Polymer Nanocomposite Materials:

Applications in Integrated Electronic Devices Ye Zhou

Visit to download the full and correct content document: https://ebookmass.com/product/polymer-nanocomposite-materials-applications-in-inte grated-electronic-devices-ye-zhou/

More products digital (pdf, epub, mobi) instant download maybe you interests ...

Polymer Nanocomposite-Based Smart Materials: From Synthesis to Application Rachid Bouhfid

https://ebookmass.com/product/polymer-nanocomposite-based-smartmaterials-from-synthesis-to-application-rachid-bouhfid/

3D and 4D Printing of Polymer Nanocomposite Materials: Processes, Applications, and Challenges 1st Edition Kishor Kumar Sadasivuni

https://ebookmass.com/product/3d-and-4d-printing-of-polymernanocomposite-materials-processes-applications-andchallenges-1st-edition-kishor-kumar-sadasivuni/

Principles of Electronic Materials and Devices 4th Edition Safa O. Kasap

https://ebookmass.com/product/principles-of-electronic-materialsand-devices-4th-edition-safa-o-kasap/

Quantum Materials, Devices, and Applications Mohamed Henini

https://ebookmass.com/product/quantum-materials-devices-andapplications-mohamed-henini/

Polymer Nanocomposite Membranes for Pervaporation 1st Edition Sabu Thomas

https://ebookmass.com/product/polymer-nanocomposite-membranesfor-pervaporation-1st-edition-sabu-thomas/

Polymer science and innovative applications materials, techniques, and future developments Deepalekshmi Ponnamma

https://ebookmass.com/product/polymer-science-and-innovativeapplications-materials-techniques-and-future-developmentsdeepalekshmi-ponnamma/

Lectures on Digital Design Principles (River Publishers

Electronic Materials, Circuits and Devices) 1st Edition

Pinaki Mazumder

https://ebookmass.com/product/lectures-on-digital-designprinciples-river-publishers-electronic-materials-circuits-anddevices-1st-edition-pinaki-mazumder/

Applications of Polymer Nanofibers Anthony L. Andrady

https://ebookmass.com/product/applications-of-polymer-nanofibersanthony-l-andrady/

Electronic Devices and Circuits S. Salivahanan

https://ebookmass.com/product/electronic-devices-and-circuits-ssalivahanan/

PolymerNanocompositeMaterials

PolymerNanocompositeMaterials

ApplicationsinIntegratedElectronicDevices

Editedby

YeZhou

GuanglongDing

Editors

YeZhou

ShenzhenUniversity InstituteforAdvancedStudy Room358,AdministrationBuilding 518060Shenzhen China

GuanglongDing

ShenzhenUniversity InstituteforAdvancedStudy Room400-3,CollegeofEST 518060Shenzhen China

Cover ©Alexa_Space/Shutterstock

Allbookspublishedby Wiley-VCH arecarefullyproduced.Nevertheless, authors,editors,andpublisherdonot warranttheinformationcontainedin thesebooks,includingthisbook,to befreeoferrors.Readersareadvised tokeepinmindthatstatements,data, illustrations,proceduraldetailsorother itemsmayinadvertentlybeinaccurate.

LibraryofCongressCardNo.: appliedfor

BritishLibraryCataloguing-in-Publication Data

Acataloguerecordforthisbookis availablefromtheBritishLibrary.

Bibliographicinformationpublishedby theDeutscheNationalbibliothek TheDeutscheNationalbibliotheklists thispublicationintheDeutsche Nationalbibliografie;detailed bibliographicdataareavailableonthe Internetat <http://dnb.d-nb.de>

©2021WILEY-VCHGmbH,Boschstr. 12,69469Weinheim,Germany

Allrightsreserved(includingthoseof translationintootherlanguages).No partofthisbookmaybereproducedin anyform–byphotoprinting, microfilm,oranyothermeans–nor transmittedortranslatedintoa machinelanguagewithoutwritten permissionfromthepublishers. Registerednames,trademarks,etc. usedinthisbook,evenwhennot specificallymarkedassuch,arenotto beconsideredunprotectedbylaw.

PrintISBN: 978-3-527-34744-5

ePDFISBN: 978-3-527-82648-3

ePubISBN: 978-3-527-82650-6

oBookISBN: 978-3-527-82649-0

Typesetting SPiGlobal,Chennai,India

Printedonacid-freepaper 10987654321

Contents

Preface xi

1IntroductionofPolymerNanocomposites 1 TengLi,GuanglongDing,Su-TingHan,andYeZhou

1.1Introduction 1

1.2TheAdvantageofNanocomposites 3

1.3ClassificationofNanoscaleFillers 5

1.3.1One-DimensionalNanofillers 5

1.3.2Two-DimensionalNanofillers 6

1.3.3Three-DimensionalNanofillers 6

1.4ThePropertiesofPolymerNanocomposites 6

1.5SynthesisofPolymerNanocomposites 7

1.5.1Ultrasonication-assistedSolutionMixing 8

1.5.2ShearMixing 9

1.5.3ThreeRollMilling 9

1.5.4BallMilling 10

1.5.5Double-screwExtrusion 10

1.5.6InSituSynthesis 10

1.6ConclusionsandFutureOutlook 11 References 11

2FabricationofConductivePolymerCompositesandTheir ApplicationsinSensors 21 JiefengGao

2.1Introduction 21

2.2FabricationMethodsforCPCs 22

2.2.1MeltBlending 23

2.2.2SolutionBlending 25

2.2.3InSituPolymerization 27

2.3Morphologies 27

2.3.1RandomDispersionofNanofillerinthePolymerMatrix 27

2.3.2SelectiveDistributionofNanofillersontheInterface 29

2.3.2.1SegregatedStructure 29

2.3.2.2SurfaceCoating 31

2.4ApplicationinSensors 32

2.4.1StrainSensor 33

2.4.2PiezoresistiveSensor 33

2.4.3GasSensor 35

2.4.4TemperatureSensor 38

2.5Conclusion 40 References 41

3BiodegradablePolymerNanocompositesforElectronics 53 WeiWu

3.1Introduction 53

3.2BiodegradablePolymerNanocompositesinElectronics 55

3.2.1Polylactide 55

3.2.2PCL 58

3.2.3PVA 59

3.2.4PVP 61

3.2.5Cellulose 62

3.2.6Chitosan 64

3.2.7Silk 65

3.3ChallengesandProspects 66 ListofAbbreviations 67 References 67

4PolymerNanocompositesforPhotodetectors 77 RajWaliKhan,ZhengWen,andZhenhuaSun

4.1Introduction 77

4.2PhotodetectorBrief 79

4.2.1Photodiode 80

4.2.2Photoconductor 80

4.3PhotodetectorsBasedonNovelSemiconductors 82

4.4PhotodetectorsBasedonPolymerNanocomposites 87

4.4.1Polymer–PolymerNanocomposite 88

4.4.2Polymer–SmallMolecularOrganicNanocomposite 98

4.4.2.1MEH-PPV–SmallMolecularOrganicNanocomposite 98

4.4.2.2P3HT-SmallMolecularOrganicNanocomposite 99

4.4.3Polymer–Polymer–SmallMolecularOrganicNanocomposite 107

4.4.4Polymer–SmallMolecularOrganic–SmallMolecularOrganic Nanocomposite 110

4.4.5Polymer–InorganicNanocrystalsNanocomposite 112

4.4.5.1MEH-PPV–InorganicNanocrystalsNanocomposite 112

4.4.5.2P3HT–InorganicNanocrystalsNanocomposite 115

4.4.6Polymer–SmallMolecularOrganic–InorganicNanocrystals Nanocomposite 120

4.5Outlook 123

ListofAbbreviations 123 References 124

5PolymerNanocompositesforPressureSensors 131 Qi-JunSunandXin-HuaZhao

5.1Introduction 131

5.2ParametersforPressureSensors 132

5.2.1PressureSensitivity 132

5.2.2LinearSensingRange 134

5.2.3LODandResponseSpeed 134

5.2.4Reliability 134

5.3WorkingPrinciplesandExamplesofPolymerNanocompositeBased PressureSensors 135

5.3.1CapacitivePressureSensors 135

5.3.2PiezoresistivePressureSensors 137

5.3.3PiezoelectricandTriboelectricTactileSensorsBasedonPolymer Nanocomposites 143

5.4ApplicationsofthePolymerNanocompositeBasedPressure Sensors 148

5.4.1HumanWristPulseDetection 148

5.4.2SubtleHumanMotionDetection 149

5.4.3TextureRoughnessDetection 151

5.4.4E-skinApplication 152

5.5PerformanceofPressureSensorswiththePolymerNanocomposites ReportedOverthePastDecade 153

5.6Conclusion 154 References 154

6TheApplicationofPolymerNanocompositesinEnergy StorageDevices 157

NingyuanNie,MengmengHu,JieLiu,JiangqiWang,PanpanWang, HuaWang,ZhenyuanJi,ZheChen,andYanHuang

6.1Introduction 157

6.2Electrodes 158

6.2.1ForBattery 158

6.2.1.1Polymer–Graphene/CarbonNanotube 158

6.2.1.2PolymerInorganic 161

6.2.1.3Polymer–OrganicSaltGraphene 163

6.2.2ForSupercapacitor 164

6.2.2.1Polymer–MetalOxide 165

6.2.2.2Polymer–Graphene/CarbonNanotube 165

6.2.2.3Polymer–MetalOxide–Graphene/CarbonNanotubes 169

6.3Electrolytes 171

6.3.1ForBattery 171

6.3.2ForSupercapacitor 172

6.4Separator 174

6.4.1ForBattery 174

6.4.2ForSupercapacitors 175

6.5Conclusion 176 References 177

7FunctionalPolymerNanocompositeforTriboelectric Nanogenerators 189 XingyiDai,JianchengHan,QiuqunZheng,Cheng-HanZhao,and Long-BiaoHuang

7.1Introduction 189

7.2TriboelectricNanogenerators 190

7.3FunctionalPolymerNanocomposite 194

7.4Self-healingTriboelectricNanogenerators 197

7.5ShapeMemoryTriboelectricNanogenerators 201

7.6BiodegradableTriboelectricNanogenerators 204

7.7Conclusion 208 References 208

8PolymerNanocompositesforResistiveSwitching Memory 211 QaziMuhammadSaqib,MuhammadUmairKhan,andJinhoBae

8.1Introduction 211

8.2ResistiveSwitchingMemoryforPolymerNanocomposite 213

8.2.1ResistiveSwitching 213

8.2.2ResistiveSwitchingMemoryOperatingMechanism 214

8.2.2.1FormationandRuptureofConductiveFilaments 214

8.2.2.2CationsandAnionsMigration 216

8.2.2.3ElectronsTrappingandDe-tapping 216

8.2.2.4OtherConductionMechanisms 216

8.2.3FabricationTechniques 217

8.2.4PolymerNanocompositeMaterials 218

8.3PolymerNanocompositeBasedRSMDevices 218

8.3.1OxideBasedPolymerNanocompositeRSM 218

8.3.2MetalBasedNanoparticlesforPolymerNanocompositeRSM 222

8.3.3GrapheneBasedPolymerNanocompositeRSM 224

8.3.4QuantumDotBasedPolymerNanocompositeRSM 227

8.3.5PolymerBasedNanocompositesforRSM 229

8.3.62DMaterialBasedPolymerNanocompositesRSM 231

8.3.7OtherMaterialsUsedforPolymerNanocompositeBasedRSM 232

8.4ConcludingRemarks 233 Acknowledgments 234 References 234

8.APerformanceComparisonAccordingtoDeviceMaterialand Structure 243

9PolymerNanocompositesforTemperatureSensingand Self-regulatingHeatingDevices 247 YiLiu,HanZhang,andEmilianoBilotti

9.1Introduction 247

9.2ConductingMechanismandPercolationTheory 248

9.3PTCTheory 249

9.4MainFactorsInfluencingthePTCEffect 250

9.4.1EffectofFillerSizeandShape 250

9.4.2EffectofFillerDispersionandDistribution 253

9.4.3EffectofMixedFiller 254

9.4.4EffectofPolymerThermalExpansionandCrystallinity 255

9.4.5EffectofPolymerTransitionTemperature 257

9.4.6EffectofPolymerBlend 257

9.5TemperatureSensors 259

9.6Self-regulatingHeatingDevices 259

9.7Conclusions 262

References 263

10PolymerNanocompositesforEMIShieldingApplication 267 AjithaA.RamachandranandSabuThomas

10.1Introduction 267

10.2MechanismofEMIShieldingofPolymerComposites 268

10.2.1MaterialsforEMIShielding 269

10.3PolymerNanocompositesforEMIShieldingApplication 270

10.3.1NanofillerIncorporatedConductingPolymerComposites 270

10.3.2PolymerBlendNanocompositesforElectromagneticInterference(EMI) Shielding 271

10.3.3ConductingPolymersforEMIShieldingApplication 272

10.4CharacterizationTechniquesUsedfortheElectricalStudiesofPolymer Composites 274

10.4.1ConductivityStudiesofPolymerComposites 274

10.4.2ElectromagneticInterference(EMI)ShieldingStudies 276

10.5Conclusion 278

References 279

Index 285

Preface

Polymernanocompositescombiningthemeritsofpolymers(e.g.lightweight, flexibility,lowcost)andfunctionalpropertiesofnanomaterialscausedbysmall sizeeffect,quantumsizeeffect,andsurface/boundaryeffectshowadjustable optical,electrical,biological,andmechanicalcharacteristicsandattractextensive researches.Variouspolymernanocompositeswithamazingperformanceshave beenpreparedandutilizedfordevelopingintegratedelectronicdevicesinanumber ofemergingareasandexhibithugecommercialvalue,thankstotheirsimple preparationtechniquesandcountlesscombinations.Thisbookhighlightsthe recentresearchesaboutthebasicconceptions,preparation/characterizationtechniques,properties,devicedesignstrategies,andintriguingapplicationsofpolymer nanocomposites.Theexisting/potentialapplicationprospectsandchallengesfor thepolymernanocompositesarealsodiscussed.Weexpectthatthisbookcan offerawell-timedassistancetotheacademicresearchersintherapidlyexpanding applicationsincludingenvironment,sensor,energyconversion/storage,biology, andinformationstorageasasimpleandconvenienceinstrument.

Herein,wewouldliketothankalltheauthorswhohavemadecontributionsin thisbook.WewanttoexpressoursincerestappreciationandrespecttoMs.KatherineWong,Dr.ShaoyuQian,Ms.PinkySathishkumar,MathangiBalasubramanian andothereditorsatWileyforallthehelpofferedduringthewholebookediting process.Wealsowanttothankallthereadersinterestedinthisbook.Inthisbook, wehaveintroducedtheconcepts,properties,andmechanismsofpolymernanocompositesandsummarizedtheirrecentapplicationsinsomehottestfields.Theapplicationchallenges,commercialprospects,andpotentialresearchdirectionsofpolymer nanocompositesarealsopointedoutanddiscussed.Weaimtoprovideacomprehensive,popular,andup-to-datebookfortheresearchers.Althoughwehavedoneour besttomakethisbookbetter,therestillinevitablyaresomeomissionsandmistakes. Pleasegrantyourcriticismsandinstructions.

Wehopethatthisbookcanprovidereferencesandguidesforresearchersinpolymernanocompositesbasedelectrondevices,aswellaspromotetheinterestsofthe studentstothisfield.

01June2020 YeZhou GuanglongDing

IntroductionofPolymerNanocomposites

TengLi 1 ,GuanglongDing 2 ,Su-TingHan 1 ,andYeZhou 2

1 ShenzhenUniversity,InstituteofMicroscaleOptoelectronics,Room909,Shenzhen,Guangdong518060, China

2 ShenzhenUniversity,InstituteforAdvancedStudy,Room358,Shenzhen,Guangdong518060,China

1.1Introduction

Polymershavebeenoneofthemostimportantcomponentsinalmosteveryareaof humanactivitytoday.Nowadays,polymersasmultifunctionalmaterialsgradually replacemetals,glass,paper,andothertraditionalmaterialsinvariousapplications duetoitslightweight,flexibility,andlowcost[1].Inmostoftheirapplications, theappliedmaterialsarenotcomposedofasinglechemicalcomponentbut mixturesystemsofmultiplecomponentswithpolymersandotheradditives.By incorporatingdifferentadditives,suchasmetal,minerals,orevenair,awidevariety ofmaterialswithuniquephysicalpropertiesandcompetitiveproductioncostscan beproduced.Forexample,glassfiber-reinforcedplasticsarecompositematerials manufacturedbylaminatingunsaturatedpolyesterresinwithglassfiberandfiller, whichcanincreasemechanicalstrengthandheatresistance[2].

Inaddition,scientificresearchshowsthatthesizeoffillingmaterialinfiberreinforcedcompositeshasagreatinfluenceonthematerialproperties,sincethesizeof thefillingparticleslargelydeterminesthesurfaceinteractionsofadhesion,particle movement,dispersion,andbondingbetweenthesurfaceandmatrix[3].Withthe particlesizeofthefillerthatgraduallyreducestothenanoscale,someproperties dependingontheinterfacehaveundergonegreatchanges,suchasgasadsorption, chemicalactivity,electricalproperties,andcatalyticactivity.Examplesofdifferent sizesofmaterialsareshowninFigure1.1,andahydrogenatomisabout0.1nm insize,whileahumanhairis104 nmindiameter.Amongthem,nanomaterials areemployedtodescribethematerialsthathaveatleastonedimensioninthesize rangefromapproximately1to100nm[4].Differentfromthebulkandmicroscale materials,nanomaterialsareuniqueinthattheyhavemanyunusual,useful,and interestingproperties.Forexample,bulkgoldisaverystablepreciousmetalin goldencolor,whichcanbekeptforalongtimeunderatmosphericenvironment, soitisusedastheinitialcurrencybypeople.Unlikebulkgold,goldnanoparticles dispersedinwaterwillshowdifferentcolorsaccordingtothesizeofnanoparticles, PolymerNanocompositeMaterials:ApplicationsinIntegratedElectronicDevices, FirstEdition. EditedbyYeZhouandGuanglongDing. ©2021WILEY-VCHGmbH.Published2021byWILEY-VCHGmbH.

Figure1.1 Nanomaterialspeculiaritiesofsizescale.

andtheyhavehighreactivitythatcanevenbeusedascatalystatlowtemperature [5].Sincemostofthepropertiesofnanomaterialsdependontheirsize,shape, andsurfacestructure,theirultrafinesizealwaystendsnanomaterialstoaggregate intobulkmaterials,especiallywithoutproperstabilizationintheirformationand application[6].Thisisbecausetheagglomerationprocessmakesthehighsurface energyandactivityofnanomaterialsdecreasetoamorestablestate.Therefore,in ordertopreservethepropertiesofnanomaterials,itisnecessarytodistributethem uniformlyinmatricestopreventfromaggregatingintobulkmaterials[7].

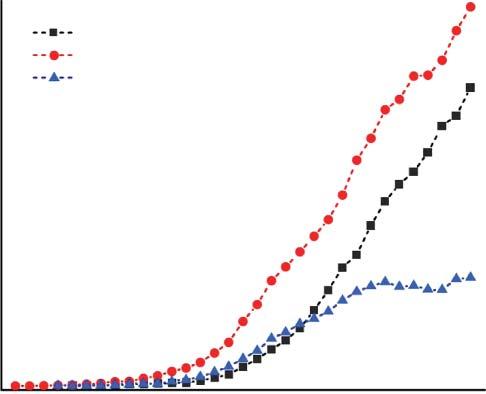

Polymernanocomposites(PNCs)arethemixtureofpolymersandnanomaterials, havingatleastone-dimensionalstructureandonecomponentmaterialinthe nanometerregimeoflessthan100nm.Combiningnanomaterialsintothepolymer matrixnotonlymakesitpossibletoproduceanewclassofpropertiesprovided byuniformlydispersednanomaterials,butalsogreatlyimprovesmostofexpected propertiesoftheoriginalpolymer,suchasmechanicalproperties,heatresistance, biodegradability,andsoon[8].Asearlyas1970,theterm“nanocomposites”was firstproposedbyTheng[9],andPNCsbegantodevelopincommercialresearch institutionsandacademiclaboratoriesinthelate1980s[10,11].Overthepast decade,PNCshavemadegreatprogressinvariousfields,whichisreflectedby theexponentialgrowthofpublicationsfromtheirinception(Figure1.2).The existenceofnanomaterialsinpolymermatrixchangesthesurfacechemicaland physicochemicalpropertiesofPNCs,wherethegeometry,surfacechemistry, aspectratio,andsizeofnanomaterialsarethekeyparameterstoregulatethese performances.Therefore,PNCsareanewclassofmaterialswithuniqueproperties, whicharefarsuperiortotraditionaldopedandcompositepolymersystems.The largeinterfaceinteractionbetweennanomaterialsandpolymermatrixsurfacesand thedifferenceofnanoscalefundamentallydistinguishPNCsfromthetraditional system.Thedevelopmentofnanomaterialsandpolymerscienceandtechnology

Nanocomposite

1.2TheAdvantageofNanocomposites 3

Figure1.2 Numberofpublicationsperyearon“nanomaterials,”“nanocomposites,”and “polymernanocomposites,”accordingtoSciFinderScholaron30April2020.

haspromotedmanyapplicationsofPNCs,whichcoveralmostallfieldsofpolymer materialapplicationfields,suchasmicroelectronics,magneticelectronics,biologicalmaterials,sensor,energystorage,andsoon[12].Therefore,thechaptersinclude uniqueperspectivesofdifferentexpertswiththeirknowledgeandunderstandingof PNCsinthisbook.

1.2TheAdvantageofNanocomposites

Sincethefillersofnanocompositesarenanoscale,theperformancesofnanocompositescanbeimprovedbytheadvantagesofthereductionoffillersizeandthe increasedsurfacearea.Intermsofsize,thefilleris3ordersofmagnitudesmaller thanthetraditionalsubstitute.Inaddition,thequantumconfinementeffectscaused bythenanomaterialswillleadtonewphysicalphenomena,whichcanbeapplied inelectricalandopticalresearch.Manyofthesepropertiesarerelatedtothesize ofthepolymerchain,andthepolymerchainclosetothefillersisaffectedbythe interactionbetweenthepackingsurfaceandthepolymermatrix,whichisdifferentfromthepolymerchainfarawayfromtheinterface.Thesizeofpolymerchain canbereflectedtheradiusofgyration Rg ,andthethicknessoftheinterfaceregions (t)aroundtheparticleisindependentoftheparticlesize.Therefore,thevolumeof interfacematerial(V interface )relativetothevolumeofparticle(V particle )willincrease withthedecreaseofparticlesize.

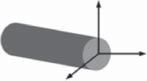

Figure1.3showsthefunctionalrelationshipbetweenthe V interface /V particle varies andtheaspectratioofparticles[13].Theaspectratioreflectstheshapeofthe

Figure1.3 Thegraphontheleftshowsthefunctionrelationshipbetweentheratioof interfacialvolumetotheparticlevolume(V interface /V particle )andtheparticleaspectratio. Theredshellrepresentstheinterfaceofparticle,wherethebluenucleusrepresentsthe particle.Thegraphontherightdefinestheparticleaspectratioandtheratioofthe interfacialthicknesstotheparticlesize(�� )withdifferentshapes(r isradius, I islength, h is height).Theinterfacethickness(t )isconsideredtobeindependentofparticlesize.When theparticlesizeisreducedtolessthan100nm,thephysicalpropertiescanbecontrolled bythevolumeoftheinterfacearoundtheparticle,whichisespeciallyobviousforthe sphereandrod.Source:WineyandVaia[13].

particles,whichcanbedividedtoplate(aspectratio <1),sphere(aspectratio = 1), androd(aspectratio >1). �� representsthesizeofthefiller,thatis,theratioofthe interfacethickness t totheminimumdimensionsizeoftheparticle.Forspherical androd-shapedparticles, �� isequaltothe t/r ,but �� is2t/h inplate-shapedparticles. Whentheparticleismicroscale, �� isapproximatelyequalto0.01,andtheparticle volumeexceedsthevolumeoftheinterfaceregioninallshapes.Astheparticle sizedecreases, V interface /V particle valuesgraduallyincreases.When �� goesabove one, V interface isgoingtoexceed V particle .Whentheparticlesreachthenanoscale (�� = 10),theinterfacevolumeismorethan10timesthatoftheparticle.Moreover, particleswithdifferentshapeshavedifferent V interface /V particle inthesame �� .The three-dimensionspherehasthehighestvalue,followedbythetwo-dimensionalrod andtheone-dimensionalplate.Withthedecreaseofparticlesize,thegapbecomes moreobvious,andeventhe V interface /V particle ofsphericalparticlesis2ordersof magnitudelargerthanthatofplate-shapedparticles.Therefore,theadditionof nanoscalefillershasagreatimpactontheperformanceofpolymerinPNCs.Even ifthevolumefractionoffillersisverysmall,theresultinginterfaceregionvolume willbeverylarge.

AstheinteractionbetweenpolymerandparticleisstrengthenedinPNCs,the interparticleinterfaceandcoordinationwillbereflectedinthemacroscopicproperties.Duetothenanoscaleofparticles,thesecondaryformingconstituentshavea veryhighaspectratioofover100.Whenthevolumefractionis1–5%,thesefillers

1.3ClassificationofNanoscaleFillers 5 canreachthepercolationthresholds,whichrefertothecriticalvalueofthevolume fractionofthepackedparticlesthatcanmutateacertainphysicalpropertyofthe compositematerialsystem.Therefore,themechanicalandtransportperformances ofPNCscanbegreatlyimprovedundertheconditionoflowloadnanoparticles. Especiallyfortheconductiveparticles,whenthevolumefractionoftheseparticlesincreasestoacertaincriticalvalueinpolymer,conductivityofthepolymer suddenlyincreasessharplyfrominsulatortoconductor,andthechangerangeisup to10ordersofmagnitude.

1.3ClassificationofNanoscaleFillers

Sofar,varioustypesofnanomaterialshavebeenfoundtobeabletoformPNCs withpolymers.Accordingtodifferentapplications,nanoparticleswithcorrespondingpropertiescanbeselectedintothepolymersystemtoachievetheexpected performance.Ingeneral,thesenanofillerssuitableforPNCapplicationscanbe mainlydividedintoone-,two-,andthree-dimensionalmaterialsaccordingtotheir differentdimensions(Table1.1).

1.3.1One-DimensionalNanofillers

One-dimensionalnanofillersareplate-likematerialswithone-dimensionaldimensionslessthan100nm,whichareusuallyafewnanometersthickandrelatively longsheets[14].Mostone-dimensionalnanofillershaveuniquemorphology

Table1.1 Overviewofnanomaterialsclassifiedbytheirnanoscaledimensions.

• Montmorilloniteclays (MMT)

• Nanographeneplatelets (NGPs)

• Layereddouble hydroxide(LDHs)

• Carbonnanofibers(CNFs)

• Carbonnanotubes(CNTs)

• Halloysitenanotubes (HNTs)

• Nickelnanostrands(NiNs)

• Aluminumoxidenanofibers (Nafen)

• Nano-silica(n-silica)

• Nano-alumina(n-Al2 O3 )

• Nano-silver(n-Ag)

• Nano-titaniumdioxide (n-TiO2 )

• Nano-siliconcarbide(n-SiC)

• Nano-zincoxide(n-ZnO)

• POSS

1IntroductionofPolymerNanocomposites characteristics,suchasnanoplate[15],nano-disk[16],nano-wall[17–23],etc., whichplayanimportantroleinfunctionalnano-devices[24,25].Recently,the widelystudiedmaterialsaremontmorilloniteclays(MMT)[26],nanographene platelets(NGPs)[27,28],ZnOnanosheets[29–31],Fe3 O4 nanosheets[30],and soon,whichhaveexcellentelectrical,optical,andmagneticproperties[32],and arewidelyusedinthefieldsofmicro–nanoelectronics,biosensors,andchemical engineering[33].Theone-dimensionalnanofillersarecommonnanomaterialsin electronicandthermaldevicesduetotheirshapecharacteristics.

1.3.2Two-DimensionalNanofillers

Two-dimensionalfillersarethematerialswithtwodimensionslessthan100nm, andtheyaremostlyintheformofrods[14].Thetypicaltwo-dimensionalnanomaterialsarecarbonnanofibers(CNFs),carbonnanotubes(CNTs),halloysite nanotubes(HNTs),nickelnanostrands(NiNS ),andaluminumoxidenanofibers (Nafen).Inaddition,themostcommontwo-dimensionalnanofillersinPNCs arenanotubes[34],plantfibers[35–39],nanowires[40],carbonfibers[41–44], oxides[45–55],graphene[56,57],molybdenumdisulfide(MoS2 )[58],andhexagon boronnitride(h-BN)[59].Comparedwithone-andthree-dimensionalfillers, two-dimensionalfillershavebetterflameretardancyandstripedcharacteristic, resultinginwideapplicationsinthefieldsofcatalysis,electronics,optics,sensing, andenergy[3,26,60–62].

1.3.3Three-DimensionalNanofillers

Three-dimensionalnanofillersarenanomaterialswiththreedimensionsonthe nanometerscale,sotheyaremostlysphericalorcube-shaped[63],whichis alsocommonlyreferredtozero-dimensionalparticles.Themostcommonthreedimensionalfillersarepolyhedraloligomericsilsesquioxane(POSS),nanosilicon, nanometalparticles,nanometaloxides,andquantumdots(QDs)[33,64].Among them,metalsandmetaloxidenanoparticleshavetheadvantagesofhighstability, catalyticactivity,andeasypreparation,andtheyareoftenusedinthefieldsof catalysis[65],purification[66–69],coatings[70–74],andbiologicalfields[75,76], togetherwithvariouspolymers.One-,two-,andthree-dimensionalnanofillers allhavevariousspecialproperties,andwillultimatelypromotetheremarkable performanceofPNCsbyloadingincompatiblepolymers.

1.4ThePropertiesofPolymerNanocomposites

InPNCs,manypropertiesoftheoriginalpolymercanbegreatlyimproved,aswellas newpropertiesresultingfromtheadditionofnanoparticles.AsshowninFigure1.4, themainpropertiesofPNCsarelisted,coveringphysical,chemical,andbiologicalareas.Ingeneral,theimprovementlevelofpropertiesisdeterminedbythesize,

1.5SynthesisofPolymerNanocomposites 7

Conductivity

Figure1.4 Significantpropertiesofpolymernanocomposites.

loadingcapacity,aspectratio,dispersionuniformity,andinterfaceinteractionsofthe nanofillerswithpolymermatrix[4].

Forexample,mostpolymersdon’tpossessconductivityexceptsomeconducting polymers,whichisduetothecovalentbondingofpolymersandthelackofelectron channelsorionmigration.Interestingly,newPNCsformedbyaddingconductive nanofillerstoinsulatingpolymersexhibitmanyelectricalproperties.Asearlyas 1994,Ajayanetal.usedCNTsasreinforcementmaterialstopreparePNCs[77].

Sincethen,therehavebeenalotofresearchesonusingCNTsasfillerstoimprove theelectricalpropertiesofPNCs.Onlyasmallvolumefractionofsuchfillersis neededtoimprovetheelectricalpropertiesofpolymersbyseveralordersofmagnitudeeffectively[78].

1.5SynthesisofPolymerNanocomposites

InthesynthesisofPNCs,itisnecessarytouniformlydistributethefillersintomatrix inordertorealizethefunctionsoffillers.However,duetothefactthatthefillers arenanoscale,theuniformdispersionismuchdifferentfromthatofthemicroscale fillers,whichismainlymanifestedinthefollowingaspects.First,ifthefilling operationiscarriedoutaccordingtothevolumefraction,muchmorenanometer fillersthanthemicrofillersarerequiredatthesamevolumefraction.Therefore, thenanoparticlesinmatrixareverycrowdedwithgreatervanderWaalsandelectrostaticinteractionsbetweentheparticles,makingitdifficulttodistributeevenly. Second,theanisotropicnanofillershaveaveryhighaspectratio,whichmakesthem

1IntroductionofPolymerNanocomposites

Table1.2 Summaryofcommonmethodsforsynthesisofpolymernanocomposites.

TechniqueSuitablefillerSuitablematrixSolventControllingfactors

Ultrasonicationassisted solutionmixing

AlltypesLiquidorviscous monomersor oligomersof thermosets

ShearmixingNanosheetsLiquidorviscous monomersor oligomersof thermosets

Threeroll milling

Nanosheets andnanotubes

Liquidorviscous monomersor oligomersof thermosets

BallmillingAlltypesLiquidorsolid thermoplasticsand thermosets

Double-screw extrusion

AlltypesSolid thermoplastics

InsitusynthesisAlltypesLiquidorviscous monomersor oligomersof thermosets

RequiredSonication powerandtime

RequiredShapesofthe rotorblades, rotatingspeed andtime

Not required

Not required

Not required

Speedofroller, gapbetween adjacentroller

Timeofmilling, ballsize, rotatingspeed, ball/nanofiller ratio

Processing temperature, screw configuration, rotationspeed

RequiredChemical reaction conditions, temperature, condensation rate

morepronetoagglomerate.Forexample,monolayergraphenehasaspectratioof about104 ,sotheytendtoreducetheirsurfaceenergyby π–π stacking.Third,a largeamountofnanofillerswithhugesurfaceareaisloadedinthepolymermatrix, whichwillproducealargeinterfaceareaandchangetheoverallperformances ofthePNC.Therefore,thedecisivestepinthesynthesisofPNCsistheuniform dispersionofnanofillersinpolymermatrix.AsshowninTable1.2,thecommon methodstodispersenanofillersandpreventtheaggregationofnanoparticlesby usingexternalenergyaresummarized.

1.5.1Ultrasonication-assistedSolutionMixing

ThemostwidelyusedapproachtoproducePNCsisultrasonication-assistedsolution mixing[79–83].Inthismethod,thenanofillersandpolymerareinitiallydissolved inasolution.Thenthenanofillersareevenlydistributedinthematrixinassistant oftheultrasound.Afterwards,thePNCsareobtainedbyevaporationofthesolvent.

1.5SynthesisofPolymerNanocomposites 9

Thenanoparticlesareseparatedfromtheagglomerationstatetothesmallerunits bytheultrasonicenergy,whichishigherthantheenergyofinteractionbetween thenanomaterialsintheaggregates.Withtheincreaseofultrasonictime,theaggregatesofnanofillersarebrokendownintosmallerones,andevenbecomeindividual nanoparticlesindependentofothernanoparticlesinthepolymer.Inaddition,this processoftenoccursatahightemperature,whichcaninitiateinsitupolymerization ofreactivemonomersortheirsolubleprepolymerswithnanomaterialstoenhance interfacialinteractions[84].

Duetothesimpleoperationandstableperformance,theultrasonic-assisted solutionmixingmethodhasbeenwidelyusedintheresearchesofnewnanocomposites.However,duetothepooreffectofultrasoundinhighviscositysolution, mostofthepolymersneedtobedissolvedinahighboilingpointsolventand maintainalowconcentration,whichwillaffecttheprocessofsolventremovaland ultimatelyreducethequalityofthenanocomposites.Therefore,whenusingthis method,itisimportanttopayattentiontothechoiceofsolvent.

1.5.2ShearMixing

Comparedwiththeultrasonic-assistedmethod,shearmixingisamuchmore commonandsimplemethod,whichonlyrequiresthestirringprocessandhasthe potentialforindustrialmassproduction[85].Intheprocessofstirring,theshear forcegeneratedbystirrerrotatingisusedtoseparatetheaggregatesofnanofillers. Duetothelowstrengthoftheshearforce,thenanoparticleswillbeseparated understirringandthenaggregatedagain,soitisgenerallynecessarytoincreasethe speedoftheagitatortocompletetheseparation.Thismethodgenerallydoesnot destroythestructureofnanofillers;thereforeitissuitablenotonlyforseparating looselyboundnanoaggregates,butalsoforstrippingoffsomelayerednanosheets. Inaddition,thismethodneedstobecarriedoutinlowviscositysolventjustlike ultrasonicassistedmethod.

1.5.3ThreeRollMilling

Threerollermillingisamethodofdispersingnanofillersbytheshearingforce betweenrollsinhighviscositymatrix,suchasink,pastematerial,coating,etc.The machineofthreerollmillingiscomposedofthreecylindricalrollerswithdifferent rotatingspeeds,andtheadjacentrollersrotateintheoppositedirection.Theparticle sizedistributionanduniformityofthepackingcanbewellcontrolledasthespeeds oftherollersandthegapbetweenthemareadjustable.Inaddition,theshearing forcegeneratedbetweentherollersishigherthanthatgeneratedbystirring,so themethodcanbeappliedtohighviscositymaterials,andcarriedoutunderthe conditionoflittleornosolvent.Therefore,thismethodisoftenusedtodisperse someanisotropicnanofillers,suchasCNTs[86–89],graphenenanosheets[90–92], nanoclays[93–95],andsoon.

However,itshouldbenotedthatthedistancebetweenadjacentrollersshouldbeat least1 μm,sothedispersioneffectofnanosphereswiththree-dimensionaldirection

1IntroductionofPolymerNanocomposites

lessthan100nmwillnotbegood.Theaggregatesofnanospherescanonlybeturned intosmallerunits,notbrokenintoindividualparticle.Ontheotherhand,therotationoftherollerrequirestheadditionofviscousmaterials,andnanofillerscanonly bedispersedinthethermosettingmatrixbutnotinthethermoplasticmatrix.

1.5.4BallMilling

Ballmillingiswidelyusedinmetallurgyandmineralprocessingindustry[96].The principleofballmillingistogrindandmixpowdersinaclosedspacebyusing thehugeshearforceandcompressionforceproducedbyhardballcollision.Inthe synthesisofPNCs,thismethodcandisperseCNTs[97],graphenenanoparticles [98–101],silicananoparticles[102],andBNs[103,104]intothermoplasticand thermosettingpolymers.Thehighshearforceproducedbyballmillingcanpeel offsometwo-dimensionalnanostructures,suchasgraphene,MoS2 ,andBNs,but maynotseparatetheinterlayerstructureconnectedbyionicbonding[105–110]. Inaddition,ballmillingisnotonlysuitableforsolvent-freeconditionsbutalso solvent-freeconditions,sonanofillerscanbedirectlydispersedinsomesolid thermoplasticmatrix,suchaspolyethylene(PE)[101,111],polyphenylenesulfide [104,112],andpolymethylmethacrylate(PMMA)[102].

1.5.5Double-screwExtrusion

Double-screwextrusiondispersesnanofillersinthermoplasticmatrixbyhuge shearforcegeneratedbyhighspeedrotationofdouble-screwathightemperature [113,114].Thismethodhasbeenwidelyusedinindustryduetotheadvantagesof solvent-freeandenvironment-friendlytechnology.Withthismethod,thefillerscan bedispersedintothepolymerinahighcontentwaytoachievethewell-controlled performance,andappliedtodifferentsizesofnanoparticles,suchasgraphene sheets[115],CNTs[116],andsilicondioxide[117].Thismethodneedshigher temperature,whichishelpfultoreducetheviscosityofpolymerandloadmore nanofillers,butalsohastheriskofdecomposingpolymersandnanofillers.The reasonisowingtotheexistenceoflowthermalstabilityfunctionalgroupsinthe materials.Whenthetemperatureistoohigh,thefracturewilloccur,resultingin thedeteriorationoftheperformanceofPNCs[118].Moreover,thegapbetweenthe screwsistoolargetokeepsomeaggregatesofnanofillersevenly,whichwillnot achievetheuniformmonodispersingofnanofillers.So,itisnecessarytocombine othertechnologiestofurtherimprovetheperformance[119,120].

1.5.6InSituSynthesis

Inadditiontotheaforementionedmethodsofdispersingpreparednanofillersinto polymers,anotherimportantsynthesisstrategyisinsitusynthesis,whichdirectly generatesnanoparticlesinpolymersthroughmolecularprecursors[121].This methodcanbedividedintochemicalandphysicalinsitusynthesis[122].Chemical insitusynthesisisusedtosynthesizenanoscalefillersbychemicalreaction,such

asthehydrothermalmethodandsol–gelmethod[123,124].Thephysicalinsitu synthesisistransformingtheprecursorofgasphaseintoinorganicnanoparticles throughplasmaaction,andthencondensingtheorganiccompoundsonthesurface ofinorganicparticlestocoverthepolymershelltoformPNCs[125].

1.6ConclusionsandFutureOutlook

Inthischapter,thebasicprinciples,properties,andsynthesismethodsofPNCsare clearlydescribed.Thecompositematerialhasuniquestructureandperformance, andhasawiderangeofapplicationsinmanyfields.Theparticlesize,orientation, shape,dispersion,andvolumedispersionofnanofillersaffectthepropertiesof PNCs.Mostofthephysical,chemical,andmechanicalpropertiesofPNCsdepend ontheinterfaceinteractionbetweenthefillerandthematrix.Therefore,theuniformdispersionofnanofillersisthemostimportantconsiderationinthesynthesis ofPNCs.PNCshaverecentlybecomepartofmoderntechnology,buttheseareas arestillintheearlystageofdevelopment.Withmoreandmorescientistsand engineerscontributingtotheunderstandingofPNCs,thesefunctionalmaterials willbeappliedinmoreandmorefields.

References

1 Karak,N.(2019). FundamentalsofNanomaterialsandPolymerNanocomposites. Elsevier.

2 Brunner,G.(2014). SupercriticalFluidScienceandTechnology,vol.5 (ed.G.Brunner).Elsevier.

3 Pradhan,S.,Lach,R.,Le,H.H.etal.(2013).Effectoffillerdimensionalityon mechanicalpropertiesofnanofillerreinforcedpolyolefinelastomers. ISRN Polym.Sci. 2013:1–9.

4 Jordan,J.,Jacob,K.I.,Tannenbaum,R.etal.(2005).Experimentaltrendsin polymernanocomposites-areview. Mater.Sci.Eng.,A 393:1–11.

5 Xiao,J.andQi,L.(2011).Surfactant-assisted,shape-controlledsynthesisofgold nanocrystals. Nanoscale 3:1383–1396.

6 Koo,J.(2015). AnOverviewofNanomaterials.CambridgeUniversityPress.

7 Vigneshwaran,N.,Ammayappan,L.,andHuang,Q.(2011).EffectofGum arabicondistributionbehaviorofnanocellulosefillersinstarchfilm. Appl. Nanosci. 1:137–142.

8 Hussain,F.,Hojjati,M.,Okamoto,M.,andGorga,R.E.(2006).Reviewarticle: polymer-matrixnanocomposites,processing,manufacturing,andapplication:an overview. J.Compos.Mater. 40:1511–1575.

9 Theng,B.K.G.(1970).Interactionsofclaymineralswithorganicpolymers.some practicalapplications. ClaysClayMiner. 18:357–362.

10 Usuki,A.,Kawasumi,M.,Kojima,Y.etal.(1993).Swellingbehaviorofmontmorillonitecationexchangedfor ω-aminoacidsby ∈-caprolactam. J.Mater.Res. 8:1174–1178.

1IntroductionofPolymerNanocomposites

11 Kojima,Y.,Usuki,A.,Kawasumi,M.etal.(2011).Mechanicalpropertiesof nylon6-clayhybrid. J.Mater.Res. 8:1185–1189.

12 Ray,S.S.andBousmina,M.(2007). PolymerNanocompositesandTheirApplications.AmericanScientificPublishers.

13 Winey,K.I.andVaia,R.A.(2011).Polymernanocomposites. MRSBull. 32: 314–322.

14 Verdejo,R.,Bernal,M.M.,Romasanta,L.J.etal.(2018).Reactivenanocomposite foams. Cell.Polym. 30:45–62.

15 Nieto,A.,Lahiri,D.,andAgarwal,A.(2012).Synthesisandpropertiesofbulk graphenenanoplateletsconsolidatedbysparkplasmasintering. Carbon 50: 4068–4077.

16 Schmidt,F.P.,Ditlbacher,H.,Hohenester,U.etal.(2012).Darkplasmonic breathingmodesinsilvernanodisks. NanoLett. 12:5780–5783.

17 Jung,S.-H.,Oh,E.,Lee,K.-H.etal.(2008).Sonochemicalpreparationof shape-selectiveZnOnanostructures. Cryst.GrowthDes. 8:265–269.

18 Siril,P.F.,Ramos,L.,Beaunier,P.etal.(2009).Synthesisofultrathinhexagonal palladiumnanosheets. Chem.Mater. 21:5170–5175.

19 Dong,X.,Ji,X.,Jing,J.etal.(2010).Synthesisoftriangularsilvernanoprisms bystepwisereductionofsodiumborohydrideandtrisodiumcitrate. J.Phys. Chem.C 114:2070–2074.

20 Nayak,B.B.,Behera,D.,andMishra,B.K.(2010).Synthesisofsiliconcarbide dendritebythearcplasmaprocessandobservationofnanorodbundlesinthe dendritearm. J.Am.Ceram.Soc. 93:3080–3083.

21 Vizireanu,S.,Stoica,S.D.,Luculescu,C.etal.(2010).Plasmatechniquesfor nanostructuredcarbonmaterialssynthesis.acasestudy:carbonnanowall growthbylowpressureexpandingRFplasma. PlasmaSourcesSci.Technol. 19:34016.

22 Mann,A.K.P.andSkrabalak,S.E.(2011).Synthesisofsingle-crystalline nanoplatesbyspraypyrolysis:ametathesisroutetoBi2 WO6 . Chem.Mater. 23:1017–1022.

23 Tiwari,J.N.,Tiwari,R.N.,andKim,K.S.(2012).Zero-dimensional, one-dimensional,two-dimensionalandthree-dimensionalnanostructured materialsforadvancedelectrochemicalenergydevices. Prog.MaterSci. 57: 724–803.

24 Kim,K.S.,Zhao,Y.,Jang,H.etal.(2009).Large-scalepatterngrowthof graphenefilmsforstretchabletransparentelectrodes. Nature 457:706–710.

25 Bae,S.,Kim,H.,Lee,Y.etal.(2010).Roll-to-rollproductionof30-inch graphenefilmsfortransparentelectrodes. Nat.Nanotechnol. 5:574–578.

26 Isitman,N.A.,Dogan,M.,Bayramli,E.,andKaynak,C.(2012).Theroleof nanoparticlegeometryinflameretardancyofpolylactidenanocomposites containingaluminiumphosphinate. Polym.Degrad.Stab. 97:1285–1296.

27 Shen,J.,Hu,Y.,Li,C.etal.(2009).Synthesisofamphiphilicgraphene nanoplatelets. Small 5:82–85.

28 Li,B.andZhong,W.-H.(2011).Reviewonpolymer/graphitenanoplatelet nanocomposites. J.Mater.Sci. 46:5595–5614.

29 Umar,A.andHahn,Y.B.(2006).ZnOnanosheetnetworksandhexagonalnanodiscsgrownonsiliconsubstrate:growthmechanismandstructuralandoptical properties. Nanotechnology 17:2174–2180.

30 Bai,W.,Zhu,X.,Zhu,Z.,andChu,J.(2008).Synthesisofzincoxidenanosheet thinfilmsandtheirimprovedfieldemissionandphotoluminescenceproperties byannealingprocessing. Appl.Surf.Sci. 254:6483–6488.

31 Mani,G.K.andRayappan,J.B.B.(2014).AsimpleandtemplatefreesynthesisofbranchedZnOnanoarchitecturesforsensorapplications. RSCAdv. 4: 64075–64084.

32 Li,B.L.,Setyawati,M.I.,Chen,L.etal.(2017).Directingassemblyanddisassemblyof2DMoS2 nanosheetswithDNAfordrugdelivery. ACSAppl.Mater. Interfaces 9:15286–15296.

33 Vengatesan,M.R.andMittal,V.(2016). Nanoparticle-andNanofiber-BasedPolymerNanocomposites:AnOverview.Wiley-VCH.

34 Yang,J.,Zhang,Z.,Friedrich,K.,andSchlarb,A.K.(2007).Creepresistant polymernanocompositesreinforcedwithmultiwalledcarbonnanotubes. Macromol.RapidCommun. 28:955–961.

35 Fahmy,T.Y.A.,Mobarak,F.,Fahmy,Y.etal.(2005).Nanocomposites fromnaturalcellulosefibersincorporatedwithsucrose. WoodSci.Technol. 40:77–86.

36 GarciadeRodriguez,N.L.,Thielemans,W.,andDufresne,A.(2006).Sisal cellulosewhiskersreinforcedpolyvinylacetatenanocomposites. Cellulose 13: 261–270.

37 Fahmy,T.Y.A.andMobarak,F.(2008).Nanocompositesfromnaturalcellulosefibersfilledwithkaolininpresenceofsucrose. Carbohydr.Polym. 72: 751–755.

38 Lee,K.-Y.,Bharadia,P.,Blaker,J.J.,andBismarck,A.(2012).Shortsisalfibre reinforcedbacterialcellulosepolylactidenanocompositesusinghairysisalfibres asreinforcement. Compos.PartA:Appl.Sci.Manuf. 43:2065–2074.

39 Ibrahim,I.D.,Jamiru,T.,Sadiku,E.R.etal.(2016).Impactofsurfacemodificationandnanoparticleonsisalfiberreinforcedpolypropylenenanocomposites. J.Nanotechnol. 2016:1–9.

40 Lonjon,A.,Laffont,L.,Demont,P.etal.(2010).Structuralandelectricalpropertiesofgoldnanowires/P(VDF-TrFE)nanocomposites. J.Phys.D 43:345401.

41 Xu,Y.andHoa,S.V.(2008).Mechanicalpropertiesofcarbonfiberreinforced epoxy/claynanocomposites. Compos.Sci.Technol. 68:854–861.

42 Pozegic,T.R.,Anguita,J.V.,Hamerton,I.etal.(2016).Multi-functionalcarbon fibrecompositesusingcarbonnanotubesasanalternativetopolymersizing. Sci.Rep. 6:37334.

43 Ulus,H.,¸Sahin,Ö.S.,andAvc��,A.(2016).Enhancementofflexuralandshear propertiesofcarbonfiber/epoxyhybridnanocompositesbyboronnitridenano particlesandcarbonnanotubemodification. FibersPolym. 16:2627–2635.

44 Ye,G.(2017).Preparationofpoly(7-formylindole)/carbonfibersnanocomposites andtheirhighcapacitancebehaviors. Int.J.Electrochem.Sci. 12:8467–8476.

1IntroductionofPolymerNanocomposites

45 Lu,X.,Chao,D.,Chen,J.etal.(2006).Preparationandcharacterizationof inorganic/organichybridnanocompositesbasedonAunanoparticlesand polypyrrole. Mater.Lett. 60:2851–2854.

46 Subedi,D.P.,Madhup,D.K.,Sharma,A.etal.(2012).Retracted:studyofthe wettabilityofZnOnanofilms. Int.NanoLett. 2:1.

47 ´ Slosarczyk,A.,Barełkowski,M.,Niemier,S.,andJakubowska,P.(2015).Synthesisandcharacterisationofsilicaaerogel/carbonmicrofibersnanocomposites driedinsupercriticalandambientpressureconditions. J.Sol–GelSci.Technol. 76:227–232.

48 Dhandapani,S.,Nayak,S.K.,andMohanty,S.(2016).Compatibilityeffect oftitaniumdioxidenanofiberonreinforcedbiobasednanocomposites:thermal,mechanical,andmorphologycharacterization. J.VinylAdd.Technol. 22: 529–538.

49 Ma,J.-L.,Chan,T.-M.,andYoung,B.(2016).Experimentalinvestigationof cold-formedhighstrengthsteeltubularbeams. Eng.Struct. 126:200–209.

50 Saranya,M.,Ramachandran,R.,andWang,F.(2016).Graphene-zincoxide (G-ZnO)nanocompositeforelectrochemicalsupercapacitorapplications. J.Sci. Adv.Mater.Devices 1:454–460.

51 Shehata,N.,Gaballah,S.,Samir,E.etal.(2016).Fluorescentnanocomposite ofembeddedceriananoparticlesincrosslinkedPVAelectrospunnanofibers. Nanomaterials 6:102.

52 Shehata,N.,Samir,E.,Gaballah,S.etal.(2016).EmbeddedceriananoparticlesincrosslinkedPVAelectrospunnanofibersasopticalsensorsforradicals. Sensors 16:1371.

53 Sunny,A.T.,Vijayan,P.P.,Adhikari,R.etal.(2016).Copperoxidenanoparticlesinanepoxynetwork:microstructure,chainconfinementandmechanical behaviour. Phys.Chem.Chem.Phys. 18:19655–19667.

54 Alswata,A.A.,Ahmad,M.B.,Al-Hada,N.M.etal.(2017).Preparationofzeolite/zincoxidenanocompositesfortoxicmetalsremovalfromwater. Results Phys. 7:723–731.

55 Fambri,L.,Dabrowska,I.,Ceccato,R.,andPegoretti,A.(2017).Effectsof fumedsilicaanddrawratioonnanocompositepolypropylenefibers. Polymers 9:41.

56 Wang,X.andSong,M.(2013).Tougheningofpolymersbygraphene. Nanomater.Energy 2:265–278.

57 Paszkiewicz,S.,Pawelec,I.,Szymczyk,A.,andRosłaniec,Z.(2015).Thermoplasticelastomerscontaining2Dnanofillers:montmorillonite,graphene nanoplateletsandoxidizedgrapheneplatelets. PolishJ.Chem.Technol. 17: 74–81.

58 Wang,X.,Xing,W.,Feng,X.etal.(2017).MoS2 /polymernanocomposites: preparation,properties,andapplications. Polym.Rev. 57:440–466.

59 Ribeiro,H.,Trigueiro,J.P.C.,Silva,W.M.etal.(2019).HybridMoS2 /h-BN nanofillersassynergicheatdissipationandreinforcementadditivesinepoxy nanocomposites. ACSAppl.Mater.Interfaces 11:24485–24492.

60 Rao,K.S.,Senthilnathan,J.,Ting,J.M.,andYoshimura,M.(2014).Continuousproductionofnitrogen-functionalizedgraphenenanosheetsforcatalysis applications. Nanoscale 6:12758–12768.

61 Shahjamali,M.M.,Salvador,M.,Bosman,M.etal.(2014).Edge-gold-coated silvernanoprisms:enhancedstabilityandapplicationsinorganicphotovoltaics andchemicalsensing. J.Phys.Chem.C 118:12459–12468.

62 Wan,J.,Kaplan,A.F.,Zheng,J.etal.(2014).Twodimensionalsilicon nanowallsforlithiumionbatteries. J.Mater.Chem.A 2:6051–6057.

63 Bhattacharya,M.(2016).Polymernanocomposites-acomparisonbetween carbonnanotubes,graphene,andclayasnanofillers. Materials 9:262.

64 Kumar,A.P.,Depan,D.,SinghTomer,N.,andSingh,R.P.(2009).Nanoscale particlesforpolymerdegradationandstabilization-Trendsandfutureperspectives. Prog.Polym.Sci. 34:479–515.

65 Shifrina,Z.B.,Matveeva,V.G.,andBronstein,L.M.(2020).Roleofpolymer structuresincatalysisbytransitionmetalandmetaloxidenanoparticlecomposites. Chem.Rev. 120:1350–1396.

66 Sotto,A.,Boromand,A.,Balta,S.etal.(2011).Dopingofpolyethersulfone nanofiltrationmembranes:antifoulingeffectobservedatultralowconcentrationsofTiO2 nanoparticles. J.Mater.Chem. 21:10311–10320.

67 Huang,J.,Zhang,K.,Wang,K.etal.(2012).Fabricationof polyethersulfone-mesoporoussilicananocompositeultrafiltrationmembranes withantifoulingproperties. J.Membr.Sci. 423–424:362–370.

68 MaríaArsuaga,J.,Sotto,A.,delRosario,G.etal.(2013).Influenceofthetype, size,anddistributionofmetaloxideparticlesonthepropertiesofnanocompositeultrafiltrationmembranes. J.Membr.Sci. 428:131–141.

69 Zhao,S.,Yan,W.,Shi,M.etal.(2015).Improvingpermeabilityandantifouling performanceofpolyethersulfoneultrafiltrationmembranebyincorporationof ZnO-DMFdispersioncontainingnano-ZnOandpolyvinylpyrrolidone. J.Membr. Sci. 478:105–116.

70 Macyk,W.,Szaciłowski,K.,Stochel,G.etal.(2010).Titanium(IV)complexesas directTiO2 photosensitizers. Coord.Chem.Rev. 254:2687–2701.

71 Paz,Y.(2010).ApplicationofTiO2 photocatalysisforairtreatment:patents’ overview. Appl.Catal.,B 99:448–460.

72 Su,W.,Wang,S.,Wang,X.etal.(2010).Plasmapre-treatmentandTiO2 coating ofPMMAfortheimprovementofantibacterialproperties. Surf.Coat.Technol. 205:465–469.

73 Olad,A.andNosrati,R.(2013).Preparationandcorrosionresistanceof nanostructuredPVC/ZnO–polyanilinehybridcoating. Prog.Org.Coat. 76: 113–118.

74 Wang,N.,Fu,W.,Zhang,J.etal.(2015).Corrosionperformanceofwaterborneepoxycoatingscontainingpolyethyleniminetreatedmesoporous-TiO2 nanoparticlesonmildsteel. Prog.Org.Coat. 89:114–122.

75 DiCarlo,G.,Curulli,A.,Toro,R.G.etal.(2012).Greensynthesisof gold-chitosannanocompositesforcaffeicacidsensing. Langmuir 28:5471–5479.

1IntroductionofPolymerNanocomposites

76 Matos,A.C.,Marques,C.F.,Pinto,R.V.etal.(2015).Noveldopedcalcium phosphate-PMMAbonecementcompositesaslevofloxacindeliverysystems. Int.J.Pharm. 490:200–208.

77 Ajayan,P.M.,Stephan,O.,Colliex,C.,andTrauth,D.(1994).Alignedcarbon nanotubearraysformedbycuttingapolymerresin-nanotubecomposite. Science 265:1212–1214.

78 Mao,C.,Zhu,Y.,andJiang,W.(2012).Designofelectricalconductivecomposites:tuningthemorphologytoimprovetheelectricalpropertiesofgraphene filledimmisciblepolymerblends. ACSAppl.Mater.Interfaces 4:5281–5286.

79 Jang,J.,Bae,J.,andYoon,S.-H.(2003).Astudyontheeffectofsurfacetreatmentofcarbonnanotubesforliquidcrystallineepoxide–carbonnanotube composites. J.Mater.Chem. 13:676–681.

80 Stankovich,S.,Dikin,D.A.,Dommett,G.H.etal.(2006).Graphene-basedcompositematerials. Nature 442:282–286.

81 Yousefi,N.,Gudarzi,M.M.,Zheng,Q.etal.(2013).Highlyaligned, ultralarge-sizereducedgrapheneoxide/polyurethanenanocomposites:mechanicalpropertiesandmoisturepermeability. Compos.PartA:Appl.Sci.Manuf. 49: 42–50.

82 Yousefi,N.,Sun,X.,Lin,X.etal.(2014).Highlyalignedgraphene/polymer nanocompositeswithexcellentdielectricpropertiesforhigh-performanceelectromagneticinterferenceshielding. Adv.Mater. 26:5480–5487.

83 Shen,X.,Wang,Z.,Wu,Y.etal.(2016).Multilayergrapheneenableshigher efficiencyinimprovingthermalconductivitiesofgraphene/epoxycomposites. NanoLett. 16:3585–3593.

84 Yousefi,N.,Lin,X.,Zheng,Q.etal.(2013).Simultaneousinsitureduction, self-alignmentandcovalentbondingingrapheneoxide/epoxycomposites. Carbon 59:406–417.

85 Paton,K.R.,Varrla,E.,Backes,C.etal.(2014).Scalableproductionoflarge quantitiesofdefect-freefew-layergraphenebyshearexfoliationinliquids. Nat.Mater. 13:624–630.

86 Gojny,F.H.,Wichmann,M.H.G.,Köpke,U.etal.(2004).Carbon nanotube-reinforcedepoxy-composites:enhancedstiffnessandfracturetoughnessatlownanotubecontent. Compos.Sci.Technol. 64:2363–2371.

87 Thostenson,E.T.andChou,T.-W.(2006).Processing-structure-multi-functional propertyrelationshipincarbonnanotube/epoxycomposites. Carbon 44: 3022–3029.

88 Viets,C.,Kaysser,S.,andSchulte,K.(2014).DamagemappingofGFRPvia electricalresistancemeasurementsusingnanocompositeepoxymatrixsystems. CompositesPartB 65:80–88.

89 Souri,H.,Nam,I.W.,andLee,H.K.(2015).Electricalpropertiesandpiezoresistiveevaluationofpolyurethane-basedcompositeswithcarbonnano-materials. Compos.Sci.Technol. 121:41–48.

90 Ahmadi-Moghadam,B.andTaheri,F.(2014).Effectofprocessing parametersonthestructureandmulti-functionalperformanceof epoxy/GNP-nanocomposites. J.Mater.Sci. 49:6180–6190.

91 Chandrasekaran,S.,Sato,N.,Tölle,F.etal.(2014).Fracturetoughnessand failuremechanismofgraphenebasedepoxycomposites. Compos.Sci.Technol. 97:90–99.

92 Li,Y.,Zhang,H.,Bilotti,E.,andPeijs,T.(2016).Optimizationofthree-rollmill parametersforin-situexfoliationofgraphene. MRSAdv. 1:1389–1394.

93 Dalir,H.,Farahani,R.D.,Nhim,V.etal.(2012).Preparationofhighlyexfoliated polyester-claynanocomposites:process-propertycorrelations. Langmuir 28: 791–803.

94 Park,J.-J.andLee,J.-Y.(2013).Effectofnano-sizedlayeredsilicateonACelectricaltreeingbehaviorofepoxy/layeredsilicatenanocompositeinneedle-plate electrodes. Mater.Chem.Phys. 141:776–780.

95 Kothmann,M.H.,Ziadeh,M.,Bakis,G.etal.(2015).Analyzingtheinfluenceof particlesizeandstiffnessstateofthenanofilleronthemechanicalproperties ofepoxy/claynanocompositesusinganovelshear-stiffnano-mica. J.Mater.Sci. 50:4845–4859.

96 Zhang,D.L.(2004).Processingofadvancedmaterialsusinghigh-energy mechanicalmilling. Prog.MaterSci. 49:537–560.

97 Gupta,T.K.,Singh,B.P.,Mathur,R.B.,andDhakate,S.R.(2014).Multi-walled carbonnanotube-graphene-polyanilinemultiphasenanocompositewithsuperior electromagneticshieldingeffectiveness. Nanoscale 6:842–851.

98 Wu,H.,Zhao,W.,Hu,H.,andChen,G.(2011).One-stepinsituballmilling synthesisofpolymer-functionalizedgraphenenanocomposites. J.Mater.Chem. 21:8626–8632.

99 Jiang,X.andDrzal,L.T.(2012).Reductioninpercolationthresholdofinjection moldedhigh-densitypolyethylene/exfoliatedgraphenenanoplateletscomposites bysolidstateballmillingandsolidstateshearpulverization. J.Appl.Polym. Sci. 124:525–535.

100 Tang,L.-C.,Wan,Y.-J.,Yan,D.etal.(2013).Theeffectofgraphenedispersiononthemechanicalpropertiesofgraphene/epoxycomposites. Carbon 60: 16–27.

101 Gu,J.,Li,N.,Tian,L.etal.(2015).Highthermalconductivitygraphite nanoplatelet/UHMWPEnanocomposites. RSCAdv. 5:36334–36339.

102 Castrillo,P.D.,Olmos,D.,Amador,D.R.,andGonzalez-Benito,J.(2007).Real dispersionofisolatedfumedsilicananoparticlesinhighlyfilledPMMApreparedbyhighenergyballmilling. J.ColloidInterfaceSci. 308:318–324.

103 Donnay,M.,Tzavalas,S.,andLogakis,E.(2015).Boronnitridefilledepoxywith improvedthermalconductivityanddielectricbreakdownstrength. Compos.Sci. Technol. 110:152–158.

104 Gu,J.,Guo,Y.,Yang,X.etal.(2017).Synergisticimprovementofthermalconductivitiesofpolyphenylenesulfidecompositesfilledwithboronnitridehybrid fillers. Compos.PartA:Appl.Sci.Manuf. 95:267–273.

105 Lin,Y.andConnell,J.W.(2012).Advancesin2Dboronnitridenanostructures: nanosheets,nanoribbons,nanomeshes,andhybridswithgraphene. Nanoscale 4:6908–6939.

1IntroductionofPolymerNanocomposites

106 Yao,Y.,Lin,Z.,Li,Z.etal.(2012).Large-scaleproductionoftwo-dimensional nanosheets. J.Mater.Chem. 22:13494–13499.

107 Lee,D.,Lee,B.,Park,K.H.etal.(2015).Scalableexfoliationprocessforhighly solubleboronnitridenanoplateletsbyhydroxide-assistedballmilling. Nano Lett. 15:1238–1244.

108 Brent,J.R.,Savjani,N.,andO’Brien,P.(2017).Syntheticapproachesto two-dimensionaltransitionmetaldichalcogenidenanosheets. Prog.MaterSci. 89:411–478.

109 Buzaglo,M.,Bar,I.P.,Varenik,M.etal.(2017).Graphite-to-graphene:totalconversion. Adv.Mater. 29:1603528.

110 Teng,C.,Xie,D.,Wang,J.etal.(2017).Ultrahighconductivegrapheneraper basedonball-millingexfoliatedgraphene. Adv.Funct.Mater. 27:1700240.

111 Gu,J.,Guo,Y.,Lv,Z.etal.(2015).Highlythermallyconductive POSS-g-SiCp/UHMWPEcompositeswithexcellentdielectricpropertiesand thermalstabilities. Compos.PartA:Appl.Sci.Manuf. 78:95–101.

112 Gu,J.,Xie,C.,Li,H.etal.(2013).Thermalpercolationbehaviorofgraphene nanoplatelets/polyphenylenesulfidethermalconductivitycomposites. Polym. Compos. 35:1087–1092.

113 Wu,C.L.,Zhang,M.Q.,Rong,M.Z.,andFriedrich,K.(2002).Tensileperformanceimprovementoflownanoparticlesfilled-polypropylenecomposites. Compos.Sci.Technol. 62:1327–1340.

114 Fawaz,J.andMittal,V.(2014). SynthesisofPolymerNanocomposites:Reviewof VariousTechniques.Wiley-VCH.

115 Kim,I.-H.andJeong,Y.G.(2010).Polylactide/exfoliatedgraphitenanocompositeswithenhancedthermalstability,mechanicalmodulus,andelectrical conductivity. J.Polym.Sci.,PartB:Polym.Phys. 48:850–858.

116 Villmow,T.,Pötschke,P.,Pegel,S.etal.(2008).Influenceoftwin-screw extrusionconditionsonthedispersionofmulti-walledcarbonnanotubesin apoly(lacticacid)matrix. Polymer 49:3500–3509.

117 Zou,H.,Wu,S.,andShen,J.(2008).Polymer/silicananocomposites:preparation,characterization,properties,andapplications. Chem.Rev. 108:3893–3957.

118 Venugopal,G.,Veetil,J.C.,Raghavan,N.etal.(2016).Nano-dynamicmechanicalandthermalresponsesofsingle-walledcarbonnanotubesreinforced polymernanocompositethinfilms. J.AlloysCompd. 688:454–459.

119 Moniruzzaman,M.,Du,F.,Romero,N.,andWiney,K.I.(2006).IncreasedflexuralmodulusandstrengthinSWNT/epoxycompositesbyanewfabrication method. Polymer 47:293–298.

120 Isayev,A.I.,Kumar,R.,andLewis,T.M.(2009).Ultrasoundassistedtwinscrew extrusionofpolymer–nanocompositescontainingcarbonnanotubes. Polymer 50:250–260.

121 Hanemann,T.andSzabó,D.V.(2010).Polymer-nanoparticlecomposites:from synthesistomodernapplications. Materials 3:3468–3517.

122 Caseri,W.R.(2013).Nanocompositesofpolymersandinorganicparticles: preparation,structureandproperties. Mater.Sci.Technol. 22:807–817.

123 Xiong,M.,Zhou,S.,Wu,L.etal.(2004).Sol–gelderivedorganic–inorganic hybridfromtrialkoxysilane-cappedacrylicresinandtitania:effectsofpreparationconditionsonthestructureandproperties. Polymer 45:8127–8138.

124 Cao,Z.,Jiang,W.,Ye,X.,andGong,X.(2008).PreparationofsuperparamagneticFe3 O4 /PMMAnanocompositesandtheirmagnetorheological characteristics. J.Magn.Magn.Mater. 320:1499–1502.

125 Vollath,D.andSzabó,D.V.(1999).Coatednanoparticles:anewwayto improvednanocomposites. J.Nanopart.Res. 1:235–242.

FabricationofConductivePolymerCompositesandTheir ApplicationsinSensors

JiefengGao

YangzhouUniversity,SchoolofChemistryandChemicalEngineering,No180,RoadSiwangting,Yangzhou, Jiangsu225002,China

2.1Introduction

Comparedwithtraditionalconductivematerialslikemetals,conductivepolymers (CPs)exhibitexcellentflexibility,lightweight,lowcost,andeasyprocessing characteristics.Therefore,CPshavebecometheresearchhotspotinrecentdecade andbeenwidelyusedinmanyfieldssuchaselectromagneticinterference(EMI) shielding,sensors,andwearableelectronics[1–3].Generally,CPscanbedivided intotwocategories:(i)structural(intrinsic)structuralconductivepolymers(SCPs) and(ii)conductivepolymerscomposites(CPCs).

SCPsrefertoamaterialpossessinginherentconductivityprovidedbythe structurecarrier.TheSCPswerefirstlydiscoveredinthe1970s,whicharoused theattentionofresearchersonthechemicalstructureandtheelectricalproperties ofpolymers[4,5].ThecommontypesofSCPspossessingconjugatedbonds arepolyacetylene,polypyrrole(PPy),polyaniline(PANI),polyphenylacetylene (PPA),andtheirderivatives.However,thevalueofelectricalconductivityforthe conjugatedpolymermaterialsisrelativelysmall,usuallyrangingfrom10 10 to 10 5 Scm 1 .Theelectricalconductivityofpolymermaterialscanbeenhanced by104 Scm 1 bydopingvariousmoleculeslikesaltions,hyaluronicacid,and peptides[6,7].ThedopedSCPsshowbothelectricalconductingpropertyfrom metallicmaterialandmanymeritslikeflexibility,lightweight,etc.,frompolymer material.Therefore,TheSCPshavedemonstratedtheirpotentialapplicationsin flexibleelectronics,sensors,andEMIshielding[8–10].However,theSCPshave theirinherentdeficienciesincludingpoorsolubility,mechanicalproperties,and highcost.Usually,furthermodificationorcompoundingwithotherpolymersis neededtoimprovetheiroverallperformance[11].

CPCsrefertoonekindofelectricallyconductivepolymercompositematerials fabricatedbyincorporatingtheconductivefillers[carbonblack(CB),carbon nanotubes(CNTs),graphene,etc.]intoinsulatingpolymermatrix[12–14].The electricalconductivityofCPCsishighlyrelatedwiththepercolatedconductive PolymerNanocompositeMaterials:ApplicationsinIntegratedElectronicDevices, FirstEdition. EditedbyYeZhouandGuanglongDing. ©2021WILEY-VCHGmbH.Published2021byWILEY-VCHGmbH.

2FabricationofConductivePolymerCompositesandTheirApplicationsinSensors networkconstructedbydifferentconductivenanofillers.Itisbelievedthatmostof theresistancecomesfromtunnelingbetweenadjacentconductivefillersdispersed inpolymermatrix[15].CPCsbasedonnon-conductivepolymerelastomersand conductivefillershavecausedwideconcernofbothacademicandindustrialgroup andbecomeahottopicofpolymercompositesduetoitseasypreparation,controllableelectricalproperty,excellentflexibility,andstretchability.Inthischapter,we systematicallyintroducethedevelopmentandprospectofCPCsthroughseveral partsincludingthefabricationmethodofCPCs,morphology,andmicrostructureof CPCsandtheirapplicationassensors.

2.2FabricationMethodsforCPCs

Asknown,conductivefillers,especiallynano-sizedconductiveparticles,areeasy toaggregateinthepolymerduetotheirhigh-aspect-ratio,resultinginuneven distribution,whichmaydeterioratethecomprehensiveperformanceofCPCs[16]. Therefore,surfacemodificationofnanofillersandspecialprocessingtechnique arerequiredtoenhancethedispersionofconductivenanofillersinthepolymer, whichmainlyincludesthefollowingmethods:(i)Thephysicalblending[17]. Theconductiveparticlesareuniformlydispersedintothepolymermeltmatrixor polymersolutionundertheultra-strongexternalfieldforces(shear,tensile,etc.). (ii)Insitupolymerization[18].Theconductiveparticleswerefirstlydispersedin theorganicsolventcontainingthepolymermonomer.Afterthepolymerization reaction,thepreviouslyevenlydispersedconductiveparticleswereanchoredinthe polymermatrixinsitu.(iii)Chemicalmodificationofconductivefiller[19].After thechemicalreaction,thesurfaceofconductiveparticlesisgraftedwithfunctional groupssuchashydroxylgroup,carboxylgroup,aminogroup,etc.Thesegroups havegoodinteractionswiththepolymer,suchascovalentbondandhydrogen bond,whichcaneffectivelyavoidthenanofillersaggregationandhenceimprove theirdispersioninthepolymermatrix.(iv)Introductionofsurfactant[20].The surfactantwillwraparoundtheconductiveparticles,increasingtheircompatibility inpolymersolutionormelt,thusimprovingthedispersionofthefillers.

ForCPCs,theelectricalconductivityisdependedonthetransportationofcharge carriers(current)alongtheconductivenetworkconstructedbyconductivefillersin thepolymermatrix.Generally,asuddenincreaseofseveralordersofmagnitudein conductivity(transitionfrominsulatortoconductor)canbefoundastheconcentrationofconductingphasereachesacriticalvalueinthepolymermatrix,whichis definedasthepercolationthreshold.Abovethisthreshold,theconcentrationdependenceoftheconductivityoftheCPCs(σ)canbedescribedbyascalinglaw

where σ0 representstheintrinsicconductivityofthefillers, t representsthe electricalconductivityexponent, �� representsthevolumefractionofconductive particles,and ��c representsthevolumefractionatpercolationtransition[21].Ina randomconductingnetwork,theexponent t onlydependsonthedimensionality