowcanbedescribedasfollowing:

where n isthenumberofelectronstransferredpermolecule, F istheFaradayconstant(96500C/mol), A istheelectrodearea(cm2 ), C0 istheconcentrationofspecies inthebulksolution(mol/cm3 ), D istheapparentdiffusioncoefficient(cm2 /s), t is timeinseconds, I 0 isthemaximumcurrentflowat t = 0, R isthecellresistance,and C isthedoublelayercapacitance.Thenfittingtheexperimentaldatatothisequation andsubstitutingtheconstant k,atlast,aplotofthetime–evolutionfaradaiccurrent willbeobtained,andthecorrespondingfaradic-correctedCEscanbecalculated. Usually,thefaradic-correctedCEsarelargerthantheuncorrectedresults,because thetotalchargeingress/egress(i.e. Qd )islargerthanthefaradiccharge(i.e.QF).

1.3.4OpticalMemory

TheopticalorECmemory(alsocalledopen-circuitmemory)ofanECmaterial canbedefinedasthepropensityofthematerialtoretainitsredox/coloredstate uponremovingtheexternalbias.Usually,thememoryeffectareoftenobserved infilm-stateECmaterialssuchasconjugatedpolymers,whichwelladheredonto theelectrode,andhencerestrictthemovementoftheelectrons.Incontrast,some solution-basedECDs(e.g.viologens)willexhibitaself-erasingeffect,whichmeans thecoloredstatedisappearedrapidlyintheabsenceofappliedvoltagebecausethe electronsdiffusefreelyinthistypeofdevice.Thememoryeffectisusefulforthe energy-savingdevicesandalsocanbeappliedfordatastorage.Figure1.9shows

Figure1.9 Open-circuitmemory testsofPBOTT-BTDspraycoated onanITO-coatedglassslidein 0.1MTBAPF6/ACNat423nm: (a)short-and(b)long-term performance.Source:Lietal.[21].

anopticalmemorytest.Theshort-termmemorywasinvestigatedbyapplyinga potentialpulsefor2secondspriortoformingtheopen-circuitstatefor100seconds; thetransmittancechangeat423nmwasmonitoredsimultaneously(Figure1.9a). Thenalong-termmemoryisalsostudiedbyapplyingapotentialfortwoseconds andremovingthebiasforonehour(Figure1.9b).TheECconjugatedpolymers remainintheinitialtransmittancecontrastwellintheabsenceofanapplied voltage,whichexhibitsagoodopticalmemory.

1.3.5Stability

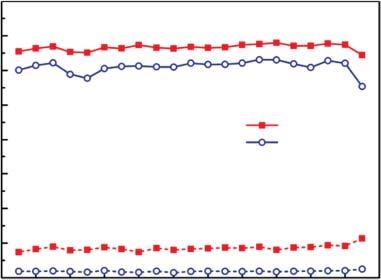

Inmostcasesoflaboratorystudy,researchersrecordthenumberofredoxcycles thatanECmaterialstandwithoutsignificantlossintheperformanceasthe electrochemicalstability,irreversibleoxidationorreductionatextremepotentials,sidereactionswithwateroroxygen,andheatreleaseinthesystemduring switchesmaycausethedegradationofelectrochemicalstability.Usually,the chargedensity Qd recordedunderelectrochemicalcyclingisupto104 –106 ,as showninFigure1.10a.ThechargedensityofaTi-dopedV2 O5 ECfilmhaven’t changedthrough2 × 106 cycles;meanwhilethetransmittancechangeatacertain wavelengthduringcontinuouscyclingisalsoimportanttodescribethestability

Figure1.10 Chargedensity (a)andtransmittance (b)variationcurvesofECD withthecyclenumber K :1000.Source:Wei etal.[30].

Bleached solid line Colored dot line

ofanECmaterial.SuchasshowninFigure1.10b,thetransmittanceoftheECD remainsstablethrough200000cycles.Actually,theCEchangeafternumerous cyclesalsocanbeusedtoevaluatethelong-termstabilityofECmaterials,because itcontainsinformationofbothtransmittanceandchargedensity.

However,ifweconsidertherealapplicationofECDinbuildingwindows,there aremorestrictconditionsfordurabilityandreliability.Forinstance,alifetime over20yearswithmorethan106 switchingcyclesisnecessary.Extremeweather conditionssuchastemperaturesbelow 20 ∘ Candabove +40 ∘ Carehugechallenge forbothECmaterialsandelectrolytes,aswellasotherdegradationfactorssuch ashighsolarirradiationlevels,fasttemperaturechanges,uneventemperature distributionandadditionalstresses,rain,humidity,mechanicalshock,anddrying. Therefore,in1998,CarlM.Lampertproposedastandardtestguidelineforindustry applicationofEC[31],asshowninFigure1.11.Recently,theInternationalOrganizationforStandardization(ISO)alsohaslaunchedaninternationalstandard:Glass inbuilding–Electrochromicglazings–acceleratedagingtestandrequirements (ISO18543)forECuseinbuildings.

EC color/bleach cycling

UVa stability

Heat storage

Low temperature storage

Humidity/temperature storage

Thermal cycling

Thermal shock

1. 25 000 cycles at 25 °C

2. 10 000 cycles at – 20 °C

3. 25 000–100 000b cycles with UVa at 65 °C

Prolonged cycles (12 h colored, 12 h bleach) for a total exposure of 6000 MJ/m2, UV intensity integrated between 300 and 400 nm

500 h at 90 °C

1000 h at 20 °C to – 30 °C

1000 h at 70 °C, 90% humidity

85 °C for 4 h, followed by – 40° C for 4 h and followed by 37 °C for 16 h at 100% R.H. (4 h of ramp between each condition) (repeat four times)

One hour colored and one hour bleached. Test in a UV chamber, with UVa lamp on during coloration. Spray with 25 °C water in bleached state (24 cycles)

aBlack panel temperature during the bright periods of 60 °C, and 25 °C in the dark periods.

bAsahi has used up to 100 000 cycles.

Figure1.11 RecommendedtestingguidelinesforECwindowsforexteriorarchitectural applications.Source:Lampertetal.[31].

1.4Conclusion

Inthischapter,abroadoverviewofelectrochromism,ECmaterials,devicestructure,developmenthistory,andkeyparametersofelectrochromismhavebeen introducedbriefly.Moredetaileddescriptionsofeachareawillbediscussedin Chapters2–15.Insummary,researchinECtechnologieshasachievedsignificant breakthroughsoverthedecades.ManygenerationsofECmaterialshavebeen developed,rangingfromtraditionalmetaloxidestomorerecentorganicpolymers, smallmolecules,andhybridmaterials.Moreover,benefitfromtheECDdesignand structuraloptimization,flexiblesubstrate-baseddeviceswerefabricatedwiththe low-priceroll-to-rollprocess,whichmakestheECtechnologyhavelargescope applications,suchassmartwindowsforreducingbuildingenergyconsumption, self-poweredECwindowusingorganicphotovoltaiccellsaspowersupplement,car rear-viewmirrorsforgreatersafety,andsmartsunglassesforbetterUV-radiation protection.Manyofthesetechnologiesandapplicationshavebeencommercialized andareavailableonthemarket.Withtheconcertedeffortsofresearchersand engineers,webelievethatthenewECmaterialsandadvancedtechnologieswill constantlydevelopandmoreadvancedECDwithlowmanufacturingcostwillbe exploitedtorealizepracticalapplications.

References

1 Fletcher,S.(2015).Thedefinitionofelectrochromism. JournalofSolidStateElectrochemistry 19(11):3305–3308.

2 Camurlu,P.(2014).Polypyrrolederivativesforelectrochromicapplications. RSCAdvances 4(99):55832–55845.

3 Wang,Z.,Wang,X.,Cong,S.etal.(2020).Fusingelectrochromictechnology withotheradvancedtechnologies:anewroadmapforfuturedevelopment. MaterialsScience&EngineeringR:Reports 140.

4 Wu,W.,Wang,M.,Ma,J.etal.(2018).Electrochromicmetaloxides:recent progressandprospect. AdvancedElectronicMaterials 4(8).

5 Mortimer,R.J.(2011).Electrochromicmaterials. AnnualReviewofMaterials Research 41(1):241–268.

6 Platt,J.R.(1961).Electrochromism,apossiblechangeofcolorproducibleindyes byanelectricfield. TheJournalofChemicalPhysics 34(3):862–863.

7 Hutchison,M.R.(1913).Electrographicdisplayapparatusandmethod.USPatent 1,068,774,filed29July1913.

8 LehovecK.(1957).Photonmodulationinsemiconductors.USPatent2,776,367, filed1January1957.

9 Neff,V.D.(1978).Electrochemicaloxidationandreductionofthin-filmsof prussianblue. JournaloftheElectrochemicalSociety 125(6):886–887.

10 Michaelis,L.andHill,E.S.(1933).Theviologenindicators. TheJournalof GeneralPhysiology 16(6):859–873.

11 Schoot,C.J.,Ponjee,J.J.,vanDam,H.T.etal.(1973).Newelectrochromic memorydisplay. AppliedPhysicsLetters 23(2):64–65.

12 Garnier,F.,Tourillon,G.,Garzard,M.,andDubois,J.C.(1983).Organicconductingpolymersderivedfromsubstitutedthiophenesaselectrochromicmaterial. JournalofElectroanalyticalChemistry 148:299–303.

13 Mengoli,G.,Musiani,M.M.,Schreck,B.,andZecchin,S.(1988).Electrochemical synthesisandpropertiesofpolycarbazolefilmsinproticacidmedia. Journalof ElectroanalyticalChemistryandInterfacialElectrochemistry 246(1):73–86.

14 Zheng,H.B.,Lu,W.,andWang,Z.Y.(2001).Electrochemicalandelectrochromic propertiesofpoly(ethernaphthalimide)sandrelatedmodelcompounds. Polymer 42(8):3745–3750.

15 Oishi,Y.,Takado,H.,Yoneyama,M.etal.(1990).Preparationandproperties ofnewaromaticpolyamidesfrom4,4′ -diaminotriphenylamineandaromatic dicarboxylicacids. JournalofPolymerSciencePartA:PolymerChemistry 28(7): 1763–1769.

16 Cheng,S.-H.,Hsiao,S.-H.,Su,T.-H.,andLiou,G.-S.(2005).Novelaromatic poly(amine-imide)sbearingapendenttriphenylaminegroup:synthesis,thermal, photophysical,electrochemical,andelectrochromiccharacteristics. Macromolecules 38(2):307–316.

17 Arimoto,F.S.andHaven,A.C.(1955).Derivativesofdicyclopentadienyliron. JournaloftheAmericanChemicalSociety 77(23):6295–6297.

18 Whittell,G.R.andManners,I.(2007).Metallopolymers:newmultifunctional materials. AdvancedMaterials 19(21):3439–3468.

19 Wade,C.R.,Li,M.,andDinc ˘ a,M.(2013).Faciledepositionofmulticolored electrochromicmetal–organicframeworkthinfilms. AngewandteChemieInternationalEdition 52(50):13377–13381.

20 Hao,Q.,Li,Z.-J.,Lu,C.etal.(2019).Orientedtwo-dimensionalcovalentorganic frameworkfilmsfornear-infraredelectrochromicapplication. Journalofthe AmericanChemicalSociety 141(50):19831–19838.

21 Li,W.,Ning,J.,Yin,Y.etal.(2018).Thieno[3,2-b]thiophene-basedconjugated copolymersforsolution-processableneutralblackelectrochromism. Polymer Chemistry 9(47):5608–5616.

22 Beaujuge,P.M.andReynolds,J.R.(2010).Colorcontrolin π-conjugatedorganic polymersforuseinelectrochromicdevices. ChemicalReviews 110(1):268–320.

23 Jiang,M.,Sun,Y.,Ning,J.etal.(2020).Diphenylsulfonebasedmulticolored cathodicallycoloringelectrochromicmaterialswithhighcontrast. Organic Electronics 83:105741.

24 FredSchubert,E.,Chapter16. HumanEyeSensitivityandPhotometricQuantities inLight-EmittingDiodes,2e.CambridgeUniversityPress.

25 Kraft,A.(2018).Electrochromism:afascinatingbranchofelectrochemistry. ChemTexts 5(1):1–18.

26 Padilla,J.,Seshadri,V.,Filloramo,J.etal.(2007).Highcontrastsolid-stateelectrochromicdevicesfromsubstituted3,4-propylenedioxythiophenesusingthedual conjugatedpolymerapproach. SyntheticMetals 157(6–7):261–268.

27 Hsiao,S.-H.andLin,S.-W.(2016).Electrochemicalsynthesisofelectrochromic polycarbazolefilmsfrom N -phenyl-3,6-bis(N -carbazolyl)carbazoles. Polymer Chemistry 7(1):198–211.

28 Hassab,S.,Shen,D.E.,Österholm,A.M.etal.(2018).Anewstandardmethodto calculateelectrochromicswitchingtime. SolarEnergyMaterialsandSolarCells 185:54–60.https://doi.org/10.1016/j.solmat.2018.04.031.

29 Fabretto,M.,Vaithianathan,T.,Hall,C.etal.(2008).Faradaicchargecorrected colourationefficiencymeasurementsforelectrochromicdevices. Electrochimica Acta 53(5):2250–2257.

30 Wei,Y.,Zhou,J.,Zheng,J.,andXu,C.(2015).ImprovedstabilityofelectrochromicdevicesusingTi-dopedV2 O5 film. ElectrochimicaActa 166:277–284.

31 Lampert,C.M.,Agrawal,A.,Baertlien,C.,andNagai,J.(1999).Durabilityevaluationofelectrochromicdevices–anindustryperspective. SolarEnergyMaterials andSolarCells 56(3):449–463.