ZincSurfaces

inArchitectureandArt

L.WilliamZahner

Thisbookisprintedonacid-freepaper.

Copyright©2021byJohnWiley&Sons,Inc.Allrightsreserved

PublishedbyJohnWiley&Sons,Inc.,Hoboken,NewJersey PublishedsimultaneouslyinCanada

Nopartofthispublicationmaybereproduced,storedinaretrievalsystem,ortransmittedinanyformorbyany means,electronic,mechanical,photocopying,recording,scanning,orotherwise,exceptaspermittedunderSection 107or108ofthe1976UnitedStatesCopyrightAct,withouteitherthepriorwrittenpermissionofthePublisher,or authorizationthroughpaymentoftheappropriateper-copyfeetotheCopyrightClearanceCenter,222Rosewood Drive,Danvers,MA01923,(978)750-8400,fax(978)646-8600,oronthewebatwww.copyright.com.Requeststo thePublisherforpermissionshouldbeaddressedtothePermissionsDepartment,JohnWiley&Sons,Inc.,111 RiverStreet,Hoboken,NJ07030,(201)748-6011,fax(201)748-6008,oronlineatwww.wiley.com/go/permissions.

LimitofLiability/DisclaimerofWarranty:

Whilethepublisherandauthorhaveusedtheirbesteffortsinpreparingthisbook,theymakenorepresentationsor warrantieswiththerespecttotheaccuracyorcompletenessofthecontentsofthisbookandspecificallydisclaim anyimpliedwarrantiesofmerchantabilityorfitnessforaparticularpurpose.Nowarrantymaybecreatedor extendedbysalesrepresentativesorwrittensalesmaterials.Theadviceandstrategiescontainedhereinmaynotbe suitableforyoursituation.Youshouldconsultwithaprofessionalwhereappropriate.Neitherthepublishernorthe authorshallbeliablefordamagesarisingherefrom.

Forgeneralinformationaboutourotherproductsandservices,pleasecontactourCustomerCareDepartment withintheUnitedStatesat(800)762-2974,outsidetheUnitedStatesat(317)572-3993orfax(317)572-4002.

Wileypublishesinavarietyofprintandelectronicformatsandbyprint-on-demand.Somematerialincludedwith standardprintversionsofthisbookmaynotbeincludedinebooksorinprint-on-demand.Ifthisbookrefersto mediasuchasaCDorDVDthatisnotincludedintheversionyoupurchased,youmaydownloadthismaterialat http://booksupport.wiley.com.FormoreinformationaboutWileyproducts,visitwww.wiley.com.

LibraryofCongressCataloging-in-PublicationData

Names:Zahner,L.William,author.|JohnWiley&Sons,publisher.

Title:Zincsurfaces:aguidetoalloys,finishes,fabrication,and maintenanceinarchitectureandart/L.WilliamZahner.

Othertitles:Zahner’sarchitecturalmetalsseries

Description:Hoboken,NewJersey:Wiley,[2021]|Series:Zahner’s ArchitecturalMetalsSeries

Identifiers:LCCN2021003278(print)|LCCN2021003279(ebook)|ISBN 9781119541615(paperback)|ISBN9781119541639(adobepdf)|ISBN 9781119541592(epub)

Subjects:LCSH:Zinc—Surfaces.|Zinc—Finishing.|Zinccoatings.| Architecturalmetal-work.|Artmetal-work.

Classification:LCCTS640.Z342021(print)|LCCTS640(ebook)|DDC 661/.0661—dc23

LCrecordavailableathttps://lccn.loc.gov/2021003278

LCebookrecordavailableathttps://lccn.loc.gov/2021003279

CoverDesign:Wiley

CoverImages:(Main) StevenHollArchitects’,InstituteforContemporaryArt(ICA),VirginiaCommonwealth University,photographedbyIwanBann,c.2017.(Border) Patternonzincplates ©somnuk/GettyImages

10987654321

ThisbookisdedicatedtomygoodfriendVerneChristensen. (adesignerwhoprovedAlessandroVolta’stheorywhenwebuiltabeautifulcurvedzincroofbelowhis coppergutters)

PreweatheredZincSurface73

ClearCoatingwithPigmentation77 BlackenedZinc77

CustomPatinaFinish79

DarkVariegatedPatinasonZinc80

ZincOxidePatinas87

ZincIridescentPatina93

GalvanizedZincSurfaces93

GalvanizedSteelStructuralShapes99

DarkeningGalvanizedSteel100

ZincPhosphateCoatingsonGalvanizedSteel101

ZincFabric102

OtherMethodsofApplyingZinctoSteel103

ZincAnodizing104

CHAPTER4Expectations105

CHAPTER7Corrosion215

Introduction215

ZincasaProtectiveCoating216

GalvanizedSteel218

ZincAlloyCoatingsonSteel219

ZincPowderinPaintCoatings220

Sherardizing221

ThermalSpray221

ZincAnodes222

Battery222

WhenZincDoesNotProtectSteel224

ZincCorrosion225

InteriorExposures227

ExteriorExposures228

ShelteredExteriorSurfaces230

UniformCorrosion235

UndersideCorrosion236

WetStorageStain237

GalvanicCorrosion239

DeterminingFactorsforGalvanicCorrosion242

DifferenceinElectro-Potential243

GeometricRelationship243

Distance244

ElectrolyteEffects244

TemperatureEffects245

PittingCorrosion246

IntergranularCorrosion248

StressCorrosionCracking248

ZincArtifactsandStatues249

DeicingSalts251

Chlorides252

Fertilizer253

Saponification254

CorrosiveSubstancesinProximity254

CHAPTER8MaintainingtheZincSurface257

Introduction257

ZincSurfaces258

WhyaMaintenanceProcedure260

DevelopaMaintenanceStrategy260

RestoringthePreweatheredAppearance264

EffectsofDifferentEnvironments266

Preface

Anexpertisanordinarymanwho-whenheisnothome–givesadvice. OscarWilde Zincisthemysteriousmetalusedinartandarchitecture.

IntheUnitedStates,itisaparadox.Ontheonehand,itisconsideredanOldWorldmetal, usedforcenturiesacrossEurope.Parisisdefinedbytheroofsofzincthatblanketthecity.Yetitis relativelynewtoNorthAmericanarchitecture.

Asametalofartcastingorfenestration,littlewasknownuntiltheearly1990s.Sure,weknew oftheprocessofdippingsteelinamoltenjacketofzinc.Hot-dippedgalvanized,astrangefondue formetal,isaprocessthatiswellknown,butnotalwaysunderstood.

TheleadingzincminesthatsuppliedtheworldwereonceinthemiddleoftheUnitedStates, aregionwiththetownofJoplin,Missouri,asthecenter.Mostzincmininghasendedinthearea, butinthelate1800sandearly1900sthiswastheepicenterofzinc.Millionairesweremadebythe dozensastheareawastunneledoutlikeagiantanthill.

InNorthAmerica,thesheetmetalindustry,artcastingindustry,anddesigncommunityknew littleaboutzinc.Publicationsandtrainingdocumentsthroughoutthearchitecturalmetalindustry madenomentionofzinc.Theoldcatalogscalledthemetal whitebronze, perhapsattemptingto elicitafeelingofnoteworthinessbytakingonthename bronze.Metalfoundries,artschools,and metalworkersintheUnitedStateslackedanyrealknowledgeofthemetal.Withtheexceptionof galvanizing,themetalwasallbutforgottenaftertheearlypartofthetwentiethcentury.

WhenIfirststartedworkatZahner,a125-year-oldmetalfabricationcompanylocatedinthe Midwest,zincwasnotknownasanarchitecturalmetal.Wedidnotstockthemetal,norwasitspecifiedinanyindustrypublications.Weworkedwithsteel,terne,copper,aluminum,stainlesssteel, andlead,butnotzinc.Oneofthefirstintroductionstothemetaloccurredduringtherestoration oftheFollyTheater,aturn-of-the-centurytheaterbuiltin1900.Whentheworkersremovedpartsof themetalcorniceanddecorativemetalbalusterin1979,theyhaddifficultydeterminingwhatthe metalwas.Thismetalhadlasted80yearsandstilllookedingoodshape.Itwassilverunderthe paint,soitwasnotcopper.Itwasnotmagneticsoitwasnotterne-platedsteelorgalvanizedsteel. Itwasheavy,soitwasn’taluminum,andaluminumhadnotbeenincommonuseby1900.The pieceswerespunandassembledinsectionsbysoldering.Itwasnotanymetalwewerefamiliar with.Itwaszinc.Fromthe oldcountry.

Theotherconnectiontozincgoesback125years.AndrewZahner,mygreatgrandfather,started thismetalcompanyIworkfor,inJoplin,Missouri,in1897.Backinthelate1800s,thisregionin

southwesternMissouri,ontheedgeoftheOzarkMountains,wasthesiteofoneofthelargestmining operationsinAmerica–firstforleadusedtomakebulletsandlaterforzinc.Zinc,knowninthearea as jack, madetheregiononeofthewealthiestintheUnitedStates.Everymajorrailroadatthe timewentthroughtheJoplinregiontotransporttheorearoundtheUnitedStatesandtoportsto supplytheEuropeanmarket.TheorewasofsuchhighqualitythattheEuropeanspurchaseditfrom Missouri.

ThisboomingregionattractedayoungAndrewZahner,andhestartedasmallmetalfabrication firmtoproducecornicesandotherdecorativefeaturesforthewealthymerchantsinthearea.

AndrewZahnersurelyknewaboutzinc.

Theboom/bustcycleeventuallyhittheJoplinareaintheearly1900s,andAndrewmoved thecompanytoitscurrenthomeinKansasCity.Theknowledgeofzincwasleftbehindwiththe dyingminesofthecentralUnitedStates.Now,125yearslater,Iwriteabookonthismetal,zinc. ItisunfortunatethatIdidnothaveAndrewasaresource.

Overthelastcoupleofdecades,wehaveworkedwiththemetalzinconnumerousprojects.We haveexpandedourknowledgeofthemetalandhaveuncoveredmanynewandinterestingwaysof workingwithzinc.Wehavecreatednewpatinasandsurfaceenhancements,andwehaveexplored casting.ThemoreIworkwiththemetalzinc,themoreIfinditanintriguingmaterialofdesign.

WorkingwithmydaughterKat,whooperatesZahnerMetalConservation,restoring100-yearoldzincstatuesandstatuettesgivesadeepappreciationforhowtheartistworkedwiththemetal andproducedamazingdetailusingcastingtechniquesthathaveallbeenforgotten.

Thisbook,thefifthintheseriesonmetals,isintendedtosparktheinterestinthemetalzinc andexplorethepossibilitiesithastoofferthedesignerandtheartist.Thenextpagesshouldhelp tounravelthisinterestingmaterialofdesignandintroducethereadertohowthismetalwillappear andfunction.

L.WilliamZahner

IntroductiontoZinc

It’sabusiness.IfIcouldmakemoremoneydowninthezincmines,I’dbe miningzinc

Source:RogerMaris

ELEMENT30ZN– SPELTER

Zinc,themetalthatcouldchangecopperintogold,atleastthatwasthewishoftheearlyalchemists. Theycalledthemetal counterfeht1 .Itlookedlikesilver,butitwasn’t.Addingittomoltencopper andthecopperwouldturntoabeautifulgoldencolor,butitwasnotgold.Itwasan“imitation” a counterfeht.Thisoddmetal,ifitwasametalatall,wasamystery.

Zincwentalsobythename spelter, usedmainlybythosewhoworkedwiththemetal.Spelter waspossiblyacorruptionofthenamefor“pewter,”thedullgray,lead-tinalloy.TheDutch,first toimportthemetalintoEuropeusedtheword, spiauter forawordtodescribeamixtureoflead andtin2 .So,itverywellmayhavebeenanearlymarketingploytogivevaluetothisdubiousmetal. Spelterwasthenamegiventothismetalupuntilrelativelyrecenttimes.Today,thenamezinchas firmlytakenholdontheperiodictableofelements.

Othernames,inparticular calamine, werefrequentlyusedforthismetalbeforeitwasofficially ametal.Calamine,theprincipalmineralofzinc,wasthenameusedacrossWesterncivilizations sincethetimeoftheRomans.Calamineiszincsulfide,andthereareregionsinEuropewherethe richmineraldepositsofzincsulfideweremined.

Calamine,aswell,lostoutasanamefortheprincipalmineralformofzincandisnowbetter knownasthepopulartopicalpoisonivycream,eventhoughthelotioncontainszincoxide,notthe

1 TheGerman,GeorgiusAgricola,inhisbook, Deremetallica,writtenin1556.

2 DawkinsJ.M., ZincandSpelter, 1950,ZincDevelopmentAssociation,p.24.

zincsulfideofthemineralform.Insteadofcalamine,theterm sphalerite isusedasthenameforthe zincsulfidemineral.Foralongwhiletheterm zincblende, fromtheGerman zincblende,wasalso usedtodescribethemineral.Confusionreignedonwhatthismineralormetalactuallywas.

Asametal,zincinawroughtorcastformcamelate,sometimeinthemiddleofthesixteenth centurytotheWesterncivilizations,definitelyearlierinIndia.Chinaalsowasanearlyzincproducer,usingcrucibleswithcharcoaltoheattheore.Theymadecoinsfromzincinthefourteenth century.TheRomanswouldproducebrassfromcopperbyaddingcalamineandheatingitinsmall crucibles.Thezincwasobtainedbyreducingtheore,releasingcarbondioxide,andthefumesofzinc wouldrapidlybeabsorbedintothecopper.Oncemelted,theslag-coveredblockwouldbehammered andthebrightyellowcolorwouldappear.

Theprocessofmakingbrasswaswellknownthroughoutantiquity.Themethodofcreatingbrass fromsphalerite(orcalamine,asitwasthenknown)wasdescribedinseveraltexts.Onesuchtext, SchedulaDiversariumArtium,writtenbyTheophilusPresbyterintheeleventhcentury,describes theheatingofcruciblesinanopenfurnace,addingcalamine,thenstripsofcopper.Placebackon thefurnacefor9hoursandyouarriveatagoldenyellowcolorpleasingtolookat.Figure1.1shows themineralsphaleritewithalargelumpofcopperonaplateofbrass.

Zincappearedasaknownmetallaterthanleadandtin.Themineralwasknownbutasadistinct metal,zincwasnot.Alongwithothercolorfulzincminerals,sphaleritewaseasytoidentifyandso wasminedinantiquityasamineraltoaddtocoppertoproducethebeautifulyellowbrass.Granted, itwasoftenmistakenforgalena,aleadsulfidemineral,atonetimeavaluablemineralformaking bullets.

EarlybrassartifactsdatingbacktotheeighthcenturyBCEwereuncoveredintheGordiontomb excavatedinAnatolia.Thecopper–zincmetalwascalled oreichalkos andlater orichalcum bythe Romans.Theprocessofproducingbrasswaswellknownanddocumented.Mostbrassproduction wasestablishednearthezincminesbecauseitwaseasiertocartcoppertothearea,thanthelarge quantityofzincmineralneeded.

FIGURE1.1 Sphaleritepluscoppertomakebrass.

Thereasonzincasaknownmetalwaslatetodiscoveryisthedifficultyofrefinement.Upuntil themid-1700s,metalsweremadebyroastingtheoresandburningofftheoxidestofreethemetal. Troubleis,zinchasalowboilingpointasmetalsgo.Assufficientheatisappliedtoreducetheore, zincturnstogasandthefumesescape.Thus,thereductionoftheorethewayothermetalsare producedjustdidnotworkforzinc.

Thewaytheearlyalchemistsfoundthis counterfeht,itwouldcondenseonthewallsoftheflue andincracksandcrevicesofthestoneafterroastingmetaloresthatcontainedzinc.Zincisoften foundinoresofothermetals,particularlylead,copperandsilver.Whentheoreswereheatedthe zincwouldgoupasvaporsandcondenseonthestone.Whenitcondensed,itformedlong,whiskery tuffsthealchemistscalled lanaphilosophica, meaning“philosopher’swool.”

Assistantstothealchemistswouldscrapeandcollectthiswoolysubstanceoffthestoneandout ofthecracksofthefluewalls.Thealchemistsplacedavalueonthisspecialmetalthatwasliketin butwhenaddedtocopperwouldtransformthecopperintoagoldenyellow.

Alchemistsymbolforzinc.

Zincisasilvermetalwithaslightbluishhue.Zinccanbepolishedtoabright,silverbutquickly tarnisheswhenhandled.Aszincagesitturnstoarichgraycolorwithwhitishoxidesinareaswhere moistureisallowedtoaccumulate.

Zinciselement30ontheperiodictableofelements,Figure1.2.Withtheredmetal,copper,on onesideandgallium,abluegraymetalthatmeltsinyourhand,ontheother,zincfallsinthetwelfth rowwithcadmiumandmercury.

Zinchasseveralisotopes,buttheisotopezinc67isratherspecial.Zinc67occursinapproximately4%ofnaturalzinc.Thisisotopeishighlysensitivetominutevariationsintransmittedenergy. Whenitdetectsenergy,itemitselectromagneticradiationmakingthisisotopezinc67valuablefor highaccuracymeasuringequipment.Zinc67isusedtodetectgammarayvibrationswithincredible sensitivityinthehighlyaccurateatomicclock.

Zinchasahexagonalcrystalstructure,whicheventhoughitiscloselypacked,itislessdense thanthecubicstructureofironorcopper.Figure1.3.depictsacloselypackedhexagonalcrystal. Thismetallurgicalstructureshowsthecrystalofzinchassixatomsinanearplaneandanother sixslightlyfurtheraway.Thismakesthebondsofthebasalplaneslightlystrongerthanthebondsof theparallelplane.Thisdifferenceindistanceandstrengthgiveszincananisotropythattranslates toformsmadeofzinc.3

3 Porter,Frank, ZincHandbook,MarcelDeckerInc.,NY,p.45.

FIGURE1.2 Periodictable.

VIIIA

Anotheraspectofzincisitsabilitytorecrystallizerapidlyafterdeformation.Thispreventswork hardeningfromoccurringduringformingoperationsanditalsoprovidesalevelof“self-lubrication” asthecrystalsslipoveroneanotherduringformingprocesses.

Note,thespanglethatformsongalvanizedsteelisalargecrystalofzincthatformsasitcools. Ithasthesixtriangularwedge-likesymmetryreflectingthehexagonalcrystalstructureofthezinc crystallattice.Figure1.4showsaclose-upimageofthespangleformedwhenzinccoolsonasteel

FIGURE1.3 Zinchexagonalcrystalstructure.

FIGURE1.4 Spangleofgalvanized.

FIGURE1.5 Zinccoatingonsteelusingacontrolledrefinementofthecoolingprocess.

substrate.Thewedgesthatexpandoutfromacentralpointarecalleddendritesandtheparallellines arecalledsubdendrites.Whennewlydevelopedthegalvanizedsurfacehasacrystallinereflective qualityduetothewaythesubdendritesscatterthereflectivelight.Thesurfaceseemstocomealive asyouwalkaroundanewlygalvanizedsteelplatewiththeglitteringreflectionbouncingoffthe variationsinthecrystals.

Thisreflectiveness,achievedbyhot-dippingsteelintomoltenzinc,isanaturalsurfacethat formsduetoslightimperfectionsinthezincbathorslightroughnessonthesteelsurface.These imperfectionsinitiatetheformationofthedendritegrowth.

Artisticaffectscanbeenhancedtotakeadvantageofcoolingratesofthemoltenzinc.Thesetechniquesarestillindevelopmentinordertobetterunderstandingtheparametersinvolved.However, coolingrates,“seeding”themoltenbathwithotherelementscaninfluencetheeffects.

Thedifficultyarisesintheindustrialcontrolsinplacebythegalvanizingfacilities.Artistic expressionisnotintheirnormalparlance.

Figure1.5showsa“wave-like”appearancethathasdevelopedonflatsteelsheet.Thereflectivity enhancesthethree-dimensionalappearanceofthezincsurface.

Asthesurfaceoxidizes,thezinccrystalsstillvaryinappearancecreatingadull,lowerreflective patchworkappearance.Thedendritesarestillthere,theyhavejustdevelopedalayerofzinc oxidethatmutesthereflectivity.Figure1.6showsagalvanizedplatethathasbeenexposed toweather.

FIGURE1.6 Galvanizedthathasweathered.

ZincELEMENT30

Atomicnumber30

Crystalstructure: Close-packedhexagonal

Mainmineralsource: Sphalerite(Calamine)

Color: Bluishwhite

Oxide: White

Density: 7,068kg/m3

Specificgravity: 7.0

Meltingpoint: 419∘ C

Thermalconductivity: 112W/m ∘ C

Coefficientoflinearexpansion: 19 × 10-6 m/m∘ C

Electricalconductivity: 26%IACS

Modulusofelasticity: 108GPa

MostofthezincfoundontheEarth’ssurfaceisfromhydrothermalactivitythatbrought themetaltoornearthesurface.Zincisnotfoundinthenativestate.Zincisalwaysfoundin combinationwithotherelementsandmetals.Zincisthe24th mostabundantelementwithinthe uppercrustoftheEarth.

Zinchasapoorstrengthtoweightratioascomparedtoothermetalsusedinindustry.

Zincalloysareductileatroomtemperature.Zinccastingsarenotductile.

Zincissubjecttofracturewhenformedatlowtemperatures.

Highelasticity–resiliencyundershockloading

Softedge

Zincandzincoxidesarenontoxicunlessconsumedinlargeamounts.Zincoxidefumesare hazardouswheninhaledandwillcauseflu-likesymptomsthatcanlast1–2days.

Ithassuperiorcorrosionresistanceinmanynaturalenvironments.ZincissubjecttocorrosioninlowpHandhighpHenvironments.

FINISHES:

Millfinish–asrolled. Semi-bright

Preweathered–darkened

Zinccanbepainted.

Coil-coatedzincsheetinvariouscolorsareavailableonthemarket. Oil-basedpaintsarenotrecommended.Saponificationcandevelop.

Platingwithothermetalssuchascopper,silver,nickel,andgoldarepossible.

Artificialpatina:

Brightappearance:

Reflectanceofultraviolet: ofinfrared:

Zinccanreceiveartificialpatinasofwhite,black, browns,mottledbrownswithgreenandreddish oxidesaswellasiredescenthuesoftransparent greens,purplesandreds.

Zinccanbepolishedbutthelusterquicklydiminishes asoxidesform.Thecoloristypicallyamattegrayto grayishblue.

Theoxideofzincabsorbsultravioletlight.Itsusein sunprotectioniswellknown.Protectionisafforded byabsorptionoftheultravioletradiationandnot allowingittopasstotheskin.

Zincoxideinpowderformisusedextensivelyinpaint. Itisawhitepowderandwillreflectinfraredradiation.

Relativecost: Medium

Strengthening:

Recycleability:

Zincdoesnotgainstrengthfromcoldworkingas othermetalsdo.Instead,alloyingwithsmallamounts ofcopperandtitaniumareusedtoimprovestrength andaddcreepresistance.

Zinciseasilyrecycledbecauseofthelowmelting point.Zinciscapturedinfromgalvanizecoatedsteels asvaporduringtherecyclingprocessofcoatedsteels.

Weldingandjoining: Zinccanbeweldedandsoldered.

Casting:

Zincisacommoncastingmetal.Usedformanysmall castpartswherestrengthislessarequirement

Plating: Zinccanbeelectroplatedwithothermetals.

Etchingandmilling:

THEZINCATOM

Zinccanbeetchedchemicallyandreadilymachined.

Allmetalshaveatmostthreeelectronsintheiroutershell.Zinc,element30ontheperiodicchart, hastwoelectronsintheoutershell.Thisgivesitanoxidationstateof +2,makingthezincatom divalentinallcompounds.Figure1.7depictsatypicalzincatomwiththetwoelectronsintheouter orbitshell.Forzinc,thereisalwaystwocovalentbondsformedwhenthezincatomcombineswith otherelements.

OxygenreadilyjoinswithzinctoformZnOandZn(OH)2,withoxygenalonemakingadouble bondandthetwohydroxidecombinationseachwithasinglebond.

30 Protons

35 Neutrons

30 Electrons

Outer shell holds two electrons

FIGURE1.7 Zincatomwithtwoelectronsintheothershell.

High-purityzincisastrongoxidizerandwhenexposedtotheatmospherequicklytarnishes andformstheoxideandhydroxide.Thestandardpotentialofzinccanbeexpressedthermodynamically4 as:

Zn↔Zn2+ + 2e E0 = –0.763 v

Thisrepresentsastrongdrivetocombinewithotherelements.

4 Zhang,Z.G.CorrosionandElectrochemistryofZinc.PlenumPress,NY,1996.

HISTORY

ThediscoveryofzincasametaliscreditedintheWesttotheSwissalchemist,Paracelsus.Dr.Paracelsus,ashewasknownbecausehewasaphysicianandaphilosopheraswell,in1526,describeda metalhecalled zinek, asoneofthesevenknownmetals.ParacelsuslivedaroundBaselandwrote extensivelyonvarioussubjects.Heiscredited,amongotherthings,asthefatheroftoxicology.

ZincorewasminedinGermanyforthemakingofbrassintheregionaroundtheHarz Mountains.ThenearbytownofGoslar,Germany,wasacenterofminingandzincminingexisted fromaround1550.By1650,alarge-scalezincoreproductionandrefinementwasunderway. Theminesaroundthisregionproducediron,silver,copper,lead,andzinc.

Theprocessofrefiningthemetalstillwasamysterytothewest.ChinaandIndiawouldsupply themetalinarefinedstatetoEuropeancompaniesforproducingbrassbyalloyingwithcopper. Eventually,bythemiddlepartoftheeighteenthcentury,zinc-miningoperationsinSwedenandthe regionaroundSilesiawouldbecomeimportantsourcesfortheore.

Intheearly1700s,Bristol,England,theBristolBrassCompanywouldimportzincfromIndia. WilliamChampion,thesonofthefounderofthecompany,createdamethodofsmeltinghisown zincusingaprocessnotablysimilartoonedevelopedcenturiesearlierinIndia.Thecompanypreviouslywouldimportthezinctomakeitsbrassplates,nowitcouldproduceandrefineitsownzinc fromore.WilliamChampionhasbeencreditedwiththeearlymanufactureofindustrialquantities ofzinc.

ChampionsawhowthemetalworkersinIndiawereextractingzincfromtheorepyrometallurgicallybyaddingadistillationprocesstocapturethefumesandcondensethezincoxide.Thezinc washeatedtoturnitintovapor,thevaporwouldcondenseonthecoolerwallsofachambersimilar tothewayitwouldcondenseonthecoolerstonewallsofthealchemistsflue.Thiscondensedzinc waszincoxide.Thekeywastoremovetheoxygenbyaddingcharcoaltotheheatedchamberand thiswouldremovetheoxygenfromthezincoxidecreatingcarbondioxideandleavingthezincasa lumpofmetal.

Inthosedays,brasswasthemainproductthatsetthedemandforzinc.Brasswasusedtoclad thehullsofEnglishsailingships.Muntzmetal,analloyofcopperandzinc,contains40%zinc. Developedspecificallyasacladdingforshiphullsin1832,Muntz,namedafteritsinventor,George FredrickMuntzofBirmingham,England,replacedcopperasananti-foulingcladdingonthehulls ofoceangoingships.Becauseithadzinc,itwassignificantlycheaperthanpurecopperandstill wouldprotectthewoodhullsfromteredoshipworms.Muntzmetalwasalsomuchstrongerthan copper,andthezincloweredthemeltingpointto904∘ Cfrom1085∘ Cforcopper.

Zincisametalthathasbeeninandoutofartandarchitectureovertheyears.Sinceitsdiscovery,ormoreso,sincethetimewhencastingandrollingintosheets,zinchasfounduseinarchitecture.TheskylineofParisisatestimonytothebeautyanddurabilityofthemetal.Napoleon, around1805instructedthechemistJean-JacquesDonytodeveloptherichminesofzincoreinthe Vielle-Montagne.Donydevelopedamethodofrefiningtheoreusingahorizontaldistillingprocess thatinvolvedaseriesofretortssetintoafurnace.Theorewouldberoasted,andthezincfumeswould bereleasedandcondensate,formingmoltenzinc.Figure1.8isadiagrammaticrepresentationofthe retortprocess.

DiagramofaHorizontalRetort.

Source:DevelopedbyDony.

Donysettheseretortsinserieswithinafurnaceandrequiredavastamountofheatenergy.The processremainedinuseuntilthefirsthalfofthetwentiethcentury.First,thereactionrequiredthe temperaturewithintheretorttoreach1100∘ Corgreaterforthechemicalreactiontooccurbetween ZnOandcarbon.Thecarbonwasintroducedfromthecharcoal,whichwouldburn,creatingcarbon dioxidegas.Furtherheatwouldbeappliedtovaporizethezinc.Zincoxidewouldformasavapor, andwhenitcombinedwiththeheatedcarbon,theoxygenwouldbestrippedawayandventoutas carbondioxide.Thezincwouldbecondensingonthecoolerportionoftheretortandcollectalong thebottomasliquidmetal.

Theseretortswouldbesetintoarraysandchargedwithoreandcharcoal.

Withthisnewsourceofthemetal,rollingintosheetsandplateswaspossibleusingrolling techniquesperfectedwithcopperandironplates.Thefirstzinc-rollingmillforsheetsofzincwas developedbyDonyin1812,makingthismetalavailableasanarchitecturalcladdingmaterialto competewithcopperandtin-platedsteel.

Zinchasalonghistoryinartandarchitecture.Itsuseasanalloymetalwithcoppertomake brasswaswellunderstoodbytheRomansandEgyptians,whowereattractedbytheallureofthe goldencolortheadditionofthemineralcalaminemadewithcopper.Atleasttheyunderstoodthat somethingintheorewouldinteractwithcopperandproducebrass.Zincasametalwasunknown toearlycivilizationsbecauseitcouldnotbeseparatedfromitsoreasothermetals.Whencopper, lead,tin,orironorewereheatedthemetalwouldfalltothebottomofthefurnacebutzincwould boilandturntovapor.

InChinaandinIndia,earlymetalworkersfoundwaysofisolatingzincbyroastingtheoresin crucibleswithcharcoalandthenallowingthemtocool.Zincwouldseparateinsmalllumpswhere itcouldbecollectedandremelted.

FIGURE1.8

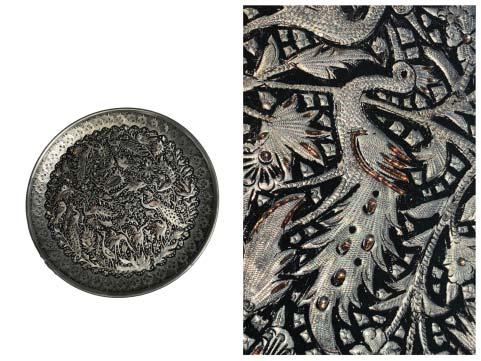

FIGURE1.9 AnexampleofmodernBidriwaremadefromzinc.

Inthefourteenthcentury,therewasanartformcalledBidrithatusedhammeredcopperand zincformswithincredibleinlayartwork.Figure1.9isamodernexampleoftheartwork.Bidriisa productthatoriginatedinsouthcentralIndiaandisattributedtotheBahamanisultansinthefort cityofBidar.Theyusedtheprocessofengravingandrepossétoproduceelaboratedesignsinmetal bowlsandplatesaswellasthebasesofhookahs.

Theywouldofteninlayothermetalssuchassilverorgoldandthendarkenthebackground metalwithsulfidecompoundsandpolishoffthetopsections.

ThisareaofIndiaisstillamajorcenterformanufacturinguniquemetalwork.Today,brass, copper,andzincarestillhandcraftedhereintheoldtradition.Itisimportanttonote,theseincredible artpieceswerecreatedfromzinc–copperalloys,wherethezincwas4timestheamountofcopper inthebasemetaltoasmuchas16times.ZincwasbeingproducedinlargequantitiesinIndiaas earlyasthefourteenthcentury.

TherewasnoknownprocessofproducingzincinEuropeuntilseveralcenturieslater.In1982, anarcheologicalstudyoftheminesintheregionaroundZawarinRajasthanwasundertakenbya British-Indianresearchgroup.Theyfoundintactfurnacesandclayretortsthatindicatedsmeltingof zinconasignificantscalehadbeenunderwaycenturiesago5 .Theclayretortswerepositionedatan angle.Theneck-downareawaslowerthantheenlargedsectionandpositionedthroughawallofclay andstoneintoacoolerchamber–muchthesamewayasWilliamChampionandJean-JacquesDony arrangedtheirretortstocapturezincvaporandcondenseittocreateapureformofzinc.William ChampiontraveledoftentoIndia,andapparentlyhestudiedtheIndianprocessandbroughtitback toEngland.

5 JagdishMittal, BidriWareandDamasceneWorkinJagdishandKamlaMittalMuseumofIndianArt,Hyderabad, 2011,p.39.

OtherexamplesofzincusedinthefarEasternculturespredatethearrivalofthemetaltoEurope. Zincwasrarerthancopperandironintheseearlytimes,andtheutilityofthemetalwasnotyet understooduntillargerquantitiescouldbeproduced.

InEurope,oncemoreintenserefinementofthemetaltookformandquantitiesofthemetal becameavailable,artistsandartisanbegantounderstandcertainbeneficialcharacteristics.Onewas thelowmeltingtemperature,muchlowerthancopperoriron.Oncemelted,ithadgoodfluidityand couldbepouredintosimplermoldsandachievegooddetail.

Zinc-caststatuesdatebacktothemid-tolate-1700sinEurope,whereitwasextensivelypromotedforuseinnorthernEurope.InPrussia,itwasusedonbuildingsandornamentforthenew capitalcityofBerlin.KarlFriedrichSchinkel,thearchitect,artist,andcityplannerpushedforits useinstatuaryandbuildingornamentationintheearly1800s,wherethesilverybluemetalwas usedtoadornthenewPrussiancapital.

InParis,onehastomarvelatthesilveryroofsandornamentationthatdistinguishesthatcity. TheBaronHausmann,PrefectoftheSeineDepartmentofFranceunderNapoleonIII,undertook avastredevelopmentofthefamouscityinthemid-1800s.Thisstartedthecladdingofthefamous mansardsofParis.Supposedly,theBaronHausmannhadarelativeinthezinc-miningbusiness.It couldalsohavebeenthatHausmannwantedtohaveacrèmecoloredstoneusedforthewallsofhis buildingdesignandtheuseofcoppermayhaveledtostaining.Oneofthegreatbenefitsofzincis thatitsoxidesdonotstainadjacentmaterials.

Oneofthemainsourcesofzincwasthemine,LaVielleMontagneinKelmis,called LaCalamine inFrench.Thisarea,ontheborderofGermanywasthesourceformuchofthezincusedFranceat thetimeofthisadornmentandreconstructionofParis.LaVielleMontagnestartedinthe1400sas asourceforzincusedinmanufacturingbrass.TheLaVielleMontagneZinMiningCompanywas formedtosupplyPariswiththezincneededtoredevelopthecityunderHausmann.Thecompany becameVMZincandisoneofthelargestsuppliersofzincintheworld.

ThezincminesaroundVielle-Montagne,hadbeeninusesinceRomantimesandthisreadily availableorewasidealformakingastatementforFrance.Asearlyas1815,someofthefirstroofsof Pariswerebeingcladinthissilverymetal,zinc,andtodaycloseto90%oftheroofsofthegreatcityare stillcoveredinzinc.UNESCO,theUnitedNationsEducation,ScientificandCulturalOrganization isconsideringmakingthezincroofsofParisaWorldHeritage.

ThePrussiansourceofzincwastheareaknownasSilesia.Silesia,aregioninpresent-day Poland,producedzincthatwasknownforitslowsulfur.Veryextensivemanufacturingofzincproductstookplaceinthisregion.ThecentralpartofEuropeminedandproducedmuchofthezincused intheworldduringthe1800s.

Itwassoondiscoveredthatcoatingironinmoltenzincwouldprovidegalvanicprotectiontothe ironandlatersteel.By1830,coatingironwithzincwasinwideusethroughoutEurope.Laterthat century,steelwasinventedandovertookironasabuildingmaterial.Asthelesscorrosionresistant steelcameintomajorusethelaterpartofthecentury,coatingsteelwithmoltenzincasasacrificial layerbecameamajorenterprisethatcontinuestoday.Thevastmajorityofzincusedtodayisto protectsteelbyhotdippinginbathsofmoltenzinc.