CorrosionPolicyDecisionMaking

CorrosionPolicyDecisionMaking

Science,Engineering,Management,andEconomy

Editedby

RezaJavaherdashti

EnincoEngineeringB.V. TheNetherlands

Thiseditionfirstpublished2022

©2022JohnWileyandSons,Inc.

Allrightsreserved.Nopartofthispublicationmaybereproduced,storedinaretrievalsystem,or transmitted,inanyformorbyanymeans,electronic,mechanical,photocopying,recordingor otherwise,exceptaspermittedbylaw.Adviceonhowtoobtainpermissiontoreusematerialfrom thistitleisavailableathttp://www.wiley.com/go/permissions.

TherightofRezaJavaherdashtitobeidentifiedastheauthoroftheeditorialmaterialinthiswork hasbeenassertedinaccordancewithlaw.

RegisteredOffice

JohnWiley&Sons,Inc.,111RiverStreet,Hoboken,NJ07030,USA

EditorialOffice

111RiverStreet,Hoboken,NJ07030,USA

Fordetailsofourglobaleditorialoffices,customerservices,andmoreinformationaboutWiley productsvisitusatwww.wiley.com.

Wileyalsopublishesitsbooksinavarietyofelectronicformatsandbyprint-on-demand.Some contentthatappearsinstandardprintversionsofthisbookmaynotbeavailableinotherformats.

LimitofLiability/DisclaimerofWarranty

Inviewofongoingresearch,equipmentmodifications,changesingovernmentalregulations,andthe constantflowofinformationrelatingtotheuseofexperimentalreagents,equipment,anddevices, thereaderisurgedtoreviewandevaluatetheinformationprovidedinthepackageinsertor instructionsforeachchemical,pieceofequipment,reagent,ordevicefor,amongotherthings,any changesintheinstructionsorindicationofusageandforaddedwarningsandprecautions.Whilethe publisherandauthorshaveusedtheirbesteffortsinpreparingthiswork,theymakeno representationsorwarrantieswithrespecttotheaccuracyorcompletenessofthecontentsofthiswork andspecificallydisclaimallwarranties,includingwithoutlimitationanyimpliedwarrantiesof merchantabilityorfitnessforaparticularpurpose.Nowarrantymaybecreatedorextendedbysales representatives,writtensalesmaterialsorpromotionalstatementsforthiswork.Thefactthatan organization,website,orproductisreferredtointhisworkasacitationand/orpotentialsourceof furtherinformationdoesnotmeanthatthepublisherandauthorsendorsetheinformationorservices theorganization,website,orproductmayprovideorrecommendationsitmaymake.Thisworkissold withtheunderstandingthatthepublisherisnotengagedinrenderingprofessionalservices.The adviceandstrategiescontainedhereinmaynotbesuitableforyoursituation.Youshouldconsultwith aspecialistwhereappropriate.Further,readersshouldbeawarethatwebsiteslistedinthiswork mayhavechangedordisappearedbetweenwhenthisworkwaswrittenandwhenitisread.Neither thepublishernorauthorsshallbeliableforanylossofprofitoranyothercommercialdamages, includingbutnotlimitedtospecial,incidental,consequential,orotherdamages.

LibraryofCongressCataloging-in-PublicationData

Names:Javaherdashti,Reza,editor.

Title:Corrosionpolicydecisionmaking:science,engineering,management, andeconomy/editedbyRezaJavaherdashti.

Description:Firstedition.|Hoboken,NJ:Wiley,2022.|Includes bibliographicalreferencesandindex.

Identifiers:LCCN2021031559|ISBN9781119764311(hardback)|ISBN 9781119764328(adobepdf)|ISBN9781119764335(epub)

Subjects:LCSH:Corrosionandanti-corrosives.

Classification:LCCTA462.C656752022|DDC620.1/1223–dc23

LCrecordavailableathttps://lccn.loc.gov/2021031559

CoverDesign:Wiley

CoverImage:©Phonix_aPk.sarote/Shutterstock

Setin9.5/12.5ptSTIXTwoTextbyStraive,Pondicherry,India 10987654321

To: NikolaTesla

Themanwhochangedtheworld

Contents

Preface xiii

AuthorsandContributors xv

1Introduction 1

RezaJavaherdashti References 5

2AShortReviewofSomeImportantAspectsoftheScienceof Corrosion 7

RezaJavaherdashtiandAliGhanbarzadeh

2.1Introduction 7

2.1.1EssentialsofElectrochemicalCorrosion 9

2.1.2PredictionofCorrosion 12

2.1.2.1StandardHydrogenElectrode/ElectrochemicalSeries 12

2.1.2.2GalvanicSeries 13

2.1.2.3PourbaixDiagrams 15

2.2ImportantTechnicalTreatmentStrategiesforCorrosionTreatment 16

2.2.1DesignModification-change/MaterialsSelection 17

2.2.2ChemicalTreatment 21

2.2.3ElectricalTreatment 22

2.2.4MechanicalTreatment 23

2.2.5PhysicalTreatment 23

2.2.5.1Paints,CoatingSystems,andPrematureDestructioninIndustrial Facilities 23

2.2.5.2FeaturesofSubstrate 24

2.2.5.3CharacteristicsoftheEnvironmentandLocalFeatures 26

2.2.5.4PaintsQualityControl 34

2.2.5.5PaintWarehousingandStorage 35

2.2.5.6RoleofExecutorsandContractors 36

2.2.5.7SurfacePreparation 36

2.2.5.8TechnicalPaintingOperations 39

2.2.5.9InspectionandManagement 41

2.3Conclusion 43 References 44

3SmartCorrosionManagementElements 47 RezaJavaherdashtiandFaranakJavaherdashti

3.1Introduction 47

3.1.1Risk,Importance,andHowTheyAreInterrelated? 48

3.1.2CorrosionManagement:WhatItIsandWhatItIsNot 56

3.1.3ManagementofCorrosion 58

3.1.3.1CorrosionReactionsGeometry 59

3.1.3.2Failure 60

3.1.3.3CorrosionPreventionandCorrosionControl 67

3.1.3.4CMModel 69

3.1.4Phase1:Definition 70

3.1.5Phase2:Application 73

3.1.6Phase3:Monitoring 74

3.1.7Phase4:Feedback 75

3.1.7.1CorrosionCostEstimationModel 76

3.1.7.2CorrosionKnowledgeManagement(CKM) 79

3.2ManagementofCorrosionandCOVID19 90

3.3Environment 93

3.4ApplicationofManagementofCorrosionSchemetoUndergroundFire WaterRing 96

3.5DamageManagement 99

3.6Algorithm 100

3.7FinalRemarks 104 References 107

4EconomicsandCorrosion 111 MahsaMostashar-Nezami

4.1Introduction 111

4.2Economics 112

4.2.1WhatIsEconomics 112

4.2.2GrossDomesticProduct 114

4.2.2.1TheExpenditureApproach 115

4.2.2.2TheIncomeApproach 117

4.2.2.3TheValue-AddedApproach 117

4.2.2.4Income,Consumption,Saving,andInvestment 117

4.2.2.5GrossNationalProduct 123

4.2.3IntroductiontoNationalAccount 123

4.2.3.1ProductionAccount,theIntermediateConsumption,andthe ConsumptionofFixedCapital 124

4.2.4NetPresentValue(NPV)andNetFutureValue(NFV) 128

4.2.5Input–OutputModelinEconomics 129

4.2.5.1TechnicalCoefficients 130

4.2.5.2PriceandtheInput–outputTable 135

4.2.5.3DynamicInput–outputAnalysis 137

4.2.6Depreciation,ConsumptionofFixedCapital,orCorrosion 137

4.3CorrosionEconomics 138

4.3.1Input–outputModelinCorrosion 138

4.3.1.1MatrixofTechnicalCoefficients 139

4.3.1.2MatrixofCapitalCoefficients 140

4.3.1.3Input–outputModel 142

4.3.1.4FinalDemand 143

4.3.1.5WorldI,WorldII,WorldIII 144

4.3.1.6EstimatingCorrosionCostbyBattelle 144

4.3.2LifeCycleCost(LCC) 149

4.3.2.1Life-CycleCostModel 149

4.4CorrosionandSustainability 152

4.5Conclusion 154

4.6Summary 155 References 155

5EffectiveManagementofProcessAdditives(EMPA) 159 MohamedrezaHamedghafarian

5.1Introduction 159

5.2AGasPlant 160

5.3Utilities 161

5.4ProcessAdditives(Chemicals) 165

5.5EffectiveManagementofProcessAdditives(EMPA) 175

5.5.1ProductionCosts 175

5.5.2QualityControl 175

5.5.3Corrosion 176

5.5.4Energy 177

5.5.5Environment 178

x Contents

5.5.6ProcessIssues 180

5.5.6.1ProductionReduction 180

5.5.6.2Off-specProducts 181

5.5.6.3OperationHistory1 202

5.5.6.4OperationHistory2 203

5.5.6.5OperationHistory3 214

5.5.6.6OperationHistory4 214

5.6MisleadingTrendswithCorrosionConclusions 215

5.6.1PhosphateSolutionPreparation(BoilerInternalTreatment) 215

5.6.2PuttingAKettle-typeReboilerintoServicethatHasBeenUnder Maintenance 219

5.6.3ProblemsinSamplingfromDeaeratorandOxygenScavenger Analyzation 220

5.6.4ProblemsinSamplingandAnalyzingSpecificConductivityfrom DemineralizedWater 222

5.6.5AnImproperSamplePointandMistakeinDeterminingFreeResidual Chlorine 223

5.7Chemicals,TheirCorrosion,andImpactsofTheirCorrosionsonthe Environment 225

5.7.1OperationHistory5 226

5.8ConfiguringEMPA 226

5.9SettingupanEMPA 229

5.9.1DescriptionofActivities 230

5.9.1.1Selection 230

5.9.1.2OperationHistory6 230

5.9.1.3OperationHistory7 232

5.9.1.4OperationHistory8 233

5.9.1.5OperationHistory9 234

5.9.1.6Procurement 236

5.9.1.7OperationHistory10 236

5.9.1.8OperationHistory11 237

5.9.1.9Delivery 237

5.9.1.10OperationHistory12 238

5.9.1.11OperationHistory13 239

5.9.2Storage 240

5.9.2.1OperationHistory14 241

5.9.2.2OperationHistory15 242

5.9.2.3OperationHistory16 242

5.9.2.4OperationHistory17 243

5.9.2.5OperationHistory18 244

5.10Consumption 245

5.10.1OperationHistory19 246

5.10.2OperationHistory20 246

5.10.3OperationHistory21 247

5.10.4OperationHistory22 248

5.10.5OperationHistory23 249

5.10.6OperationHistory24 249

5.10.7OperationHistory25 256

5.10.8OperationHistory26 257

5.10.9OperationHistory27 257

5.10.10OperationHistory28 259

5.11Reporting 259

5.12Documentation 260

5.13Summary 263

Abbreviations 263

References 265

6ApplicationofTRIZforCorrosionManagement 269 RezaJavaherdashtiandMehdiBasirzadeh

6.1Introduction 269

6.2BasicStructureofTRIZ 271

6.2.1TheEssenceofTRIZin50Words 273

6.3LevelofInvention 274

6.4HistoryofTRIZ 275

6.5AbouttheFounderofTRIZ 276

6.5.1GenrichSaulovichAltshuller 276

6.6ContradictionasaMeanstoFormulateanInventiveProblem 278

6.7ProcedureofInventiveDesign 280

6.8ConceptDevelopmentUsingTRIZ 281

6.9ContradictionMatrix(39×39) 283

6.9.1Listofthe39Features 284

6.9.2Listofthe40Principles 285

6.10UsingtheTRIZMatrix 286

6.10.1TRIZProblemSolvingMethodology 286

6.10.2Realityofthe “Four-BoxScheme” Theory 288

6.11PhysicalContradictionResolution 289

6.12IdealityandtheIdealFinalResult(IFR) 294

6.13TRIZCrossoverQMS 299

6.14TheEvolutionaryS-Curve 299

6.15NineWindows 301

6.16TrendsofEngineeringSystemEvolution 302

6.17GeometricEvolutionofLinearConstructions 305

6.18Trimming 306

6.18.1MakingThingsBetterandLessExpensive 306

6.19Input–Output–TrimmingOperator(I–O–T) 308

6.20ResourceAnalysis 310

6.21FunctionAnalysis 311

6.22Substance-FieldAnalysis 312

6.23Tool-Object-Product(TOP)FunctionAnalysis 312

6.24GenericModelofaFunction 314

6.24.1PreciseDescriptionofaFunction 315

6.24.2LinkbetweenFunctions 315

6.24.3IncreasingEffectivenessofFunctionAnalysis 315

6.25TRIZOffersFiveBasicFunctionModels 315

6.26PsychologicalInertia 315

6.27Size-Time–CostOperator 317

6.28Applyingthe40InventivePrinciplesinCorrosionManagement 318

6.29Conclusion 334

6.30GlossaryofTRIZTerms 334

6.ATRIZContradictionTable 339 References 345

7EnvironmentalImpactsofCorrosionandAssessmentStrategies 349 RezaJavaherdashti

7.1Introduction 349

7.1.1CharacterizationoftheDisaster 350

7.1.2WhyEnvironment? 352

7.1.3CorrosionImpactandCorrosionEffect 355

7.1.4ModelingEnvironmentalImpacts 356

7.1.4.1NecessaryElementsforConstructionofCorrosionImpact Modeling 358

7.2SomeUsesofRule365 363

7.2.1ApplicationofRule365toAssessCorrosionEffects 364

7.3Conclusions 365 References 365

Index 369

Preface

CorrosionManagement(CM)hasbecomeaveryhottopicthesedays.ManyprofessionalgroupsrelatedtocorrosionfromtheUSAtoAustraliainvitetheircorrosionexpertstogivelectures/webinarsonthistopic.Therearetwocommonpoints amongalltheselecturesandwebinars;oneisthatthelecturersspeakabouthowto addresscorrosionintheirownindustriesandpresumablymanageittoanaudiencewhoarethemselvescorrosionprofessionals,andtheotheristhattheinvited speakersarealwayscorrosionprofessionalsthemselves.Managementofmatter, thatinourunderstandingisequaltoCM,isnolessimportantthanmanagement ofenergy,andthereforeitmustbeexplainedinsuchawaythatnon-corrosionists alsounderstandandappreciateit.Namely,politicians,non-corrosionistengineers andprofessionals,economistsandenvironmentalistsmustalsorealizethesignificanceofcorrosionanditspropermanagement.

ThethemeofCMhasbecomesorepetitiveandpredictablethatonecanenvisage almosttheentiretyofthecontent:afewwordsabouttheeconomyofcorrosion (normallyborrowedfromfiguresgiveninsomewell-knownwebsites);afewwords aboutthesystems(s)inwhichcorrosionisofinterest(orrather,whatthespeaker hassomeexperienceabout);howthecorrosionhasbeenrecognizedandaddressed technicallyinthesesystems;andthenthesectionentitled “LessonstoLearn.”

However,noneofthesewebinarsorlecturespointoutmatterswhichareoutof “theboxofcorrosion”:therearenowordsabouttheimpactofthethermodynamic natureofcorrosionoritsmanagementandthedifficultiesitcreates,orhowto explainandcontrolecologicalmeasuresimposedbycorrosionandCMtechniques, noristhereanythingrelatedtohowcreativitycanbeanessentialissueinfinding solutionsforcorrosionproblems.

Thisbookisfirstofitskindthatlooksatcorrosionnotjustasatechnicalmatter butasamultidisciplinaryissuethatinvolvesmanyskillsandfaculties mainly non-technicalinthesensethatengineeringliteratureandnomenclatureareconsideredtechnical.

Inthisbookwehavetriedtoshowthatwhileduetothethermodynamicnature ofcorrosion,itcannotbestopped.Itisnecessarytorecognizemanymisunderstandingsassociatedwithcorrosion(suchasthedifferencebetweencorrosionpreventionandcorrosioncontrol)andredefinemanybasicconcepts(suchasthe conceptoffailurewithinthecontextofintroducingthetermspseudo-FFSand Zugzwangeffectstate)tounderstanditcorrectlyfromapracticalpointofviewthat canbecalledManagement.

WewouldalsoliketocallourapproachtowardCM “SmartManagementof Corrosion” inthesensethatithasthecapabilitytoadaptitselfwithallindustries, notjustafew,andalsobecausemanagementofcorrosionbenefitsfromcontributionsfrombothCMandCorrosionKnowledgeManagement(CKM).

Wehopeourreaderswillenjoyreadingthisbookasmuchaswedidwritingit andapplyingitsprinciplesinourdailyprofessionallives!

RezaJavaherdashti TheNetherlands

April2021 xiv Preface

AuthorsandContributors

R.Javaherdashti

• GeneralManager,EnincoEngineeringB.V.,TheNetherlands

• PhD(Materialsscience–Corrosion)

• Morethan25yearsofexperience;successfullydelivered400+projectsincorrosionmanagement,problem-solving,expert-witnessing,andRootCause Analysisinvariousindustriesglobally

• CertifiedcorrosionandMIClecturerbyASME(USA)andSocietyofPetroleum Engineers(USA)

• Performed5000+hoursofteachingcorrosionmanagementandMICtovarious industries(fromoil&gastomining,aviation,andchemicalindustries worldwide)

• Authored/co-authoredseveralinternationallyreferencedbooksoncorrosion (publishedbyElsevier,Springer,CRCPress,etc.)aswellasresearchpapersand RootCauseAnalysisreports

• E-mail:javaherdashti@enincoating.com

• LinkedInprofile:https://www.linkedin.com/in/dr-reza-javaherdashti9a2a2415/

F.Javaherdashti

• SenioradvisoratIMI(IndustrailManagementInstitute),I.R.Iran

• PhD(Management)

• Senioradvisorinbusinessmanagement,branding,andCRM

• Morethan28yearsofexperienceinnationalandinternationalmanagement consulting

• Morethan10,000hoursofteachingmanagementprinciplesandconsultancyfor severalindustries

• E-mail:Farnak.javaherdashti@gmail.com

xvi AuthorsandContributors

A.Ghanbarzadeh

• ResearchatRIPI(ResearchInstituteofPetroluem),I.R.Iran

• M.Sc.(ChemicalEngineering)

• AcademicmemberandHeadofresearchprojectsonprotectivecoatingsatRIPI

• 31yearsofworkexperience

• Authoredfourbooksand12papers

• E-mail:ali.ghanbarzadeh@gmail.com

• LinkedInprofile:https://www.linkedin.com/in/ali-ghanbarzadeh-a5abba55/

M.MostasharNezami

• CEO,AtavArt,privatelyheldco,I.R.Iran

• MAinGeneralEconomicsandBSinAccounting

• Morethan17yearsofexperienceintheaccounting,financial,andeconomic studies

• Carriedoutan8-yearresearchstudyintheeconomicsofrenewableenergies, andintroducedanapplicablewayforusingrenewableenergiesasresident’s dailyenergy

• Morethan400hoursteachingofAccounting,FinanceManagement,and Economics

• Attended “ModelThinking ” traingcourseofferdbyUniversityofMichigan

• WrotemorethantenarticlesineconomicanalysisintheNationalPress

• E-mail:mahsanezami60@yahoo.com

• LinkedInprofile:https://www.linkedin.com/in/mahsa-mostashar-nezamia539b578

M.R.Hamedghafarian

• SeniorProcessEngineerofGasPlantsUtilities&Off-Sites,MinistryofPetroleum,I.R.Iran

• M.Sc.inAdvancedChemicalEngineering

• B.Sc.inChemicalEngineering(naturalgasprocessing)

• Committeemember/GasPlantCorrosion

• ChairmanCommittee/BaselinePollutionDeterminationingasplants (WastewaterTreatment)

• Morethantwelveyearsofexperienceinoperationanddesignofgasprocessing plants(ReceptionFacilitiesandUtilities)

• Sevenpapersinclassicalthermodynamics,corrosion,environment,process additivesmanagement,andCO2 captureinIraniancongresses

• Translationoftwobooksonwatertreatmentchemicals,andtechnicalreport writinginchemicalengineering

AuthorsandContributors

• Morethan1000hoursteachingTroubleshootinginUtilityProcesses,Corrosion, HeatExchangerDesign,IndustrialWastewaterTreatment,ProcessEngineering Documentation,andWaterTreatmenttopicsinRefineriesandGasplants

• AssociatememberoftechnicalstaffinIranianCorrosionAssociation

• MemberofIranianSocietyofEngineeringEducation

• E-mail:mohamedreza.hamedghafarian@gmail.com

• LinkedInprofile:https://www.linkedin.com/in/mohamedreza-hamedghafarian-955463a0/

M.Basirzadeh

• BoardmemberatKavoshMeyarTabasumPasargadCompany

• IndustrialManagementMSC,TehranAmirkabirUniversity

• IranianTRIZteacherandconsultant

• AuthoroffourbooksinFarsilanguageaboutTRIZandcreativity

• E-mail:irantriz@gmail.com

• LinkedInprofile:https://www.linkedin.com/in/mehdi-basirzadeh-4980481

Introduction

RezaJavaherdashti

GeneralManager,EnincoEngineeringB.V.,TheNetherlands

Thisbookisafirst-handanswertotwoquestions:

1)Whatcorrosionmanagement(CM)reallymeans; 2)WhattoexpectfromCM.

Letusbemorespecificindescribingwhatwemeanbytheabove.Forthoseof youwhohavebeentooengagedwithyourintegritymanagementtasksthatcannot findtimetowatchmoviesandparticularlyhorrormovies,Idorecommendto watchthemovie “FinalDestination;Part5,” andwatchitwiththeeyesofacorrosion/integritymanagementspecialist.Inthismovie(anditspreviousparts)what isshownisthatsomethingoflittleimportancegoeswrong,andinaseriesof unpredictable,sadevents,one(orsometimesmore)oftheactorsarekilledina verydramatic,graphicway.Assaid,themainlessonlearnedfromthismovieis thatoneproblemcanleadtoanotherandintheend,acatastrophicresultoccurs. Thesameisalsotruewithneglectingcorrosioninanintegritymanagementplan; somethingthatonewouldthinkisnotthatimportantwillleadtoanother,andifit isinits “pseudo-FFS1” (Fit-For-ServiceState)stage,theresultatitsbestcouldbe arrivingata “Zugzwangeffect” [1]stage,orsimplysaid,failure.

InclassicalacademicliteraturerelatedtoManagementanditsprinciples,perhapsoneofthebestdefinitionshavebeengivenbyHenryFayolas “Tomanage istoforecastandtoplan,toorganize,tocommand,toco-ordinateandtocontrol [1].” Ontheotherhand,corrosionhasalsoacleardefinitionthatcanbesimplified as thechemicalreactionbetweenanelectrondonor(anode)andelectronreceiver 1PleasestudyChapter3forabetterunderstandingoftheseterms.

CorrosionPolicyDecisionMaking:Science,Engineering,Management,andEconomy,FirstEdition. EditedbyRezaJavaherdashti. ©2022JohnWiley&Sons,Inc.Published2022byJohnWiley&Sons,Inc.

2 1Introduction

(cathode)viaamediumthatallowsexchangeofionsandametallicpaththatallows electrontransfer 2 However,whatisCM?Infact,whenitcomestocorrosionscience,weknowthatwearetalkingaboutlaboratories,white-collarresearchers, academicenvironments,andthesearchforunderstandingfundamentalsand mechanismsofcorrosionprocesses.Inthiscontext,innovationandhowinnovativeresearchmustbecarriedoutisoffundamentalsignificance.Whenwetalk aboutcorrosionengineering,itisthewaytheaccumulatedscienceandknowledge aboutcorrosionandcorrosionprocesseswillbecomeapplicableinthefield.For instance,theuseofcathodicprotectiontoletstructuressurvivelonger,oruse ofcorrosioninhibitorsandbiocidestochemicallycontrolcorrosion.Figure1.1 canservetoshowtheessentialelementsofcorrosionengineeringandhowcorrosionengineeringandotherengineeringdisciplinesareinterconnectedwitheach other.Weseethatwhentalkingaboutcorrosionengineering,weareactuallytalkingaboutamultidimensionaltopicthatinitswholenessismorecomplexthan otherengineeringdisciplinesnotinbasedonthesubjectoffocus,butonthemethodologiesthatapplytoaddresscorrosionanditsvariousaspectssuchasmonitoringandtreatment:

Corrosion engineering essential elements

Corrosion engineering

Figure1.1 Corrosionengineeringanditsrelationtootherengineeringdisciplines(right), essentialfeaturesandcomponentsofcorrosionengineering(left)(Usedbypermissionfrom Eng.RikyBernardo – Qatar).

2Themetallicpathwhenreferredtocorrosionunderreallifeconditionshasnomeaningbecause corrosionalreadyistakingplaceonmetals.

Alloftheseapplicationshavetheirowncodesandstandards.Whenwetalk aboutcorrosiontreatment,weknowthatwearetalkingaboutfivestrategiesto dealwithcorrosion(physicalmeasures,chemicalmeasures,electricalmeasures, mechanicalmeasures,anddesign/materialselectionmeasures).Corrosionmonitoringistoaddressmethodsandtechnologiesbywhichseverityofcorrosion withinitscourseofactionisstudiedbycodesandmeasurespertainingtocorrosion monitoring.Alloftheabovebringtomindcertaincodes,workingenvironments andspecialties,andexpertise.However,whatisCM?Itobviouslyhasapartdealingwithcorrosionandapartdealingwithmanagement.Theconfusionarisesfrom here;howcanmanagementwhichisseeminganon-technicalissue,bematched withcorrosionwhichisahighlytechnicalissue?

Allthematerialswrittentodateonthemanagementofcorrosionarejustlookingatthescience/engineering,andtosomeextenteconomyofcorrosion,without detailingwiththeactualrequirements(forexample,abouttheeconomicnomenclaturethatisneededtounderstandcostofcorrosion).Someofthepublications aboutCMdosufferfromthedefectsmentionedabove.SomeexamplesofCMliteratureare:

A.Morshed, “AnIntroductiontoCorrosionManagementinIndustry,” NACE, USA,2017.

A.Morshed, “AnIntroductiontoAssetCorrosionManagementintheOiland GasIndustry,2ndedition,” NACE,USA,2016.

A.S.Groysman, “CorrosionProblemsandSolutionsinOilRefiningandPetrochemicalIndustry,” Springer,2017.

“MyManual:PracticalCorrosionManagement,” amanualpublishedbyIDC Technologies,2009,Perth,Australia.

EvenIMPACTreportbyex-NACE(nowAMPP)thatwaspublishedin2016had somesectionsonmanagementandeconomywithoutanyfocusonengineering andscienceaspectofcorrosion.

Noeconomist,environmentalsciencesspecialist,oranon-technicalmanageris likelytoreadthosebooks(andsimilarones)orattendCMseminarsandwebinars. Thereasonissimple;corrosionhasnotbeendefinedforthesenon-corrosionist professionals.Perhaps,theimportanceofcorrosionhassometimesbeenflagged bysomepoliticians,3 aswellaspassingbillstoallowtheestablishmentofcertain corrosionrelatedentities,say,withinthearmy,butapartfromthoseindividual sparks,nooverall,systematicunderstandingaboutcorrosionanditsvarious aspectsexistsyet.

OuriconoclastapproachtowardCMiswhatwecall “SmartManagementofCorrosion” inthesensethat(i)itissmartbecausethissystemcanadaptitselfwithany

3https://www.defenseindustrydaily.com/Sen-Tom-Coburn-Americas-Fiscal-Defense-Crisis06412,lastvisited15February2021.

industryand,contrarytotheexistingassumptionthatCMistobediscussedwithin thecontextofacertainindustry(oilandgas),smartmanagementofcorrosionis notindustry-specific;and(ii)itfocusesofthemanagementsiderather+thanthe corrosionside.OurunderstandingisthatcurrentCMsystemsmainlydealiwith theriskofcorrosion,howeveritisessentialtoalsodealwiththecostofcorrosion, whethereconomiccostorecologicalcost.Managementofcorrosionisatermthat actsasanumbrellatobothCM(riskofcorrosion)andcorrosionknowledge management(CKM)(costofcorrosion)simultaneouslyandbeingassuch, ManagementofCorrosionisamoregeneraltermthanCMalone. Therearethreeveryimportantfeaturesaboutcorrosion:

1)CorrosionandFailure:Corrosionisinevitableandmanageable;failureis inevitableandnon-manageable.Beingnon-manageabledoesnotmeanthat itcannotbeprevented,itsimplymeansthatwhenfailurehappens,ithappens! Thisdistinguishmentbetweenthesetwotermsifofvitalimportance;theprejudiceofmanywhodealwithcorrosionissuesisthattheyareentitledtofinda waytopreventorcontrolcorrosion.4 Corrosionoccursanywayduetothethermodynamicnatureofit,itisourduty,though,topreventfailures.Itisthrough failuresandleaksthatnotonlyeconomiccostsareimposed(fromshutdown coststomaintenanceandreplacement),butalsoenvironmentaleffectsalso occur.Studyofcorrosionprocessesendinginleakandfailureisthetaskofa corrosionspecialist,post-mortemforensicinvestigationofthefailureiswhat aforensicinvestigatordoestohelpbuildarootcauseanalysisreport,but whoistomeasuretheseriousnessoftheenvironmentaleffectsthusproduced? Whoisgoingtoestimatetheeconomicloss(directcostandindirectcost)?

2)RiskandLikelihood:Ifthelikelihoodofgettingacertaintypeofcorrosionrelatedfailureislow,itdoesnotnecessarilymeanthatisriskisalsolow andviceversa.Theconfusionbetweenriskandlikelihoodiswithnodoubt oneofthemostimportantsourcesofproblemsthatcanevenreachtothelevel ofdisasters.Itisthemindsetthatcanbeobservedinindustryquitefrequently andithasthepotentialofbeinglethal.

3)CorrosionandAging:Agingimpliesthatastructurehasbeeninservicefor quitealongtime,whereascorrosioncanactuallyoccurinstructuresrightafter beingputintoservice.Therefore,corrosion-relatedfailurescouldhappenin structuresafterarelativelyshortperiodofservice(sometimesmonths).

Inourprofessionaljudgment,managementofcorrosionneedstoaddressall aspectsofcorrosionaswehavetriedtodointhisbook;corrosionandthealgorithmofinnovation(TRIZ;theTheoryofInventiveProblemSolving)havebeen coveredtotherequiredextentinChapters2and6.InChapter2,someimportant

4Corrosionpreventionandcorrosioncontrolarenotthesameandcannotbeused interchangeably.Wewillgetbacktothisconceptlaterinthisbook.

aspectsofcorrosionscienceisre-defined,thatis,asmuchasneeded.Theengineers lookingaftercorrosionissuesmaynotthemselveshaveattendedpre-employment corrosioncourses,andthusduringtheiremploymentyearstheyattendcoursesor conferenceswithspecifictitles,orevenlearnfromeachotherand/ortheircolleaguesverbally.Thereisaverysmallminoritywho,withapre-employmentbackgroundincorrosion,stillkeeptheirknowledgeuptodate.Thisauthorduringhis morethantwodecadesofconsulting,aswellaseducationtrainingcourses,has seentheseissuesveryclearly.

Theexecutiveforceforanymanagementofcorrosionschemeishumansandnot robots,althoughweoftenforgetthis.Alongwithit,wealsohappentoforgetthe goldenwisdom “Toerrishuman.” Infact,agreatnumberofindustrialdisasters includingthoserelatedtocorrosion stemfromhumanerror.Oneofthewaysby whichhumanerrorcanbehighlydecreasedisviatraining.InIMPACTreportby AMPP,thecostfortrainingisnotmentionedascostbutasinvestment.Creating motivationandpayingspecialattentiontotrainingisofparamountsignificancein acorrosionknowledgemanagement(CKM)scheme,andisanintegralpartof smartmanagementofcorrosion.Inadditiontothescienceofcorrosion,itisimportanttofindthebestwaytoinventsolutions.Withdecadesofsplendidpast,TRIZ canbeaninstrumentalfactorincreatinginnovationpatterns.Thisauthorhas showntheapplicationpowerofTRIZinsomeofhispublications.Researchers needtobefamiliarwithTRIZtofindbettersolutionswhichareinnovativeand feasibleparticularlyinthefieldofmanagementofcorrosion.

TheheartofthisbookwhichisSmartManagementofcorrosionisthetopicof Chapter3.EngineeringaspectsofcorrosionisexplainedinChapter5.Nomatter whatourinterpretationaboutmanagementofcorrosion,understandingcorrosion inactionisamust.

Discussingenoughabouteconomicsasrequiredtodefinecorrosiondamageis addressedinChapter4,whereasenvironmentaleffectsofcorrosionhasbeen addressedinChapter7.

Thisbookishighlylikelytoexperiencea “SemmelweisReflex” whichessentially means “tosticktopreexistingbeliefsandtorejectfreshideasthatcontradictthem [2].NoliteratureofCMknowntousissuessuchdetailsofeconomy,environment, TRIZ,andinnovativeinterpretationofCMaswewillcoverinthistext.

References

1 Aquinas,P.G.(2011). PrinciplesandPracticesofManagement.Phagwara,India: LovelyProfessionalUniversity.

2 Gupta,V.K.,Saini,C.,Oberoi,M.etal.(2020) “SemmelweisReflex:AnAge-Old Prejudice,” WorldNeurosurgery.https://pubmed.ncbi.nlm.nih.gov/31837492,last visited13February2021.

AShortReviewofSomeImportantAspectsoftheScience ofCorrosion

RezaJavaherdashti1∗ andAliGhanbarzadeh2†

1 GeneralManager,EnincoEngineeringB.V.,TheNetherlands

2 ResearchatRIPI(ResearchInstituteofPetroleum),I.R.Iran

2.1Introduction

Corrosionisaprocessthathappensnaturally.Thewaycorrosionhappensisastory thathasbeenrepeatedinallbookswrittenonthesubject,butitwillstillmake senseifwerepeatithere.Themainreasonfordoingsoisthatthethermodynamics behindcorrosionisnotonlyimportantfromascientific/engineeringpointofview, butalsofromacorrosionmanagement(CM)approach.(Wehavedescribedthe significanceofthethermodynamicnatureofcorrosionandhowitisimportant inengineeringpractices,andparticularlyCMandmanagementofcorrosionin Chapter3.)

CorrosionisderivedfromaGreekwordthatmaybetranslatedas “bittenaway.” Someauthors includingus justifythiswordbyimplyingthatacorrodedpart seemstohavebeenbitten.Theinvisiblebiteprobablycomesfromtheverynature ofthemetalbecausemetalsarenotfoundintheirpureform thatiswithouthavingoxides,sulfates,carbonates,andthelike intheirnaturalform.Evenwhatwe calliron(thatoriginallymeans “comingfromheaven” probablyduetoitbeing mainlyfoundinmeteors)isnotnaturallyfoundasatotallypurematerialfree ofnon-metallicmaterials.Metalssuchasiron,copper,andthelikearealways foundintheirores.Oreisarockpartthatcontainsthesemetalsascompounds andnotelements.Theserocksareextractedandcrushedandthemetallic compoundswithinthemarethenextracted.Thesecondandthemostimportant stagefromacorrosionpointofview,however,istheextractionofmetalfromthe

∗https://www.linkedin.com/in/dr-reza-javaherdashti-9a2a2415. †https://www.linkedin.com/in/ali-ghanbarzadeh-a5abba55.

CorrosionPolicyDecisionMaking:Science,Engineering,Management,andEconomy,FirstEdition. EditedbyRezaJavaherdashti. ©2022JohnWiley&Sons,Inc.Published2022byJohnWiley&Sons,Inc.

“surrounding” non-metalliccompoundsaroundit.Thecoreprocessinmetal extractionisthereductionprocessesduringwhichelectronsareaddedtoelectrons alreadyexistinginthemetalelementitself.Thesereductionprocesses,collectively referredtoas “extractionmetallurgyprocesses” arebasicallythosehappeningin metallurgyplants.Itisbytheseprocessesthatmetalswithhighpurityarebeing produced.

Inthissense,thepuremetalisnotatrestwhencomparedtoitsstatewhenit wasinitsore.Inotherwords,thestateofenergyintwostagesof “in-ore” and “as-extracted” willbefardifferentfromeachother;Gibbsfreeenergyof “in-ore” ismuchlowerthanthatof “as-extracted. ” Thismeansthatanywayby whichthisexcessofenergycanbereleasedwillfavorcorrosion.

Nowthatitisunderstoodthattheforcebywhichcorrosionisbeingdriven comesfromtheverynatureofmaterials,particularlymetals,weneedtounderstandsomebasicconceptsuponwhichthewholeelectrochemicalcorrosionprinciplesarebased.Whyelectrochemicalcorrosion?Itisbecauseanumberof corrosionprocessesrangingfromcorrosionunderinsulationtomicrobiologically influencedcorrosion(MIC)toatmosphericcorrosionareallgatheredunderthe umbrellaofelectrochemicalcorrosion.Therefore,inthischapter,wewillreview anddescribesomefundamentalaspectsofelectrochemicalcorrosion,whatitis, andhowitcanbetreated.AswewillseeinChapter3 about “smartmanagement ofcorrosion,” preventionofcorrosionisdifferentfromcorrosioncontrol.Very briefly,preventionofcorrosioncanbeappliedtoaGreenfieldprojectrelatedto corrosion,orequipmentwhichisstilltooyounginitsservicelifesothatoptions suchasmodificationofdesignormaterialsselection/upgradeorevenchangeand modificationofprocessparametershaveyettobeconsidered.Corrosioncontrol, ontheotherhand,isappliedtoaBrownfieldprojectorequipmentwhichhasbeen inserviceforaquitelongtime(perhapsmorethanayear),sothatnotonlyareany changeormodificationinanyprocessparametersnotpermissible,butalsooptions suchaschangeofdesignormaterialsselectioncanbehighlylikelytobeconsideredtoocostlytobeapplied.By “corrosiontreatment” weaddressbothcorrosion controlandcorrosionpreventionwhereapplicable,percase.

Wewillthereforestartwithverydefinitionoftheelementsofanelectrochemical corrosionprocessandcontinuewithavailabletoolstopredictcorrosion,thatis,to foreseeifitwilloccurornot,andthenwecontinuewithfivetreatmentapproaches towardcorrosion.Thefiveapproachesare(i)chemicaltreatment,(ii)electricaltreatment,(ii)mechanicaltreatment,(iv)design/materialselection,and(v)physical treatment.Whatwehavetoadvisefromthebeginningisthatthefourthtreatment approachcanstillbeanoptioneveniftheproblemiscategorizedasacorrosioncontrolissue.Inthisregard,itisthecostofapplicationthatwillbethemajorplaying factorifdesign/materialselectionistobebetterappliedforacorrosioncontrol approach.

Ourapproachinthissectionmaysoundsomewhatradicaltothosewhohave beenusedtoreadingmaterialsintheirusualcontext,becauseinsteadofbeing

2.1Introduction 9

tooacademic,ourunderstandingofcorrosiontheoryandpracticeisdirectlyfocusingonitspragmatic,immediatebenefitsforthereadersandwhoeverengagedin theso-calledCMpractice.Wewouldnotallowourreaderstobe,literally,buried underformulas,diagrams,andthelike.Wewanttobestraight-forwardandwrite frankly!

2.1.1EssentialsofElectrochemicalCorrosion

Ifcorrosionisanaturalprocessbywhichenergyofthesystemislowered,thenany approachtowardcorrosionmustbethesamewhenfacinganynaturalprocess.The mainthinghere,however,isthataslongascorrosionhasnotbeenallowedto makeaholeinanasset theprocesswecallthrough-wallpitting itissafe.This approachmaysoundquitedifferentfromwhatwehavebeentaughtsofar;any manualonCMstartswiththeunwrittenassumptionthatthejobforacorrosion engineeristopreventcorrosion.Infact,thejobofacorrosionengineer andfor thatmatteranintegritymanagementexpert istopreventthrough-wallpitting occurrenceasmanifestedbysevere,localizedcorrosion.

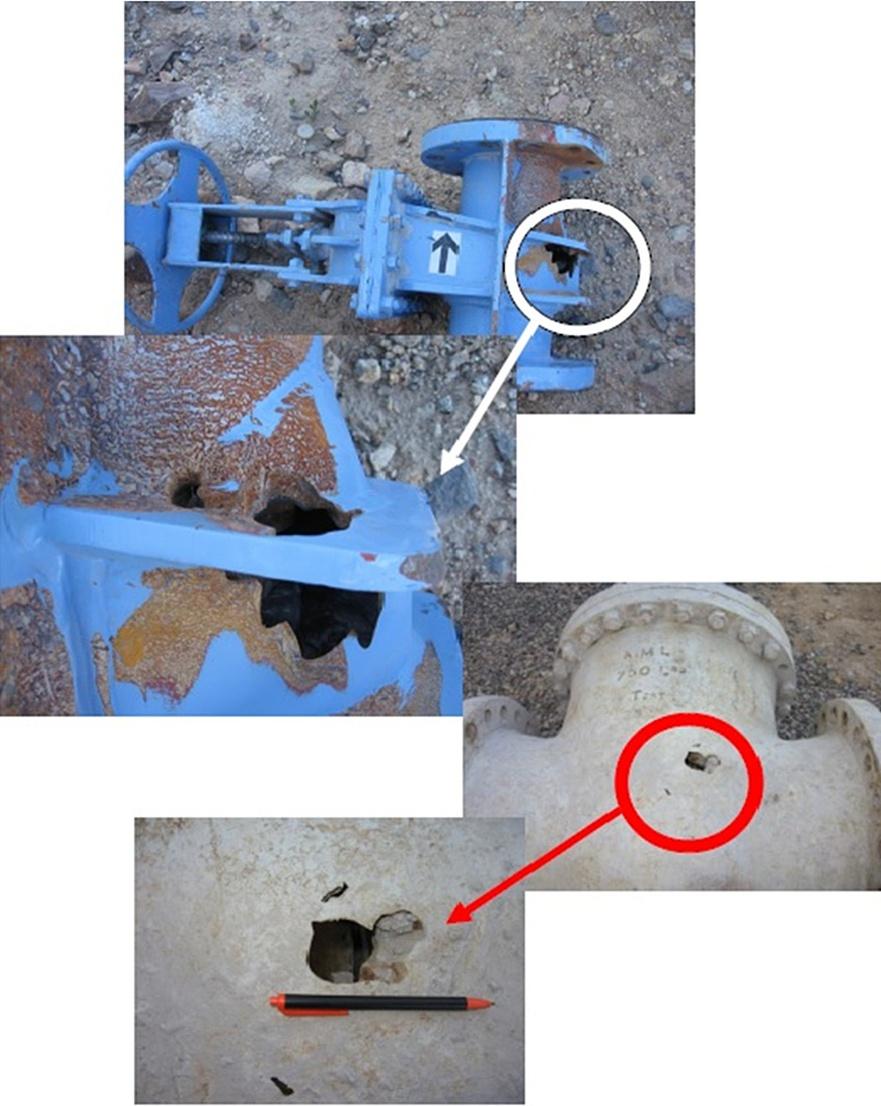

Figure2.1 showsanexampleoftwoassetsthathavebeenseverelycorroded throughlocalizedcorrosion.Inbothofthefigurestherearethreeelementsofcorrosionthatcanberecognized.Theanodeisthespotatwhichanodicreaction occurs,andincasessimilartothoseshowninFigure2.1,itiswhereseverpitting intheformofseverethrough-wallpittinghappens.Attheanode,electronsare beingreleasedandtravelviathemetallicmaterialbodytowardthecathode,the cathodecouldbeadjacenttotheanode.However,thepointisthatinlocalizedcorrosion,contrarytouniformcorrosion,anodeandcathodespotsdonotmoverelativetoeachother,sothattheanodeisfixedandfromtheveryspottheanode becomesfixed,pittingstarts.Itisalsoduetothisfeaturethatlocalizedcorrosion happensinoneparticularspotonthemetallicstructure.Thismayalsobethemain characteristicoflocalizedcorrosionthatmakesitspredictionalmostimpossible; onecannotknowwherethatattackwilloccurandwithwhatseverity,normally measuredintermsofcorrosionrateandexpressedbypittingfactor,itcanoccur. Themoistureonthemetallicsurfacethatisbasicallythewatervaporalreadyavailableintheairwillbethemainelectrolytethroughwhichionexchangecan happen.

Itisquiteunderstandableiftheseveryconceptsthatformelectrochemical corrosion ormoregenerallyreferredtoasaqueouscorrosion leavealotof questionsforthereaders.Forexample,fromaspatialpointofview,whilethepositionofanodeisvisiblehowcanwedecidewhereexactlythecathodeadjacenttoit is?Isitontheleftsideoftheanode?Itsrightside?Whereisitlocated?Another matterishowdoweknowiftheanodeandcathode “creep” relativetoeachother onametallicsurface?And,forthatmatter,howdoweknowifoneparticularspot andnotanotherspotonthemetalwillbecometheanode?

Figure2.1 Twoexamplesofseverelycorrodedequipmentleadingintoathrough-wall localizedfailure.Theanodeisthepointatwhichperforationhasoccurred(whitearrow)and thecathodeisimmediatelyadjacenttoitsothatelectronflowhappensviathemetallic surface(orangearrow),whileionictransferhappensthroughthemoisturelayeralready formedonthemetal.(Source: TakenfromthecollectionofDr.R.Javaherdashti.)

Theabovequestionsareactuallysomeoffundamentalimportanceshouldwebe writingthisbookasatextbook.Therearenumerousbooksandpapersthatmay becomehandyinansweringthesequestionsandevenmorepuzzlingones.Forus, however,theabovequestionscarrynovalueatall.Fromapracticalpointofview, allweneedtocareaboutarethefollowingfivebasicconcepts: