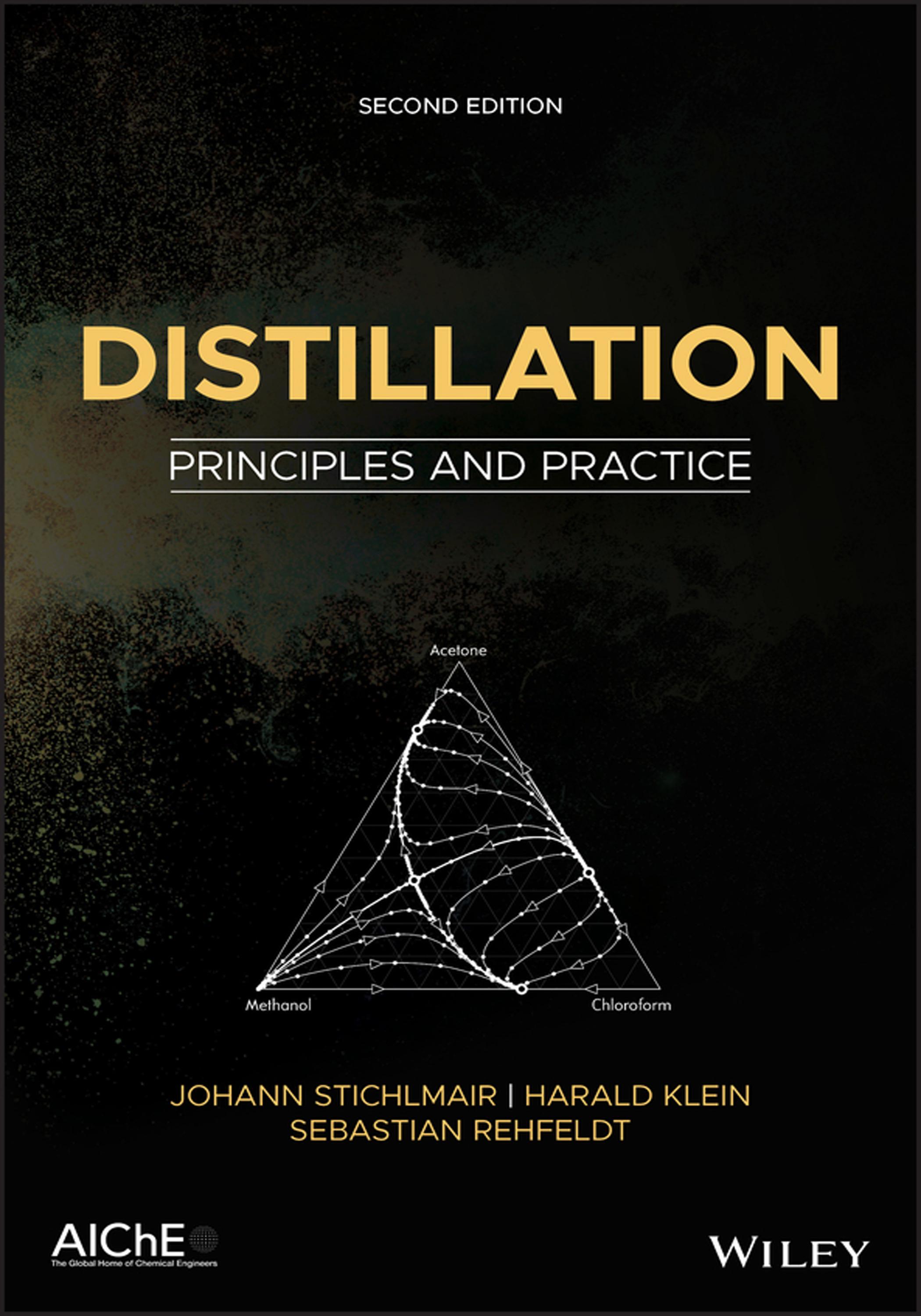

DISTILLATION

Principles and Practice

SecondEdition

Prof.Dr.-Ing.JOHANNSTICHLMAIR

Prof.Dr.-Ing.HARALDKLEIN

Dr.-Ing.SEBASTIANREHFELDT

Copyright©2021byAmericanInstituteofChemicalEngineers,Inc.Allrightsreserved. AJointPublicationoftheAmericanInstituteofChemicalEngineersandJohnWiley&Sons,Inc.

PublishedbyJohnWiley&Sons,Inc.,Hoboken,NewJersey.

EditionHistory Wiley-VCH(1e,1998)

Allrightsreserved.Nopartofthispublicationmaybereproduced,storedinaretrievalsystem,ortransmitted, inanyformorbyanymeans,electronic,mechanical,photocopying,recordingorotherwise,exceptas permittedbylaw.Adviceonhowtoobtainpermissiontoreusematerialfromthistitleisavailableat http://www.wiley.com/go/permissions.

TherightofProf.Dr.-Ing.JohannStichlmair,Prof.Dr.-Ing.HaraldKlein,andDr.-Ing.SebastianRehfeldtto beidentifiedastheauthorsofthisworkhasbeenassertedinaccordancewithlaw.

RegisteredOffice

JohnWiley&Sons,Inc.,111RiverStreet,Hoboken,NJ07030,USA

EditorialOffice 111RiverStreet,Hoboken,NJ07030,USA

Fordetailsofourglobaleditorialoffices,customerservices,andmoreinformationaboutWileyproductsvisit usatwww.wiley.com.

Wileyalsopublishesitsbooksinavarietyofelectronicformatsandbyprint-on-demand.Somecontentthat appearsinstandardprintversionsofthisbookmaynotbeavailableinotherformats.

LimitofLiability/DisclaimerofWarranty

Inviewofongoingresearch,equipmentmodifications,changesingovernmentalregulations,andtheconstant flowofinformationrelatingtotheuseofexperimentalreagents,equipment,anddevices,thereaderisurgedto reviewandevaluatetheinformationprovidedinthepackageinsertorinstructionsforeachchemical,pieceof equipment,reagent,ordevicefor,amongotherthings,anychangesintheinstructionsorindicationofusage andforaddedwarningsandprecautions.Whilethepublisherandauthorshaveusedtheirbesteffortsin preparingthiswork,theymakenorepresentationsorwarrantieswithrespecttotheaccuracyorcompleteness ofthecontentsofthisworkandspecificallydisclaimallwarranties,includingwithoutlimitationanyimplied warrantiesofmerchantabilityorfitnessforaparticularpurpose.Nowarrantymaybecreatedorextendedby salesrepresentatives,writtensalesmaterialsorpromotionalstatementsforthiswork.Thefactthatan organization,website,orproductisreferredtointhisworkasacitationand/orpotentialsourceoffurther informationdoesnotmeanthatthepublisherandauthorsendorsetheinformationorservicestheorganization, website,orproductmayprovideorrecommendationsitmaymake.Thisworkissoldwiththeunderstanding thatthepublisherisnotengagedinrenderingprofessionalservices.Theadviceandstrategiescontainedherein maynotbesuitableforyoursituation.Youshouldconsultwithaspecialistwhereappropriate.Further,readers shouldbeawarethatwebsiteslistedinthisworkmayhavechangedordisappearedbetweenwhenthiswork waswrittenandwhenitisread.Neitherthepublishernorauthorsshallbeliableforanylossofprofitorany othercommercialdamages,includingbutnotlimitedtospecial,incidental,consequential,orotherdamages.

LibraryofCongressCataloging-in-PublicationData

Names:Stichlmair,Johann,author.|Klein,Harald,author.|Rehfeldt, Sebastian,author.

Title:Distillation:principlesandpractice/JohannStichlmair,Harald Klein,SebastianRehfeldt.

Description:Secondedition.|Hoboken,NewJersey:Wiley-AIChE,[2021]| Includesbibliographicalreferencesandindex.

Identifiers:LCCN2020024694(print)|LCCN2020024695(ebook)|ISBN 9781119414667(cloth)|ISBN9781119414698(adobepdf)|ISBN 9781119414681(epub)

Subjects:LCSH:Distillation.

Classification:LCCTP156.D5S852021(print)|LCCTP156.D5(ebook)| DDC 660/.28425–dc23

LCrecordavailableathttps://lccn.loc.gov/2020024694

LCebookrecordavailableathttps://lccn.loc.gov/2020024695

Coverimage:©MinaDeLaO/GettyImages CoverdesignbyWiley

Setin9.5/12.5ptTeXGyreTermesbySPiGlobal,Chennai,India 10987654321

2.1.3MolarMixingandPartialMolarStateVariables

2.1.4SaturationVaporPressureandBoilingTemperatureofPureComponents

2.1.5FundamentalEquationandtheChemicalPotential

2.1.6Gibbs–DuhemEquationandGibbs–HelmholtzEquation

2.2CalculationofVapor–LiquidEquilibriuminMixtures

2.2.1BasicEquilibriumConditions

2.2.2GibbsPhaseRule

2.2.3CorrelationsfortheChemicalPotential

2.2.4CalculatingActivityCoefficientswiththeMolarExcessFreeEnergy ................

2.2.5ThermodynamicConsistencyCheckofMolarExcessFreeEnergyandActivity Coefficients

2.2.6Iso-fugacityCondition ..............................................................

2.2.7FugacityoftheLiquidPhase

2.2.8FugacityoftheVaporPhase

2.2.9Vapor–LiquidEquilibriumUsinganEquationofState

2.2.10FugacityofPureLiquidasStandardFugacity:Raoult’sLaw 47

2.2.11FugacityofInfinitelyDilutedComponentasStandardFugacity:Henry’sLaw 48

2.2.12CorrelationsDescribingtheMolarExcessFreeEnergyandActivityCoefficients 49

2.2.13UsingExperimentalDataofBinaryMixturesforCorrelationsDescribingtheMolar ExcessFreeEnergyandActivityCoefficients

2.2.14Vapor–LiquidEquilibriumRatioofMixtures

2.2.15RelativeVolatilityofMixtures

2.2.16BoilingConditionofLiquidMixtures

2.2.17Condensation(DewPoint)ConditionofVaporMixtures

2.3BinaryMixturesandPhaseDiagrams

2.3.1BoilingCurveCorrelation

2.3.3 (

(T , x , y )-Diagram

2.3.5McCabe–ThieleDiagram

2.3.6BoilingandCondensationBehaviorofBinaryMixtures

2.3.7GeneralAspectsofAzeotropicMixtures

2.3.8LimitingCasesofBinaryMixtures

2.4TernaryMixtures

2.4.1BoilingandCondensationConditionsofTernaryMixtures

2.4.5DerivationofDistillationLines

3.1ContinuousClosedDistillationandCondensation

3.1.1ClosedDistillationofBinaryMixtures

3.1.2ClosedDistillationofMulticomponentMixtures

3.2BatchwiseOpenDistillationandOpenCondensation

3.2.1BinaryMixtures

3.2.2TernaryMixtures

3.2.3MulticomponentMixtures

3.3Semi-continuousSingle-StageDistillation

3.3.1Semi-continuousSingle-StageDistillationofBinaryMixtures

4MultistageContinuousDistillation(Rectification)

4.1Principles

4.1.1Equilibrium-StageConcept

4.1.2Transfer-UnitConcept

4.1.3ComparisonofEquilibrium-StageandTransfer-UnitConcepts

4.2MultistageDistillationofBinaryMixtures

4.2.1CalculationsBasedonMaterialBalances

4.2.2CalculationBasedonMaterialandEnthalpyBalances

4.2.3DistillationofBinaryMixturesatTotalRefluxandReboil

4.2.4DistillationofBinaryMixturesatMinimumRefluxandReboil

4.2.5EnergyRequirementforDistillationofBinaryMixtures

4.3MultistageDistillationofTernaryMixtures

4.3.1CalculationsBasedonMaterialBalances

4.3.2DistillationofTernaryMixturesatTotalRefluxandReboil

4.3.3DistillationofTernaryMixturesatMinimumRefluxandReboil

4.3.4EnergyRequirementofTernaryDistillation

4.4MultistageDistillationofMulticomponentMixtures

4.4.1RigorousColumnSimulation

5ReactiveDistillation,CatalyticDistillation

5.1Fundamentals

5.1.1ChemicalEquilibrium

5.1.2StoichiometricLines

5.1.3Non-reactiveandReactiveDistillationLines

5.1.4ReactiveAzeotropes

5.2TopologyofReactiveDistillationLines

5.2.1ReactionsinTernarySystems

5.2.2ReactionsinTernarySystemswithInertComponents

5.2.3ReactionswithSideProducts

5.2.4ReactionsinQuaternarySystems

5.3TopologyofReactiveDistillationProcesses

5.3.1SingleProductReactions

5.3.2DecompositionReactions

5.3.3SideReactions

5.4ArrangementofCatalystsinColumns

5.4.1HomogeneousCatalyst

5.4.2HeterogeneousCatalyst

6MultistageBatchDistillation

6.1BatchDistillationofBinaryMixtures

6.1.1OperationwithConstantReflux

6.1.2OperationwithConstantDistillateComposition

6.1.3OperationwithMinimumEnergyInput

6.1.4ComparisonofEnergyRequirementforDifferentModesofDistillation

6.2BatchDistillationofTernaryMixtures

6.2.1ZeotropicMixtures

6.2.2AzeotropicMixtures

6.3BatchDistillationofMulticomponentMixtures

6.4InfluenceofColumnLiquidHold-uponBatchDistillation

6.5ProcessesforSeparatingZeotropicMixturesbyBatchDistillation

6.5.1TotalSlopCutRecycling

6.5.2BinaryDistillationoftheAccumulatedSlopCuts

6.5.3RecyclingoftheSlopCutsattheAppropriateTime

6.5.4CyclicOperation

6.6ProcessesforSeparatingAzeotropicMixturesbyBatchDistillation

6.6.1ProcessesinOneDistillationField

6.6.2ProcessesinTwoDistillationFields

6.6.3ProcessSimplifications

6.6.4HybridProcesses

7EnergyEconomizationinDistillation

7.1EnergyRequirementofSingleColumns

7.1.1ReductionofEnergyRequirement

7.1.2ReductionofExergyLosses

7.2OptimalSeparationSequencesofTernaryDistillation

7.2.1ProcessandEnergyRequirementofthe

7.2.2ProcessandEnergyRequirementofthe

7.2.3ProcessandEnergyRequirementofthePreferred

7.3ModificationsoftheBasicProcesses

7.3.1Material(Direct)CouplingofColumns

7.3.2ProcesseswithSideColumns

7.3.3Thermal(Indirect)CouplingofColumns

7.4DesignofHeatExchangerNetworks

7.4.1OptimumHeatExchangerNetworks

7.4.2ModifyingtheOptimumHeatExchangerNetwork

7.4.3DualFlowHeatExchangerNetworks

7.4.4ProcessModifications

8IndustrialDistillationProcesses

8.1ConstraintsforIndustrialDistillationProcesses

8.1.1FeasibleTemperatures

8.1.2FeasiblePressures

8.1.3FeasibleDimensionsofColumns

8.2FractionationofBinaryMixtures

8.2.1RecyclingofDilutedSulfuricAcid

8.2.2AmmoniaRecoveryfromWastewater

8.2.3HydrogenChlorideRecoveryfromInertGases

CONTENTS

8.2.4LindeProcessforAirSeparation

8.2.5ProcessWaterPurification

8.2.6SteamDistillation

8.3FractionationofMulticomponentZeotropicMixtures

8.3.1SeparationPaths

8.3.2ProcesseswithSideColumns 431

8.4FractionationofHeterogeneousAzeotropicMixtures

8.5FractionationofAzeotropicMixturesbyPressureSwingProcesses

8.6FractionationofAzeotropicMixturesbyAdditionofanEntrainer 439

8.6.1ProcessesforSystemsWithoutDistillationBoundary

8.6.2ProcessesforSystemswithDistillationBoundary 444

8.6.3HybridProcesses 455

8.7IndustrialProcessesofReactiveDistillation

8.7.1SynthesisofMTBE

8.7.2SynthesisofMono-ethyleneGlycol 471

8.7.3SynthesisofTAME 473

8.7.4SynthesisofMethylAcetate 474

9DesignofMassTransferEquipment

9.1TypesofDesign

9.1.1TrayColumns

9.1.2PackedColumns

9.1.3CriteriaforUseofTrayorPackedColumns

9.2DesignofTrayColumns

9.2.1DesignParametersofTrayColumns

9.2.2OperatingRegionofTrayColumns

9.2.3Two-PhaseFlowonTrays 497

9.2.4MassTransferintheTwo-PhaseLayeronColumnTrays 518

9.3DesignofPackedColumns 533

9.3.1DesignParametersofPackedColumns 534

9.3.2OperatingRegionofPackedColumns 545

9.3.3Two-PhaseFlowinPackedColumns 549

9.3.4MassTransferinPackedColumns 568

9.AAppendix:PressureDropinPackedBeds 587

10ControlofDistillationProcesses 601

10.1ControlLoops 602

10.1.1SingleControlLoop 602

10.1.2RatioControlLoop 604

10.1.3DisturbanceFeedforwardControlLoop 604

10.3.1BasicControlSystemsWithoutCompositionControl

10.3.2One-PointCompositionControlConfigurations

10.4.2SharpSeparationsofIdealMixtureswithConstantRelativeVolatilityatMinimum RefluxandBoilupRatio

10.4.3ExtendedApplicationRangesoftheBasicControlConfigurations

10.5.4AzeotropicDistillationProcessbyUsinganEntrainer

Preface

Distillationisthemostimportantandthemosteffectivetechnologyforthefractionationofmulticomponentmixtures.Fieldsofapplicationareallbranchesoftheprocess industry,forinstance,petroleumrefineries,chemicalindustries,andfoodindustries. Theoftenverytalldistillationtowersdominatetheviewofmanychemicalsites.Accordingtoitsgreatimportance,distillationisahighlydevelopedtechnology.

Thefundamentalmechanismofdistillationisthemasstransferbetweenagaseous andaliquidphase.Thedrivingforceforthisinterfacialmasstransferisthedifference betweentheactualandtheequilibriumconcentrationofthephases.

Thebookconsistsof10chapters.Chapter1dealswiththebasicprincipleofdistillationandwithsomehistoricalaspectsoftheart.

Chapter2concentratesonthethermodynamicsofvapor–liquidequilibrium,since agoodknowledgeofvapor–liquidequilibriumisanindispensableprerequisiteforthe designofdistillationprocesses.Ascomparedtomanyothertextbooks,themixtures arenotlimitedtotwocomponents,butternarymixturesalongwiththeirboiling surfacesandtriangulardiagramsareconsidered.

TheChapters3–6dealwiththethermodynamicsofsingle-stagedistillation (Chapter3)andmulti-stagedistillation(Chapter4),whichisoftencalledrectification,reactivedistillation(Chapter5),andbatchdistillation(Chapter6).Special attentionisgivenasdescribedabovetoternarymixtures,sincetheyrepresentamore generalcasethanbinarymixturesmosttextbooksondistillationfocuson.

InChapter7theenergyrequirementofdistillationprocessesisdiscussed.This chapterdemonstrateshowthelargeenergyrequirementofdistillationprocessescan bedrasticallyreducedbyinternalcolumncouplingandintelligentprocessmodifications.

ImportantexamplesofindustrialdistillationprocessesarepresentedinChapter8. Here,specialattentionisgiventoprocessesforthefractionationofazeotropicmixtures.

ThedesignofdistillationcolumnsistreatedinChapter9withfocusontray columnsandpackedcolumns.Finally,thecontrolofdistillationcolumnsisthe objectiveofChapter10wheretheconceptofsplitstreamcontrolisapplied.

Theprimeintentionofthistextbookistoletthereaderdevelopadeepunderstandingoftheartofdistillation.Manyfullyworkedoutexamplesdemonstratetheeasy applicabilityofthetheoreticalfindings.Theseexamplesarearrangedinboxesto

facilitatethereadabilityofthetext.

Ofcourse,notonlytheauthorsareinvolvedinthecompletionofsuchacomprehensivebook.Atthispointwewouldliketothankeveryonewhocontributedtothesuccessofthisproject:FelicitasEngel,M.Sc.,PhilippFritsch,M.Sc., PatrickHaider,M.Sc.,FlorianHanusch,M.Sc.,RobertKender,M.Sc.,ThomasKleiner,M.Sc.,MaximilianNeumann,M.Sc.,Dr.-Ing.AnnaReif,MarcXia,M.Sc., AlexanderEder,B.Sc.,FlorianKaufmann,M.Sc.,andJanOettig,B.Sc.,aswellas thevaluableexpertiseofDr.-Ing.VolkerEngel.ManythanksalsotoStephanKorell forhishelpfuladviceontheLATEXimplementation.

JohannStichlmair, HaraldKlein, SebastianRehfeldt

Munich,February2020

Nomenclature

LatinSymbols

a lowboiler –

a specificsurfacearea m2/m3

aeff specificeffectiveinterfacialarea m2/m3

a/v2 cohesionpressurevanderWaalsequation Pa

a coefficientcubicequationofstateofmixture J m3/kmol2

aii coefficientcubicequationofstateofpurecomponent i J · m3/kmol2

aij crosscoefficientcubicequationofstateofcomponent i and j J · m3/kmol2

ai activityofcomponent i –

A area m2

Ai AntoineorWagnerparameterofcomponent i –

Aij binaryparameterMargulesandvanLaarequationofcomponent i and j –

b highboiler(binarymixture)orintermediate boiler(ternarymixture) –

b constant –

b co-volumevanderWaalsequation m3

b coefficientcubicequationofstateofmixture m3/kmol

bi coefficientcubicequationofstateofpurecomponent i m3/kmol

B moleamountofbottomproduct kmol

B widthofpackingchannelbase m ˙

B bottomflowrate kmol/s

B virialcoefficientofmixture m3/kmol

NOMENCLATURE

Bi AntoineorWagnerparameterofcomponent i –

Bii virialcoefficientofpurecomponent i m3/kmol

Bij crossvirialcoefficientofcomponent i and j m3/kmol

c highboiler(ternarymixture)orintermediate boiler(quaternarymixture) –

c specificormolarheatcapacity J/(kg K) J/(kmol K)

c,C constant –

C secondmixturevirialcoefficientofmixture m6/kmol2

Ci AntoineorWagnerparameterofcomponent i –

CG capacityfactor m/s

Ch empiricpackingfactor –

d highboilerquaternarymixture –

d diameter,distance m

D diameter m

D diffusioncoefficient m2/s

D moleamountofoverheadproduct(distillate) kmol

˙ D overhead(distillate)flowrate kmol/s

DE dispersioncoefficient(eddydiffusioncoefficient) m2/s

Di Wagnerparameterofcomponent i –

e entrainer –

EOG overallgas-sidepointefficiency –

EOGM overallgas-sidetrayefficiency –

E exergy J

f frictionfactor –

fi fugacityofcomponent i Pa

f 0 i standardfugacityofcomponent i Pa

FF -factor(gasload) Pa0 5

F moleamountoffeed kmol

F feedflowrate kmol/s

Fi surfaceareafraction/molefractionUNIQUAC equationofcomponent i –

g gravitationalacceleration g =9.81m/s2 m/s2

g molarGibbsfreeenergy J/kmol

gi gasflowrateofcomponent i kmol/s

gi partialmolarGibbsfreeenergyofcomponent i J/kmol

NOMENCLATURE

∆g molarmixingGibbsfreeenergy J/kmol

gE molarexcessfreeenergy J/kmol

gE i partialmolarexcessfreeenergyofcomponent i J/kmol

∆gij binaryparameterNRTLequationofcomponent i and j –

G moleamountofvapor kmol

˙ G gas/vaporflowrate kmol/s

G Gibbsfreeenergy J

GE excessfreeenergy J

Gij binaryparameterNRTLequationofcomponent i and j –

h specificormolarenthalpy J/kg J/kmol

hi partialmolarenthalpyofcomponent i J/kmol

∆h molarmixingenthalpy J/kmol

h height m

hdyn dynamichold-up

m3/m3

hdyn0 dynamichold-upbelowloadingpoint m3/m3

hf frothheight m

hL clearliquidheight m

hL liquidhold-up m3/m3

hp heightofpressuredrop m

hstat statichold-up m3/m3

hw weirheight m

H enthalpy J

˙ H enthalpyflowrate W

H trayspacingorpackingheight m

Hij Henrycoefficientofcomponent i incomponent j Pa

HL molarhold-upofliquid kmol

HETP heightequivalenttoonetheoreticalplate m

HTU heightofatransferunit m

J strippingfactor –

k numbersofcomponentsinmixture –

k masstransfercoefficient kmol/(m2 s)

kij binaryparametercubicequationofstateof component i and j –

NOMENCLATURE

Ki vapor–liquidequilibriumratioofcomponent i –

KR reactionequilibriumconstant –

l (path)length m

li liquidflowrateofcomponent i kmol/s

L amountofliquid kmol

L liquidflowrate kmol/s

Lp wettedperimeter m

m slopeofequilibriumcurve –

m exponent –

M mass kg

M moleamountofmixtureinthemiddlevessel kmol

ˆ M molecularweight kg/kmol

˙ M mixtureflowrate kmol/s

n numberofequilibriumstages –

n exponent –

N moleamount kmol

N molarflowrate kmol/s

NTU numberoftransferunits –

p pitch m

p pressure Pa

pi partialpressureofcomponent i Pa

p0 i saturationvaporpressureofpurecomponent i Pa

p+ referencepressure Pa

Ph numberofphases –

Poy i Poyntingcorrectionofcomponent i –

qi relativevanderWaalssurfaceUNIQUACequationofcomponent i –

qF caloricfactor(thermalstate)ofthefeed –

Q heat J

Q dimensionlessconcentrationchange –

Q heatflow W

ri relativevanderWaalsvolumeUNIQUACequationofcomponent i –

r molarlatentheatofvaporization J/kmol

ˆ R idealgasconstant ˆ R =8314J/(kmol · K)J/(kmol · K)

R reactoreffluentflowrate kmol/s

RG externalreboil(boilup)ratio –

NOMENCLATURE

RL externalrefluxratio –

s molarentropy J/(kmol K)

s platethickness m

S lengthofpackingchannelside m

˙ S molarflowrateafterdecanter,sideproduct kmol/s

S entropy J/K

S correctionfactor(Example2.2) –

t time s

T temperature K

T 0 i boilingtemperatureofpurecomponent i K

u superficialvelocity m/s

∆uij binaryparameterUNIQUACequationofcomponent i and j –

U internalenergy J

v molarvolume m3/kmol

vi partialmolarvolumeofcomponent i m3/kmol

∆v molarmixingvolume m3/kmol

V volume m3

˙ V volumetricflowrate m3/s

Vi volumefraction/molefractionUNIQUACequationofcomponent i –

wi mass(weight)fractionofcomponent i –

wiG massfractionofcomponent i ingasphase kg/kg

wiL massfractionofcomponent i inliquidphase kg/kg

W work J

xi molefractionliquidphaseofcomponent i –

xi transformedmolefractioncompletechemical reactionofcomponent i –

X function

Xi transformedconcentrationofcomponent i in reactivesystems –

yi molefractionvaporphaseofcomponent i –

yi estimatedmolefractionvaporphaseofcomponent i (Example2.3)

z numberofinteractingmoleculesUNIQUAC equation –

NOMENCLATURE

z numberofparticlesorchannels –

z locus,dimensionlesstraylength –

zi molefractiontwo-phasemixtureofcomponent i –

Z compressibilityfactor –

Zf numberofindependentstatevariables(degrees offreedom) –

GreekSymbols

α dischargecoefficient –

αi(T ) temperaturefunctioncubicequationofcomponent i –

αij non-randomnessfactorNRTLequationofcomponent i and j –

αij relativevolatility(separationfactor)ofcomponent i and j –

β masstransfercoefficient m/s

γL liquid-phasedistribution –

∆ difference

∆p pressuredrop Pa

∆ densitydifference kg/m3

∆SgE sumofsquaresfor gE J2/kmol2

∆λij binaryparameterWilsonequationofcomponent i and j –

ε porosity,voidage,relativecontent –

ζ dragcoefficient,orificecoefficient –

ζE frictionfactorinErgunequation –

η dynamicviscosity Pa s

ϑ contactangle °

π poleontheenthalpy–concentrationdiagram J/mol

π circleconstant π =3.14159 –

Λij binaryparameterWilsonequationofcomponent i and j –

µi chemicalpotentialofcomponent i J/kmol density kg/m3

σ surfacetension kg/s2

NOMENCLATURE

τ contacttime s

τL liquidresidencetimeinthetwo-phaselayer s

ϕ relativefreeareaofatray –

ϕi fugacitycoefficientofcomponent i

φj correctionfactorofcomponent i

Φ Underwoodparameter

Φfl floodingfactor –

γi activitycoefficientofcomponent i

γ∞ i activitycoefficientatinfinitedilutionofcomponent i

νi stoichiometriccoefficientofcomponent i

ωi acentricfactorofcomponent i

τij binaryparameterNRTLandUNIQUACequationofcomponent i and j

Subscripts

a lowboiler

ac active

azeo azeotrope

b highboiler(binarymixture)orintermediateboiler(ternarymixture)

B bottomproduct

c highboiler(ternarymixture)orintermediateboiler(quaternary mixture)

c criticalstatevariable

c column

c continuousphase

cap bubblecap

cl clearanceunderdowncomer

cr critical

C condenser,cooling

d highboilerquaternarymixture

d dispersedphase

d downcomer

d dry

D overheadproduct(distillate)

e end

e entrainer

eq equivalent

E entrainment

Exp experimentalvalue

f froth

fl flooding

F feed

Fr Froudenumber

G gas

h hole

h hydraulic

H heating

irr irrigated

j stagenumber

k numberofcomponents

lam laminar

L liquid

m intermediate

m mean

max maximum

min minimum

n numberofplatesorsteps

n nominal

o openings

o overflow

OG overallgasphase

OL overallliquidphase

p particle

P pinchpoint

r residual

r reducedstatevariable(relatedtocriticalstatevariable)

R reboiler

s packingsection

s particleswarm

S solid

SP sidepinch

NOMENCLATURE

NOMENCLATURE

t plate/tray

turb turbulent

T transitionpoint

vc venacontracta

v valve

w weir

α start

ω end

0 orifice,singleparticle

∞ infinity

Superscripts

0 purecomponent

azeo azeotrope

C combinatorialpartUNIQUACequation

E excessstatevariable id idealgas id0 pureidealgas

n iterationsteporstepondistillationline new newestimate(Example2.3)

R residualpartUNIQUACequation liquidphase vaporphase

ˆ molar

∗ equilibriumstate modified

Abbreviations

A-1absorber

C-1column

E-1heatexchanger,extractor

R-1reactor

S-1decanter

DimensionlessNumbers

Bo = g σ · a2

Fr = u2 g d

Pe = l2 D · τ

Re = u d η

Sc = η D

We = u2 d σ

Bondnumber

Froudenumber

Pecletnumber

Reynoldsnumber

Schmidtnumber

Webernumber

NOMENCLATURE

1 Introduction

Distillationisawidelyusedmethodforseparatingliquidmixturesintotheircomponents.Itistheworkhorseforseparationinthepetroleum,petrochemical,chemical, andrelatedindustries.Theconsensusisthatitwillcontinuetodominatetheseindustriesinthefuture,too.

1.1PrincipleofDistillationSeparation

Distillationutilizesaverysimpleseparationprinciple:anintimatecontactiscreated betweenthestartingmixtureandasecondphaseinordertoenhanceaneffective masstransferbetweenthesetwophases.Thethermodynamicconditionsarechosen sothatprimarilythecomponenttobeseparatedfromthefeedmixtureentersthe secondphase.Thephasesaresubsequentlyseparatedintotwosinglephaseswith differentcompositions.

Threestepsarealwaysinvolvedintheimplementationofthisseparationprinciple; seeFigure1.1:

Figure1.1Generalprincipleoffractionationinthermalseparationtechnology.The essentialmechanismisthemasstransferbetweentwophases.

Distillation: Principles and Practice, Second Edition. Johann Stichlmair, Harald Klein, and Sebastian Rehfeldt. © 2021 American Institute of Chemical Engineers, Inc. Published 2021 by John Wiley & Sons, Inc.

1INTRODUCTION

• Generationofatwo-phasesystem

• Masstransferacrosstheinterface

• Separationofthephases

Manyseparationtechniquesutilizethisveryeffectiveseparationprinciple.Absorption,desorption,evaporation,condensation,anddistillationinvolveagaseousanda liquidphase.Solventextractionusestwoliquidphases.Separationtechniquesthat utilizeafluidphaseandasolidphaseincludeadsorption,crystallization,drying,and leaching.Inmostoftheseseparationprocesses,thenecessarytwo-phasesystemis generatedbyaddinganauxiliaryphasetothefeedmixture.Thesubstancestobe separatedcollectindilutedformintheauxiliaryagent.Indistillation,however,the secondphaseiscreatedbypartialvaporizationoftheliquidfeed.Hence,theuseof anauxiliarysubstance(oftencalledamassseparatingagent),whichrequirescostly recovery,isavoided,andthecomponentstobeseparatedarerecoveredasrelatively puresubstances.Indeed,distillationrequiresonlyenergyintheformofheat,which cansubsequentlybeeasilyremovedfromthesystem.Thisisanimportantadvantage ofdistillation.

Inpractice,distillationrequiresintimatecontactingofvaporandliquidundersuch conditionsthatthedesiredcomponentsoftheliquidenterthevaporphase.Governingtheseconditionsisthevapor–liquidequilibrium.Manyactivitiesontheart ofdistillationaredevotedtofindouthowcloselythevapor–liquidequilibriumcan beapproached.Inanycase,itisnecessarytoseparatetheliquidandvaporphases afterward.

Thevaporandliquidarebroughtintointimatecontactbycountercurrentorcrosscurrentflow,andmassexchangeoccursbecausethetwophasesarenotinthermodynamicequilibrium.Thephasesproducedduringdistillationareformedbyevaporationandcondensationoftheinitialmixture.Theseparationprocesscanbecontrolled onlybytheheatsupply.

Thebasisforplanningdistillationprocessesistheknowledgeofthevapor–liquid equilibrium.Asstatedearlier,theseparationdependsprimarilyontheconcentration oftheindividualsubstancesinthevaporandliquidphases.Inthisbook,principlesof vapor–liquidequilibriumarediscussedinChapter2,withspecialattentiongivento theequilibriumofternaryandmulticomponentmixtures.Thermodynamicanalysis ofdistillationandrectificationisessentialtoestablishtheoptimalconditionsformass transfer.Thedecisivefactoristhedrivingforceformasstransfer,i.e.thedifference betweentheactualconcentrationsofthesubstancesandtheirequilibriumconcentrations.Operatingconditionshavetoensurethatthisdifferenceissufficientlylarge. Appropriaterelationshipsandmethodsfordeterminingmasstransferaredescribed inChapters3–6.ExamplesofindustriallyimportantseparationprocessesandenergyrequirementarediscussedinChapters7and8,respectively.Sinceseparationis achievedbybringingthetwophasesintointimatecontact,inpractice,theproblems createdbymultiphaseflowandmasstransferbetweenphasesmustbeconfronted. Thestateoftheartofmultiphaseflowispresentlyratherpoor.Two-phaseandmultiphaseflowisanunderdevelopedfieldoffluidmechanics.Asaresult,justempirical approachesarepresentlyavailableforpracticalequipmentdesign,asdescribedin

Chapter9.Chapter10dealswiththecontrolofsingledistillationcolumnsandof distillationprocesses.

1.2Historical

Althoughseveralauthors(e.g. Krell 1958)supporttheviewthattheartofdistillationhasbeenwellknowntoancientGreece,thisopinionhasneverbeenproven byhistorians.Ancientphilosophershavebeen,however,veryclosebythecorrect understandingoftheprinciplesofdistillation,forinstance,atthemerephilosophical debateonthecirculationofwaterinnature.Aristoteles(384-322 BCE)writesinhis Meteorologia:"...severalauthorssupportasimilarviewontheoriginofrivers.The waterelevatedbythesunandasraincondensedhumiditycollects...".Inthesame book,hewriteslateron:"Thatevaporatedseawaterisdrinkableand,aftercondensation,doesnotbecomeseawateragain,thatcanwestatefromexperience."However, nopracticalapplicationsofthesetheoreticalconsiderationshavebeenreported,and nodeviceforperformingtheprocessofdistillationisdescribedinancientliterature. AncientEgyptandancientChinaaswellhadprobablynoknowledgeoftheartof distillation. Forbes 1970agreeswithseveralotherauthors(e.g. Underwood 1935) intheopinionthattheartofdistillationhasbeeninventedandpioneeredinusein Alexandria,Egypt,inthefirstcentury CE

Figure1.2Distillationandrectificationequipmenttakenfrom TheAlchemyofAndreas Libavius [Libavius 1964]:(a)boiler,(b)oven,(c)coolers,(d)receiver,(e)headpiece,and (f)receiver.

Inthefollowingcenturiestheknowledgeofdistillationspreadwidelyandwasused aroundtheeleventhcenturyforthefirsttimeinnorthernItalytoproducealcoholic beverages.Thedevelopmentofdistillationequipmenthasbeeninfluencedtremendouslybythisspecialfieldofapplication.Aninterestingdistillationequipment,de-

1INTRODUCTION

scribedinthebook TheAlchemyofAndreasLibavius,publishedin1597,isillustrated inFigure1.2[Libavius 1964];itwasusedforthebatchdistillationofalcohol.

Heatissuppliedtotheliquidcontentsoftheboiler(a),builtintotheoven(b),and thevaporformedwasallowedtocondenseintwocoolers(c).Coolingwaterwas changedperiodically.Theonlyvisibleprocesswasthedrippingofthecondensate intothereceiver(d).ThisseparationtechniquewasnamedaftertheLatinworddestillare,whichmeans"drippingortricklingdown".Eveninearlytimes,itwaswell knownthatahigheralcoholcontentcouldbereachedbyusingaseconddistillation step.IntheapparatusshowninFigure1.2,twodistillationscouldbecarriedoutsimultaneously.Condensatefromthefirstdistillationisreturnedtotheheadpiece(e), theso-calledrectificatorium,whichisheatedwithvaporrisingfromtheboiler.The vaporproducedintheheadpieceiscondensedinthetwocoolers(c).Aliquidwith ahigheralcoholcontentisthencollectedinasecondreceiver(f).Thetermrectificationisderivedfromthisprocess,which,especiallyinEurope,isusedtodescribe multistagedistillation.TheLatinwordsrectefaceremean"torectifyorimprove". Indeed,uptothisday,termrectificationreferstoaprocessbywhichafurtherconcentrationchangeisachievedafterthefirstevaporationstep.

Fromsuchdevicesdistillationcolumnshavebeenfinallydevelopedduringthe followingcenturies.Manyauthors(e.g. Underwood 1935; Forbes 1970)agree ingivingthecreditofinventiontotheFrenchmanCellier-Blumenthal[CellierBlumenthal 1818].Interestingarethecircumstancesthatenhancedthedevelopmentofimproveddistillationdevices.

In1807NapoleonorganizedablockadeagainstEngland,whichansweredbya blockadeagainsttheEuropeancontinent.Inconsequence,goodsfromtheoversea coloniesnolongerreachedEurope,whichresultedinshortagesofsugarcane,among manyothergoods.Itwaswellknownthatsugarcanbeproducedfrombeetsgrown inEuropeaswell[Ullmann 1969].However,thebrownsugarfrombeetswasmuch lessattractivetothenoblementhanthewhitesugarfromcanes.Napoleonopened acompetitionforproducingwhitesugarfrombeetsbysettingaveryhighprize. Afavorableprocesswasextractionofsugarfromthebeetsbyalcoholinsteadof water–aprocessproposedagaininrecentyears[Ullmann 1969].Thealcoholwas recycledwithinthisprocess.However,afterlongerperiodsofoperationtime,the alcoholneededpurificationsincesomewateraccumulatedinthealcohol.CellierBlumenthaldevelopedthefirstdistillationcolumn(atraycolumn)forthisprocess.

Inthenineteenthandtwentiethcenturies,theartofdistillationdevelopedrapidly promptedbytheoilandpetrochemicalindustry[Deibele 1992]andbythechemicalandpharmaceuticalindustry[Fair 1984].Thepresentimportanceofdistillation isdocumentedbythefactthatapproximately 40000 distillationcolumnsareunder operationintheUnitedStates[HumphreyandSeibert 1992].Thesecolumnsconsumeabout 3% ofthetotalenergyrequirementoftheUnitedStates[Gmehling etal. 1994].

REFERENCES 5

References

Cellier-Blumenthal,J.B.(1818).Brevet d’inventionetdeperfectionnementde quinzeans,pourdesappareilsdestinésàla distillationcontinueetàl’évaporation. FrenchPatentNo.2266.

Deibele,E.(1992).DieEntwicklungder Destillationstechnikim19.Jahrhundert. PhDthesis.TechnicalUniversityofMunich. Fair,J.R.(1984).Historicaldevelopmentof distillationequipment. AIChESymposium Series 79(235):1–14. Forbes,R.J.(1970). AShortHistoryoftheArt ofDistillation.Leiden:E.J.Brill. Gmehling,J.,Menke,J.,Krafczyk,J.,and Fischer,K.(1994). AzeotropicData,PartI andII.Weinheim:VCHPublishers. Humphrey,J.L.andSeibert,A.F.(1992).New

horizonsindistillation. Chemical Engineering 99(12):86. Krell,E.(1958). Handbuchder Laboratoriumsdestillation.Berlin:VEB DeutscherVerlagderWissenschaften. Libavius,A.(1964). DieAlchemiedesAndreas Libavius.EinLehrbuchderChemieausdem Jahre1597.Weinheim:VerlagChemie. Ullmann,F.(1969). UllmannsEnzyklopädie derTechnischenChemie,vol.19,p.201and p.217.MünchenBerlinWien:Urban& Schwarzenberg. Underwood,A.J.V.(1935).Thehistorical developmentofdistillingplant. Transactions –InstitutionsofChemicalEngineers 13: 34–63.