AutomatedSamplePreparation

MethodsforGC-MSandLC-MS

Hans-JoachimHübschmann

Author

Dr.Hans-JoachimHübschmann

UrbaneNamba1213

2-1-34Minatomachi,Naniwa-ku

Osaka556-0017

Japan

CoverDesign: ©ADAMDESIGN, Weinheim,Germany

CoverImage: ©CTCAnalyticsAG

Allbookspublishedby WILEY-VCH arecarefully produced.Nevertheless,authors,editors,and publisherdonotwarranttheinformation containedinthesebooks,includingthisbook, tobefreeoferrors.Readersareadvisedtokeep inmindthatstatements,data,illustrations, proceduraldetailsorotheritemsmay inadvertentlybeinaccurate.

LibraryofCongressCardNo.: appliedfor BritishLibraryCataloguing-in-PublicationData Acataloguerecordforthisbookisavailable fromtheBritishLibrary.

Bibliographicinformationpublishedbythe DeutscheNationalbibliothek TheDeutscheNationalbibliothekliststhis publicationintheDeutscheNationalbibliografie;detailedbibliographicdataareavailable ontheInternetat <http://dnb.d-nb.de>

©2022WILEY-VCHGmbH,Boschstr.12, 69469Weinheim,Germany

Allrightsreserved(includingthoseof translationintootherlanguages).Nopartof thisbookmaybereproducedinanyform–by photoprinting,microfilm,oranyothermeans–nortransmittedortranslatedintoamachine languagewithoutwrittenpermissionfromthe publishers.Registerednames,trademarks,etc. usedinthisbook,evenwhennotspecifically markedassuch,arenottobeconsidered unprotectedbylaw.

PrintISBN: 978-3-527-34507-6

ePDFISBN: 978-3-527-81750-4

ePubISBN: 978-3-527-81752-8

oBookISBN: 978-3-527-81751-1

Typesetting Straive,Chennai,India

Printedonacid-freepaper 10987654321

ForPaulina

InMemoryofAmalia

Contents

Foreword xiii

Preface xv

1Introduction 1

1.1APerspectiveonHumanPerformance 2 References 5

2TheAnalyticalProcess 7

2.1LaboratoryLogistics 7

2.1.1AnalyticalBenefitsofInstrumentalWorkflows 9

2.1.1.1DataQuality 11

2.1.1.2TurnkeyOperation 11

2.1.1.3GreenAnalyticalChemistry 11

2.1.1.4Productivity 12

2.1.2StandardOperationProcedure 13

2.1.3EconomicalAspects 15 References 16

3WorkflowConcepts 19

3.1SamplePreparationWorkflowDesign 19

3.1.1TransferofStandardMethodstoAutomatedWorkflows 20

3.1.2MethodTranslation 21

3.1.2.1SketchingtheAutomatedWorkflow 22

3.1.2.2RoboticSystemConfiguration 22

3.1.3OnlineorOfflineConfiguration 25

3.2InstrumentalConcepts 25

3.2.1Workstations 25

3.2.2RevolvingTrayAutosamplers 26

3.2.3SelectiveComplianceArticulatedRobots 28

3.2.4CartesianRobots 28

3.2.5MultipleAxisRobots 32

3.2.6CollaborativeRobots 33

3.3SampleProcessing 35

3.3.1SequentialSamplePreparation 35

3.3.2Prep-aheadMode 35

3.3.3IncubationOverlapping 36

3.3.4BatchProcessing 36

3.3.5ParallelProcessingWorkflows 38

3.3.6SampleIdentification 38

3.3.6.1Barcodes 38

3.3.6.2Radio-FrequencyIdentificationChips 40

3.4ToolChange 41

3.4.1ManualToolChange 41

3.4.2AutomatedToolChange 42

3.4.3ToolIdentification 44

3.5ObjectTransport 46

3.5.1MagneticTransport 46

3.5.2GripperTransport 48

3.5.3NeedleTransport 50

3.6VialDecapping 50 References 52

4AnalyticalAspects 55

4.1LiquidHandling 55

4.1.1AboutDropsandDroplets 55

4.1.2Syringes 56

4.1.2.1PrecisionandAccuracy 57

4.1.2.2SyringeNeedles 58

4.1.2.3SyringeNeedlePointStyles 59

4.1.2.4SyringePlungerTypes 60

4.1.2.5SyringeTermination 61

4.1.2.6OperationalParameters 62

4.1.3VialBottomSensing 66

4.1.4Pipetting 67

4.1.4.1AirDisplacementPipettes 68

4.1.4.2PositiveDisplacementPipets 69

4.1.4.3PipettingModes 69

4.1.4.4Aspiration 71

4.1.4.5Dispensing 73

4.1.4.6Liquid-LevelDetection 74

4.1.4.7LiquidClasses 75

4.1.4.8PipetTips 75

4.1.4.9FunctionalPipetTips 78

4.1.4.10PipetTipMaterials 81

4.1.5Dilutor/DispenserOperation 82

4.1.6FlowCellSampling 84

4.2SolidMaterialsHandling 85

4.2.1WorkflowswithSolidMaterials 86

4.2.2AutomatedSolidsDosingbyPowderDispensing 86

4.3Weighing 88

4.4Extraction 90

4.4.1LiquidExtraction 91

4.4.2PressurizedFluidExtraction 92

4.4.2.1SolventsandExtraction 93

4.4.2.2MiniaturizationandAutomation 94

4.4.2.3In-CellClean-Up 96

4.4.2.4InternationalStandardMethods 97

4.4.3Liquid/LiquidExtraction 97

4.4.4DispersiveLiquid/LiquidMicro-Extraction 100

4.4.4.1AutomatedDLLMEWorkflows 103

4.4.4.2DLLMEforSoilandUrine 103

4.4.4.3DLLMEforPesticidesinFood 104

4.4.4.4DLLMEHyphenationwithLC 104

4.4.5SorptiveSamplePreparation 104

4.4.5.1Solid-PhaseMicro-Extraction 105

4.4.5.2SPMEFiber 109

4.4.5.3SPMEArrow 112

4.4.5.4Solid-PhaseMicro-ExtractionwithDerivatization 116

4.4.5.5DirectSolid-PhaseMicro-ExtractionMassSpectrometry 119

4.4.5.6StirBarSorptiveExtraction 121

4.4.5.7Thin-FilmMicro-Extraction 123

4.5Clean-UpProcedures 124

4.5.1Filtration 124

4.5.1.1FilterMaterials 125

4.5.1.2SyringeFilter 126

4.5.1.3FilterVials 127

4.5.2Solid-PhaseExtraction 129

4.5.2.1TheGeneralSPEClean-UpProcedure 133

4.5.2.2On-LineSPE 134

4.5.2.3Micro-SPEClean-Up 137

4.5.2.4Syringe-BasedMicro-SPE 141

4.5.3GelPermeationChromatography 143

4.5.3.1StandardizedMethods 145

4.5.3.2WorkflowandInstrumentConfiguration 145

4.5.3.3GPC-GCOnlineCoupling 146

4.5.3.4Micro-GPC-GCOnlineCoupling 147

4.6Centrifugation 148

4.7Evaporation 150

4.8Derivatization 153

4.8.1ForLCandLC-MS 154

4.8.1.1AromaticAcidChlorides 154

4.8.1.2Dansylchloride 155

x Contents

4.8.1.3NinhydrinReaction 155

4.8.1.4FMOCDerivatization 155

4.8.2ForGCandGC-MS 156

4.8.2.1Silylation 156

4.8.2.2Acetylation 157

4.8.2.3Methylation 157

4.8.2.4Methoxyamination 158

4.8.2.5FluorinatingReagents 158

4.8.3ForGCandGC-MSIn-PortDerivatization 159

4.9TemperatureControl 163

4.9.1Heating 163

4.9.1.1IncubationOverlapping 163

4.9.2Cooling 164

4.10Mixing 166

4.10.1Vortexing 166

4.10.2Agitation 167

4.10.3Spinning 169

4.10.4MixingwithSyringes 169

4.10.5CycloidalMixing 169 References 171

5IntegrationintoAnalysisTechniques 191

5.1GCVolatilesAnalysis 191

5.1.1StaticHeadspaceAnalysis 192

5.1.1.1OvercomingMatrixEffects 194

5.1.1.2MeasurestoIncreaseAnalyteSensitivity 195

5.1.1.3StaticHeadspaceInjectionTechnique 195

5.1.2MultipleHeadspaceQuantification 197

5.1.3DynamicHeadspaceAnalysis 201

5.1.3.1PurgeandTrap 202

5.1.3.2DynamicHeadspaceAnalysiswithIn-TubeExtraction 204

5.1.3.3DynamicHeadspaceAnalysisUsingSorbentTubes 207

5.1.3.4NeedleTrapMicroextraction 208

5.1.4TubeAdsorption 210

5.2GCLiquidInjection 222

5.2.1SandwichInjection 222

5.2.2HotNeedleInjection 222

5.2.3LiquidBandInjection 224

5.2.4AutomatedLinerExchange 226

5.3LC–GCOnlineInjection 230

5.4LCInjection 233

5.4.1DynamicLoadandWash 234

5.4.2UsingLCInjectionPortswithaPipetteTool 235 References 237

6SolutionsforAutomatedAnalyses 247

FirstAboutSafety 248

6.1Dilution 248

6.1.1GeometricDilutionofReferenceStandards 248

6.1.2DilutionforCalibrationCurves 251

6.1.3PreparationofWorkingStandards 256

6.2Derivatization 259

6.2.1Silylation 260

6.2.2SPMEOn-FiberDerivatization 262

6.2.3MetaboliteProfilingbyMethoximationandSilylation 266

6.3TasteandOdorCompoundsTraceAnalysis 271

6.4SulfurCompoundsinTropicalFruits 276

6.5EthanolResiduesinHalalFood 284

6.6VolatileOrganicCompoundsinDrinkingWater 289

6.7Geosminand2-MIB 295

6.8SolventElutionfromCharcoal 301

6.9SemivolatileOrganicCompoundsinWater 304

6.10PolyaromaticHydrocarbonsinDrinkingWater 315

6.11FattyAcidMethylester 321

6.11.1Application 321

6.12MCPDandGlycidolinVegetableOils 328

6.13MineralOilHydrocarbonsMOSH/MOAH 339

6.14PesticidesAnalysis–QuEChERSExtractClean-Up 347

6.15Glyphosate,AMPA,andGlufosinatebyOnlineSPE-LC-MS 362

6.16Pesticides,PPCPs,andPAHsbyOnline-SPEWaterAnalysis 368

6.17ResidualSolvents 375

6.18ChemicalWarfareAgentsinWaterandSoil 382

6.19ShaleAldehydesinBeer 390

6.20PhthalatesinPolymers 394

References 400

AAppendix 413

A.1RoboticSystemControl 413

A.1.1MaestroSoftware 413

A.1.2ChronosSoftware 414

A.1.3GraphicalWorkflowProgramming 415

A.1.4SampleControlSoftware 416

A.1.5LocalSystemControl 417

A.1.6ScriptControlLanguage 418

A.2SystemMaintenance 418

A.2.1Syringes 418

A.2.1.1ManualSyringeHandling 418

A.2.1.2SyringeCleaning 418

A.2.1.3PlungerCleaning 419

A.2.1.4NeedleCleaning 419

xii Contents

A.2.1.5ConfirmingtheDispensedVolumeofaSyringe 420

A.2.1.6Sterilization 420

A.2.2Pipettes 421

A.2.2.1Calibration 421

A.2.2.2PipettePartsMaintenance 421

A.2.3SystemHardwareMaintenanceSchedule 422

A.3SyringeNeedleGauge 423

A.4PressureUnitsConversion 425

A.5Solvents 425

A.5.1SolventMiscibility 425

A.5.2SolventStability 428

A.5.2.1HalogenatedSolvents 428

A.5.2.2Ethers 429

A.5.3SolventViscosity 429

A.6MaterialResistance 429

A.6.1Glass 432

A.6.2Polymers 432

A.6.3StainlessSteel 433 References 437

Glossary 441 References 451

Index 453

Foreword

IfeelhonoredbyHans-JoachimHübschmannaskingmetowritethisForewordto hisnewestbook, AutomatedSamplePreparation:MethodsforGC-MSandLC-MS Ihavereadthenear-finaldraftwithpleasure,andIamimpressedinallrespectswith thework,whichwasagreatdealofworkindeed!Hans-Joachim’schoicesoftopic, title,chapters,sections,andtheirorganizationweresplendid,andhepresentedthe rightamountofdetailedyetconciseinformationwithmuchconsiderationandcare. Manybooksarewrittentofollowtrendsthatcoverthesameinformationasother booksalreadyavailable,butHans-Joachimfoundaperfectnichebyfocusingon automationofsamplepreparationforinstrumentalchromatographicanalysis.Itisa topicthathasrarelybeenpublishedbefore,noteveninjournalsduetotheprofitable advantagesgainedbylaboratoriesthatsuccessfullyimplementautomatedmethods. Hans-JoachimandImetforthefirsttimein2016atafoodscienceconference inSingapore.Wehadanimmediateconnectioninourworkinvolvingautomated mini-cartridgesolid-phaseextraction,whichhasexpandedtoalargerconnectionaftermanyconversationsandemailexchangessincethen.Iamgratefulto Hans-JoachimforhisvaluableknowledgeandinputwhenIhaverequestedit,and Iampleasedtogaintheperspectivefromtheauthorofthiswork,aswellasan 880-page3rdEditionopus, HandbookofGC-MS:FundamentalsandApplications. Inmyopinion,thethreemostimportanttrendsinsamplepreparationarestreamlining,miniaturization,andautomation.Thefundamentalchemistryofdissolution, precipitation,vaporization,partitioning,adsorption,hydration,chelation,andother phenomenathatformthebasisofalloldandnewsamplepreparationtechniques havebeenknownforcenturies.However,thetechnicalartofanalyticalchemistry requirestheskilltomanipulatethosechemicalpropertiesinthemostefficientway possibletostillachieveaccurateresultsforthepurposeoftheanalysis.

MichelangeloAnastassiadesandIdidnotinventanynewchemistrywhenwe developedthe“quick,easy,cheap,rugged,andsafe”(QuEChERS)approachforsamplepreparationin2002,butwestreamlinedandminiaturizedexistingtoolsinan elegantsolutionattherighttimewhencommercialGC-MSandLC-MSinstruments weresensitiveanduniversallyselectiveenoughtoallowanalysisofawidescopeof analytes.Inthisbook,Hans-JoachimdescribesthenextstepforQuEChERS,which entailsautomation,andI’vebeencallingitQuEChERSER(morethanQuEChERS isalso“elegantandrobust”).

Devisingandimplementingautomatedmethodstakes“brains,”whichconstitutes thefourthimportanttrendinsamplepreparation.Unliketheothertrendsthatcontinuallyentail“moremoremore,”requiredintelligenceamonglaboratoryworkers istrendinginbothdirectionsthesametime.Thegrowthinsheerknowledgeand thecomplexityofproblems,tools,andtechnologyhasrequiredmorebrainstosolve modernproblems,butlessbrainsareneededtoperformroutineoperations,especiallywhenusingautomatedmethods.Fordecadesnow,laboratorieshavesaved moneybyhiringlesseducated,lesstalented,andlessskilledtechnicians(thereby lessexpensive)toperformchemicalanalyses.Infact,manylaboratoryownersconsiderita“nobrainer”tofullyautomateasmuchoftheiroperationsaspossibleso theycanhireasfewstaffaspossible.

DespitewhatCSIandotherfictionaldepictionsofanalyticalchemistrymayshow, inwhichperfectlyaccurateresultsarebeautifullydisplayedoncolorfulviewscreens inamatterofseconds,real-worldanalysesarenotthatfastandeasy!Real-world analystsarenotassmartasAbbySciutofromNCISeither,andnobodyiswriting theplotsandscriptsforthemleadingtohighcertaintyresultsthatneatlysolvethe criticalproblemofthehour.Withrespecttoreliabilityanddataquality,brainless robotscanoutperformevenAbby(withoutthepersonalityquirks,needforsleep, orsalarydemands).Thereal-lifeAbbyisasmartandsavvytechnicaloperatorwho writesthescriptandmaintainstheautomatedinstruments.

Analyticalchemiststendtoberesponsible,hard-workingpeoplewhoaremotivatedbylaziness,whichisaperfectcombinationtotraitsneededtoimplement laboratoryautomation.Ifitwaseasy,laboratoryautomationwouldhavebeenimplementedagesago.Unfortunately,reliable,inexpensive,anduser-friendlyautomated toolshavenotbeencommerciallyavailableuntilveryrecently,andthelackoftechnicalknow-howandabilitiesoflaboratorystaffremainsthegreatestobstacle.

ThisishowHans-JoachimHübschmann’sbookaboutthe AutomatedSample Preparation:MethodsforGC-MSandLC-MS comesinhandy.Thesmartest(andthe dumbest)brainsdonothavetoworkhardtosolveproblemsatalliftheownersof thesebrainshaveknowledgethatthesameorsimilarproblemshavealreadybeen solvedbyothers!Hans-Joachimandthisbookcanhelpboththebrainyandnotso brainyanalystsoftheworld,andtheirbosses,makethefictionalworldofCSIand NCISbecomeastepclosertoreality.

Disclaimer

Theopinionsexpressedinthisforewordaretheauthor’sownanddonotreflectthe viewoftheUSDA.

StevenJ.Lehotay,PhD(LeadScientist) Wyndmoor,Pennsylvania;USA June25,2020 USDAAgriculturalResearchService EasternRegionalResearchCenter

Preface

Althoughsamplepreparationisconsideredanenablingtechnology,itisamong themostvitalcomponentsofananalyticalscheme.

DouglasE.Raynie,2019[1]

Thistextbookabout AutomatedSamplePreparation originatedfromthefrequent requestofmanyanalyticallaboratoriesforintegratedanalyticalsamplepreparation methods.

But,whythefocuson“automated”?Infact,themotivationtoemployinstrumentalworkflow-basedsamplepreparationisnot“automation”byitself.Incontrast, “automation”isthesolutiontoseveralvoiceddrawbacksandbottlenecksinthelaboratory.Thetraditionalmanualsamplepreparationisoftenslowandlabor-intensive, nottomentionthepotentialexposureofthelaboratorystafftohazardouschemicals. Amainaspecttobediscussedis“manual,”withallhumanimpactondataquality, datacomparability,anderror.Multistepmanualsamplepreparationcanamountto 75%ofthetotalmethoderror[2].Drivenbytheneedsofinternationalfood,health care,andlifescienceindustrieswithregulationsandstandards,thedataofchemical analysesarenotforanonlylocalapproachanymore,butofglobaluseandimpact. Also,thepotentialenvironmentalimpactofthetraditionalanalyticalmethodsinuse isincreasinglyscrutinized.Thisisduetothegrowingrequirednumberofsamples forasteadilyincreasingnumberofcontaminantsandresidues,andnottoneglect, theenvironmentalimpactofthealsogrowingusageofconsumablesandsolvents, creatingcriticallaboratorywaste.

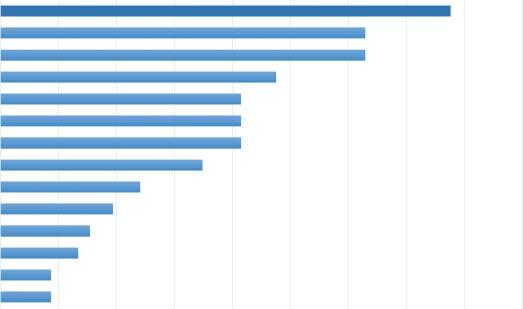

Inthepast,suchtopicsdidnotreceivemuchattentionuntilquiterecentlywiththe overduediscussionandawarenessoftheimpactofsamplepreparationontheerror ofanalysis.OntherecentsurveyquestionoftheAnalyticalMethodsCommitteeof theAnalyticalDivisionoftheRoyalSocietyofChemistry“Whatcausedyourlast poorproficiencytestscore?”theunequivocalresponsewith41%ofimpactwassamplepreparation,equipmentproblems,andhumanerror,with“samplepreparation” ontopofallresponses[3].Figure1illustratesgraphicallythehighman-madeimpact onanalyticalresults.Significantimprovementsinstandardizedandautomatedsamplepreparationarerequiredtokeeppacewithqualityandproductivitydemands.

Sample preparation

Equipment

Human error

Calibration

Method selection

Calculation error

Reporting

Test material

Transport/storage

Primary sampling

Other

Lab environment

Sample tracking PT provider

Figure1 Causesoferrorinchemicalanalysis,after[3].

Consideringallthese,samplepreparationhasevolvedasaseparatediscipline withintheanalyticalandmeasurementsciences[2].Thiscompendium Automated SamplePreparation:MethodsforGC-MSandLC-MS informsindetailonthe availabletoolsforthetransferofcurrentmanualpreparationprocedurestothe automatedlevelwith x ,y,z-roboticsystems.Thediscussedconceptsforautomation trytoansweronhowtoimprovedataquality,elaborateontheinherentpotential foragreenanalyticalchemistry,andfinallyconcludeonimprovementsforsample throughput,methodrobustness,andproductivity.

Theobjectiveofthistextbookistoprovideanoverviewofthecurrentpotential andprovenexamplesforemployingsuchroboticsystemsinstalledinstrument-top orstandalonewithestablishedtools,modules,andflexibleworkflowsforavariety ofsamplepreparationtechniques.

The AutomatedSamplePreparation:MethodsforGC-MSandLC-MS coversin thefirstpartthetechnicalconceptsusedinroboticsystemsforautomatedsample preparationworkflows.Thispartenablesthereadertocreatewell-targetedandefficientlyoperatingworkflowswithenoughsafetymarginforrobustness.Itprovides guidelinestotransfermanualprocedurestoroboticsystems.Besidestheanalytical expertiseinthedesignofpreparationmethods,theknowledgeofthetechnicalpossibilitiesandlimitations,aswellasasenseoflogisticsfortherequiredsequentialor parallelstepsofoperation,arediscussed.

Asecondpartgoesintodetailofpopularanalyticalsamplepreparationworkflows.Itcoverstypicalprogram-drivensamplepreparationexamplesfromfood, environmental,forensic,andpharmaceuticalanalyses.Theseexamplesareproven workflowsfoundinmanyanalyticallaboratoriesandfollowthepublishedofficial guidelines.Eachofthemcanserveasatemplateforindividualuseoradditional modification.

Mysincerethankstomanyfriendsandcolleaguesfordiscussions,criticalreview, andcontributions.IamverygratefultoSteveLehotayforthehighlyappreciated exchangeonallaspectsoflaboratorysampleprocessing,AndréAlthoffforthe

Preface xvii valuablediscussions,andAtsukoBanshoforhercontinuedsupport,advice,and patience,myfamilyandfriendswhodidnotgetmuchofmytimeandattention duringthepreparationofthisproject.

Thecomprehensivecompilationoftechnicalmaterial,images,anddetailed operationalandanalyticalbackgroundinformationwouldnotbepossiblewithout thecontributionbymanycompaniesactivelyinvolvedinautomatedsample preparation.Iamespeciallyindebtedtothefollowingcompaniesforkindly providingreview,discussions,andapprovalsfortheuseofin-depthinformation, graphics,andimagematerialfortools,modules,anddatamakingtheillustration ofautomatedworkflowspossible:AgilentTechnologies,namely,PaulBarboniand EricDenoyer;AistiScienceCo.Ltd.,namely,SasanoSadato;AxelSemrauGmbH &CoKG,namely,AndreasBruchmann;TobiasUber,BrechbühlerAG,namely, PhilippeMottay;CTCAnalyticsAG,namely,JonathanBeck,ChiewMeiChong, StefanCretnik,ToniEberwein,FlorianGafner,ThomasLäubli,GwenLim,Jianxia Lv,GerhardNagel,GünterBöhm,ThomiPreiswerk,KaiSchüler,andMelchior Zumbach;CDSAnalytical,namely,RogerTank;EntechInstruments,namely,Dan CardinandJohnQuintana;ePrepPtyLtd.,namely,PeterDawes;Evosep,namely, EricVerschuuren;GERSTELGmbH&CoKG,namely,RalfBremer,OliverLerch, andKajPetersen;GLSciencesB.V.,namely,GeertAlkema;HamiltonBonaduz AG,namely,BeatScheu;ITSPSolutionsInc.,namely,KimGamble;LabTech InstrumentsLtd.,namely,XueLiu;LecoCorporationJapan,namely,Michico Kanai;MarkesInternationalLtd.,namely,MassimoSantoro;MettlerToledoAG, namely,JoanneLaukart;PlasmionGmbH,namely,Jan-ChristophandThomas Wolf;SIMGmbH,namely,RolfEichelberg;SparkHollandB.V.,namely,Florianvan derHoeven;ThermoFisherScientific,namely,ChristinaJacob,ClaudiaMartins, andFaustoPigozzo;ThomsonInstrumentCompany,namely,SamEllis;Trajan ScientificandMedical,namely,GlennClivazandAndrewGooley;andYaskawa EuropeGmbH,namely,RichardTontsch.

Iamsurethattherearemanymorecolleaguescontributingdirectlyorindirectly withdiscussionsduringcollaborations,conferences,andpublicationswhomIhave notmentionedandIapologizetothemforanyomissions.

Hans-JoachimHübschmann Mainz,July2020

References

1 Raynie,D.E.(2019).The(mis)educationofananalyst. LCGCNorthAmerica 37 (11):796–800.

2 Mitra,S.(ed.)(2003). SamplePreparationTechniquesinAnalyticalChemistry. Hoboken,NewJersey,USA:Wiley-Interscience.

3 AnalyticalMethodsCommittee,AMCTBNo56(2013).Whatcausesmosterrorsin chemicalanalysis? AnalyticalMethods 5(12):2914–2915.https://doi.org/10.1039/ c3ay90035e.

Introduction

Samplepreparationremainsthesinglemostchallengingaspectofchemical analysis

MaryEllenP.McNally[1]

Samplesarrivingintheanalyticallaboratoryusuallycannotbeapplieddirectlyto analyticalinstruments.Afterhomogenizationofthematerial,amoreorlesscomplex pre-treatmentconsistingofseveralstepsisrequiredforalmosteverysamplebefore analysis.Eachstepiscriticalandcanbeasourceoferrorandadditionalcontamination.Oftentheusedmethodsgeneratehazardouswastefromsolvents,chemicals, andconsumablesused.Mostofthecostinchemicalanalysisisassociatedwiththe effortsinsamplepreparationprocedures.

Thegoalofthesamplepreparationprocessistheextractionoftheanalytesfrom theincompatiblematrix.Especiallyintraceanalysis,thetargetanalytesinlow concentrationareembeddedinahighexcessofahardtoeliminatematrix.The enrichmentoftheanalytestoasuitablelevelofconcentrationfordetectionand quantificationoftenalsoincludesanecessaryclean-upfromtheco-extracts.The samplepreparationrequiresmostofthetimeandthebestskillsintheanalytical laboratory.Manyofthesetasksarestillmanualtoday.Arecentsurveyrevealedthat two-thirdsoftheanalysistimeisspentonsamplepreparation[2].Optimumand fit-for-purposepreparationmethodsforanalytesindiversematricesaresubjectto discussioninthousandsofscientificpublicationseveryyear.GoogleScholarfinds morethan2millionhitsfeaturingspecificsamplepreparationsaloneinthelast 10years![3].Thedemandformulti-analytemethodsforlargergroupsofcompoundswithapotentialoccurrenceinthesamesample,targetedornon-targeted, likepesticides,mycotoxins,drugs,orpersonalcareproducts,justtonameafew areas,isincreasinglyaddressed.Thecontinuouslygrowingnumberofanalytesin differentmatricesisthemainreasonforsteadilyongoingimprovements.

Theseveryfirststepsintheanalyticalworkflowhavethehighestimpacton thequalityoftheanalyticaldata.Manylaboratoriesusemanual,time-and labor-intensiveprocedures.Butthemanualsamplepre-processingisthebiggest knownsourceoferrorintheanalyticalsequence,nomatterhowpreciseand sensitiveamassspectrometerinthefinalstepmaybe,itcannotcorrectfor[4].

AutomatedSamplePreparation:MethodsforGC-MSandLC-MS, FirstEdition.Hans-JoachimHübschmann. ©2022WILEY-VCHGmbH.Published2022byWILEY-VCHGmbH.

Errorsinanalyticalmeasurementsaretherandomvariability,expressedasthe precisionofthemethod,systematicbiasaffectingthetruenessofresults,andgross mistakes,thehandlingerrors.Methodvalidationassessesprecisionandtrueness ofamethod,whilehumanspuriouserrors,reportedasthegreatestsourceof errors,cannotbecorrectedinthecourseofanalysis[5].Itisreportedfromthe surveythatoperatorandsampleprocessingerrorsamountupto50%ofallknown potentialsourcesoferror.Evidently,measuresinthisareaimproveanalytical qualitysignificantly.Hereisthestandardizationofsamplepreparationprocedures ageneralgoal.Theintroductionofinstrumentalandintegratedsamplepreparation workflowsaddressestheseweakpointsinthesampleprocessingsequenceofthe otherwiseexcellentlyvalidatedprocedures.

Standardizationofanalyticalmethodsincludingsamplepreparationsfordifferentkindsofsamplesisavailableforallroutineareaswithvalidatedprocedures publishedasEuropeanstandards(EN),themethodsoftheInternationalOrganizationforStandardization(ISO),theAssociationofOfficialAnalyticalChemists (nowAOACInternational),AmericanOilChemists’Society(AOCS),theFood andDrugAdministrations(FDA),theEnvironmentalProtectionAgencies(EPA), Pharmacopias,andsimilarorganizations.Intheseestablishedmethods,sample preparationisoftentherate-determiningstepforsamplethroughputandtoooften theerror-pronepartoftheanalyticalmethod.Inthiscontext,standardizationcalls forautomation,notviceversa.Automationreducesthequitenormalhumanmanualvariationandmistakesinthesampleprocessingusingadequatelyconfigured robotsforthestandardworkflows.

Inchemicalanalysis,theinstrumentationforchromatographicseparationand detection,inparticularwiththeuseofmassspectrometry,reachedanoperational andperformancelevelofhightechnicalmaturity.Sensitivity,selectivity,separation powerandmassresolution,speedofanalysis,anddataprocessingwerethemajor instrumentaldevelopmentswithsignificantenhancementsinrecentyears.Barely exploitedarefeaturesforamajorstepaheadforaninstrumentalandroboticsample processing.Theobviousgapisthemissinguseofsuchamazinginstrumentspecificationsforagreenersamplepreparationatthefrontend.Muchsmallersample sizesarepossibletoreachlegallyrequiredquantitationlimitstoday.Theminiaturizationandstandardizationwithautomatedroboticworkflowsfortheanalytical sampleprocessingsignificantlyreleasefromthehumanimpactondataquality.This handbookabout AutomatedSampleProcessing focusesonthetools,modules,and workflowsforthenextlevelofagreeneranalyticalchemistry.

1.1APerspectiveonHumanPerformance

Incontrasttothenotableimprovementininstrumentperformanceandreliability, therewasnotmuchfocusinthepastontheinstrumentalintegrationofthetraditionalmanuallyperformedsamplepreparationworkflows,knowingthesignificant impactofhumanerroronreliableandtrueanalysisresults.Ageneralindustryview ofhumanperformanceandrootcauseofeventsmonitoredisshowninFigure1.1.

Figure1.1 Humanperformanceinanalyticallaboratories.Source:AdaptedfromU.S. DepartmentofEnergy[6].

Humanerrorisnotrandom.Mistakesaresystematicallyconnectedtofeaturesof people’stools,thetaskstheyperform,andtheoperatingenvironmentinwhichthey work[6].About80%ofalleventsareattributedtohumanerror.Furtherbroken down,70%arerelatedtoorganizationalweaknessescausedbyhumansinthepast and30%aredirectlyrelatedtohumanmistakesinthemanualworkflow.

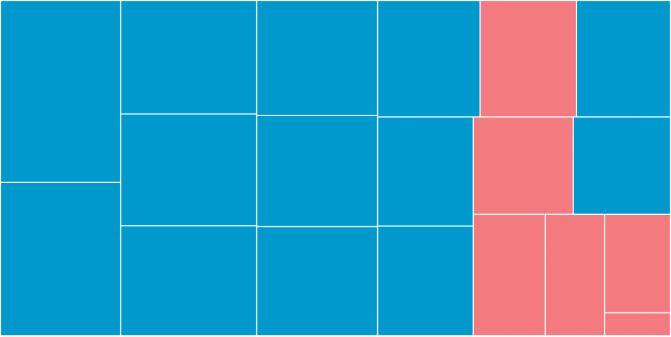

Surveyresultsconfirmdramaticallythesourcesoferrorinchemicalanalysis, illustratedinFigure1.2withthesizeofthesquareareasrepresentingtheirimpact. Themajorsourceoferrorisseeninsuchmanualsamplepreparationstepswith about30%ofallthepotentialcauses.Ontop,operator-generatederrorandvariation areestimatedheretocontributetoanadditional19%.Theintroductionofinstrumentalautomatedsamplepreparationworkflowshenceisexpectedtoreducesuch well-knownhumanerrorsbyhalfinroutineanalysismethods[5].

Samplestobeanalyzedusuallyrequireanoftenmultifacetedpreparationover severalstepsforextractionandconcentrationbeforeapplicationtoananalytical instrumentforanalytedetection.Morethan65%oftherespondentstotherecent surveyreportedtheuseofthreeormoresamplepreparationstepsforonesample. Therateofmorecomplexsamplepreparationwentupsignificantlyfromprevious

Figure1.2 Surveyresultsaboutsourcesoferrorswithimpactinsampleanalysis(square areasin%).Source:AdaptedfromMajors[2].

years’responses,anumberandapparentdemandstronglyincreasing[7].Thedegree ofsamplepreparationdependsmainlyontheanalytes,thephysicalstatusofthesample,thesingleormulti-compoundapproach,andfinallytheanalyticalmethodtobe applied.Itcancoverawiderangefromjustdilute-and-shoottomultistepmethods withextraction,concentration,andderivatization.Thecommongoalistoreachjust enoughandfit-for-purposesampleclean-uptokeeptheanalyticalinstrumentation inthevalidatedstatusforlargeseriesofsamplesandreducepreventivemaintenance downtimetothenecessary.Inthevastmajorityofanalyticalmethods,therequired samplepreparationinthepastandstilltodayismanual.Alargegapwaslefthere, withonlyafewexceptionswithsomeselectedtechniques,fortheadaptationofanalyticalsamplepreparationmethodsontheinstrumentlevel.Thesolutionsprovided inthistextbookaddressthisnotoriousgapwiththeintegrationofroboticworkflows formanyroutinetasks.Adedicatedsectioncoversautomatedturnkeysolutions liketheanalysisofpesticides,off-odors,polyaromatichydrocarbons(PAH),fatty acidmethylesters(FAMEs),mineraloilhydrocarboncontaminations(MOHs),or volatileorganiccompounds(VOCs),justtonameafewthatarepresentedindetail forreproduction.

Therecentremarkableimprovementsininstrumentsensitivityandselectivity,in particularinmassspectrometryusingtandeminstrumentation(MS/MS)andhigh massresolutionandaccuratemasscapabilities(HR/AM),greatlyfacilitatedthe miniaturizationofsuchmethods,allowinggreeneranalyticalchemistrywith thereductionofsamplesizesandsolventuse.Thissamplevolumereductionto themicro-scaleopensupthewayforcompatible,instrument-topautomationand furtherstandardizationofmulti-methods.Thiswelcometrendanswersalsothe demandforimproveddataqualityandhighersamplethroughput,especiallyin food,environmental,andpharmaceuticalsafetyanalyses.

Anotherimportantaspectandastrongimprovementisseeninthehyphenation ofinstrumentswithworkflowsintegratingthecurrentlyseparatedprocesses. Theavailabilityofonlinesamplepreparation,whichfinallyincludesthetransfer andinjectionofthepreparedextracttotheanalyticalinstrument,istodaystill theexceptioninanalyticalinstrumentdesign.Ongoingtechnicaldevelopment startscoveringsomeselectedsamplepreparationprocedureswithbenchtopor instrumenttop-mountedroboticpreparationsystems.Theintegratedsoftware controlforeaseofusewithjustonesampleacquisitionsequenceonscreenisstilla bigbutsolvablegaptocomplywithoperatordemandsandtherequirederror-free operation.Severalindependentdevelopmentsofintegratedsoftwarecontrolof theroboticsampleprocessingsystemswithexternaldevicesandthehyphenated analyticalinstrumentsdemonstratesuccessfullythebenefitsandfeasibility.

And,eveninlightofthecontinuouslyincreasinglaboratoryautomation,anecessarypracticalremarkatthispointforthehands-onlaboratorywork,forsafetyand agreenanalyticalchemistry:goodlaboratorypracticedictatesthatallwhohandle solventsandchemicalsshouldfamiliarizethemselveswiththecompounds’material safetydatasheets(MSDS)andmanufacturer’srecommendationsforhandling,use, storage,anddisposaloftheusedchemicals.

References

1 McNally,M.E.P.(2013).Samplepreparation:thestateoftheart. LCGCEurope 26(2):110–112.

2 Majors,R.E.(1991).Overviewofsamplepreparation. LC-GCTheMagazineof SeparationScience 9(1):16–20.

3 GoogleScholar(2018).scholar.google.com/,searchfor“samplepreparation”in years“2008–2018”(20April2018).

4 Hein,H.andKunze,W.(2004). UmweltanalytikmitSpektroskopieundChromatographie.3rdEd.,Weinheim,Germany:Wiley-VCH.

5 Lehotay,S.J.,Mastovska,K.etal.(2008).Identificationandconfirmationof chemicalresiduesinfoodbychromatography-massspectrometryandothertechniques. TrACTrendsinAnalyticalChemistry 27(11):1070–1090.https://doi.org/ 10.1016/j.trac.2008.10.004.

6 U.S.DepartmentofEnergy(2009). DOEStandard–HumanPerformanceImprovementHandbook–Vol.1PerformanceandPrinciples,vol.DOE-HDBK-1.Washington,DC,USA:www.hss.energy.gov/nuclearsafety/ns/techstds/.

7 Raynie,D.E.(2016).Trendsinsamplepreparation. LCGCEurope 29(3):142–154.

TheAnalyticalProcess

Thesimplificationofsamplepreparationanditsintegrationwithbothsampling andconvenientintroductionofextractedcomponentstoanalyticalinstruments isasignificantchallengeandanopportunityforthecontemporaryanalytical chemist.

JanuszPawliszyn[1]

2.1LaboratoryLogistics

Allchemicalanalysescompriseaseriesofconsecutivestepsstartingwiththesample collection,transferintothelaboratory(ifnotanalyzedonsite),registration,andallocationtooneormoreanalyticaltestinggroupsasneeded[2].Thefirsttask,ofutmost importanceintheindividualsampleprocessing,isthepreparationofarepresentativetestportionofthesample[3].Thesamplepreparationfollowswithextraction, clean-up,and/orconcentrationfortheinstrumentalmeasurement.Dataanalysis andreportingconcludetheusuallaboratoryprocedures(Table2.1).

Lookingatthesampleprocessingstepsindetail,wecandistinguishthosethatare relatedtothebulksample(lot,primarysample)typicallywith,forinstance,freezing,cutting,cryogeniccomminution,blendingormilling,andfinallydividingto achieveahomogeneousaspossiblelaboratorytestportionforanalysis,theanalyticalsample[4–6].Itismandatorytostartwithsufficientlylargesamplequantitiesin thegramtokilogramrange(exceptforabinitiohomogeneoussampleswater,beverages,blood,etc.),whicharehandledmanuallyusingappropriatehomogenization equipment[7,8].Theinitialsampleprocessingtoachieverepresentativetestportionsoftheoriginalsampleisofparamountimportance,“orelsetheentireanalysis isnotjusttime,money,andeffortwasted,itactuallycanprovidefalseresultsto deceiveandunderminetheentirepointoftheanalysis”[9].Thefocusoncareful sampleprocessingpriortoanalysisisbecomingevenincreasinglycrucialforautomatedsamplepreparationandhigh-throughputanalysisofonlysmalltestportions

2TheAnalyticalProcess

Table2.1 Stepsinlaboratorychemicalanalysis.

Process steps

S

Sample preparation

Chemical analysis

Data analysis

Reporting

Activities

Preservation

Sub-sampling

Generate a representative test portion

Milling, grinding, dissolution, comminution

Extraction

Clean-up

Concentration

Derivatization

Separation (chromatography)

Detection (spectrometry)

Identification

Calibration

Integration

Quantitation

Validation

Sample collection Manual or automated online sampling Manual sample handling Robotic automation Data system automation

Summarize results

Bold-facedstepsaresubjecttoautomatedinstrumentalworkflows.

onthemilligramlevel.Eventhebestrecoveriesandmostpreciseanalysiscannot correctforerrorsandbiasoccurringduringtheinitialsampleprocessing.

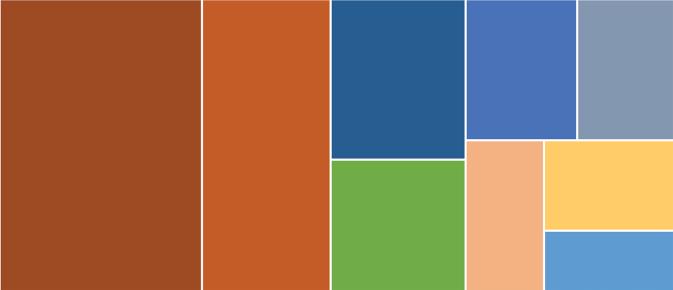

Mostofthefrequentlyappliedsamplepreparationsteps,manyofthemhaveto beperformedinsequence,havetheinherentpotentialtobetransferredtointegratedsamplepreparationplatformsusingappropriatelyprogrammedworkflows andtools[10].Arecentsurveyidentifiedthemostfrequentlyusedsampleprocessingstepsinanalyticallaboratories[11].TheresultsareshowninFigure2.1.The areainthisgraphicsrepresentsthefrequencyofuse.Thebluehighlightedboxes expresstheirpotentialforworkflowautomationonintegratedsamplepreparation platforms. Weighing

Figure2.1 Frequentlyusedsamplepreparationstepsandtheirpotentialforworkflow automationonintegratedsamplepreparationplatforms.Processesinbluecanbe automatedmoreeasilythanthoseinred.Source:AdaptedfromMajors[12].

Aconstanttrendwithacontinuedincreasingordecreasingfrequencyof applicationisreportedoverthelasttwodecadesforthetenmostimportantsample preparationtechniques[11,13]:

Columnchromatography

Dilution

Liquid–liquidextraction

(with ∼ stable, ↗ increasing,and ↘ decreasinguse)

Concerningtheanalysistechniquesusedinenvironmentalandfoodsafety analysis, StevenJ.LehotayandYibaiChenanalyzedthecurrenttrendsbasedonthe frequencyofscientificpublicationsduringthelasttwodecades[14].Relatingtothe applicationareaofpublications,thesubjectsonfoodsafetyanalysesoutperform theformerfocusonenvironmentalanalysis.Whilegaschromatography(GC) slightlydeclinedinattentionovertheyears,aconstantgrowthofliquidchromatography(LC)methodswithclassicaldetectionwasfound.Notunexpectedly,mass spectrometry(MS)playsthemostimportantroleasthedetectionmethodforchromatographicanalyses.Astronggrowthisnotedwithhigh-resolutionaccurate-mass instrumentation(HR/AM)usingorbitraporquadrupole/time-of-flightMS systems. ThestrengthofHR/AMdetectionundoubtedlyisthenon-targetedanalysisfor unknowncontaminationsormetabolites.WhilethepublicationofnewGC-MS methodsreachedaconstantlevel,theLC-MS detectionmethodsshowedstrong growth.TriplequadrupoleMS instrumentation(MS/MS)foundincreasingapplicationinthedevelopmentofnewmethods,bothforGC-MS/MS andevenstrongerfor LC-MS/MS.ThisrepresentsthedominantapplicationofMS/MS instrumentation forthetargetedanalysisofregulatedmethods.

2.1.1AnalyticalBenefitsofInstrumentalWorkflows

Routinechemicalanalysesbenefitfrommanyundeniableanalyticaladvantagesof instrumentalsamplepreparationworkflows. Standardizedmethodscanbeimplementedasaninstrumentalworkflow.Thesestandardizedmethodsprovidedetailed descriptionsoftheappliedmaterials,solvents,andchemicalsandanoptimized oftenvalidatedsetofparameterstobeused.Atime-consumingmethoddevelopmentisavoided,targetingthecomparabilityoftheanalyticaldata.But,evenwith standardizedanalyticalmethods,weknowthathumanfactorsareinvolvedleading

toawiderangeofpossibleresults.Consistentinter-laboratorycomparisonofdata isveryoftenrelatedtowell-experiencedtechnicians.Manypublicationsaboutsuccessfulautomationofanalyticalworkflowsreportdifferentaspectsthatwereshown tobebeneficialandincentivizedtheimplementationofautomatedprocesses:

● Standardworkflowsforroutinemethods

● Turnkeyconfigurationsavoidlengthymethoddevelopment

● Shortfamiliarizationtime

● Quickimplementationintoproductionmode

● Standardizationindifferentlaboratorylocationsofinternationalcompanies

● Consistenthigh-qualitycomparabledata

● Lessvariationinresults,independentofindividualfactors,changeofoperators

● Traceability

● Reductioninsampleamountandsolvents

● Greenanalyticalchemistrybyminiaturization,micro-extractionmethods

● Facilitatedsampletransport

● Costreductionrelatedtoexpensivestandards,reagents,consumables

● Increasedsamplethroughput

● Proportionatelyscalablewithincreasedsamplevolume

● 24/7operation

● Shorterprocessingtimes,shorterreportingtime

● Lesscontaminationfromlabware

● Reducedhumanerror

● Reducedreworkandnumberofrepeatanalyses

● Safety,reducedhumanexposuretochemicalreagentsandergonomicinjuries

● Onlineoperationwithmeasurementsystems

● Onlinesamplingfromairorwaterstreams

● At-siteunattendedoperation

Abarrierinsettingupautomatedsampleprocessingworkflowsisoftenseenwith theinitialcapitalexpense,missingtechnicalexpertiseandnewanalyticalchallenges handlingsmallsampleamounts.Thetechnicaloperationandlogicofroboticworkflowsmayappearcomplicatedandrequiresanewlearningexperience.Regularsystemmaintenance,inparticular,preparationstepstoavoidmalfunctionsandcarryoverneedtobeimplemented.Themanufacturer-providedstandardprogramsare typicallypreparedforspecificsingleworkflowswithaninherentlackofflexibility andmayrequirecustomizationforthelaboratory.Often,instrumentalworkflowsfor sampleprocessingarethencustomizedsolutionsforthemethodsofchoiceincollaborationwiththevendorapplicationteams.Inmanyavailableturnkeysolutions,the samplepreparationmethodsareimplementedbyasuitableinstrumentworkflow withanalreadypredefinedorrange-limitedsetofparametersreducingsignificantly therequiredtimetoimplementandtrainamethodinthelaboratory,alsopreventing invalidinputforprocesssafety.Theautomatedsamplepreparationontheinstrumentallevelhasthepotentialtobecomeroutinewidelyindependentfrompersonal handlingvariationorinterpretation,toprovidecomparableandpredictabledata.

2.1.1.1DataQuality

Instrumentalworkflowsdeliveraconsistentqualityofdata,independentofthe humanfactor.Datageneratedarecomparableandindependentfromanindividual operatororlocationservingwell-suitedemerginginternationalrequirements relatedto,e.g.globaltradeoranalyticalstandardsharmonization.

Ontopofthat,sampleturnaroundtimesaresignificantlyreducedbythereduction ofrepeatsamplemeasurementsduetounavoidablemistakesinmanualwork.Automatedworkflowsarewelldocumented.Theinstrumentoperationandparameters usedaretraceablebyaccessinglogfiles. Samplesandrelatedresultscanbetracked andidentifiedbybarcodelabeling.

2.1.1.2TurnkeyOperation

Instrumentalworkflowsestablishtheanalyticalsamplepreparationmethods withanintegratedorprogrammedoperatingsequenceinthelaboratory. Standard methodworkflowsareincreasinglyalsocommerciallyavailableforroboticsample preparationsystemsintheapplication-specificconfiguration.Nolengthymethod developmentisrequiredallowingaquickinstallation,shortfamiliarization,and transferintoproduction.Typically,suchworkflowsaredocumentedasstandard operationprocedure(SOP)tobecomepartofthelaboratoryinternalquality management,keepingtointernationalqualitystandardsforincreasedregulatory compliance(see Section2.1.2).

2.1.1.3GreenAnalyticalChemistry

Theconceptofgreenanalyticalchemistry(GAC)coversthedevelopmentofanalyticalproceduresthatreplaceorminimizetheusageofhazardousreagentsand solventsandmaximizeoperatorsafetytoestablishenvironmentallyfriendlysamplepreparationtechniques[15,16].TheprinciplesofGACaresummarizedinthe term SIGNIFICANCEandillustratedinTable2.2[17].

Animportantaspectinthiscontextistheminiaturizationandautomationofsamplepreparationprocedures,representedbythesecond“I”inTable2.2.Traditional manualmethodsusuallyworkonalargerdeciliterscaleaswestillseeinsome establishedofficialmethods.Manualextractionmethodslikethewidelyusedliquid/liquidextractionsaretypicalexamples,e.g.theliquidextractionoforganophosphoruspesticidesfromwastewater,sludge,orsedimentsusingdeciliteramounts ofpotentiallyhazardousdichloromethane(DCM)[18,19]. Severalextractionsteps withfollowingclean-upstepsforpurificationandconcentrationoftheextractbefore analysisoftheanalytesarerequired.Anexampleofhownewtechnologiesimprove analyticalperformanceandatthesametimesignificantlyreducecriticalandexpensivesolventuseistheincreasingreplacementoftheclassical Soxhletextractionby pressurizedorsupercriticalfluidextraction[20].

Miniaturizationoftheextractionprocessonthemicroliterleveloffersthepotentialforautomationandtobecomecompatiblewiththeinjectionvolumestypically appliedwithanalyticalinstrumentation[21].Downscalingofsampleandsolvent volumesisasignificantachievementnotonlyforGACbutalsoforthelogistics andeconomyoftheanalyticallaboratory.Theincreasedusageofmicro-methods

Table2.2 Principlesofgreenanalyticalchemistry[17].

SSelectdirectanalyticaltechniques

IIntegrateanalyticalprocessesandoperations

GGenerateaslittlewasteaspossible

NNeverwasteenergy

IImplementautomationandminiaturizedmethods

FFavorreagentsfromrenewablesources

IIncreasesafetyfortheoperator

CCarryoutinsitumeasurements

AAvoidderivatization

NNumberofsamplesandsizeshouldbeminimal

CChoosemulti-analyteormulti-parametermethods

EEliminateandreplacetoxicsolvents

Source:AdaptedfromGałuszkaetal.[17].

comesfromtheirsimplehandling,rapidsampling,lowcost,solventlessnature,good recoveries,andlargeenrichmentfactors[22,23].Micro-methodslikethesolid-phase micro-extraction(SPME)achievethesameanalyticalresults,avoidingsolventseven completely,enablingthemultipleuseofthe SPMEdevice[24].Anotherinfluentialdevelopmentisthereplacementofthehugewastageofsolid-phaseextraction cartridgesbyreplacementwithonlinemethods,forinstanceasalreadyofficially establishedforpesticidesindrinkingwaterwiththeUS EnvironmentalProtection Agency(EPA)Method543[25].

Thebigbenefitofmicro-methodsistheircompatibilitywithinstrumentalsample preparationconcepts.Micro-methodsworkinthehighermicroliterrange,which matcheswelltheinjectionvolumesofchromatographicanalysismethods.Inpractice,theterm“miniaturization”wouldfitbettertheautomatedapproachofusing areducedtestportionamountandlimitedsolventvolumes.Highextractvolumes arenotrequiredfortheminiaturizedanalysisscheme,onlyleadtounnecessary concentrationsteps.Workingonthesamevolumelevel,evenwithmanysolutions withoutsolventsatall,invitesforautomationofthesamplepreparationprocesses asfurtherdescribedinChapter3.Thisoffersagreattechnicalopportunityforthe integrationofthesamplepreparationprocesseswithanalyticalinstrumentoperation,anotherperfectfitforautomatedsamplepreparationmethodswiththegreen analyticalchemistryconcept.

2.1.1.4Productivity

Productivityistheotherimportantaspectofestablishinginstrumentalsampleprocessingworkflows.Todaylessthan10%oftheworkloadinanalyticallaboratoriesis dedicatedonlytoinstrumentalanalysis.Morethantwo-thirdsofthetimeinanalyticallaboratoriesisrequiredforsampleprocessing[26].Aproductiveuseofsuchabig timeslicewouldopenupmanyimprovementopportunitiesforextendedservices,

highersamplethroughput,andlastnotleastreducedcostpersamplesineveryanalyticallaboratory.

Instrumentalworkflowsallowandaredesignedforunattendedoperation. Such workflowsbecomethebasisforanautomatedprocessingregimeinthelaboratory. Eitherastand-aloneorofflineandtheonlinecouplingtoanalyticalinstrumentation canberealized,forinstance,withthewidespreaduseofGC-MS orLC-MS systems. Aso-called“prep-ahead”functionalityforexecutingapreparationworkflowonline duringanongoinganalysisrunoffersathroughputoptimizedmeasurementcycle foramaximumdutycycleoftheanalyticalinstrumentationandafasterreturnof investment(see Section3.3.2).Forcontinuousmonitoringfromwaterstreamsorfor reactionmonitoring,the“prep-ahead”functionfacilitateshigh-frequencysampling intervals.A24/7operationcanfinallybeachievedwithsufficientsample,solvent, andreagentcapacitymadeavailablefromsuitablereservoirsontheautomatedsamplepreparationequipment.Theuseofmicroplatesin96-or384-wellformatisa goodexampleofrecentproductivitydevelopmentsforfoodsafetyandlifescience applications.

2.1.2StandardOperationProcedure

Ingeneral,an SOPisacomprehensiveworkflowdocumentationwithinthequality assurance(QA)systemofananalyticallaboratory,butnotlimitedtoanalyticalpurposes.The SOPprovidesapprovedinformationabouttheprincipleofananalytical procedure,therequirementsforinstruments,tools,chemicals,andthestep-by-step guidanceonhowtoexecutethistask.“Thedevelopmentanduseof SOPsareanintegralpartofasuccessfulqualitysystemasitprovidesindividualswiththeinformation toperformajobproperly,andfacilitatesconsistencyinthequalityandintegrityofa productorend-result”[27].

Whydoweneed SOPs?Laboratorystafffollowwell-establishedandapproved samplepreparationandanalyticalprocedureswithbestpractices.Theguidanceon therequiredworkstepsstandardizestheworkflowbetweendifferentstaffandlocations,reducingthepersonalimpactorinterpretation,improvesthecomparability ofdata,andreduceserrors.Withtheseaspects, SOPsarealsothebasisforin-house trainingprograms.Internationalregulationsforinstance,thoseissuedbythe US EPA,theInternationalOrganizationfor Standardization/European Standard (ISO/EN),ortheUS FoodandDrugAdministrationrequiretheapplicationof published SOPsforcompliance.

SOPsarelaboratoryspecificandneedtobelocallyestablishedevenforthe in-houseorpublishedmethodsrepresenting,forinstance,thelocallyavailable resources,consumables,andoperationoftheinstrumentationtobeused.Itmust bewrittenincleartextwithallnecessarydetailstoavoidanymisunderstandings.

SOPsshouldbevalidatedbyawell-experiencedpersonusuallythelabmanager andapprovedbyathirdperson,e.g.theQAmanager,foruse.Documentcontrol withtitle,revisionnumber,date,author,andlabmanagerapprovalispartoftheQA plan. SOPsareversion-controlleddocuments.Thecurrent SOPmustbeathandfor theoperatingstaffandauditingpurposes.

2TheAnalyticalProcess

Requiredcomponentsof SOPsare:

● Purposeofthe SOP

● Scopeofapplicationandlimitations

–Principleofthemethod

–Referencetoregulationsorpublishedprocedures

–Qualificationoftheoperator

– Safety,potentialrisk,andhazardinformation

–Definitionoftermsandabbreviationsused

● Safetyinformation

–Handlingofdangeroussubstances

–Workplacepreparation

● Protectivemeasures

– Storage

● Equipment

–Tools,glassware

–Analyticalinstruments,setup,andmethodparameters

–Calibration

● Chemicalsandreagents

–Analyticalstandards,qualitycontrol(QC)materials

– Solvents,gases

–ChemicalswithCAS numbers,purity,sources

● Step-by-stepworkflow

– Samplehandling,collection,preservation

– Standardpreparations

– Samplepreparation,clean-up,concentration

–Analysisanddataacquisition

● QC –Blanks

–Calibrationsamples

– Spikedblanks

–Matrixspike

–Laboratorycontrolsamples

● Dataanalysis

–Possibleinterferences

–Dataprocessing

–Resultscalculation

–Reporting

–QCmeasures

● Wastemanagement

● References

Roboticx,y,z-systemsexecuteworkflowsandhencebecomeanintegralpartof an SOP-guidedsampleprocessingandanalysisprocess.Theseworkflowsfollow strictlythegiven SOPinitsstep-by-stepoperationandthechosenparameterset.

Morecomplexworkflowsarerecommendedtobeaccompaniedbyachecklistfor thepreparationofsamplesequences.

2.1.3EconomicalAspects

Twomajoraspectsdrivetheincreasedapplicationofintegratedandstand-alone roboticsystems:first,aboutthewayofimplementationofsuchautomatedsystems inalaboratory,andsecond,evenlyimportant,aboutthequalityoftheanalytical process.

Theapplicationconceptofhyphenatedroboticsamplepreparationsystemscannotbelimitedtothehardwareonly.Asanessentialrequirement,flexibleandprecise toolsneedtobemadeavailableonthesystemtoperformanintendedworkflow. Equallyimportanttotherobotichardware,thesameasweknowfromlaptopsor anyothercomputersystem,istheprogramdrivingthehardware,usingtheinstalled toolsandmodulesfortheintendedpurpose.Inthesameway,withoutasuitable wordprocessor,evenapowerfullaptopcannotbeusedforwritingasingleletter. Workflowsforroboticsystemsaredeliveredasdedicatedprograms,forinstance,as turnkeysolutions,toexecutesamplepreparationandinjectiontasksstep-by-stepas definedanddocumentedinan SOPasoutlinedin Section2.1.2.Typically,theseprogramsofferauserinterfacewiththemainanalyticalparametersasdefaultsorforan advancedmodifiedoperation.Foronlineanalyses,theroboticsystemsarepreferably integratedintothechromatographydatasystems(CDS)oftheinstrumentmanufacturerorgetcontrolledbyan“umbrella”-likesoftwaresolutionintegratingthe roboticworkflowandinvolvedanalyticalinstruments[28,29].Theselectedworkflow,sampleindices,andinjectionparameterbecomepartofaunifiedacquisition sequencetable.Instand-aloneinstallations,theroboticsystemsareoperatedviaa localterminalorcomputer-connected.

Inmanycases,theseworkflowprogramscovertheregulatedandstandardized analyticalmethods.Alsocustomizedmodificationsaccordingtolocalregulation needsorindividualcustomizationsaremadeavailablethisway.

Asuccessfulimplementationofaroboticsamplepreparationneedsboththe appropriatesystemtoolsandmodulestogetherwiththeanalyticalprogramto operatethemforthedesired SOP,respectivelytheintendedanalyticalworkflow. Thisconceptallowsanefficientimplementationofaneworadditionalanalytical workflowinthelaboratory.Thetime-andlabor-consumingprocessofdeveloping anewmethodfromscratchisavoided,andstepstoproductivityaresignificantly reduced.

Automationisthewelcomeside-effectoftheprogrammedworkflowcontroland CDS integration.Thesamplecapacityofroboticsystemsoftencanbeextendedup toseveralhundredsofsamplesfor24/7operation.CDS integrationwithanalytical instrumentationthenallowstheproductiveexecutionofsamplepreparationsteps tobeperformedduringtheongoinganalysisruns.Thisso-called“prep-ahead” modesignificantlyimprovesthedutycycleofcostlyanalyticalinstrumentation forincreasedsamplethroughputwithminimizedinstrumentidletimes(see Section3.3.2).Inmanycases,thestate-of-the-artnetworkconnectivityofthe